Polyphosphoester polymer, preparation method thereof, modified porous silicon nanoparticles and preparation method and application of modified porous silicon nanoparticles

A polyphosphate and polymer technology, applied in the field of pharmaceutical preparations, can solve the problems of refractory degradation, reduced cell effective uptake, slow drug release, etc., and achieves increased affinity, good biocompatibility, degradability, and affinity. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

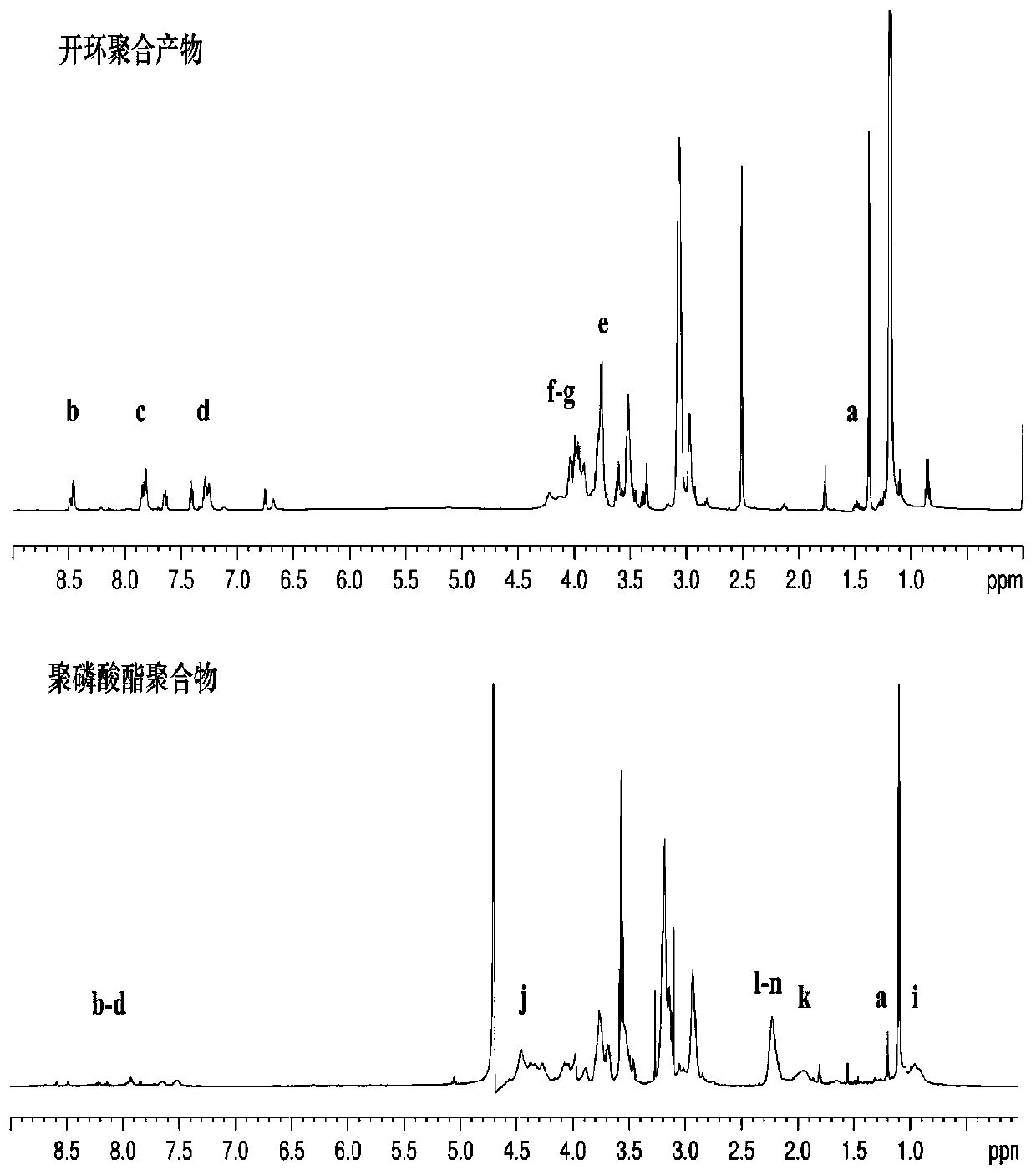

[0035] The present invention provides the preparation method of polyphosphate polymer described in above-mentioned technical scheme, comprises the following steps:

[0036] mixing N-(tert-butoxycarbonyl)ethanolamine, hydroxyethyl dithiopyridinated phosphate and the first solvent, and performing ring-opening polymerization reaction under the action of an organometallic catalyst to obtain a ring-opening polymerization product;

[0037] Mixing the ring-opening polymerization product with a reducing agent and a second solvent to perform a depyridine reaction to obtain a depyridine product;

[0038] The depyridine product is mixed with the zwitterionic monomer and the third solvent, and click chemical reaction is carried out under the catalysis of 4-dimethylaminopyridine to obtain the polyphosphate polymer having the structure shown in formula I.

[0039] In the invention, N-(tert-butoxycarbonyl)ethanolamine, hydroxyethyl dithiopyridinated phosphate and the first solvent are mixed,...

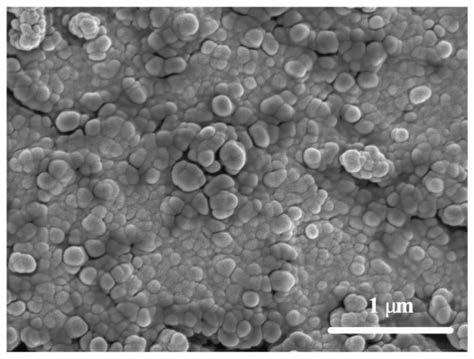

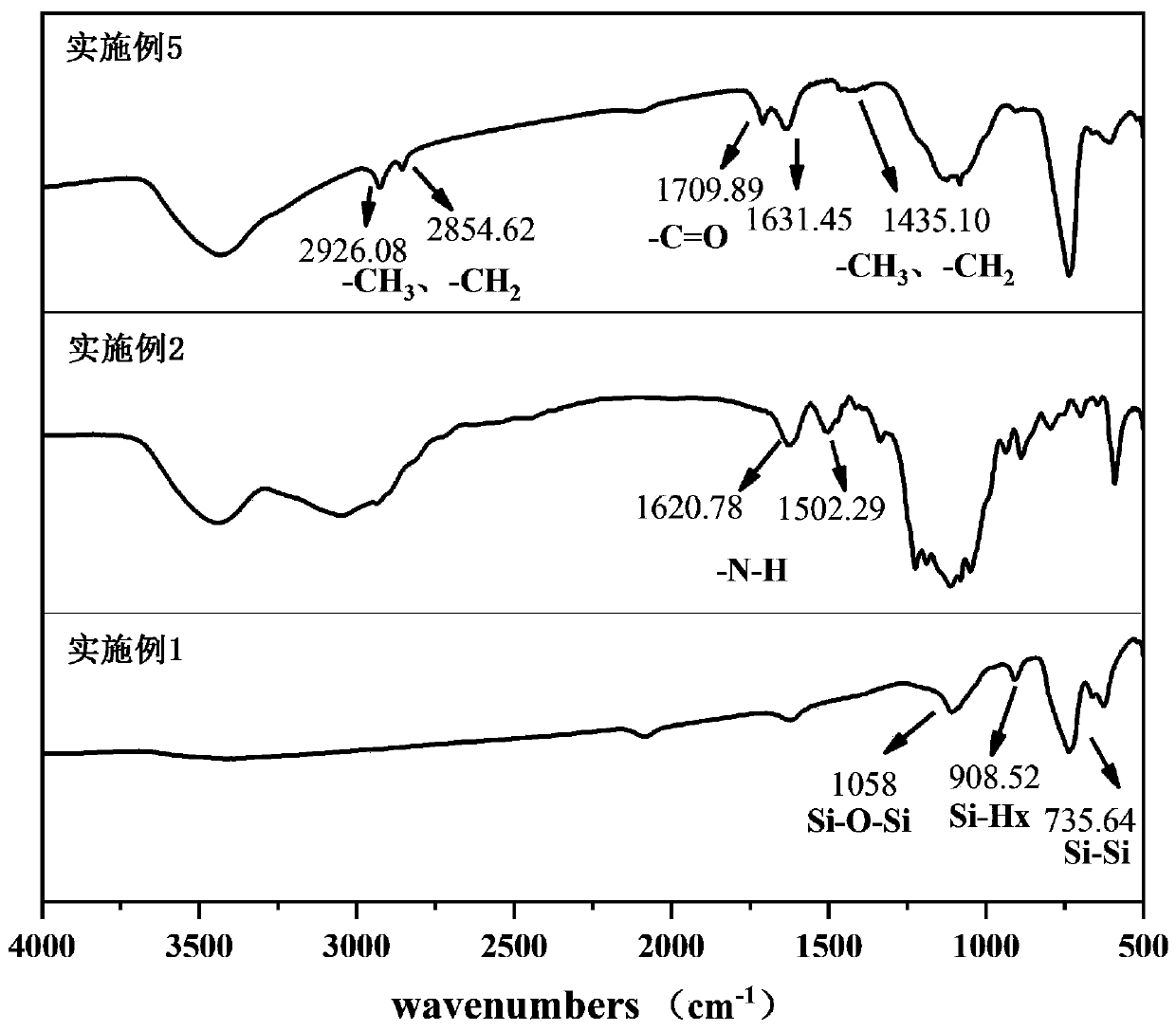

Embodiment 1

[0079] A silicon wafer (n-type doped single crystal silicon, with a resistivity of 0.01 to 1 Ω·cm) is placed in a mixed reagent of hydrogen peroxide and concentrated sulfuric acid (the mass concentration of the hydrogen peroxide is 40.0%, and the mass concentration of the concentrated sulfuric acid is 98.0%, the volume ratio of the hydrogen peroxide and concentrated sulfuric acid is 3:1) in ultrasonic cleaning 5min, then successively adopt acetone, absolute ethanol and deionized water to clean to remove surface impurities; the silicon chip after cleaning is put into electrochemical In the etching device, add the mixed reagent of hydrofluoric acid and ethanol (the mass concentration of described hydrofluoric acid is 40.0%, the volume ratio of described hydrofluoric acid and ethanol is 2:1), at 100mA / cm 2 Continue to etch for 20min under the current intensity, add absolute ethanol to clean, continue to add the mixed reagent of hydrofluoric acid and ethanol (the mass concentration...

Embodiment 2

[0082] (1) Prepare the ethanol dispersion of porous silicon nanoparticles according to the method of Example 1, collect porous silicon nanoparticles after centrifugation at 12000rpm for 15min, disperse 100mg of porous silicon nanoparticles in 20mL of anhydrous methanol, add 1.5mL of 3-aminopropyl Trimethoxysilane, heated up until the system refluxed (40°C), carried out amination treatment for 10 h, cooled naturally to room temperature, and washed by anhydrous DMSO for several times, and the obtained aminated porous silicon nanoparticles were stored in anhydrous DMSO, 4 Store at ℃ until use.

[0083] (2) After centrifuging the anhydrous DMSO dispersion of aminated porous silicon nanoparticles in step (1), the aminated porous silicon nanoparticles were collected, and 100 mg of aminated porous silicon nanoparticles, 60 mg of insulin and hydrochloric acid (6 mL, a concentration of 0.02 mol / L), mixed with stirring, and incubated at 25°C for 1.2h; then centrifuged at 9000rpm for 5mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com