A mixed conductor material of a-site and b-site co-doped strontium titanate with a-site vacancy

A mixed conductor and co-doping technology, which is applied in the manufacture of oxide conductors, non-metallic conductors, cables/conductors, etc., can solve problems such as poor ionic conductivity, increase vacancy concentration, improve ionic conductivity and comprehensive conductivity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

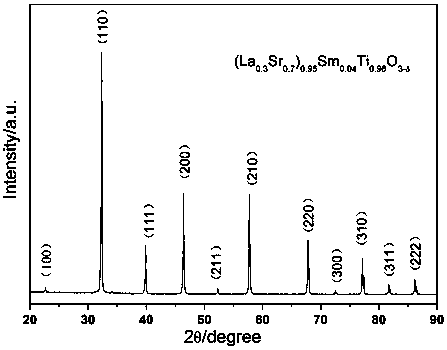

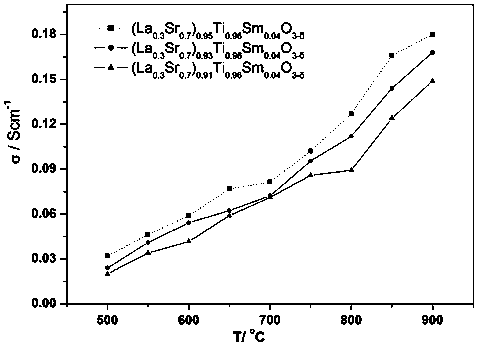

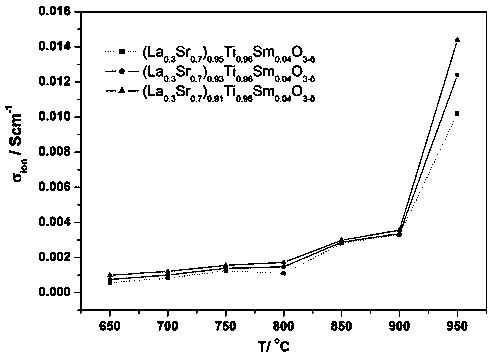

[0028] Embodiment 1: (La 0.3 Sr 0.7 ) 0.95 Ti 0.96 SM 0.04 o 3−δ Synthesized by solid phase reaction method

[0029] to La 2 o 3 , Sr(CO 3 ) 2 ,,Sm 2 o 3 ,TiO 2 As raw material, according to (La 0.3 Sr 0.7 ) 0.95 Ti 0.96 SM 0.04 o 3−δ The proportion of the elements in the mixture is prepared, using absolute ethanol as the medium, milling in an agate ball milling tank for 8 hours, mixing evenly, drying in an oven, submerging the dried powder and sieving (100 mesh), after sieving The powder was filled in a corundum crucible and synthesized at 1100°C for 10 hours in an air atmosphere. Sieve the synthesized powder (100 mesh), add 50 vol% carbon powder, 5 vol% PVA solution, mix and dry press to form, and keep the prepared sample at 1500°C for 5 hours to make a porous mixed conductor material.

Embodiment 2

[0030] Embodiment 2: (La 0.3 Sr 0.7 ) 0.93 Ti 0.96 SM 0.04 o 3−δ hydrothermal synthesis of

[0031] The raw material was La(NO 3 ) 3 , Sr(NO 3 ) 2 , Sm(NO 3 ) 3 , TiCl 4 As raw material, according to (La 0.3 Sr 0.7 ) 0.93 Ti 0.96 SM 0.04 o 3−δ The mixture was configured in a metering ratio of 1 mol / L KOH solution as a solvent, and the reaction was carried out in a sealed autoclave, and the temperature of the autoclave was raised to 150°C and kept for half an hour. After the autoclave is naturally cooled, the precipitate is washed and dried to obtain a synthetic powder. The synthesized powder was sieved (200 mesh), 10 wt% soluble starch and 5 volume% PVA solution were added, mixed and dry-pressed, and the prepared sample was kept at 1450°C for 10 hours to make a porous mixed conductor material .

Embodiment 3

[0032] Embodiment 3: (La 0.3 Sr 0.7 ) 0.91 Ti 0.96 SM 0.04 o 3−δ sol-gel synthesis

[0033] to La 2 o 3 , SrAc 2 , Sm 2 o 3 , Ti(CH 3 CH 2 CH 2 CH 2 O) 4 According to (La 0.3 Sr 0.7 ) 0.91 Ti 0.96 SM 0.04 o 3−δ Weigh the stoichiometric ratio, dissolve strontium acetate in deionized water, then dissolve butyl titanate in the mixed solution of isopropanol and absolute ethanol, stir well and add La 2 o 3 and Sm 2 o 3 . Take strontium acetate solution, add tetrabutyl titanate and La 2 o 3 and Sm 2 o 3 In the mixed solution, after magnetic stirring at room temperature for 30 minutes, let it stand for 12 hours, put it into an oven and dry it at 50 ℃ to form a fluffy xerogel. After the dry gel powder is ground, it is pre-fired at 1100°C for 12 hours to remove organic matter and obtain a powder.

[0034] The co-doped strontium titanate powder synthesized at 1100°C was dry-pressed at 50MPa, densified and sintered at 1400°C for 5 hours in the atmosphere, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com