Titanium carbide/carbon core-shell nanowire array loaded nitrogen-doped lithium titanate composite material and its preparation method and application

A nanowire array and composite material technology is applied in the field of titanium carbide/carbon core-shell nanowire array-supported nitrogen-doped lithium titanate composite material and its preparation, which can solve the problems of limited application, low electronic conductivity and the like, and achieve improved The effect of lithium titanate oxygen vacancy concentration, high electrical conductivity and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] (1) Using atomic layer deposition (ALD) technology to grow a layer of Al on titanium mesh 2 o 3 , Al source and O source are respectively Al(CH 3 ) and H 2 O, the reaction temperature is 200 °C, and the supported Al 2 o 3 titanium mesh.

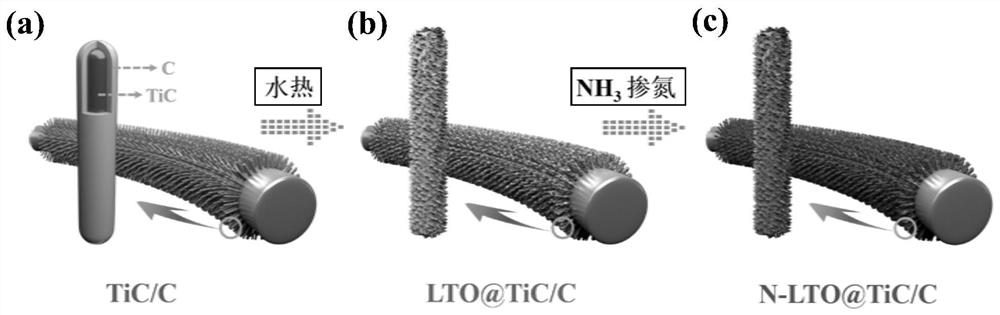

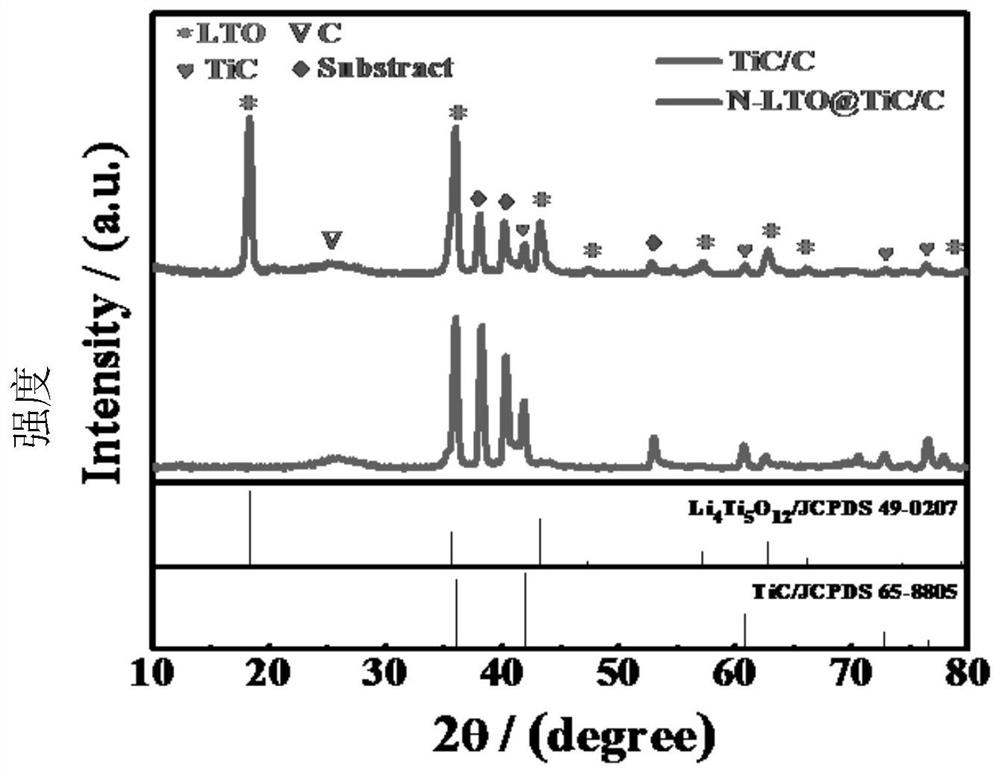

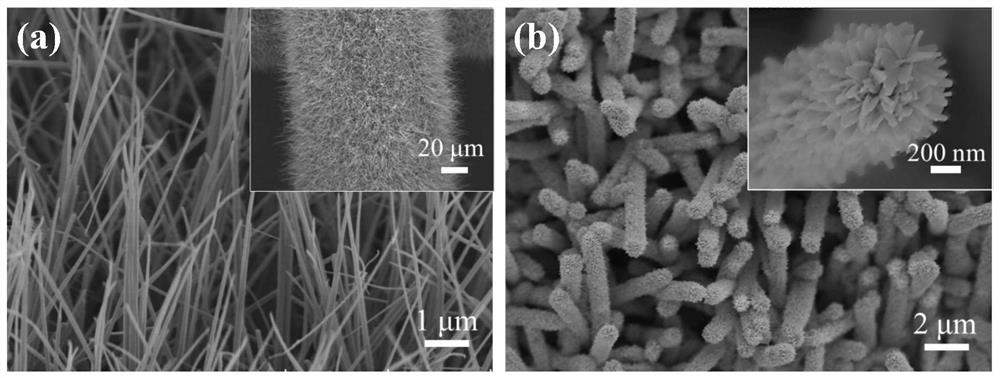

[0040] (2) Utilize chemical vapor deposition (CVD) technology in step (1) gained loading Al 2 o 3 TiC / C core-shell nanowire arrays grown on Ti mesh. will load Al 2 o 3 The titanium mesh is placed in a tube furnace, and a mixed gas of argon and hydrogen carrying acetone vapor is introduced. The flow rate of argon is 100 sccm, and the flow rate of hydrogen carrying acetone vapor is 10 sccm. React at 800 ° C for 1 hour to form TiC / C nanowire core-shell array to obtain titanium carbide / carbon core-shell nanowire array composite electrode material.

[0041] (3) Dissolve 0.9g of lithium hydroxide, 2mL of hydrogen peroxide and 1.2g of isopropyl titanate in 50mL of water to form solution A;

[0042] (4) The titanium carbide / carbon ...

Embodiment 2

[0049] (1) Using atomic layer deposition (ALD) technology to grow a layer of Al on titanium mesh 2 o 3 . Al source and O source are respectively Al(CH 3 ) and H 2 O, the reaction temperature is 250°C.

[0050] (2) Utilize chemical vapor deposition (CVD) technology in step (1) gained loading Al 2 o 3 TiC / C core-shell nanowire core-shell arrays grown on Ti mesh. will load Al 2 o 3 The titanium mesh is placed in a tube furnace, and a mixed gas of argon and hydrogen carrying acetone vapor is introduced. The flow rate of argon is 130 sccm, and the flow rate of hydrogen carrying acetone vapor is 15 sccm. React at 850 ° C for 2 hours to obtain TiC / C core-shell nanowire core-shell array.

[0051] (3) Dissolve 1g of lithium hydroxide, 3mL of hydrogen peroxide and 1.3g of isopropyl titanate in 60mL of water to form solution A;

[0052] (4) The titanium carbide / carbon core-shell nanowire array composite electrode material obtained in step (2) was placed in solution A, subjecte...

Embodiment 3

[0057] (1) Using atomic layer deposition (ALD) technology to grow a layer of Al on titanium mesh 2 o 3 . Al source and O source are respectively Al(CH 3 ) and H 2 O, the reaction temperature is 300°C.

[0058] (2) Utilize chemical vapor deposition (CVD) technology in step (1) gained loading Al 2 o 3 Titanium carbide / carbon nanowire core-shell arrays grown on titanium mesh. will load Al 2 o 3 The titanium net is placed in a tube furnace, and a mixed gas of argon and hydrogen carrying acetone vapor is introduced. The flow rate of argon is 150 sccm, and the flow rate of hydrogen carrying acetone vapor is 20 sccm. React at 900 ° C for 3 hours to obtain TiC / C nanowire core-shell arrays.

[0059] (3) Dissolve 1.1g of lithium hydroxide, 4mL of hydrogen peroxide and 1.4g of isopropyl titanate in 70mL of water to form solution A;

[0060] (4) The titanium carbide / carbon core-shell nanowire array composite electrode material obtained in step (2) was placed in solution A, subj...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com