Composite vacuum plating method

A technology of vacuum coating and substrate, applied in vacuum evaporation coating, sputtering coating, ion implantation coating and other directions, can solve the problems of complex process, high processing cost, tedious grinding, etc. The effect of stable chemical properties and good physical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

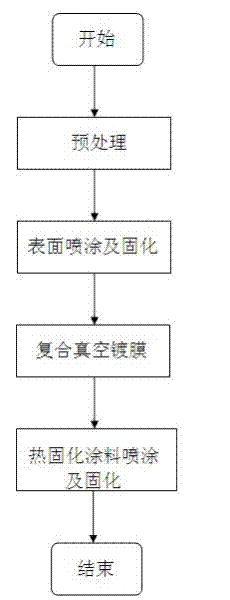

[0034] Such as figure 1As shown, a composite vacuum coating method, taking an aluminum alloy sheet with a product size of 120mm long x 80mm wide x 8mm thick as an example, is described as follows:

[0035] (1) Pre-treat the surface of the aluminum alloy sheet: use a cloth wheel coated with kraft glue to dip in 280# emery to basically flatten the aluminum sheet, and then use a degreasing agent to remove the oil. The degreasing agent can be an alkali metal salt , surfactant, also can be alkali metal alkali and tensio-active agent, can also be alkali metal salt, alkali metal alkali and tensio-active agent, present embodiment uses alkali metal salt, alkali metal alkali and tensio-active agent namely Na 2 CO 3 : 30g / L, Na 3 PO 4 : 30g / L, NaOH: 1g / L, surface sodium lauryl sulfate: 1g / L, after degreasing at 70℃, wash with water, and finally dry;

[0036] (2) Surface spraying and curing: use electrostatic spraying method to spray polyester powder and epoxy resin copolymer coating ...

Embodiment 2

[0049] Such as figure 1 As shown, a composite vacuum coating method, taking a zinc alloy sheet whose product size is 100mm long x 60mm wide x 6mm thick as an example, is explained as follows:

[0050] (1) Pretreat the surface of the zinc alloy sheet: the method is the same as in Example 1, except that the degreasing agent used is K 2 CO 3 : 30g / L, K 3 PO 4 : 30g / L, KOH: 1g / L, fatty acid diethanolamide: 2g / L, degreasing at 50°C;

[0051] (2) Surface spraying and curing: The difference from Example 1 is that the curing temperature is 220°C and the curing time is 30 minutes;

[0052] (3) Composite vacuum coating: Hang the zinc alloy sheet into the vacuum furnace, the target / base distance is 200mm, pre-vacuumize, when the vacuum degree reaches 6.0×10 -3 After Pa, the throttle valve is opened, the workpiece frame rotates at a rate of 3r / min, and the working gas is filled with argon to maintain the vacuum at 0.25Pa. Count 1 piece, the target material is nickel target, the coat...

Embodiment 3

[0062] Such as figure 1 As shown, a composite vacuum coating method, taking the aluminum alloy sheet whose product size is 100mm long x 60mm wide x 6mm thick as an example, the surface spraying and curing, composite vacuum coating, thermosetting coating spraying and curing steps are the same in this embodiment Example 1, the degreaser is Na in the pretreatment step on the surface of the aluminum alloy sheet substrate 2 CO 3 : 50g / L, Sodium Lauryl Sulfate: 1g / L Fatty Acid Diethanolamide: 1 g / L, degreasing at 60°C.

[0063] After the above surface treatment, the main properties of the aluminum alloy sheet coating are as follows:

[0064] (1) Color: bright white;

[0065] (2) Hardness: 1H;

[0066] (3) Adhesion (100 cells): 100%;

[0067] (4) Salt spray resistance (CASS test): ≥120h;

[0068] (5) Heat resistance: 170°C / 2h, no peeling off of the coating, no change point;

[0069] (6) Temperature change resistance: 85°C / 1h→-20°C / 30min is a cycle, after 4 cycles, the coating ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com