Method for guiding fixed-point cell growth by preparing chemical micro-patterns on surfaces of various materials

A micropattern and cell technology, which is applied in the field of preparation of highly selective cell micropatterns, can solve the problems of elastic stamp pollution, etc., and achieve the effect of low cost, simple operation process and mild preparation conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

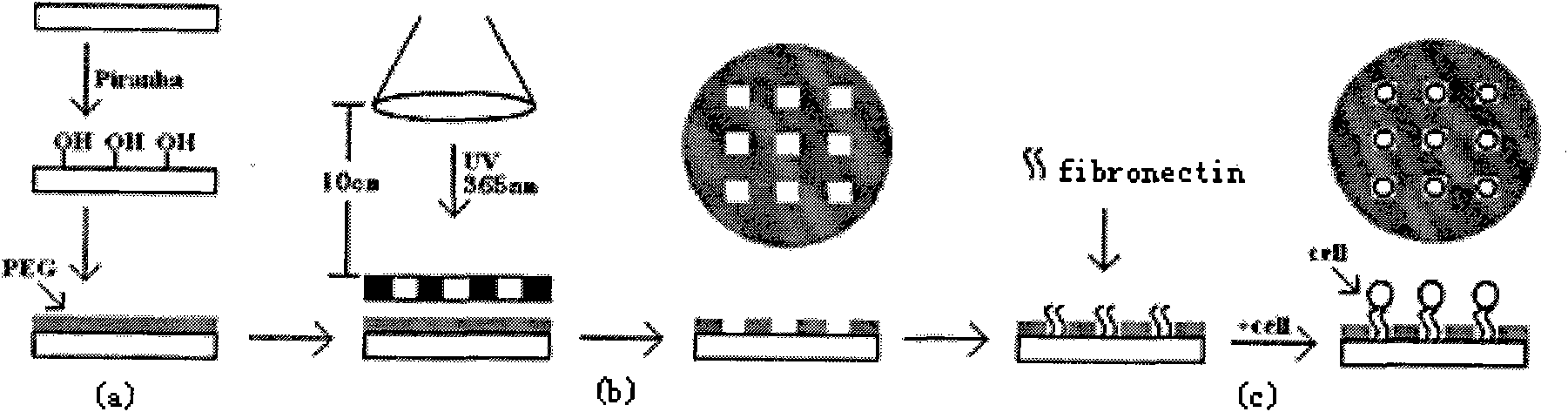

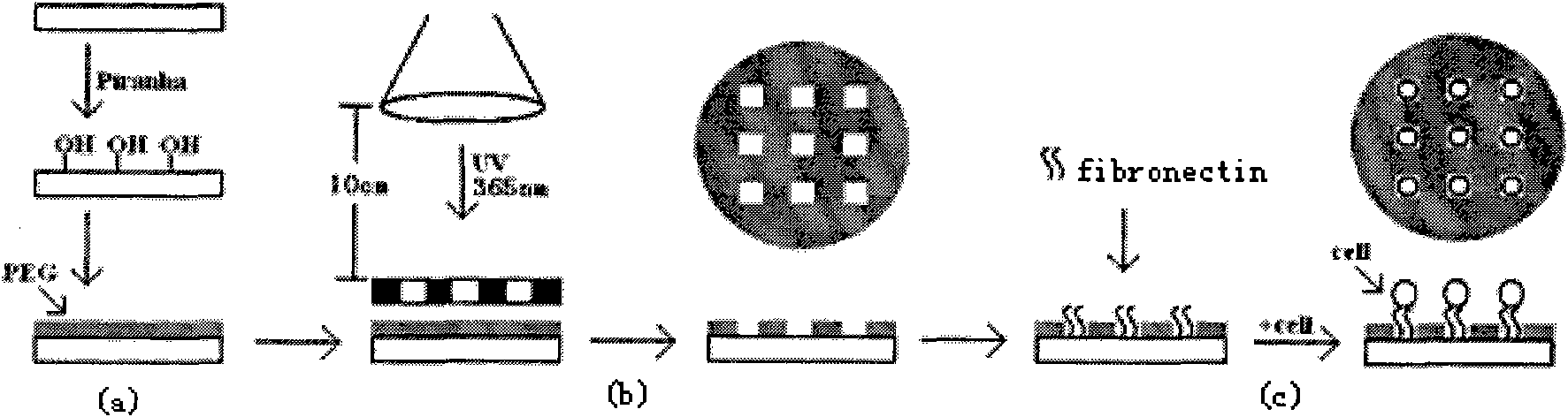

[0040] Substrate surface hydroxylation: Place a circular glass slide with a diameter of 12 mm in piranha solution (H 2 SO 4 :H 2 o 2 =3:1v:v) Soak at 80°C for 30min until no air bubbles are generated, then sonicate in the order of ultrapure water, ethanol, and ultrapure water for 10min each, rinse with a large amount of ultrapure water after each sonication, and finally blow dry with nitrogen , baked in a drying oven at 120°C for 10 minutes to obtain a surface rich in silanol.

[0041] Preparation of PEG anti-protein adsorption film: silanization reaction is adopted, the concentration of PEG silane is 6mM, the reaction adopts condensation reflux device, the reaction time is 18h, the reaction temperature is 60°C in silicone oil bath, and toluene and isopropanol are used at the end of the reaction. Sonicate for 5 minutes, and rinse the surface with a large amount of ultrapure water after each sonication, and finally dry it with nitrogen.

[0042] UV light PEG anti-protein ad...

example 2

[0046] Except for the preparation of the anti-protein adsorption membrane, other steps are the same as Example 1. The preparation of PEGMA anti-protein adsorption membrane is by atom transfer radical polymerization (ATRP). First, triaminotriethoxysilane (APTES) is coupled on the surface rich in silicon hydroxyl groups, and then connected to the surface initiator isobutyryl bromide. , using bipyridine as a ligand and cuprous bromide as a catalyst for surface polymerization, the reaction atmosphere is nitrogen, the reaction temperature is 25 degrees, and the surface is washed with a large amount of ultrapure water after the reaction. The micropattern surfaces formed on polyethylene glycol PEG film and polyethylene glycol methacrylate PEGMA film were seeded at a concentration of 2 × 10 4 cells / ml of 3T3 fibroblasts, the results of direct observation with a microscope are as follows figure 1 shown in the fifth section. The continuous cell culture showed that the stability of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Stability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com