Zinc oxide coating modified in vivo implanted artificial organ and preparation method thereof

An artificial organ, zinc oxide film technology, applied in the direction of metal material coating process, coating, prosthesis, etc., can solve the problems of poor blood compatibility, limited application scope, poor biocompatibility, etc., and achieve good compactness. , good repeatability, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

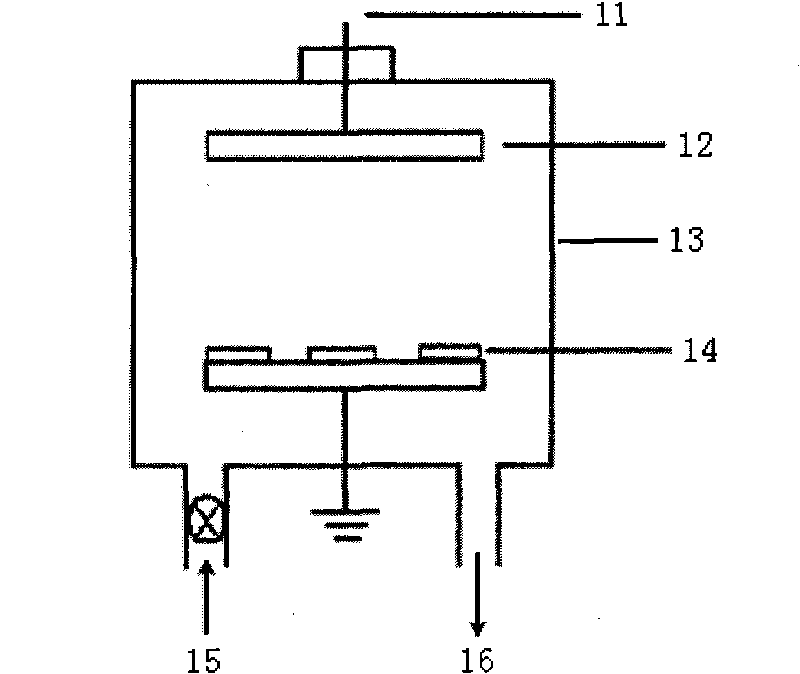

[0043] Preparation of zinc oxide film coating by radio frequency magnetron sputtering

[0044] Using RF magnetron sputtering method, the background vacuum is 3.0×10 -3 Pa, high-purity argon (99.99%) is used as the sputtering gas, the working pressure is between 4 Pa, titanium alloy is selected as the base, and the deposition substrate temperature (the surface temperature of the base that carries the artificial organ substrate during sputtering) is room temperature To 300℃, adjust the power of RF sputtering to 50~190W, the RF voltage is 500~1000V, for 99.99% zinc oxide ceramic target and different doping concentration (molar content of light rare earth element) zinc oxide ceramic target (see below Table 1) Sputtering was performed to prepare a series of zinc oxide thin film coatings.

[0045] Table 1

[0046] Doping element

Embodiment 2

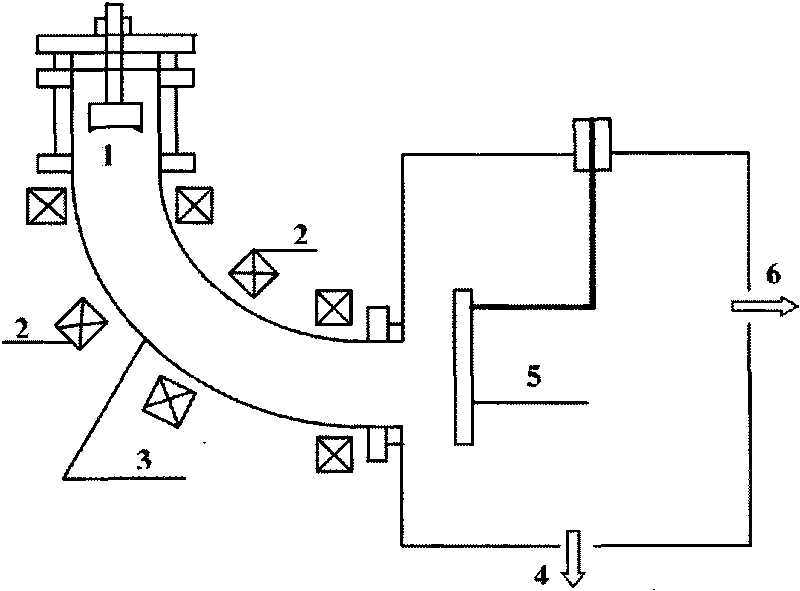

[0048] Zinc oxide film coating deposited by magnetic filtered arc ion plating in pure oxygen atmosphere

[0049] Using the method of magnetic filtered arc ion plating, the background vacuum is 6.0×10 -3 Pa, select titanium alloy as the substrate, clean with argon ion for 10 minutes, magnetic filter solenoid current 7.15A, central magnetic field is 12.0mT, high purity oxygen (99.99%) is used as reaction gas, and oxygen flow is changed to control working pressure. 99.9% metallic zinc was used as the cathode target to prepare a series of zinc oxide thin film coatings (see Table 2 below).

[0050] Table 2

[0051] Oxygen flow

Embodiment 3

[0053] Deposition of zinc oxide film coating in mixed gas atmosphere by magnetic filtered arc ion plating

[0054] Using the method of magnetic filtered arc ion plating, the background vacuum is 6.0×10 -3 Pa, select titanium alloy as the substrate, clean with argon ions for 10 minutes, magnetic filter solenoid current 7.15A, and center magnetic field 12.0mT. Pass in mixed gas, use argon and nitrogen as protective gas, control the flow ratio of argon and nitrogen, and then pass in reactive gas oxygen to change the working pressure to control the working pressure, the arc current is 30-40A, and the arc voltage is 30-40V Using 99.9% metallic zinc as the cathode target, a series of zinc oxide thin film coatings were prepared (see Table 3 below).

[0055] table 3

[0056] Argon nitrogen flow ratio

PUM

| Property | Measurement | Unit |

|---|---|---|

| Optical bandgap | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com