Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

44results about How to "Will not affect the shape" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

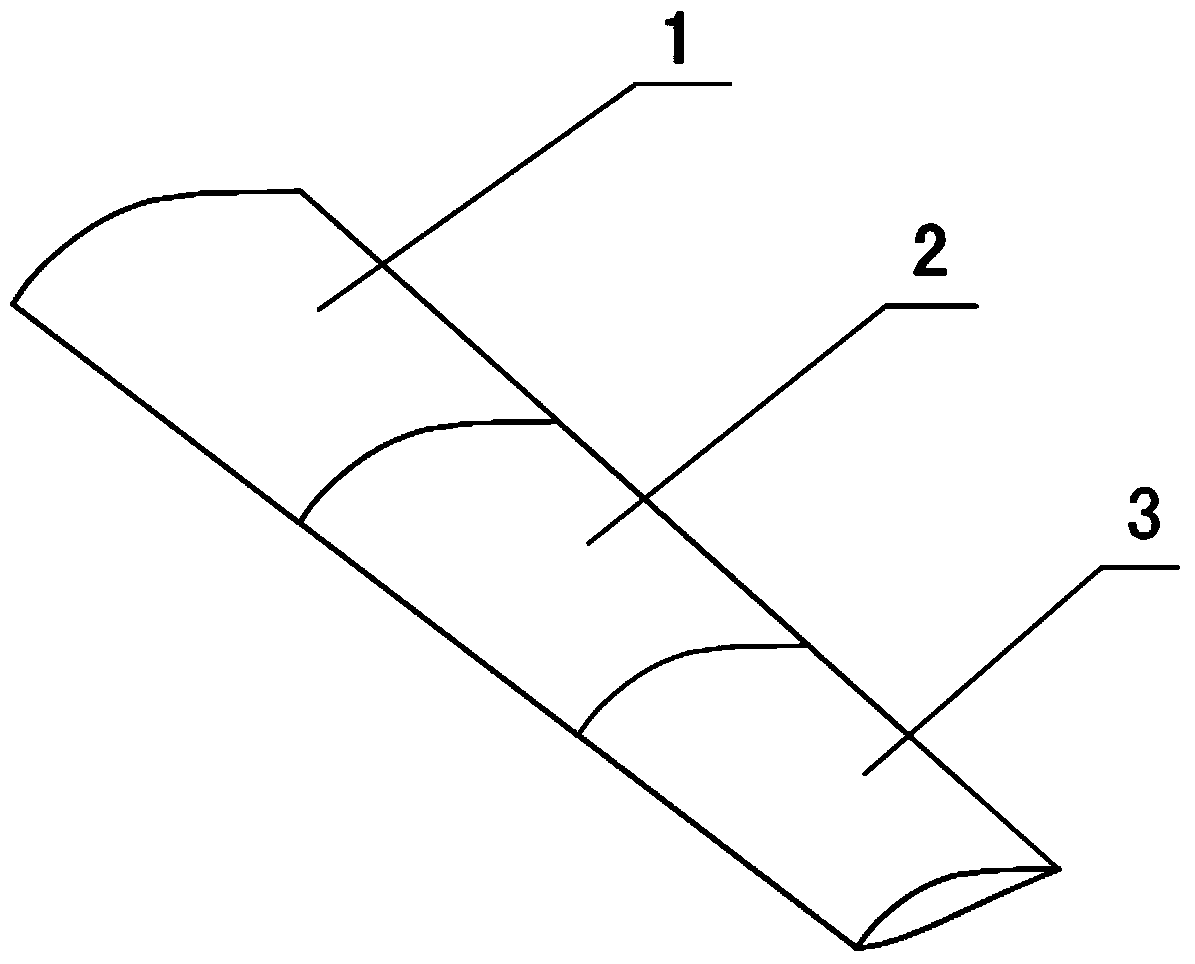

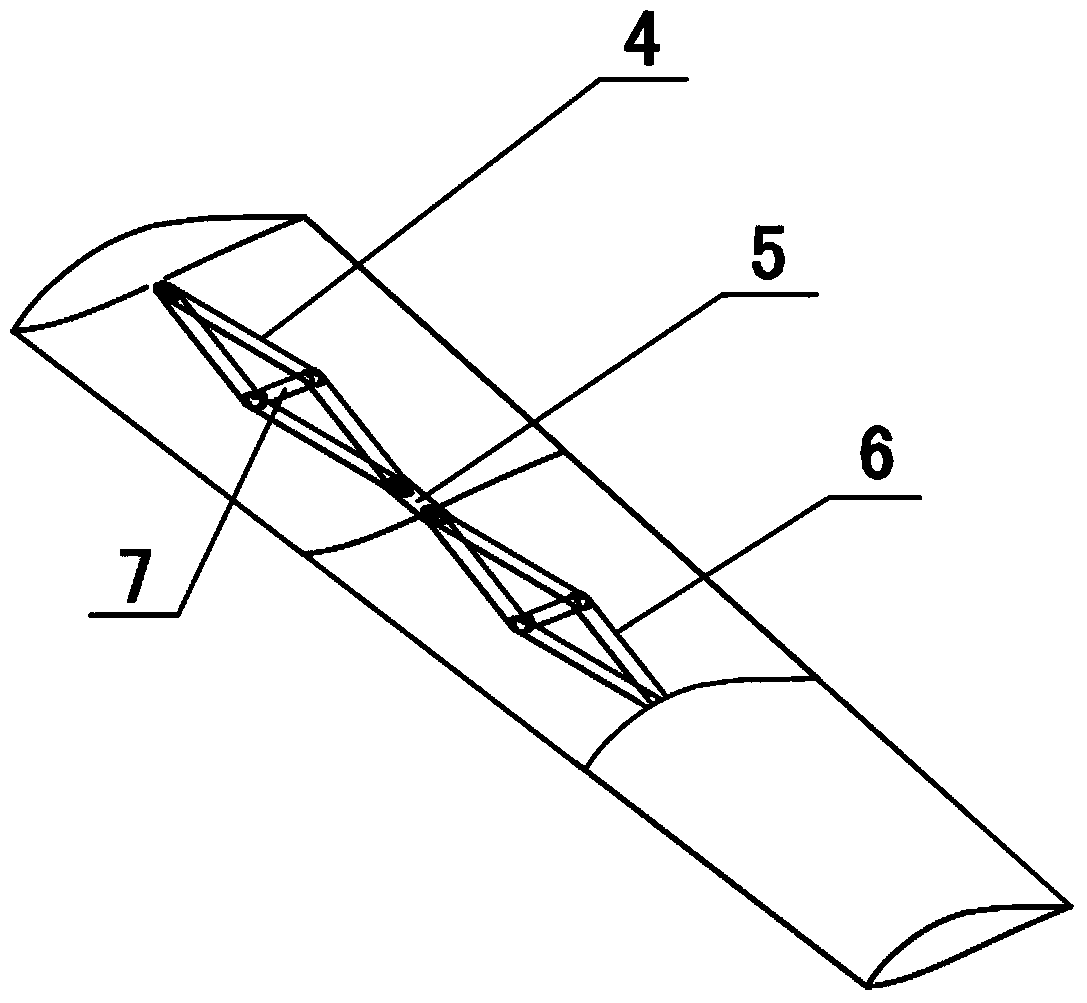

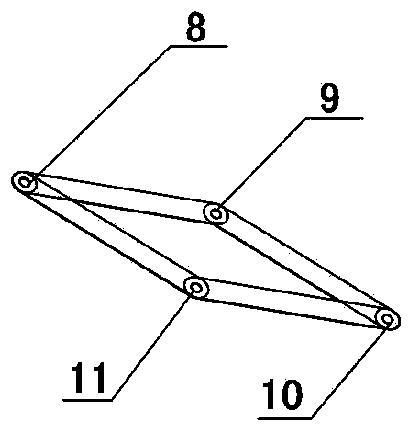

High-precision and light-weight controllable telescopic wing mechanism

InactiveCN104176238AAchieve shrinkageWill not affect the shapeWing adjustmentsFlight vehicleControl system

The invention discloses a high-precision and light-weight controllable telescopic wing mechanism. Deformation of an intelligent material is controlled by programming to realize expansion and contraction of drivers; when all the stages of the drivers contract, a four-connection-rod mechanism extends; a middle wing extends out of a fixed wing, and an outer wing extends out of the middle wing, so that extension of an overall wing is realized; when the drivers extend, the four-connection-rod mechanism is shortened; the outer wing returns into the middle wing, and the middle wing returns into the fixed wing, so that contraction of the overall wing is realized. Components in the mechanism are rigid elements in rigid connection, so that transmission is stable and accurate. Under the action of a control system, a telescopic wing can precisely realize expansion and contraction; the mechanism is light in mass, high in transmission speed and low in error; when a pneumatic appearance requirement of an aircraft in different stages is met, the total mass and the safety of the aircraft cannot be greatly affected; the telescopic wing controls the deformation of the intelligent material through programming, so that random extension and high-precision controllable contraction of the wing are realized, and an effect of controlling an element can be achieved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

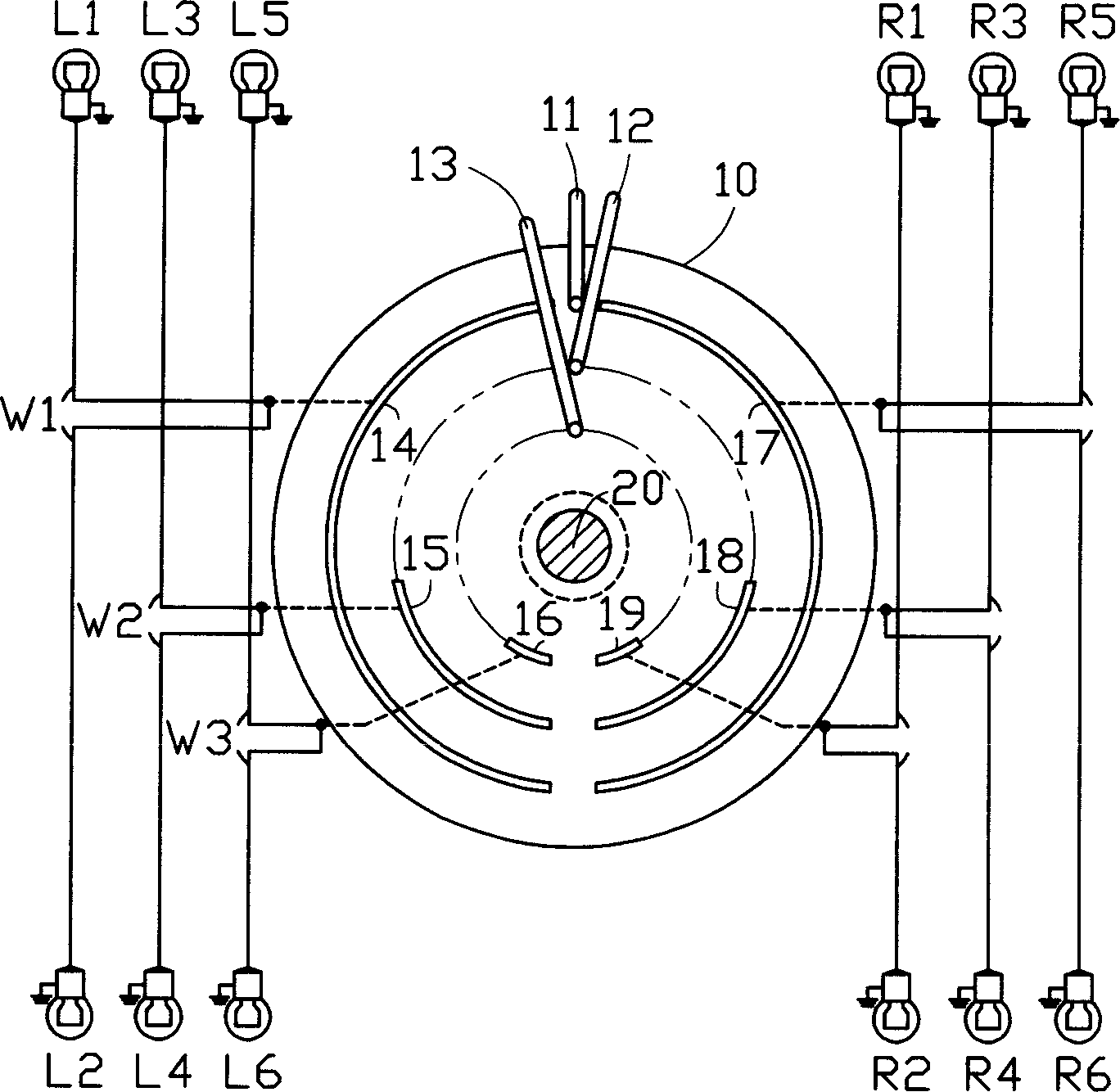

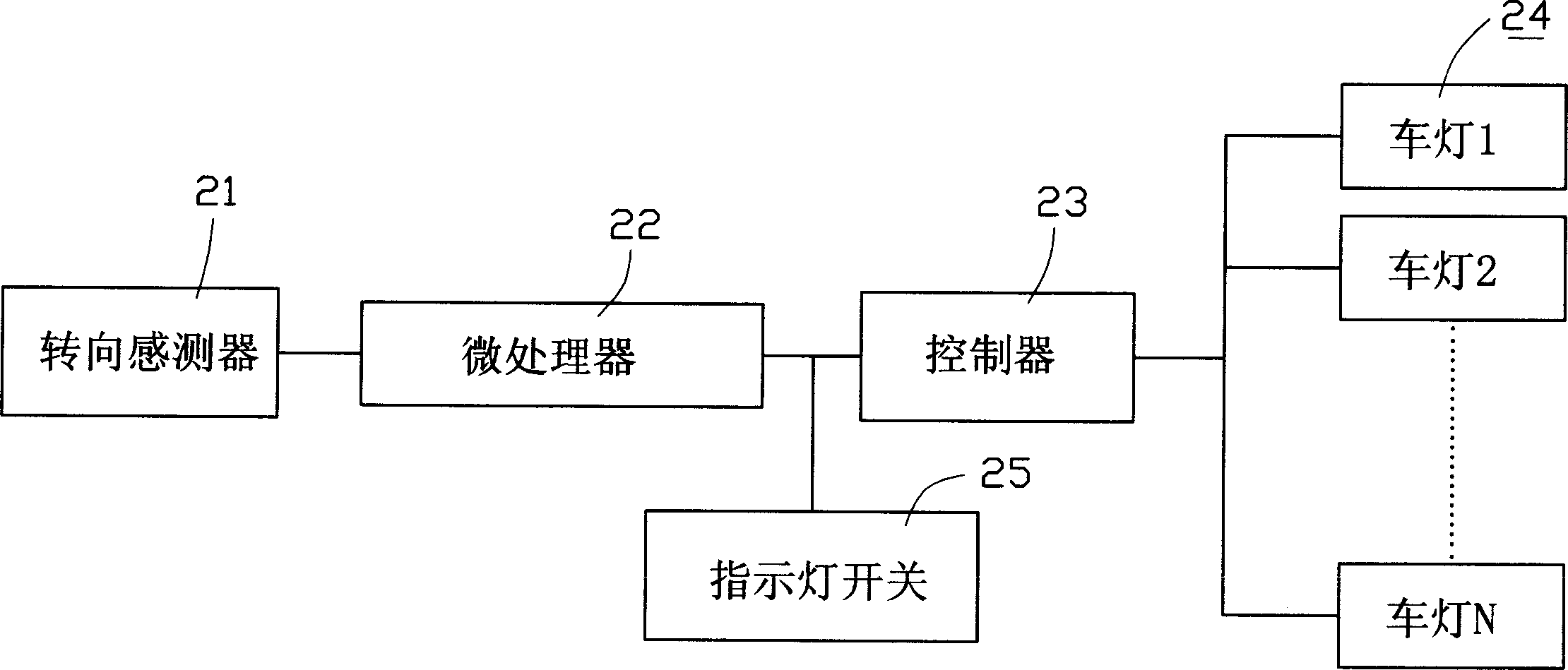

Automobile steering indicator

InactiveCN1743204ACan automatically display the rotation statusWill not affect the shapeOptical signallingTurn angleControl signal

The auto turning indicator capable of displaying auto turning angle comprises an angle sensor, a control device which can create control signals according to turning direction, angle and speed, and several luminous elements joining to the control device, which can light to respond control signal and create changeable mode. The turning indicator can use the present auto light to carry out, for example, indicating light, braking light, head rising displayer. The turning indicator can be integrated on the attachment of exiting auto.

Owner:EXON SCIENCE INC

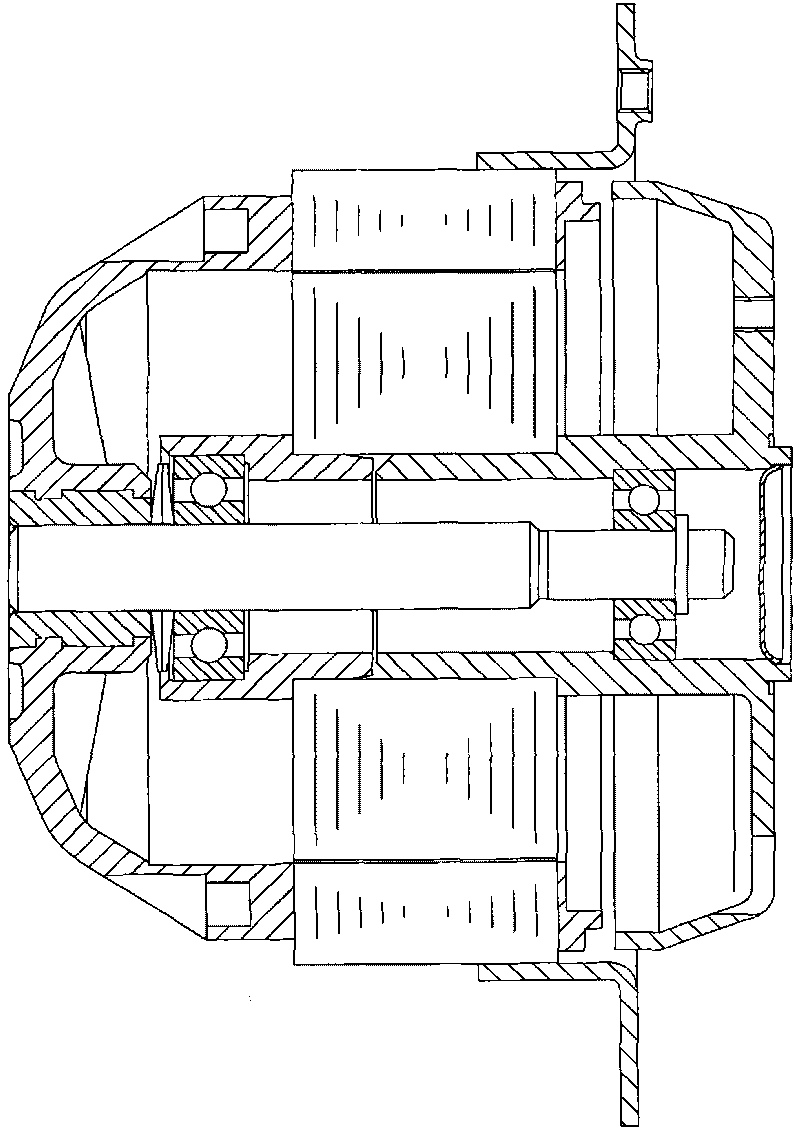

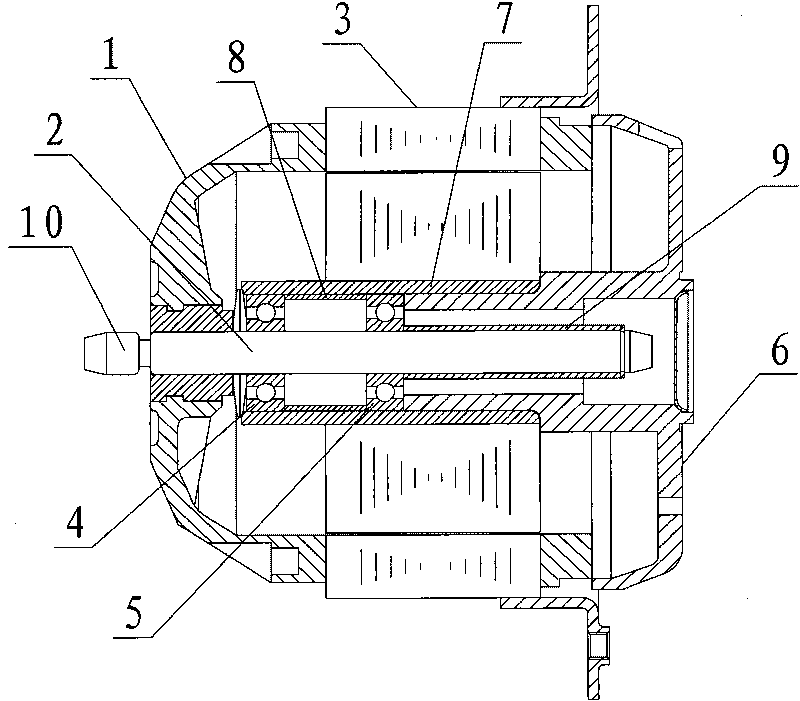

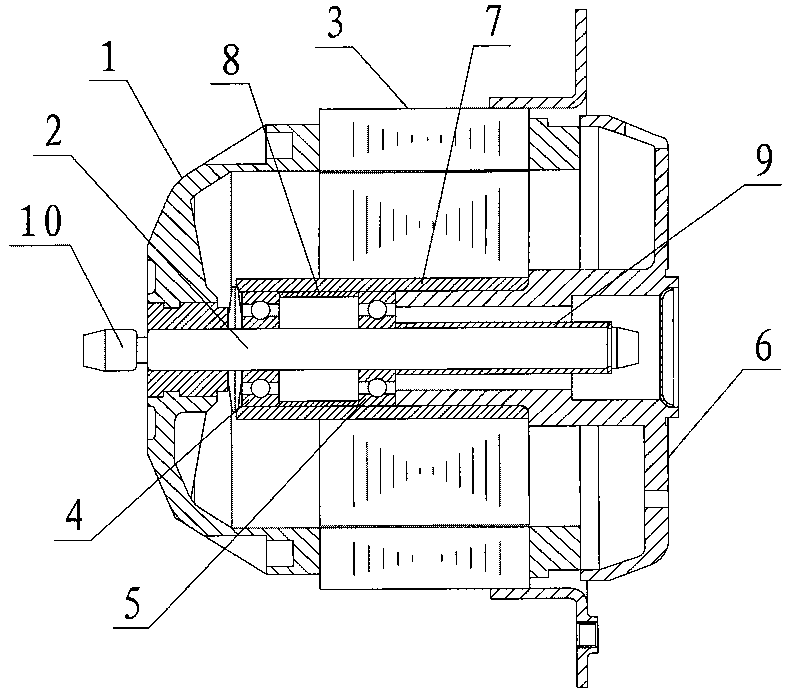

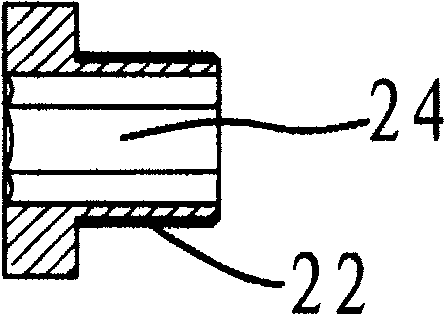

Outer rotor motor

ActiveCN101728893AGuaranteed concentricityNot easy to vibrateSupports/enclosures/casingsLow noiseEngineering

The invention relates to an outer rotor motor, comprising an outer rotor, a rotating shaft, a stator iron core, a first bearing, a second bearing and an end cover. The inner hole of the stator iron core is provided with a first bushing in a pressing manner; the first bearing and the second bearing have the same specification and are both arranged in the first bushing. The first bearing is arranged at the end of the first bushing close to one end of the outer rotor, and the second bearing and the first bearing are separated by a second bushing. A third bushing is clamped between one end of therotary shaft close to one end of the inner cavity of the end cover and the second bearing by a gasket. The end of the rotary shaft close to one end of the outer rotor is provided a guiding part convenient to press and mount by the rotating shaft. The first bearing and the second bearing n are mounted in the same part so as to ensure the concentricity of two mounted bearings; during the operation of the motor, the two bearings are not easy to vibrate, the outer rotor is not easy to move up and down, thus, the motor of the outer rotor has low noise and less bounce.

Owner:常州威灵电机制造有限公司

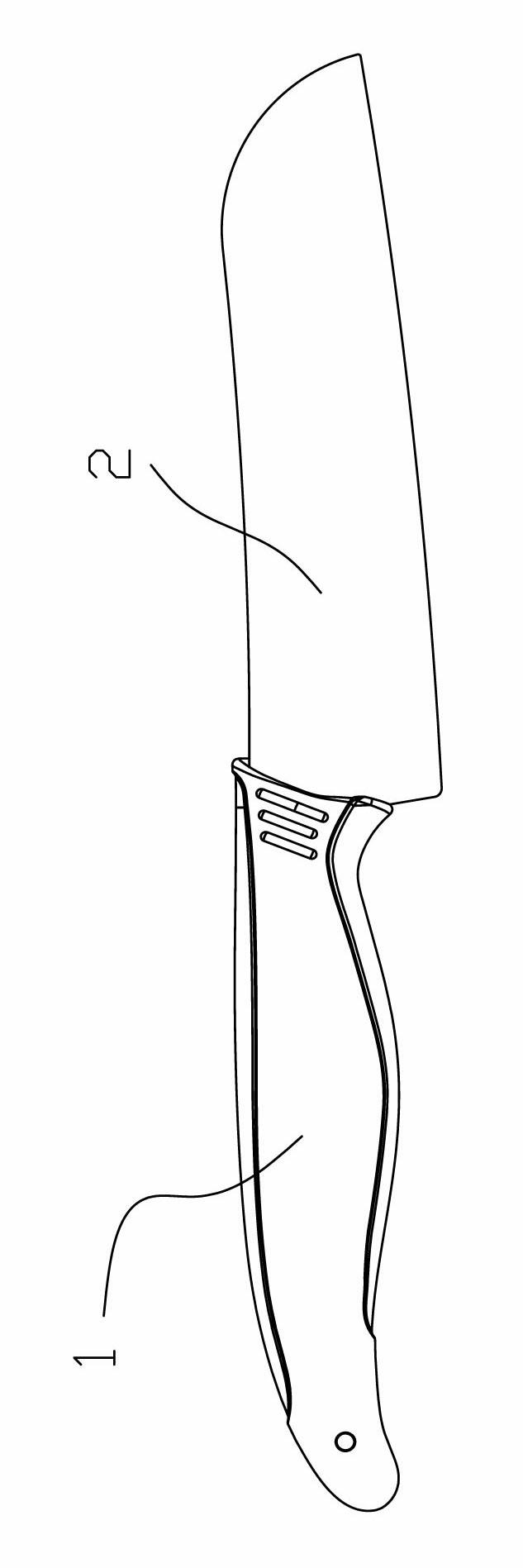

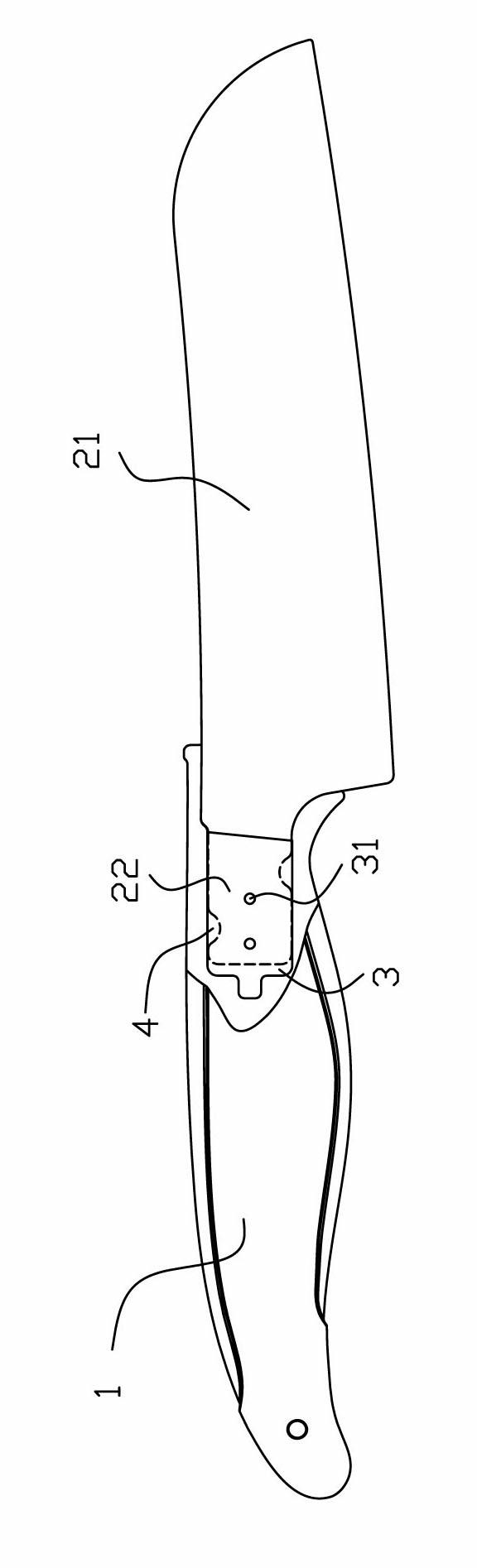

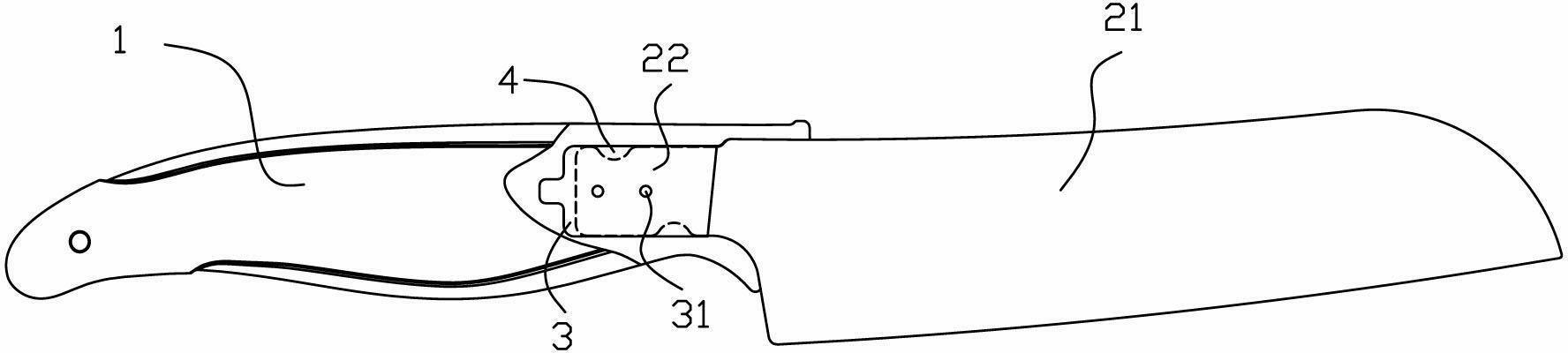

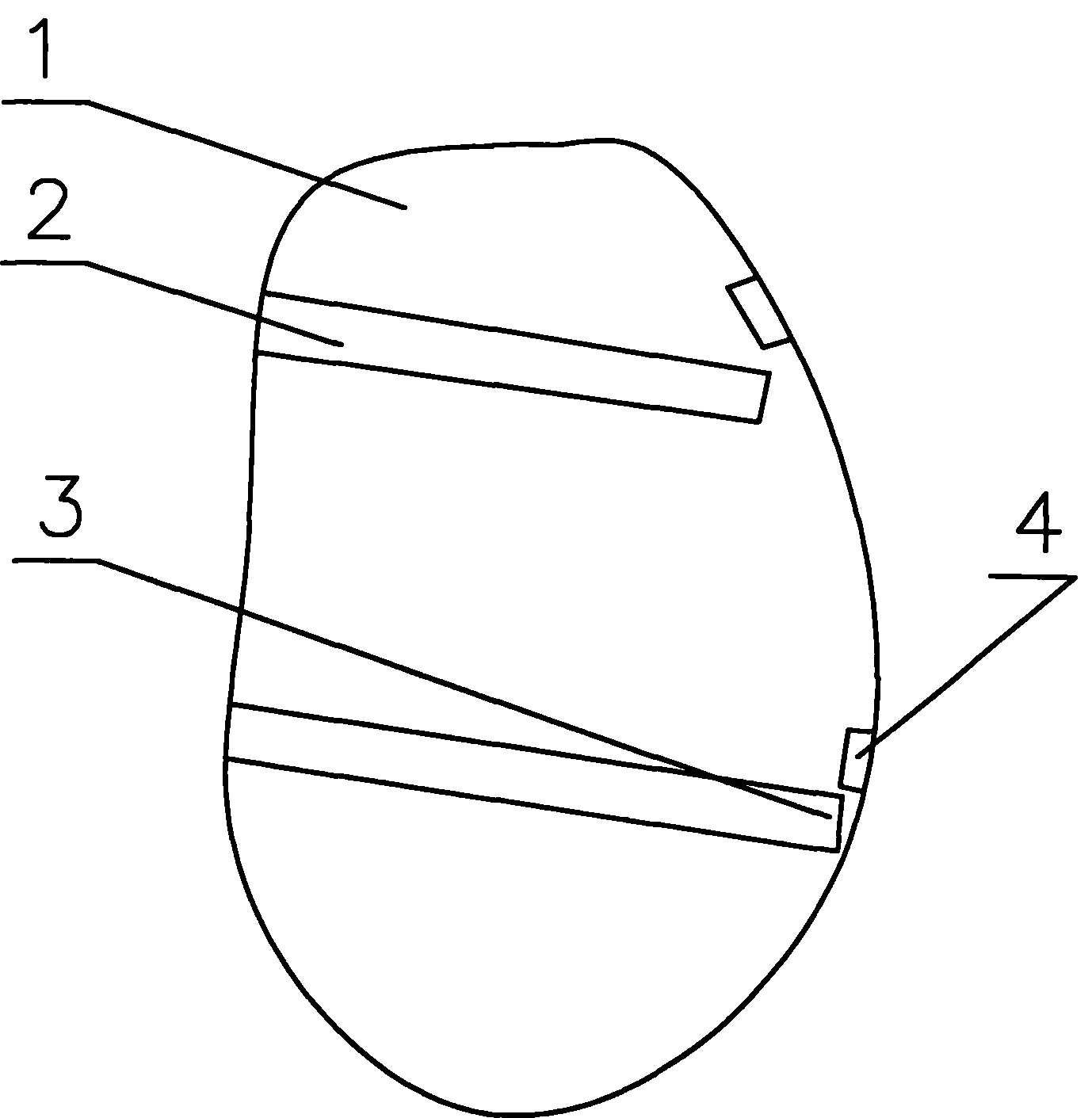

Ceramic knife and manufacturing method thereof

InactiveCN102114638ASimple structureImprove the heating effectMetal working apparatusMetal-working hand toolsPlastic materialsCeramic knife

The invention discloses a ceramic knife and a manufacturing method thereof. The ceramic knife comprises a plastic hilt, a ceramic blade and a metal piece, wherein, the ceramic blade is spliced in the plastic hilt through a connecting sheet; the metal piece is arranged in the outer position of the connecting sheet; a position equipped with the metal piece on a structure to be heated is heated through a thermatron when the ceramic knife is manufactured, molten plastic material is welded on the metal piece and the connecting sheet, and the ceramic knife is obtained after the molten plastic material is cooled down. The ceramic knife has a simple structure, the connection stability between the ceramic blade and the plastic hilt is easy to control, the finished product ratio is high, the manufacture effect can be controlled effectively, the manufacturing cost can be lowered greatly, the firm degree of formed structure is improved greatly by compared with the gluewater connection, the ceramic knife also has the advantage of compact and beautiful appearance, and the installing and fixing speed of the ceramic knife can be increased greatly; in addition, the metal piece in the ceramic knife can be detected through a metal detector when security inspection is carried out, so that safety accidents caused by the ceramic knife can be avoided.

Owner:ZHUHAI YUEKE JINGHUA TECH

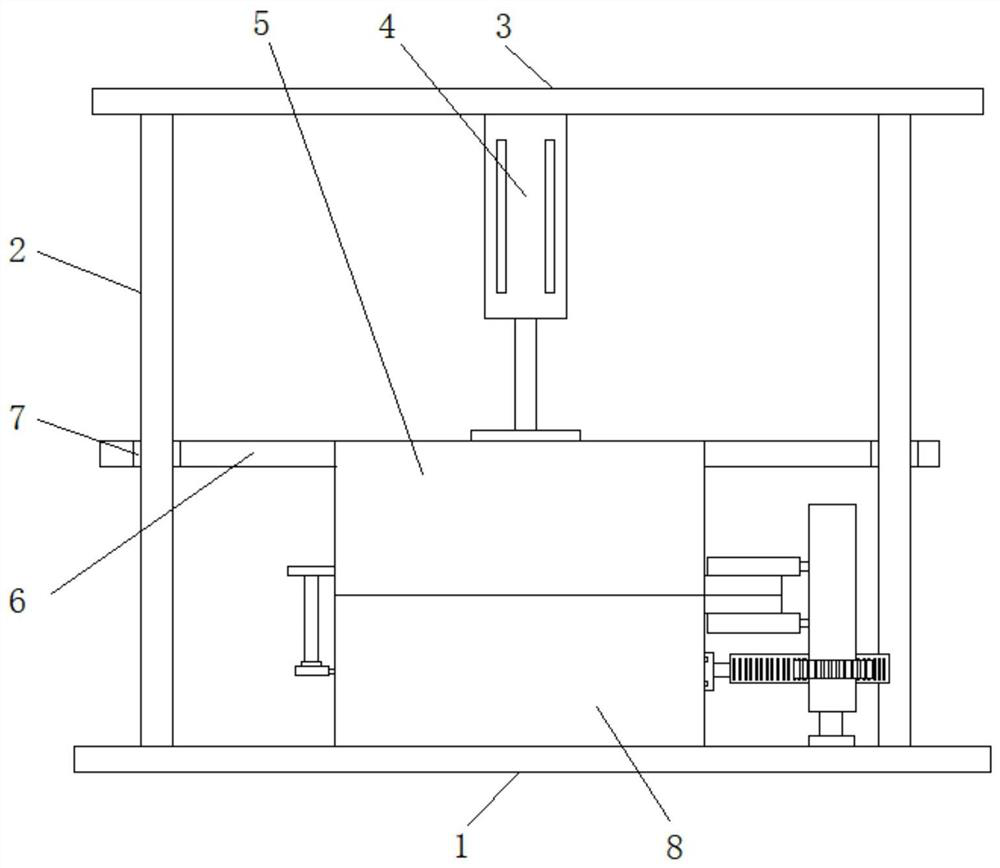

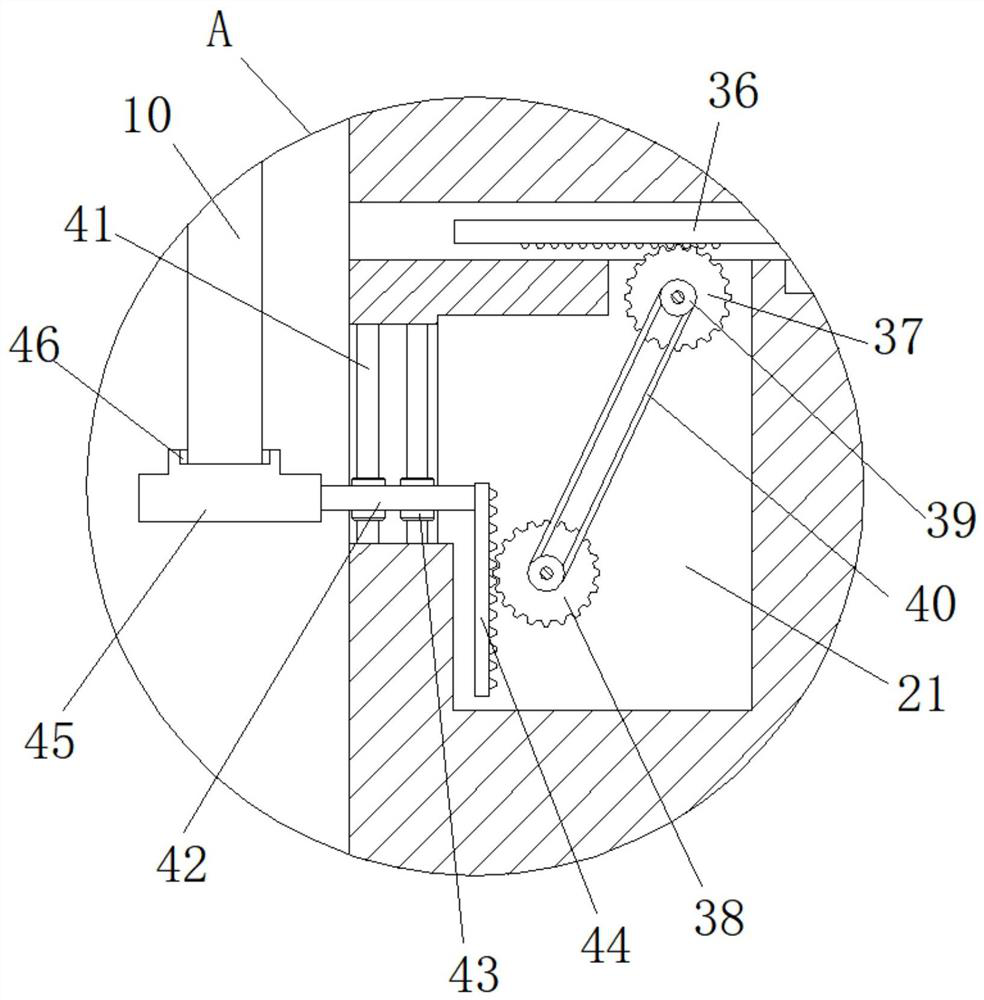

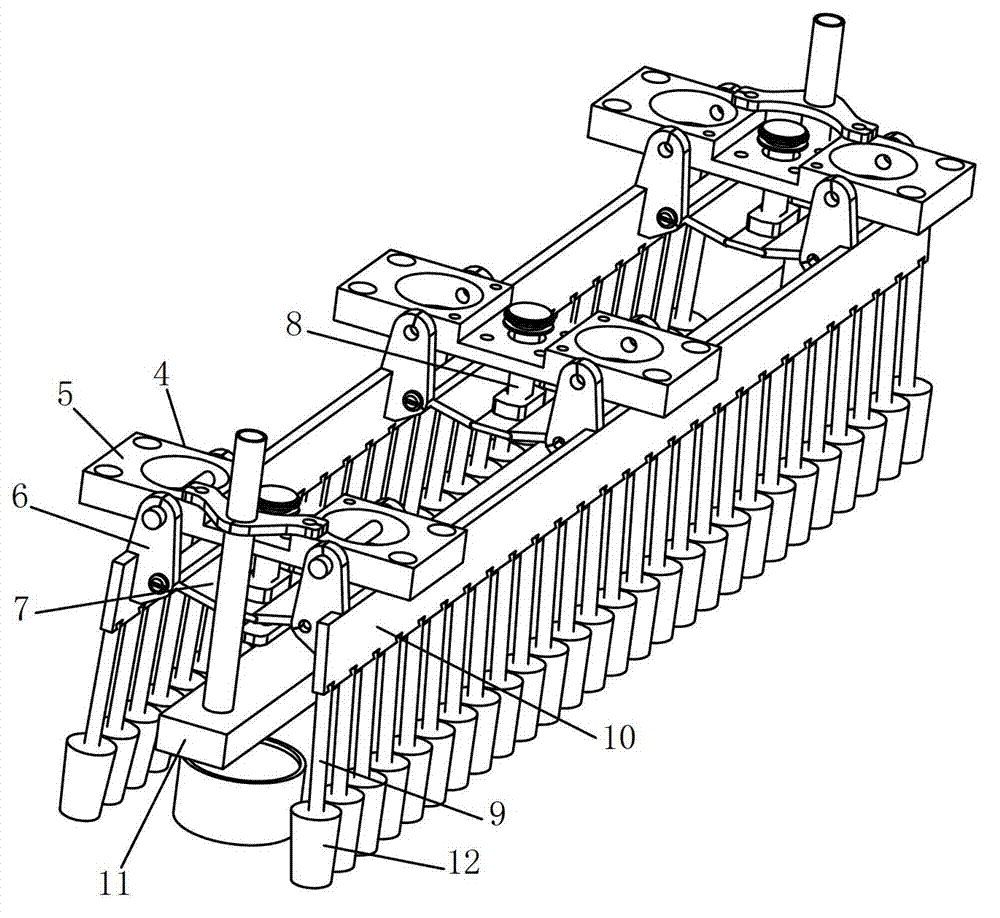

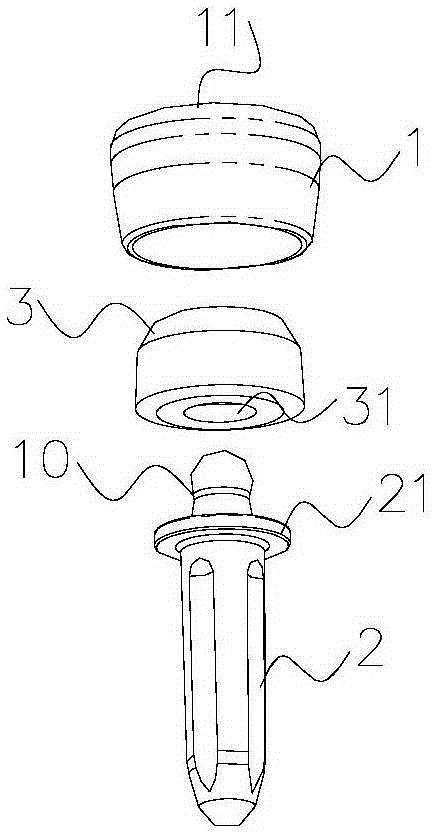

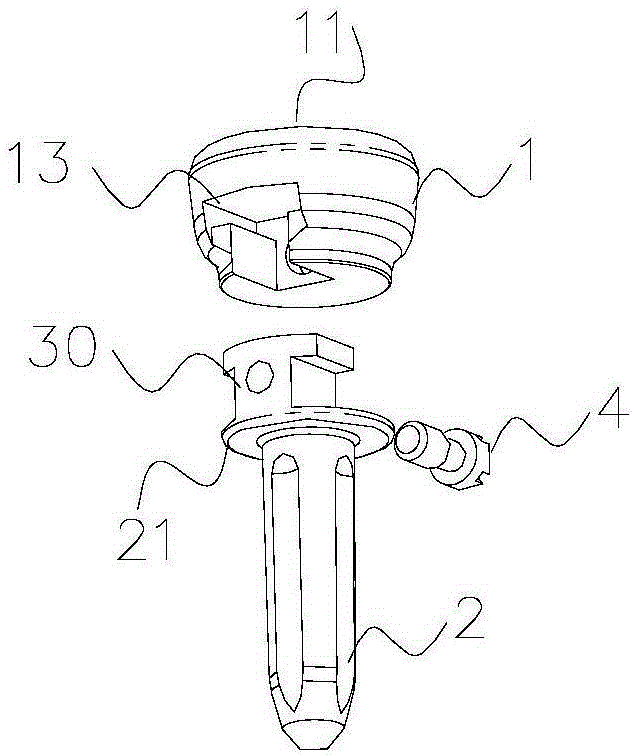

Injection mold capable of automatically stripping

InactiveCN112248380AAchieve the effect of automatic demouldingWill not affect the shapeElectric machineryEngineering

The invention relates to the technical field of injection molds, and discloses an injection mold capable of automatically stripping. The injection mold comprises a supporting base, wherein supportingrods are fixedly connected to four corners of the top end of the supporting base, a fixing plate is fixedly connected among the top ends of the four supporting rods, an air cylinder is fixedly installed at the bottom end of the fixing plate, an output shaft of the air cylinder is fixedly connected with an upper mold, the top end of the supporting base is fixedly connected with a lower mold, the lower mold is matched with the upper mold, and a first mounting cavity and a second mounting cavity are formed in the lower mold. The injection mold is reasonable in structure and convenient to use, anejector block can be automatically driven to move upwards to push an injection molding part to be demolded in the process that the air cylinder drives the upper mold to move downwards, the automatic demolding effect can be achieved without additionally arranging a driving motor, more energy is saved, the locking effect is achieved, so that the upper mold and the lower mold are matched more tightly, no gap is generated in the injection molding process, and the yield of injection molding finished products is higher.

Owner:芜湖友恒模具有限公司

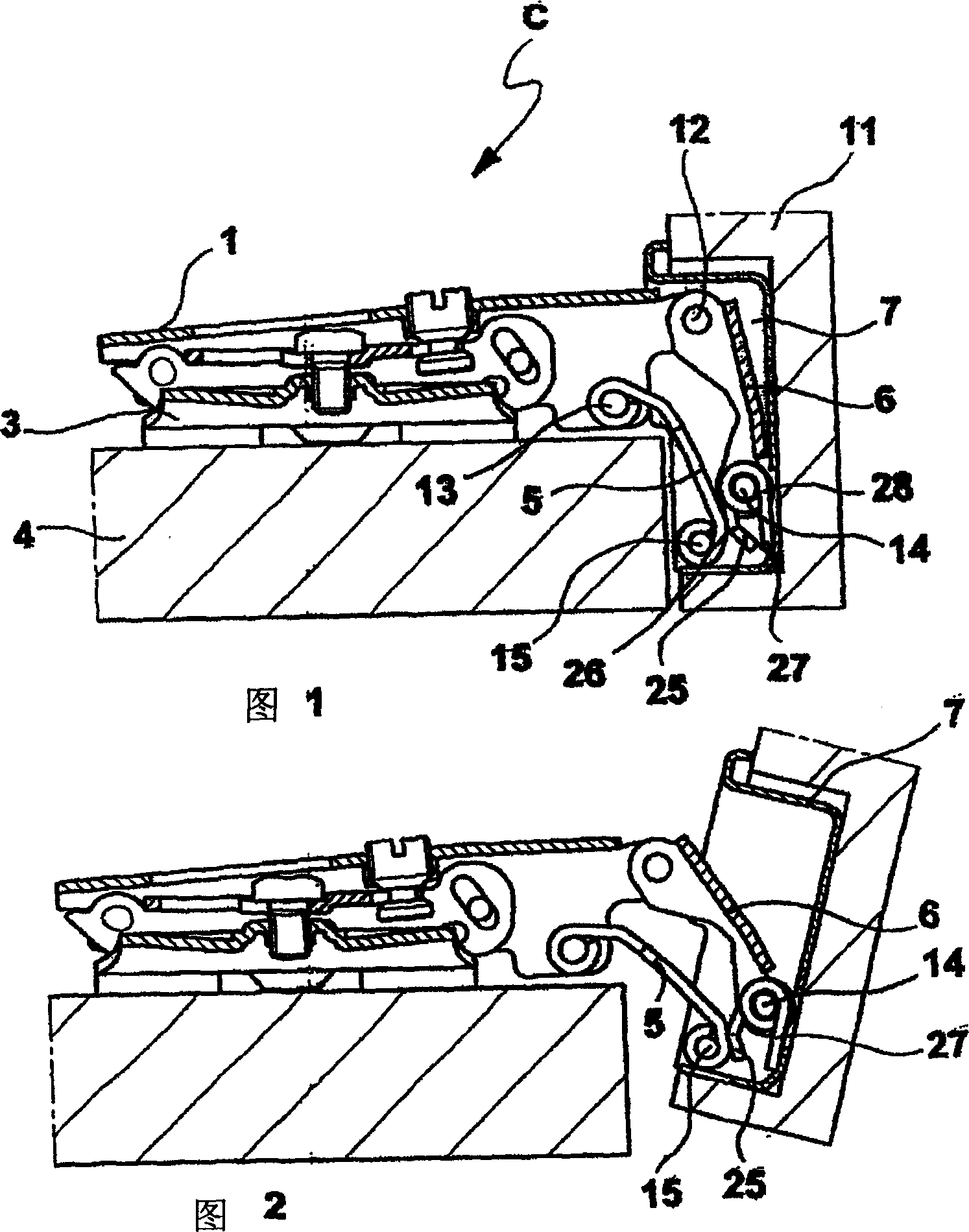

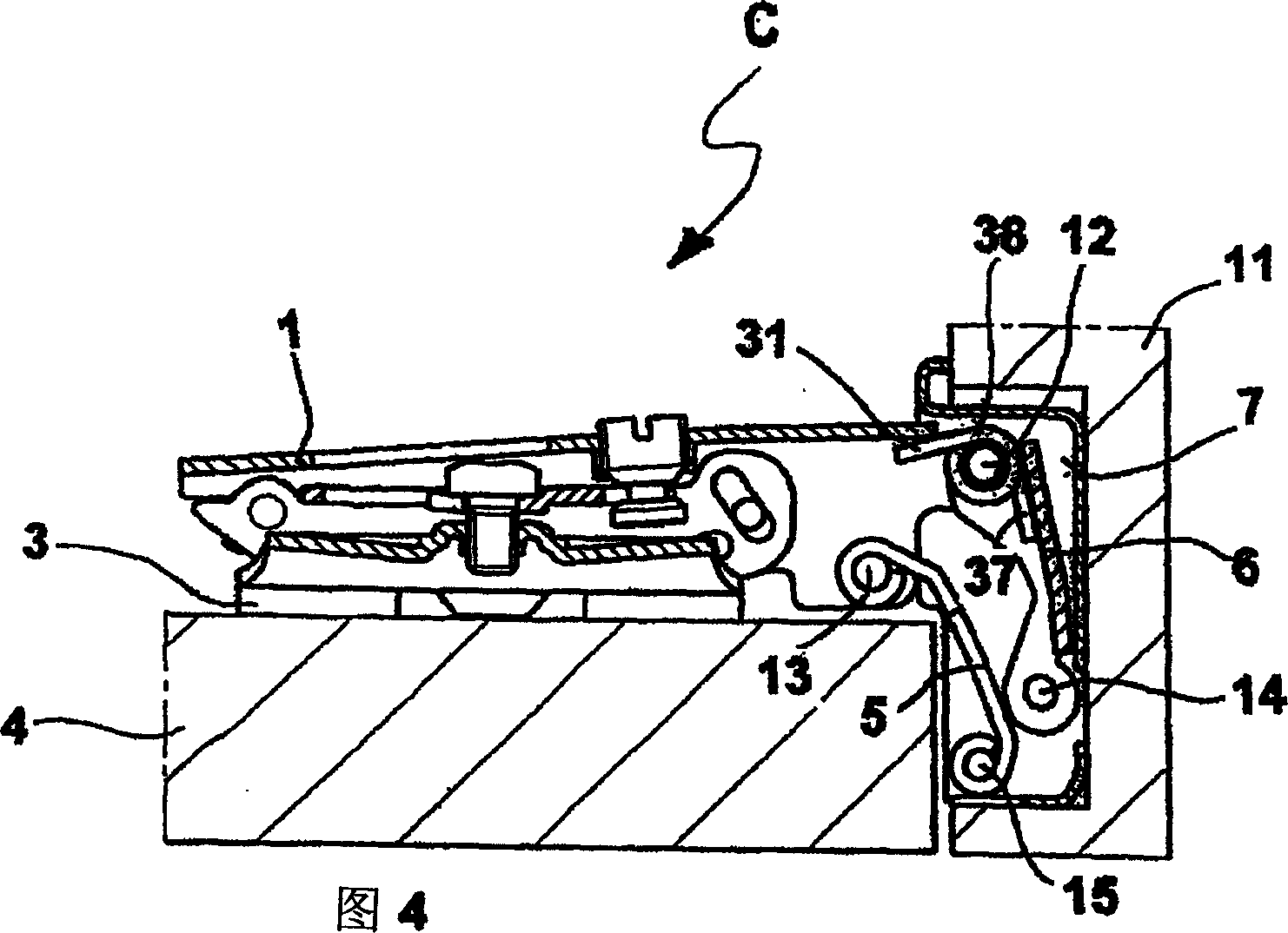

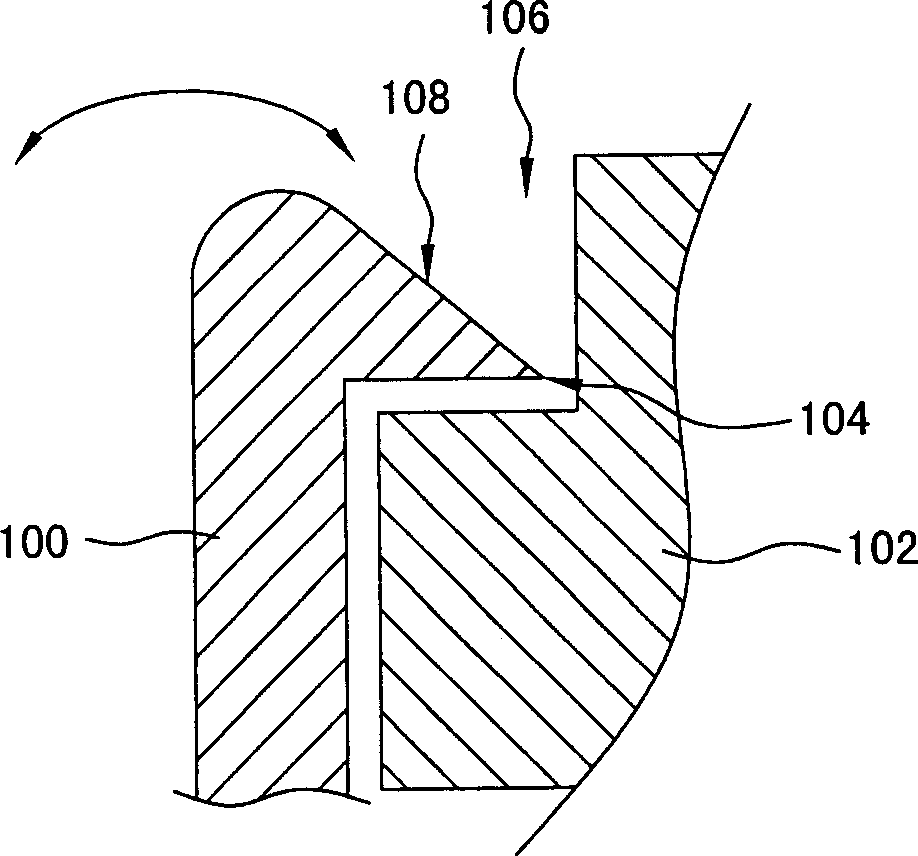

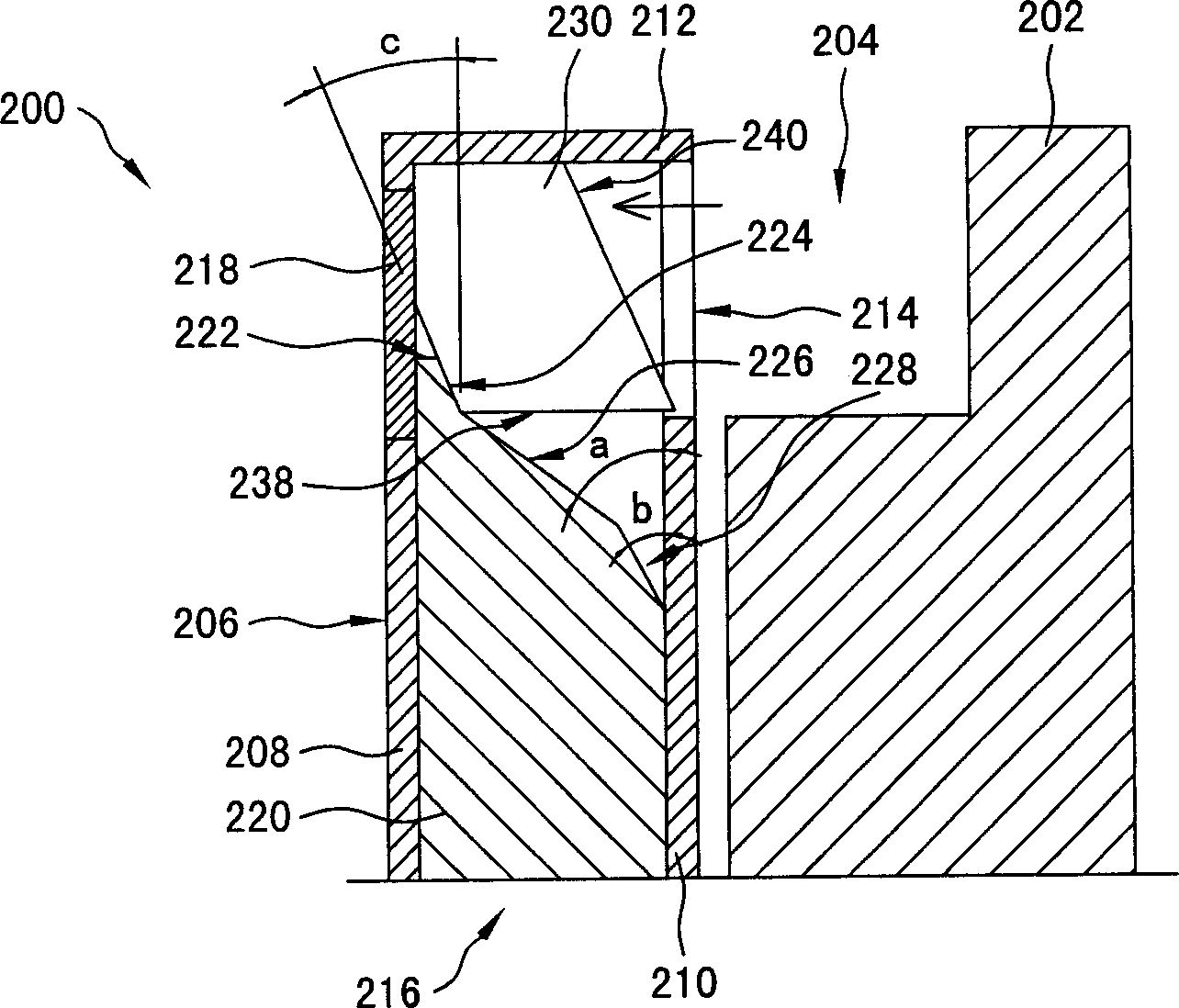

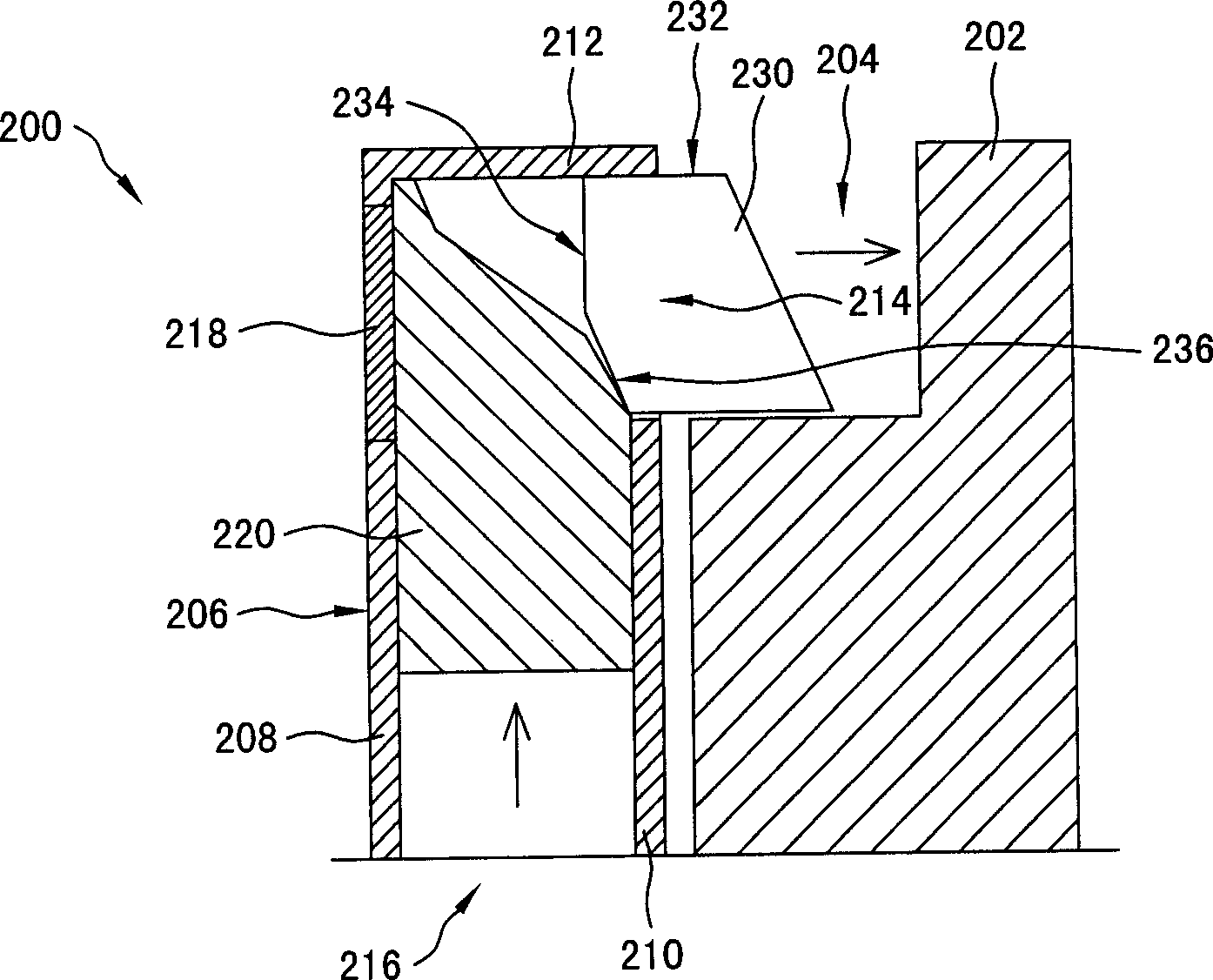

Furniture hinge with spring

ActiveCN1906372AWill not affect the shapeEasy to replacePin hingesWing openersMechanical engineeringHinge angle

Furniture hinge with a fixing arm (1) for fixing to a piece of furniture (4), a member (7) for fixing to a door (11), linked by two rockers (5, 6), forming an articulated quadrilateral so as to allow the rotation thereof, a V-shaped spring (28, 38, 48), placed at an end of a rocker (6), with an arm of the spring resting on the member for fixing to the furniture (4) or to the door (11) and the other arm of the spring resting on one of the rockers (5, 6), so as to create a lever arm that compresses the spring (8) producing a moment in the opening direction of the door (11), when this is in the closed position.

Owner:ARTURO SALICE

Electric automobile with self-charging function

InactiveCN105034840AWill not affect the shapeSolve battery lifeElectric propulsion mountingVehicular energy storageElectricityElectrical battery

The invention relates to an electric automobile with a self-charging function. The electric automobile comprises an automobile body which comprises a chassis frame and a shell. The chassis frame comprises a frame body and a battery. The battery is installed on the frame body. The electric automobile is characterized by further comprising a solar cell panel, an inverter, a V-shaped conducting elastic piece, a conductive contact and a pull handle. The solar cell panel is assembled on the frame body in a sliding mode. The inverter is installed on the frame body and electrically connected with the battery. The V-shaped conducting elastic piece is installed on the frame body and electrically connected with the inverter. The conductive contact electrically connected with the solar cell panel is fixed to the solar cell panel. The pull handle is an L-shaped pull handle and is installed on the solar cell panel. Saw teeth mutually corresponding are arranged on the upper portion of the pull handle and the lower portion of the frame body. The pull handle is connected with a housing which is a part of the shell. The solar cell panel can be utilized for self-charging, and appearance of the electric automobile is not affected.

Owner:天津科斯特汽车技术有限责任公司

Production method of plastic packaging bags

ActiveCN108656563AFast heat sealingWill not affect the shapeDomestic articlesTubular articlesPlastic packagingPlastic film

The invention discloses a production method of plastic packaging bags and belongs to the technical field of plastic bag production. The production method of the plastic packaging bags is characterizedby including the following steps that reshaping is performed, wherein a reshaping roller is adopted to reshape a plastic film, and the plastic film after being reshaped is cropped, the plastic film after being cropped is pulled and the two sides of the plastic film are made to coincide with each other by depending on molds on the two sides, and a cylindrical shape is formed; middle sealing is performed, wherein the plastic film is pulled at the speed of 40-120 m / min, hot air is blown to the coinciding portion of the plastic film, middle sealing of the plastic film is completed, a plastic cylinder is formed, the temperature of the hot air is 118-192 DEG C, and the air pressure of the hot air is 0.2-0.4 MPa; and bottom sealing is performed, wherein the plastic cylinder is subjected to transverse heat sealing and is cut off, and the plastic bags are formed. According to the production method of the plastic packaging bags, middle sealing is performed in the manner of thermal radiation, heat sealing on the plastic film can be achieved in the pulling process of the plastic film, and therefore the heat sealing speed of the plastic film is increased, and the production speed of the plastic bags is greatly improved.

Owner:淄博洁林塑料制管有限公司

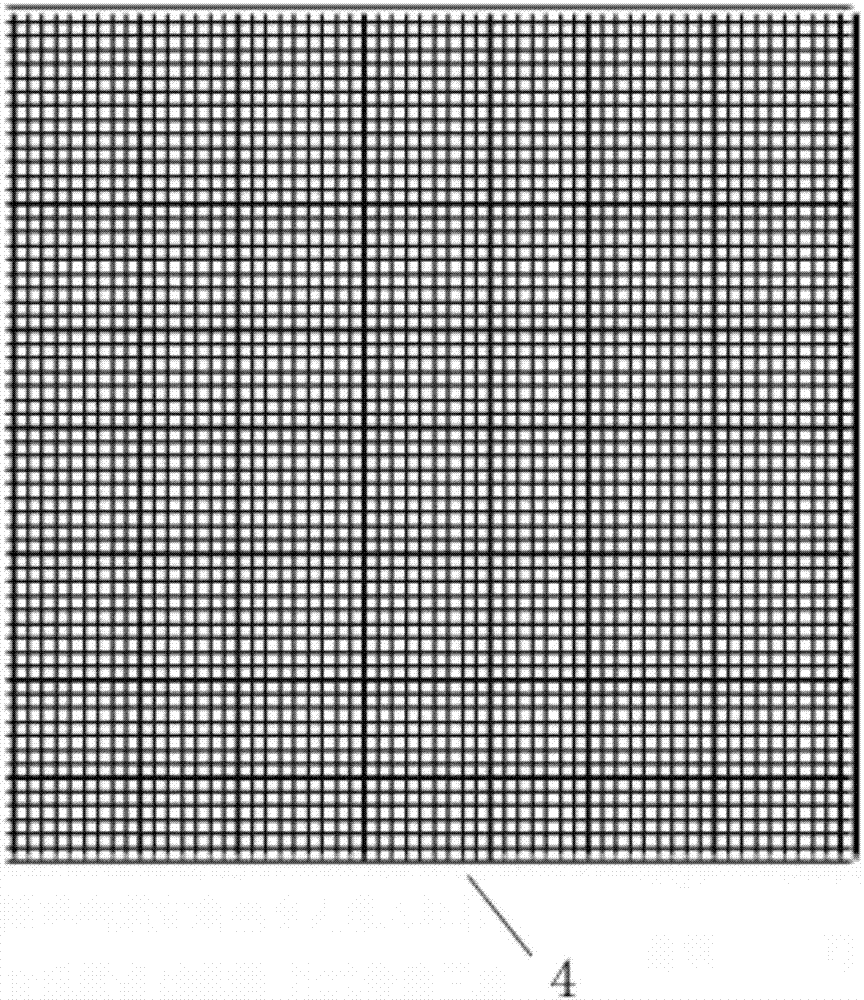

Electron beam moire fringe generation apparatus and electron optical imaging system

InactiveCN107492476AWill not affect the shapeNo scan timeElectrode and associated part arrangementsImage converterElectron optics

The invention provides an electron beam moire fringe generation apparatus and an electron optical imaging system. The electron beam moire fringe generation apparatus comprises an excitation light source, a light-transmitting window, a photoelectric negative electrode, a positive electrode grid mesh, a tube shell, a framing image converter tube and a fluorescent screen; strip-shaped grooves are arranged on the surface of the photoelectric negative electrode for generating first electronic optical grating; the mesh number of the positive electrode grid mesh is matched with the space frequency of the grooves; and the positive electrode grid mesh is arranged close to the photoelectric negative electrode and used for generating second electronic optical grating and forming electron beam moire fringe under the effects of the first electronic optical grating and the second electronic optical grating. By virtue of the electron beam moire fringe generation apparatus provided by the invention, moire fringe can be generated under the interaction of the photoelectric negative electrode and the positive electrode grid mesh directly, without needing scanning time, so that efficiency is improved.

Owner:SHENZHEN UNIV

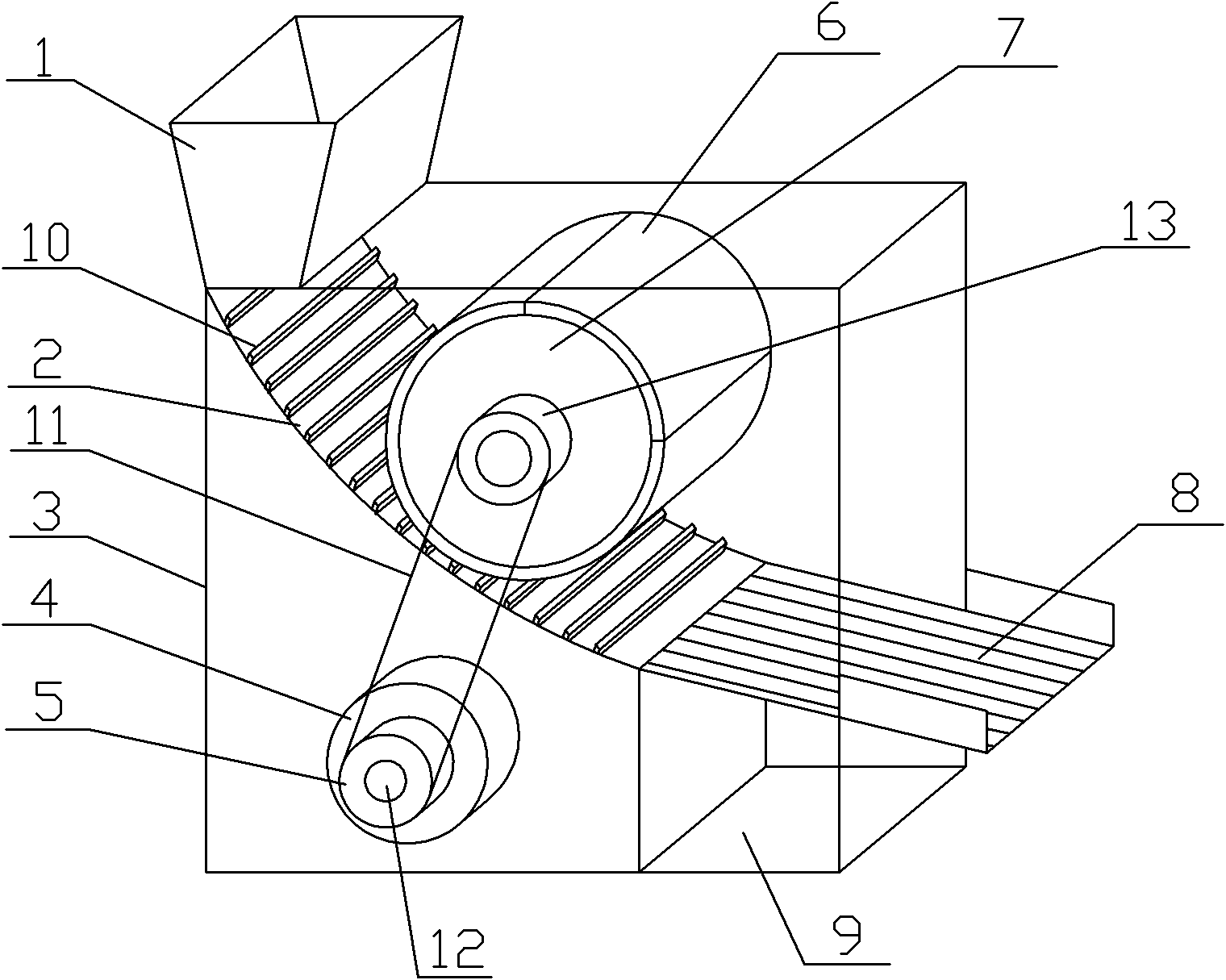

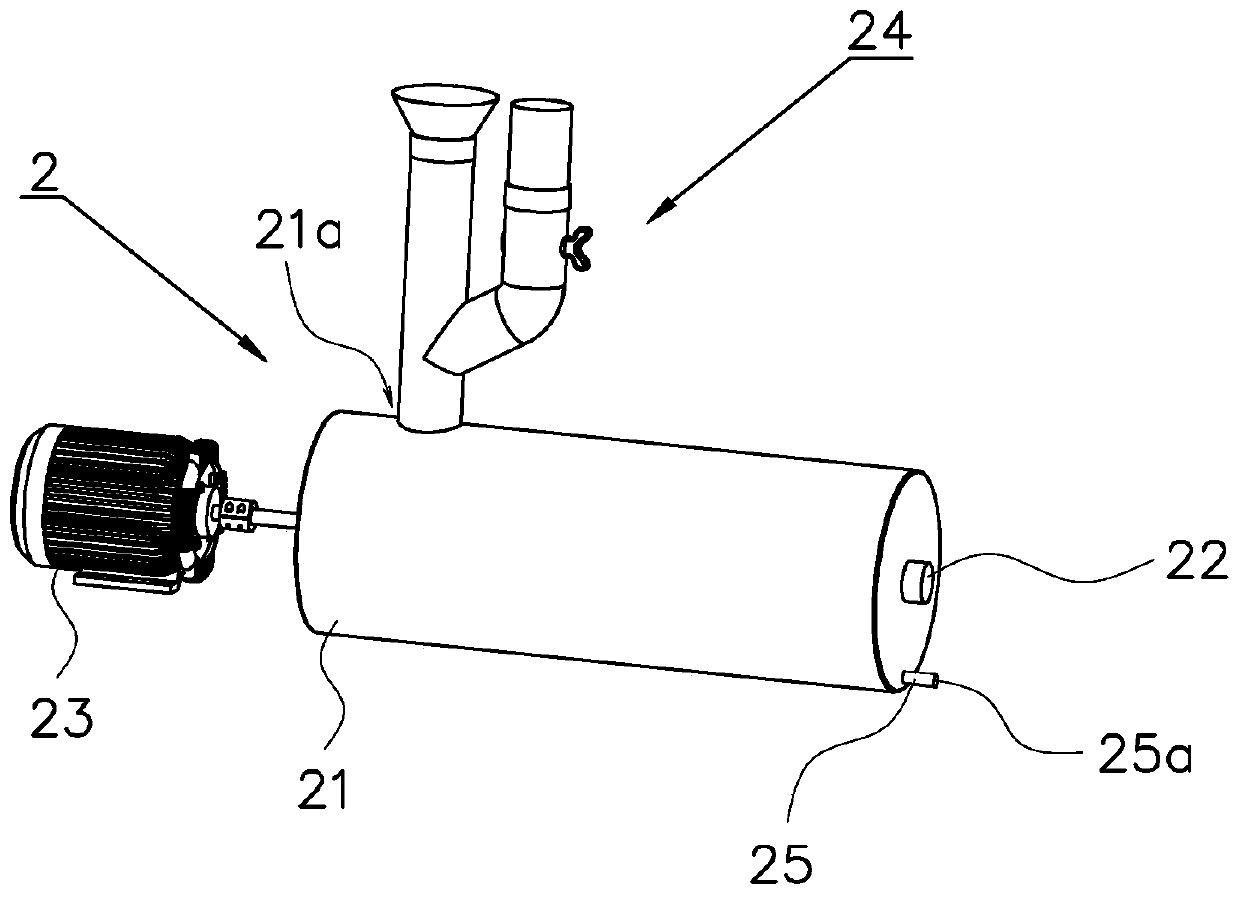

Quick peanut skin stripping machine

The invention discloses a quick peanut skin stripping machine, which belongs to a stripping machine. The stripping machine comprises a machine shell, a material inlet, a stripping wheel and a motor, wherein the material inlet is formed on the upper part of the machine shell; the stripping wheel and the motor are arranged in the machine shell; a motor shaft of the motor is provided with a motor belt pulley; the motor belt pulley is connected with a stripping belt pulley which is coaxial with the stripping wheel through a belt; the stripping wheel is provided with a hair brush; a slow stator cambered surface is formed in the machine shell on the lower part of the material inlet and provided with a plurality of transverse bumps; the end part of the slow stator cambered surface is provided with a mesh screen which extends out of the machine shell; and the lower part of the mesh screen is provided with a material collecting box. Compared with the prior art, the quick peanut skin stripping machine has the characteristics of simple structure, good stripping effect, capabilities of not damaging peanut kernels or not influencing the profiles of the peanut kernels, and lowering working intensity and the like, and has high popularization value and high application value.

Owner:INST OF AGRO FOOD SCI & TECH SHANDONG ACAD OF AGRI SCI

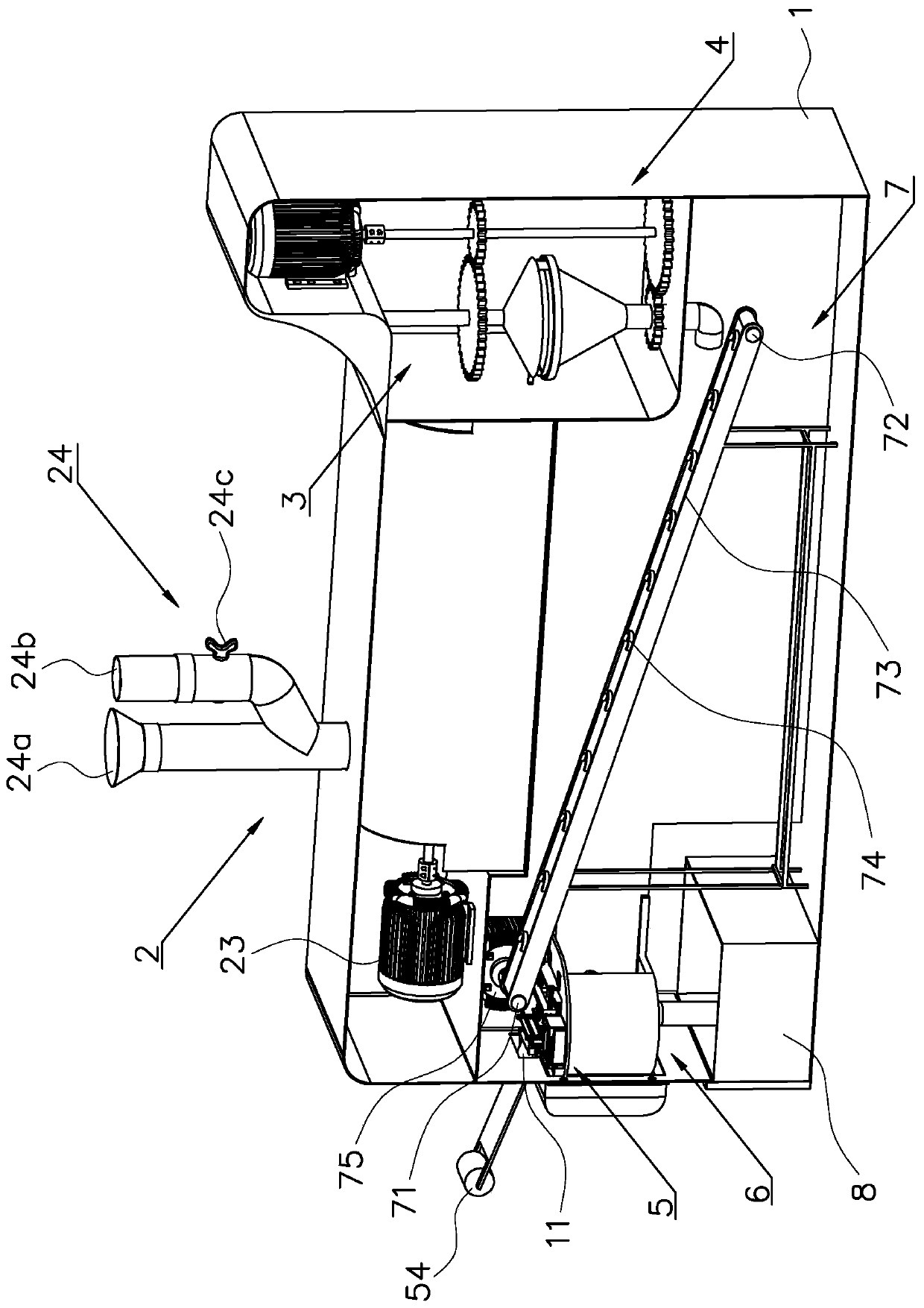

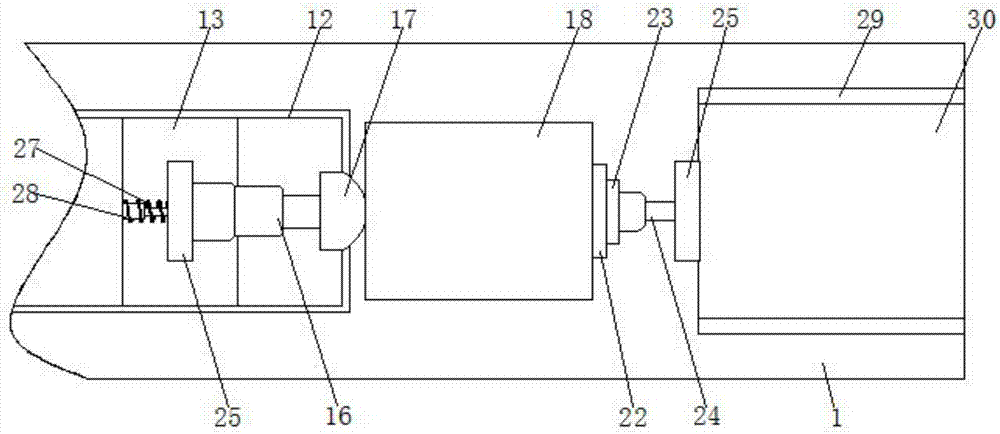

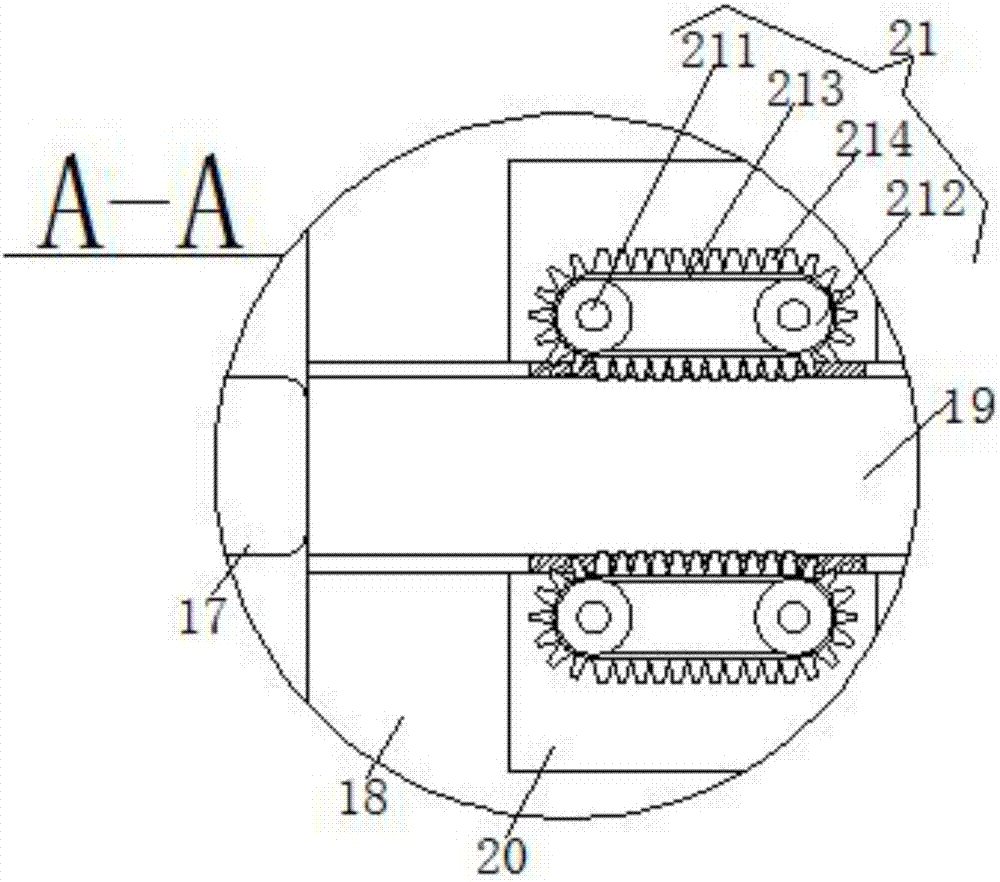

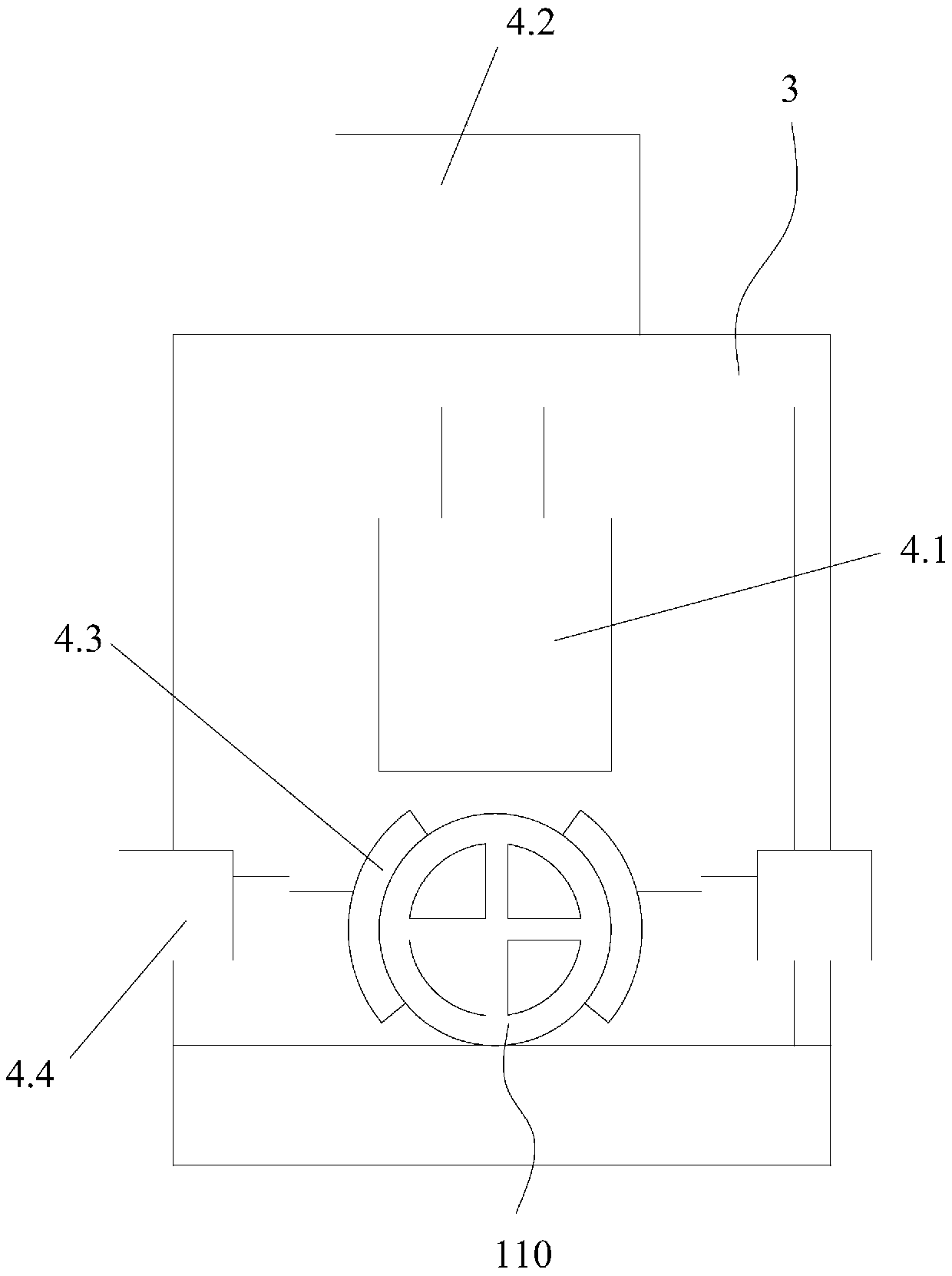

Full-automatic pill making machine

PendingCN111096905AOmit stepsSimplify process structurePharmaceutical product form changeEngineeringMechanical engineering

The invention discloses a full-automatic pill making machine. The pill making machine comprises a frame; the interior of the frame is provided with a medicine material uniform-mixing mechanism with afeeding hole and a medicine ball extrusion hole, a pill making mechanism with a medicine ball entrance and a pill exit, and a pill packaging mechanism with a pill entrance and a discharge hole, wherein a used for cutting off medicine balls extruded from the medicine ball extrusion hole is further arranged at the position of the medicine ball entrance; a package conveying mechanism is arranged between the pill exit and the pill entrance; the package conveying mechanism is used for conveying packages one by one to a position between the pill exit and the pill entrance; and the pill packaging mechanism is used for performing roll forming pills with the packages. According to the pill making machine, the medicine materials are directly extruded and made into the pills after being evenly mixed,and thus, not only are the steps of making medicine bars and transporting the medicine bars omitted, but also the process and the equipment structure are simplified; meanwhile, full-automatic pill making and packaging of soft pills, such as dog-days stickers is realized, and the production efficiency of the soft pills such as the dog-days stickers is greatly improved.

Owner:HANGZHOU CITY XIAOSHAN DISTRICT TRADITIONAL CHINESE MEDICAL HOSPITAL

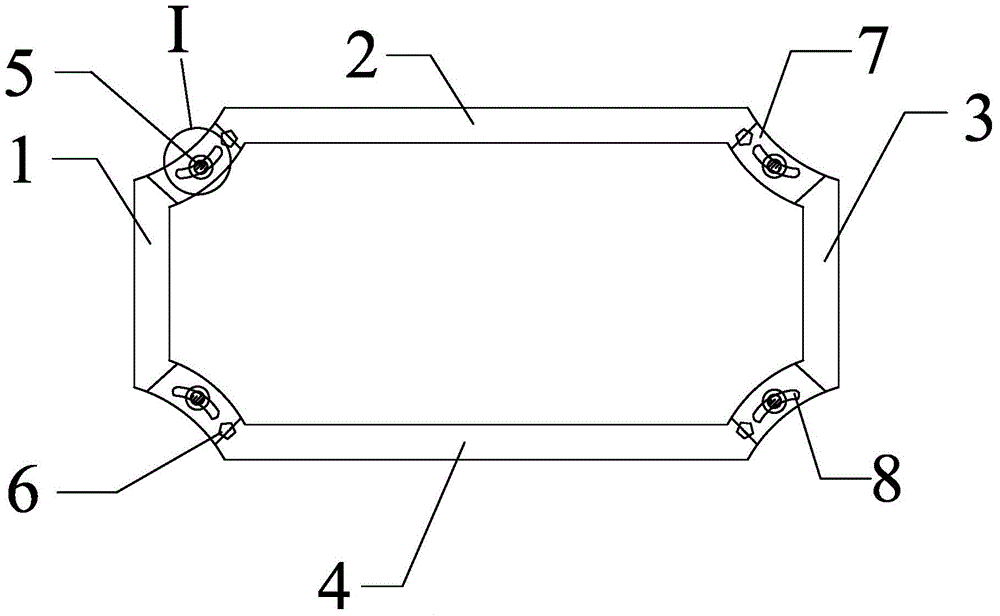

Frame-shear piezoelectric friction damping device

InactiveCN104153482AWill not affect the shapeDoes not affect functionalityShock proofingSolar cellHigh pressure

The invention discloses a frame-shear piezoelectric friction damping device. The frame-shear piezoelectric friction damping device comprises a frame and four friction damping devices, wherein the frame adopts a rectangular frame structure, and comprises four steel plates which are connected end to end; connecting parts are arranged at both ends of the steel plates respectively; through slots are formed in the connecting parts; the through slots in the connecting parts of the two adjacent steel plates correspond to each other, and are connected through the friction damping devices; the friction damping devices can slide along the through slots; each friction damping device comprises a bolt, and a friction damping pad, a stacked piezoelectric sheet stack and a nut which sequentially sleeve the screw of the bolt. Sizes of the steel plates can be adjusted to be consistent with sizes of used beam columns, so that the construction speed is high and the efficiency is high; a solar cell is used, so that power consumption is low, a high-voltage power supply is not required to be mounted, and detachment, replacement and installation of the solar cell and the stacked piezoelectric sheet stack are simple and feasible; due to four-point friction, energy consumption effect is relatively good.

Owner:DALIAN UNIV OF TECH

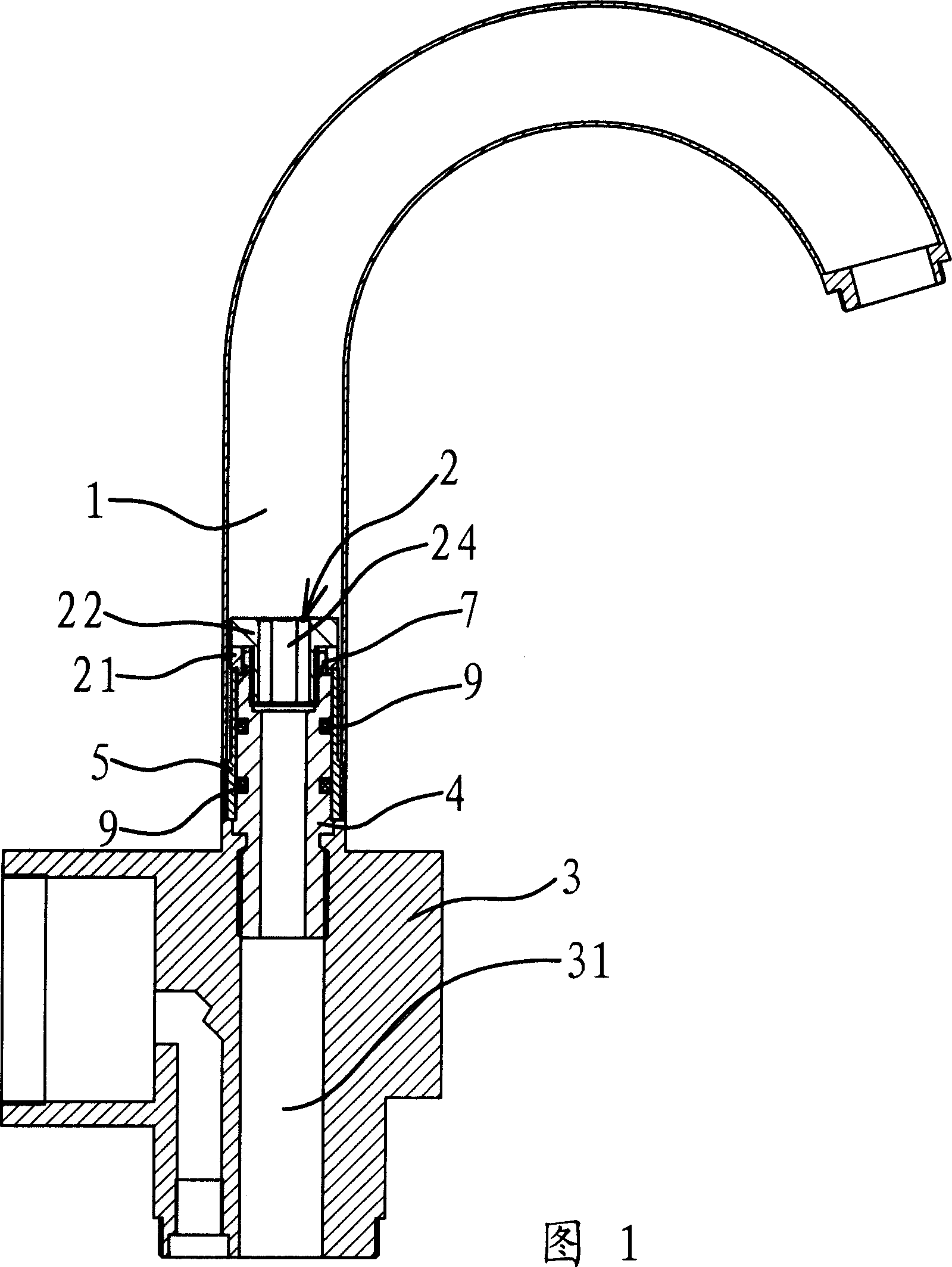

Watertap discharging tube connecting device

This invention discloses a connecting device of water tap discharging tubes. The water tap discharging pipe connecting device is installed between valve and discharging pipe of water tap. It includes a cylinder-shaped connector which is fixed on valve body and interlinked with water outlet in valve body. The discharging tube is sleeved on connector and can rotate around connector. There is a stop edge at inside of discharging tubeí»s connect end. A pressing cap with central hole is coupled with connector or end placed in the discharging tube. The outer edge of pressing cap presses at the stop edge. The stop edge inside discharging tube is pressed to via fastening and makes discharging tube can not disengage connector, but discharging tube can rotate around connector to change angle of discharging tube.

Owner:盛连送

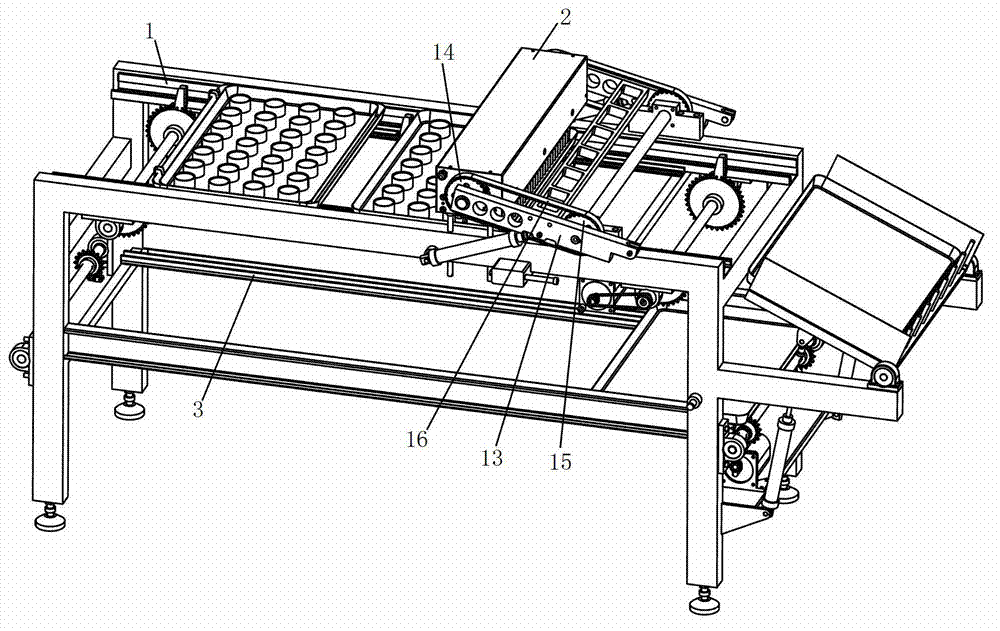

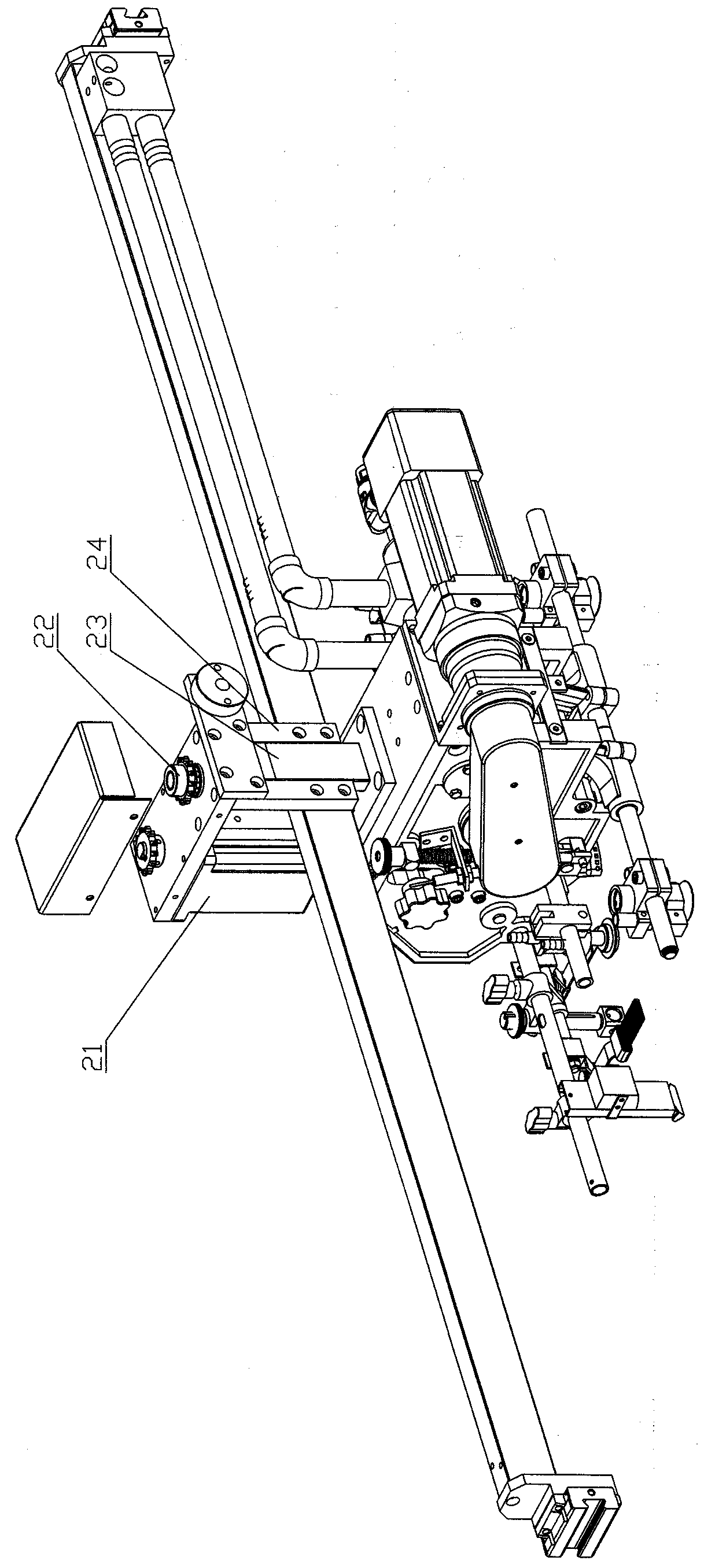

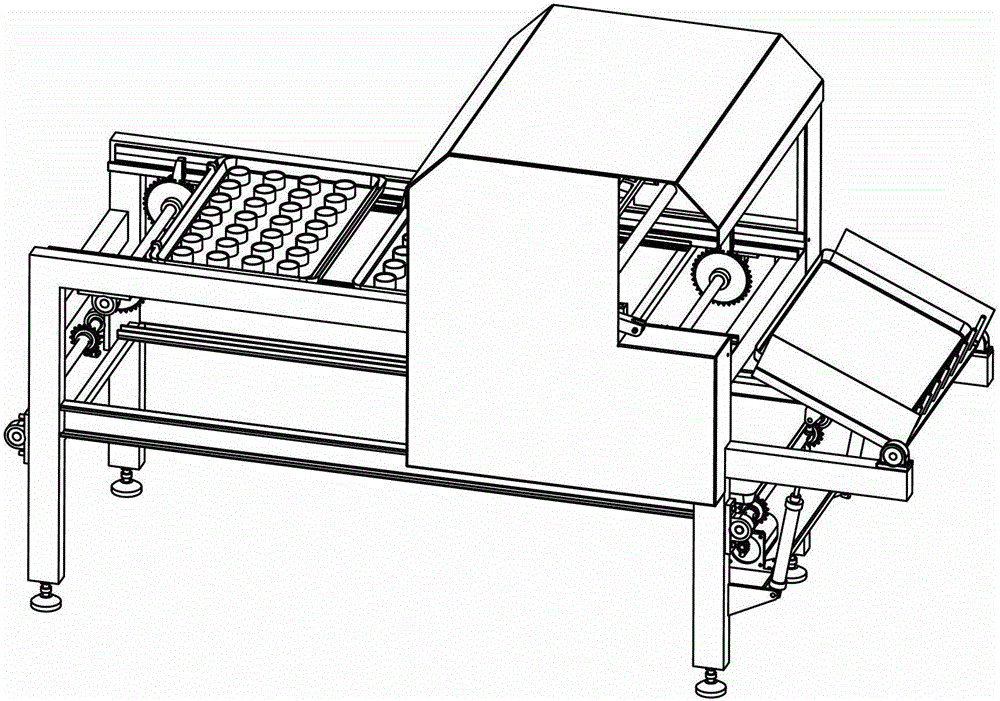

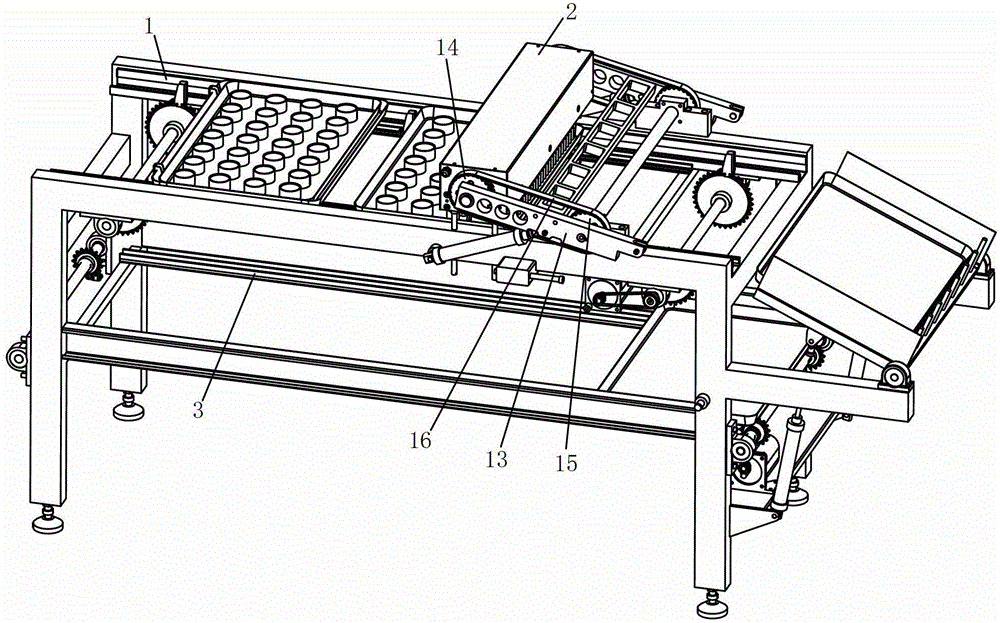

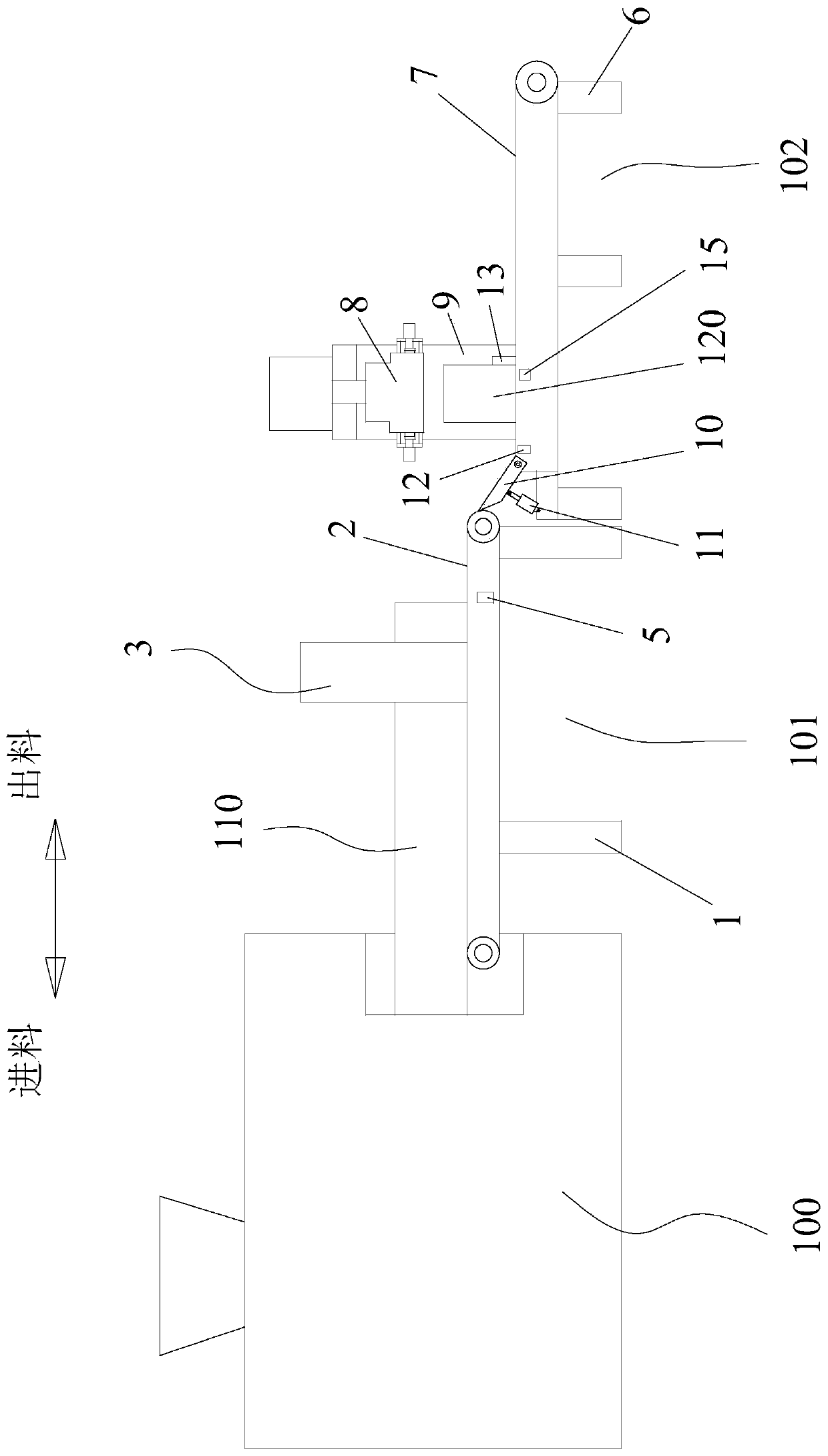

Material transporting table

InactiveCN103171894ADoes not affect aestheticsWill not affect the shapeConveyor partsEngineeringFood material

The invention discloses a material transporting table. The material transporting table comprises a tray feed rail, a grabbing mechanism and a tray recovery rail, wherein the grabbing mechanism is arranged on the end portion of the tray feed rail. A tray recovery frame is arranged at the front end of the tray feed rail, and the tray recovery rail is arranged below the tray feed rail. The grabbing mechanism can be used for achieving transporting of materials among different platforms, in the process of transporting, the materials do not need to be turned over so that the materials can not be deformed, integral attractiveness of the materials can not be influenced, and especially when food materials are transported, appearance of food surfaces can not be influenced. Through clamping bars in rows arranged on transition plates at two ends of a grabbing arm and soft foaming silicon rubber cases sleeved on the clamping bars, soft materials can be grabbed mechanically and conveniently, and the surface structures of the materials can not be damaged easily. The material transporting table can be used for automatic material packaging of large-scale machines, manual work is reduced, and work efficiency is improved.

Owner:FENGLEI PRECISION MACHINERY

Capitulum radius replacement prosthesis

ActiveCN105193522AIn line with the characteristics of daily behavior sportsImprove stabilityAnkle jointsJoint implantsArticular surfacesHuman anatomy

The invention provides a capitulum radius replacement prosthesis. The capitulum radius replacement prosthesis comprises a capitulum radius and a radius broach, wherein the capitulum radius is in the shape of a circular truncated cone, the end face of the large-diameter end of the capitulum radius serves as the articular surface and is sunk inwards to form a spherical articular cavity, and the sphere center of the spherical articular cavity is located on the axis of the radius broach; a round connecting plane is arranged at the end of the radius broach, the diameter of the connecting plane is identical with that of the small-diameter end of the capitulum radius, and the small-diameter end of the capitulum radius is connected with the connecting plane of the radius broach through a connecting part in a matched mode. The capitulum radius replacement prosthesis accords with human anatomy and daily performance kinetic characteristics and has high stability and safety. Through the improvement of bone cement constituents, biocompatibility between the capitulum radius replacement prosthesis and bone substances is improved, complications such as deviation, looseness, infection and instability do not occur easily, service life is long, and different connecting parts can be adopted according to the conditions of patients to guarantee the optimal using effect of the capitulum radius replacement prosthesis.

Owner:北京威高亚华人工关节开发有限公司

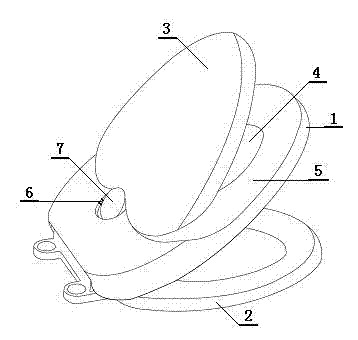

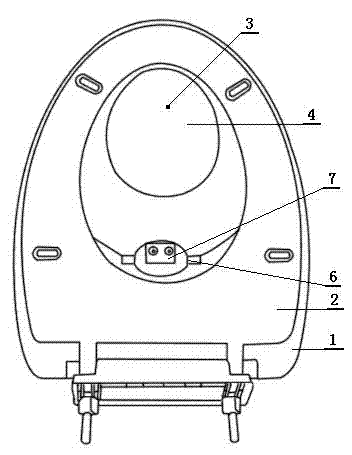

Closestool cover plate commonly used by adults/children

The invention relates to a closestool cover plate commonly used by adults / children. The closestool cover plate is composed of an upper cover plate and a lower base plate which are installed through a shaft. The closestool cover plate is characterized in that a child sitting-defecating hole with the upper face provided with a small rotatable cover plate is arranged in the front of the upper cover plate, the child sitting-defecating hole is sunken downwards slightly, the small cover plate is arranged in the position close to the rear of the upper cover plate through a shaft, and the small cover plate is inosculated with the upper cover plate in overall shape when covering the position close to the front of the upper cover plate. When the closestool cover plate is used, the adults can turn over the upper cover plate according to conventional action to defecate in a sitting state, the children can turn over the small cover plate to defecate in a sitting state, and the closestool cover plate is very convenient to use and can be commonly used by both the adults and the children. In the implementation process, only the structure of the position close to the front of the upper cover plate is changed, the small cover plate is additionally designed and manufactured, the structure of an original lower base plate, the rear end of the original upper cover plate and an original shaft mounting system are not changed, and therefore the closestool cover plate is convenient to implement and little in cost increase and overall appearance influences on the upper cover plate, and the closestool cover plate has high practicability and wide market application prospect because the closestool cover plate can be commonly used by both the adults and the children.

Owner:李斌

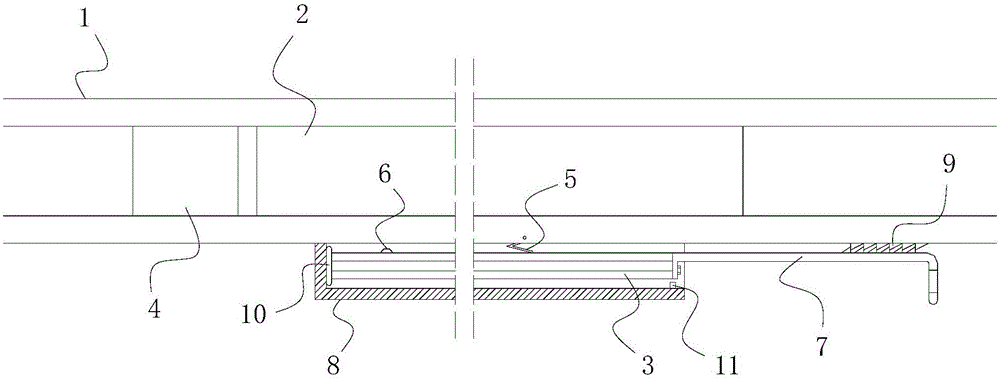

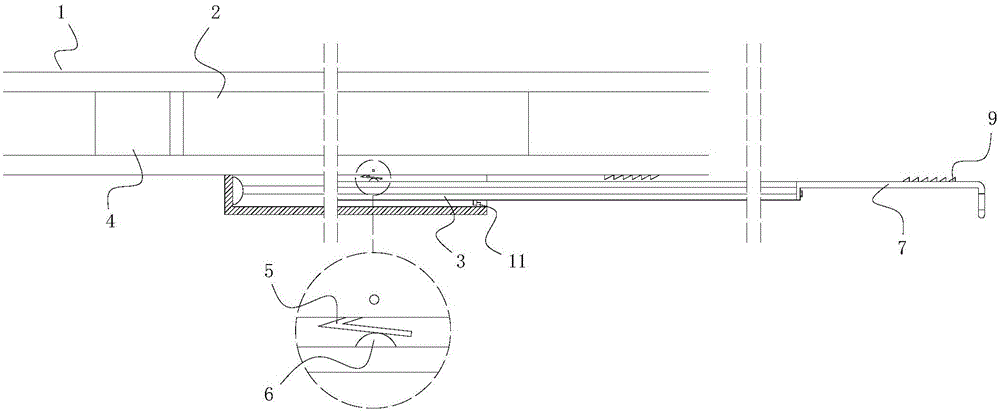

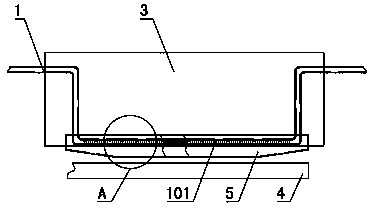

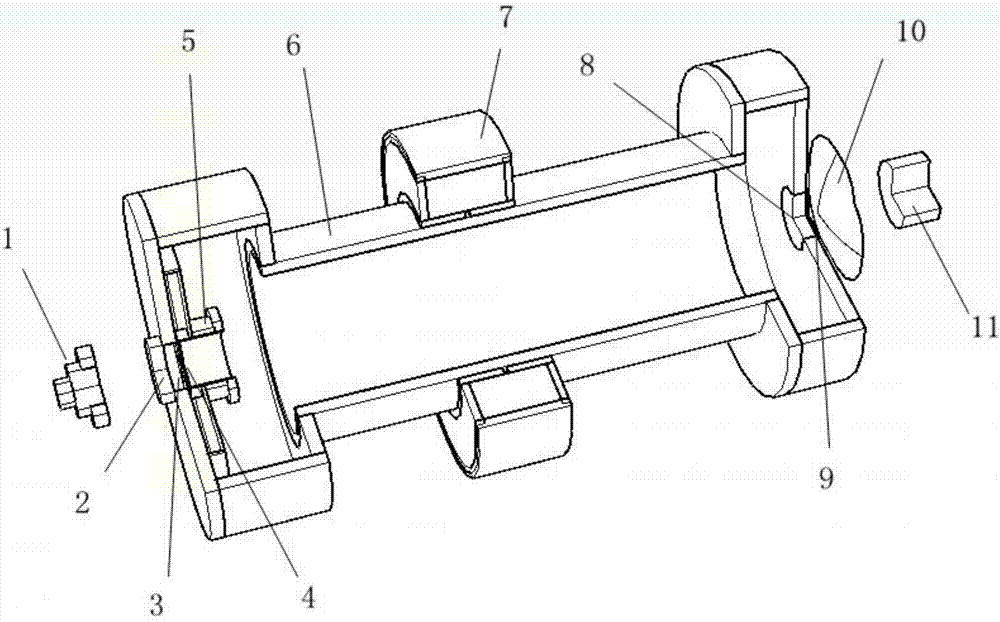

Paper feeder

PendingCN109095228AWill not affect the shapeWill not be affected by packagingArticle feedersCardboardElectrical control

The invention discloses a paper feeder. The paper feeder comprises a frame and a paper feeding head and is characterized by comprising a height adjustment device for adjusting the height of the paperfeeding head and a longitudinal adjustment device for adjusting the longitudinal position of the paper feeding head. Driving sources of the height adjustment device and the longitudinal adjustment device are both connected with an electrical connector. The paper feeder has advantages that electric driving is adopted in height and longitudinal adjustment of the paper feeding head, lifting of a feeding table board and side board width adjustment, and the driving sources are connected with the electrical connector to realize automatic operation.

Owner:ZHEJIANG JINBAO MACHINERY

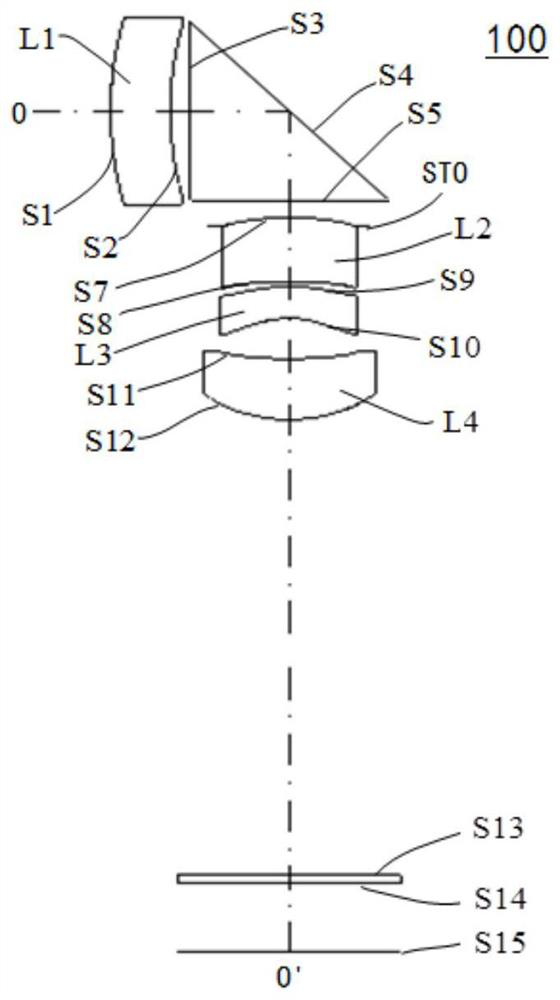

Optical imaging system, module and electronic equipment

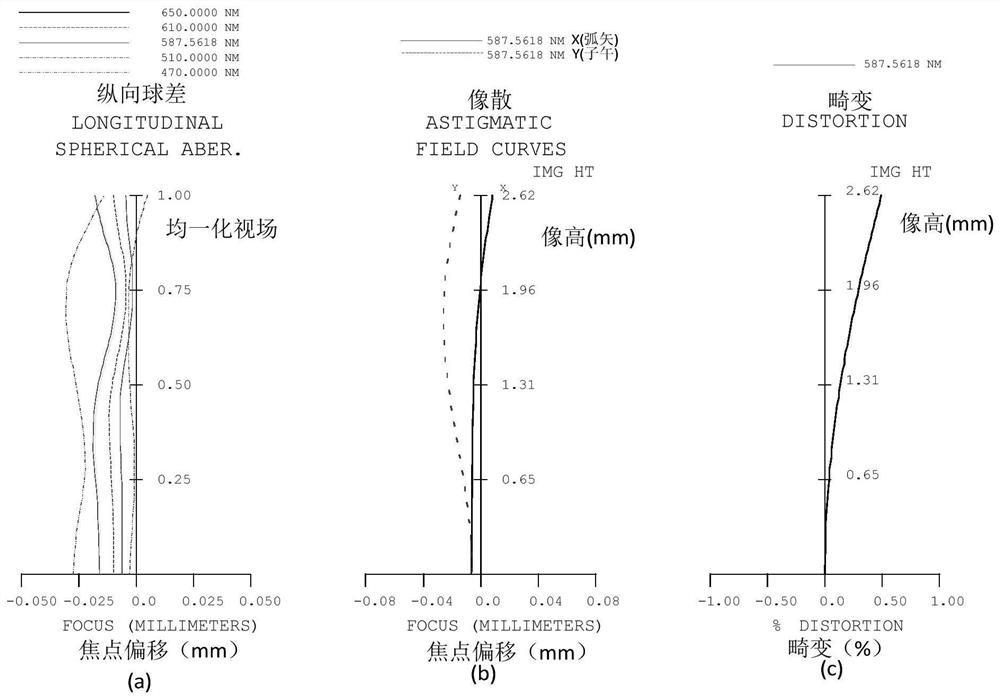

The invention discloses an optical imaging system, a module and electronic equipment. The optical imaging system includes, in order from an object side to an image side along an optical axis, a first lens, a prism, a second lens, a third lens and a fourth lens; the first lens has negative refractive power; the object-side surface of the first lens is convex at a position close to the optical axis, and the image-side surface of the first lens is concave at a position close to the optical axis; the prism turns an optical path; the prism is provided with a reflecting surface; the second lens has refractive power; the object side surface of the second lens is a convex surface at a position close to the optical axis; the third lens has refractive power, the object side surface of the third lens is a convex surface at a position close to the optical axis; and the fourth lens has refractive power. The optical imaging system meets the following conditional expressions: 0.1 mm <-1><EFL / (TTL21*TTL22)<0.3 mm <-1>. According to the optical imaging system provided by the embodiment of the invention, the light flux is large while the micro design is met, the view field range is large, and the requirements of high-definition images and long-range shooting are met.

Owner:JIANGXI JINGCHAO OPTICAL CO LTD

Clamp hook device

ActiveCN1905784AAvoid damageWill not affect the shapeCasings/cabinets/drawers detailsInstrument housingEngineeringMechanical engineering

Owner:ASUSTEK COMPUTER INC

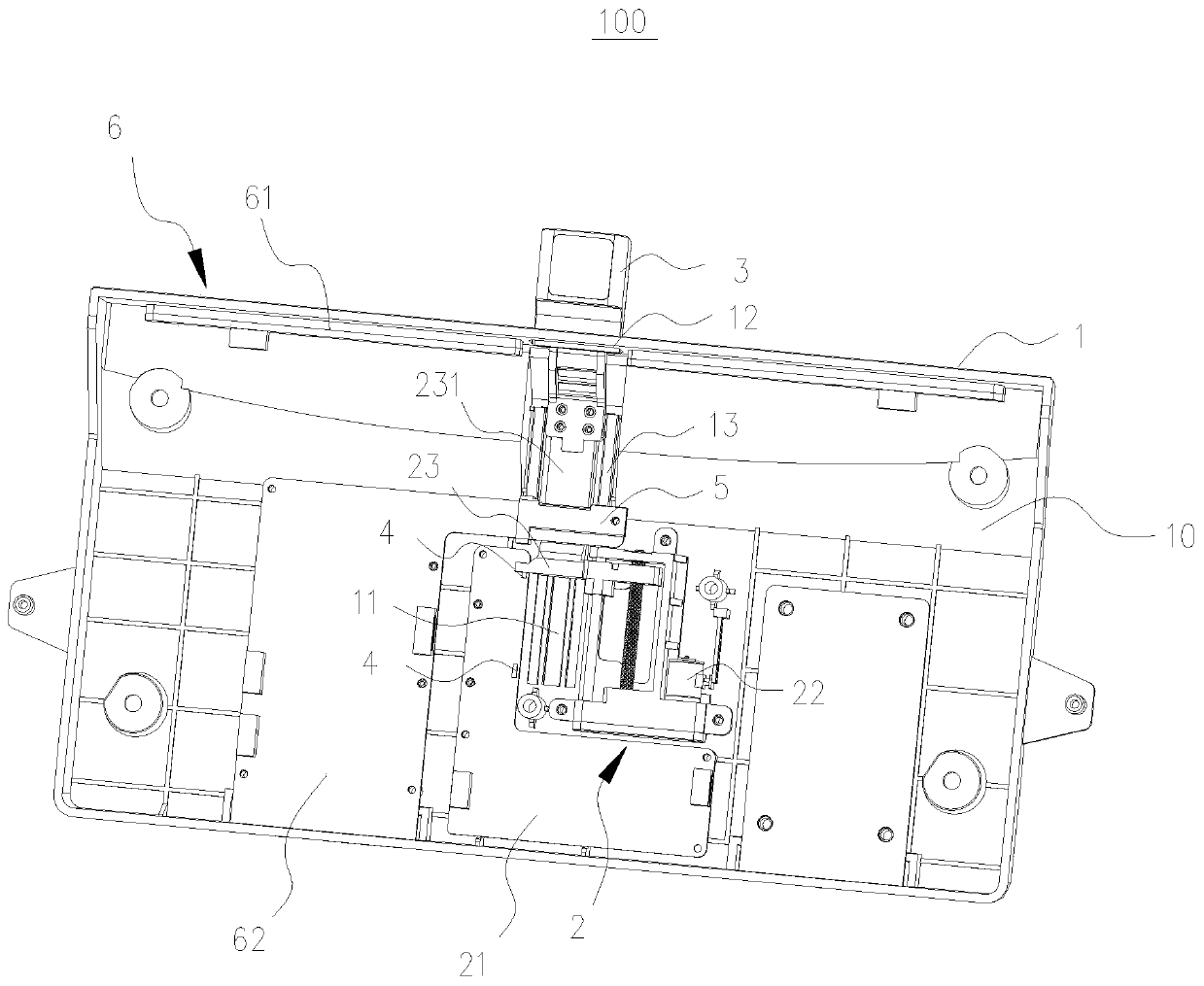

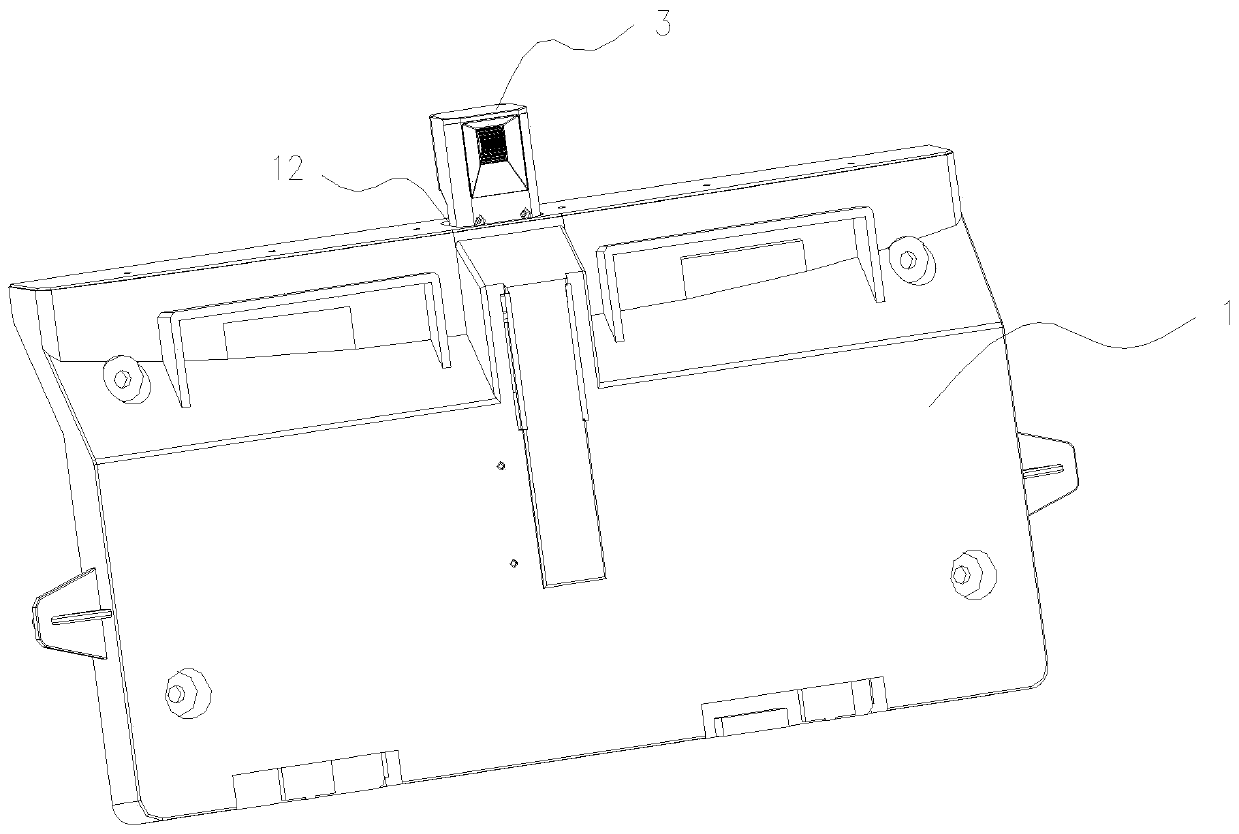

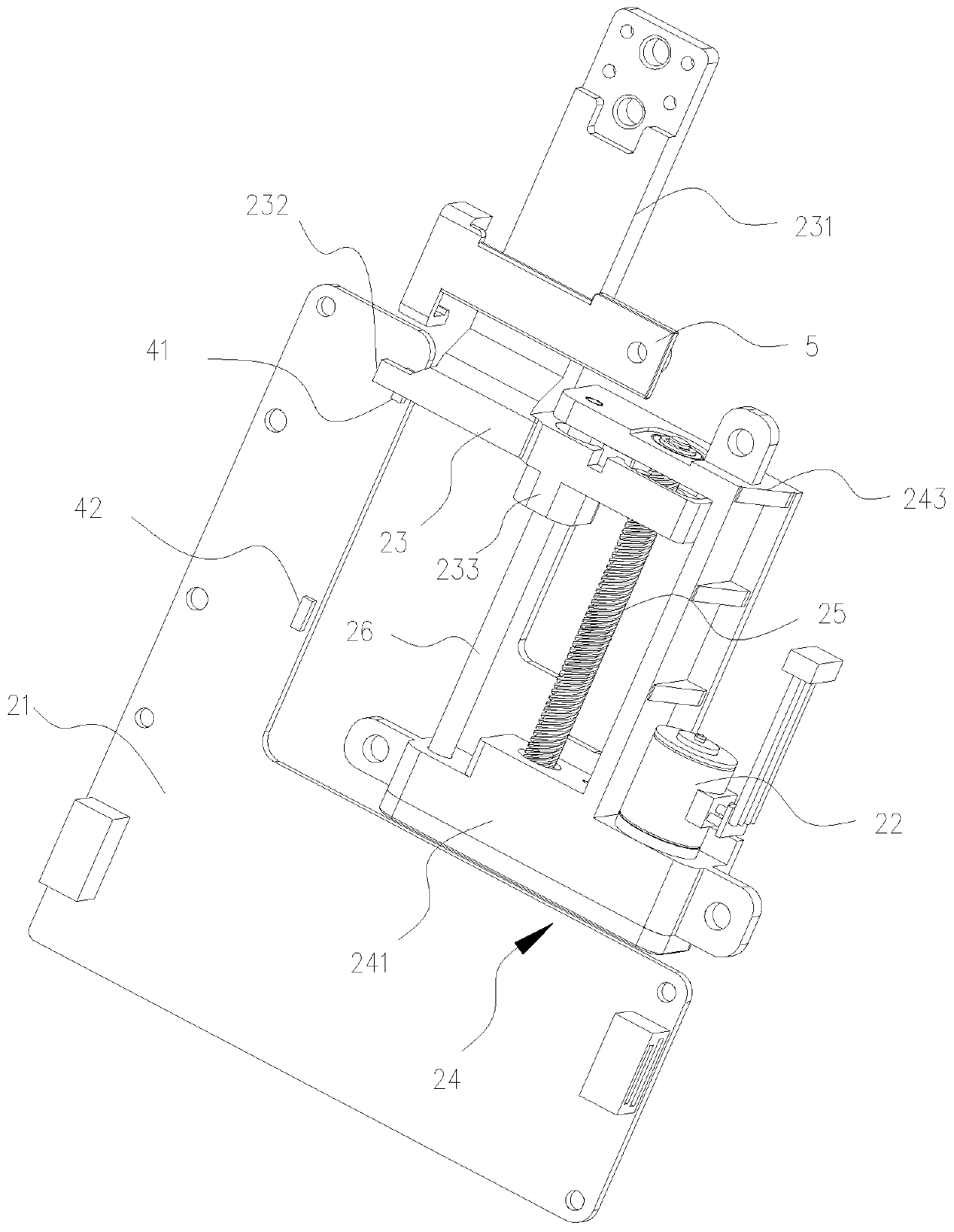

Electronic device and camera device thereof

InactiveCN111526269AEasy to useImprove experienceTelevision system detailsColor television detailsEngineeringMechanical engineering

The invention provides an electronic device and a camera device thereof. The camera device comprises a mounting shell, a camera module and a telescopic driving mechanism, wherein the mounting shell isdetachably arranged on a shell of the electronic equipment, the mounting shell is provided with a mounting groove and a guide rail arranged at the bottom of the mounting groove, and an opening communicated with the mounting groove is formed in one side of the mounting shell; the camera module is arranged in the mounting groove; the telescopic driving mechanism is arranged in the mounting groove and provided with a switching support movably arranged on the guide rail, one end of the switching support is fixedly connected with the camera module, and the switching support drives the camera module to stretch out and draw back along the guide rail through the opening. Therefore, the camera module can extend out of the casing as required by a user, thereby being convenient for the user to use;after being used, the device can be retracted to be hidden in the whole machine, so the convenience of user operation and the user experience are improved on the premise that the overall appearance isnot influenced.

Owner:HISENSE VISUAL TECH CO LTD

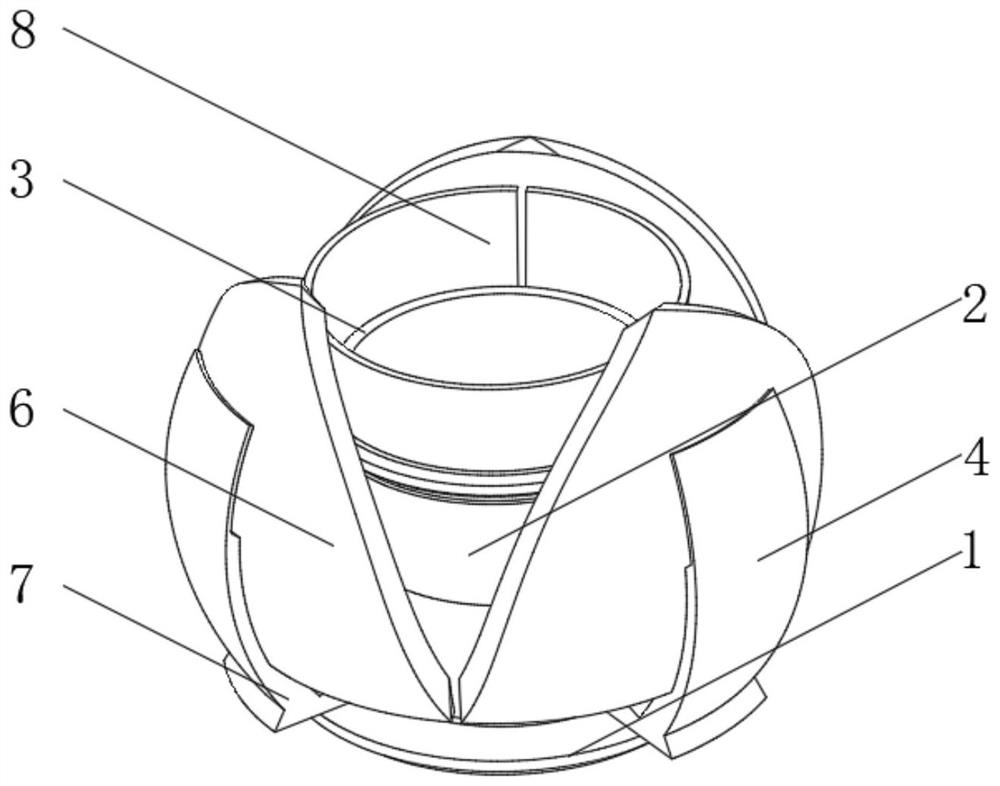

Gardening model flowerpot capable of automatically closing for preventing fire

InactiveCN111955213AWill not affect the shapeDoes not affect aestheticsFire rescueCultivating equipmentsStructural engineeringFlowerpot

The invention discloses a gardening model flowerpot capable of automatically closing for preventing fire. The gardening model flowerpot comprises a flowerpot base, wherein the top of the flowerpot base is fixedly connected with a protection outer pot; a flowerpot is placed above the protection outer pot; the side edge of the flowerpot base is provided with an arc-shaped protection rail rack; the inner side of the arc-shaped protection rail rack is provided with an inner rail slideway; the inner side of the inner rail slideway is provided with a model protection top plate; the bottom of the arc-shaped protection rail rack is provided with a heat conduction base; and a flowerpot placement groove is arranged in the protection outer pot. The gardening model flowerpot relates to the technical field of gardening protection. According to the gardening model flowerpot capable of automatically closing for preventing fire, the problems that when an existing flowerpot is on fire, exposed flowersand plants are directly roasted to die, no corresponding protection equipment is arranged to protect the flowers and plants and certain protective articles are manually protected can be solved, a purpose of automatically working to carry out integral closed protection can be realized, safety protection performance is better, and the gardening model flowerpot can be suitable for a wide scene.

Owner:袁文莹

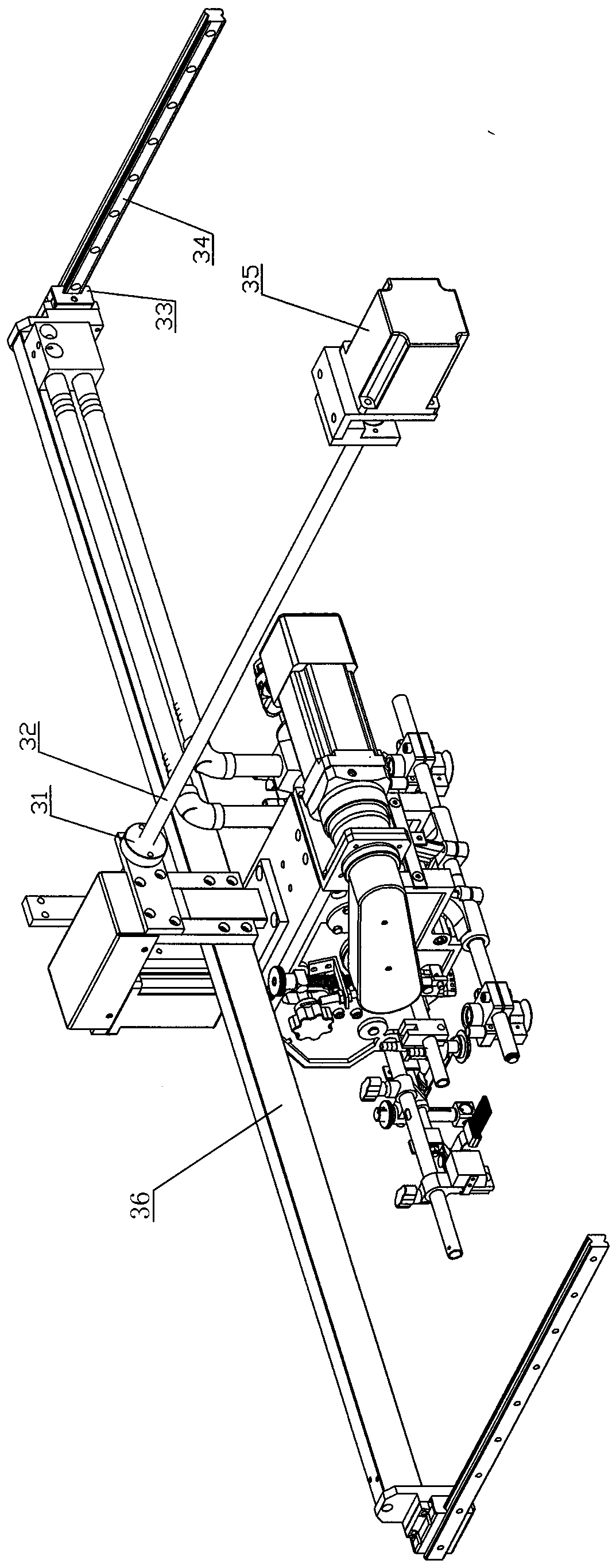

Material conveyor

InactiveCN103171894BDoes not affect aestheticsWill not affect the shapeConveyor partsFood materialEngineering

The invention discloses a material transporting table. The material transporting table comprises a tray feed rail, a grabbing mechanism and a tray recovery rail, wherein the grabbing mechanism is arranged on the end portion of the tray feed rail. A tray recovery frame is arranged at the front end of the tray feed rail, and the tray recovery rail is arranged below the tray feed rail. The grabbing mechanism can be used for achieving transporting of materials among different platforms, in the process of transporting, the materials do not need to be turned over so that the materials can not be deformed, integral attractiveness of the materials can not be influenced, and especially when food materials are transported, appearance of food surfaces can not be influenced. Through clamping bars in rows arranged on transition plates at two ends of a grabbing arm and soft foaming silicon rubber cases sleeved on the clamping bars, soft materials can be grabbed mechanically and conveniently, and the surface structures of the materials can not be damaged easily. The material transporting table can be used for automatic material packaging of large-scale machines, manual work is reduced, and work efficiency is improved.

Owner:FENGLEI PRECISION MACHINERY

Watertap discharging tube connecting device

This invention discloses a connecting device of water tap discharging tubes. The water tap discharging pipe connecting device is installed between valve and discharging pipe of water tap. It includes a cylinder-shaped connector which is fixed on valve body and interlinked with water outlet in valve body. The discharging tube is sleeved on connector and can rotate around connector. There is a stop edge at inside of discharging tube's connect end. A pressing cap with central hole is coupled with connector or end placed in the discharging tube. The outer edge of pressing cap presses at the stop edge. The stop edge inside discharging tube is pressed to via fastening and makes discharging tube can not disengage connector, but discharging tube can rotate around connector to change angle of discharging tube.

Owner:盛连送

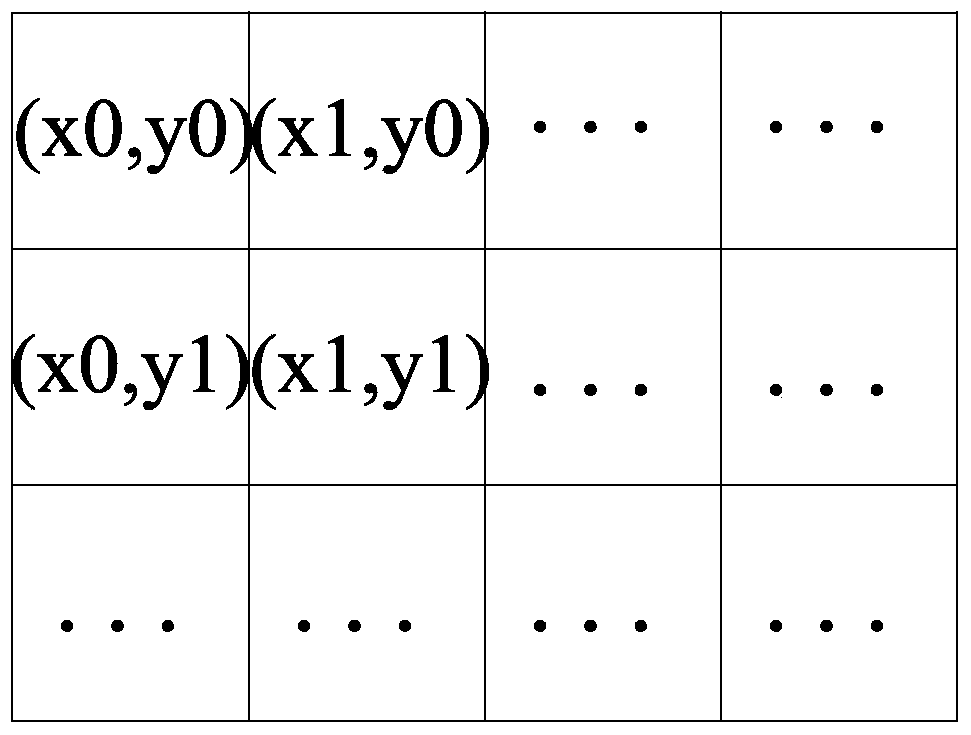

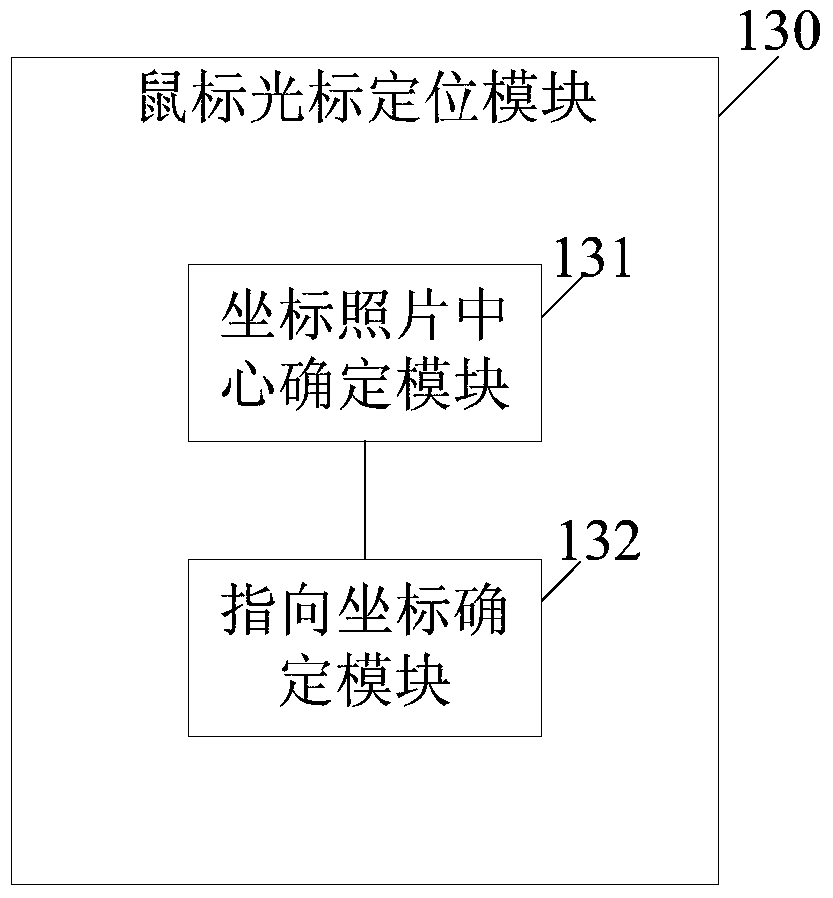

Mouse cursor pointing control method, device and system

ActiveCN104731372BWill not affect the shapeShort delayInput/output processes for data processingFrame sequenceComputer graphics (images)

The embodiment of the invention discloses a mouse cursor pointing control method, device and system. The system includes a mouse cursor pointing control device, a display, a processor and a pointing device, and a camera is installed on the pointing device. The mouse cursor pointing control device includes: a coordinate frame inserting module for inserting a coordinate frame into the image frame sequence being displayed on the display, the coordinate frame includes a plurality of coordinate grids, each coordinate grid corresponds to a coordinate; the coordinate photo is received The module is used to receive the coordinate photo sent by the pointing device. The coordinate photo is the image of the coordinate grid pointed by the pointing device taken by the camera when the user points the pointing device to the display. The mouse cursor positioning module is used to locate the coordinates according to the coordinates on the coordinate photo. The coordinates corresponding to the grid determine the pointing coordinates; the coordinate sending module is used for sending the pointing coordinates to the processor, so that the processor controls to move the mouse cursor to the position corresponding to the pointing coordinates on the display.

Owner:深圳市巨烽显示科技有限公司

Installation structure of glass run channel

ActiveCN102416851BWon't curlWill not affect the shapeEngine sealsVehicle sealing arrangementsEngineeringCar door

Owner:KINUGAWA RUBBER IND CO LTD

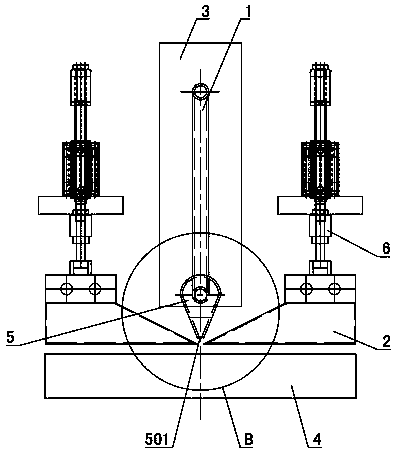

Heat-sealing device for plastic bag or plastic tube

PendingCN108501387ARealization of heat sealingFast heat sealingDomestic articlesTubular articlesEngineeringPlastic film

The invention provides a heat-sealing device for a plastic bag or a plastic tube, and belongs to the technical field of heat-sealing equipment for plastic tubes or plastic bags. The heat-sealing device is characterized in that the heat-sealing device comprises an air uniformizing box (5) and a platform (4) arranged on one side of the air uniformizing box (5) in a spaced mode; an air outlet (501) is formed in the side, close to the platform (4), of the air uniformizing box (5) and is parallel to the platform (4); and the air uniformizing box (5) is connected with a hot air pipe (1). According to the heat-sealing device for the plastic bag or the plastic tube, the air outlet is formed in the side, close to the platform, of the air uniformizing box, hot air in the hot air pipe is evenly sprayed out along the air outlet after passing through the air uniformizing box, and the to-be-sealed side of a plastic film is placed between the platform and the air outlet, so that heat-sealing of the plastic film can be achieved in the pulling process of the plastic film, and accordingly, the heat-sealing speed of the plastic film is increased; and the plastic film does not need to be squeezed relative to the platform, so that the appearance of the plastic bag or the plastic tube is not affected, and the situation that the plastic film is torn up due to inaccurate matching between heat-sealingand puling of the plastic film is avoided.

Owner:淄博洁林塑料制管有限公司

Automatic hydraulic impact die packaging machine capable of achieving fast nail packaging

The invention discloses an automatic hydraulic impact die packaging machine capable of achieving fast nail packaging. The automatic hydraulic impact die packaging machine comprises a bottom plate. A carrier plate is embedded on the upper surface of the bottom plate. A servo motor is arranged on the front face of the carrier plate. The output end of the servo motor is connected with a driving gear in a sleeved manner. A fixed plate is arranged on the upper surface of the carrier plate. The front face of the fixed plate is movably connected with the axis of the back face of a driven gear through a pin shaft. The driving gear is engaged with the driven gear. The side surface of the driven gear is fixedly connected with the bottom end of a first transmission rod. According to the automatic hydraulic impact die packaging machine, through the arrangement of a hammer head, the hammer head is driven by the first transmission rod and a second transmission rod to knock a vertical plate, and a material is impacted; through the improvement on conveying devices, the material is stirred by two sets of friction blocks opposite in rotating direction at the same time, and the material is extruded out from a nail hole; and through the improvement on an upper arc clamp plate and a lower arc clamp plate, a nail is clamped by the upper arc clamp plate and the lower arc clamp plate, and the effect of fast nail packaging is achieved.

Owner:乐清市风讯自动化科技有限公司

Hat arranged on clothes

The invention relates to a hat arranged on clothes. A peak of the hat is provided with a connecting belt, and the connecting belt passes through the face of people. The hat has the advantages that: 1) the hat is fixed through the connecting belt, the hat cannot easily fall off from the head of the human body in the wind, in addition, the connecting belt is in transverse arrangement, soft and warm keeping plus materials can be selected, the effect of fixing the hat is realized, and simultaneously, the warm keeping effect is also realized; and 2) one end of the connecting belt is fixed at one end of the hat, the other end of the connecting belt is connected with the other end of the hat through a magic tape, the connecting mode is simple, and in addition, the shape and the attractive appearance of the hat cannot be influenced.

Owner:朱永华

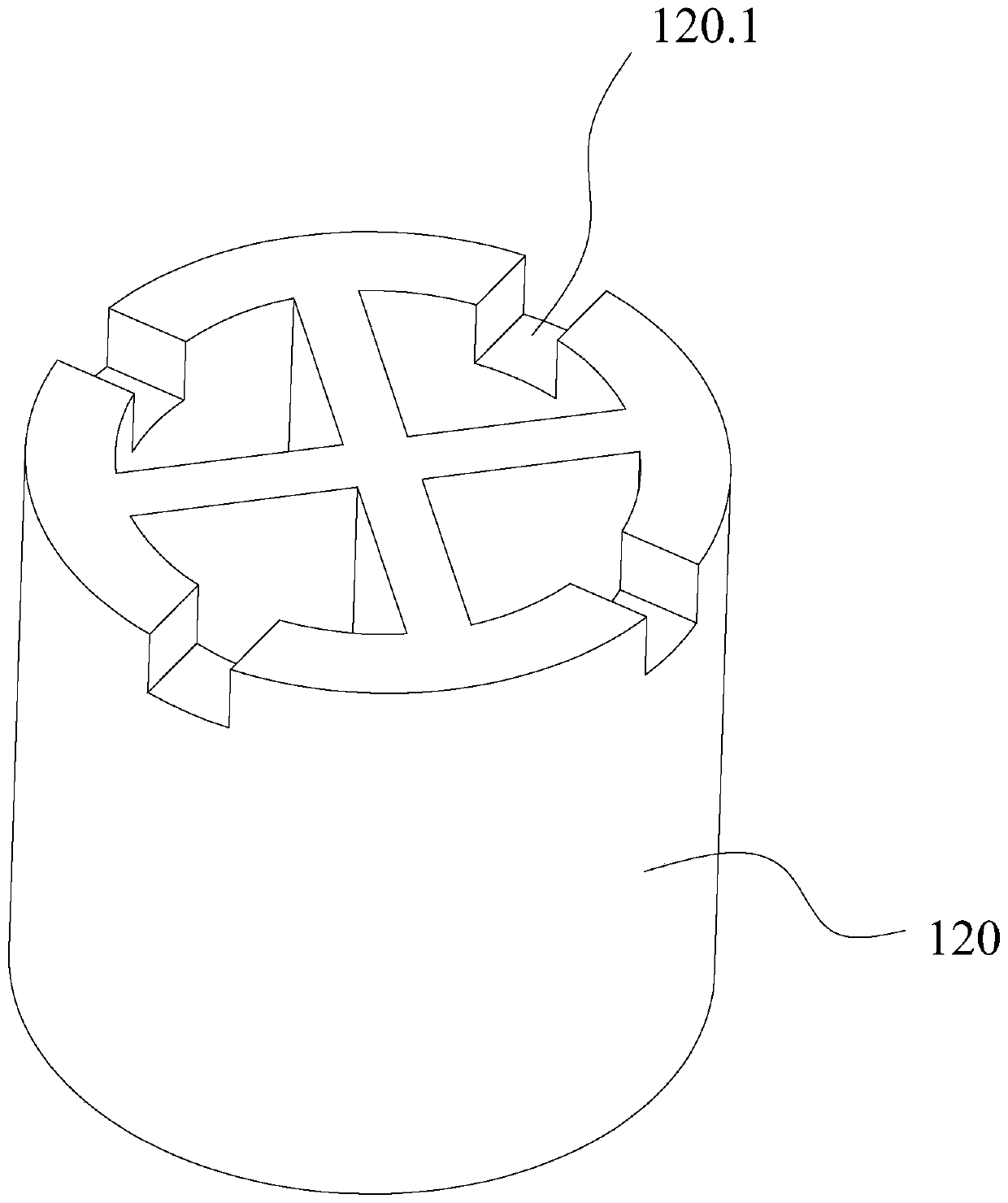

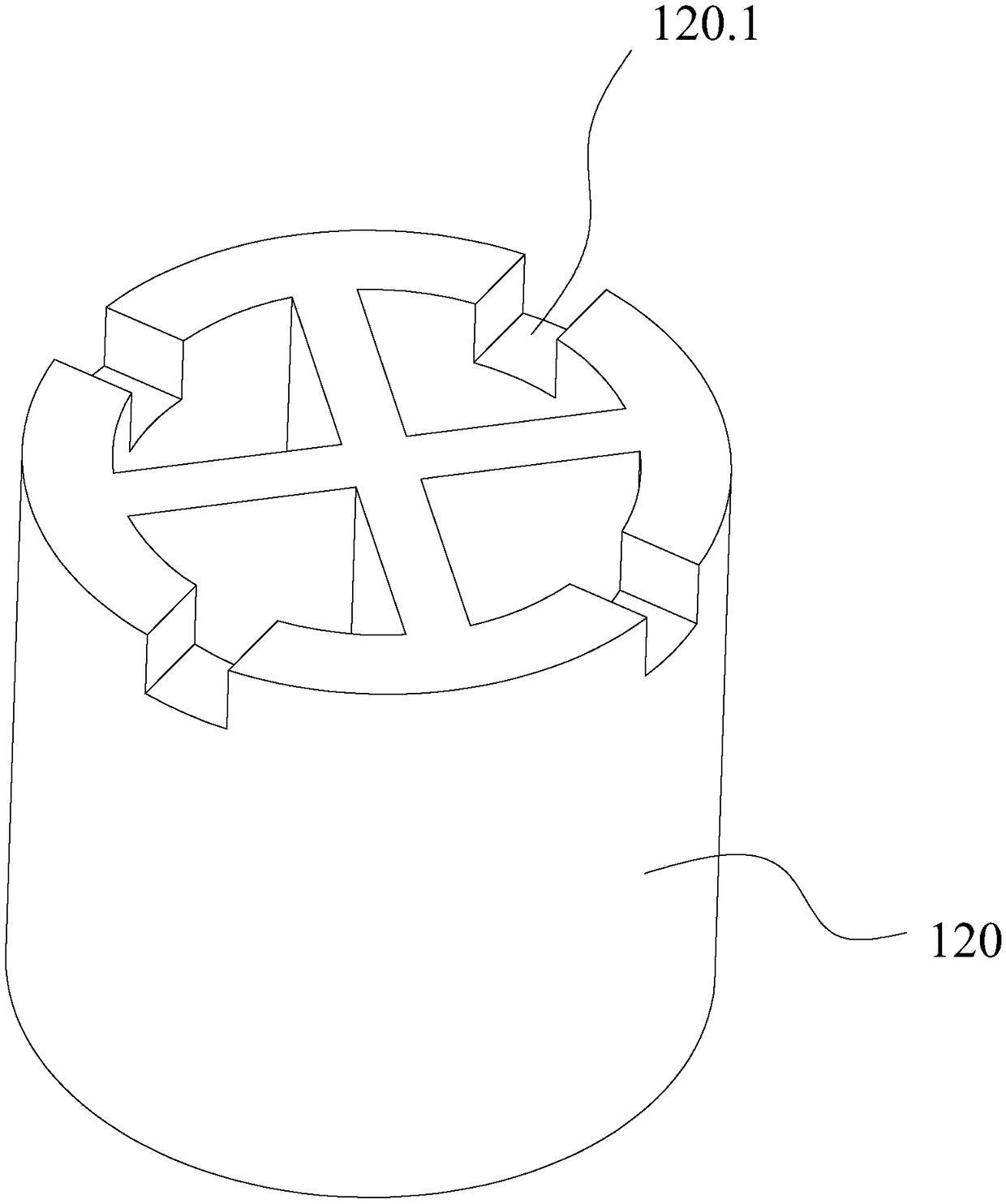

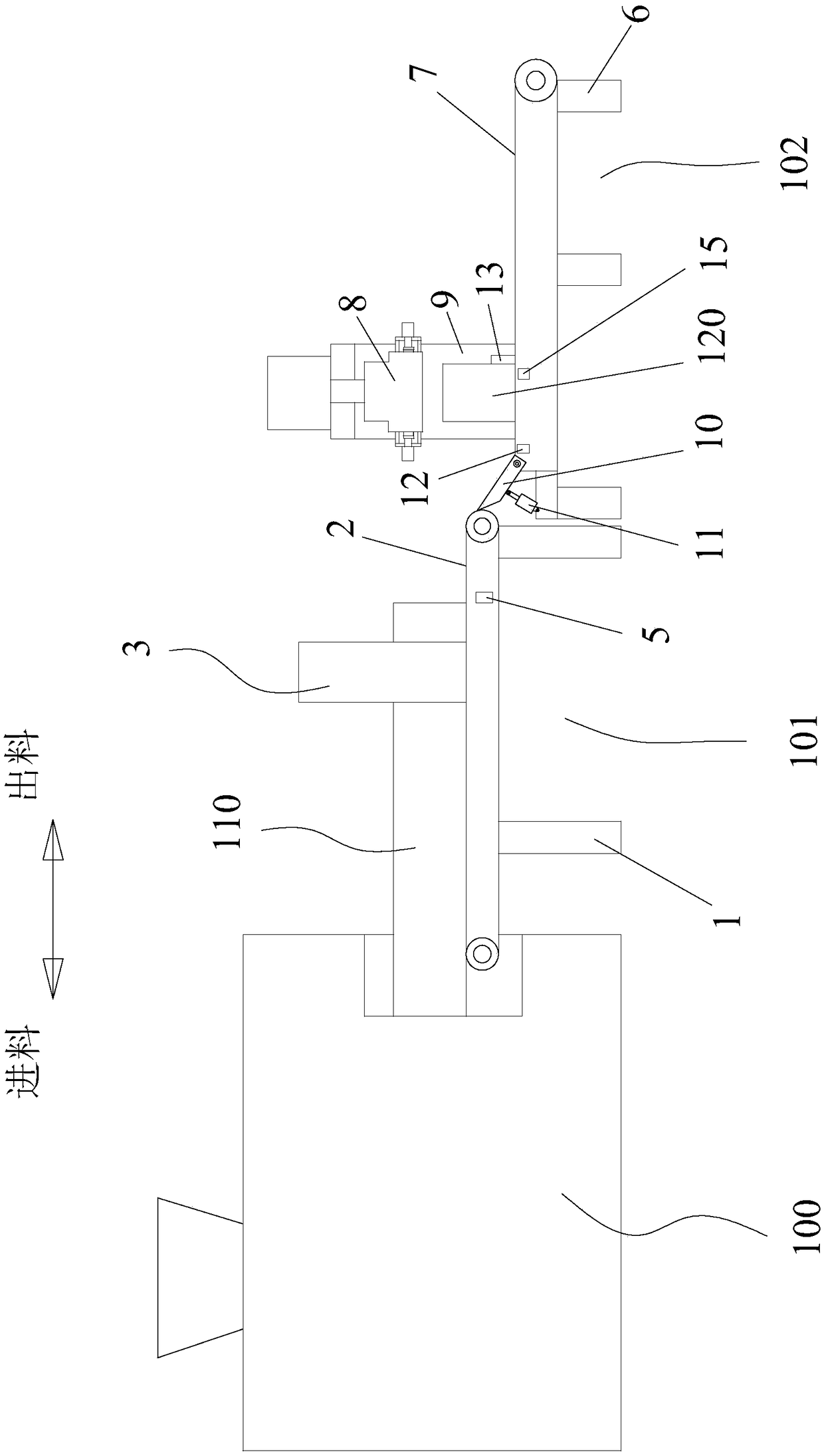

A kind of ceramic packing molding machine

InactiveCN109016080BEffective automation controlPrecise automatic controlCeramic shaping apparatusWorking accessoriesMolding machineConveyor belt

The invention discloses a ceramic filler molding machine. The ceramic filler molding machine comprises an extrusion molding machine, a cutting device and a finish machining device which are sequentially arranged side by side, wherein the cutting device comprises a first rack and a first conveyor belt; a supporting frame is arranged on the first rack; a cut-off mechanism which moves up and down isarranged on the supporting frame and used for cutting off a blank filler extruded by the extrusion molding machine; the finish machining device comprises a second rack, a second conveyor belt and at least one grooving mechanism; the grooving mechanism is used for cutting a notch positioned at the end part of a filler body being cut off; and the cut-off action and the notch cutting action are monitored and controlled through corresponding sensing control elements. By adoption of the ceramic filler molding machine disclosed by the invention, the machining process of filler cut-off and notch cutting at the end part can be automatically completed, thereby achieving the high efficiency.

Owner:李亿明

Ceramic filler molding machine

InactiveCN109016080AEffective automation controlPrecise automatic controlCeramic shaping apparatusWorking accessoriesMolding machineInjection molding machine

The invention discloses a ceramic filler molding machine. The ceramic filler molding machine comprises an extrusion molding machine, a cutting device and a finish machining device which are sequentially arranged side by side, wherein the cutting device comprises a first rack and a first conveyor belt; a supporting frame is arranged on the first rack; a cut-off mechanism which moves up and down isarranged on the supporting frame and used for cutting off a blank filler extruded by the extrusion molding machine; the finish machining device comprises a second rack, a second conveyor belt and at least one grooving mechanism; the grooving mechanism is used for cutting a notch positioned at the end part of a filler body being cut off; and the cut-off action and the notch cutting action are monitored and controlled through corresponding sensing control elements. By adoption of the ceramic filler molding machine disclosed by the invention, the machining process of filler cut-off and notch cutting at the end part can be automatically completed, thereby achieving the high efficiency.

Owner:李亿明

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com