Full-automatic pill making machine

A pill making machine and fully automatic technology, which is applied in the direction of making medicines into special physical or taking form devices, etc., can solve the problems of inconvenient cutting and pill making, easy adhesion to the conveyor belt, and inability to accumulate in large quantities. The effect of improving user experience, increasing production efficiency, and extending the validity period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

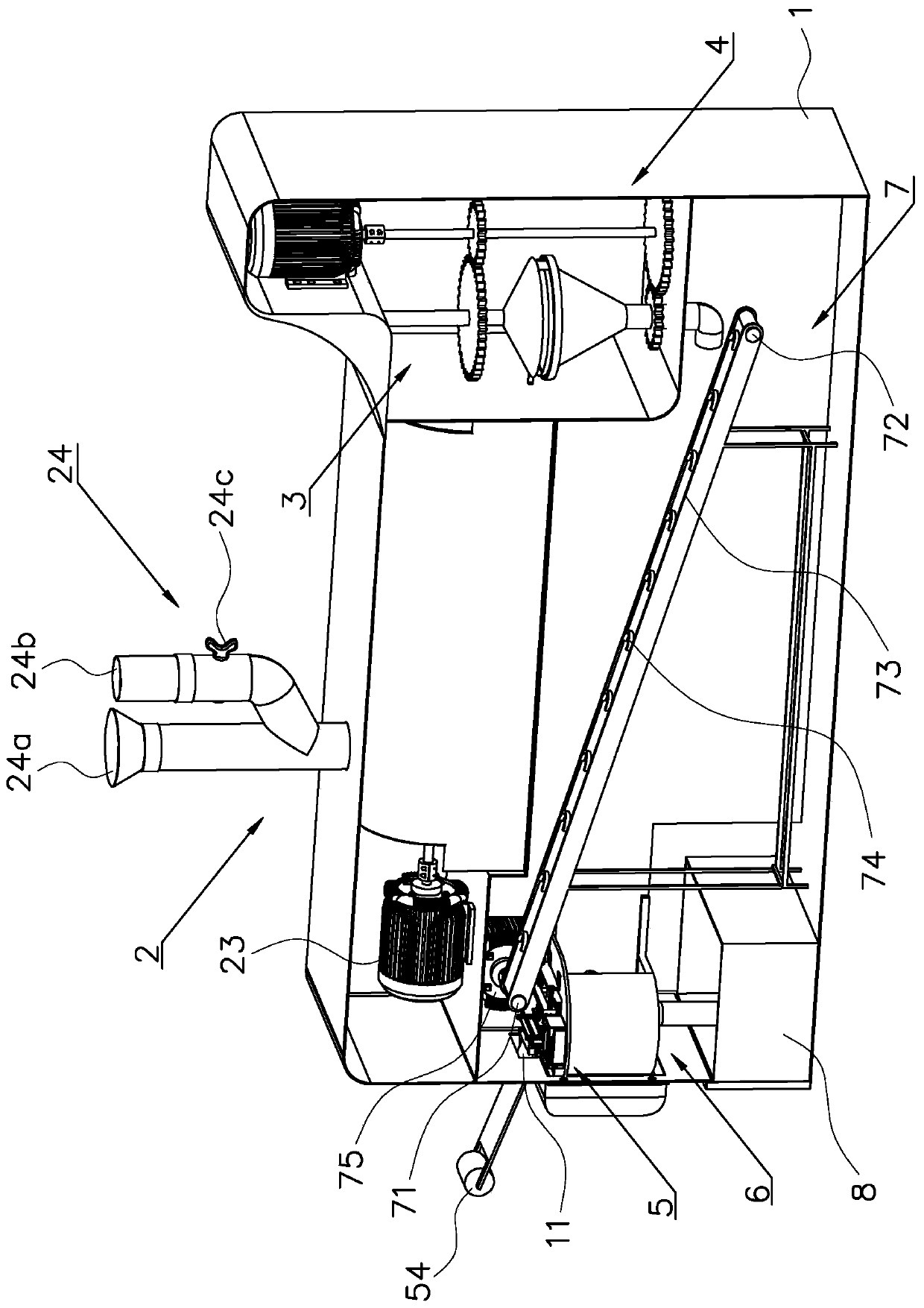

[0051] Such as figure 1 As shown, this embodiment is a fully automatic pill making machine, which is especially suitable for preparing pills with high water content and high surface viscosity, such as Sanfutie. The automatic pill making machine includes a frame 1. According to the pill making process, the frame 1 is sequentially equipped with a material mixing mechanism 2, a cutting mechanism 3, a pill making mechanism 4, a package conveying mechanism 5 and a pill packaging mechanism 6. .

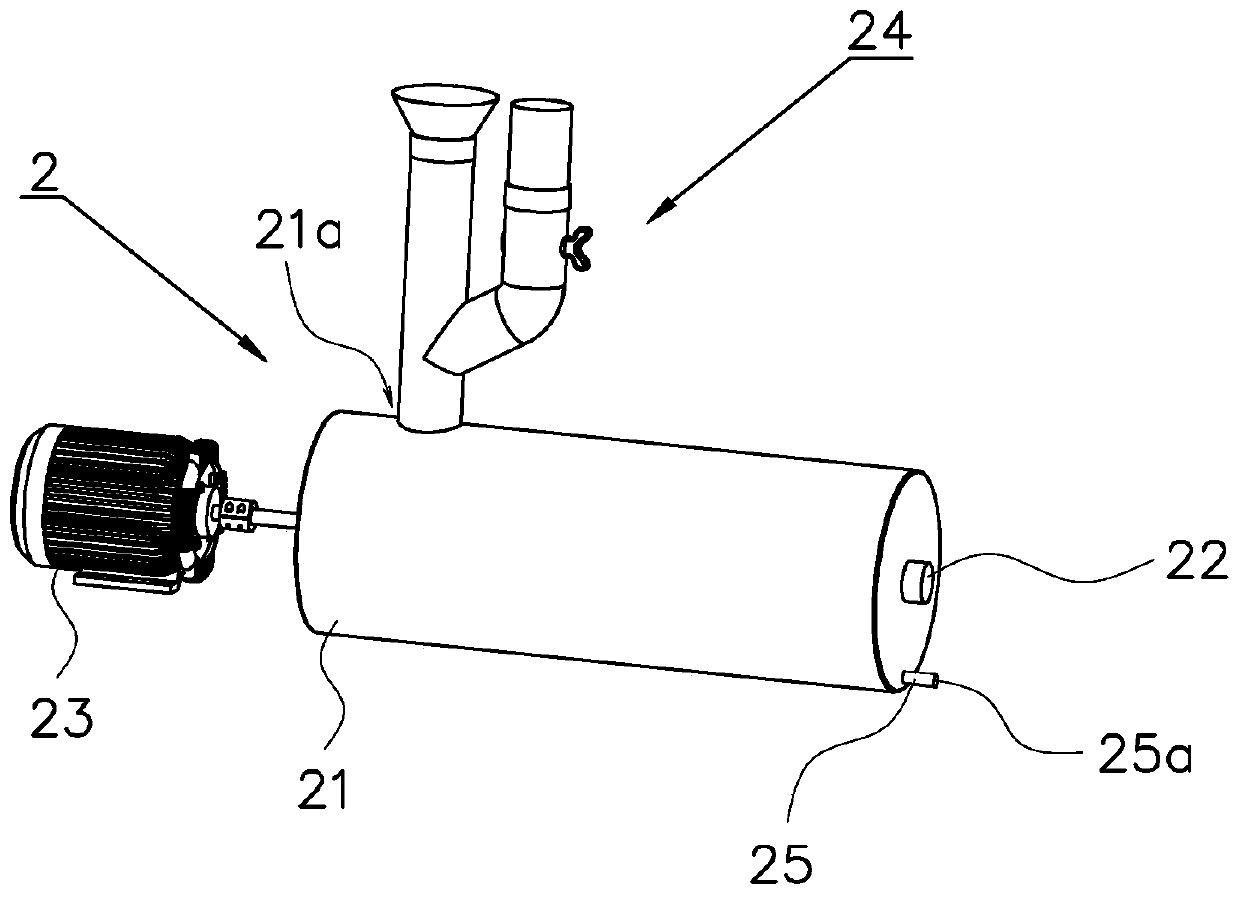

[0052] Among them, such as figure 1 and figure 2 As shown, the material mixing mechanism 2 is used to mix and extrude the components of the pill. The medicinal material mixing mechanism 2 includes a screw extruding barrel 21 fixedly connected with the frame 1, the screw extruding barrel 21 is horizontally arranged in the frame 1, and a screw extruding rod 22 is installed in the spiral extruding barrel 21 for rotation A mixing motor 23 for driving the screw extrusion rod 22 to rotate is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com