Paper feeder

A paper feeding and paper machine technology, applied in the directions of object supply, pile separation, thin material handling, etc., can solve the problems of increasing the lateral size of the equipment, potential safety hazards, increasing the height of the equipment, etc., and achieves the beautiful appearance and overall structure of the equipment. Small, easy to install and adjust

Pending Publication Date: 2018-12-28

ZHEJIANG JINBAO MACHINERY

View PDF0 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Most of the sheet-fed automatic screen printing machines use a paper feeder to realize automatic paper feeding. There are several problems in the traditional sheet-fed paper feeder. 1. The circulating power of the paper feeder is transmitted through the main machine to drive the paper feeder to separate the paper. and delivery, when the paper specifications change, it is necessary to manually adjust the front, rear, up and down of the paper feed head, and adjust the left and right positions of the side stoppers to adapt to the changes in the paper, while manual adjustment has the problem of low efficiency; 2. In traditional sheet-fed paper feeders, in order to adjust the paper head up and down, back and forth, the air source is generally introduced from the outside with hoses. These pipelines need to be of sufficient length, and the redundant pipelines are often towering above the equipment, which increases the The height of the equipment increases the cost of equipment packaging and transportation, and it is exposed to the outside, posing safety hazards and hindering the visual inspection of the equipment; The switches are scattered and placed externally, which not only poses safety hazards, but also increases the horizontal size of the equipment, which is not conducive to packaging and transportation

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

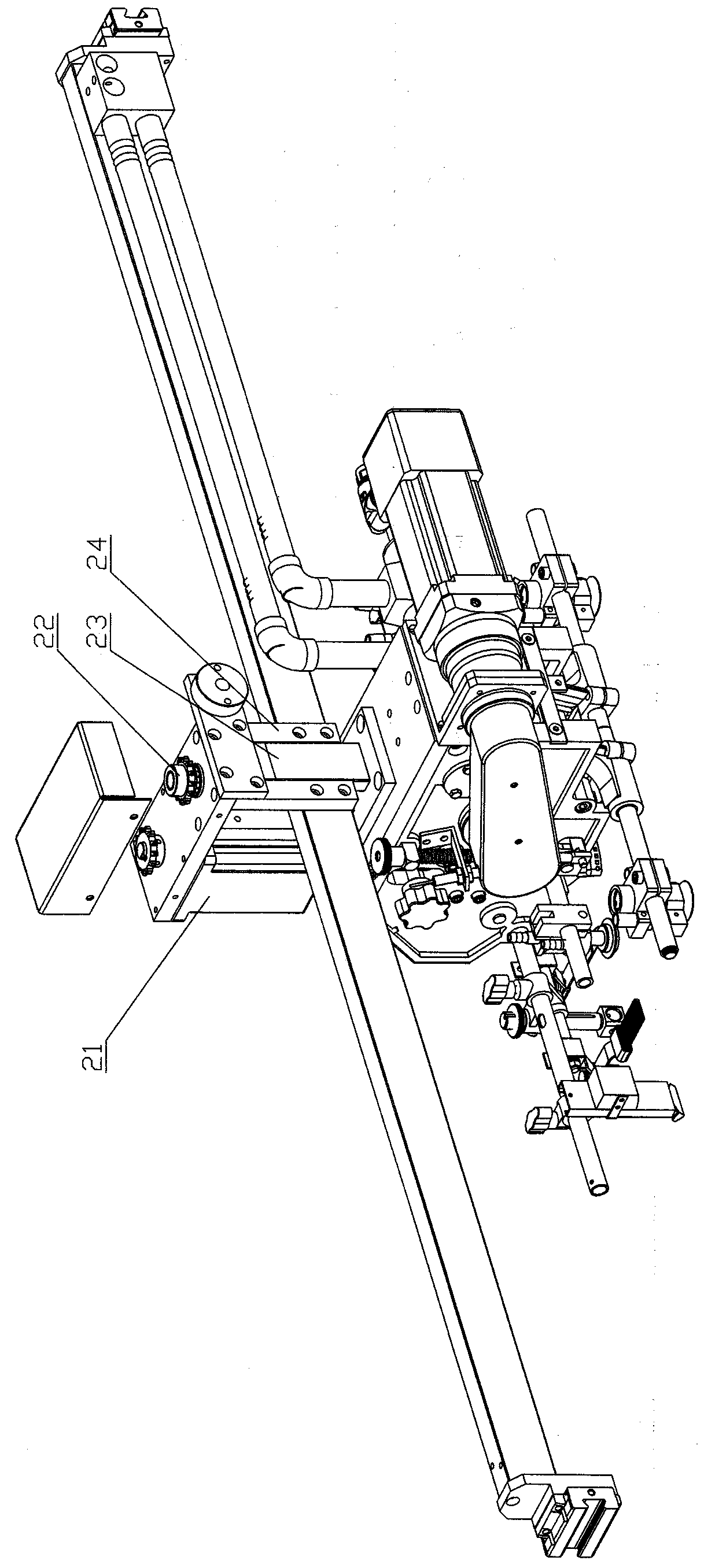

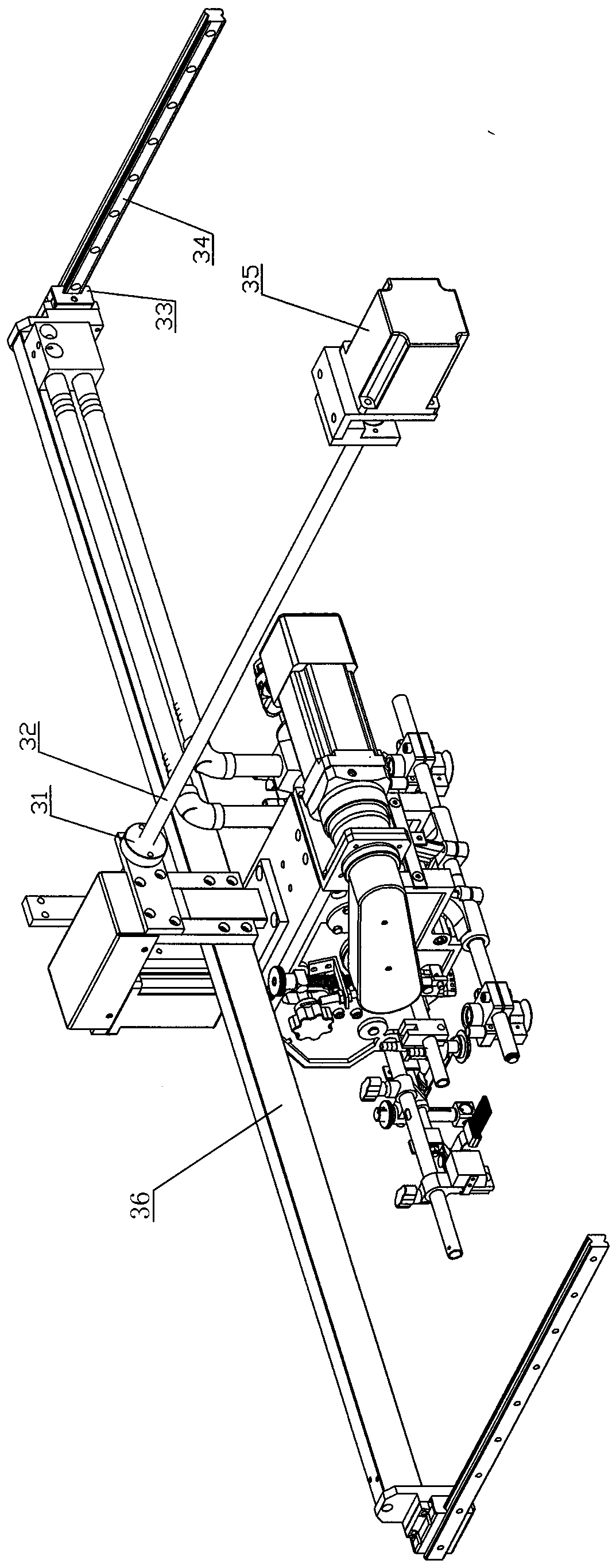

The invention discloses a paper feeder. The paper feeder comprises a frame and a paper feeding head and is characterized by comprising a height adjustment device for adjusting the height of the paperfeeding head and a longitudinal adjustment device for adjusting the longitudinal position of the paper feeding head. Driving sources of the height adjustment device and the longitudinal adjustment device are both connected with an electrical connector. The paper feeder has advantages that electric driving is adopted in height and longitudinal adjustment of the paper feeding head, lifting of a feeding table board and side board width adjustment, and the driving sources are connected with the electrical connector to realize automatic operation.

Description

technical field The invention relates to an improved invention of a paper feeder, in particular to a paper feeder used in combination with a screen printing machine. Background technique Most of the sheet-fed automatic screen printing machines use a paper feeder to realize automatic paper feeding. There are several problems in the traditional sheet-fed paper feeder. 1. The circulating power of the paper feeder is transmitted through the main machine to drive the paper feeder to separate the paper. and delivery, when the paper specifications change, it is necessary to manually adjust the front, rear, up and down of the paper feed head, and adjust the left and right positions of the side stoppers to adapt to the changes in the paper, while manual adjustment has the problem of low efficiency; 2. In traditional sheet-fed paper feeders, in order to adjust the paper head up and down, back and forth, the air source is generally introduced from the outside with hoses. These pipeline...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B65H5/34

CPCB65H5/34B65H2801/21

Inventor 宁豪方新通李乾坤

Owner ZHEJIANG JINBAO MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com