Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

30results about How to "Uniform and stable tension" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

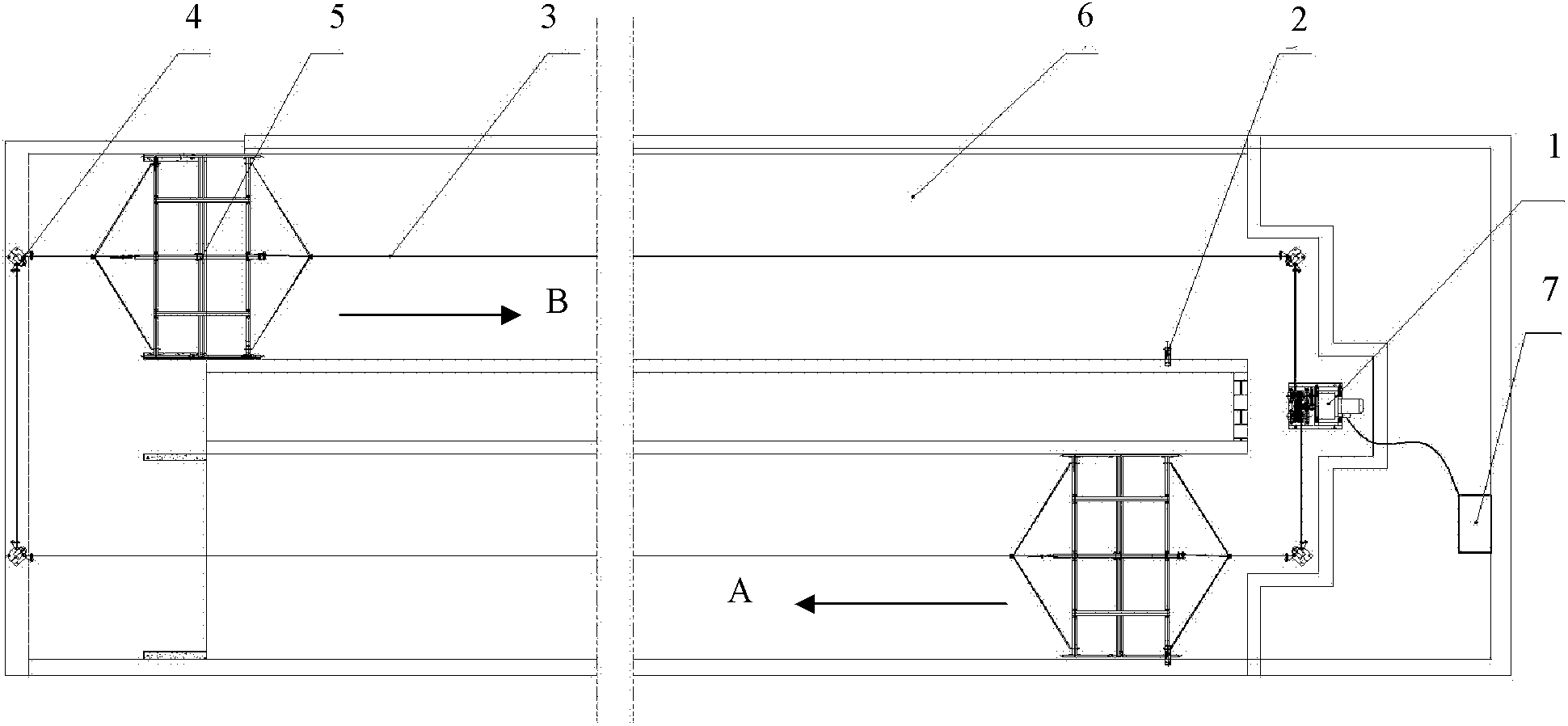

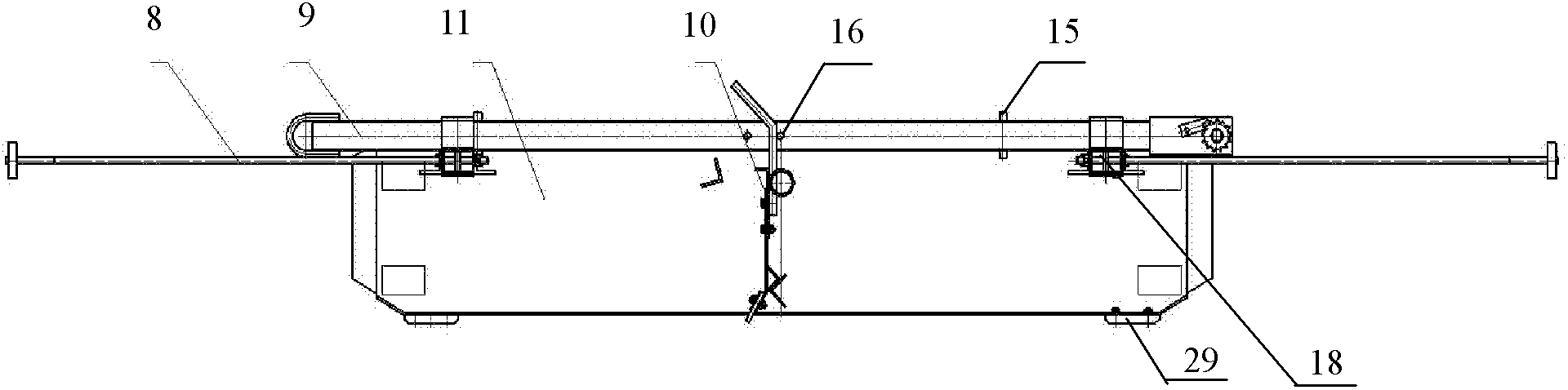

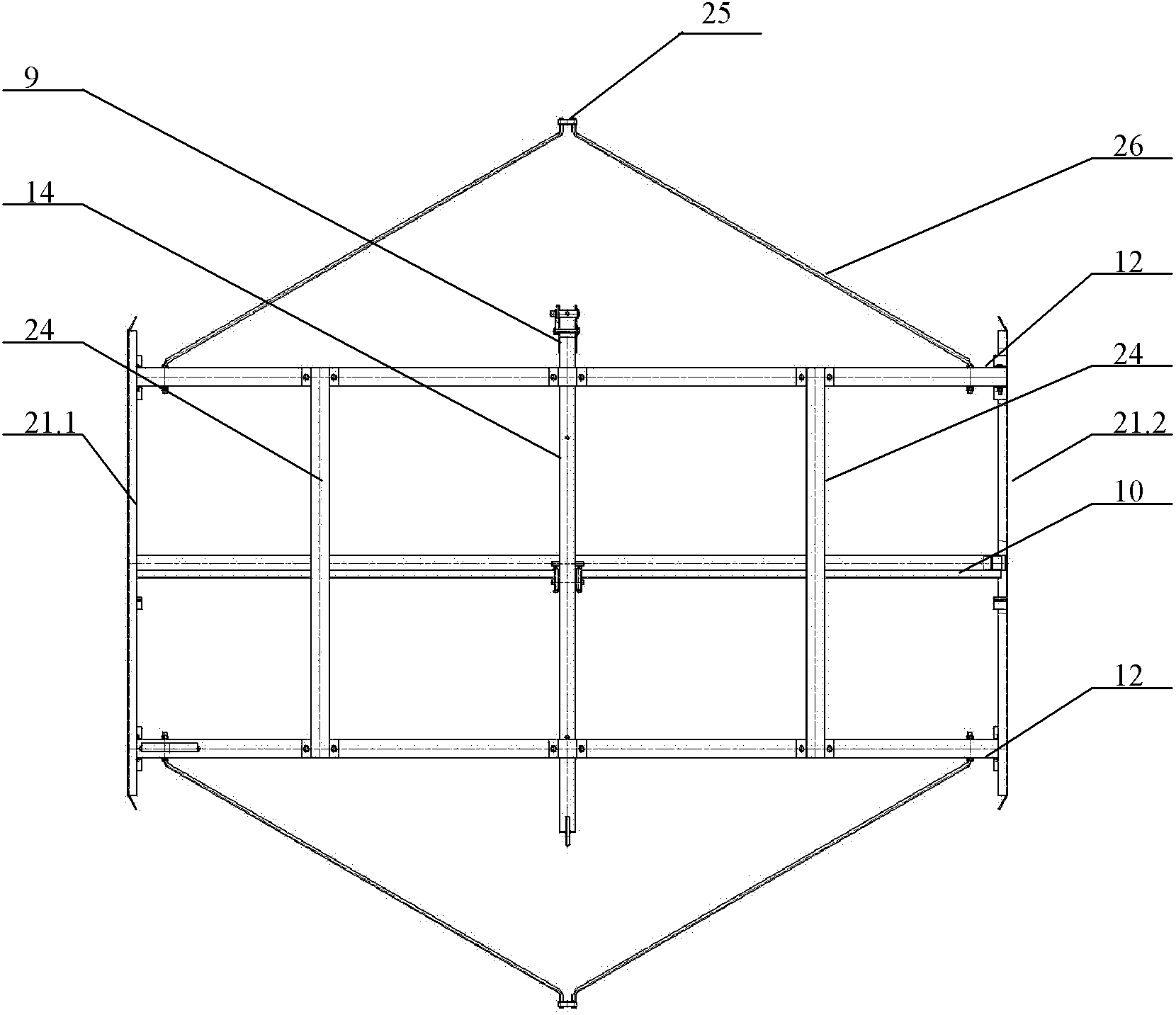

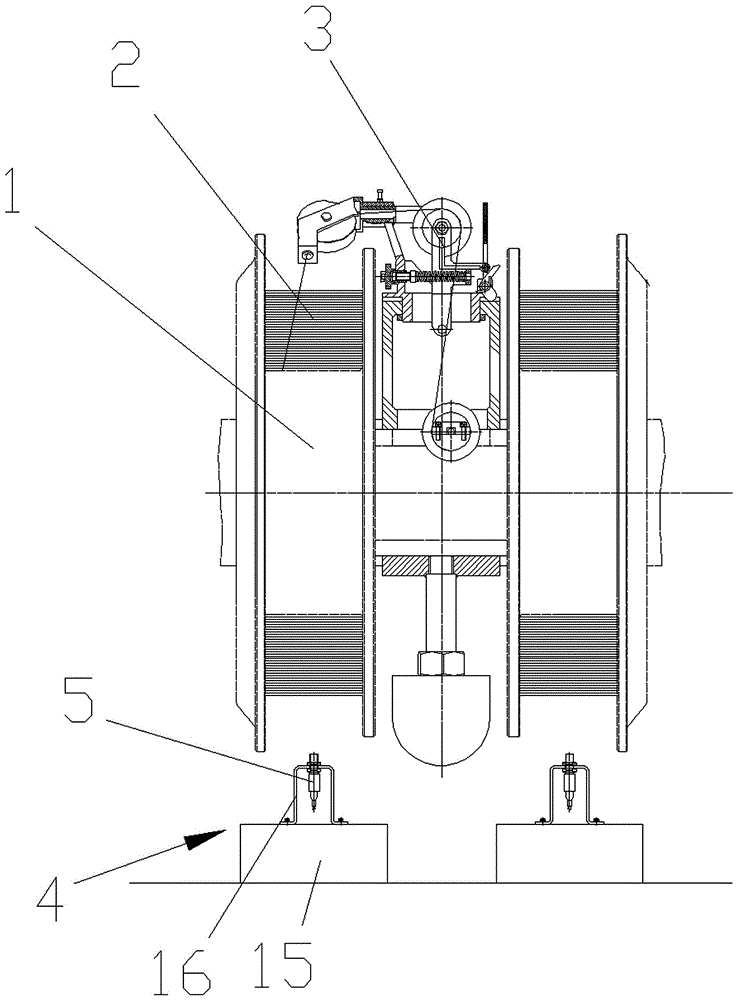

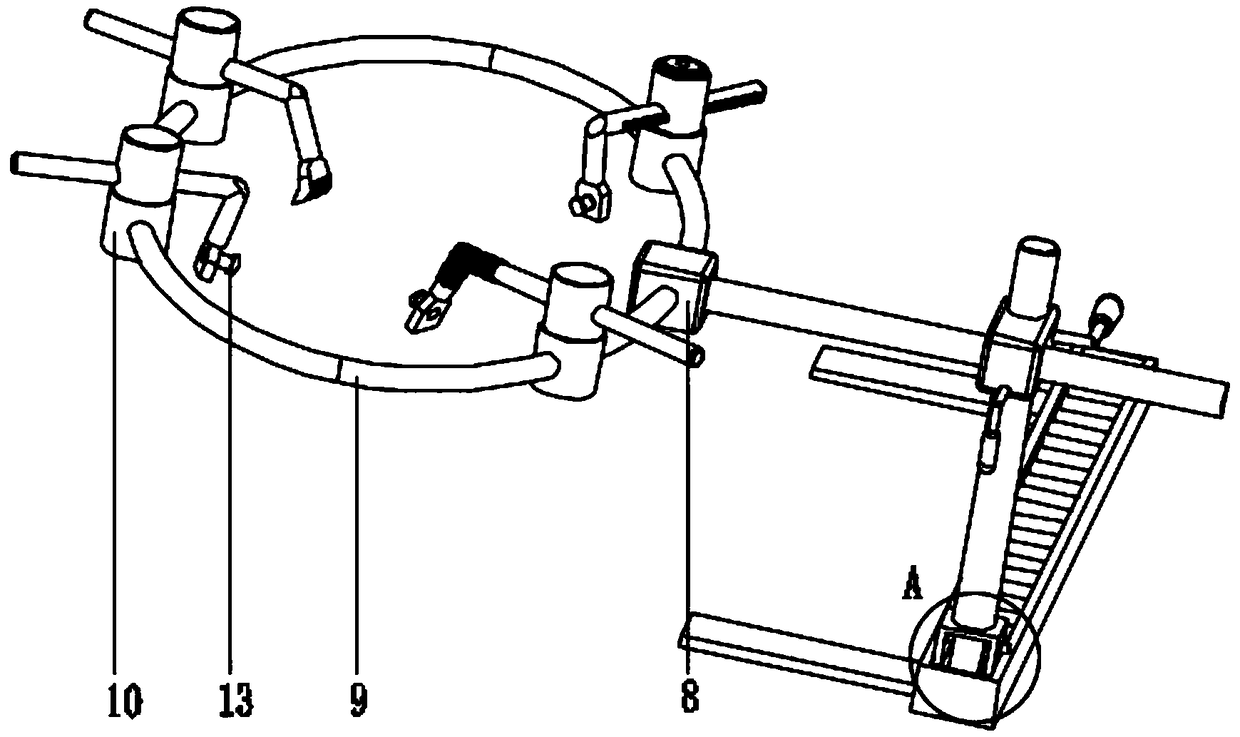

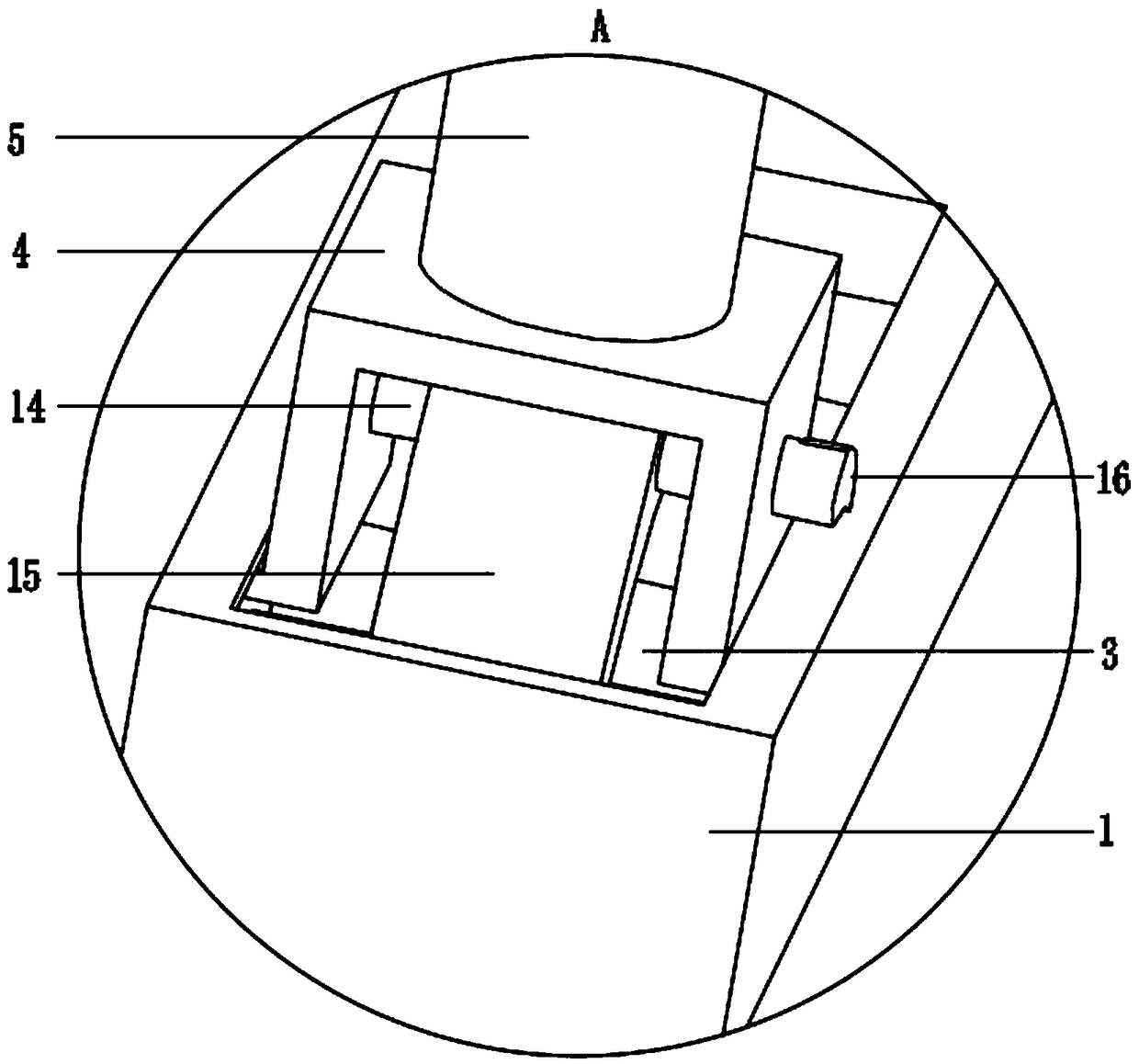

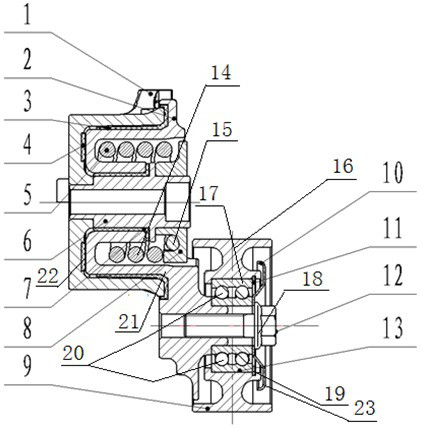

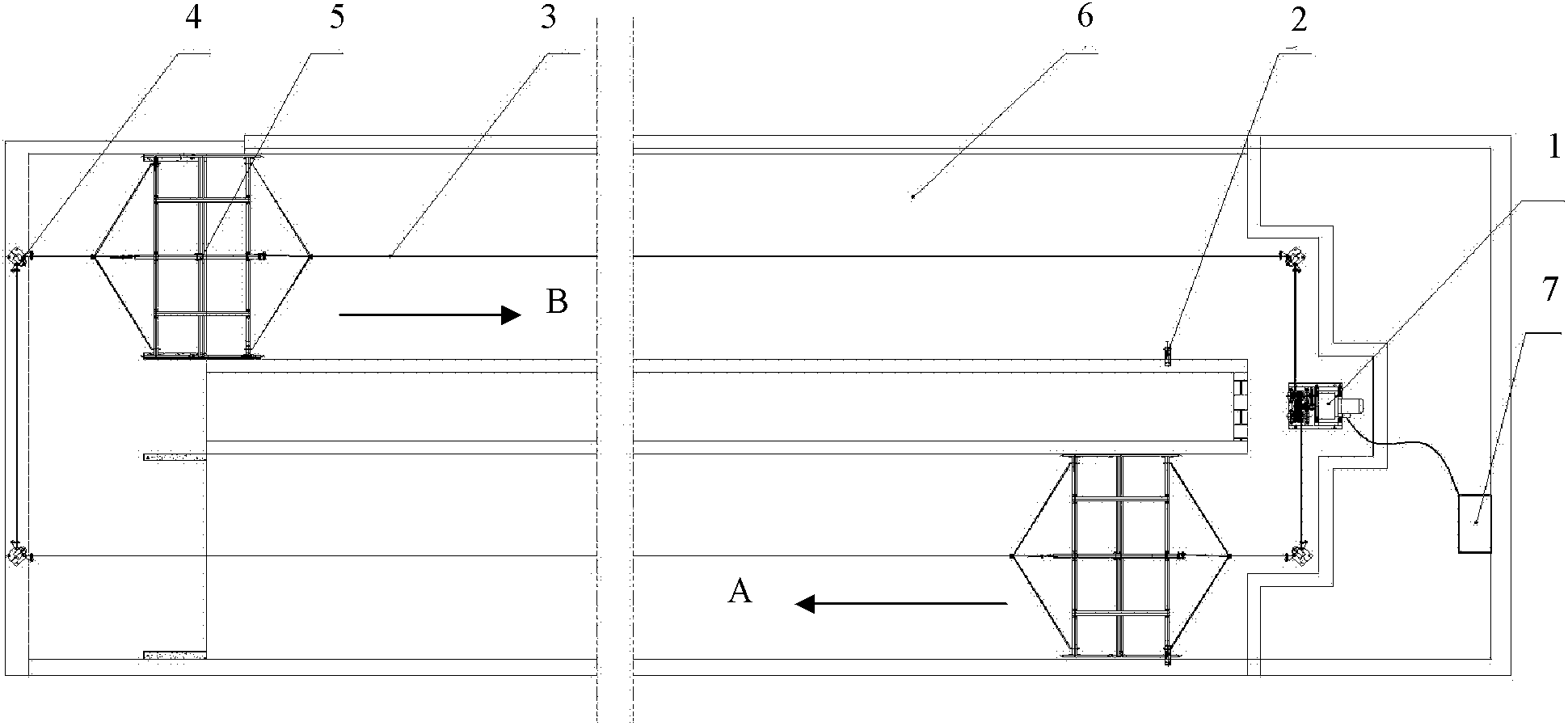

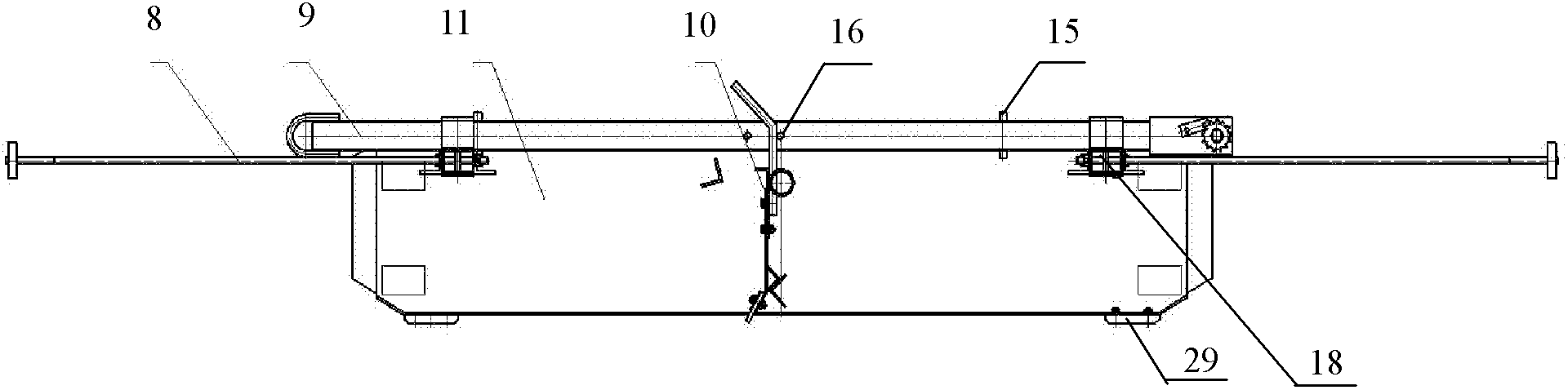

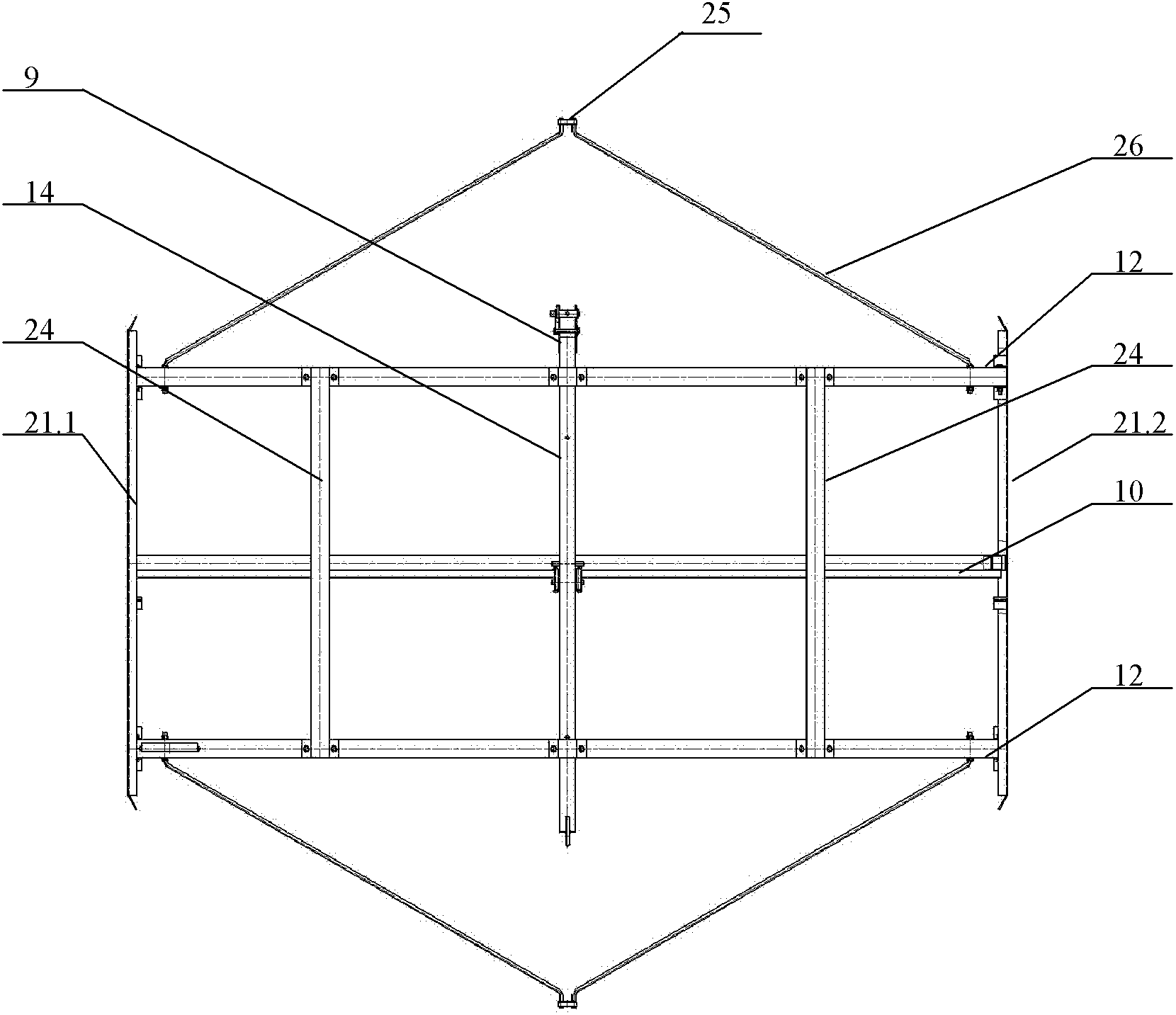

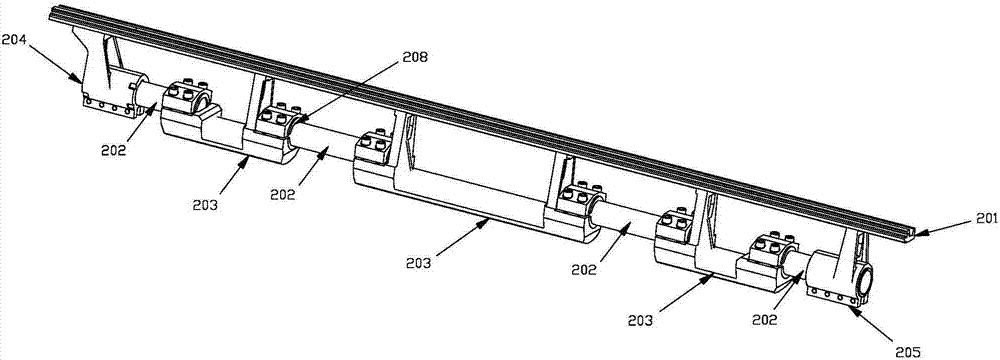

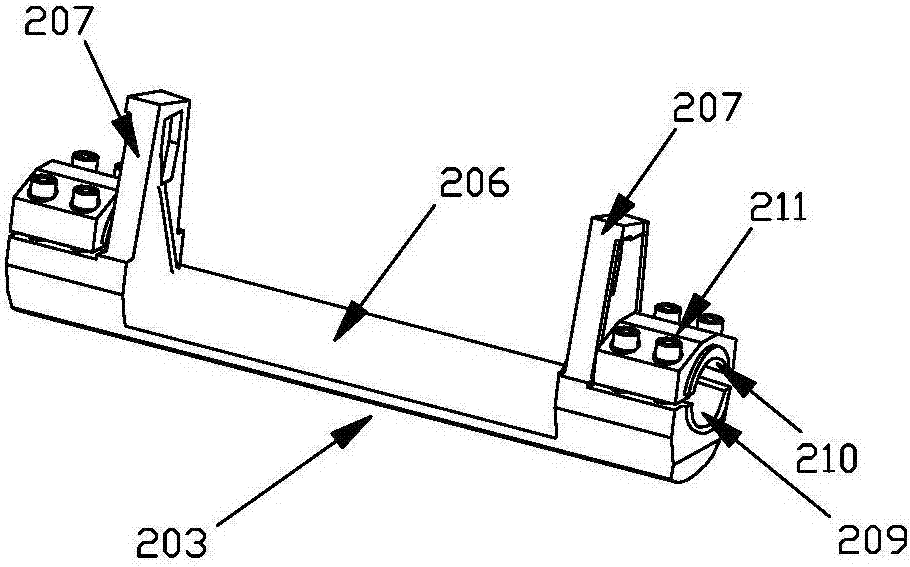

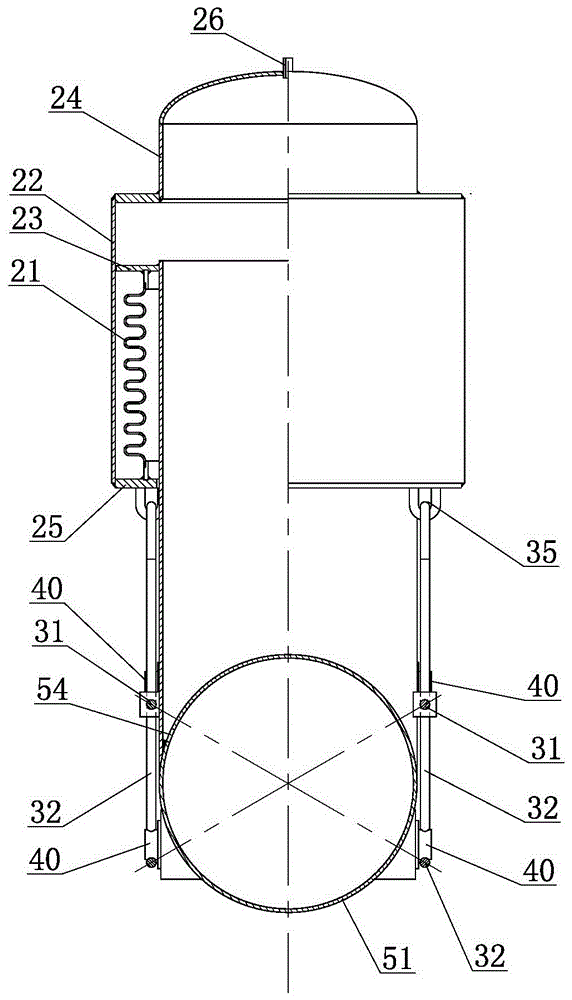

Scraper type dung cleaner for use in hog house

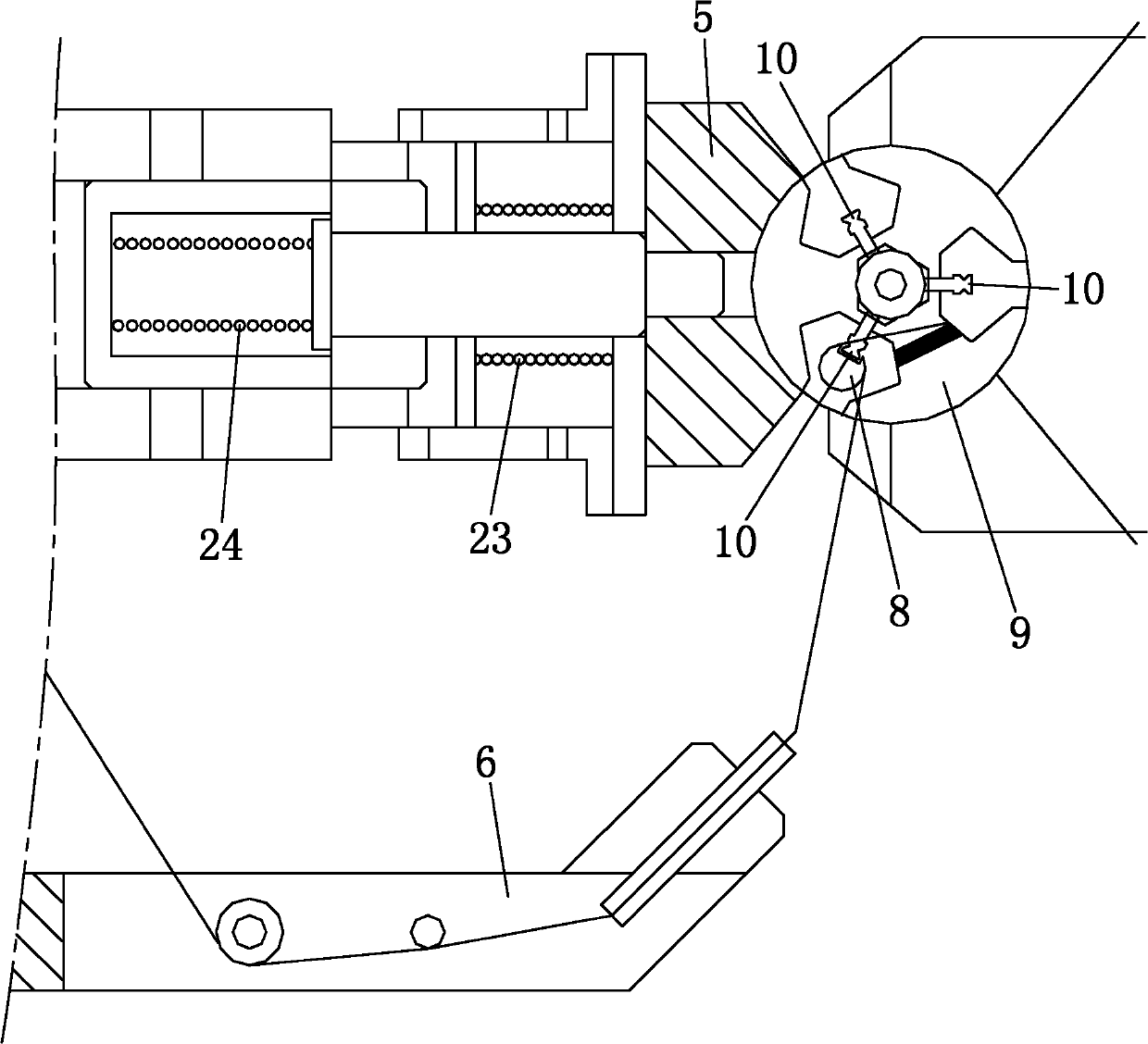

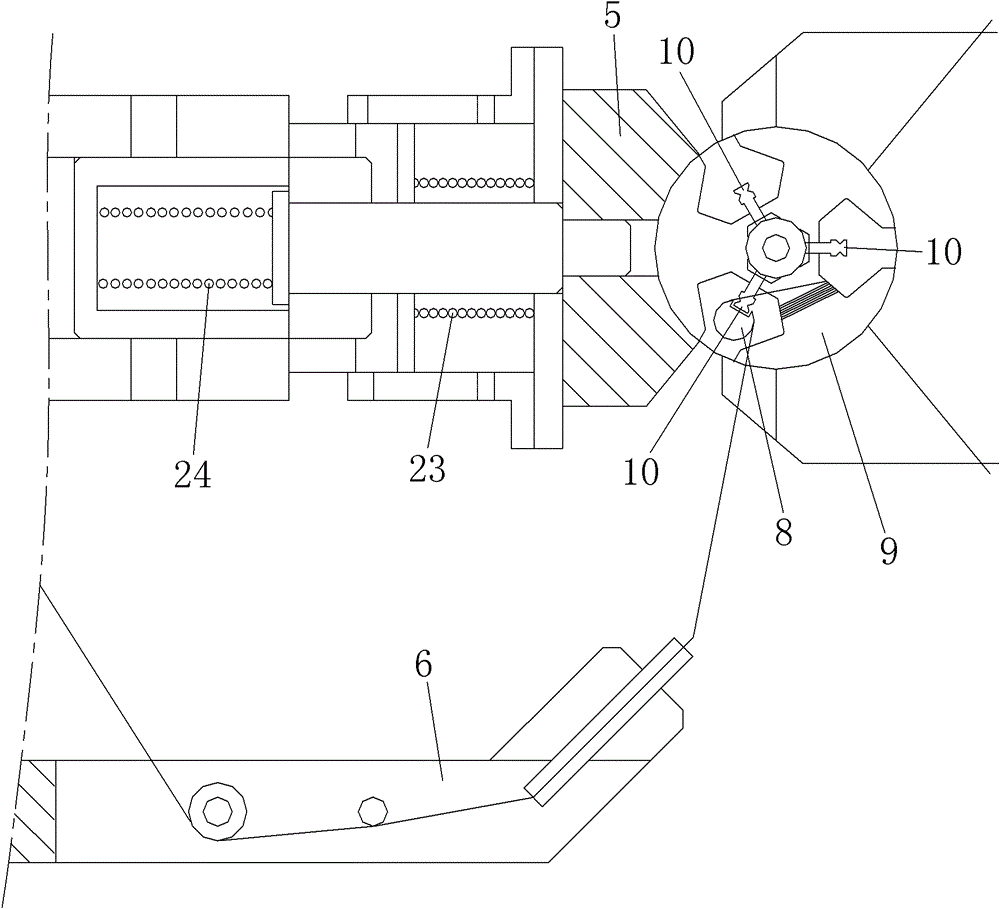

InactiveCN102487834AStable structureUniform and stable tensionAnimal housingSteering wheelEngineering

The invention discloses a scraper type dung cleaner for use in a hog house, which comprises a driving mechanism, a detecting device, a traction rope, a steering wheel, a dung scraping device and a control electric cabinet, wherein the dung scraping device comprises a traction regulating frame, a pull rod device, a dung scrapping plate and a side plate mechanism; the traction regulating frame is fixedly connected with the side plate mechanism and is in sliding connection with the pull rod device; the pull rode device comprises a traction ring, a pull rod, a limiting shaft, a deflector rod, anda pawl device; the traction ring and the pawl device are arranged at the two ends of the pull rod respectively and are connected with the traction rope; the deflector rod, and the limiting shaft are arranged on the pull rod; a sliding connector which connects the pull rod and the traction regulating frame is in contacted connection with the limiting shaft; the upper end of the dung scraping plateis in contacted connection with the deflector rod,; and a scraper rotating shaft arranged on the dung scraping plate is connected with a supporting stub on the side plate mechanism. The scraper type dung cleaner with a reasonable structure can realize mechanical dung cleaning, lower labor intensity and improve production efficiency.

Owner:GUANGDONG NANMU MACHINERY & EQUIP

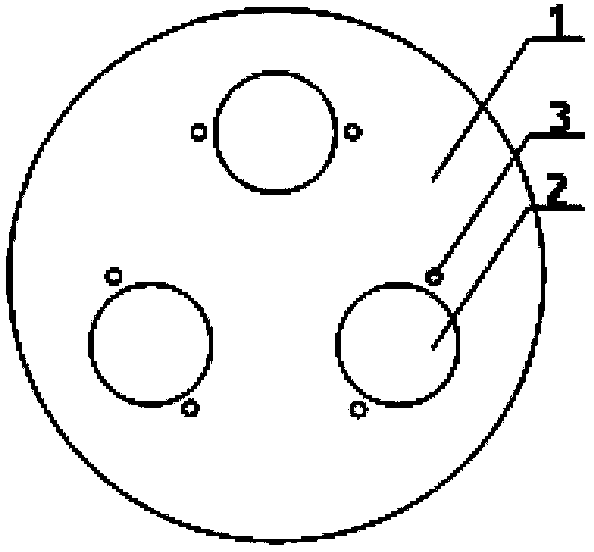

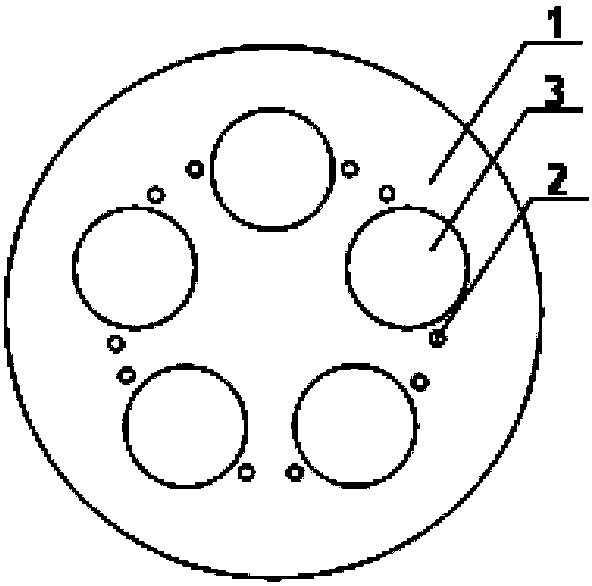

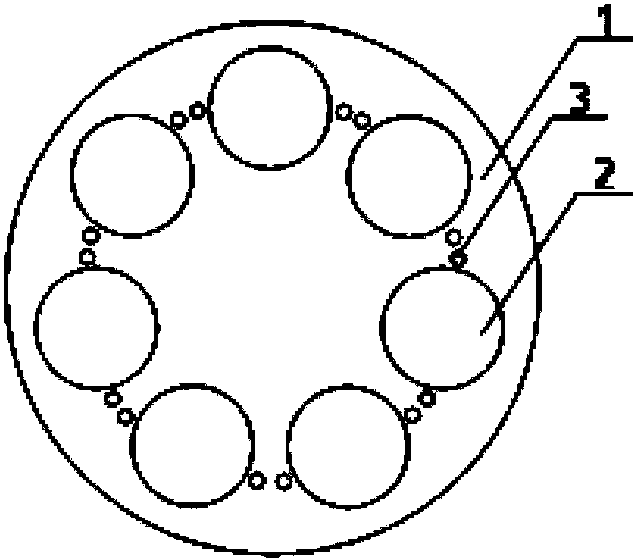

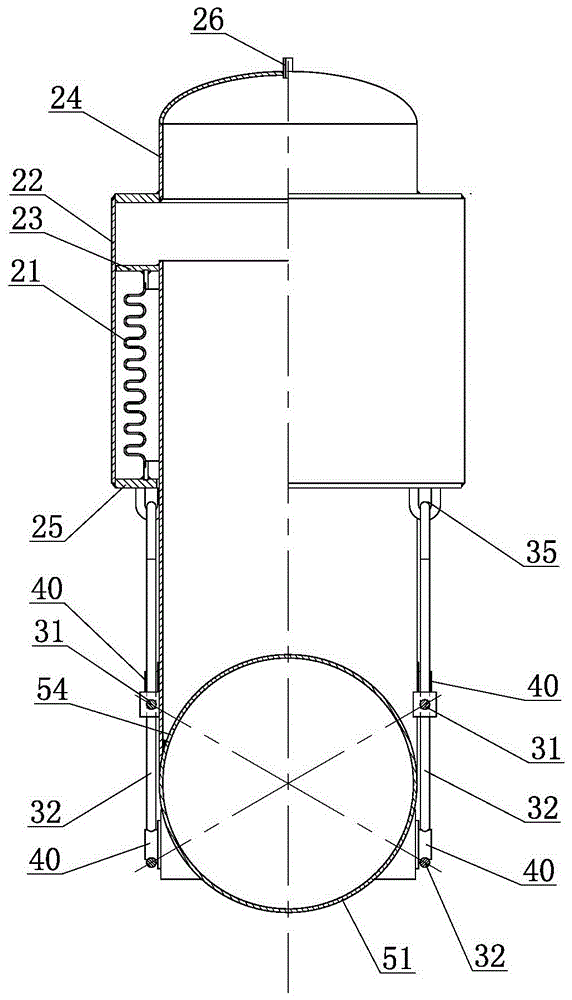

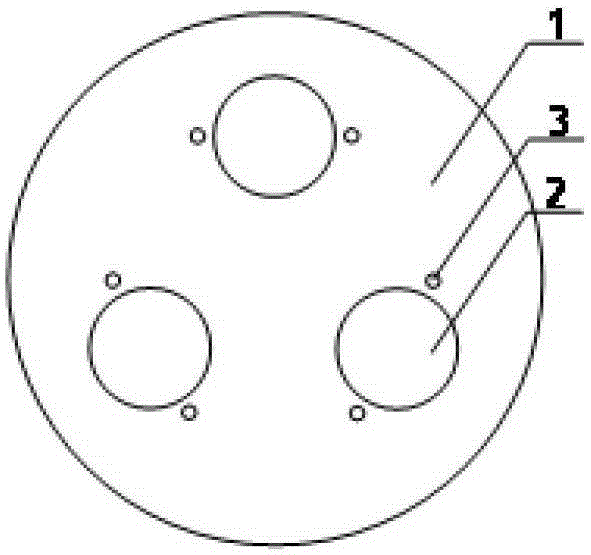

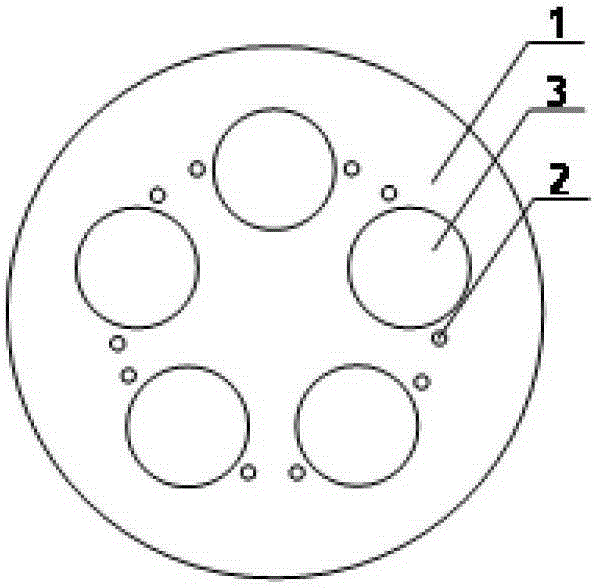

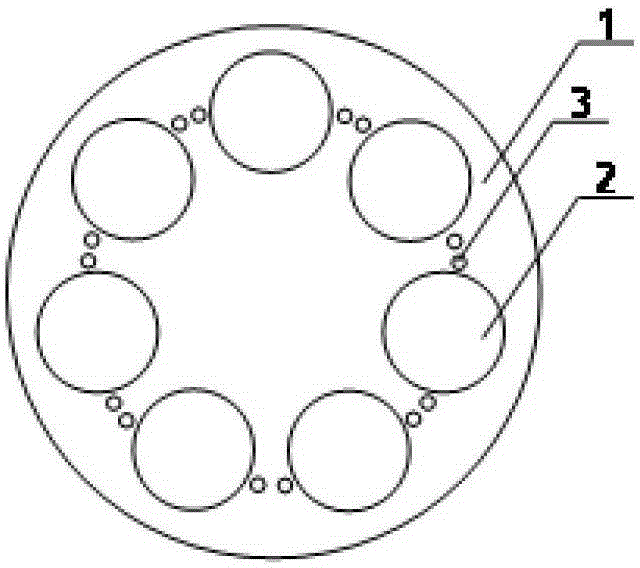

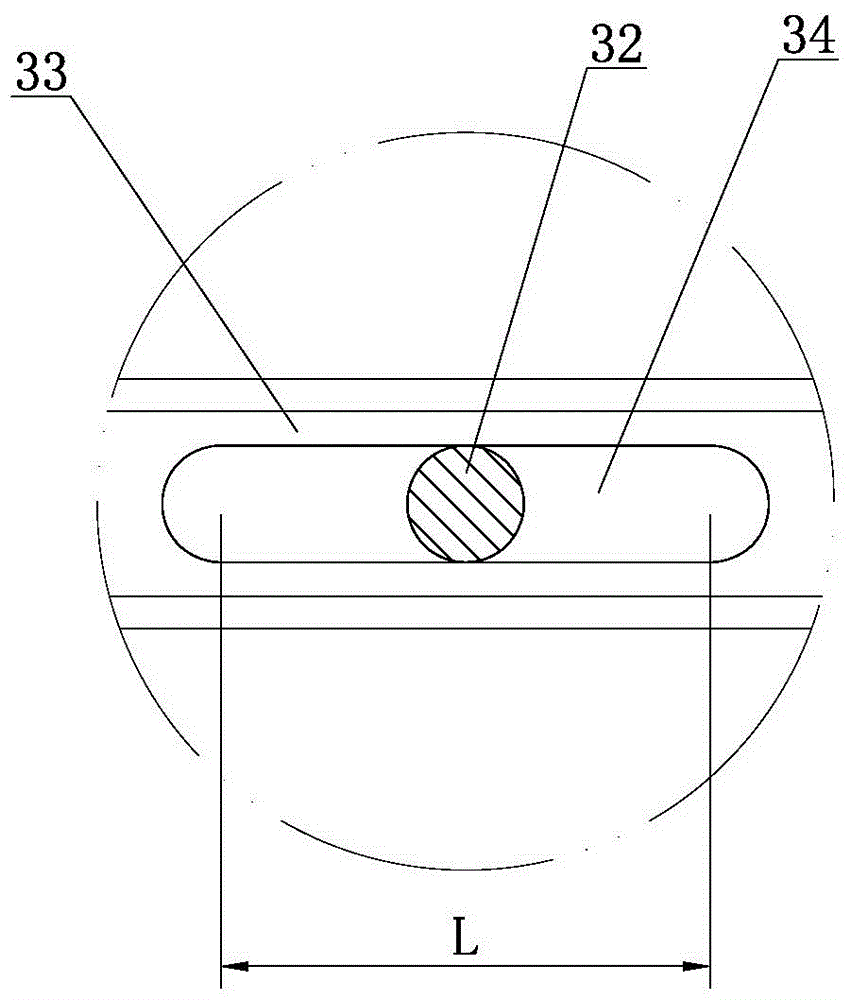

Device for evenly tensioning anchor cable

ActiveCN103422676ASimple structureEasy to operateBuilding material handlingBulkheads/pilesEngineeringPosition control

A device for evenly tensioning an anchor cable comprises two oil cylinder position control plates and a plurality of small tensioning oil cylinders. The two oil cylinder position control plates are arranged at the two ends of the tensioning oil cylinders respectively, at least two position control drawing zones are arranged on the peripheries of the oil cylinder position control plates at equal intervals, each position control drawing zone corresponds to one tensioning oil cylinder and is provided with a steel strand hole and two position control plate screw holes, wherein the two position control plate screw holes are located around the steel strand hole. The tensioning oil cylinders comprise oil cylinder bodies which are cylindrical. Oil cylinder base plates are arranged at the rear ends of the oil cylinder bodies, oil cylinder end plates are arranged at the front ends of the oil cylinder bodies, and the oil cylinder inner walls of the oil cylinder bodies form steel strand cavities through which steel strands pass. The device is simple in structure and convenient to load and unload, equal prestress can be applied to all the steel strands of the whole anchor cable, and therefore integrality and durability of the anchor cable are improved.

Owner:XIAN RES INST OF CHINA COAL TECH& ENG GROUP CORP

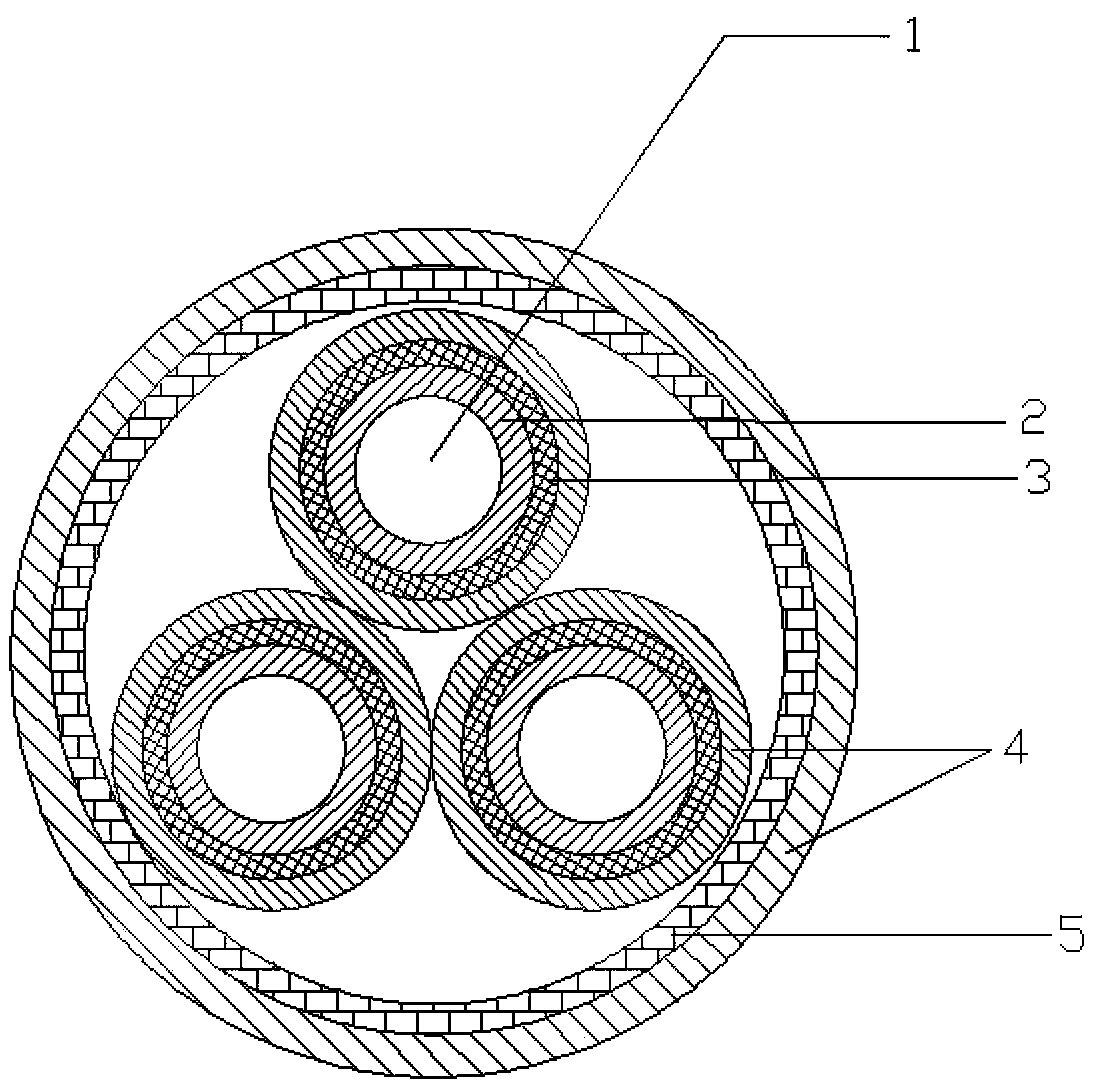

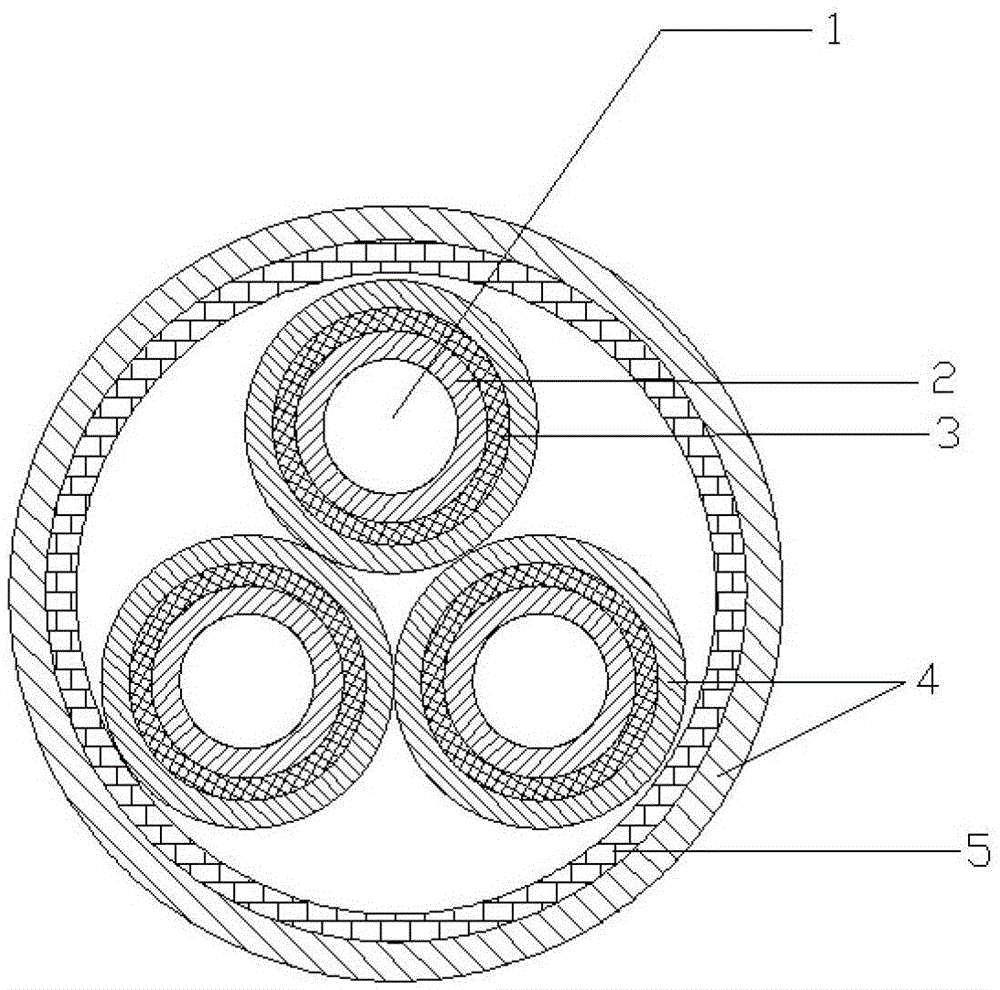

Heat-resistant seamless lapped aviation cable and preparation method thereof

ActiveCN103390449AUniform and stable tensionHeating fastInsulated cablesInsulated conductorsPolytetrafluoroethylenePolyimide

The invention discloses a heat-resistant seamless lapped aviation cable and a preparation method thereof. The heat-resistant seamless lapped aviation cable comprises a conductive core wire formed by twisting a plurality of insulating core wires, and a sheathing layer wrapping the conductive core wire; each insulating core wire comprises a conductor core and an insulating layer wrapping the conductor core; each insulating layer sequentially comprises a polytetrafluoroethylene modified turning belt, a polyimide film and a polytetrafluoroethylene sealing tape in sequence from the inside out. According to the invention, a seamless lapping and sintering technology is utilized and three-layer combination insulation is adopted, so that the heat-resistant seamless lapped aviation cable can be obtained, and favorable electrical performance and mechanical strength of the cable can be ensured. The heat-resistant seamless lapped aviation cable provided by the invention can resist the temperature ranging from minus 65 DEG C to 280 DEG C and can satisfy the requirement of being used under the high-temperature environment of 280 DEG C for a long time.

Owner:GUANGZHOU KAIHENG SPECIAL WIRE & CABLE

Screen printing and its making technology

InactiveCN1495017AUniform and stable tensionUniform thicknessScreen printersPlate printingScreen printingEmulsion

To make the thickness of a printing film uniform by early stabilizing a fabric tensioning tension, making a screen thickness constant, improving adhesive properties of a resist film to a screen, improving a dimensional accuracy, upgrading ink permeability, increasing a paste transfer amount, omitting a waste print, and improving a positional accuracy of a printed product. In the screen printing plate, an image layer made of a photosensitive resin is formed on a surface of a screen spread in a frame. In this case, a metal screen having a recess portion formed of a roughness of 0.05 to 20 [mu]m is formed. A surface of the screen in the frame is coated with a photosensitive emulsion, dried to form a photosensitive resin layer, then exposed through a mask to form a latent image, and an image layer is formed by developing. In this case, powder particles having 100 to 2,000 mesh are blown to the screen and / or the surface of the screen is ground by buffing.

Owner:MURAKAMI CORP

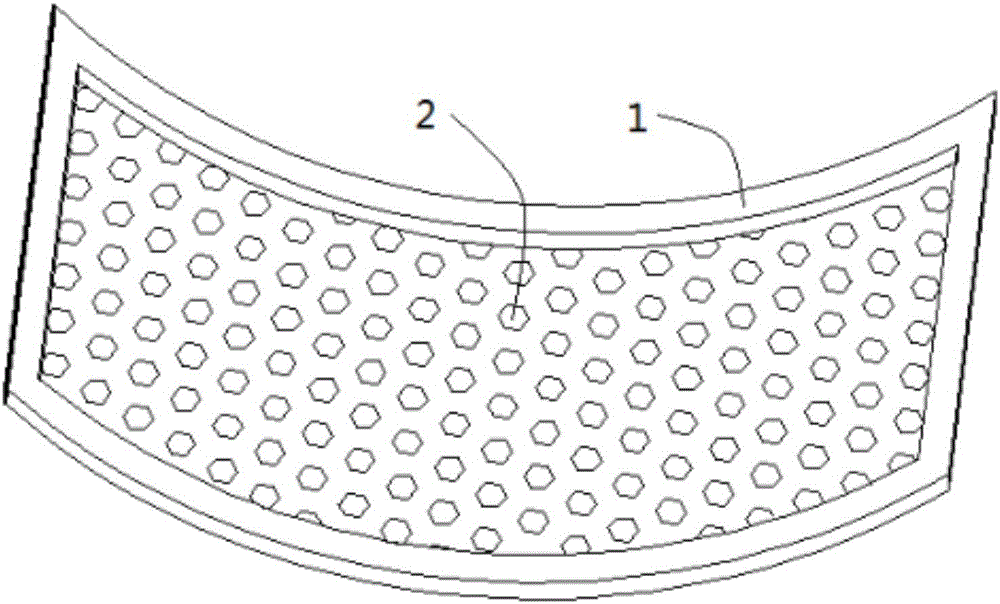

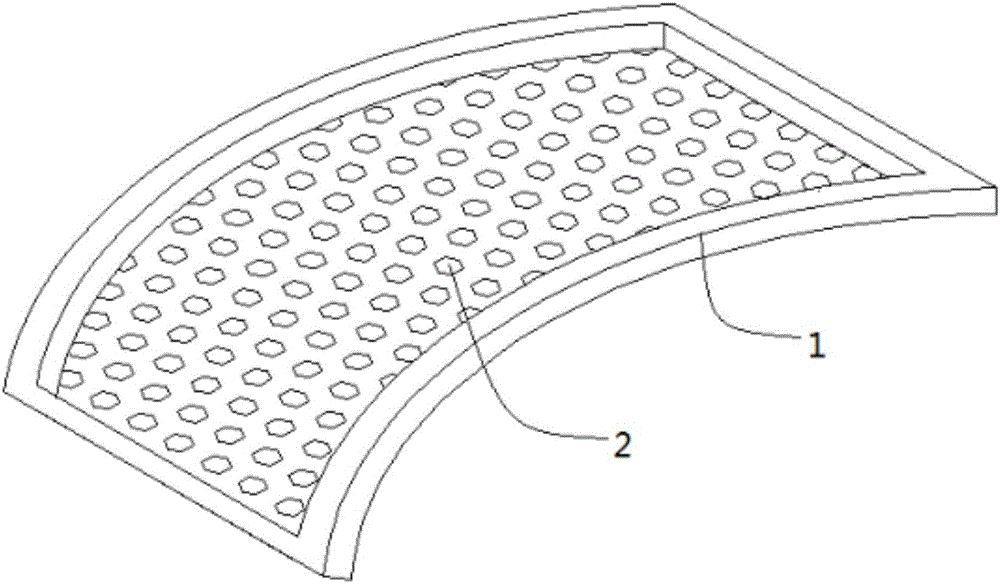

Arc-shaped screen printing plate, and manufacturing method and printing method thereof

InactiveCN106218209AUniform and stable tensionLow costScreen printersPhotomechanical apparatusScreen printingVacuum extraction

The invention discloses an arc-shaped screen printing plate. The arc-shaped screen printing plate comprises a screen frame and a screen gauze, wherein the screen gauze is in fit connection with one side of the periphery of the screen frame via an adhesive; the outer contour of the screen frame is arc-shaped; and the screen frame is made of an aluminum alloy material. The invention also related to a method for manufacturing the arc-shaped screen printing plate and a printing method of the arc-shaped screen printing plate. The radian of the arc-shaped screen printing plate manufactured by the method fully fits with that of arc-shaped printed products and is as same as that of a flat plate; the screen frame is made of an aluminum alloy profile; the screen gauze fully fits with a printing film via vacuum extraction so as to ensure that the tension of the screen gauze is stable and uniform; the service life of the arc-shaped screen printing plate is as same as that of a plane screen printing plate; meanwhile, the aluminum alloy profile can be reused, so that the cost is reduced; according to the exposure process, the flat plate burning principle is adopted and the vacuum extraction is adopted, so that the printing film fully fits with the screen gauze, and development in a ratio of 1 to 1 is achieved; in particular, the effect of printing full-version patterns with gradientscreen spots of the arc-shaped screen printing plate is as same as that of the plane printing effect.

Owner:上海陈兴印刷器材有限公司

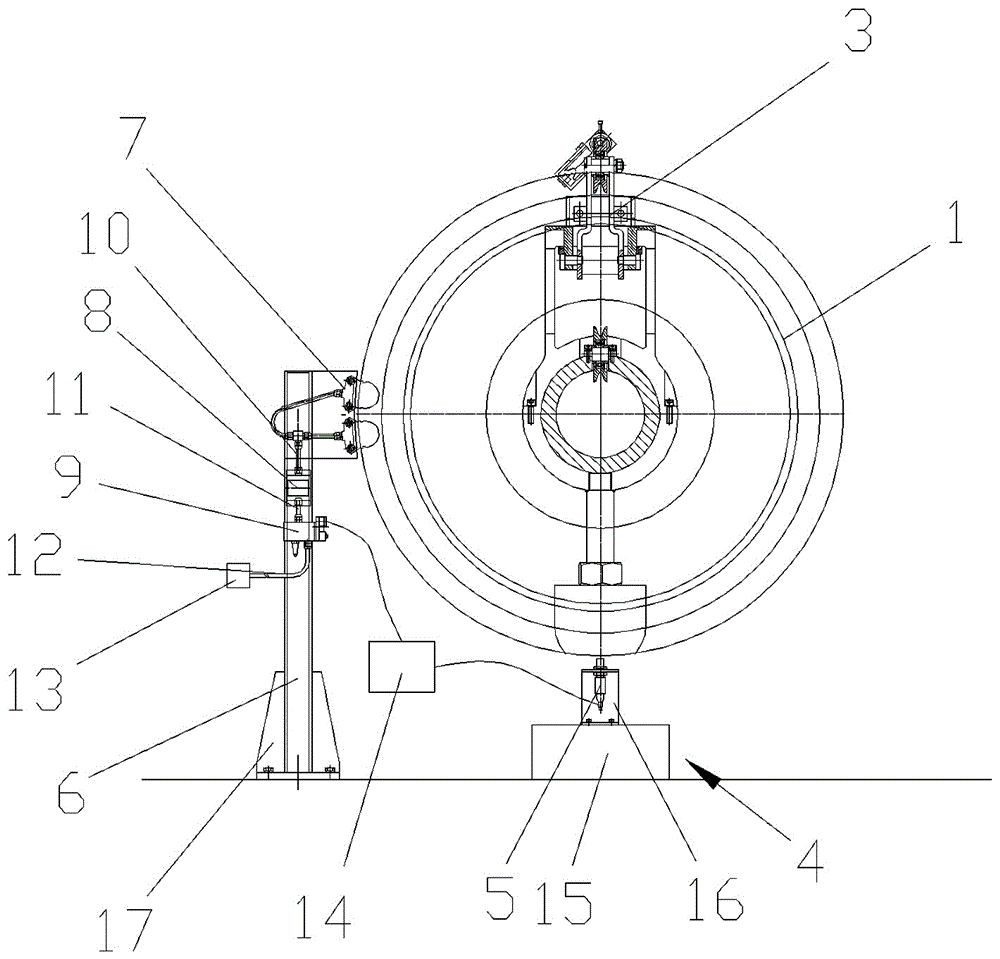

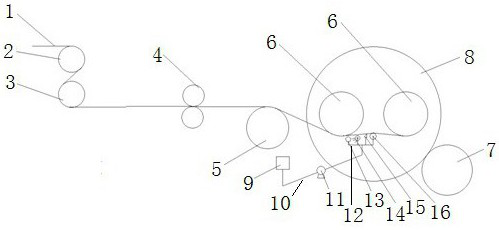

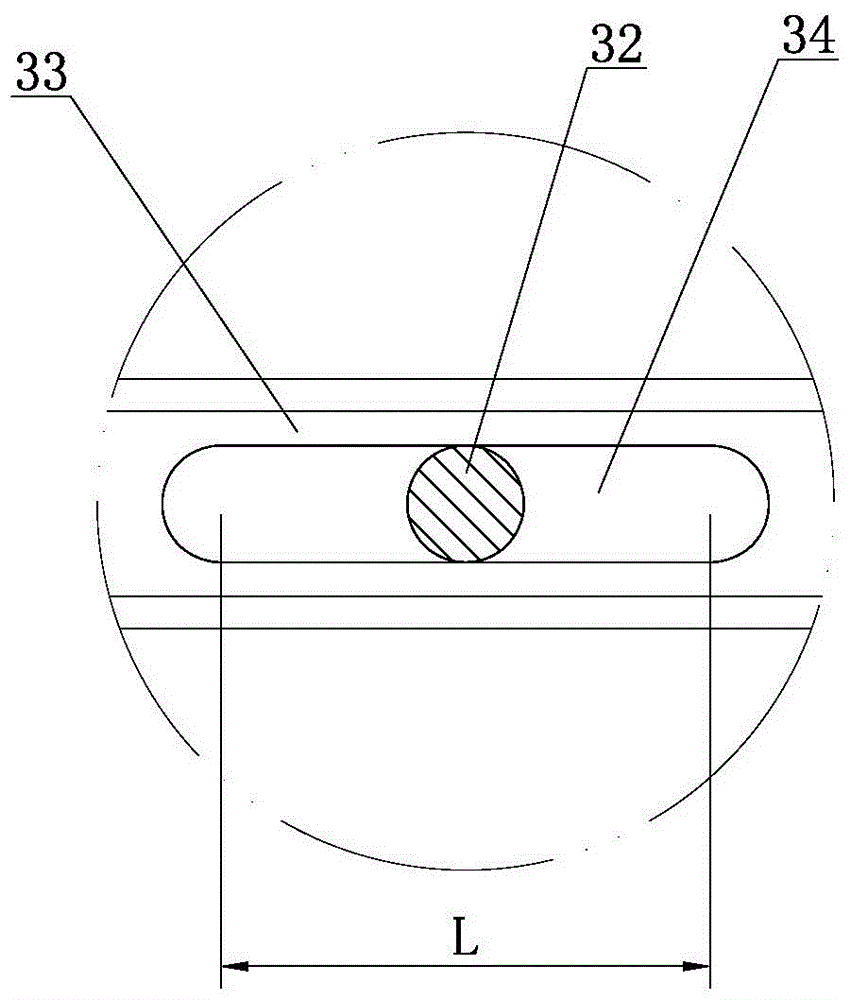

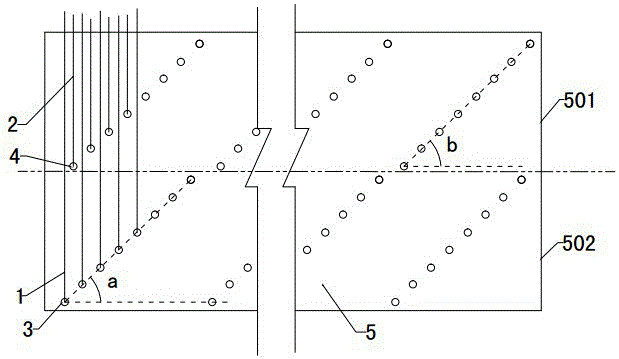

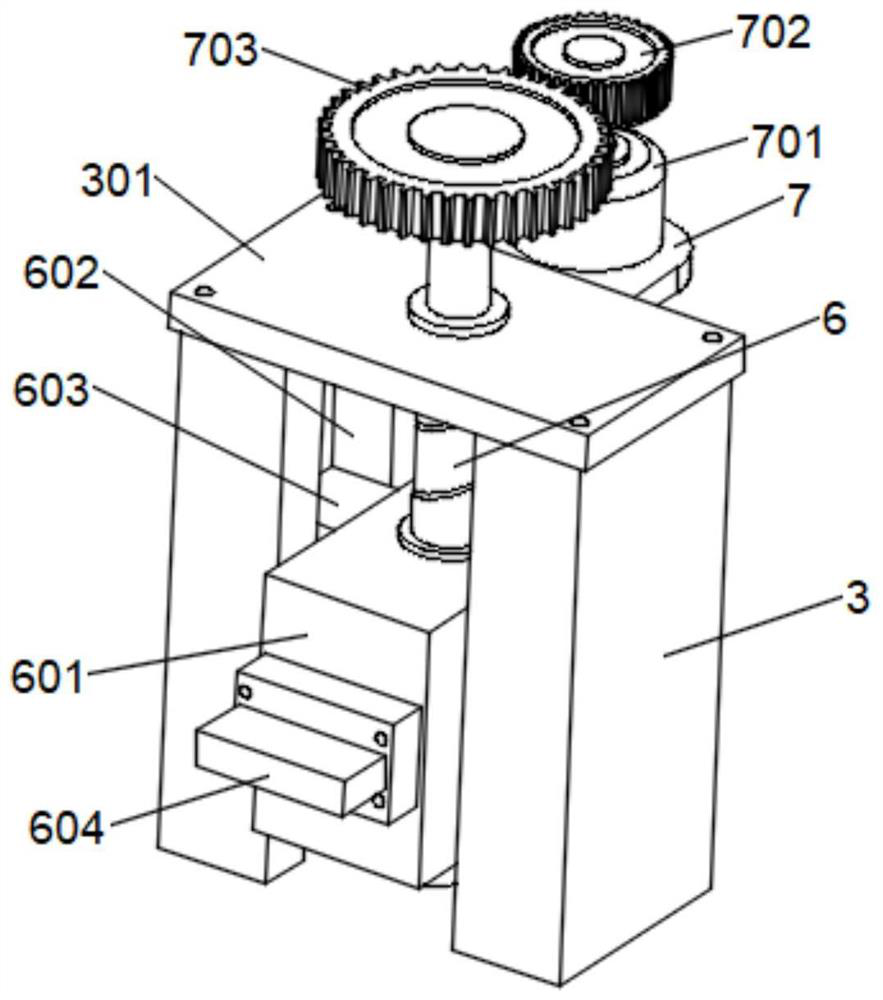

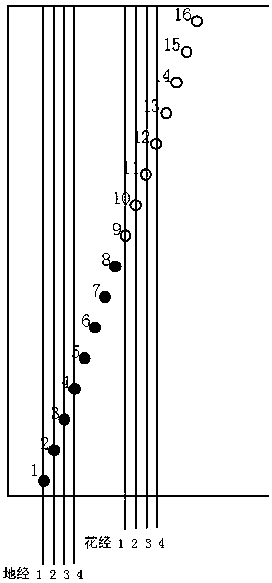

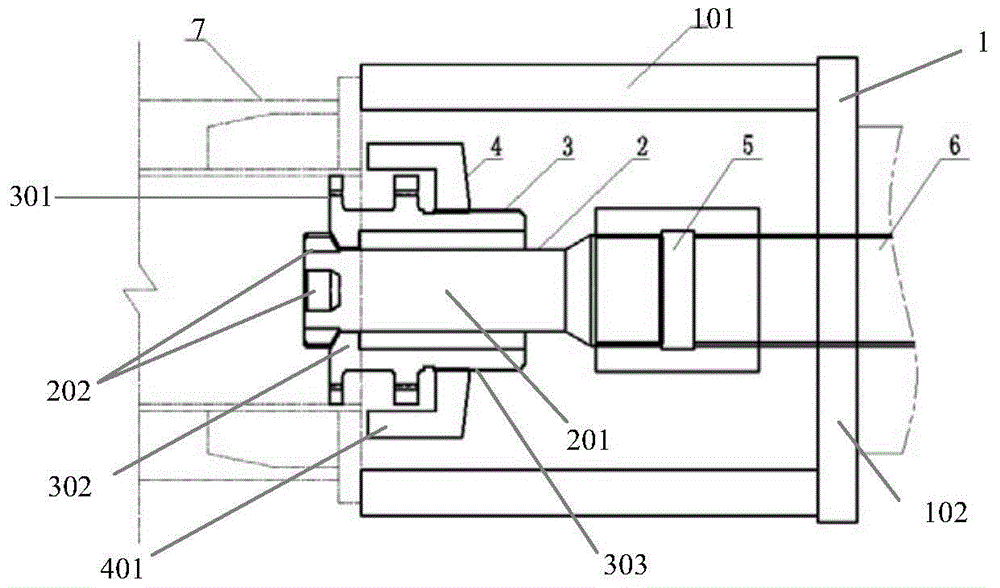

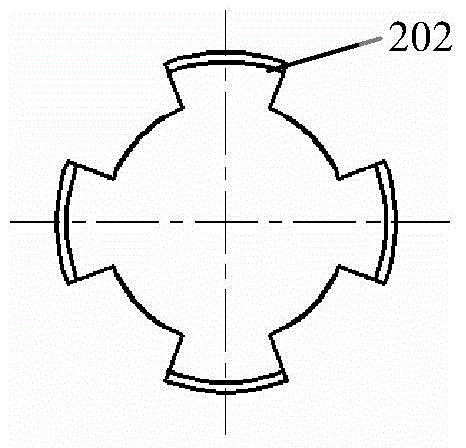

Tension detection control device for center-based stranding machine

InactiveCN106782912AUniform and stable tensionImprove stranding qualityCable/conductor manufactureElectrical conductorSolenoid valve

The invention relates to a tension detection control device for a center-based stranding machine, comprising a pay-off spool (1). A cable core (2) is twined and connected on the pay-off spool, a range sensor (5) that is in induction fit with the cable core is arranged below the pay-off spool, one side of the pay-off spool is provided with a brake (7), a proportional pressure valve (8) and a solenoid valve (9) which are mounted through a brake support (6) and connected by a pipeline, and the solenoid valve is connected with an air source (12) through a third pipeline (12); and the tension detection control device further comprises a control device (14) connected with the range sensor and the solenoid valve. The tension detection control device has the advantages that the device is used for detecting the match degree of the change, from a full plate to a shallow plate, of a wire conductor stored in the pay-off spool and the line outgoing speed of a complete machine, matches up with an air pressure disc brake through an inductor detection feedback mode in the process of releasing the conductive cable core, and automatically adjusts the stability of line releasing tension of the wire conductor stored in the pay-off spool, so that the cable releasing tension is guaranteed to be uniform and stable, and the cable stranding quality is improved.

Owner:安徽长江精工装备科技有限公司

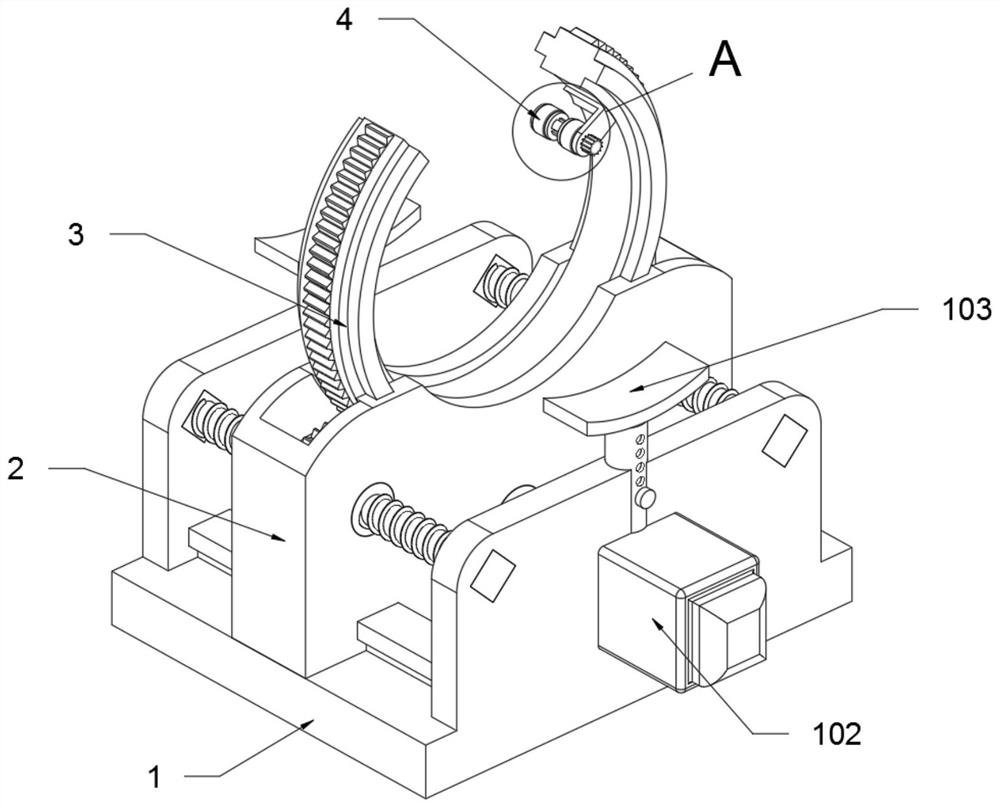

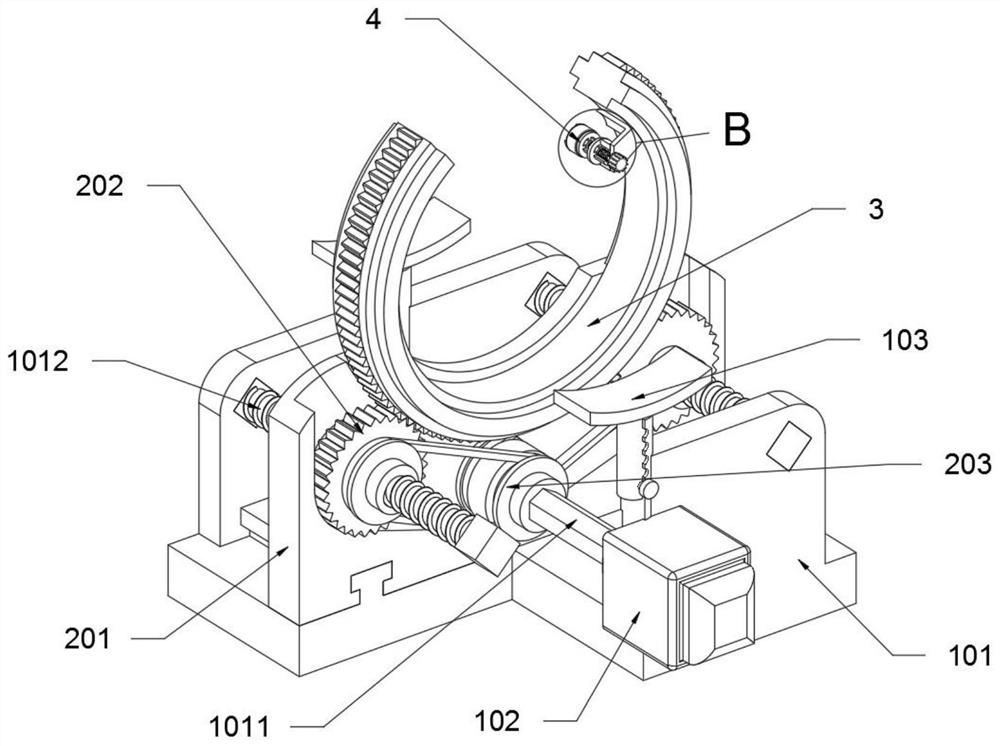

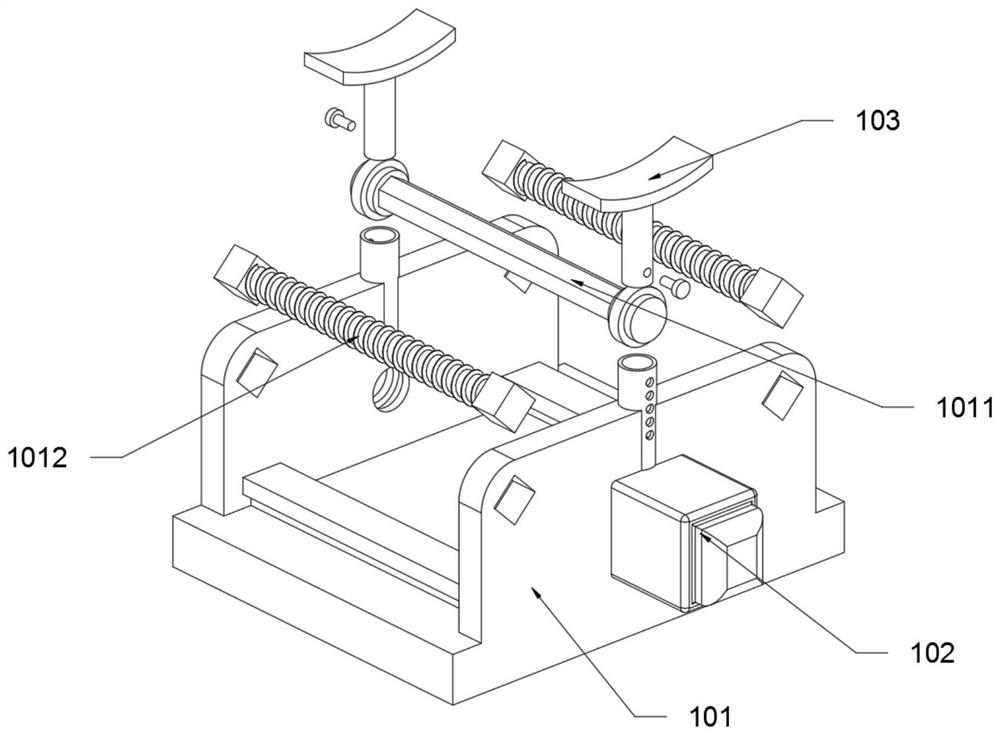

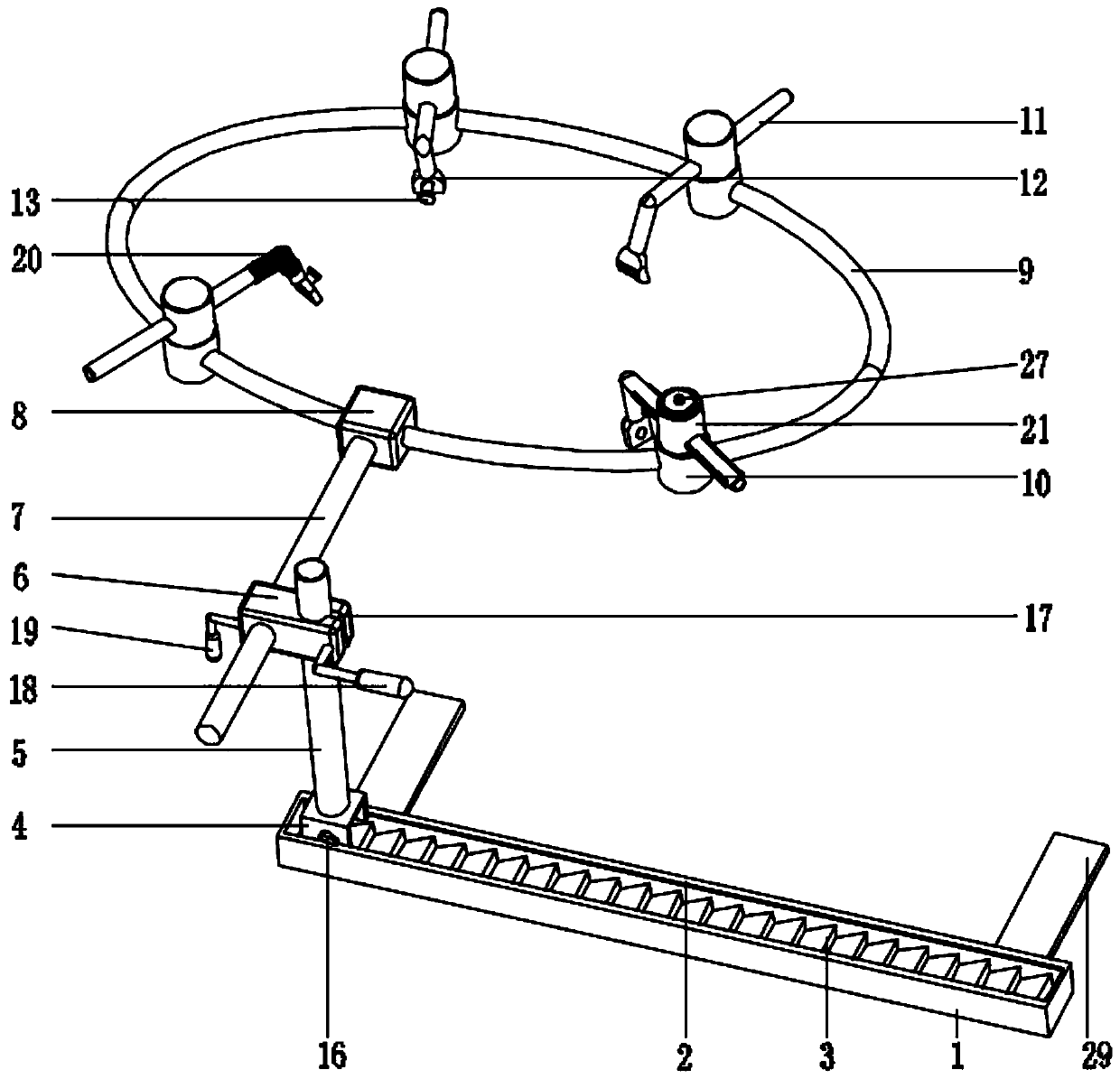

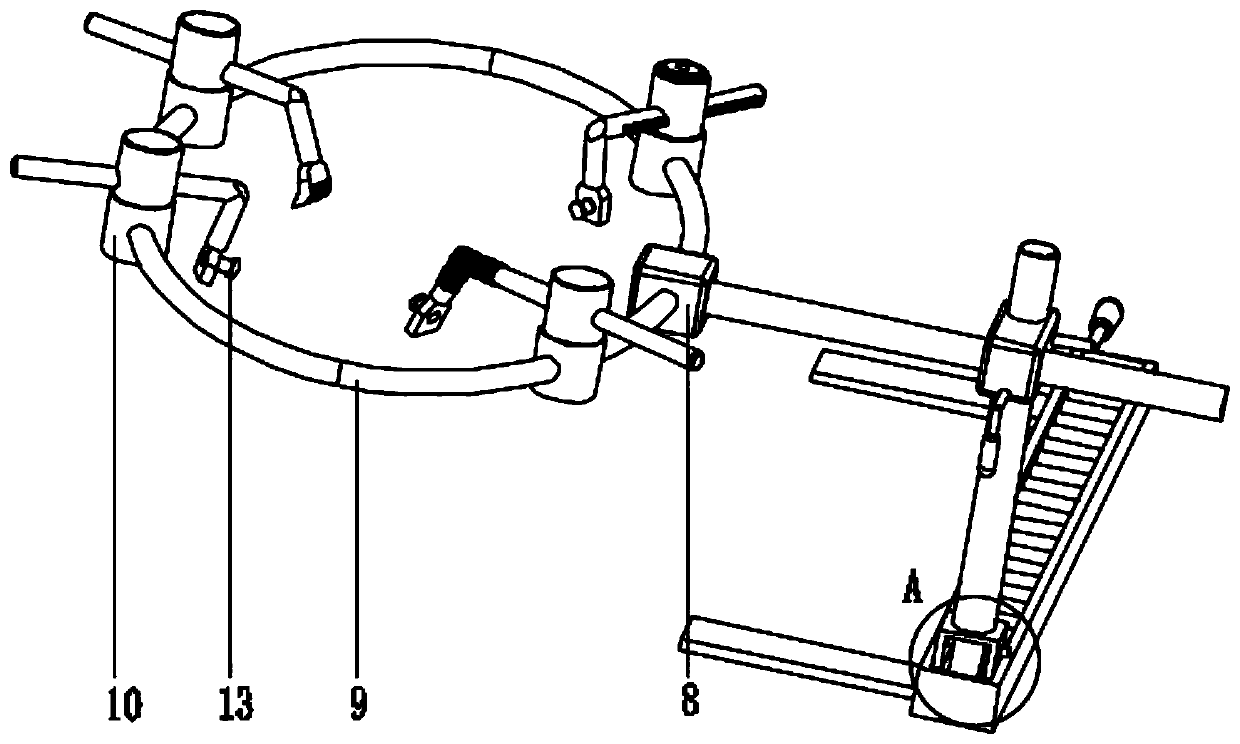

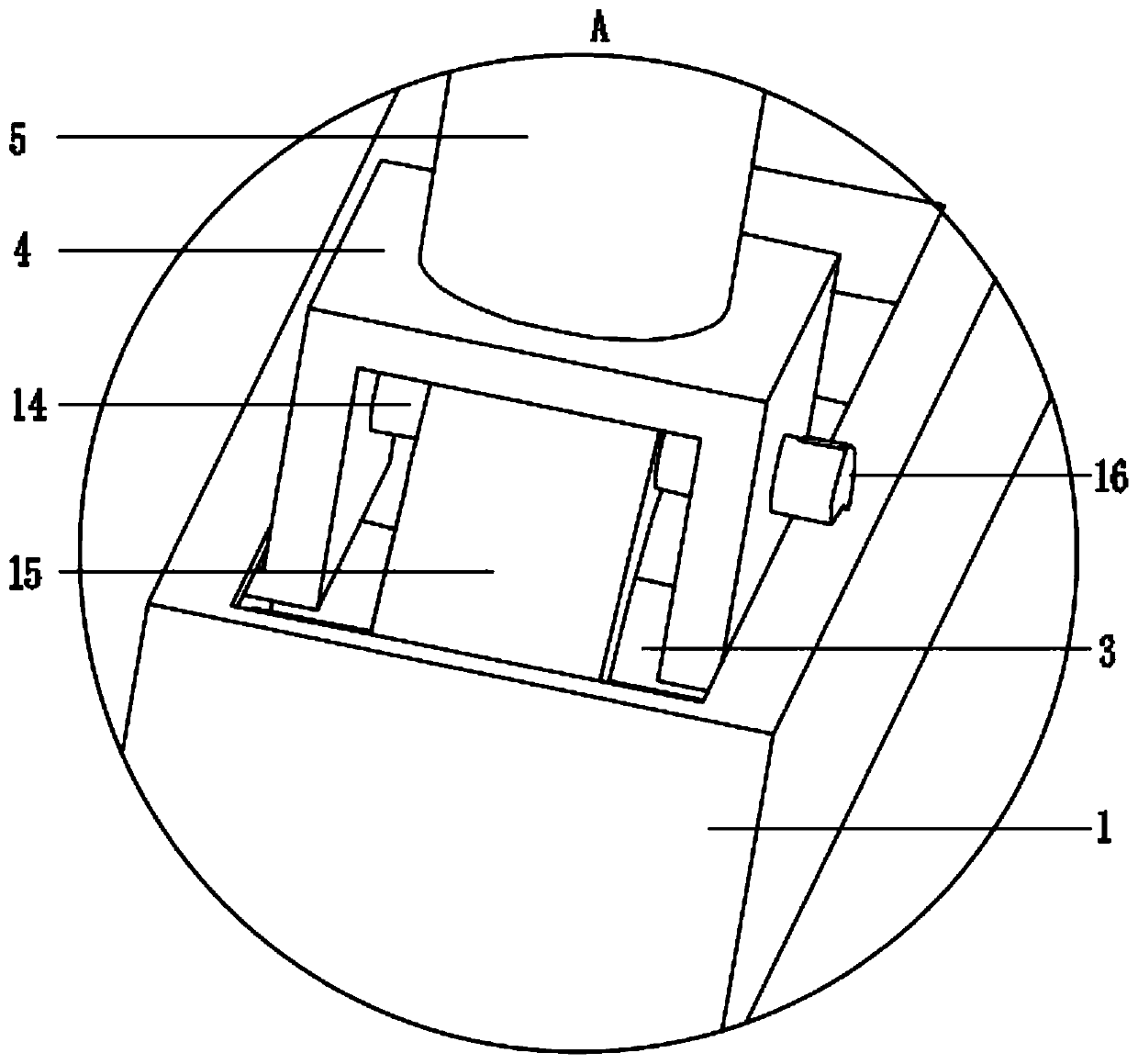

Orthopedic surgery aid

InactiveCN109498076ADoes not block operabilityDo not block the line of sightSurgeryPull forceMedicine

The invention discloses an orthopedic surgery aid in the technical field of medical auxiliary devices. The orthopedic surgery aid comprises a sliding rod, a slideway is arranged on the inner wall of the sliding rod, trench teeth are arranged at the bottom of the sliding rod, a supporting block is slidably arranged in the middle of the sliding rod, a sliding plate is arranged at the bottom of the supporting block and slidably connected with an adjusting rod, an annular connection block is fixedly connected at the end of the adjusting rod, an oval ring is fixedly connected in the middle of the annular connection block, four rubber blocks are uniformly connected on the outer wall of the connection block slidably, the top of each rubber block is slidably connected with a pulling hook handle, the side wall of each pulling hook handle is fixedly connected with a linear limiting plate, a pulling hook plate is fixedly connected at the end of each pulling hook handle, and a thread is connectedin the middle of each pulling hook plate in a threaded manner. The orthopedic surgery aid can quickly adjust and position pull hooks and is balanced and stable in tension, manpower-saving, free of blocking doctor's operation and sight and capable of cooperating with multiple groups of pull hooks to realize good effect.

Owner:CHANGZHOU NO 2 PEOPLES HOSPITAL

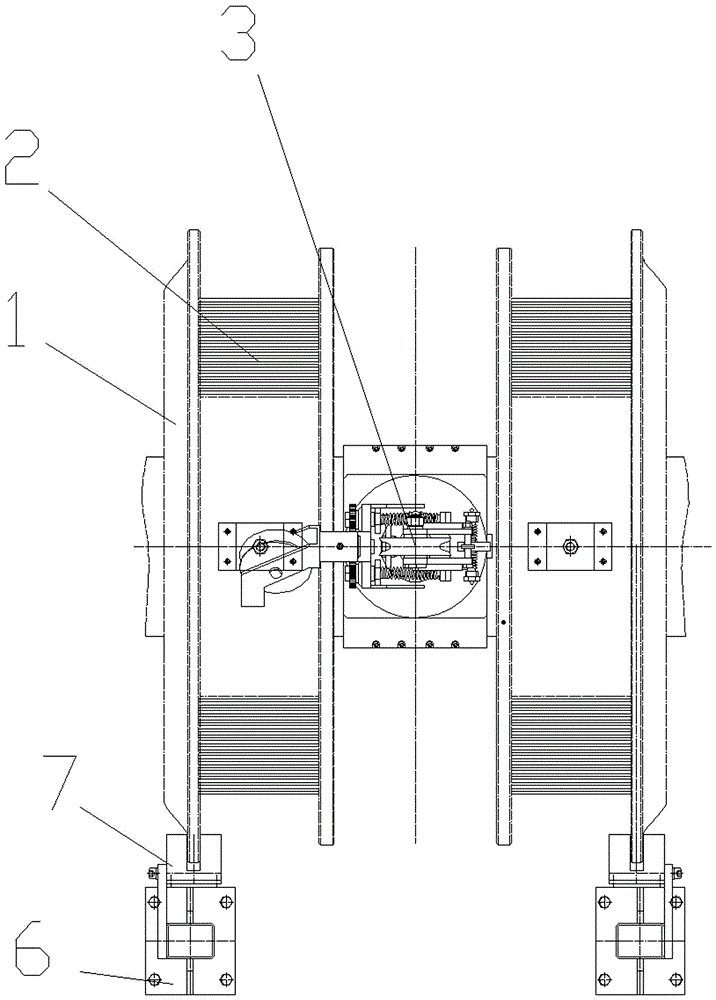

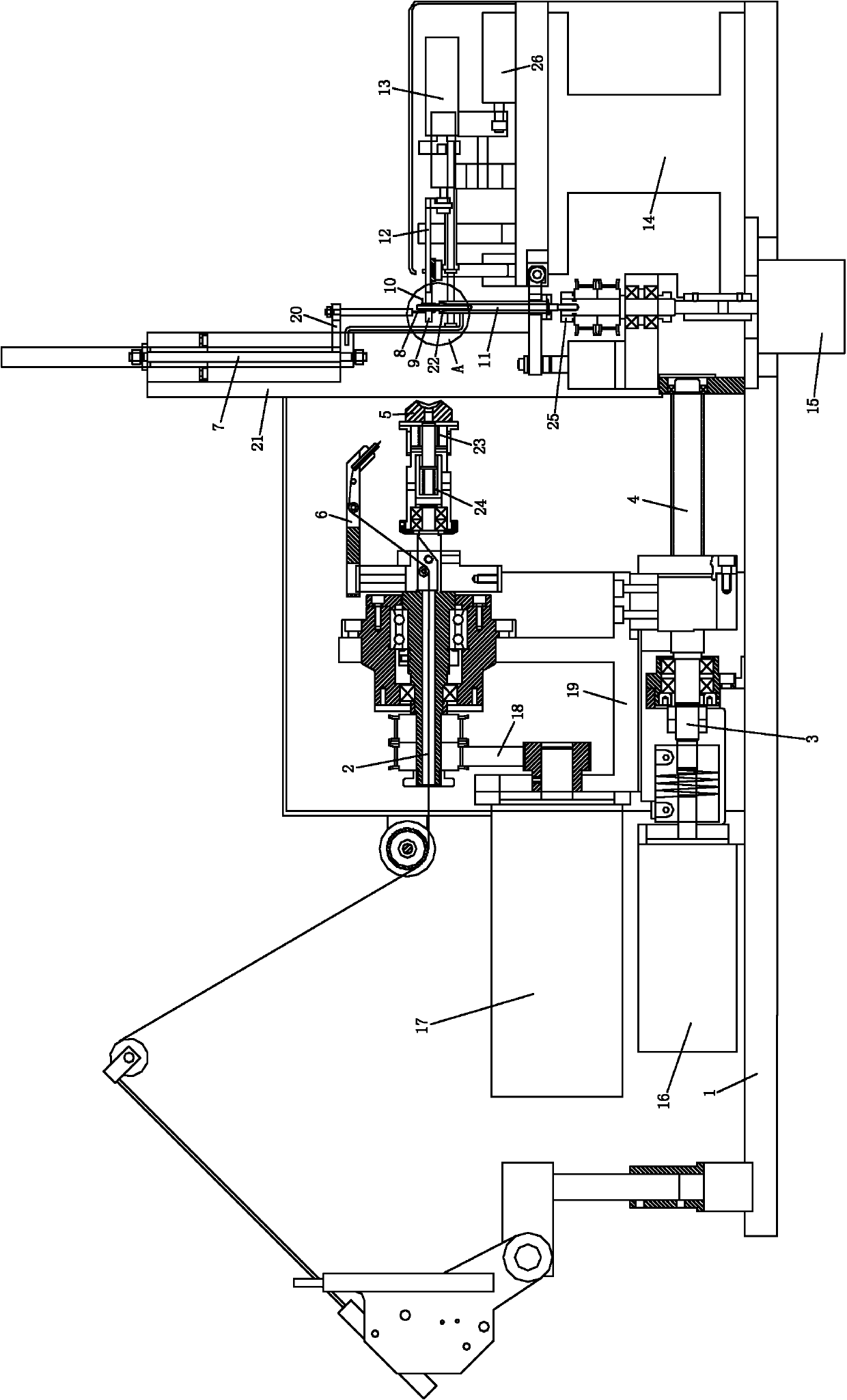

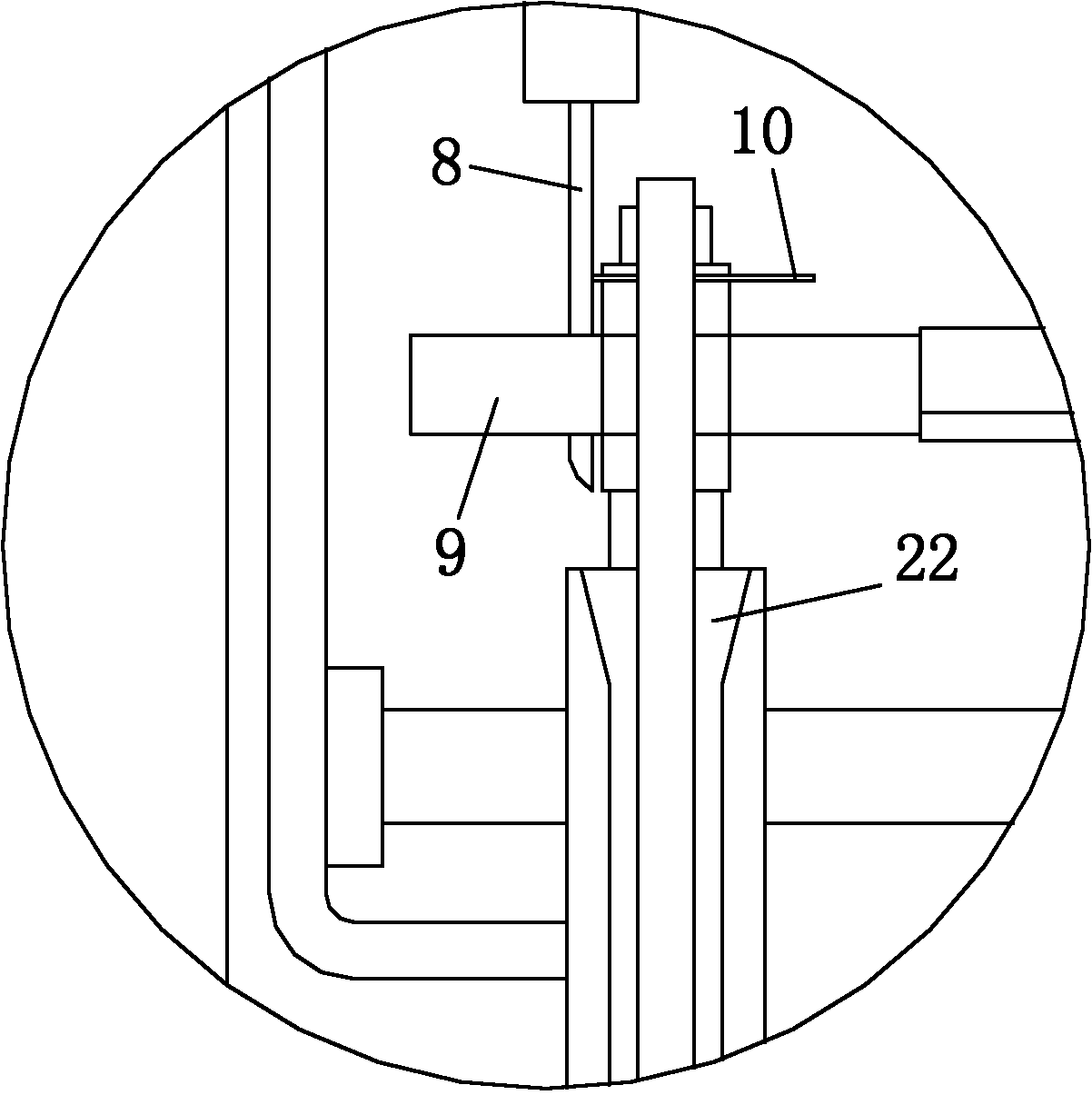

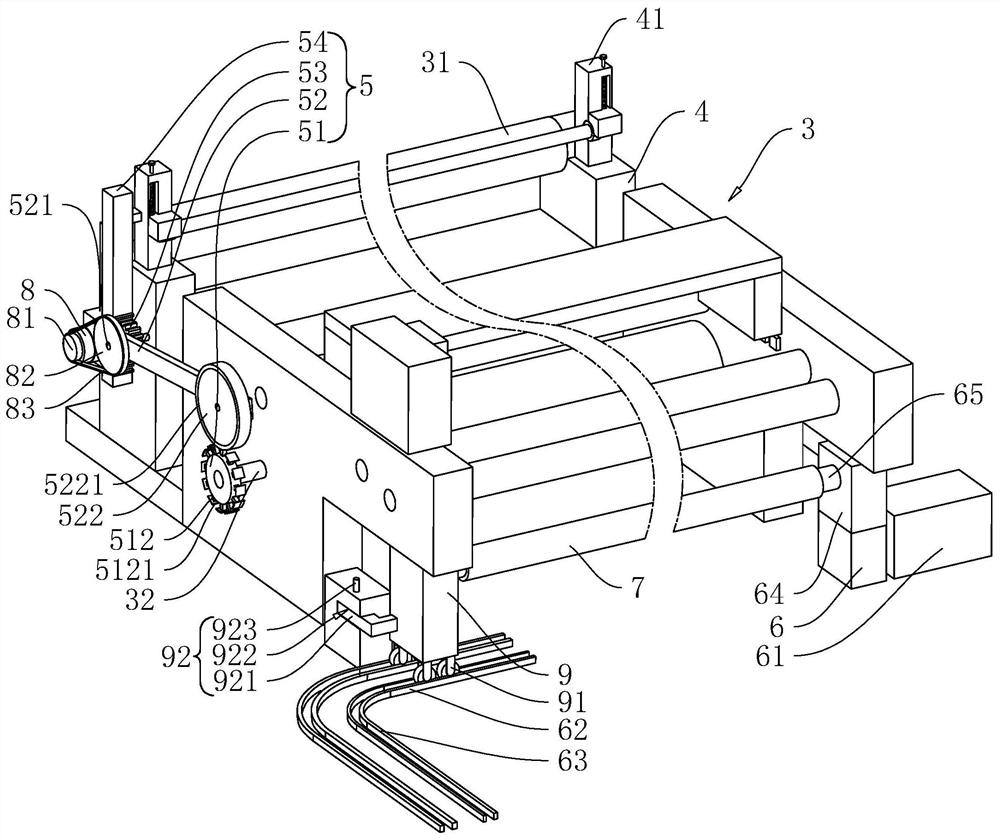

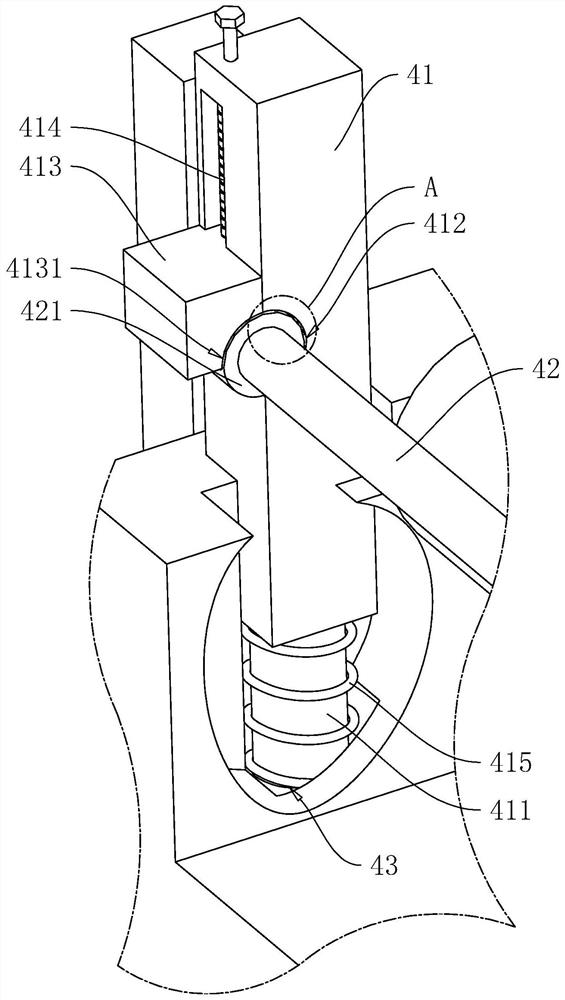

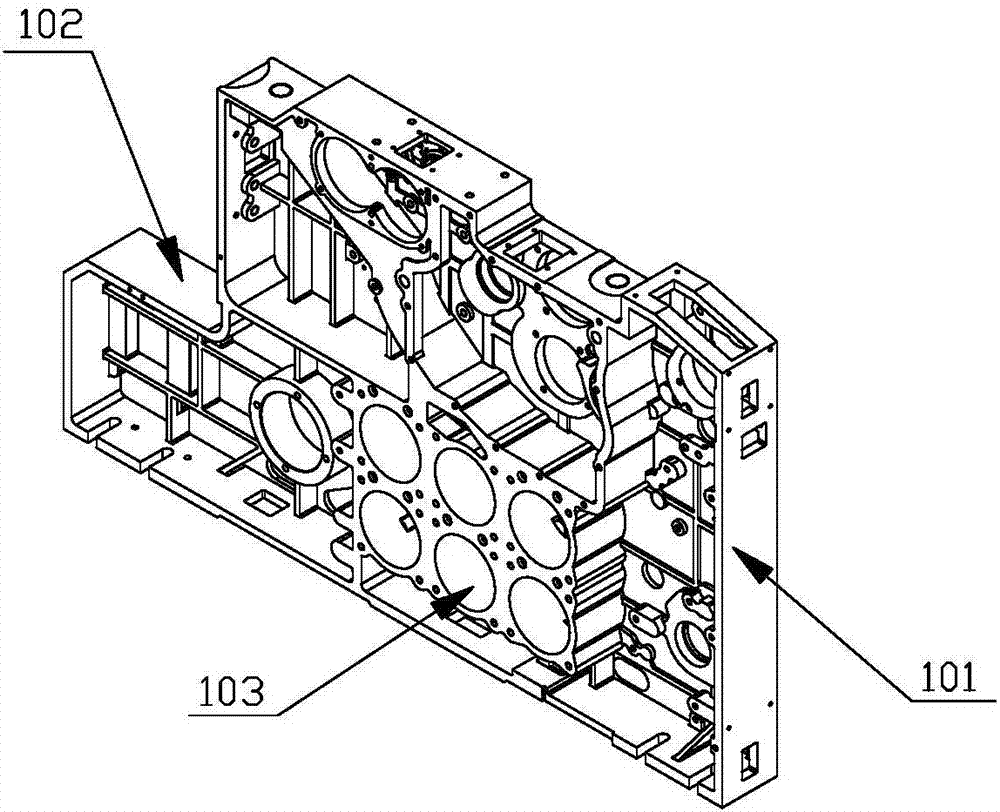

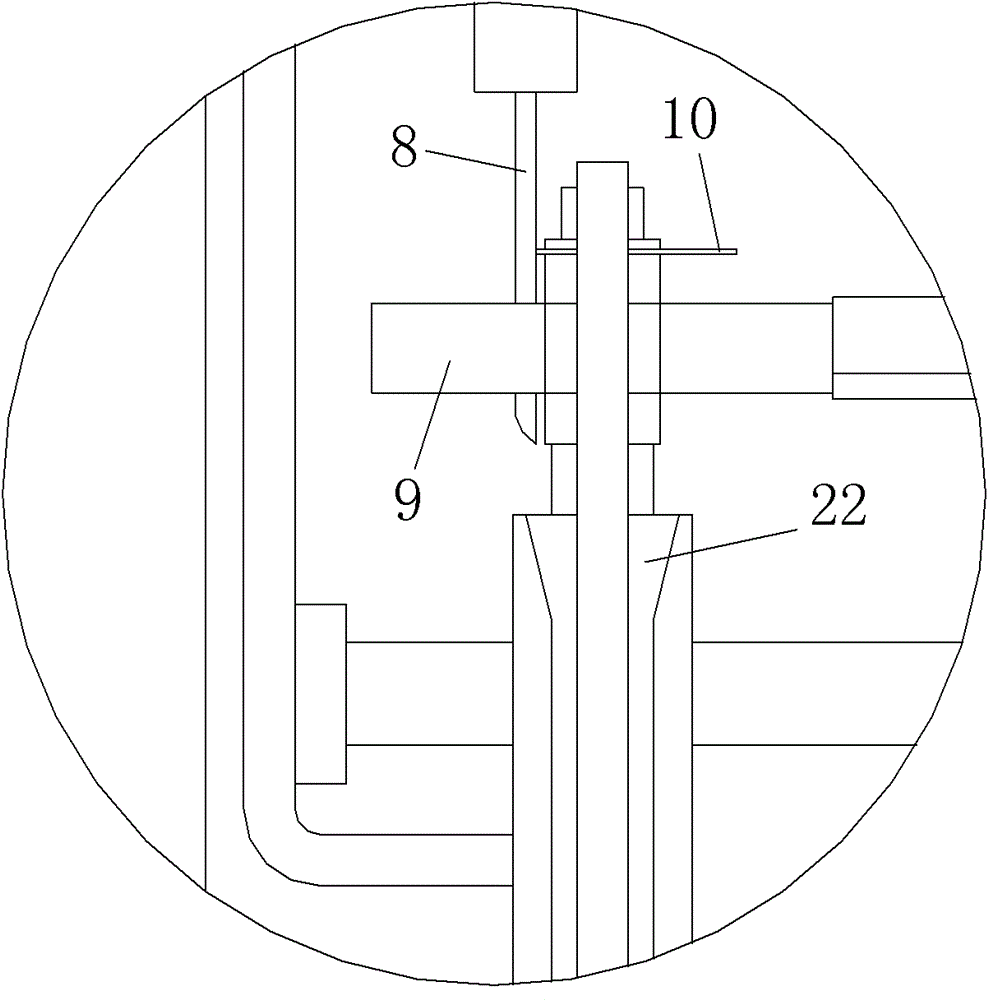

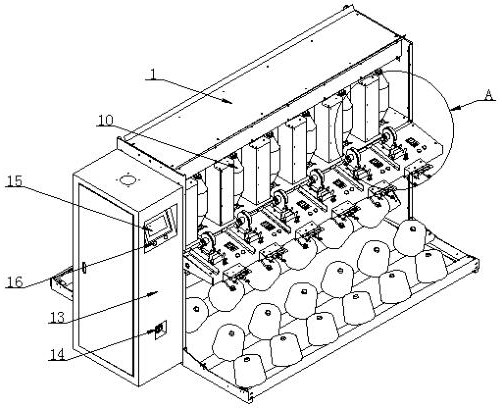

Automatic T-shaped framework small motor rotor winding device and alpha winding-end winding method

InactiveCN102170203AImprove balanceReduce labor intensityManufacturing dynamo-electric machinesMotor drivePull force

The invention relates to an automatic T-shaped framework small motor rotor winding device. A winding feeding mechanism and a winding driving mechanism are arranged on a working bed plate; the winding feeding mechanism has a secondary feeding structure and comprises a feeding motor and a flying fork head driven by the secondary feeding structure, and the feeding motor drives the flying fork head towards the right to realize primary feeding by a first compression spring and continuously drives the flying fork head towards the right to realize secondary feeding by a second compression spring; a winding end air cylinder is arranged on an outer frame of the working bed plate, a piston of the winding end air cylinder is connected to a tooling fixing plate, a winding end guide pin is arranged onthe tooling fixing plate, and the winding end guide pin is adaptive to a metal reversing sheet of a small motor rotor. In the invention, the winding end guide pin is utilized to wrap the front end ofthe metal reversing sheet and is combined with the secondary feeding of the flying fork head to realize the full-automatic winding of a T-shaped framework of the small motor rotor, and artificial winding is not needed, so that the labor intensity of workers is reduced, the production efficiency is greatly improved, and the pulling force of a tensioner in the winding process is uniform and stable,therefore, the winding quality is stable and unified.

Owner:ZHEJIANG SCI-TECH UNIV

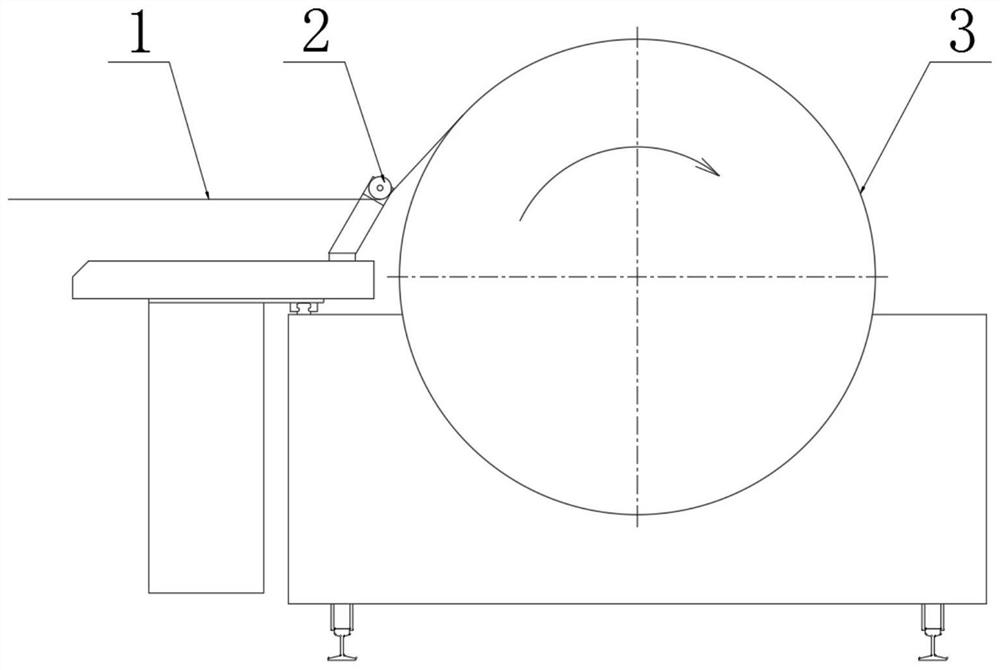

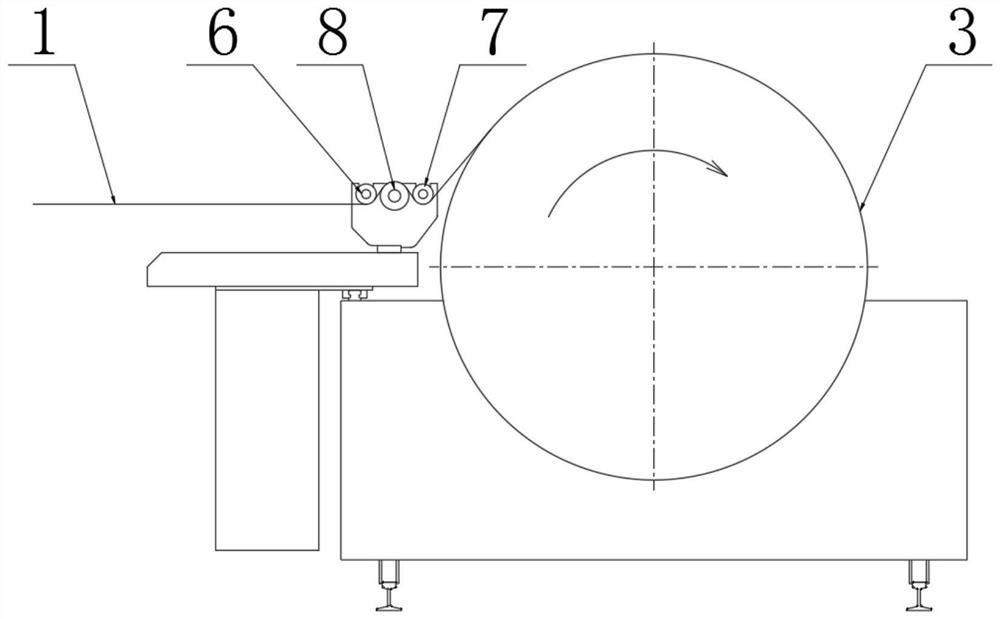

Automatic winding and roll changing system for wet-process lithium battery diaphragm

PendingCN114212584AImprove flatnessRealize automatic roll changeCell component detailsWebs handlingDrive wheelEngineering

The invention discloses a wet-process lithium battery diaphragm automatic winding and roll changing system which comprises a guide roller and a tension roller which are vertically arranged at an interval, a tension bearing is installed at the end of the tension roller, a pair of shearing rollers which are vertically arranged at an interval are arranged behind the guide roller and the tension roller in the advancing direction of a diaphragm, and the upper side and the lower side of the diaphragm are attached to the two shearing rollers respectively. A moving roller is arranged behind the shearing roller, a winding and reel changing mechanism is arranged behind the moving roller and comprises a driving wheel and a driven wheel driven by the driving wheel to rotate, two winding rollers with the same height position are arranged on the two sides of the axis of the driven wheel respectively, and a film scratching mechanism is arranged below the winding roller close to the driven wheel. The membrane scratching mechanism comprises a support and a driving mechanism for driving the support to move up and down, an electrostatic generator, a rotating brush, a cutter and a pressing roller are installed on the support, the driven wheel rotates during roll changing, the positions of the two winding rollers are exchanged, and a membrane sequentially bypasses the positions below the two winding rollers; when the diaphragm is scratched, the driving mechanism drives the support to move upwards, and the cutter cuts off the diaphragm.

Owner:SINOMA LITHIUM BATTERY SEPARATOR CO LTD

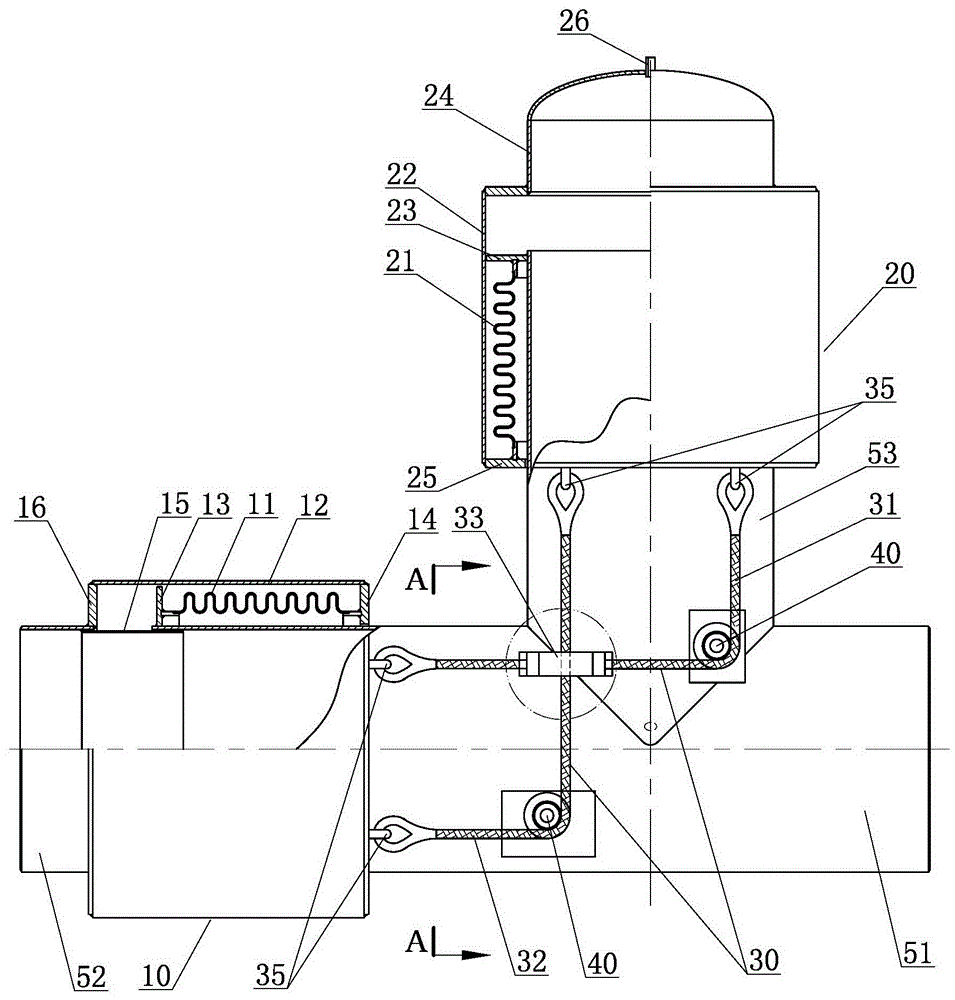

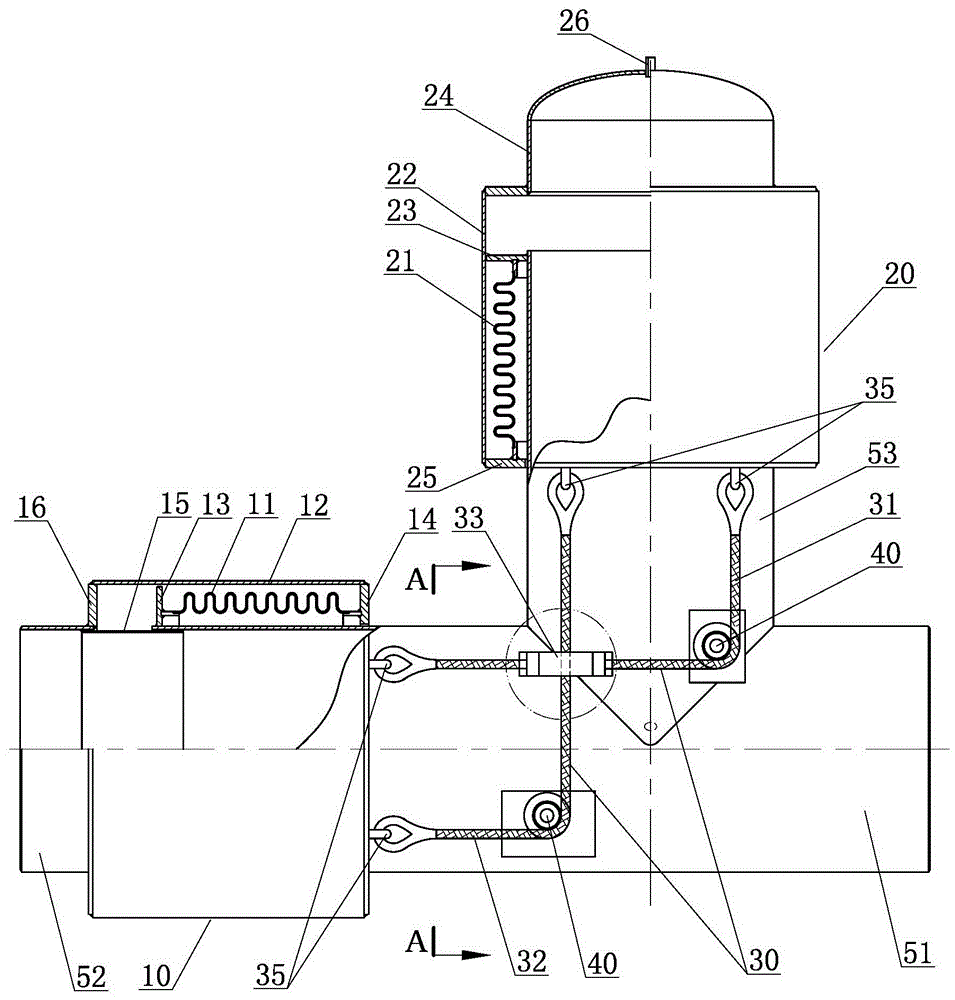

Resistance-free balanced-type ripple compensator

ActiveCN105673981ASame elastic deformationUniform and stable tensionPipeline expansion-compensationInstabilityExternal pressure

The invention relates to a resistance-free balanced-type ripple compensator. The resistance-free balanced-type ripple compensator comprises a work corrugated pipe assembly with the two ends connected with main pipes and a balanced corrugated pipe assembly perpendicularly connected with the main pipes. Connecting pull ropes are arranged between the work corrugated pipe assembly and the balanced corrugated pipe assembly, the two ends of the connecting pull ropes are connected with the work corrugated pipe assembly and the balanced corrugated pipe assembly respectively, and the connecting pull ropes are bent through a turning fixed pulley. The resistance-free balanced-type ripple compensator has the advantages that tension is transmitted between the work corrugated pipe assembly and the balanced corrugated pipe assembly through the connecting pull ropes, and swinging generated during pulling is eliminated; the multiple pull ropes equal in length are adopted and have same elastic deformation, the pull ropes and the turning fixed pulley are simple in structure and high in reliability, and tension is even and stable. External-pressure type ripper compensator bodies are adopted for the work corrugated pipe assembly and the balanced corrugated pipe assembly, and the instability of a ripple compensator during large expansion is avoided. The resistance-free balanced-type ripple compensator can be suitable for a pipe with large expansion.

Owner:北京航天凌云波纹管江苏有限公司

A kind of high temperature resistant insulation seamless wrapping aviation cable and its preparation method

ActiveCN103390449BLong-term useUniform and stable tensionInsulated cablesInsulated conductorsAviationElectrical conductor

The invention discloses a heat-resistant seamless lapped aviation cable and a preparation method thereof. The heat-resistant seamless lapped aviation cable comprises a conductive core wire formed by twisting a plurality of insulating core wires, and a sheathing layer wrapping the conductive core wire; each insulating core wire comprises a conductor core and an insulating layer wrapping the conductor core; each insulating layer sequentially comprises a polytetrafluoroethylene modified turning belt, a polyimide film and a polytetrafluoroethylene sealing tape in sequence from the inside out. According to the invention, a seamless lapping and sintering technology is utilized and three-layer combination insulation is adopted, so that the heat-resistant seamless lapped aviation cable can be obtained, and favorable electrical performance and mechanical strength of the cable can be ensured. The heat-resistant seamless lapped aviation cable provided by the invention can resist the temperature ranging from minus 65 DEG C to 280 DEG C and can satisfy the requirement of being used under the high-temperature environment of 280 DEG C for a long time.

Owner:GUANGZHOU KAIHENG SPECIAL WIRE & CABLE

Bandage quick dressing change auxiliary device for medical care

The invention discloses a bandage quick dressing change auxiliary device for medical care, relates to the technical field of medical care, and solves the problems that the operation of manually and circularly winding and binding a bandage in the prior art is troublesome and low in efficiency, and the tightening force is not uniform when the bandage is wound, the bandage quick dressing change auxiliary device comprises a winding ring; and the winding ring is inserted into the movable shell. A winding ring of the device can automatically wind a bandage outside a bandage damping assembly around an affected part of a patient under the cooperation effect of a driving motor and a moving assembly, operation is convenient, bandage winding does not need manual operation, the moving assembly can automatically move while the bandage is wound through the winding ring, wound dressing change nursing can be carried out on wounds with different lengths, the adaptability is high, the tightening force of the bandage can be adjusted through the bandage damping assembly, and therefore the winding force of the bandage is uniform and stable.

Owner:朱鹏豫

Anchor cable uniform tensioning device

ActiveCN103422676BSimple structureEasy to operateBuilding material handlingBulkheads/pilesEngineeringPosition control

A device for evenly tensioning an anchor cable comprises two oil cylinder position control plates and a plurality of small tensioning oil cylinders. The two oil cylinder position control plates are arranged at the two ends of the tensioning oil cylinders respectively, at least two position control drawing zones are arranged on the peripheries of the oil cylinder position control plates at equal intervals, each position control drawing zone corresponds to one tensioning oil cylinder and is provided with a steel strand hole and two position control plate screw holes, wherein the two position control plate screw holes are located around the steel strand hole. The tensioning oil cylinders comprise oil cylinder bodies which are cylindrical. Oil cylinder base plates are arranged at the rear ends of the oil cylinder bodies, oil cylinder end plates are arranged at the front ends of the oil cylinder bodies, and the oil cylinder inner walls of the oil cylinder bodies form steel strand cavities through which steel strands pass. The device is simple in structure and convenient to load and unload, equal prestress can be applied to all the steel strands of the whole anchor cable, and therefore integrality and durability of the anchor cable are improved.

Owner:XIAN RES INST OF CHINA COAL TECH& ENG GROUP CORP

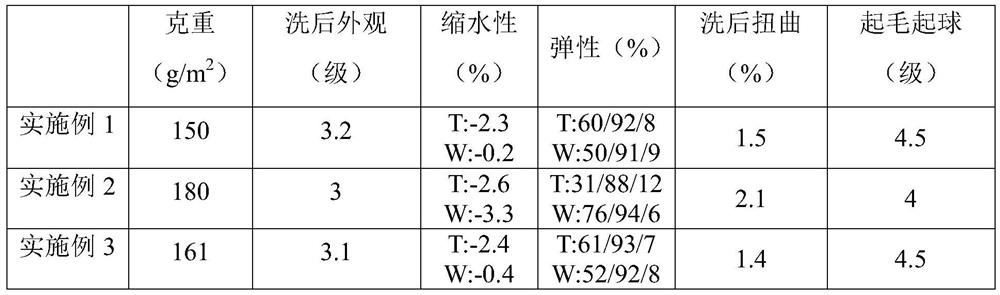

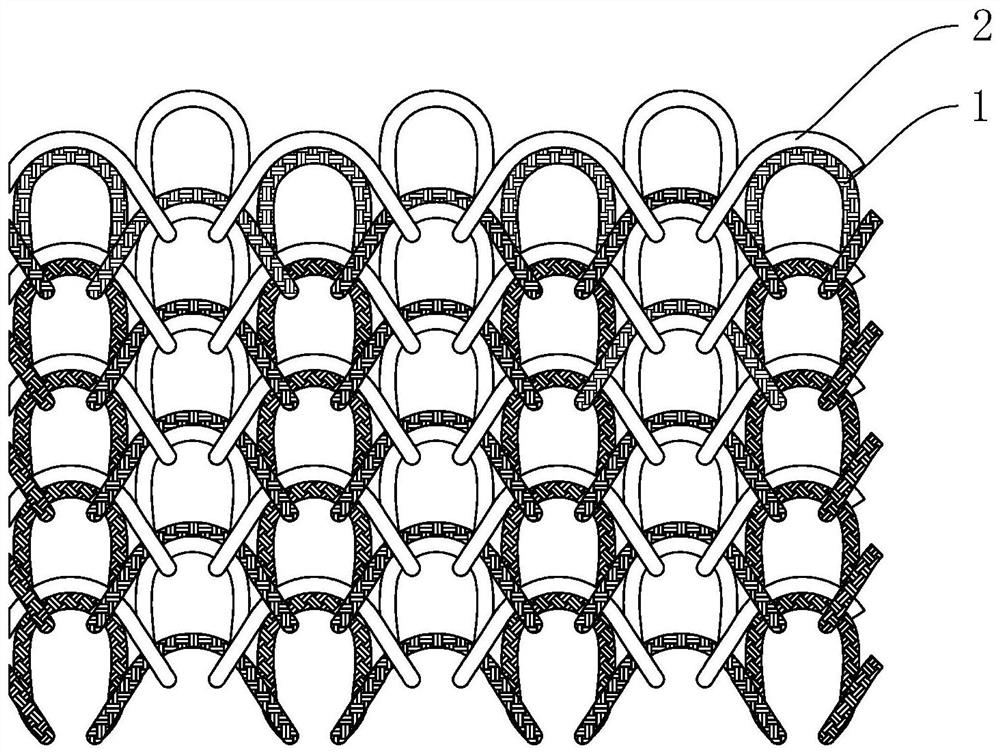

Weft knitting shirt fabric and production process thereof

The invention relates to the technical field of textiles, and concretely relates to a weft knitting shirt fabric and a production process thereof. The knitted shirt fabric is made of low-temperature spandex, cotton yarn and polyester, and is produced by weaving with the low-temperature spandex and the cotton yarn as one path and the polyester as one path according to mini-jacquard weave, and then carrying out an after-finishing process. According to the mini-jacquard weave, a low-temperature spandex and cotton yarn coil and a polyester coil are arranged at intervals in the longitudinal direction, and the weave distribution is that the minimum circulation unit in the longitudinal direction is composed of 12 transverse rows, and the minimum circulation unit in the transverse direction is composed of 6 coil wale rows. According to the invention, an innovative weft knitting weave structure is matched with low-temperature spandex weaving, the cotton yarns and the low-temperature spandex are woven according to the same rule, the cotton yarns and the low-temperature spandex are arranged at intervals with the polyester, the weave structure is compact, the finished fabric has excellent dimensional stability and elastic recovery, the characteristics of moisture absorption, air permeability and soft hand feeling of the fabric are retained, the stiff and smooth performance is good, and the shape preserving performance is good.

Owner:LUTAI TEXTILE

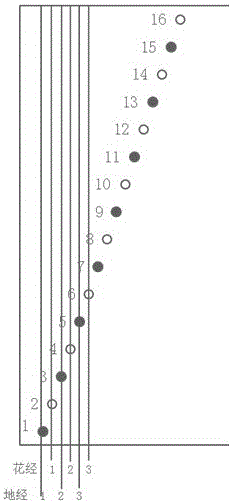

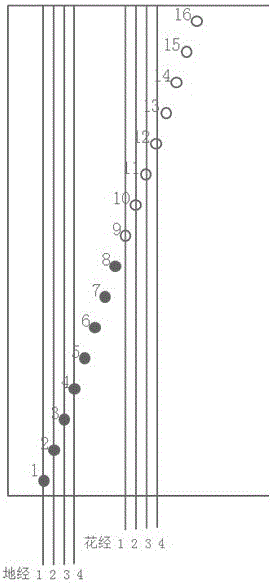

Partition comber board for jacquard weaving and mounting method

Owner:ZIBO YINSHILAI TEXTILE

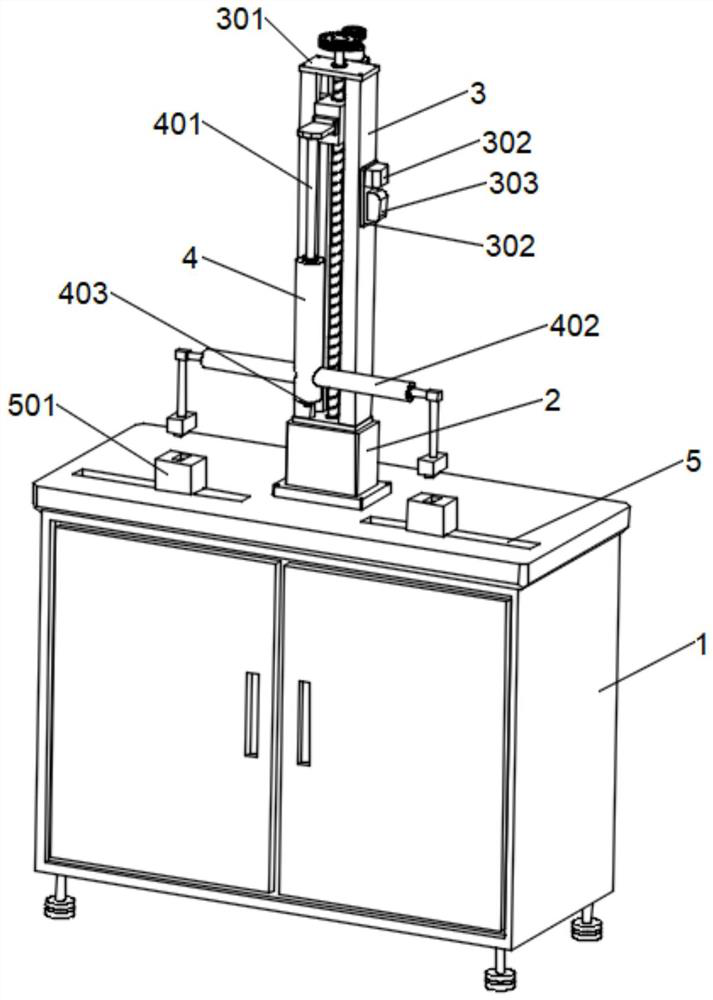

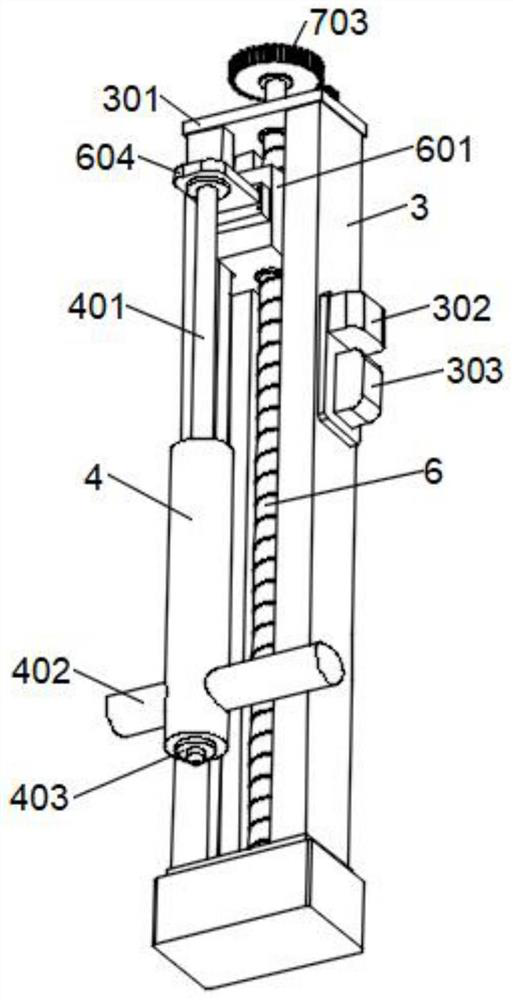

Gauze tensile detection device suitable for spinning processing

PendingCN114323990AEasy to stretch testImprove the efficiency of tensile testingMaterial strength using tensile/compressive forcesElectric machineryEngineering

The invention relates to the technical field of gauze tensile detection devices, in particular to a gauze tensile detection device suitable for spinning processing, which comprises a detection table, a fixed seat and a support stand, the fixed seat is fixed at the middle position of the upper surface of the detection table, and sideslip assemblies are symmetrically arranged on two sides of the upper surface of the detection table. And two groups of support stands are symmetrically fixed on two sides of the upper surface of the fixed seat. According to the invention, at the moment when the gauze is broken during tension detection, the industrial camera captures the breakage of the gauze and sends a signal to the processor, at the moment, the processor transmits node detection data corresponding to the pressure sensor to a detection center through the communication module so as to record and analyze the data, and meanwhile, the processor sends a signal to the controller so as to detect the breakage of the gauze. When the gauze is detected, the controller controls the driving motor to stop working, so that the tensile detection of the gauze is conveniently completed, the tedious process of manual detection is avoided to a certain extent, the labor intensity of a detector is reduced, and meanwhile, the tensile detection efficiency of the gauze is also improved.

Owner:ANHUI HANLIAN TEXTILE CO LTD

orthopedic surgery aid

Owner:CHANGZHOU NO 2 PEOPLES HOSPITAL

High-reliability tensioning wheel with asymmetric damping structure

The invention provides a high-reliability tensioning wheel with an asymmetric damping structure. The high-reliability tensioning wheel with an asymmetric damping structure aims to solve the technicalproblem that a belt in the prior art is low in tension and uneven in tension. The high-reliability tensioning wheel with the asymmetric damping structure comprises a supporting sleeve, a first supporting plate, a second supporting plate, a center shaft sleeve, a double-row deep groove ball bearing, a spring, a cover plate, a first belt pulley and a second belt pulley. According to the high-reliability tensioning wheel with the asymmetric damping structure, one end of the spring is connected with the cover plate and fixed to a fixing part supporting sleeve, the other end of the spring is connected with the supporting plates to guarantee rotation, and therefore the requirement that the tensioning wheel provides torque is met, and the double-row deep groove ball bearing is adopted, so that stable and uniform tension on the belt is ensured.

Owner:CHENGDU JIALING HUAXI OPTICAL & PRECISION MACHINERY

a fabric production equipment

Owner:杭州中纺织造有限公司

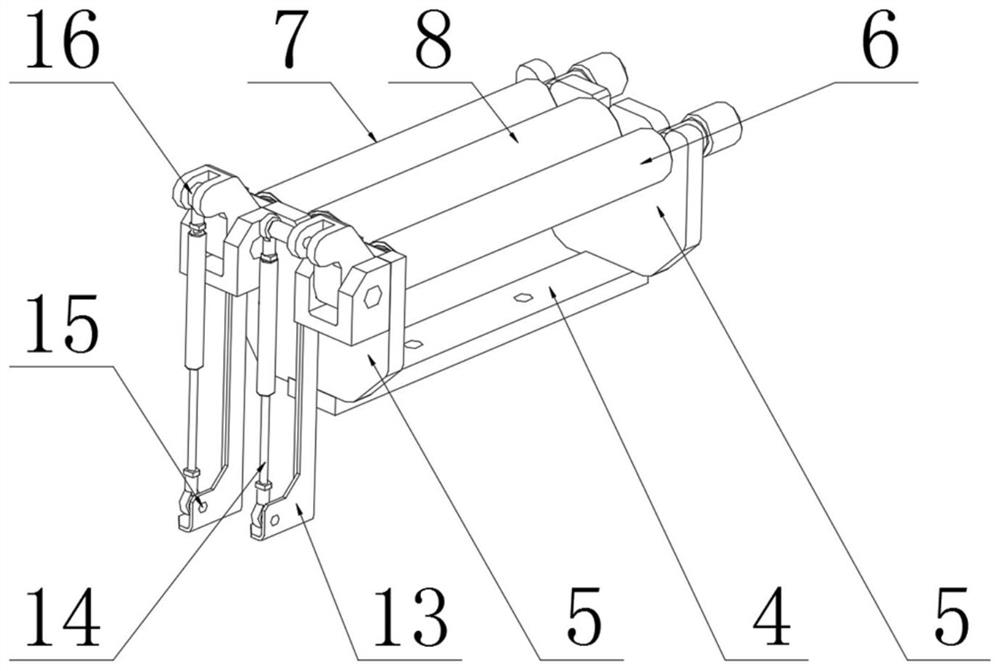

Three-roller type yarn guide roller device of warping table

PendingCN114737291AUniform and stable tensionReduce spreadWarping machinesOther manufacturing equipments/toolsYarn tensionStructural engineering

The three-roller type yarn guide roller device comprises a yarn guide roller bottom plate (4), a left side plate (5) and a right side plate (5) are arranged on the yarn guide roller bottom plate (4), a front yarn guide roller assembly (6) and a rear yarn guide roller assembly (7) are arranged between the left side plate (5) and the right side plate (5), and a middle yarn guide roller assembly (8) is arranged between the front yarn guide roller assembly (6) and the rear yarn guide roller assembly (7). According to the three-roller type yarn guide roller device of the warping table, the three yarn guide rollers are arranged on the same horizontal plane in a front-middle-rear mode, yarn is wound to the upper portion of the middle yarn guide roller from the bottom of the front yarn guide roller and then wound to the large roller through the bottom of the rear yarn guide roller to be warped, the yarn is warped under the holding of the three yarn guide rollers in the S-shaped winding mode, and therefore the yarn quality is improved. Yarn tension is more uniform and stable, yarn diffusion can be effectively reduced, and strip splicing is more accurate and neat.

Owner:江阴市华方新技术科研有限公司

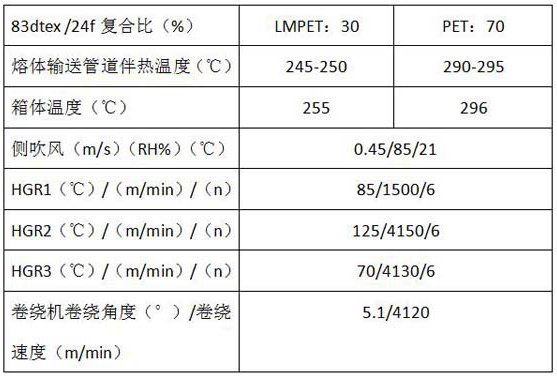

Preparation process of LMPET/PET sheath-core type composite elastic fiber

InactiveCN112251828AGood orientationHigh strengthSpinning head liquid feederMelt spinning methodsFiberSpinning

The invention relates to a preparation process of a LMPET / PET sheath-core type composite elastic fiber. The preparation process comprises: 1, conveying an LMPET melt and a PET melt to a composite spinning box through a melt conveying pipeline and a metering pump correspondingly, and mounting a filter and a booster pump on the melt conveying pipeline; and 2, extruding the melt through a sheath-corespinneret plate, cooling the extruded melt by side blowing, and carrying out bundling and oiling, pre-interlacing, drafting, interlacing and winding. The process is simple in technology, stable in product quality and low in production cost.

Owner:JIANGSU HUAYA FIBER

Scraper type dung cleaner for use in hog house

InactiveCN102487834BStable structureUniform and stable tensionAnimal housingProduction rateSteering wheel

The invention discloses a scraper type dung cleaner for use in a hog house, which comprises a driving mechanism, a detecting device, a traction rope, a steering wheel, a dung scraping device and a control electric cabinet, wherein the dung scraping device comprises a traction regulating frame, a pull rod device, a dung scrapping plate and a side plate mechanism; the traction regulating frame is fixedly connected with the side plate mechanism and is in sliding connection with the pull rod device; the pull rode device comprises a traction ring, a pull rod, a limiting shaft, a deflector rod, anda pawl device; the traction ring and the pawl device are arranged at the two ends of the pull rod respectively and are connected with the traction rope; the deflector rod, and the limiting shaft are arranged on the pull rod; a sliding connector which connects the pull rod and the traction regulating frame is in contacted connection with the limiting shaft; the upper end of the dung scraping plateis in contacted connection with the deflector rod,; and a scraper rotating shaft arranged on the dung scraping plate is connected with a supporting stub on the side plate mechanism. The scraper type dung cleaner with a reasonable structure can realize mechanical dung cleaning, lower labor intensity and improve production efficiency.

Owner:GUANGDONG NANMU MACHINERY & EQUIP

an air jet loom

Owner:青岛东佳机械制造有限公司 +1

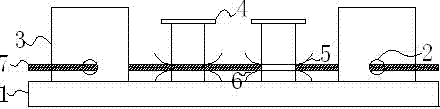

Weaving machine weft yarn tension adjusting device

The invention discloses a weaving machine weft yarn tension adjusting device which comprises a base (1), positioning plates (3) and a plurality of tension maintaining parts (4). Each positioning plate (3) is provided with a positioning hole (2), the tension of a weft yarn (7) can be maintained by the tension maintaining parts (4), the positioning plates are fixedly connected on two sides of the base, and the tension maintaining parts are fixedly connected in the middle of the base. The weaving machine weft yarn tension adjusting device has the advantages that pendulosity of the weft yarn is reduced by the aid of the positioning holes in the positioning plates, the uniform and stable tension of the weft yarn is basically maintained by the aid of the tension maintaining parts in the middle of the base, the end breakage rate of the weft yarn is effectively reduced in the weaving process, production efficiency is greatly increased, and product quality is improved.

Owner:铜陵华洋特种线材有限责任公司

A non-resistance balanced corrugated compensator

ActiveCN105673981BSame elastic deformationUniform and stable tensionPipeline expansion-compensationInstabilityEngineering

The invention relates to a resistance-free balanced-type ripple compensator. The resistance-free balanced-type ripple compensator comprises a work corrugated pipe assembly with the two ends connected with main pipes and a balanced corrugated pipe assembly perpendicularly connected with the main pipes. Connecting pull ropes are arranged between the work corrugated pipe assembly and the balanced corrugated pipe assembly, the two ends of the connecting pull ropes are connected with the work corrugated pipe assembly and the balanced corrugated pipe assembly respectively, and the connecting pull ropes are bent through a turning fixed pulley. The resistance-free balanced-type ripple compensator has the advantages that tension is transmitted between the work corrugated pipe assembly and the balanced corrugated pipe assembly through the connecting pull ropes, and swinging generated during pulling is eliminated; the multiple pull ropes equal in length are adopted and have same elastic deformation, the pull ropes and the turning fixed pulley are simple in structure and high in reliability, and tension is even and stable. External-pressure type ripper compensator bodies are adopted for the work corrugated pipe assembly and the balanced corrugated pipe assembly, and the instability of a ripple compensator during large expansion is avoided. The resistance-free balanced-type ripple compensator can be suitable for a pipe with large expansion.

Owner:北京航天凌云波纹管江苏有限公司

Screen printing making technology

InactiveCN1255277CUniform and stable tensionUniform thicknessScreen printersPlate printingScreen printingLatent image

THRE IS PROVIDED A PLATE FOR SCREEN PRINTING, COMPRISING: A SCREEN STRETCHED OVER A FRAME; AND AN IMAGE LAYER, FORMED OF A PHOTO-CURED RESIN, PROVIDED ON THE SURFACE OF THE SCREEN, THE SCREEN COMPRISING A METALLIC SCREEN HAVING CONCAVES WITH A DEPTH OF 0.05 TO 20µm.THERE IS ALSO PROVIDED A PROCESS FOR PRODUCING A PLATE FOR SCREEN PRINTING, COMPRISING THE STEPS OF:FORMING A PHOTO-SENSITIVE RESIN LAYER ON THE SURFACE OF A METALLIC SCREEN STRETCHED OVER A FRAME; EXPOSING THE PHOTO-SENSITIVE RESION LAYER THROUGH A MASK TO FORM A LATENT IMAGE; AND DEVELOPING THE EXPOSED RESIN LAYER TO FORM AN IMAGE LAYER,THE SURFACE OF THE METALLIC SCREEN HAVING BEEN ROUGHENED BY BLOWING GRAINS HAVING A SIZE OF 100 TO 2,000 MESH AGAINST THE SURFACE OF THE METALLIC SCREEN AND / OR BY BUFFING.

Owner:MURAKAMI CORP

A method for assembling a partitioned board using jacquard weaving

Owner:ZIBO YINSHILAI TEXTILE

Automatic T-shaped framework winding device for small motor rotor and alpha winding-end winding method

InactiveCN102170203BImprove balanceReduce labor intensityManufacturing dynamo-electric machinesPull forceMotor drive

Owner:ZHEJIANG SCI-TECH UNIV

A lift-type high-speed doubling process

The invention discloses a lift-type high-speed doubling process, which is mainly completed by a lift-type high-speed doubling machine. The lift-type high-speed doubling machine includes a doubling machine body and a winding tube. The doubling machine body One side of the doubling machine body is fixedly connected with an electrical box, and the top of the inner cavity of the doubling machine body is fixedly connected with a forming part, and the forming part includes a stepping motor, a first fixing plate and a second fixing plate, and the stepping motor The output end is fixedly connected with the synchronous wheel of the stepper motor, and the first guide rail and the second guide rail are fixedly connected between one side of the first fixed plate and the second fixed plate. Under the cooperation of the first guide rail, the stepping motor drives the slider to move up and down, and the winding motion of the spindle DC motor forms the spiral winding motion of the yarn.

Owner:新昌县恒佳纺织机械厂

A prestressed concrete pole tensioning and anchoring device

ActiveCN104139456BFirmly connectedStable deliveryCeramic shaping apparatusPrestressed concreteMechanical engineering

The present invention discloses a tension and anchor device for prestressed concrete poles, which comprises tension brace, tension rod, tension head and tension and anchor plate and uses steel mould and tension jack. In the direction of circular degree of the said tension brace, four uniform support legs are set and welded with stiffening plate and end plate, and screws are set inside the end plate. At the head of the said tension rod, a tension claw is set, and at the tail connection screws are set to match with the jack piston rod. At the said tension head, prestressed steel holes are drilled, in the head a slope plate is set, and on the other end, connection screws are set to match with the anchor plate. Screws are set in the said tension and anchor plate to match with the tension head. Such tension and anchor device has a simple structure and safe and reliable connection. Steel Mould

Owner:STATE GRID CORP OF CHINA +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com