Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

30results about How to "To achieve the compaction effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

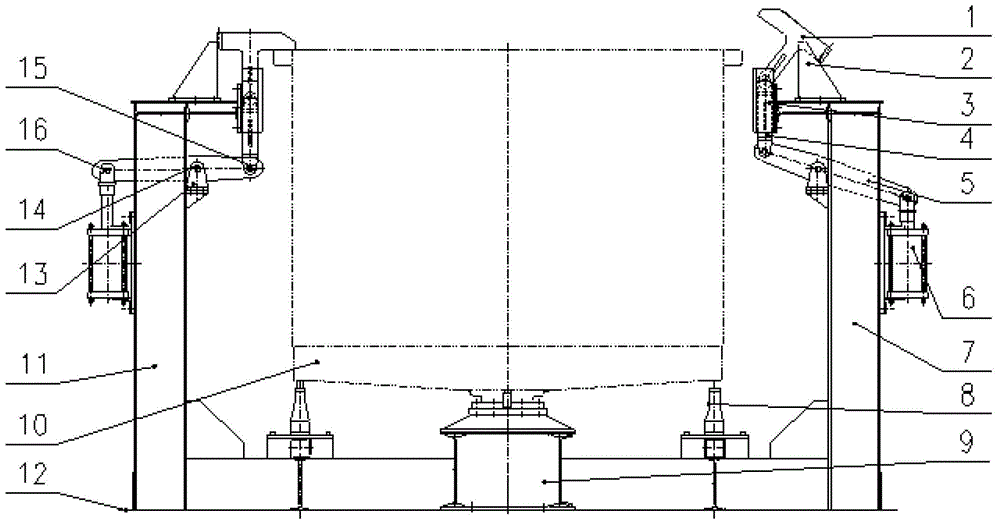

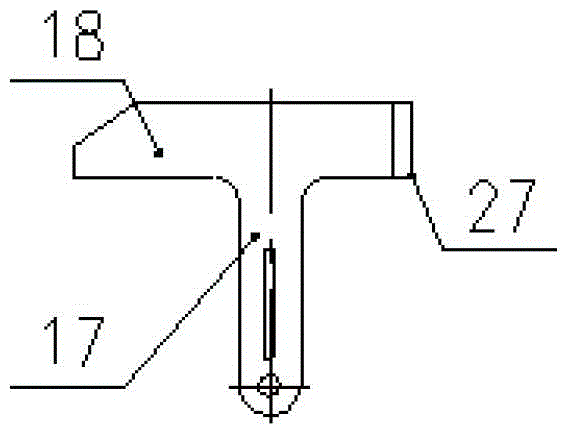

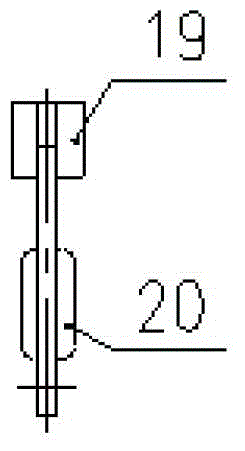

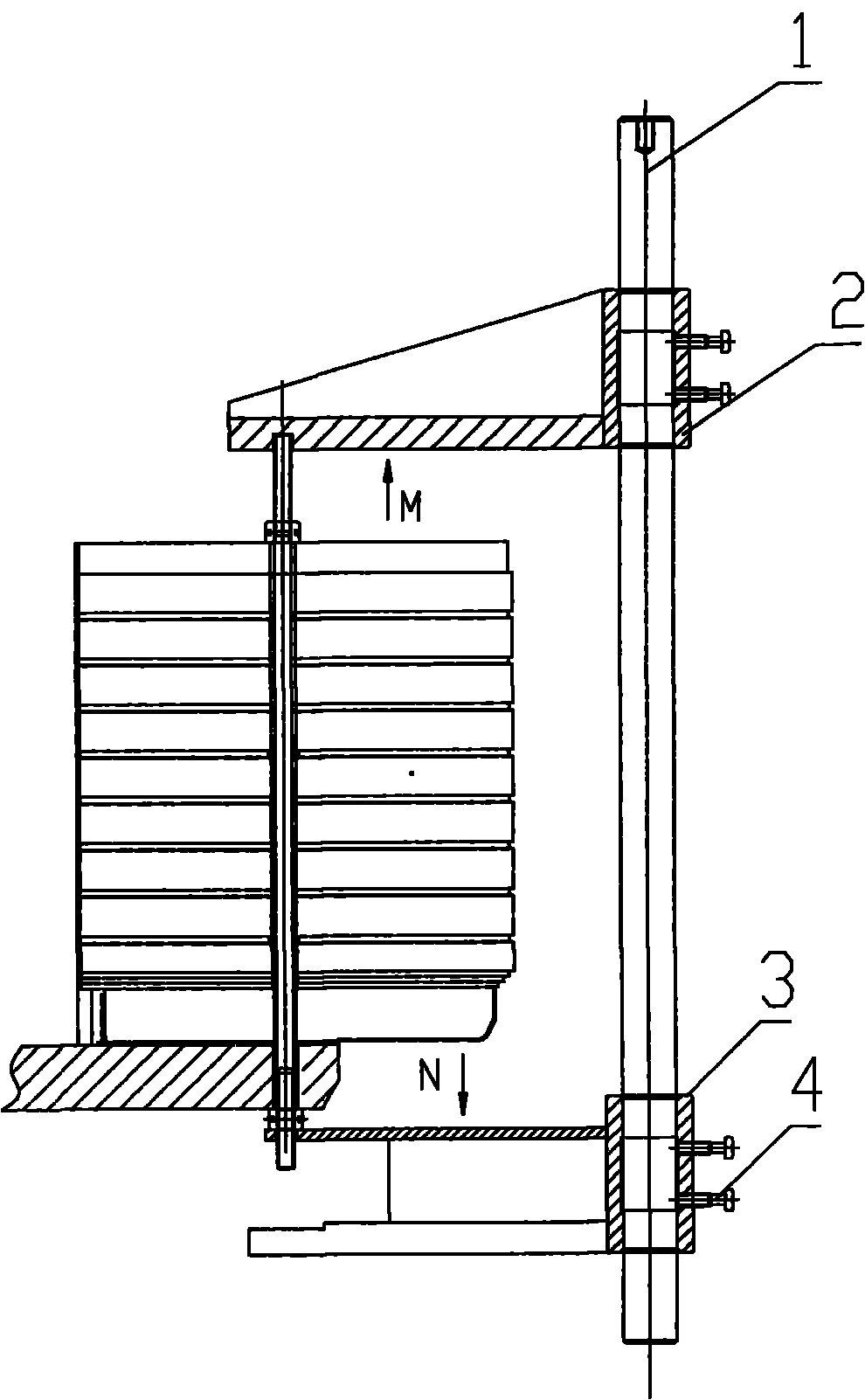

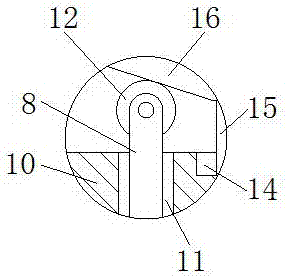

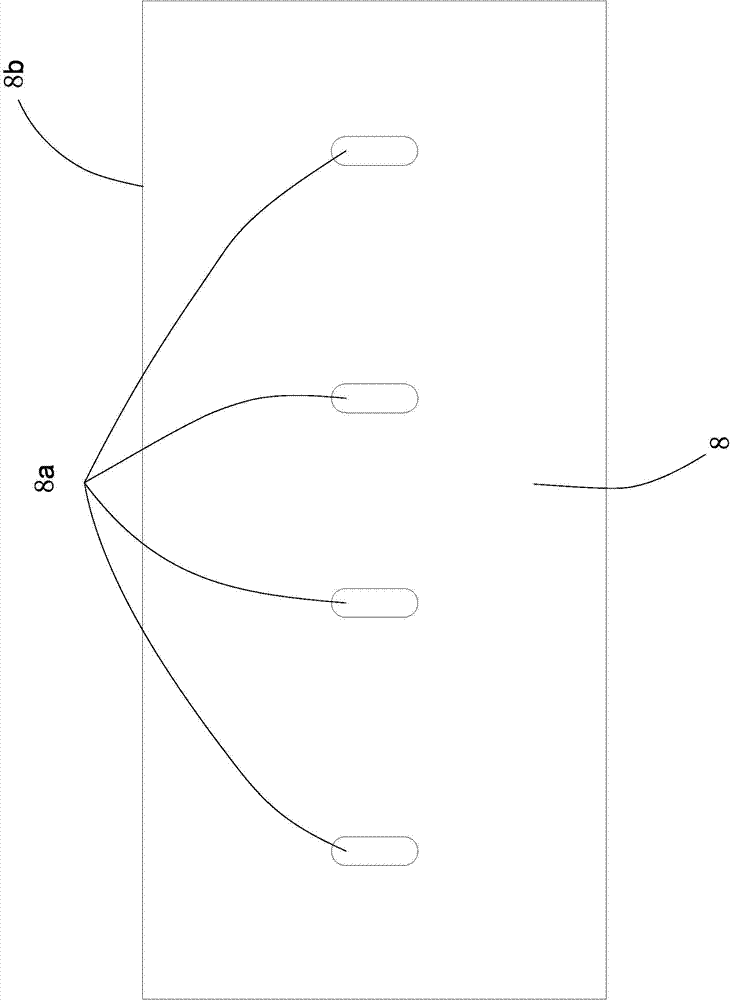

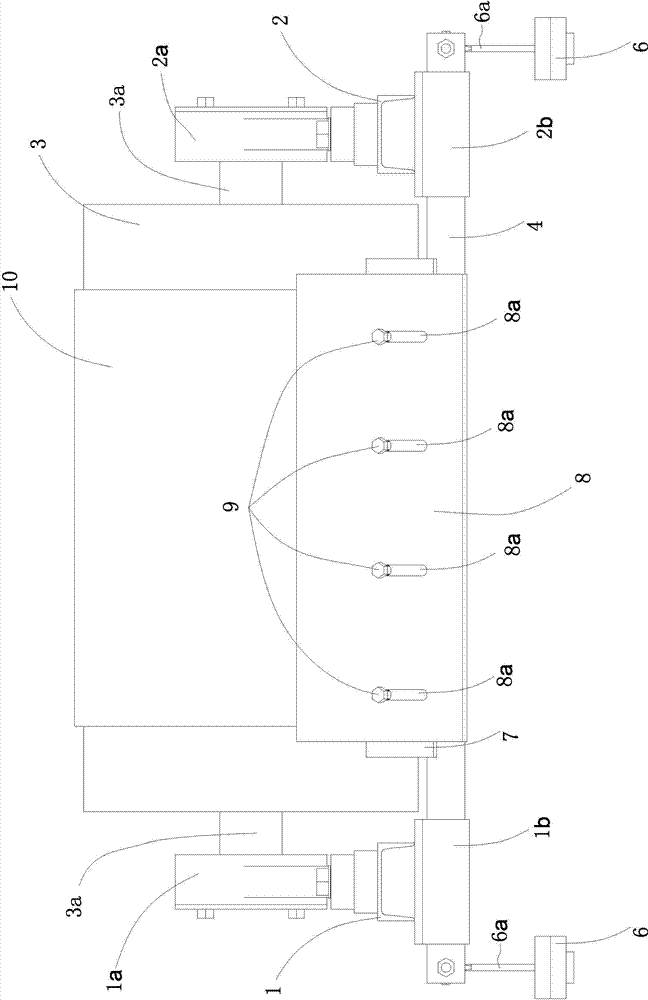

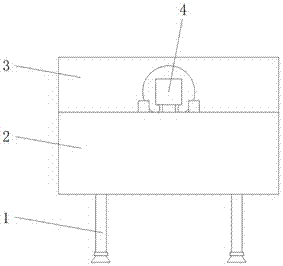

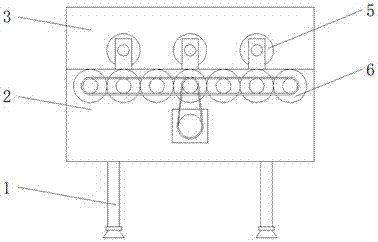

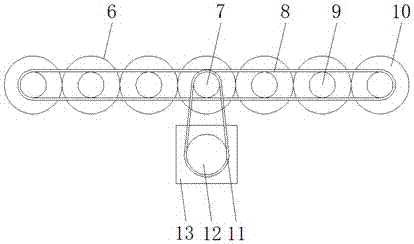

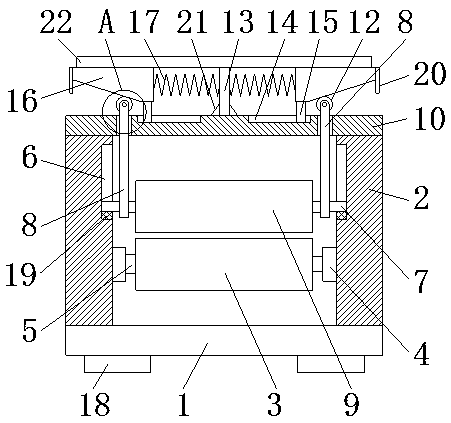

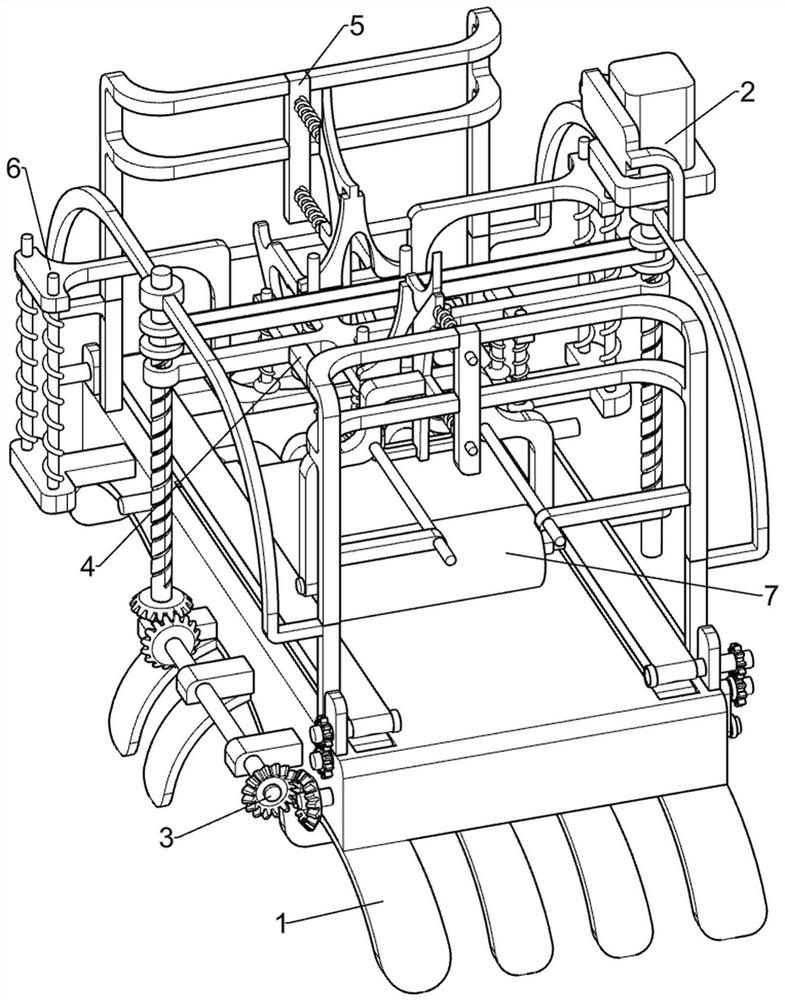

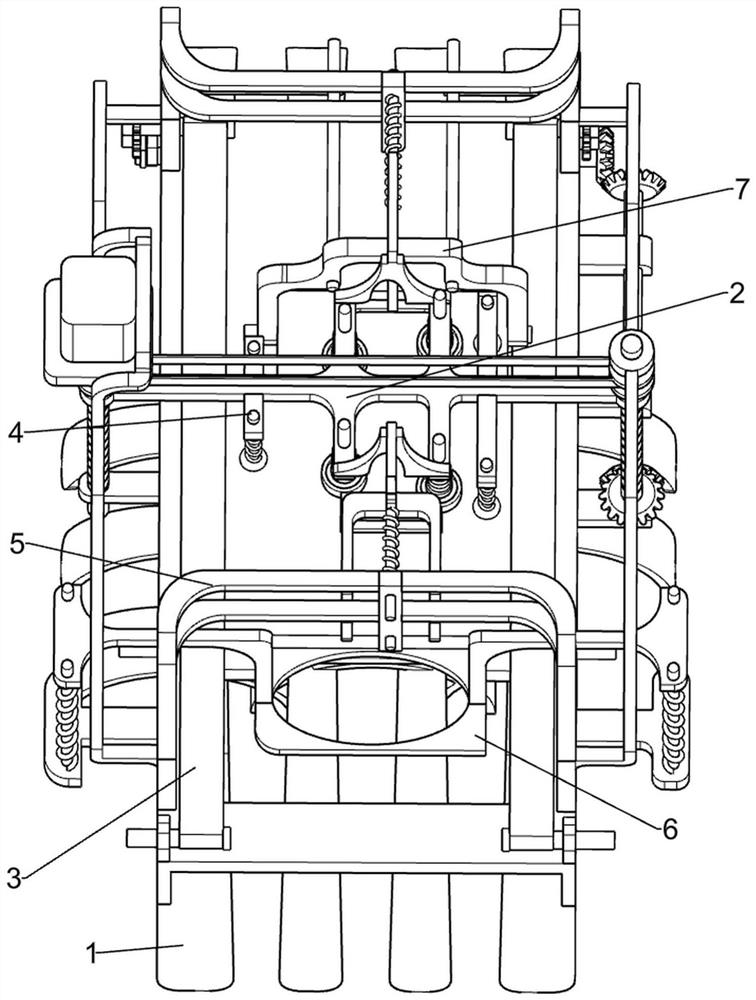

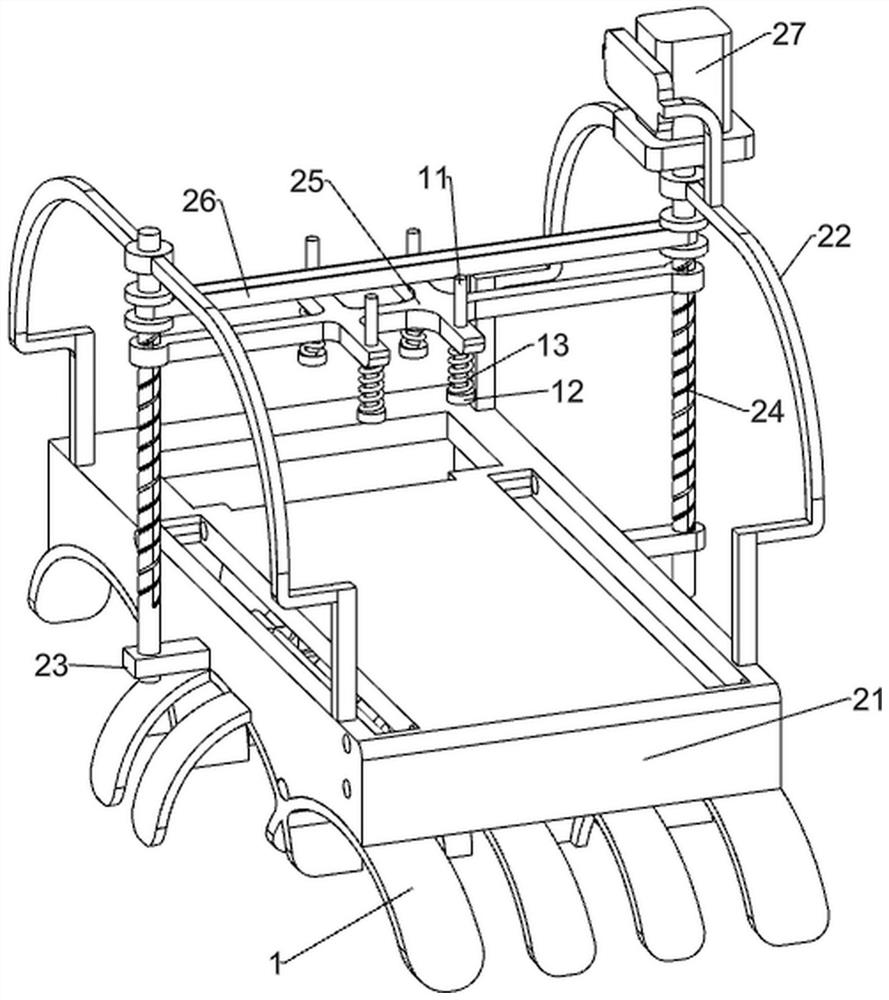

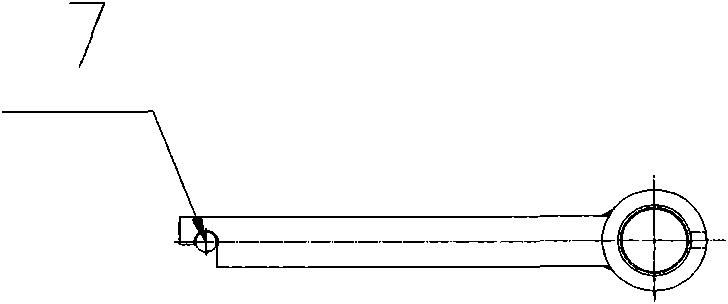

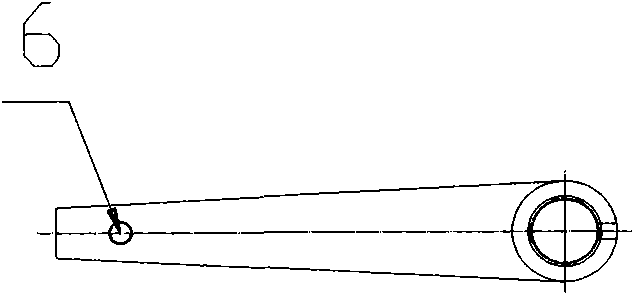

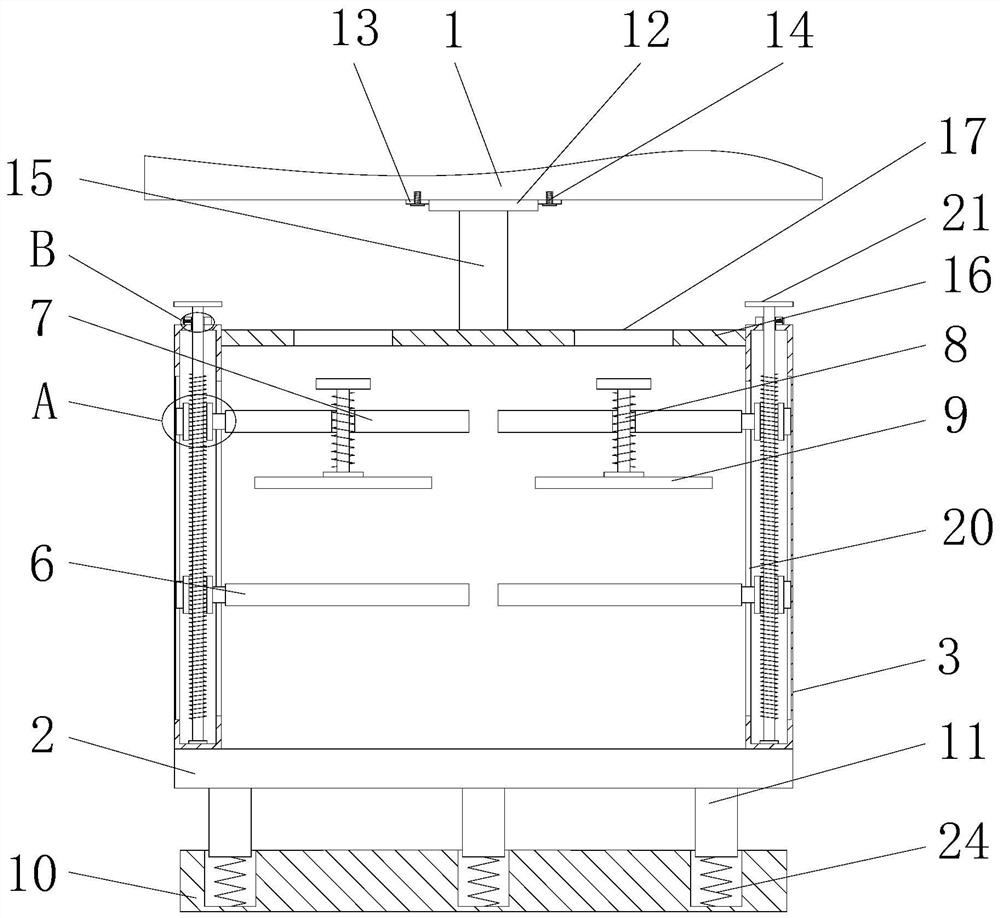

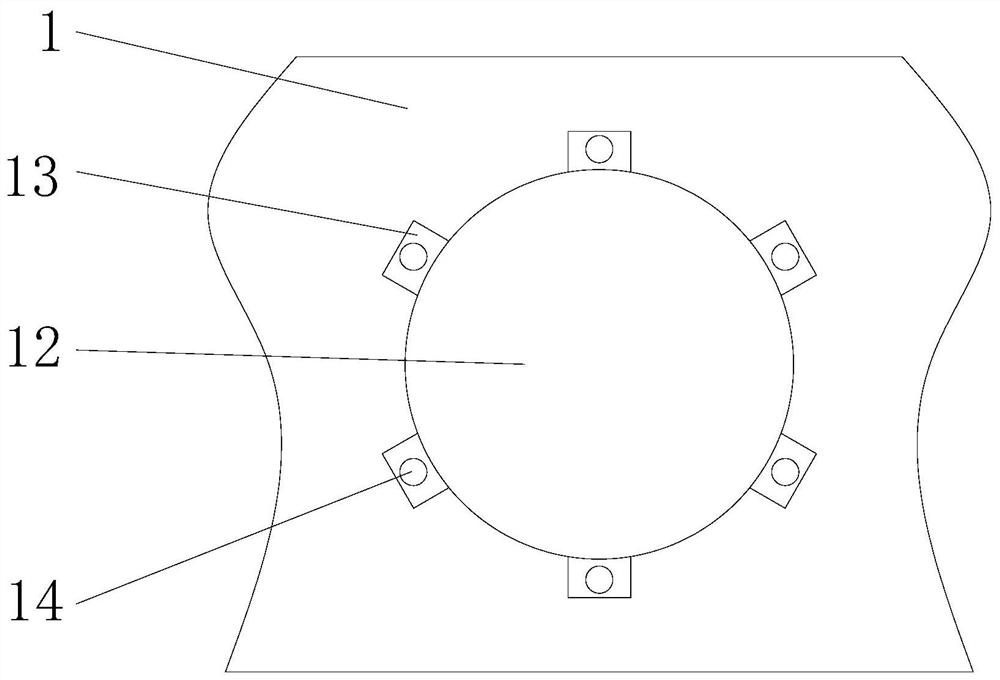

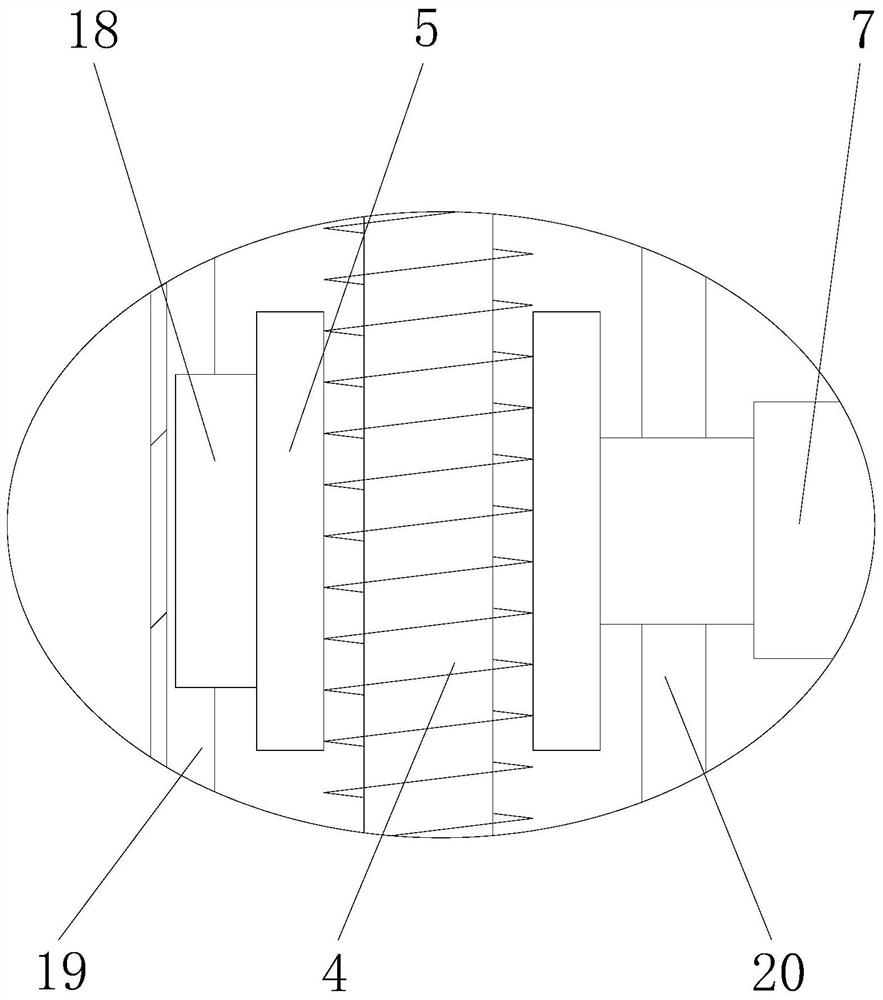

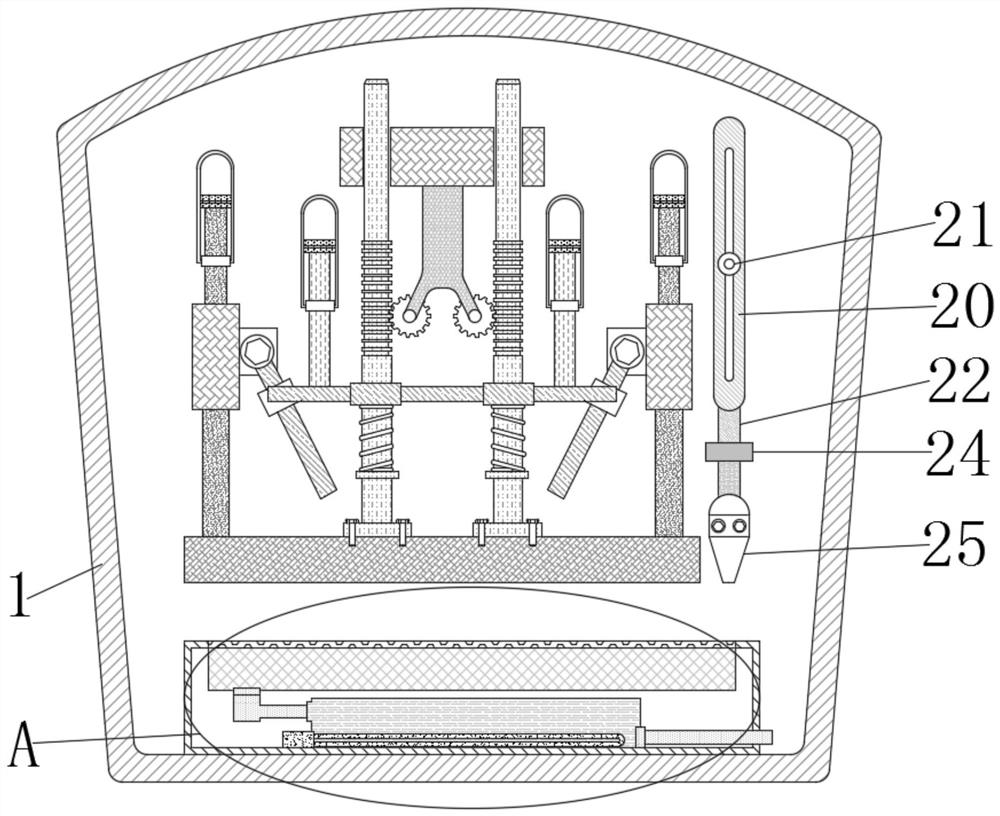

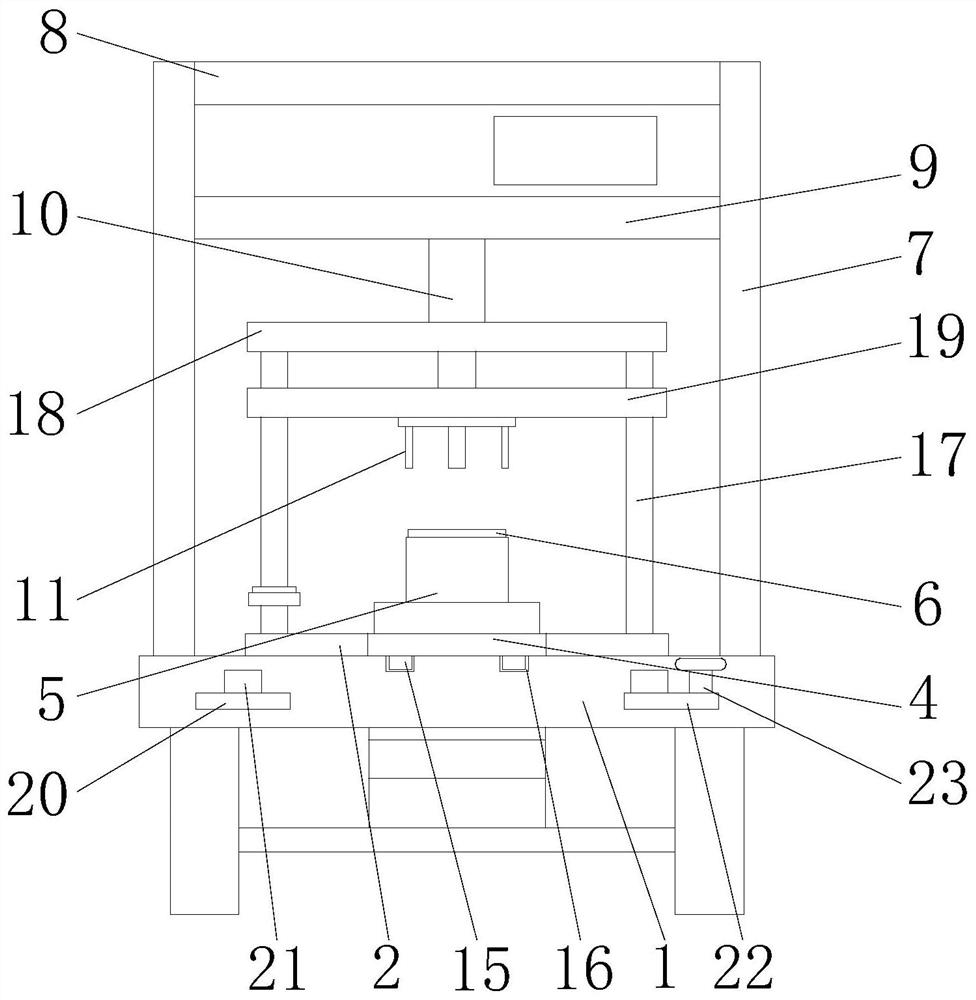

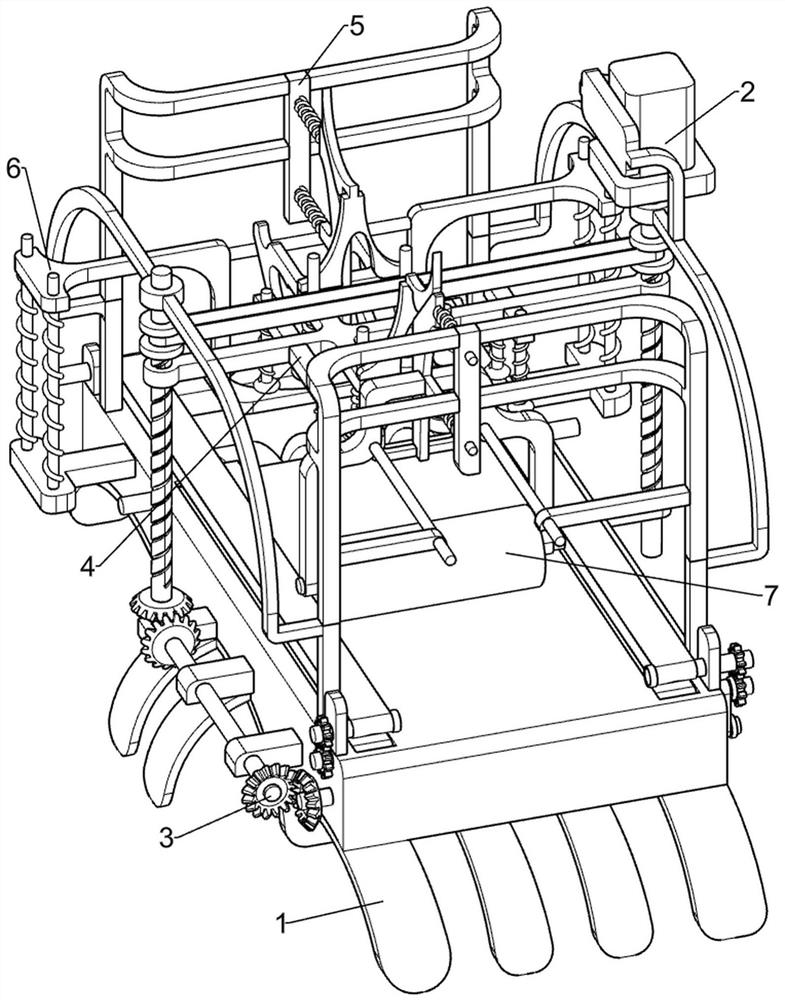

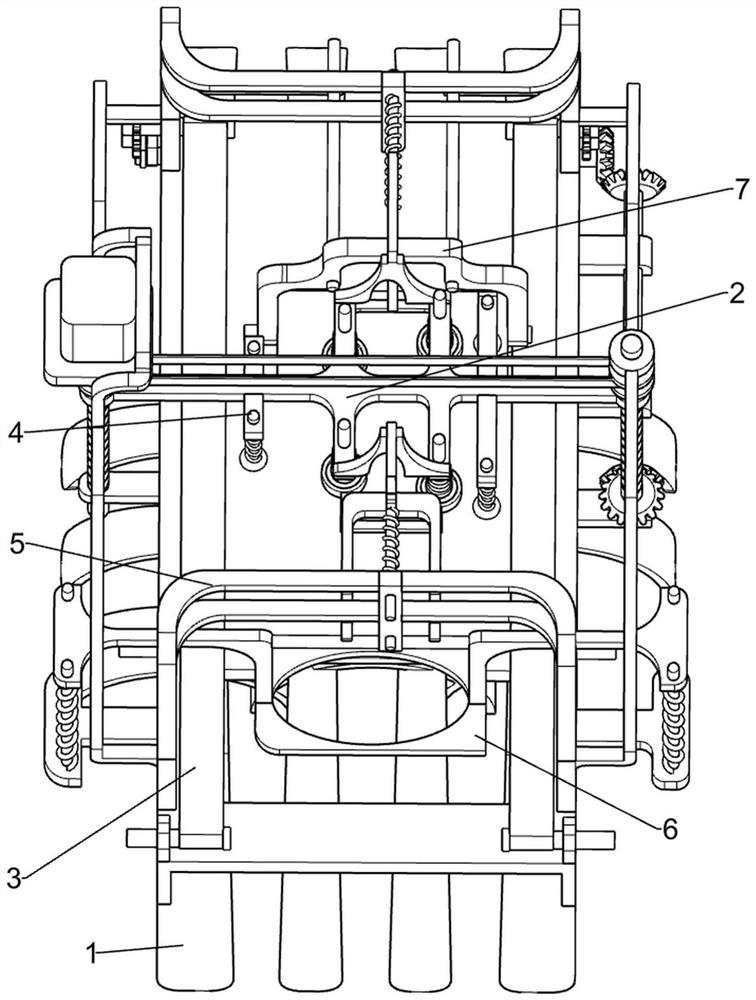

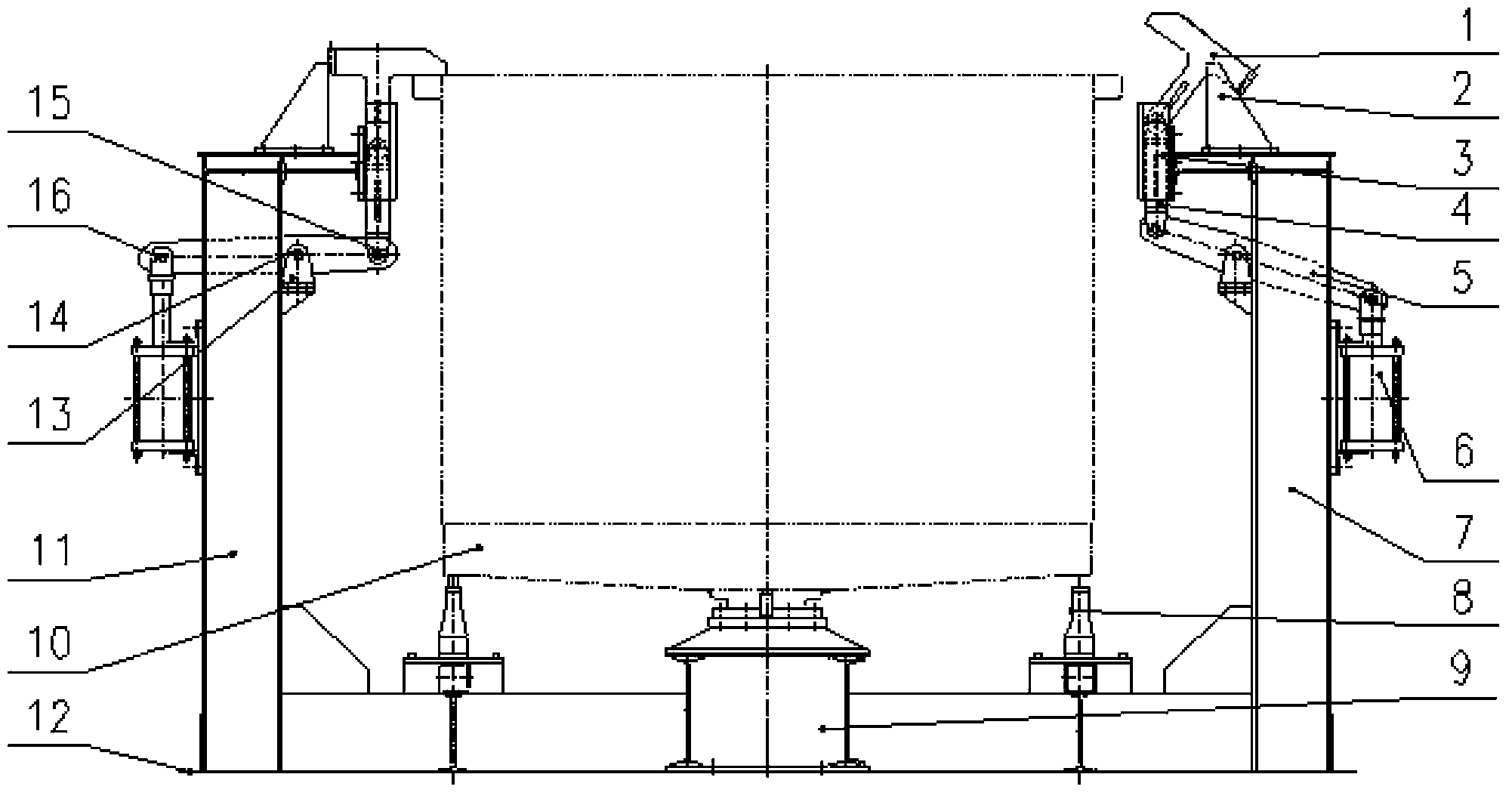

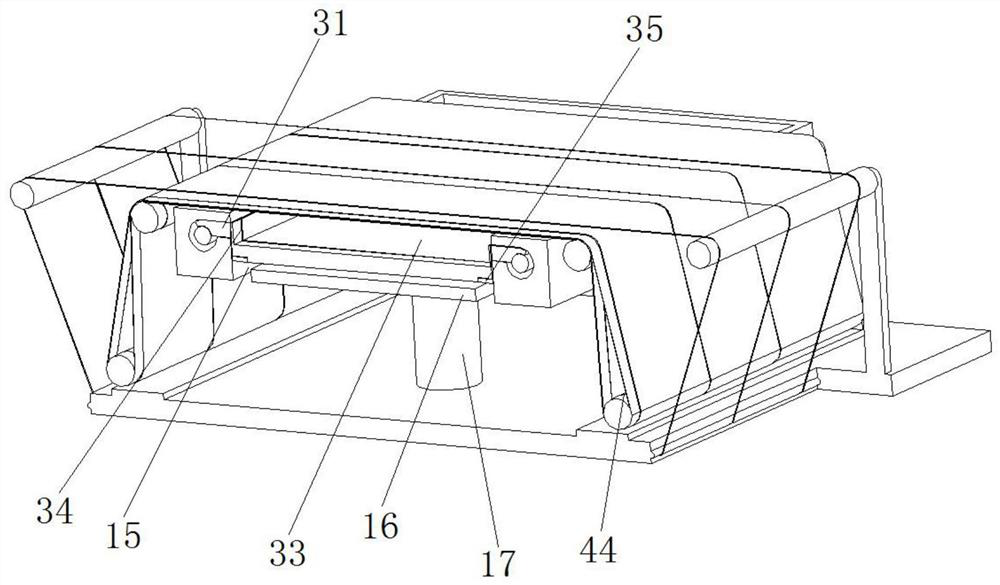

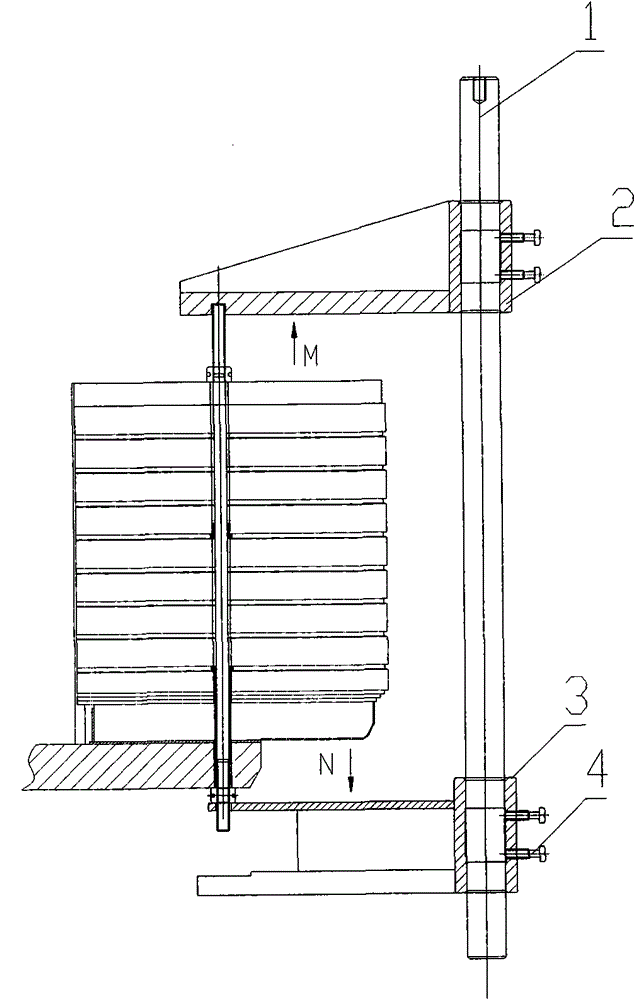

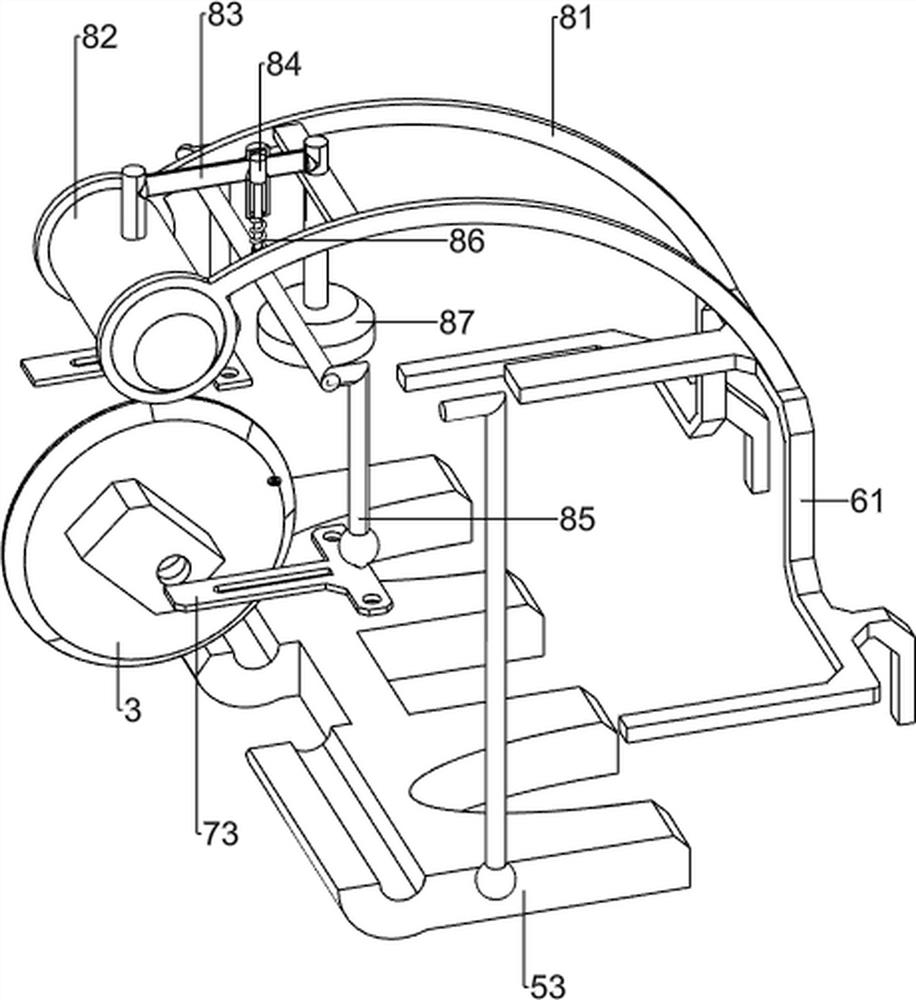

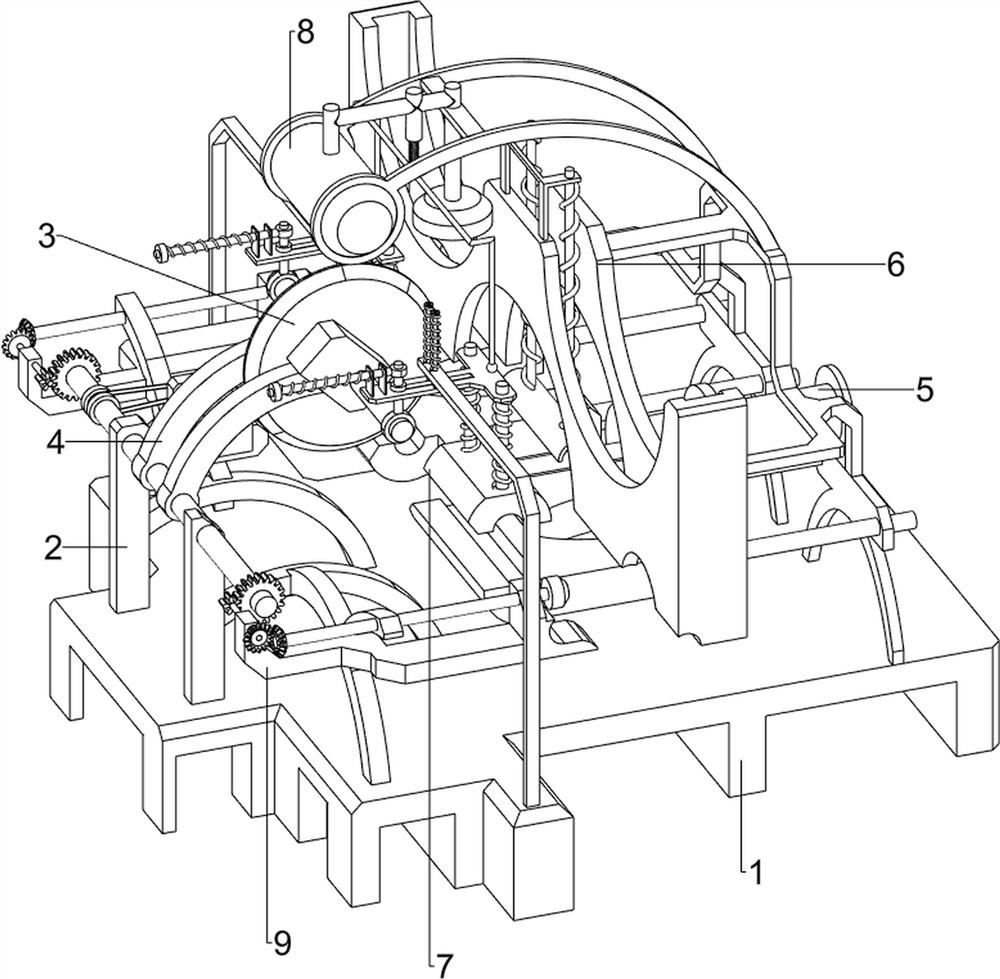

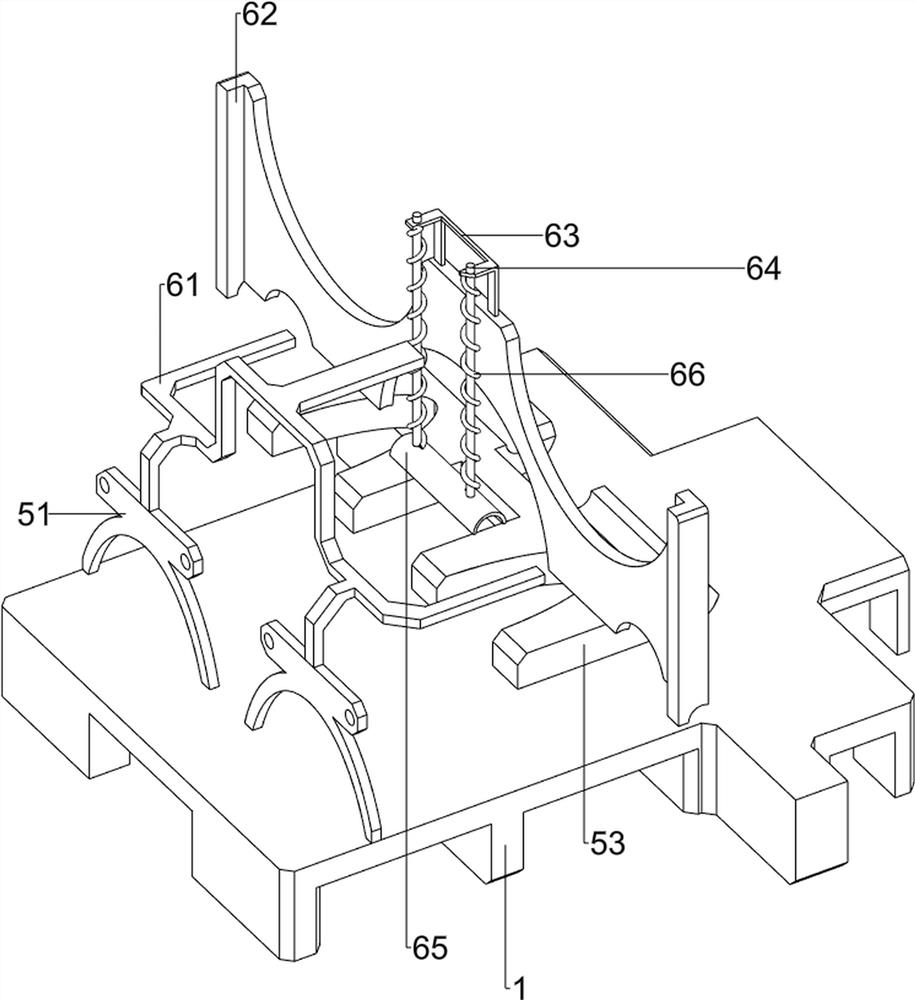

Pressing tool for assembling truck body

ActiveCN102744547AHigh strengthOpen smoothlyWelding/cutting auxillary devicesAuxillary welding devicesTruckPiston rod

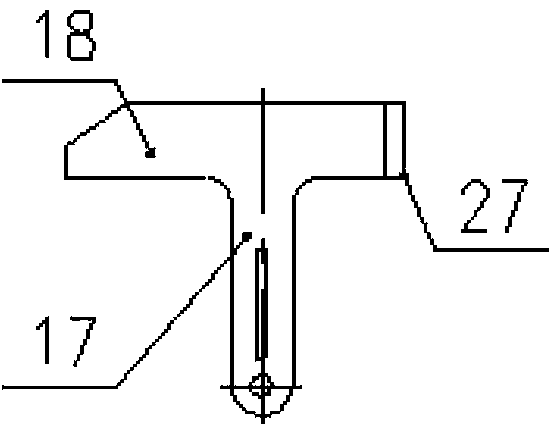

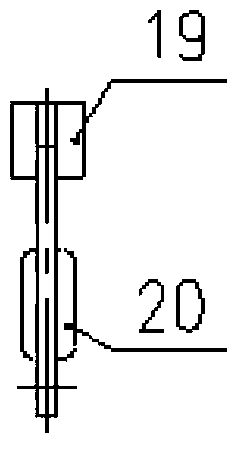

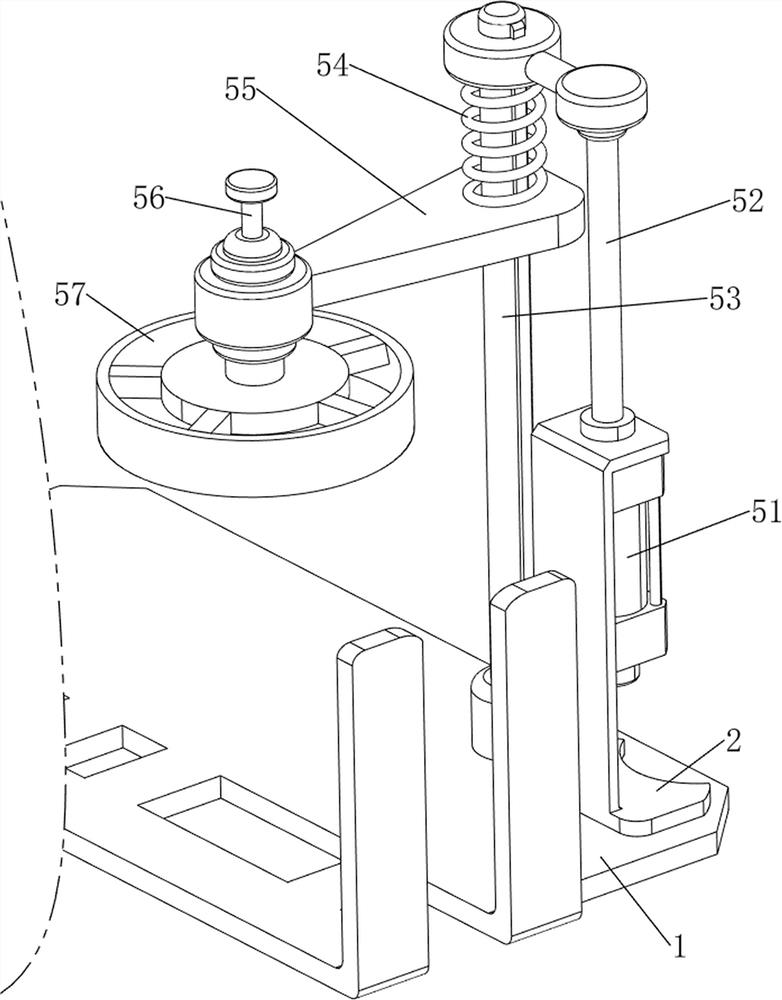

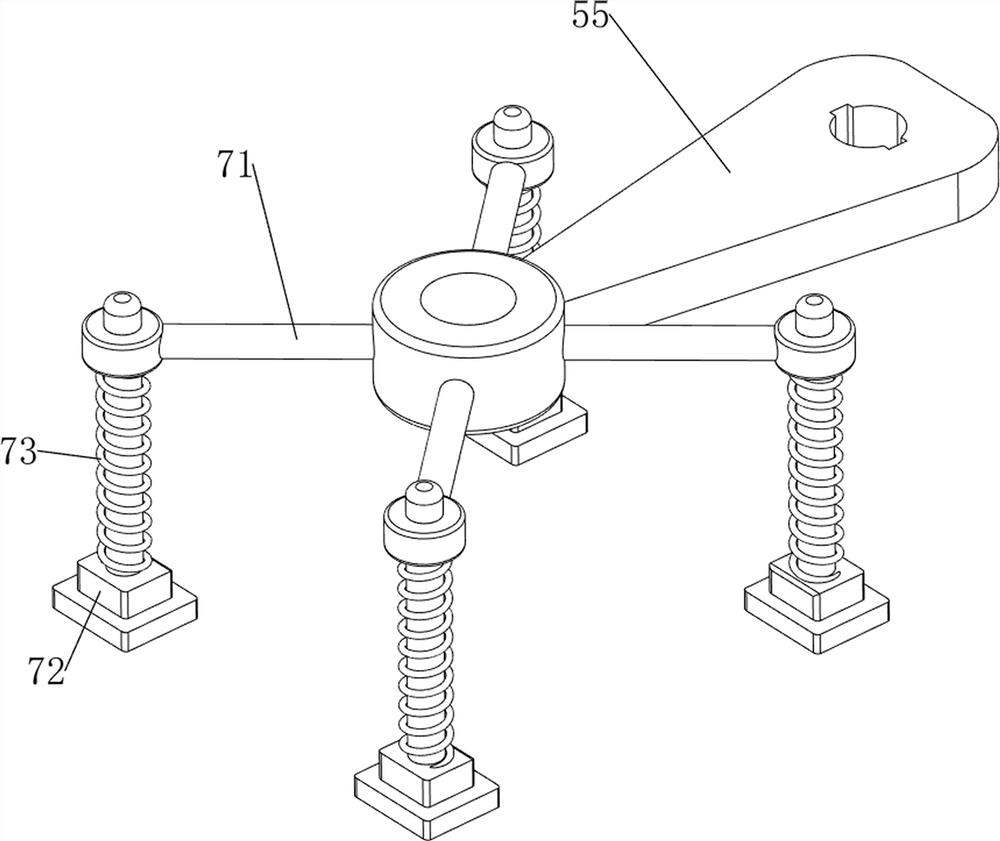

The invention discloses a pressing tool for assembling a truck body. The pressing tool comprises an upright device, a pressing hook, a jack device and a workpiece locating device, wherein the upright device comprises uprights and bases, which are positioned on the two sides; the top ends of the uprights are provided with anti-rebound devices; guide devices and lug seats are arranged on the inner sides of the uprights; cylinders are arranged on the outer sides of the uprights; connecting devices matched with the guide devices are arranged on the inner sides of the guide devices; upper ends of the connecting devices are hinged with pressing hooks; pin holes and pin shafts I are arranged on the lug seats; the pin holes are matched with the pin shafts I; force amplifying levers, which rotate relative to the pin shafts I, are arranged on the pin shafts I; upper long circular holes and lower long circular holes are respectively formed in two ends of the force amplifying levers, wherein the upper long circular holes are hinged with connecting holes at lower ends of the connecting devices by pin shafts II; the lower long circular holes are hinged with connecting holes on end part joints of cylinder piston rods by pin shafts III; jack devices and workpiece locating devices are arranged on the inner sides of lower ends of the uprights; and the bases of the uprights, bottom surfaces of the jack devices and bottom surfaces of the workpiece locating devices are respectively connected with foundation embedded plates.

Owner:CRRC SHANDONG CO LTD

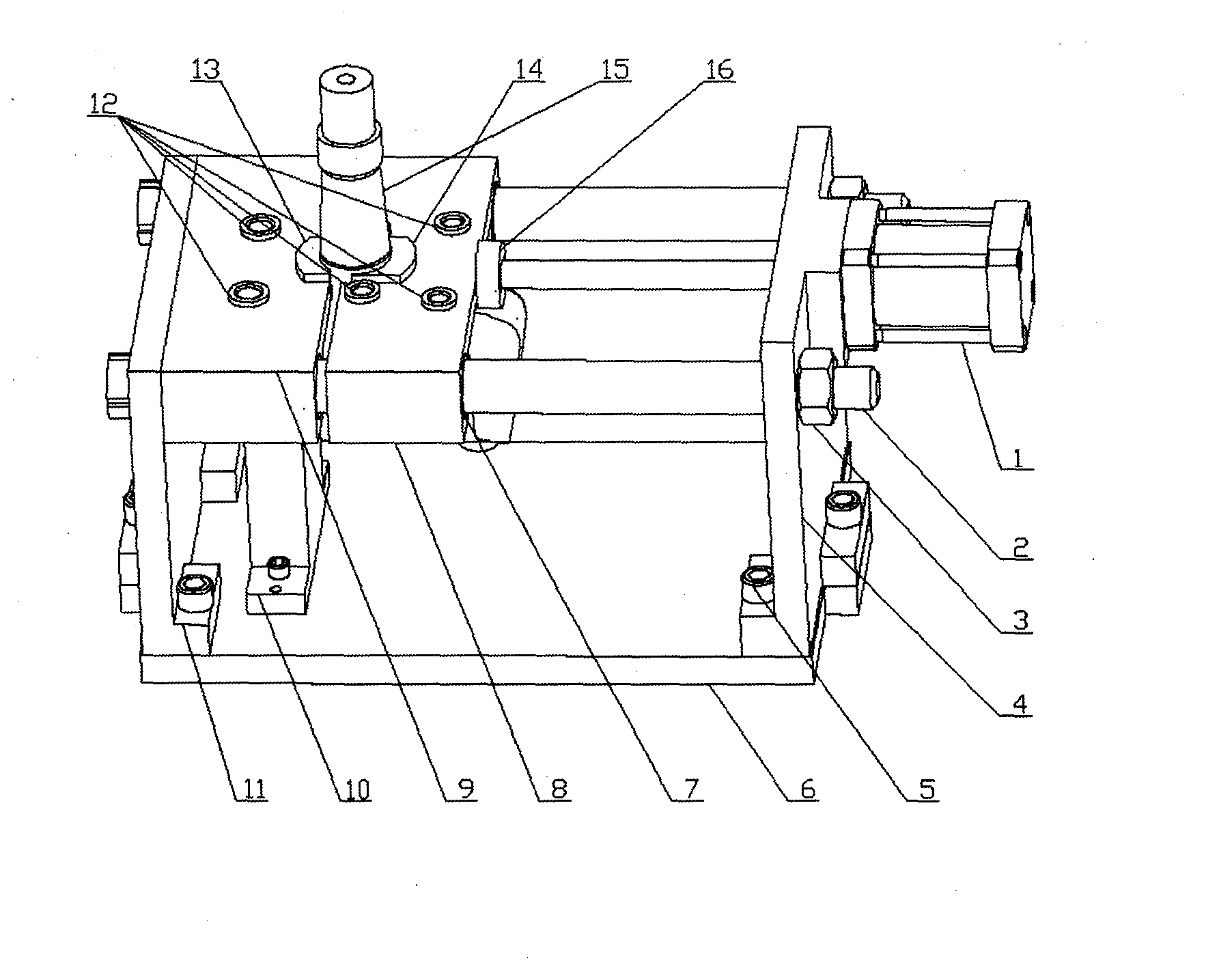

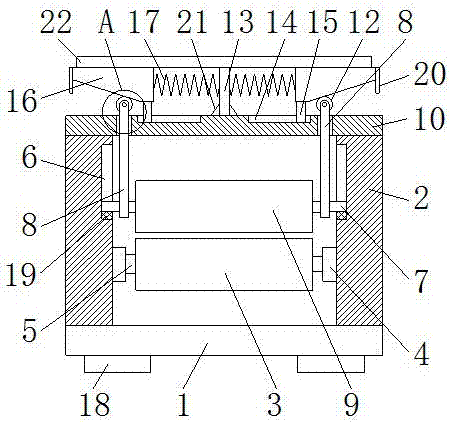

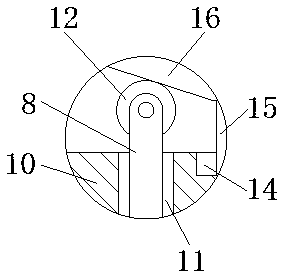

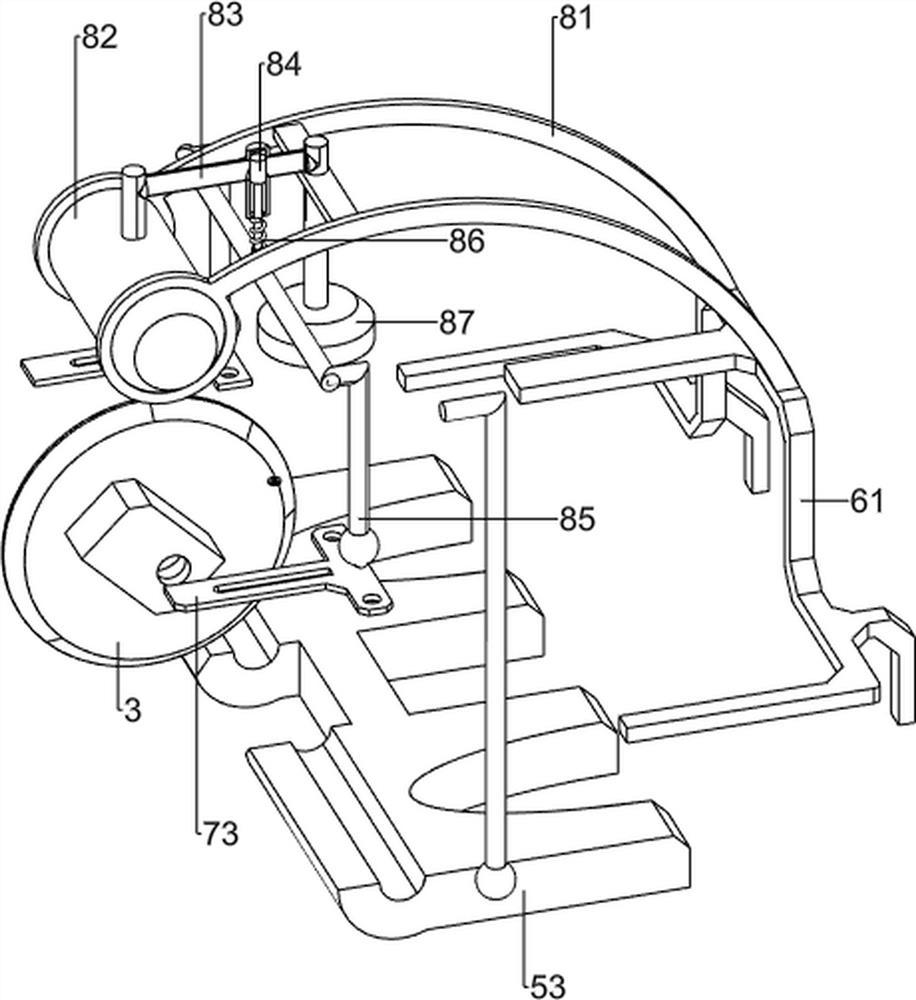

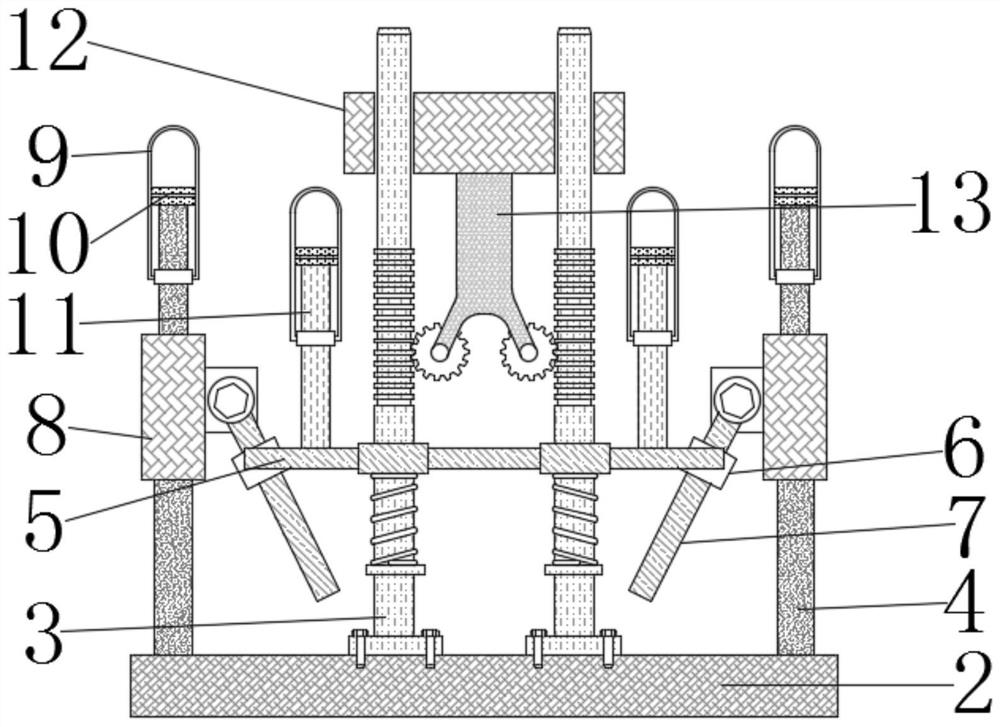

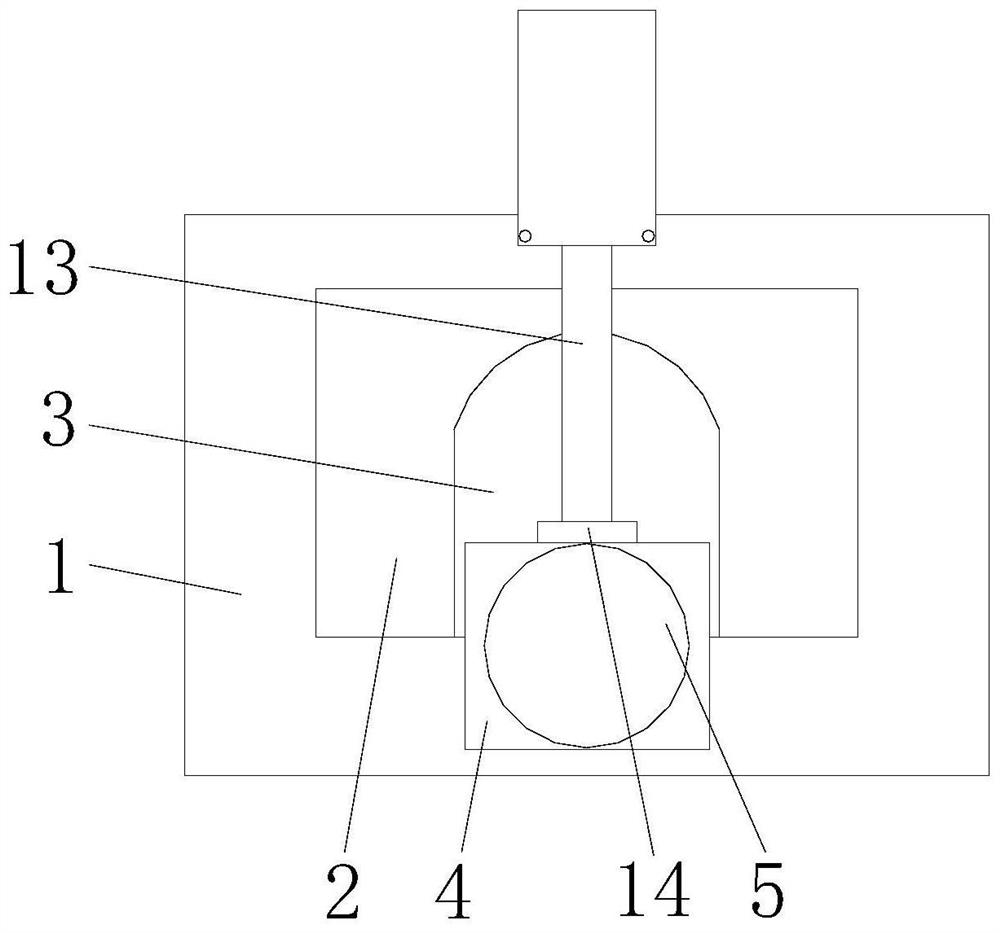

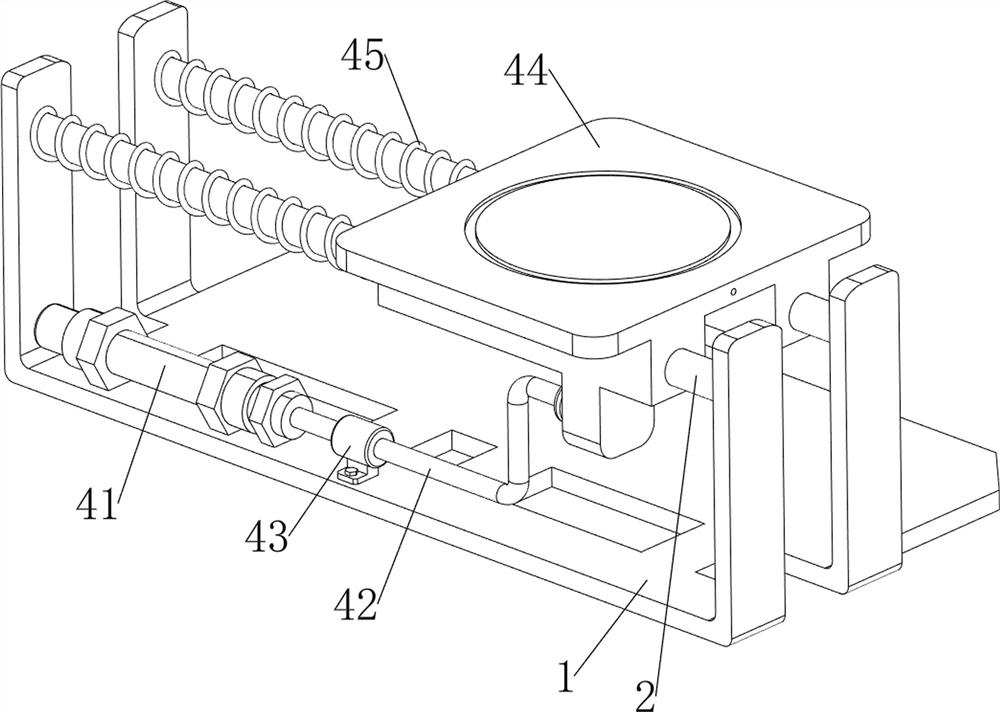

Machining clamp for automobile steering knuckle flange end face holes

InactiveCN103722393AGuaranteed parallelTo achieve the compaction effectPositioning apparatusMetal-working holdersNumerical controlStructural engineering

The invention discloses a machining clamp for automobile steering knuckle flange end face holes. On the premise that original technical requirements are met, the machining clamp utilizes the technical characteristic that a shaft part of a part and the end face of a flange are mutually perpendicular, positioning is performed with an accurate reference shaft diameter, it is guaranteed that the axis is perpendicular to drill plates, the flange end face is in a parallel state, and the technical requirements are effectively guaranteed. According to the design of the novel clamp, the two separable drill plates are adopted, when the movable drill plate is pulled open by a hydraulic device, a workpiece is placed between the fixed drill plate and the movable drill plate, the hydraulic device pushes half rings in linkage with the movable drill plate and the fixed drill plate to automatically correct the shaft part of the workpiece along two guide rods and hoop the shaft part on the half ring of the fixed drill plate, so that clamping work is finished. It is sufficiently guaranteed that the two drill plates are in parallel under the limit of the two guide rods, the shaft part is completely kept perpendicular after the workpiece is compressed by the drill plates in parallel, the fixed drill plate is kept still, positioning half rings connected with the drill plates always keep the center of the part unchanged, and therefore the technical requirements are met. Due to the fact that one-off hydraulic clamping is adopted, the time for clamping the part is reduced, one worker can achieve multi-machine operation through an automatic numerical control machining tool, and therefore production cost is reduced.

Owner:曹立新 +3

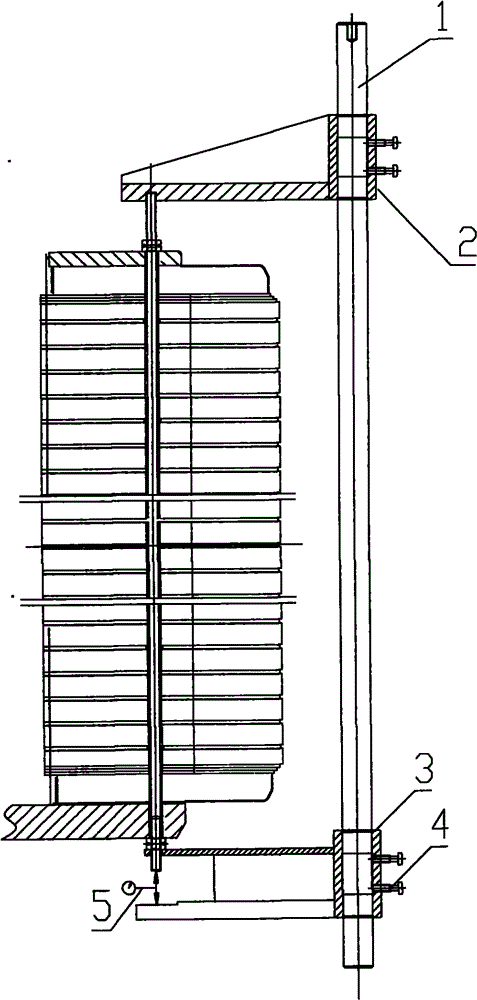

Press mounting method for generator stator core stretching screw

ActiveCN101908797ATo achieve the compaction effectGuaranteed pressureManufacturing stator/rotor bodiesEngineeringActual length

The invention relates to a press mounting method for a generator stator core stretching screw. The invention belongs to the technical field of hydraulic generators. The generator stator core laminations are pressed together by a stretching screw. The method comprises the following steps: (1) test press mounting of stretching screw: measuring the actual length of the stretching screw without pressurizing, carrying out test press on the stretching screw by using a stretching screw measuring sleeve, measuring the elongation of the stretching screw while pressurizing, and recording the pressure reference value; and (2) stretching quantity measurement and press mounting of stretching screw: measuring the initial distance between the lower end surface of the stretching screw and the upper plane of the lower measuring rib by using a stretching screw measuring tool, recording while prepressing and totally pressing, measuring the distance between the lower end surface of the stretching screw and the upper plane of the lower measuring rib when pressurizing to the pressure reference value, and measuring while pressurizing until the requirement is satisfied, thereby realizing press mounting. The invention has the advantages of simple technique, convenient operation, accurate and reliable data, favorable core press mounting effect and the like.

Owner:TIANJIN TIRNFR HEAVY HYDROELECTRIC FRCILITY CO LTD

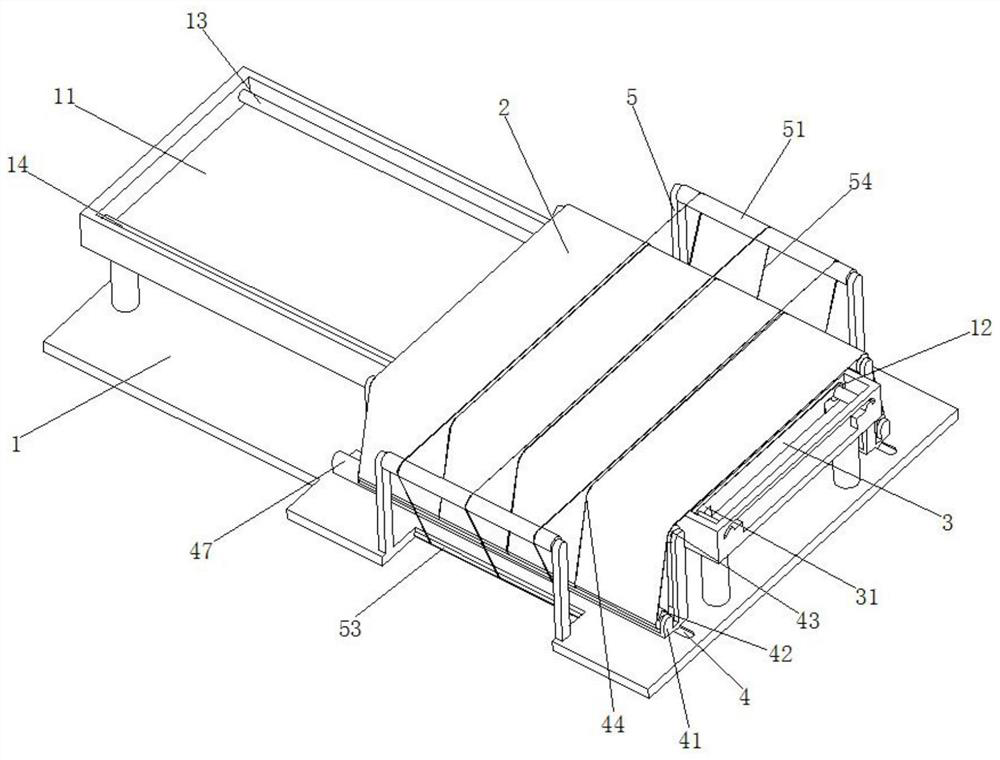

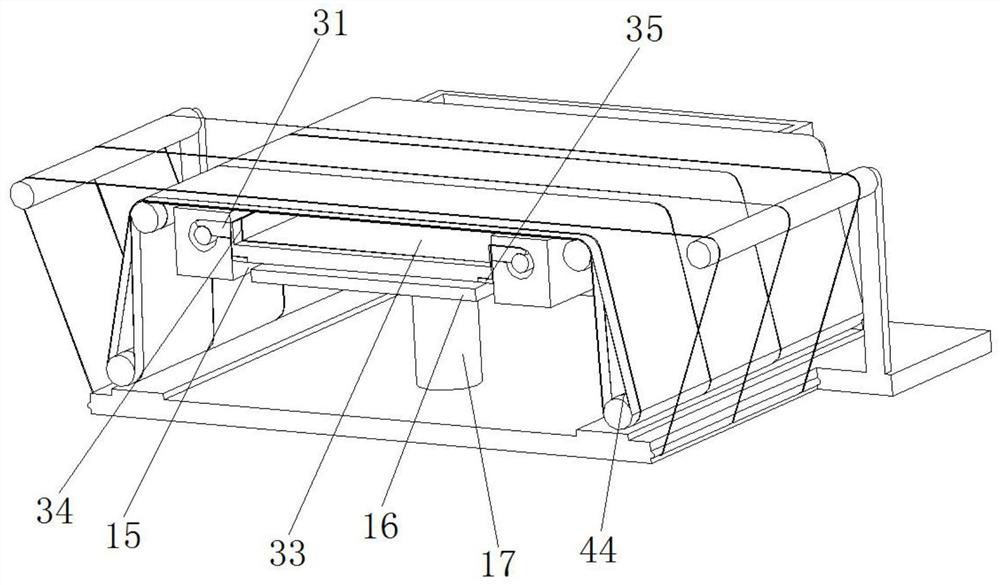

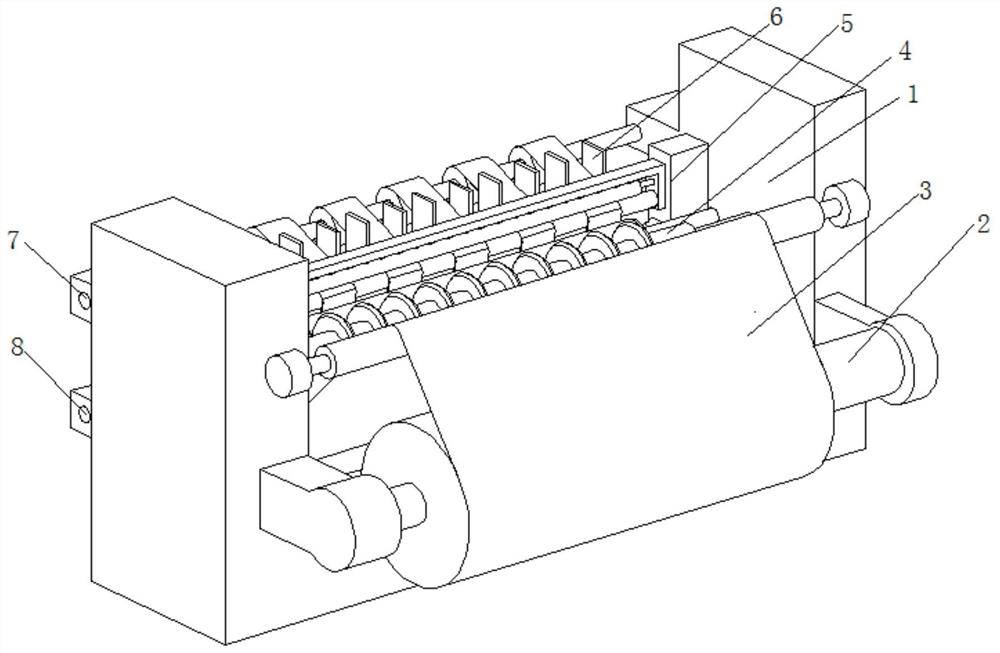

Spinning rolling device with good pressing and rolling effect

InactiveCN107227548ATo achieve the compaction effectSolve the problem of prone to creasing and reduce the quality of textile fabricsWeft knittingLoomsEngineeringSlide plate

The invention discloses a spinning rolling device with good pressing and rolling effect, which comprises a bottom plate; both sides of the top part of the bottom plate are fixedly connected with fixing plates, and a roll cylinder is arranged at the top part of the bottom plate and situated between the fixing plates; the bottom parts of the fixing plates closing to one side of the roll cylinder are fixedly connected with bearings, and one side of every bearing far from the fixing plates is fixedly connected with a rotary shaft, one end of the rotary shaft far from the bearings is fixedly connected to both sides of the roll cylinder; the top part of one side of every fixing plate closing to one side of the roll cylinder is provided with a first cute. Through cooperative use of the first chute, the first slide rod, a bracket, the roll cylinder, the cross plate, a through hole, a roll wheel, a fixing block, a second chute, a second slide rod, a trapezoid block, a spring, and a slide plate, the spinning cloth can be pressed tightly in the process of rolling the textile cloth, thus the device solves the problem that the textile cloth is easy to crumple after being rolled and the textile cloth quality is reduced for the existing spinning rolling device cannot press the textile cloth tightly in rolling the textile cloth.

Owner:苏州晔鸿纺织有限公司

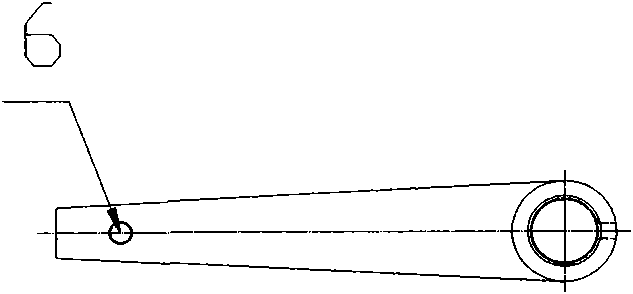

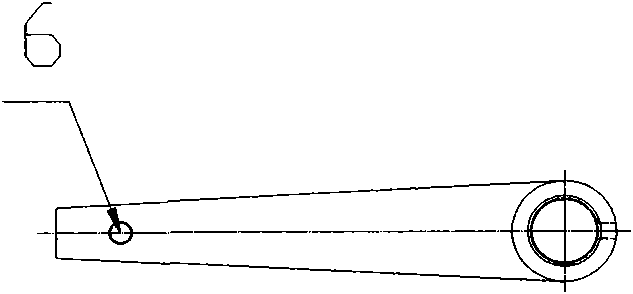

Belt cleaner

The invention provides a belt cleaner which comprises a scraper. The scraper is fixed onto a rotary shaft, the rotary shaft is fixedly connected with adjusting mechanisms, the adjusting mechanisms comprise connecting rods, front ends of the connecting rods are fixedly connected with the rotary shaft along the radial direction of the rotary shaft, and balancing weights are connected to rear ends of the connecting rods. During usage, the cleaner is fittingly fixed to the front of a rotary drum of a belt conveyor, the balancing weights drive the rotary shaft to rotate by the lever principle, the rotational angle of the rotary shaft is adjusted by means of increasing or reducing the balancing weights, the scraper applies pressure in the direction of the belt, and an effect of pressing the scraper with the belt is realized; and when the belt moves along the peripheral direction of the rotary drum of the belt, the scraper scratches foreign matters on the surface of the belt, and an effect of cleaning the foreign matters on the surface of the belt is realized.

Owner:芈鑫

Deburring device for spinning fabric

InactiveCN107529569ATo achieve the compaction effectTo achieve the effect of transmissionSevering textilesWebs handlingDrive wheelEngineering

The invention discloses a deburring device for a spinning fabric. The deburring device comprises a mounting tank, a support wheel rotating shaft, a 8215B speed reduction motor, a Y90S-2 cutting motorand a fabric limiting block, wherein a fabric driving device is mounted inside the mounting tank; a driving wheel is mounted at the output end of the 8215B speed reduction motor; the driving wheel isconnected with a driving wheel above through a belt; support wheel rotating shafts which are symmetrically distributed are mounted on two sides of the driven wheel; a dustproof cover is mounted at theupper end of the mounting tank; a deburring device is mounted in the middle of the top end of the mounting tank inside the dustproof cover; the Y90S-2 cutting motor is welded at the top end of the mounting tank through motor fixing support feet at the lower end; two motor fixing support feet are arranged; a motor rotating shaft is mounted at the output end of the Y90S-2 cutting motor; and the motor rotating shaft is sleeved by a cutting disc. By adopting the deburring device, burr of edged of a fabric can be removed in the fabric conveying process, and the produced and process fabric is relatively attractive in appearance and relatively convenient to use.

Owner:湖州织里欧梦服饰有限公司

A textile winding device with good rolling effect

InactiveCN107227548BTo achieve the compaction effectIncrease frictionWeft knittingLoomsSlide plateEngineering

The invention discloses a spinning rolling device with good pressing and rolling effect, which comprises a bottom plate; both sides of the top part of the bottom plate are fixedly connected with fixing plates, and a roll cylinder is arranged at the top part of the bottom plate and situated between the fixing plates; the bottom parts of the fixing plates closing to one side of the roll cylinder are fixedly connected with bearings, and one side of every bearing far from the fixing plates is fixedly connected with a rotary shaft, one end of the rotary shaft far from the bearings is fixedly connected to both sides of the roll cylinder; the top part of one side of every fixing plate closing to one side of the roll cylinder is provided with a first cute. Through cooperative use of the first chute, the first slide rod, a bracket, the roll cylinder, the cross plate, a through hole, a roll wheel, a fixing block, a second chute, a second slide rod, a trapezoid block, a spring, and a slide plate, the spinning cloth can be pressed tightly in the process of rolling the textile cloth, thus the device solves the problem that the textile cloth is easy to crumple after being rolled and the textile cloth quality is reduced for the existing spinning rolling device cannot press the textile cloth tightly in rolling the textile cloth.

Owner:苏州晔鸿纺织有限公司

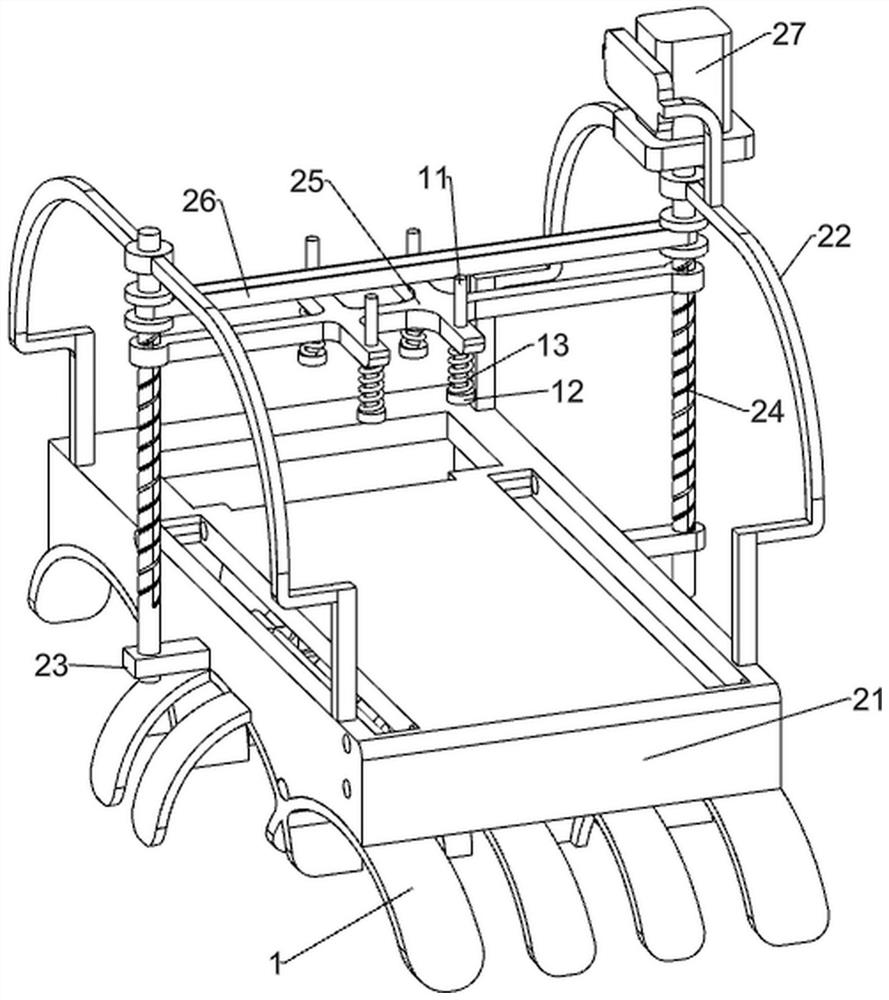

Colorful pattern embossing device for jeans

ActiveCN112937095AUniform printingQuality improvementRotary pressesStructural engineeringTextile printer

The invention relates to an embossing device, in particular to a colorful pattern embossing device for jeans. The colorful pattern stamping device for the jeans can automatically conduct transferring and embossing, and is convenient and fast. The colorful pattern stamping device for the jeans comprises a base frame, a printing mechanism, first sliding rods, pattern printing blocks, first springs and a conveying mechanism. The printing mechanism is arranged on the base frame. The four first sliding rods are arranged on the printing mechanism in a sliding mode. Each pattern printing block is arranged at the bottom of the corresponding first sliding rod. Each first spring is connected between the corresponding pattern printing block and the printing mechanism, and each first spring is wound on the corresponding first sliding rod. The conveying mechanism is arranged on the printing mechanism. The first sliding rods and the pattern printing blocks are driven by a moving plate to move downwards, when the first sliding rods and the pattern printing blocks move downwards to make contact with the jeans, the first springs are compressed, the printing effect is achieved, and time and labor are saved in the operation.

Owner:江西仔衣库服饰有限公司

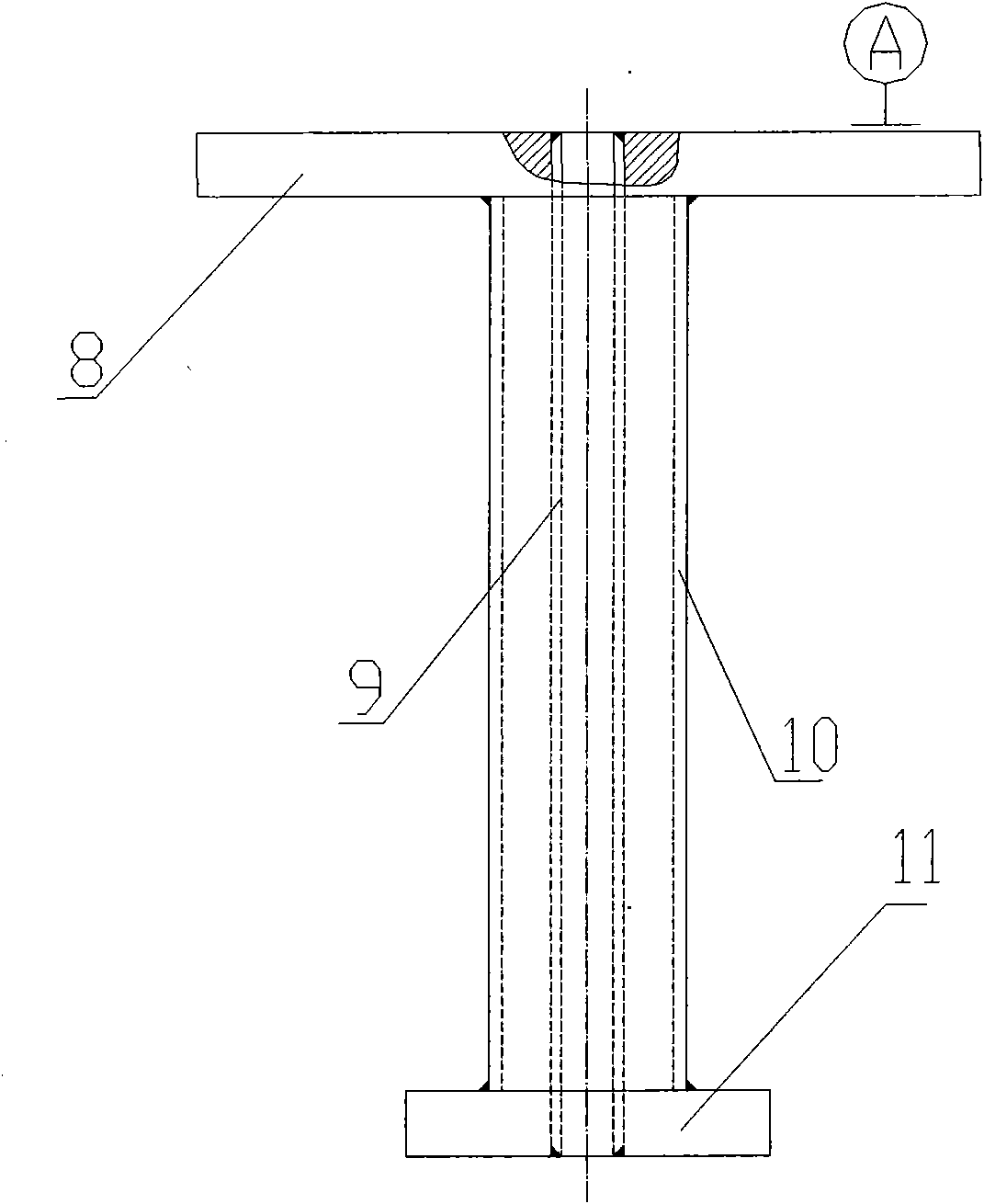

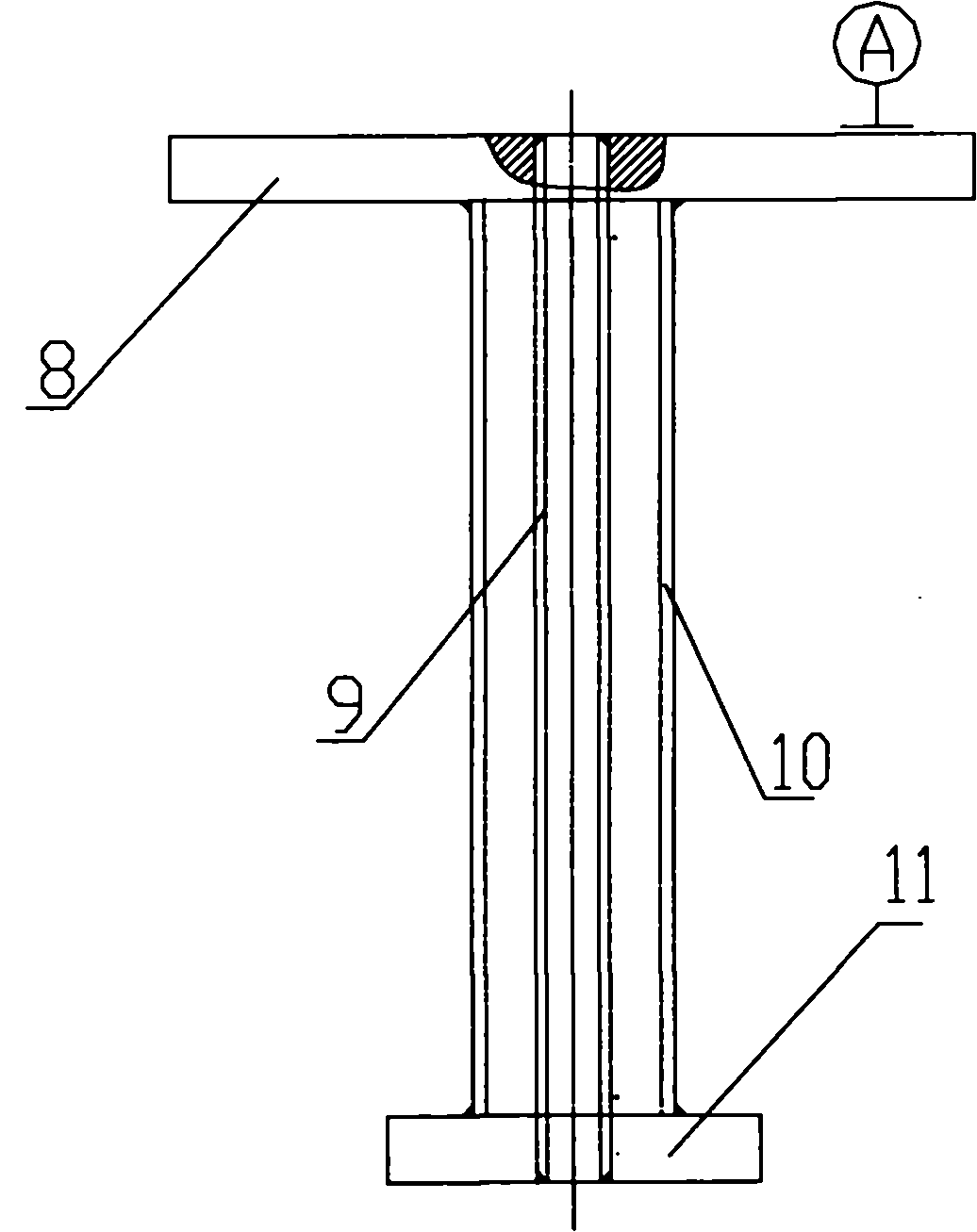

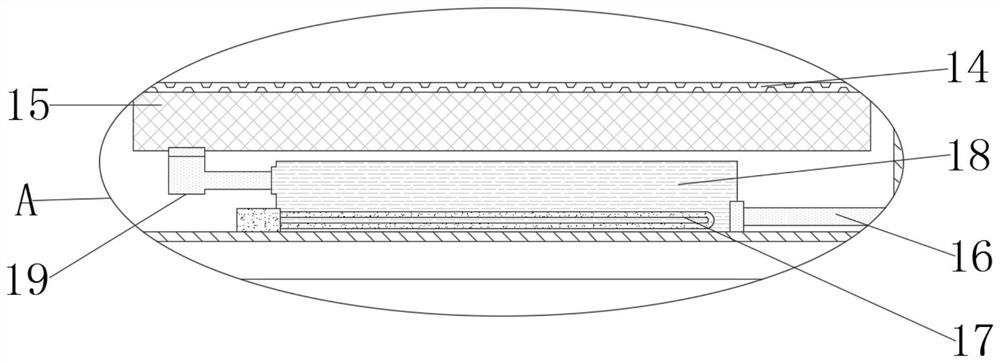

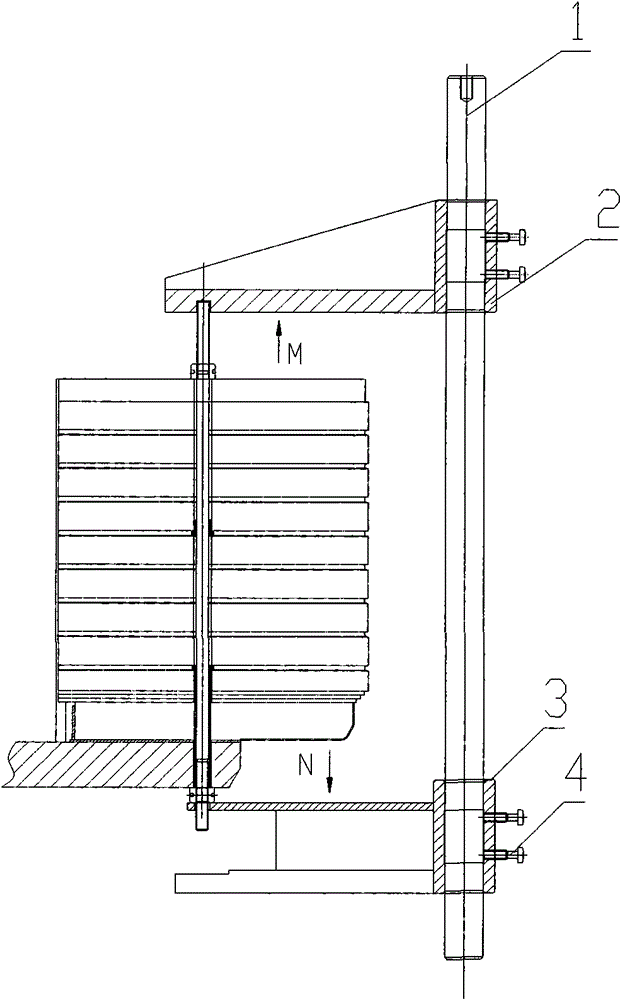

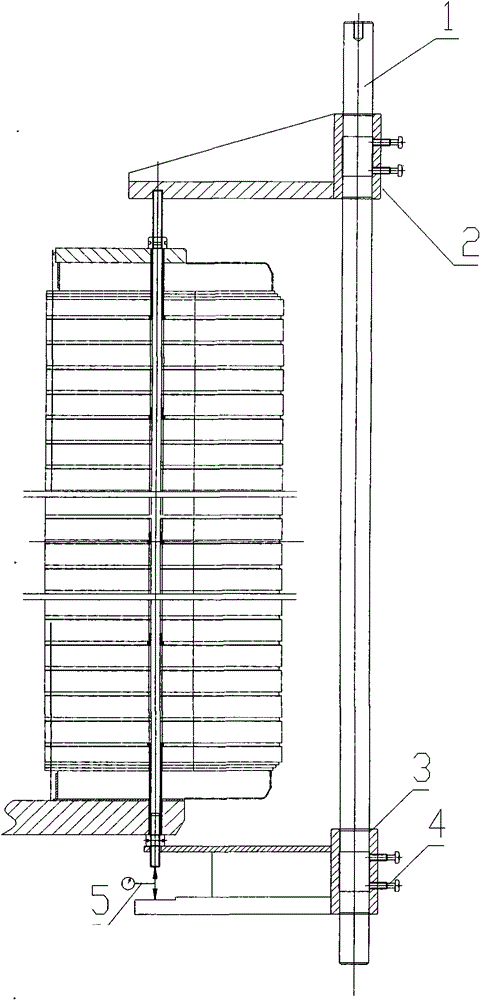

Elongation measurement tool for stator iron core tension screw of hydraulic turbine generator

The invention relates to an elongation measurement tool for a stator iron core tension screw of hydraulic turbine generator, belonging to the technical field of hydraulic turbine generator and characterized in that: the elongation measurement tool for the tension screw is composed of a brace, an upper measurement rib, a lower measurement rib and a measurement dial indicator, wherein the brace is equipped with the upper and lower measurement ribs, and the lower measurement rib is provided with the measurement dial indicator. The elongation measurement tool according to the invention has the advantages of simple structure, convenient operation, low cost, good practicability, saving time and labor, accurate and reliable data, high press-mounting accuracy of iron core, good press-mounting effect, etc.

Owner:TIANJIN TIRNFR HEAVY HYDROELECTRIC FRCILITY CO LTD

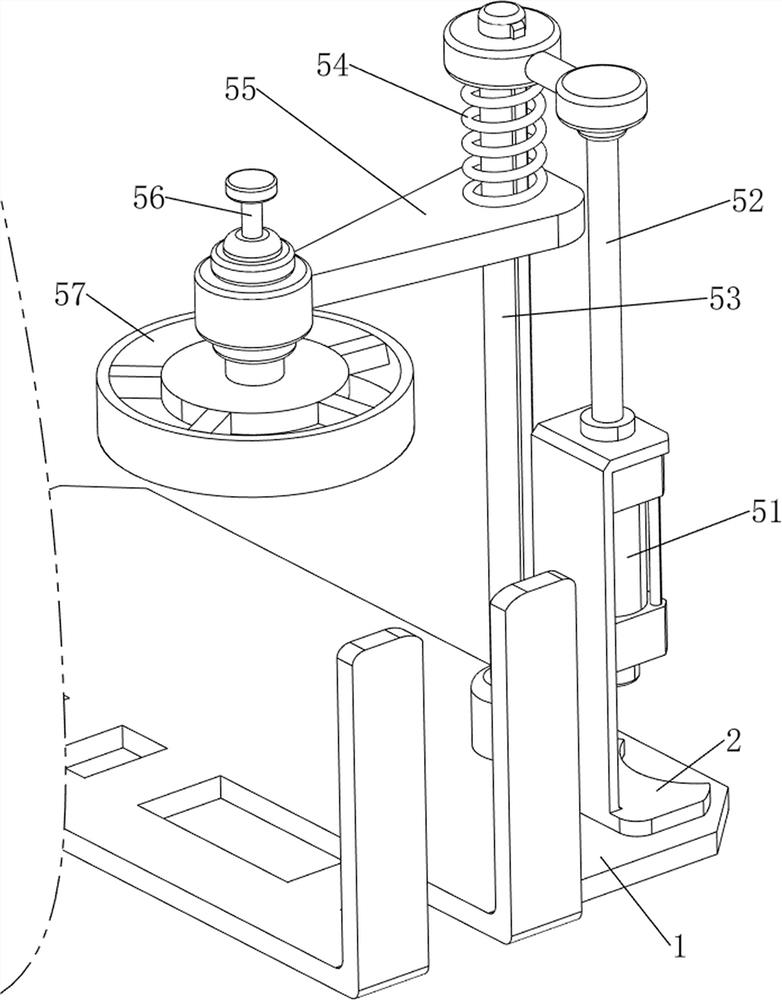

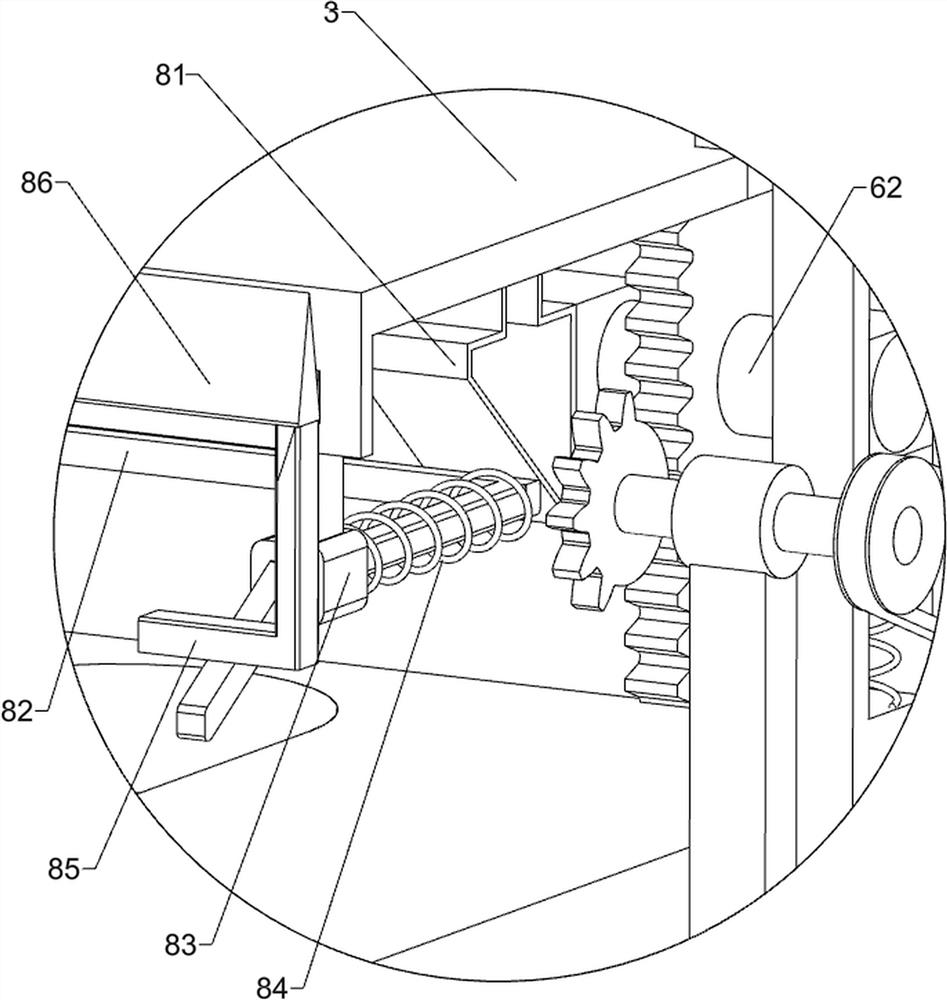

Steel pipe equidistant segmentation equipment for municipal construction

ActiveCN113042805ATo achieve the effect of rotationSave human effortTube shearing machinesMaintainance and safety accessoriesTransmission beltAgricultural engineering

The invention relates to segmentation equipment, in particular to steel pipe equidistant segmentation equipment for municipal construction. The steel pipe equidistant segmentation equipment for municipal construction achieves automatic clamping and automatic cooling and is simple in operation. The steel pipe equidistant segmentation equipment for municipal construction comprises a bottom plate, supports, a rotating mechanism, an electric cutting wheel and a feeding mechanism. The supports are arranged on the two sides of the bottom plate. The rotating mechanism is arranged between the two supports. The electric cutting wheel is arranged on the rotating mechanism. The feeding mechanism is arranged on the bottom plate. An output shaft of a servo motor rotates to drive a transmission belt and a first rotating shaft to rotate, and therefore first connecting blocks are driven to rotate, then the rotating electric cutting wheel drives a second rotating shaft to rotate, the rotating effect is achieved, and manpower is saved; and steel pipes are placed on a carrying plate, then an air cylinder is started, an telescopic rod of the air cylinder drives the carrying plate and sliding columns to move leftwards, and the feeding effect is achieved.

Owner:广东昆大钢管有限公司

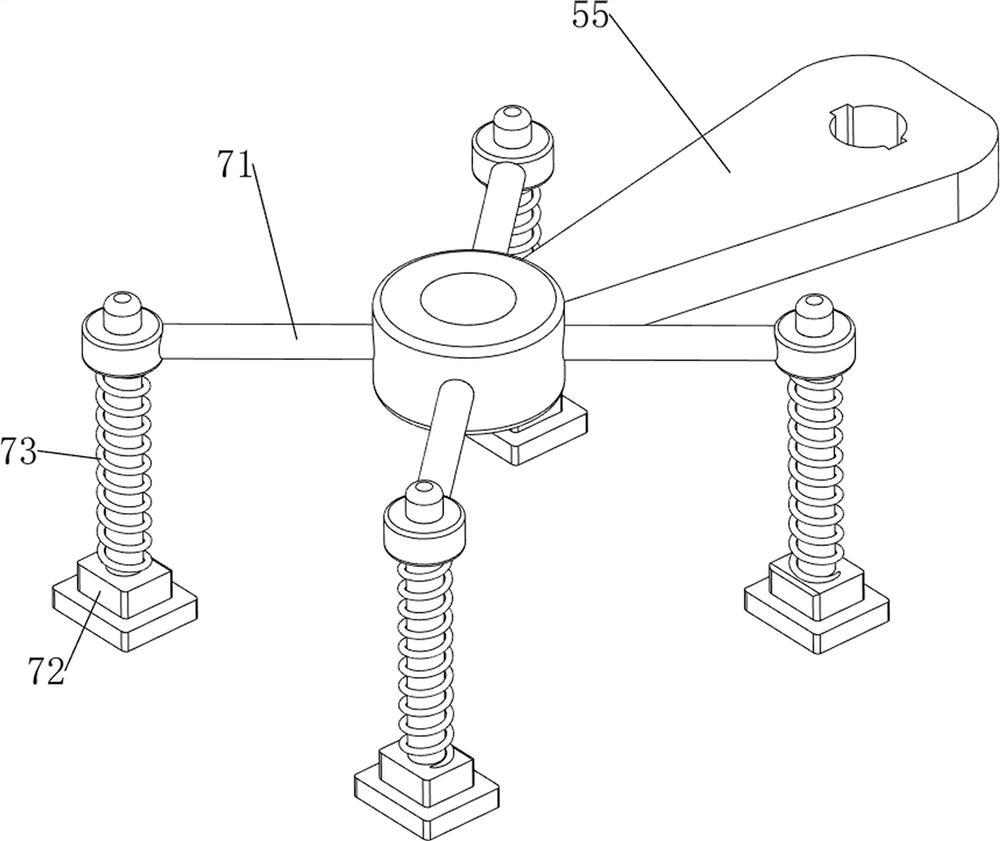

Carrying platform for unmanned aerial vehicle

PendingCN112660390ATo achieve the effect of occlusionTo achieve the compaction effectFreight handlingAircraftsThreaded pipeUncrewed vehicle

The invention provides a carrying platform for an unmanned aerial vehicle, which comprises a vehicle body, a first fixing plate is arranged at the bottom of the vehicle body, supporting plates are fixedly connected to the two sides of the top of the first fixing plate, threaded rods are movably connected to the interiors of the supporting plates through bearings, and the two sides of the surfaces of the threaded rods are sleeved with threaded pipes; and one side of the threaded pipe is fixedly connected with a first connecting plate and a second connecting plate through connecting blocks correspondingly. According to the carrying platform for the unmanned aerial vehicle, the effect of driving the first fixing plate to move is achieved through the vehicle body, the effect of placing objects is achieved through the first fixing plate, the effect of shielding the objects is achieved through the supporting plate, and the effect of driving the first connecting plate and the second connecting plate to move is achieved through the threaded rod and the threaded pipe; through the first connecting plate and the second connecting plate, the effect of compressing objects is achieved, the unmanned aerial vehicle can conveniently convey the objects, the objects are not prone to moving or falling off, and people can conveniently use the unmanned aerial vehicle.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Trimming device for roving wool fabric type circular carpet for spinning

ActiveCN113319905AAchieve the effect of automatic pushAchieve cutting effectTextile disintegration and recoveryMetal working apparatusWoolEngineering

The invention relates to a trimming device, in particular to a trimming device for a roving wool fabric type circular carpet for spinning. The trimming device for roving wool fabric type circular carpet for spinning has the advantages of automatic feeding, automatic cutting and automatic clamping. The trimming device for roving wool fabric type circular carpet for spinning comprises a bottom plate and first sliding rails, wherein the first sliding rails are arranged on two sides of the bottom plate; a base arranged on the bottom plate; a feeding mechanism arranged between the bottom plate and the first sliding rail; a cutting mechanism arranged between the base and the bottom plate; and a self-locking mechanism arranged between the cutting mechanism and the feeding mechanism. A first air cylinder is started, the first air cylinder drives a first telescopic rod to move forwards, a first spring is stretched, and when a carpet is moved to the position below the cutting mechanism, the automatic pushing effect is achieved.

Owner:河北亚奥纺织有限公司

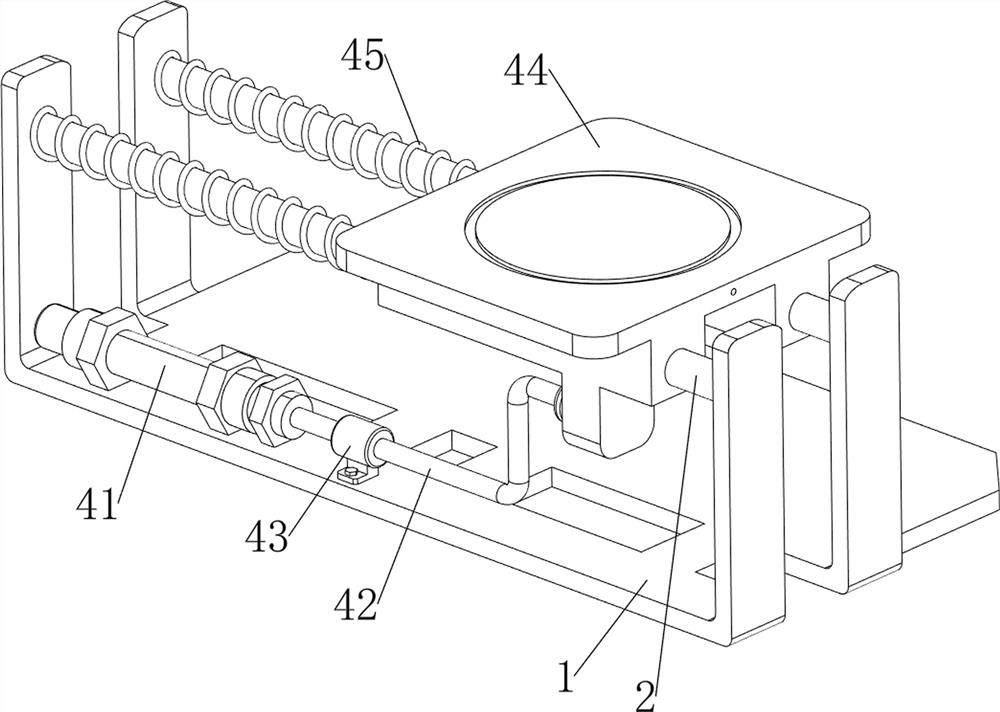

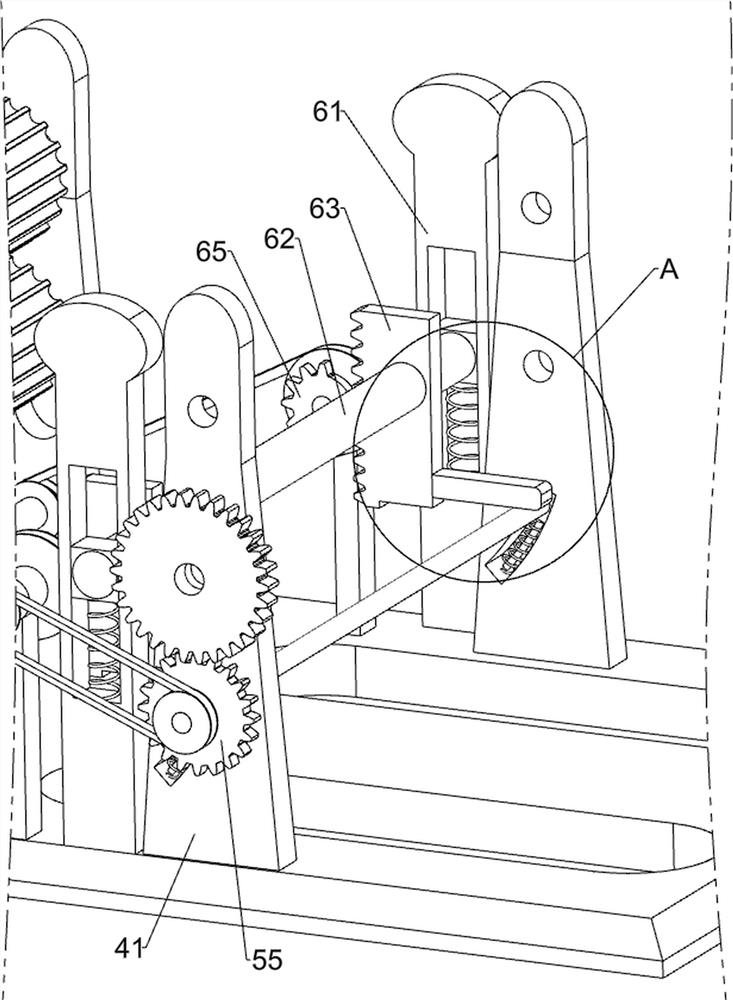

Air column bag segmenting device for express packaging

ActiveCN112478333AReach auto-segmentationTo achieve the compaction effectPackagingElectric machineryPhysics

The invention relates to a segmenting device, in particular to an air column bag segmenting device for express packaging. The air column bag segmenting device for express packaging, which can realizeautomatic segmenting of an air column bag and can compact the air column bag automatically during segmenting is provided. The air column bag segmenting device for express packaging comprises a base, adouble-axis motor, a support table, a transmission assembly and a control assembly, wherein the double-axis motor is arranged on one side of the top of the base; the support table is arranged on thetop of the base; the transmission assembly is arranged at the top of the base; and the control assembly is arranged on one side, away from the double-axis motor, of the transmission assembly. The aircolumn bag segmenting device disclosed by the invention has the effects that the air column bag can be automatically segmented and can be automatically compacted during segmenting.

Owner:湖北统邦物流有限公司

High-molecular compound manufacturing equipment for protecting household appliances

InactiveCN111483104ATo achieve the compaction effectEasy to block movementStructural engineeringMechanical engineering

Owner:杭州床邢科技有限公司

Autoclaving method for Liubao tea

InactiveCN105532951ASolve heartburnTo achieve the compaction effectPre-extraction tea treatmentHeartburnChemistry

The invention discloses an autoclaving method for Liubao tea, and relates to the technical field of tea processing. The method comprises the following steps: cooling softened tea after steaming, cooling the tea to 55-65 DEG C, and then baking and pressing for 10-15 hours. Compared with the prior art, the method comprises the following steps: cooling the steamed tea, cooling the tea to 55-65 DEG C and then baking and pressing, so that the problem of heartburn of the tea easily caused by high-temperature baking and pressing is solved; meanwhile, required time for cooling after baking and pressing is also shortened; and a high-temperature baking and pressing compaction effect can also be achieved by baking and pressing after cooling.

Owner:广西梧州茶厂有限公司

Laser cutting device for soft fabric

InactiveCN112935597ATo achieve the compaction effectEasy to cutWelding/cutting auxillary devicesAuxillary welding devicesHydraulic cylinderStructural engineering

The invention relates to the technical field of fabric cutting, and discloses a laser cutting device for soft fabrics. The laser cutting device comprises a machine body, wherein a pressing plate is slidably mounted on the machine body, a main pressing rod is slidably mounted above the pressing plate, an auxiliary pressing rod is slidably mounted at the right end of the main pressing rod, a sliding rod is fixedly mounted above the main pressing rod, a sliding block is slidably installed at the right end of the sliding rod, the sliding block is slidably installed on the rotating rod, a hydraulic cylinder is fixedly installed above a fixed block, a piston body is slidably installed in the hydraulic cylinder, and a hydraulic rod is slidably installed below the piston body. According to the laser cutting device for the soft fabric, the fabric is placed on a fixing plate, oil enters the hydraulic cylinder to enable the piston body to move downwards, the auxiliary pressing rod and the hydraulic rod are driven to move downwards, the hydraulic rod drives the main pressing rod to move downwards through the sliding rod, and the main pressing rod and the auxiliary pressing rod drive a pressing plate to move downwards to press the fabric, so that the effect of pressing the fabric is achieved.

Owner:广州骁庆科技有限公司

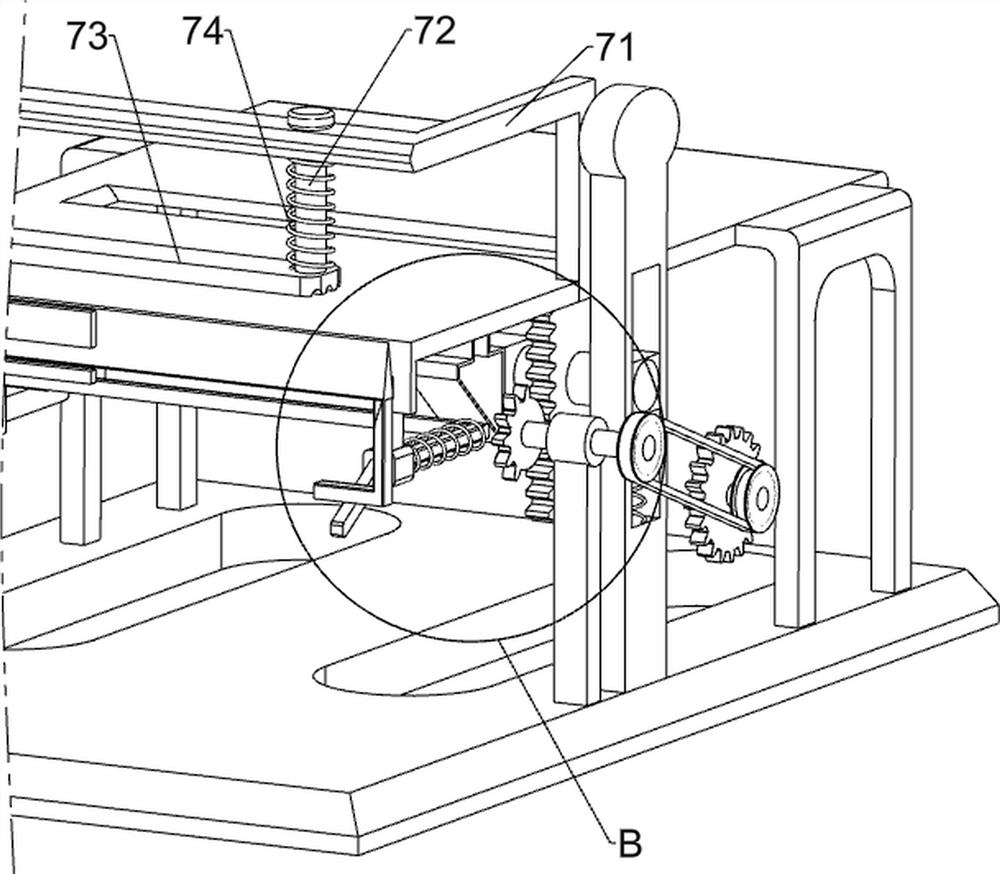

Wood door clamp with controllable down-pressing force

InactiveCN108748587ATo achieve the compaction effectTo achieve the purpose of lockingWood working apparatusEngineeringLever pressing

Owner:湖州欧贝得门业有限公司

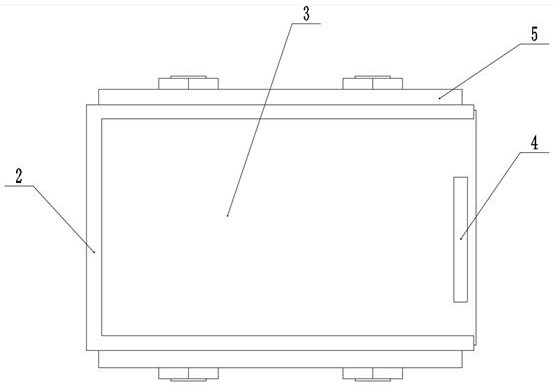

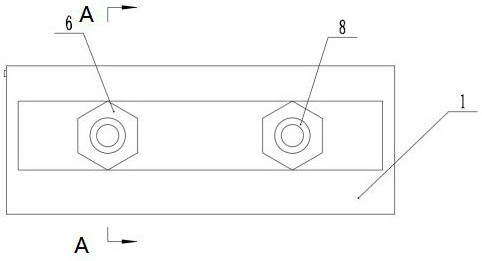

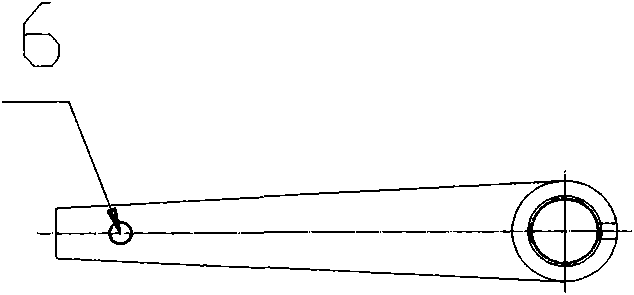

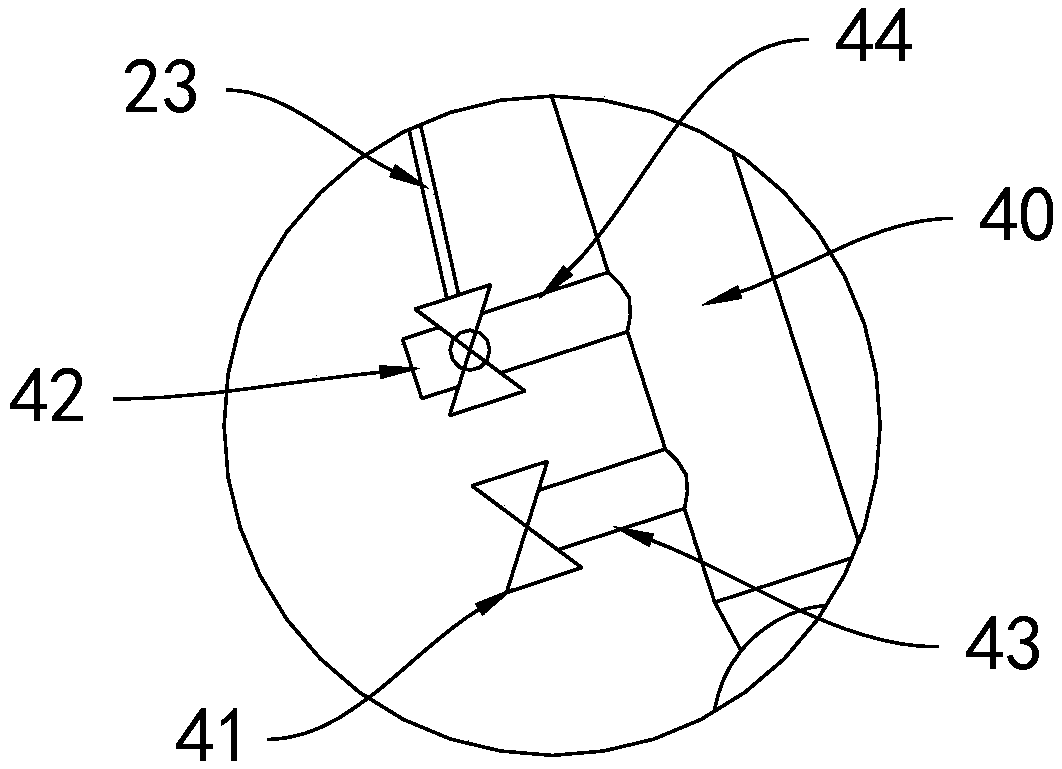

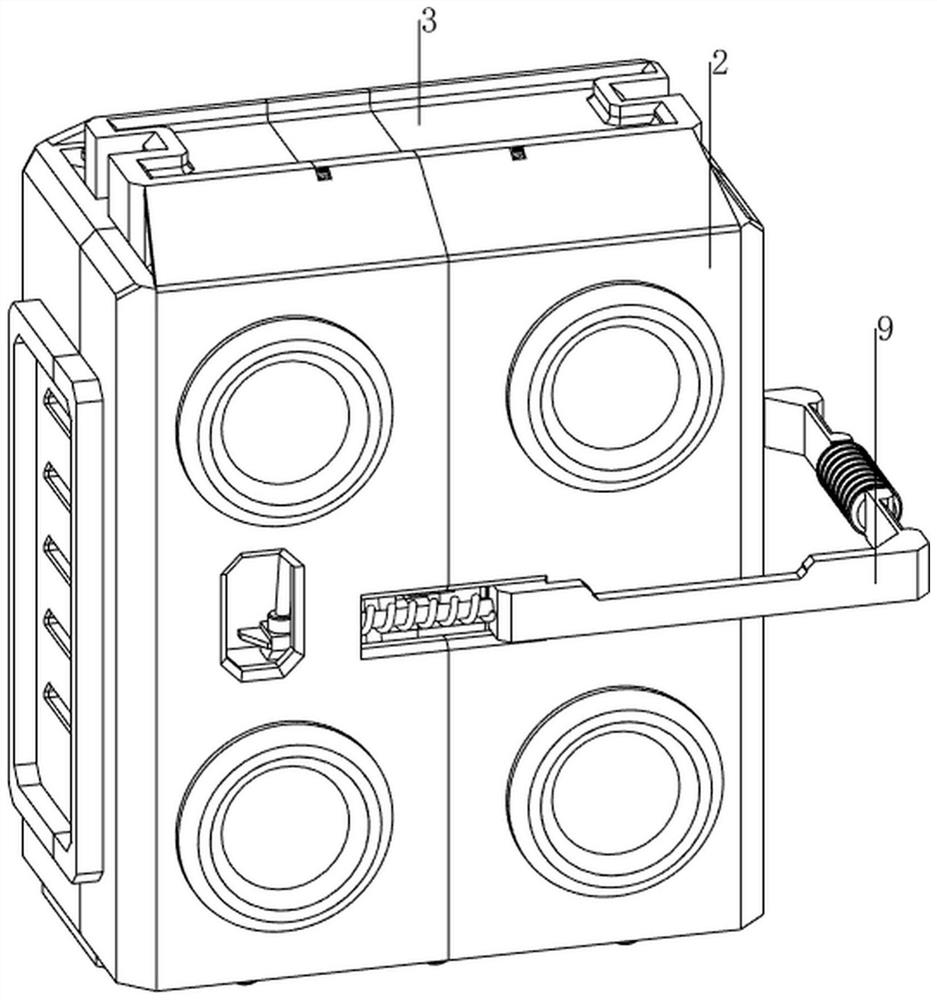

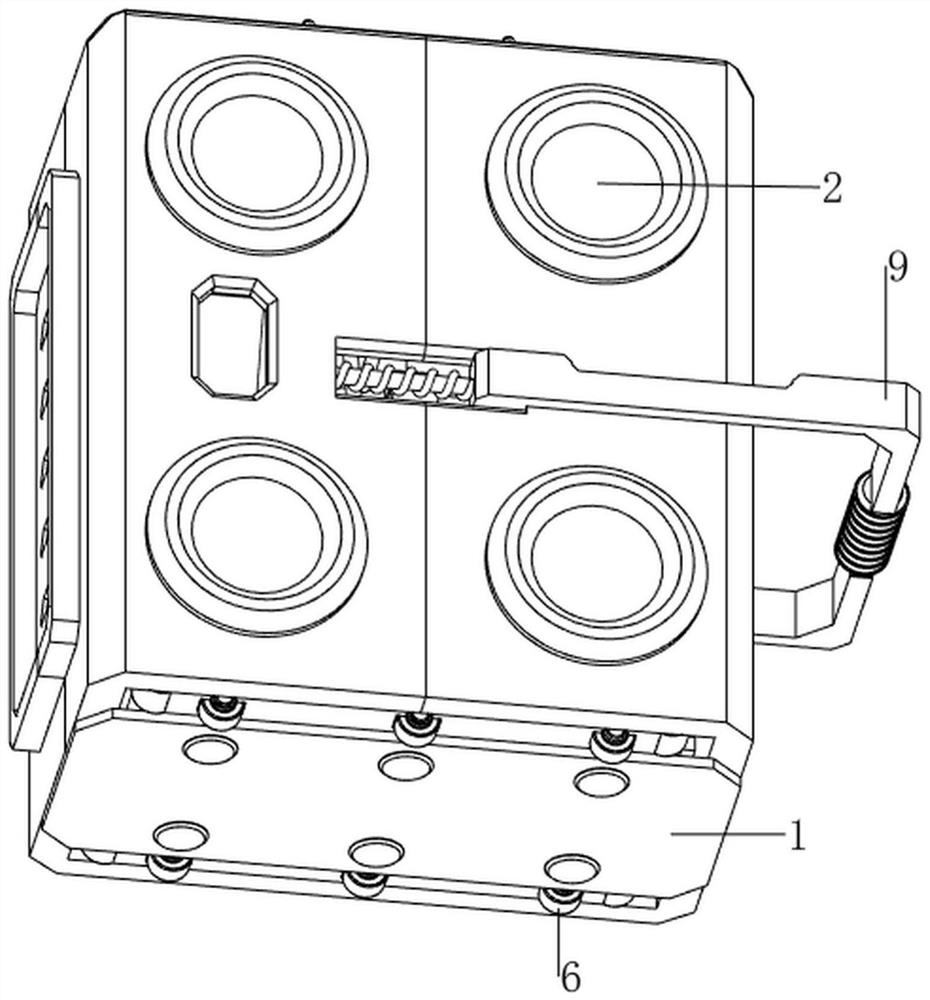

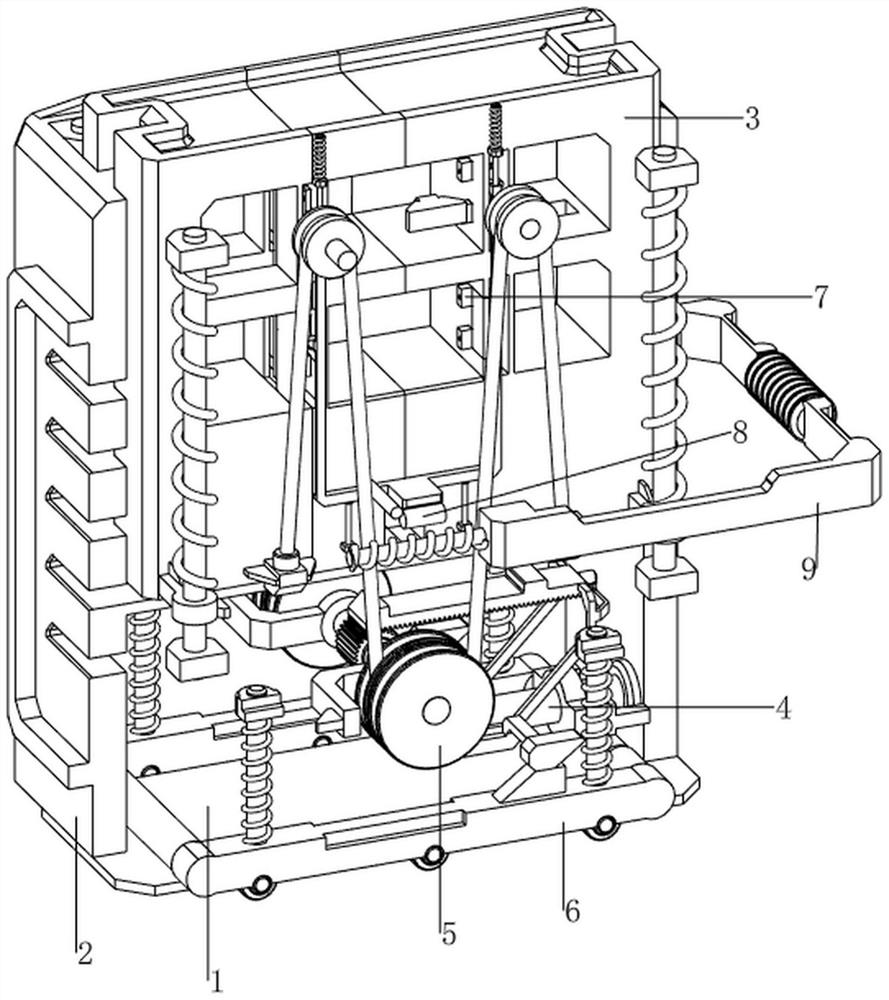

Outdoor junction box for building electrical circuit

InactiveCN113381356ATo achieve the compaction effectEasy to fixElectrical apparatusStructural engineeringWire fixation

An outdoor junction box for a building electrical circuit is a square box body, the square box body is provided with peripheral side plates, a bottom plate and a top sliding cover plate, the square box body comprises a shell (1), a waterproof sealing device, a fixed connecting device and a connector (11), the waterproof sealing device is arranged at the upper end of the shell, and the fixed connecting device and the connector are arranged in the shell. The outdoor junction box is characterized in that the waterproof sealing device is arranged at the upper end of the shell and comprises a waterproof cover (3), a limiting plate (2) and a protruding plate (4), fixing plates (5) are arranged at the left end and the right end of the shell respectively, and the fixed connecting device is arranged in each fixing plate and comprises a hexagonal nut (6), a waterproof leather sheath (7), a connecting ring (8), a threaded rod (9) and a hollow screw (12). The outdoor junction box for the building electrical circuit has the advantages of being capable of compressing the electric wire, stable in electric wire fixation, good in sealing effect, simple and rapid in installation and sealing and suitable for being widely used.

Owner:CHINA MCC5 GROUP CORP

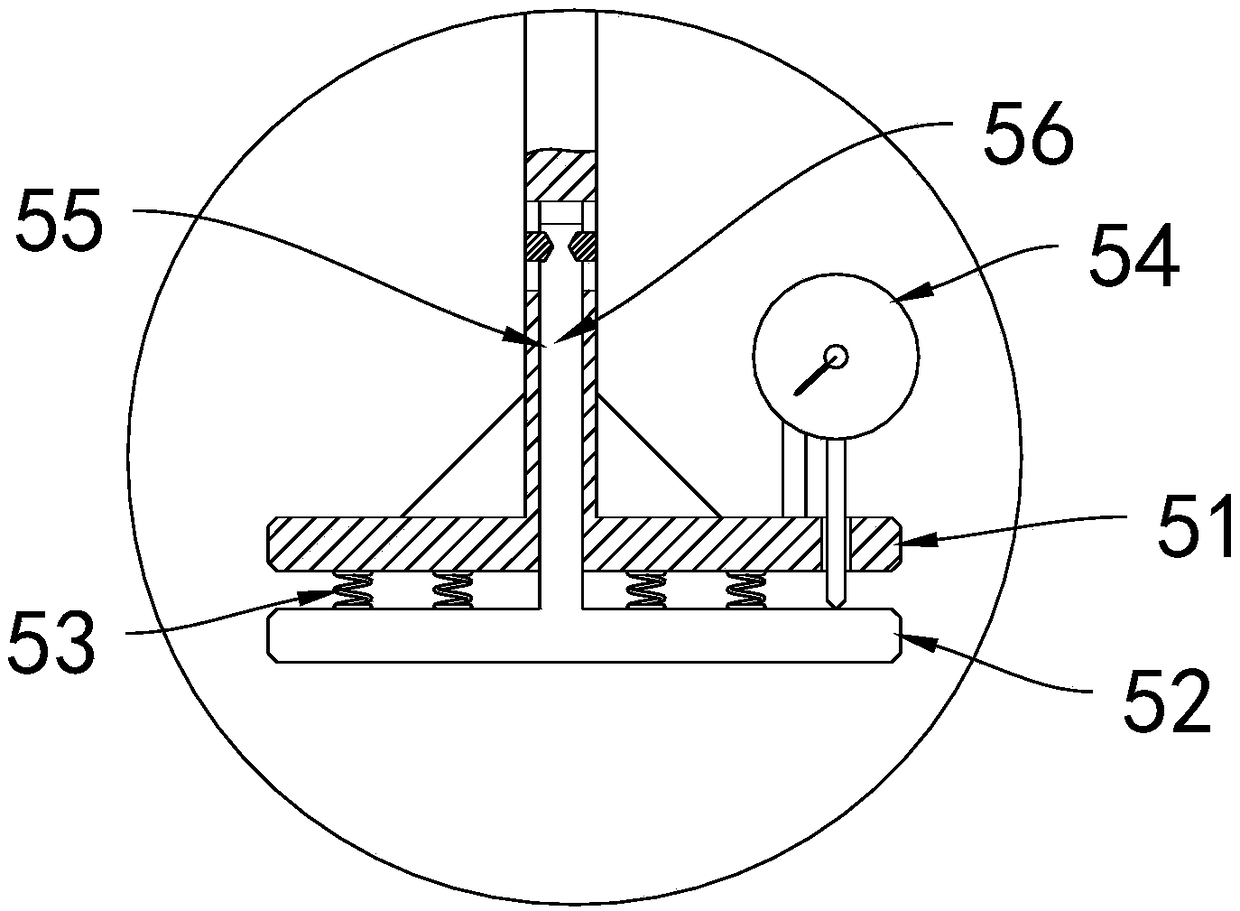

Motor rotor winding shaping machine

PendingCN111786515ATo achieve the compaction effectAchieve support effectManufacturing stator/rotor bodiesElectric machineControl theory

The invention discloses a motor rotor winding shaping machine. The shaping machine comprises a base, a first placing plate is fixedly connected to the top of the base, a groove is formed in the frontsurface of the first placing plate, a second placing plate is slidably connected to the interior of the groove, a shaper is fixedly connected to the top of the second placing plate, a pressing plate is movably connected to the top of the shaper, and supporting rods are fixedly connected to the two sides of the top of the base. According to the invention, the first placing plate and the second placing plate are arranged, the effect of placing the shaper is achieved; through the shaper, the effect of placing the rotor winding is achieved, through the pressing plate, the effect of pressing the rotor winding is achieved, through the first supporting plate and the second supporting plate, the effect of supporting the first air cylinder is achieved, through the first air cylinder, the effect ofdriving the inserting rod to move is achieved, through the inserting rod, the effect of shaping the rotor winding is achieved, and the shaping machine can effectively tidy wound wires and is convenient for people to use.

Owner:福建省昌辉机电有限公司

An embossing device for jeans with colorful patterns

ActiveCN112937095BTo achieve the effect of printingOperation saves time and effortRotary pressesTextile printerEngineering

Owner:江西仔衣库服饰有限公司

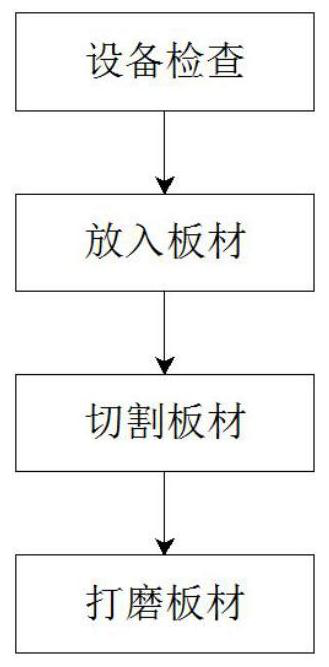

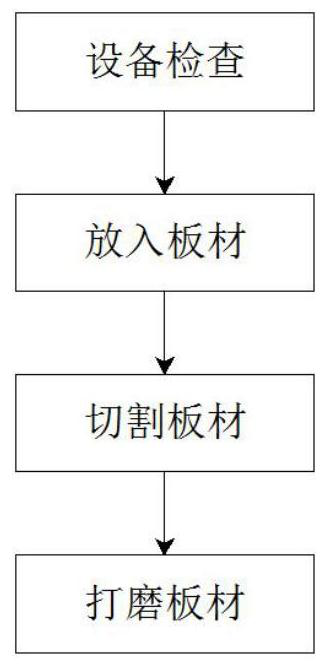

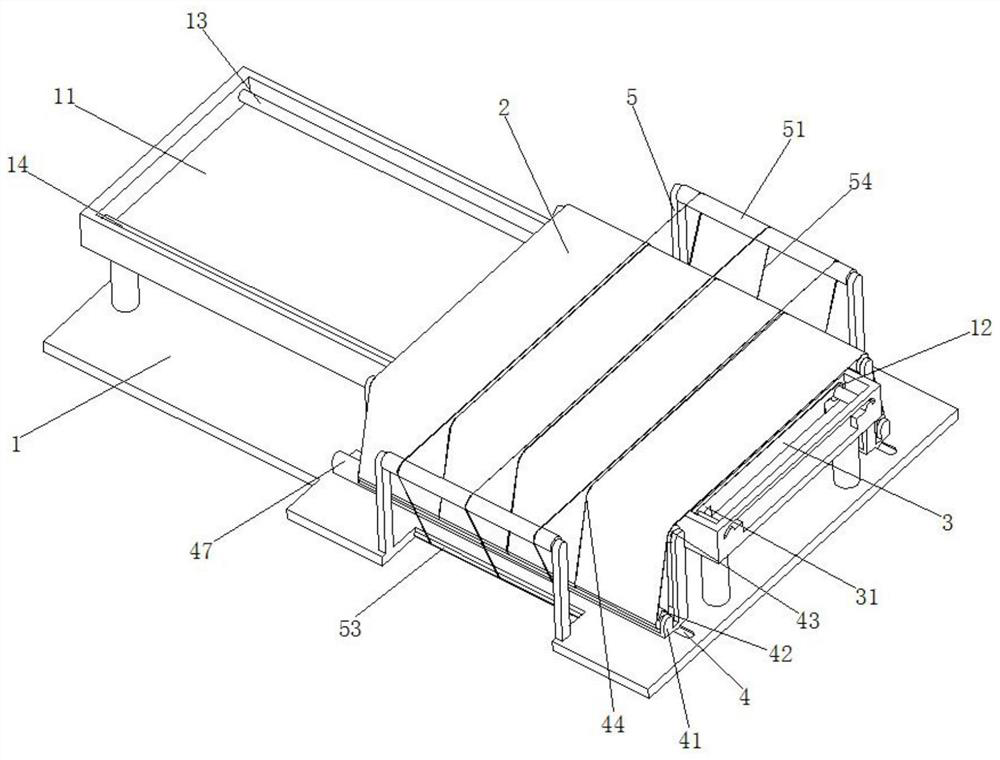

Copper-clad plate manufacturing process

ActiveCN112045430AAvoid deformationImprove yield rateOther manufacturing equipments/toolsPositioning apparatusEngineeringScrew thread

The invention relates to the field of plate manufacturing, in particular to a copper-clad plate manufacturing process. According to the copper-clad plate manufacturing process, a copper-clad plate manufacturing device is in use. The copper-clad plate manufacturing device comprises a machine tool, a polishing belt and a bracket. A movable trough is fixedly installed on the top of the machine tool,and insertion grooves of arc-shaped structures are symmetrically formed in the inner wall of the movable trough. A lead screw and a guide rod are inserted into the insertion grooves respectively, a first groove of a rectangular structure is formed in the movable trough, a pressing plate is arranged in the first groove, the bracket is of a rectangular structure, insertion blocks are symmetrically and fixedly installed on the two sides of the bracket, the sides, away from the bracket, of the insertion blocks are each of an arc-shaped structure, and the insertion blocks are correspondingly connected with the insertion grooves in an inserted mode. The bottom of each insertion block makes contact with the lead screw and the guide rod respectively, threads are formed in the side, making contactwith the lead screw, of the insertion block, and a second groove is formed in the bracket. With the copper-clad plate manufacturing process, a copper-clad plate can be prevented from deforming duringcutting, and meanwhile, burrs generated during cutting can be removed, and the copper-clad plate cutting process is suitable for promotion.

Owner:深圳可瑞高新材料股份有限公司

Pressing tool for assembling truck body

ActiveCN102744547BPrevent reboundMove up and down smoothlyWelding/cutting auxillary devicesAuxillary welding devicesJackscrewTruck

Owner:CRRC SHANDONG CO LTD

An edge trimming device for woolen woolen round carpets for textile use

ActiveCN113319905BAchieve the effect of automatic pushAchieve cutting effectTextile disintegration and recoveryMetal working apparatusStructural engineeringMechanical engineering

The invention relates to an edge trimming device, in particular to an edge trimming device for woolen woolen round carpets for weaving. The invention provides an automatic feeding, automatic cutting and automatic clamping device for cutting edges of woolen woolen round carpets for textile use. A device for trimming edges of woolen woolen round carpets for textile use, comprising: a bottom plate and first slide rails, both sides of the bottom plate are provided with first slide rails; a base, a base is provided on the bottom plate; a feeding mechanism, the bottom plate and the first A feeding mechanism is provided between the slide rails; a cutting mechanism is provided between the base and the bottom plate; a self-locking mechanism is provided between the cutting mechanism and the feeding mechanism. In the present invention, by starting the first cylinder, the first cylinder drives the first telescopic rod to move forward, the first spring is stretched, and when the carpet is moved below the cutting mechanism, the effect of automatic pushing is achieved.

Owner:河北亚奥纺织有限公司

A copper clad laminate manufacturing process

ActiveCN112045430BAvoid deformationImprove yield rateOther manufacturing equipments/toolsPositioning apparatusCopperScrew thread

The present invention relates to the field of sheet material manufacturing, in particular to a copper clad laminate manufacturing process, which uses a copper clad laminate manufacturing device, the copper clad laminate manufacturing device includes a machine tool, a grinding belt and a bracket, the top of the machine tool is fixedly installed with a moving slot, which moves The inner wall of the groove is symmetrically provided with arc-shaped slots, and the screw and the guide rod are respectively inserted in the slots. There is a No. 1 groove with a rectangular structure in the moving groove, and a pressure plate is arranged in the No. 1 groove. The bracket is a rectangular structure, and the two sides of the bracket are symmetrically fixed with plug-in blocks. The side of the plug-in block away from the bracket is an arc-shaped structure. They are respectively in contact with the lead screw and the guide rod, the side of the insert block in contact with the lead screw is provided with threads, and the bracket is provided with a No. 2 groove. The invention can avoid the deformation of the copper clad laminate during cutting, and can remove the burrs after cutting, and is suitable for popularization.

Owner:深圳可瑞高新材料股份有限公司

Thermoplastic polyurethane (TPU) film slitter guide roller mechanism

PendingCN112589880AThe effect of preventing offsetThe effect of preventing deviationMetal working apparatusArticle deliveryThermoplastic polyurethaneMechanical engineering

The invention relates to the technical field of slitter guide rollers, and discloses a thermoplastic polyurethane (TPU) film slitter guide roller mechanism. The TPU film slitter guide roller mechanismcomprises a machine body; the front portion of the machine body is rotatably connected with a feeding roller; the surface of the feeding roller is fixedly connected with a film roll body; the interior of the machine body is rotatably connected with a knife roller; an adjusting mechanism is arranged at the position, located behind the knife roller, of the machine body; the surface of the adjustingmechanism is provided with a guide mechanism; an upper take-up roller and a lower take-up roller are rotatably connected to the portion, located on the rear portion of the adjusting mechanism, of themachine body; and the upper take-up roller is located above the lower take-up roller. According to the TPU film splitter guide roller mechanism, by installing the adjusting mechanism and the guide mechanism, the effect of adjusting the tension degree of the guide roller is achieved through mutual operation of all structures in the adjusting mechanism and the guide mechanism, and meanwhile, the effect that split film bodies different in thickness can be pressed is achieved when the tension degree is adjusted, thereby achieving the effect of guiding the film bodies different in cutting width tobe conveyed.

Owner:浙江长鸿纺织科技有限公司

Press mounting method for generator stator core stretching screw

ActiveCN101908797BTo achieve the compaction effectGuaranteed pressureManufacturing stator/rotor bodiesEngineeringActual length

The invention relates to a press mounting method for a generator stator core stretching screw. The invention belongs to the technical field of hydraulic generators. The generator stator core laminations are pressed together by a stretching screw. The method comprises the following steps: (1) test press mounting of stretching screw: measuring the actual length of the stretching screw without pressurizing, carrying out test press on the stretching screw by using a stretching screw measuring sleeve, measuring the elongation of the stretching screw while pressurizing, and recording the pressure reference value; and (2) stretching quantity measurement and press mounting of stretching screw: measuring the initial distance between the lower end surface of the stretching screw and the upper planeof the lower measuring rib by using a stretching screw measuring tool, recording while prepressing and totally pressing, measuring the distance between the lower end surface of the stretching screw and the upper plane of the lower measuring rib when pressurizing to the pressure reference value, and measuring while pressurizing until the requirement is satisfied, thereby realizing press mounting. The invention has the advantages of simple technique, convenient operation, accurate and reliable data, favorable core press mounting effect and the like.

Owner:TIANJIN TIRNFR HEAVY HYDROELECTRIC FRCILITY CO LTD

Elongation measurement tool for stator iron core tension screw of hydraulic turbine generator

ActiveCN101949673BTo achieve the compaction effectGuaranteed pressureMechanical measuring arrangementsEngineeringDynamo

The invention relates to an elongation measurement tool for a stator iron core tension screw of hydraulic turbine generator, belonging to the technical field of hydraulic turbine generator and characterized in that: the elongation measurement tool for the tension screw is composed of a brace, an upper measurement rib, a lower measurement rib and a measurement dial indicator, wherein the brace is equipped with the upper and lower measurement ribs, and the lower measurement rib is provided with the measurement dial indicator. The elongation measurement tool according to the invention has the advantages of simple structure, convenient operation, low cost, good practicability, saving time and labor, accurate and reliable data, high press-mounting accuracy of iron core, good press-mounting effect, etc.

Owner:TIANJIN TIRNFR HEAVY HYDROELECTRIC FRCILITY CO LTD

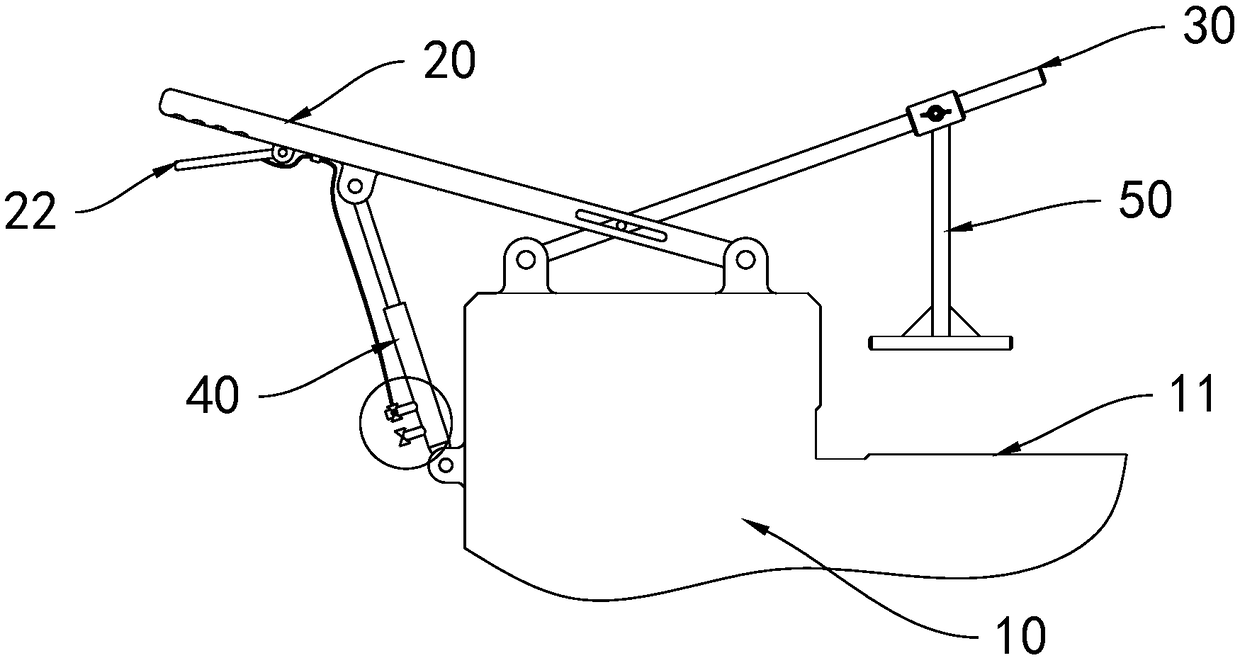

Labor-saving wooden door clamp

InactiveCN108724054ATo achieve the compaction effectTo achieve the purpose of lockingWork holdersExhaust valveInlet valve

The invention discloses a labor-saving wooden door clamp which comprises a base provided with a placement platform. An operation rod and a compression rod are hinged onto the base and crossly arranged, a sliding groove is formed in the operation rod, a sliding column sliding in the sliding groove is arranged on the compression rod, a piston rod is hinged between the operation rod and the base, a decompression handle is hinged onto the operation rod, a one-way exhaust valve and an automatic return air inlet valve are arranged on the piston rod, the automatic return air inlet valve is connectedwith the decompression handle through a brake cable, and a sliding compression plate sleeves the compression rod. The labor-saving wooden door clamp has the advantages of easiness in clamping, more labor-saving property and capability of effectively improving production efficiency. Besides, the labor-saving wooden door clamp is wide in applicable range.

Owner:湖州欧贝得门业有限公司

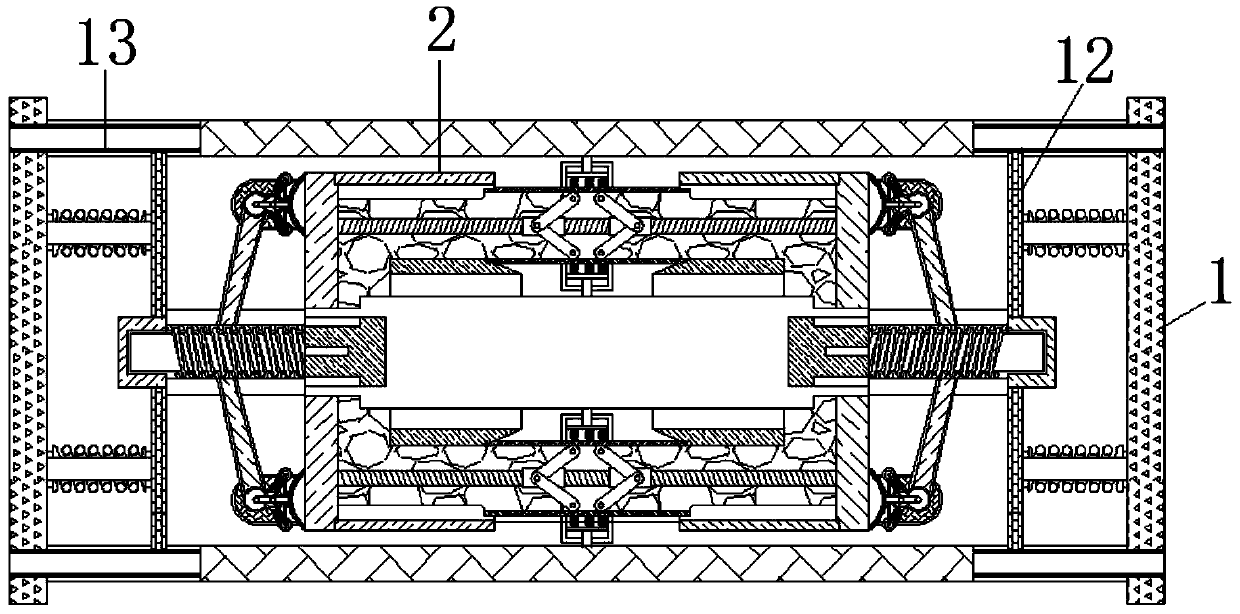

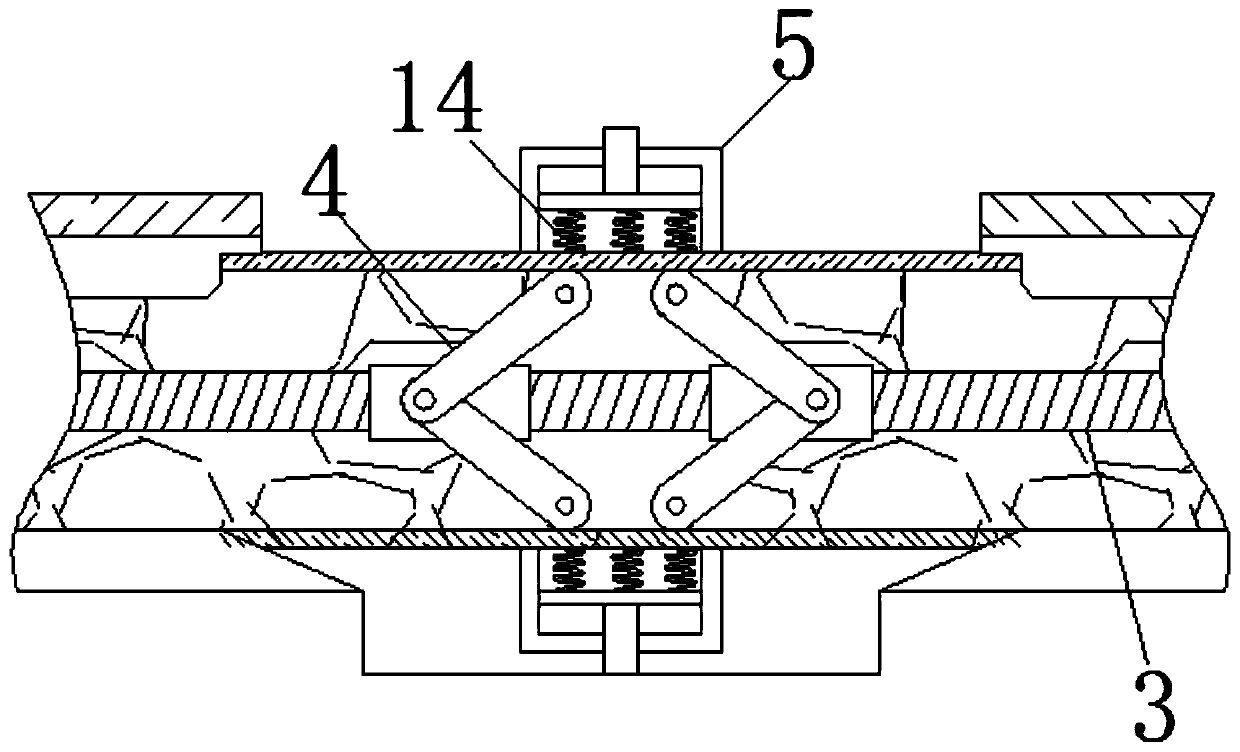

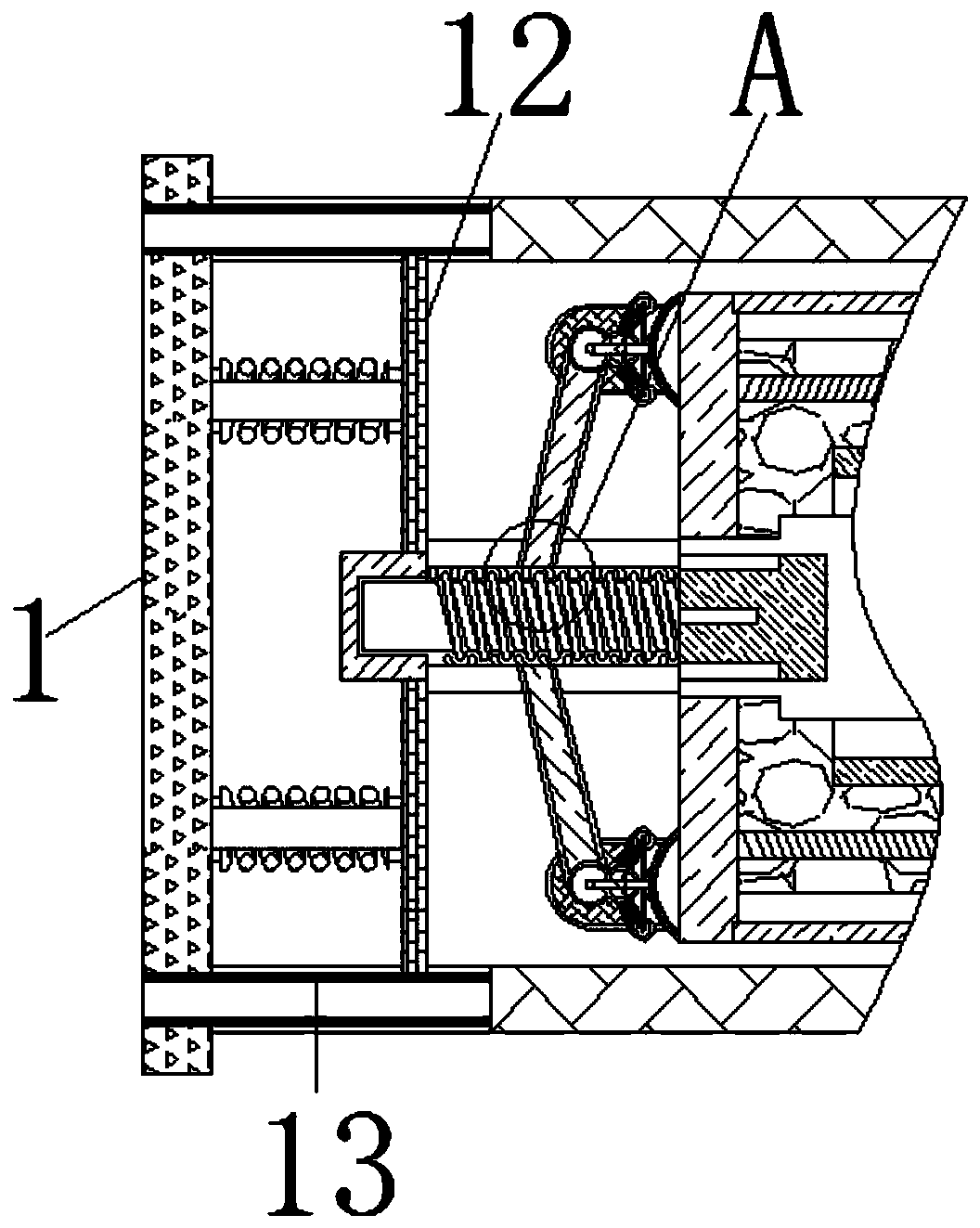

Size-adjustable convenient compact shelf

PendingCN113697273ASave human effortEasy access to itemsExternal fittingsInternal fittingsElectrical and Electronics engineeringReciprocating motion

The invention relates to a compact shelf, in particular to a size-adjustable convenient compact shelf. The invention provides the size-adjustable convenient compact shelf which is easy to take and can be moved and automatically clamped. The size-adjustable convenient compact shelf comprises a bottom plate, a mounting shell, a bearing plate frame, a pushing mechanism, a lifting mechanism and a moving mechanism, wherein the mounting shell is arranged on the upper side of the bottom plate; the bearing plate frame for placing articles is slidably arranged on the inner upper side of the mounting shell, and the pushing mechanism is arranged in the mounting shell; and the lifting mechanism is connected among the pushing mechanism, the bearing plate frame and the mounting shell, and the moving mechanism is connected between the mounting shell and the pushing mechanism. According to the compact shelf, through starting of an air cylinder, an air cylinder telescopic rod does reciprocating motion right and left to drive a connecting block to do reciprocating motion right and left, and the connecting block is moved leftwards to drive a rack to move leftwards; then, a straight gear is rotated, and therefore a rotating shaft is rotated; and the pushing effect is achieved, and manpower is saved.

Owner:JIANGXI EQUIP INDAL GROUP GREAT INSURANCENT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com