Press mounting method for generator stator core stretching screw

A technology of generator stator and tensioning screw, which is applied in the direction of manufacturing stator/rotor body, etc., can solve the problems of not ensuring the pressure between the iron core sheets, the tensioning screw cannot reach the stretching amount, and the frictional resistance is not considered. To achieve the effect of good pressing effect, accurate and reliable data, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

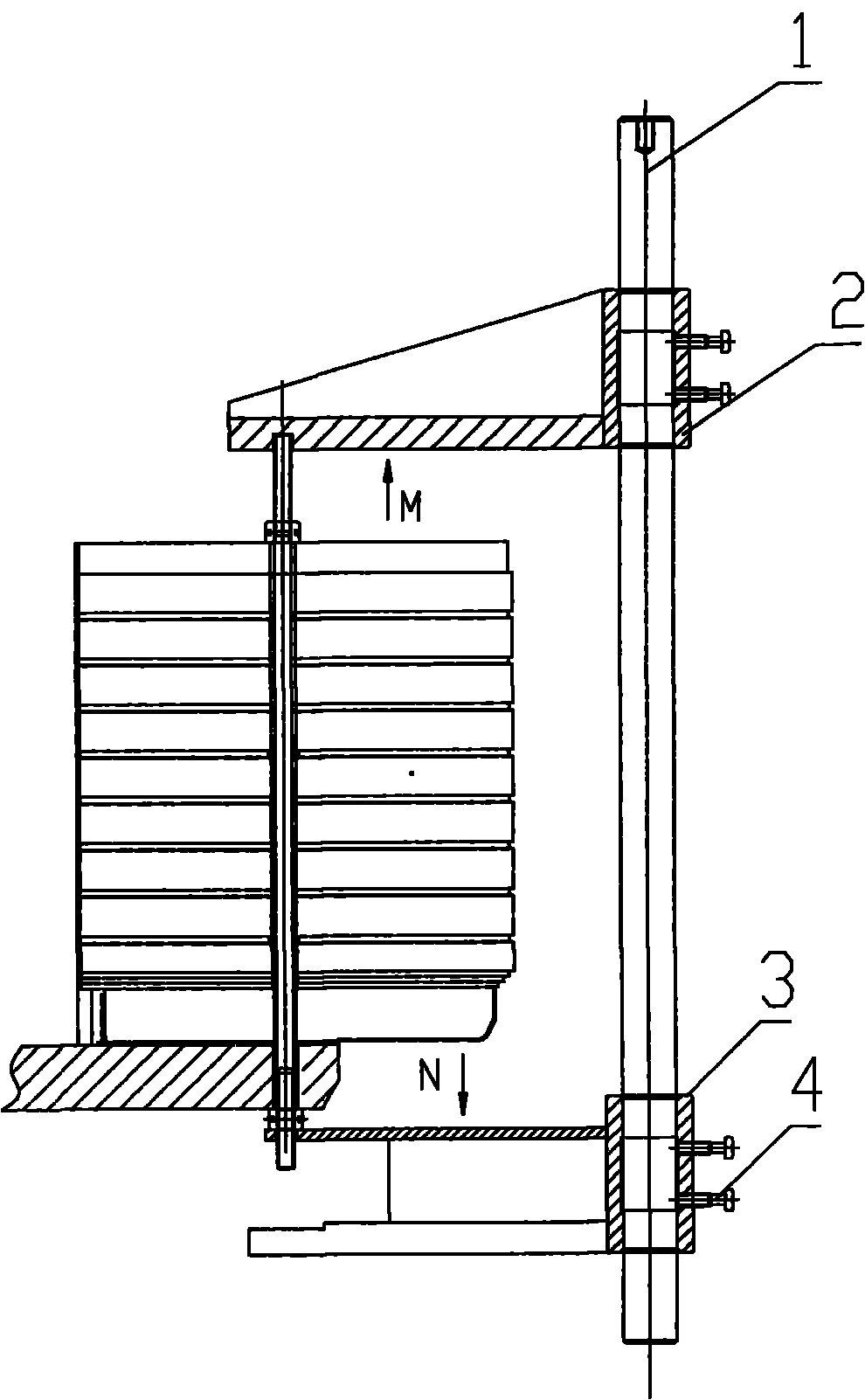

[0024] A generator stator core tensioning screw press-fitting method, the generator stator core punching pieces are press-fitted together by a tensioning screw, and the press-fitting process steps are:

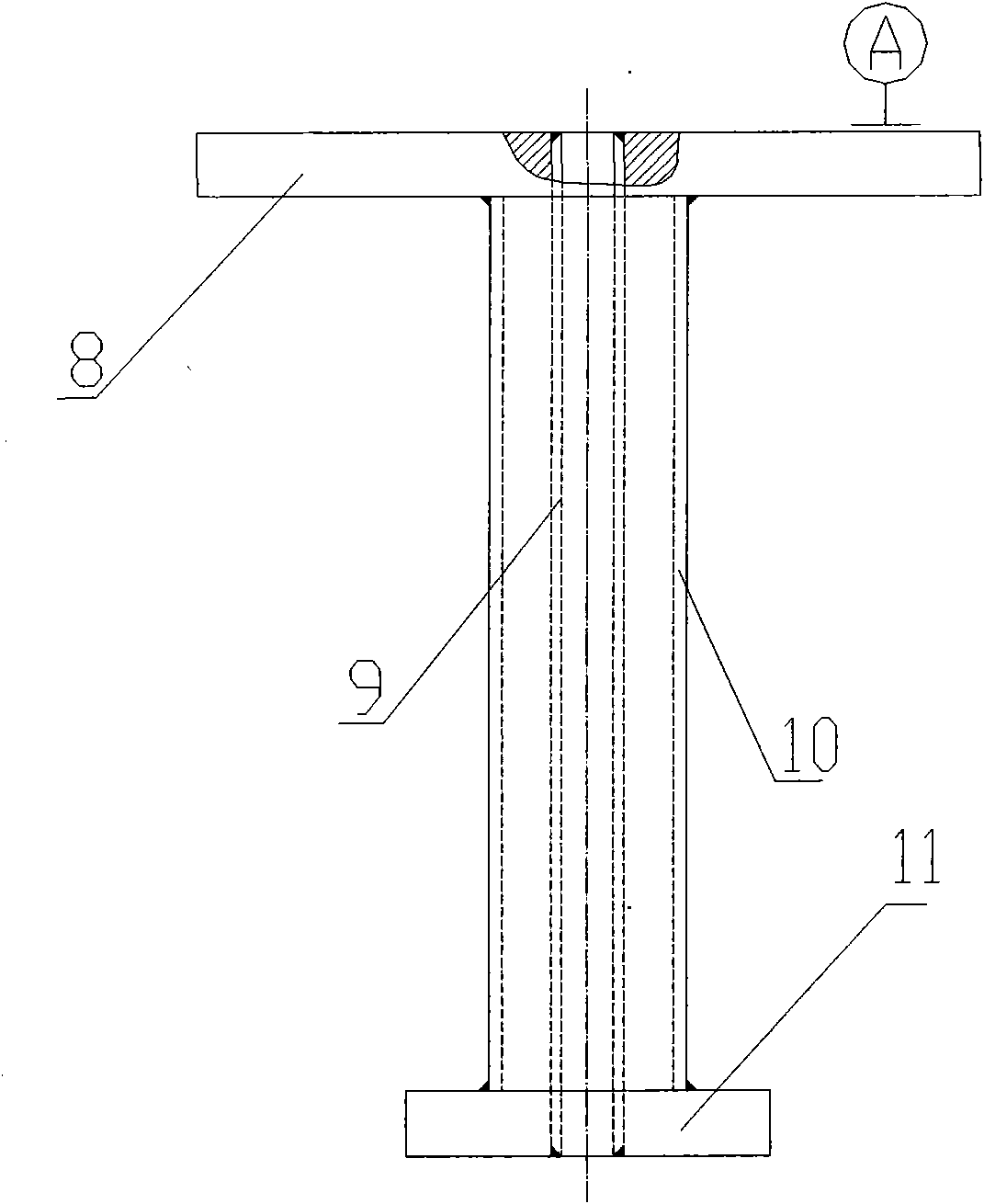

[0025] 1. Tension screw pressure test installation: measure the actual length of the tension screw without pressurization, and then use the tension screw measuring sleeve to perform pre-compression and total pressure test on the tension screw. The elongation of the stretching screw, when the elongation reaches the pre-compression value, record the pressure value of the hydraulic tensioner as the pressure reference value of the official pre-compression and total pressure;

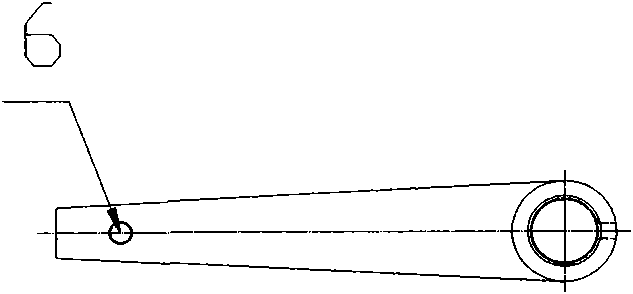

[0026] 2. Tension measurement and press-fitting of the tension screw: First, use the tension screw measuring tool to measure the original distance between the lower end surface of the tension screw and the upper plane of the lower measurement rib, keep and fix the relative position of the upper and lower meas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com