An edge trimming device for woolen woolen round carpets for textile use

A kind of circular and slubbed technology, which is applied in the field of edge trimming device of slubbed woolen rugs for textile use, and can solve the problems of reducing work efficiency and consuming manpower.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

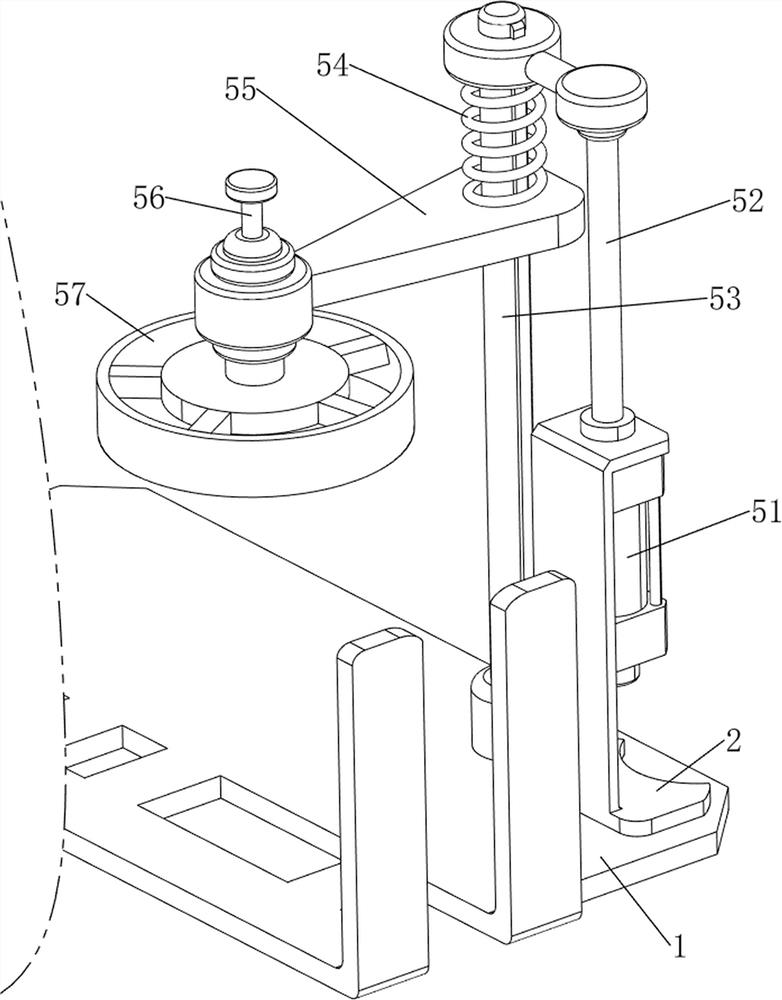

[0067] A device for trimming edges of woolen woolen round carpets for weaving, such as figure 1 As shown, it includes a base plate 1, a first slide rail 2, a base 3, a feeding mechanism 4, a cutting mechanism 5 and a self-locking mechanism 6. The left and right sides of the base plate 1 are provided with the first slide rails 2, and the upper right part of the base plate 1 There is a base 3 on the front side, a feeding mechanism 4 is set between the bottom plate 1 and the first slide rail 2, a cutting mechanism 5 is set between the base 3 and the bottom plate 1, and a self-locking mechanism is set between the cutting mechanism 5 and the feeding mechanism 4 6.

[0068] When people need to cut the edge of the carpet, they can use this kind of slub cloth type round carpet edge trimming device for weaving. First, people put the carpet on the feeding mechanism 4, and then people start the feeding mechanism 4, and the feeding mechanism 4 drives the carpet to move. Below the cutting...

Embodiment 2

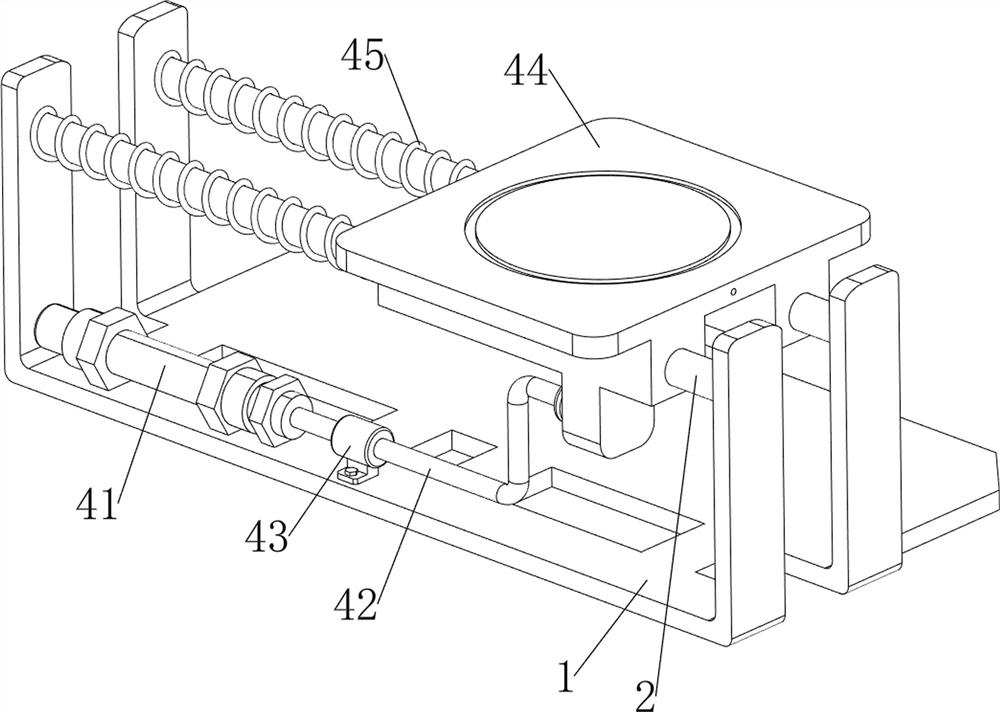

[0070] On the basis of Example 1, such as Figure 2-4 As shown, the feeding mechanism 4 includes a first cylinder 41, a first telescopic rod 42, a sliding sleeve 43, a feeding table 44 and a first spring 45, and the first cylinder 41 is installed on the rear side of the upper left part of the base plate 1. A sliding sleeve 43 is provided on the side, and a first telescopic rod 42 is connected to the first cylinder 41. The first telescopic rod 42 is slidably connected to the sliding sleeve 43, and a feeding platform 44 is slidingly provided between the two first slide rails 2. A first spring 45 is connected between the left and right sides of the feeding table 44 and the bottom plate 1 , and the first spring 45 is wound on the first slide rail 2 .

[0071] People put the carpet on the feed table 44, and then people start the first cylinder 41, the first cylinder 41 drives the first telescopic rod 42 to move forward, and the first telescopic rod 42 moves forward to drive the feed ...

Embodiment 3

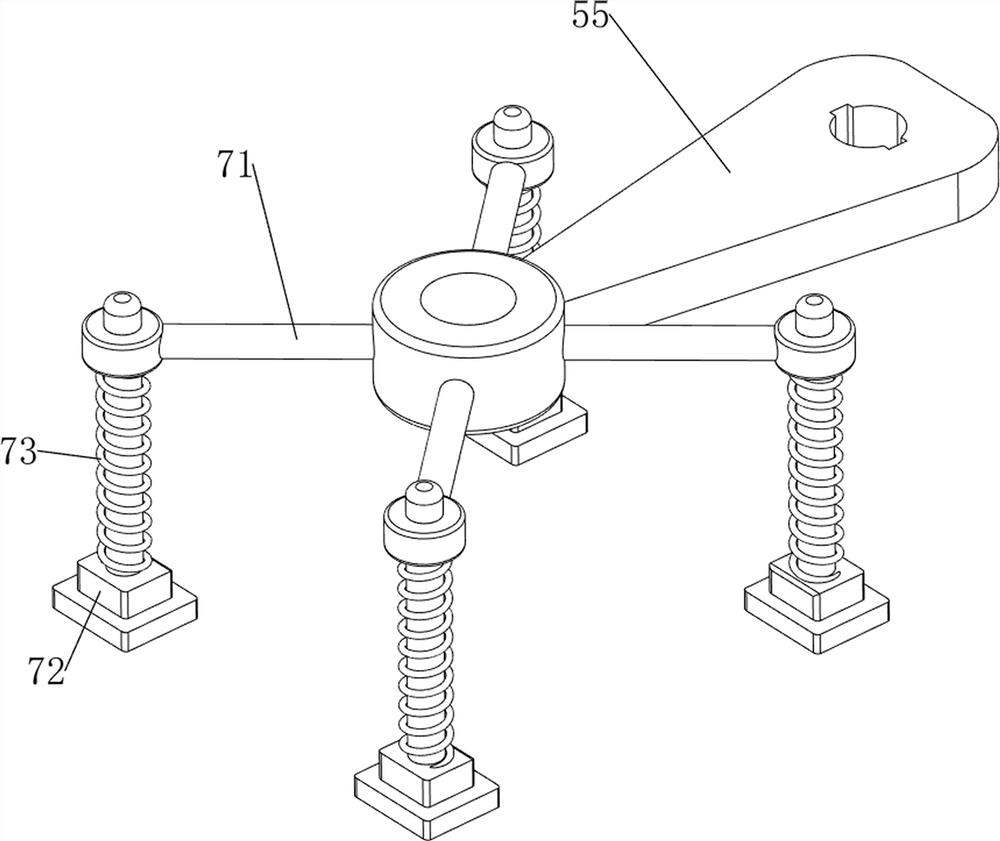

[0077] On the basis of Example 2, such as Figure 5-7 Shown, also include hold-down mechanism 7, hold-down mechanism 7 includes the 3rd bracket 71, pressing block 72 and the 5th spring 73, slide block 55 is evenly provided with four 3rd brackets 71, on the 3rd bracket 71 The sliding type is provided with a pressing block 72 , a fifth spring 73 is connected between the pressing block 72 and the third support 71 , and the fifth spring 73 is wound on the pressing block 72 .

[0078] Slide block 55 moves down and drives third bracket 71 and briquetting block 72 to move down, and when briquetting block 72 touches carpet, slide block 55 drives cutter 57 to continue to move down, and third bracket 71 moves down, thereby makes The fifth spring 73 is compressed to achieve a pressing effect. After the cutting is completed, the slider 55 moves upward to drive the third support 71 and the pressure block 72 to move upward, and the fifth spring 73 drives the pressure block 72 to reset.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com