Pressing tool for assembling truck body

A car body and wagon technology, applied in the field of railway wagons, can solve the problems of easy damage to the motor of the electric pressing device, easy fire, production cost, inconvenient operation, etc., and achieve the effect of low production cost, simple structure, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

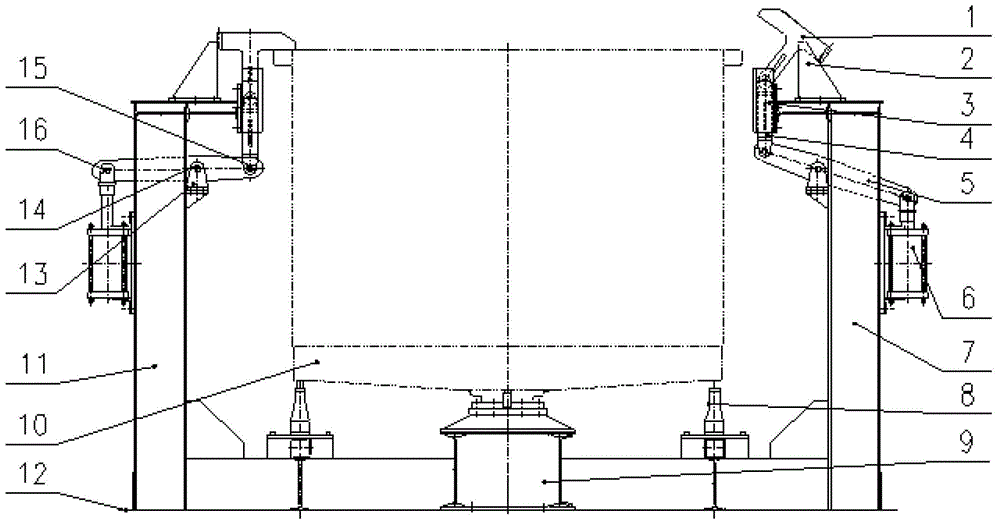

[0039] The present invention will be further described below in conjunction with accompanying drawings and examples.

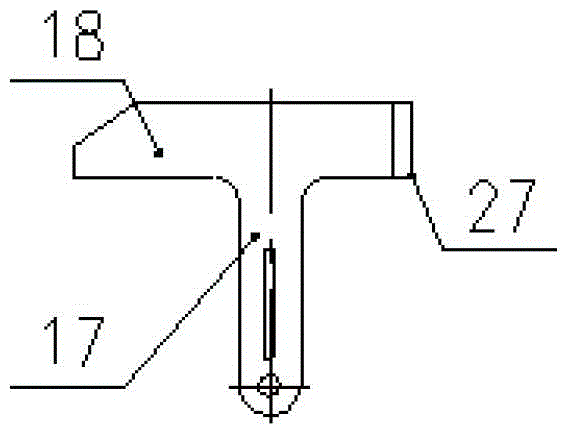

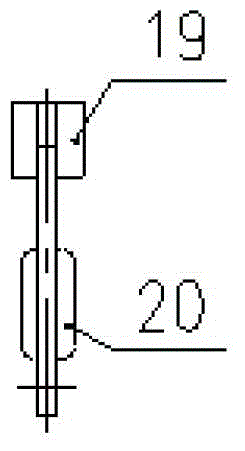

[0040] A compression tooling for truck body assembly, combined with Figure 1 to Figure 9 , including a column device 7, a pressing hook 1, a jack device 8, a workpiece positioning device 9, the column device 7 includes columns 11 and a base on both sides, the column 11 is connected to the base, and the top of the column 11 is provided with an anti-rebound device 2, The upper end of the inner side of the column 11 is provided with a guide device 3, the inner side of the column 11 is provided with an ear seat 13, the outer side of the column 11 is provided with a cylinder seat plate, and the cylinder seat plate is provided with a cylinder 6; the inner side of the guide device 3 is provided with a connecting device 4 matching it, The upper end of the connecting device 4 is hingedly connected with the pressing hook 1; the ear seat 13 is provided with a matching p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com