Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

36results about How to "Tied tightly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

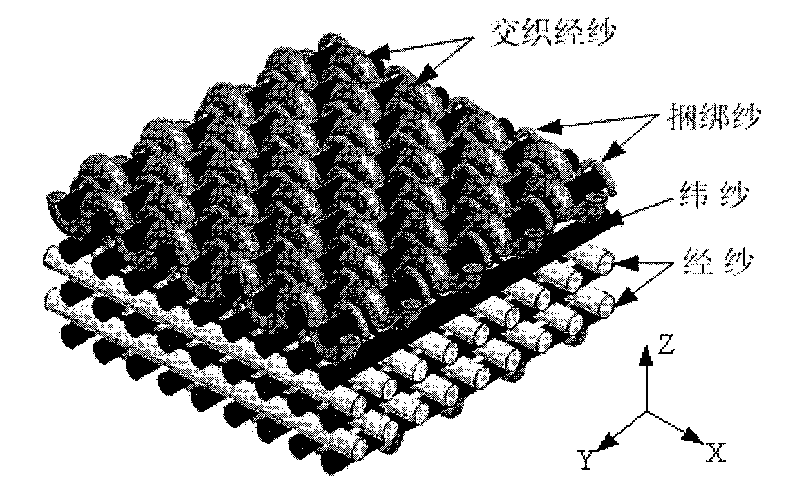

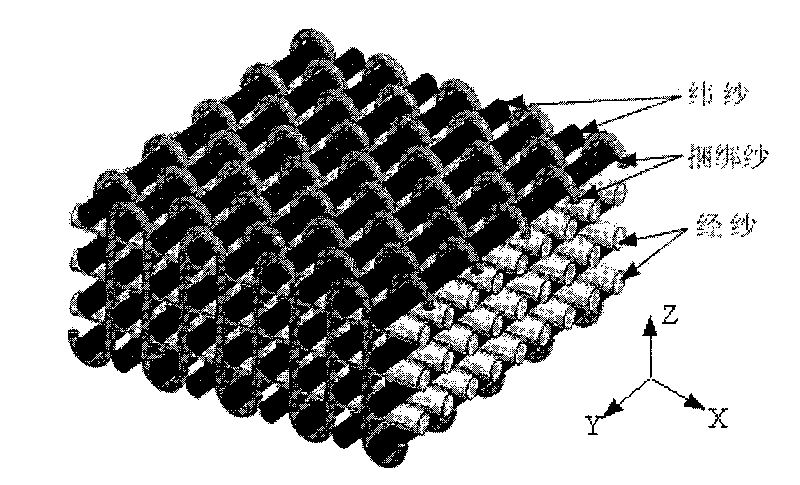

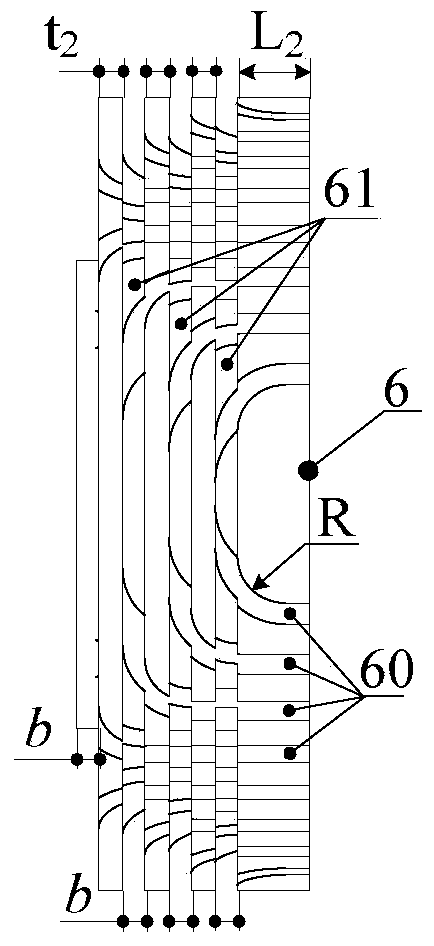

Manufacturing method for three-dimensional textile having orthogonal structure and plain weave structure

InactiveCN101718020AExpand the scope of applicationCompact structureLayered productsWoven fabricsPlain weaveEngineering

The inventions relates to a manufacturing method for three-dimensional textile having orthogonal structure and plain weave structure, comprising the steps of threading the odd yarns in the longitude yarns through a harness wire hole of one harness frame, threading even yarns through a harness wire hole of another harness frame, interweaving the two harness frames up and down in order to acquire the plain weave structure, respectively threading the odd yarns and the even yarns of binding yarns through a harness wire hole of another two harness frames, interweaving the two harness frames up and down in order to acquire the orthogonal structure of the longitude and latitude yarns of the orthogonal structure layer of the three-dimensional textile, and then integrating the longitude and latitude yarns of the plain weave structure and the yarns of the orthogonal structure layer via vertical binding yarns in order to acquire the three-dimensional textile having orthogonal structure and plain weave structure. The method of the invention is simple and is fit for commercial process. The acquired textile has excellent integrality and interlayer cutting property, meeting the demand for the embedding form of intelligent fiber.

Owner:DONGHUA UNIV

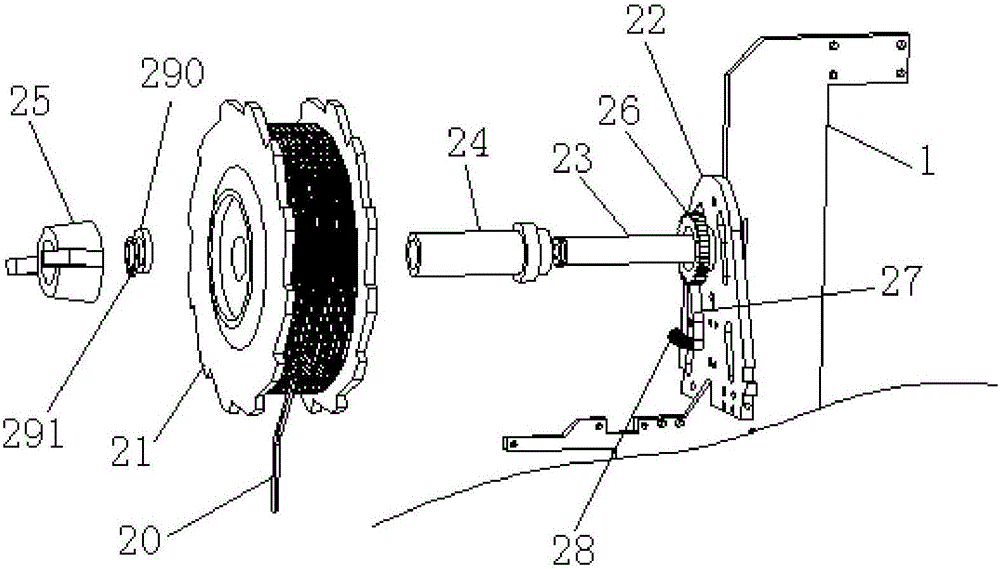

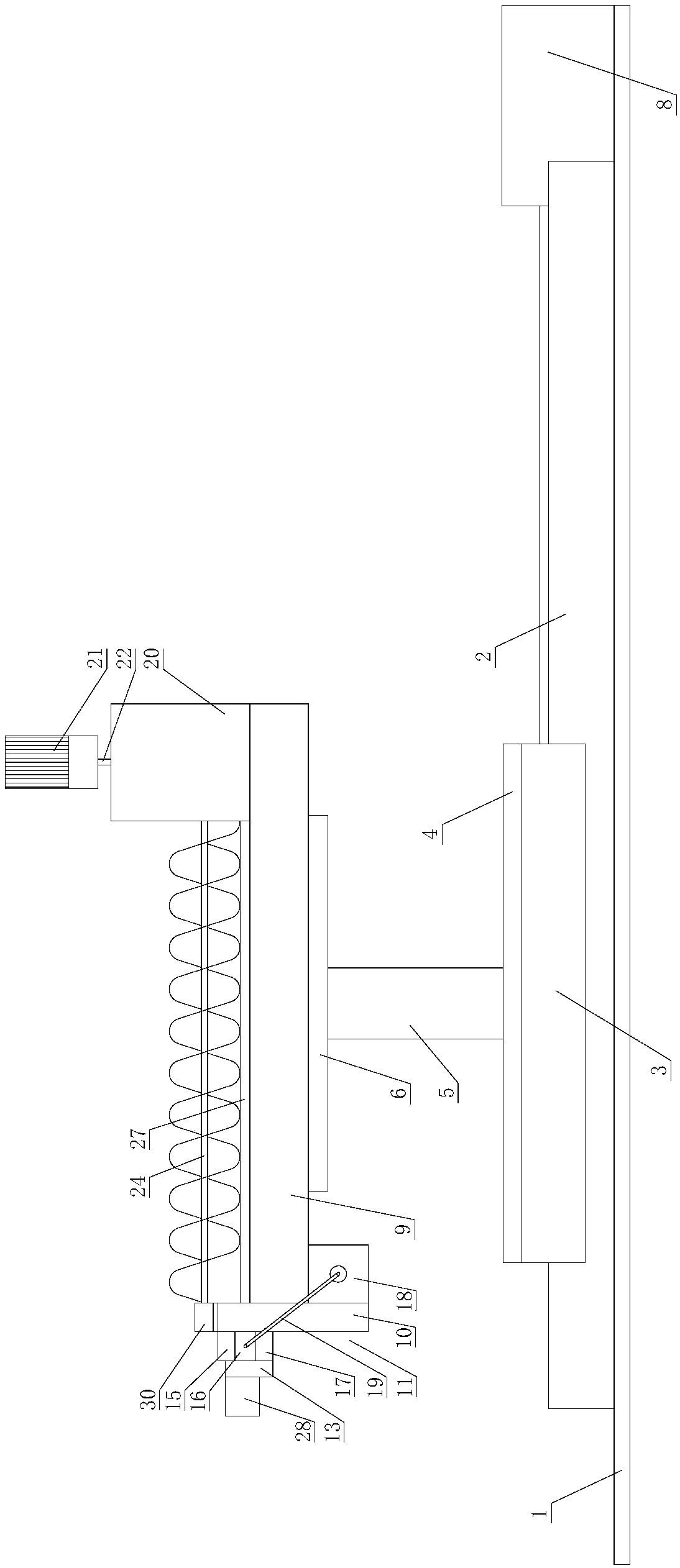

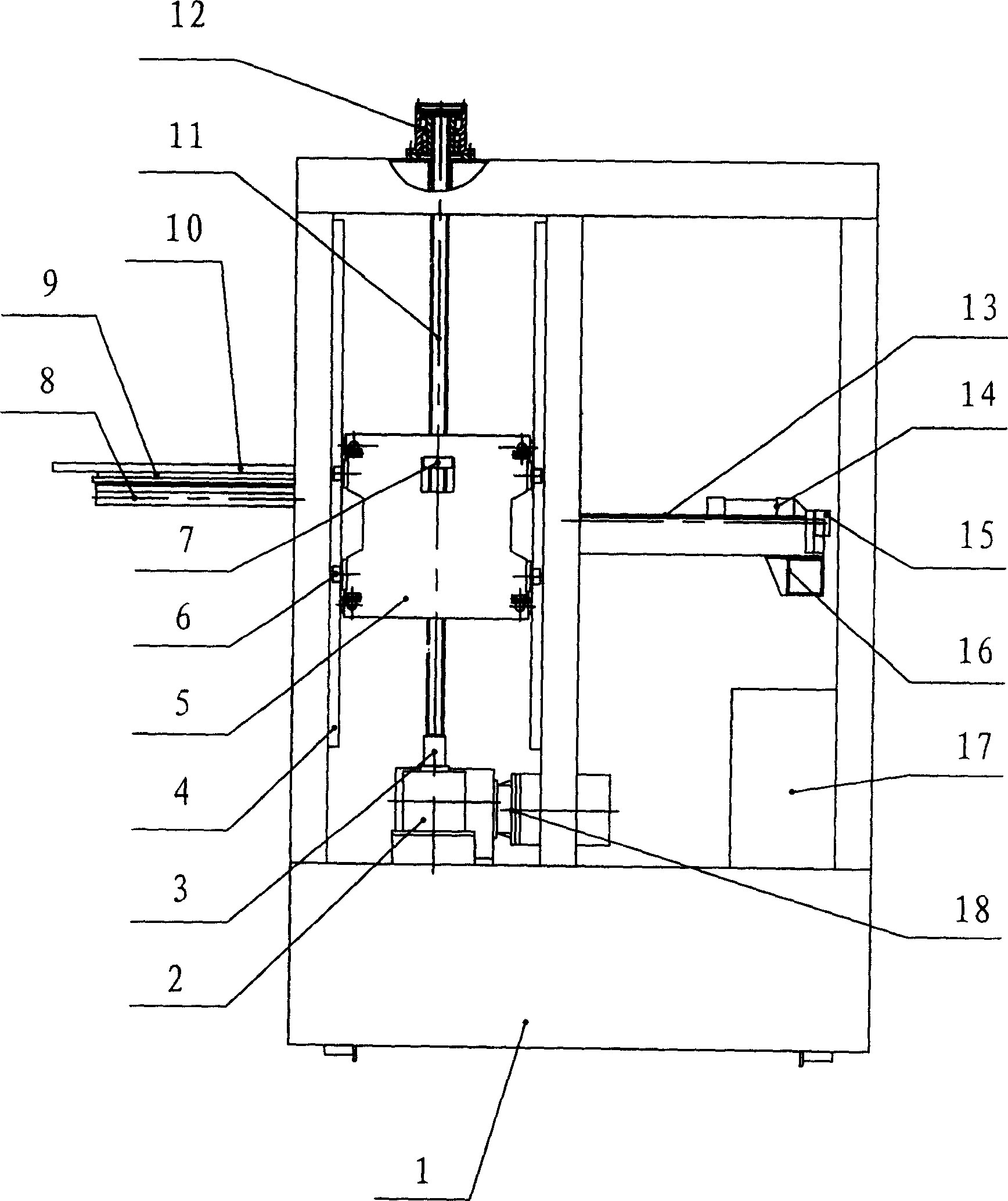

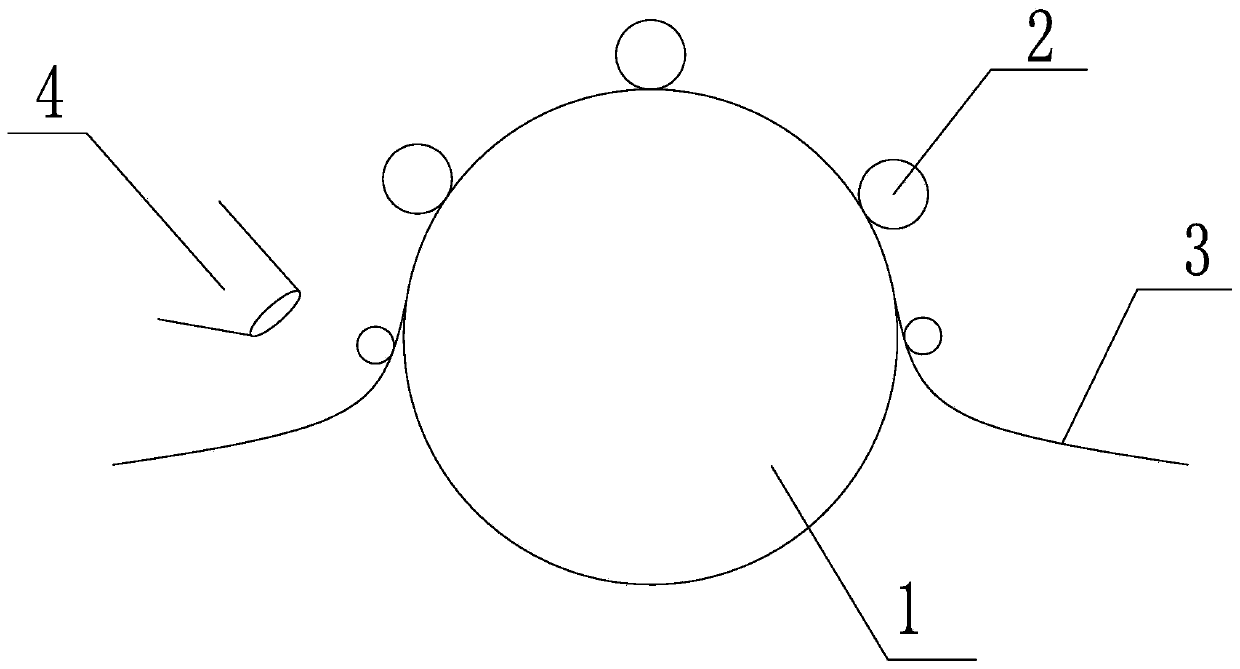

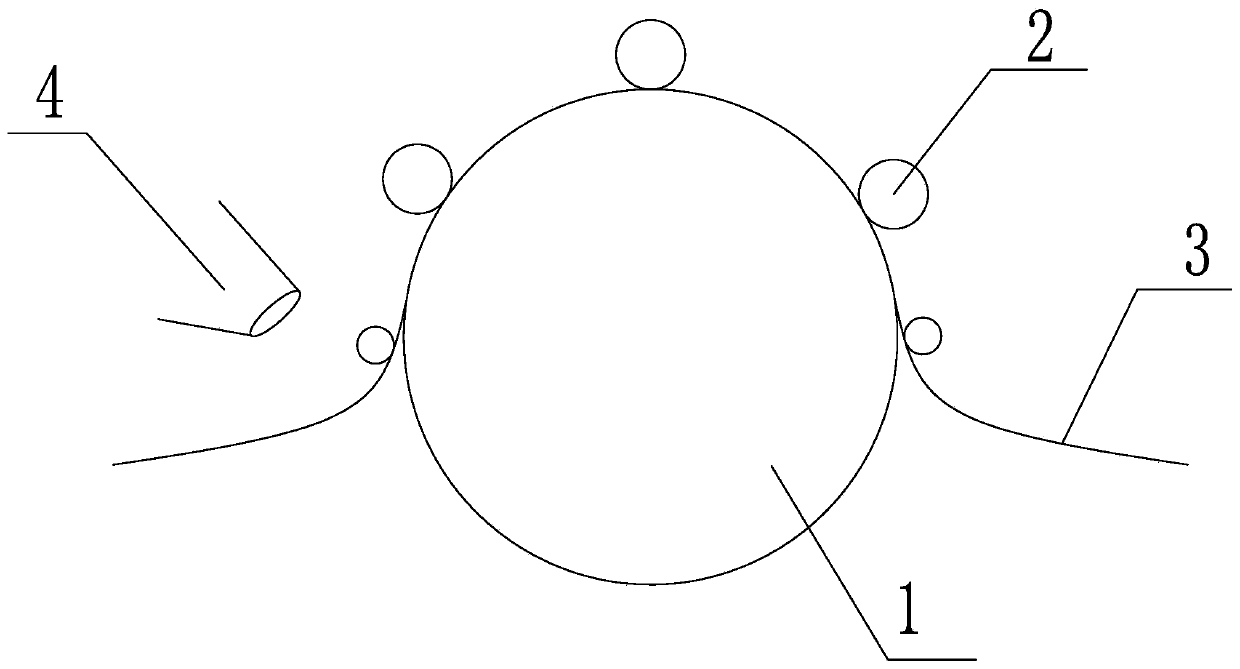

Automatic reinforcing steel bar binding machine

The invention discloses an automatic reinforcing steel bar binding machine. The automatic reinforcing steel bar binding machine comprises a machine frame, a wire binding disc mechanism, a power mechanism, a wire conveying mechanism, a wire cutting mechanism, a jaw and guiding mechanism, a wire bending mechanism and a wire twisting mechanism, wherein the wire binding disc mechanism, the power mechanism, the wire conveying mechanism, the wire cutting mechanism, the jaw and guiding mechanism, the wire bending mechanism and the wire twisting mechanism are arranged on the machine frame; and the seven mechanisms are deployed reasonably, and on the one hand, operation such as wire conveying, wire cutting, wire bending and wire twisting can be achieved rapidly and continuously through one hand, the working efficiency is greatly improved, even untrained workers can easily and proficiently operate, labor cost is reduced, and one the other hand, binding is tight to achieve the effect of manual binding. In addition, the automatic reinforcing steel bar binding machine is small and exquisite, portable, flexible, low in cost, high in adaptability, free from charging, waterproof, adaptable to severe environment and easy to promote and popularize.

Owner:李振飞

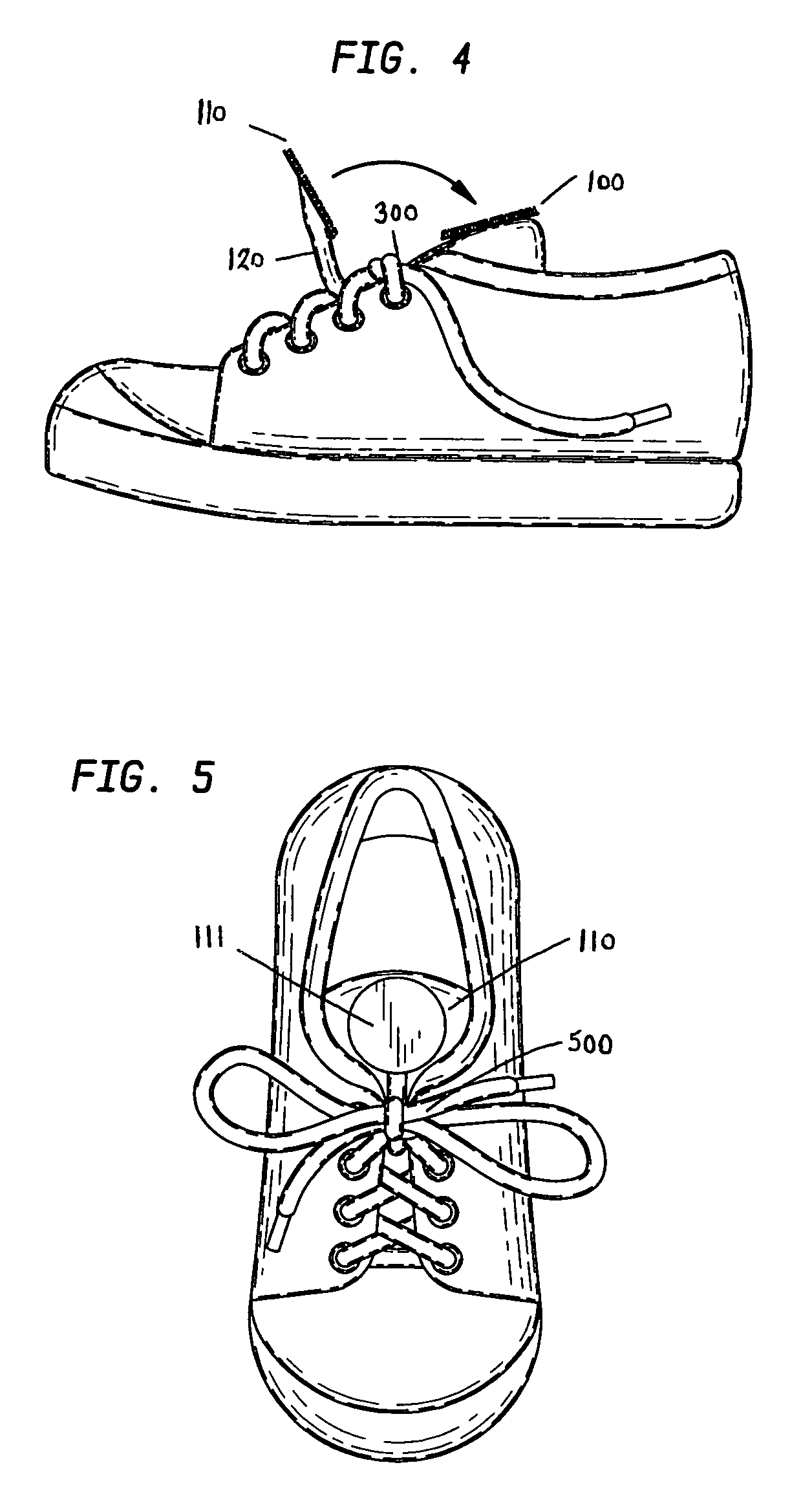

Shoelace knot assisting device

The present invention is a device for assisting users in tying their shoelaces properly. The device will help users tie bow-type knots by securing the initial crossover knot in place while the complete bow-type knot is being tied. The device can be used by children learning how to tie shoelace knots or by any person who is having difficulty tying shoelaces.

Owner:BURNS JAMES +1

Carton packaging machine

PendingCN106742211ATied tightlyEasy to transportPaper article packagingBundling machine detailsCartonEngineering

The invention relates to the technical field of packaging equipment, in particular to a carton packaging machine. The carton packaging machine comprises a machine body. A first operating platform and a second operating platform are fixedly installed on the machine body, and a certain distance is reserved between the first operating platform and the second operating platform. Protection covers are arranged at the two sides of the second operating platform. The top ends of the protection covers are connected through a horizontal baffle. A driving device is installed at the rear end of the second operating platform. A pressing plate is installed above the top of the second operating platform. The driving device is controlled by a foot switch connected with the driving device. The pressing plate is driven by a pair of air cylinders installed at the bottom of the horizontal baffle. A conveying belt and a sliding chute connected with the conveying belt are arranged at the right side of the first operating platform. A positioning block is arranged at the side, close to the driving device, of the surface of the second operating platform. The carton packaging machine is easy and convenient to operate, and the effect that packaged cartons are tightly bundled without being loosened can be guaranteed; and the packaged cartons are moved and transported through the conveying belt and then are discharged through the sliding chute, the labor intensity can be effectively relieved, and working efficiency is improved.

Owner:山东叶华纸制品包装有限公司

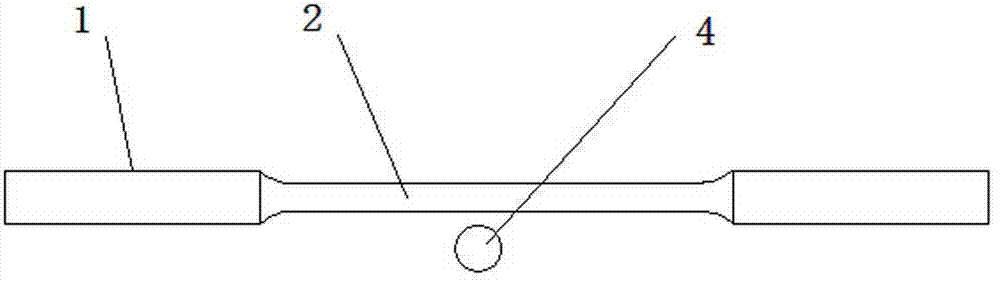

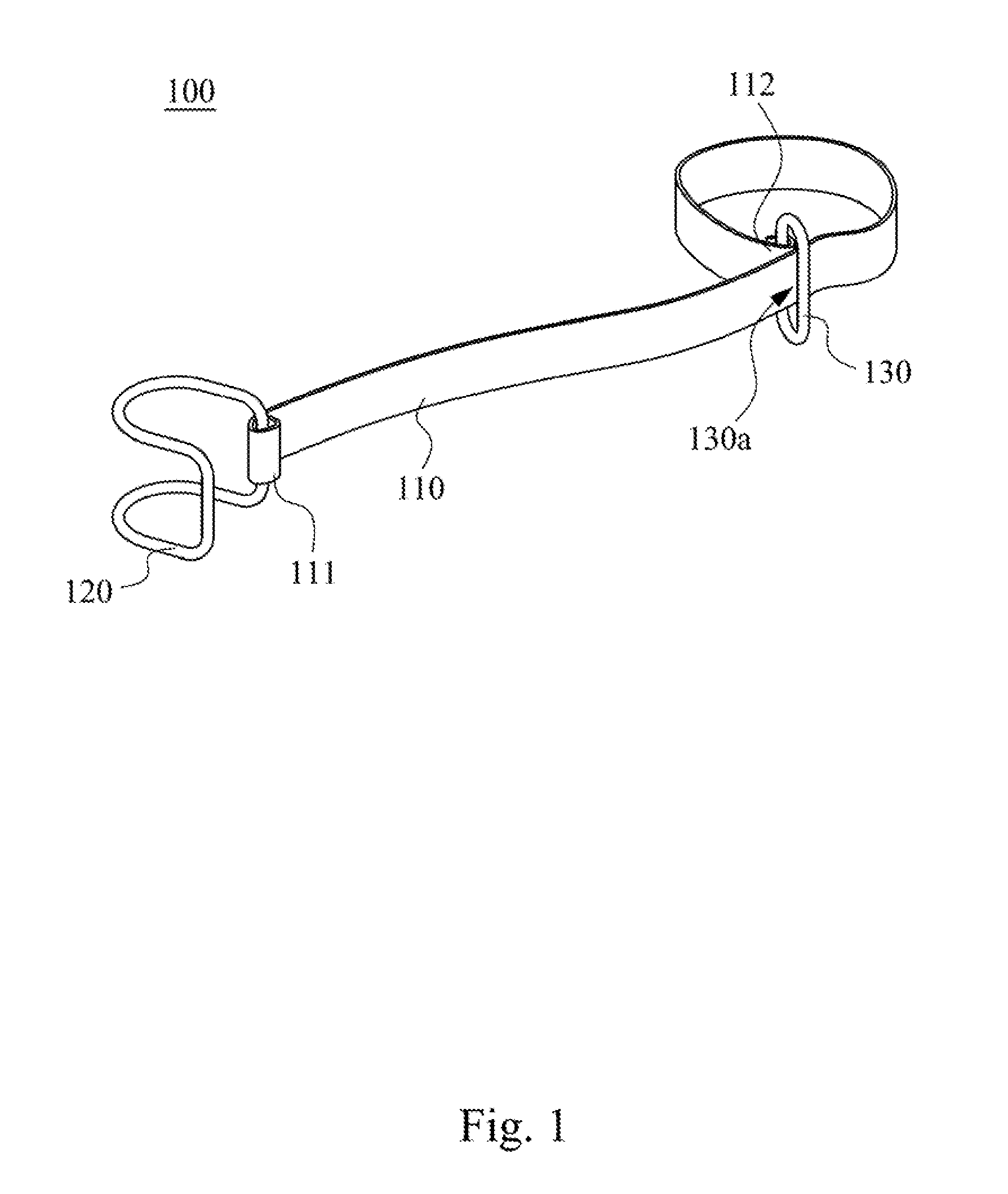

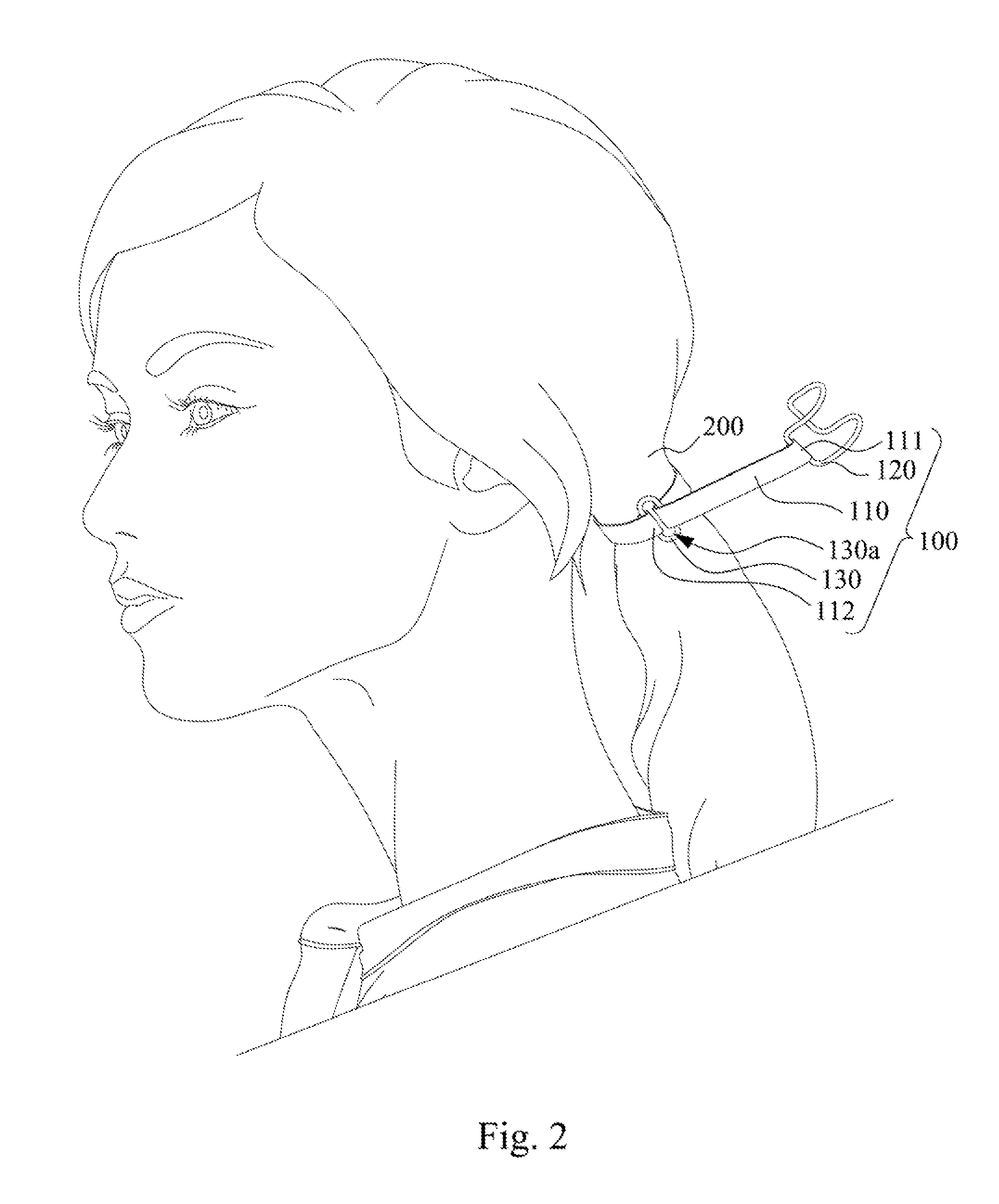

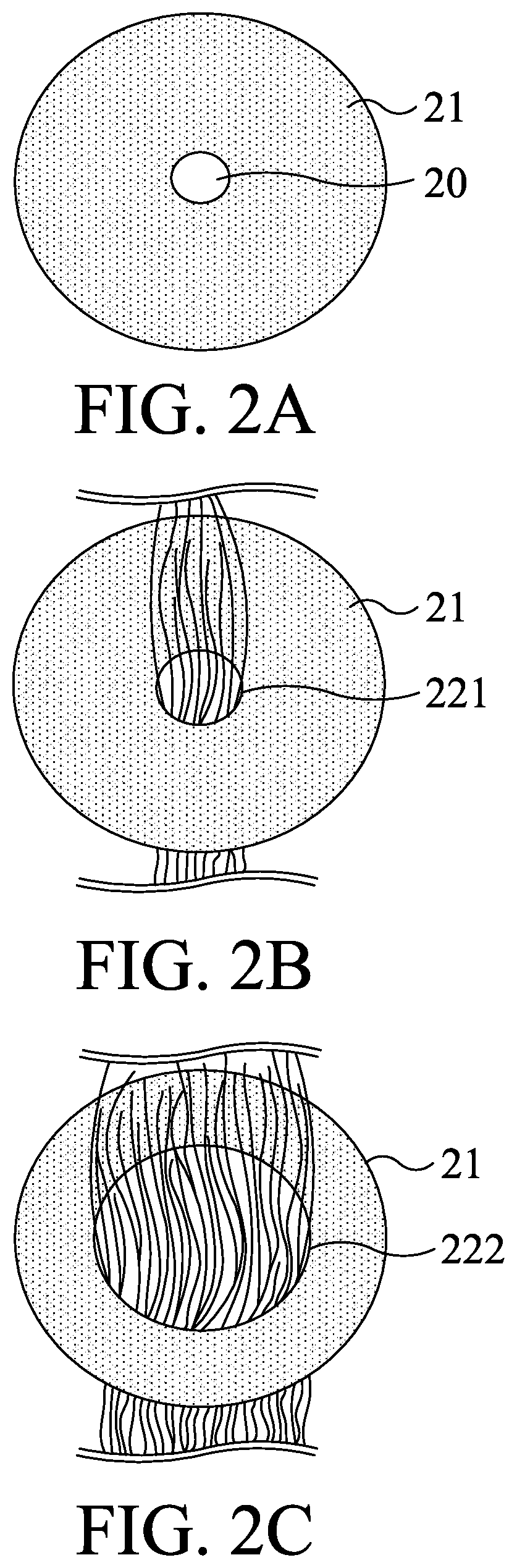

Linear hair tie

InactiveUS20200315309A1Easy to operateTied tightlyCurling devicesTravelling articlesEngineeringStructural engineering

A hair tie includes a main body, which has a first elastic body for winding around a hair bundle, and a soft material member covering the first elastic body to be in contact with the wound hair bundle. The first elastic body has a first free end and a second free end, and the hair tie further includes first and second coupling members disposed at the first and second free ends of the first elastic body, respectively, and engageable with each other to secure the winding of the first elastic body around the hair bundle.

Owner:CHANG STEPHANIE +1

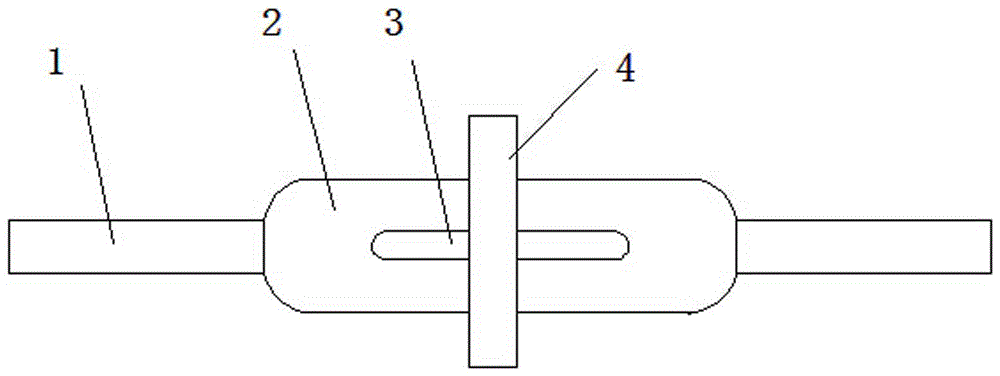

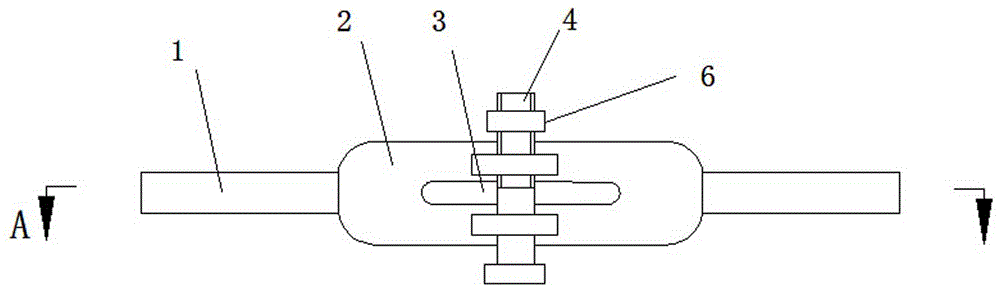

Stay wire binding tool

The invention discloses a stay wire binding tool, and relates to the technical field of electric transmission line construction. The stay wire binding tool comprises a strip-shaped plate, a long hole is formed in the middle of the strip-shaped plate, and handles are arranged at the two ends of the strip-shaped plate in the length direction. A guide column used for changing the direction of an iron wire in the stay wire binding process is further included. The stay wire binding tool is simple in structure and convenient to use, time and labor are saved, the iron wire can be bound on the stay wire fast, accurately and densely, the work efficiency of stay wire binding is greatly improved, and labor intensity is reduced. Meanwhile, the zinc coating of the stay wire cannot be damaged, and operating personnel cannot be hurt.

Owner:STATE GRID CORP OF CHINA +2

Shoelace knot assisting device

The present invention is a device for assisting users in tying their shoelaces properly. The device will help users tie bow-type knots by securing the initial crossover knot in place while the complete bow-type knot is being tied. The device can be used by children learning how to tie shoelace knots or by any person who is having difficulty tying shoelaces.

Owner:BURNS JAMES +1

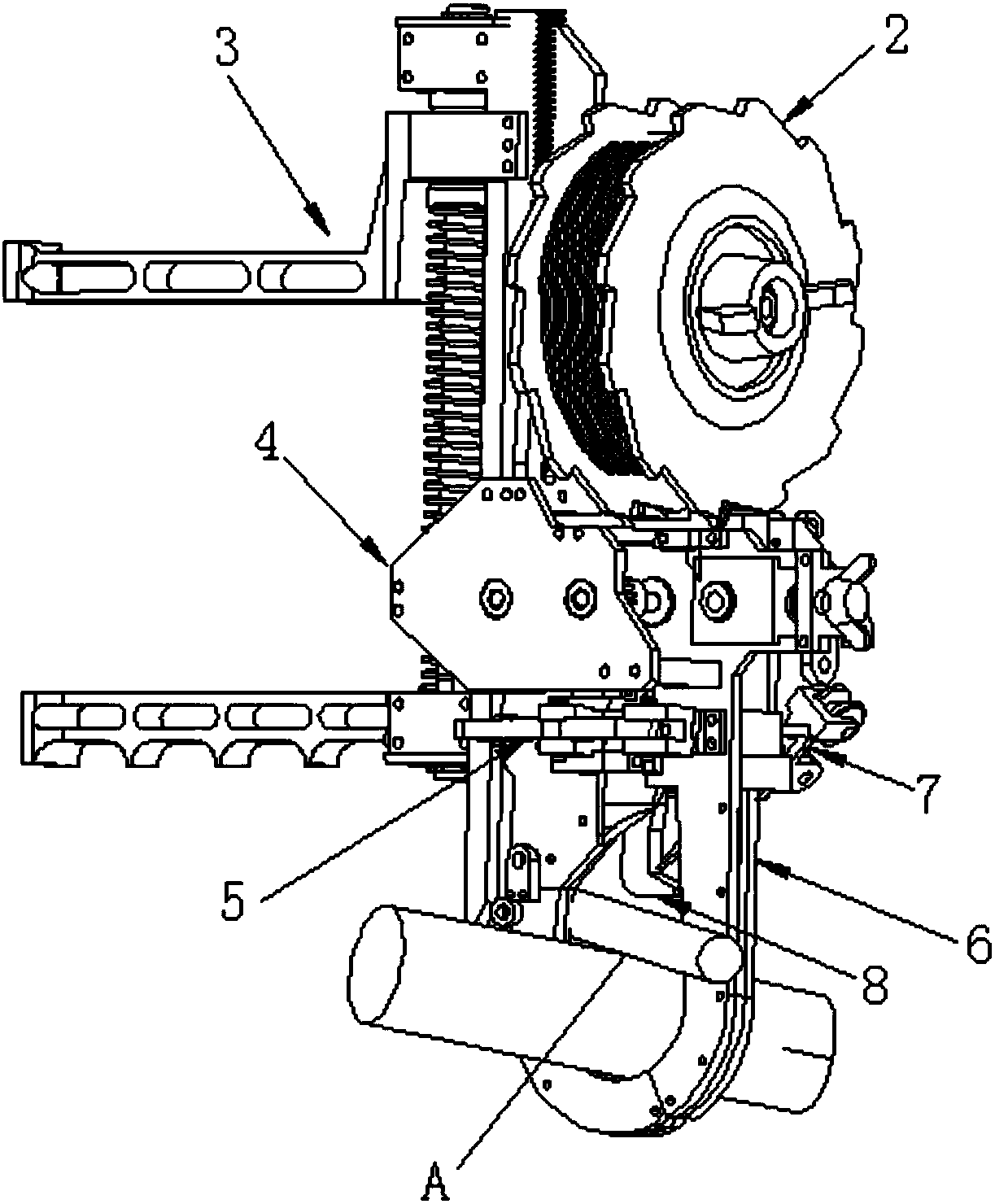

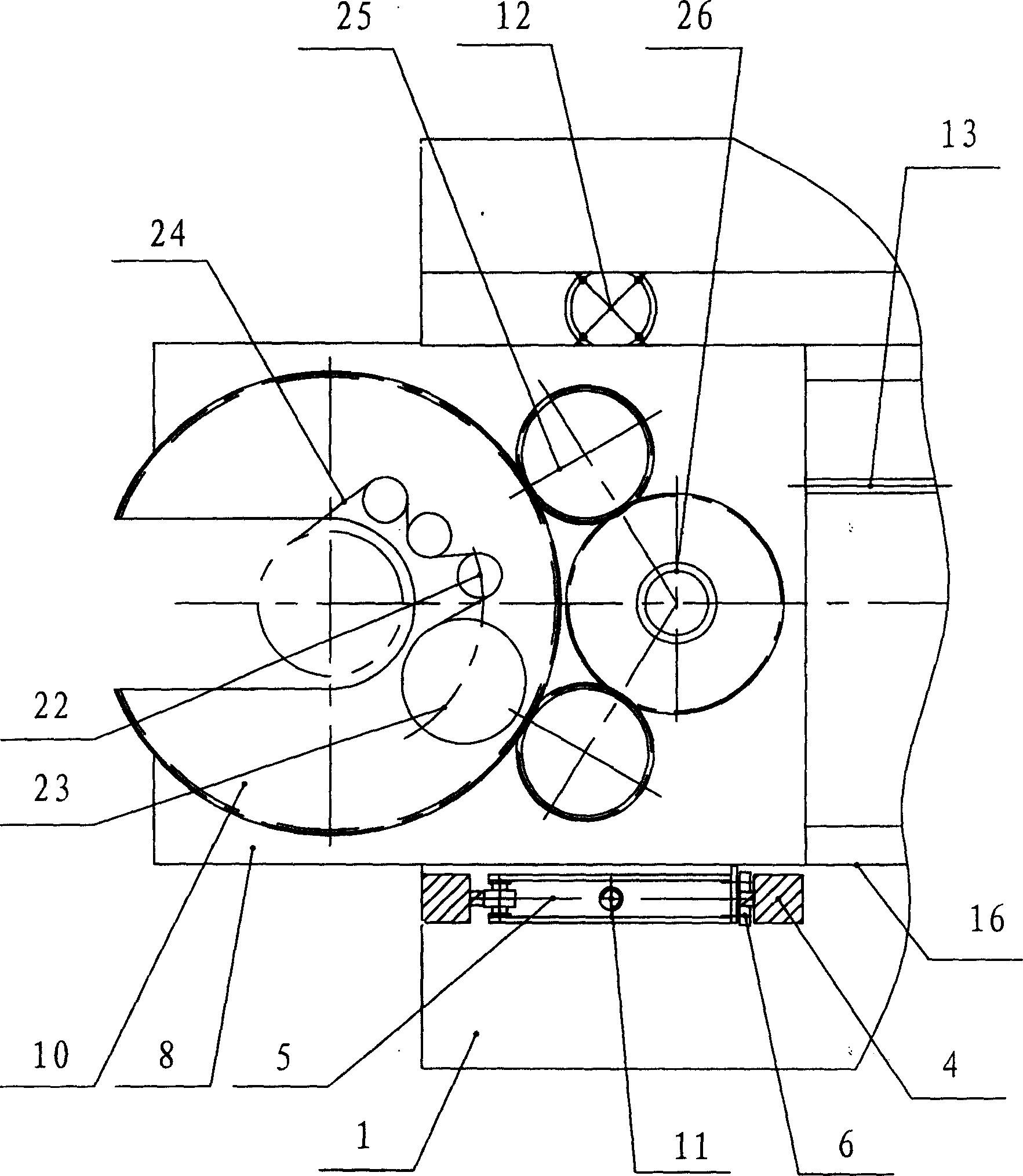

Automatic tightening and cut-off device and method for cable tie

PendingCN108438296AConsistent tightnessQuality Stable SpecificationsBundling machine detailsMachine partsDrive shaft

The invention belongs to the field of cable tie automatic tightening and cutting-off devices, and particularly relates to an automatic tightening and cutting-off device and method for a cable tie. Theautomatic tightening and cutting-off device for the cable tie comprises a base part and a main machine part, wherein the base part comprises a bottom plate, two linear guide rails are arranged on thebottom plate in parallel, and a first inlet for allowing the cable tie to pass through is formed in the vertical plate; an upper gasket, a cutting-off knife and a lower gasket are sequentially arranged between a top buckle length fixing block and the vertical plate from top to bottom, and a cut-off air cylinder is arranged at the joint of a transverse plate and the vertical plate; and the cut-offair cylinder is connected with the cutting-off knife through a cutting-off connecting rod, a servo motor is arranged on the top of a motor support, and a bevel gear B meshed with a bevel gear A is arranged at one end of a driven shaft. The automatic tightening and cutting-off device and the method for the cable tie is characterized in that the tightening degree is consistent, the quality is guaranteed, manual cutting is not needed, time and labor are saved, the labor intensity is reduced, so that the production efficiency is improved.

Owner:李昕宇

Preparation method of woven carpet without gumming process

ActiveCN108411460AEnhanced shape retention and dimensional stabilityOmit the adhesive processHeating/cooling textile fabricsWoven fabricsCopolyesterWeft yarn

The invention discloses a preparation method of a woven carpet without a gumming process. A second coating layer is a hot-melt fiber-formed filament or a staple fibre yarn, a first coating layer is apolyester fiber filament or a staple fibre yarn, the second coating layer accounts for 20%-50% of the total mass of a composite yarn, the first coating layer accounts for 10%-15% of the total mass ofthe composite yarn, the balance is a core yarn, and a pile weft yarn is obtained by adopting the manner. When the non-adhesive carpet is produced by using a hot-melt copolyester fiber as a bonding material in combination with the pile yarn made of a polyester fiber, the melting occurs when the hot-melt copolyester fiber is heated to be higher than the melting point in a hot pressing process, the conformation of a fiber macromolecular chain is changed, the whole macromolecular chain slips through the transition of chain segments, viscous flow occurs, the pile and weft yarns as well as the weftyarns and warp yarns are effectively solidified after curing, and the pull strength of the pile and the shape retention and dimensional stability of the carpet are enhanced, so that the gumming process in the carpet preparation process is omitted, and the produced carpet is more environmentally friendly.

Owner:QINGDAO UNIV

Automatic Rebar Binding Machine

The invention discloses an automatic reinforcing steel bar binding machine. The automatic reinforcing steel bar binding machine comprises a machine frame, a wire binding disc mechanism, a power mechanism, a wire conveying mechanism, a wire cutting mechanism, a jaw and guiding mechanism, a wire bending mechanism and a wire twisting mechanism, wherein the wire binding disc mechanism, the power mechanism, the wire conveying mechanism, the wire cutting mechanism, the jaw and guiding mechanism, the wire bending mechanism and the wire twisting mechanism are arranged on the machine frame; and the seven mechanisms are deployed reasonably, and on the one hand, operation such as wire conveying, wire cutting, wire bending and wire twisting can be achieved rapidly and continuously through one hand, the working efficiency is greatly improved, even untrained workers can easily and proficiently operate, labor cost is reduced, and one the other hand, binding is tight to achieve the effect of manual binding. In addition, the automatic reinforcing steel bar binding machine is small and exquisite, portable, flexible, low in cost, high in adaptability, free from charging, waterproof, adaptable to severe environment and easy to promote and popularize.

Owner:李振飞

Pocket mouth opening supporting device

The invention relates to a pocket mouth opening supporting device, and belongs to living goods. The device is composed of a supporting plate, a bearing, a pin, a supporting plate lock and the like. According to the pocket mouth opening supporting device, the supporting plate is driven to expand outward through the elastic action of the bearing, opening supporting of the pocket mouth are achieved, accordingly, troubles of opening supporting of bag type packaging and trivial bundling and fastening are completely solved. The pocket mouth opening supporting device has the advantages of being simple in structure, easy to achieve, low in cost, high in quality and high is practicability, and the device is a necessity for home life.

Owner:刘相冬

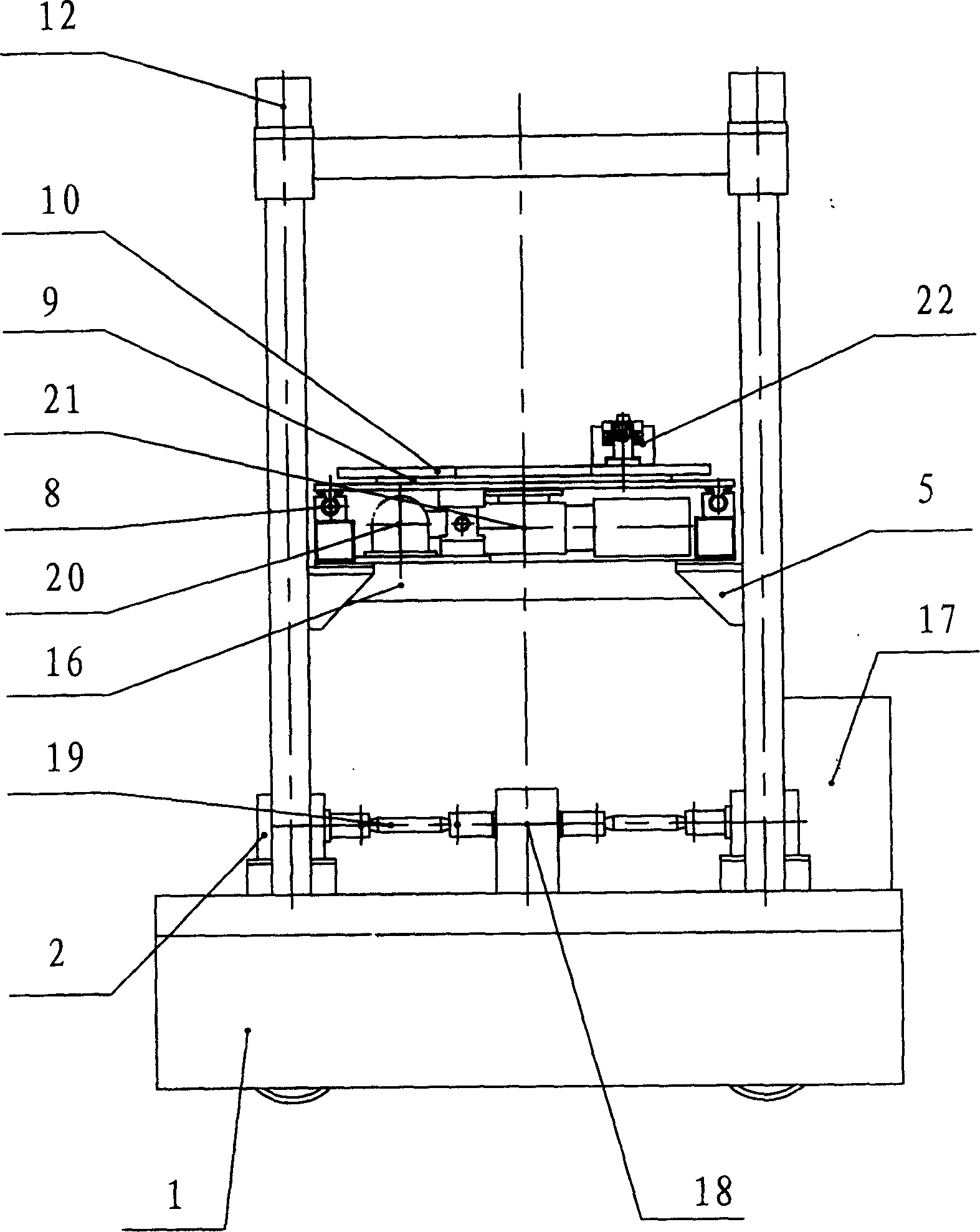

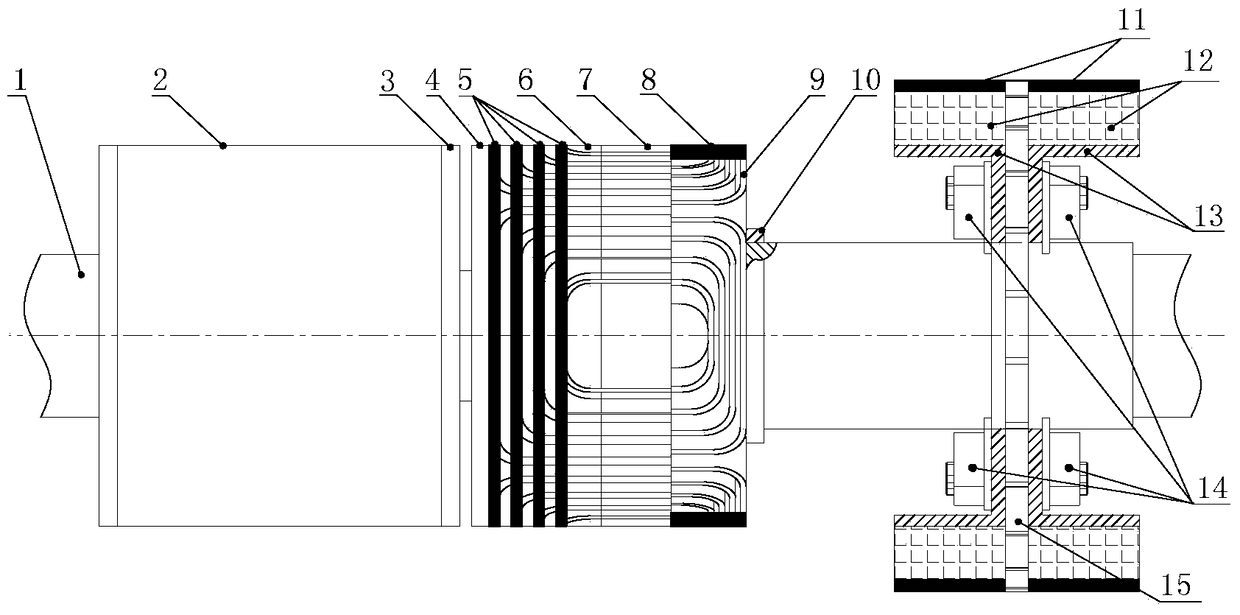

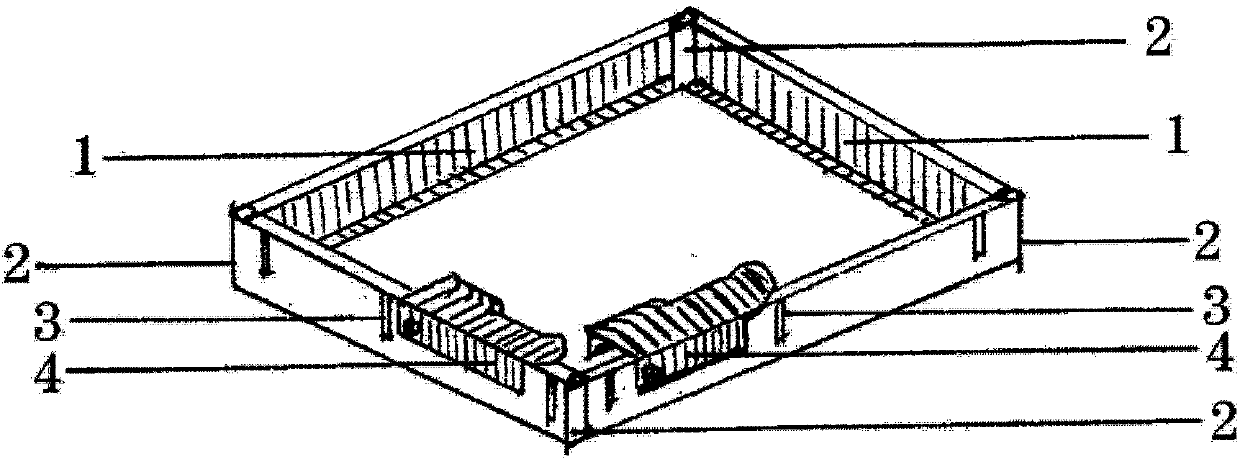

Transformer iron core adhesive band vertical bundling machine

InactiveCN1235244CContinuous windingWind evenlyInductances/transformers/magnets manufactureAdhesive beltTransformer

The machine includes frame, rising and falling transmission mechanism, winding gear and drive unit installed on the frame. Sliding supporter of the rising and falling transmission mechanism through nut on screw is installed between guide rails of frame, moving along rails to and fro. Bottom end of each screw is connected to output shaft of orthogonal reducer driven by drive unit. Movable bracket is connected between two sliding supporters. Tray of winding gear through nut on screw is installed on slide way of movable bracket. Driving gear on the tray through idle pulley drives winding gear. The invention possesses features of reasonable structure, small oscillation noise, and continuous stable seizing operation, even tight adhesive tape enwinding, labor saving and material saving.

Owner:陈星

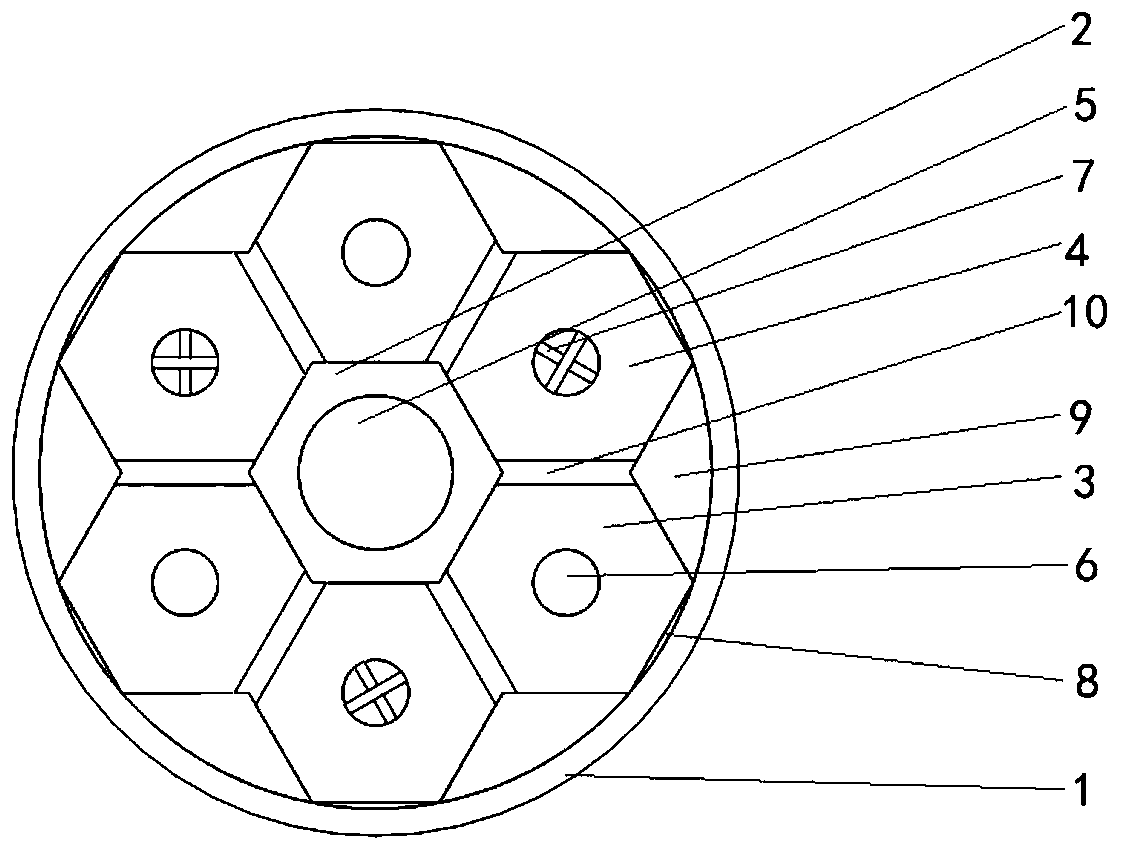

A safe tensile cable

InactiveCN109102925AHigh tensile strengthImprove securityInsulated cablesInsulated conductorsInsulation layerCopper wire

A safe tensile cable includes an insulating sleeve. A hexagonal central tube is arranged at the center of the insulating sleeve, the six sides of the central tube are adjacent to cable ducts and wireducts, and the centers of the center tube, the cable ducts and the wire ducts are provided with through holes. An aluminum wire is arranged in the through hole of the central tube, copper wire strandsare arranged in the through holes of the cable ducts, and the through holes of the wire tube are provided with tension ropes; the space between the central tube, the cable ducts and the wire ducts and the insulating sleeve is provided with a buffer layer, the space among the cable ducts, the wire ducts and the insulating layer is provided with a heat insulating layer, a support layer is arrangedbetween the adjacent cable ducts and the wire ducts. The center tube and the cable ducts and the wire tducts adjacent to the center tube are arranged, the tensile strength of the cable is improved bythe tension rope, the cable can be tightly bound on the cylinder and the like by the aluminum wire, and the safety of the cable can be improved by the heat insulation layer, and the cable ducts are isolated by the wire ducts, thereby avoiding the mutual transfer of heat and the excessive temperature of the cable.

Owner:蔡德林

Strap structure

InactiveUS20160220003A1Tied tightlyHigh strengthCurling devicesTravelling articlesEngineeringHooking

A strap structure includes a main body, a hooking structure and a through structure. The main body has a first end and a second end opposite to the first end. The hooking structure is located at the first end and has flexibility. The through structure is located at the second end. At least one portion of the main body is adapted to pass through the through structure and is wound into an annulus for a hair bundle to pass therethrough. The main body between the hooking structure and the through structure is adapted to be wound around the hair bundle in a direction counter to a direction of wounding of the main body to form the annulus, and the hooking structure is adapted to be fixed on the hair bundle.

Owner:HU HOU CHIEN

A kind of preparation method of latex-free machine-woven carpet

ActiveCN108396397BGuaranteed pull-out forceReduce dosageCarpetsWoven fabricsPolymer scienceLatex rubber

The invention discloses a method for preparing a latex-free woven carpet. The second coating layer is filament or spun yarn formed of hot-melt fibers, and the first coating layer is fiber long yarn formed of nylon 6 or nylon 66. Silk or spun yarn, the second covering layer accounts for 20%-50% of the total mass of the composite yarn, the first covering layer accounts for 10%-15% of the total mass of the composite yarn, and the rest is the core yarn. Pile weft. When hot-melt copolyamide fibers are used as bonding materials to produce adhesive-free carpets, and pile yarns made of nylon or wool fibers, when the hot-melt copolyamide fibers are heated above their melting point in the hot-pressing process, they melt, and the fibers The conformation of the macromolecular chain changes, and through the transition of the chain segment, the entire macromolecular chain slips and viscous flow occurs. After curing, the pile and weft yarn as well as the weft and warp yarn are effectively consolidated, which enhances the pull-out strength of the carpet pile and The shape retention and dimensional stability of the carpet, thereby omitting the back glue process in the carpet preparation process, makes the prepared carpet more environmentally friendly.

Owner:BINZHOU COC CARPET

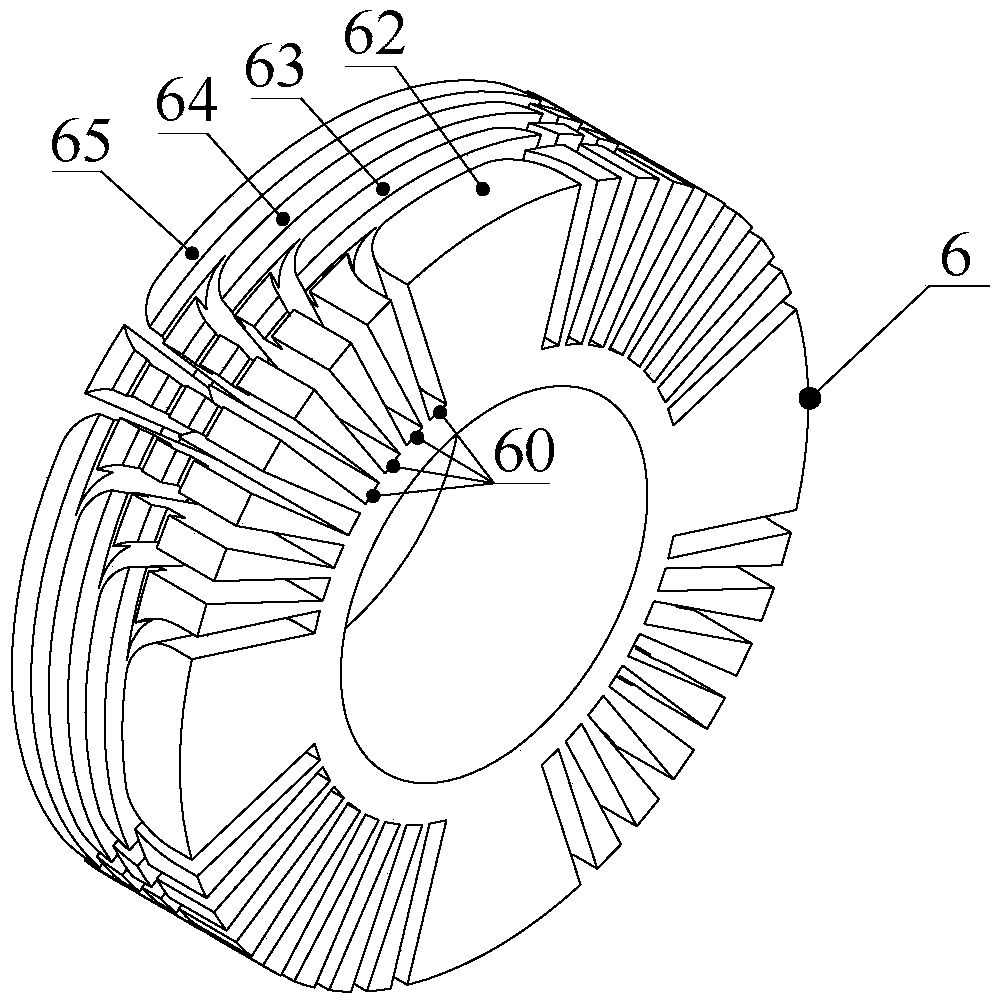

Parallel rotor structure hybrid excitation motor brushless electric excitation rotor magnetic poles

ActiveCN106357078BImprove space utilizationIncrease the total air gap areaSynchronous generatorsPermanent magnet rotorThree-phase

The invention discloses a parallel rotor structured hybrid-excited motor brushless electro-excitation rotor pole with an electro-excitation winding positioned on a rotor; the electro-excitation rotor pole is of nonsalient pole structure and is composed of a linear core pole and an end core pole positioned between a permanent magnet rotor and the linear core pole; the electro-excitation rotor pole is arranged coaxial to an exciter rotating armature and a permanent magnet rotor pole; a rotating rectifying power supply system of the electro-excitation winding combines a six-phase dual-Y-shift 30-DEG rotating armature winding and two three-phase rotating rectifying bridges, and direct current outputs of the two three-phase rotating rectifying bridges are connected in parallel; the brushless electro-excitation rotor pole makes full use of space between permanent magnets and an electro-excitation rotor in an existing parallel rotor structure, gap magnetic field adjusting capacity can be effectively enhanced, high-quality brushless power supply can be provided for the electro-excitation rotor, and the brushless electro-excitation rotor pole also has the function of fault redundant operation.

Owner:HARBIN ELECTRIC MASCH CO LTD

A kind of preparation method of machine-woven carpet without back glue process

ActiveCN108411460BGuaranteed pull-out forceReduce dosageHeating/cooling textile fabricsWoven fabricsFiberPolymer science

The invention discloses a preparation method of a machine-woven carpet without adhesive backing process. The second coating layer is filament or staple fiber yarn formed by hot-melt fibers, and the first coating layer is polyester fiber filament or staple yarn. Fiber yarn, the second covering layer accounts for 20%-50% of the total mass of the composite yarn, the first covering layer accounts for 10%-15% of the total mass of the composite yarn, and the rest is the core yarn to obtain the pile weft yarn . When hot-melt copolyester fibers are used as bonding materials to produce adhesive-free carpets, and pile yarns made of polyester fibers, when the hot-melt copolyester fibers are heated above their melting point in the hot-pressing process, they melt, and the fibers The conformation of the macromolecular chain changes, and through the transition of the chain segment, the entire macromolecular chain slips and viscous flow occurs. After curing, the pile and weft yarn as well as the weft and warp yarn are effectively consolidated, which enhances the pull-out strength of the pile and the carpet Excellent shape retention and dimensional stability, thereby omitting the back glue process in the carpet preparation process, making the prepared carpet more environmentally friendly.

Owner:QINGDAO UNIV

Preparation method of latex-free woven carpet

ActiveCN108301102ASolve the problem of impermeabilityOmit the adhesive processHeating/cooling textile fabricsCarpetsPolymer scienceNylon fiber

The invention discloses a preparation method of a latex-free woven carpet. According to the preparation method, filament yarn formed by hot-melting fibers or staple fiber yarn is used as a second cladding layer, polyester fiber filament yarn or staple fiber yarn is used as a first cladding layer, the mass of the second cladding layer accounts for 20-50% of the total mass of composite yarn, the mass of the first cladding layer accounts for 10-15% of the total mass of the composite yarn, the balance is core yarn, and in this way, pile weft yarn is prepared. As the latex-free carpet is produced by using hot-melting copolymer fibers as a bonding material, and the pile yarn prepared from nylon fibers or wool is cooperatively used, the hot-melting copolymer fibers are molten when heated to the melting point of the hot-melting copolymer fibers or above in the hot-press process, the fiber macromolecular chain conformation is changed, through transition of chain segments, the whole macromolecular chain is glided and viscously flows, and after solidification, pile and weft yarn are effectively solidified, and the weft yarn and warp yarn are effectively solidified. Accordingly, the pulling-out force of the pile is enhanced, and the shape preserving performance and the size stability of the carpet are improved, so that the backing process in the carpet preparation process is omitted, and the carpet obtained by using the method is more environmentally friendly.

Owner:BINZHOU COC CARPET

Preparation method of latex-free woven carpet

InactiveCN108411459ASolve the problem of impermeabilityOmit the adhesive processCarpetsWoven fabricsViscous flowEngineering

The invention discloses a preparation method of a latex-free woven carpet. A second wrapping layer is made of filaments or short fiber yarn formed by hot melt fiber, and a first wrapping layer is madeof polyester fiber filaments or short fiber yarn. Composite yarn comprises, by mass, 20-25% of second wrapping layer, 10-15% of first wrapping layer and the balance pile weft prepared from core yarn.When the latex-free carpet is produced from hot-melt copolyester fiber serving as an adhesive material and pile yarn prepared from nylon fiber or wool, the hot-melt copolyester fiber is melted when heated to be higher than the melting point in the hot pressing procedure, and a fiber macromolecular chain conformation changes; through transition of a chain segment, the whole macromolecular chain slides, viscous flow is generated, cured piles and the weft are effectively solidified, and the weft and warp are effectively solidified, so that the drawing strength of the piles and the shape preservation and size stability of the carpet are enhanced, then the gumming procedure in the carpet preparation process is omitted, and the prepared carpet is more environmentally friendly.

Owner:QINGDAO UNIV

A kind of preparation method of woven carpet without back glue process

ActiveCN108411458BSolve the problem of impermeabilityImprove bindingHeating/cooling textile fabricsCarpetsPolyesterFiber

The invention discloses a method for preparing a woven carpet without a backing process. The second coating layer is hot-melt fiber filament or spun yarn, and the first coating layer is polypropylene fiber filament or spun yarn. , the second covering layer accounts for 20%-50% of the total mass of the composite yarn, the first covering layer accounts for 10%-15% of the total mass of the composite yarn, and the rest is the core yarn to obtain the pile weft yarn. When hot-melt ethylene-vinyl acetate copolymer fibers are used as bonding materials to produce adhesive-free carpets, and pile yarns made of polyester fibers, when the hot-melt ethylene-vinyl acetate copolymer fibers are heated to Melting occurs when the melting point is above the melting point, and the conformation of the fiber macromolecular chain changes. Through the transition of the chain segment, the entire macromolecular chain slips and viscous flow occurs. The pull-out strength of the head and the shape retention and dimensional stability of the carpet, thereby omitting the adhesive backing process in the carpet preparation process, makes the prepared carpet more environmentally friendly.

Owner:QINGDAO UNIV

Pull wire binding tool

The invention discloses a cable binding tool and relates to the technical field of power transmission line construction. The present invention includes a strip-shaped plate body, a long hole is provided in the middle of the strip-shaped plate body, and handles are provided in the length direction of both ends of the strip-shaped plate body; column. The invention has the advantages of simple structure, convenient use, time-saving and labor-saving, and can quickly, accurately and closely bind the iron wire on the pull wire, which greatly improves the working efficiency of the pull wire binding and reduces the labor intensity; at the same time, it will not damage the galvanized wire of the pull wire layers and workers.

Owner:STATE GRID CORP OF CHINA +2

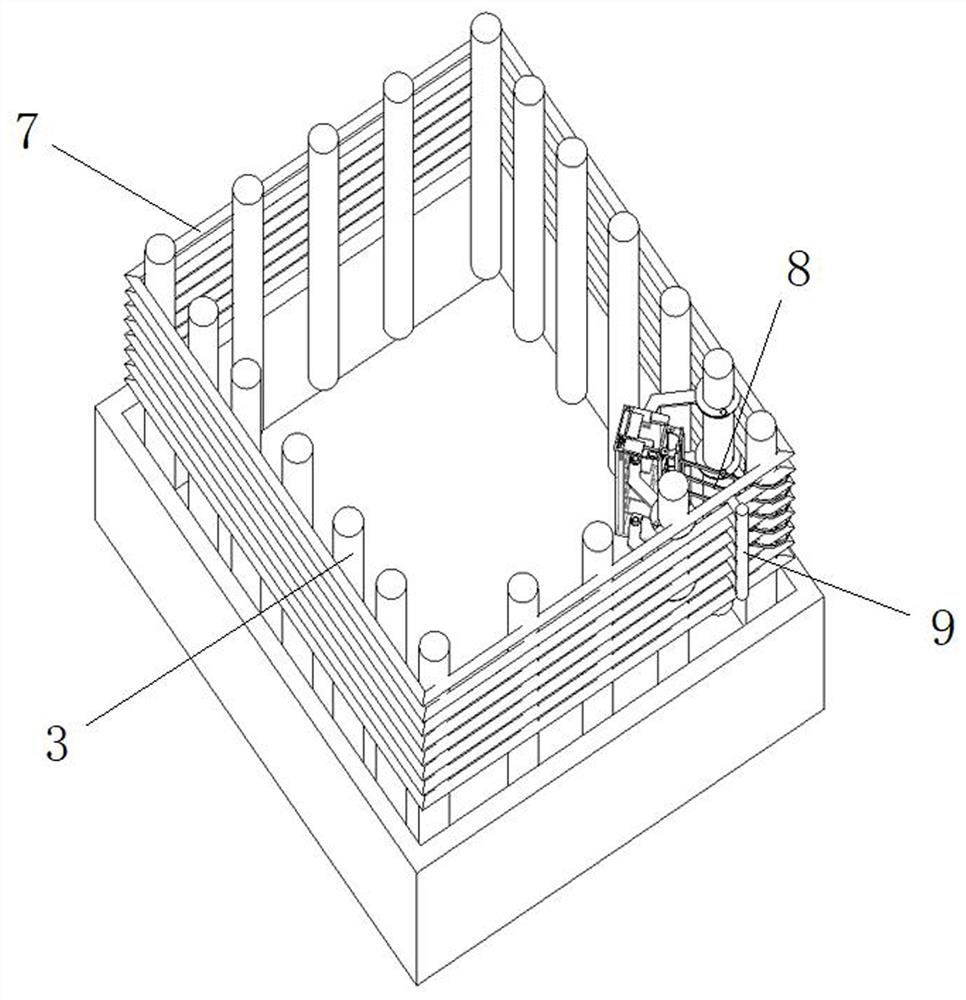

Device for binding stirrups at beam-column joint of frame structure

PendingCN114016746AGuaranteed bearing capacityReasonable and reliable structural designBuilding reinforcementsBuilding material handlingStirrupRebar

The invention particularly relates to a device for binding stirrups at the beam-column joint of a frame structure, and solves the problems that time and labor are wasted, the construction efficiency is low and the overall bearing capacity is affected when reinforcing steel bars of an existing frame structure are bound. Beam column stirrups are arranged on the outer edges of the frame column main reinforcements, plastic ribbons are connected to the staggered positions of the beam column stirrups and the frame column main reinforcements at the corners of the beam column stirrups, interval positioning reinforcements are arranged on the outer sides of the four corners of the beam column stirrups, and ribbon binding mechanisms are arranged on the inner sides of the four corners of the beam column stirrups. Each ribbon binding mechanism comprises a hollow square tube, a lifting plate is arranged in the hollow square tube, an occlusion mechanism is arranged on the lifting plate, a ribbon hole is formed in the front side wall of the hollow square tube, and heating plates are arranged on the left side and the right side of the ribbon hole. Rapid binding of the frame column main reinforcements and the beam column stirrups at the outer edges corresponding to the frame column main reinforcements is completed, the problems of shortage and binding missing of the beam column stirrups are solved, meanwhile, the construction efficiency is improved, and the overall bearing capacity of a frame structure is guaranteed.

Owner:DATONG TAIRUI GRP CONSTR +1

Production method of woven carpet with no gumming process

InactiveCN108396438ASolve the problem of impermeabilityImprove bindingCarpetsWoven fabricsViscous flowHot melt

The invention discloses a production method of a woven carpet with no gumming process. A second covering layer is made with hot-melt filaments or staple yarns; a first covering layer is made with polypropylene filaments or staple yarns; the second covering layer accounts for 20-50% of total mass of composite yarn; the first covering layer accounts for 10-15% of the total mass of the composite yarn; the balance is core yarns; pile wefts are therefore produced. During the production of a no-gum carpet with hot-melt ethylene-vinyl acetate copolymer fiber as an adhesive material, pile yarns are made in conjunction with cotton fiber and viscose fiber; the hot-melt ethylene-vinyl acetate copolymer fiber melts down when heated to above its melting point in a hot pressing step, and fiber macromolecular chain conformation varies; segmer transition allows the whole macromolecular chain to slide, a viscous flow occurs, piles, wefts and warps are effectively fixed after solidifying, pull-out strength of the piles is enhanced, and shape-maintaining property and dimensional stability are enhanced for the carpet; therefore, the gumming step in the carpet production process is omitted, so that thecarpet produced is more environmentally friendly.

Owner:QINGDAO UNIV

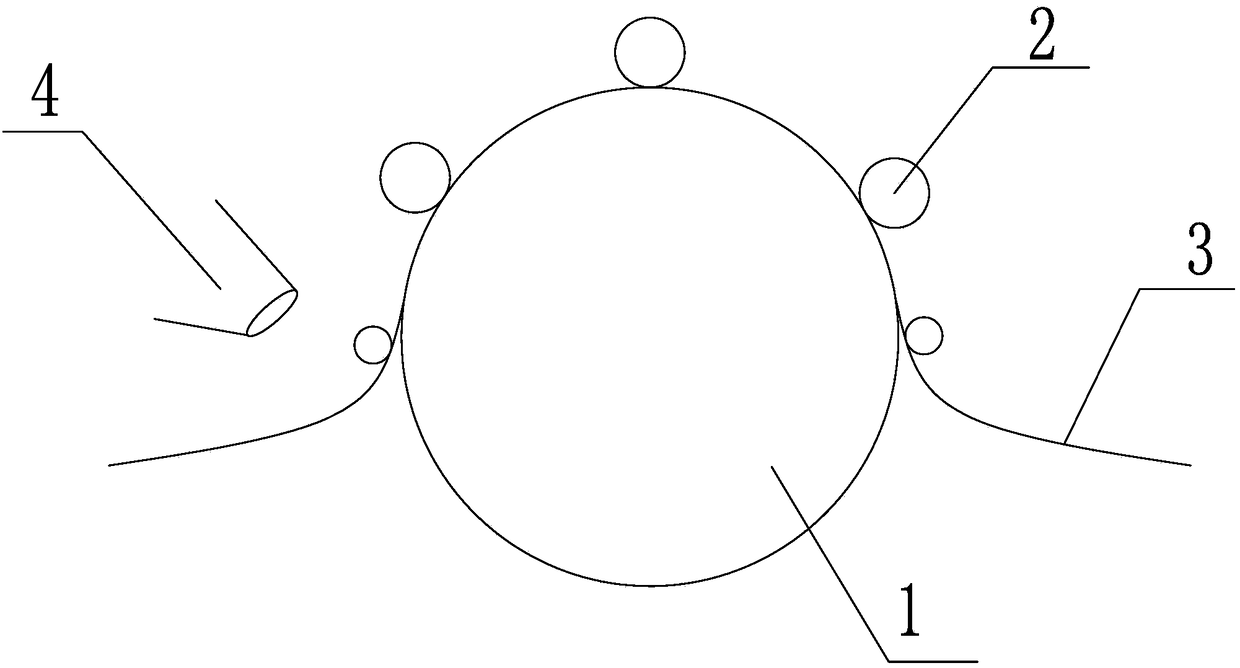

Power line binding coil making machine

InactiveCN109830916AImprove work efficiencyImprove product qualityApparatus for overhead lines/cablesEngineeringScrew thread

A power line binding coil making machine is provided. A left bracket and a right bracket are installed below a support plate. A guiding tube is installed on the left side of the support plate and hasa guiding hole therein. A left guiding wheel and a right guiding wheel are mounted on the support plate through pin rolls, and can rotate on the support plate. The upper middle part of the support plate has an open slot. An adjustment block is provided with an adjustment slot and is welded behind the support plate to make the open slot correspond to the adjustment slot. A shaft rod passes throughthe center hole of a pressing wheel, the open slot, the adjustment slot. The tail end of the shaft rod is connected with a nut. An adjustment screw passes downwards through the middle hole on the upper part of the adjustment block. The external threads on the adjustment screw are in threaded connection with the internal threads on the shaft rod in the adjustment slot. A central shaft on the rear end of a winding cylinder is mounted on the right side of the support plate, and can rotate on the support plate. The cylinder of the winding cylinder has a gap. A binding wire is inserted from the left side of the guiding tube. The winding cylinder is rotated so that the binding wire is wound around the winding cylinder to form a binding coil.

Owner:李东波

Adjustable linear hair tie

InactiveUS20200390213A1Easy to operateTied tightlyCurling devicesTravelling articlesMechanical engineeringPhysics

Owner:CHANG STEPHANIE

A kind of preparation method of woven carpet without back glue technology

ActiveCN108385244BSolve the problem of impermeabilityOmit the adhesive processHeating/cooling textile fabricsCarpetsPolymer scienceCotton fibre

The invention discloses a method for preparing a woven carpet without adhesive technology. The second coating layer is filament or staple fiber yarn formed by hot-melt fibers, and the first coating layer is polyester fiber filament or staple yarn. Fiber yarn, the second covering layer accounts for 20%-50% of the total mass of the composite yarn, the first covering layer accounts for 10%-15% of the total mass of the composite yarn, and the rest is the core yarn to obtain the pile weft yarn . When hot-melt copolyester fibers are used as adhesive materials to produce adhesive-free carpets, and pile yarns made of cotton fibers and viscose fibers, when the hot-melt copolyester fibers are heated above their melting point in the hot pressing process Melting occurs, and the conformation of the fiber macromolecular chain changes. Through the transition of the chain segment, the entire macromolecular chain slips and viscous flow occurs. The strength and the shape retention and dimensional stability of the carpet can be improved, thereby omitting the back glue process in the carpet preparation process, making the prepared carpet more environmentally friendly.

Owner:BINZHOU COC CARPET

Novel bag opening expander

Owner:湖北百水居水产品有限公司

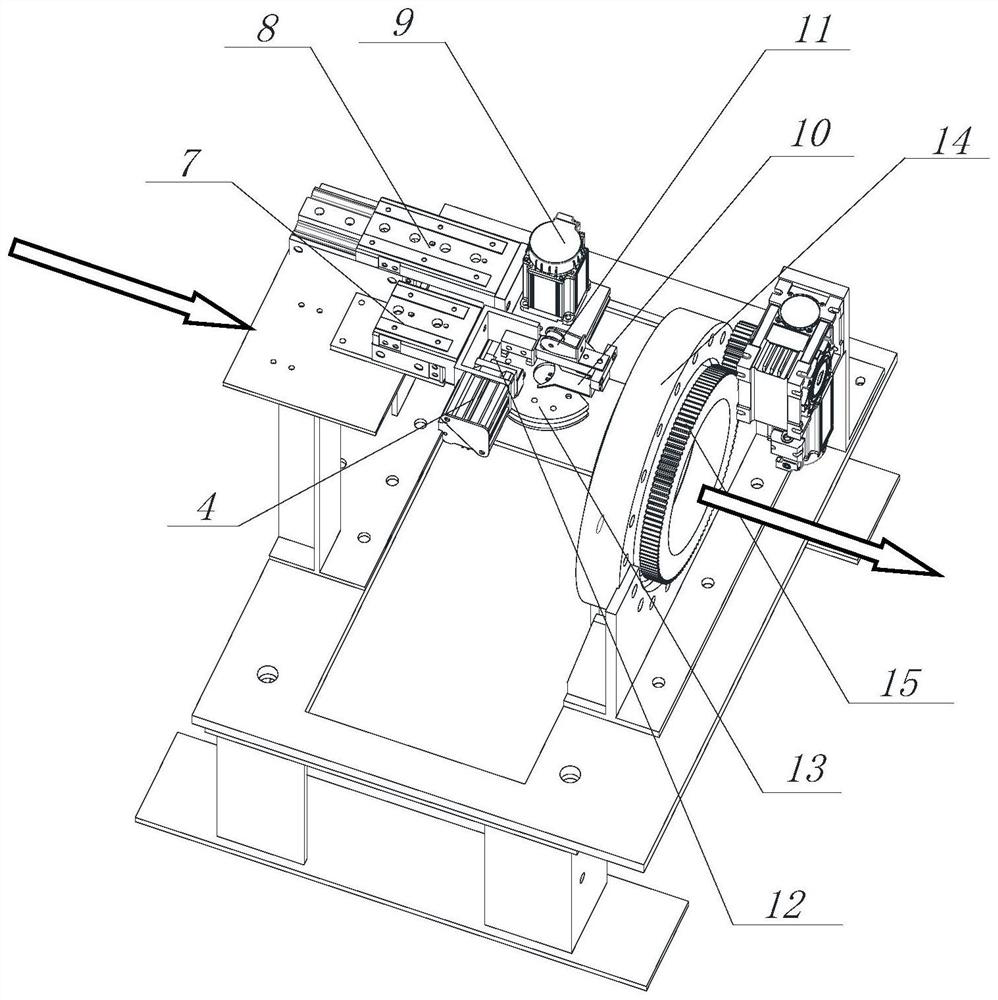

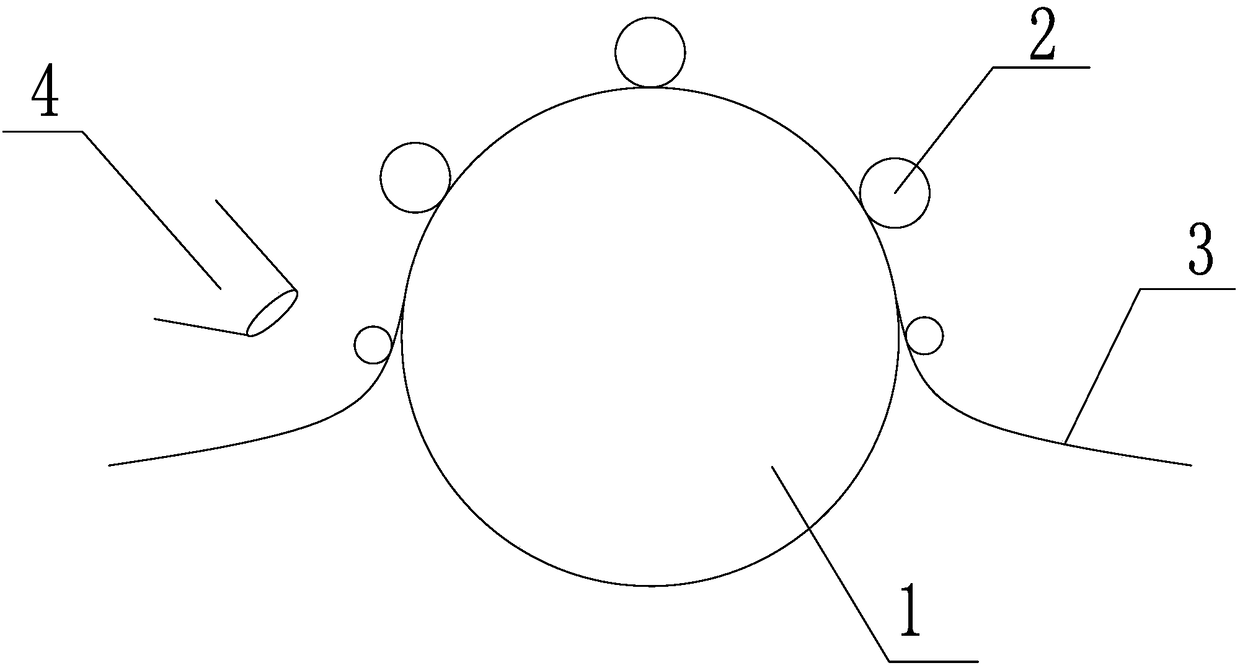

A strip material automatic strapping machine

ActiveCN112407401BSimple structureImprove efficiencyBinding material applicationBundling machine detailsStrappingGear wheel

The invention discloses a fully automatic strapping machine for strip-shaped materials, which includes a frame, and the frame is provided with a wire winding mechanism, a clamping and shearing mechanism driving a slide table, and a wire twisting mechanism driving a sliding table; the clamping and shearing mechanism drives a sliding table A clamping and shearing mechanism for clamping and cutting the iron wire is installed on the top; a wire twisting mechanism for tightening the end of the iron wire after the wire is wound is installed on the driving slide table of the wire twisting mechanism. This equipment adopts two sets of servos, one controls the number of wire winding circles, and the other controls the number of twisting circles; the unique design of cutting and clamping wire integration can complete the cutting and clamping process at one time, driven by the guide rod cylinder; tightening The gear is responsible for twisting the thread through two guide thread slots, and is driven by the gear set mechanism, which has the characteristics of simple structure, high efficiency, tight binding and low failure rate.

Owner:天津君晟科技发展有限公司

Preparation method of woven carpet without gumming process

ActiveCN108411458AImprove stabilityOmit the adhesive processHeating/cooling textile fabricsCarpetsViscous flowHot melt

The invention discloses a preparation method of a woven carpet without a gumming process. A second coating layer is a hot-melt fiber filament or a staple fibre yarn, a first coating layer is a polypropylene fiber filament or a staple fibre yarn, the second coating layer accounts for 20%- 50% of the total mass of a composite yarn, the first coating layer accounts for 10%-15% of the total mass of the composite yarn, the balance is a core yarn, and a pile weft yarn is obtained by adopting the manner. When the non-adhesive carpet is produced by using a hot-melt ethylene-vinyl acetate copolymer fiber as a bonding material in combination with the pile yarn made of a polyester fiber, the melting occurs when the hot-melt ethylene-vinyl acetate copolymer fiber is heated to be higher than the melting point in a hot pressing process, the conformation of a fiber macromolecular chain is changed, the whole macromolecular chain slips through the transition of chain segments, viscous flow occurs, thepile and weft yarns as well as the weft yarns and warp yarns are effectively solidified after curing, and the pull strength of the pile and the shape retention and dimensional stability of the carpetare enhanced, so that the gumming process in the carpet preparation process is omitted, and the produced carpet is more environmentally friendly.

Owner:QINGDAO UNIV

A kind of preparation method of latex-free woven carpet

ActiveCN108396440BDimensionally stableSolve the problem of impermeabilityCarpetsWoven fabricsPolymer scienceHigh density

The invention discloses a method for preparing a latex-free woven carpet. The second coating layer is hot-melt fiber filament or staple yarn, and the first coating layer is high-density polyethylene fiber filament or staple fiber. yarn, the second covering layer accounts for 20%-50% of the total mass of the composite yarn, the first covering layer accounts for 10%-15% of the total mass of the composite yarn, and the rest is the core yarn to obtain the hanging pile weft yarn. When using hot-melt ethylene-vinyl acetate copolymer fibers as bonding materials to produce adhesive-free carpets, and with pile yarns made of nylon fibers or wool, when hot-melt ethylene-vinyl acetate copolymer fibers are used in the heat-pressing process When it is heated above its melting point, it melts, and the conformation of the fiber macromolecular chain changes. Through the transition of the chain segment, the entire macromolecular chain slips and viscous flow occurs. The pull-out strength of the pile and the shape retention and dimensional stability of the carpet are improved, thereby omitting the adhesive backing process in the carpet preparation process, and making the prepared carpet more environmentally friendly.

Owner:QINGDAO UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com