Transformer iron core adhesive band vertical bundling machine

A binding machine and transformer technology, which is applied in the manufacture of inductors/transformers/magnets, electrical components, circuits, etc., can solve the problems of high vibration and noise, inability to work continuously, etc., and achieve improved performance, continuous and stable binding, and reduced manufacturing costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

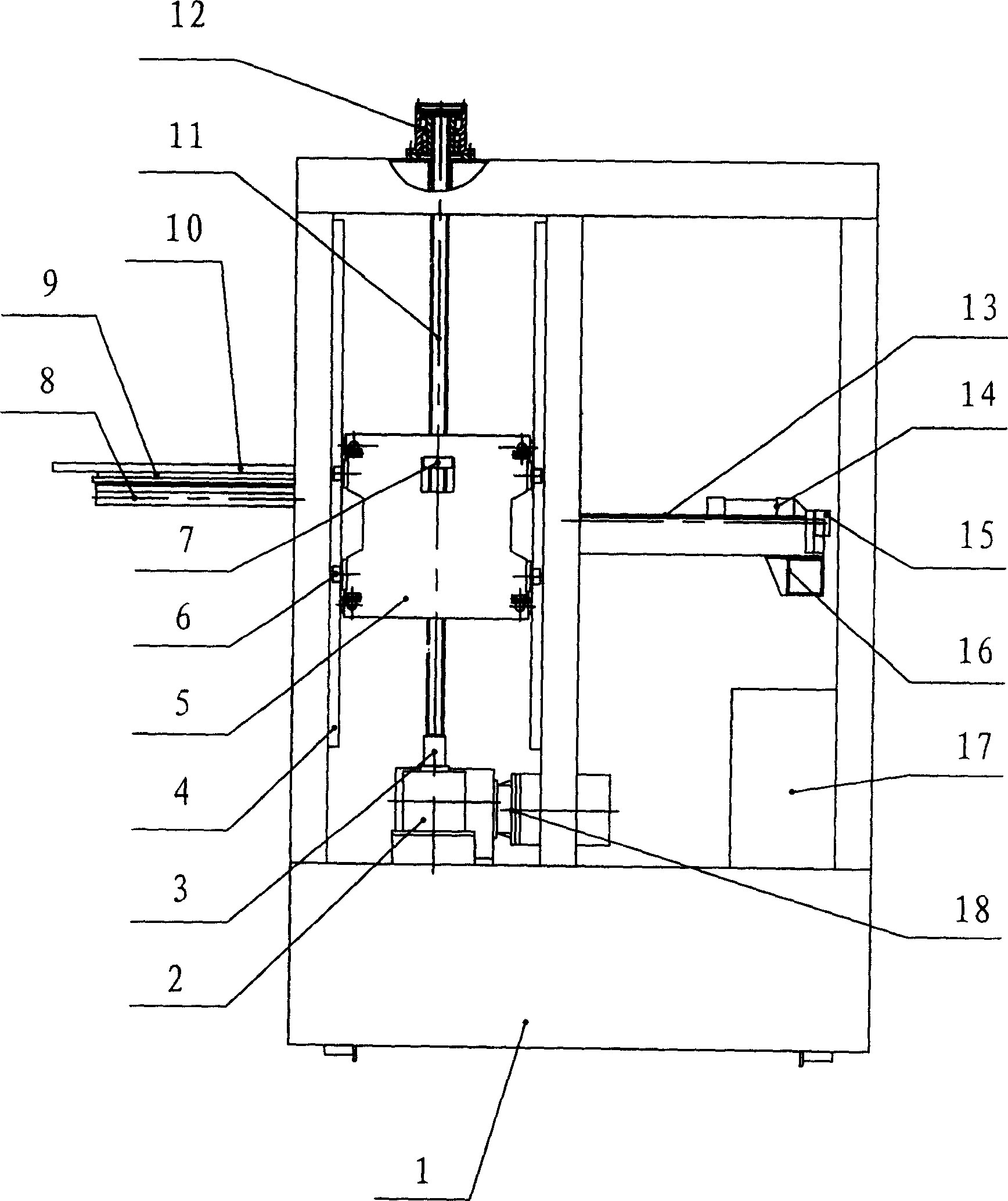

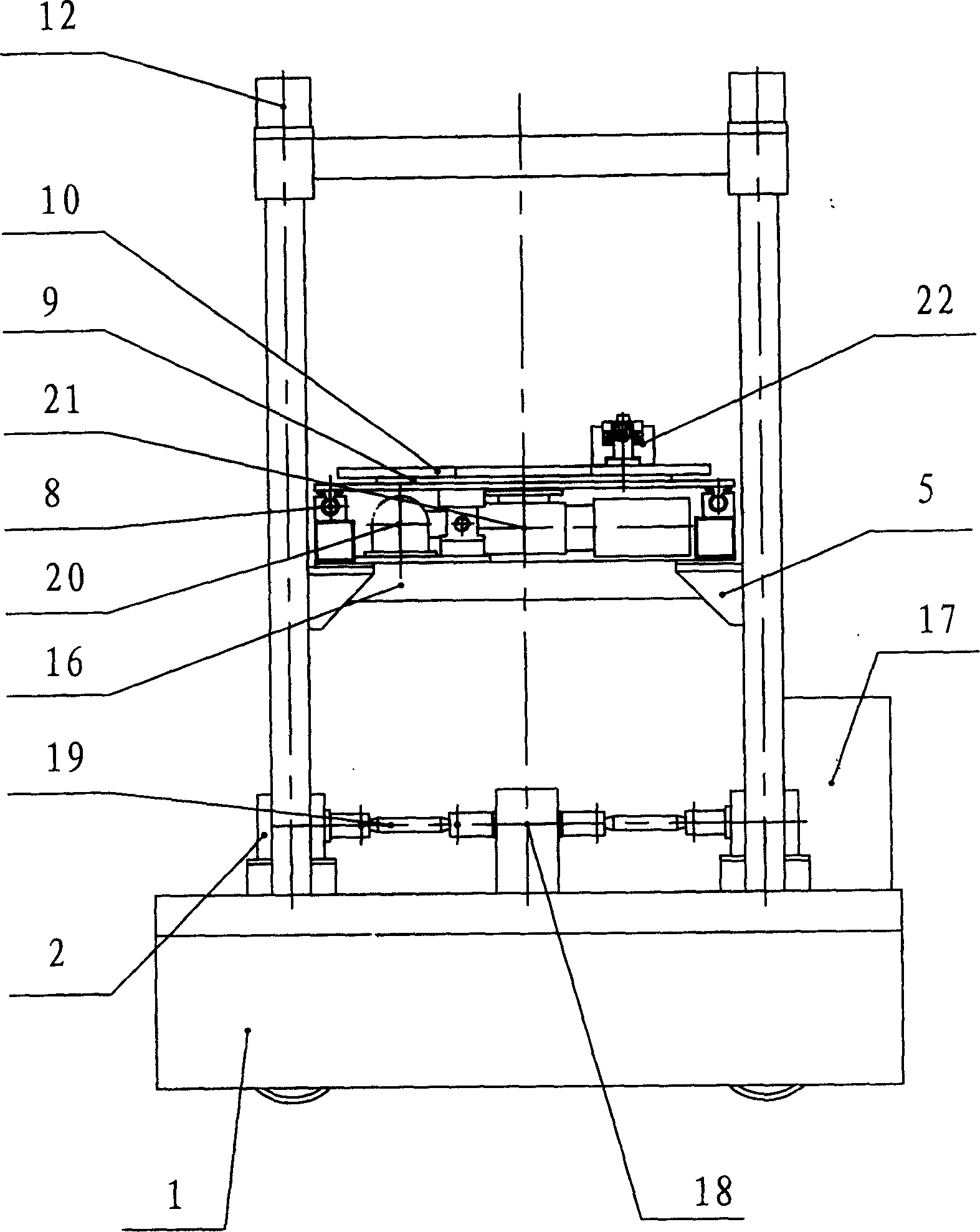

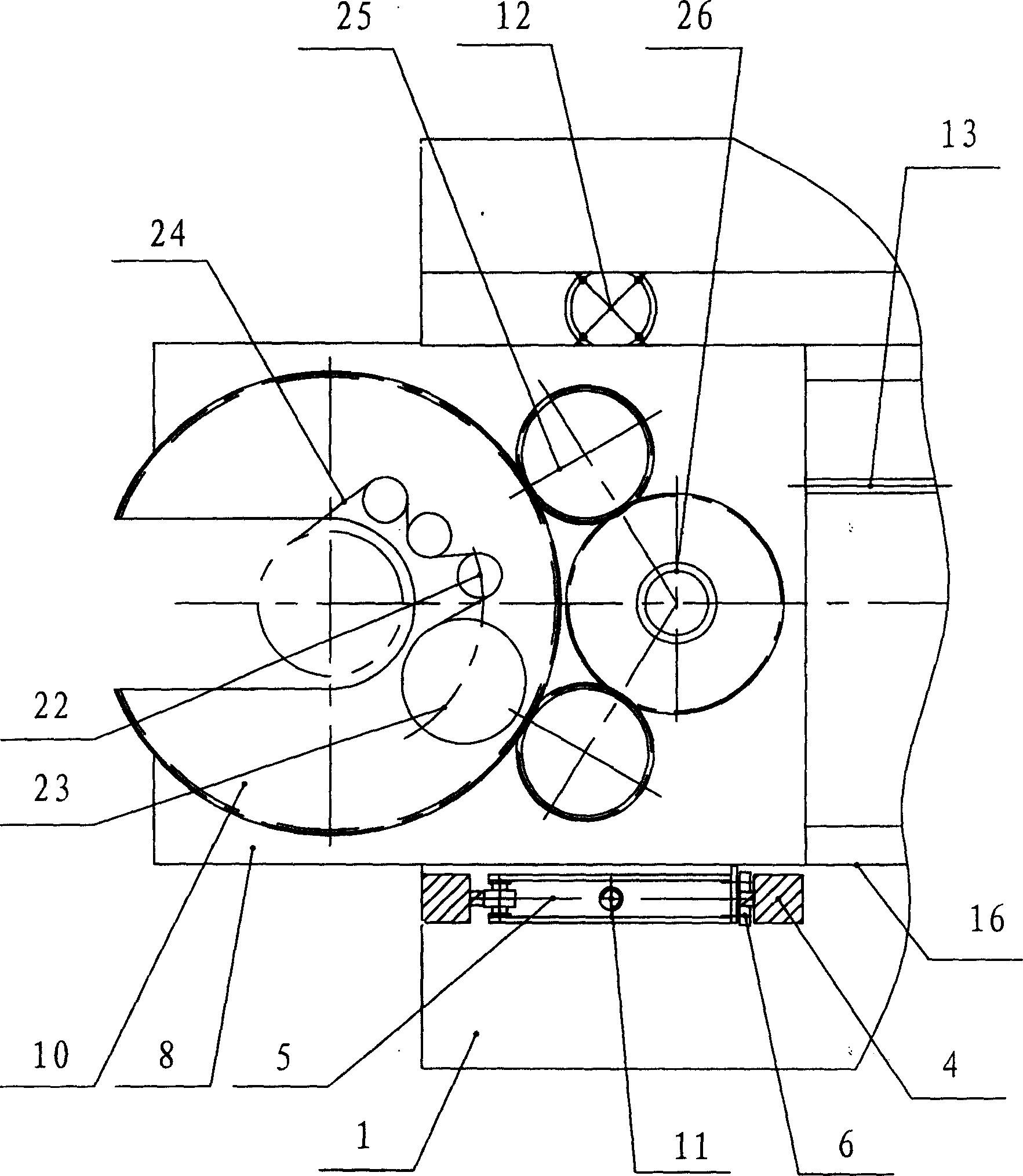

[0018] according to Figure 1-5 The specific structure and working process of the present invention will be described in detail. The device can be made into two structural forms according to the specifications of the transformer core leg and side yoke: for the diameter of the core leg and side yoke less than 400mm, the I-type structure is adopted; for the diameter of the core leg and side yoke is equal to or greater than 400mm , using a type II structure. Taking the I-type structure as an example, it includes a frame 1 and a lifting transmission mechanism assembled thereon, a winding mechanism and its lifting driving device, and a winding driving device. The frame 1 is used to adjust the relative position of the device, the transformer core column and the side yoke, and its specification and shape can be determined according to actual needs. The guide rail 4 is welded on the frame 1, and has the function of lifting and guiding and bearing the rotating torque during winding. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com