Steel plate winding device

A technology of steel coils and steel plates, applied to other manufacturing equipment/tools, manufacturing tools, etc., can solve the problem of low productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Hereinafter, preferred embodiments of the steel plate coiling device according to the present invention will be described in detail with reference to the drawings.

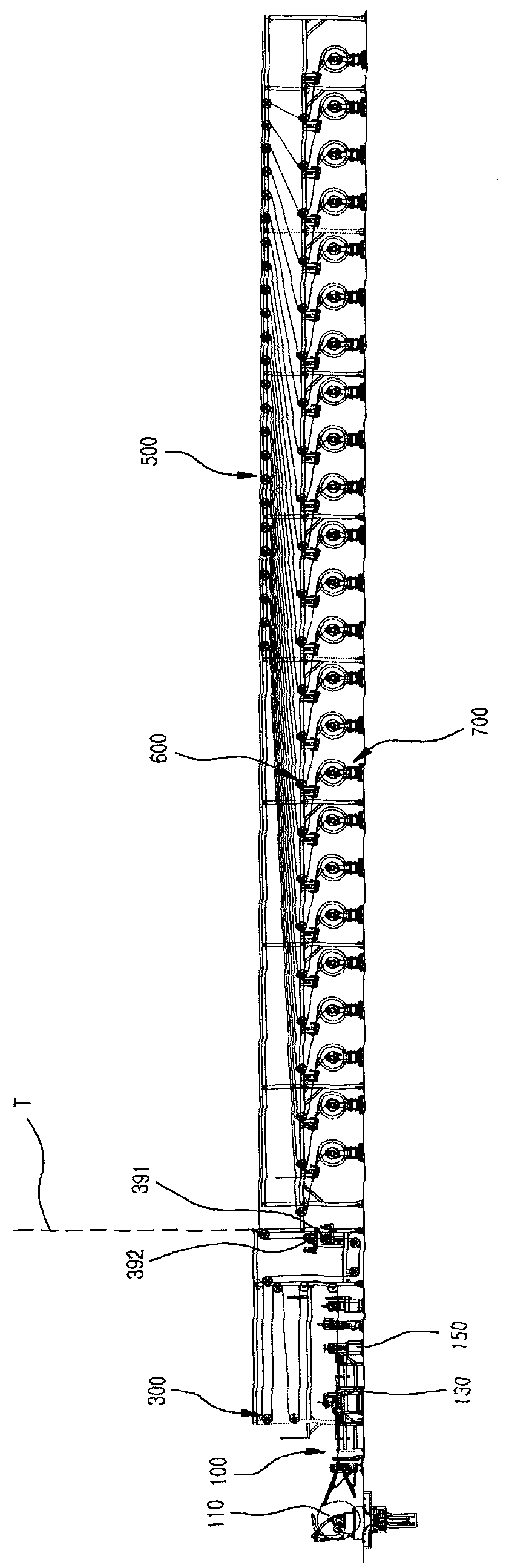

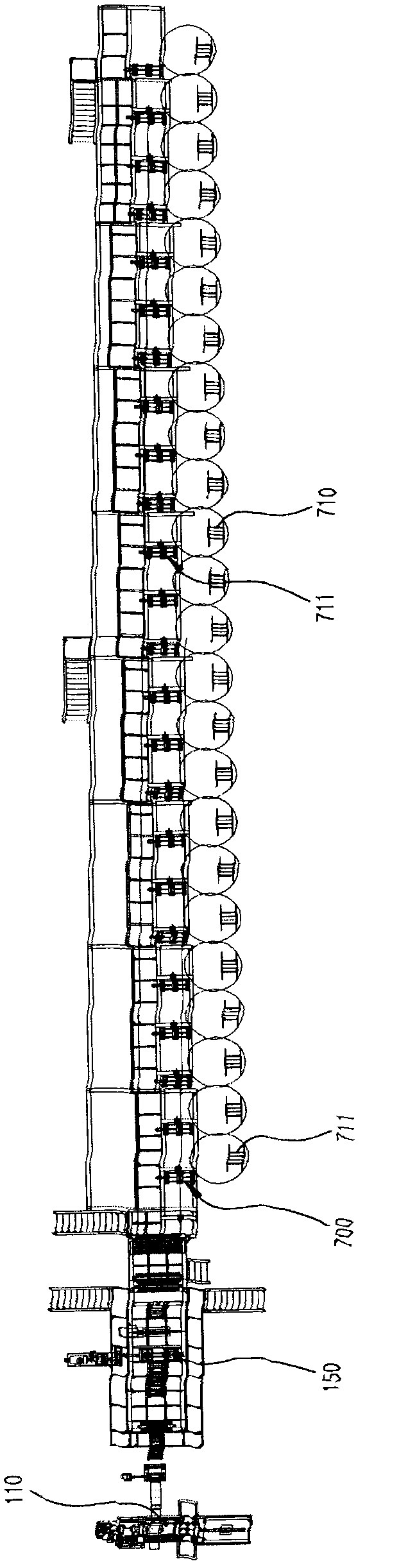

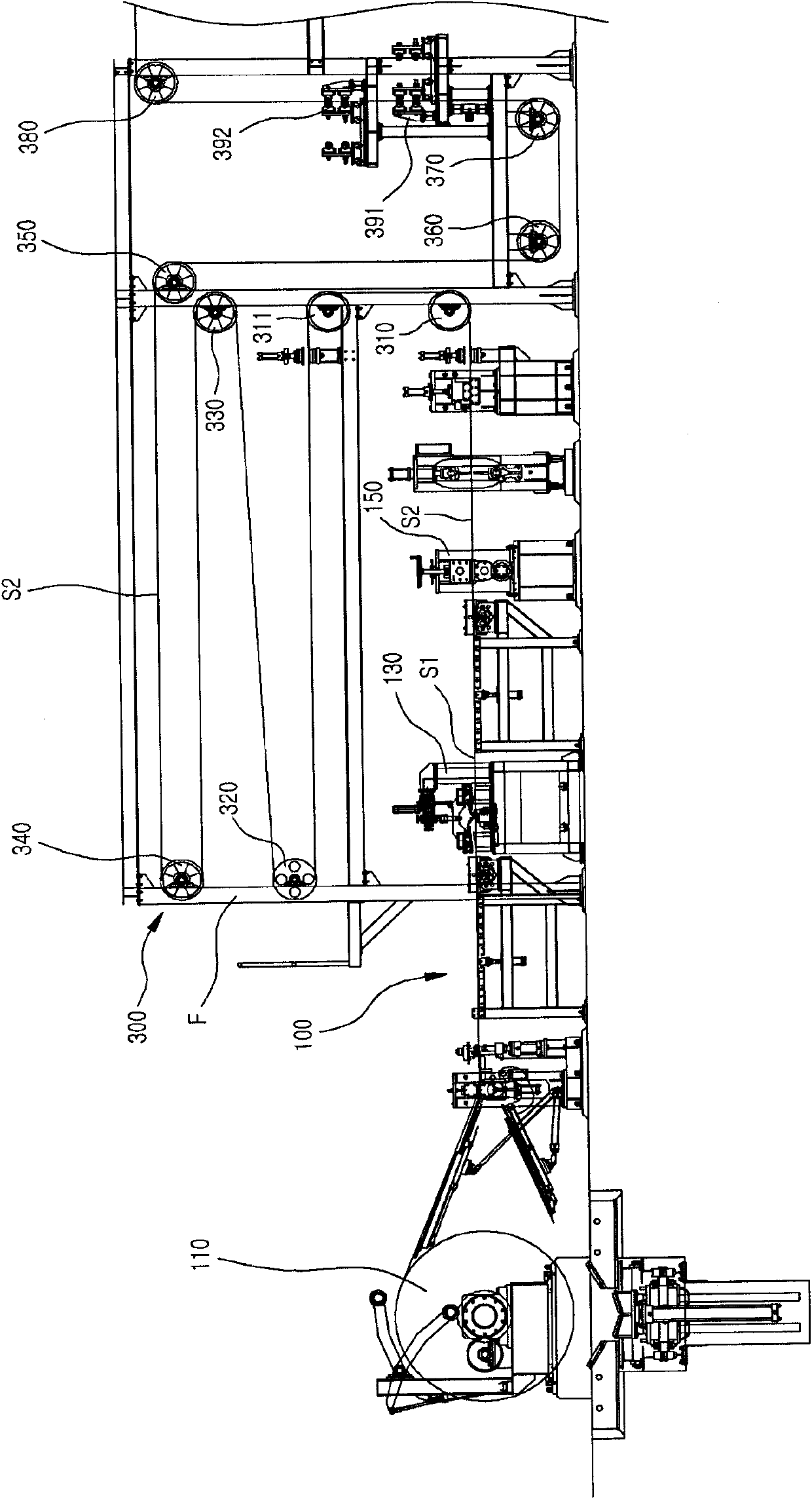

[0039] The steel plate coiling device according to the present invention includes a supply unit 100 , a first transfer unit 300 , a second transfer unit 500 and a rewind unit 700 .

[0040] Wherein, the supply unit 100 includes a drum 110 , a welding unit 130 and a slitting unit 150 .

[0041] A plurality of steel plates having a predetermined length and width, which are used as steel plates for welding wire, are wound around the drum 110 .

[0042] The welding unit 130 welds the plurality of steel plates guided from the drum in the longitudinal direction to form the first steel plate S1.

[0043] The slitting unit 150 uses the welding unit 130 to slitting (slitting) the plurality of narrow second steel plates S2 formed by extending the first steel plate S1 in the longitudinal direction.

[0044] In gener...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com