Rapid laying and anchoring system and use method

A mooring system and fast technology, applied in anchor points, ship construction, ships, etc., can solve the problems of time-consuming and cumbersome deployment process, and achieve the effect of convenient operation, enlarged volume and shortened deployment time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

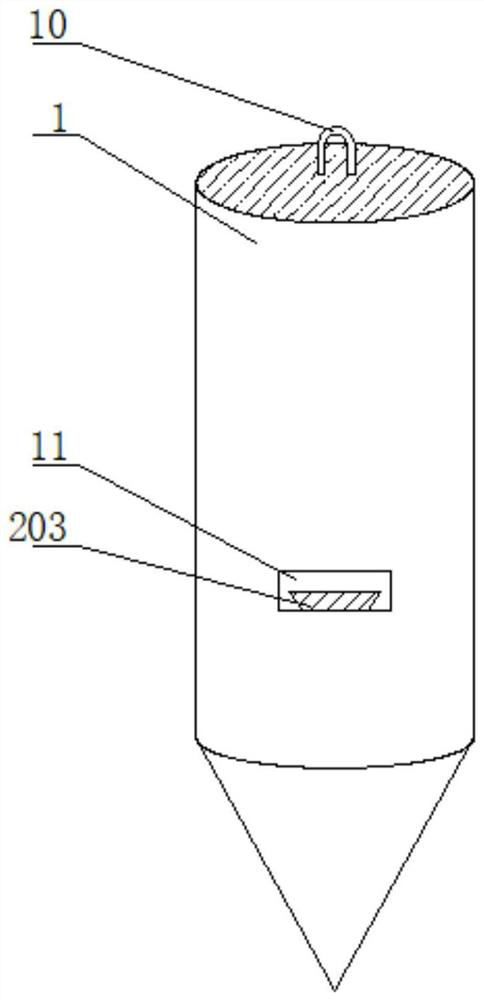

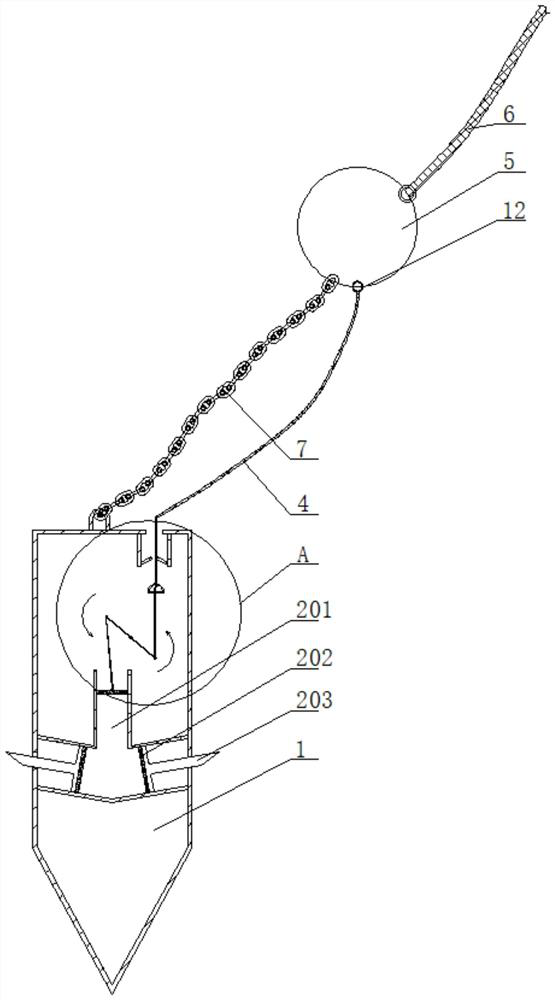

[0034] Such as Figure 1-Figure 4 As shown, the rapid deployment and mooring system of this embodiment includes an anchor body shell 1, and the anchor body shell 1 is provided with a hydraulic component 2 and a connecting rod component 3 for driving the hydraulic component 2.

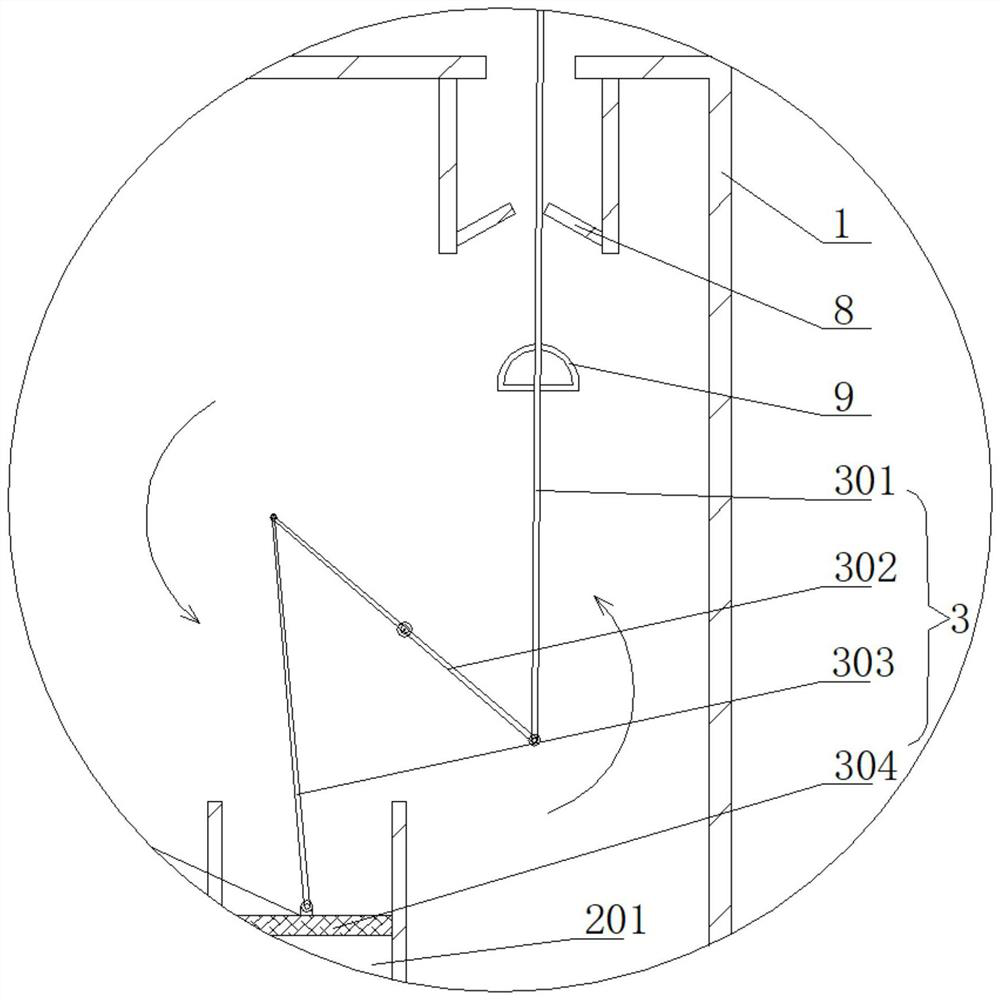

[0035] The hydraulic assembly 2 includes a hydraulic chamber 201 located in the anchor housing 1, and a piston plate 202 movable in the hydraulic chamber 201. The piston plate 202 is connected with a damping plate 203 protruding from the anchor housing 1.

[0036] The connecting rod assembly 3 includes an active rod 301 that runs through the anchor housing 1, a transmission rod 302 hinged to one end of the active rod 301, and a driven rod 303 hinged to the end of the transmission rod 302 away from the active rod 301; the midpoint of the transmission rod 302 is conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com