Device for binding stirrups at beam-column joint of frame structure

A frame structure and frame column technology, applied in the direction of structural elements, building components, building structures, etc., can solve the problems of low construction efficiency, affecting the overall bearing capacity, time-consuming and labor-intensive problems, so as to improve construction efficiency, realize stable fixation, overcome effect of shortage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

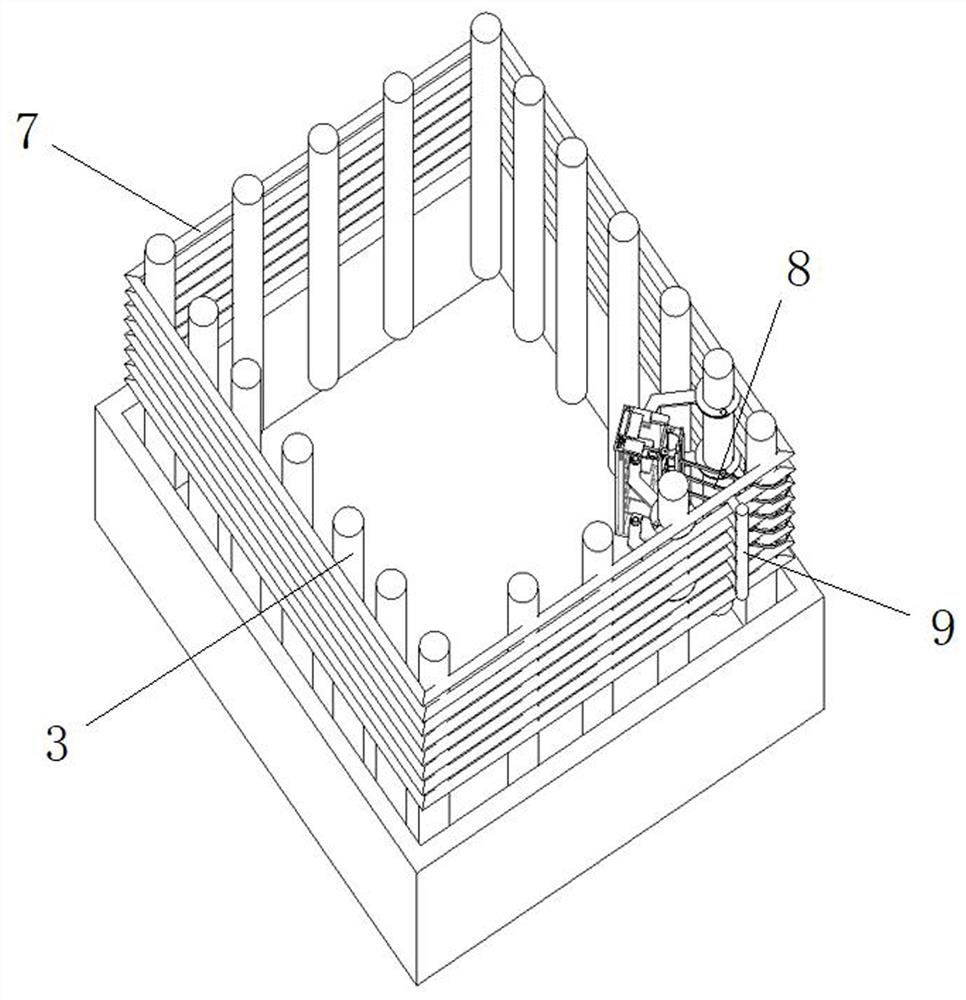

[0018] like Figure 1-4 As shown, according to one embodiment of the present invention, a device for binding stirrups at the junction of beams and columns of a frame structure is provided. It includes a vertically arranged frame column formwork 1, the upper end of the frame column formwork 1 is provided with a frame beam formwork 2 connected to it and crossed, the frame column formwork 1 is provided with a vertically placed frame column main reinforcement 3, and the frame column main reinforcement 3 The frame column stirrup 4 is fixed on the outer edge, and the frame beam formwork 2 is provided with the frame beam main reinforcement 5 placed horizontally, the frame beam stirrup 6 is fixed on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com