Automatic reinforcing steel bar binding machine

A kind of steel bar binding and automatic technology, applied in construction, building structure, building material processing and other directions, can solve the problems of high construction cost, complex structure of electric steel bar binding machine, and battery waste generation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0092] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

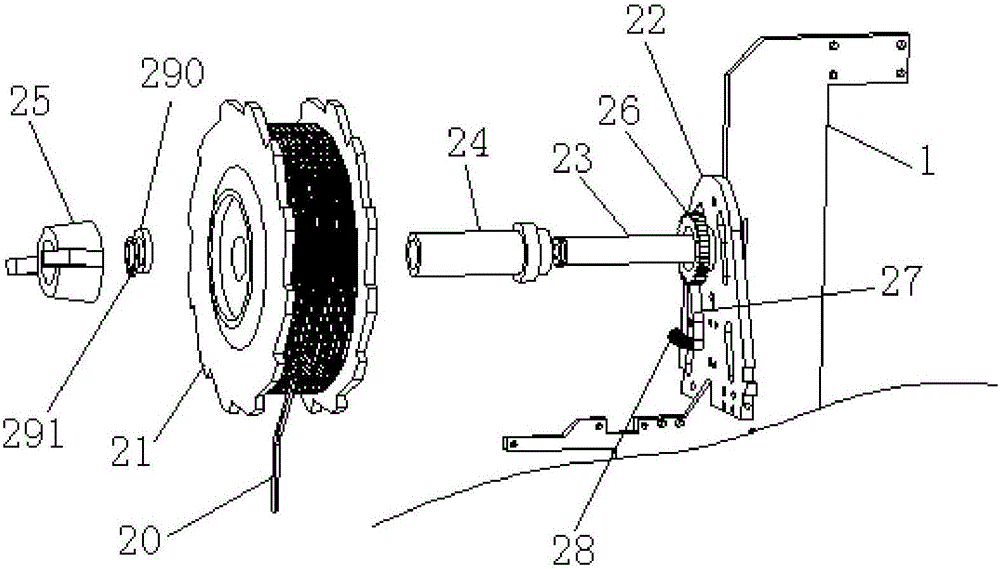

[0093] An automatic steel bar binding machine provided by the present invention includes a frame 1, and a wire binding mechanism 2, a power mechanism 3, a wire feeding mechanism 4, a wire cutting mechanism 5, and jaws respectively arranged on the frame 1. And guiding mechanism 6, twisted wire mechanism 7 and twisted wire mechanism 8, wherein, described wire-tie disc mechanism 2 has a wire-tie disc 21 for winding 20 of wire-tie, and wire-tie 20 can take single-track wire or double-track wire or The winding method of the three wires is wound on the wire-tie disc 21, and the wire-tie disc 21 is rotatably connected to the frame 1; the power mechanism 3 can drive the action of the wire feeding mechanism 4, and by means of the The action of the wire mechanism 4 drives the wire binding 20 to walk, that is, wire walking; the jaws and the guide mechanism 6 have...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com