Stay wire binding tool

A tool and bar-shaped technology, applied in the field of wire binding tools, can solve problems such as damage to the galvanized layer of the iron wire, easy burrs to hurt people, and non-conformity of the wire, so as to achieve a convenient structure that is not easy to hurt hands, easy to operate and carry, and has a reasonable structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

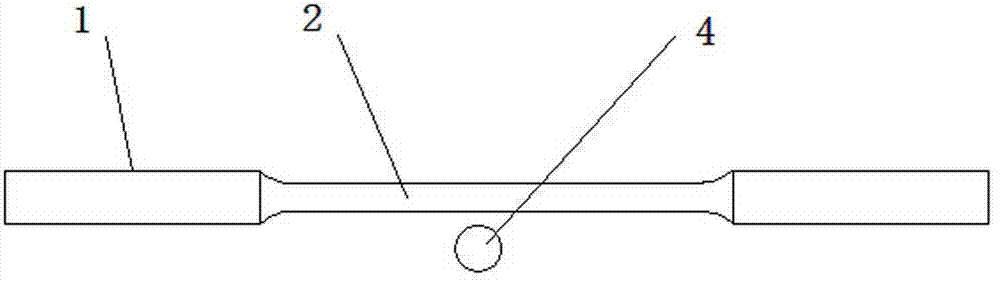

[0021] See figure 1 , figure 2 , The tool includes a strip-shaped plate body 2, the middle part of the strip-shaped plate body 2 is provided with a long strip hole 3, and the two ends of the strip-shaped plate body 2 are provided with handles 1 in the length direction; The guide post 4 for changing the direction of the iron wire, wherein the guide post 4 and the strip-shaped plate body 2 are arranged separately. When in use, the guide post 4 and the elongated hole 3 are arranged in a crisscross pattern. The guide post 4 can be an ordinary 10 ×100 bolts are sufficient. There is a rubber sleeve on the handle 1, and the rubber sleeve has a friction pattern, which not only makes the operator comfortable to hold and prevents scratches, but also increases the friction and makes the operation more labor-saving.

[0022] The length of the handle 1 is 80-120mm and the diameter is 15-25mm; the length of the strip-shaped plate body 2 is 120-180mm; the length of the guide post 4 is 50-100mm...

Embodiment 2

[0025] See Figure 4 The difference between this embodiment and the first embodiment is: on one side of the strip-shaped plate body 2, two ear holes 5 are fixed, and the two ear holes 5 are distributed on both sides of the elongated hole 3; the guide post 4 It can pass through the two ear holes 5 and is perpendicular to the elongated hole 3. When in use, the guide post 4 is inserted into the ear hole 5, the iron wire is passed around the guide post 4, and the handle 1 is held with both hands, so that the strip plate 2 closes to the outer circle of the cable, and the iron wire is tightly wound on the cable.

Embodiment 3

[0027] See image 3 , Figure 4 The guide post 4 is a bolt, and one end of the bolt is equipped with a nut 6, and the bolt is inserted into the ear hole 5, and the nut 6 is screwed on, so that the bolt will not fall, which is convenient to carry and prevents the guide post 4 from being lost.

[0028] The structure of the tool is more reasonable, lighter and more convenient to use; the tool can be used to fast, accurately and tightly bind the wire to the cable, which greatly improves the work efficiency of the cable binding and reduces the labor intensity; at the same time, it will not hurt The galvanized layer of the cable and the operator. This tool is a very simple and practical cable lashing tool.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com