Parallel rotor structure hybrid excitation motor brushless electric excitation rotor magnetic poles

A hybrid excitation motor, rotor magnetic pole technology, applied in synchronous generators, electrical components, electromechanical devices, etc., can solve the problems of uneven thickness of end sheath binding, irregular shape of end windings, and inability to be effectively utilized, etc. Achieve the effect of improving the air gap magnetic field adjustment ability, increasing the total area of the air gap, and improving space utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings.

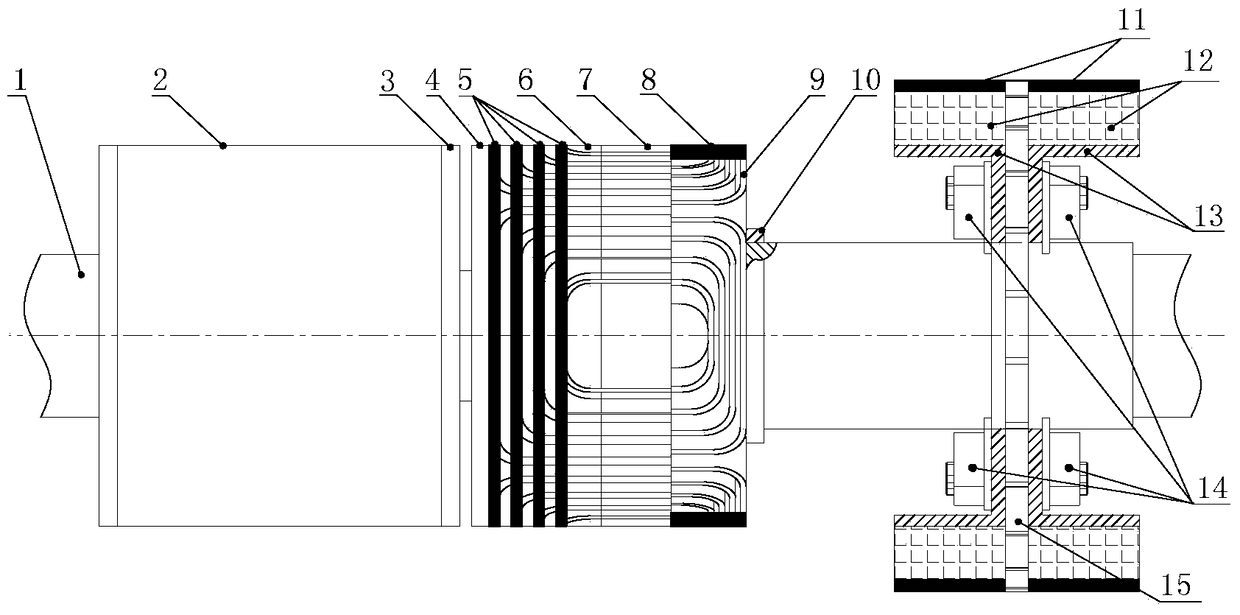

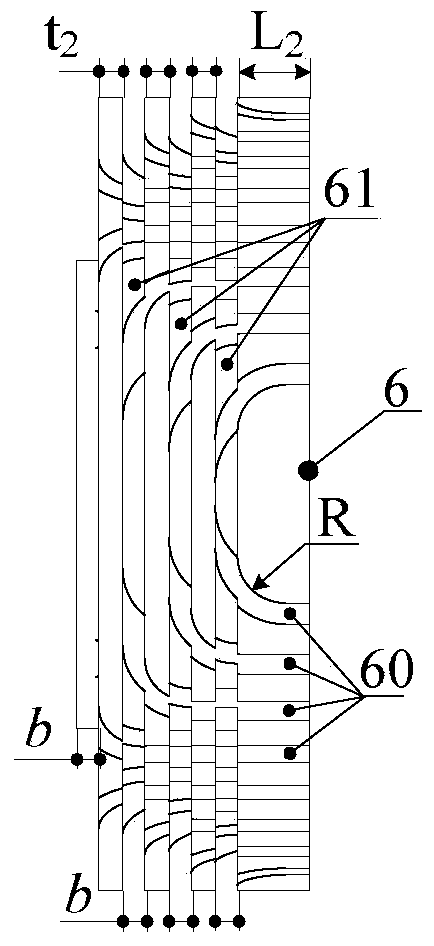

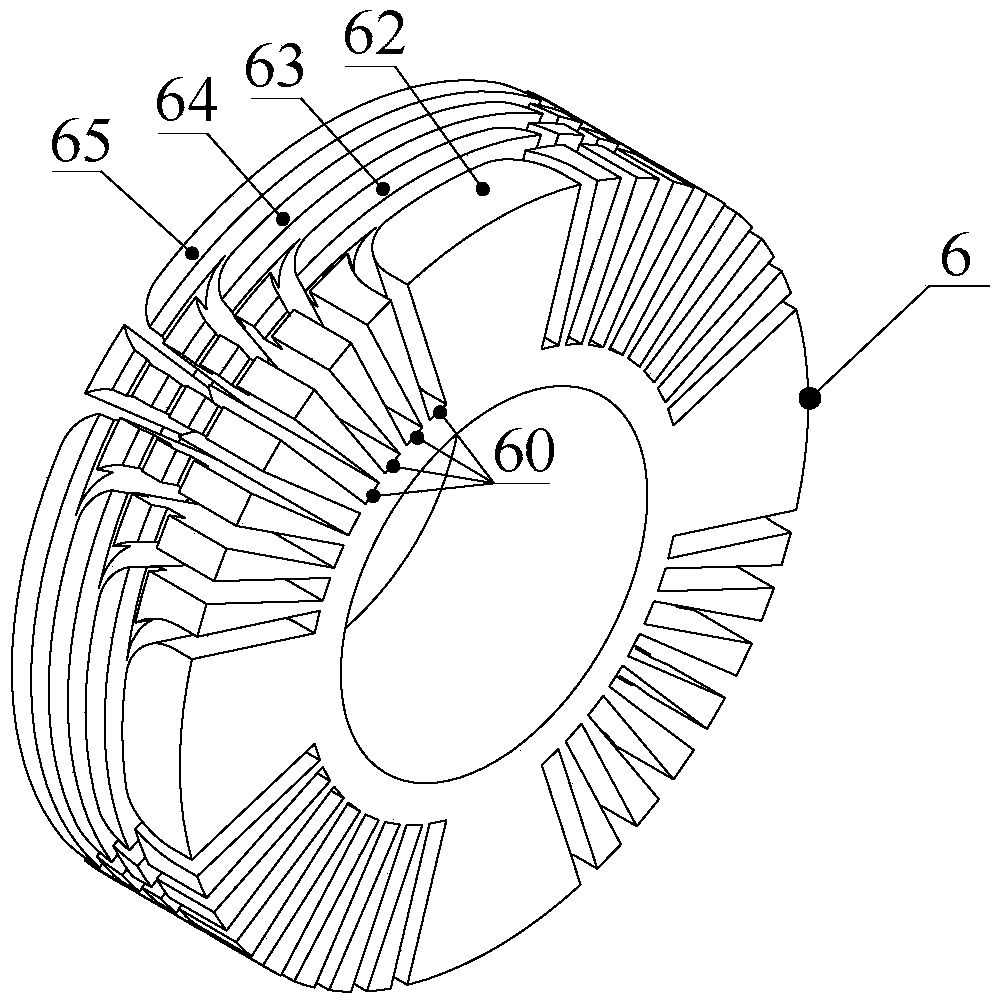

[0027] Such as figure 1 As shown, a brushless electric excitation rotor pole of a parallel rotor structure hybrid excitation motor is composed of a straight section core pole 7 and an end core pole 6 located between the permanent magnet rotor pole 2 and the straight section iron core pole 7; the straight section iron core The electric excitation rotor poles composed of magnetic poles 7 and end core poles 6 are coaxially arranged with the rotating armature core 15 of the exciter and the permanent magnet rotor poles 2; the electric excitation winding 9 adopts a rotary rectification power supply system to realize brushless power supply. The electric excitation rotor poles and the permanent magnet rotor poles 2 share a set of stator windings, and the number of poles of the two is the same. The end core poles 6 and the straight section core poles...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com