Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

46results about How to "Small slip rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

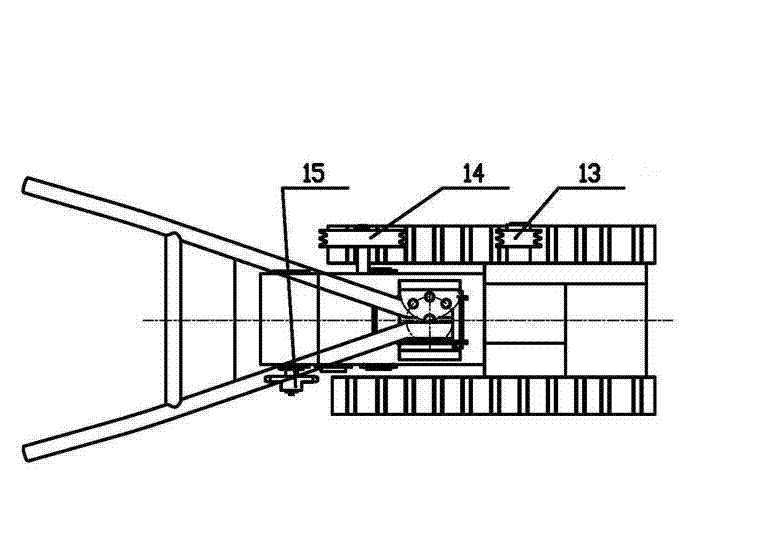

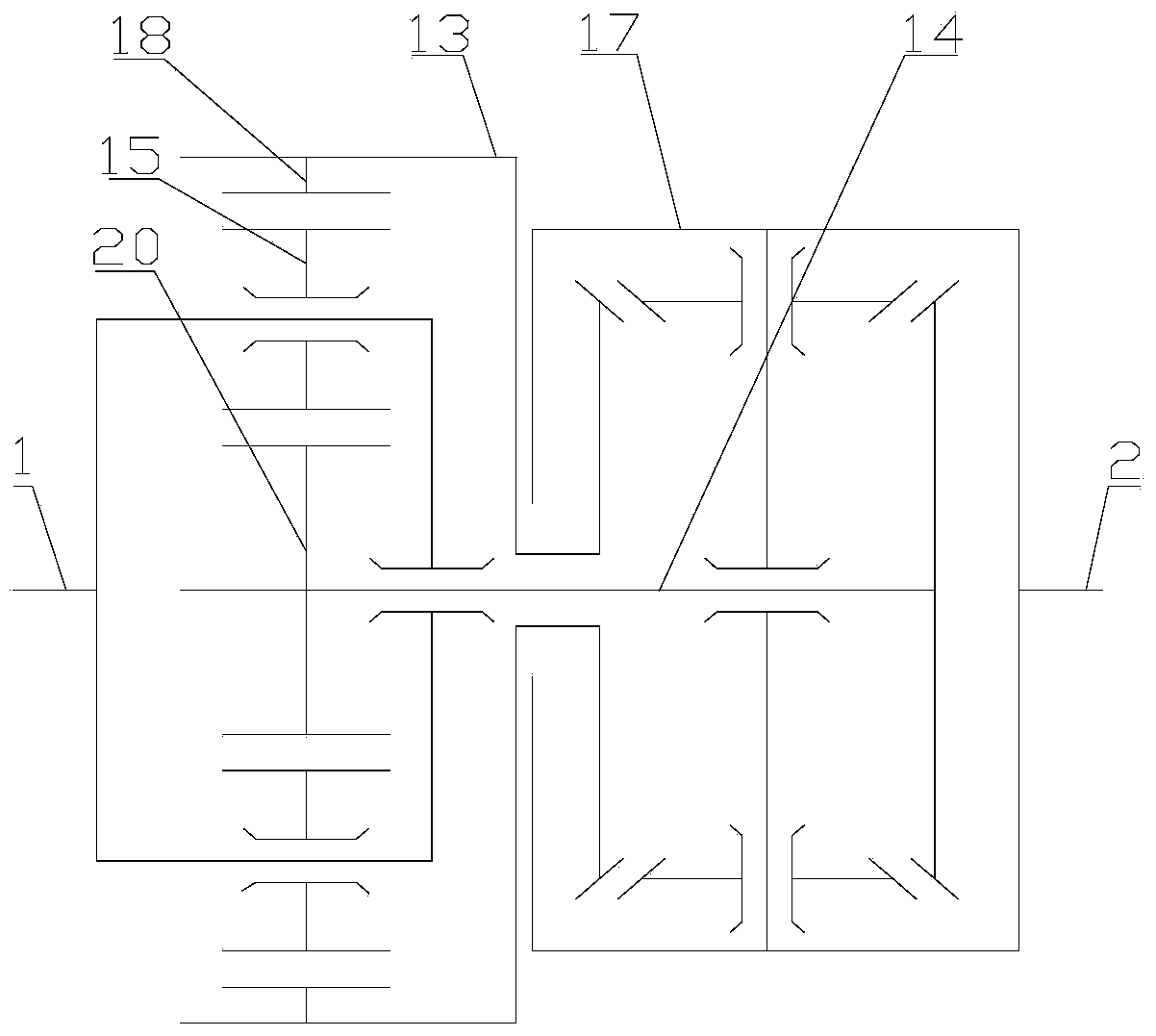

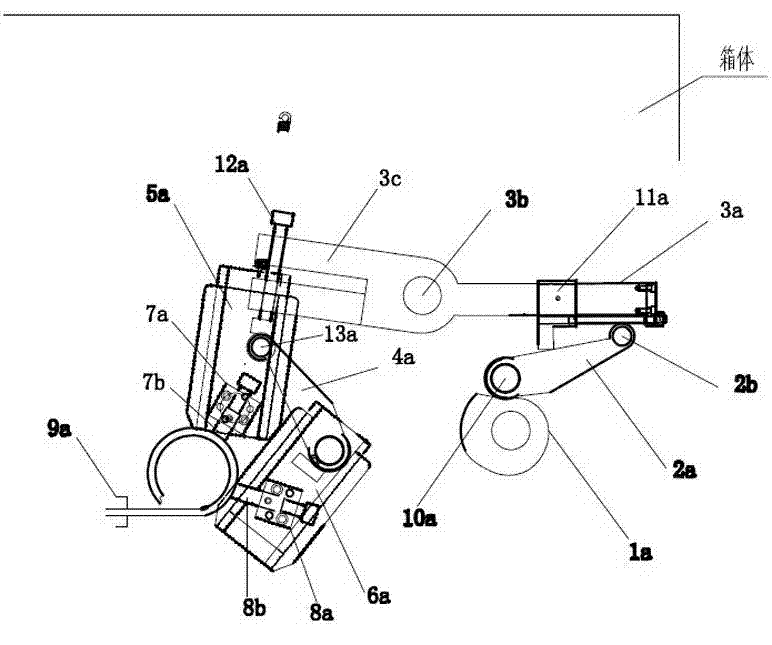

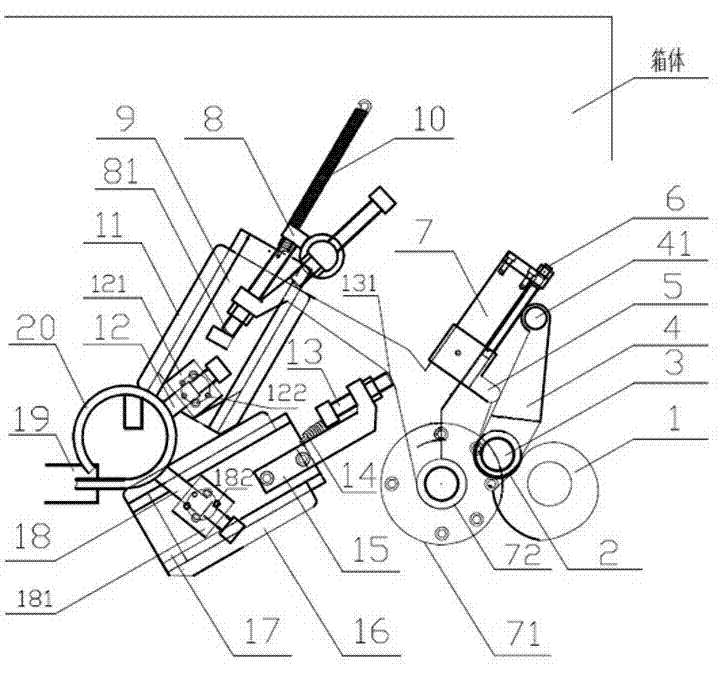

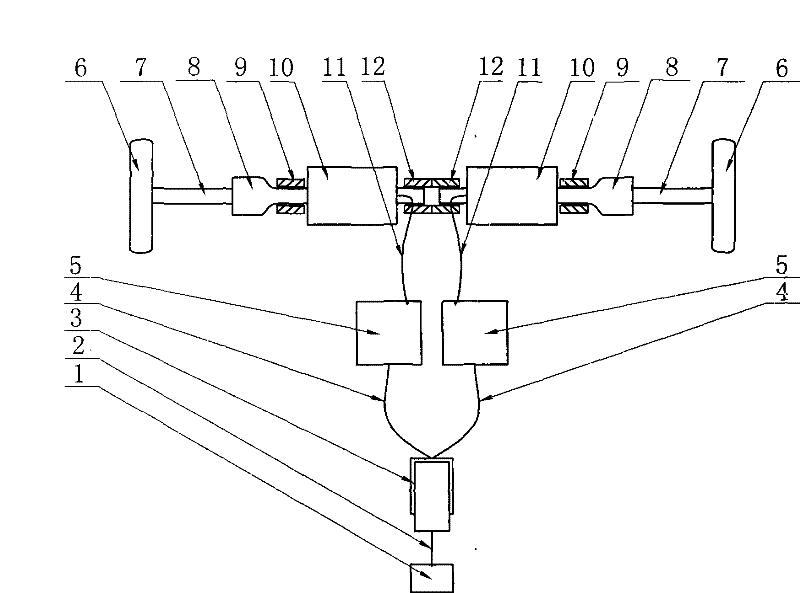

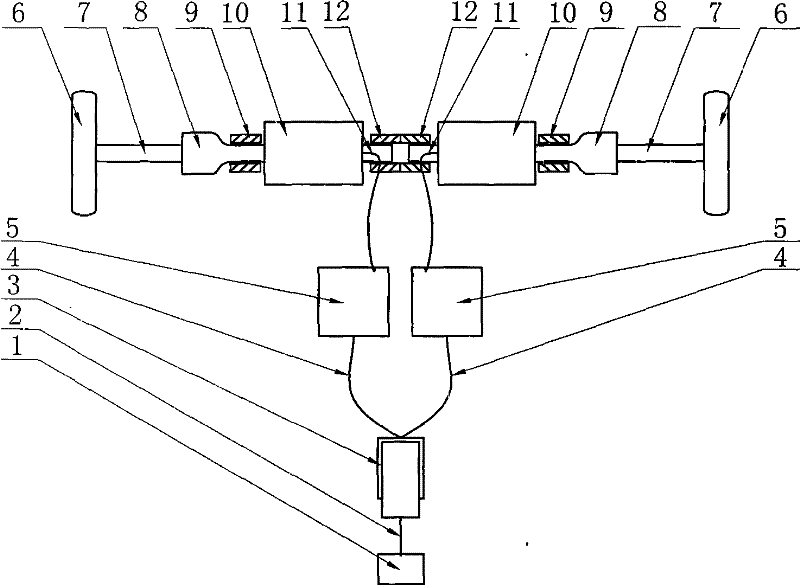

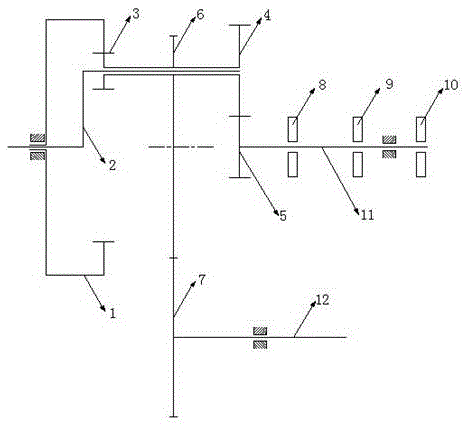

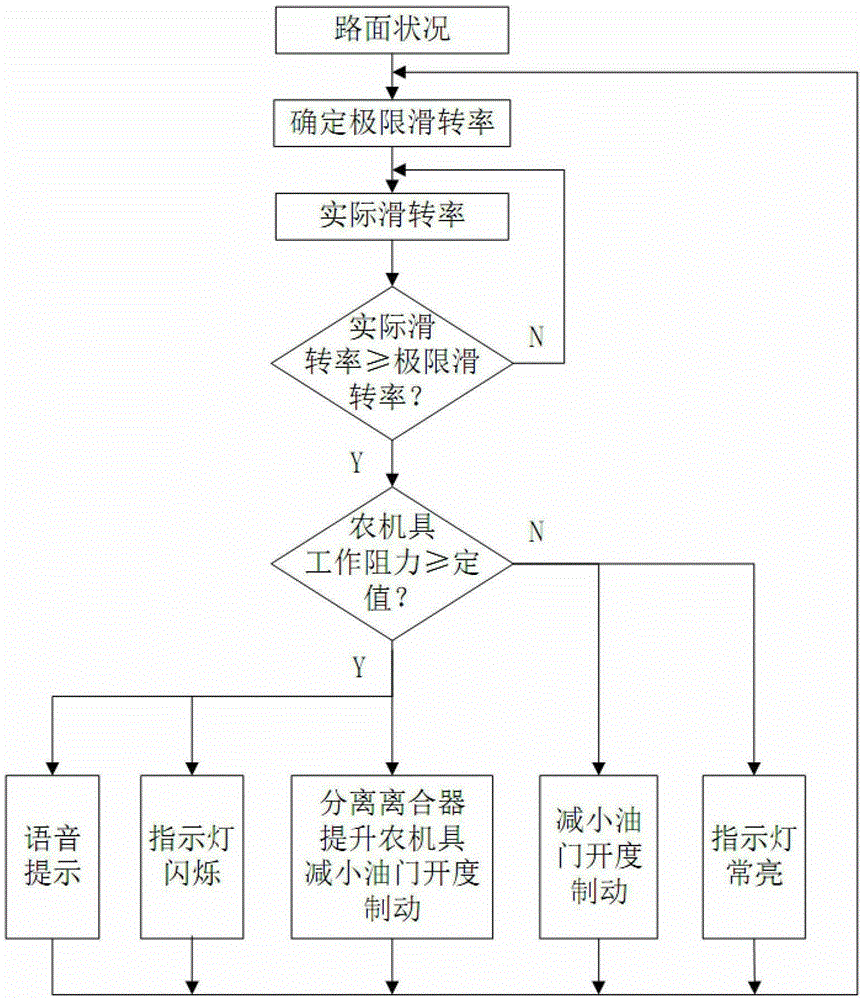

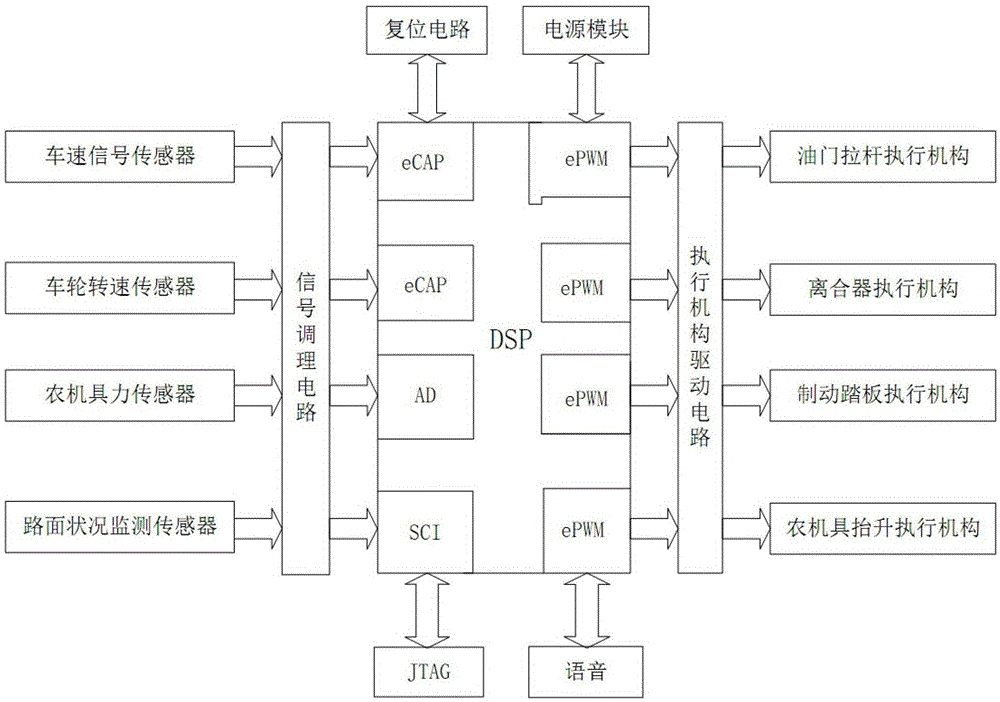

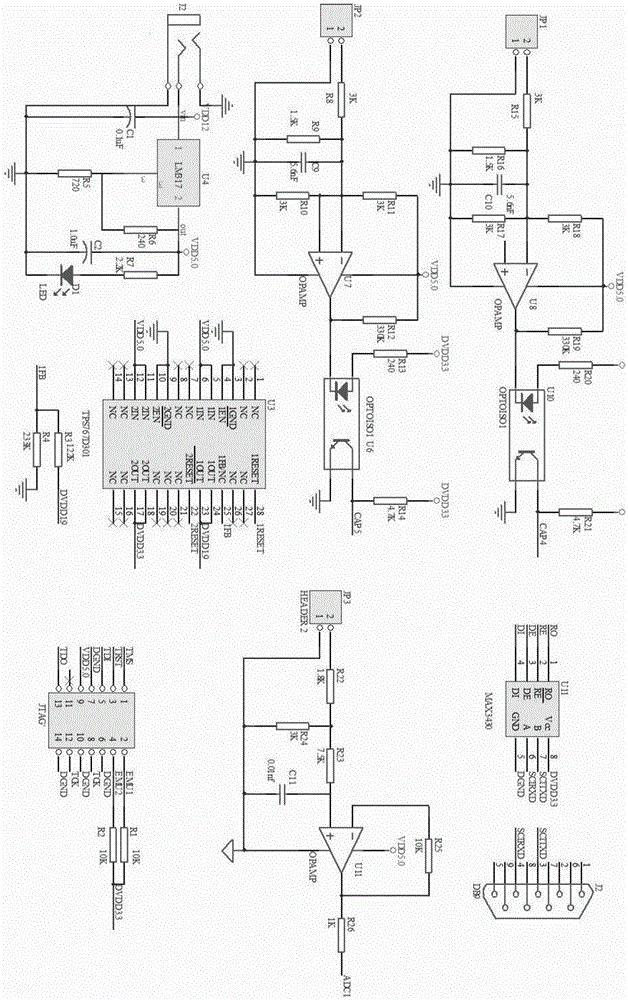

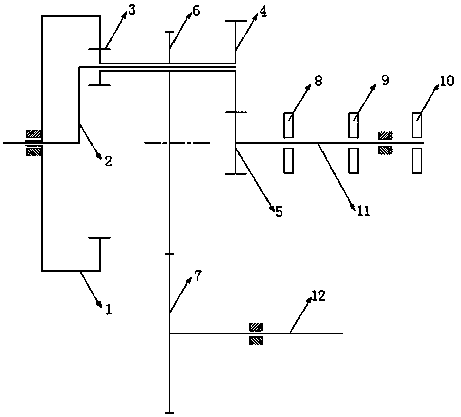

Tractor intelligent control method and intelligent control system

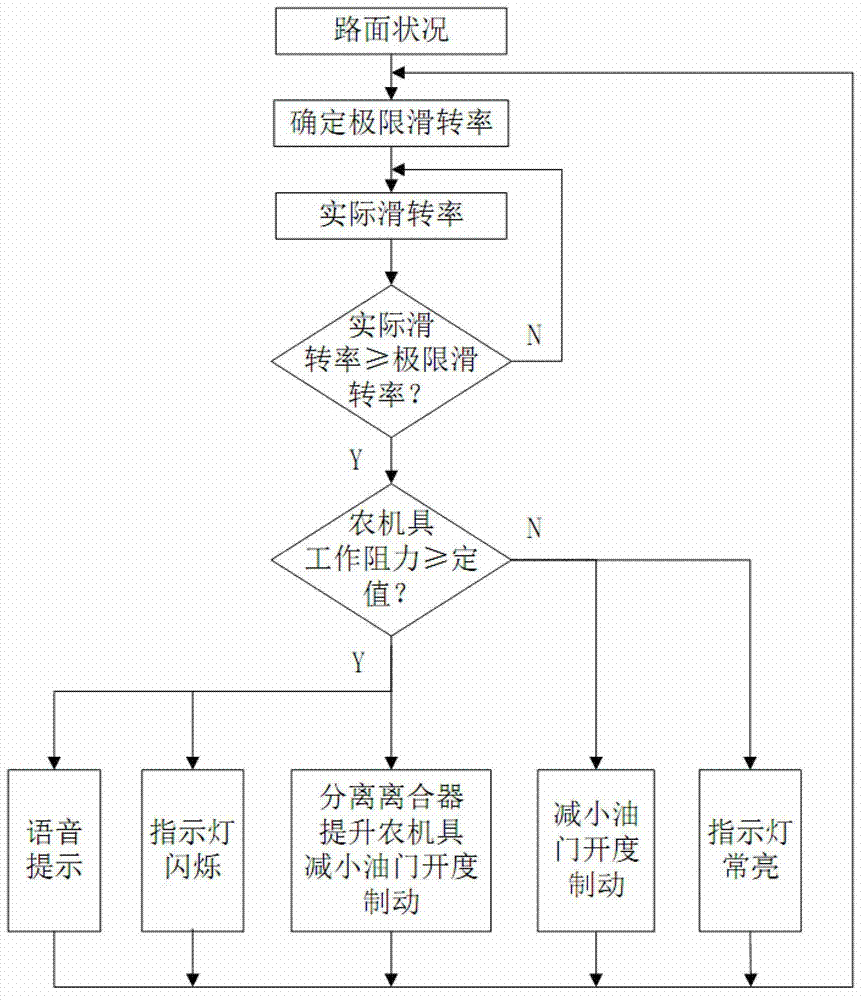

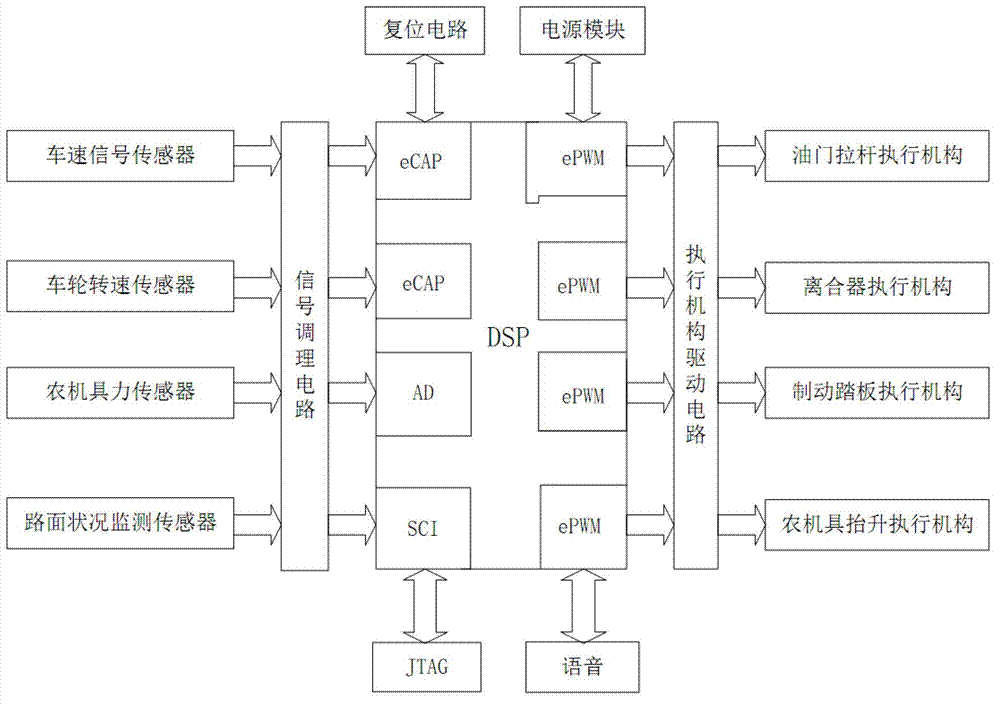

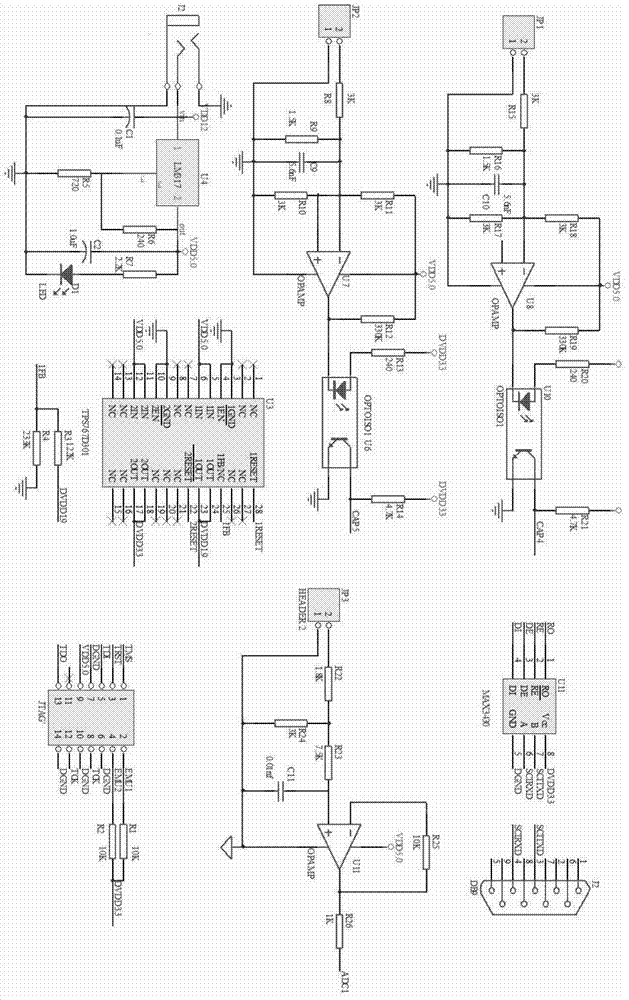

InactiveCN103158713AReduce fuel consumptionSmall slip rateInternal combustion piston enginesClutchIntelligent control system

The invention relates to a tractor intelligent control method and an intelligent control system. A corresponding signal is collected by a sensor to obtain an existing operating state of a tractor, all parameters are calculated, analyzed and judged by a controller on the basis, and after information is processed, control signals are transmitted to a stepping motor and a high-speed electromagnetic valve so as to enable a main clutch, a PTO clutch, and a brake pedal executing mechanism, an engine throttle draw bar executing mechanism, a hydraulic hanging mechanism and the like to conduct motion to prevent a driving wheel of the tractor from excessive trackslip and overload of a transmission system, ensure good comfort, fuel economy and traction, and prolong service life of the transmission system and tires of the tractor.

Owner:HENAN UNIV OF SCI & TECH

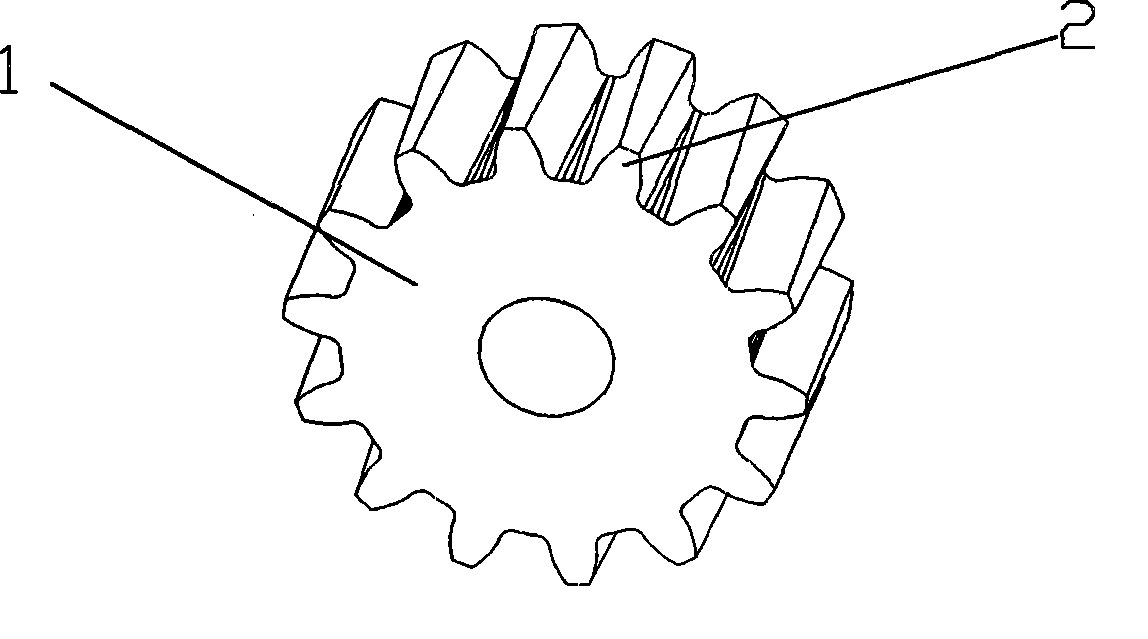

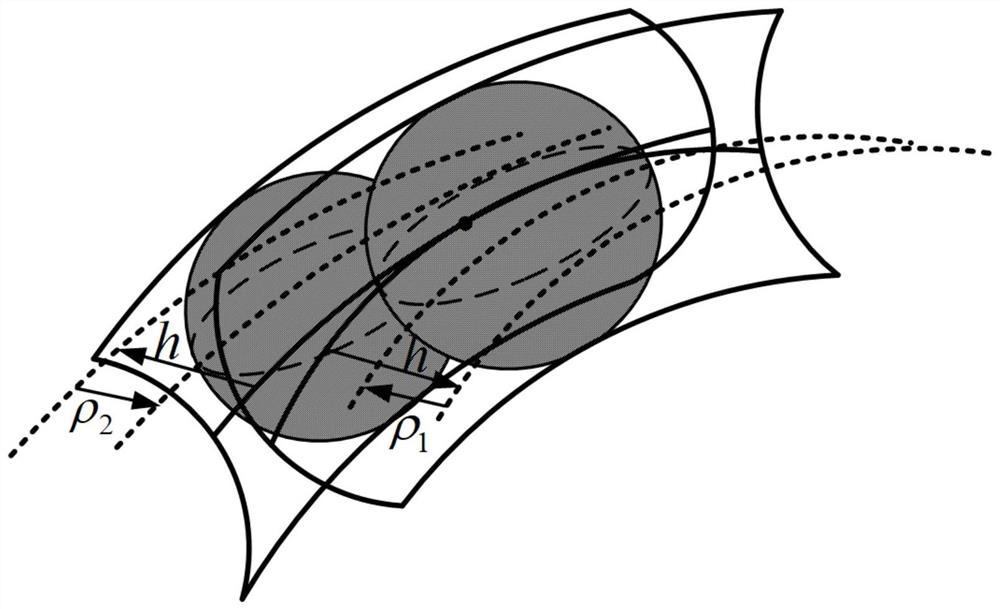

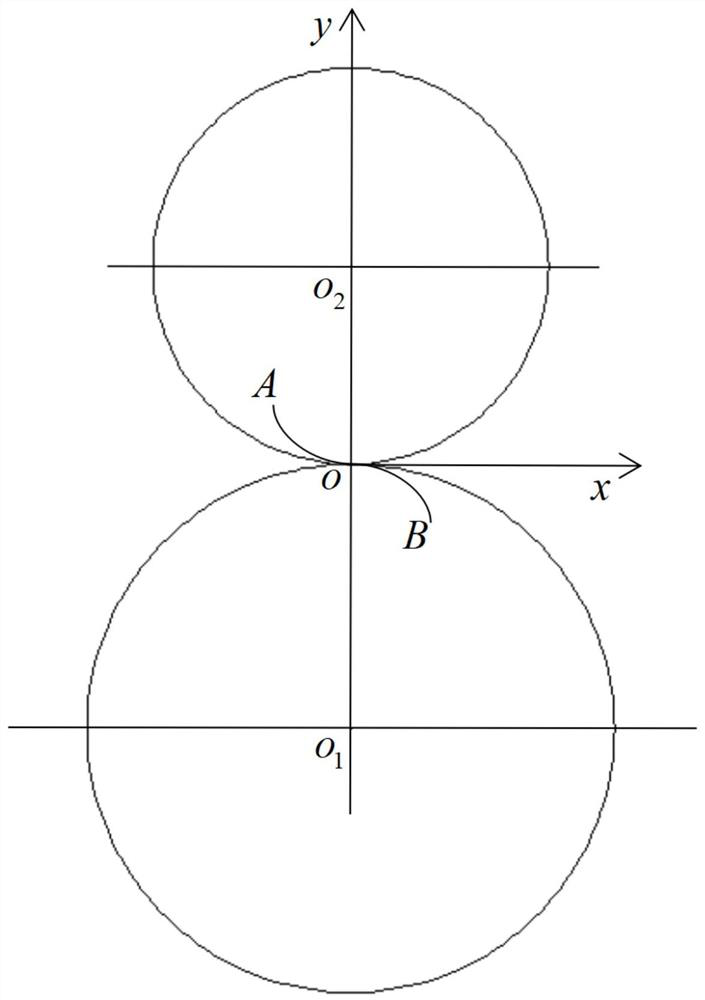

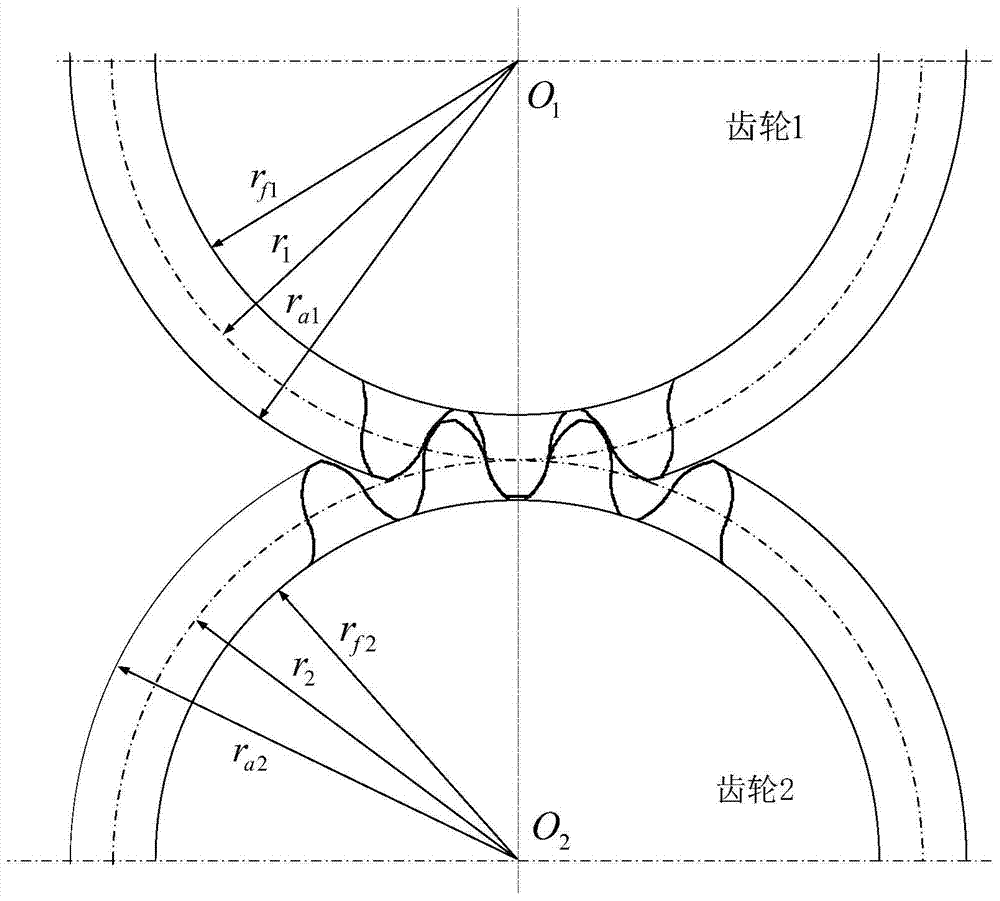

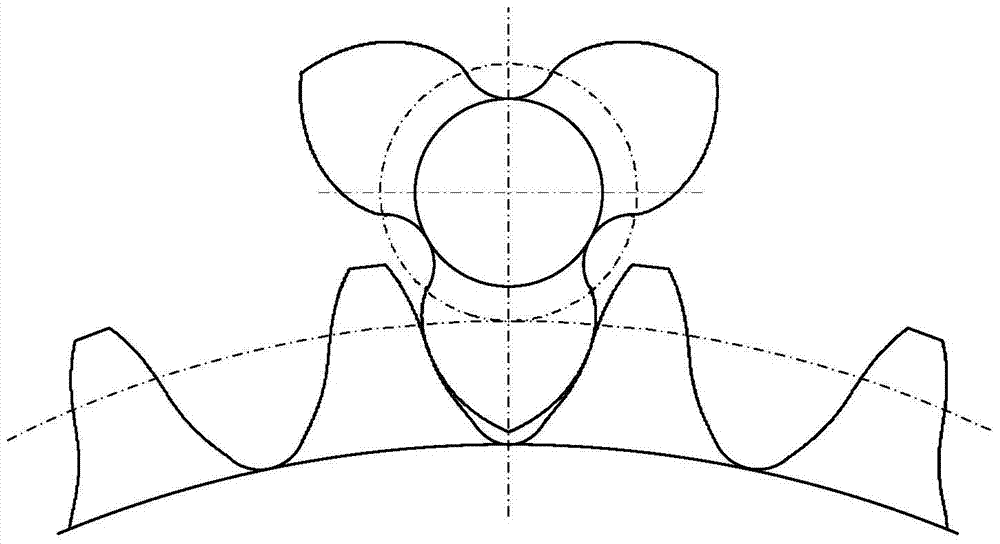

Point contact gear and meshing pair based on conjugate curves and machining tool thereof

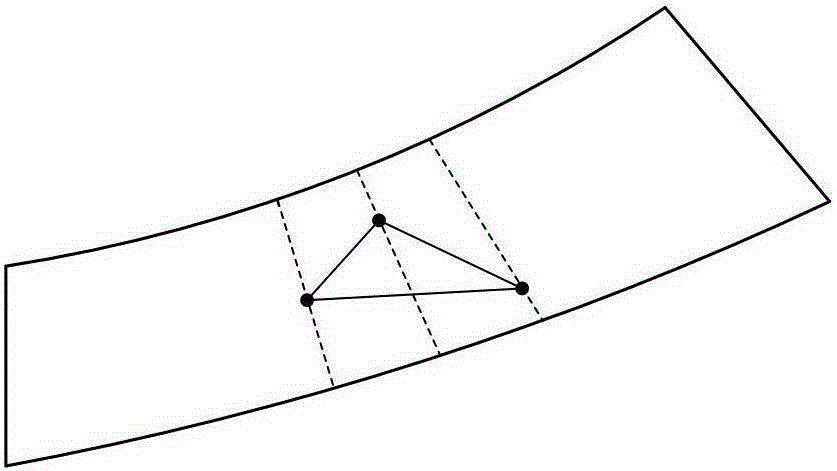

ActiveCN103939575AReduce processing costsImprove transmission efficiencyPortable liftingGear teeth manufacturing toolsEngineeringGear tooth

The invention discloses a point contact gear and a meshing pair based on conjugate curves and a machining tool of the point contact gear and the meshing pair. The point contact gear comprises a convex gear and a concave gear which are in one-point or multi-point contact meshing, and a contact curve composed of meshing points on a tooth profile curved surface of the convex gear and a contact curve composed of meshing points on the concave gear are the conjugate curves. According to the point contact gear meshing pair based on the conjugate curves, a convex gear tooth surface and a concave gear tooth surface are in one-point or multi-point contact at the same time according to the meshing mode of the meshing pair, and the contact tracks of the contact points on the tooth surfaces are smooth space curves. The meshing characters of the conjugate curves are inherited by the transmission, point contact tooth profiles are high in contact strength, high in bearing capacity, high in transmission efficiency and low in lubricating oil temperature rise, the sliding ratio is greatly lowered, and abrasion is low. Meanwhile, gear meshing achieves one-point contact or double-point contact or multi-point contact at the same time through different contact curves according to different use needs, and the problem that an existing point contact gear with a ball race pipe type envelope surface with a sphere center moving along a circle center curve as a tooth profile curved surface only achieves one-point contact in the meshing process is solved.

Owner:CHONGQING UNIV

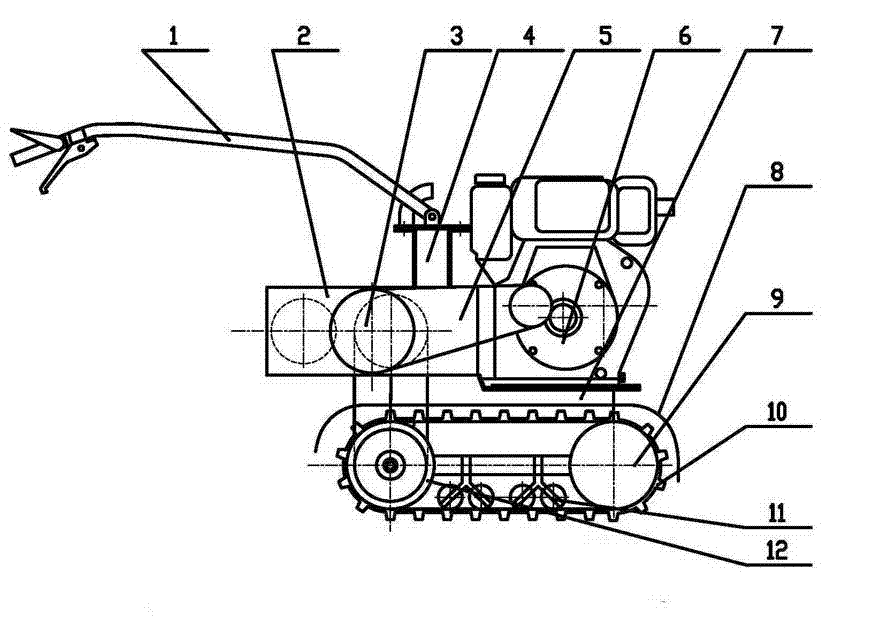

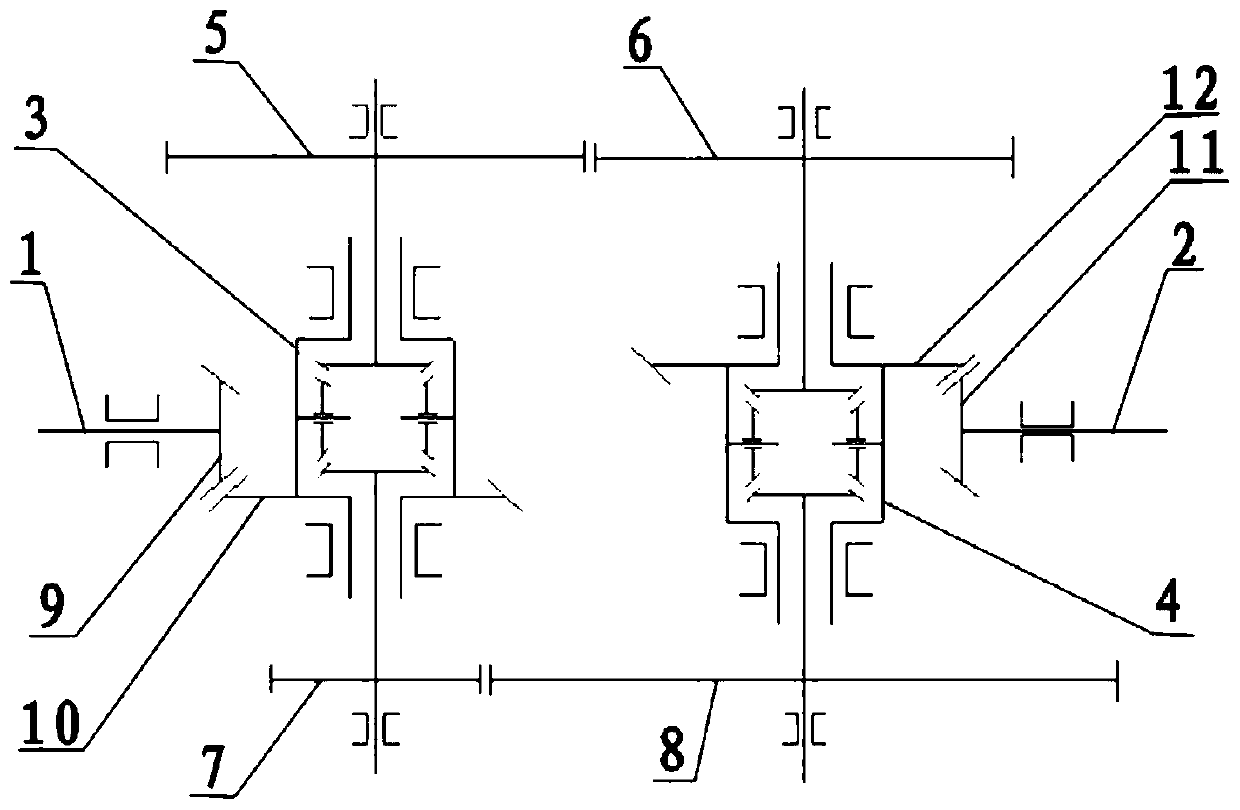

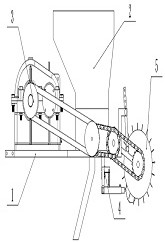

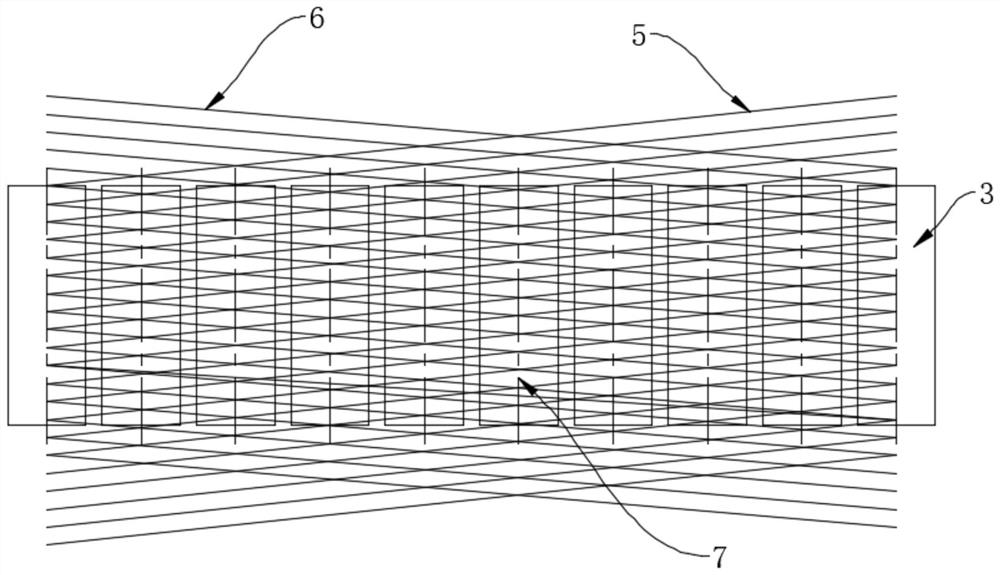

Power chassis of double crawler belt-type micro tillage machine

InactiveCN102812798AImprove job stabilityReduce the difficulty of manipulationTilling equipmentsAgricultural undercarriagesDrive wheelEngineering

The invention discloses a power chassis of a double crawler belt-type micro tillage machine. The power chassis comprises an engine, a rack, a belt transmission mechanism, a speed changing box, a chain transmission mechanism, and a crawler belt traveling mechanism arranged at the bottom of the rack, wherein power output by the engine is output to the speed changing box through the belt transmission mechanism; after speed change of the speed changing box, the power is output in two ways; one way of power is output to a crawler belt driving wheel in the crawler belt traveling mechanism to drive the whole chassis to travel; and other way of power is output to the chain transmission mechanism to drive external working parts by a chain drive driving wheel. With the adoption of the device, the operation stability of the micro tillage machine is improved, and the manipulation difficulty of a machinist is lightened; and the power chassis of the double crawler belt-type micro tillage machine also has the advantages of strong climbing ability, flexibility in steering, large tractive force and small slipping rate.

Owner:HENAN UNIV OF SCI & TECH

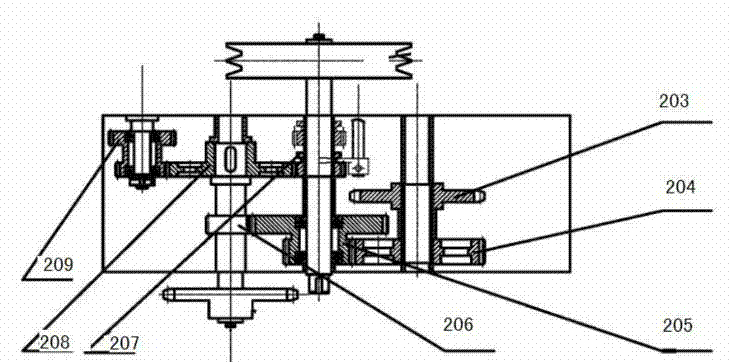

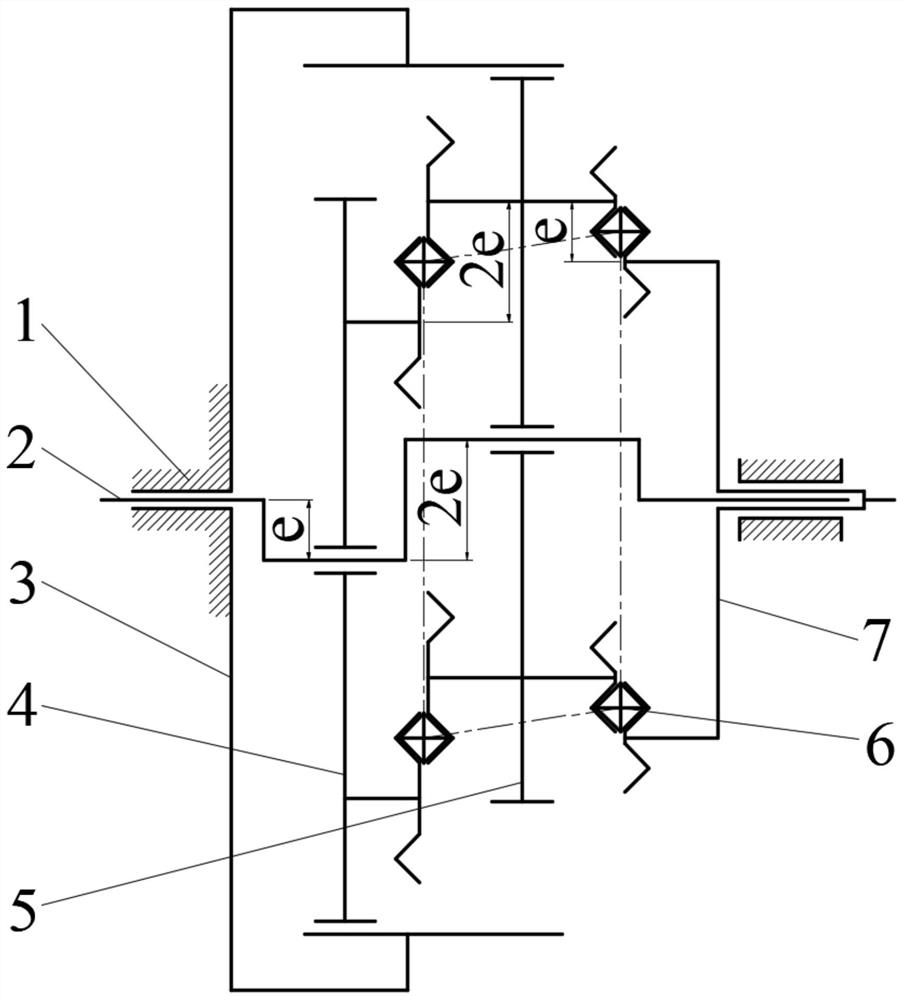

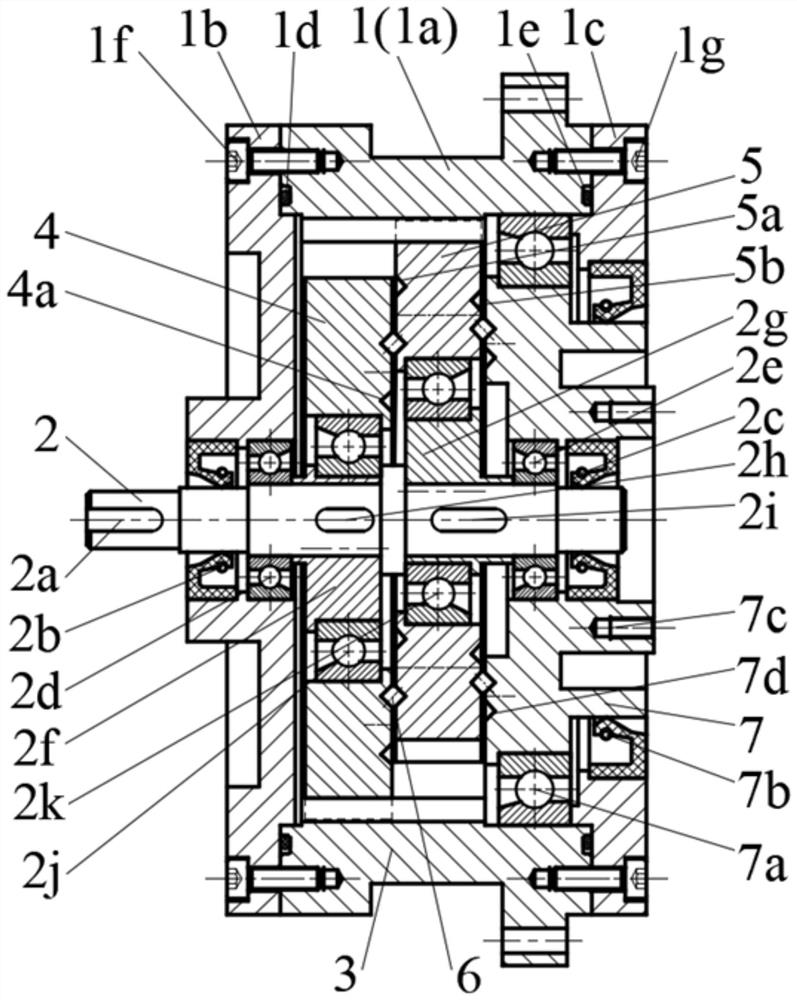

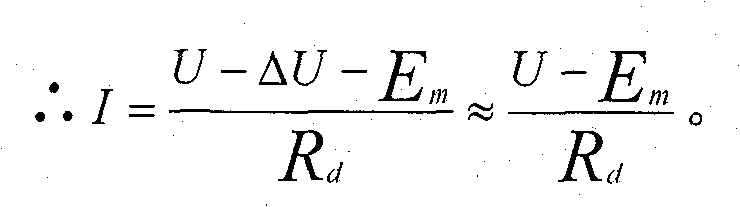

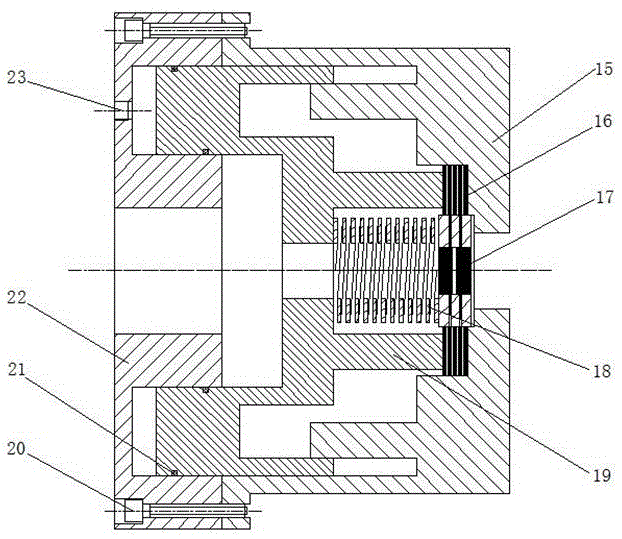

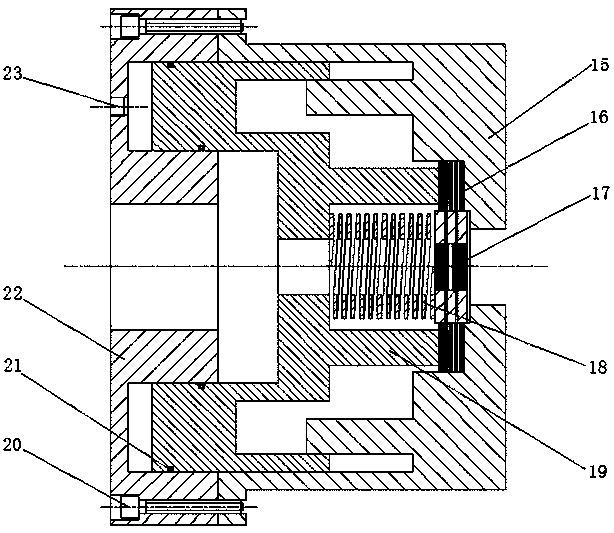

Double differential type continuously variable transmission device

InactiveCN103775579ASmall slip rateIncrease power outputToothed gearingsGearing detailsClutchGear transmission

The invention relates to the filed of transmission device, and in particular relates to a double differential type continuously variable transmission device. The double differential type continuously variable transmission device comprises an input shaft, an output shaft, a first differential mechanism, a second differential mechanism and a transmission mechanism, wherein the input shaft is connected with the first differential mechanism, the first differential mechanism is connected with the second differential mechanism through the transmission mechanism, the output shaft is connected with the second differential mechanism, and the transmission mechanism is a gear structure. According to the double differential type continuously variable transmission device provided by the invention, by using the two differential mechanisms and the transmission mechanism constituted by gear transmission, the real-time stepless speed change of the transmission device is achieved through simultaneously controlling the revolution speeds of one or more differential gears, and the design requirement of various kinds of cars on the range of transmission ratios is achieved through adjusting the transmission mechanism according to a certain rule; the problem that the speed change is slow in response and not sensitive enough is solved; the whole transmission process is performed completely by gears without any clutch and coupler device, so that the sliding ratio of the continuously variable transmission device is reduced, the bearable power output is increased, and the overload resistance and the shock resistance of the continuously variable transmission device are improved.

Owner:张宝山

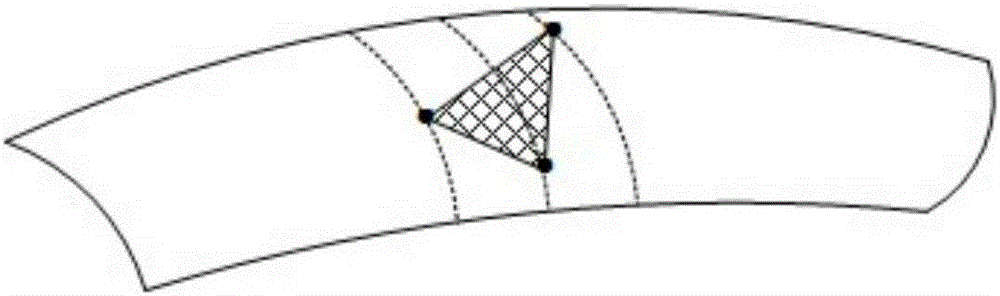

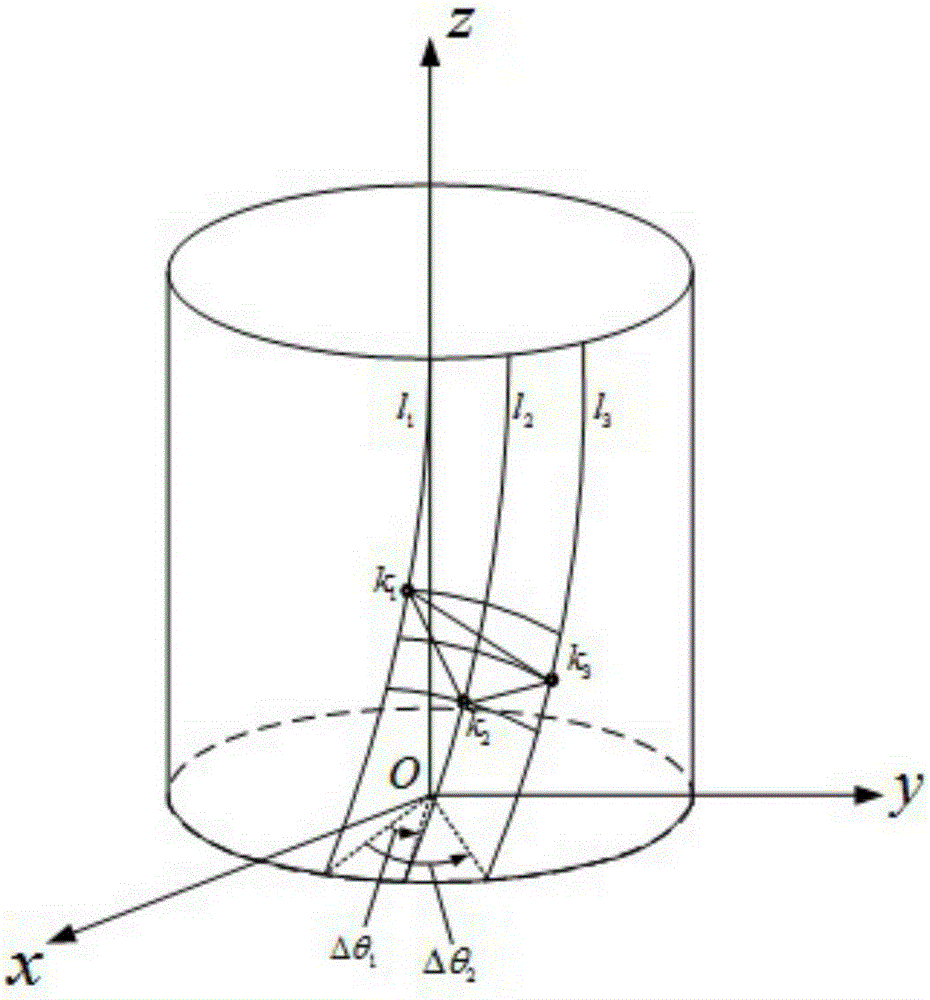

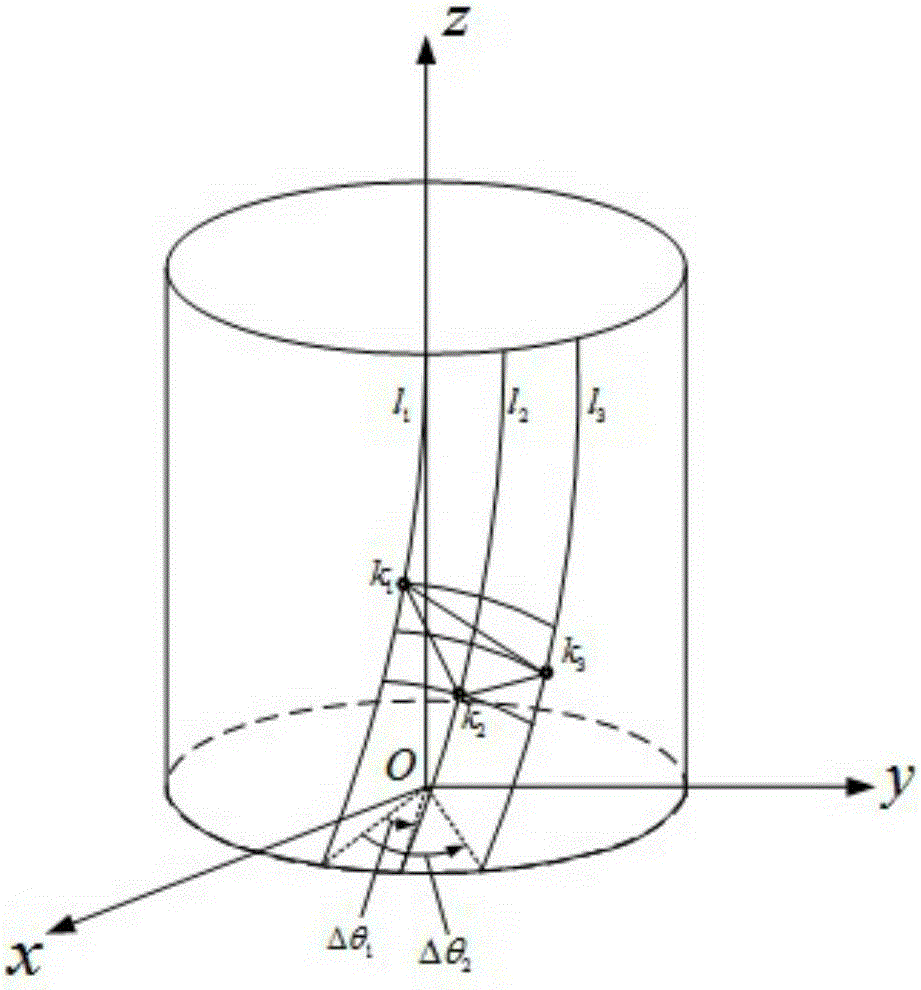

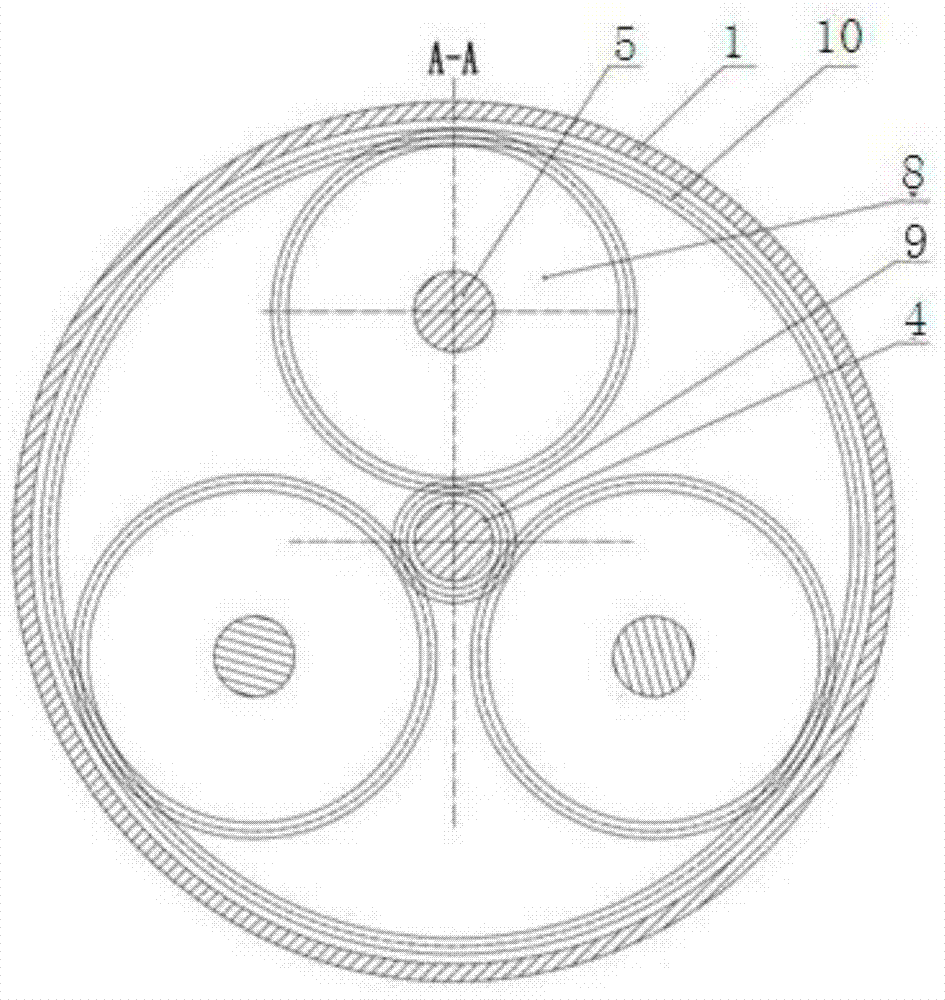

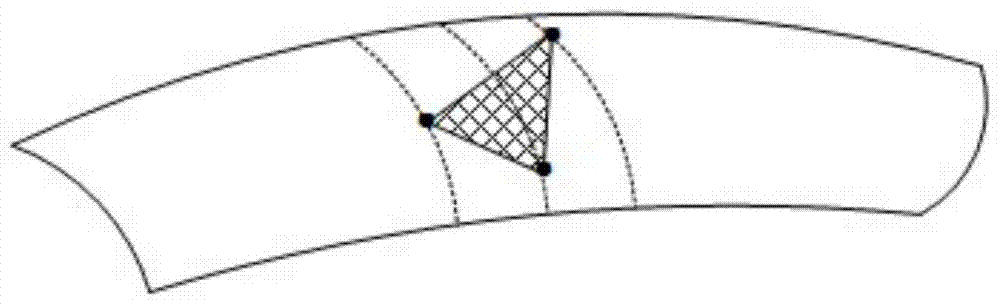

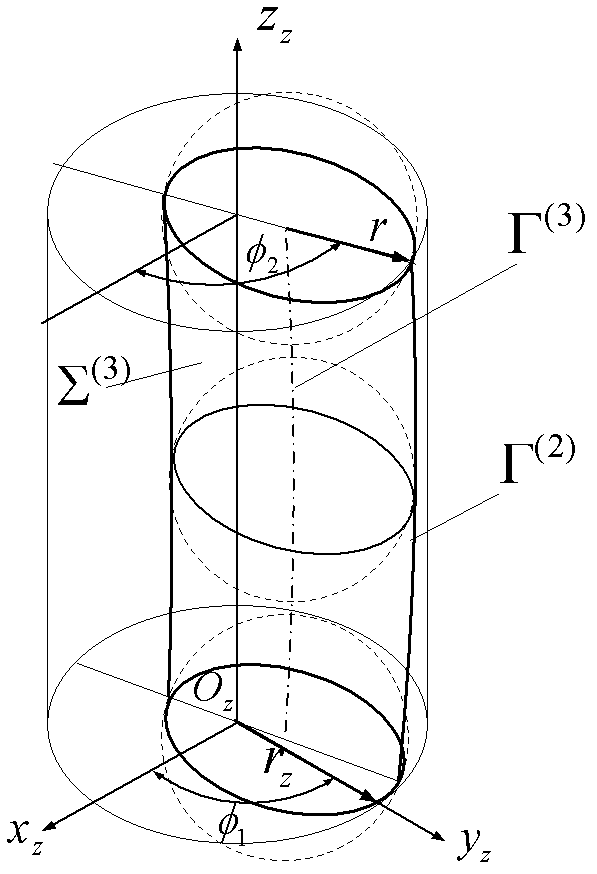

Multi-point contact cylindrical gear meshing pair based on conjugate curves

ActiveCN105202115AReduce wearReduce temperature riseToothed gearingsGearing elementsMesh pointEngineering

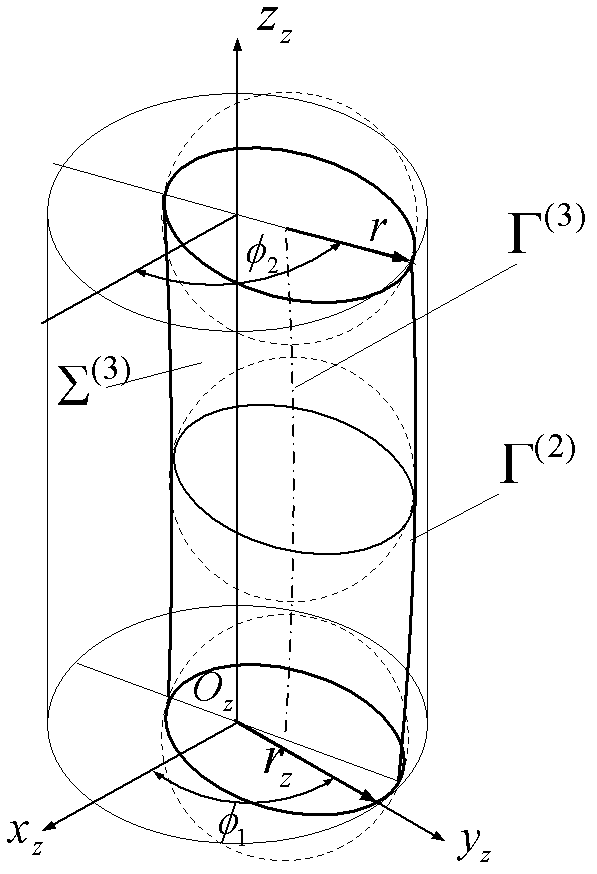

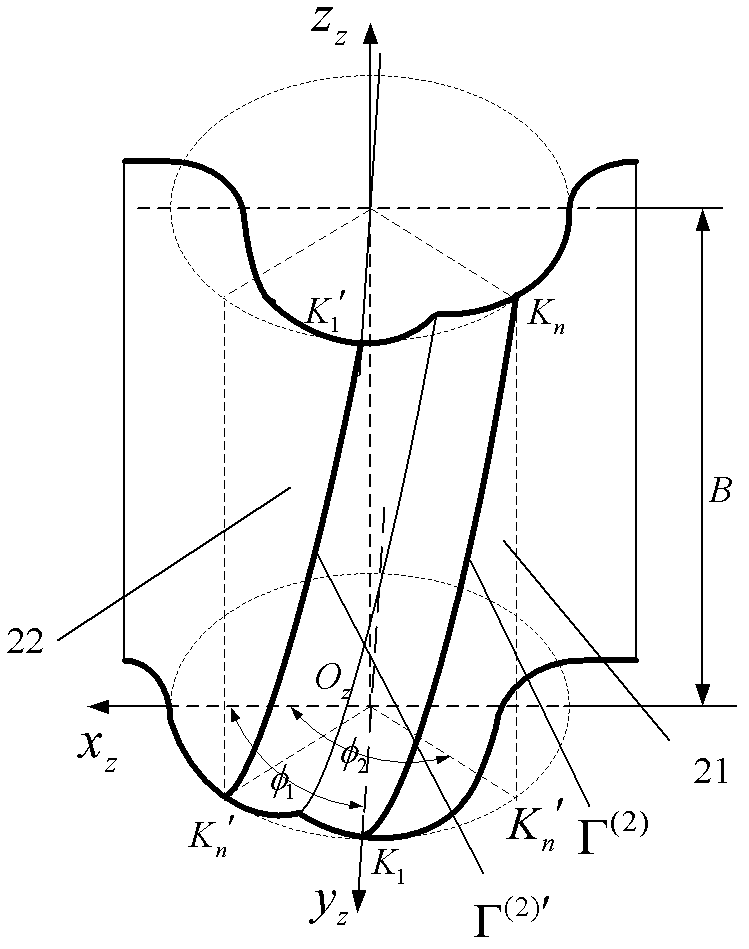

The invention discloses a multi-point contact cylindrical gear meshing pair based on conjugate curves. The multi-point contact cylindrical gear meshing pair comprises a convex-tooth gear and a concave-tooth gear which are in mutual multi-point contact meshing, wherein a meshing curve surface of the convex-tooth gear and the concave-tooth gear is a tubular curve surface; a contact curve consisting of meshing points on a tooth profile curve surface of the convex-tooth gear and a contact curve consisting of meshing points on the convex-tooth gear are the conjugate curves. According to the multi-point contact cylindrical gear meshing pair based on the conjugate curves, the meshing mode of the meshing pair is simultaneous multi-point contact of the tooth surfaces of the convex-tooth gear and the concave-tooth gear, and contact tracks of the contact points on all tooth surfaces are smooth space curves. The transmission integrates the meshing characteristics of the conjugate curves, tooth profile contact strength of point contact is high, the bearing capacity is high, the transmission efficiency is high, the lubricating oil temperature rise is slow, the sliding rate is reduced greatly, and the wear is low.

Owner:CHONGQING UNIV

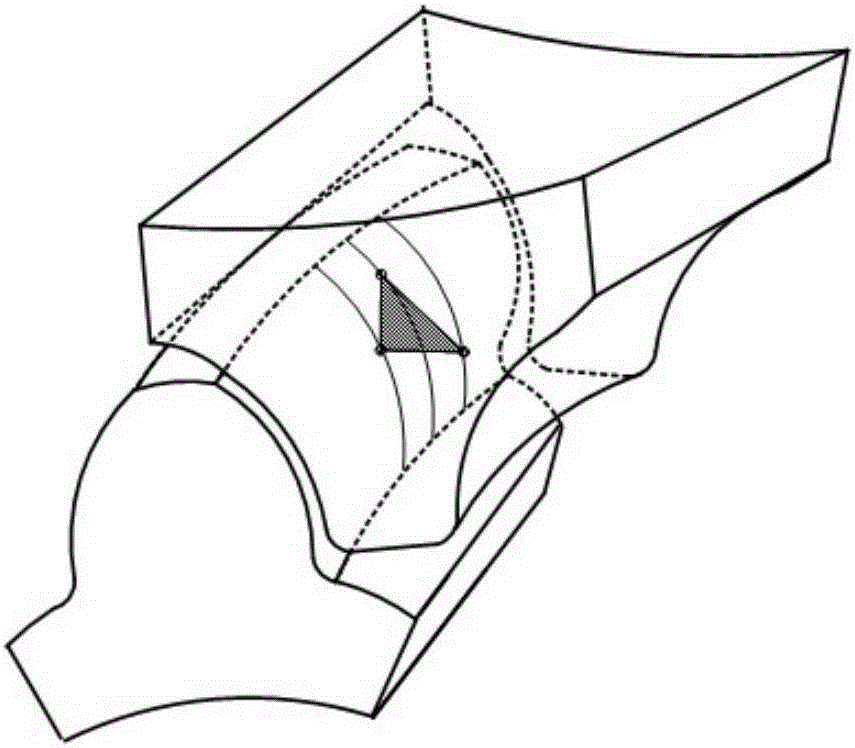

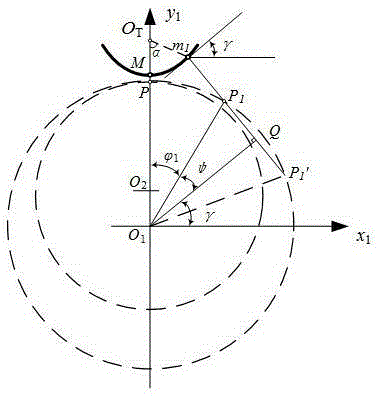

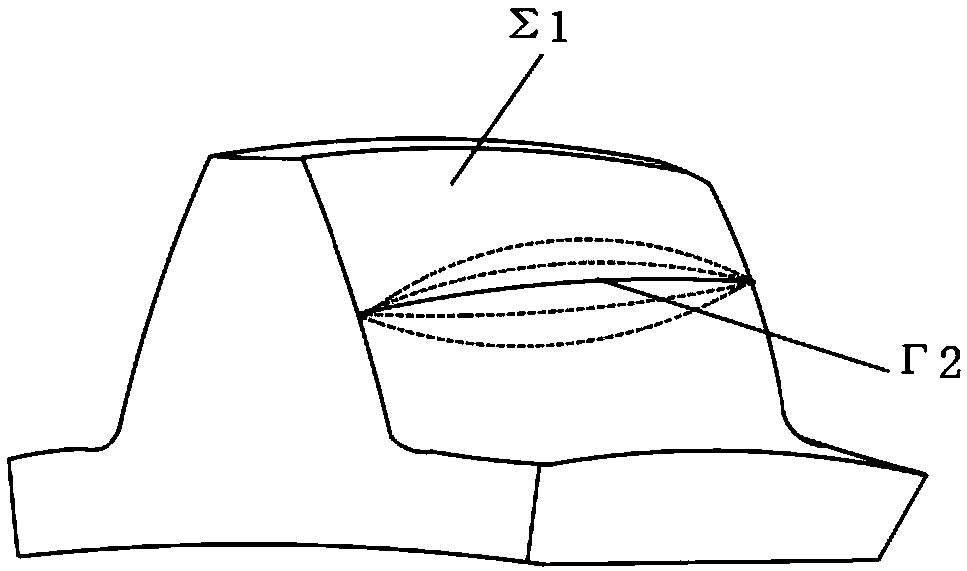

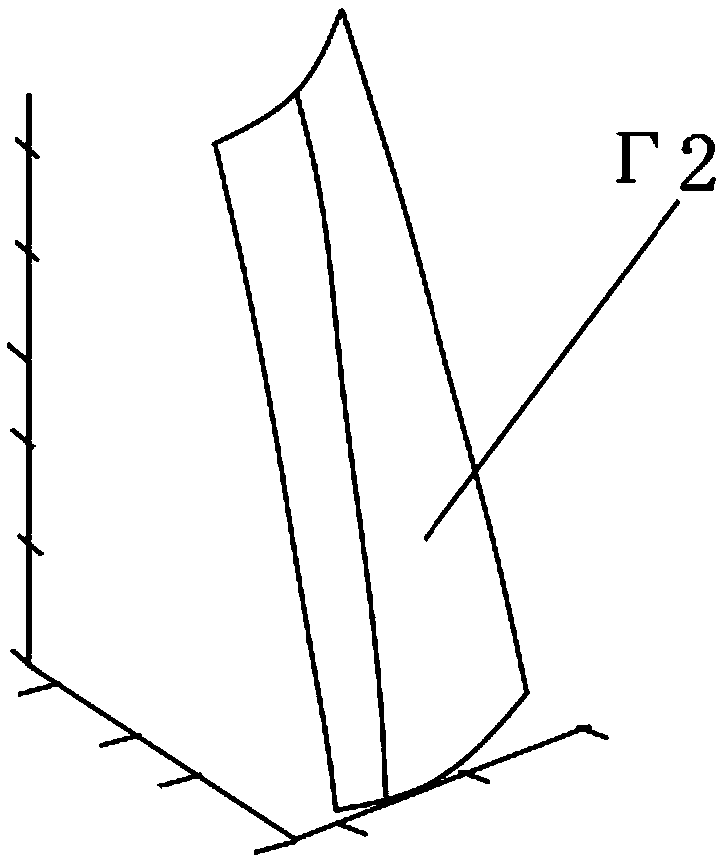

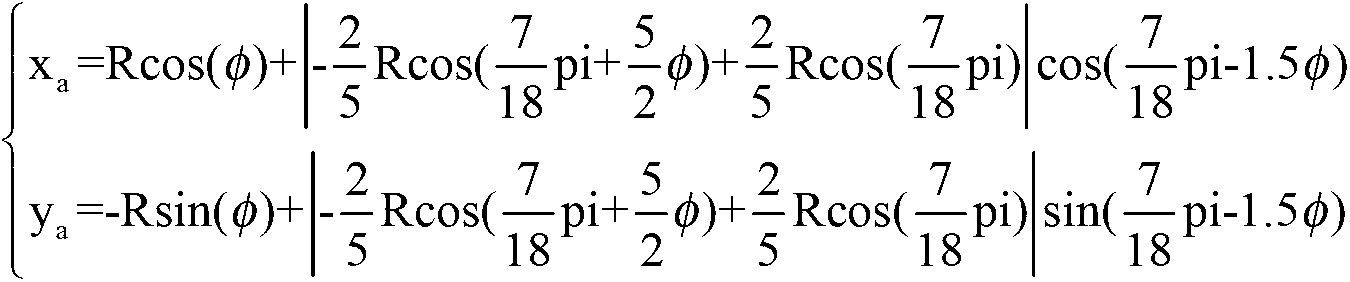

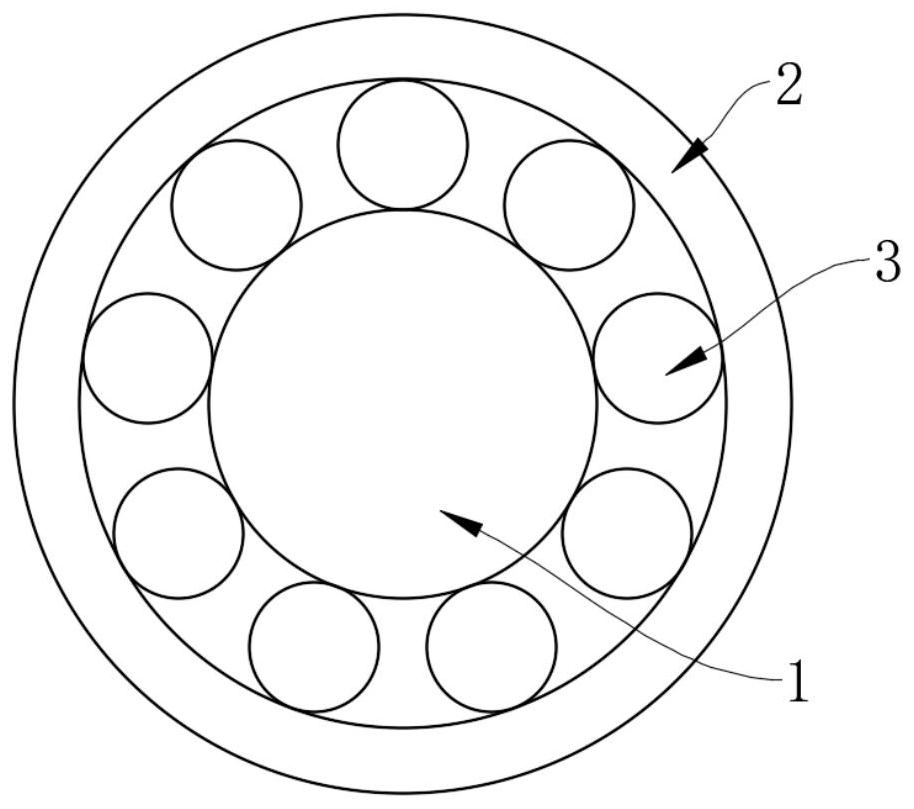

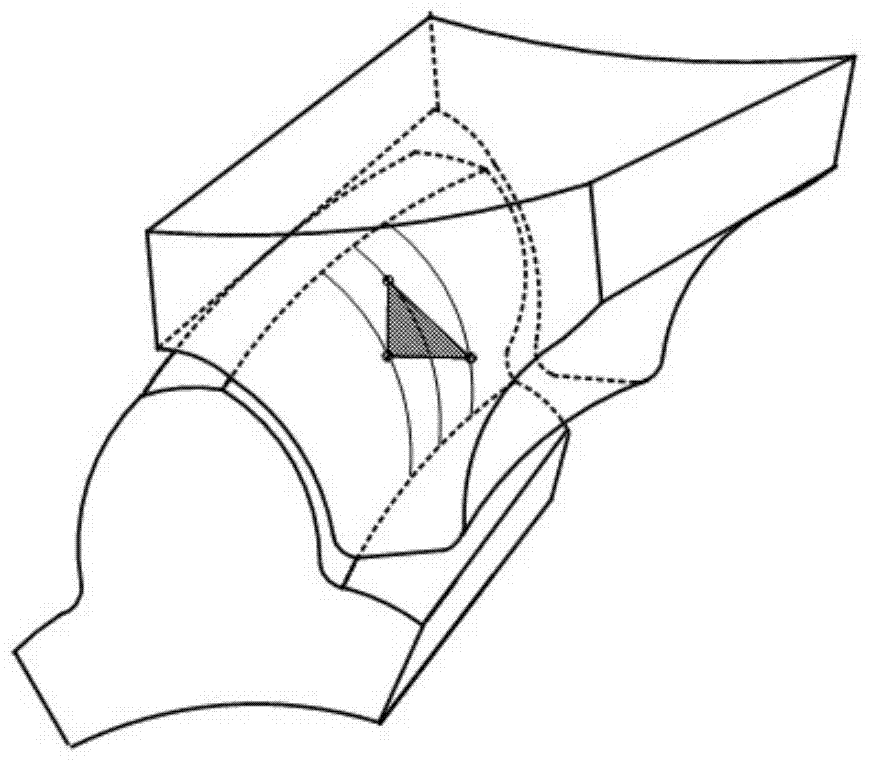

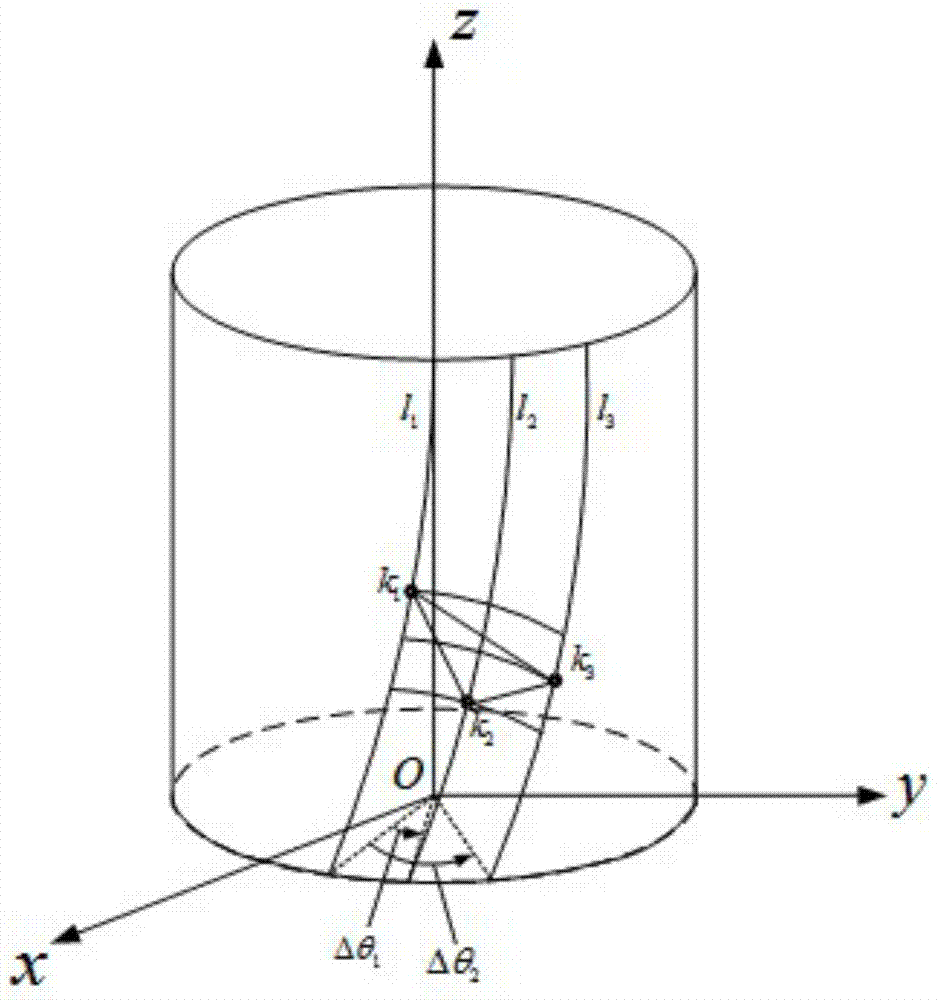

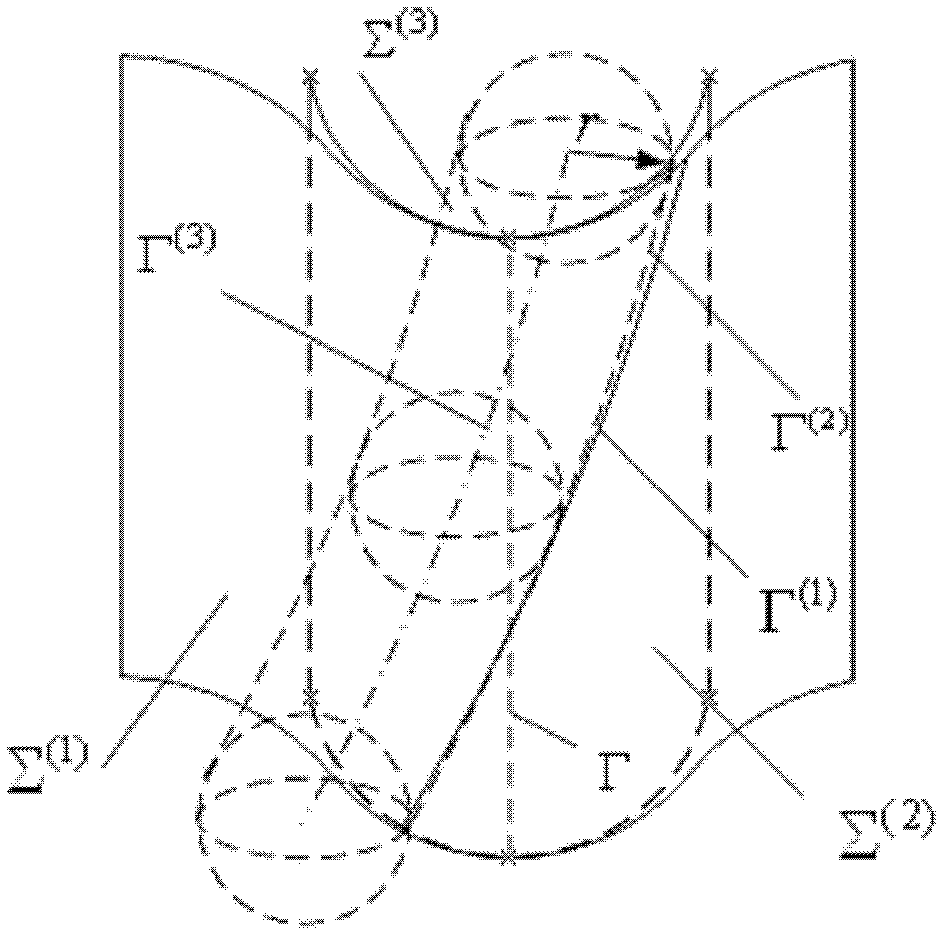

Cycloid planetary transmission gear based on line-surface conjugation

ActiveCN102252058AImprove rigidityGood transmission precisionToothed gearingsPortable liftingEngineeringCycloid

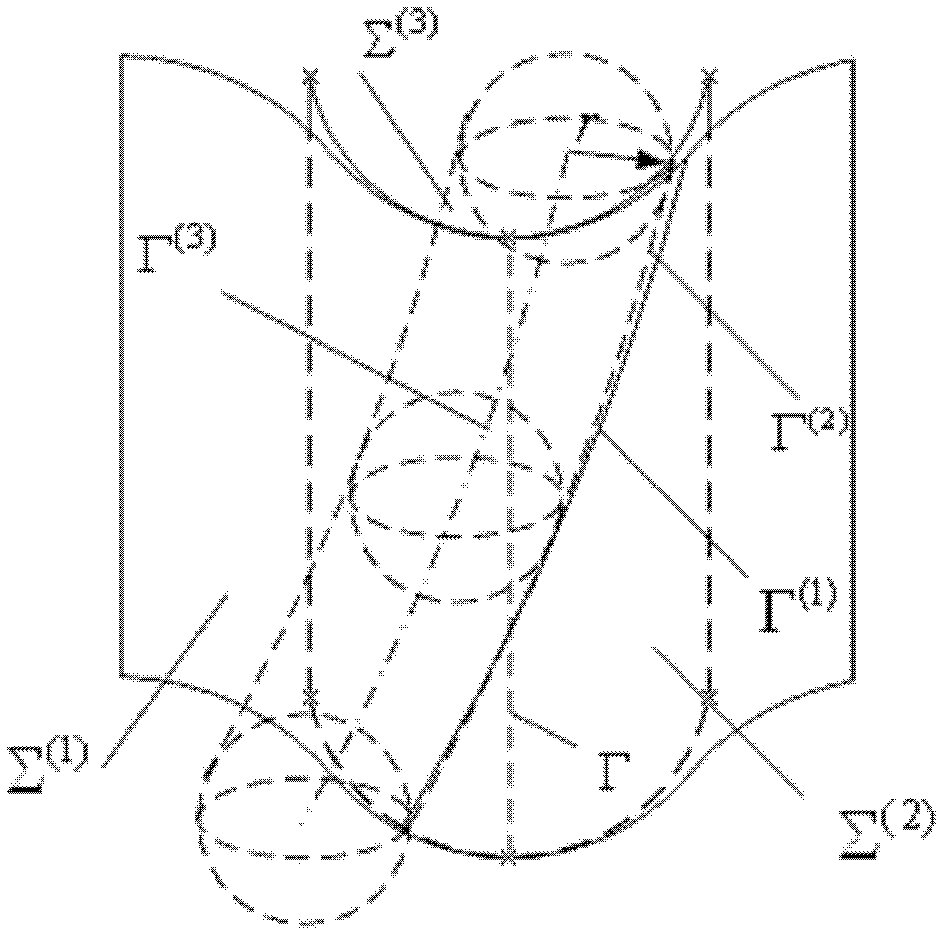

The invention discloses a cycloid planetary transmission gear based on line-surface conjugation, and relates to a cycloid planetary transmission gear which comprises a cycloid pin wheel planetary transmission meshed pair. A smooth curve line inverted L (2) is selected on a gear surface of a gear in the meshed pair, the main normal vector direction is consistent with the normal direction of the gear surface, and the curve line inverted L (2) and the gear surface of another gear in the meshed pair form line-surface conjugation mesh; the gear surface of the gear is a tubular meshed surface which is a sphere family enveloping surface sigma (3) of which the sphere center moves along an equidistant line inverted L (3); the equidistant line inverted L (3) is a smooth curve line which has a distance of r from the main normal vector direction; the spherical radius of spheres in the sphere family is the distance r between the equidistant line inverted L (3) and the smooth curve inverted L (2), and the r is less than the minimum curvature radius of the meshed section of the original gear surface. According to the invention, through changing the cycloid planetary transmission into the line-surface conjugation meshed pair, the meshed process is in the mode of point contact, the transmission ratio is great, the rigidity is good, the structure is compact, the transmission accuracy is high, the mesh can be approximately to pure rolling, the sliding ratio can be reduced greatly, thus the efficiency is improved greatly, the service life is improved, the manufacturing is simple, and the accuracy is high.

Owner:CHONGQING UNIV

Novel oil pump with ellipse-like tooth-profile rotor, ellipse-like tooth-profile rotor for oil pump, and design method of ellipse-like tooth-profile rotor

InactiveCN105257531AReduce retrofit costsHigh trafficRotary piston pumpsLubricating pumpsLow speedEllipse

The invention discloses a novel ellipse-like tooth-profile rotor. The ellipse-like tooth-profile rotor comprises an inner rotor and an outer rotor which are meshed each other, wherein the outer rotor has one or more teeth than the inner rotor; the tooth profile of each half tooth of the outer rotor consists of a section of an ellipse-like circular arc, a section of a tooth-bottom circular arc, and a circular arc chamfer which is simultaneously tangent with the ellipse-like circular arc and the tooth-bottom circular arc; the ellipticity of the ellipse-like circular arc is in square-root progressive increase with a tooth profile angle; the tooth profile of each tooth of the inner rotor is the conjugate curve of the tooth profile of the ellipse-like section of the outer rotor; during meshing, each pair of teeth of the inner rotor and the outer rotor are meshed, and meshed lines are closed. Besides, the invention further provides a design method of the ellipse-like tooth-profile rotor, and an oil pump which uses the ellipse-like rotor can be remodeled on the basis that the design of a conventional pump body is not changed, so that the remodeling cost is reduced. Besides, on the basis that the flow of the oil pump at a low speed is increased, the maximum value of a tooth-profile sliding rate at meshed boundary points, and the torque generated by oil fluid on the inner rotor are reduced; the flow performance of the rotor pump is improved; the wear is reduced, and energy sources are saved.

Owner:HUNAN UNIV

Variable diameter swinging mechanism of spring machine

The invention discloses a variable diameter swinging mechanism of a spring machine, and belongs to the technical field of key parts on a spring machine. The variable diameter swinging mechanism of the spring machine comprises a cam, a swinging rod, an adjusting block and a slide block, and also comprises a variable diameter lever which is of a structure in the shape of an inverted Chinese character 'ren'; the maximum swinging angles of the variable diameter lever and the swinging rod are all less than or equal to 10 degrees; the lower part of the variable diameter lever is installed on a lever pole; the geometric position angle of the lever pole and the cam with a rolling bearing is 90 degrees; the connecting line of the center of the cam and the swinging center of the variable diameter lever is overlapped with a central line; the middle part of the variable diameter lever is in contact connection with a second screw bolt; a first screw bolt is installed at the tail end of the variable diameter lever; the first screw bolt and the second screw bolt are both provided with spherical structures; and the central lines of the first screw bolt and the second screw bolt pass through the centers of an upper top spring base and a lower top spring base respectively. The variable diameter swinging mechanism of the spring machine provided by the invention can be used in the spring machine and has the advantages of simple structure, high transmission precision, good stability and the like.

Owner:SHAOXING JIADU SPRING MACHINE

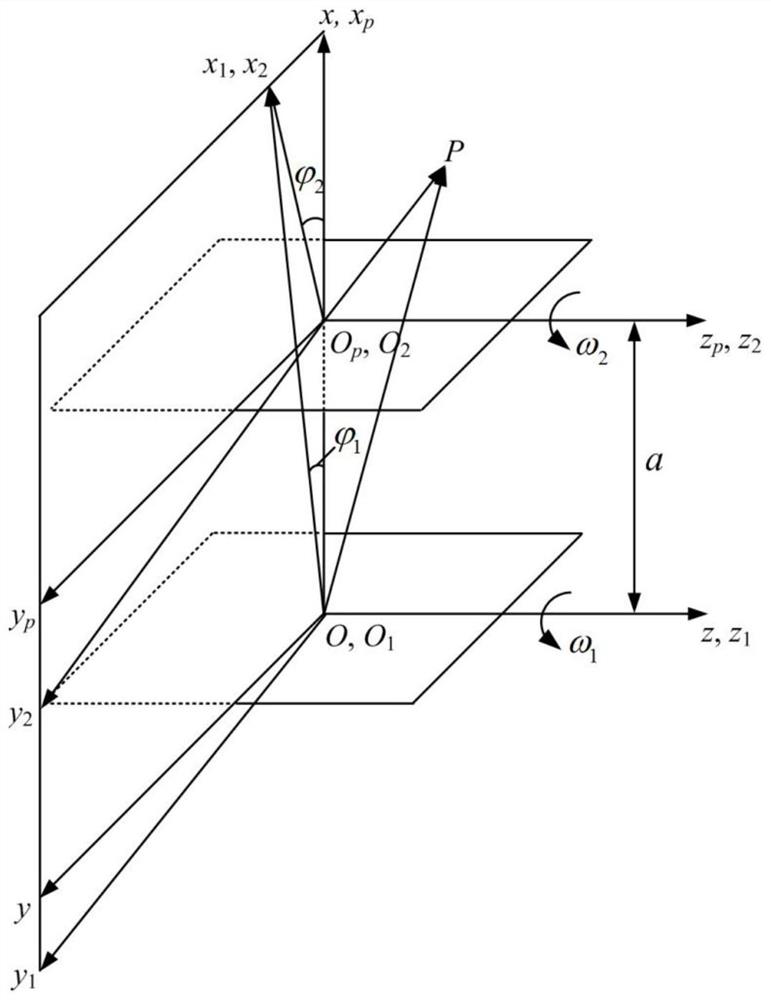

Multi-point contact bevel gear meshing pair based on conjugate curves

ActiveCN105202152AReduce wearReduce temperature risePortable liftingGearing elementsOil temperatureContact strength

The invention discloses a multi-point contact bevel gear meshing pair based on conjugate curves. The multi-point contact bevel gear meshing pair comprises a convex-tooth gear and a concave-tooth gear which are in mutual multi-point contact meshing, wherein a meshing curve surface of the convex-tooth gear and the concave-tooth gear is a tubular curve surface; a contact curve consisting of meshing points on a tooth profile curve surface of the convex-tooth gear and a contact curve consisting of meshing points on the convex-tooth gear are the conjugate curves. According to the multi-point contact bevel gear meshing pair based on the conjugate curves, the meshing mode of the meshing pair is simultaneous multi-point contact of the tooth surfaces of the convex-tooth gear and the concave-tooth gear, and contact tracks of the contact points on all tooth surfaces are smooth space curves. The transmission integrates the meshing characteristics of the conjugate curves, tooth profile contact strength of point contact is high, the bearing capacity is high, the transmission efficiency is high, the lubricating oil temperature rise is slow, the sliding rate is reduced greatly, and the wear is low.

Owner:CHONGQING UNIV

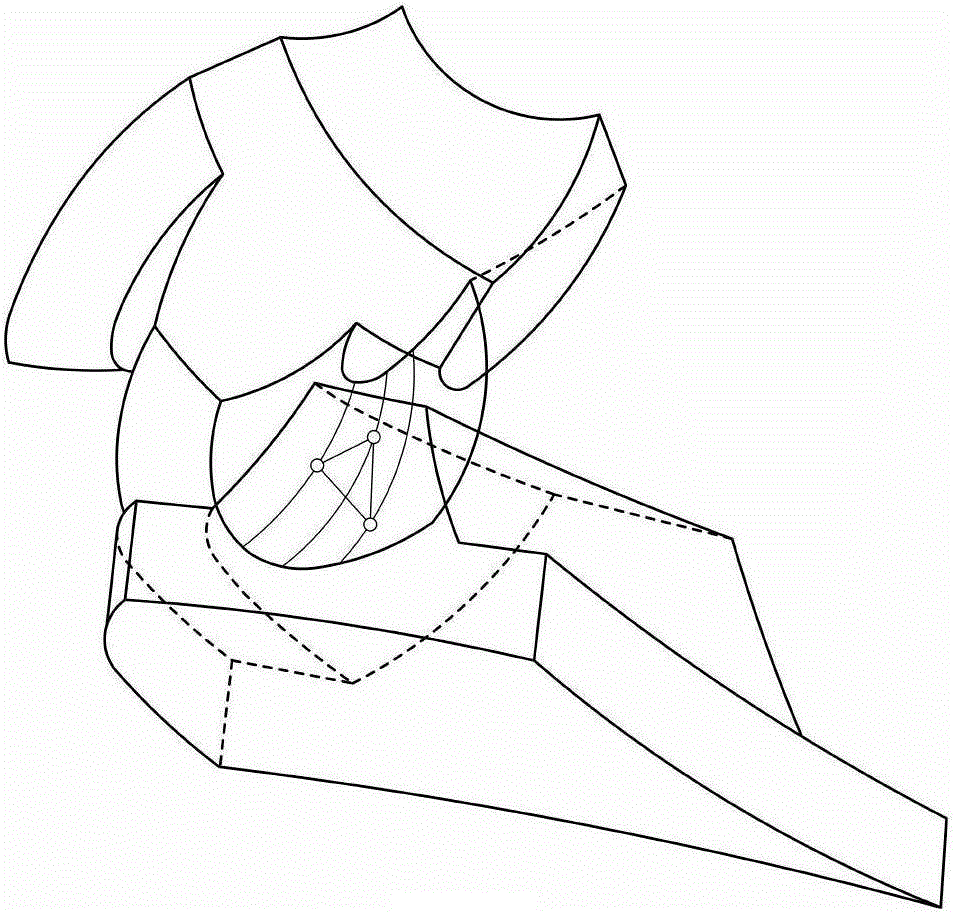

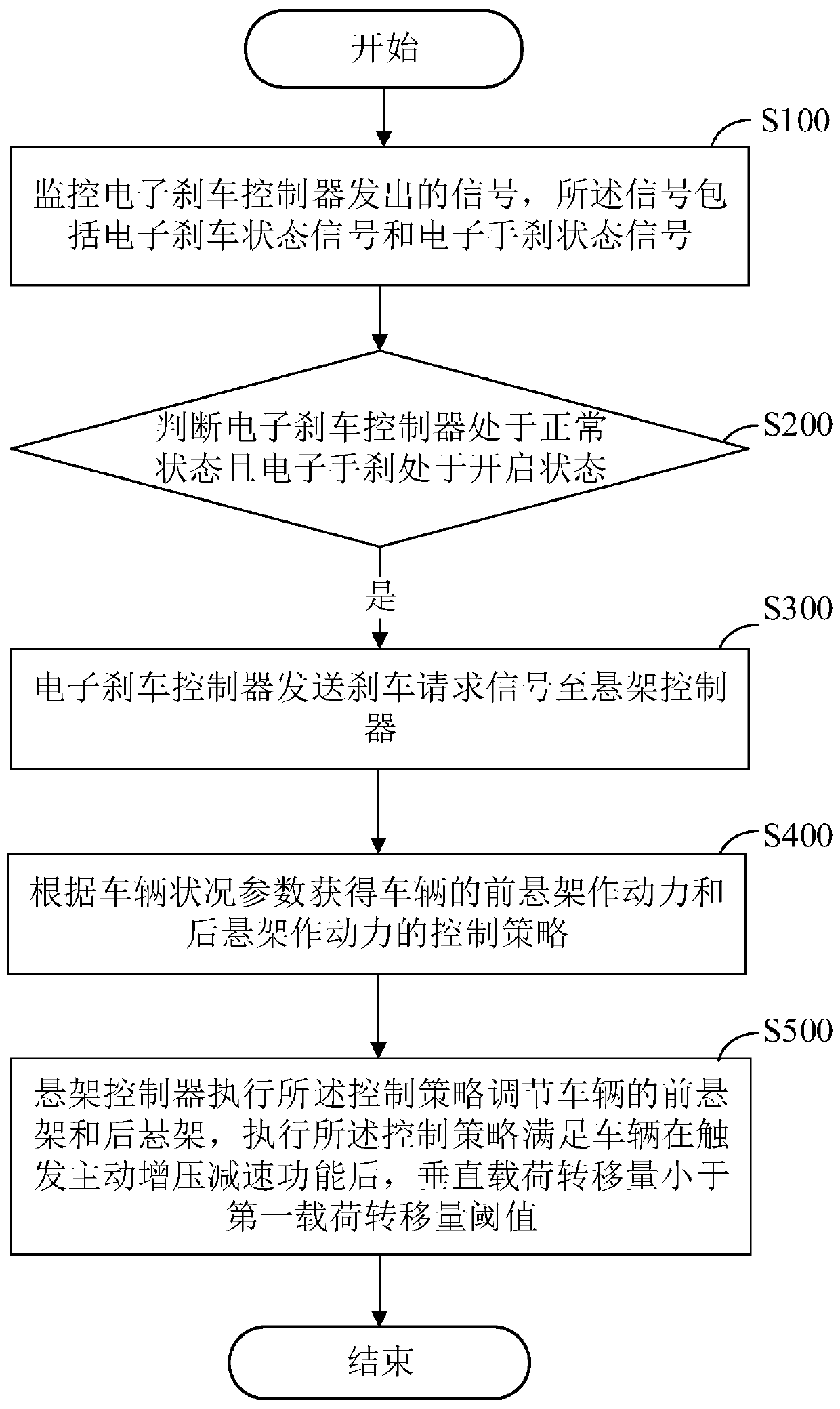

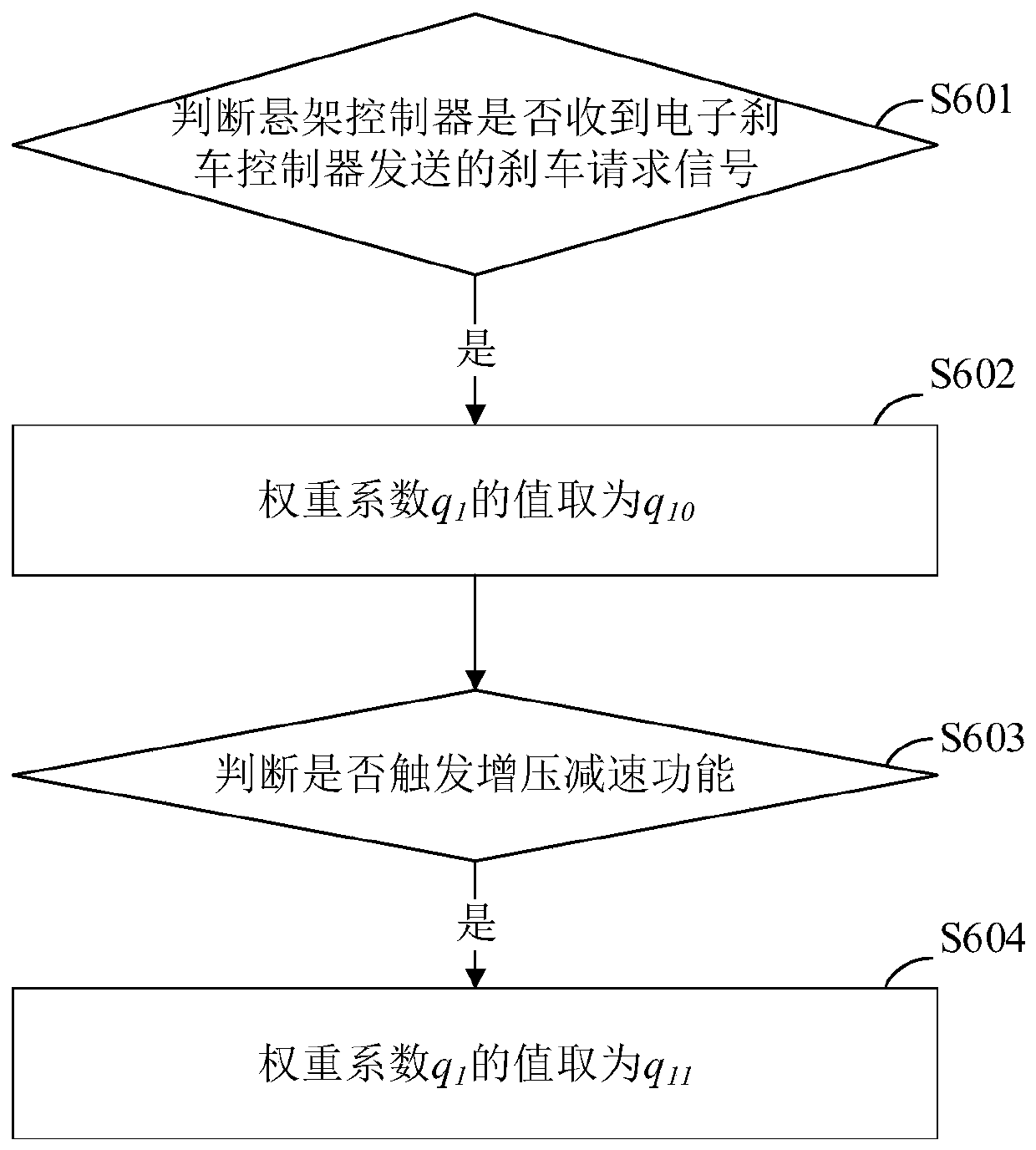

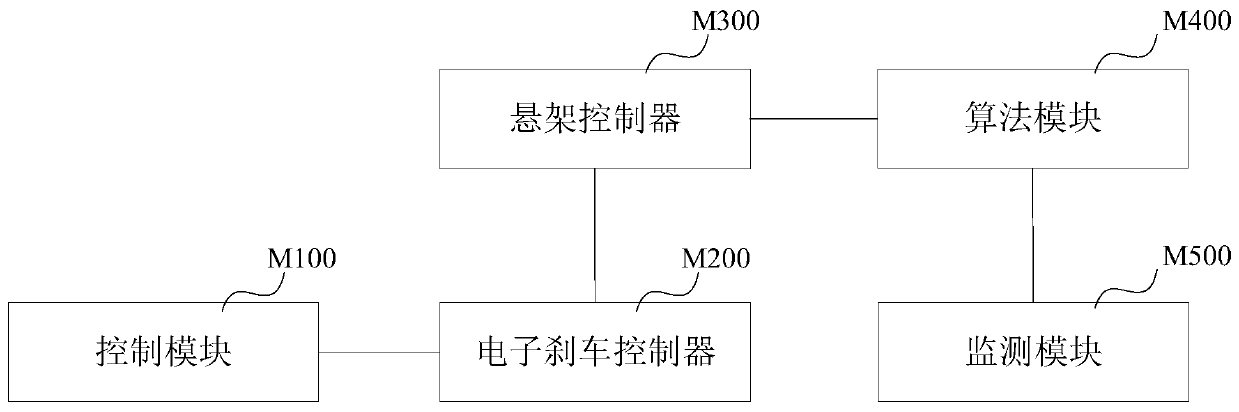

Active suspension control method, system, equipment and storage medium

ActiveCN110329030AEasy to brakeReduced vertical load transferResilient suspensionsVertical loadNormal state

The invention provides an active suspension control method, a system, equipment and storage medium. The method comprises steps that: a signal sent by an electronic brake controller is monitored; if the electronic brake controller is in a normal state and an electronic hand brake is in an open state, the electronic brake controller is used to send a brake request signal to a suspension controller;the control strategy of the front suspension actuating force Ff and the rear suspension actuating force Fr of the vehicle are acquired according to the vehicle condition parameters; the suspension controller is used to execute the control strategy to adjust the front suspension and the rear suspension of the vehicle, and the execution of the control strategy meets the condition that the vertical load transfer amount of the vehicle is smaller than a first load transfer amount threshold value after the active supercharging and decelerating function is triggered. The control method of the invention is advantageous in that signals are sent to the suspension controller by additionally providing the electronic brake controller, the suspension controller is used to receive the signals to the front and the rear suspension of the vehicle before the vehicle is really pressurized and decelerated, and the front and the rear suspension of the vehicle are controlled to be powered according to a certain control strategy, so that the abrupt feeling caused by the deceleration of the vehicle is reduced, and the braking efficiency is effectively improved.

Owner:AIWAYS AUTOMOBILE CO LTD

Tooth thickness variable cylinder profile modified gear and gearing device using same

InactiveCN101285520BHigh coincidenceEasy to processToothed gearingsPortable liftingVariable thicknessGear wheel

The invention discloses a variable tooth thickness profile shifted cylindrical gear and a transmission device using the same. The transmission device comprises a gear disk and a gear tooth; the gear adopts the tangential modification mode, and tangential modification coefficients change according to the order from small to big along the gear disk shaft, and becoming-bigger directions of tangential modification coefficients of two tooth faces of the gear tooth are the same; an included angle is formed between the two tooth faces of the gear tooth of the gear, and the meshing backlash can be adjusted by adjusting the axial relative position of gears meshed with each other, thereby effectively eliminating or reducing the backlash and return difference, reducing the vibration and noise and prolonging the service life; compared with the addendum modified variable thickness gear transmission used in the prior art, the transmission device of the invention has the advantages of smaller sliding ratio, good manufacturability of gear processing and low cost, etc.; compared with other clearance adjusting modes, the transmission device has the advantages of simple structure and small volume, etc.

Owner:CHONGQING UNIV

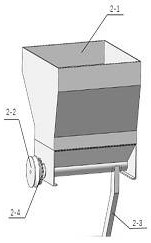

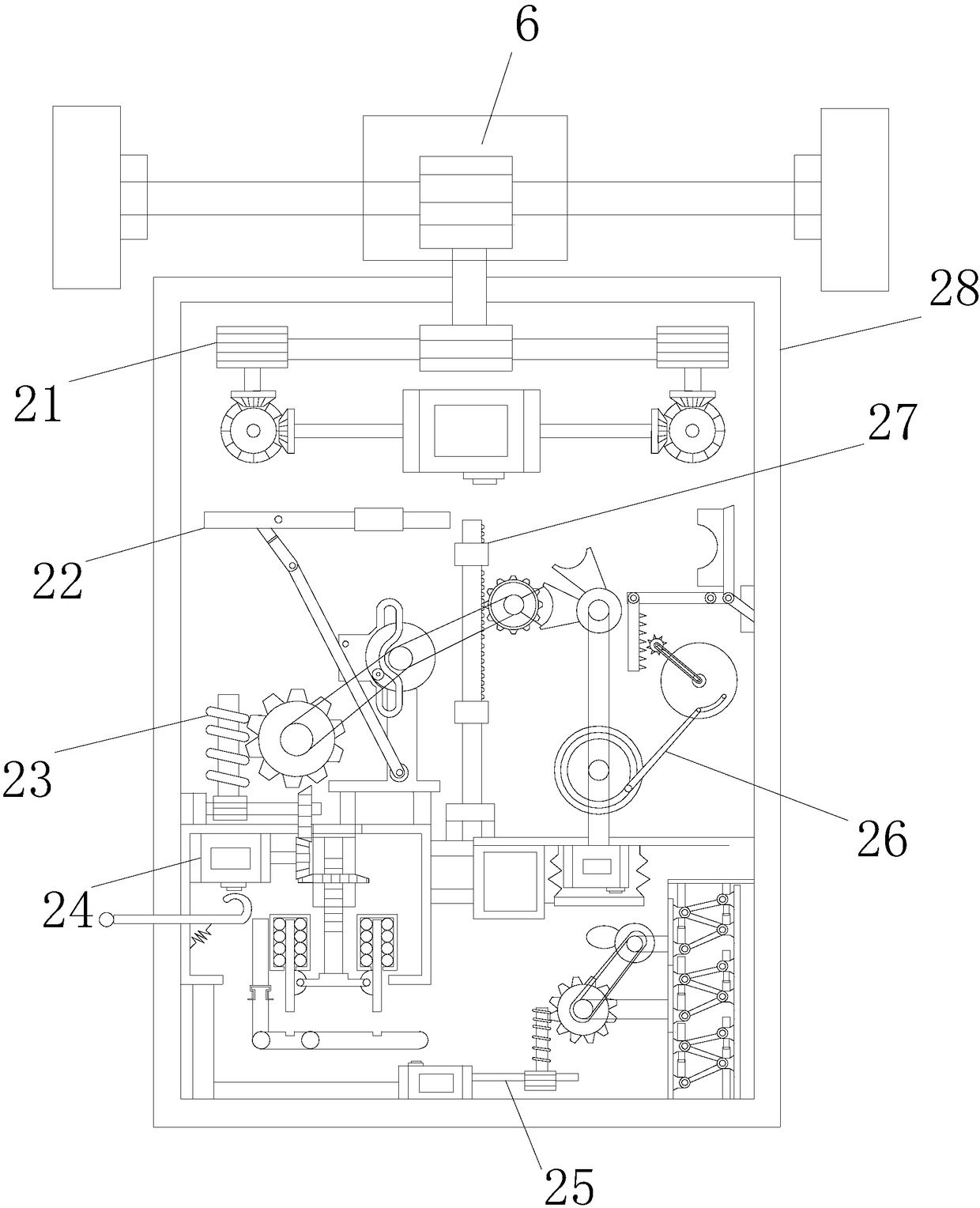

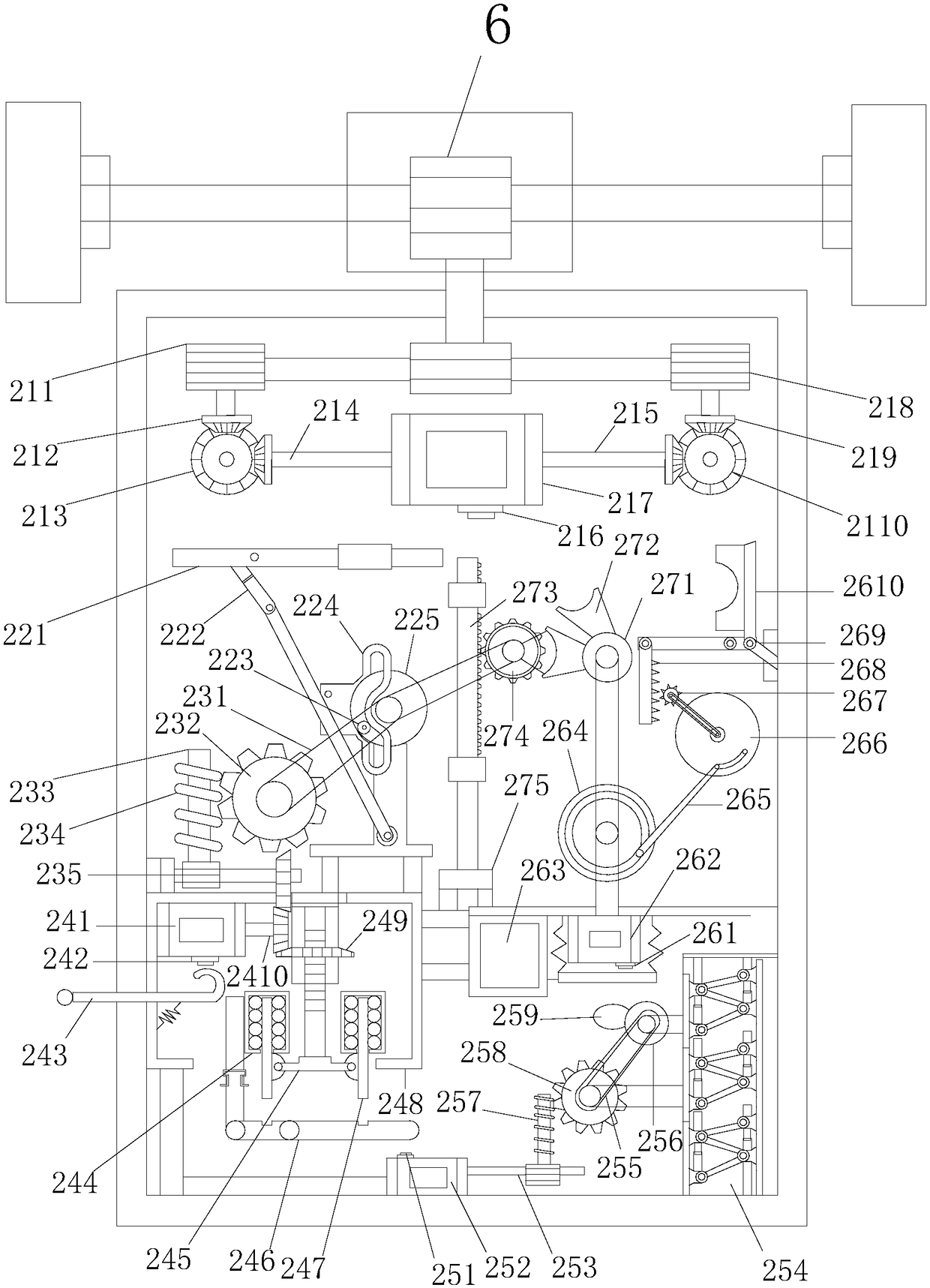

Continuously variable transmission type variable fertilizer applicator

PendingCN112136424ACompact structureEasy to operatePlantingFertiliser distributersMicrocontrollerMicrocomputer

The invention relates to fertilizing machinery, in particular to a continuously variable transmission type variable fertilizer applicator. The fertilizer applicator mainly comprises five parts, namelya rack, a fertilizing mechanism, a variable speed transmission mechanism, a soil covering mechanism and a ditching mechanism. The rack comprises a motor mounting table, a speed changer mounting table, a fertilizing mechanism mounting frame, a soil covering mechanism mounting frame and a ditching mechanism mounting frame; the fertilizing mechanism mainly comprises a fertilizer discharging auger, afertilizer hopper and a fertilizer discharging pipe; the variable speed transmission mechanism mainly comprises a stepping motor and a gearbox, and the soil covering mechanism mainly comprises a soilcovering disc and a secondary adjusting rod; and the ditching mechanism mainly comprises a ditching cutter head and a ditching cutter. According to the fertilizer applicator, a single chip microcomputer and a GPS control the speed change of the stepping motor in real time, the change of the fertilizing amount is controlled in real time, the ditching mechanism ditches and fertilizes, then the soilcovering mechanism fills and levels up ditches, and all the parts are matched with one another to achieve the variable fertilizer discharging process.

Owner:SHIHEZI UNIVERSITY

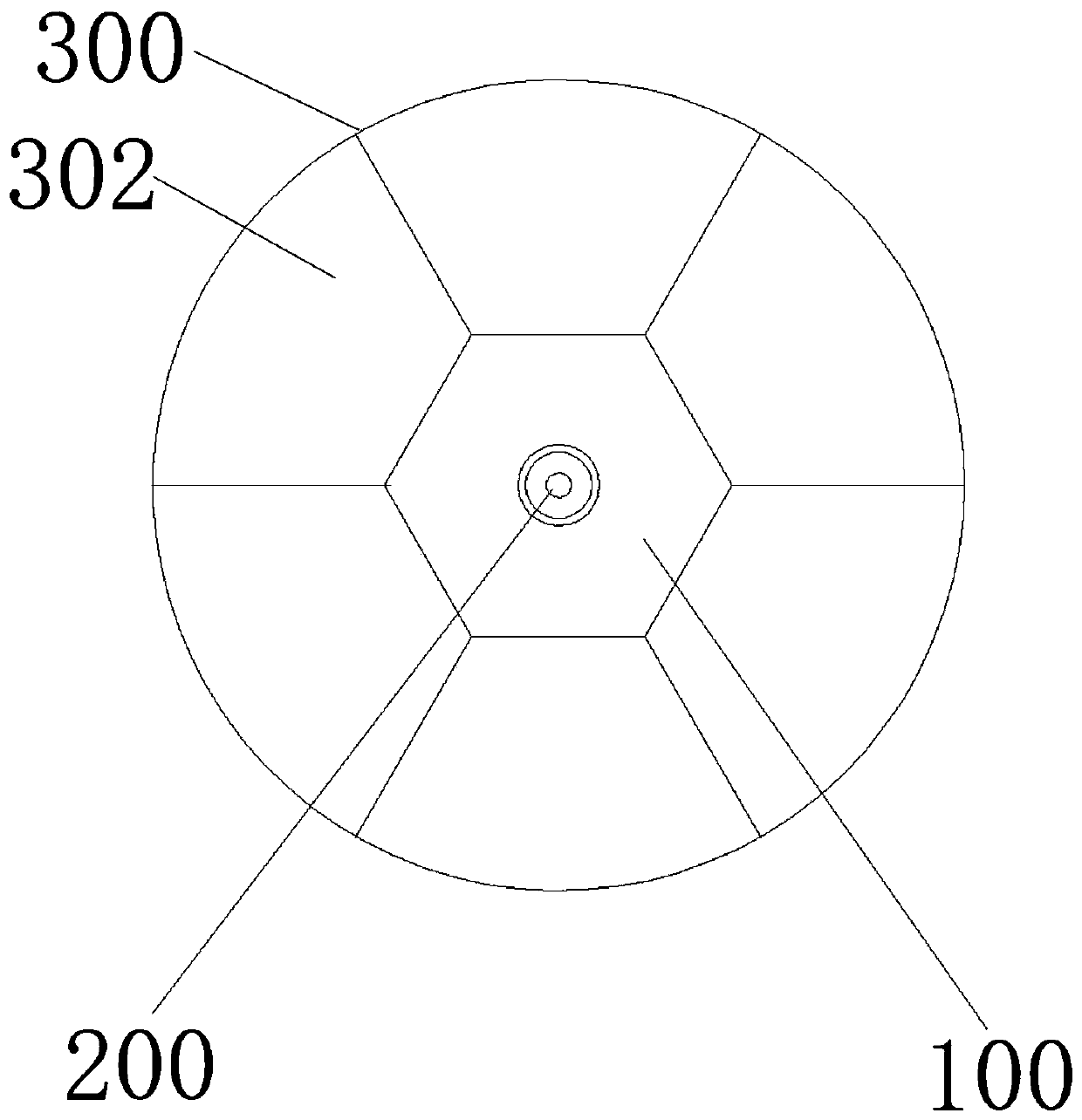

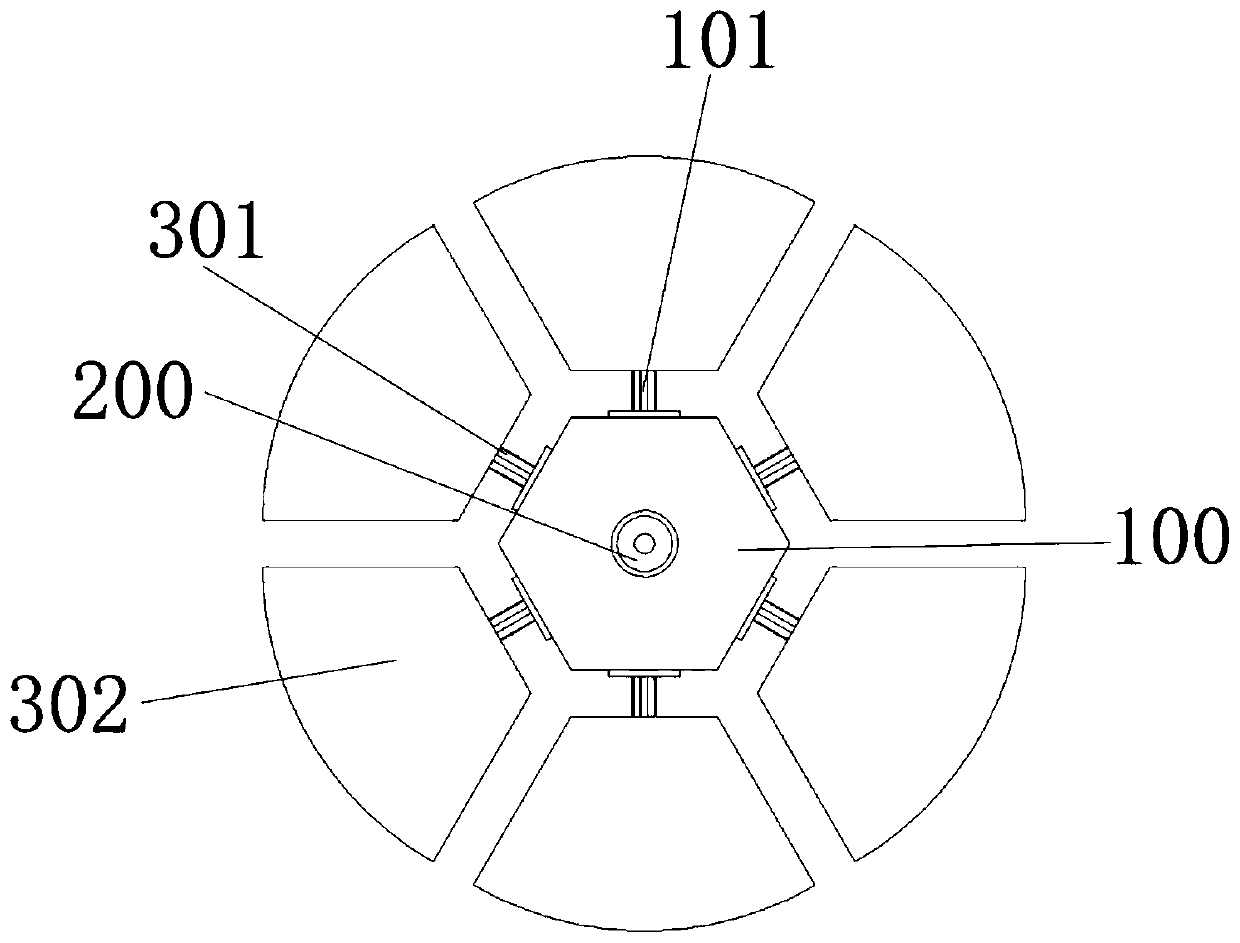

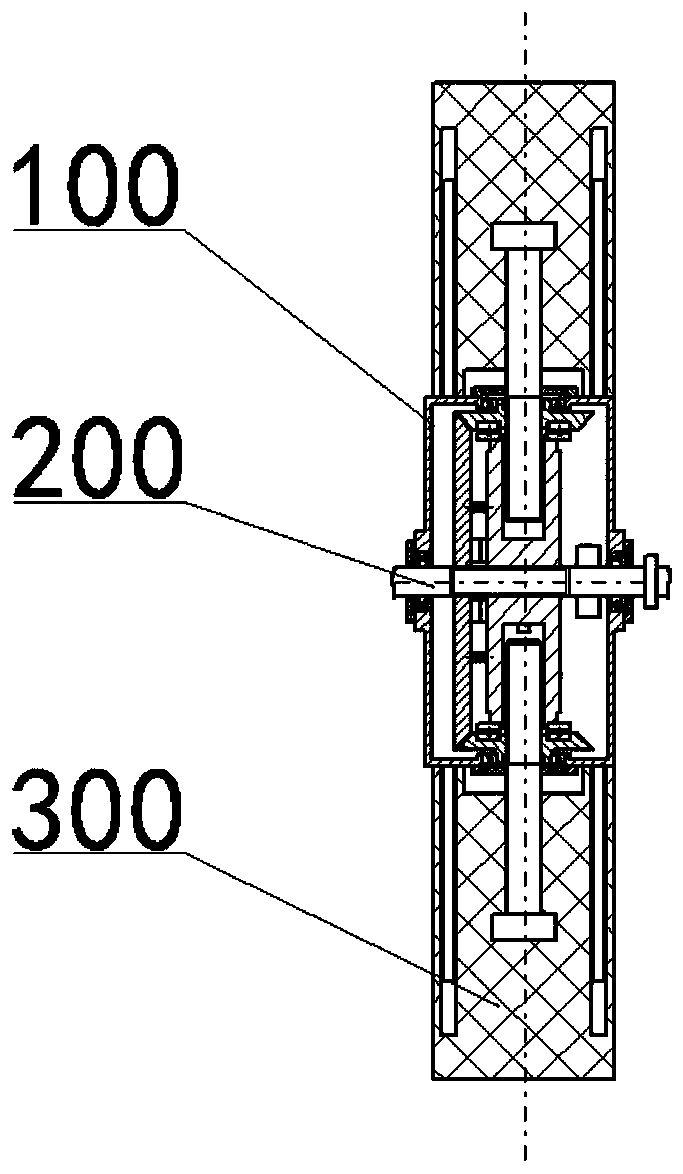

Variable wheel diameter mechanism

PendingCN110370863AReduce wheel slipImprove drive performanceAgricultural vehiclesAgricultural vehicle tyresTerrainAutomotive engineering

The invention discloses a variable wheel diameter mechanism. The variable wheel diameter mechanism comprises a hub component (100), a driving shaft (200) and a tire component (300), wherein the hub component (100) is arranged on the driving shaft (200), the section of the hub component (100) is of a regular polygon structure, the tire component (300) comprises a plurality of tire blocks (302) which are equally divided, the number of the tire blocks (302) corresponds to the number of edges of the hub component (100), the outer sides of the tire blocks (302) are of arc structures, the inner sides of the tire blocks (302) are the mounting surfaces corresponding to the side surfaces of the hub component (100), and the tire blocks (302) are correspondingly mounted on the side surface of the corresponding side surfaces of the hub component (100) so as to form a round tire. According to the variable wheel diameter mechanism, the wheel diameter of a wheel can be changed in real time, the sliprate of the wheel is reduced, the slip of the wheel is reduced, the driving performance of a vehicle is improved, and the variable wheel diameter mechanism can adapt to various terrains and landforms.

Owner:NANJING AGRI MECHANIZATION INST MIN OF AGRI

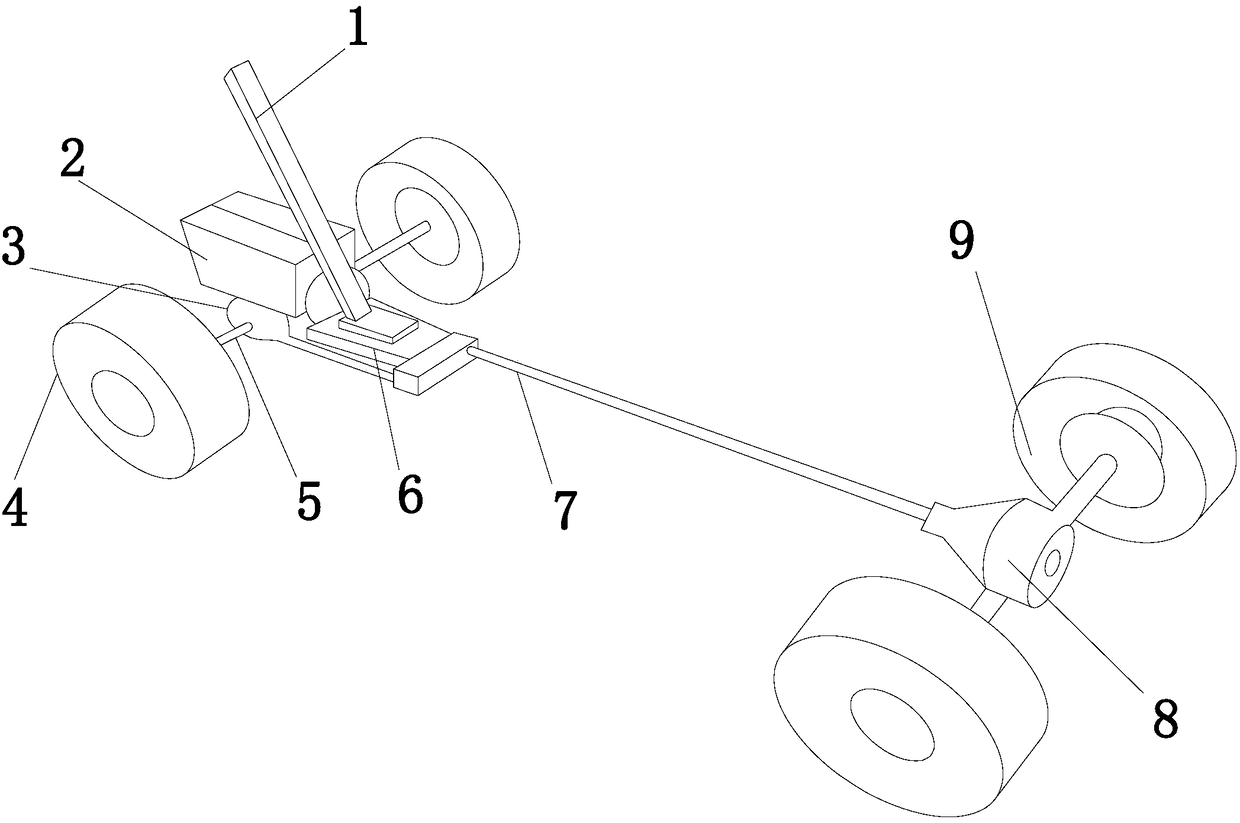

Idling driving force adjusting device

The invention discloses an idling driving force adjusting device, which structurally comprises an adjusting rod, a driving force controlling mechanism, a front differential mechanism, a front runningwheel, a connecting bearing, a front driving shaft, a rear driving shaft, a rear differential mechanism and a rear running wheel; the adjusting rod is fixed above the front driving shaft through a screw, the front driving shaft is fixed at the left side of the rear driving shaft through a screw rod, the front differential mechanism is mechanically connected to the left side of the front driving shaft, the driving force controlling mechanism comprises a gear mechanism, a sliding bar mechanism, a driving mechanism, a start mechanism, a linking mechanism, a transmission mechanism, an ejection mechanism and a metal outer frame; the idling driving force adjusting device has the beneficial effects that through the arranged driving force controlling mechanism, the driving force can be reduced bythe driving force controlling mechanism when the device is accelerating or when the speed difference of the driving wheel and the non-driving wheel is too large, so as to reduce the slippage rate of the driving wheel, the device can stably start and accelerate, peril incident of cars caused by slipping of the driving wheel can be avoided, and the safety and practicability of the idling driving force adjusting device are improved.

Owner:莆田市超逸贸易有限公司

Inner-engaged helical gear pair based on space conjugate curve

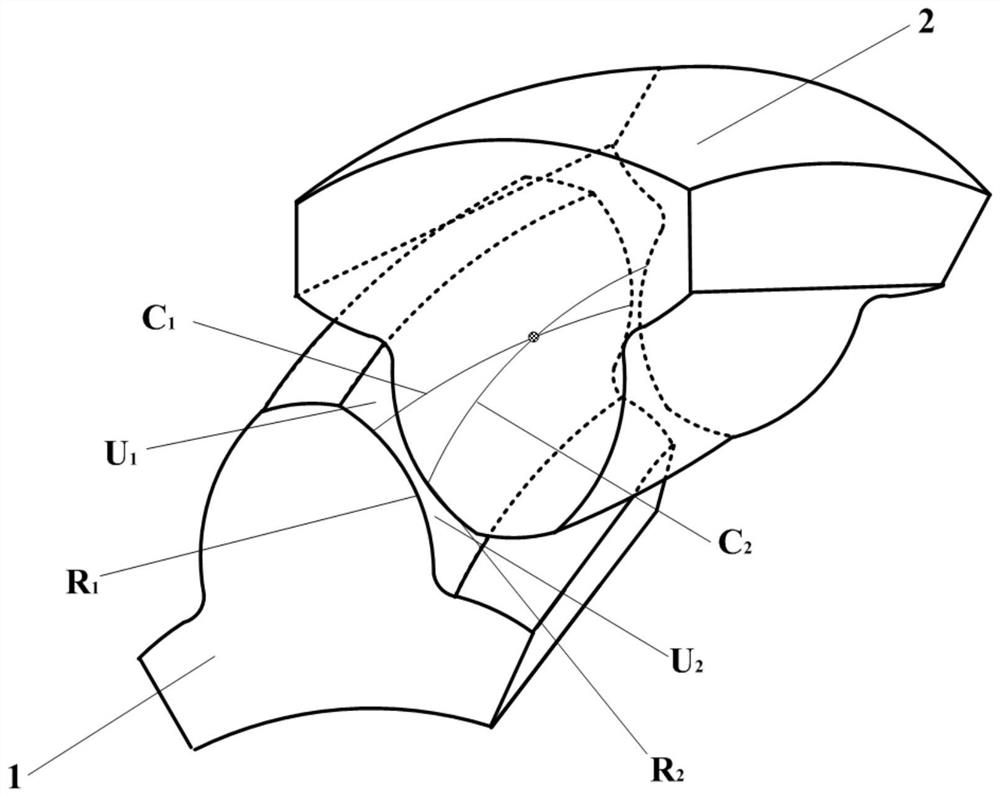

PendingCN112377595AImproved contact characteristicsReduce temperature risePortable liftingGearing elementsGear driveGear wheel

The invention belongs to the technical field of gear transmission, and particularly relates to an inner-engaged helical gear pair based on a space conjugate curve. The inner-engaged helical gear paircomprises a pair of convex tooth pinion with a convex tooth profile and a convex tooth internal gear; the convex tooth pinion and the convex tooth internal gear are both of helical gear structures, and are in a point contact state in the engagement process; and the tooth surface contact trace C1 of the convex tooth pinion and the tooth surface contact trace C2 of the convex tooth internal gear arespace conjugate curves. According to the inner-engaged helical gear pair based on the space conjugate curve, the requirement of a current electromechanical equipment transmission system for a high-performance gear can be met, and the contact characteristic of the inner-engaged helical gear pair can be expanded.

Owner:CHONGQING JIAOTONG UNIVERSITY

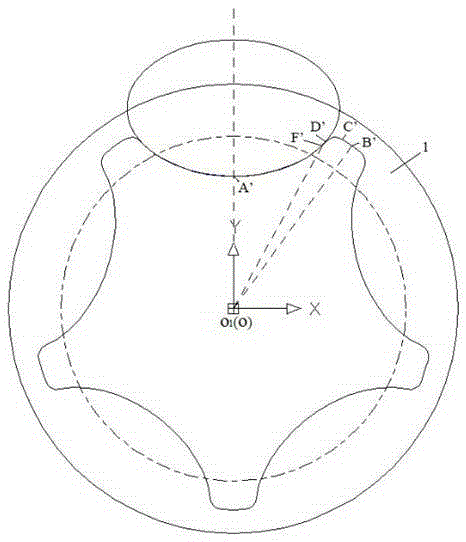

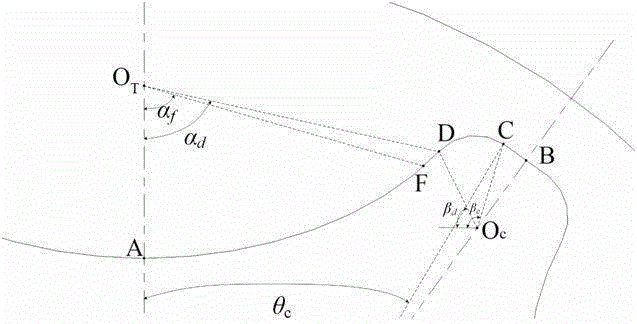

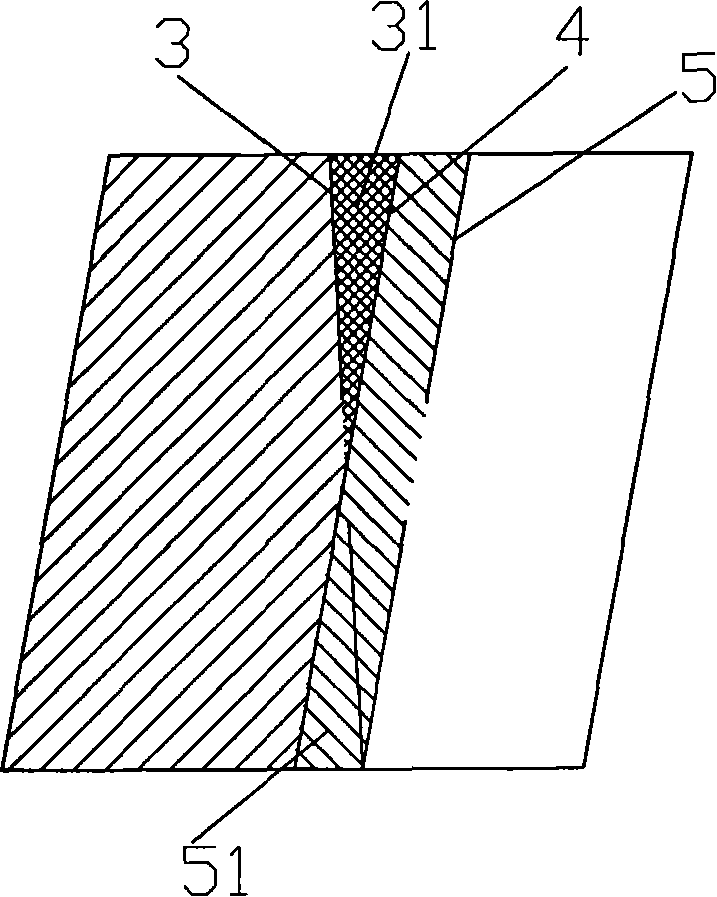

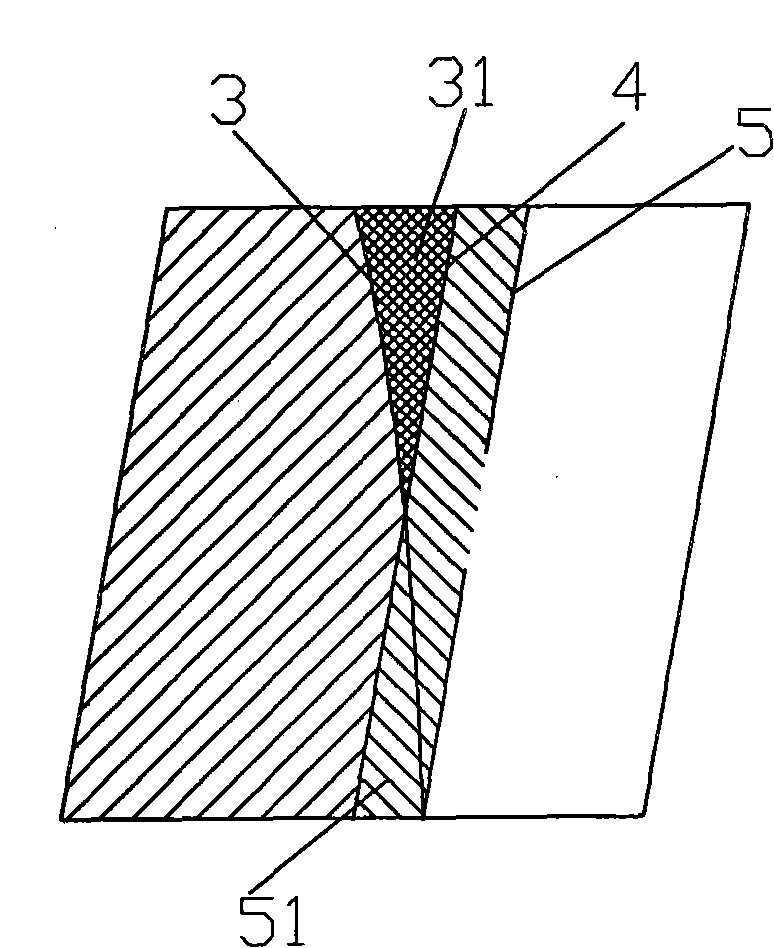

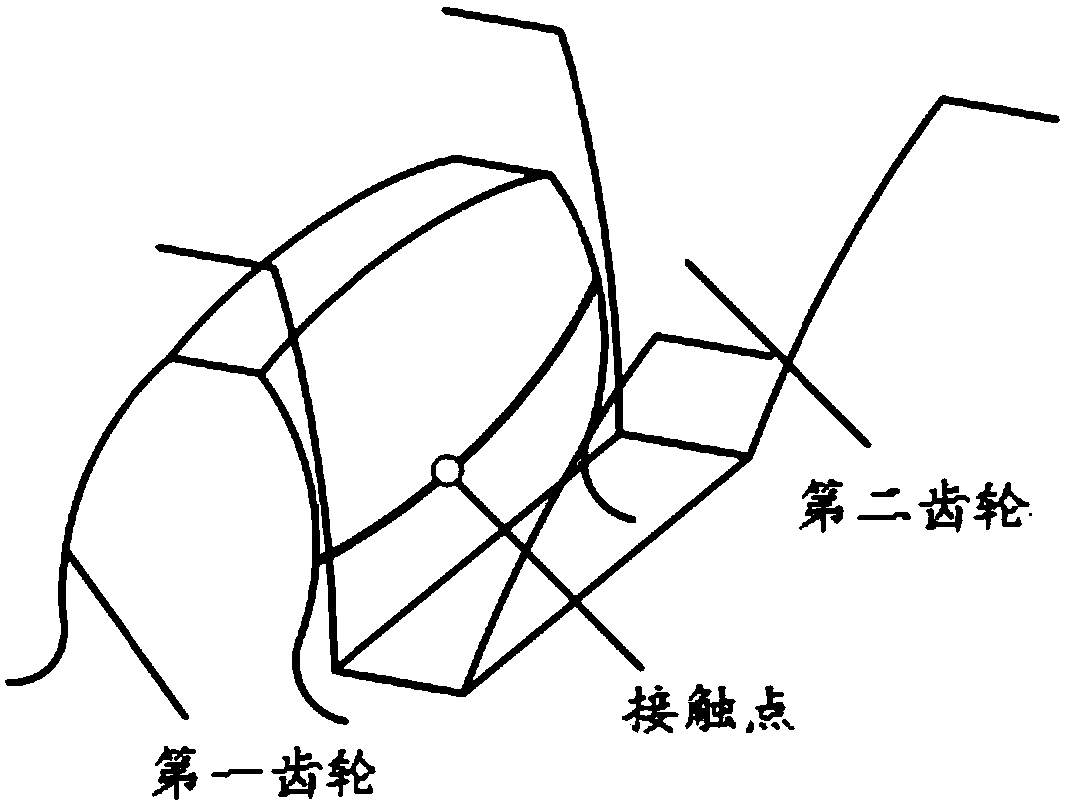

Opposite-configuration gear meshing pair based on line-plane conjugation and a design method thereof

PendingCN109657388AImprove carrying capacitySmall slip rateGeometric CADToothed gearingsGear driveInvolute gear

The invention provides an opposite-configuration gear meshing pair based on line-plane conjugation and a design method thereof, and relates to the technical field of gear transmission. The transmission mechanism comprises a first gear and a second gear which form a line-plane conjugate gear pair. The line-surface conjugate gear pair comprises a curved surface 1 and a curve 1 which are in continuous tangent contact, the curved surface 1 is located on the first gear, and only one curve on the curved surface 1 is in contact with the curve 1; At the preset moment, the curve 1 keeps point contact with the curved surface 1, and at the preset moment, the contact point of the curve 1 and the curved surface 1 is unique; Wherein the curve 1 is a smooth curve, and the curved surface 1 is a smooth curved surface. The technical problem that in the prior art, a line-plane conjugated involute gear transmission device is established based on an involute, and the tooth shape has certain limitation is solved. The line face-to-face configuration gear has the center distance separability, has the adaptive capacity to the axis deflection error and the pitching error, and is wide in application range.

Owner:CHONGQING UNIV

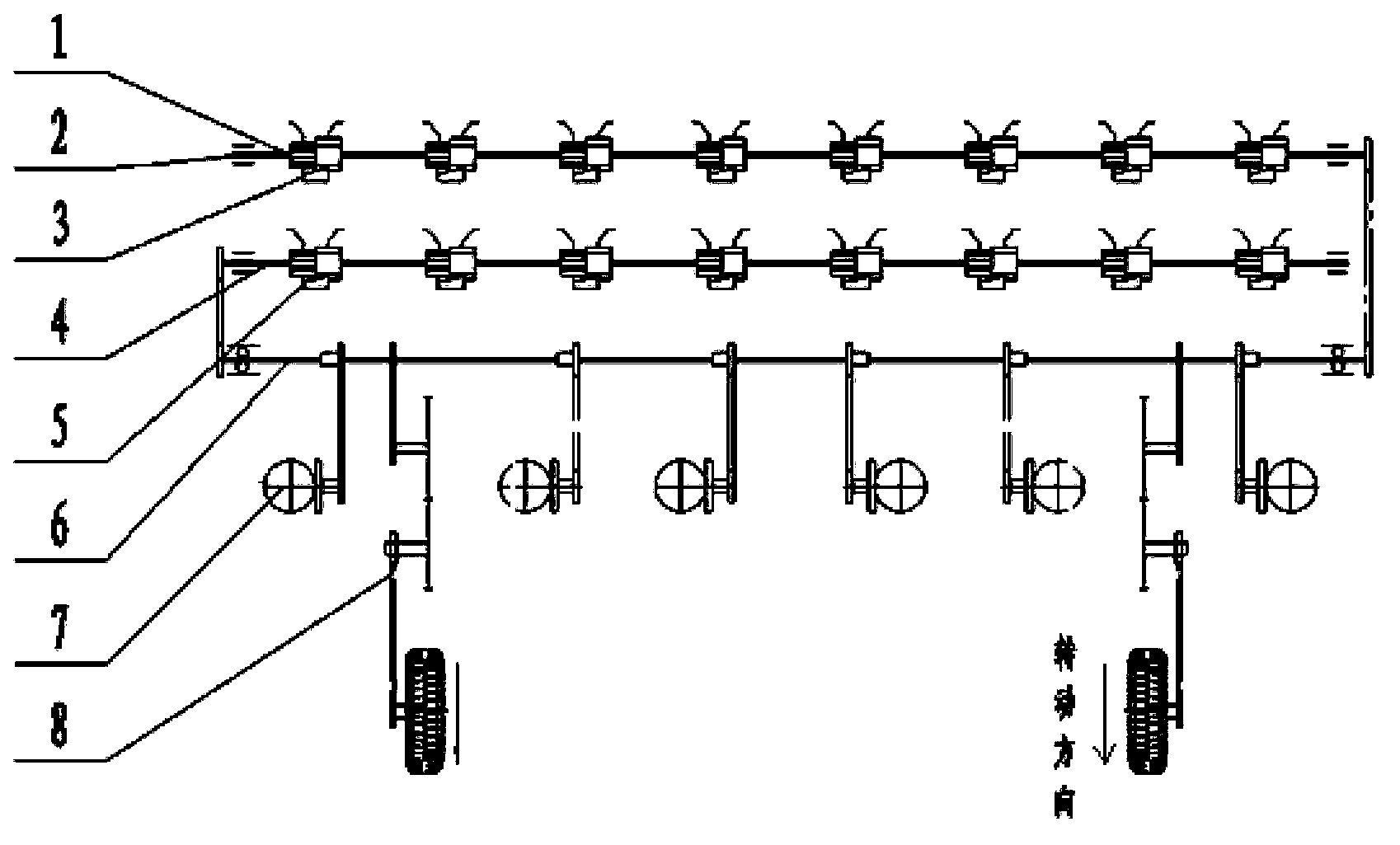

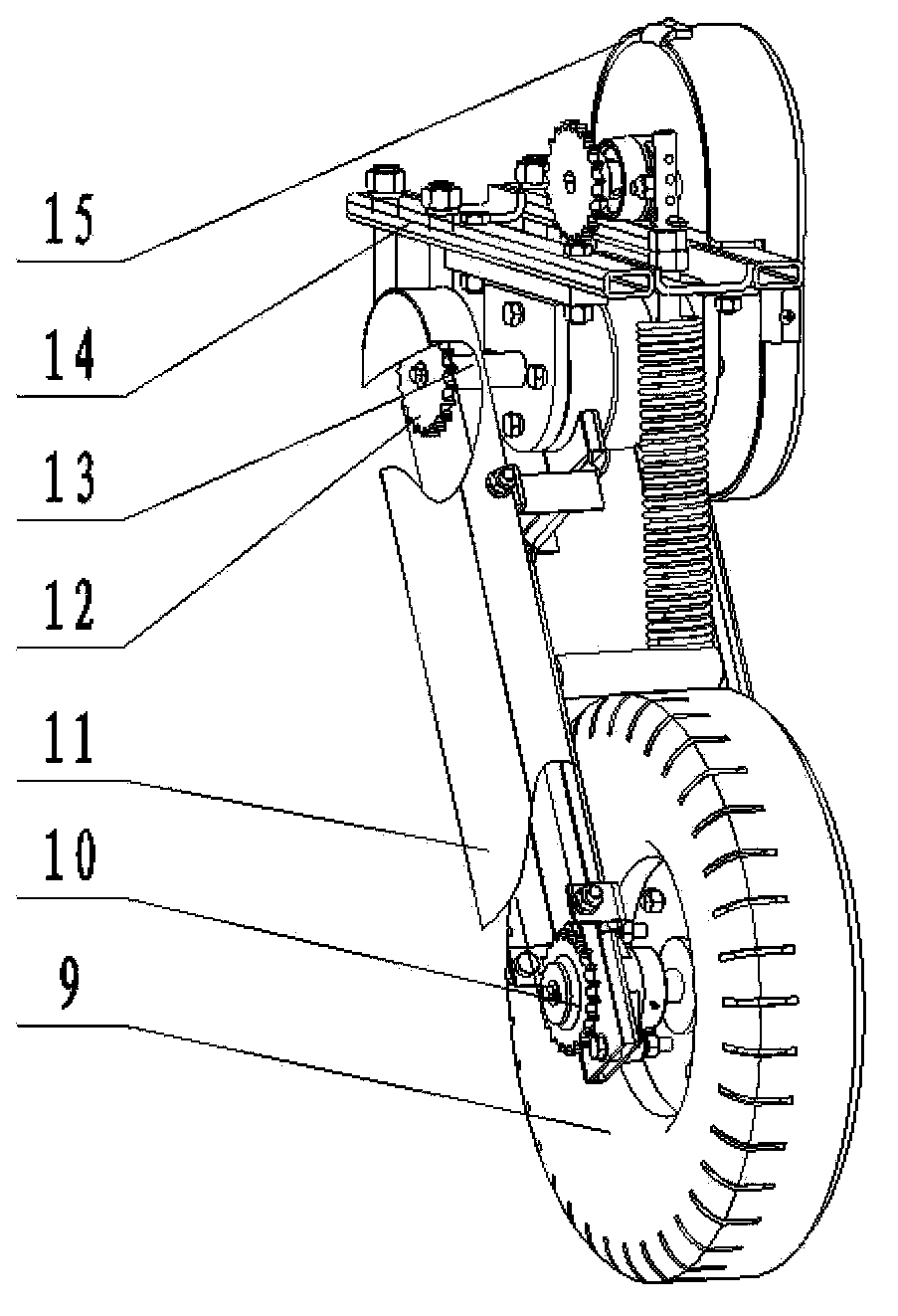

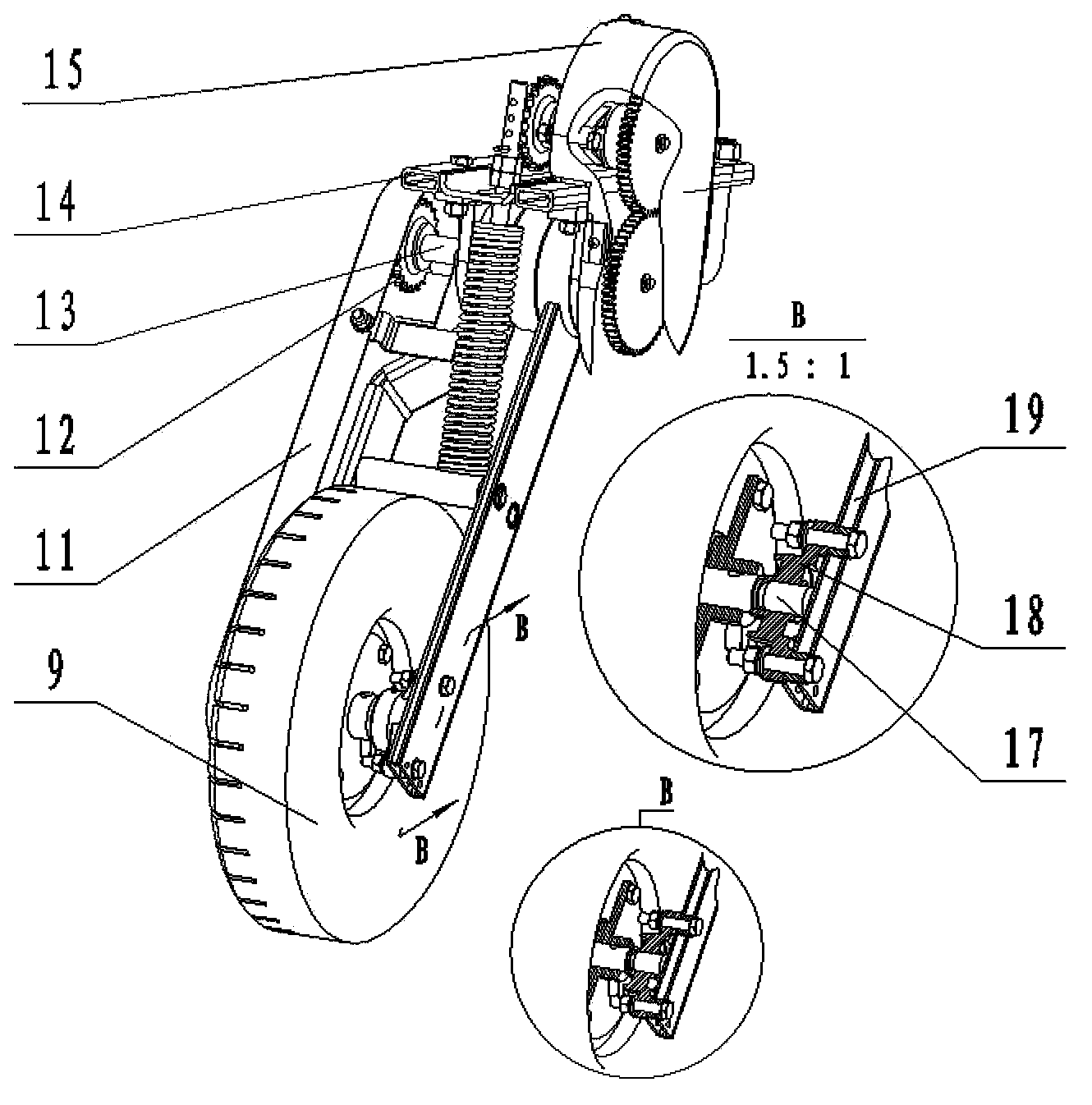

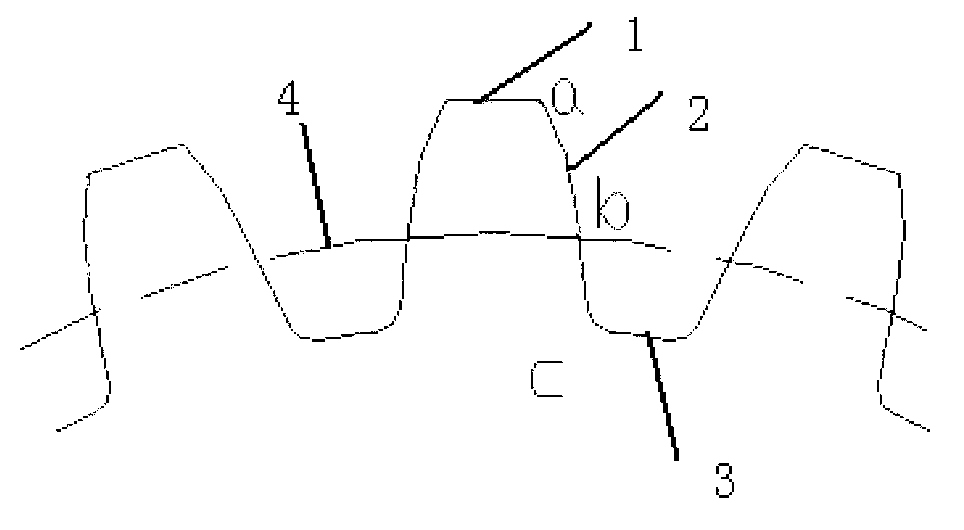

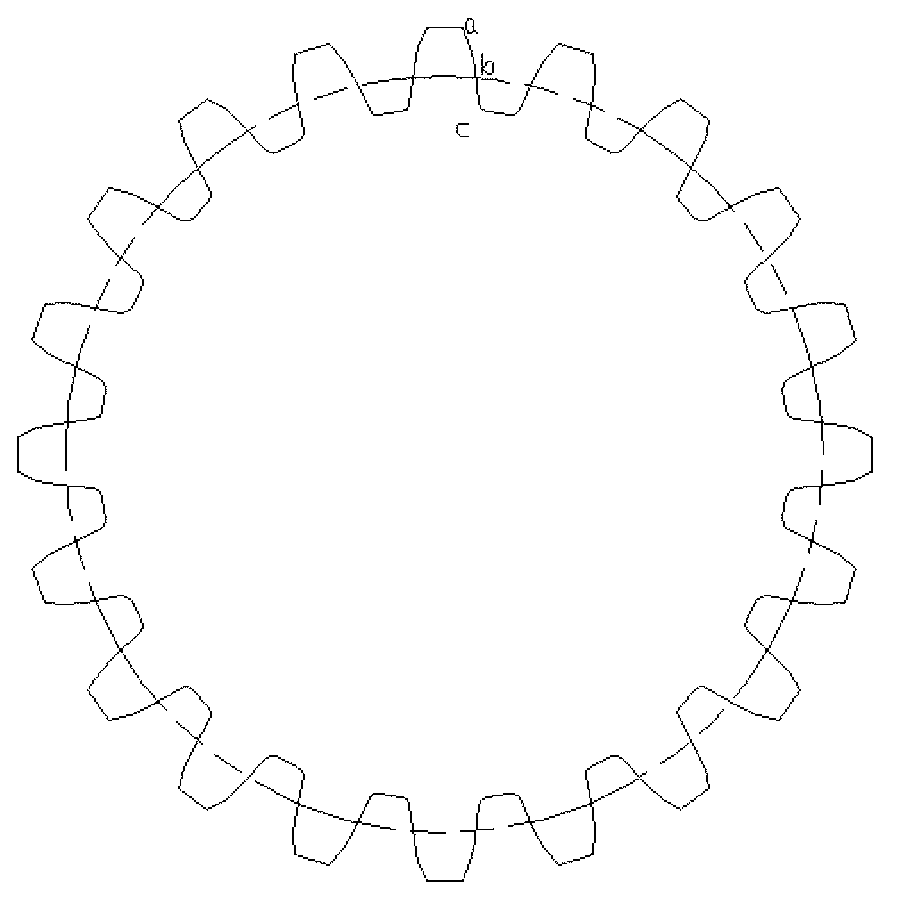

Sowing-fertilization linked ground wheel profile driving device

InactiveCN103416142ARealize integrated linkageSimultaneous seedingFertiliser and seeding apparatusFertiliser equipmentsAgricultural engineeringRapeseed

The invention belongs to the technical field of a sower in agricultural machinery and relates to a sowing-fertilization linked ground wheel profile driving device. The sowing-fertilization linked ground wheel profile driving device comprises a transmission system and a ground wheel profile driving unit. The transmission system comprises a wheat seed sowing shaft, a wheat seed sowing device, a fertilization shaft, a fertilization device, a transition shaft and a rapeseed sowing device. The ground wheel profile driving unit comprises a ground wheel group, a ground wheel transmission chain wheel, a profiling rack assembly, a middle transmission chain wheel, a middle shaft, a support assembly and a turning gear case assembly. The sowing-fertilization linked ground wheel profile driving device has a simple structure and reliable performances, is suitable for the basically-flat ground with small uneven parts, greatly reduces a slippage rate, reduces a miss-sowing rate, realizes linkage of sowing and fertilization of crops such as rape and wheat, and avoids seedling breaking and fertilization stopping in sowing. The sowing-fertilization linked ground wheel profile driving device can be used as a sowing and fertilization driving device for a plurality of sowing machines.

Owner:HUAZHONG AGRI UNIV

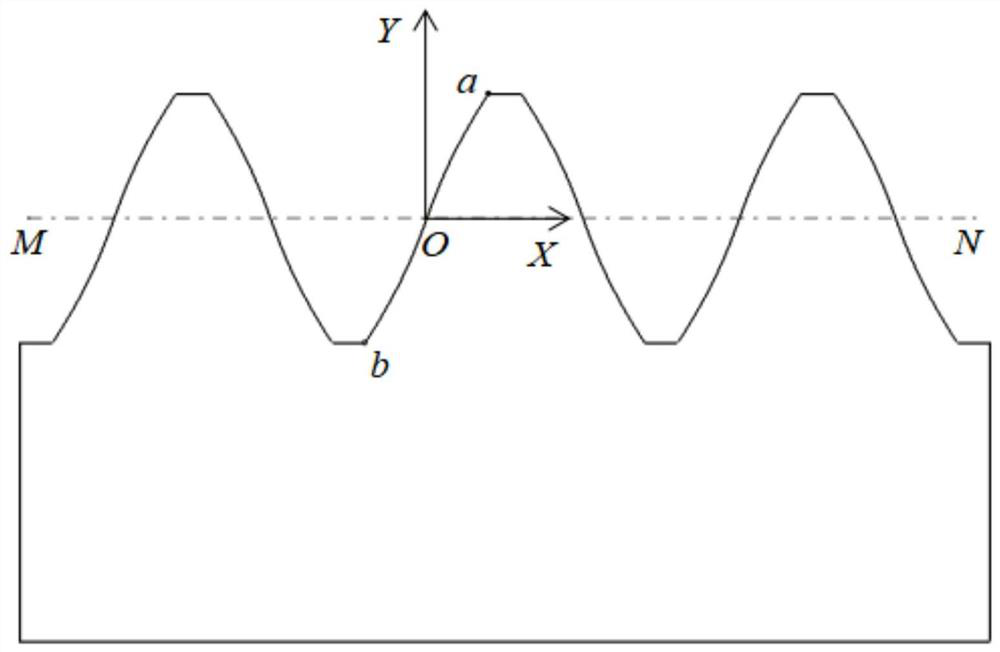

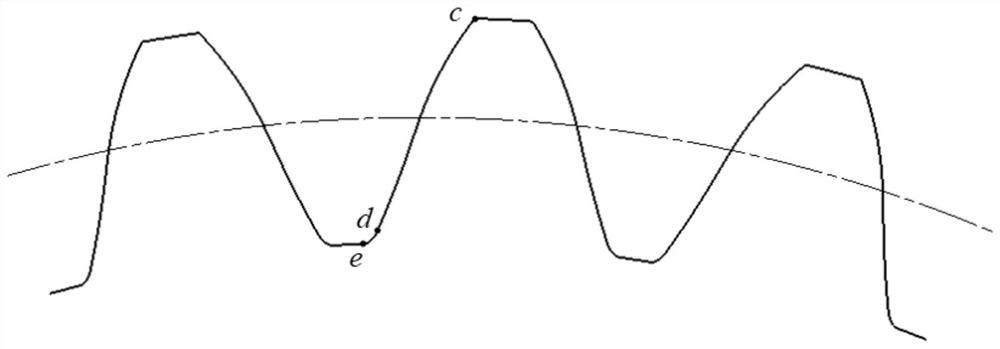

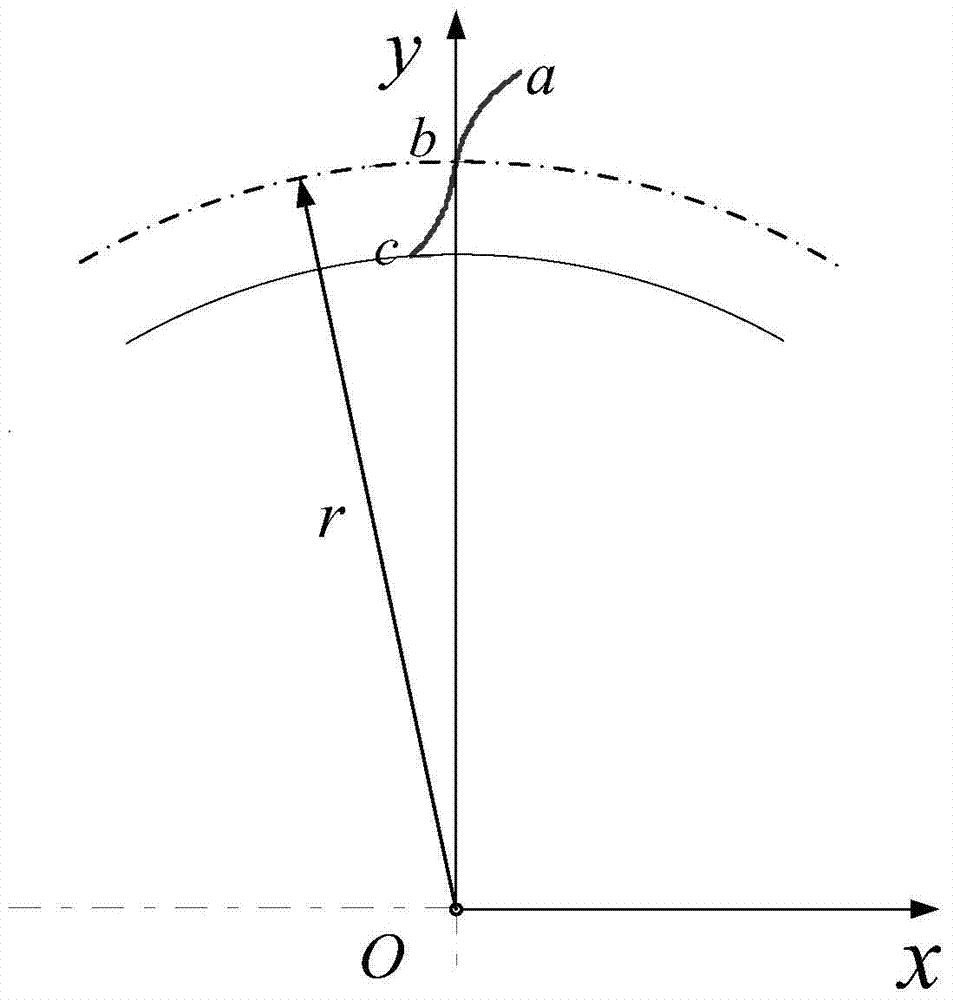

Low-slide-rate gradient pressure angle gear and design method

InactiveCN103075492ASmall slip rateImprove transmission efficiencyPortable liftingGearing elementsEngineeringDesign methods

The invention provides a low-slide-rate gradient pressure angle gear and a design method. The gear comprises a tooth profile curve, wherein the tooth profile curve is divided by a pitch circle of the gear into a tooth top section and a tooth root section, and a pressure angle of the gear is changed in a linear way in the transmission process of the gear. The design method comprises the steps that the pressure angle is designed to be linearly changed in the transmission process of the gear when the pressure angle of the gear is designed. By adopting the gear and the design method, the advantages such as low slide rate of the gear and high transmission stability of the gear can be realized.

Owner:CHONGQING UNIV

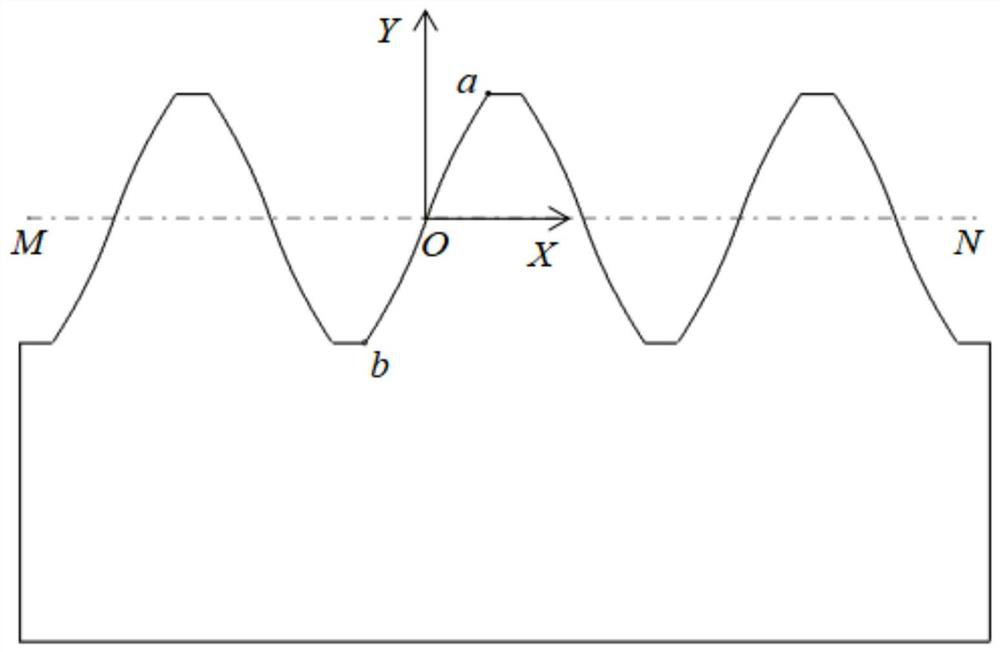

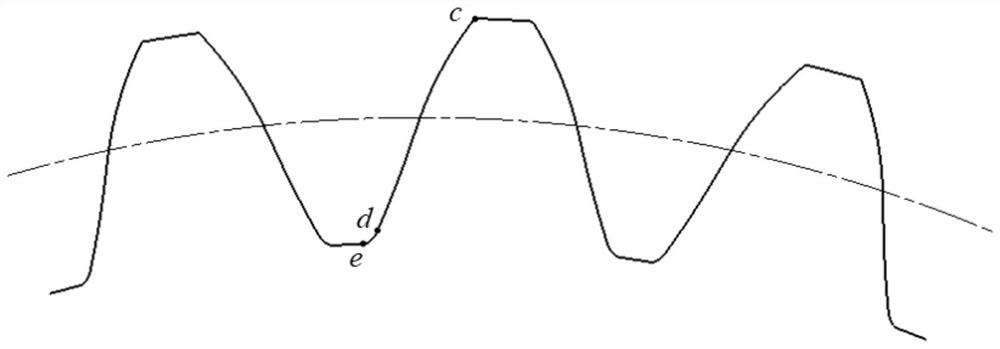

Low-sliding-rate gear and design method thereof

ActiveCN113062961ASmall slip rateReduce wearPortable liftingComplex mathematical operationsGear driveGear wheel

The invention discloses a low-sliding-rate gear and a design method thereof, and relates to the technical field of gear transmission. According to the low-sliding-rate gear and the design method, the problems that an existing gear is high in sliding rate and prone to abrasion in the transmission process can be solved, and the transmission efficiency of a gear pair can be further improved. According to the low-sliding-rate gear and the design method, a low-sliding-rate generating rack is constructed according to a proposed tooth profile meshing path curve, then the generating rack obtains the low-sliding-rate gear tooth profile through enveloping motion, due to the fact that the coefficient of a tooth profile meshing path curve equation is adjustable (on the premise that a low-sliding-rate boundary condition is met), so that the optimization of the sliding rate at any moment (except nodes, the node sliding rate is 0) in the gear transmission process can be met, so that the improvement of the transmission efficiency, the reduction of the sliding rate of gear transmission, the reduction of the abrasion of the gear in the transmission process, the improvement of the bearing capacity of the gear and the optimization of the lubricating condition of the gear are facilitated.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

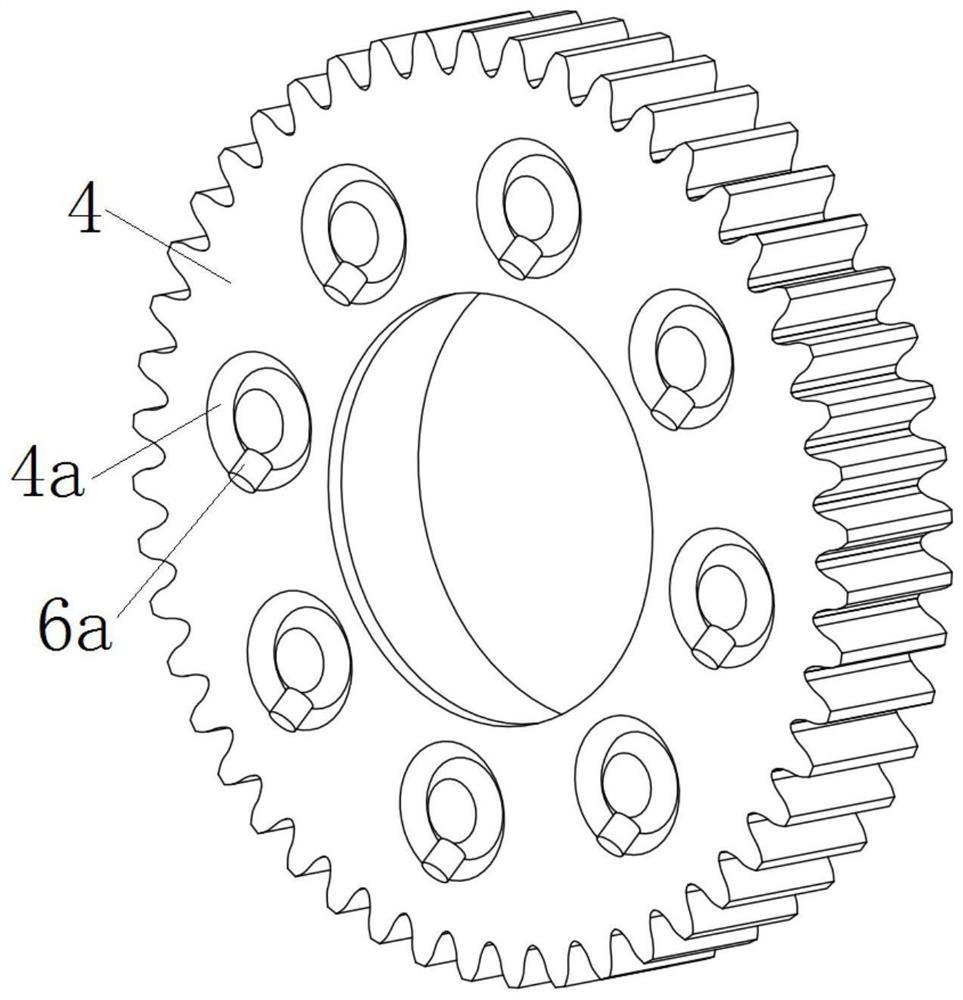

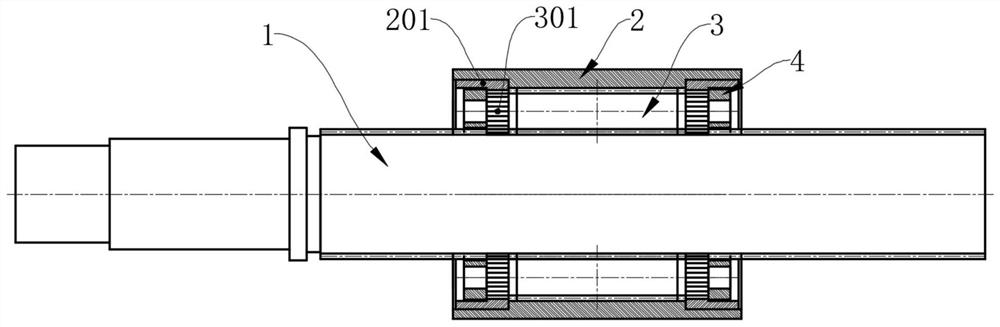

Cylindrical ring groove type double-cycloid small-tooth-difference planetary reducer

ActiveCN112780728AEasy to processAvoid High Precision AssemblyGearboxesToothed gearingsPhysicsCycloid

The invention relates to a cylindrical ring groove type double-cycloid small-tooth-difference planetary reducer, and belongs to the field of reducers. According to the reducer, two planet gears doing eccentric motion are adopted to form an N-type combined gear train to achieve speed reduction. Tooth profiles of the planetary gear and the inner gear are formed by combining inner and outer double cycloids, and a tooth crest of the planetary gear is always engaged with a tooth crest of the inner gear in the transmission process, so that the transmission efficiency of the reducer is improved, and the precision attenuation of the reducer is slowed down. Large-contact-ratio transmission can be achieved by adjusting gear parameters, meanwhile, the inner gear can be integrally machined, and high-precision assembly of pin teeth in an existing RV speed reducer is avoided. In addition, motion and power are transmitted to an output flange from the planet gear through cylindrical ring groove constant-speed mechanisms, the transmission efficiency is high, the multiple cylindrical ring groove mechanisms are matched to form a multi-rolling-body error homogenization effect similar to a bearing, and the transmission precision is improved. The whole structure is simple and compact, and the defect of application limitation in the prior art is overcome.

Owner:CHONGQING UNIV

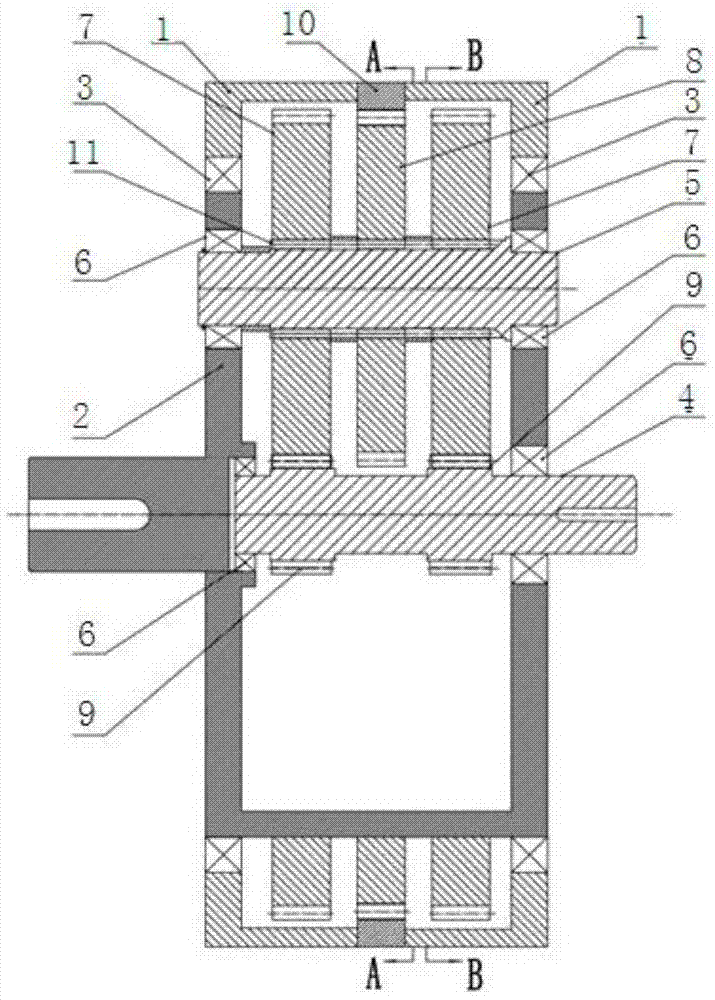

Self-adjusting electric speed differential

InactiveCN101380908BRealize self-adjusting functionLimit output torqueSpeed controllerElectric propulsion mountingDrive wheelElectronic control system

Owner:ZAOZHUANG UNIV

Composite high-order cycloidal planetary transmission device

InactiveCN104500661AImprove contact strengthImprove bending strengthToothed gearingsTransmission elementsUltimate tensile strengthContact strength

The invention discloses a composite high-order cycloidal planetary transmission device which comprises a box body and a planetary carrier. The planetary carrier is arranged on the box body through a supporting bearing. An input shaft and a plurality of planetary shafts are arranged on the planetary carrier, the planetary shafts are evenly distributed around the input shaft, and the planetary shafts and the input shaft are fixed to the planetary carrier through bearing supports. Involute planetary wheels and high-order cycloidal planetary wheels are fixed to the planetary shafts, sun wheels are correspondingly fixed to the input shaft, gear rings are correspondingly fixed to the box body, the involute planetary wheels are meshed with the sun wheels, and the high-order cycloidal planetary wheels are meshed with the gear rings. The composite high-order cycloidal planetary transmission device has the advantages of being compact in structure, high in bearing capacity, high in contact strength, low in sliding rate, high in torsion rigidity, good in impact resisting performance and the like, and the defects of application limitation in the prior art are overcome.

Owner:CHONGQING UNIV

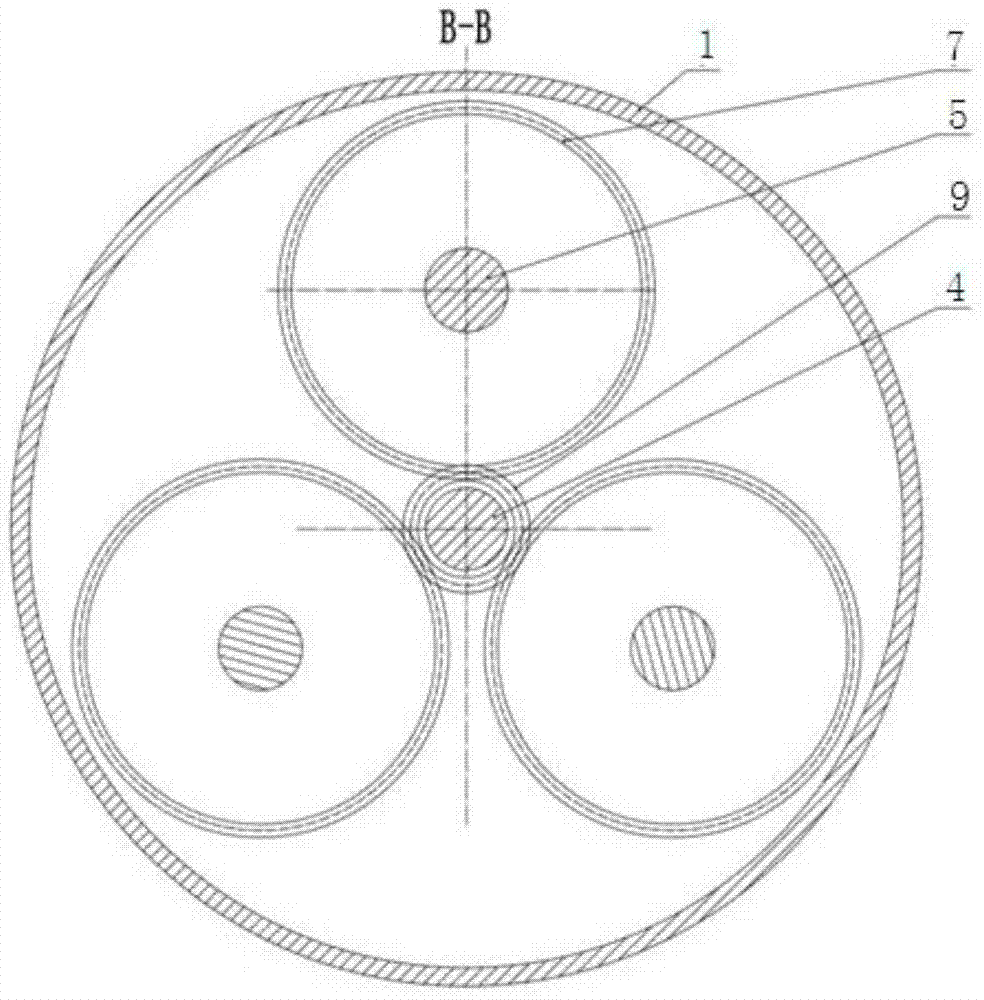

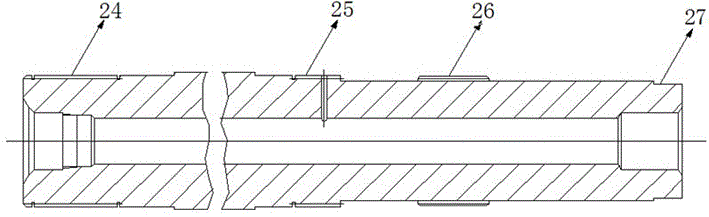

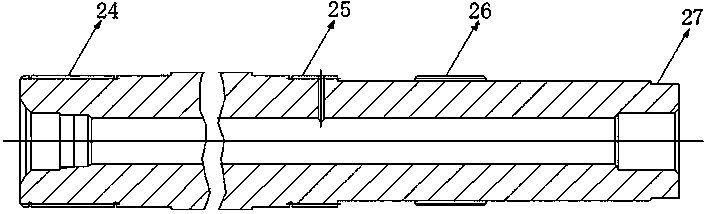

Planetary roller screw with decelerating function

The invention relates to a planetary roller screw with the decelerating function. The planetary roller screw with the decelerating function comprises a lead screw, a nut and a plurality of rollers located between the outer periphery of the lead screw and the inner periphery of the nut. The outer periphery of the lead screw is further sleeved with a retainer. The retainer is provided with a plurality of retaining holes. The rollers are arranged in the retaining holes in a penetrating manner and are in one-to-one correspondence to the retaining holes. Internal threads are arranged on the inner periphery of the nut. The outer periphery of each roller is provided with first external threads meshed with the internal threads. The outer periphery of the lead screw is provided with second externalthreads meshed with the first external threads. The screw directions of the internal threads and the first external threads are identical. The screw directions of the second external threads and thefirst external threads are opposite. According to the planetary roller screw with the decelerating function, the screw directions of the lead screw and the nuts are different, so that the transmissionratio of the roller screw can be conveniently designed by changing the diameter ratio of the lead screw and the rollers, the screw pitch of the lead screw and the number of threads of the lead screw,and the roller screw has the decelerating function.

Owner:李桐谋

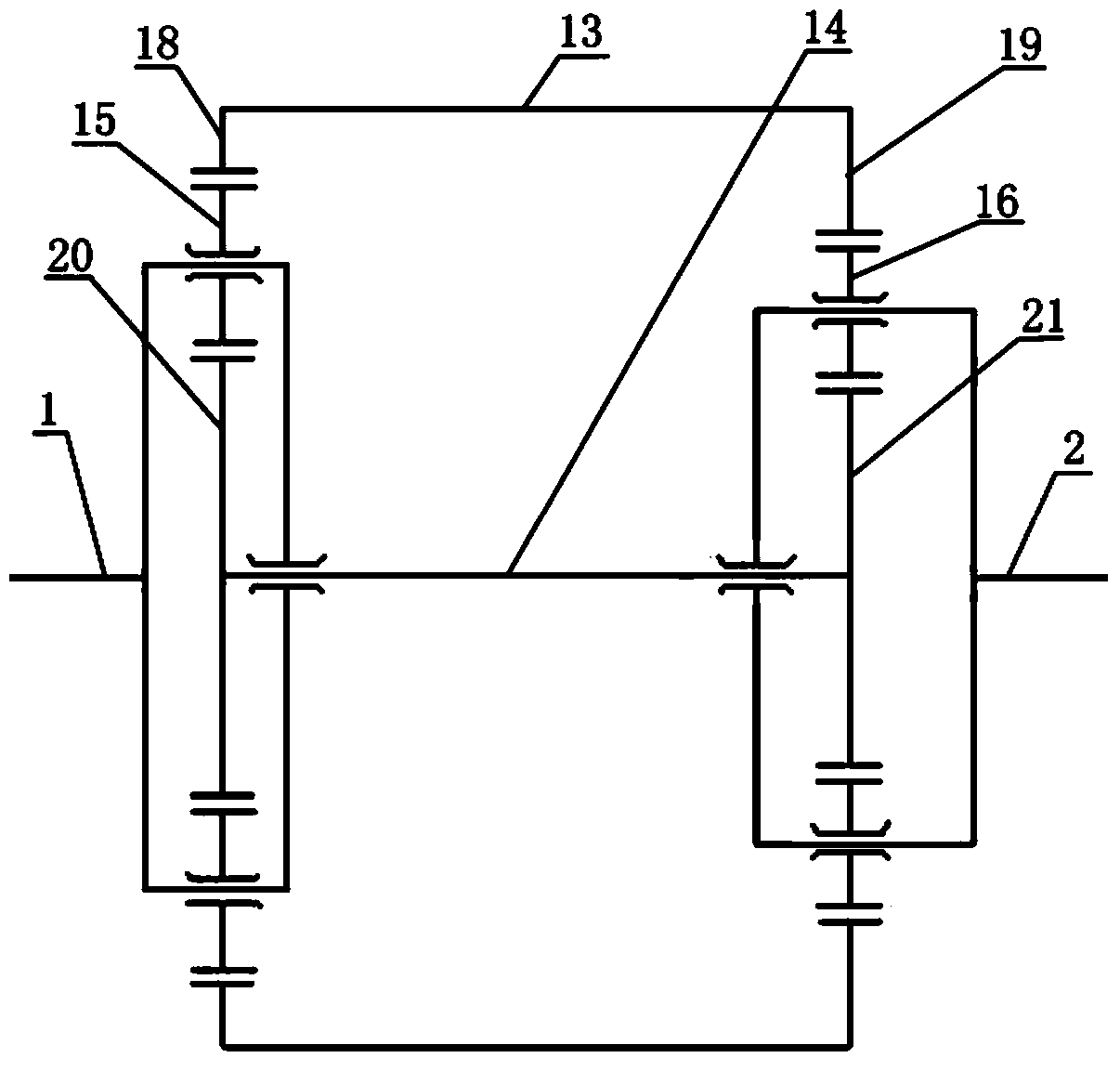

NW-type planetary gear train-based pressure stepless speed change device

InactiveCN105570400APrecise control of speed ratioSimple structureToothed gearingsGearing controlHydraulic motorTransmitted power

The invention discloses an NW-type planetary gear train-based pressure stepless speed change device. In a planetary gear train structure, a rotating body is arranged in a rack shell, and the rotating body is fixedly provided with three planetary shafts vertically distributed evenly along circumference; a duplex planetary gear which consists of a small planetary gear and a large planetary gear is arranged on each planetary shaft through a bearing; an eccentric gear is located between the small planetary gear and the large planetary gear; a sun gear is located among the three large planetary gears; in a pressure stepless speed change structure, a hollow drive shaft is arranged at a central position of the sun, and the hollow drive shaft is provided with hydraulic clutches, hydraulic motors and sensors in sequence; the hollow drive shaft is driven by the hydraulic motors; hydraulic oil is delivered into the hydraulic clutches through a hollow channel of the hollow drive shaft to transmit power to realize pressure stepless speed change. The NW-type planetary gear train-based pressure stepless speed change device disclosed by the invention is simple and compact in structure, low in manufacturing cost and stable in speed change, and drive efficiency reaches up to 99 percent.

Owner:TAIYUAN UNIV OF TECH

A tractor intelligent control method and intelligent control system

InactiveCN103158713BReduce fuel consumptionImprove traction performanceInternal combustion piston enginesDrive wheelControl signal

The invention relates to a tractor intelligent control method and an intelligent control system. A corresponding signal is collected by a sensor to obtain an existing operating state of a tractor, all parameters are calculated, analyzed and judged by a controller on the basis, and after information is processed, control signals are transmitted to a stepping motor and a high-speed electromagnetic valve so as to enable a main clutch, a PTO clutch, and a brake pedal executing mechanism, an engine throttle draw bar executing mechanism, a hydraulic hanging mechanism and the like to conduct motion to prevent a driving wheel of the tractor from excessive trackslip and overload of a transmission system, ensure good comfort, fuel economy and traction, and prolong service life of the transmission system and tires of the tractor.

Owner:HENAN UNIV OF SCI & TECH

A kind of low slip rate gear and its design method

ActiveCN113062961BSmall slip rateReduce wearPortable liftingComplex mathematical operationsGear driveGear wheel

The invention discloses a low sliding rate gear and a design method thereof, and relates to the technical field of gear transmission. A low-slip-rate gear and a design method are proposed, which can solve the problems of high slip rate and easy wear of the existing gear during the transmission process, and are beneficial to further improve the transmission efficiency of the gear pair. In the low-slip rate gear and design method of the present invention, a low-slip rate production rack is constructed according to the proposed tooth profile meshing path curve, and then the low-slip rate gear tooth profile is obtained from the production rack through the enveloping motion. The coefficients of the meshing path curve equation are adjustable (under the premise of satisfying the boundary condition of low slip rate), so it can satisfy the optimization of the slip rate at any moment in the gear transmission process (except for nodes, where the slip rate is 0). , which is conducive to improving the transmission efficiency, reducing the sliding rate of the gear transmission, reducing the wear of the gear during the transmission process, improving the bearing capacity of the gear, and optimizing the lubrication conditions of the gear.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Multipoint Contact Spur Gear Meshing Pair Based on Conjugate Curves

ActiveCN105202115BReduce wearReduce temperature riseToothed gearingsGearing elementsGear wheelGear tooth

Owner:CHONGQING UNIV

Cycloid planetary transmission gear based on line-plane conjugation

ActiveCN102252058BImprove rigidityGood transmission precisionPortable liftingToothed gearingsGear wheelEngineering

Owner:CHONGQING UNIV

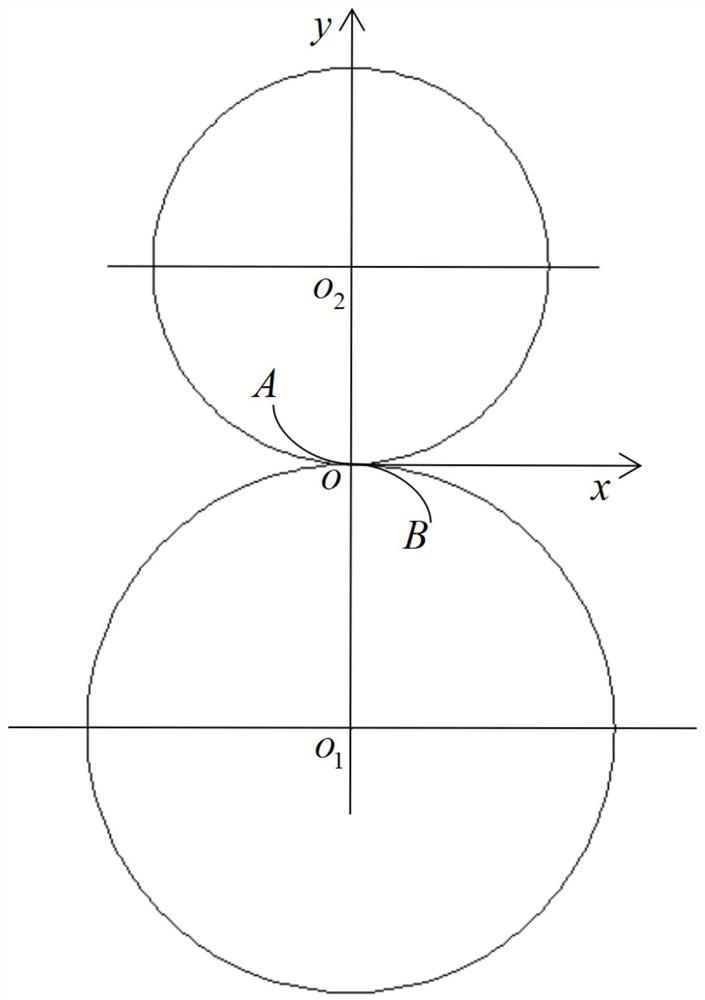

A gear with a special tooth profile curve

ActiveCN104455315BHigh contact fatigue strengthSmall slip ratePortable liftingGearing elementsHobbingGear wheel

The invention discloses a gear with a novel tooth profile curve. A tooth profile curve at the tooth top of the gear is in a convex shape. A tooth profile curve at the tooth root of the gear is in a concave shape. A meshed tooth pair of a gear pair is in convex-concave arc meshing. In a coordinate system O-xy with the gear center as an original point, through a gear parameter and tooth profile curve parameter equation, the tooth profile curve is obtained, the tooth profile curve is subjected to symmetry and rotation transformation, then the end face profile of the gear is obtained, and the gear pair formed by gears is in conjugation and in convex-concave arc meshing. The gear can be used in tooth profile design in large-load gear transmission, the bearing capacity of the gear is greatly increased compared with an involute, when a rack tool or hobbing is used for machining, machining tool design is simple, and only one tool needs to be machined. The gear is also used in design of a small-tooth-number gear pair with a small tooth number (z is smaller than or equal to 6), and accordingly the bearing capacity is improved.

Owner:TIANJIN UNIV

A pressure stepless transmission based on nw type planetary gear train

InactiveCN105570400BPrecise control of speed ratioSimple structureToothed gearingsGearing controlHydraulic motorGear wheel

The invention discloses an NW-type planetary gear train-based pressure stepless speed change device. In a planetary gear train structure, a rotating body is arranged in a rack shell, and the rotating body is fixedly provided with three planetary shafts vertically distributed evenly along circumference; a duplex planetary gear which consists of a small planetary gear and a large planetary gear is arranged on each planetary shaft through a bearing; an eccentric gear is located between the small planetary gear and the large planetary gear; a sun gear is located among the three large planetary gears; in a pressure stepless speed change structure, a hollow drive shaft is arranged at a central position of the sun, and the hollow drive shaft is provided with hydraulic clutches, hydraulic motors and sensors in sequence; the hollow drive shaft is driven by the hydraulic motors; hydraulic oil is delivered into the hydraulic clutches through a hollow channel of the hollow drive shaft to transmit power to realize pressure stepless speed change. The NW-type planetary gear train-based pressure stepless speed change device disclosed by the invention is simple and compact in structure, low in manufacturing cost and stable in speed change, and drive efficiency reaches up to 99 percent.

Owner:TAIYUAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com