Low-slide-rate gradient pressure angle gear and design method

A technology of pressure angle and slip rate, which is applied to belts/chains/gears, mechanical equipment, components with teeth, etc., and can solve problems such as high slip rate and poor stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

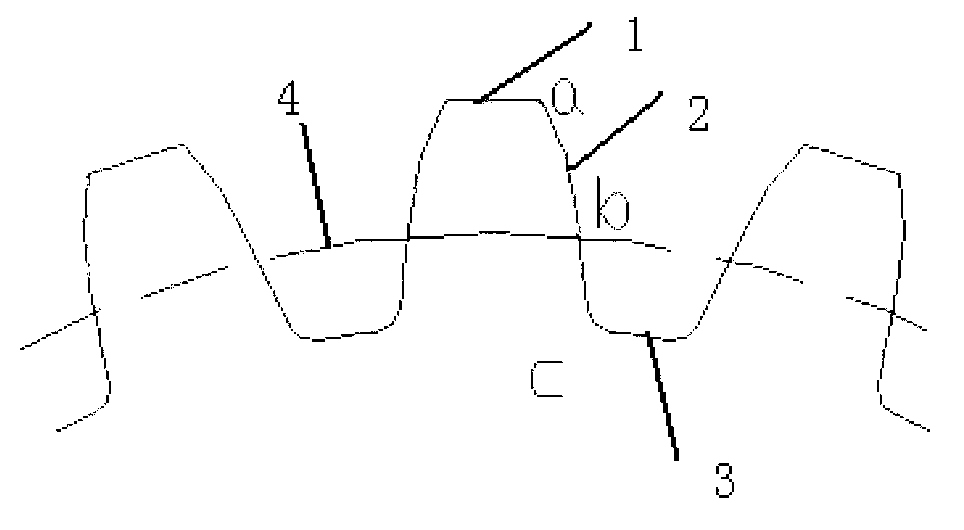

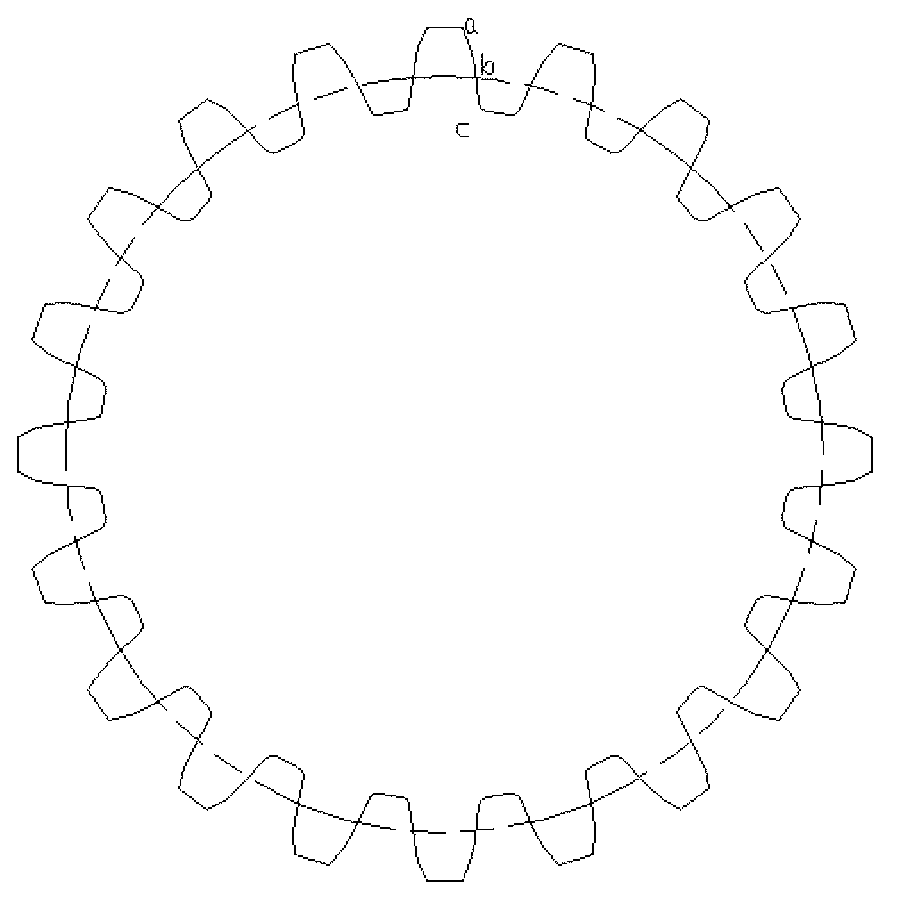

[0024] Please refer to Figure 1-2 , and in conjunction with the following descriptions to understand the low slip rate gradual pressure angle gear and design method provided by the present invention.

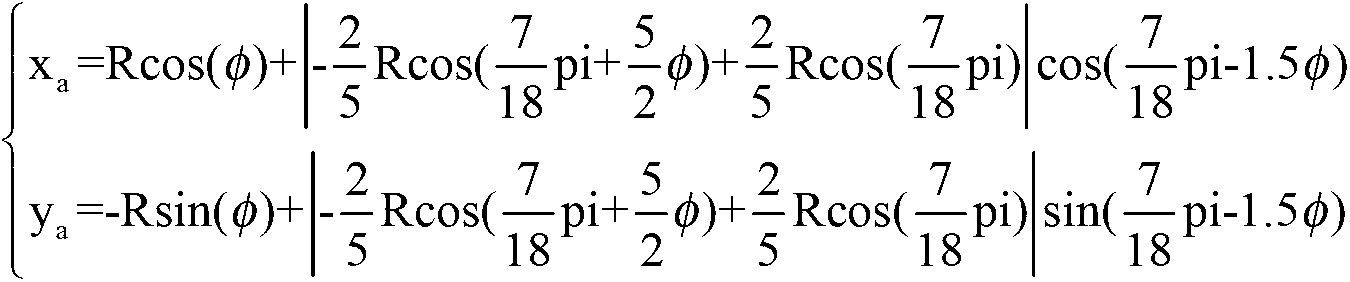

[0025] The low-slip ratio gradual pressure angle gear provided by the present invention comprises: an addendum circle part 1 , a tooth profile curve 2 and a dedendum circle part 3 . The tooth profile curve 2 is divided into the addendum section ab and the dedendum section bc by the pitch circle 4 of the gear. The equation of the tooth profile curve 2 of the present invention is derived based on the linear function of the pressure angle (the pressure angle refers to the angle between the normal direction of the tooth profile of the meshing point and the speed direction of the point), so that the pressure angle of the gear It can change linearly during the transmission process, and ensure that the pressure angle is optimized at any time during the gear transmission process, ther...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com