Double differential type continuously variable transmission device

A technology of infinitely variable transmission and differential, applied in transmission parts, gear transmissions, belts/chains/gears, etc., can solve the problems of poor overload resistance and impact resistance, large slip rate, slow response to speed changes, etc. The effect of improving overload resistance and impact resistance, reducing slip rate and increasing power output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

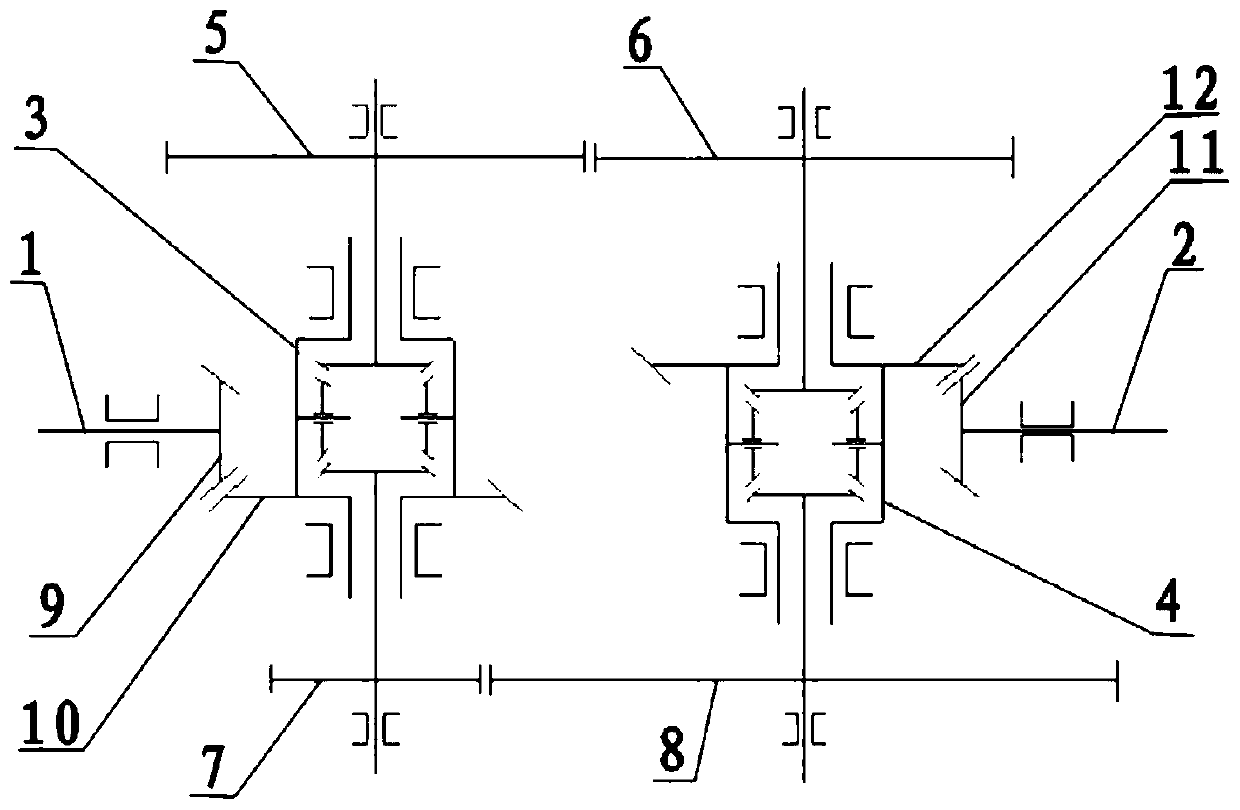

Embodiment 1

[0062] Both the first differential and the second differential are bevel gear differentials;

[0063] The transmission mechanism includes a first gear 5, a second gear 6, a third gear 7 and a fourth gear 8;

[0064] The input shaft 1 is connected to the first pot tooth 10 of the first differential through the first corner tooth 9;

[0065] The first gear 5 is arranged on one end away from the first pot tooth 10 of the first differential, and the second gear 6 meshed with the first gear 5 is arranged on an end close to the second pot tooth 12 of the second differential; The three gears 7 are arranged at one end close to the first basin teeth 10 of the first differential, and the fourth gear 8 meshed with the third gear 7 is arranged at one end away from the second basin teeth 12 of the second differential;

[0066] The output shaft 2 is connected to the second basin tooth 12 of the second differential through the second corner tooth 11;

[0067] The relationship that the inde...

Embodiment 2

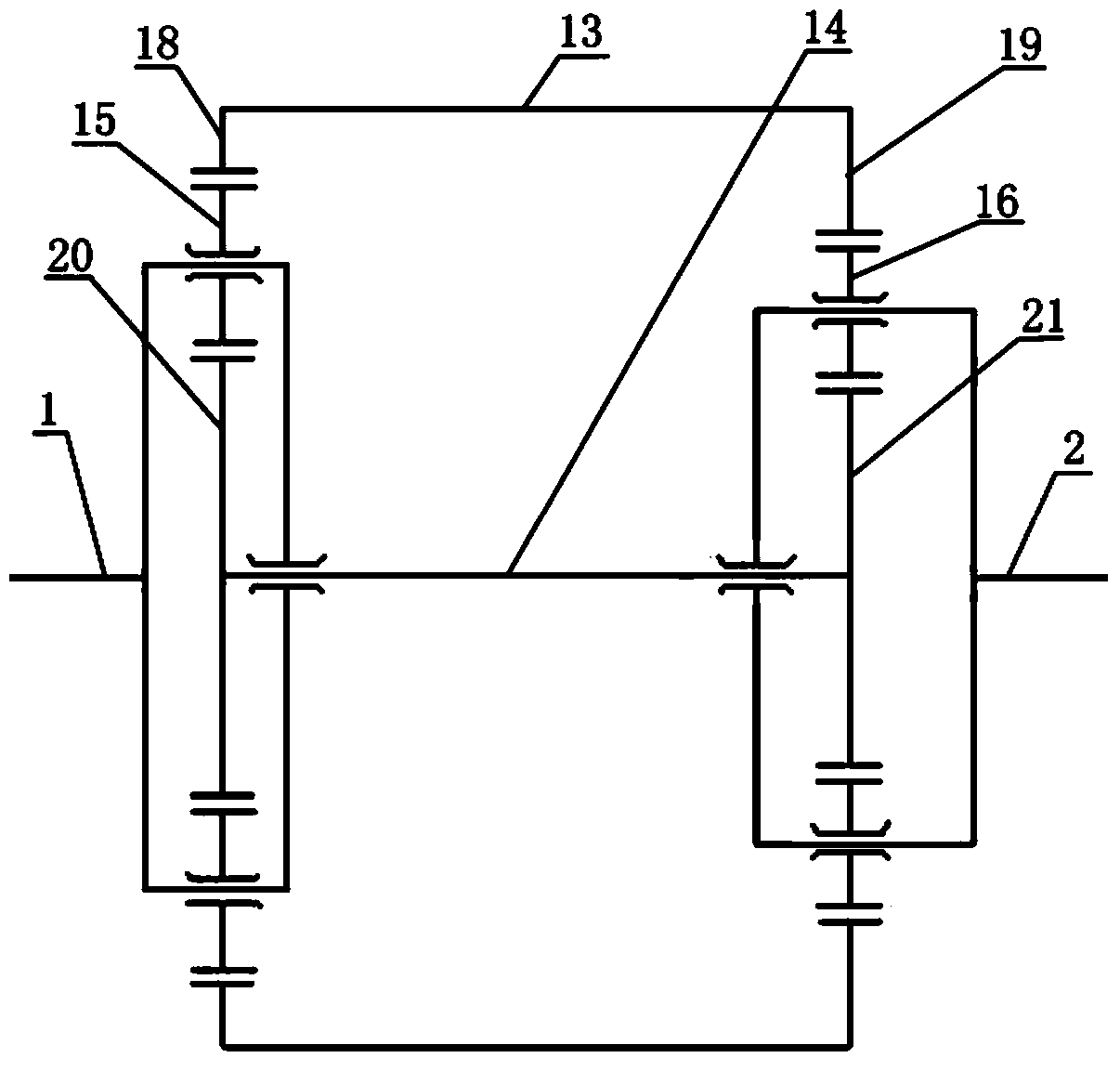

[0119] Such as figure 2 As shown, both the first differential and the second differential are sun gear differentials;

[0120] The transmission mechanism is the ring gear connection part 13 and the transmission shaft 14;

[0121] One end of the ring gear connecting portion 13 is fixedly connected to the first ring gear 18 of the first differential, and the other end is fixedly connected to the second ring gear 19 of the second differential;

[0122] One end of the drive shaft 14 is fixedly connected to the first sun gear 20 of the first differential, and the other end is fixedly connected to the second sun gear 21 of the second differential;

[0123] The input shaft 1 is connected to the first planetary gear 15 of the first differential, and the output shaft 2 is connected to the second planetary gear 16 of the second differential;

[0124] Pitch circle diameter n of the first sun gear 20 1 , The pitch circle diameter m of the first ring gear 18 1 , The pitch circle diame...

Embodiment 3

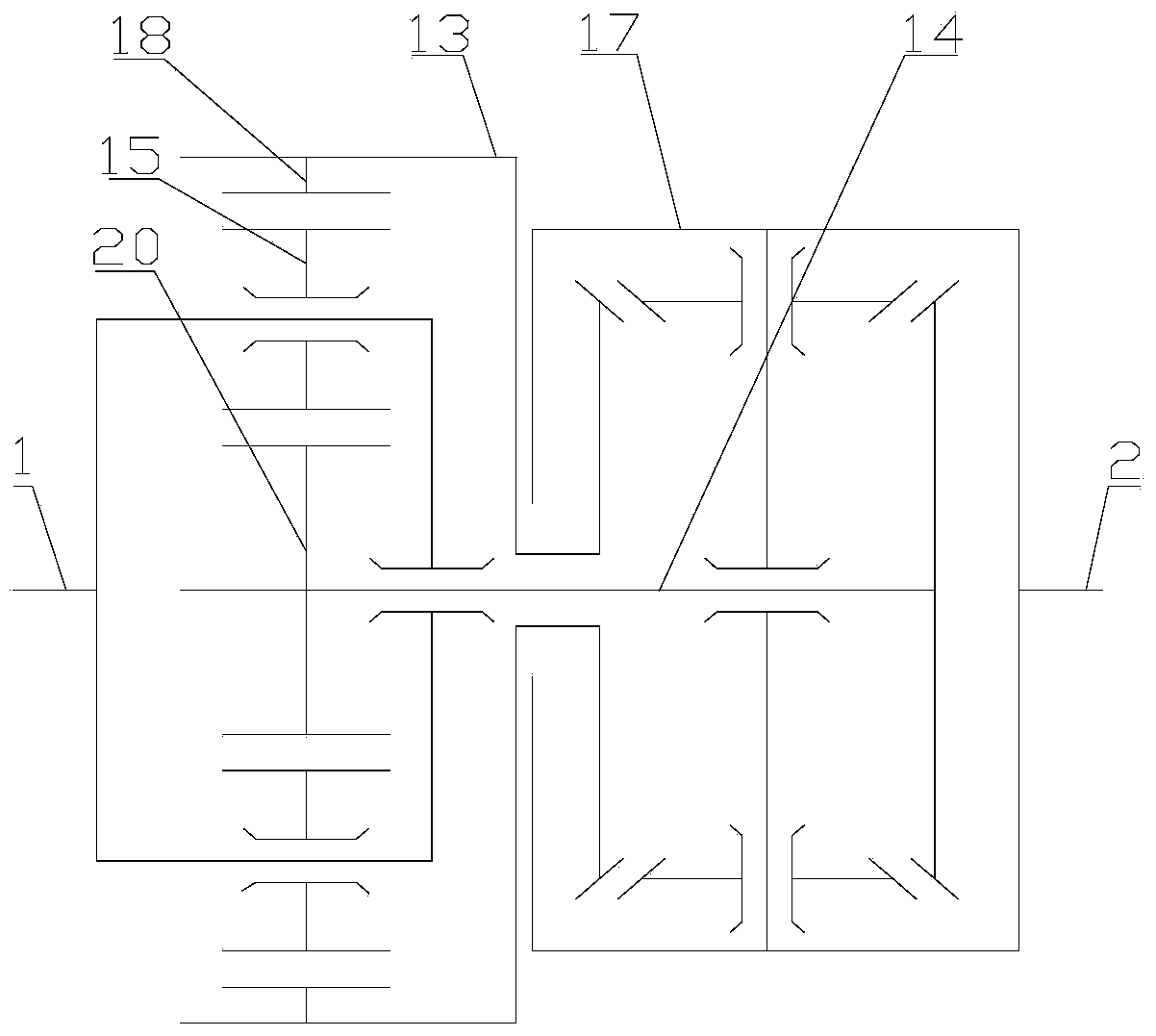

[0153] Such as image 3 As shown, the first differential is a sun gear differential, and the second differential is a bevel gear differential;

[0154] The transmission mechanism includes a ring gear connection part 13 and a transmission shaft 14;

[0155] One end of the ring gear connecting portion 13 is fixedly connected to the first ring gear 18, and the other end is fixedly connected to the side gear of the second differential;

[0156] One end of the drive shaft 14 is fixedly connected to the axis of the first sun gear 20, and the other end is fixedly connected to the other side gear of the second differential;

[0157] The input shaft 1 is connected to the first planetary gear 15, and the output shaft 2 is connected to the casing of the second differential;

[0158] Pitch circle diameter m of the first ring gear 18 1 Pitch circle diameter n of the first sun gear 20 1 The relationship is:

[0159] 01 / m 1 )1 / m 1 ) <1.

[0160] When the pitch circle diameter of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com