Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

40results about How to "Reduced necking" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

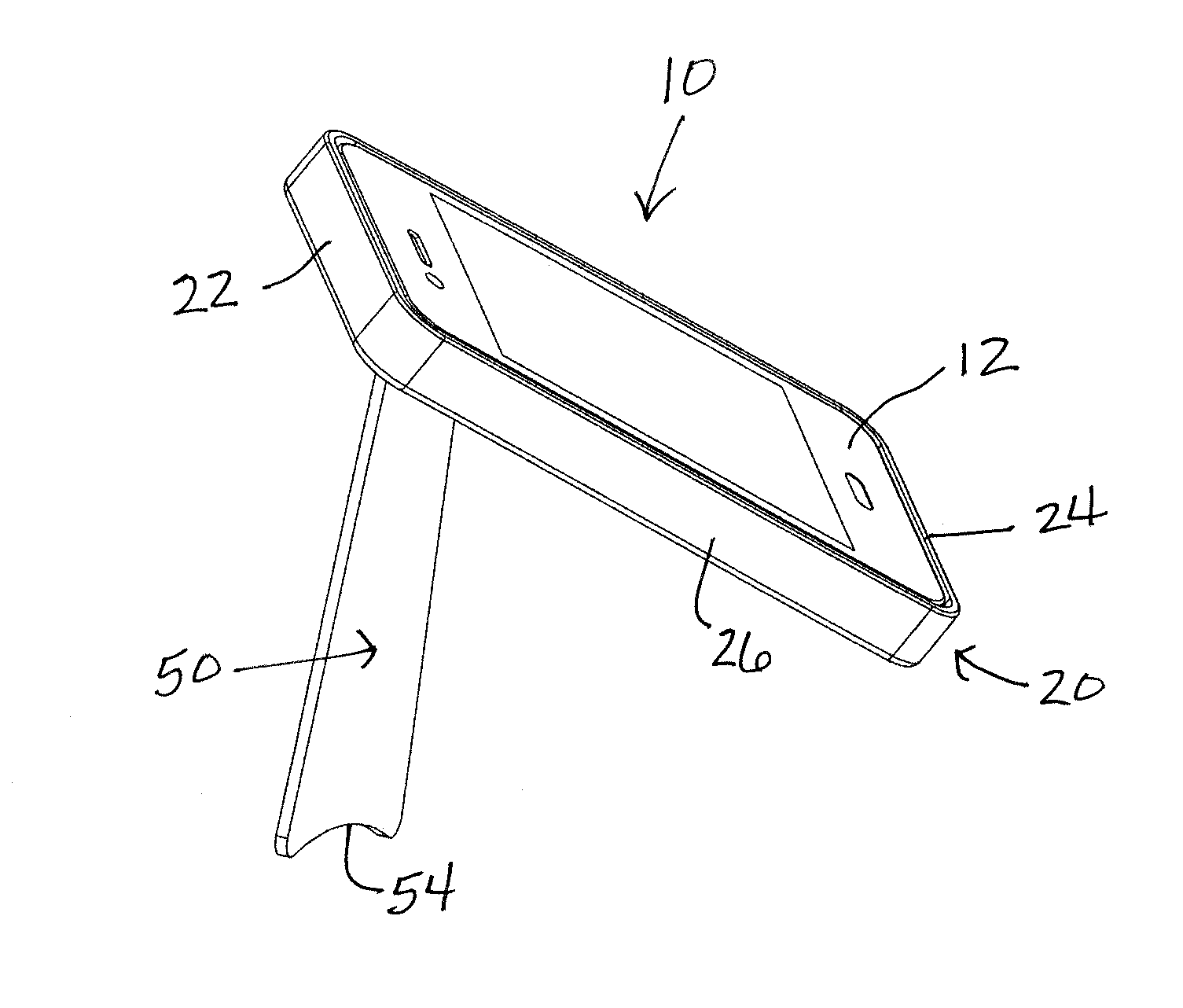

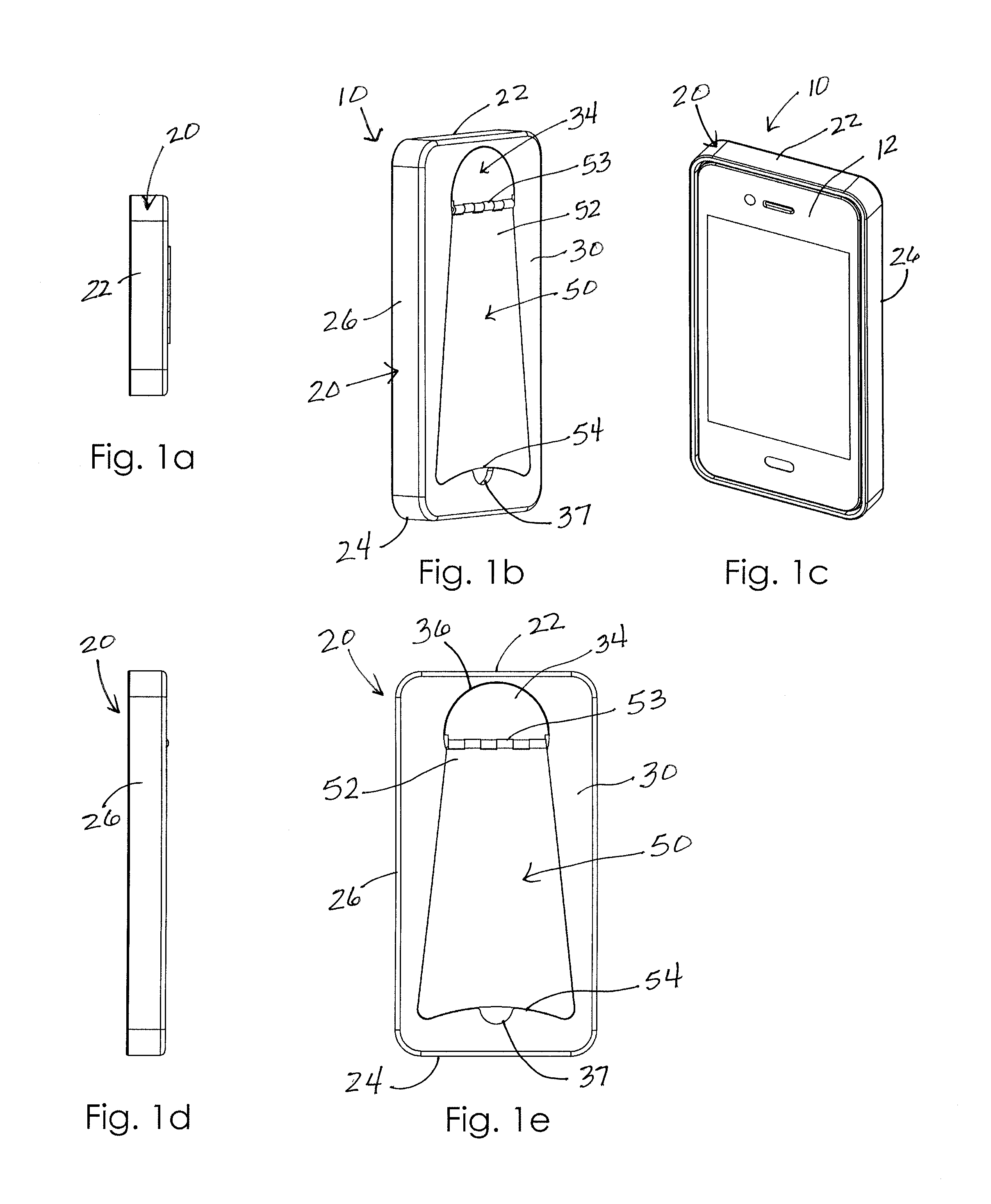

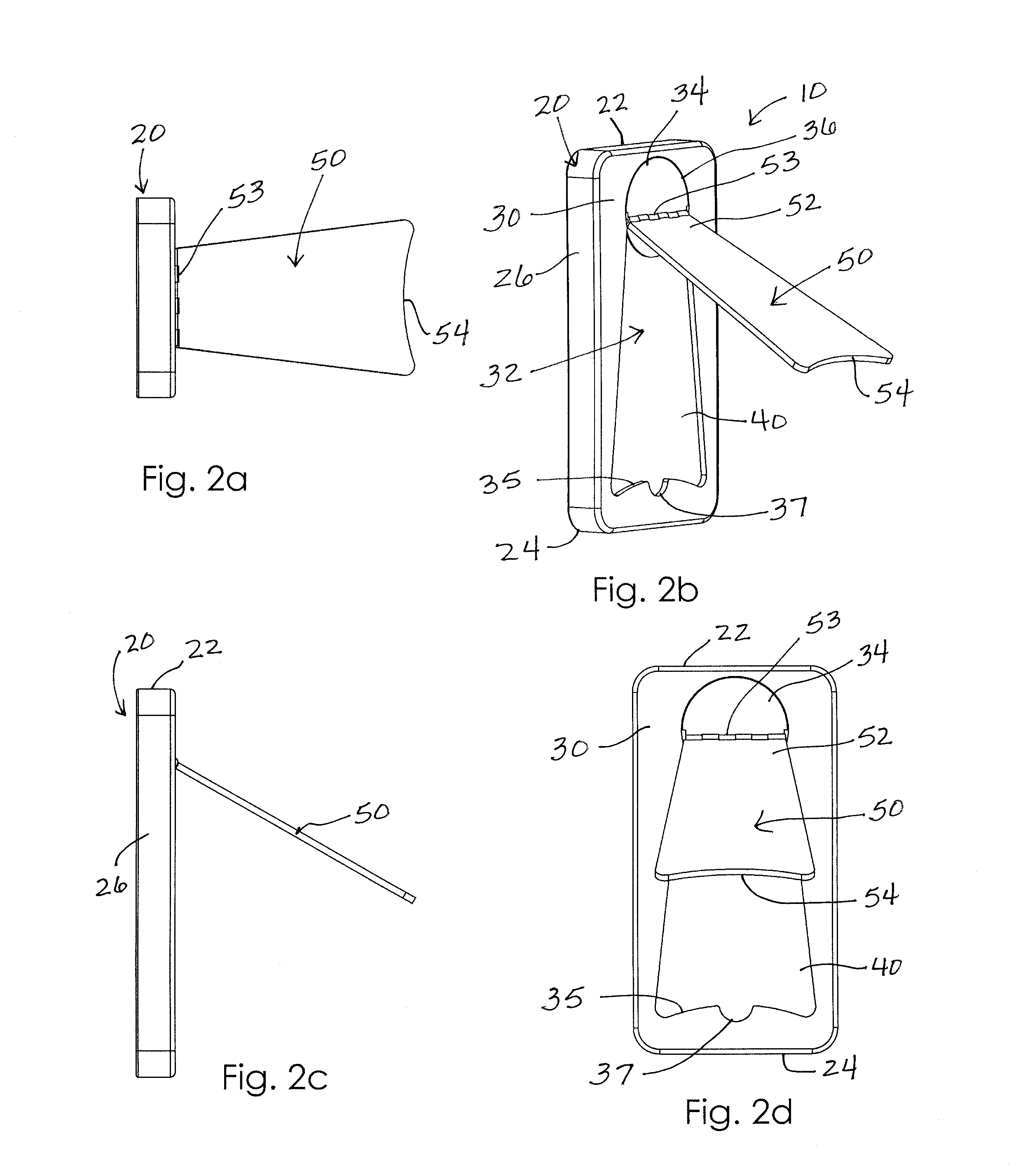

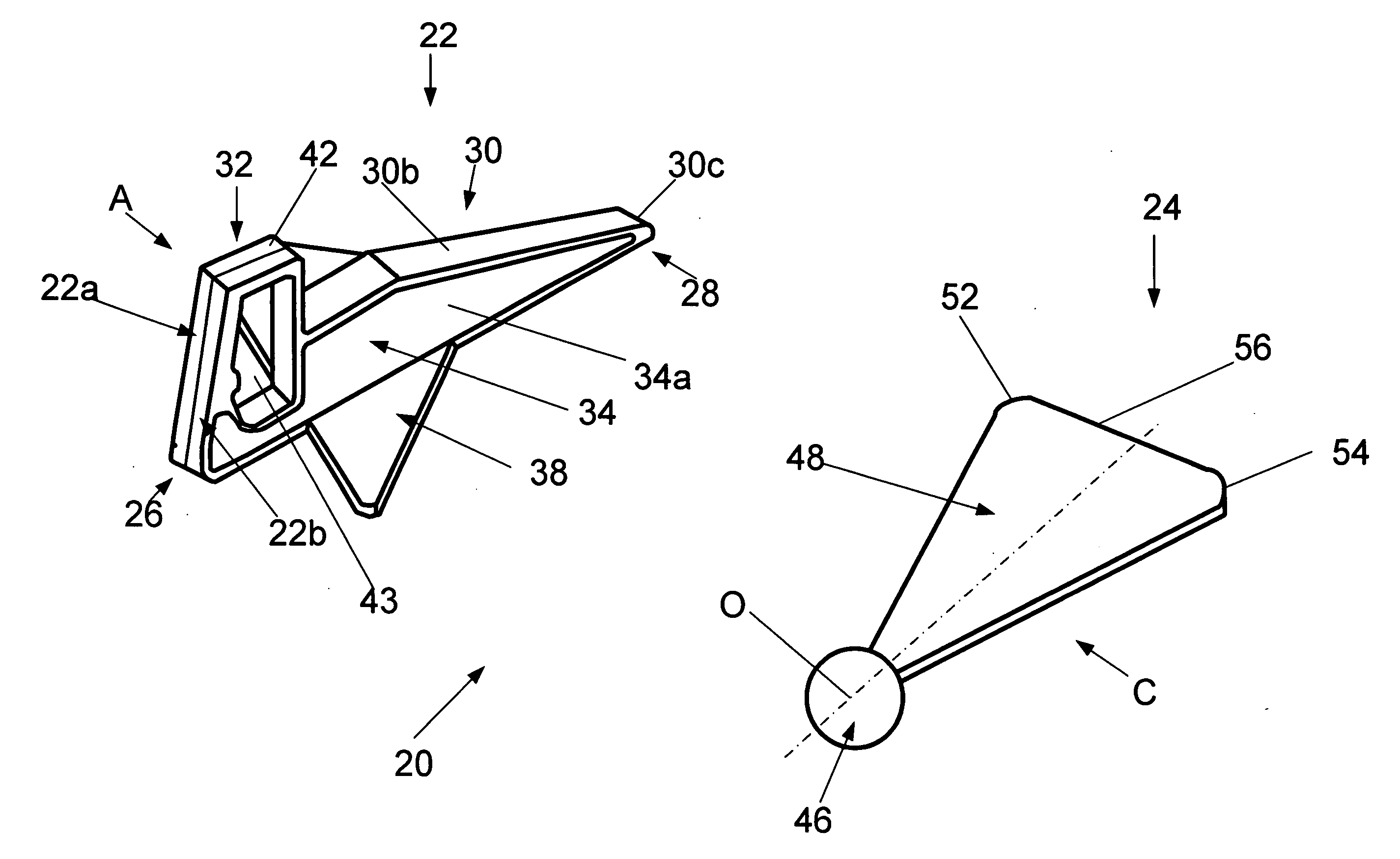

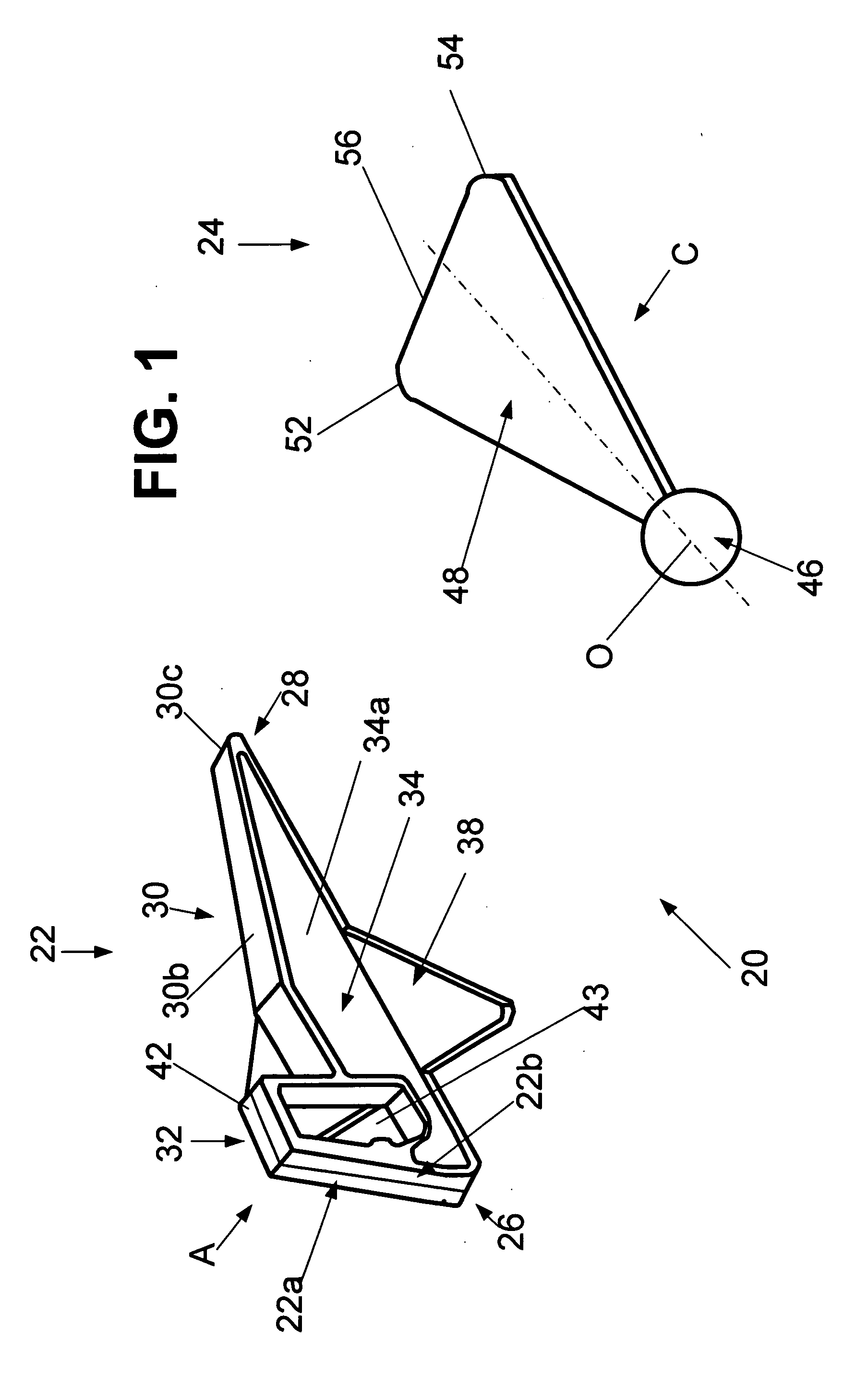

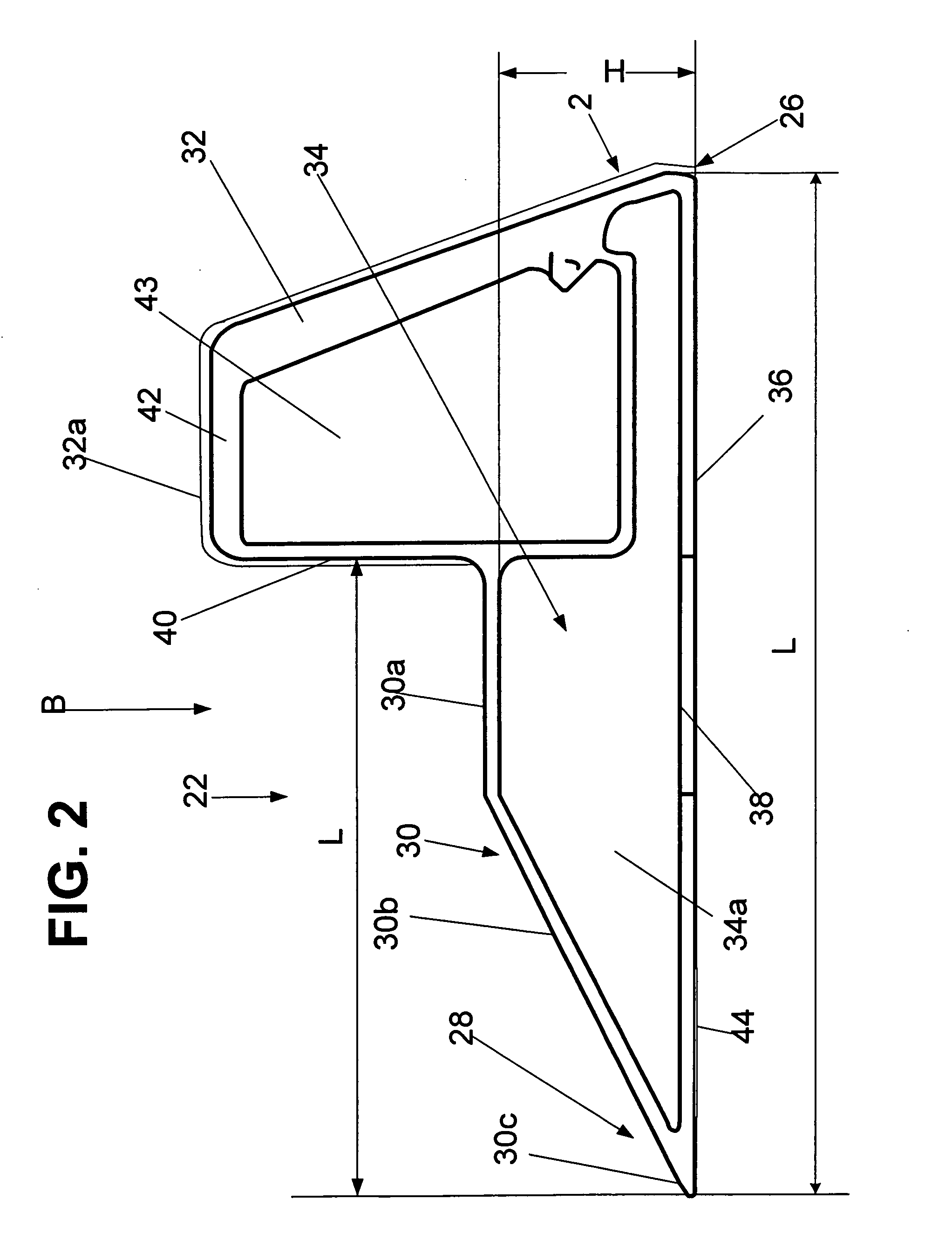

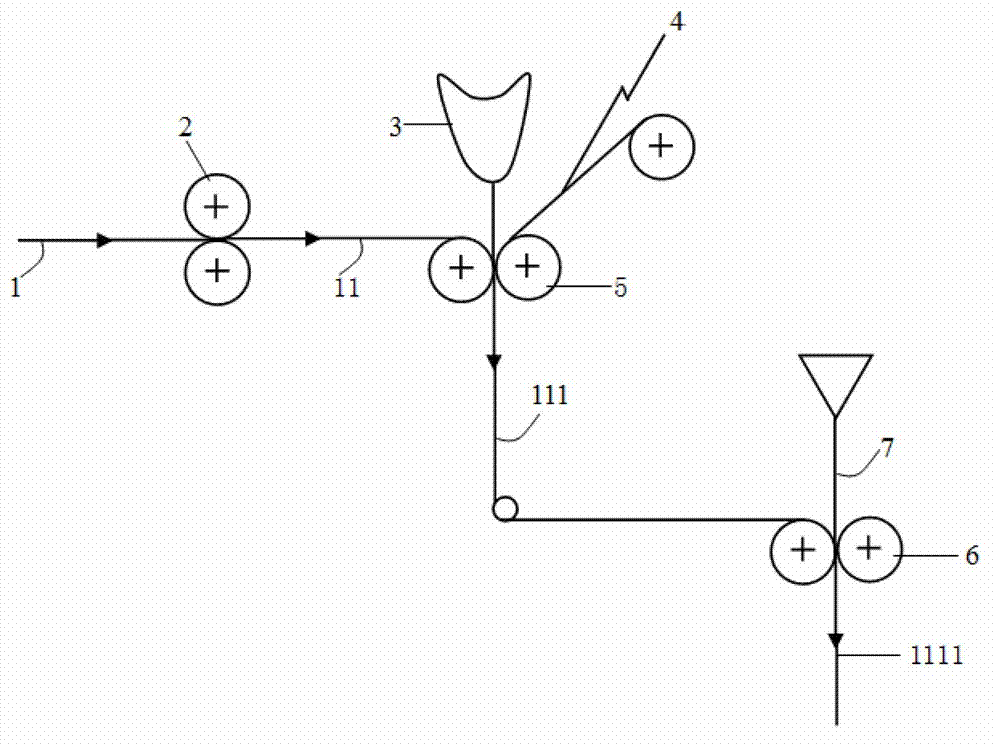

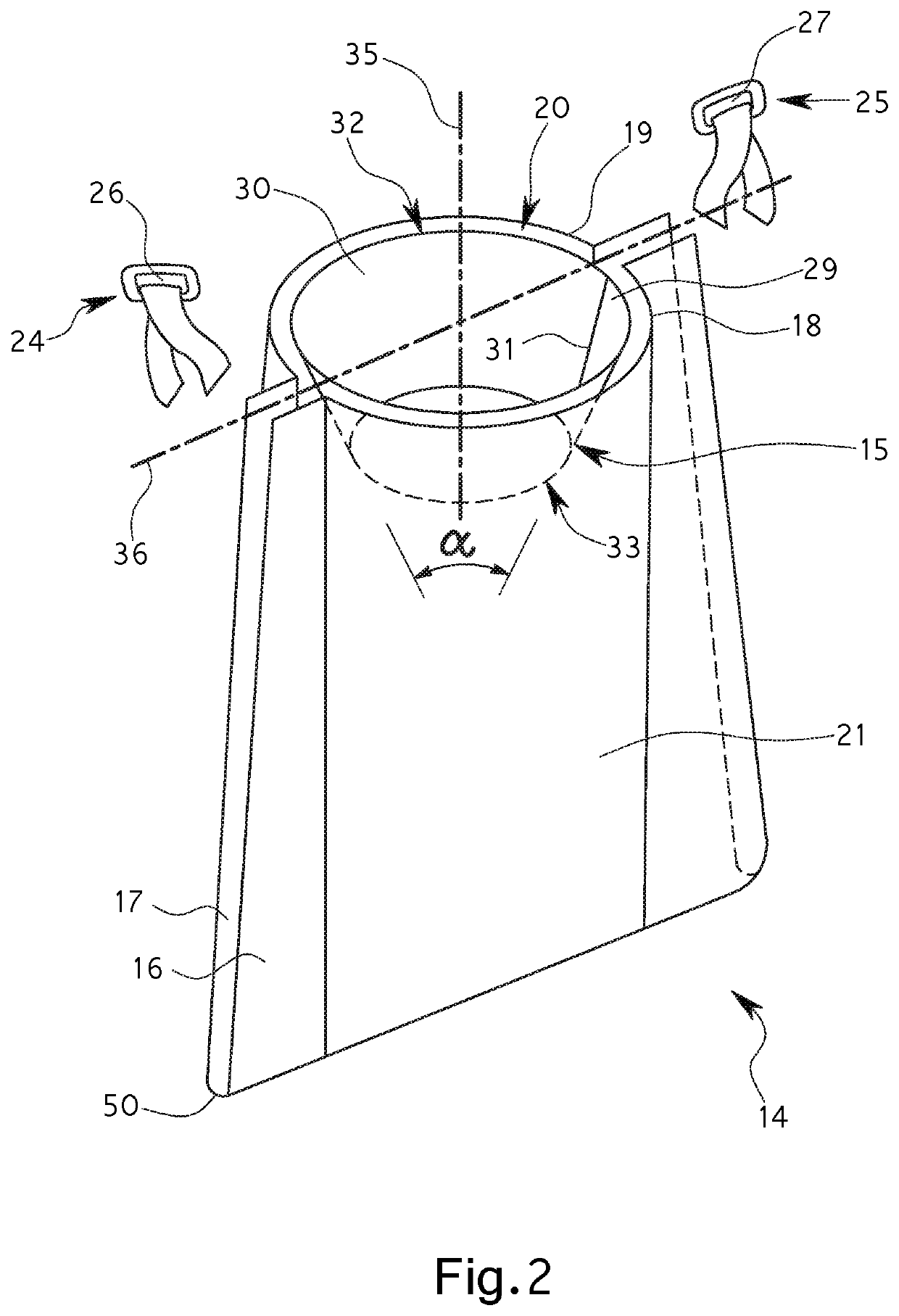

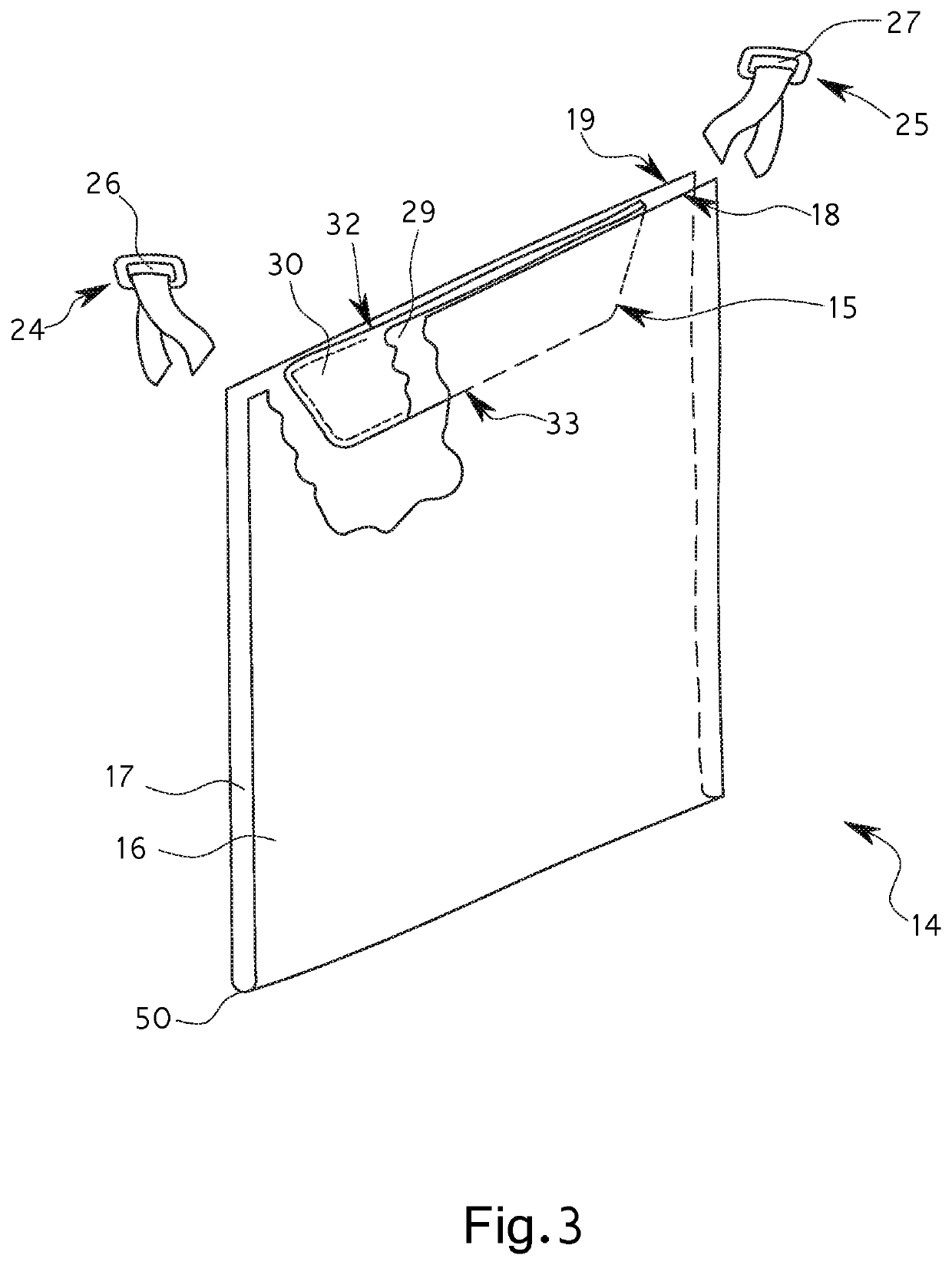

Support Apparatus for Mobile Device

InactiveUS20150011265A1Reduced neckingReduce shoulder painFinanceCurrency conversionEngineeringMobile device

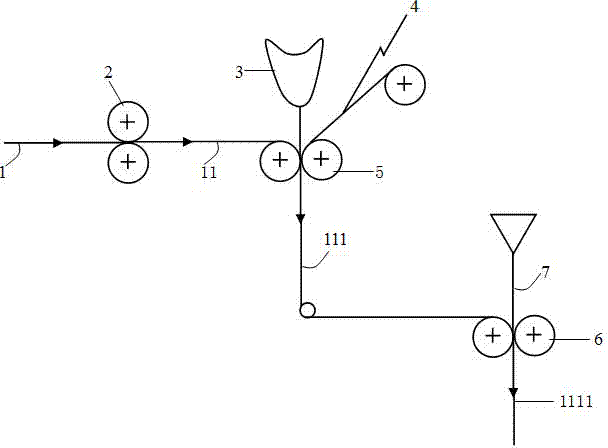

An adjustable head and shoulder support apparatus for use with a mobile phone includes a mobile device case having opposing top and bottom ends and configured to hold the mobile phone, the case including a rear face. The apparatus includes a support arm having a first end pivotally coupled to the rear face proximate the top end and a second end opposed from the first end. The support arm is pivotally movable between a stowed configuration adjacent the rear face and an extended configuration displaced from the rear face. The rear face of the case defines a recess that includes an upper portion having a generally circular configuration and a lower portion in communication with the upper portion. The support arm is nested in the lower portion of the recess at the stowed configuration and is displaced from the lower portion of the recess at the extended configuration.

Owner:WALSH JR JAMES A

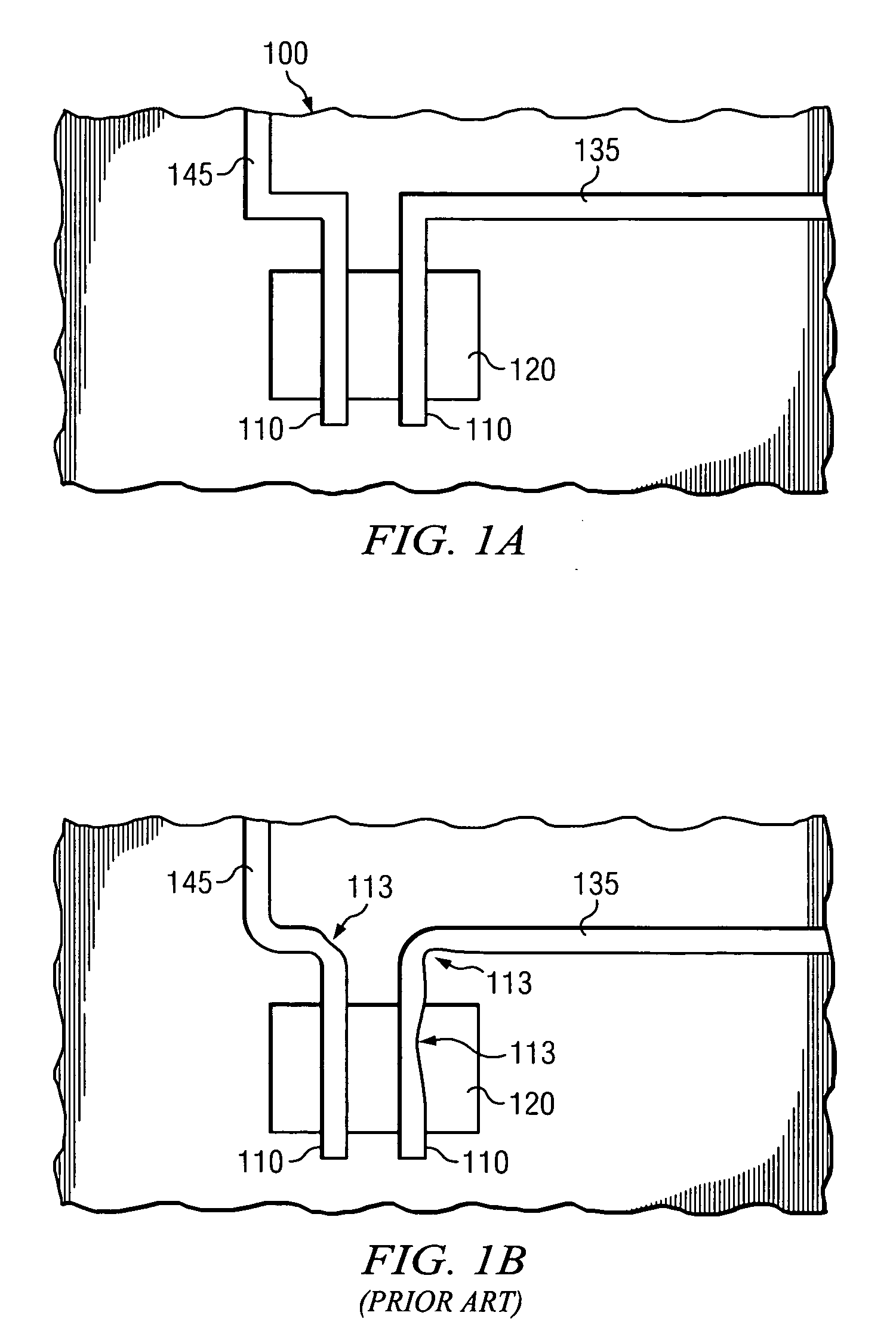

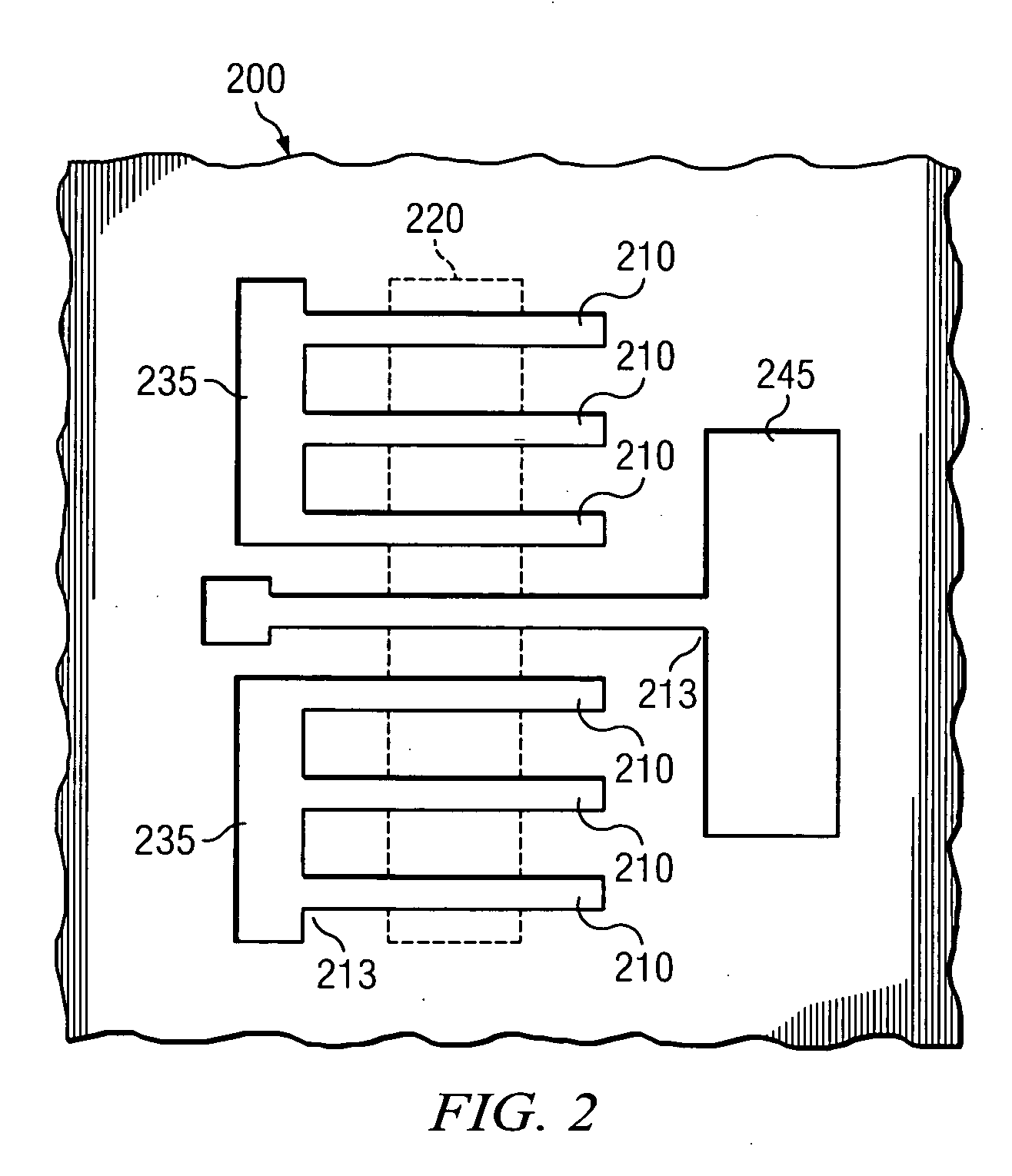

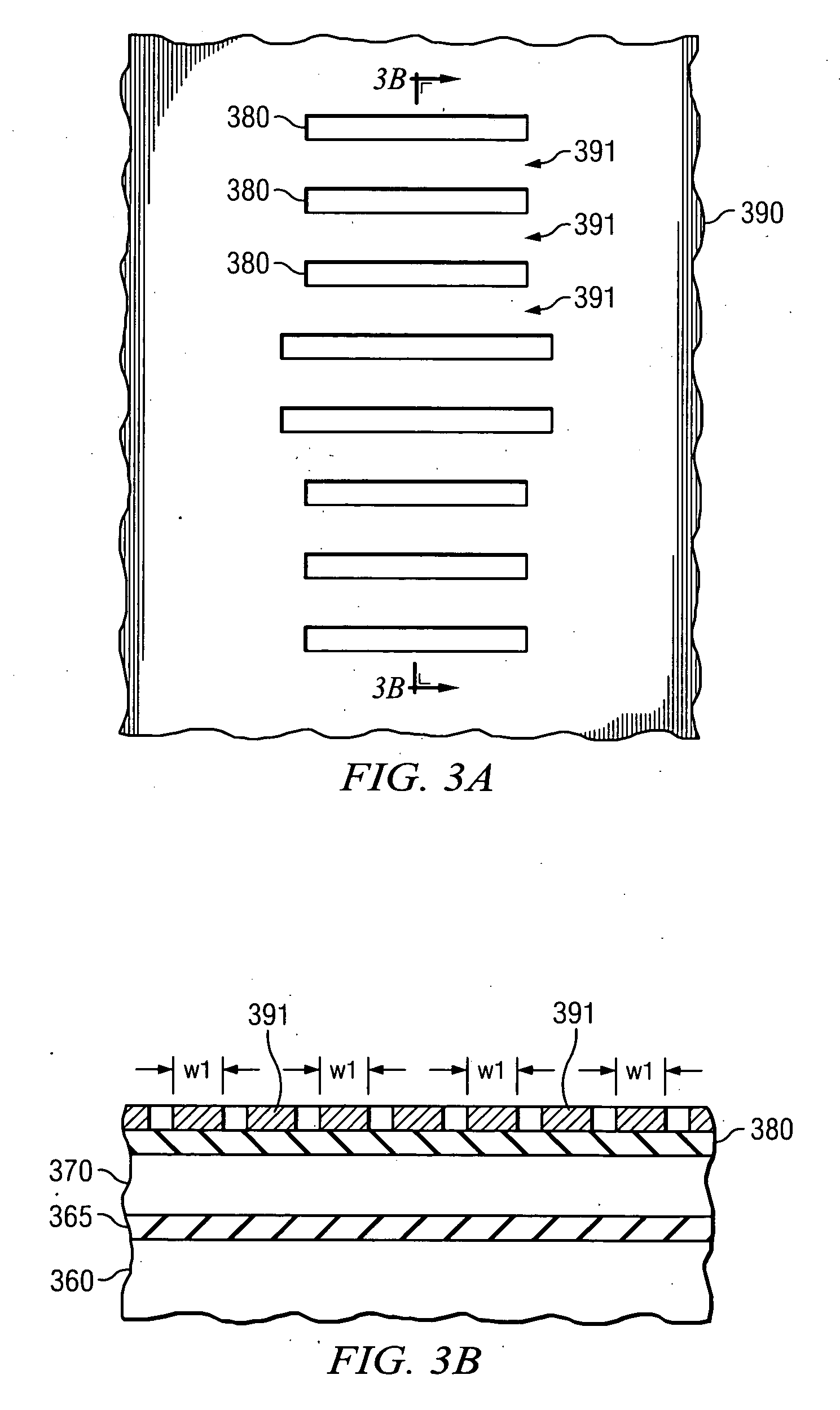

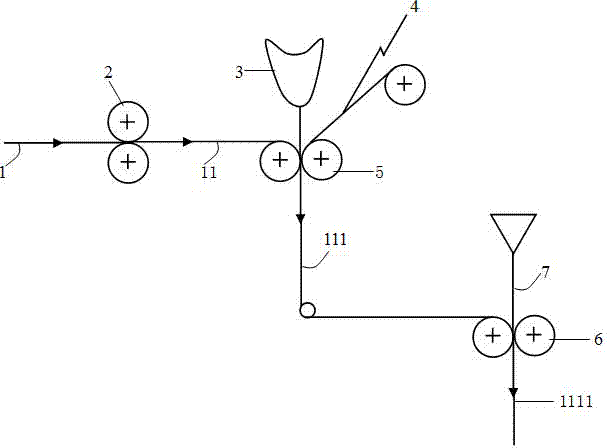

Reduction of mechanical stress on pattern specific geometries during etch using double pattern layout and process approach

InactiveUS20070099424A1Reduce widthReduced neckingDecorative surface effectsSemiconductor/solid-state device manufacturingEtchingEngineering

According to various embodiments, methods to eliminate high stress areas in a mask during a gate trim etch are provided. High stress areas can include, for example, gate regions that are anchored at only one end. The exemplary methods can include the use of a double pattern layout, for example, separating printing and etching of a pattern specific geometry in the mask into two or more portions.

Owner:TEXAS INSTR INC

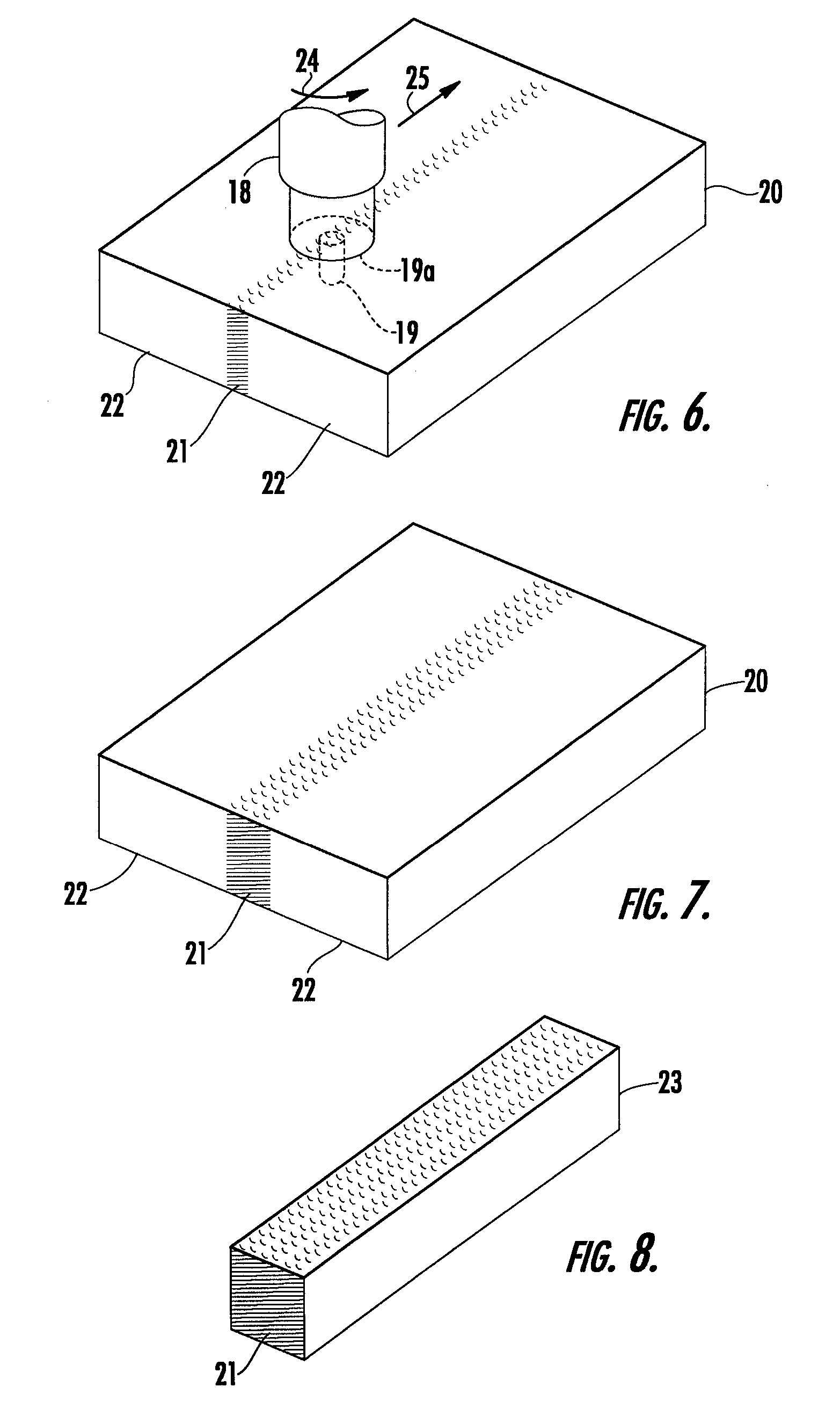

Method of manufacturing rivets having high strength and formability

InactiveUS20030218053A2Good molding effectReduced neckingRivetsWelding/cutting auxillary devicesHigh intensityMechanical property

Abstract of the Disclosure A rivet having improved formability is provided. The rivet has a shank having a head at one end. The shank and the head have a refined grain structure. The rivet is manufactured from the region of the workpiece having a refined grain structure by first forming a region having a refined grain structure in a workpiece and then forming the rivet. The refined grain structure results in improved mechanical properties, such as formability, strength, toughness, ductility, corrosion resistance, and fatigue resistance. The improved formability of the rivet reduces the formation and propagation of cracks during the manufacture and installation of the rivets.

Owner:THE BOEING CO

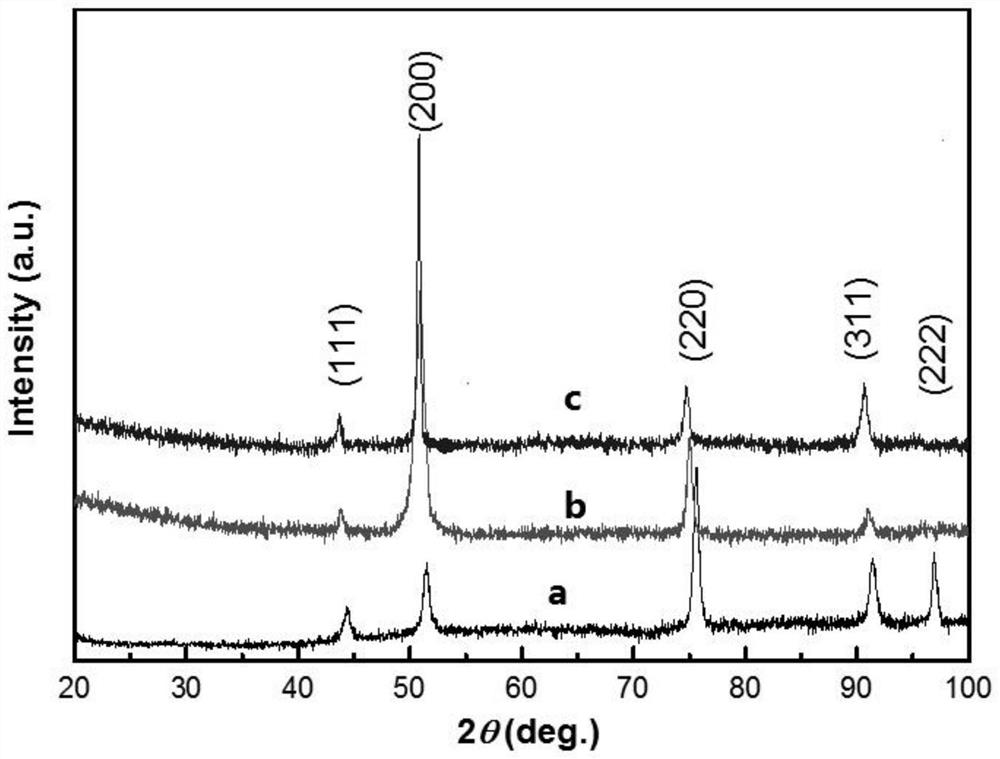

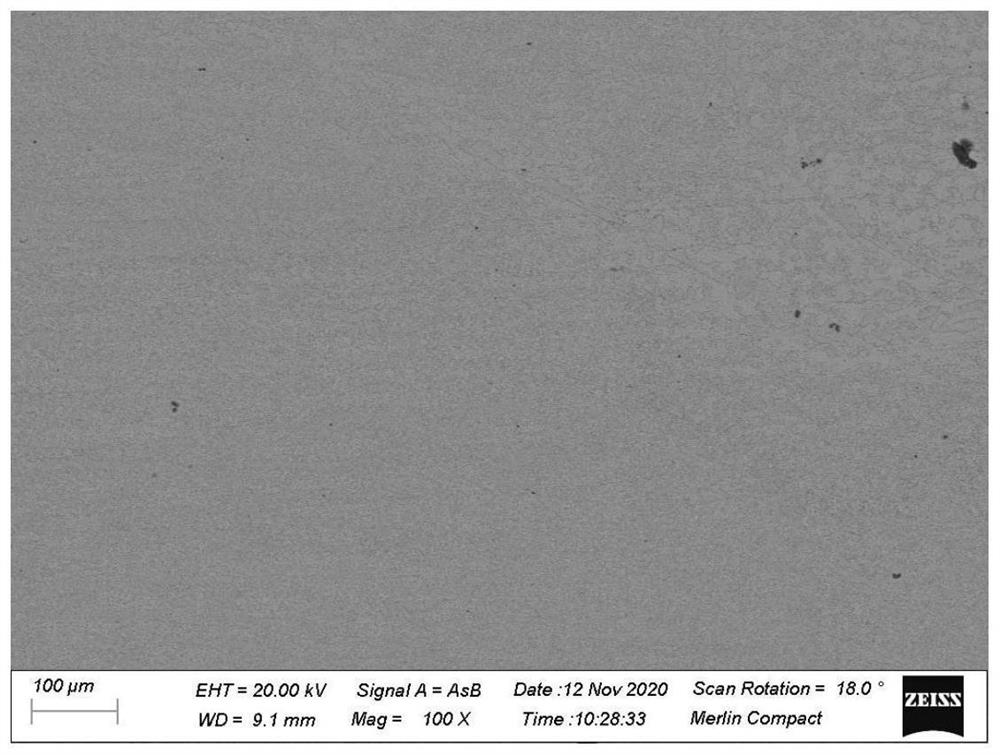

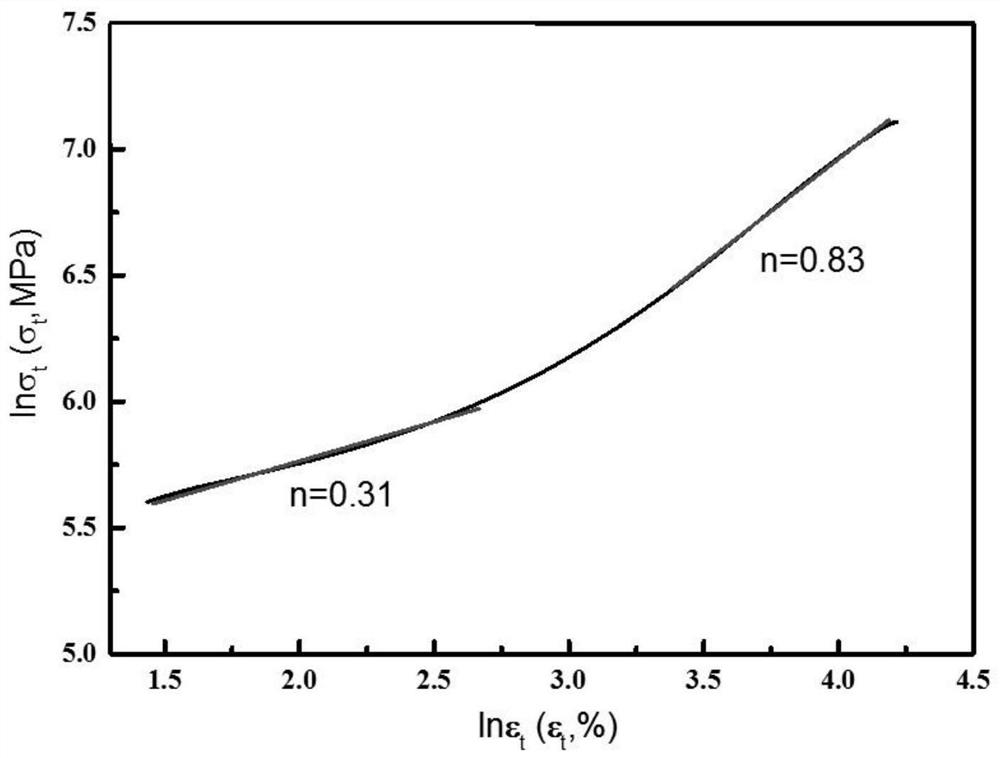

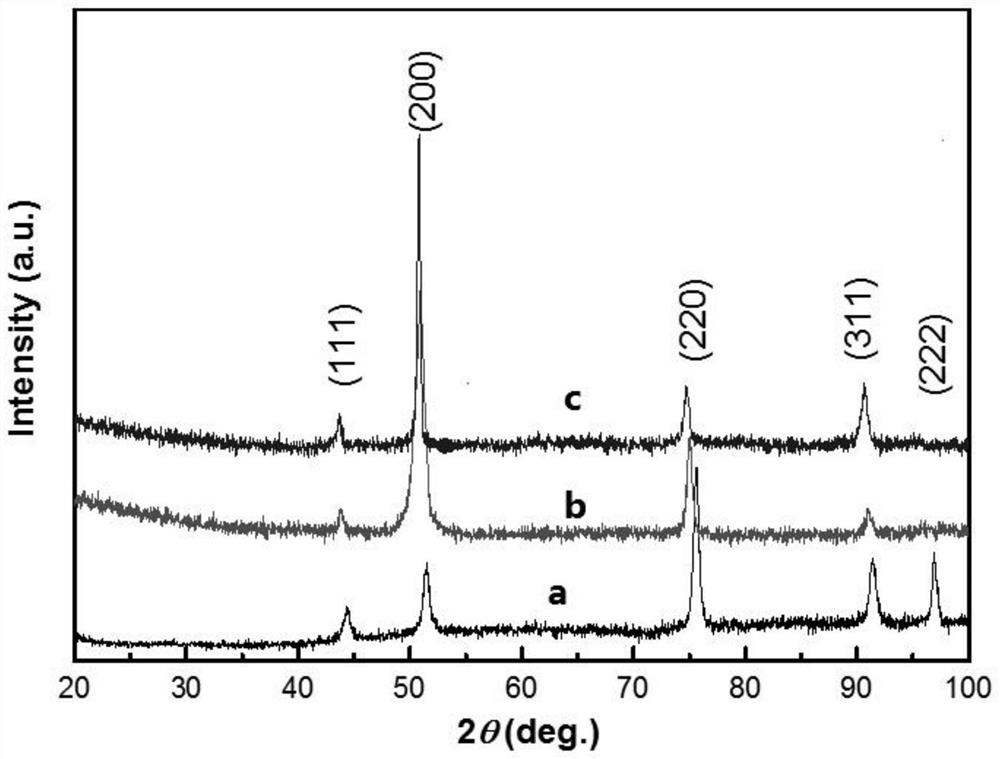

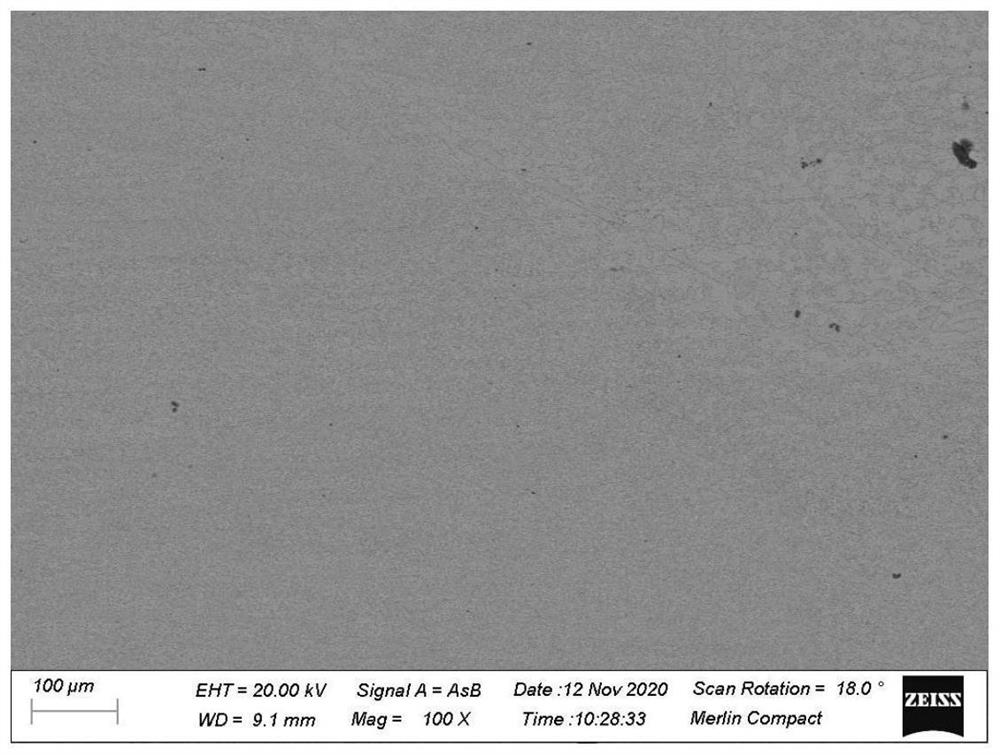

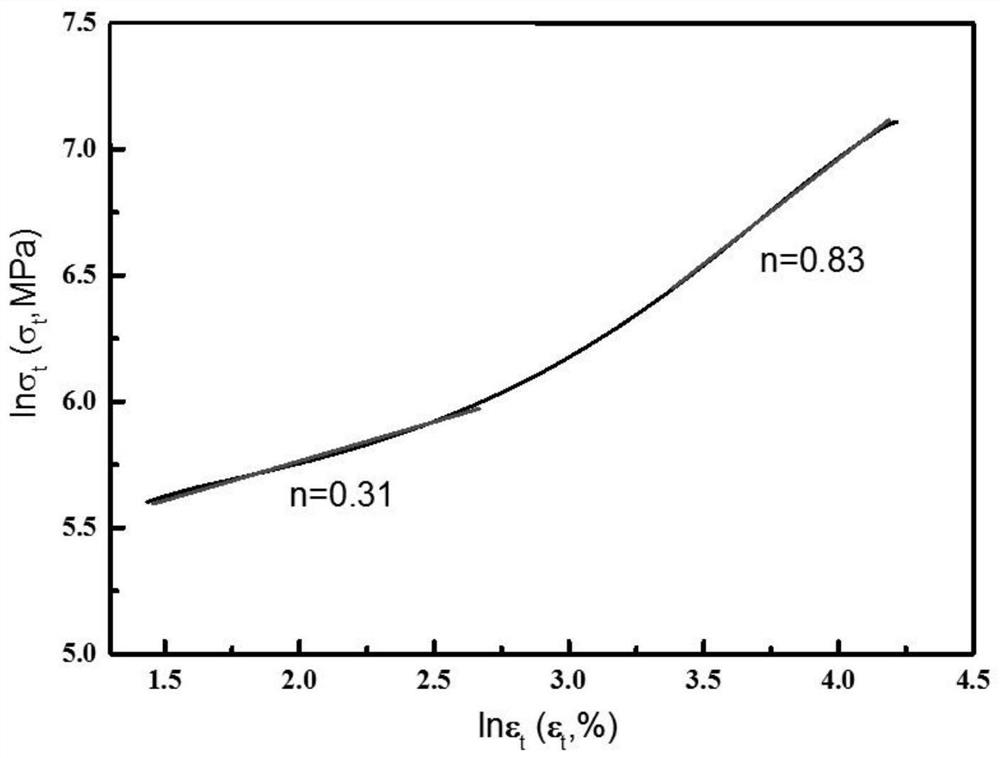

CoCrFeNiMox high-entropy alloy with non-equal atomic ratio and preparation method of CoCrFeNiMox high-entropy alloy

The invention discloses a CoCrFeNiMox high-entropy alloy with a non-equal atomic ratio and a preparation method of the CoCrFeNiMox high-entropy alloy, and relates to the CoCrFeNiMox high-entropy alloy with the non-equal atomic ratio and the preparation method of the CoCrFeNiMox high-entropy alloy. The invention aims to solve the problem that the plasticity of the existing high-entropy alloy is poor, as a result, plastic processing is restricted. The alloy expression is CoCrFeNiMox, x is 0, 2 or 4, and the alloy is prepared from the following raw material components in atomic percent: 0%-20% of Mo, 10%-40% of Co, 10%-40% of Cr, 10%-25% of Fe and 10%-25% of Ni, and the sum of the atomic percent of the components is 100%. CoCrFeNiMox high-entropy alloy is applied to the field of high-entropy alloys.

Owner:HARBIN INST OF TECH

Tool set for tucking bedsheets

InactiveUS20100175195A1Limit amount of insertionImprove lifting performanceBed-tablesBedsEngineeringKnife blades

The bedsheet-tucking tool kit consists of at least one bed-mattress lifter and at least one bedsheet tucker. The lifter has a handle and an insertable portion, the distal end of which tapers in the direction away from the handle. A stopper provided between the handle and the tapered portion limits insertion of the lifter to a position in which the bedsheet can fall behind the inserted portion. At its bottom, the lifter has a flared wing-like portion that maintains stability of the lifter in the inserted position. In order to increase friction between the bottom of the lifter and the boxspring mattress, a small portion of the bottom surface of the lifter is coated with a thin rubber-like coating. This protects the lifter from popping out from the inserted position. The handle may be coated with a rubber film. The tucking tool is made in the form of a spade with a rounded knob-like handle and a flat tucker blade.

Owner:HARRIS ADAMSON CARISA +3

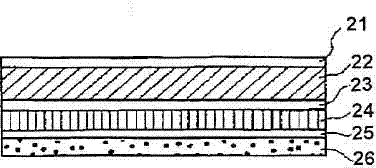

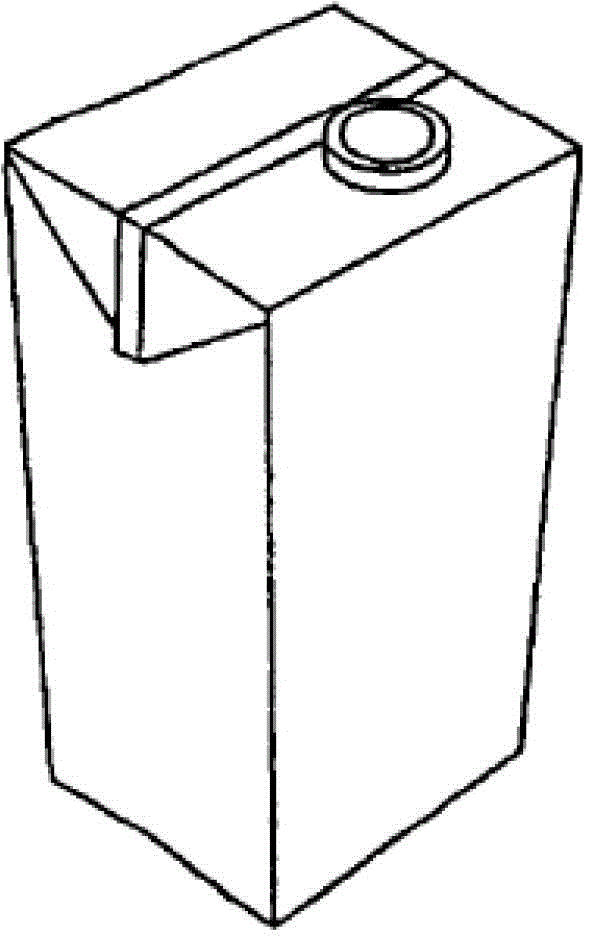

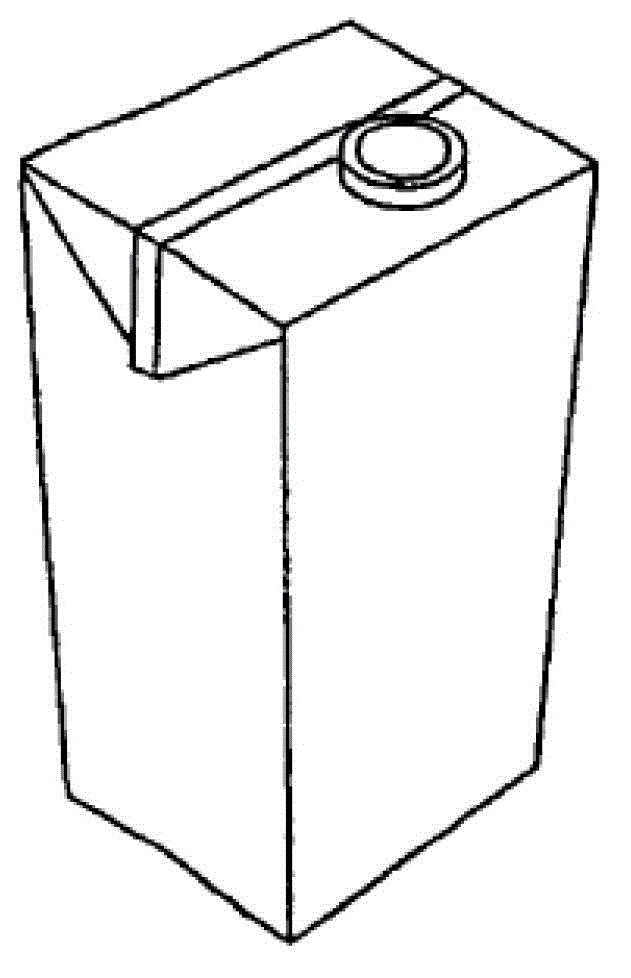

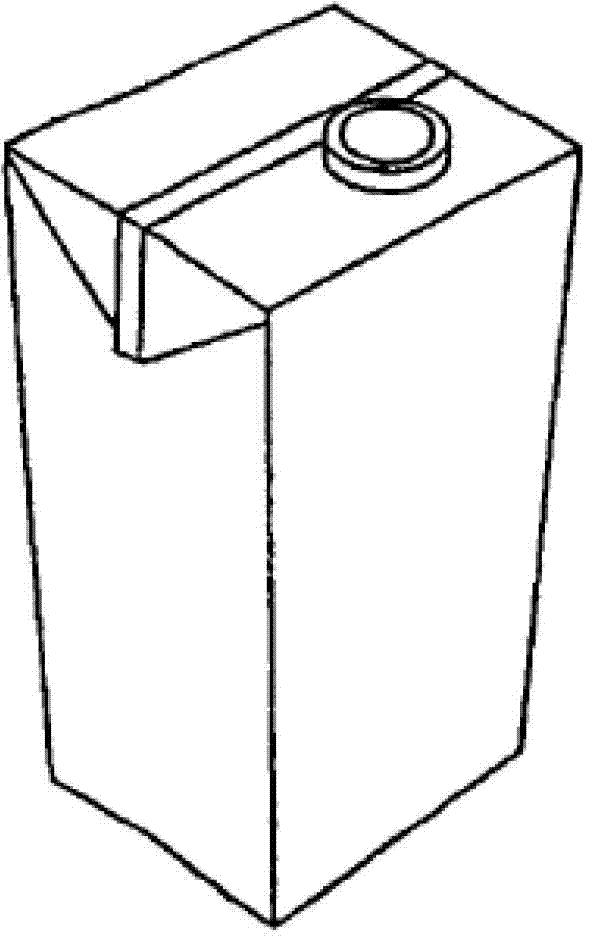

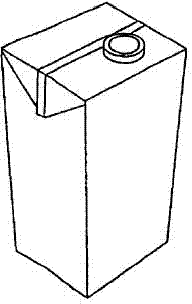

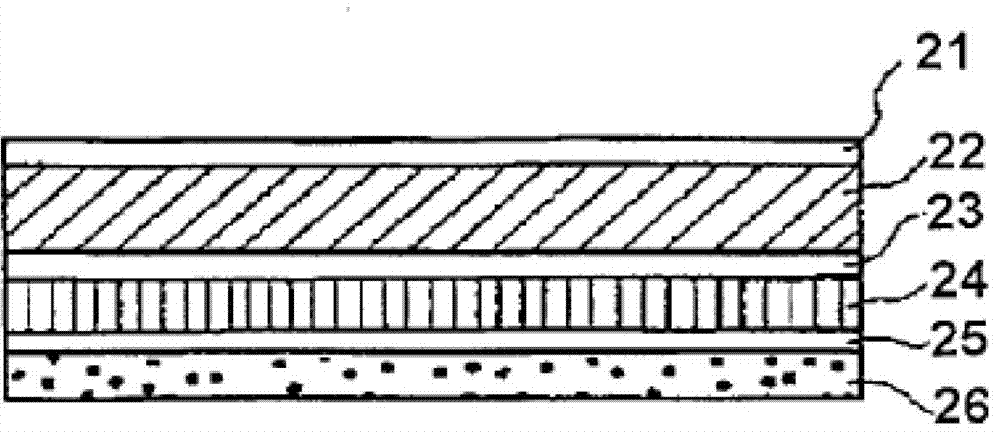

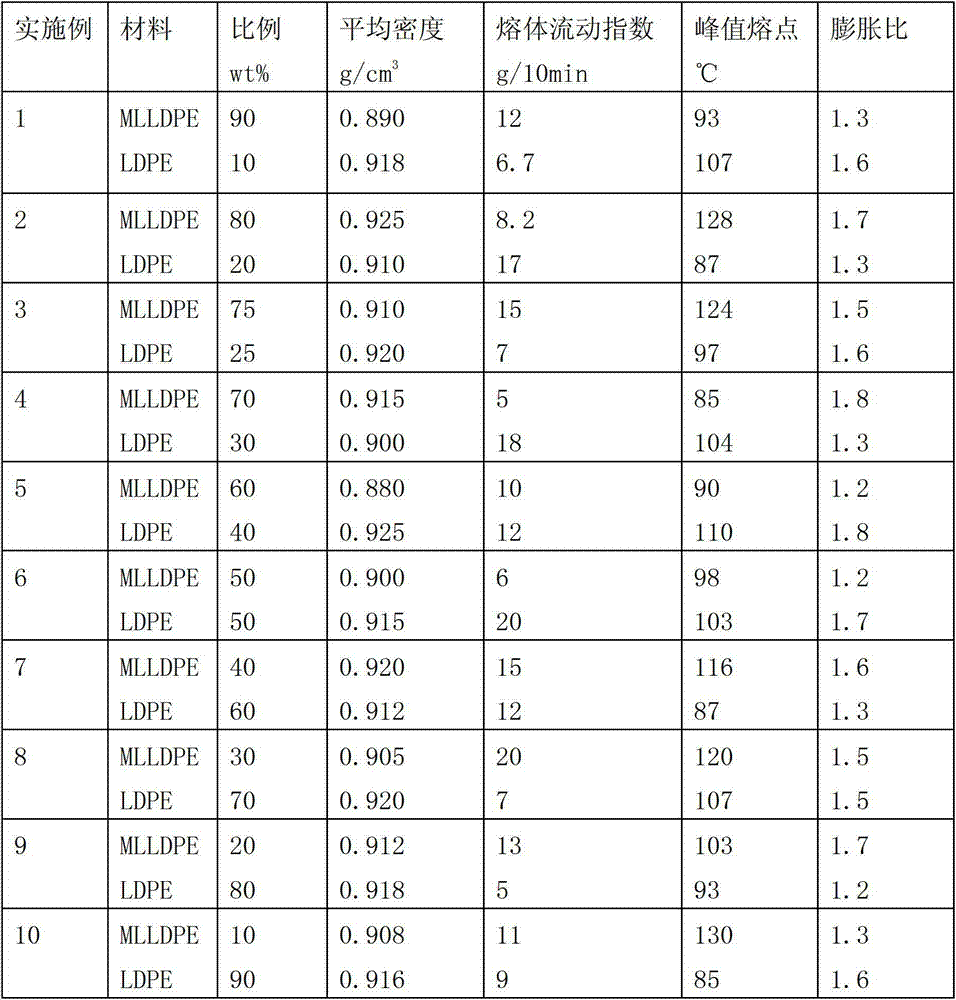

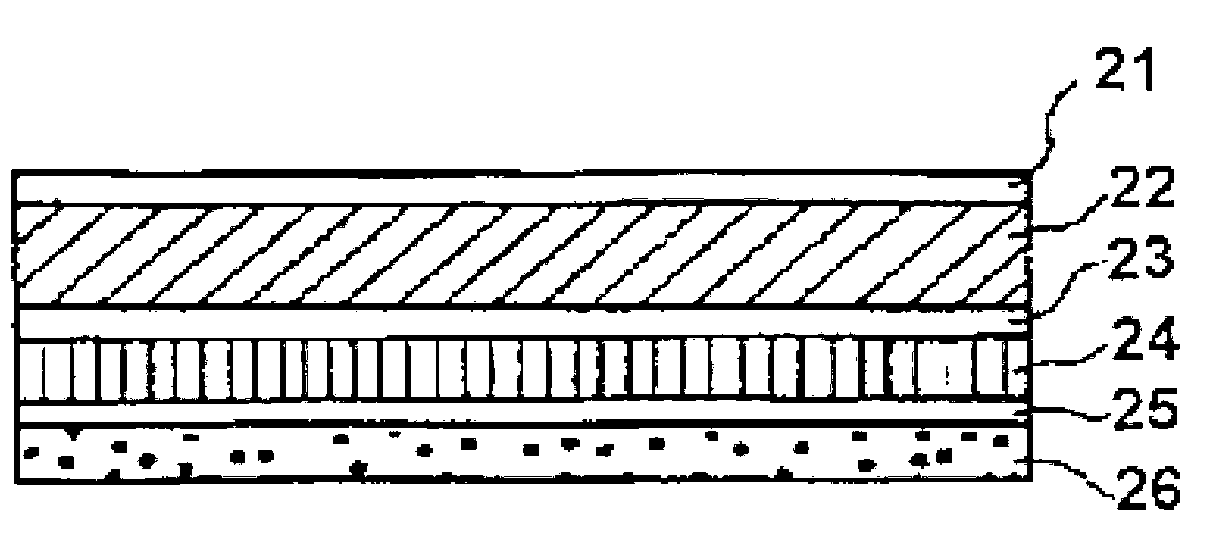

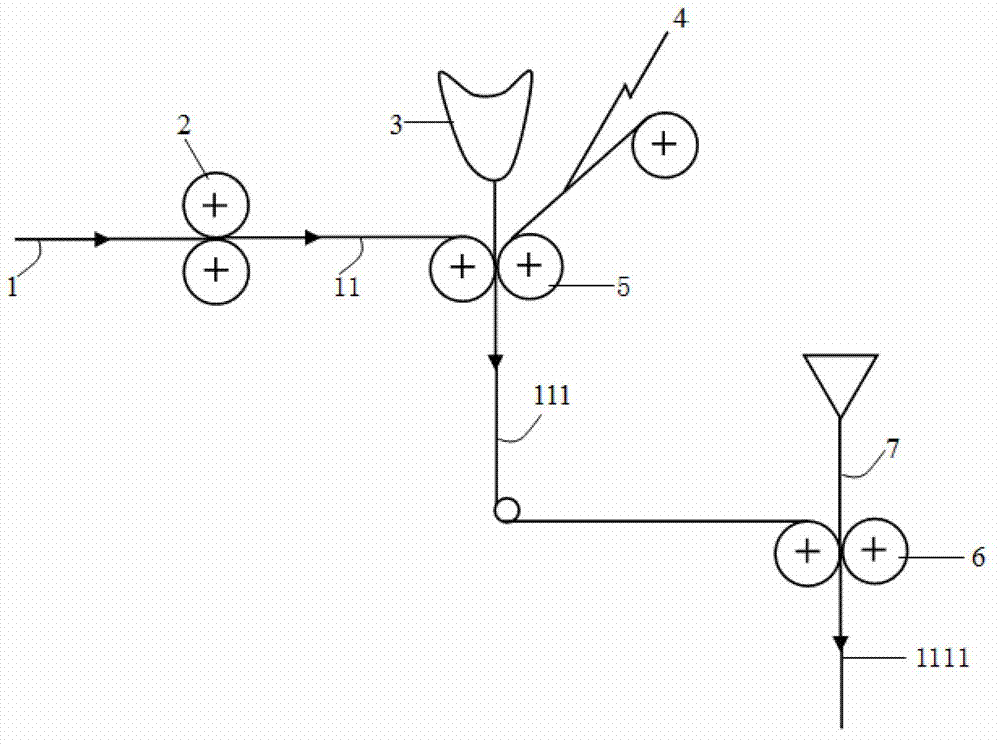

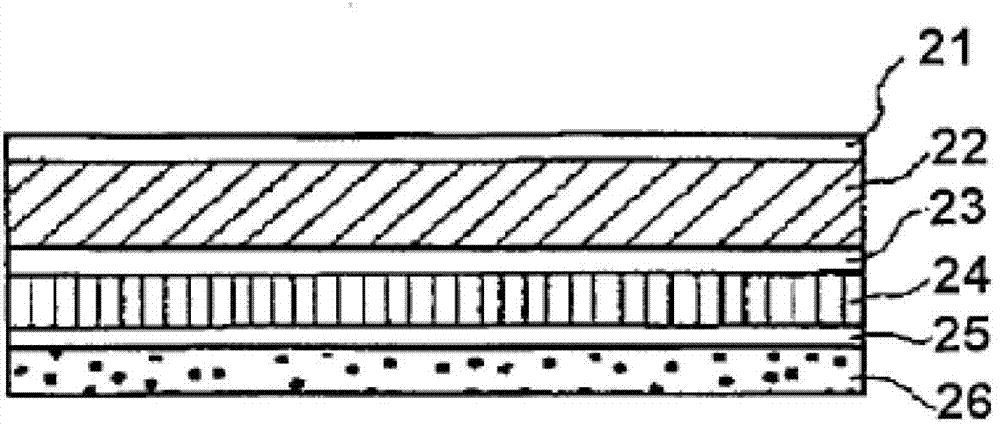

Packaging container

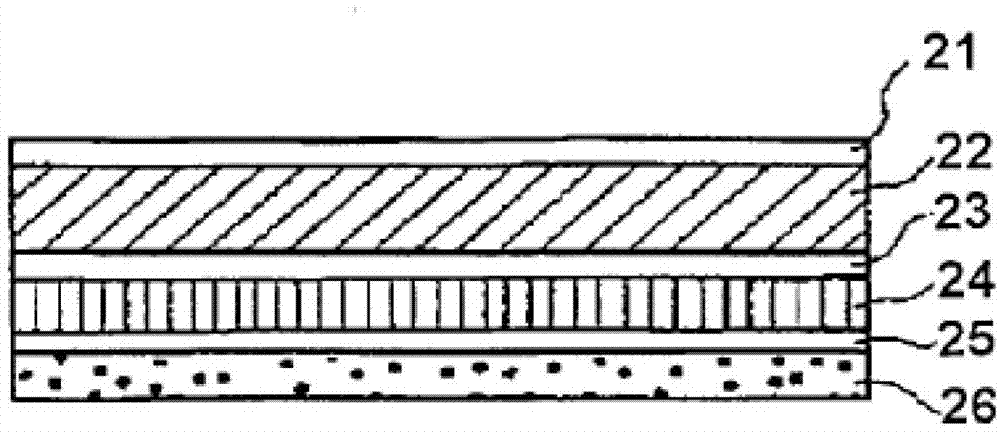

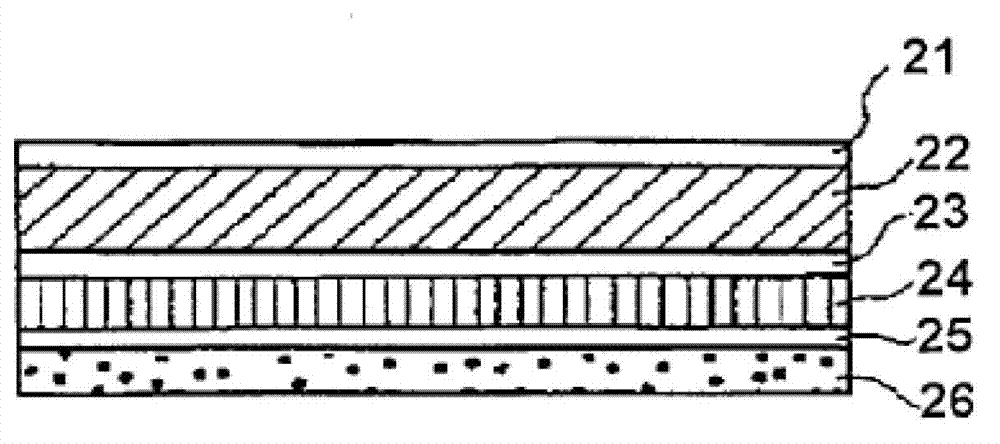

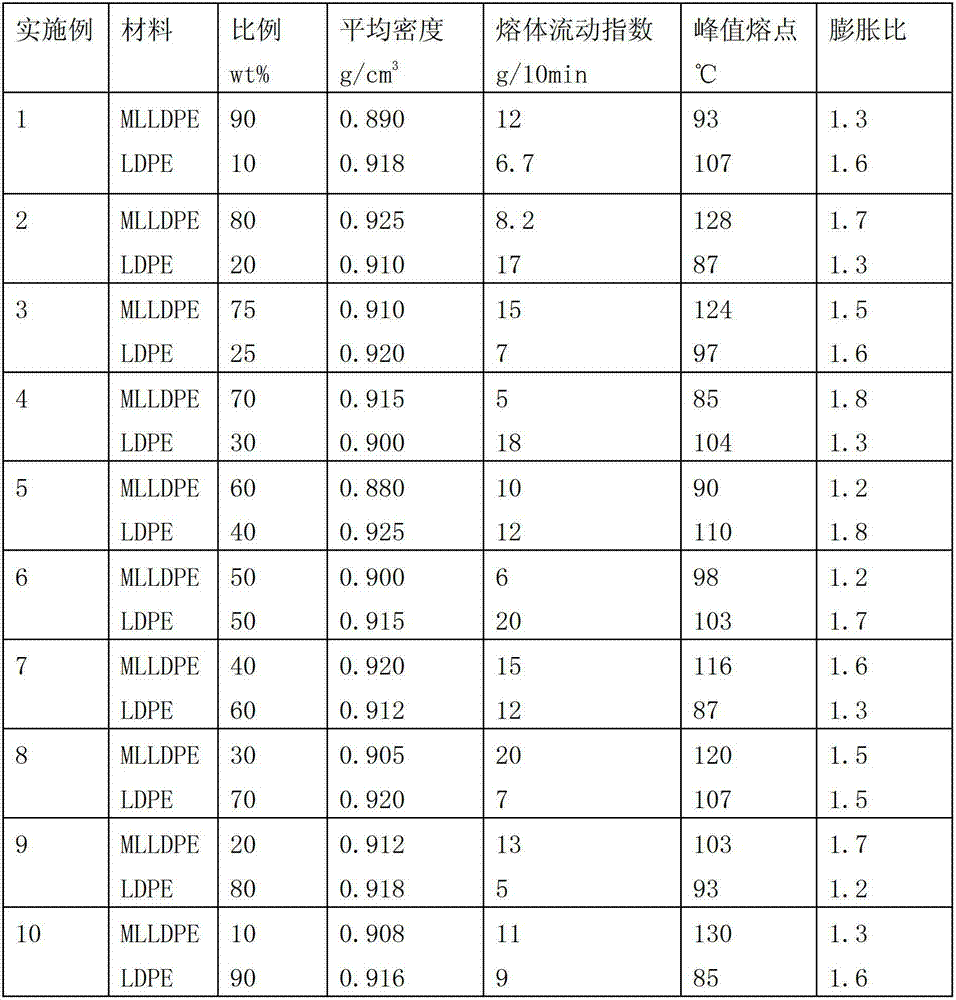

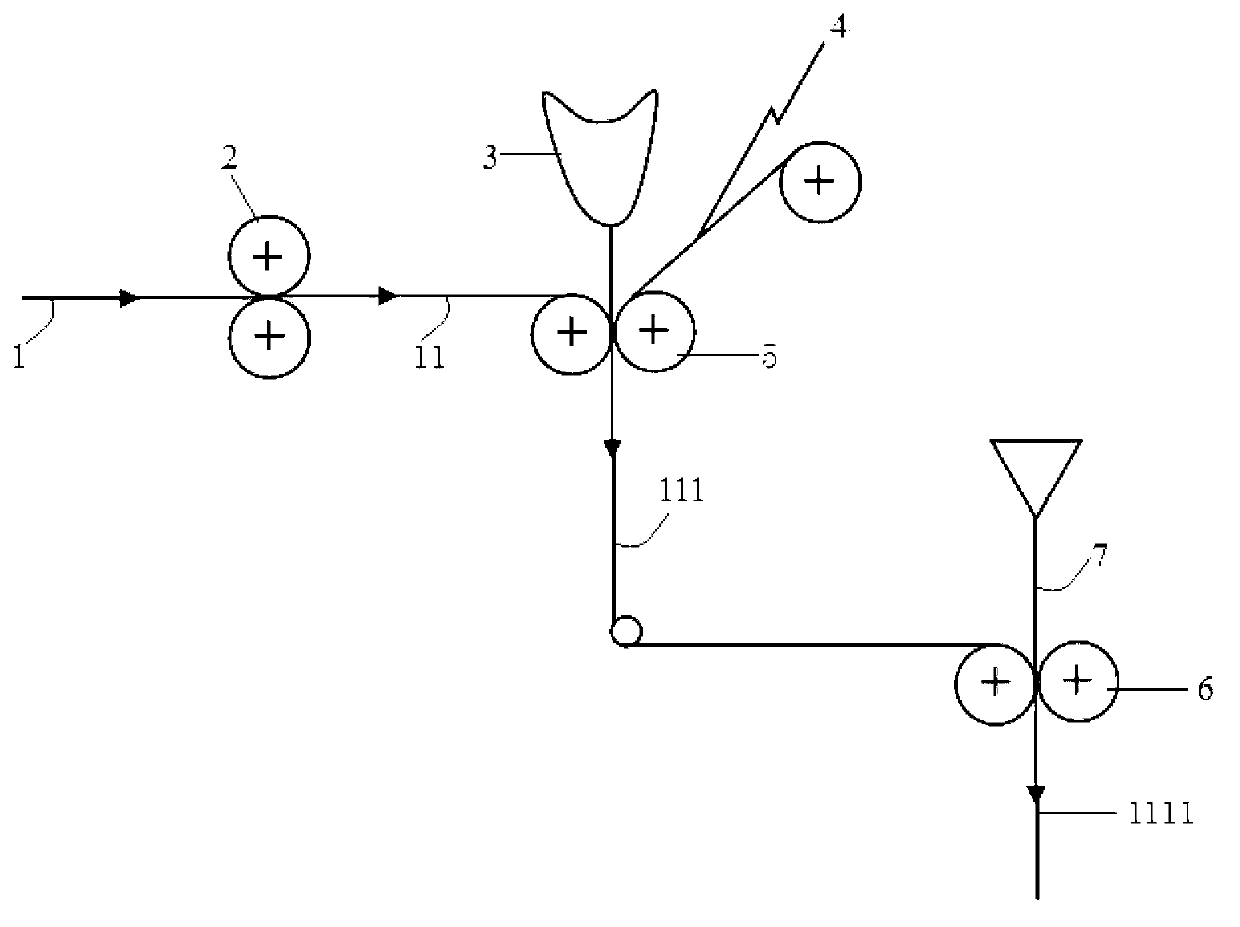

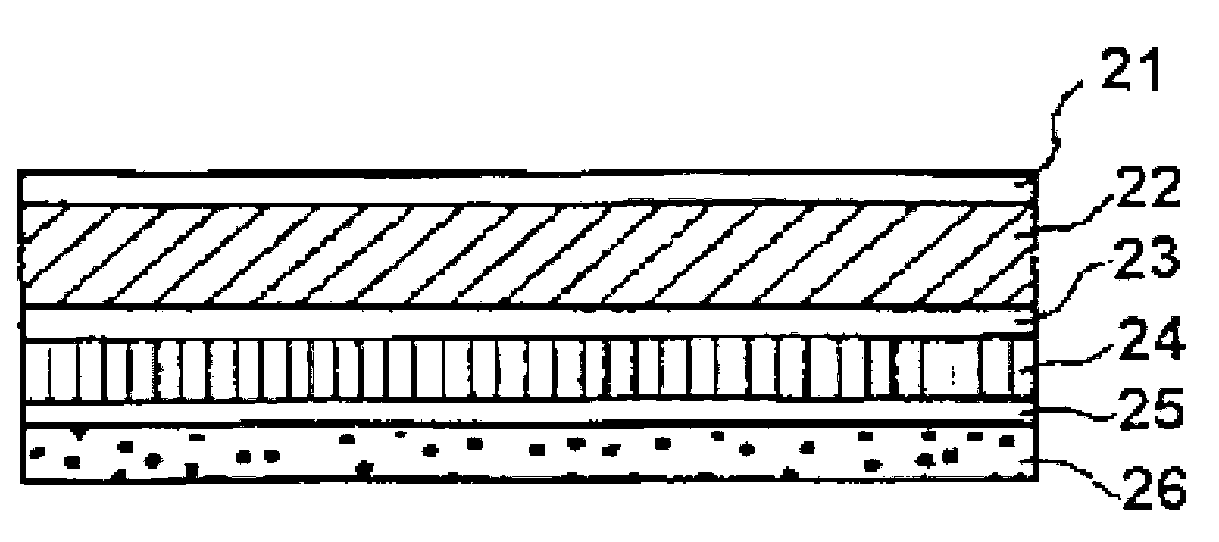

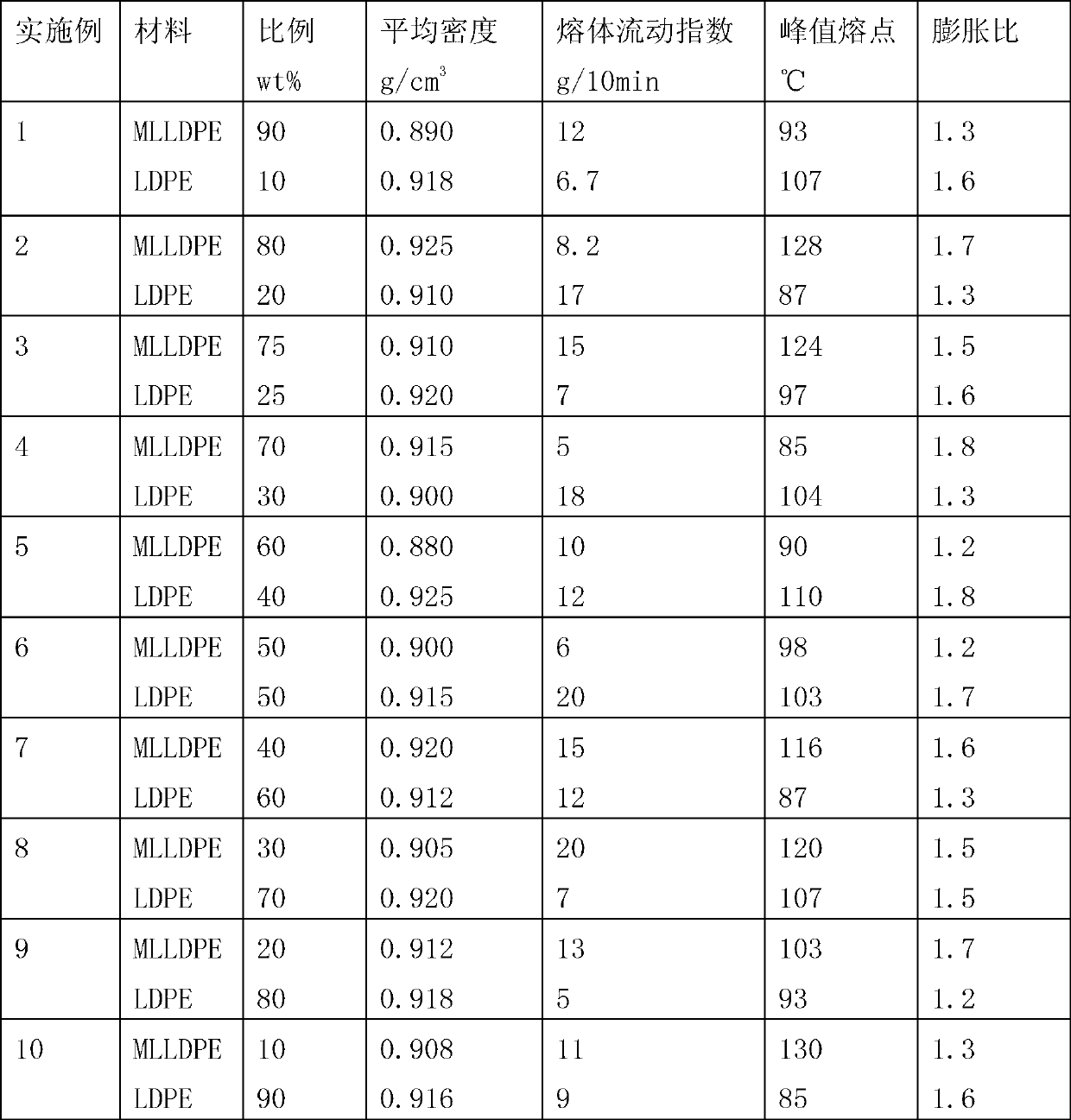

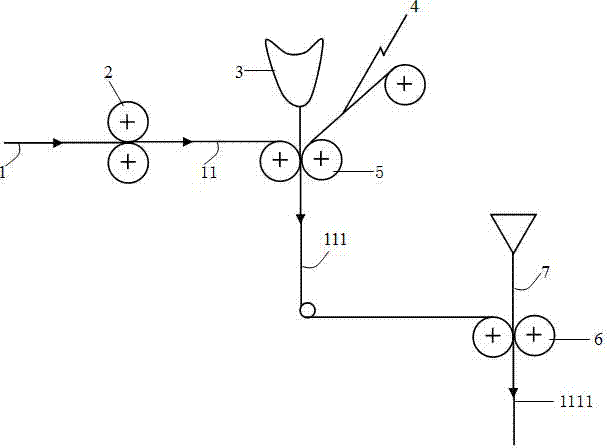

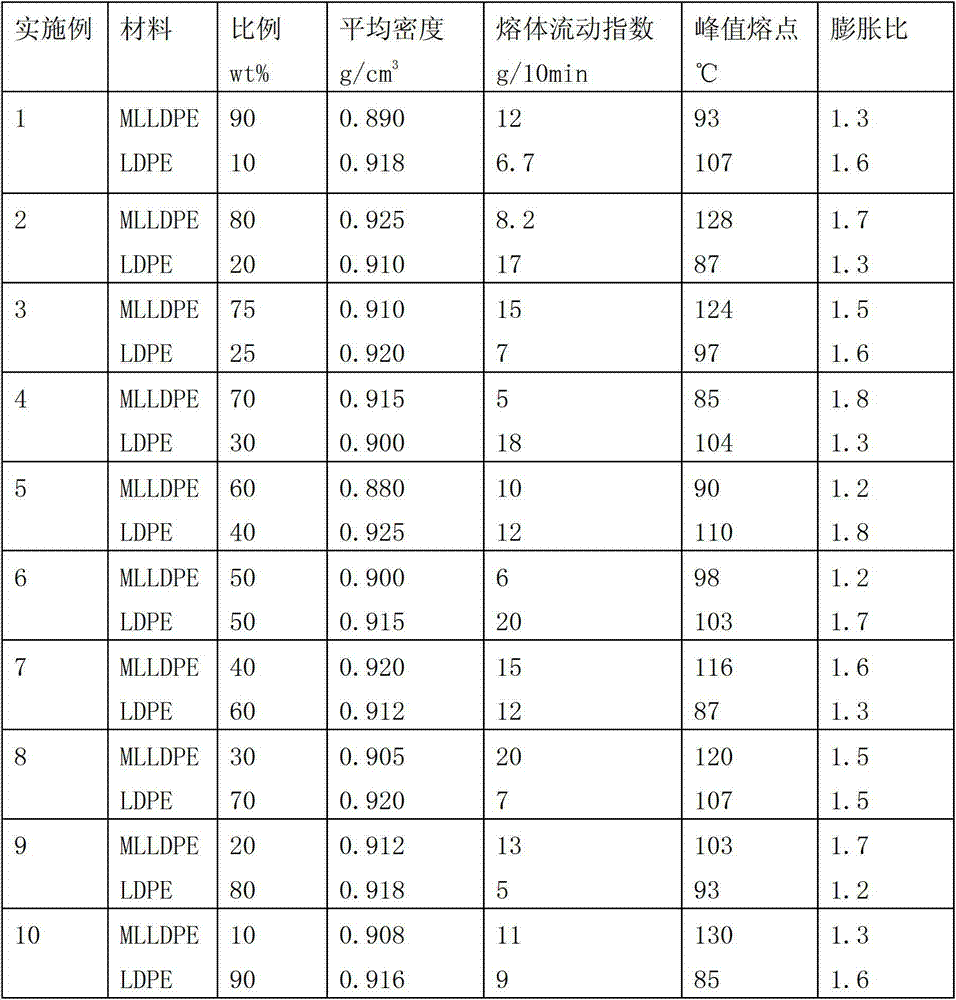

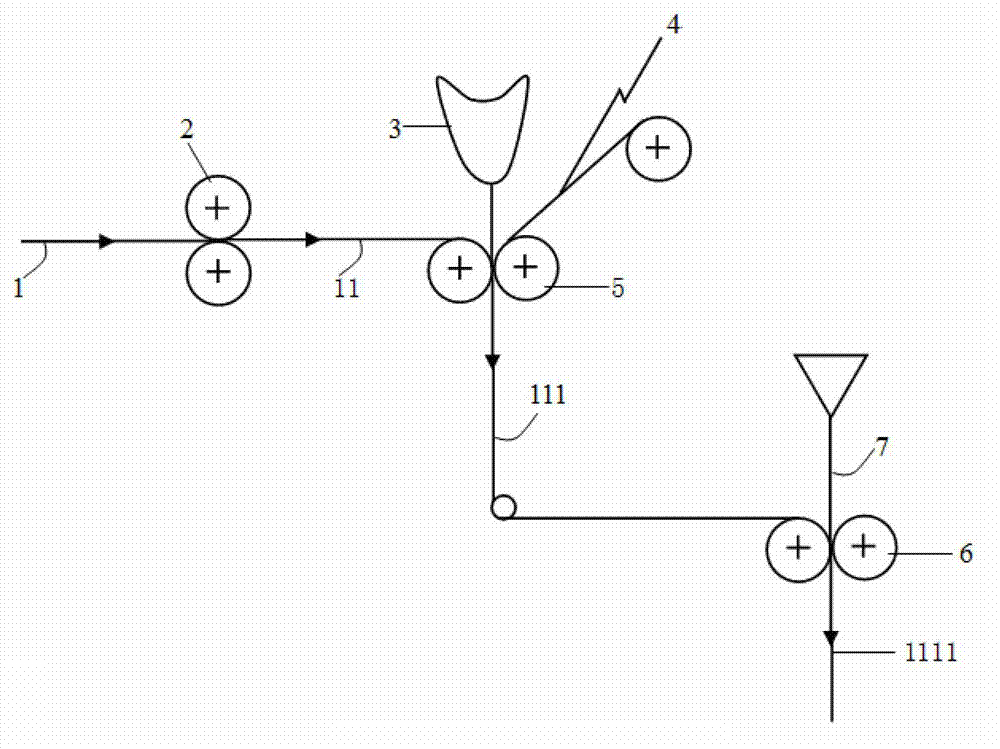

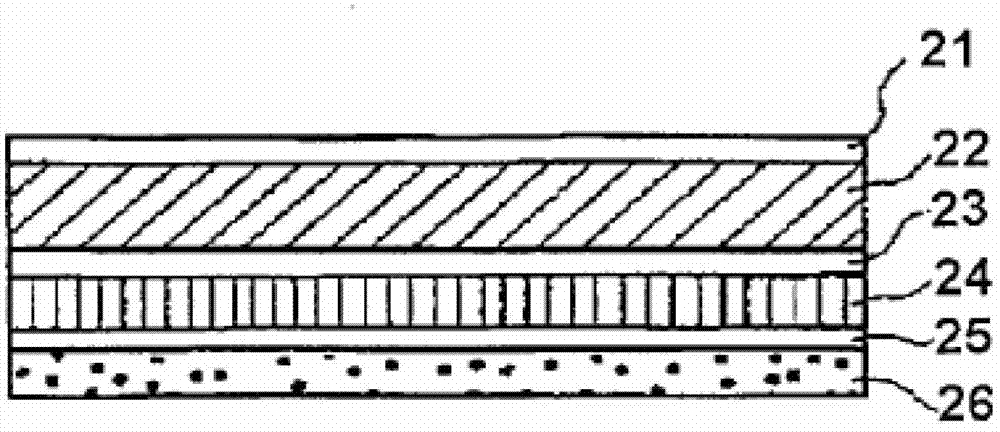

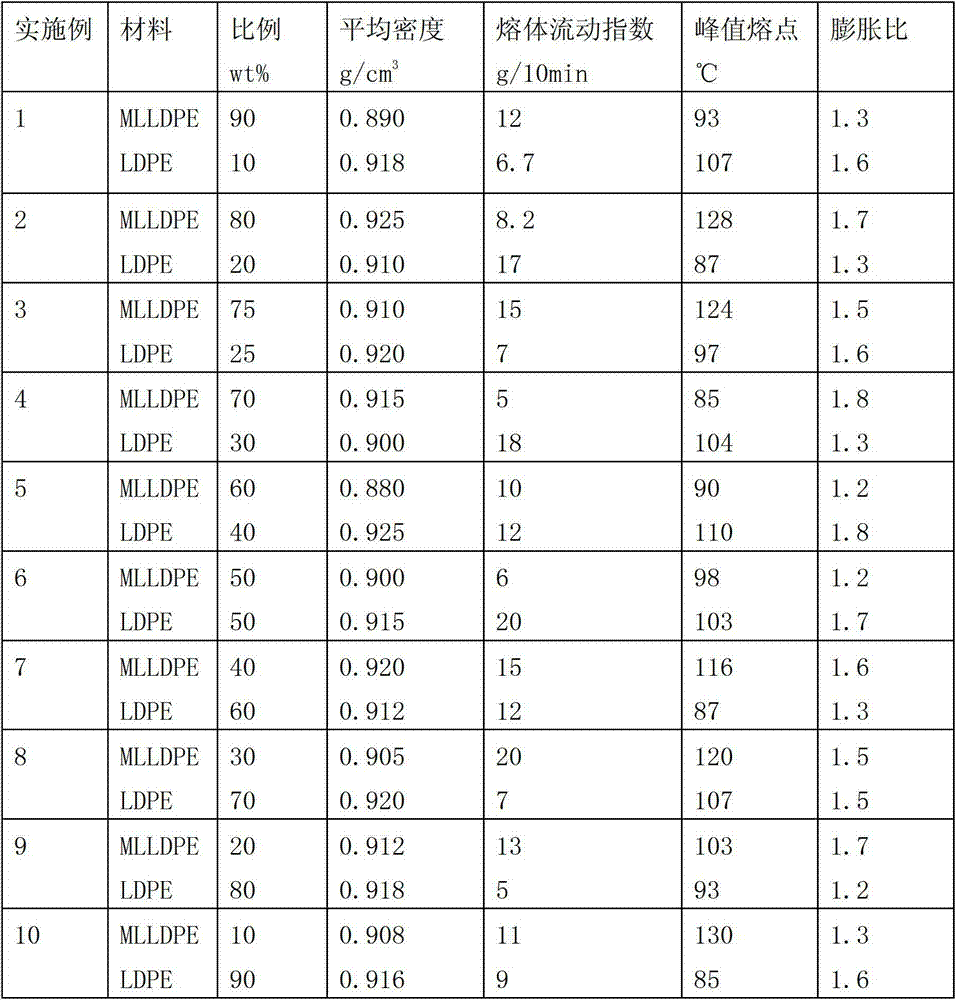

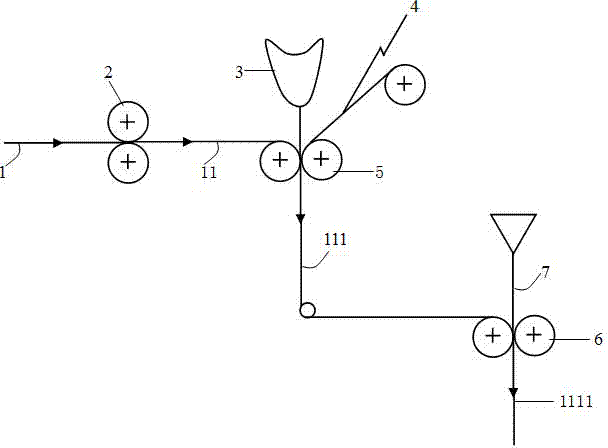

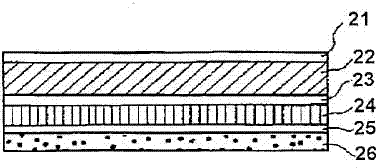

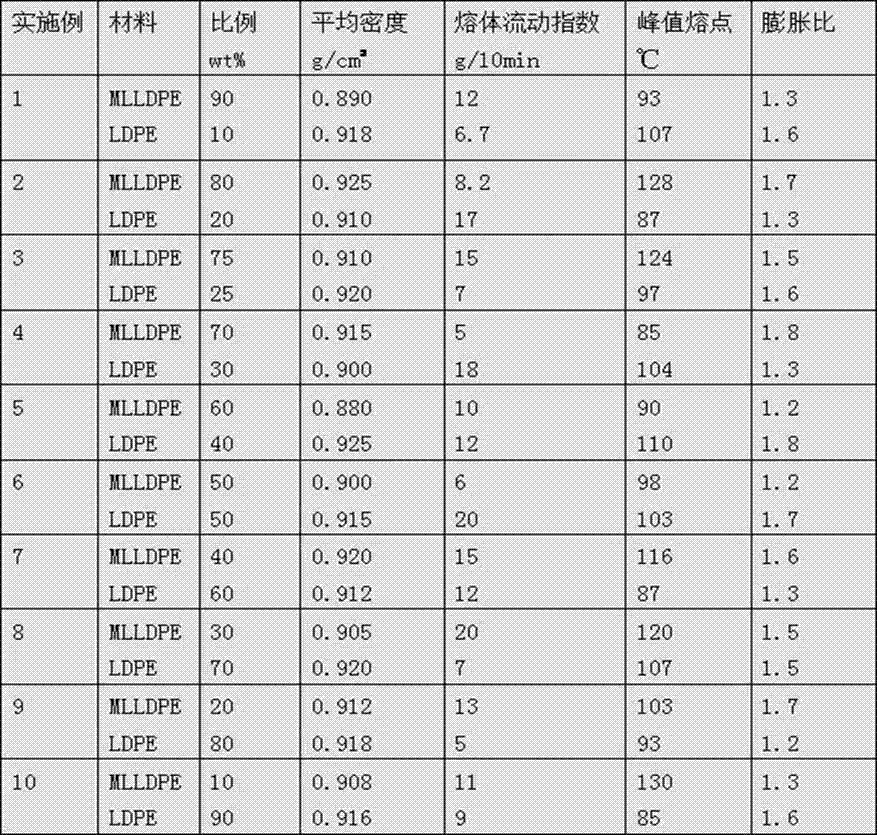

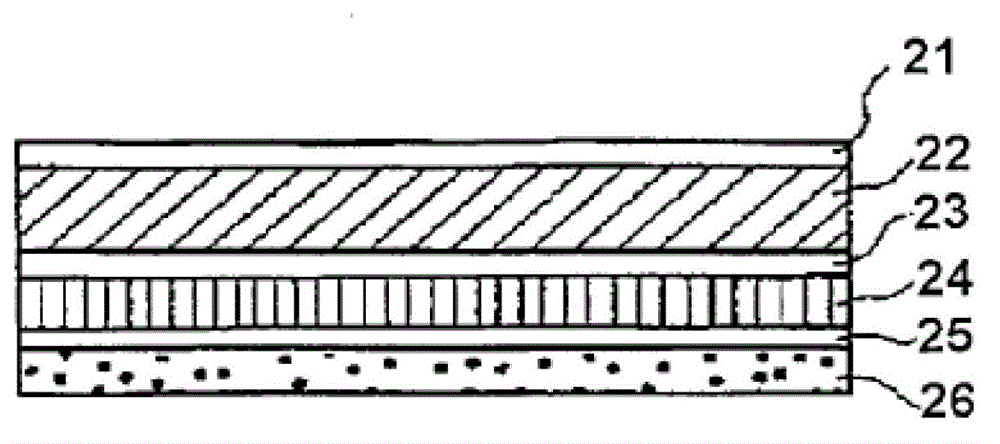

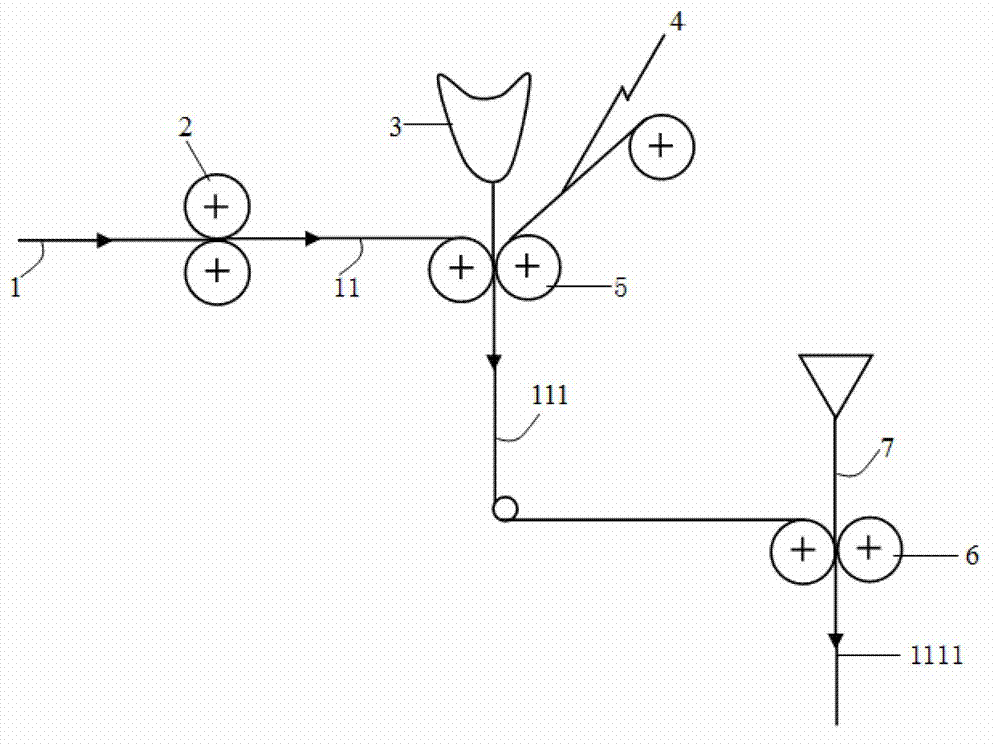

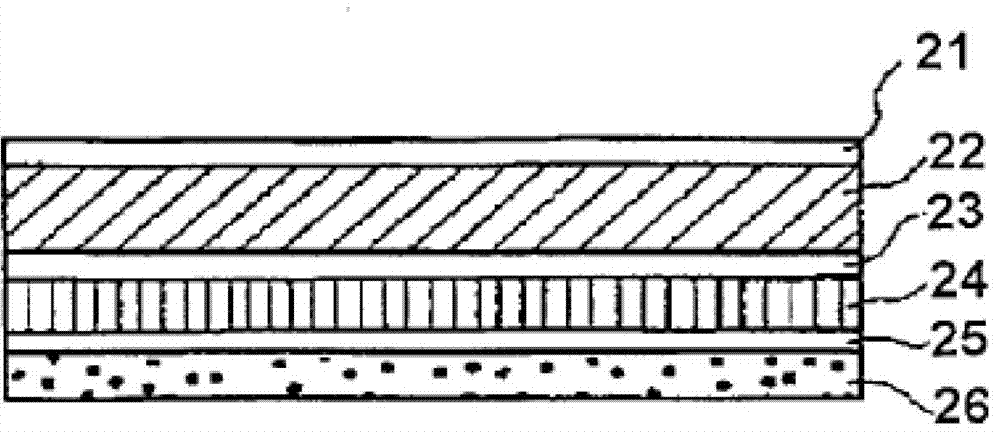

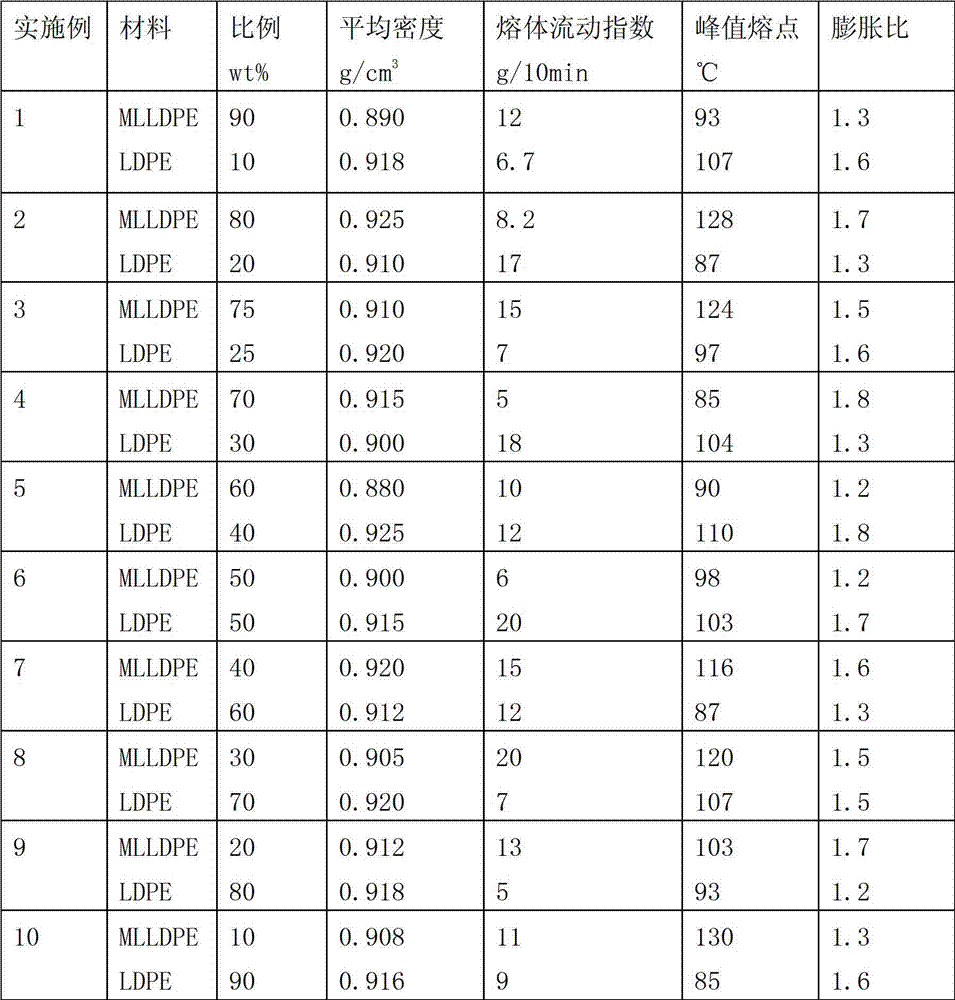

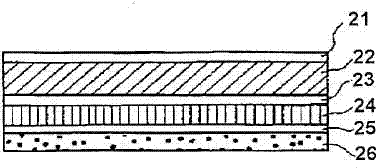

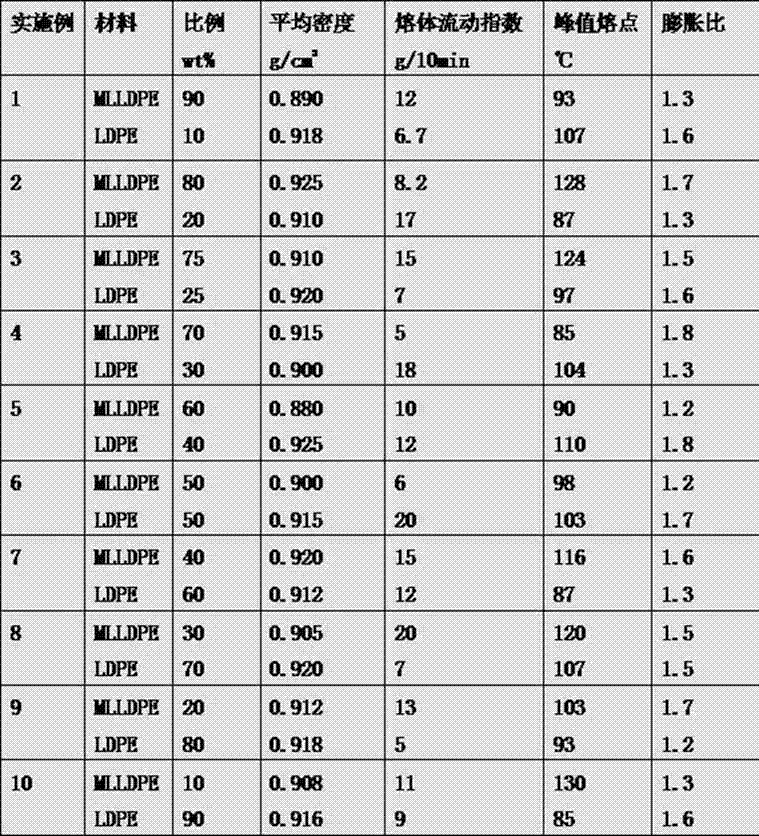

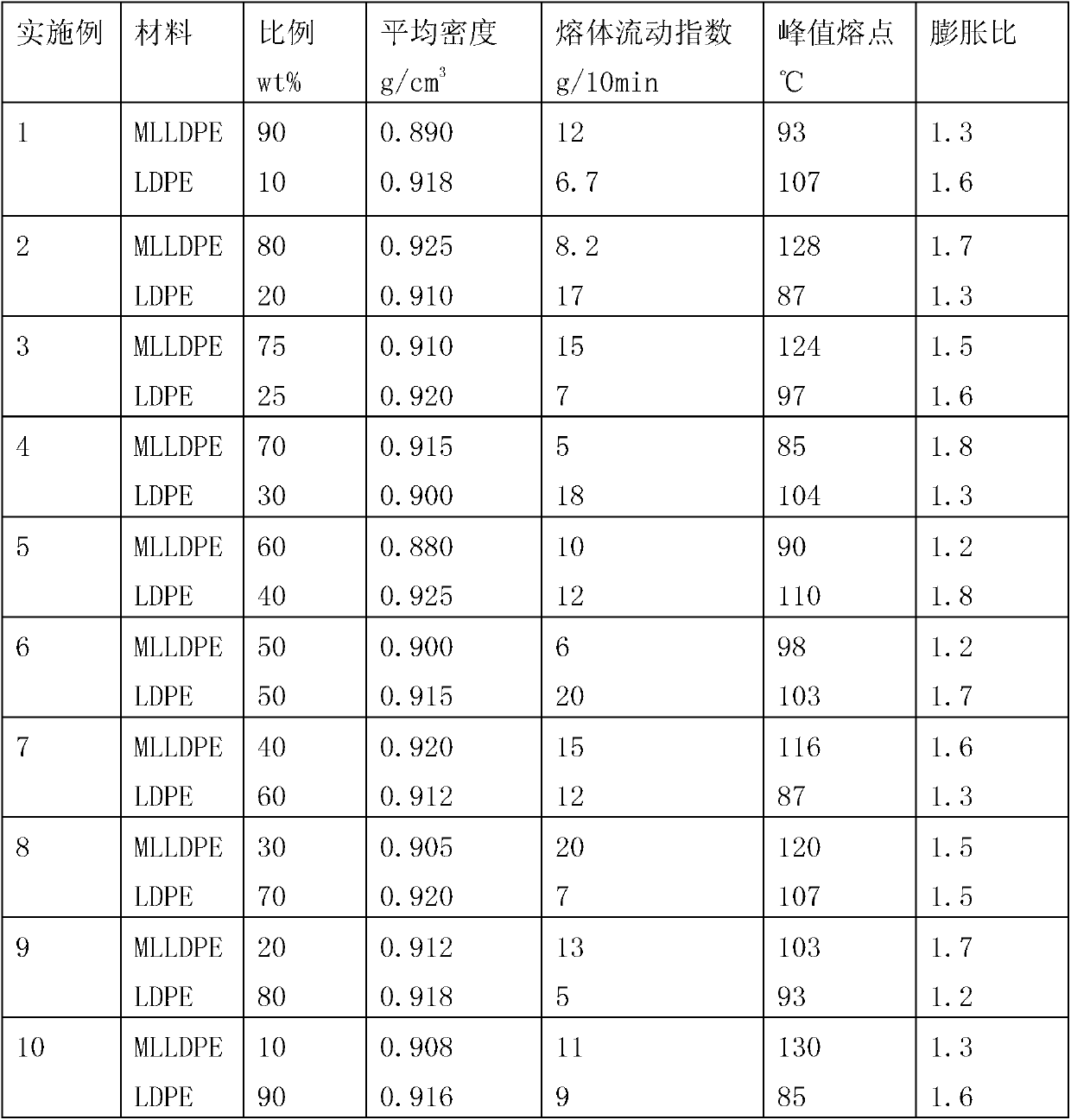

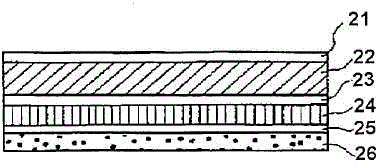

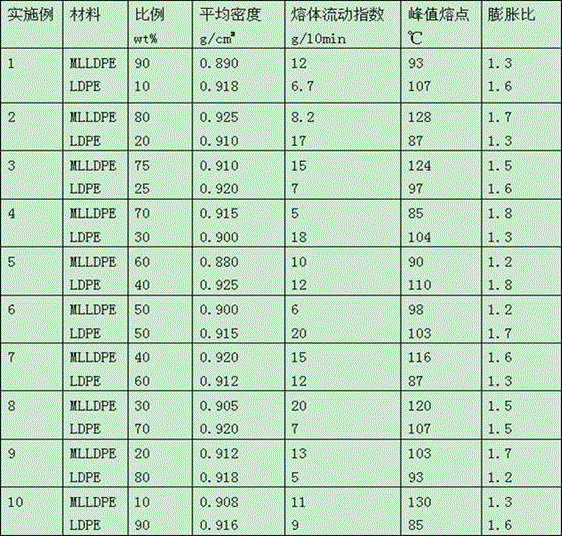

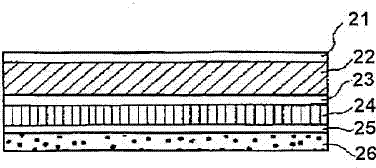

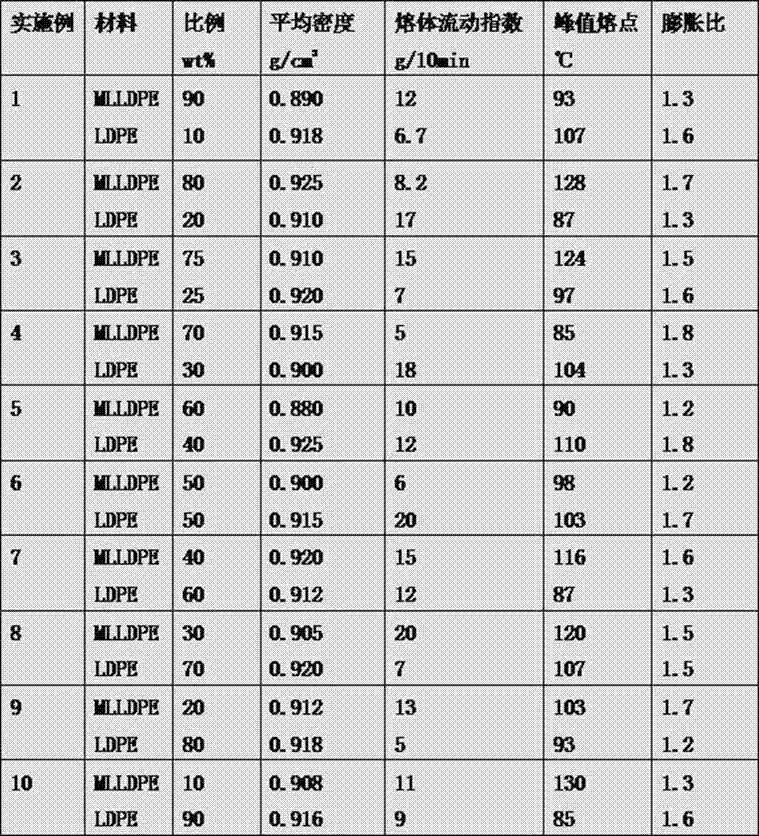

InactiveCN103043299AReduced neckingEnergy and raw material waste suppressionFlexible coversWrappersChemistryBlocking layer

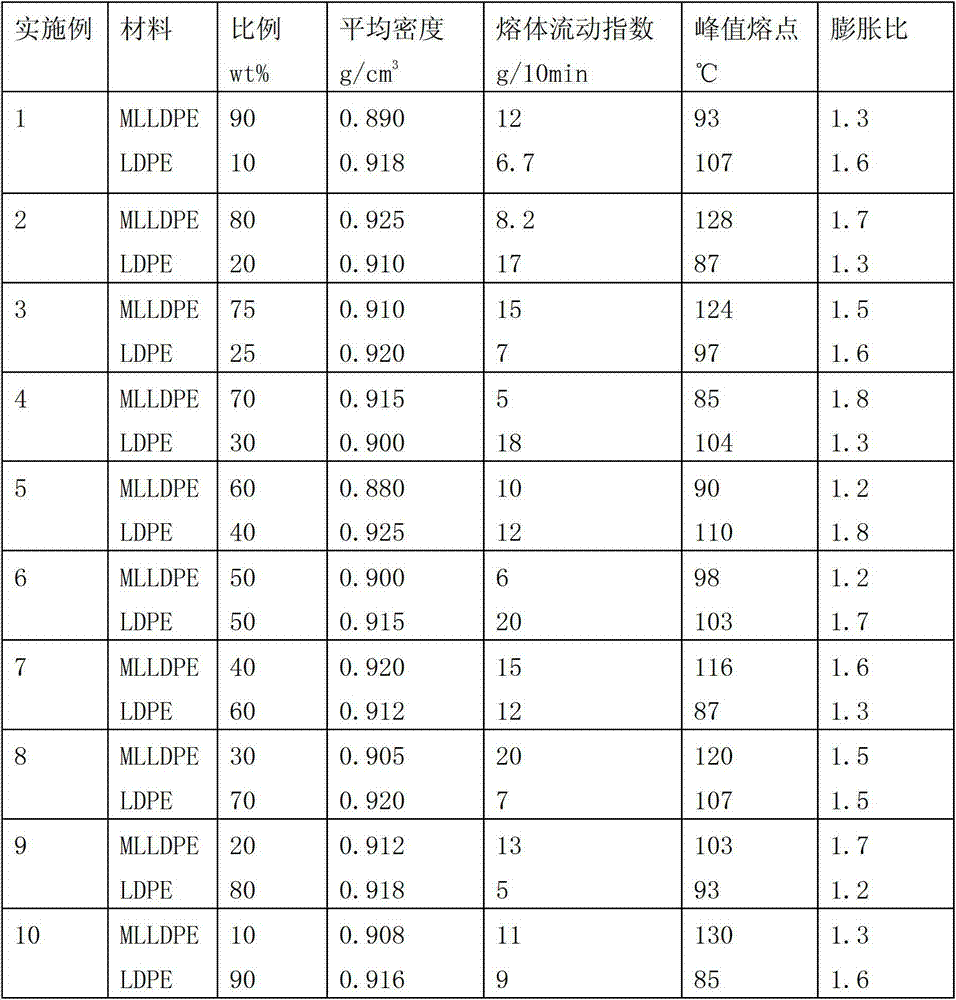

The invention provides a packaging container which comprises an outmost thermoplastic material layer, a core layer, an intermediate thermoplastic material layer, a blocking layer and an innermost thermoplastic material layer from outside to inside. The innermost thermoplastic material layer contains metalloscene catalyst polymerized linear low density polyethylene (MLLDPE) and low density polyethylene (LDPE), the MLLDPE has following parameters: average density of 0.88g / cm3-0.925g / cm3, melt flow index (190 DEG C, 2.16kg) of 5g / 10min-20g / 10min, peak melting point of 85 DEG C-130 DEG C, and expansion ratio of 1.2-1.8, and the LDPE has following parameters: average density of 0.90g / cm3-0.925g / cm3, melt flow index (190 DEG C, 2.16kg) of 5g / 10min-20g / 10min, peak melting point of 85 DEG C-110 DEG C, and expansion ratio of 1.2-1.8. A longitudinal sealing portion can realize quick thermal sealing during the process of manufacturing the packaging container, sealing intensity is high, and the manufactured packaging container is high in pass percentage and long in shelf life of liquid food.

Owner:TAIZHOU ZHUYE MACHINERY SCI & TECH

Packaging container

InactiveCN103043300AImprove pass rateCurb wasteFlexible coversWrappersLow-density polyethyleneLinear low-density polyethylene

The invention provides a packaging container which comprises an outmost thermoplastic material layer, a core layer, an intermediate thermoplastic material layer, a blocking layer and an innermost thermoplastic material layer from outside to inside. The outmost thermoplastic material layer contains metalloscene catalyst polymerized linear low density polyethylene (MLLDPE) and low density polyethylene (LDPE), the MLLDPE has following parameters: average density of 0.88g / cm3-0.925g / cm3, melt flow index (190 DEG C, 2.16kg) of 5g / 10min-20g / 10min, peak melting point of 85 DEG C-130 DEG C, and expansion ratio of 1.2-1.8, and the LDPE has following parameters: average density of 0.90g / cm3-0.925g / cm3, melt flow index (190 DEG C, 2.16kg) of 5g / 10min-20g / 10min, peak melting point of 85 DEG C-110 DEG C, and expansion ratio of 1.2-1.8. A longitudinal sealing portion can realize quick thermal sealing during the process of manufacturing the packaging container, sealing intensity is high, and the manufactured packaging container is high in pass percentage and long in shelf life of liquid food.

Owner:TAIZHOU ZHUYE MACHINERY SCI & TECH

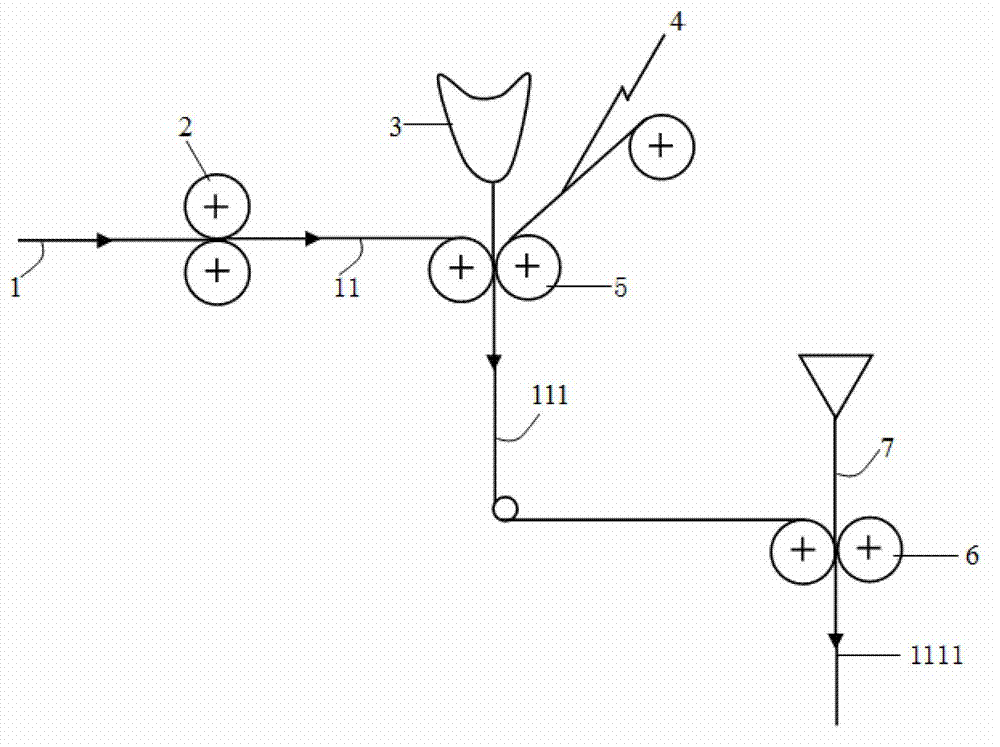

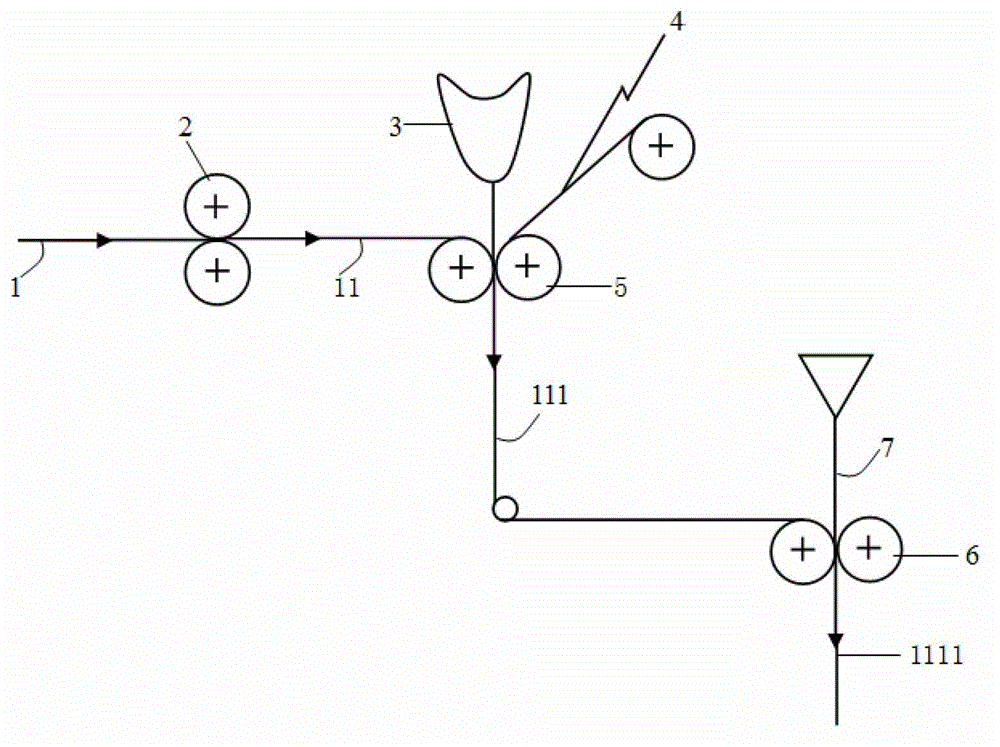

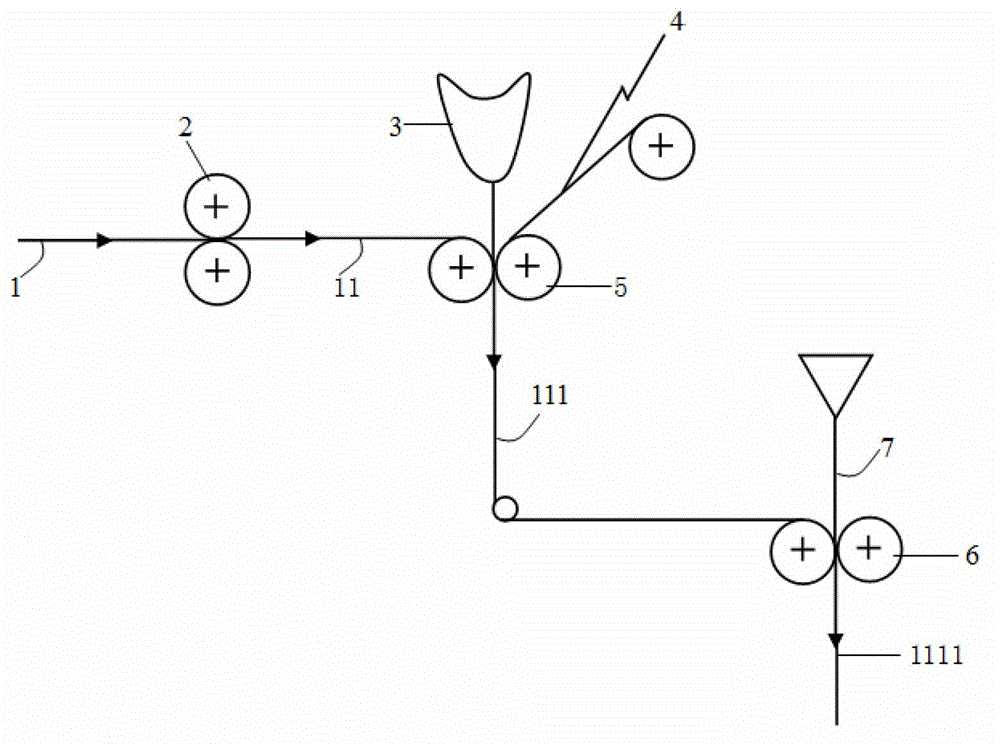

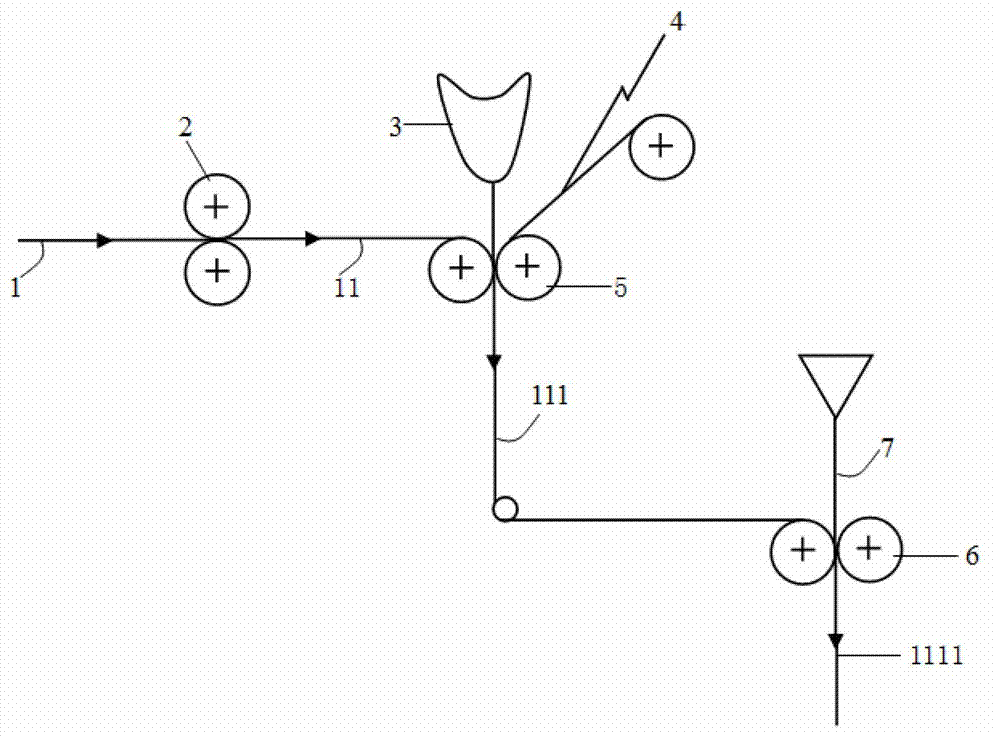

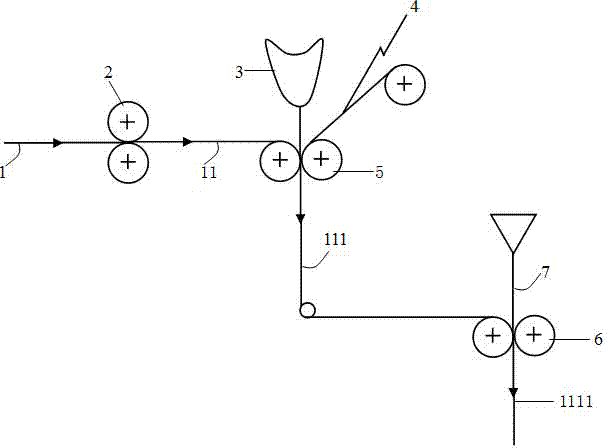

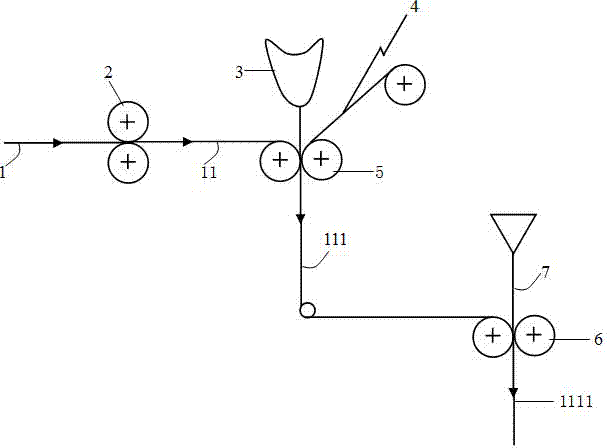

Method for manufacturing laminated packaging material

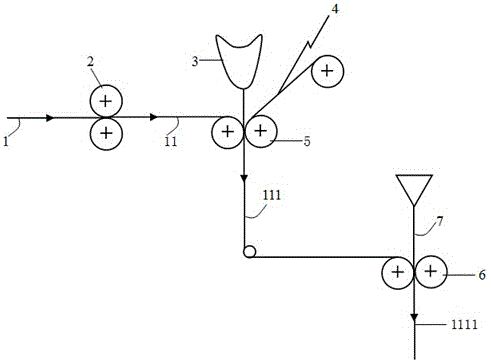

InactiveCN103042798ACurb wasteImprove seal strengthSynthetic resin layered productsLaminationLow-density polyethyleneLinear low-density polyethylene

The invention provides a method for manufacturing laminated packaging material. The method for manufacturing the laminated packaging material comprises the following steps: step 1, pressing crease lines and stamping open holes in a core layer; step 2, extruding laminated thermoplastic material on the outer side surface of the core layer to form an outermost layer; step 3, extruding laminated thermoplastic material on the inner side surface of the core layer to form an intermediate layer and combining a blocking layer with the inner side surface of the core layer through the intermediate layer at the same time; step 4, extruding laminated thermoplastic material on the blocking layer to form an adhesive layer; and step 5, extruding laminated thermoplastic material on the adhesive layer to form the innermost layer. In the step 5, the thermoplastic material of the innermost layer is formed by the blending metallocene catalyst polymerized linear low density polyethylene (MLLDPE) and low density polyethylene (LDPE). According to the invention, during the process of manufacturing a packaging container by the laminated packaging material manufactured by using the method, heat seal can be quickly performed on the longitudinal sealing part, so as to obtain the packaging container with good sealing strength, the manufactured packaging container has a high qualification rate, and the liquid food can be preserved for a long time.

Owner:TAIZHOU ZHUYE MACHINERY SCI & TECH

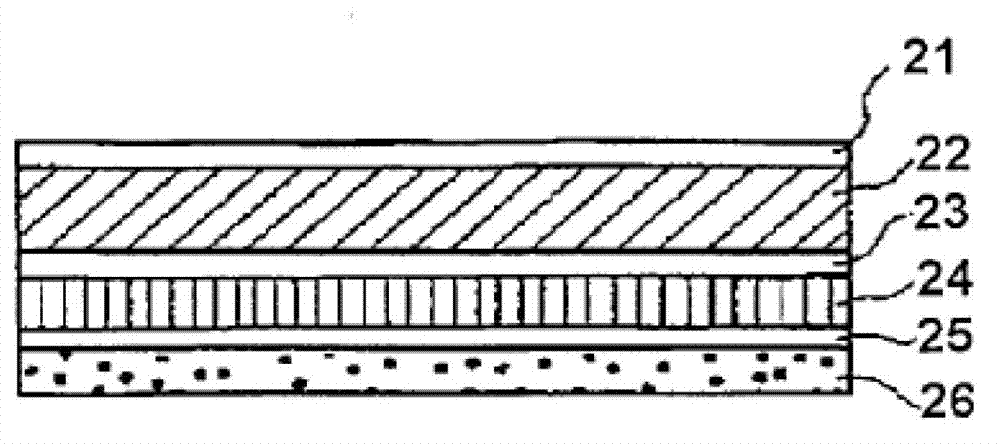

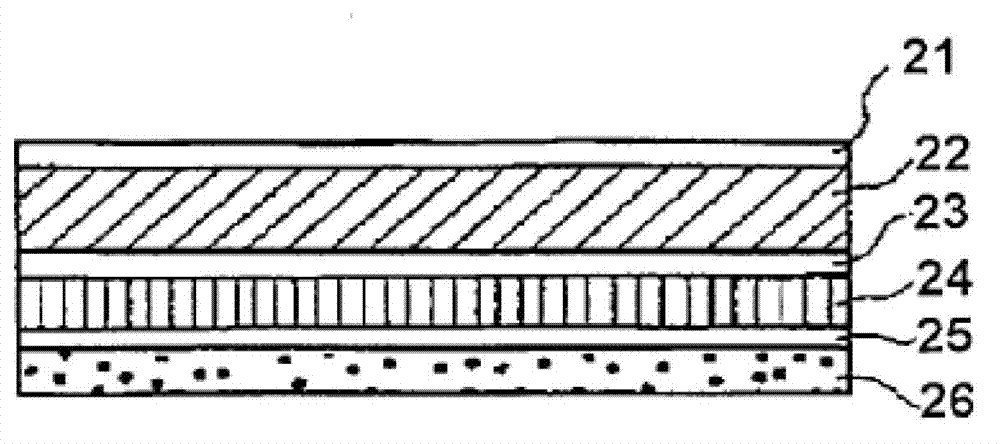

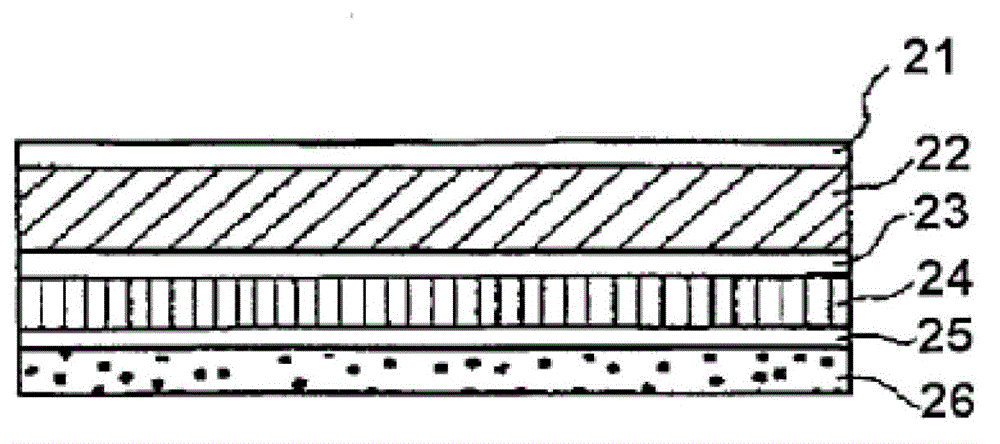

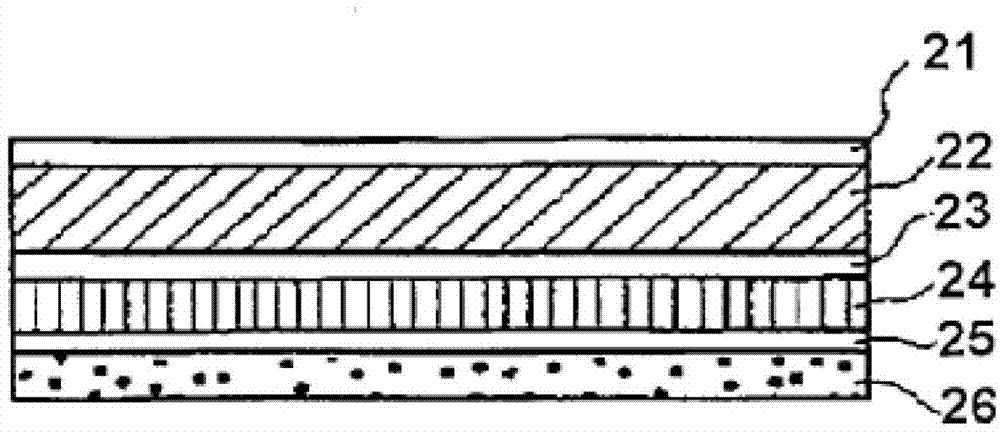

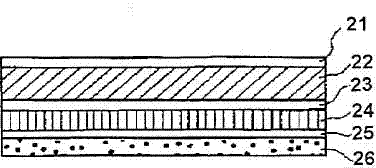

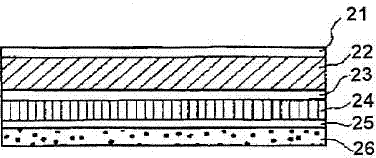

Laminated packaging material

InactiveCN103101273ACurb wasteImprove bindingFlexible coversWrappersLow-density polyethyleneLinear low-density polyethylene

The invention provides a laminated packaging material. The laminated packaging material comprises an outermost thermoplastic material layer, a sandwich layer, an intermediate thermoplastic material layer, a barrier layer and an innermost thermoplastic material layer from outside to inside, wherein the intermediate thermoplastic material layer is made of metalloscene-catalyst-polymerized linear low-density polyethylene (mLLDPE) and LDPE; for the metalloscene catalyst polymerized mLLDPE, the mean density is 0.88-0.925g / cm<3>, the melt flow index (190 DEG C and 2.16kg) is 5-20g / 10min, the peak melting point is 85-130 DEG C and the expansion ratio is 1.2-1.8; and for the LDPE, the mean density is 0.90-0.925g / cm<3>, the melt flow index (190 DEG C and 2.16kg) is 5-20g / 10min, the peak melting point is 85-110 DEG C and the expansion ratio is 1.2-1.8. Packaging containers with good sealing strength can be obtained by using the laminated packaging material, the percent of pass of the prepared packaging containers is high, and liquid food in the prepared packaging containers is long in quality guarantee period.

Owner:TAIZHOU ZHUYE MACHINERY SCI & TECH

Packaging container

InactiveCN104760360ACurb wasteReduced neckingFlexible coversWrappersLow-density polyethyleneLinear low-density polyethylene

Owner:TAIZHOU ZHUYE MACHINERY SCI & TECH

Laminated packaging material

InactiveCN103029398AReduced neckingEnergy and raw material waste suppressionFlexible coversWrappersChemistryBlocking layer

The invention provides a laminated packaging material which comprises an outermost thermoplastic material layer, a core layer, a middle thermoplastic material layer, a blocking layer and an innermost thermoplastic material layer from the outside in. The innermost thermoplastic material layer comprises metallocene catalyst polymerized linear low density polyethylene (MLLDPE) and low density polyethylene (LDPE), wherein MLLDPE has the following parameters that the average density is 0.88g / cm<3>-0.925g / cm<3>; a melt flow index (190 DEG C, 2.16kg) is 5g / 10min-20g / 10min; a peak fusing point is 85 DEG C-130 DEG C; and an expansion ratio is 1.2-1.8. LDPE has the following parameters that the average density is 0.90g / cm<3>-0.925g / cm<3>; the melt flow index (190 DEG C, 2.16kg) is 5g / 10min-20g / 10min; the peak fusing point is 85 DEG C-110 DEG C; and the expansion ratio is 1.2-1.8. Heat sealing can be conducted on a longitudinal sealing part quickly when the laminated packaging material is used for manufacturing a packaging container; the packaging container with high sealing strength is obtained; the manufactured packaging container is high in qualified rate; and a quality guarantee period of liquid food is long.

Owner:TAIZHOU ZHUYE MACHINERY SCI & TECH

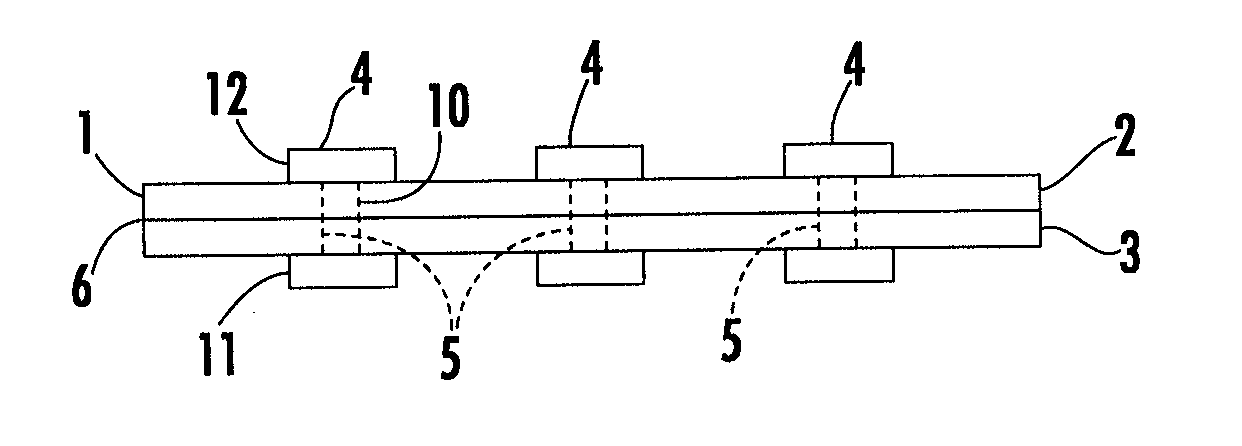

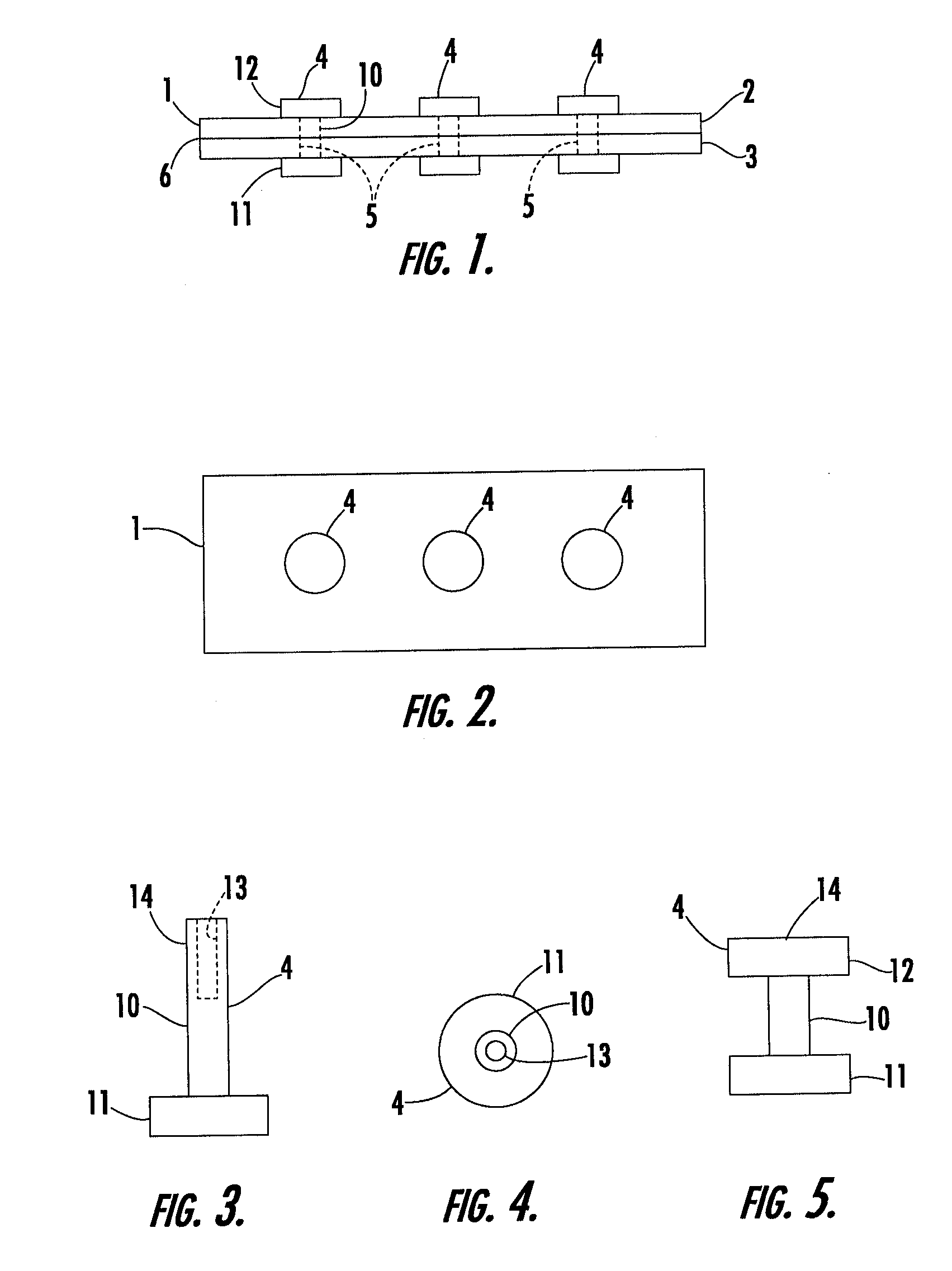

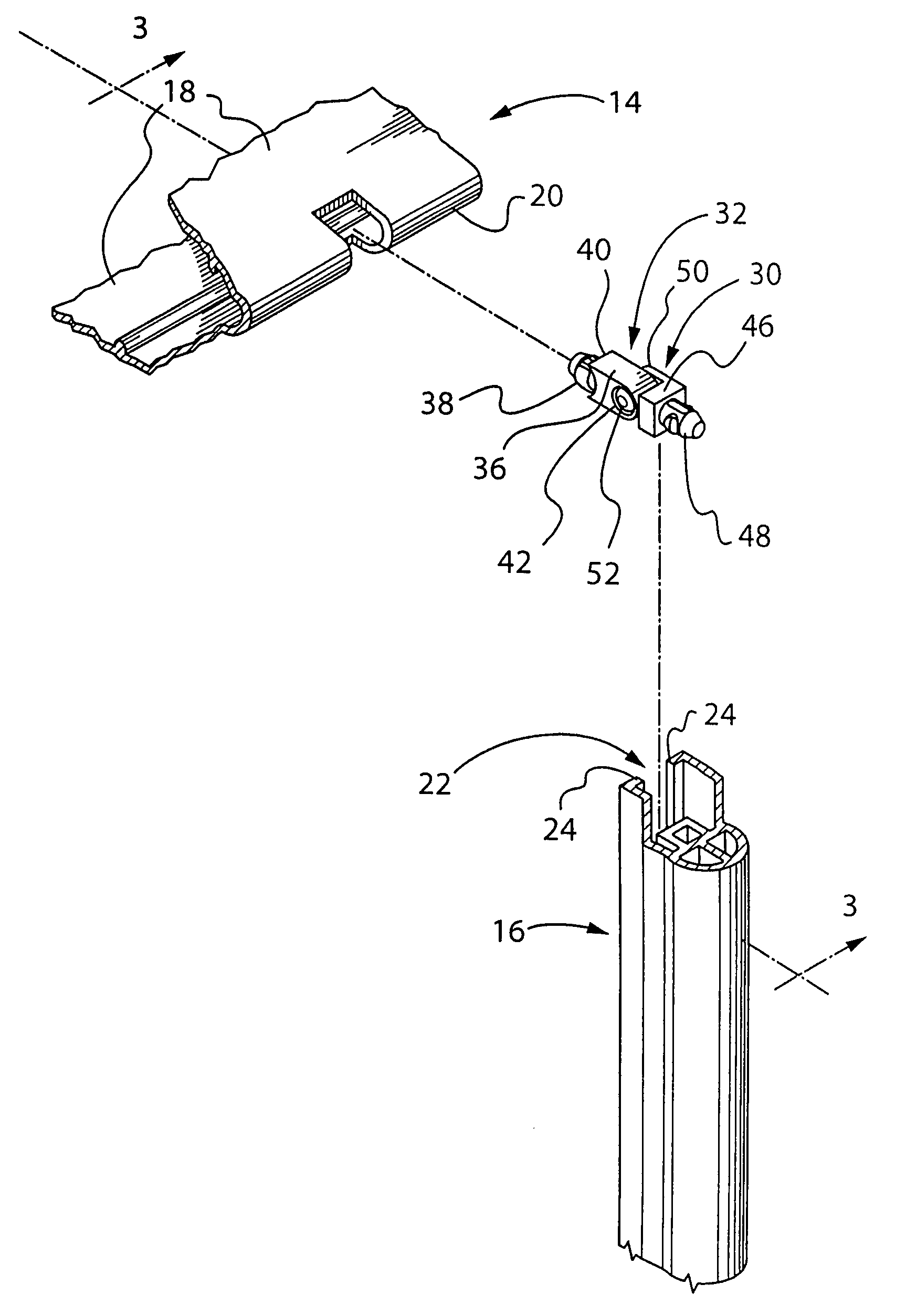

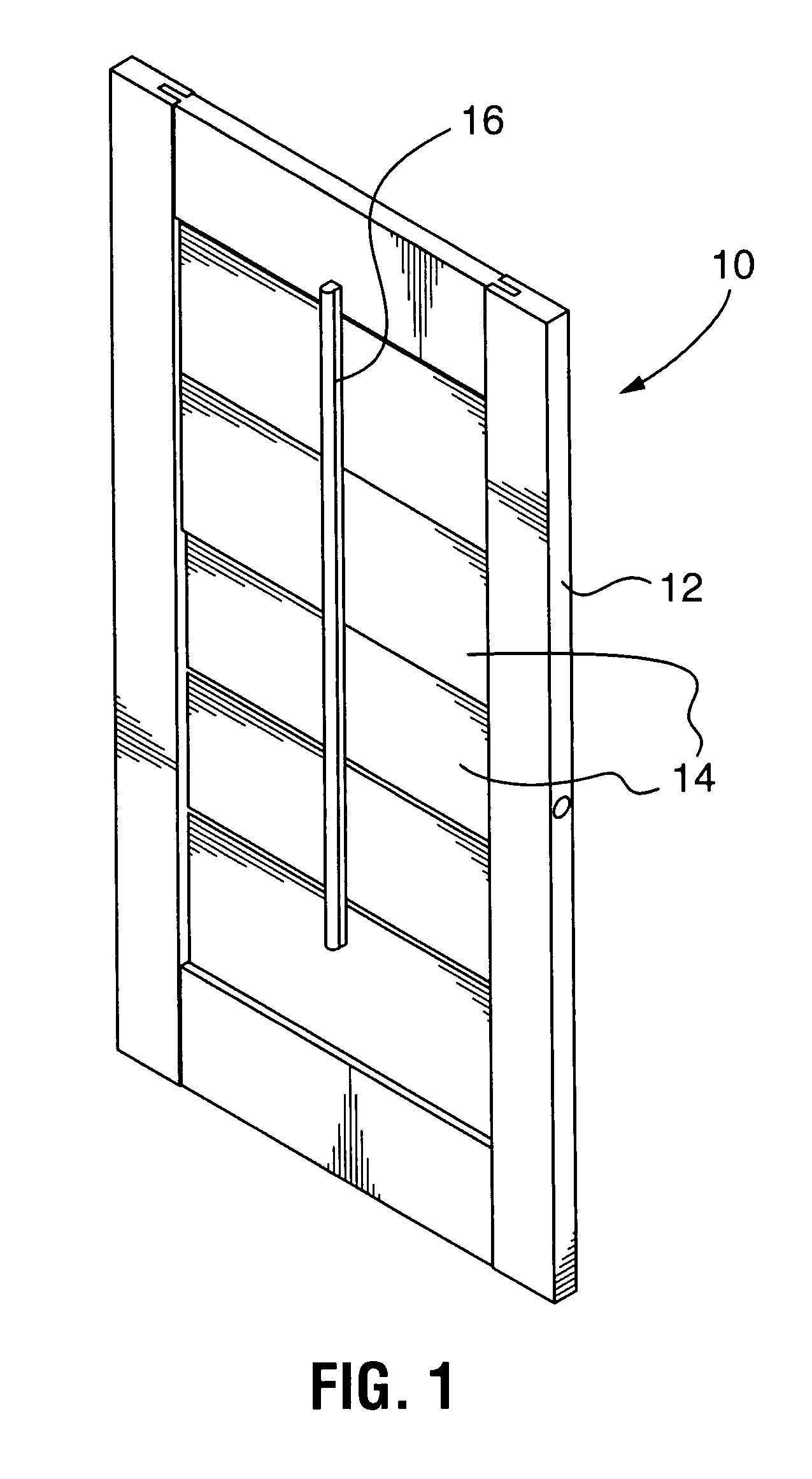

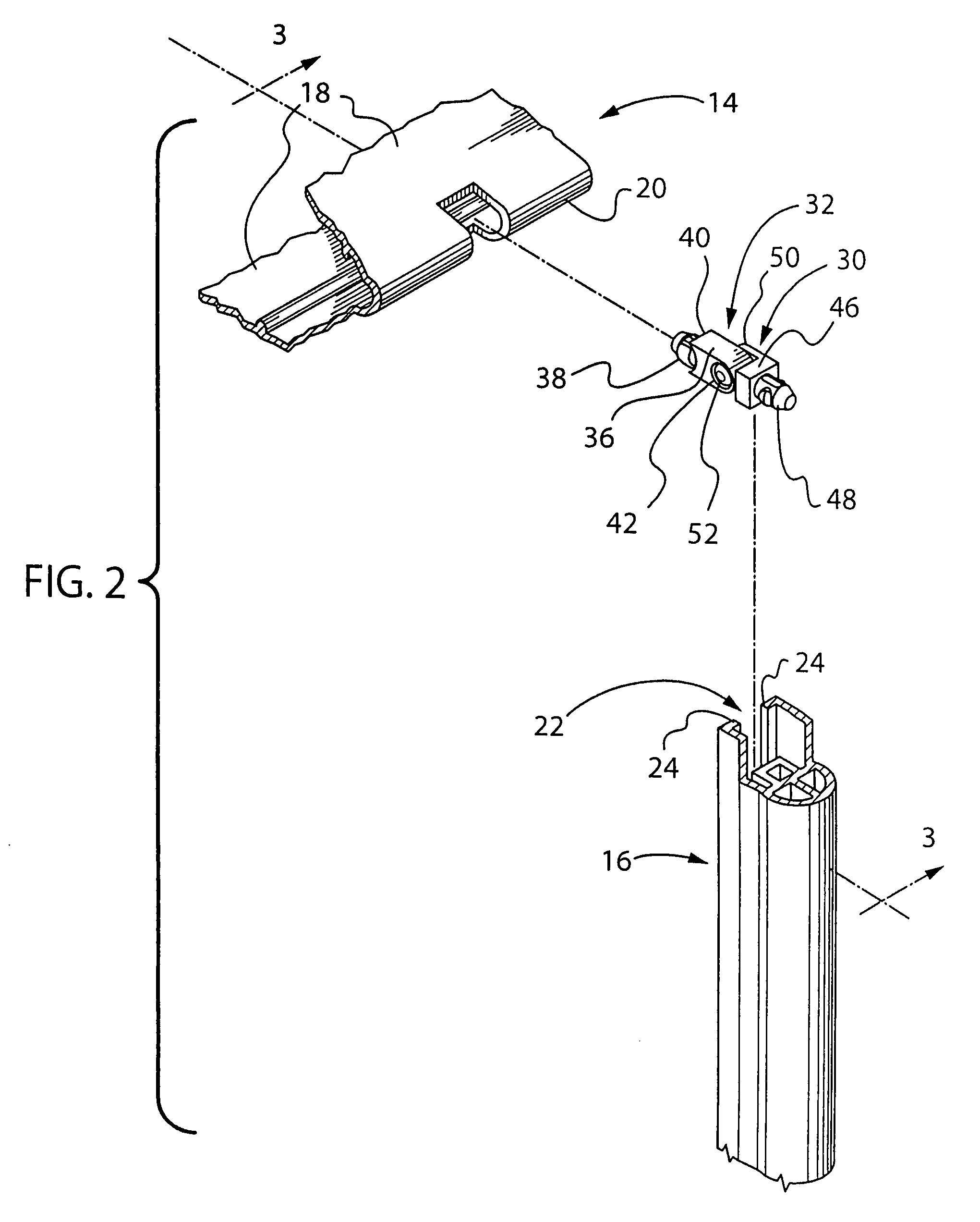

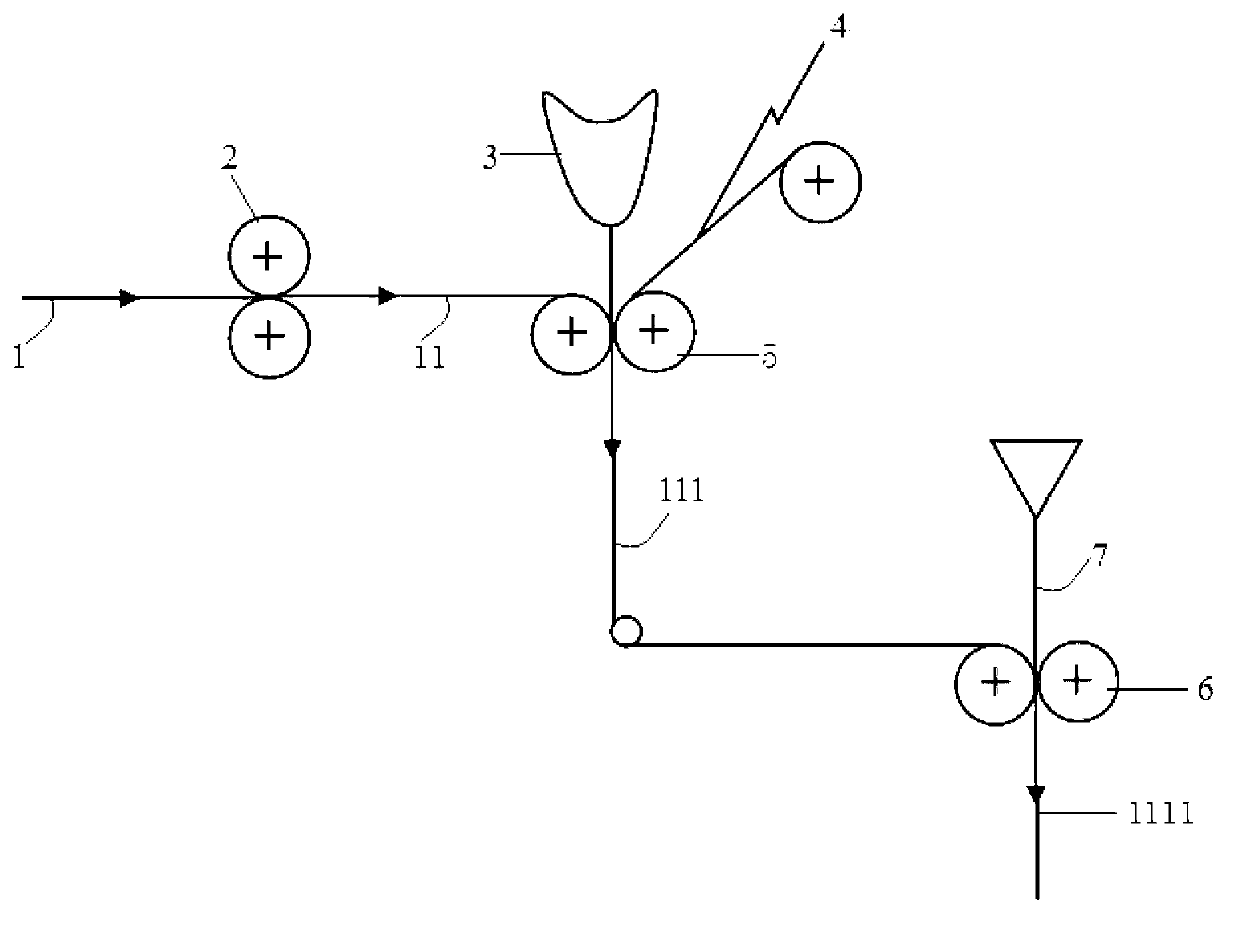

Plug in pull bar hinge

InactiveUS7603810B2Reduced neckingAvoid distortionSpecial door/window arrangementsEngineeringMechanical engineering

A shutter having a frame, and having louvres rotatably supported in the frame, and a control bar, for controlling the louvres, and having two-component connectors connecting respective louvres to the control bar, consisting of a louvre hinge member for attachment to a louvre and a control bar hinge member for, and having a louvre hinge body, a louvre plug integral with the louvre hinge body for insertion into a louvre, a concave surface on said louvre hinge body engaging said louvre which prevents twisting, a hinge opening, and having a control bar hinge body, a control bar plug, a control bar hinge pin, cooperating with said hinge opening in said louvre hinge body to provide a hinging action.

Owner:MAXXMAR

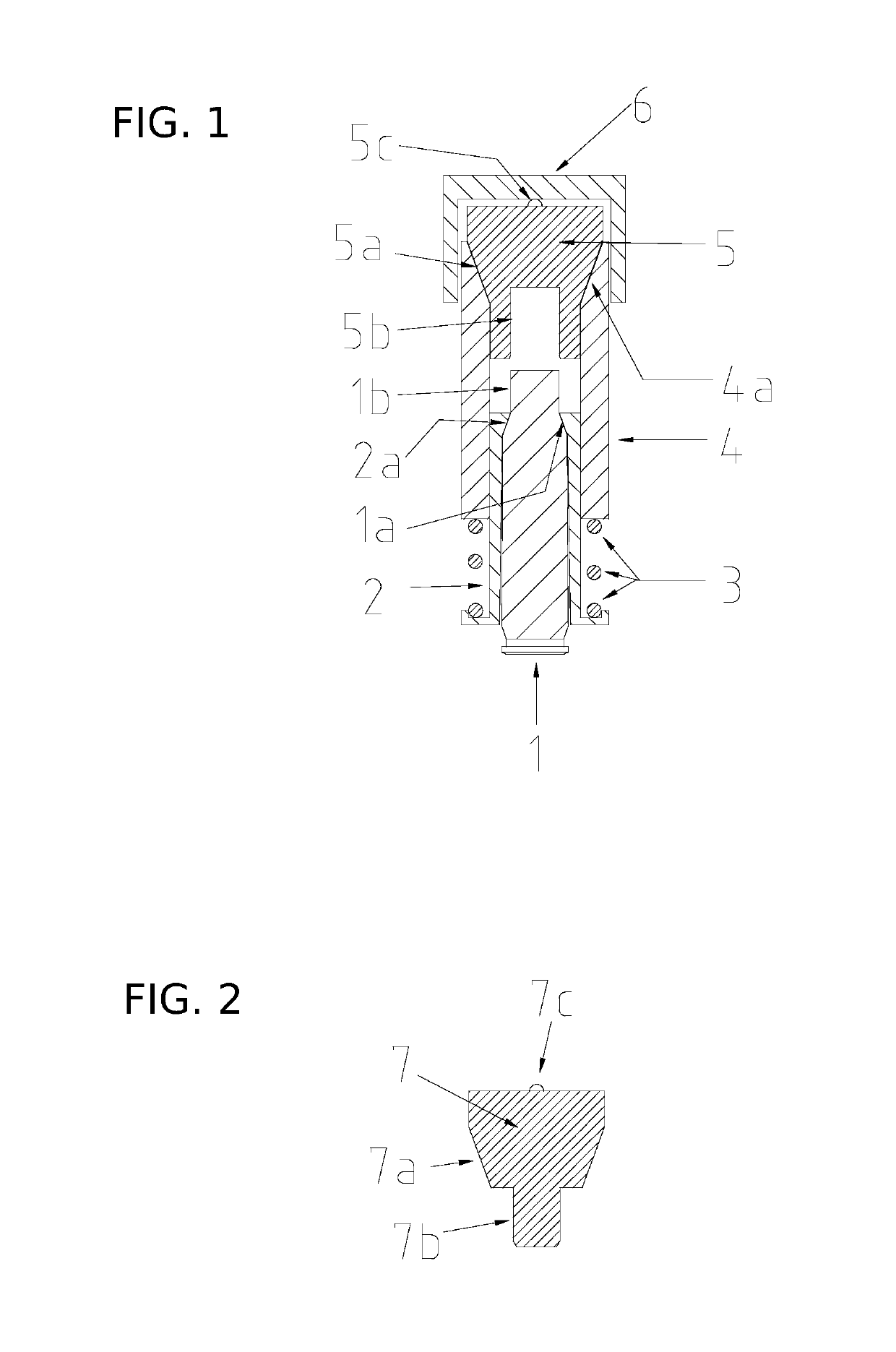

Necking sizing die for shoulder breeching rifle cartridges

ActiveUS10473444B1Easy to controlImprove accuracyAmmunition testingHollow articlesEngineeringTwo step

A neck sizing die for shoulder breeching ammunition cartridge cases that uses the shoulder to align the case, not the body. Alignment occurs before resizing. Resizing is done in a two-step process: a bushing is used to shrink the neck diameter and then an expansion button is used to increase it. Bushing and button diameters are highly selectable and easily changed. Cone-and-cup interfaces ensure concentricity of the case shoulder to the bushing or button. The unique alignment technique and two-step sizing method produces a case with a neck having an interior diameter of the user's choice with the interior wall of the neck aligned to the shoulder. This results in a case that will more reliably position the bullet concentric with the bore of the barrel than existing tools and methods.

Owner:GENT JEFFREY HOWARD

Packaging container

InactiveCN103043300BImprove pass rateCurb wasteFlexible coversWrappersLow-density polyethyleneLinear low-density polyethylene

The invention provides a packaging container which comprises an outmost thermoplastic material layer, a core layer, an intermediate thermoplastic material layer, a blocking layer and an innermost thermoplastic material layer from outside to inside. The outmost thermoplastic material layer contains metalloscene catalyst polymerized linear low density polyethylene (MLLDPE) and low density polyethylene (LDPE), the MLLDPE has following parameters: average density of 0.88g / cm3-0.925g / cm3, melt flow index (190 DEG C, 2.16kg) of 5g / 10min-20g / 10min, peak melting point of 85 DEG C-130 DEG C, and expansion ratio of 1.2-1.8, and the LDPE has following parameters: average density of 0.90g / cm3-0.925g / cm3, melt flow index (190 DEG C, 2.16kg) of 5g / 10min-20g / 10min, peak melting point of 85 DEG C-110 DEG C, and expansion ratio of 1.2-1.8. A longitudinal sealing portion can realize quick thermal sealing during the process of manufacturing the packaging container, sealing intensity is high, and the manufactured packaging container is high in pass percentage and long in shelf life of liquid food.

Owner:TAIZHOU ZHUYE MACHINERY SCI & TECH

Lamination packaging material

InactiveCN103085366BCurb wasteImprove bindingFlexible coversWrappersLow-density polyethyleneLinear low-density polyethylene

The invention provides a lamination packaging material which comprises an outermost thermoplastic material layer, a core layer, an intermediate thermoplastic material layer, a barrier layer, an adhesive layer and an innermost thermoplastic material layer from outside to inside, wherein the adhesive layer comprises metalloscene catalyst polymerized linear low-density polyethylene (MLLDPE) and low-density polyethylene (LDPE), wherein the mLLDPE has the following parameters: the average density is 0.88g / cm<3>-0.925g / cm<3>, the melt index (190 DEG C, 2.16kg) is 5g / 10min-20g / 10min, the peak melting point is 85 DEG C-130DEG C, and the expansion ratio is 1.2-1.8; and the LDPE has the following parameters: the average density is 0.90g / cm<3>-0.925g / cm<3>, the melt index (190 DEG C, 2.16kg) is 5g / 10min-20g / 10min, the peak melting point is 85 DEG C-110DEG C, and the expansion ratio is 1.2-1.8. During the process for manufacturing a packaging container by using the lamination packaging material provided by the invention, a longitudinal sealing part can be subjected to heat sealing rapidly, so as to obtain the packaging container with good sealing intensity, and the manufactured container has high yield and long durability time for liquid food.

Owner:TAIZHOU ZHUYE MACHINERY SCI & TECH

Laminated package material

InactiveCN104742474ACurb wasteImprove seal strengthFlexible coversWrappersLow-density polyethyleneLinear low-density polyethylene

The invention provides a laminated packaging material which comprises an outermost thermoplastic material layer, a core layer, a middle thermoplastic material layer, a blocking layer and an innermost thermoplastic material layer from the outside in. The innermost thermoplastic material layer comprises metallocene catalyst polymerized linear low density polyethylene (MLLDPE) and low density polyethylene (LDPE), wherein MLLDPE has the following parameters that the average density is 0.88g / cm<3>-0.925g / cm<3>; a melt flow index (190 DEG C, 2.16kg) is 5g / 10min-20g / 10min; a peak fusing point is 85 DEG C-130 DEG C; and an expansion ratio is 1.2-1.8. LDPE has the following parameters that the average density is 0.90g / cm<3>-0.925g / cm<3>; the melt flow index (190 DEG C, 2.16kg) is 5g / 10min-20g / 10min; the peak fusing point is 85 DEG C-110 DEG C; and the expansion ratio is 1.2-1.8. Heat sealing can be conducted on a longitudinal sealing part quickly when the laminated packaging material is used for manufacturing a packaging container; the packaging container with high sealing strength is obtained; the manufactured packaging container is high in qualified rate; and a quality guarantee period of liquid food is long.

Owner:TAIZHOU ZHUYE MACHINERY SCI & TECH

Packaging container

InactiveCN103043299BCurb wasteReduced neckingSynthetic resin layered productsPackagingLow-density polyethyleneLinear low-density polyethylene

The invention provides a packaging container which comprises an outmost thermoplastic material layer, a core layer, an intermediate thermoplastic material layer, a blocking layer and an innermost thermoplastic material layer from outside to inside. The innermost thermoplastic material layer contains metalloscene catalyst polymerized linear low density polyethylene (MLLDPE) and low density polyethylene (LDPE), the MLLDPE has following parameters: average density of 0.88g / cm3-0.925g / cm3, melt flow index (190 DEG C, 2.16kg) of 5g / 10min-20g / 10min, peak melting point of 85 DEG C-130 DEG C, and expansion ratio of 1.2-1.8, and the LDPE has following parameters: average density of 0.90g / cm3-0.925g / cm3, melt flow index (190 DEG C, 2.16kg) of 5g / 10min-20g / 10min, peak melting point of 85 DEG C-110 DEG C, and expansion ratio of 1.2-1.8. A longitudinal sealing portion can realize quick thermal sealing during the process of manufacturing the packaging container, sealing intensity is high, and the manufactured packaging container is high in pass percentage and long in shelf life of liquid food.

Owner:TAIZHOU ZHUYE MACHINERY SCI & TECH

Novel polylactic acid material for laminating and laminated product thereof

InactiveCN108221466ALow costEasy to shrinkPaper coatingPaper/cardboardCarvacryl acetateNew materials

The invention discloses a novel polylactic acid material for laminating and laminated product thereof. The material is formed by blending the following components in parts by weight: A, 60 to 99 phr of polylactic acid, and B, 1 to 40 phr of ethylene-vinyl acetate copolymer. The material has the advantages that the ethylene-vinyl acetate copolymer is added in the polylactic acid, synergistic effectis produced between the ethylene-vinyl acetate copolymer and the polylactic acid, the melt strength can be reduced, necking phenomenon can be reduced, when the material is applied to laminating process, the wide range can be increased, the problem of coating shrinkage can be improved, and material cost consumption caused by too wide cut edge after laminating can be reduced.

Owner:JIANGSU SUPLA BIOPLASTICS CO LTD

Laminated packaging material

InactiveCN103101273BCurb wasteImprove bindingFlexible coversWrappersLow-density polyethyleneLinear low-density polyethylene

The invention provides a laminated packaging material. The laminated packaging material comprises an outermost thermoplastic material layer, a sandwich layer, an intermediate thermoplastic material layer, a barrier layer and an innermost thermoplastic material layer from outside to inside, wherein the intermediate thermoplastic material layer is made of metalloscene-catalyst-polymerized linear low-density polyethylene (mLLDPE) and LDPE; for the metalloscene catalyst polymerized mLLDPE, the mean density is 0.88-0.925g / cm<3>, the melt flow index (190 DEG C and 2.16kg) is 5-20g / 10min, the peak melting point is 85-130 DEG C and the expansion ratio is 1.2-1.8; and for the LDPE, the mean density is 0.90-0.925g / cm<3>, the melt flow index (190 DEG C and 2.16kg) is 5-20g / 10min, the peak melting point is 85-110 DEG C and the expansion ratio is 1.2-1.8. Packaging containers with good sealing strength can be obtained by using the laminated packaging material, the percent of pass of the prepared packaging containers is high, and liquid food in the prepared packaging containers is long in quality guarantee period.

Owner:TAIZHOU ZHUYE MACHINERY SCI & TECH

Packaging container

InactiveCN103042731BImprove pass rateCurb wasteLayered productsBulk chemical productionLow-density polyethyleneLinear low-density polyethylene

The invention provides a packaging container which is characterized by comprising a thermoplastic material outermost layer, a sandwich layer, a thermoplastic material intermediate layer, a blocking layer, an adhesion agent layer and a thermoplastic material innermost layer from the outside in, wherein the adhesion agent layer comprises metallocene linear low density polyethylene (MLLDPE) and low density polyethylene (LDPE); the MLLDPE comprises the following parameters: average density of 0.88 g / cm<3> to 0.925 g / cm<3>, melt flow index (190 DEG C, 2.16kg) of 5 g / 10 min to 20 g / 10 min, peak melting point of 85 DEG C to 130 DEG C and expansion ratio of 1.2 to 1.8; and the LDPE comprises the following parameters: average density of 0.90 g / cm<3> to 0.925 g / cm<3>, melt flow index (190 DEG C, 2.16kg) of 5 g / 10 min to 20 g / 10 min, peak melting point of 85 DEG C to 110 DEG C and expansion ratio of 1.2 to 1.8. The longitudinal sealing part can be heat-sealed during the process of preparing the packaging container, the sealing strength is good, the prepared packaging container has high percent of pass, and the shelf life of liquid food is long.

Owner:TAIZHOU ZHUYE MACHINERY SCI & TECH

Laminated package material

InactiveCN104742441ACurb wasteImprove bindingSynthetic resin layered productsMetal layered productsLow-density polyethyleneMolten state

The invention provides a lamination packaging material which comprises an outermost thermoplastic material layer, a core layer, an intermediate thermoplastic material layer, a barrier layer, an adhesive layer and an innermost thermoplastic material layer from outside to inside, wherein the adhesive layer comprises metalloscene catalyst polymerized linear low-density polyethylene (MLLDPE) and low-density polyethylene (LDPE), wherein the mLLDPE has the following parameters: the average density is 0.88g / cm<3>-0.925g / cm<3>, the melt index (190 DEG C, 2.16kg) is 5g / 10min-20g / 10min, the peak melting point is 85 DEG C-130DEG C, and the expansion ratio is 1.2-1.8; and the LDPE has the following parameters: the average density is 0.90g / cm<3>-0.925g / cm<3>, the melt index (190 DEG C, 2.16kg) is 5g / 10min-20g / 10min, the peak melting point is 85 DEG C-110DEG C, and the expansion ratio is 1.2-1.8. During the process for manufacturing a packaging container by using the lamination packaging material provided by the invention, a longitudinal sealing part can be subjected to heat sealing rapidly, so as to obtain the packaging container with good sealing intensity, and the manufactured container has high yield and long durability time for liquid food.

Owner:TAIZHOU ZHUYE MACHINERY SCI & TECH

Packaging container

InactiveCN104760338AImprove pass rateCurb wasteLayered productsBulk chemical productionLinear low-density polyethyleneLow-density polyethylene

The invention provides a packaging container which is characterized by comprising a thermoplastic material outermost layer, a sandwich layer, a thermoplastic material intermediate layer, a blocking layer, an adhesion agent layer and a thermoplastic material innermost layer from the outside in, wherein the adhesion agent layer comprises metallocene linear low density polyethylene (MLLDPE) and low density polyethylene (LDPE); the MLLDPE comprises the following parameters: average density of 0.88 g / cm<3> to 0.925 g / cm<3>, melt flow index (190 DEG C, 2.16kg) of 5 g / 10 min to 20 g / 10 min, peak melting point of 85 DEG C to 130 DEG C and expansion ratio of 1.2 to 1.8; and the LDPE comprises the following parameters: average density of 0.90 g / cm<3> to 0.925 g / cm<3>, melt flow index (190 DEG C, 2.16kg) of 5 g / 10 min to 20 g / 10 min, peak melting point of 85 DEG C to 110 DEG C and expansion ratio of 1.2 to 1.8. The longitudinal sealing part can be heat-sealed during the process of preparing the packaging container, the sealing strength is good, the prepared packaging container has high percent of pass, and the shelf life of liquid food is long.

Owner:TAIZHOU ZHUYE MACHINERY SCI & TECH

Packaging container

InactiveCN104760357AImprove pass rateCurb wasteFlexible coversWrappersLow-density polyethyleneLinear low-density polyethylene

The invention provides a packaging container which comprises an outmost thermoplastic material layer, a core layer, an intermediate thermoplastic material layer, a blocking layer and an innermost thermoplastic material layer from outside to inside. The outmost thermoplastic material layer contains metalloscene catalyst polymerized linear low density polyethylene (MLLDPE) and low density polyethylene (LDPE), the MLLDPE has following parameters: average density of 0.88g / cm3-0.925g / cm3, melt flow index (190 DEG C, 2.16kg) of 5g / 10min-20g / 10min, peak melting point of 85 DEG C-130 DEG C, and expansion ratio of 1.2-1.8, and the LDPE has following parameters: average density of 0.90g / cm3-0.925g / cm3, melt flow index (190 DEG C, 2.16kg) of 5g / 10min-20g / 10min, peak melting point of 85 DEG C-110 DEG C, and expansion ratio of 1.2-1.8. A longitudinal sealing portion can realize quick thermal sealing during the process of manufacturing the packaging container, sealing intensity is high, and the manufactured packaging container is high in pass percentage and long in shelf life of liquid food.

Owner:TAIZHOU ZHUYE MACHINERY SCI & TECH

Laminated packaging material

InactiveCN103029398BCurb wasteImprove seal strengthFlexible coversWrappersLow-density polyethyleneLinear low-density polyethylene

The invention provides a laminated packaging material which comprises an outermost thermoplastic material layer, a core layer, a middle thermoplastic material layer, a blocking layer and an innermost thermoplastic material layer from the outside in. The innermost thermoplastic material layer comprises metallocene catalyst polymerized linear low density polyethylene (MLLDPE) and low density polyethylene (LDPE), wherein MLLDPE has the following parameters that the average density is 0.88g / cm<3>-0.925g / cm<3>; a melt flow index (190 DEG C, 2.16kg) is 5g / 10min-20g / 10min; a peak fusing point is 85 DEG C-130 DEG C; and an expansion ratio is 1.2-1.8. LDPE has the following parameters that the average density is 0.90g / cm<3>-0.925g / cm<3>; the melt flow index (190 DEG C, 2.16kg) is 5g / 10min-20g / 10min; the peak fusing point is 85 DEG C-110 DEG C; and the expansion ratio is 1.2-1.8. Heat sealing can be conducted on a longitudinal sealing part quickly when the laminated packaging material is used for manufacturing a packaging container; the packaging container with high sealing strength is obtained; the manufactured packaging container is high in qualified rate; and a quality guarantee period of liquid food is long.

Owner:TAIZHOU ZHUYE MACHINERY SCI & TECH

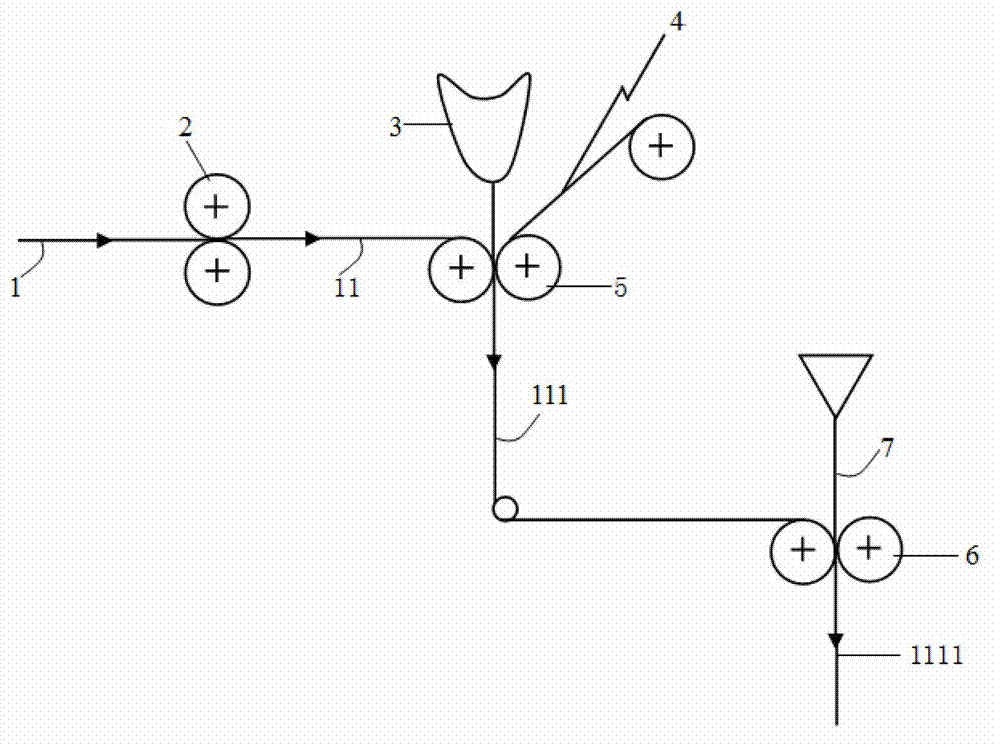

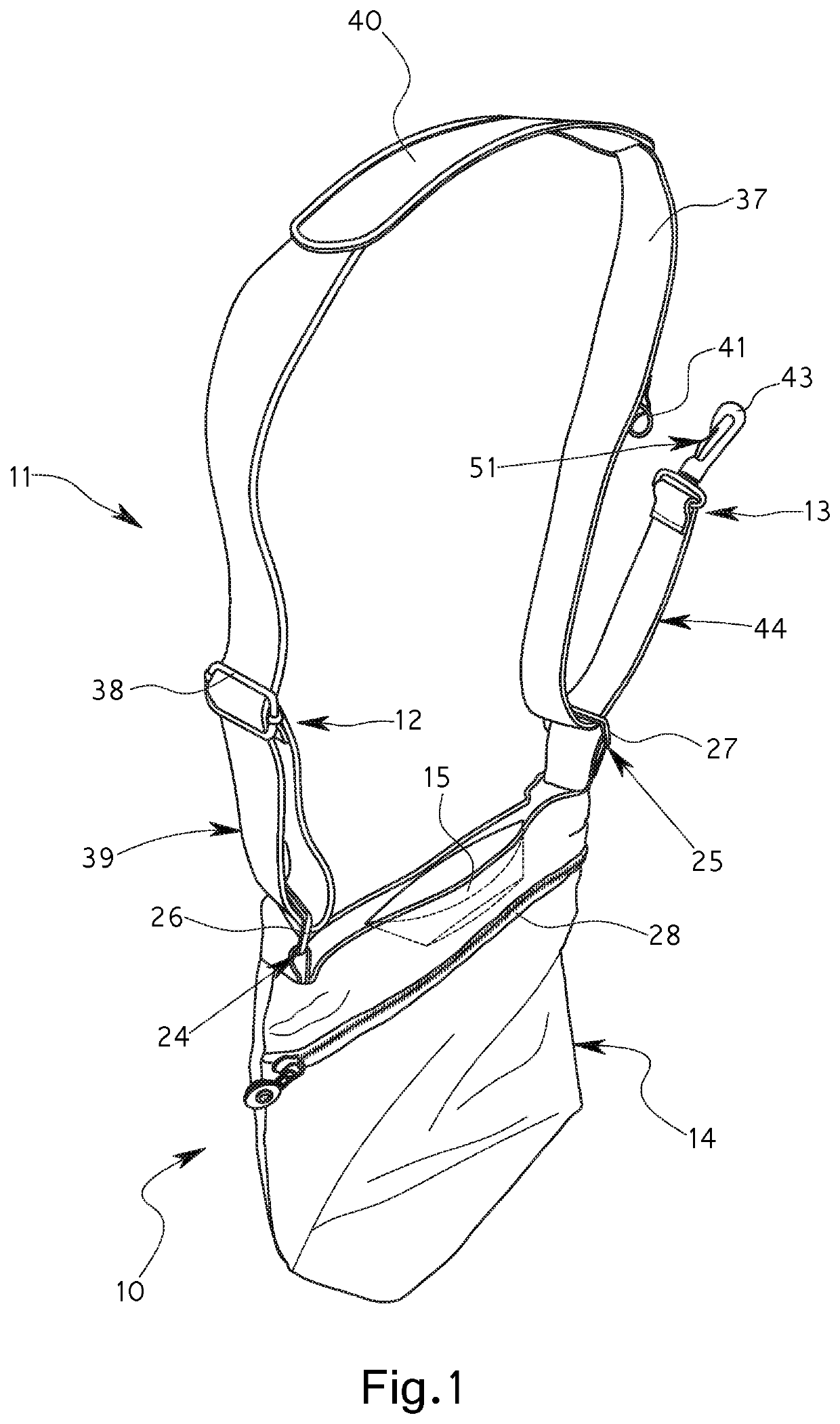

Unobtrusive elbow brace

PendingUS20210069004A1Easy to useReduced neckingTravelling sacksPursesPhysical medicine and rehabilitationPhysical therapy

An elbow brace for supporting a wearer's elbow in a desired position when using a portable electronic device to mitigate “tech neck” is made unobtrusive by incorporation into a shoulder bag having a length-adjustable shoulder strap. A flexible bag assembly comprises opposite first and second panels of flexible sheet-like material connected to define an interior compartment having a volume. An upper bag mouth is disposed between edges of the panels, with fastenings connecting its opposite ends of the edges. An elbow-receiving sleeve of flexible sheet-like material is attached in the upper bag mouth and can be opened into a generally frustoconical form, for supporting a bent elbow such that, in use, both forearm and upper arm extend from an outer end elbow-receiving sleeve. In a closed state the elbow-receiving sleeve is flattened such that opposing halves of the elbow-receiving sleeve come together.

Owner:PRIMEDTECH LTD

Laminated packaging material

InactiveCN103101274AImprove pass rateCurb wasteSynthetic resin layered productsLow-density polyethyleneLinear low-density polyethylene

The invention provides a laminated packaging material. The laminated packaging material comprises an outermost thermoplastic material layer, a sandwich layer, an intermediate thermoplastic material layer, a barrier layer and an innermost thermoplastic material layer from outside to inside, wherein the outermost thermoplastic material layer is made of metalloscene-catalyst-polymerized linear low-density polyethylene (mLLDPE) and LDPE; for the metalloscene catalyst polymerized mLLDPE, the mean density is 0.88-0.925g / cm<3>, the melt flow index (190 DEG C and 2.16kg) is 5-20g / 10min, the peak melting point is 85-130 DEG C and the expansion ratio is 1.2-1.8; and for the LDPE, the mean density is 0.90-0.925g / cm<3>, the melt flow index (190 DEG C and 2.16kg) is 5-20g / 10min, the peak melting point is 85-110 DEG C and the expansion ratio is 1.2-1.8. Packaging containers with good sealing strength can be obtained by using the laminated packaging material, the percent of pass of the prepared packaging containers is high, and liquid food in the prepared packaging containers is long in quality guarantee period.

Owner:TAIZHOU ZHUYE MACHINERY SCI & TECH

Method for manufacturing laminated package material

InactiveCN104859266ACurb wasteImprove bindingFlexible coversWrappersLow-density polyethyleneLinear low-density polyethylene

The invention provides a method for manufacturing laminated packaging material. The method for manufacturing the laminated packaging material comprises the following steps: step 1, pressing crease lines and stamping open holes in a core layer; step 2, extruding laminated thermoplastic material on the outer side surface of the core layer to form an outermost layer; step 3, extruding laminated thermoplastic material on the inner side surface of the core layer to form an intermediate layer and combining a blocking layer with the inner side surface of the core layer through the intermediate layer at the same time; step 4, extruding laminated thermoplastic material on the blocking layer to form an adhesive layer; and step 5, extruding laminated thermoplastic material on the adhesive layer to form the innermost layer. In the step 4, the thermoplastic material of the adhesive layer is formed by the blending metallocene catalyst polymerized linear low density polyethylene (MLLDPE) and low density polyethylene (LDPE). According to the invention, during the process of manufacturing a packaging container by the laminated packaging material manufactured by using the method, heat seal can be quickly performed on the longitudinal sealing part, so as to obtain the packaging container with good sealing strength, the manufactured packaging container has a high qualification rate, and the liquid food can be preserved for a long time.

Owner:TAIZHOU ZHUYE MACHINERY SCI & TECH

Laminated packaging material

InactiveCN104760379ACurb wasteImprove bindingFlexible coversWrappersLow-density polyethyleneLinear low-density polyethylene

Owner:TAIZHOU ZHUYE MACHINERY SCI & TECH

Non-equivalent atomic ratio cocrfenimo x High entropy alloy and its preparation method

Non-equiatomic ratio CoCrFeNiMo x High entropy alloy and preparation method thereof, the present invention relates to a kind of CoCrFeNiMo of non-equiatomic ratio x High-entropy alloys and methods for their preparation. The purpose of the present invention is to solve the problem that existing high-entropy alloys have poor plasticity, thereby restricting plastic processing. The alloy expression of the present invention is CoCrFeNiMo x , where x is 0, 2 or 4, and is composed of the following raw material components according to the atomic percentage: Mo is 0% to 20%, Co is 10% to 40%, Cr is 10% to 40%, and Fe is 10% to 25%. %, Ni is 10% to 25%, and the sum of the atomic percentages of the above components is 100%. The invention is applied to the field of high-entropy alloys.

Owner:HARBIN INST OF TECH

Method for manufacturing laminated packaging material

InactiveCN103042800BCurb wasteImprove bindingFlexible coversWrappersLow-density polyethyleneLinear low-density polyethylene

The invention provides a method for manufacturing laminated packaging material. The method for manufacturing the laminated packaging material comprises the following steps: step 1, pressing crease lines and stamping open holes in a core layer; step 2, extruding laminated thermoplastic material on the outer side surface of the core layer to form an outermost layer; step 3, extruding laminated thermoplastic material on the inner side surface of the core layer to form an intermediate layer and combining a blocking layer with the inner side surface of the core layer through the intermediate layer at the same time; step 4, extruding laminated thermoplastic material on the blocking layer to form an adhesive layer; and step 5, extruding laminated thermoplastic material on the adhesive layer to form the innermost layer. In the step 3, the thermoplastic material of the intermediate layer is formed by the blending metallocene catalyst polymerized linear low density polyethylene (MLLDPE) and low density polyethylene (LDPE). According to the invention, during the process of manufacturing a packaging container by the laminated packaging material manufactured by using the method, heat seal can be quickly performed on the longitudinal sealing part, so as to obtain the packaging container with good sealing strength, the manufactured packaging container has a high qualification rate, and the liquid food can be preserved for a long time.

Owner:TAIZHOU ZHUYE MACHINERY SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com