Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

71results about How to "Positive engagement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

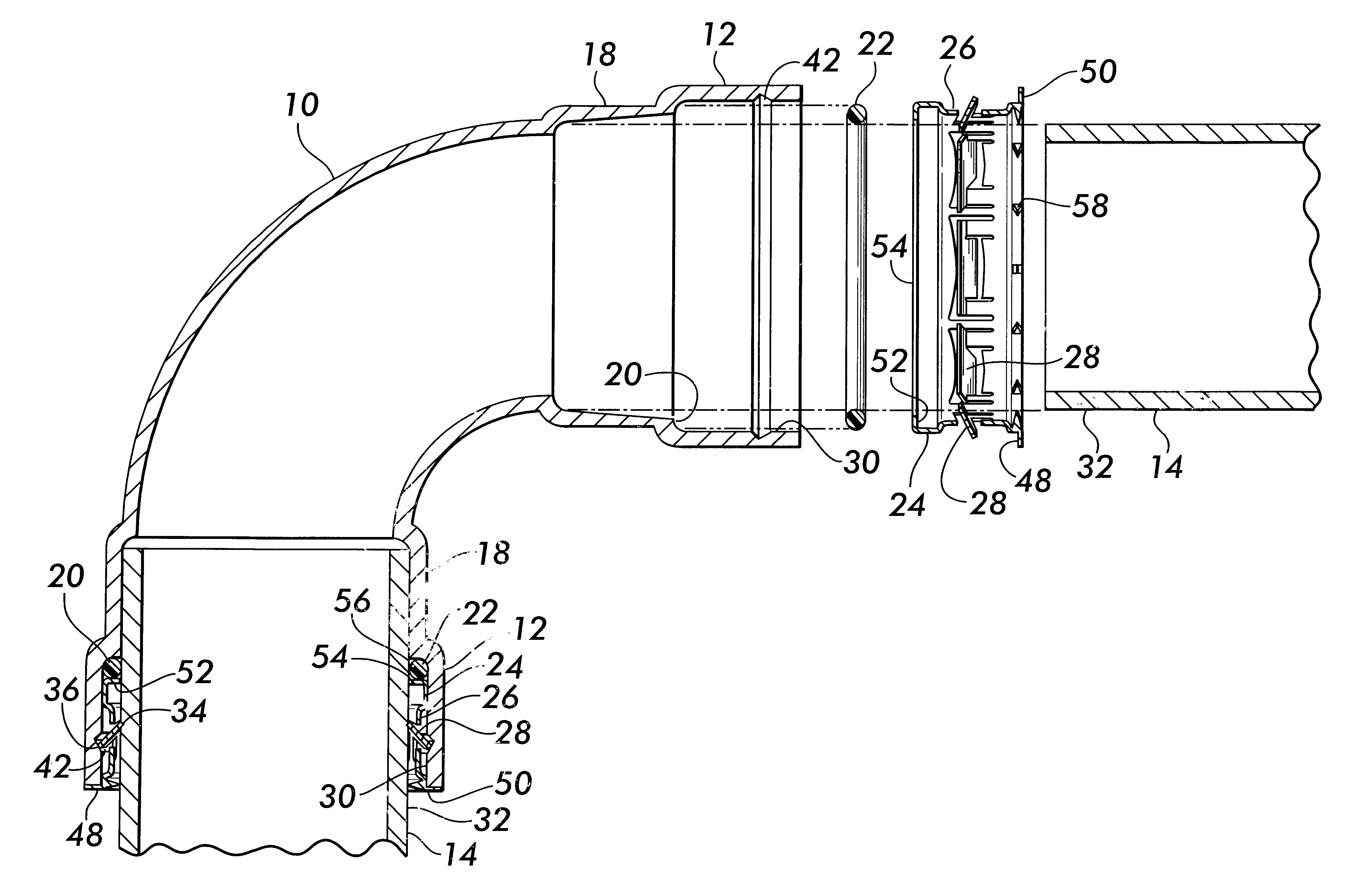

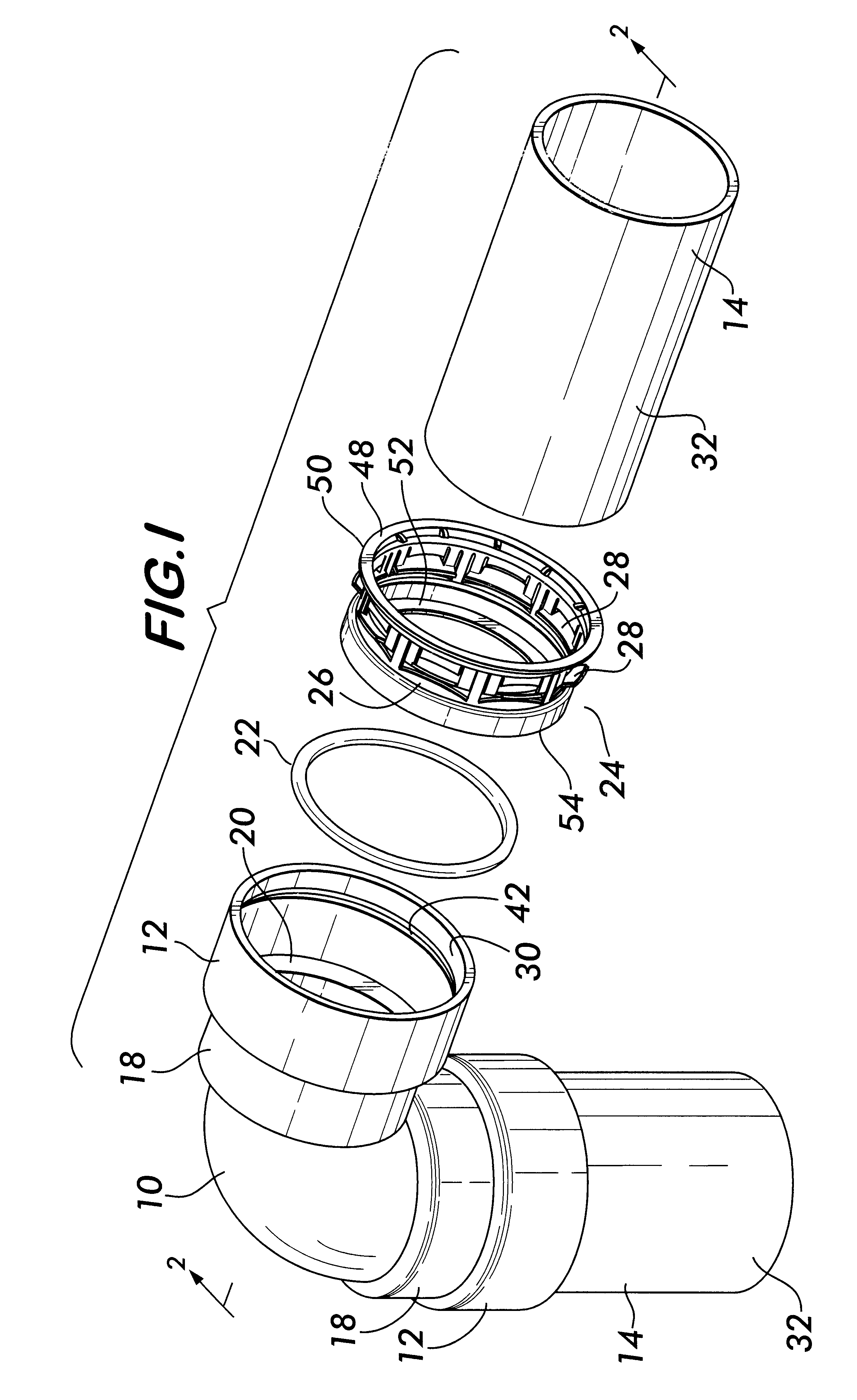

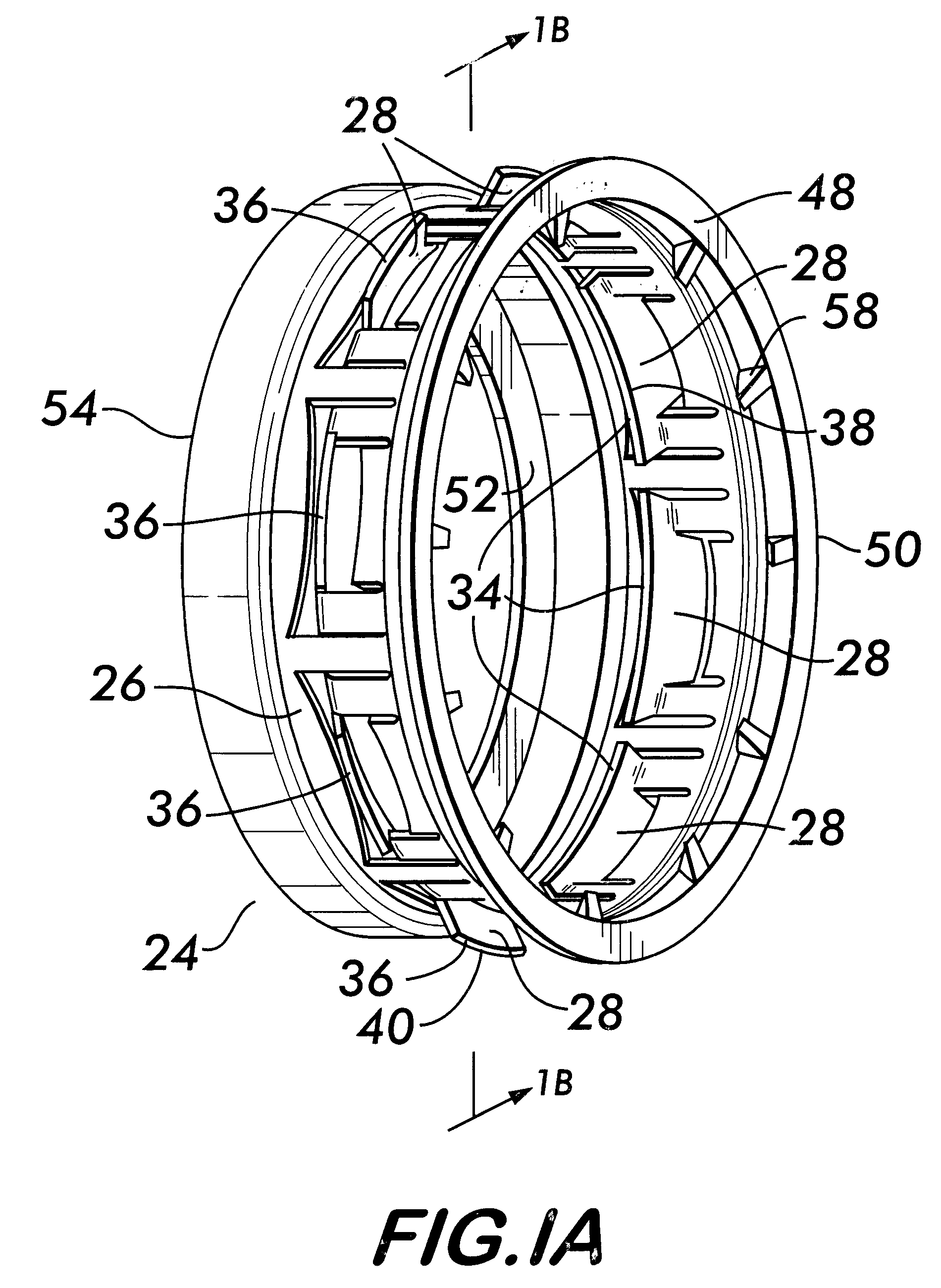

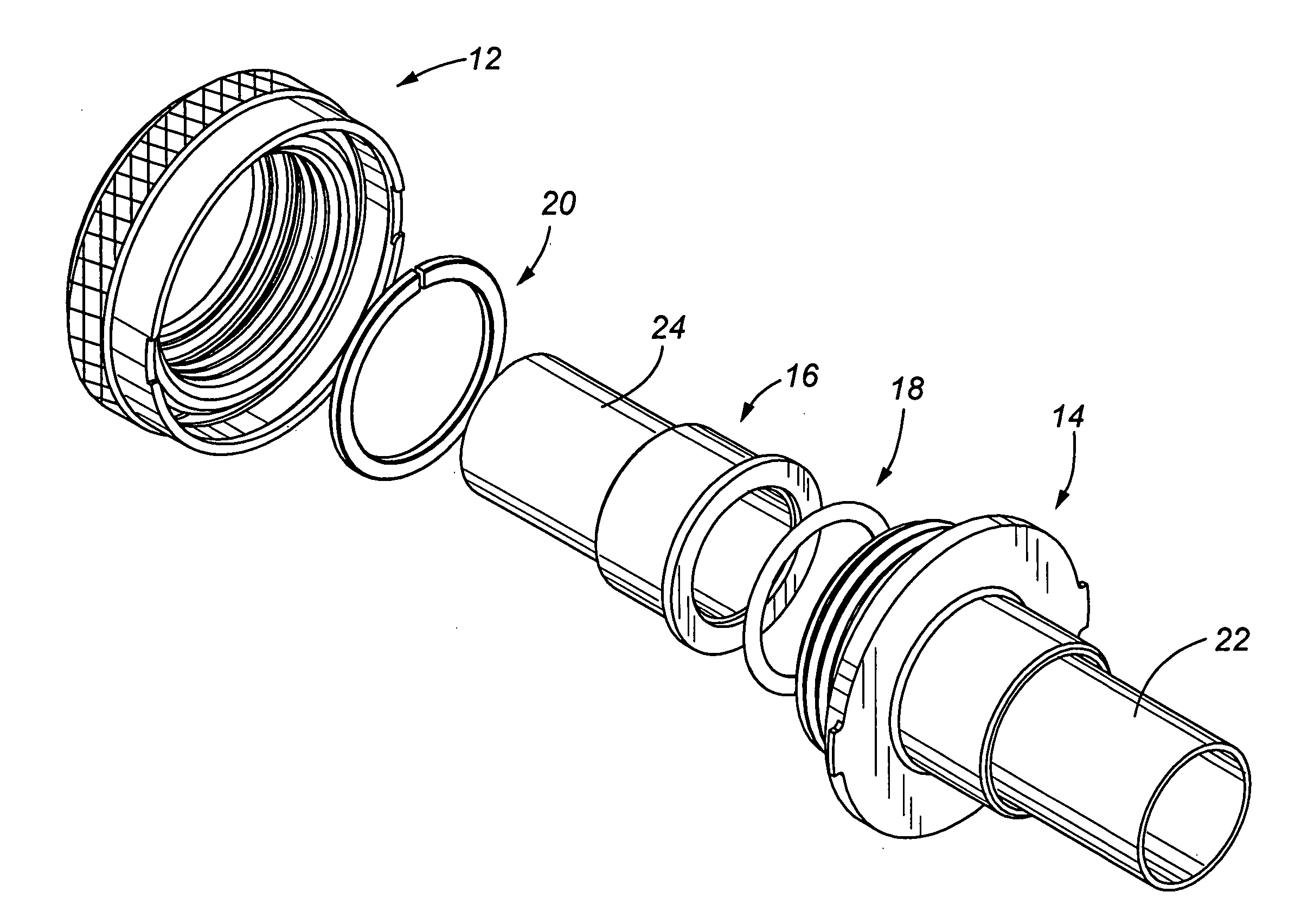

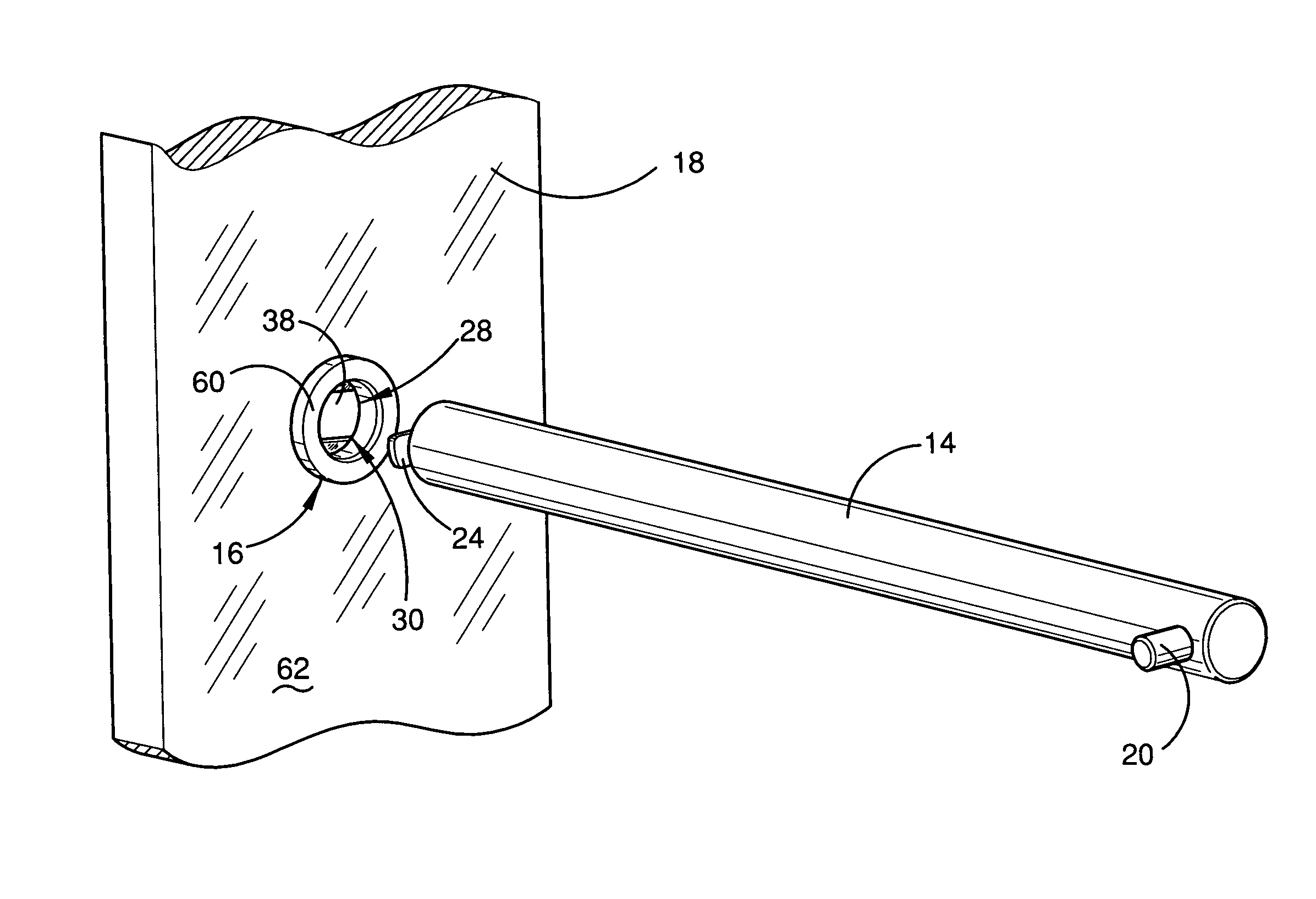

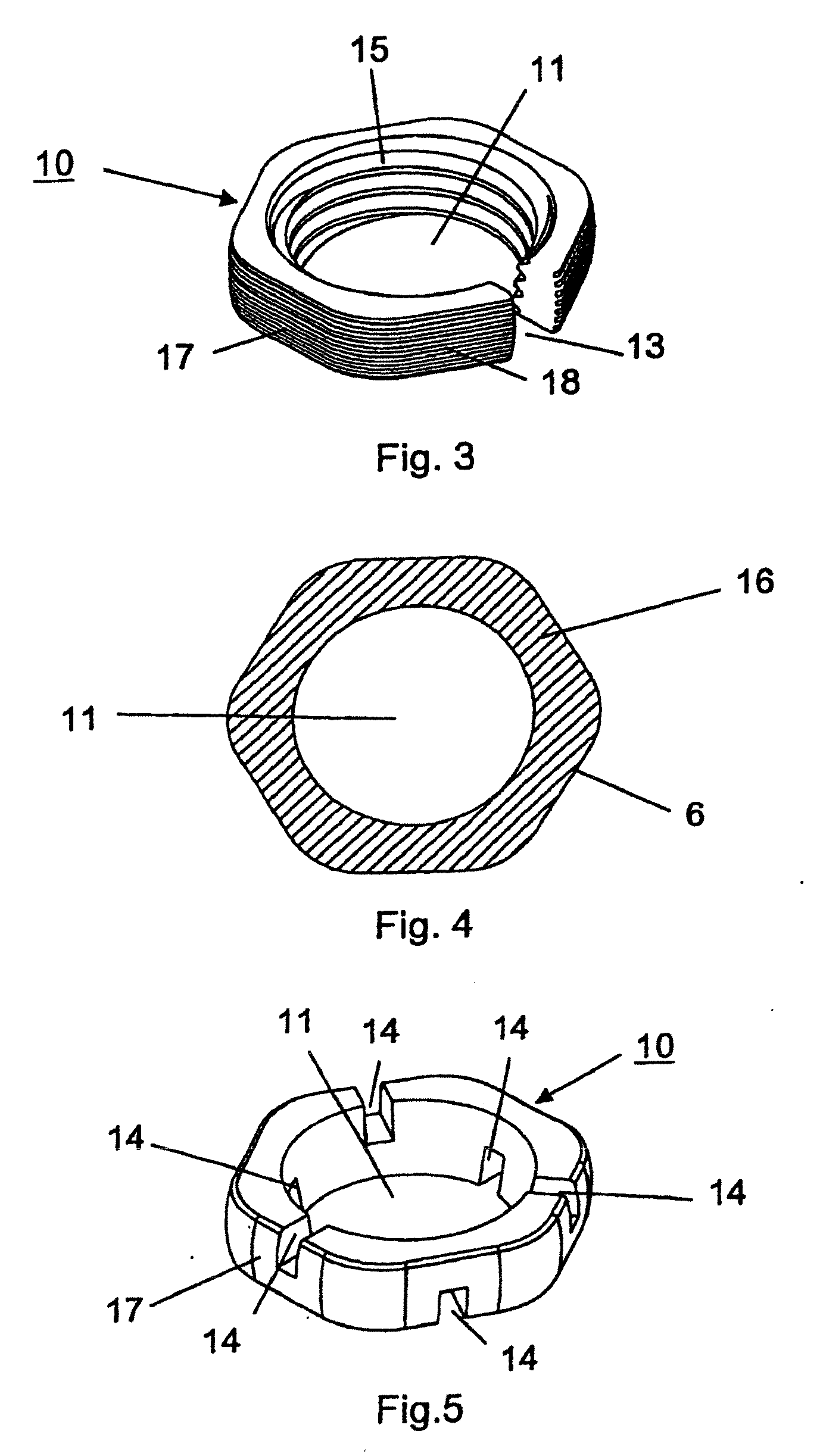

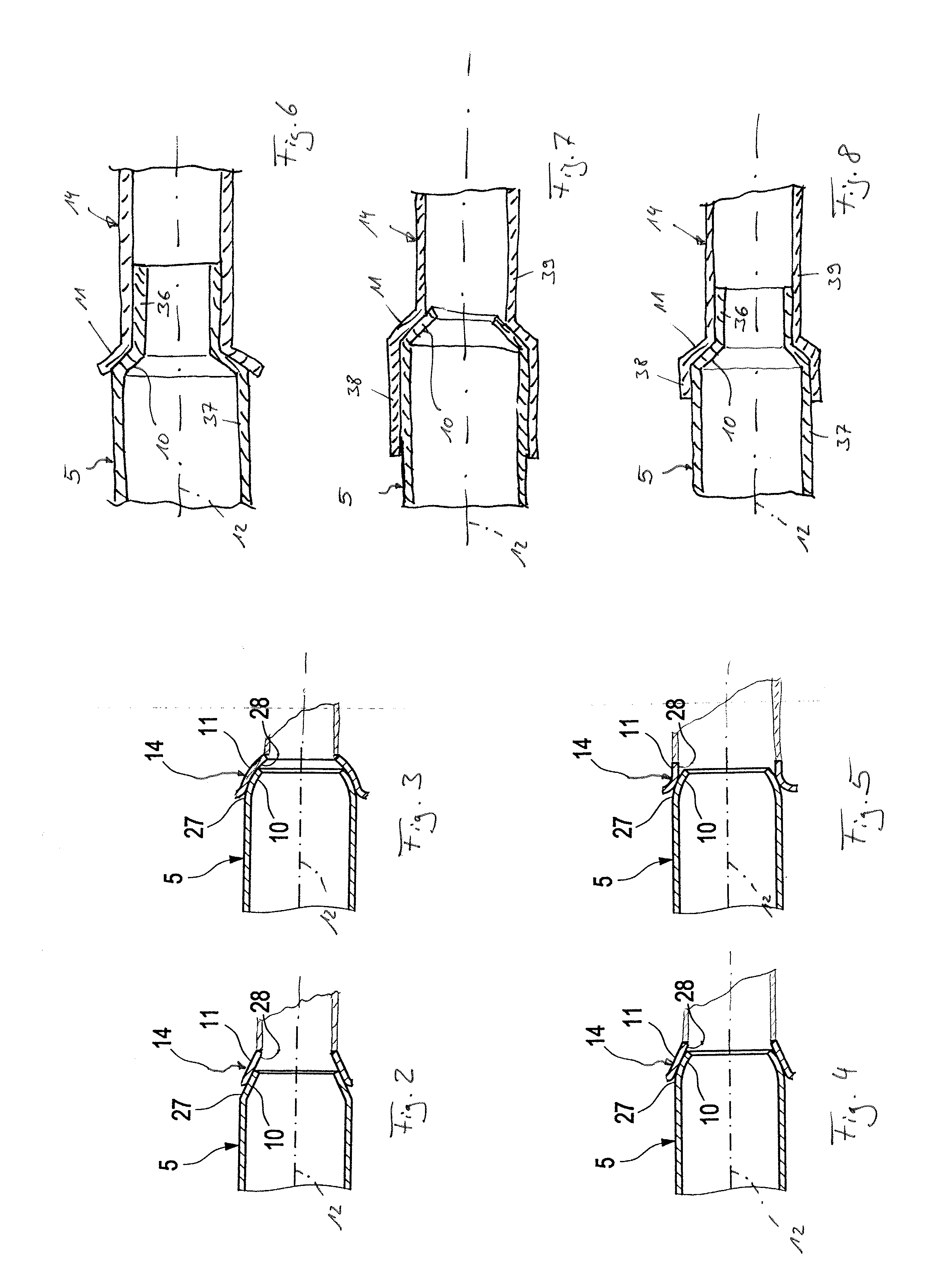

Mechanical pipe coupling with toothed retainer

InactiveUS6499771B1Reduce energy lossPositive engagementSleeve/socket jointsFluid pressure sealed jointsPipe fitting

An open end of a standard pipe fitting is enlarged in diameter to coaxially receive an O-ring and a retainer having a cylindrical surface. A plurality of locking teeth project from the cylindrical surface and are engageable with both the inner surface of the fitting and an outer surface of a pipe end inserted coaxially into the fitting open end. Each of the locking teeth have oppositely disposed edges facing obliquely inwardly and outwardly to engage both the pipe end and the fitting and resisting motion of the pipe end relatively to the fitting. In an alternate embodiment, a first plurality of teeth each have an edge facing obliquely inwardly of the fitting to engage the pipe end and resist motion tending to withdraw the pipe end from the fitting. A second plurality of teeth each have an edge facing obliquely outwardly of the fitting and resist motion tending to withdraw the retainer from the fitting.

Owner:VICTAULIC

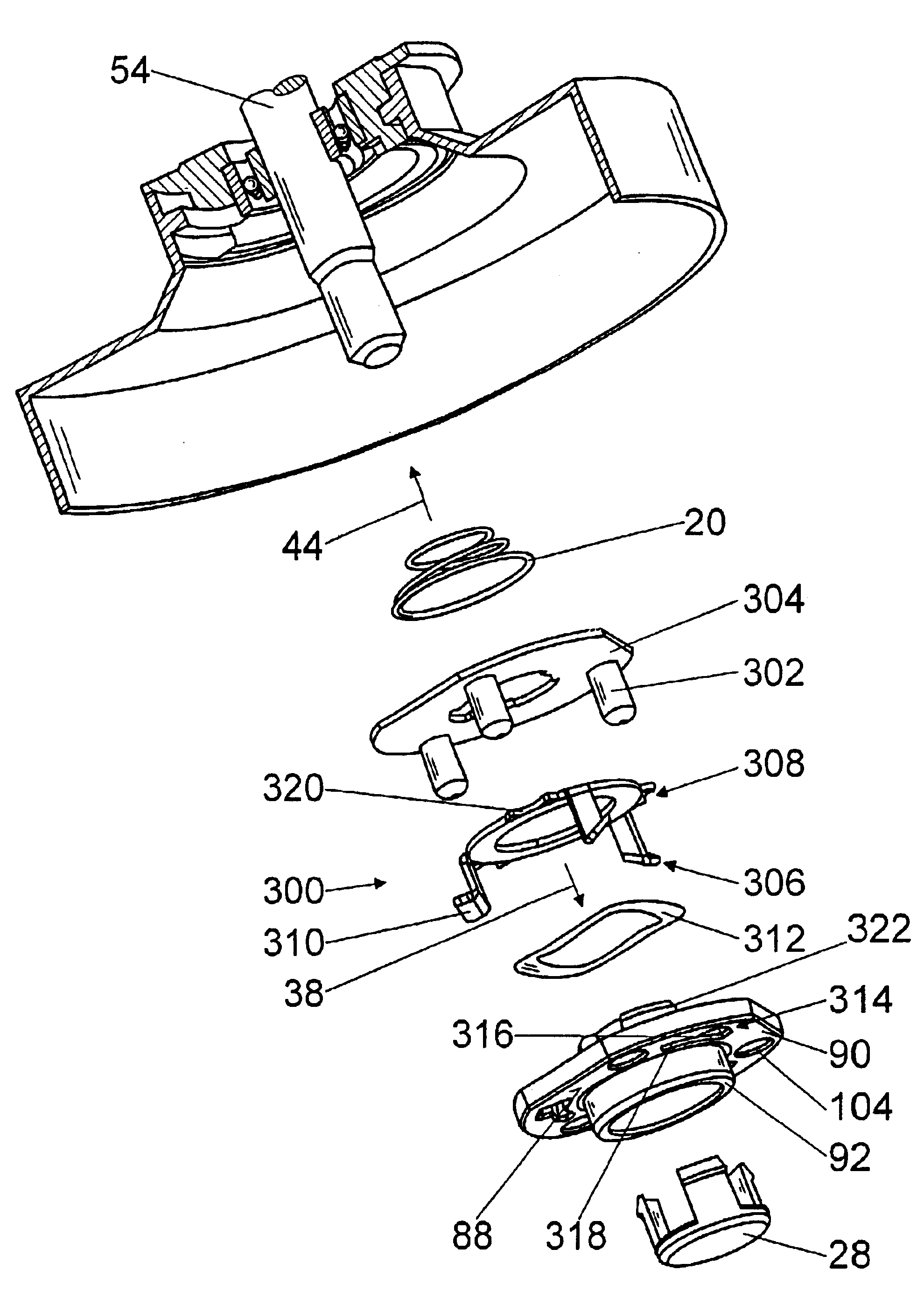

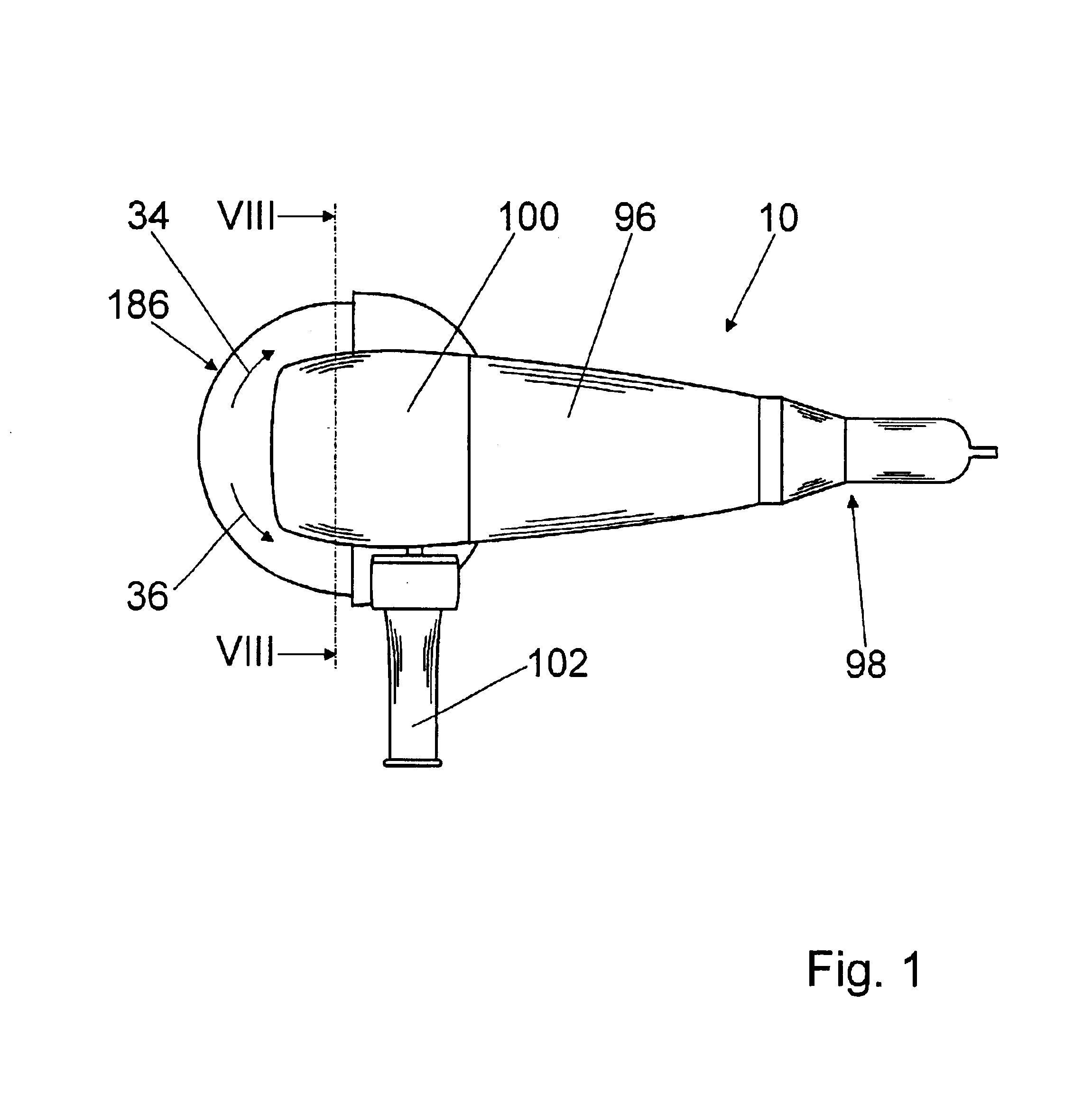

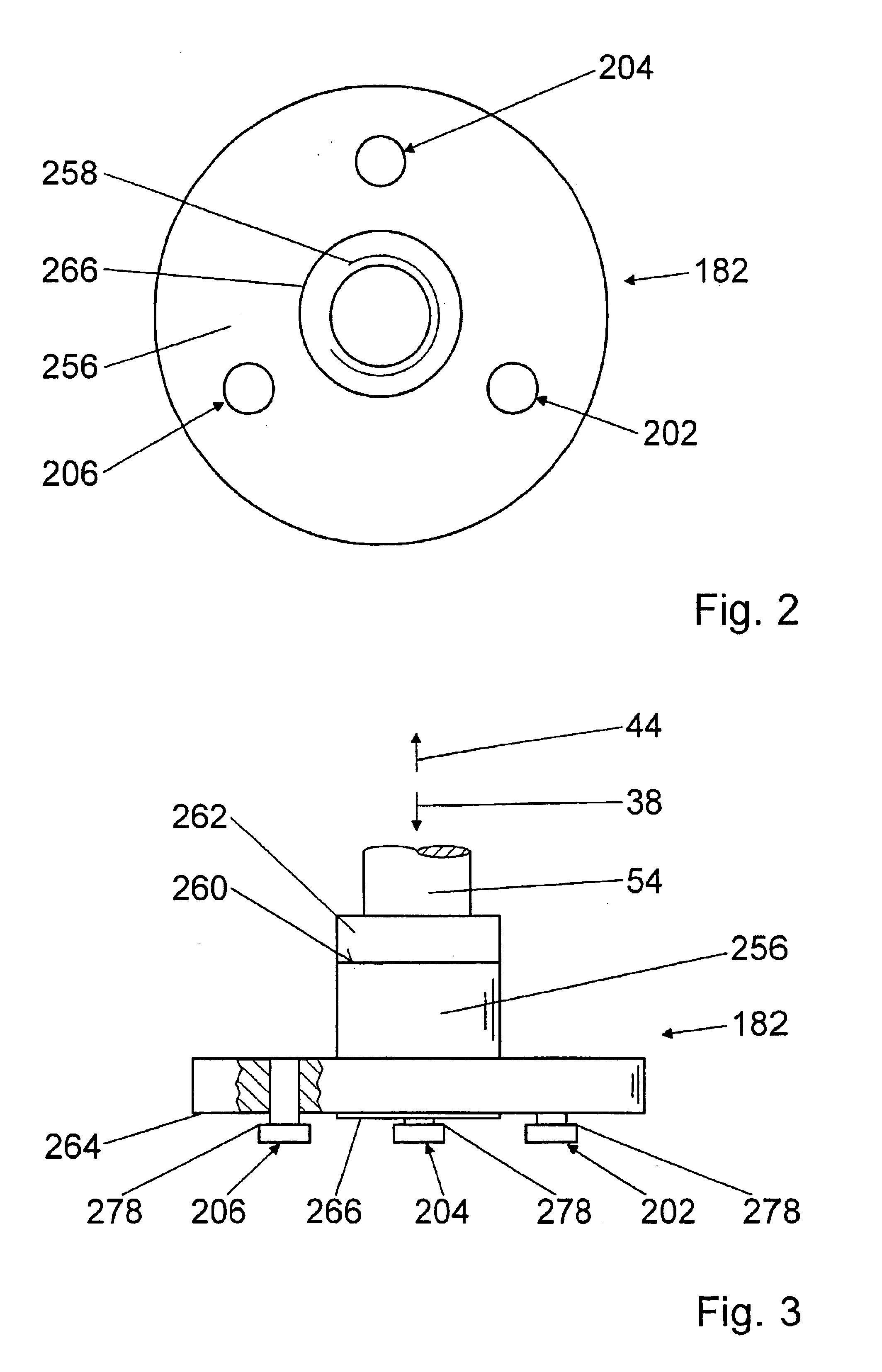

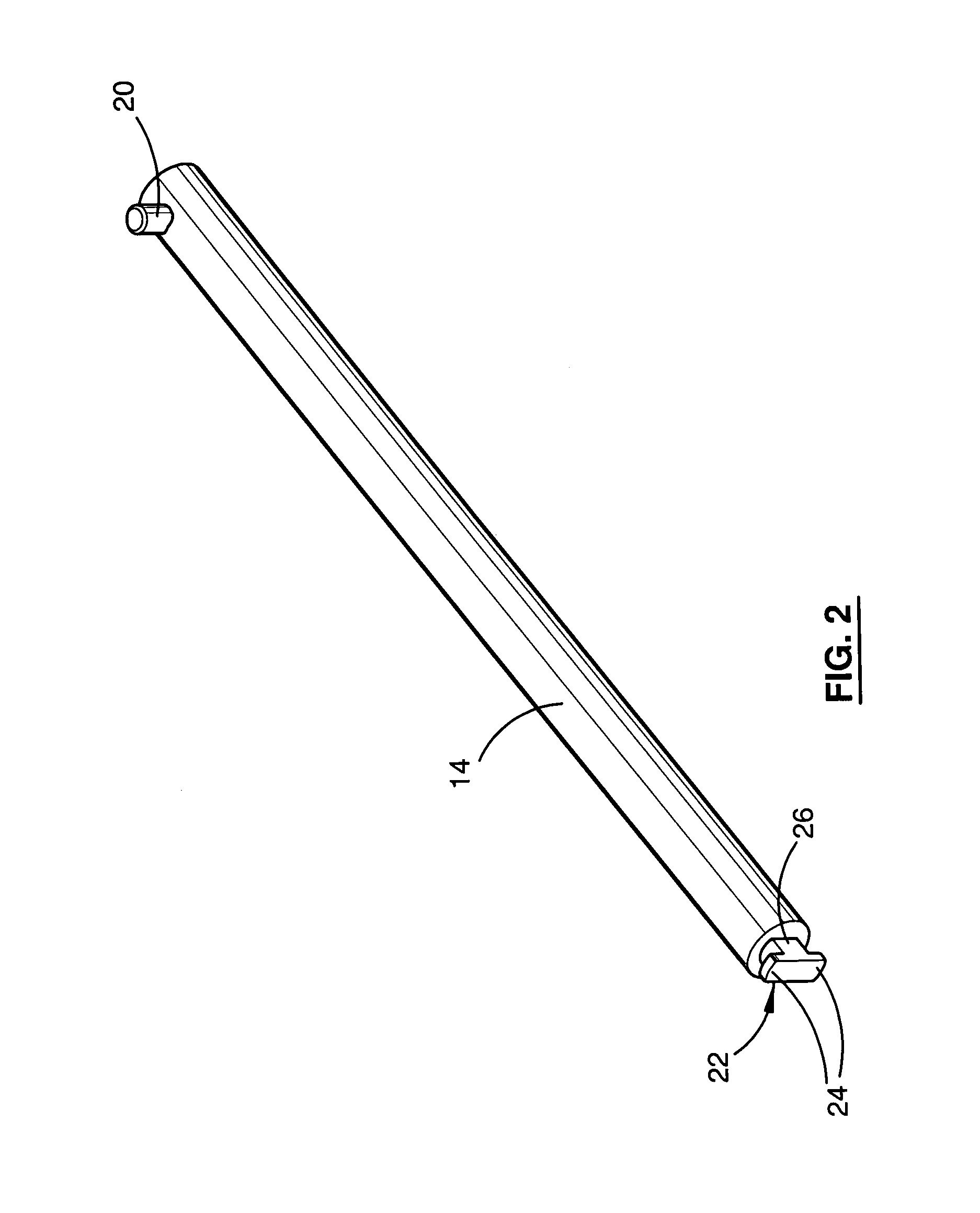

Receptacle for grinder tools

InactiveUS6869346B2Cost be sparAvoid reliabilityGrinding wheel securing apparatusSupport wheelsEngineeringAngle grinder

The invention is based on a tool receiver for a grinder, in particular for a handheld angle grinder (10), having a carrier device (12, 14, 16, 182, 184, 300), via which an application tool (18, 32, 186, 188) can be actively connected to a drive shaft (54).It is proposed that the application tool (18, 32, 186, 188) be actively connectable to the carrier device (14, 16, 182, 184) via at least one detent element (24, 26, 190, 192, 194, 196, 198, 200, 302) movable against a spring force that snaps into place in an operating position of the application tool (18, 32, 186, 188) and immobilizes the application tool (18, 32, 186, 188) with positive engagement.

Owner:ROBERT BOSCH GMBH +1

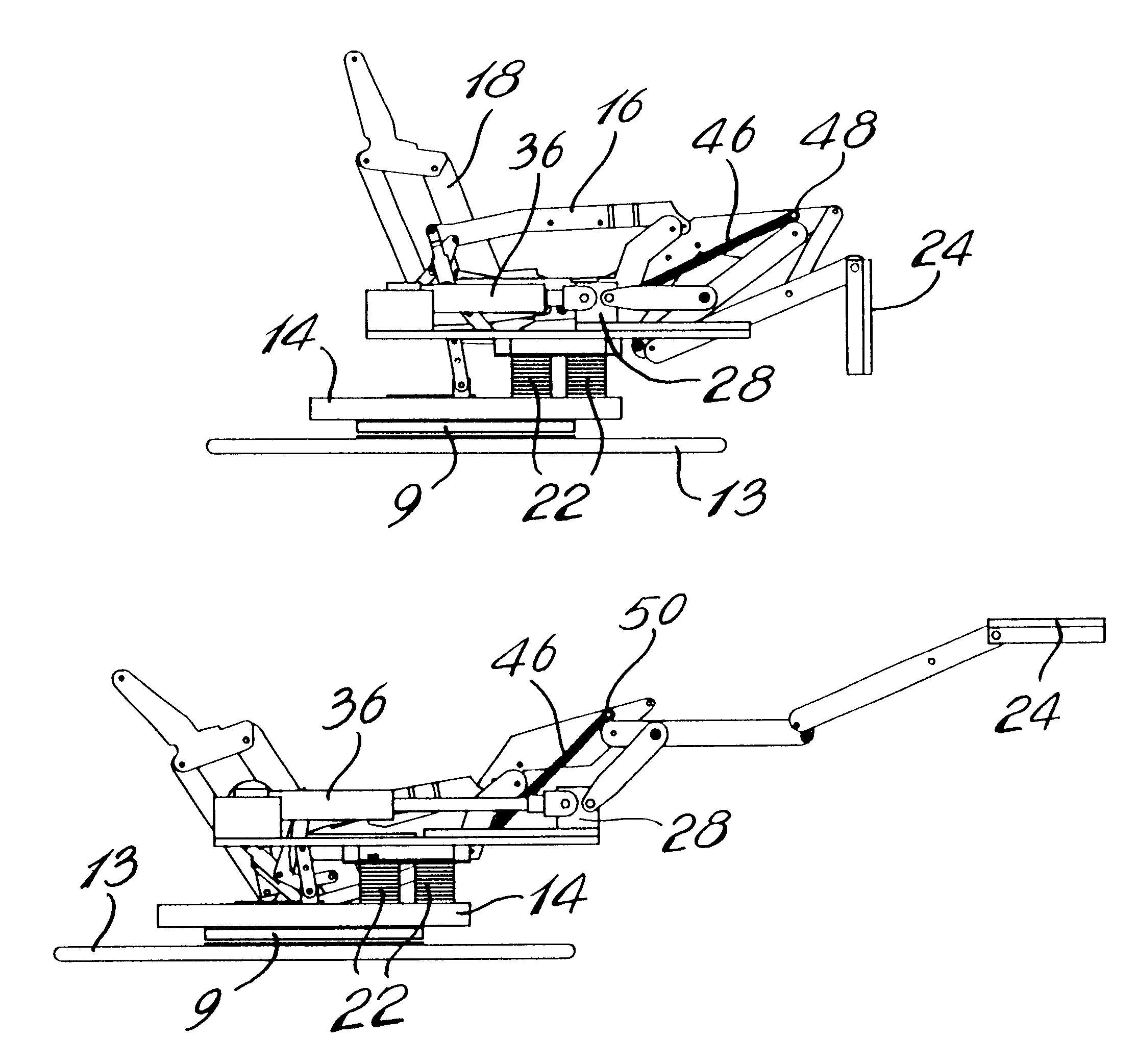

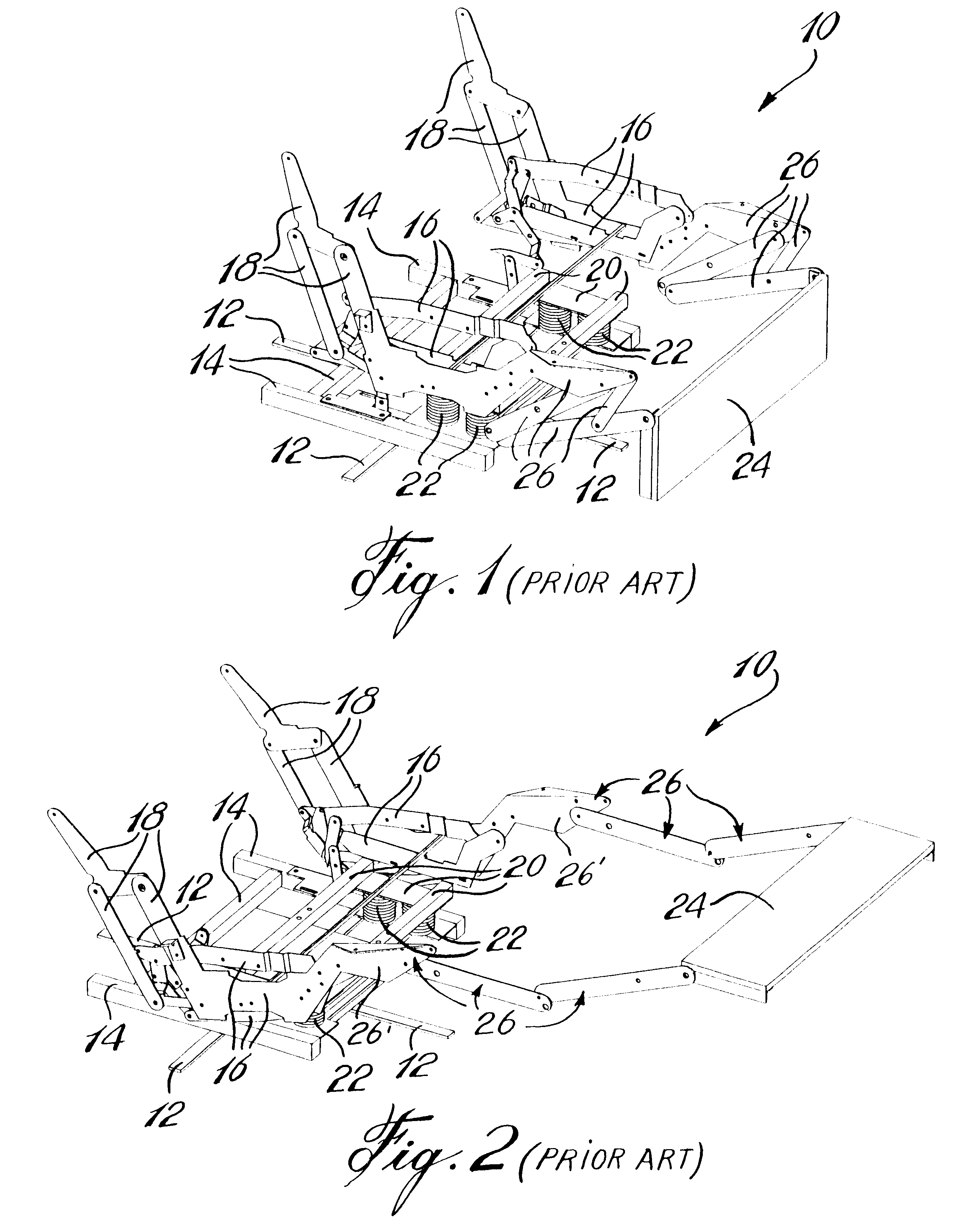

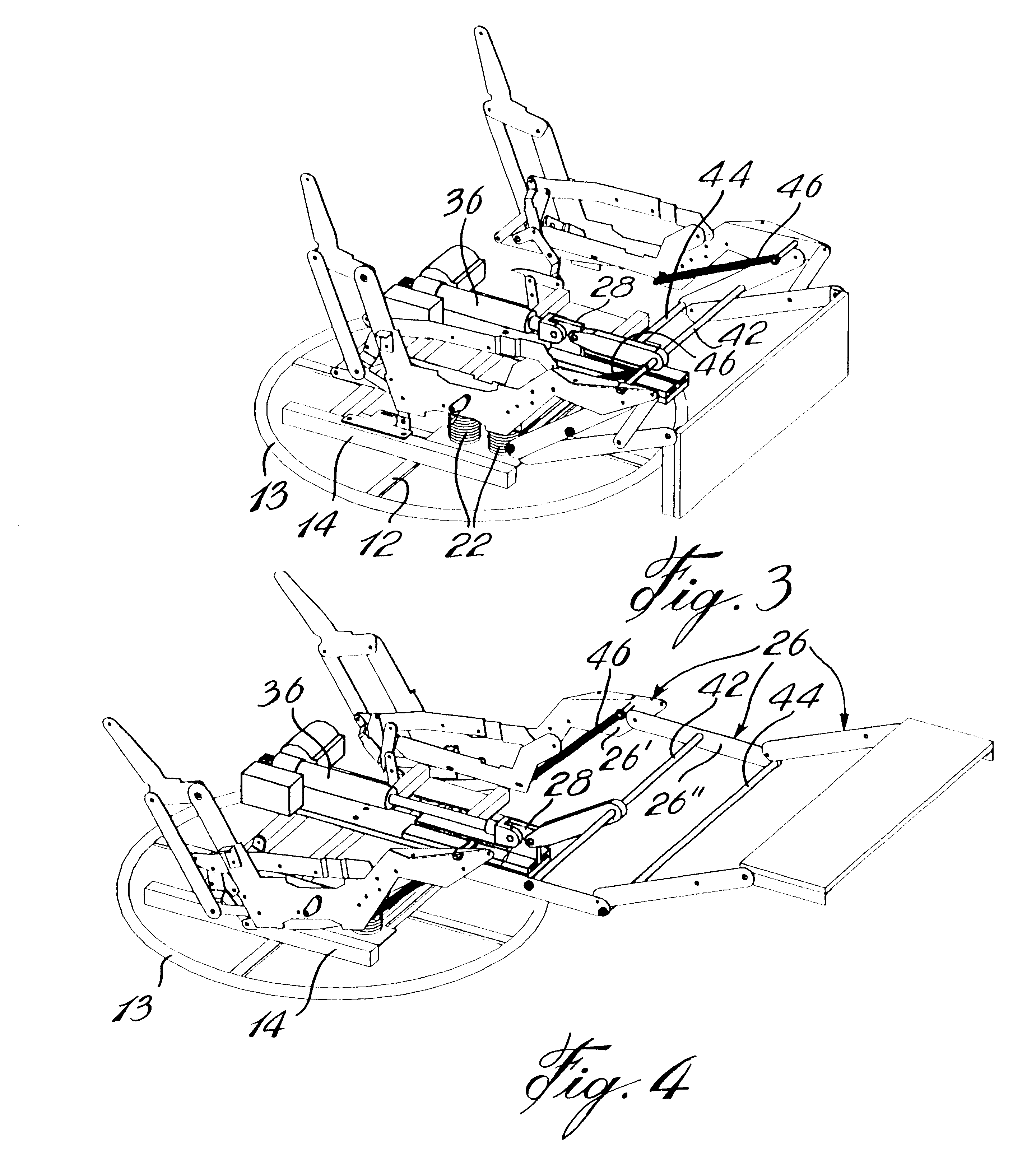

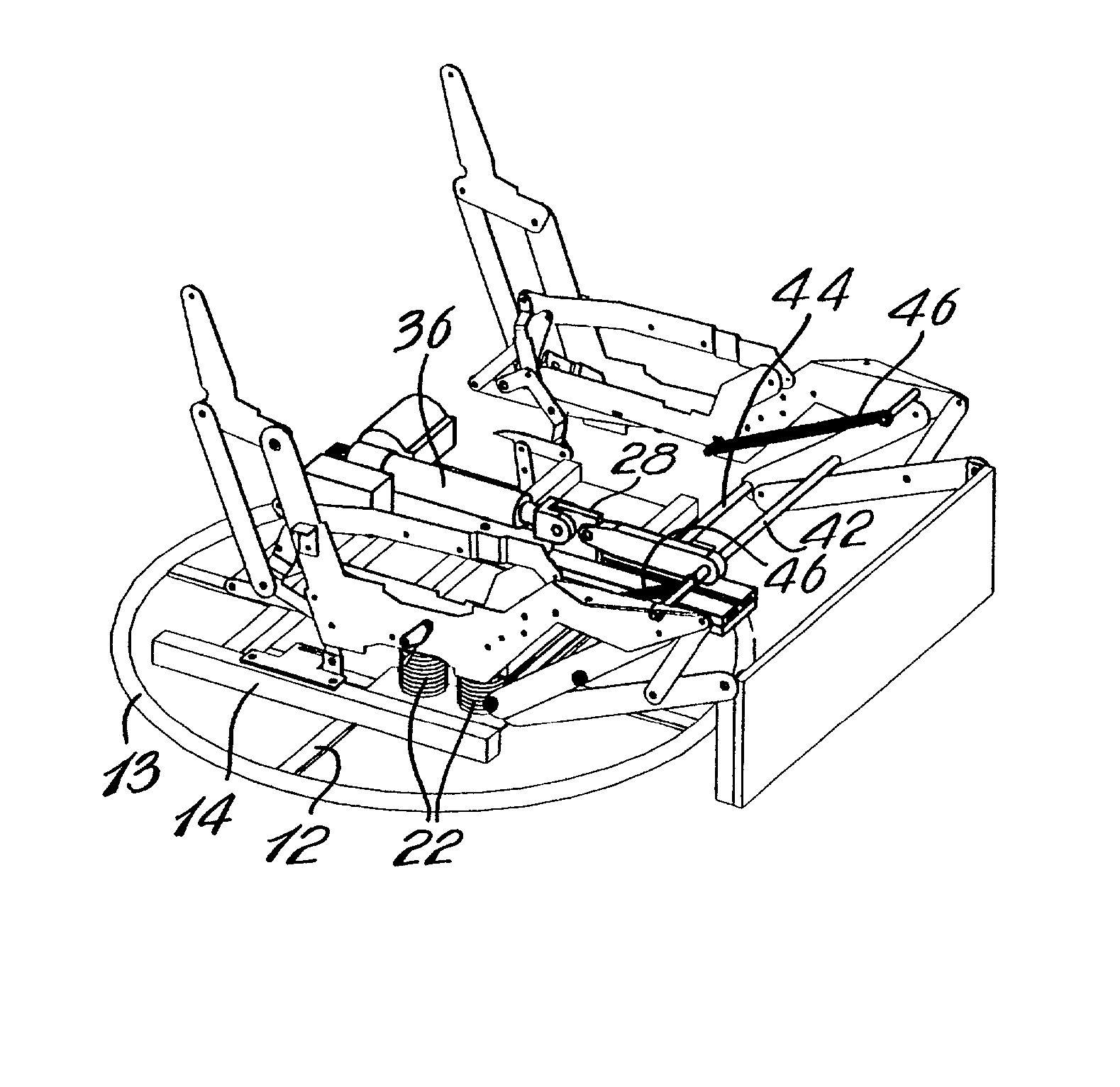

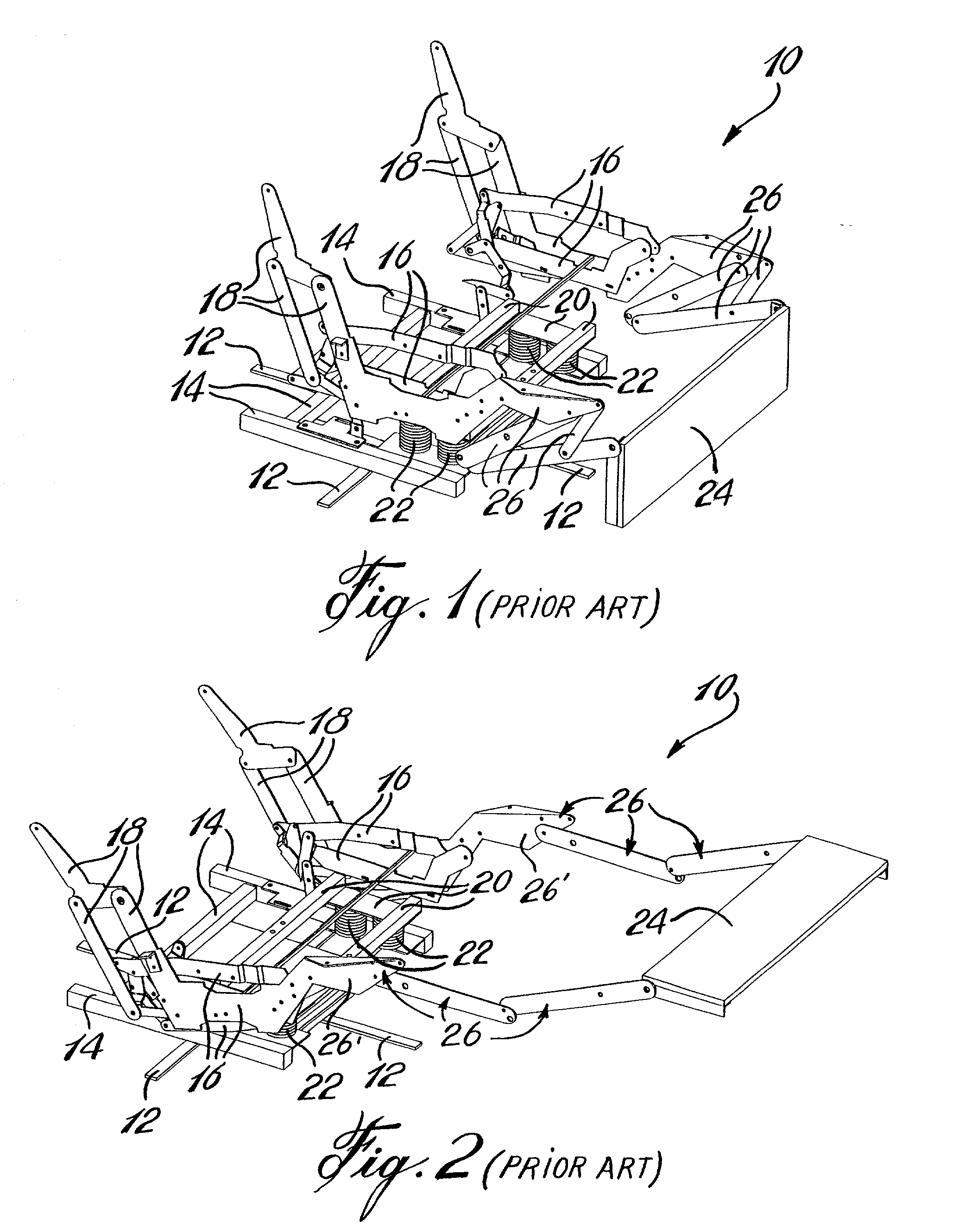

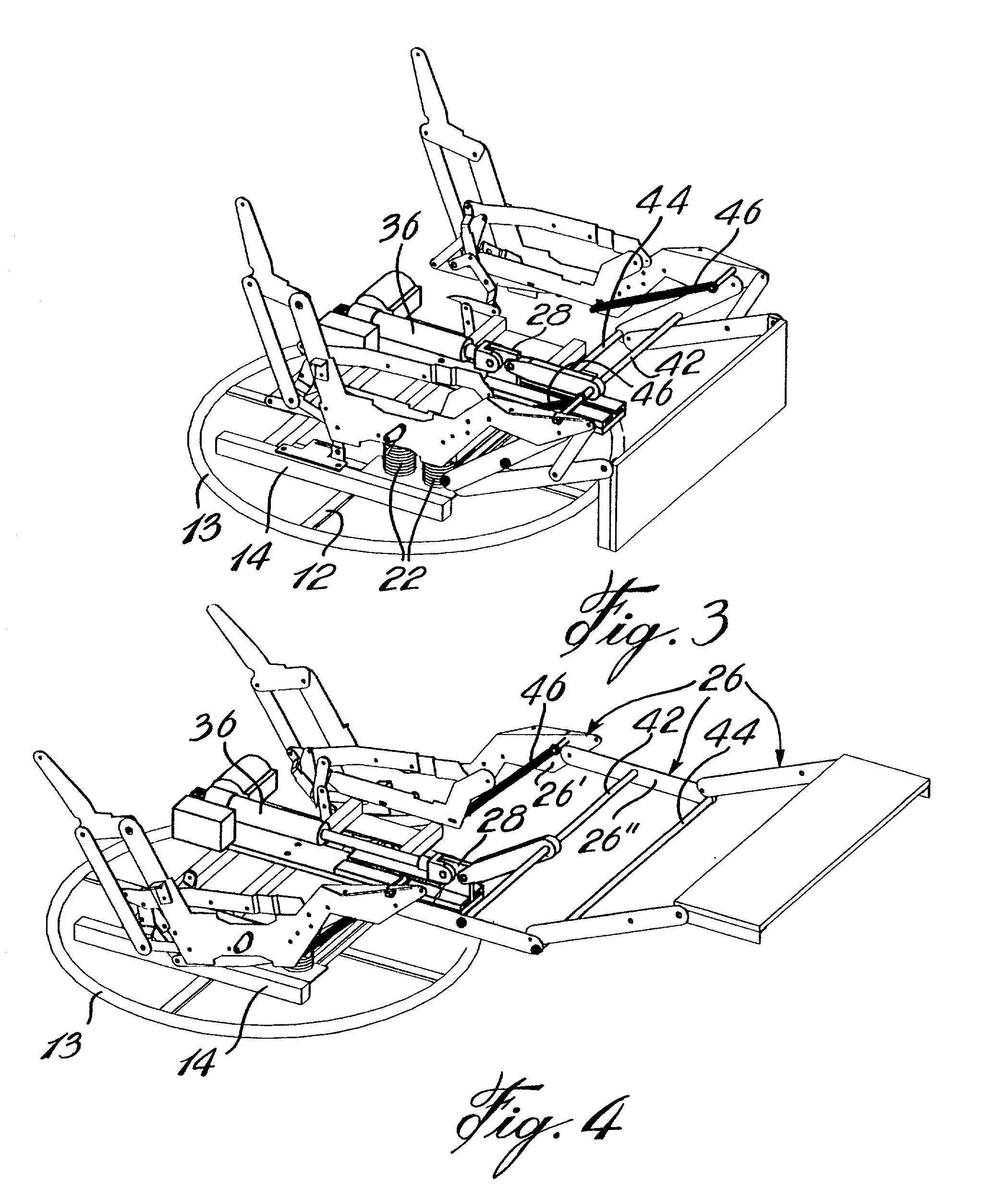

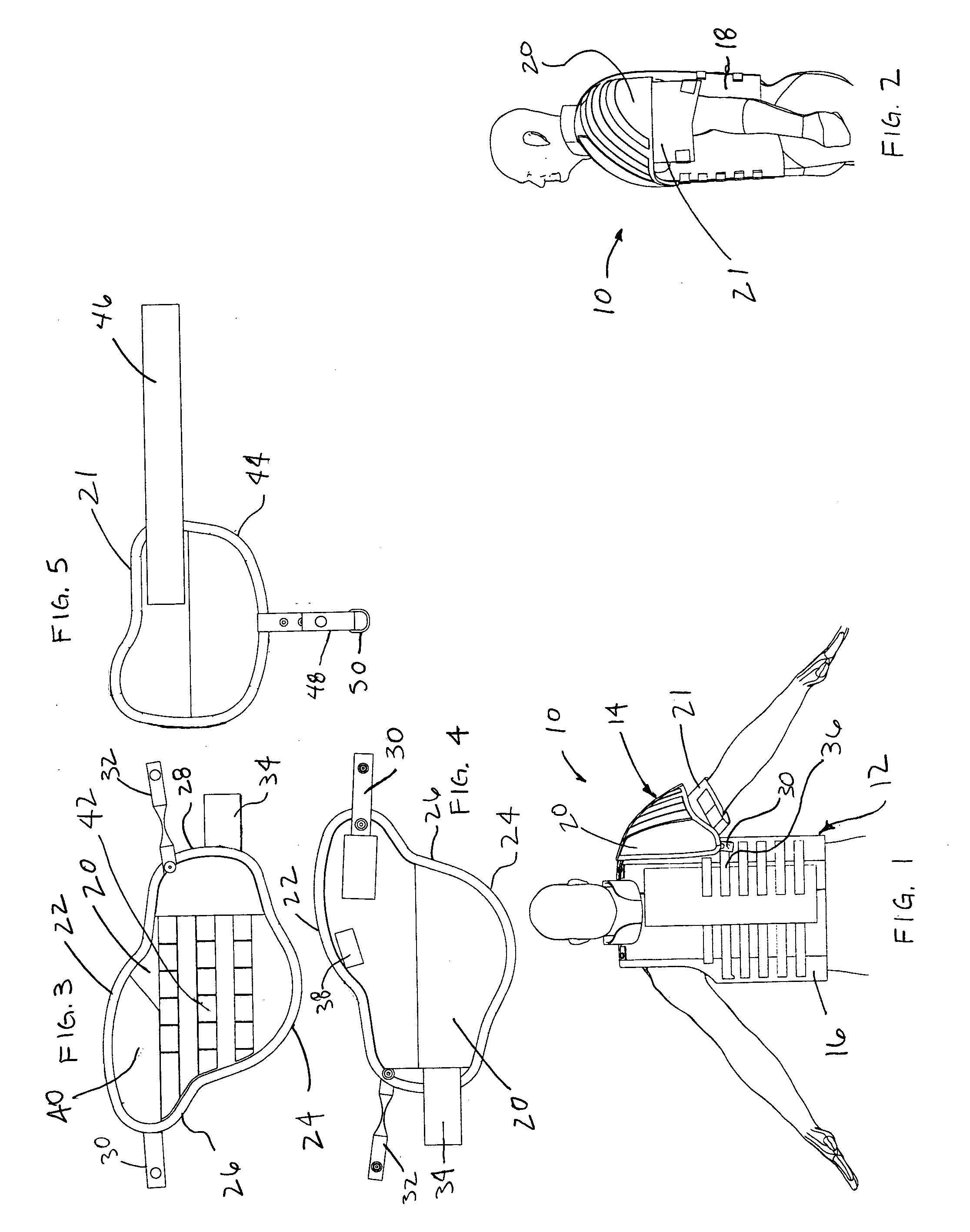

Reclining motorized multi-position chair with rocking and pivoting action

InactiveUS6659556B2Easy to modifyIncreases range of angular motionOperating chairsSofasEngineeringRestoring force

A tilt adjustment assembly for a motorized reclining chair having a base frame adapted for rest on a floor surface. A seat and a back articulated support linkage are interconnected together for displacement of a seat and back of a reclining chair. An intermediate frame is mounted on the base frame through spring attachments, whereby to impart a rocking motion to the chair. A pair of foot rest linkages interconnect each of two of the said seat articulated support linkages to a foot rest plate. The tilt adjustment assembly comprises a motor-operated actuating rod secured at a free end to a sliding member to guidingly displace that member along a straight axis in a fixed plane and to any desired position along the axis. A pivotal link arm is pivotally secured at one end of the sliding member. A transverse linkage securing rod is secured to a second end of the pivotal link arm and extends transversely thereto. The transverse securing rod has opposed ends pivotally connected to an intermediate link arm of a respective one of the pair of foot rest linkages. Tensioning springs are secured to each of the pair of foot rest linkages for applying a restoring force to the foot rest to a retracted position.

Owner:PELLERIN RENE

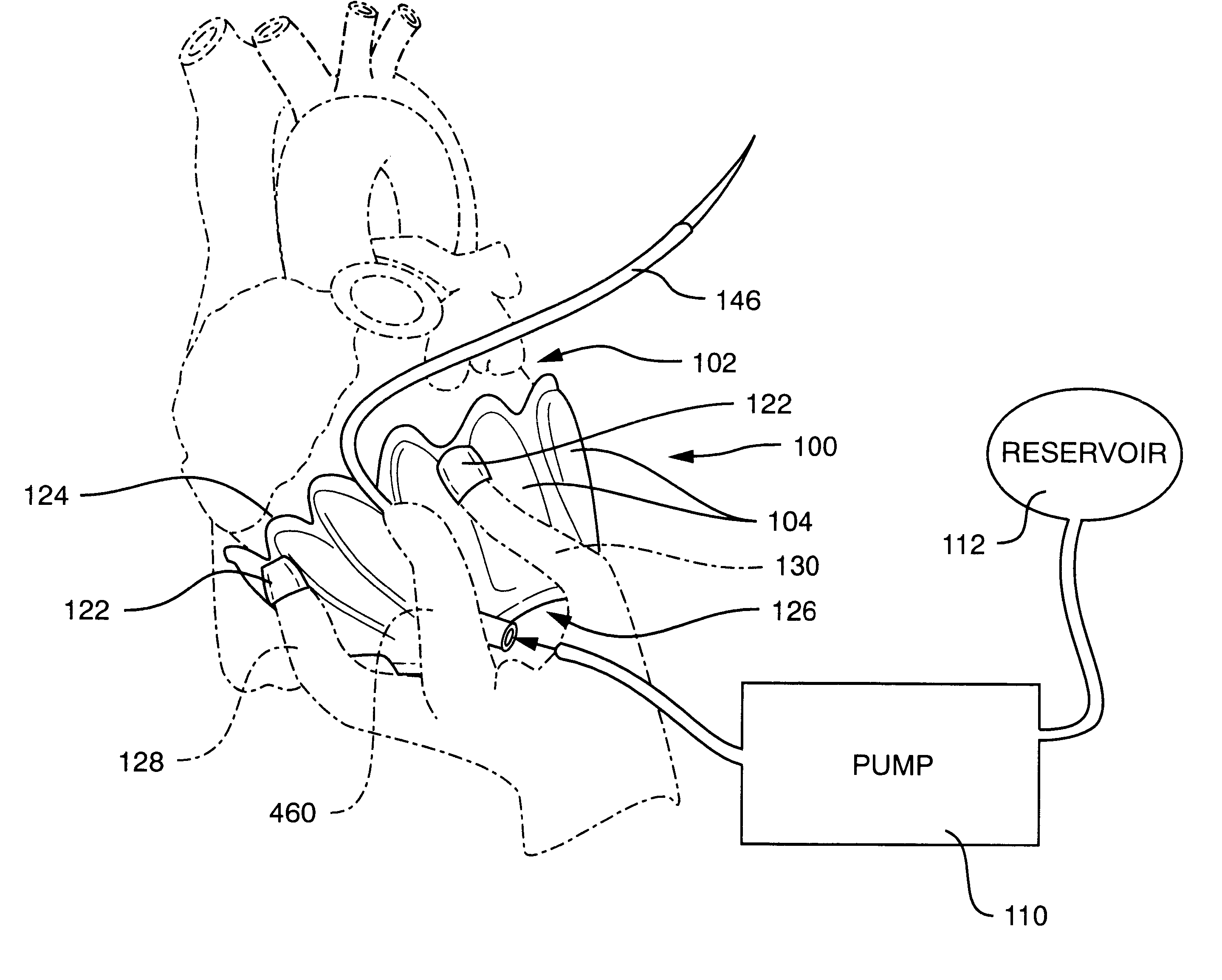

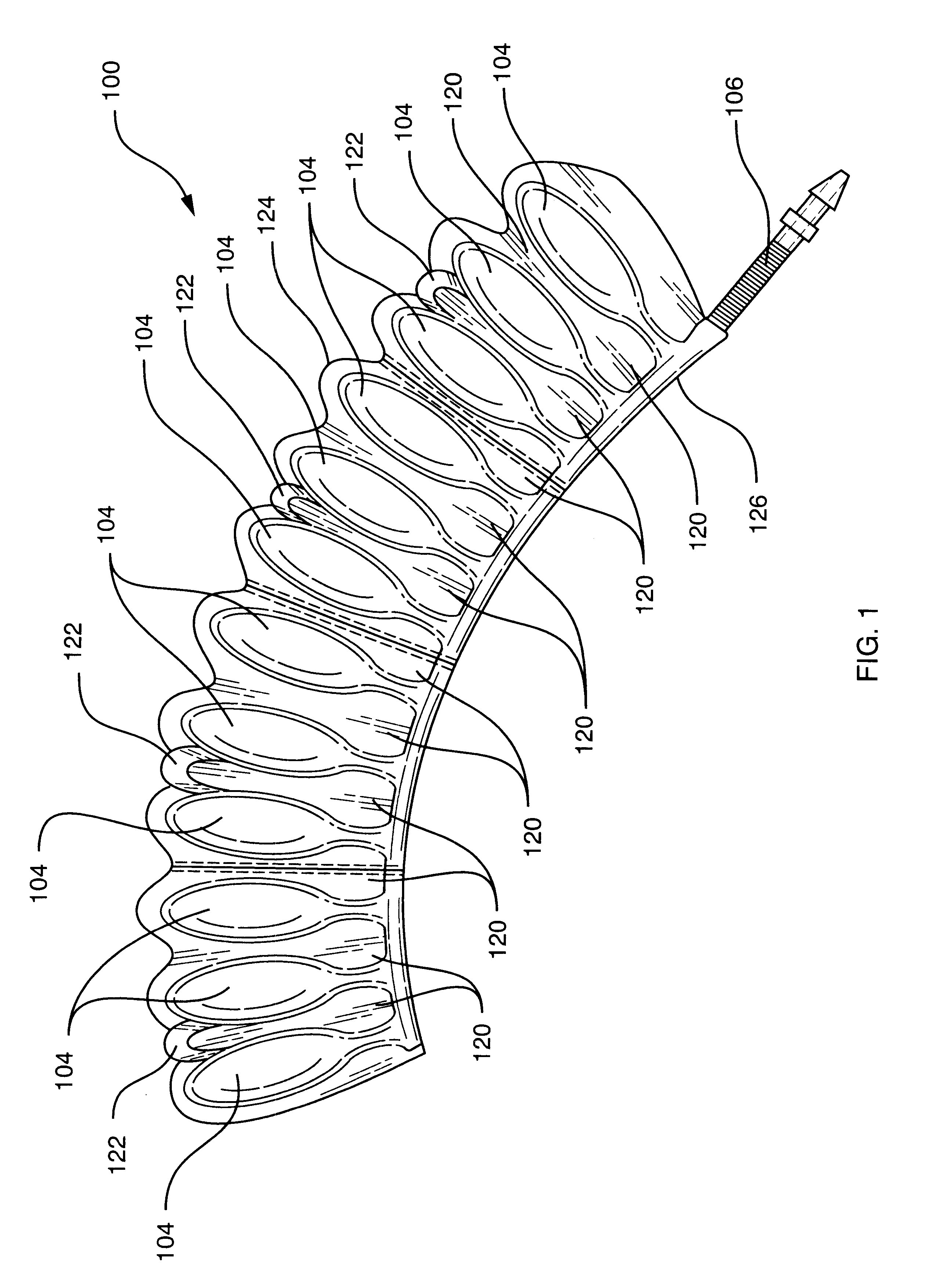

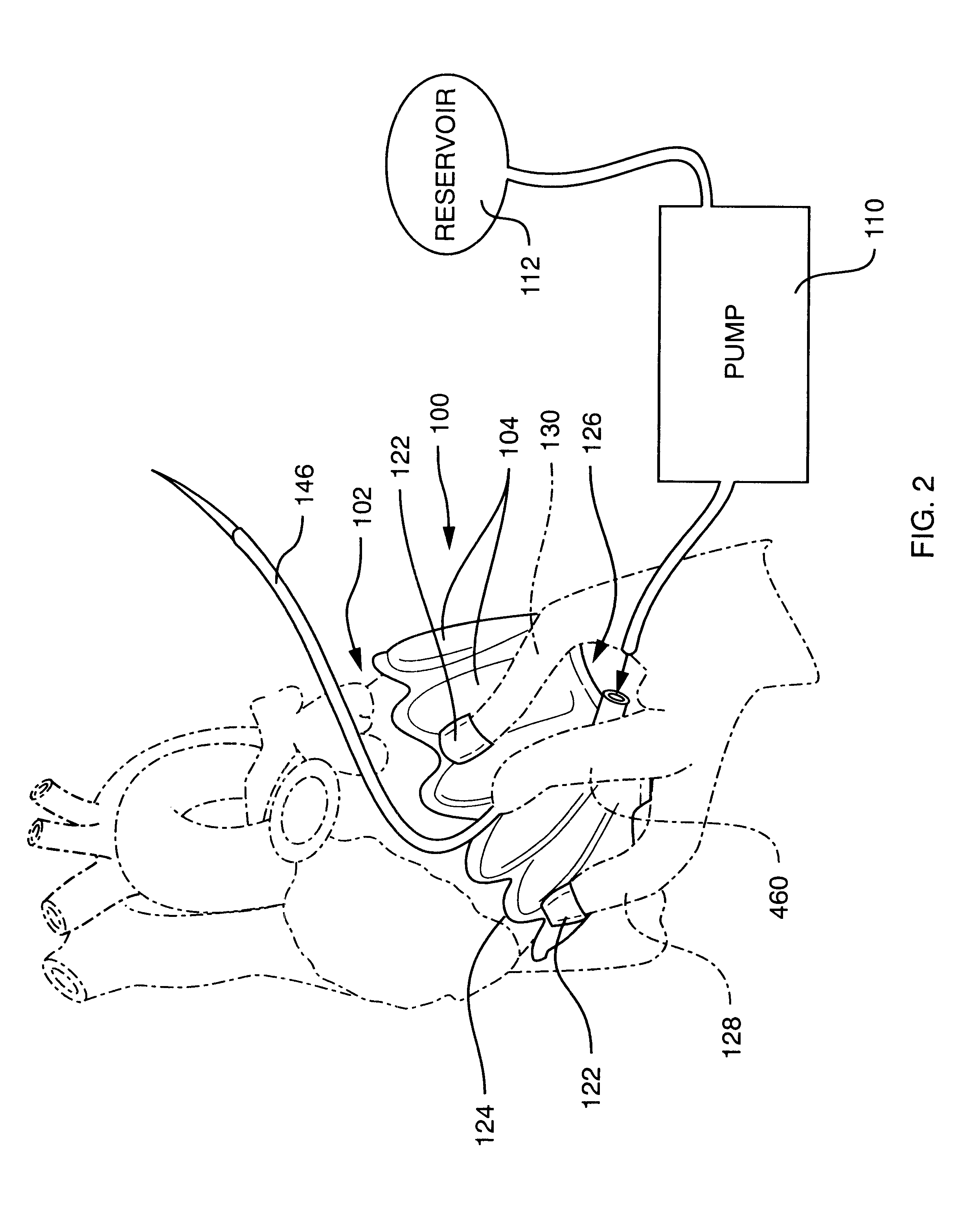

System and method for implanting a cardiac wrap

A system and method for implanting a wrap on a patient's heart or other organ provides a wrap having finger-engagement members typically defining loops that encompass all or a substantial portion of the fingers of a surgeon's treatment hand. The loops retain the fingers to the wrap during implant, and enable the fingers to be detached after the procedure is complete. The loops can be detachable from the wrap after the procedure is completed or can be formed to remain with the wrap.

Owner:ABIOMED

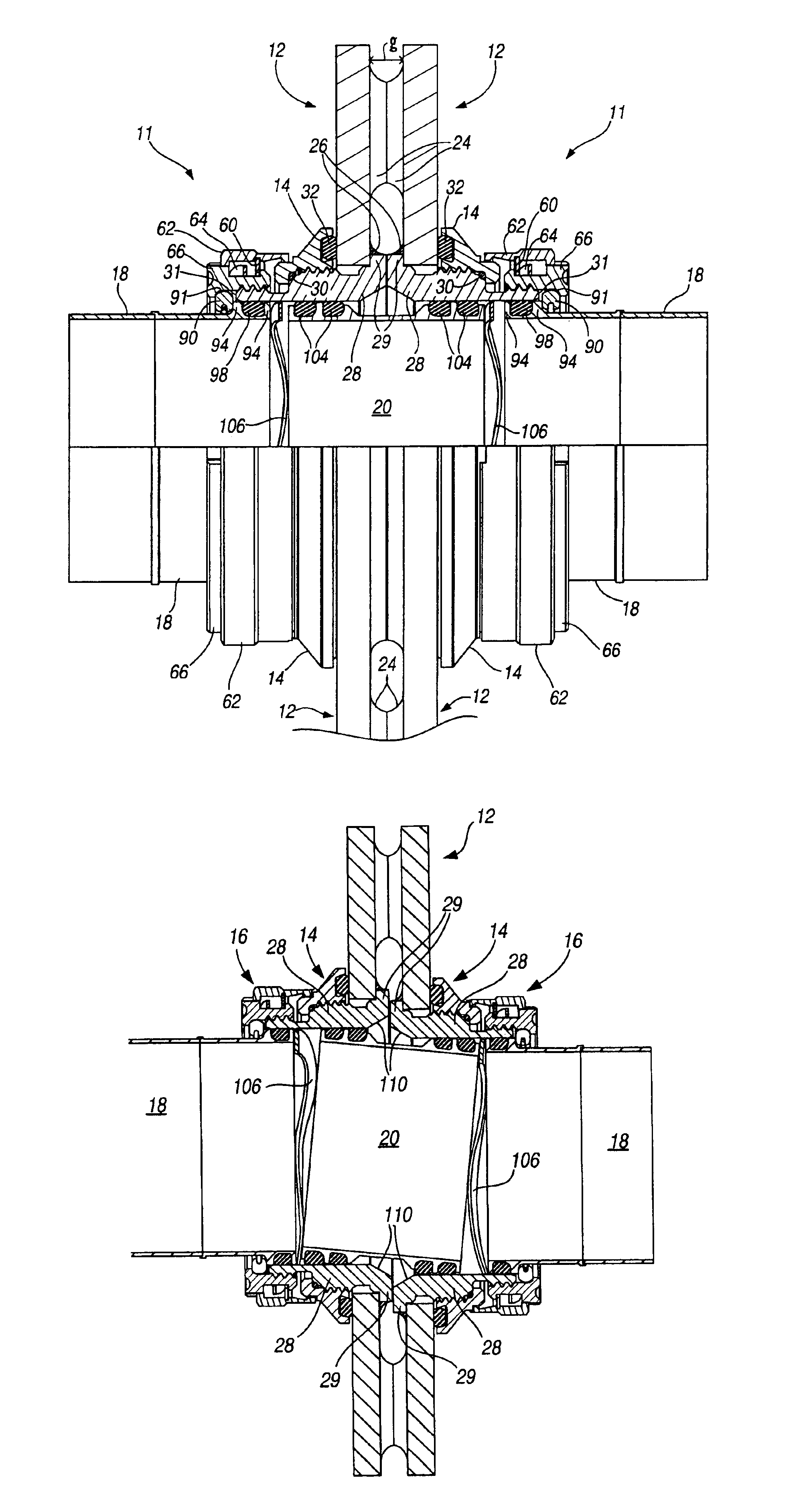

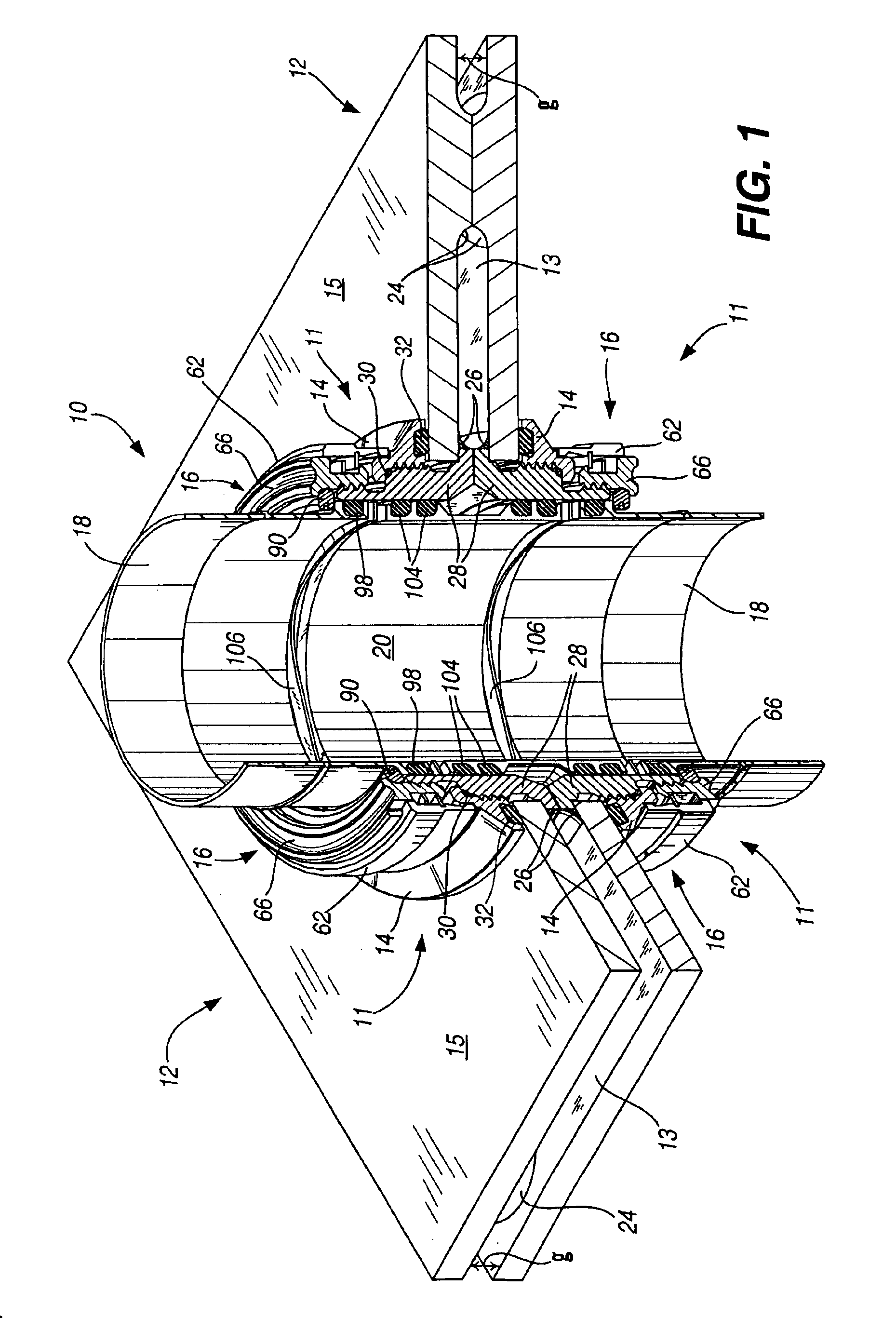

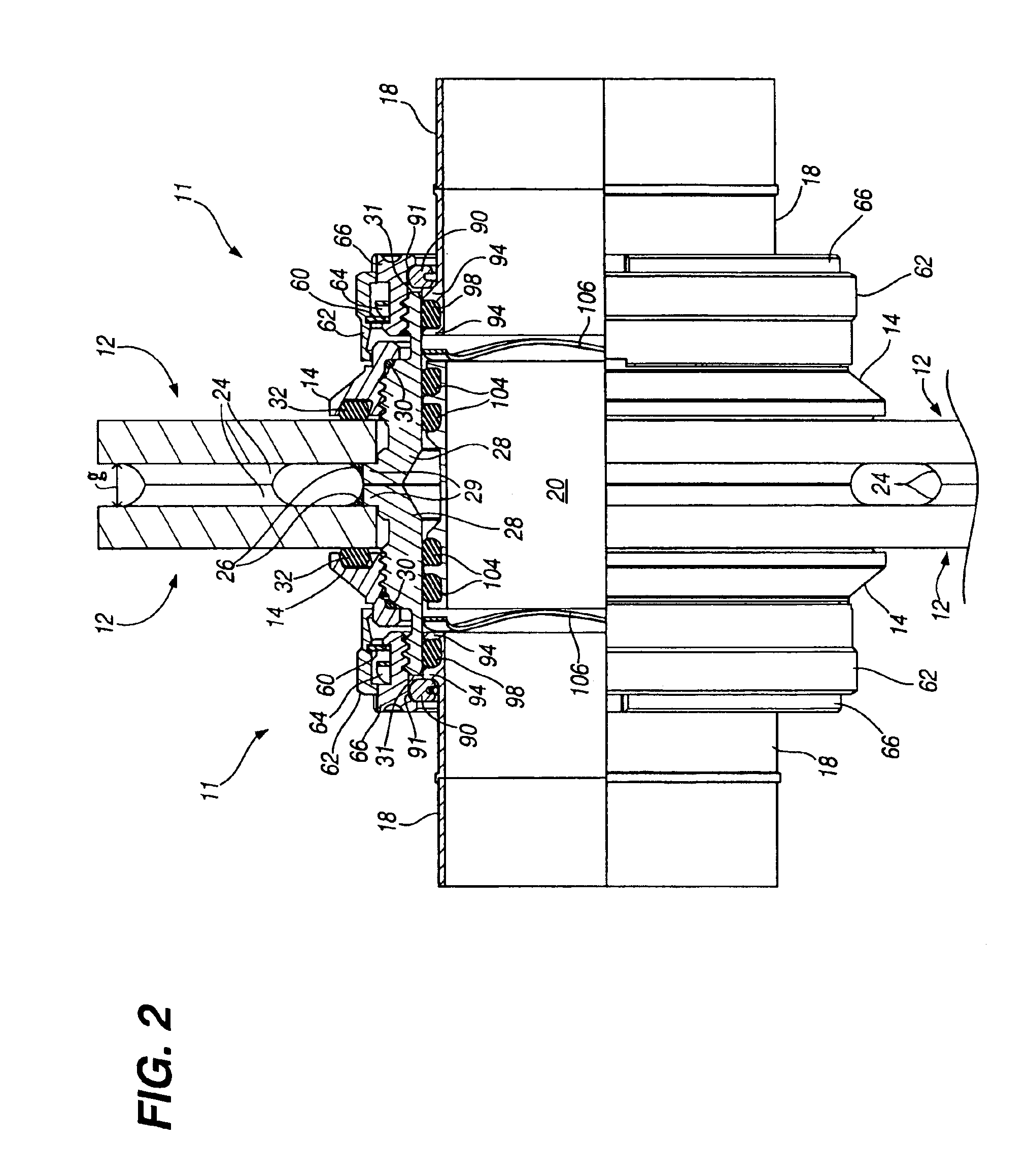

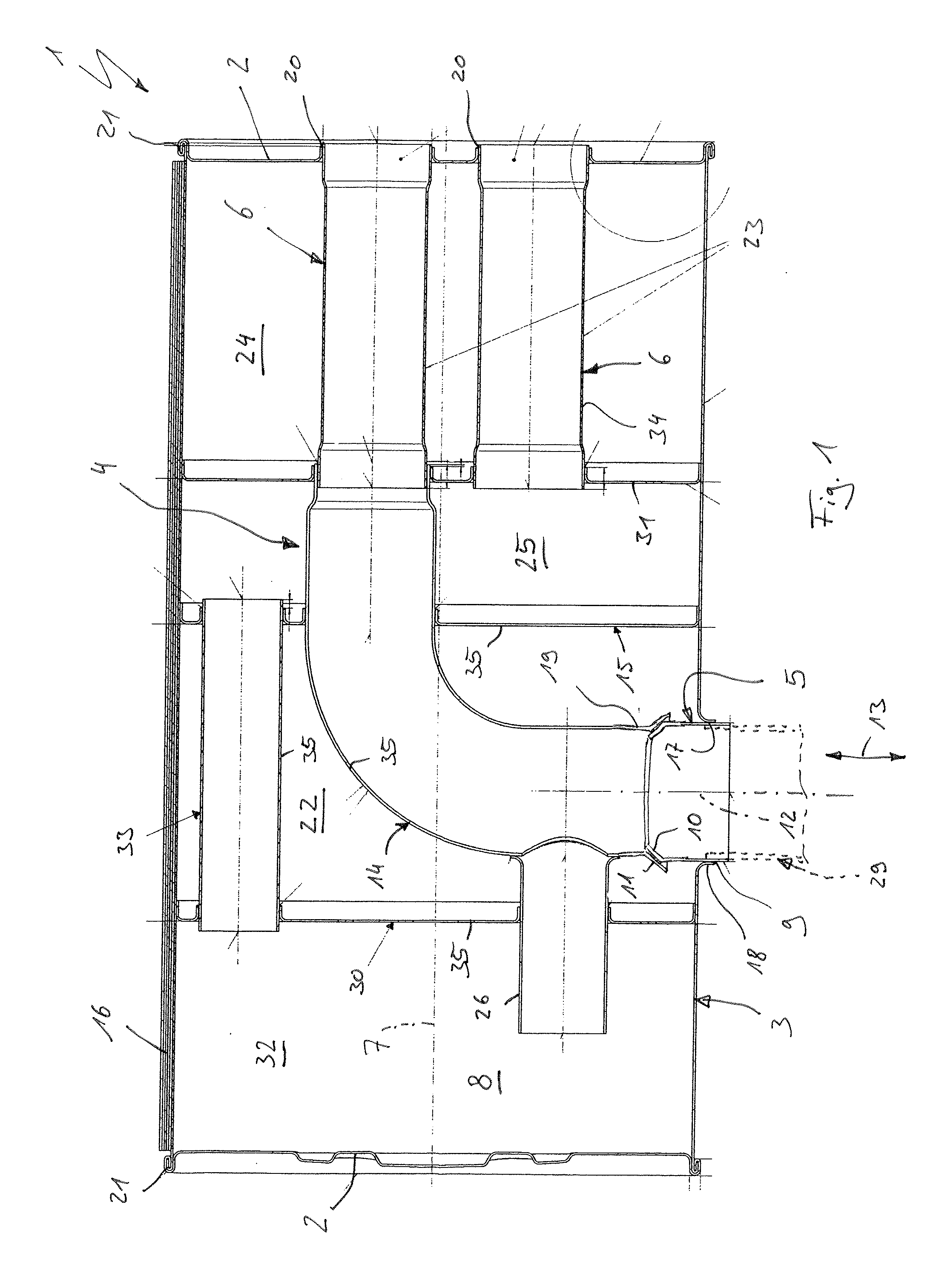

Positive locking fitting assembly

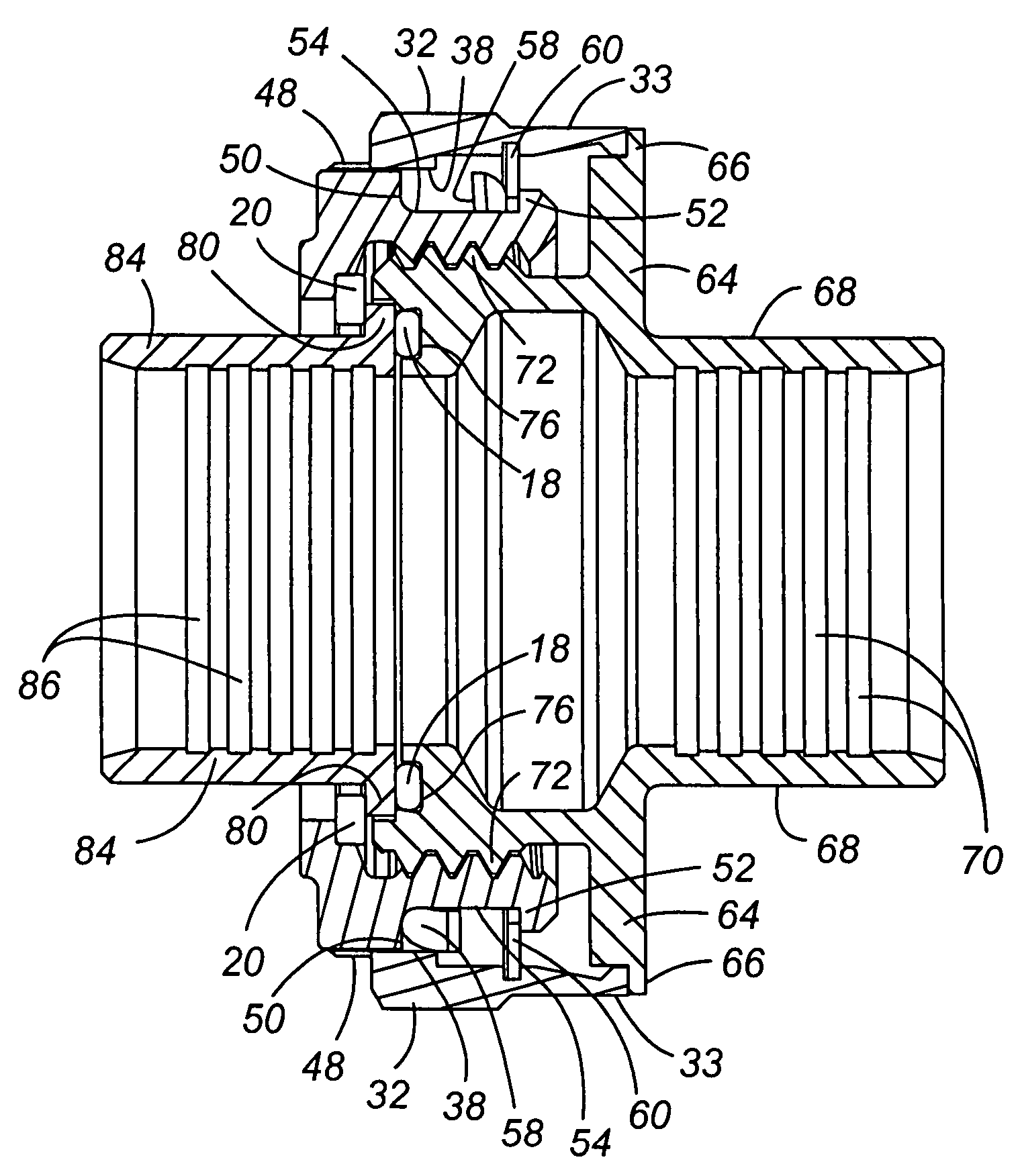

A positive locking fitting assembly is provided for interconnecting two adjacent structures, such as two modular components of an aircraft. The fitting assembly includes a pair of couplers which attach to the respective modular components, and a transfer tube which interconnects the couplers. Each coupler has a positive locking feature which prevents inadvertent uncoupling during operation. A plurality of redundant seals are incorporated throughout the construction of the fitting assembly which ensures a leak proof relationship not only between the joined pair of modular components, but also through the structure of the elements of the fitting assembly itself.

Owner:EATON INTELLIGENT POWER LIMITED

Reclining motorized multi-position chair with rocking and pivoting action

InactiveUS20030047973A1Simplify linkageIncrease rangeOperating chairsSofasEngineeringReclining chair

A tilt adjustment assembly for a motorized reclining chair having a base frame adapted for rest on a floor surface. A seat and a back articulated support linkage are interconnected together for displacement of a seat and back of a reclining chair. An intermediate frame is mounted on the base frame through spring attachments, whereby to impart a rocking motion to the chair. A pair of foot rest linkages interconnect each of two of the said seat articulated support linkages to a foot rest plate. The tilt adjustment assembly comprises a motor-operated actuating rod secured at a free end to a sliding member to guidingly displace that member along a straight axis in a fixed plane and to any desired position along the axis. A pivotal link arm is pivotally secured at one end of the sliding member. A transverse linkage securing rod is secured to a second end of the pivotal link arm and extends transversely thereto. The transverse securing rod has opposed ends pivotally connected to an intermediate link arm of a respective one of the pair of foot rest linkages. Tensioning springs are secured to each of the pair of foot rest linkages for applying a restoring force to the foot rest to a retracted position.

Owner:PELLERIN RENE

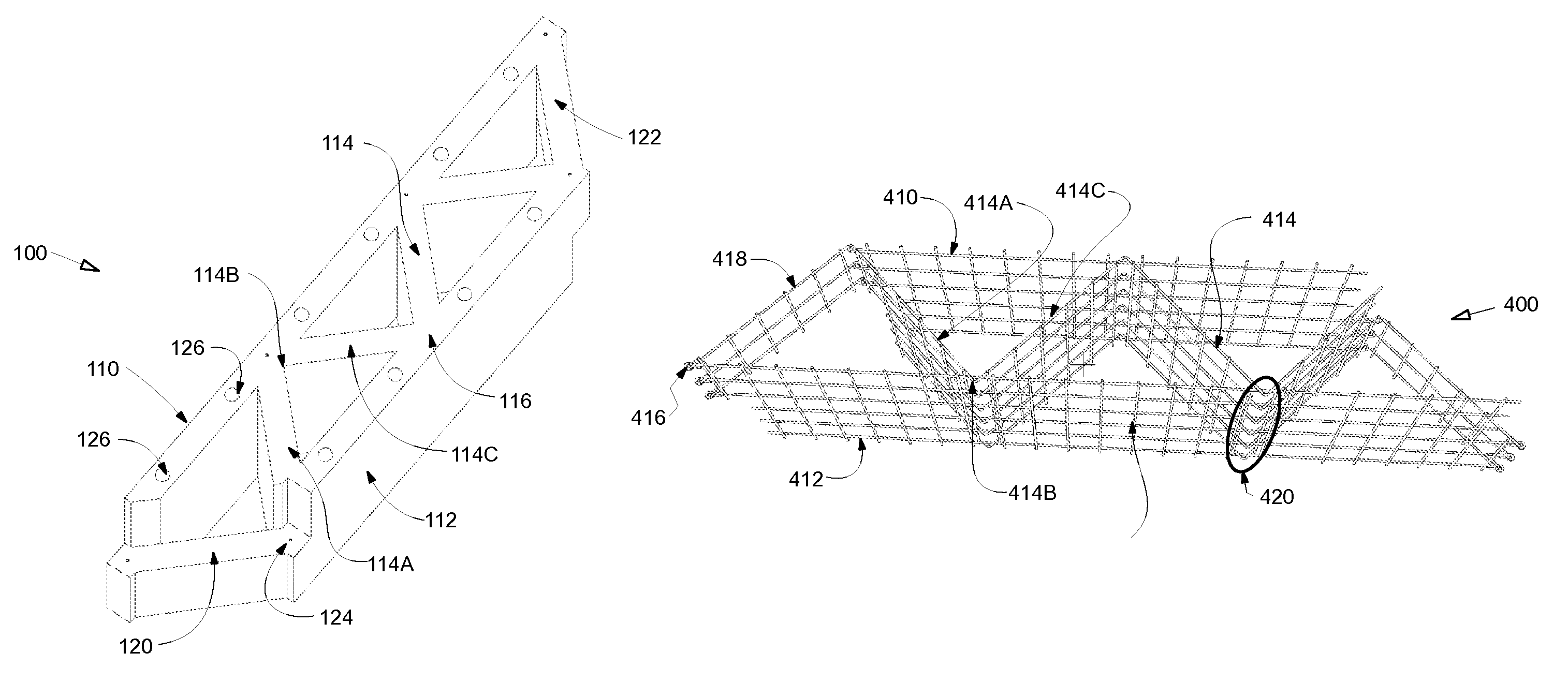

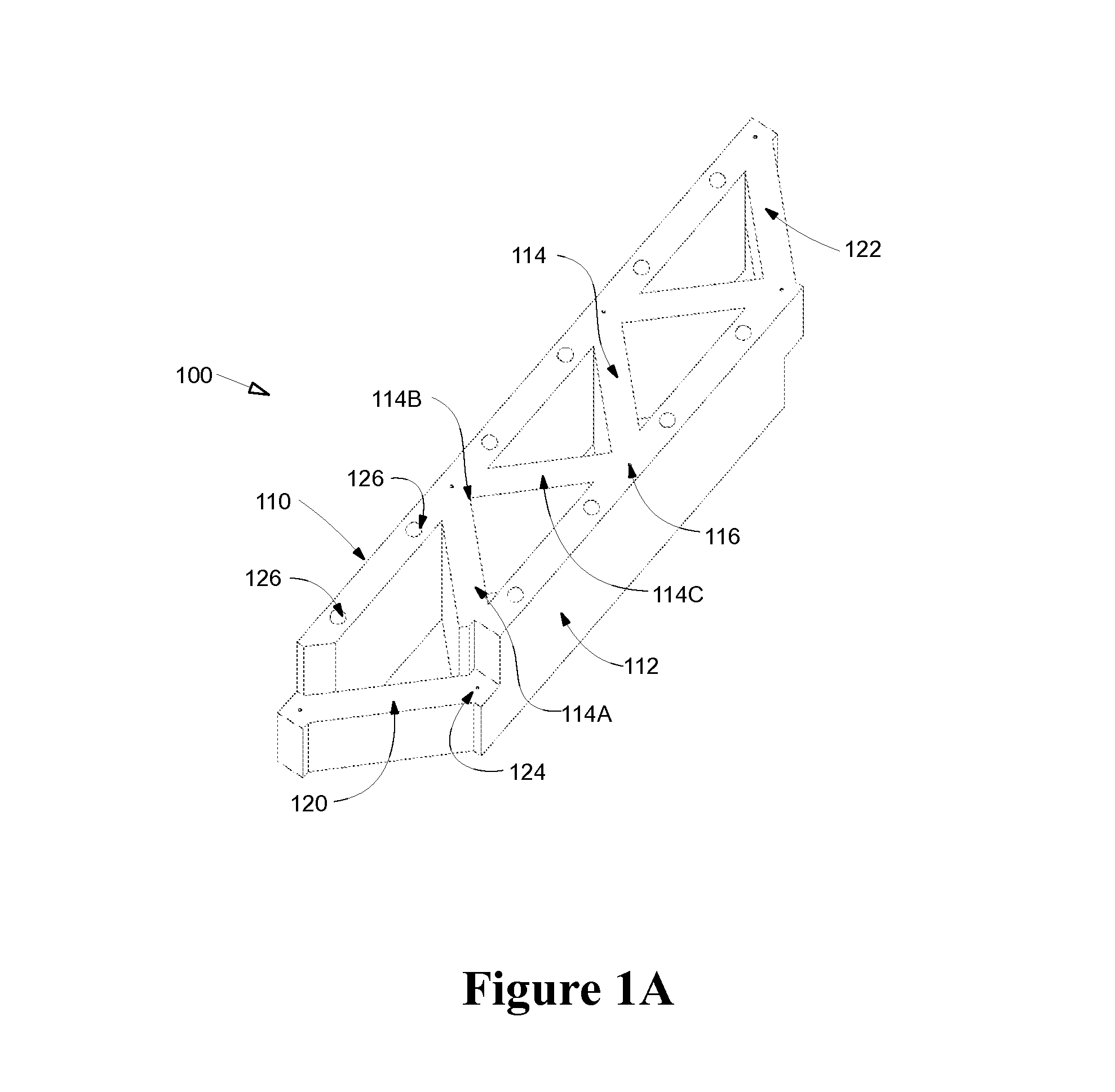

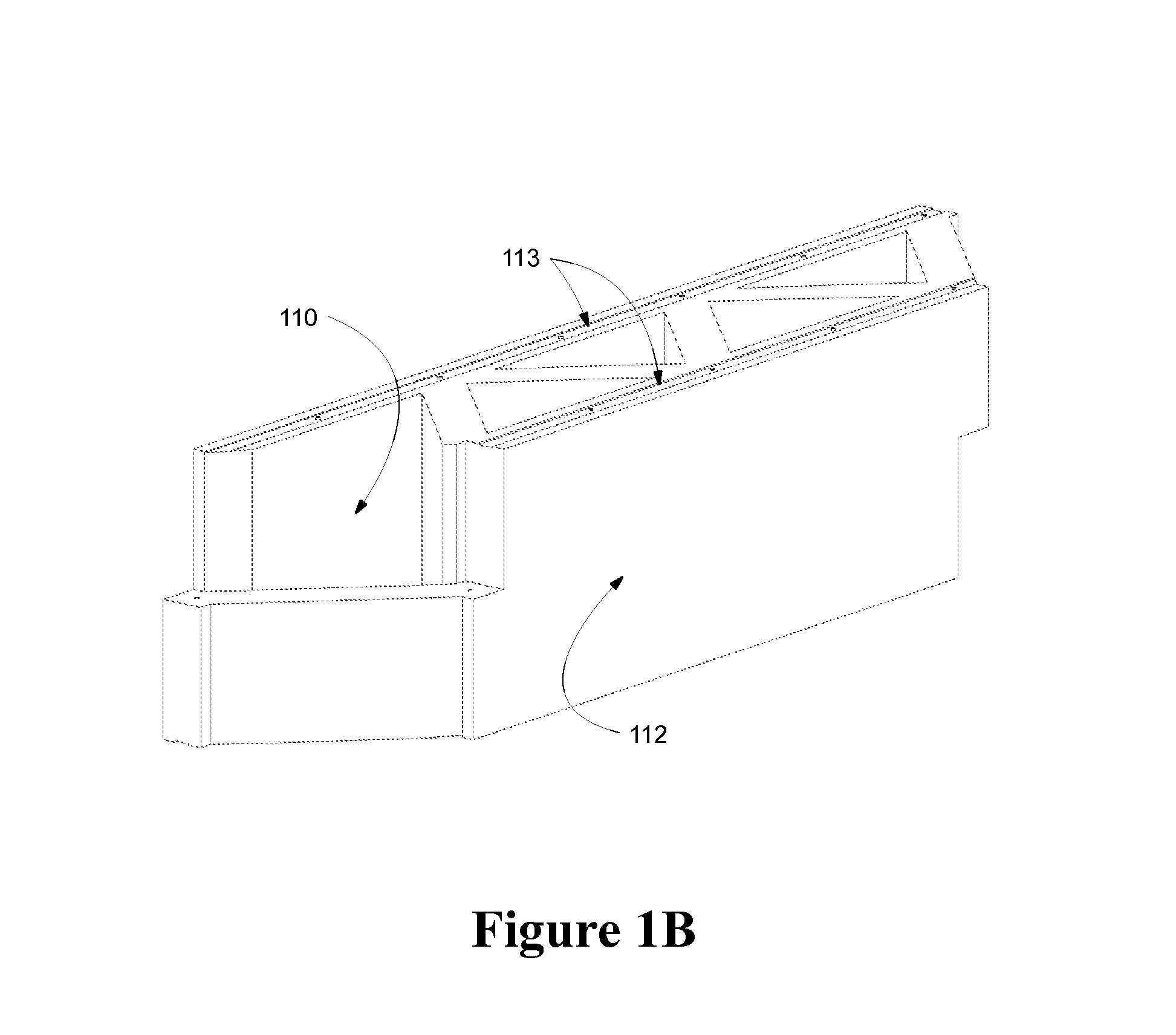

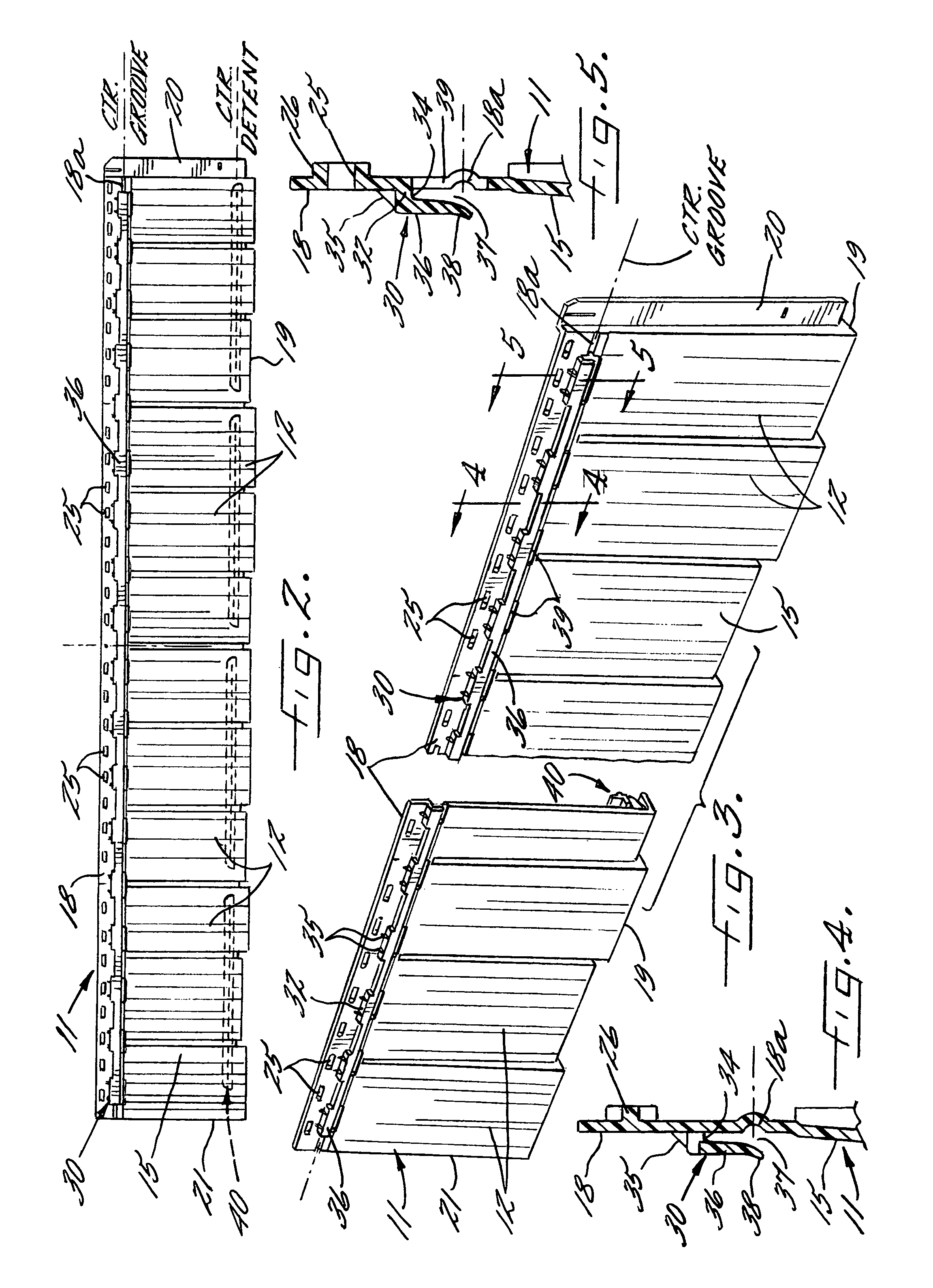

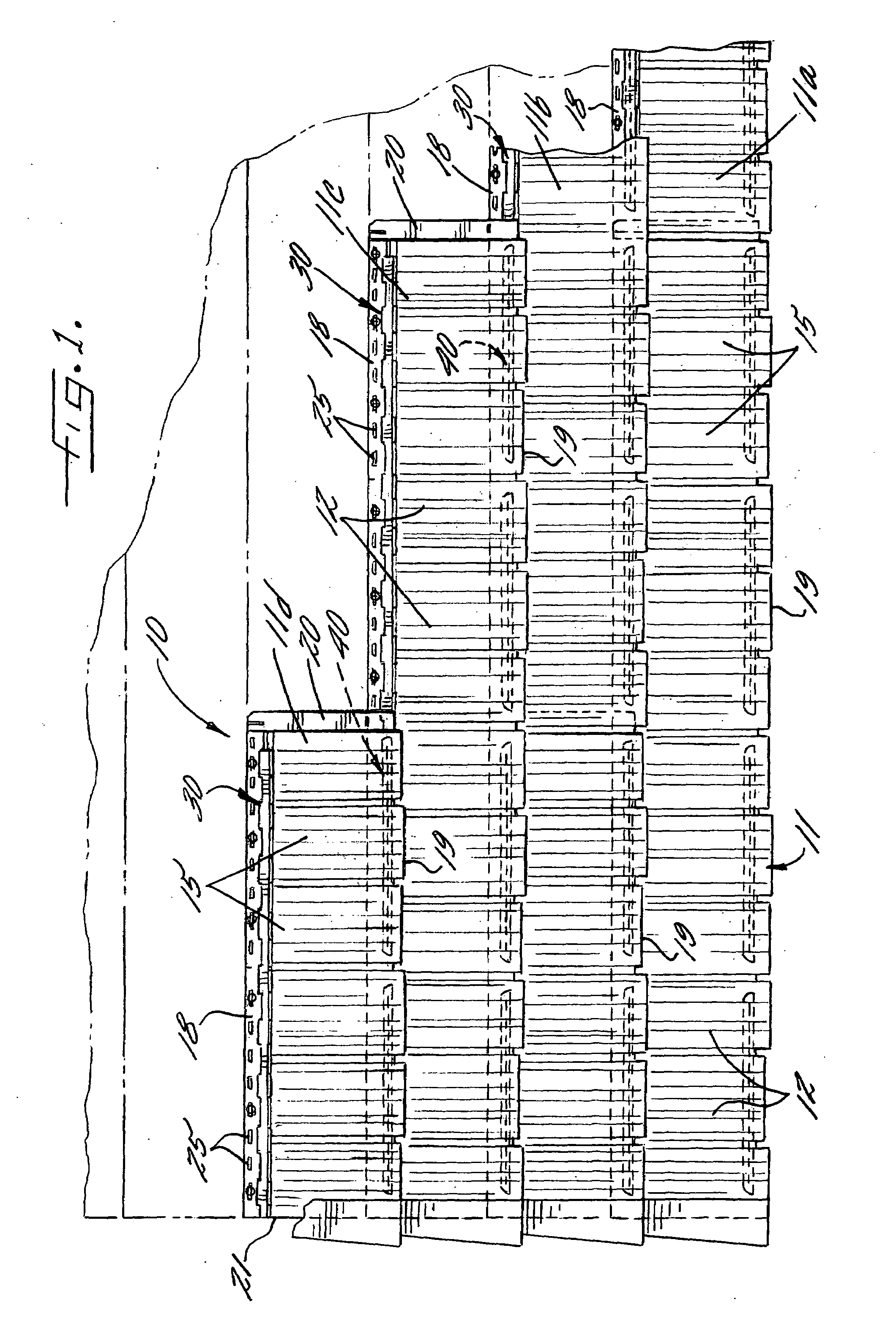

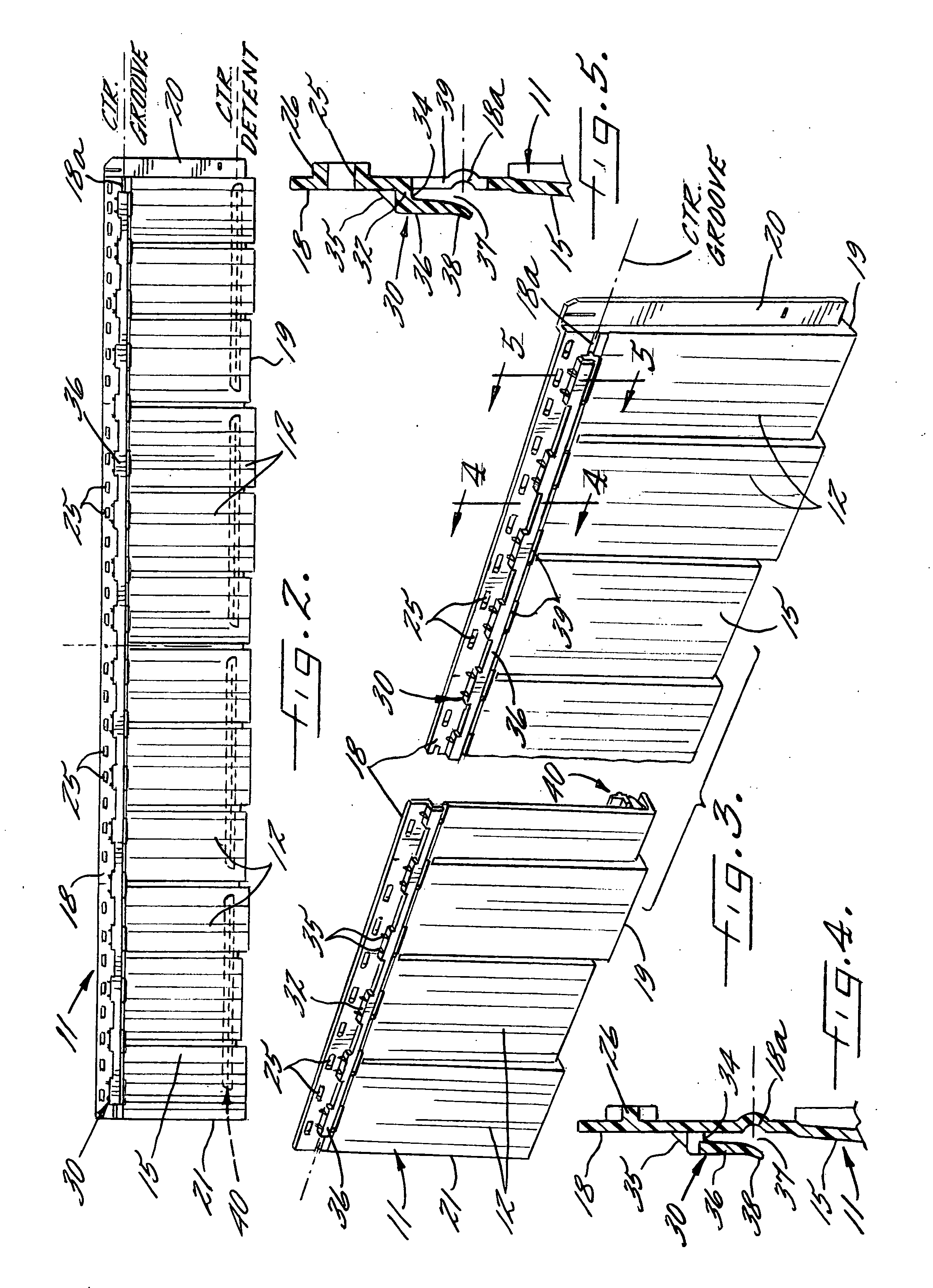

Modular building block building system

InactiveUS8646239B2Positive engagementQuality improvementStrutsConstruction materialMechanical engineeringWire mesh

A system and method for constructing and using modular building blocks. The blocks may include two walls, a course, end conditions, a reinforcing assembly, and vertical and lateral retaining members. The walls may include lateral supports disposed lengthwise on a top and a bottom surface. Lateral retainer members may be disposed into the lateral supports. The walls may also include channels extending from the top surface to the bottom surface. Vertical retainer members may be disposed into the channels. The course may be disposed between and coupled to the walls and characterized by one or more turns. The reinforcing assembly may be set inside the walls and the course. The reinforcing assembly may include wire mesh portions disposed to form interlocks, where the interlocks provide structural support for the channels. The modular building blocks may be coupled together with structurally complimentary end conditions.

Owner:RULON JOHN DAVID

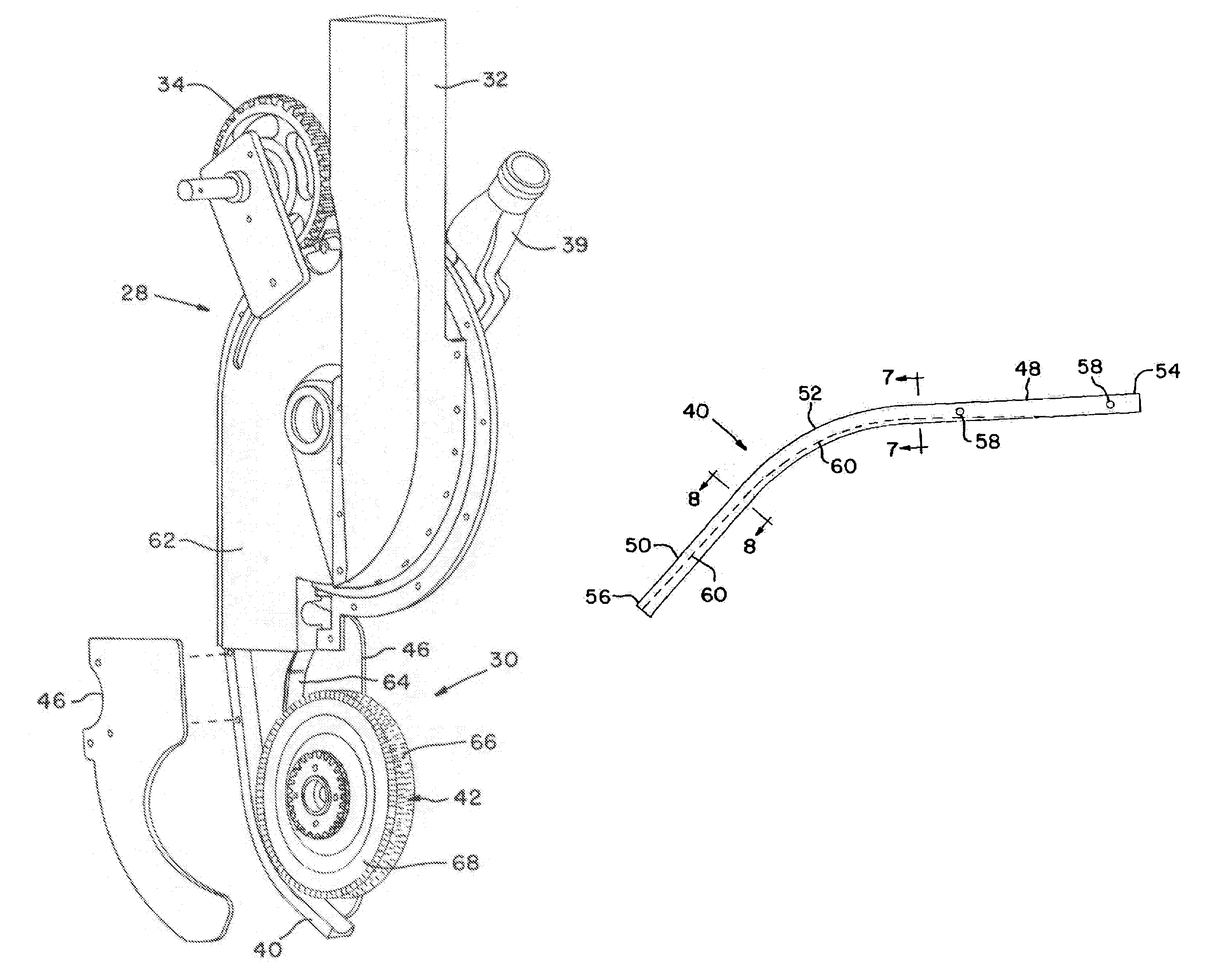

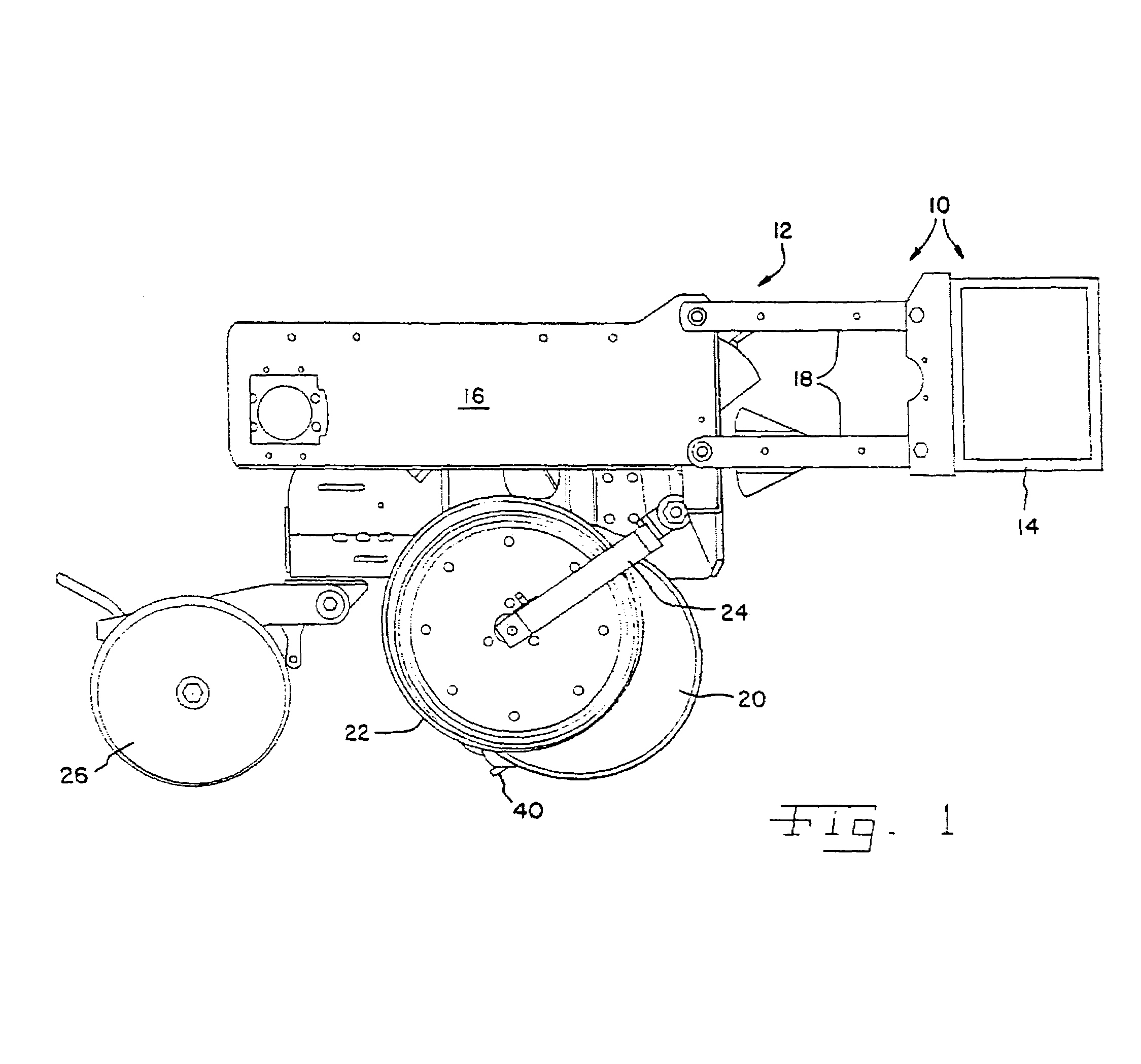

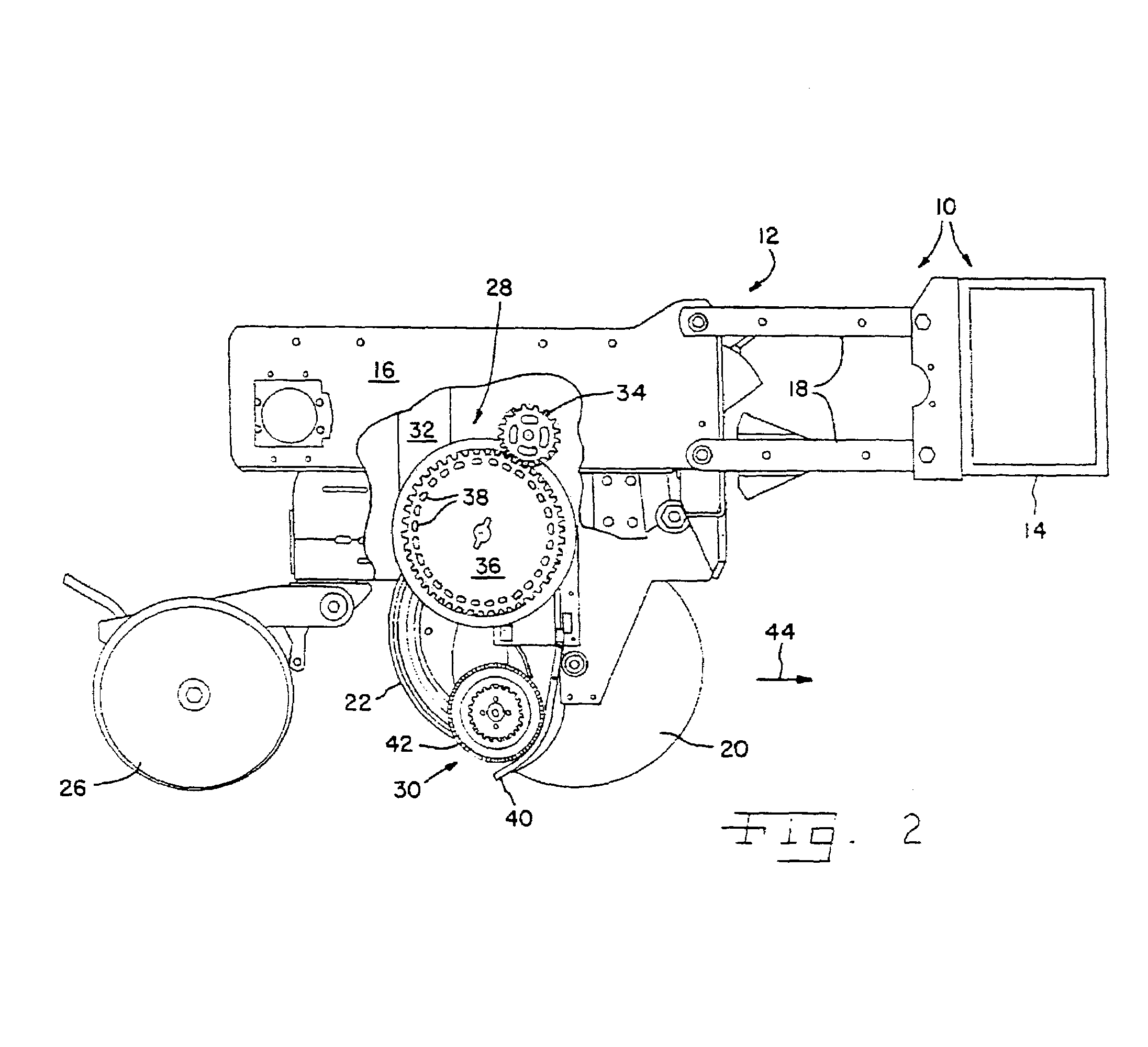

Seed slide for use in an agricultural seeding machine

ActiveUS7185596B2Positive engagementAccurate seed trajectoryPotato plantersFurrow making/coveringSeederEngineering

A seeding machine includes at least one seed metering system and at least one seed placement system. Each seed placement system is in communication with a corresponding seed metering system. Each seed placement system includes a seed slide having a bottom end and a seed trough terminating at the bottom end.

Owner:DEERE & CO

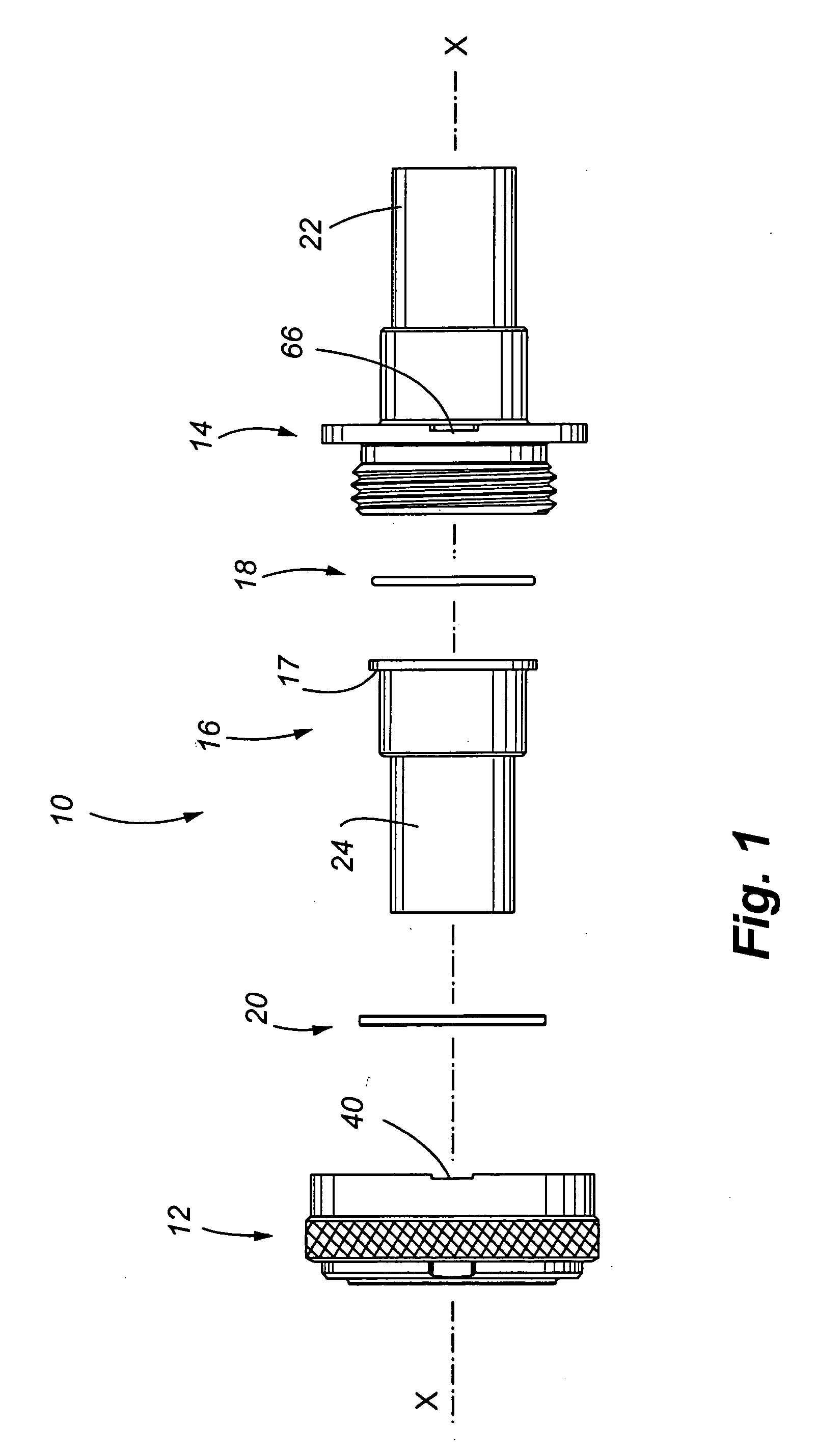

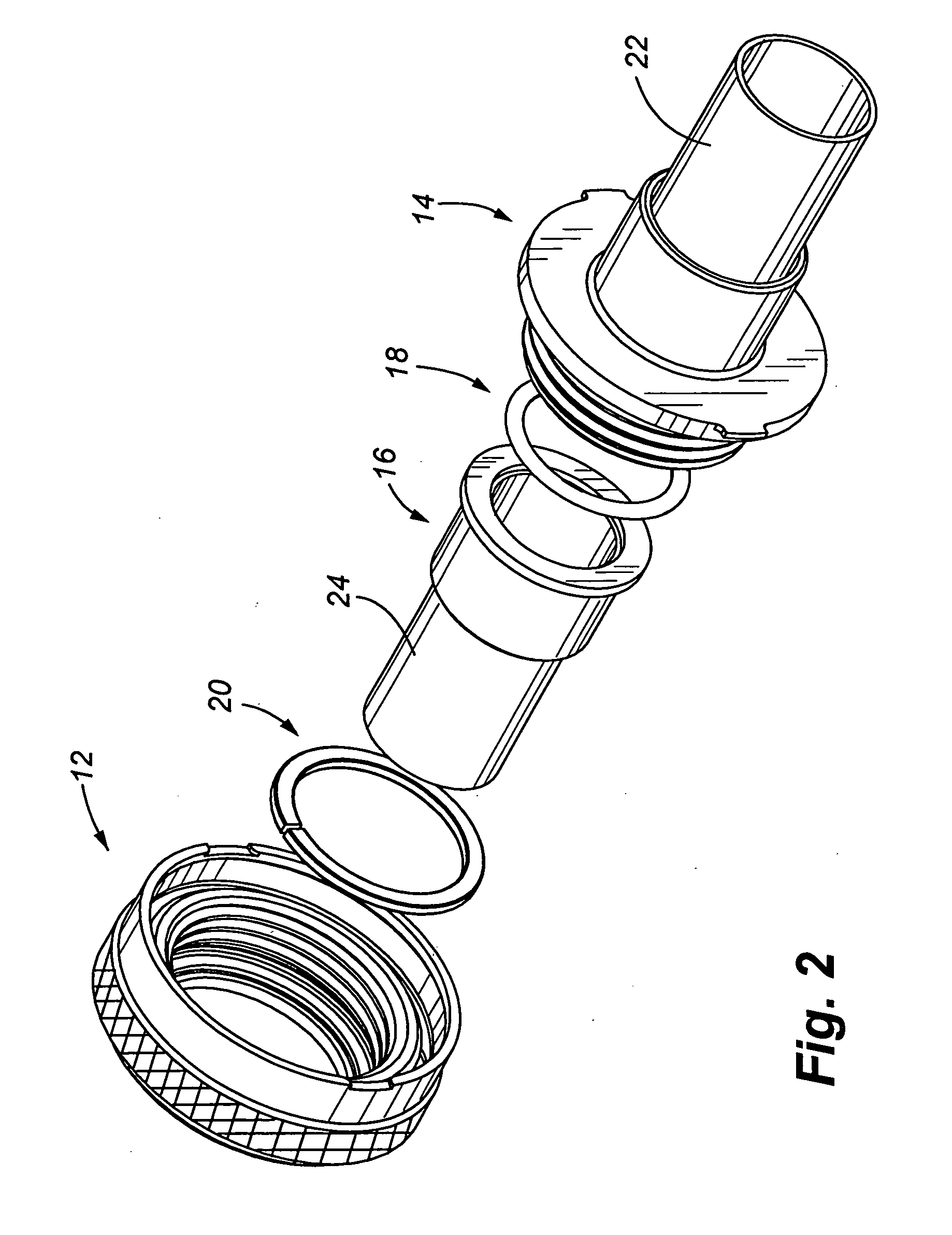

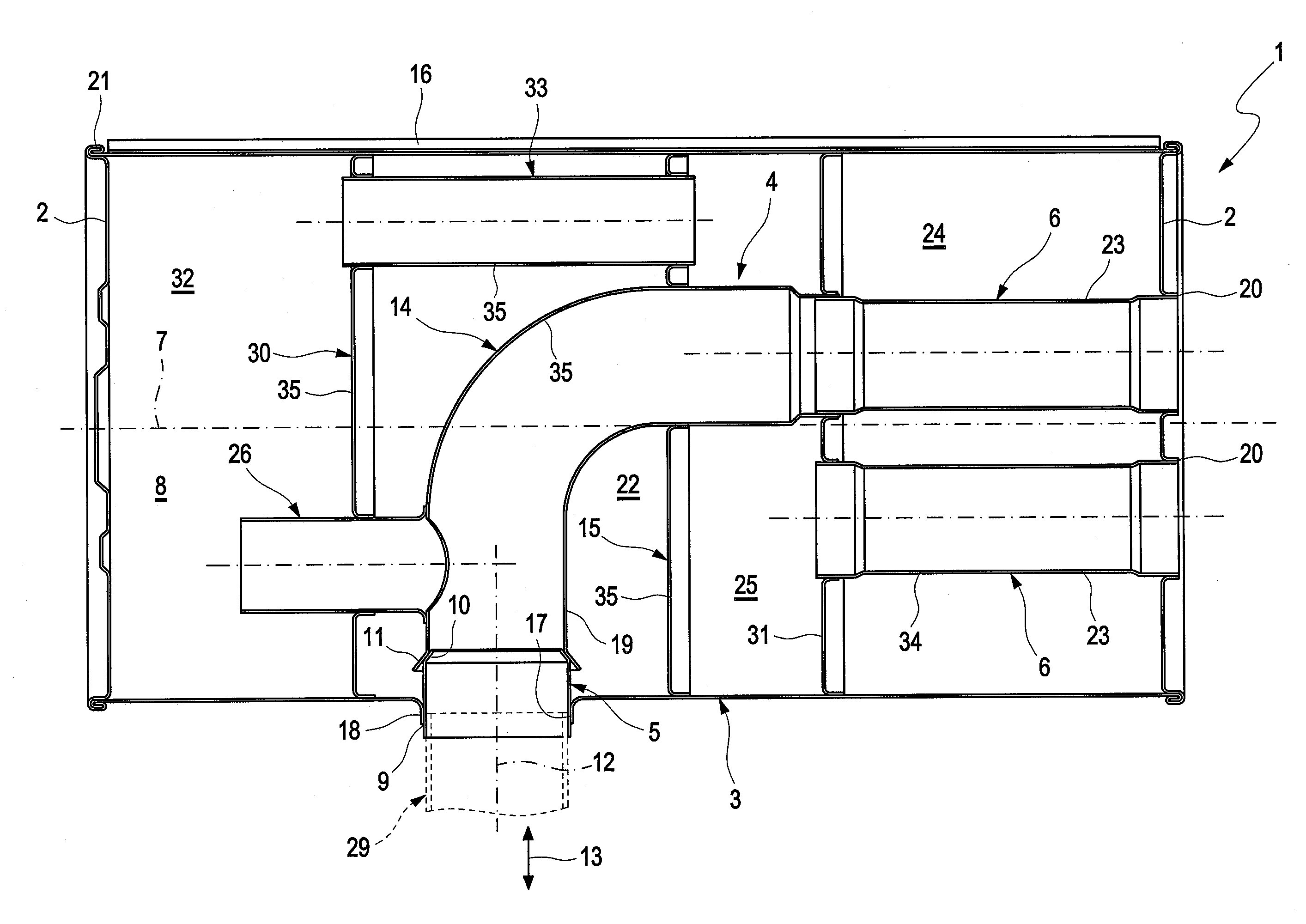

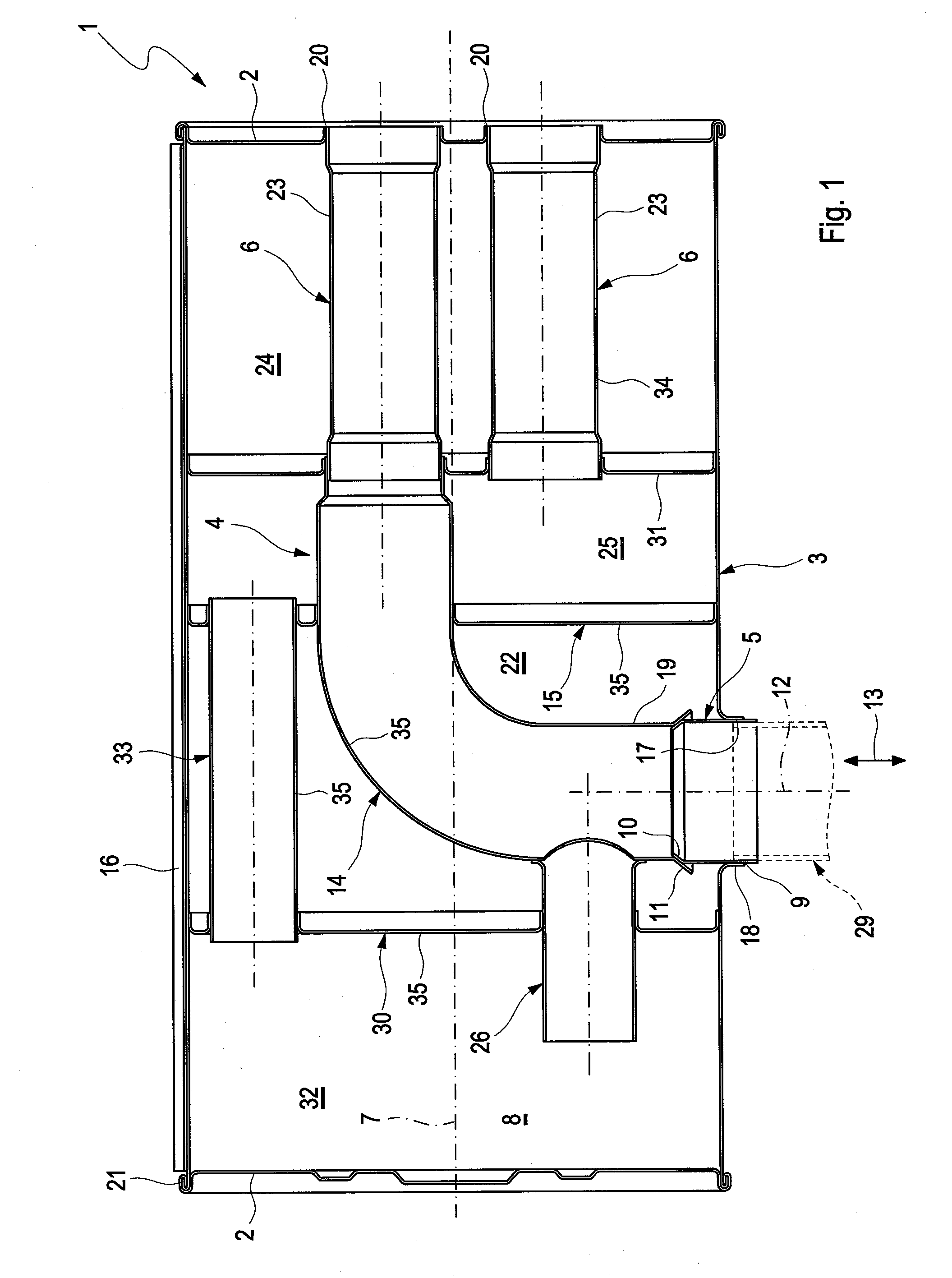

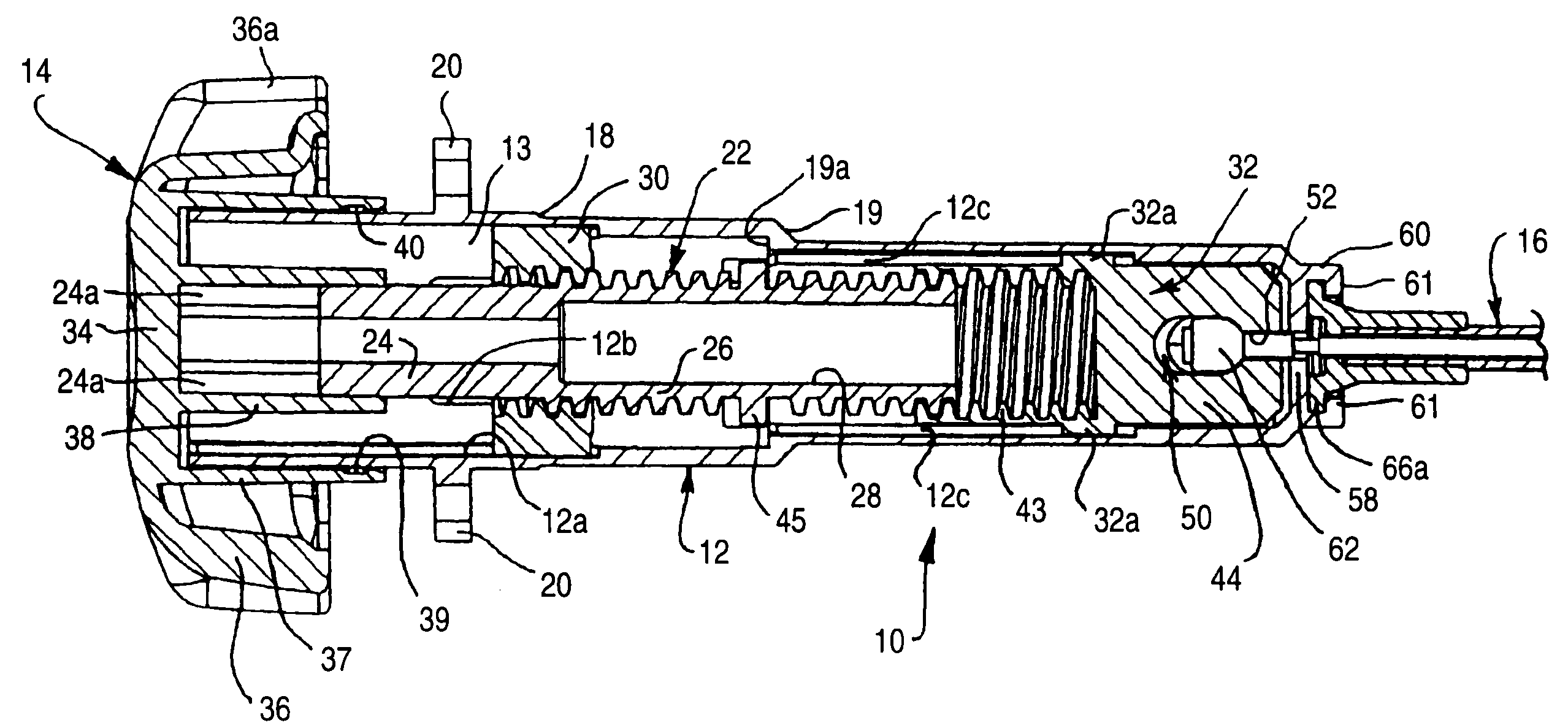

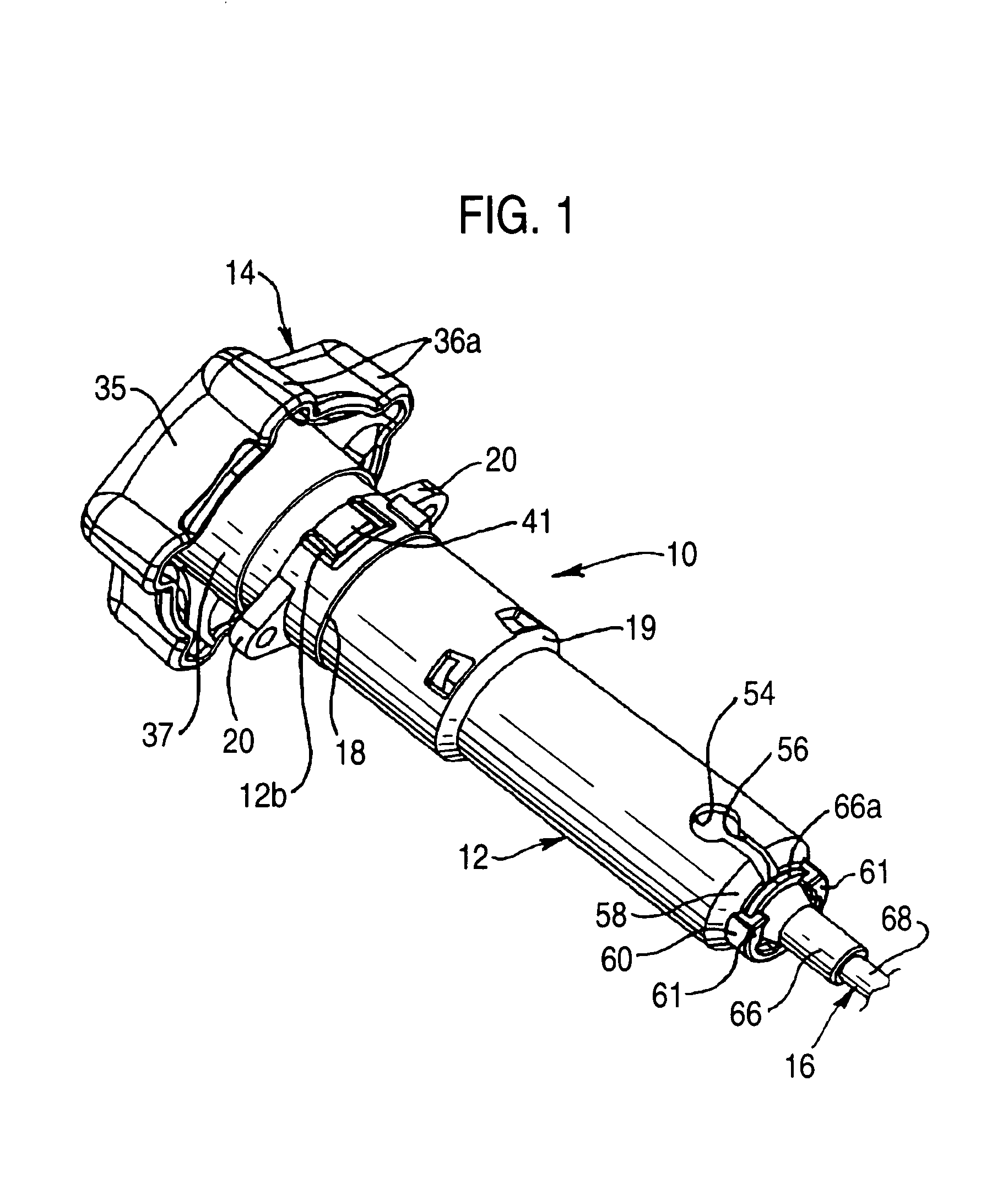

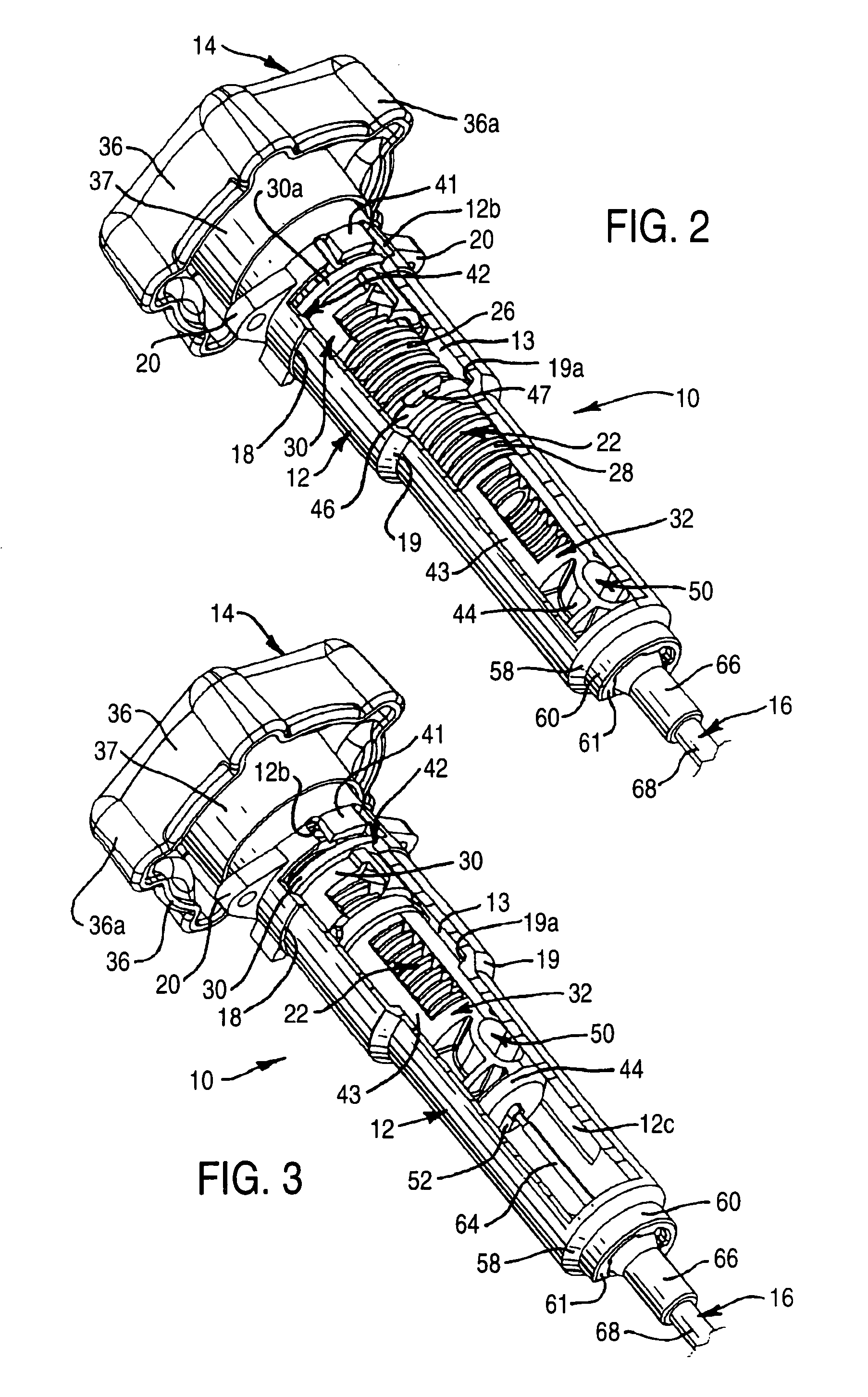

Self-locking self-bonding rigid coupling

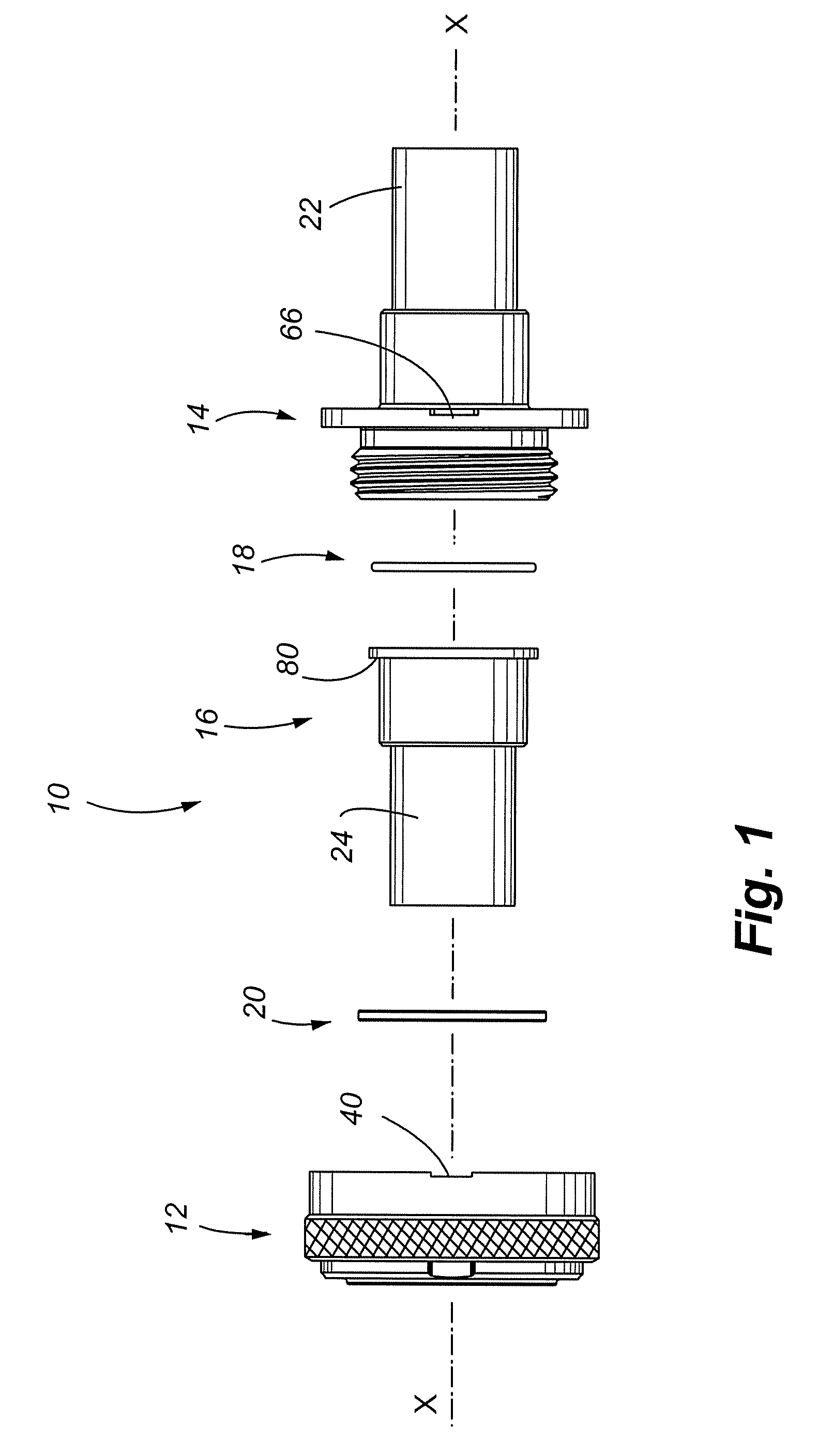

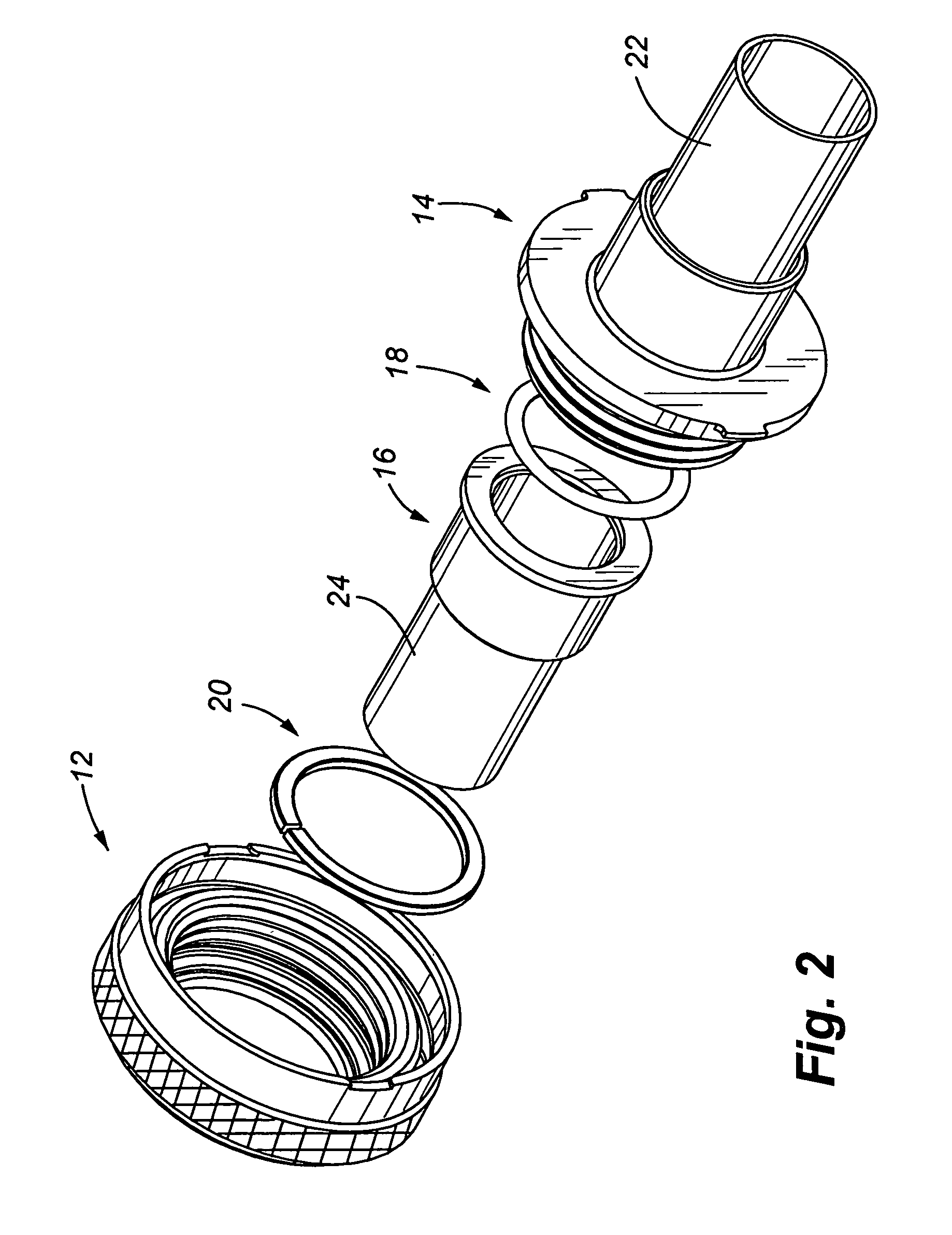

ActiveUS7222889B2Positive engagementMinimal and no static buildupEngine sealsFluid pressure sealed jointsCouplingEngineering

A coupling assembly is provided for releasably interconnecting confronting ends of conduit members. The coupling assembly creates a self-locking, and self-bonding connection wherein locking and unlocking is achieved by a predetermined amount of rotation of a lock nut group with respect to a stationary threaded flange. The overall construction of the coupling assembly creates the rigid connection between the conduit members, yet adequate sealing between the conduit members is provided by a single sealing member.

Owner:EATON INTELLIGENT POWER LTD

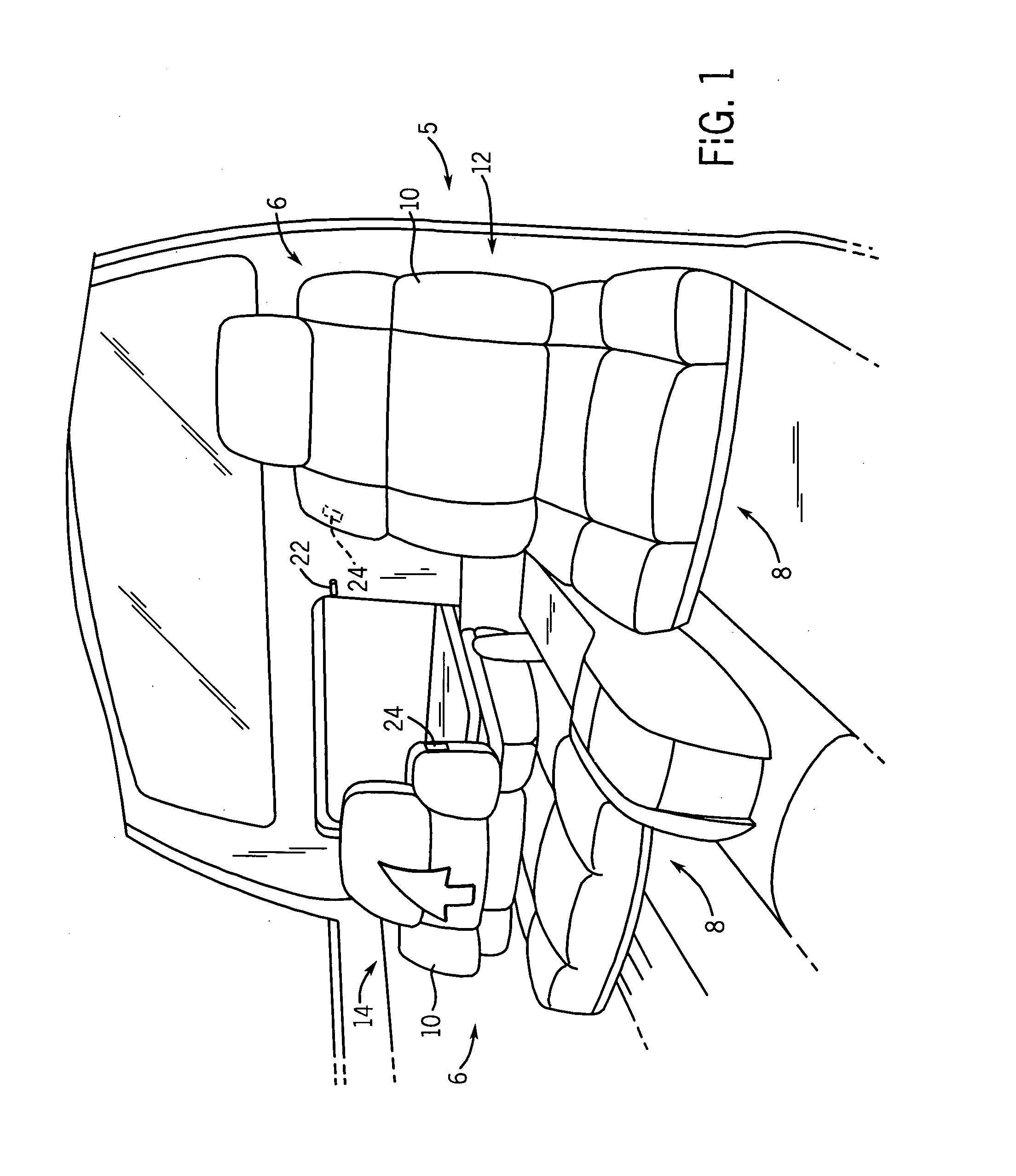

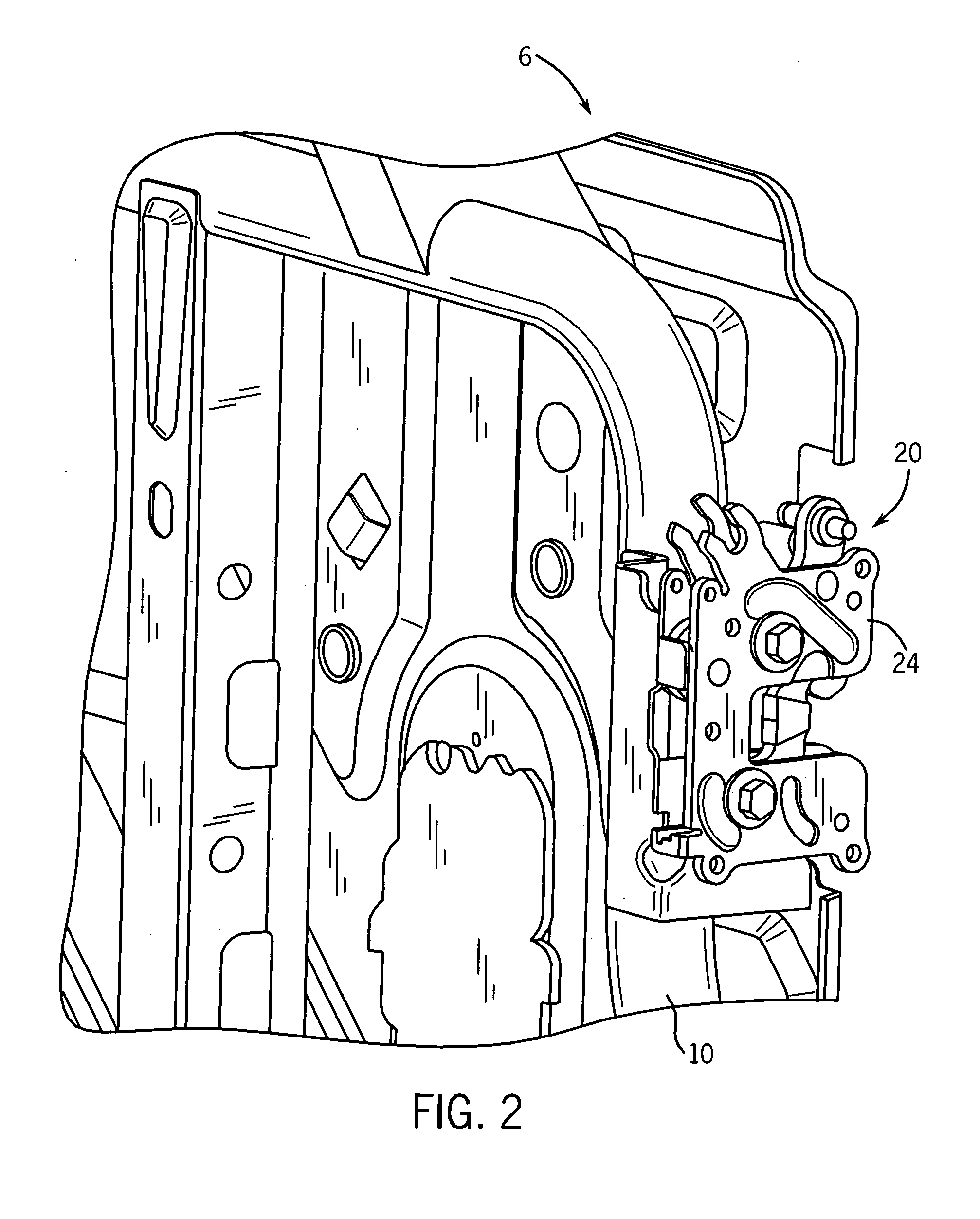

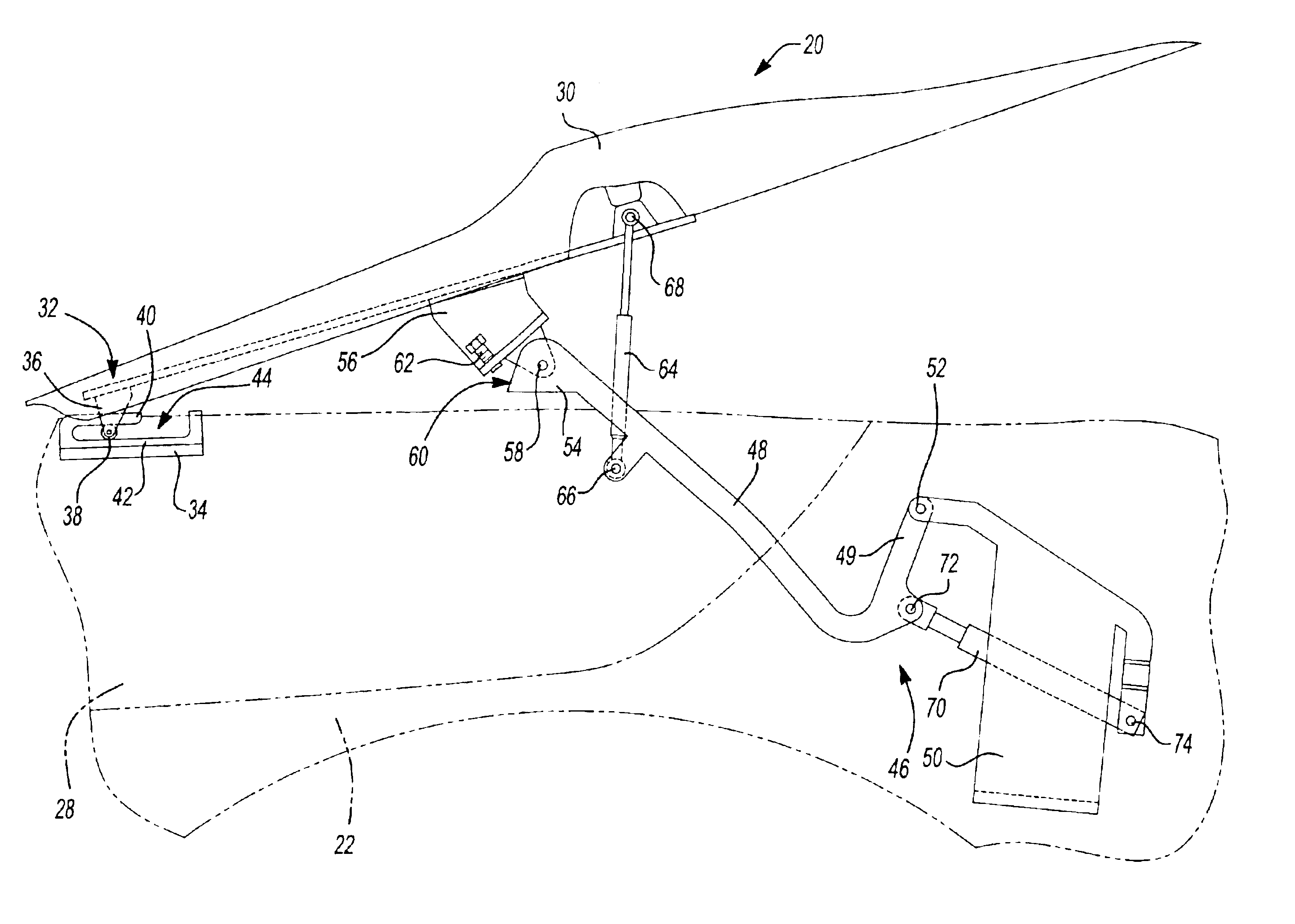

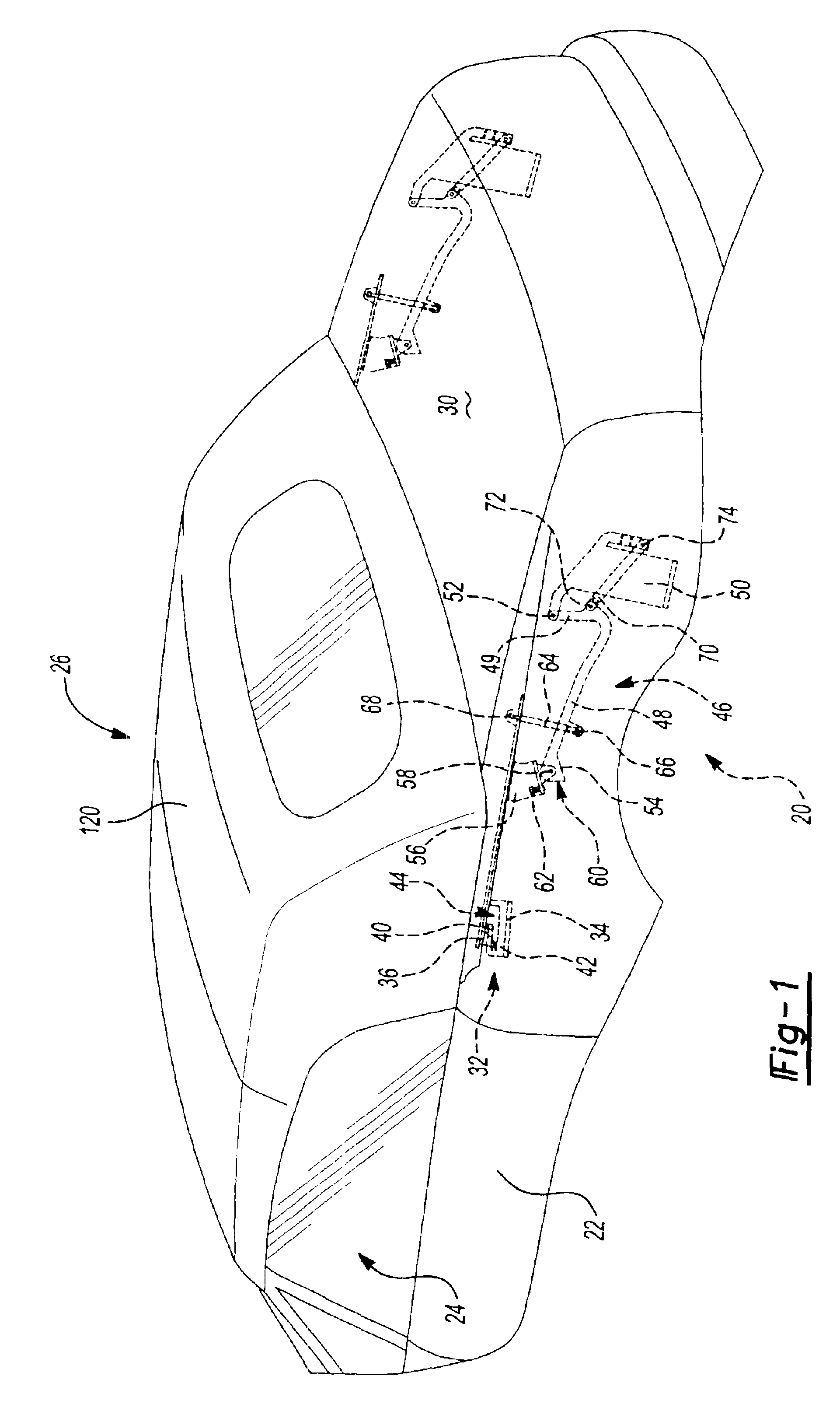

Two way positive locking latch

InactiveUS6908137B2Positive engagementBetter eliminate free play and BSRNoise-prevention/anti-rattling lockingConstruction fastening devicesEngineeringMechanical engineering

A latch for use in a vehicle having a rear seat with a fold down seatback. The latch comprises a striker member coupled to the vehicle and a latch assembly coupled to the seatback and configured to releasably engage the striker member. The latch assembly comprises a catch plate configured with two prongs and pivotably mounted on a support plate. A hook plate with two camming surfaces is configured to engage at least one of the prongs with the hook plate pivotably mounted on the support plate. The movement of the engaged prong is restricted in any direction when the hook plate is in a locked position.

Owner:ADIENT LUXEMBOURG HLDG SARL

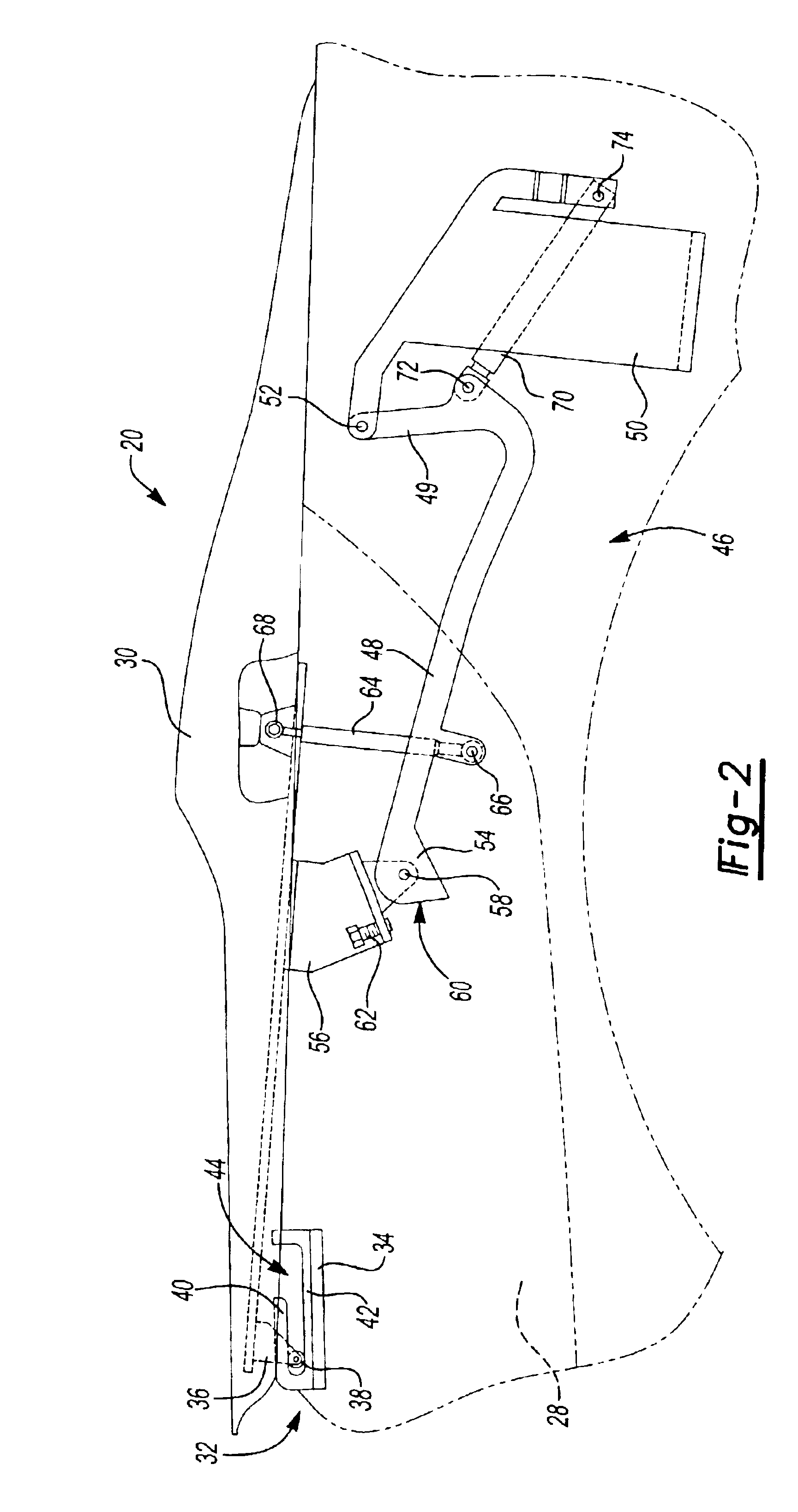

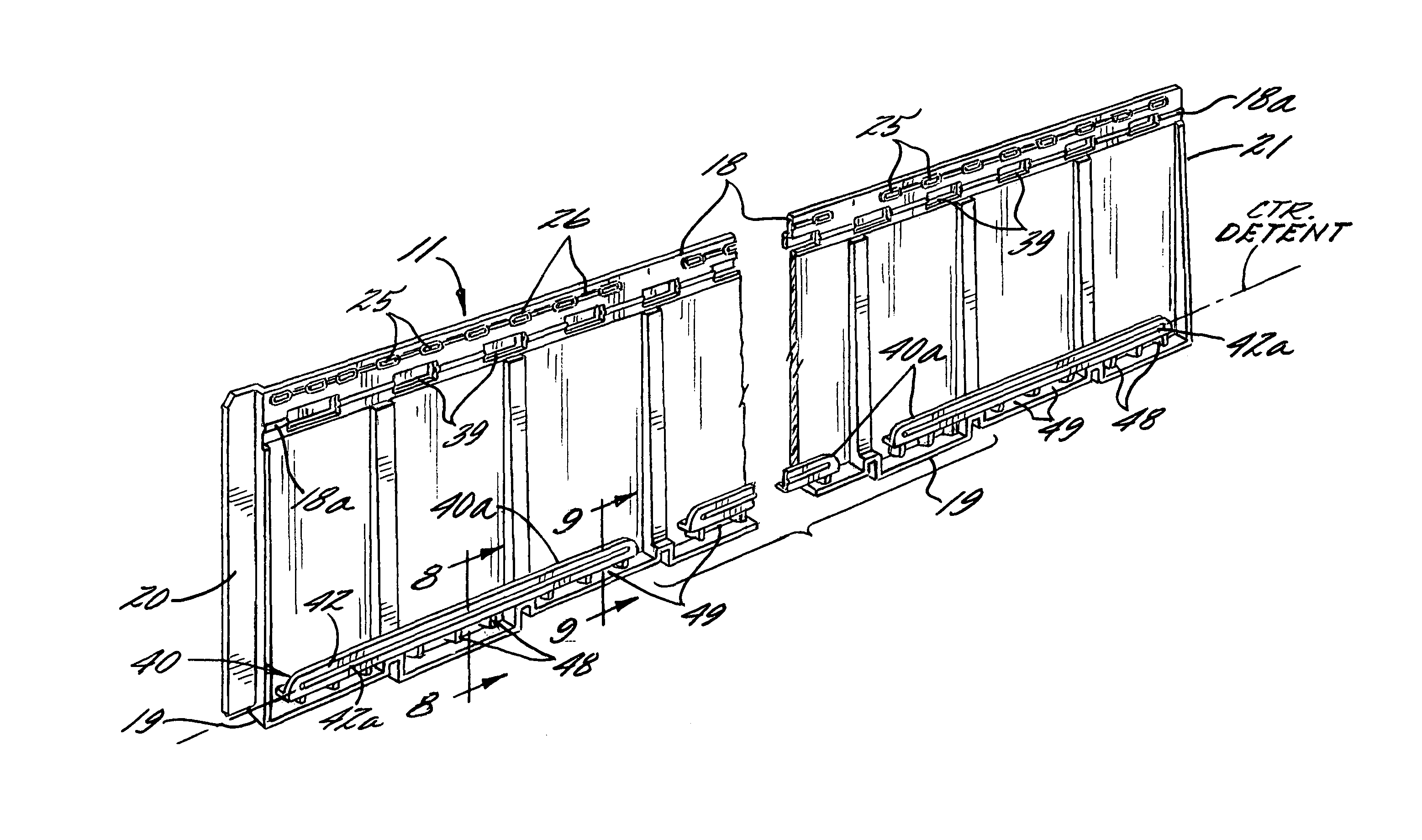

Tonneau panel mechanism

InactiveUS6866327B2Simple designLow costSuperstructure subunitsMonocoque constructionsEngineeringFace sheet

A tonneau panel mechanism engages a stationary track in a closed position and disengages from the stationary track when in the open position. The tonneau panel exhibits a first stage of motion that includes both pivotal and non-pivotal motion and a second stage of motion that consists of substantially rotational motion about a pivot. The tonneau panel mechanism can include a linkage assembly with at least one link that engages with a stop on the tonneau panel to alter the motion of the tonneau panel between the first and second stages of motion. The tonneau panel can also use an at least four-bar linkage wherein at least two of the links move relative to one another during the first stage of motion and are locked together during a second stage of motion.

Owner:SPECIALTY VEHICLE ACQUISITION

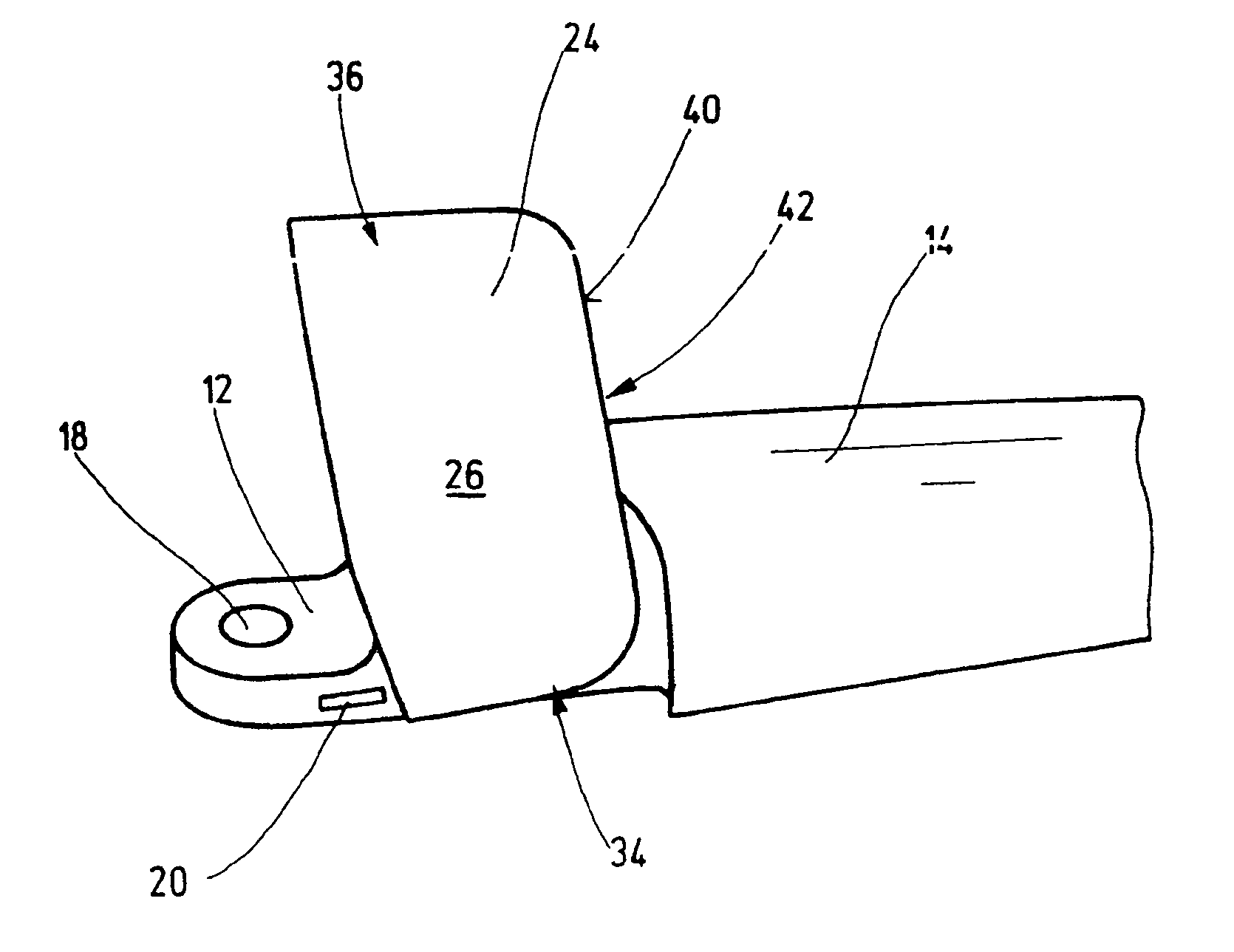

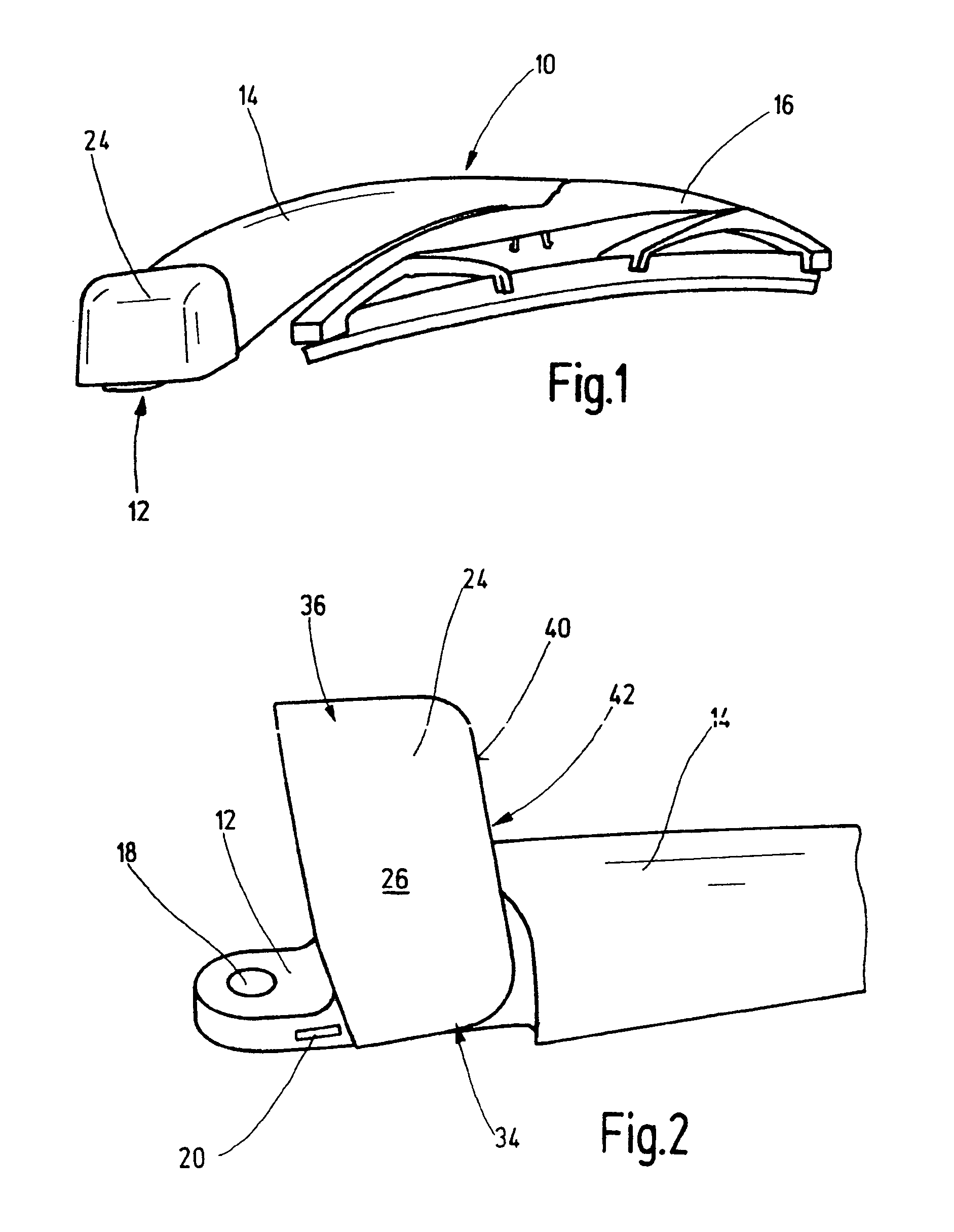

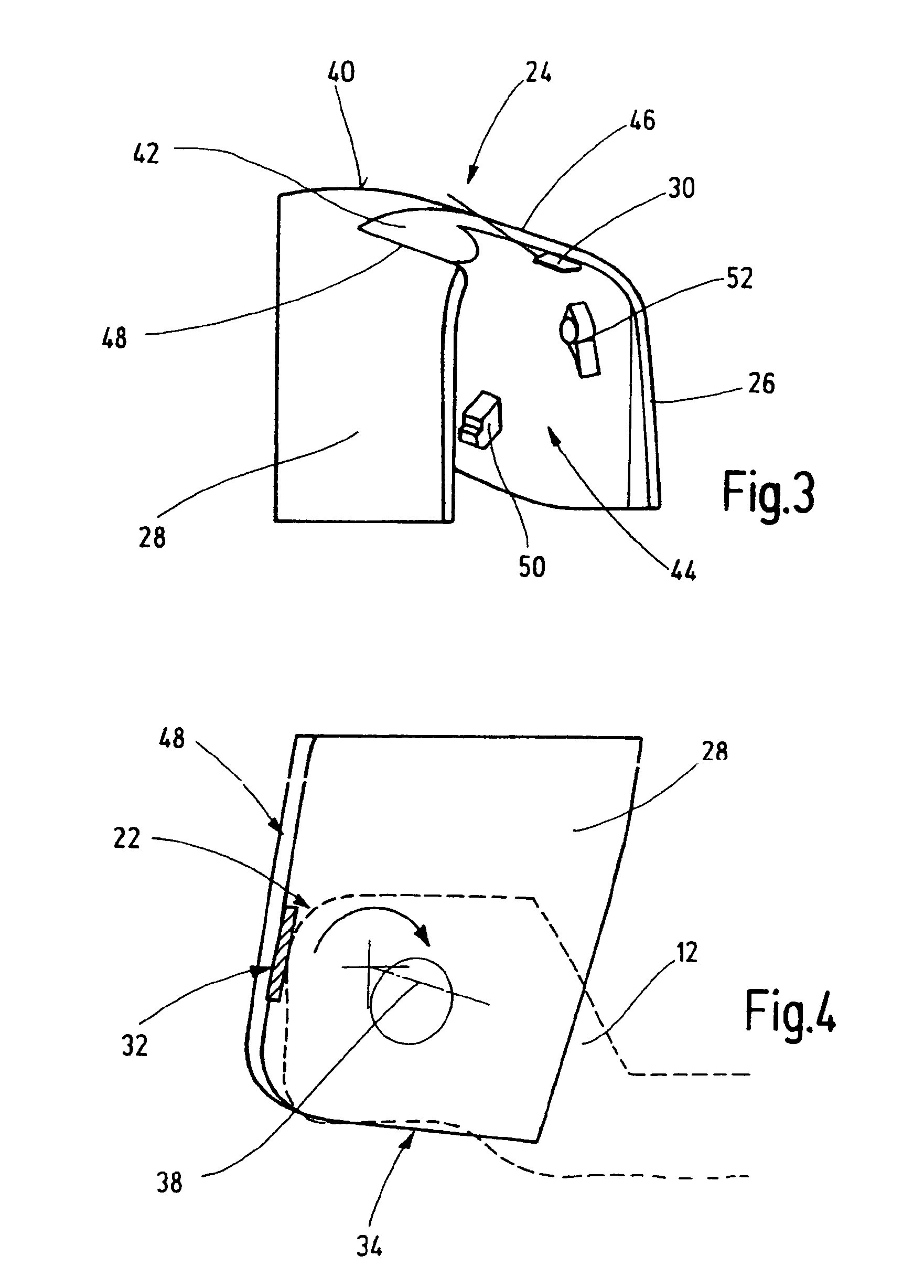

Wiper arm and cover for a wiper arm

InactiveUS7793382B2Reduced stabilityCost-effective manufacturingBrushesWork treatment devicesDrive shaftEngineering

The invention provides for a wiper arm for a windshield wiper system comprising a fixing element (12) for connection to a drive shaft, whereby a tiltably-fixed cover unit (24) is provided for at least partially releasing the fixing element (12). It is proposed that the cover unit (24) can be engaged with the fixing element (12) in the tilted position. A cover unit for a wiper arm is also proposed.

Owner:ROBERT BOSCH GMBH

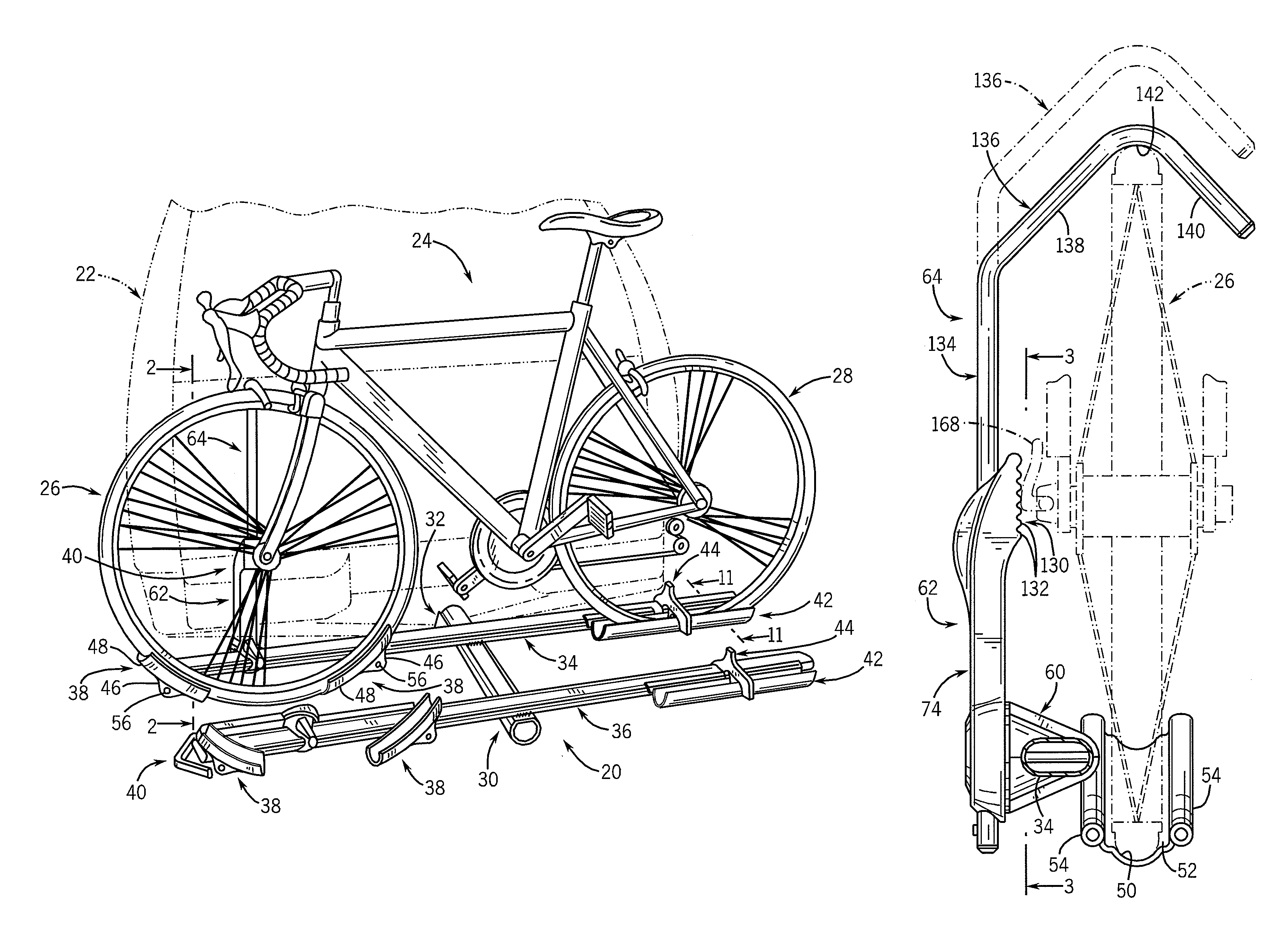

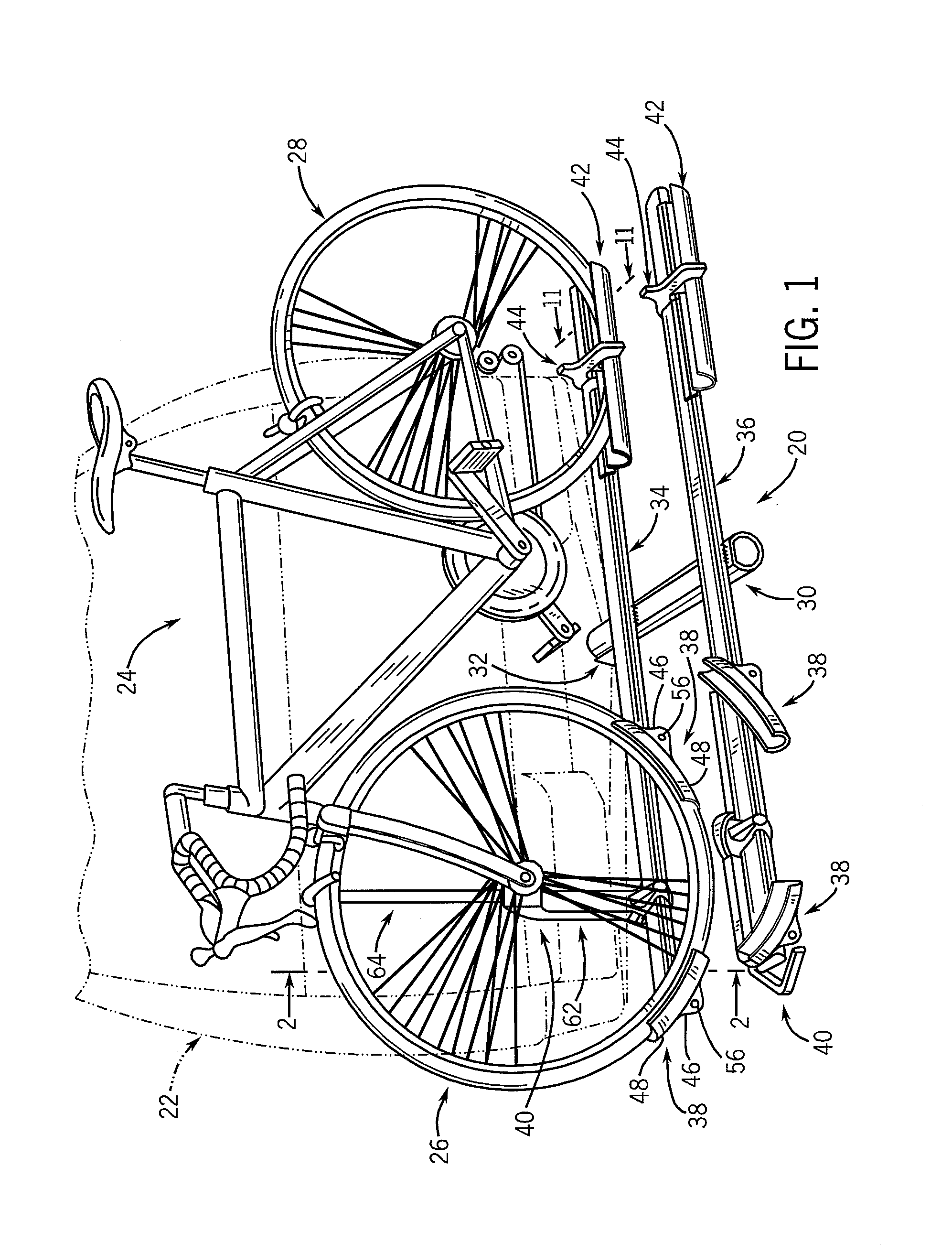

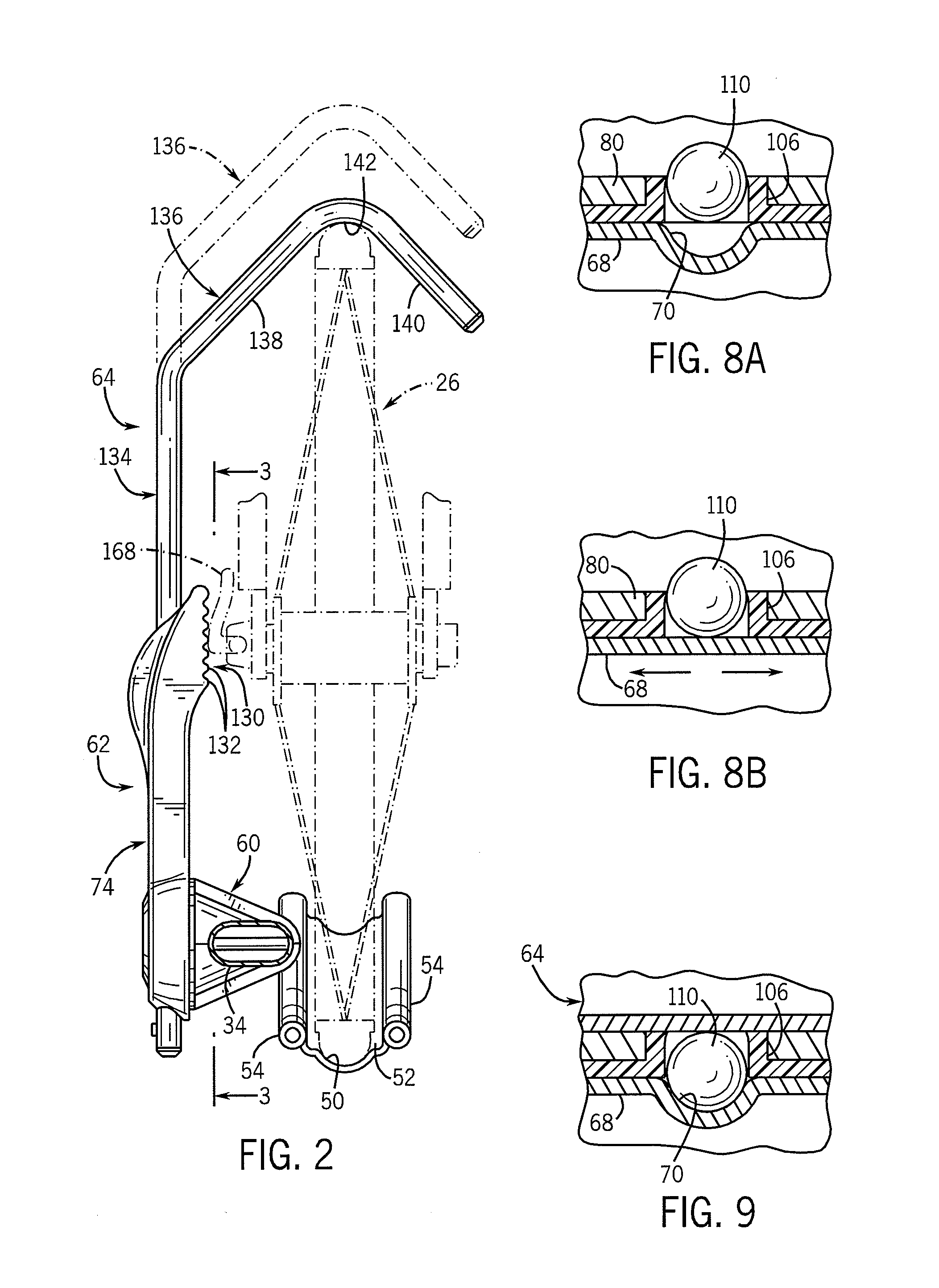

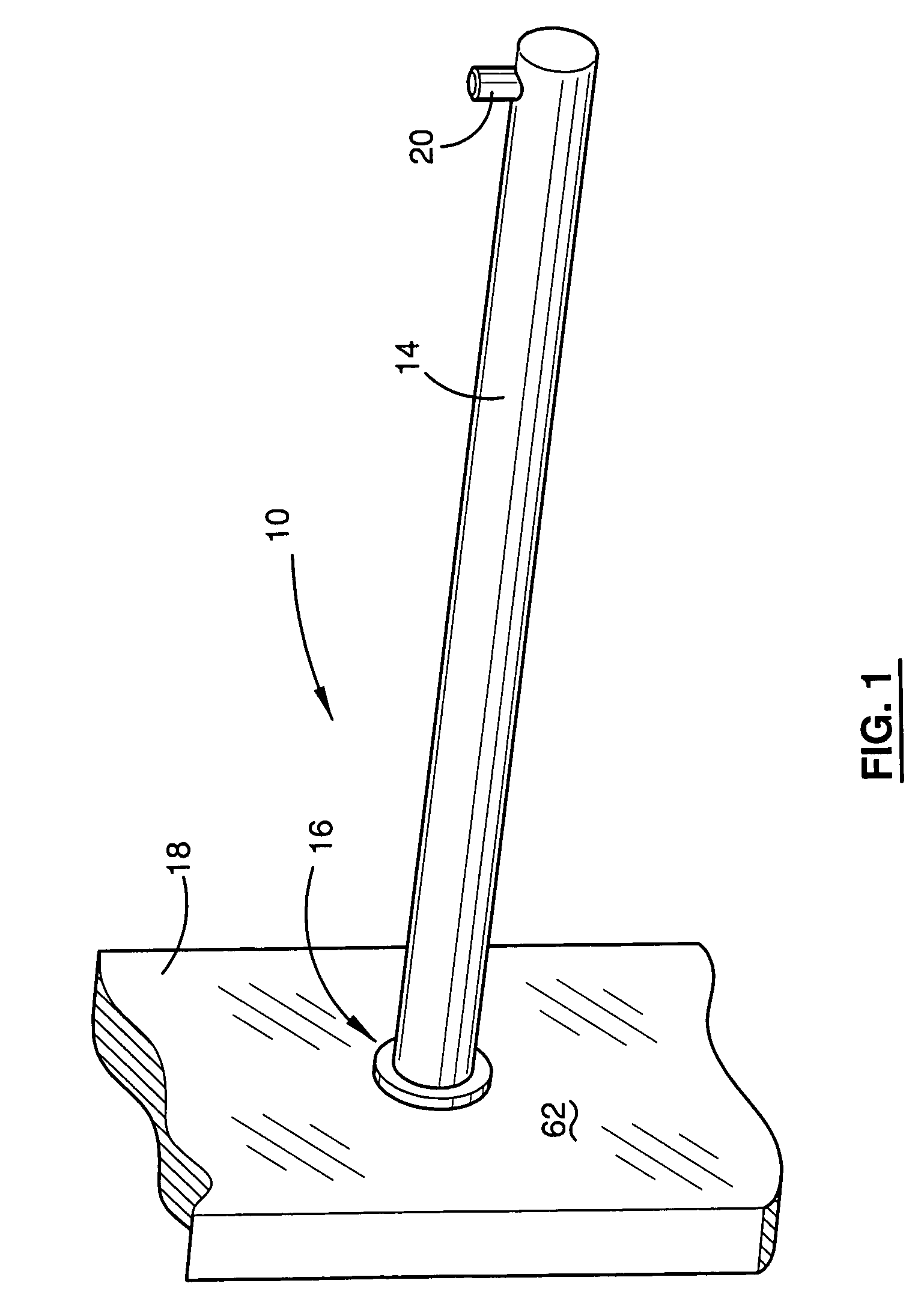

Pivoting support arrangement for maintaining a bicycle wheel in an upright position

InactiveUS7222763B2Quickly easily mountingPositive engagementTravelling carriersSupplementary fittingsMechanical engineeringStructural element

Owner:PEDRINI FABIO

Self-locking self-bonding regid coupling

ActiveUS20070052234A1Positive engagementMinimal and no static buildupEngine sealsFluid pressure sealed jointsCouplingSelf locking

A coupling assembly is provided for releasably interconnecting confronting ends of conduit members. The coupling assembly creates a self-locking, and self-bonding connection wherein locking and unlocking is achieved by a predetermined amount of rotation of a lock nut group with respect to a stationary threaded flange. The overall construction of the coupling assembly creates the rigid connection between the conduit members, yet adequate sealing between the conduit members is provided by a single sealing member.

Owner:EATON INTELLIGENT POWER LTD

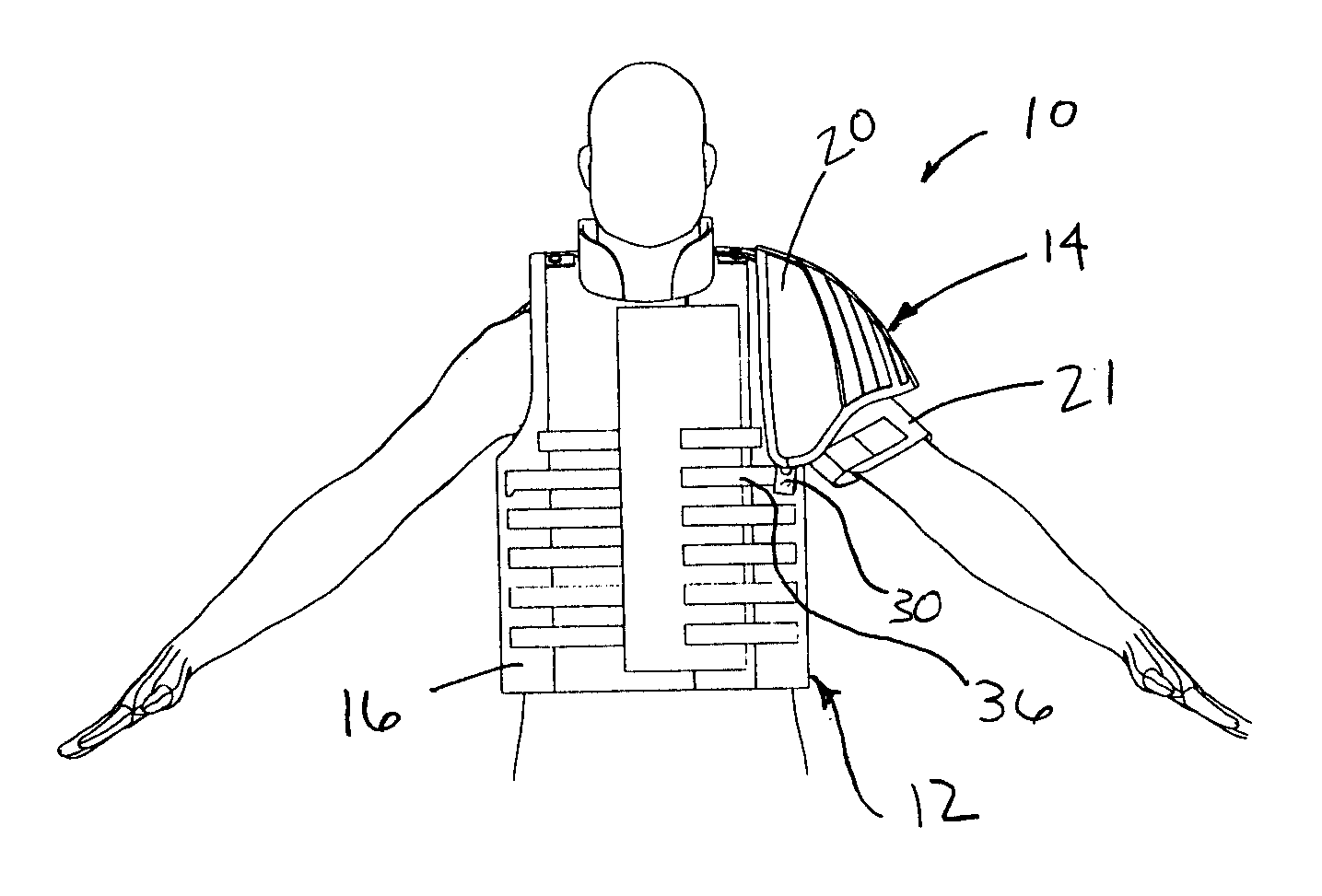

Deltoid arm protection system for ballistic body armor

ActiveUS20070028339A1Positive engagementPersonal protection gearProtective garmentDeltoid muscleBody armor

A deltoid arm protection system for a ballistic vest including an asymmetrical anatomically shaped deltoid cover having fasteners for attachment to a ballistic vest. The deltoid cover is connected to the vest and prevents any gaps forming between the deltoid cover and the vest during arm movement of the wearer. The deltoid cover includes a weapon gripping pad and attachment loops on an outer surface of the deltoid cover.

Owner:SAFARILAND

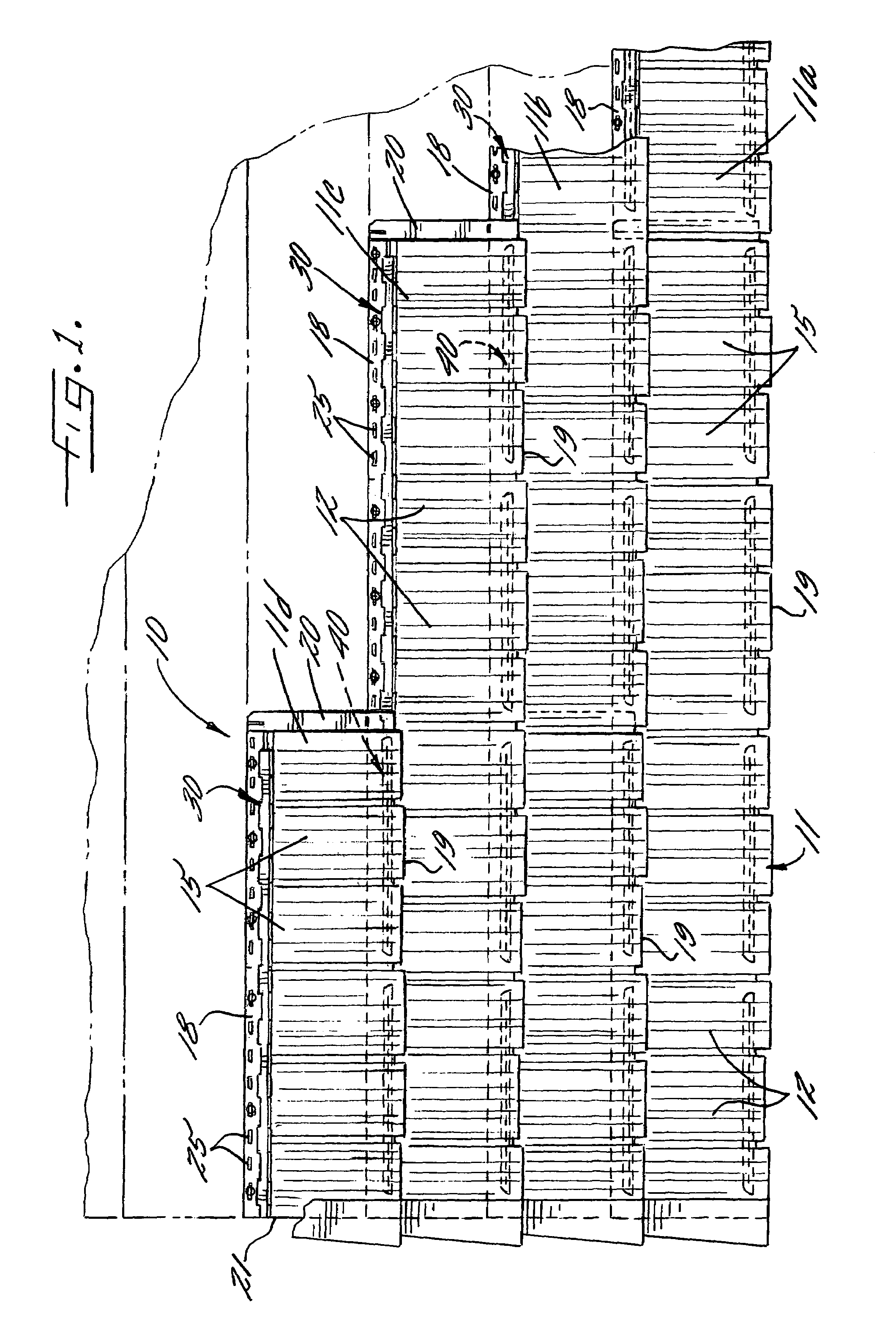

Decorative wall covering with improved interlock system

ActiveUS7980037B2Easy and engagementHelp positioningRoof covering using tiles/slatesCovering/liningsFlangeEdge region

A roof or wall covering comprising a plurality of horizontal courses of molded plastic panels each formed with a single row of simulated shake shingles. The panels have a continuous upper interlock flange that facilitates inner-engagement of the panels of overlying courses without cumbersome handling of numerous small interlock fingers which can be missed during installation. Cooperating detents are provided between the overlying lower and upper marginal edge regions which facilitate proper positioning of the panels and which support the weight of the panel during securement to a wall surface. A bottom interlock flange is supported transversely across a rear side of the panel by vertically-spaced support plates which facilitate both liquid drainage and air circulation through the installed wall covering. In the preferred embodiment, the panels in alternate courses are identically formed with different shake patterns for enhancing the natural appearance of the wall covering.

Owner:NOVIK INC

Support arm system

InactiveUS8540198B2Positive engagementCandle holdersLighting support devicesEngineeringMechanical engineering

Owner:GESSWEIN ANDREAS KLAUS +1

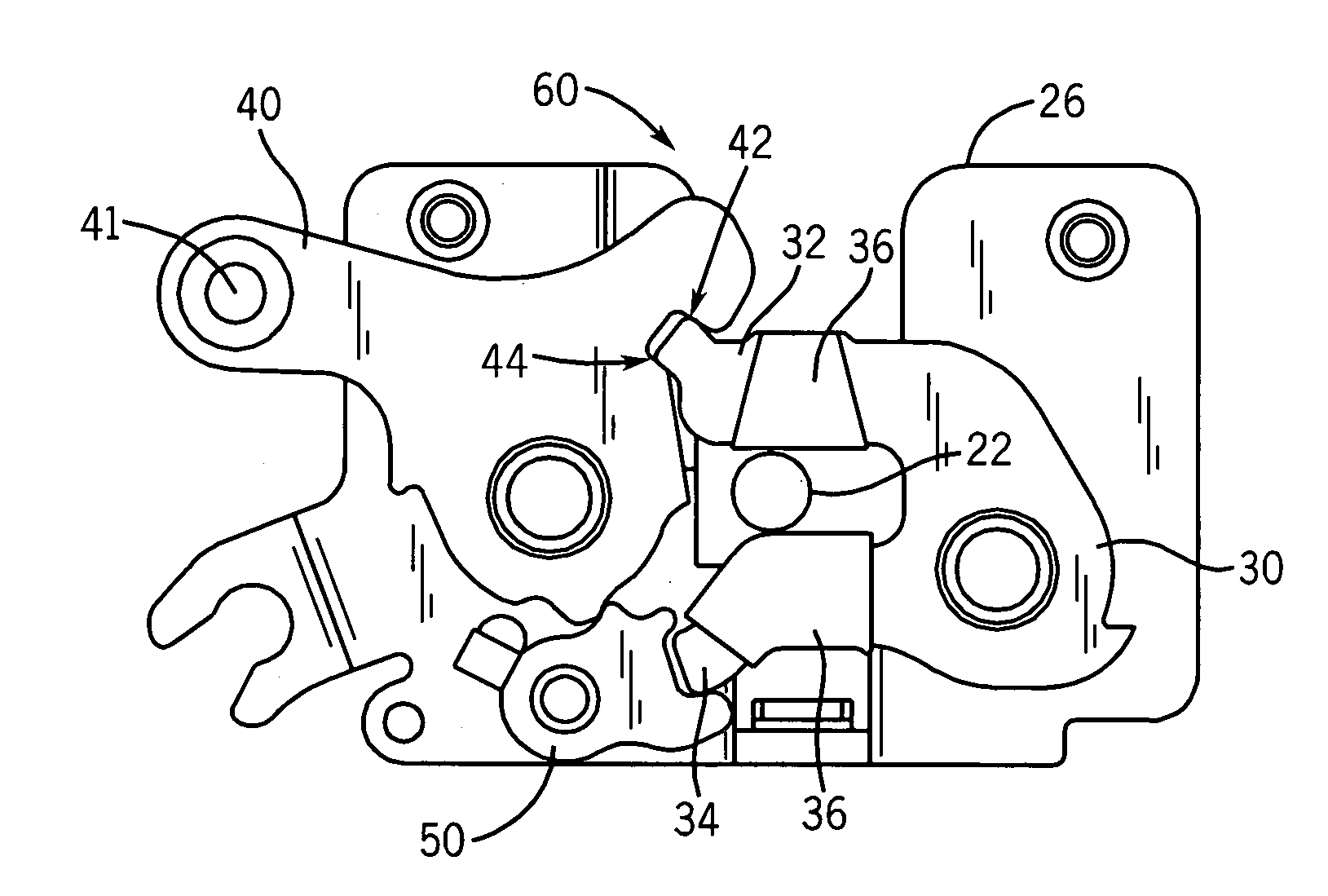

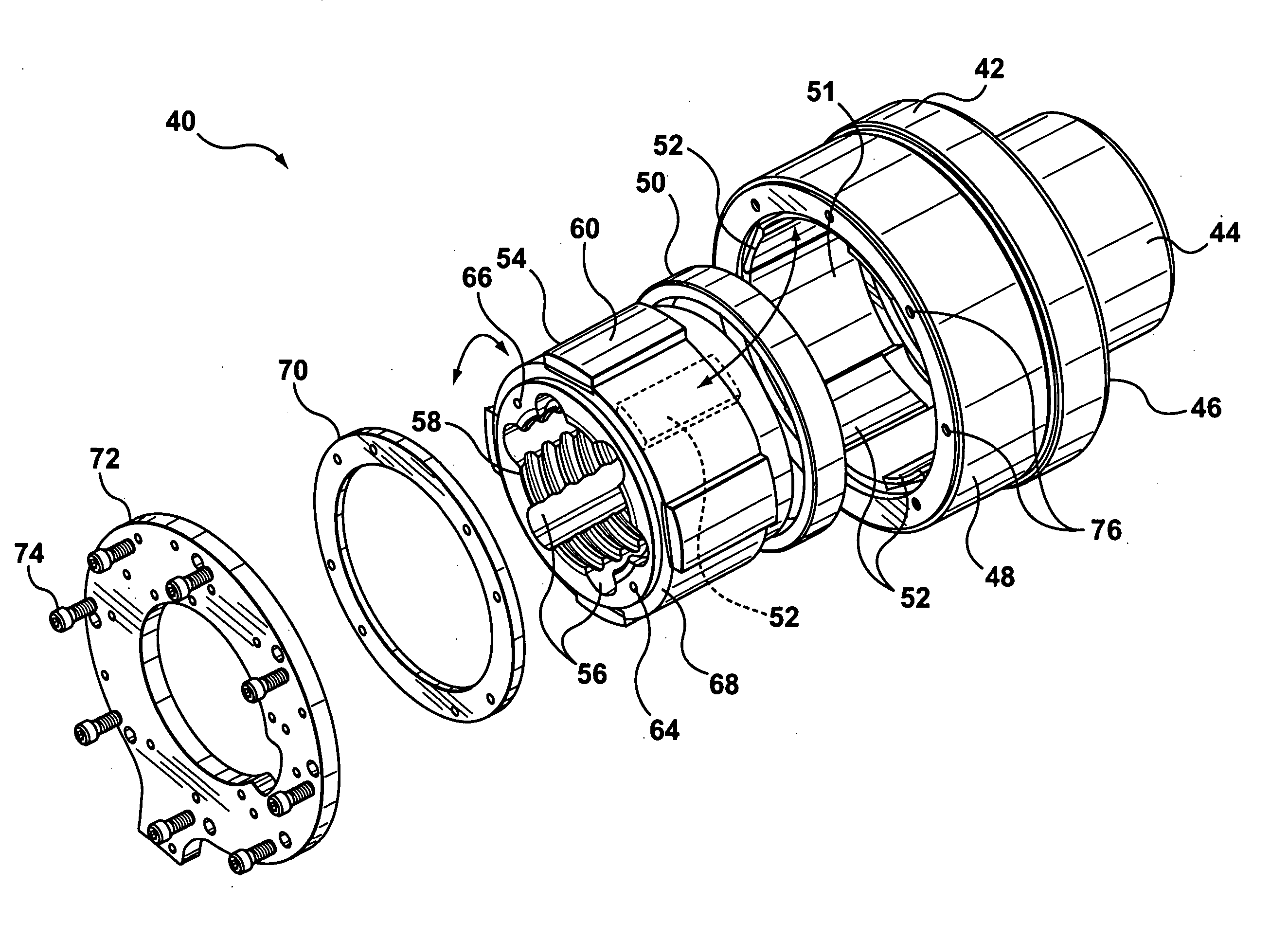

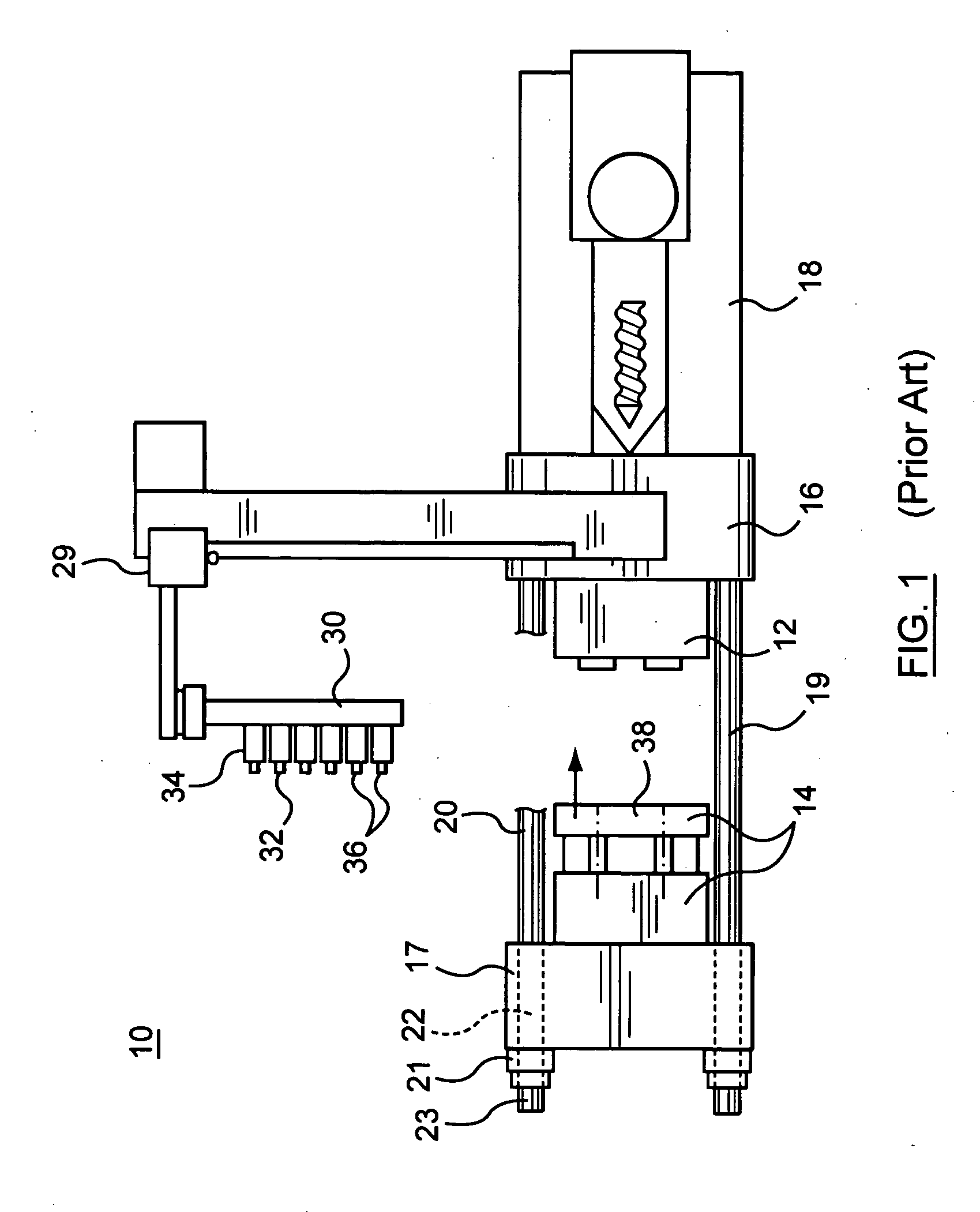

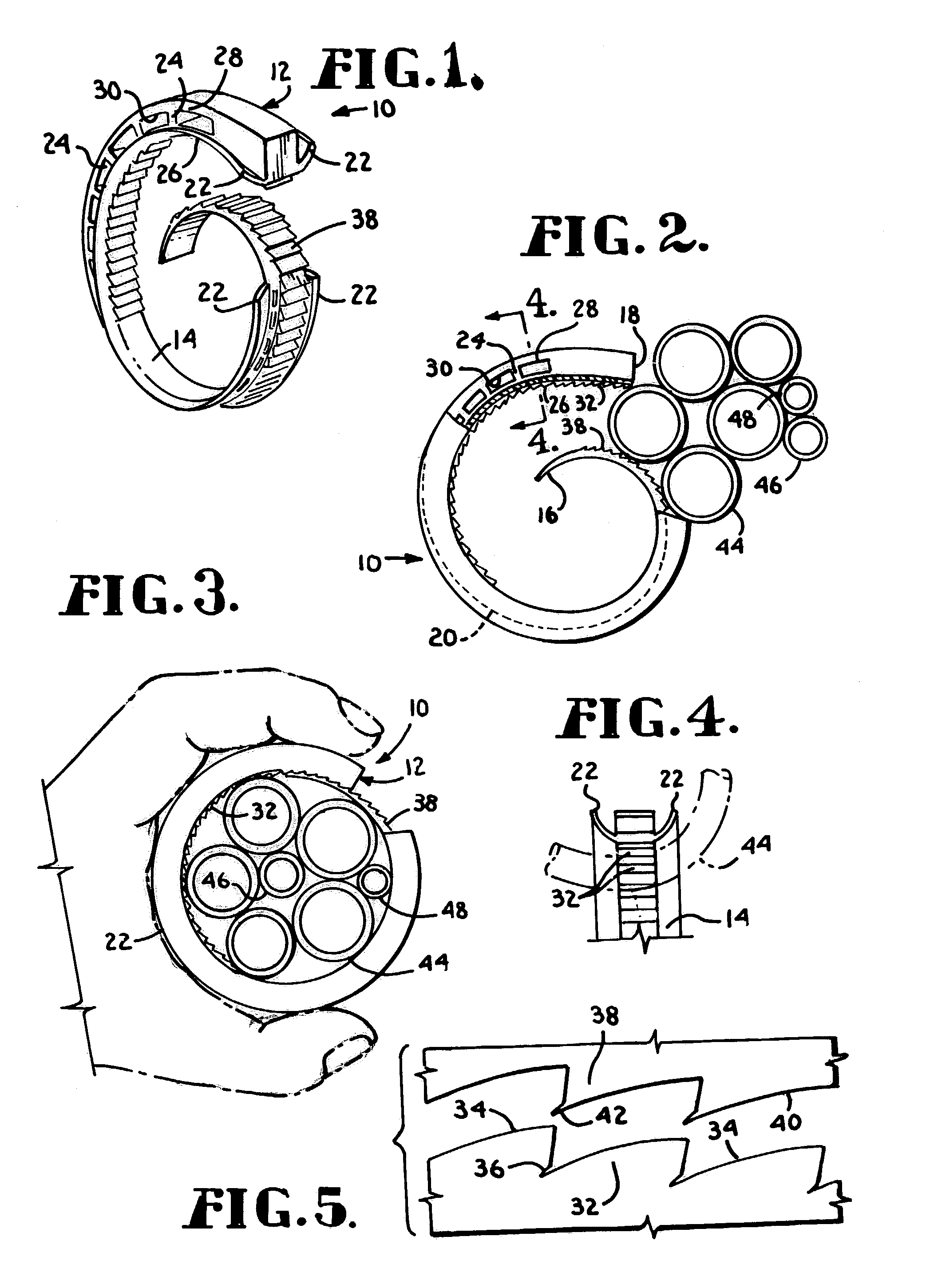

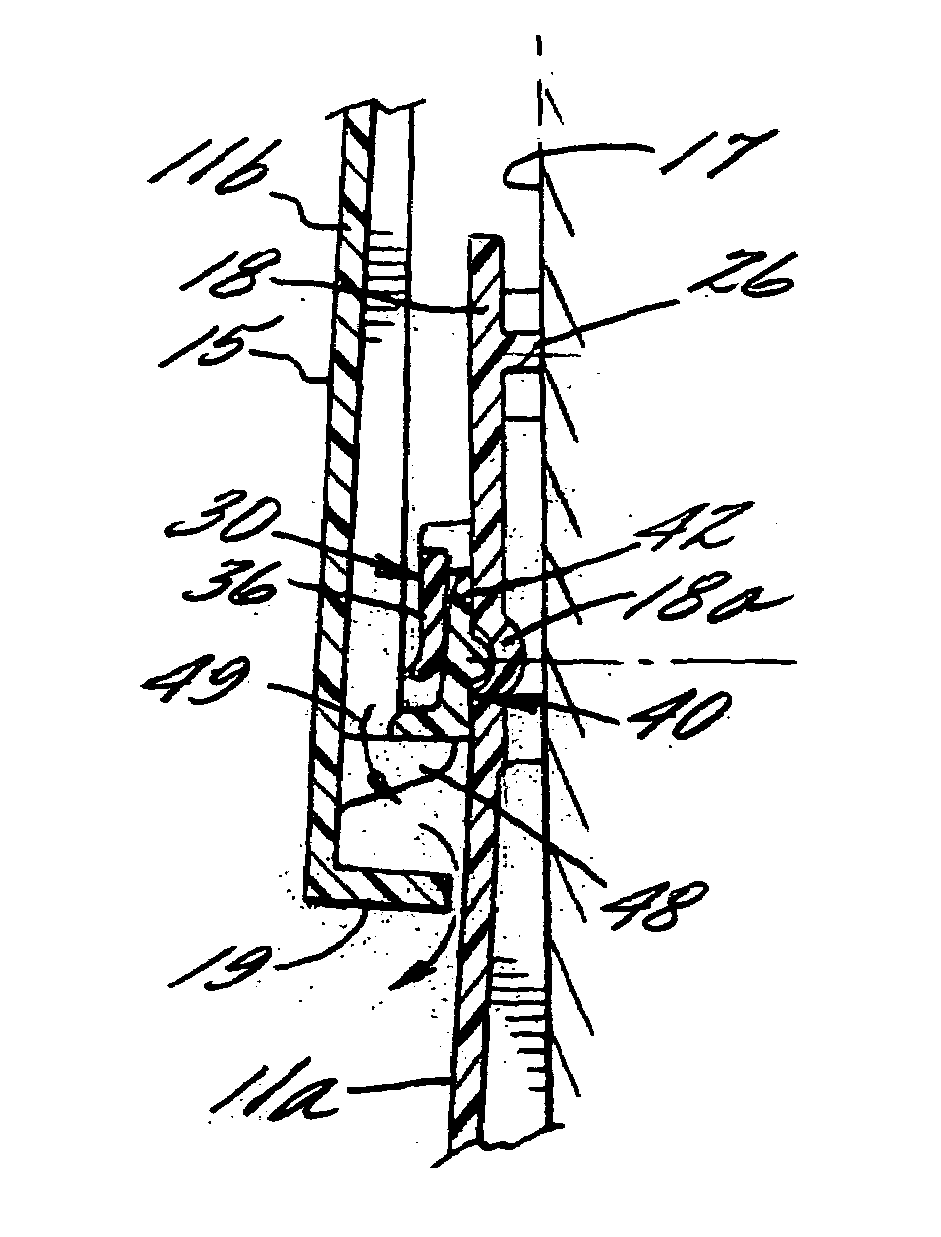

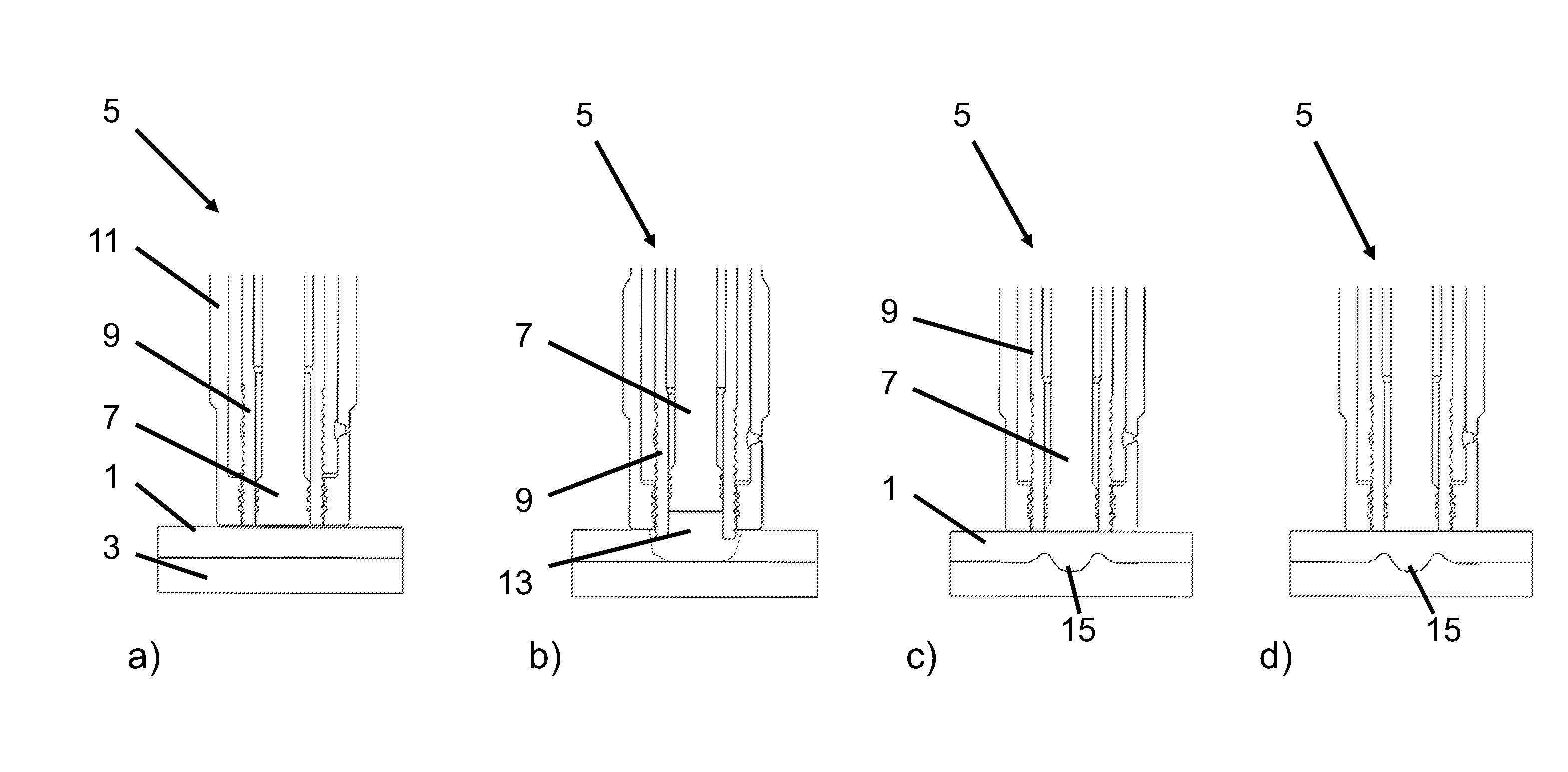

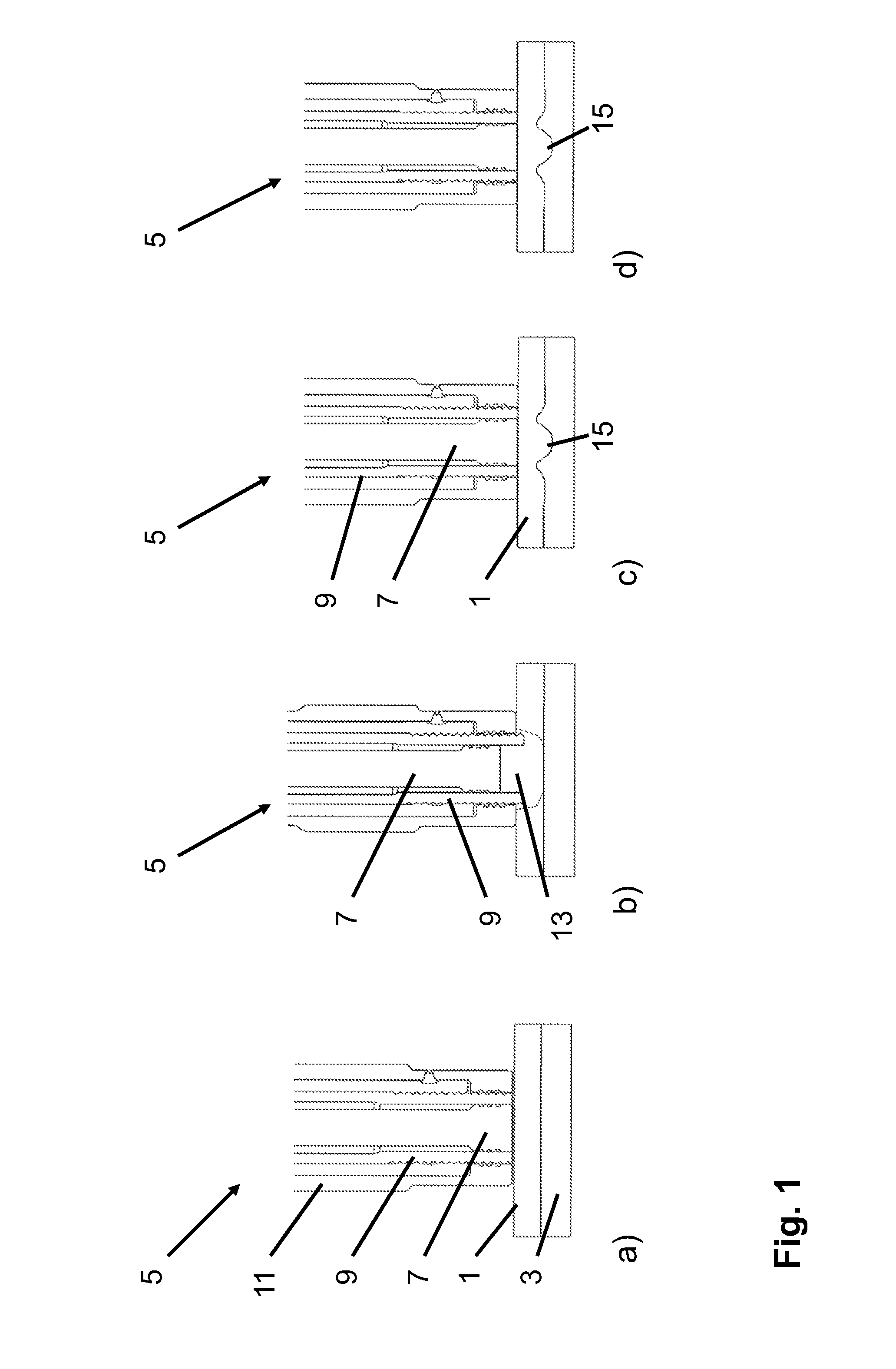

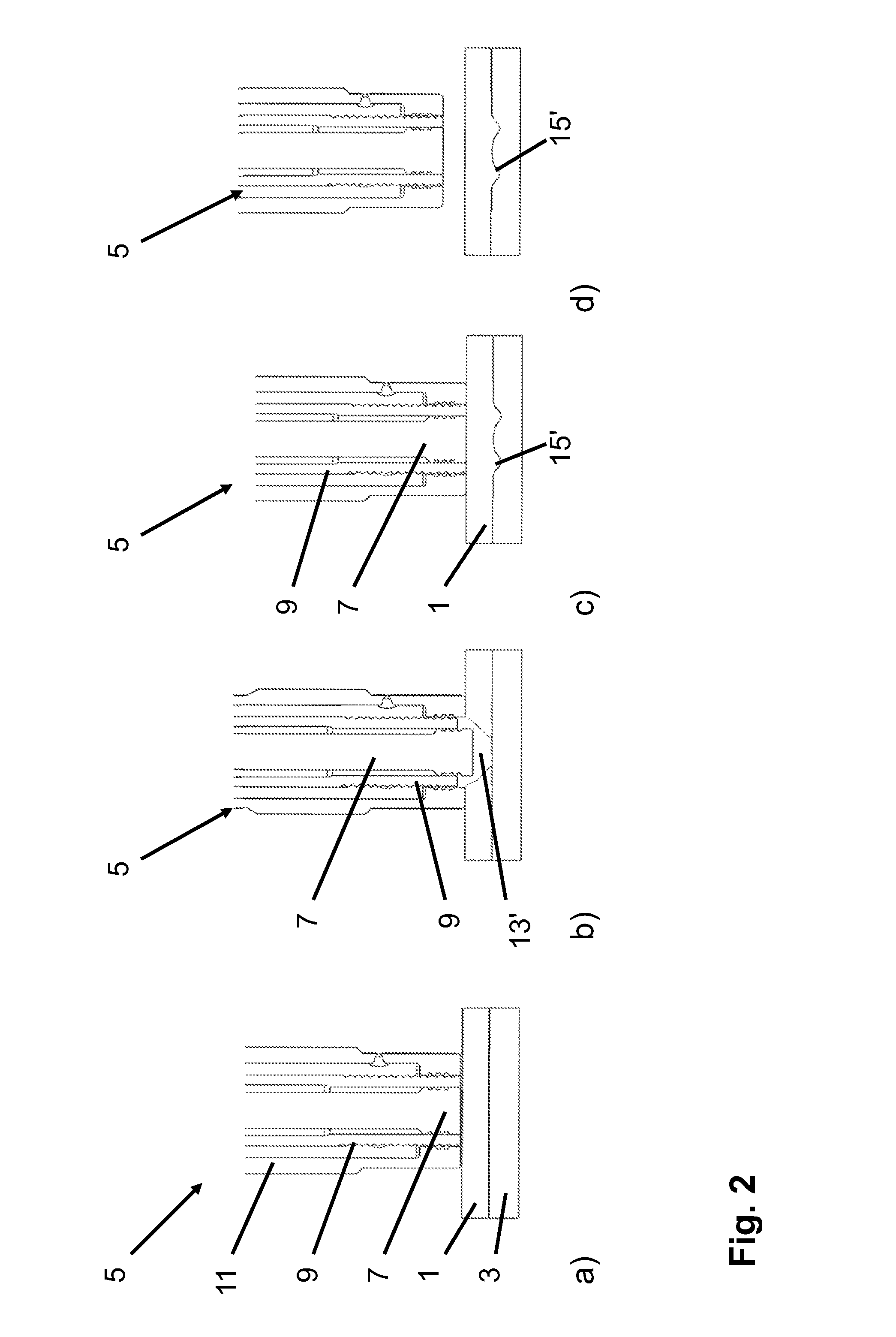

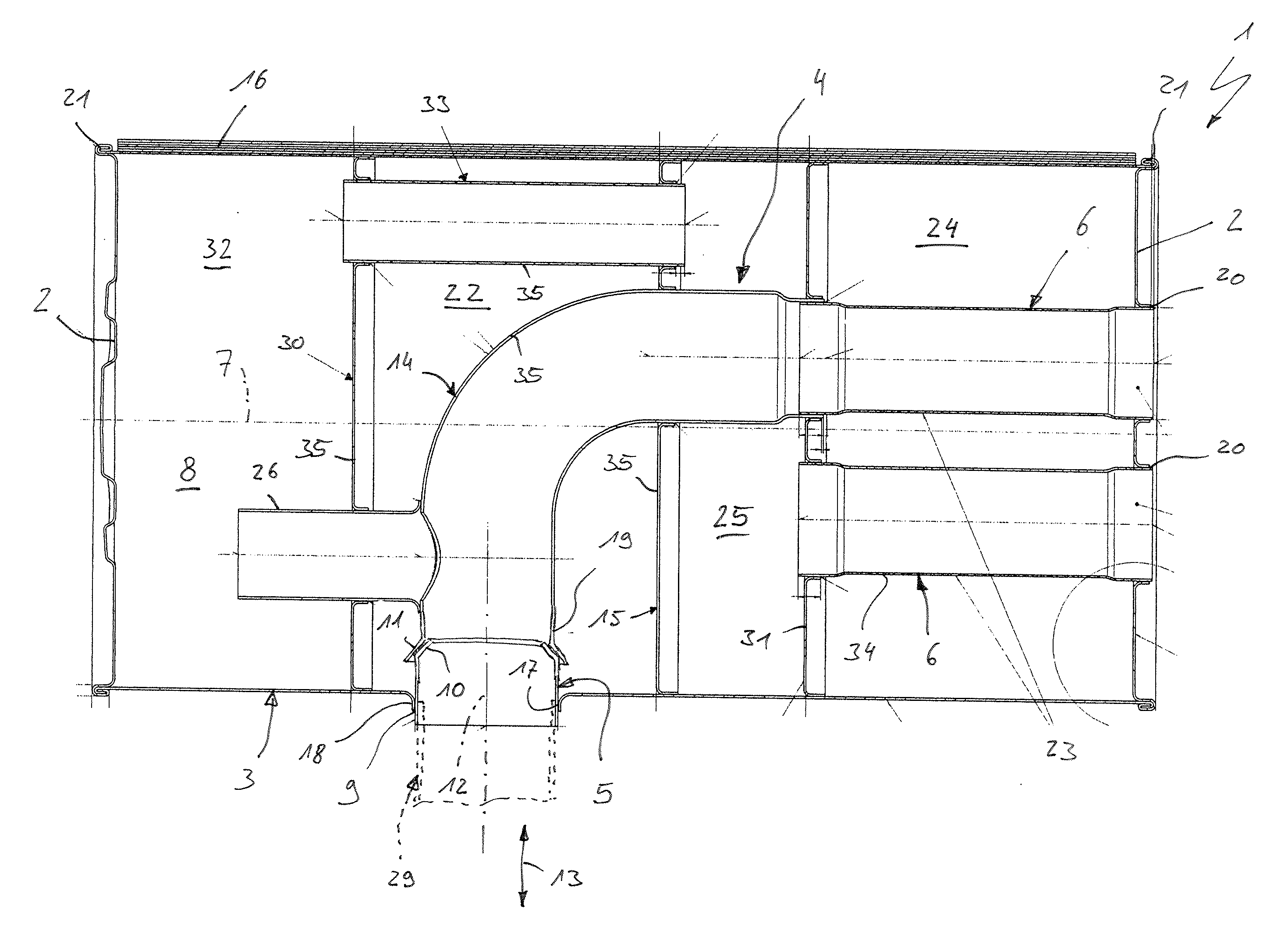

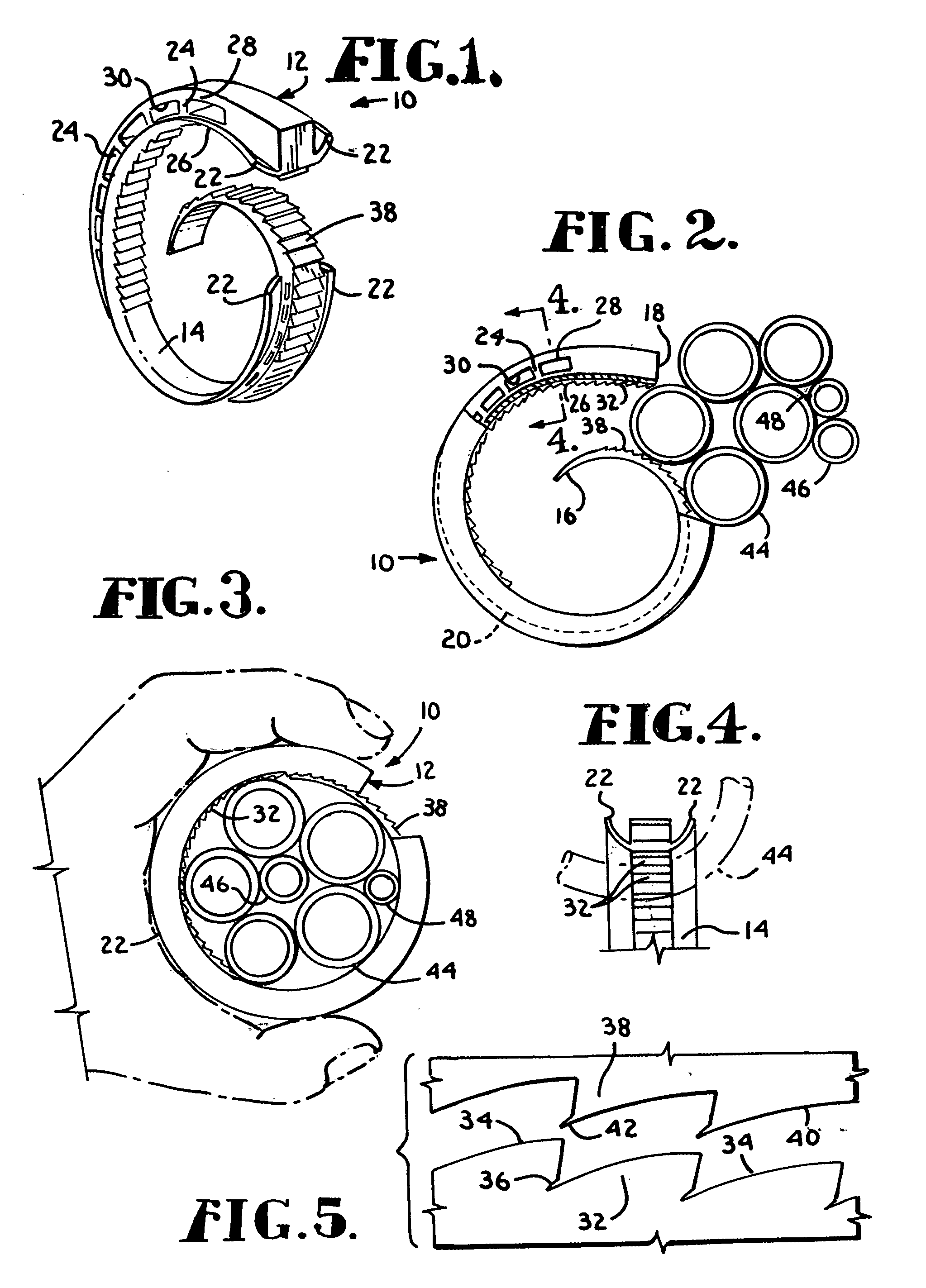

Molding machine and locking mechanism for securing tie bars

InactiveUS20050287246A1Positive engagementSimple processFood shapingMolding machineLocking mechanism

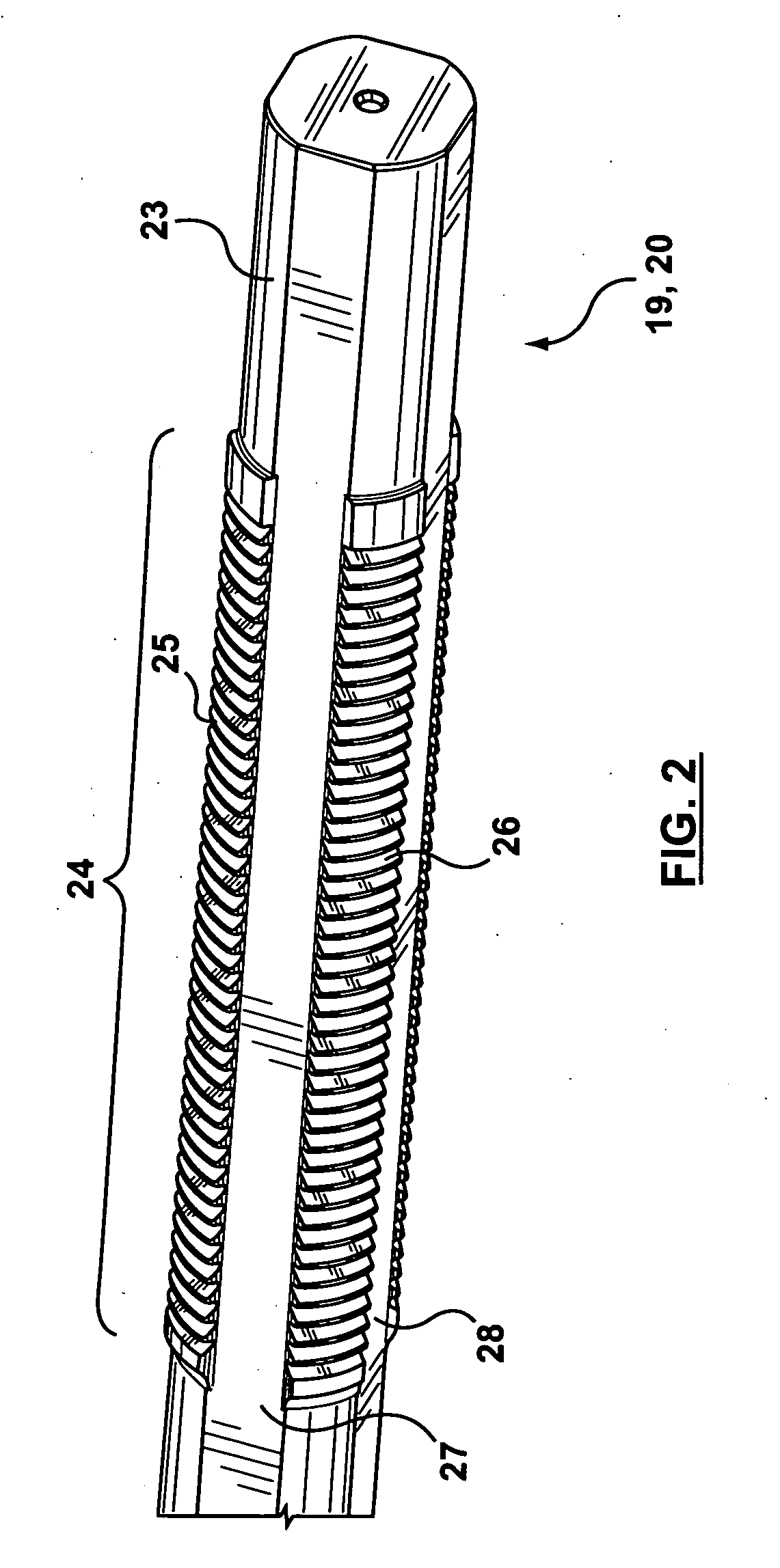

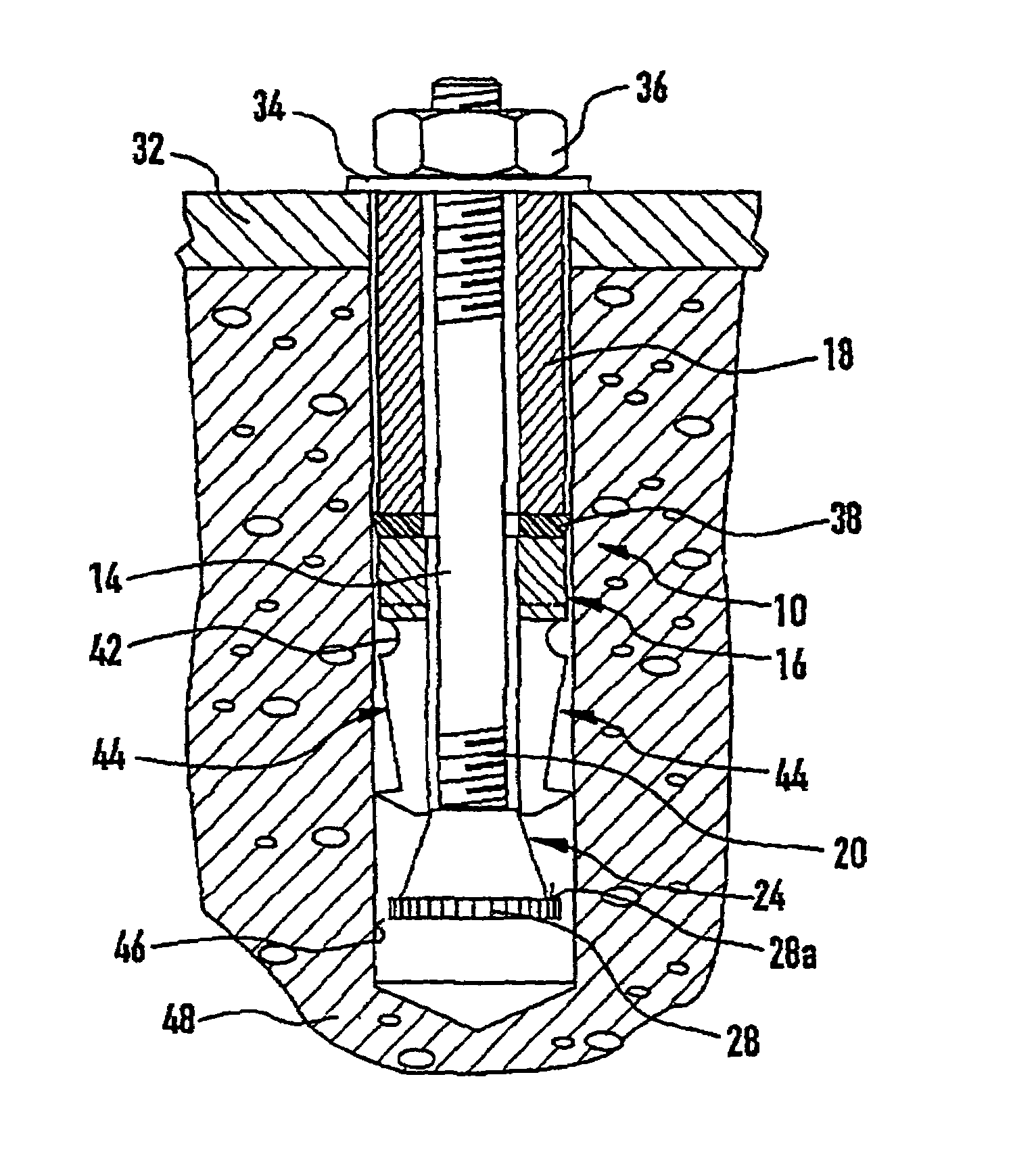

FIG. 3 illustrates a clamp piston assembly (40) comprising a body portion (44, 46, 48) in which a pocket is provided. The pocket is arranged to receive an insert in the form of a rotatable clamp bushing (48). Sets of blades or wear pads (52, 62) are positioned on both an internal surface (51) of the pocket and the external surface of the clamp bushing (48) and cooperate to form sealable chambers that extend about the circumference of the clamp bushing (48). These chambers are in fluid communication with suitable processor-controlled valves (82, 84) and hydraulic or pneumatic pumps (80) that operative to purge and inject fluid from and into the chambers. Pressurized fluid acting within selected chambers causes rotation of the clamp bushing (54). The insert also contains a row of teeth (58) arranged to selectively engage corresponding teeth (25, 26) in a tie-bar (19, 20). The clamp bushing (48) is hence independently rotatable from its surrounding body (48) that, in use, is mechanically attached to an injection molding machine (10).

Owner:HUSKY INJECTION MOLDING SYST LTD

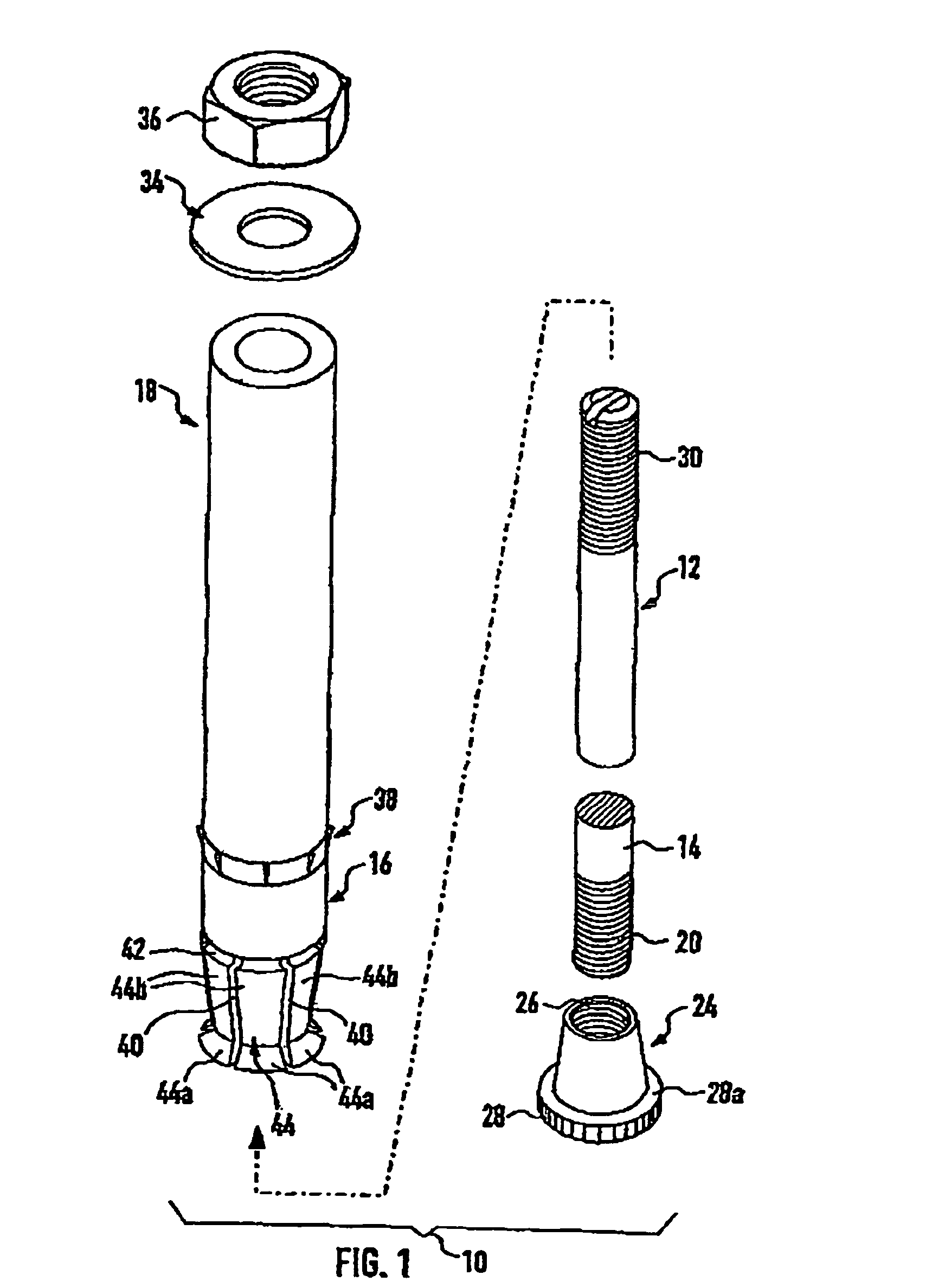

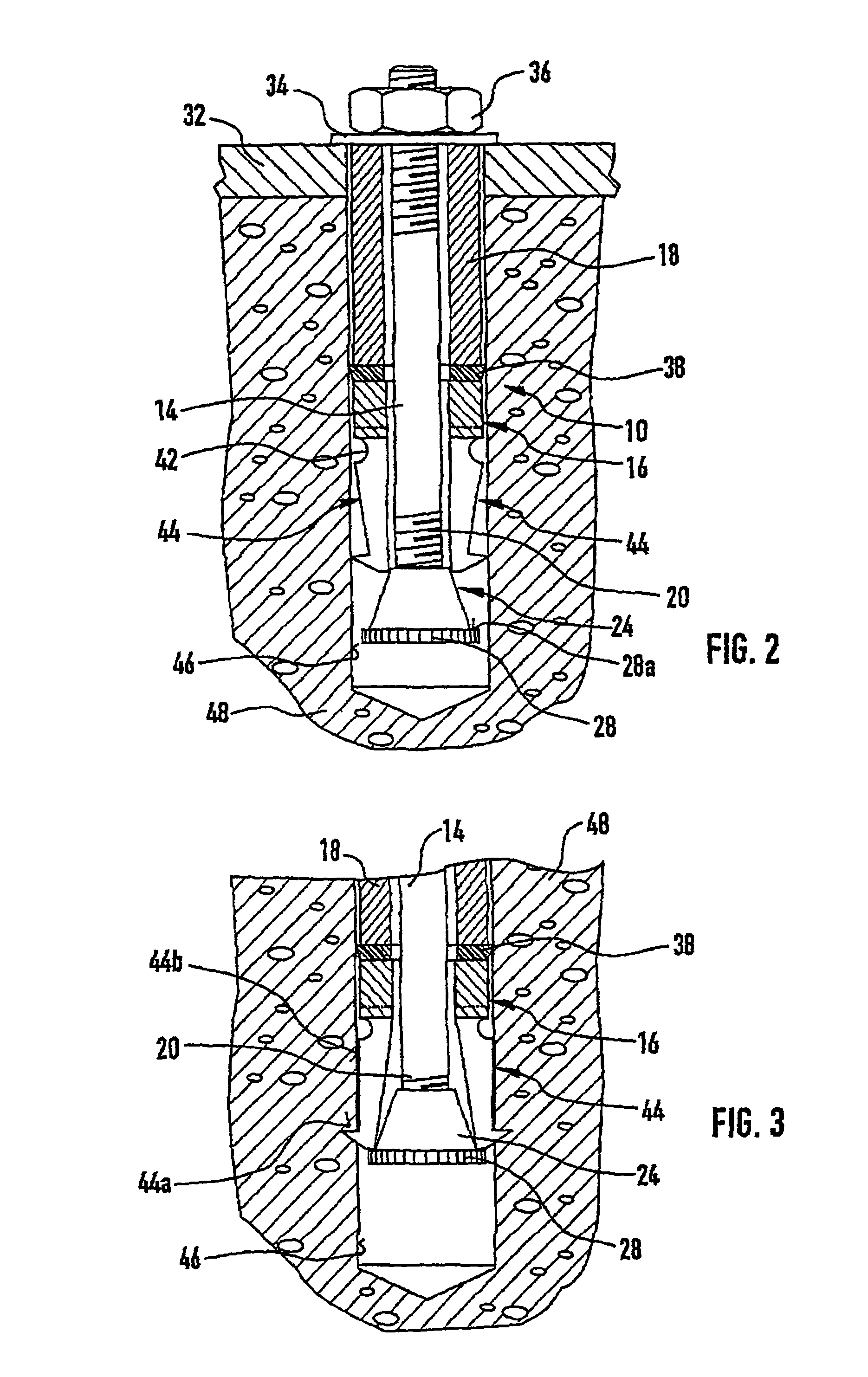

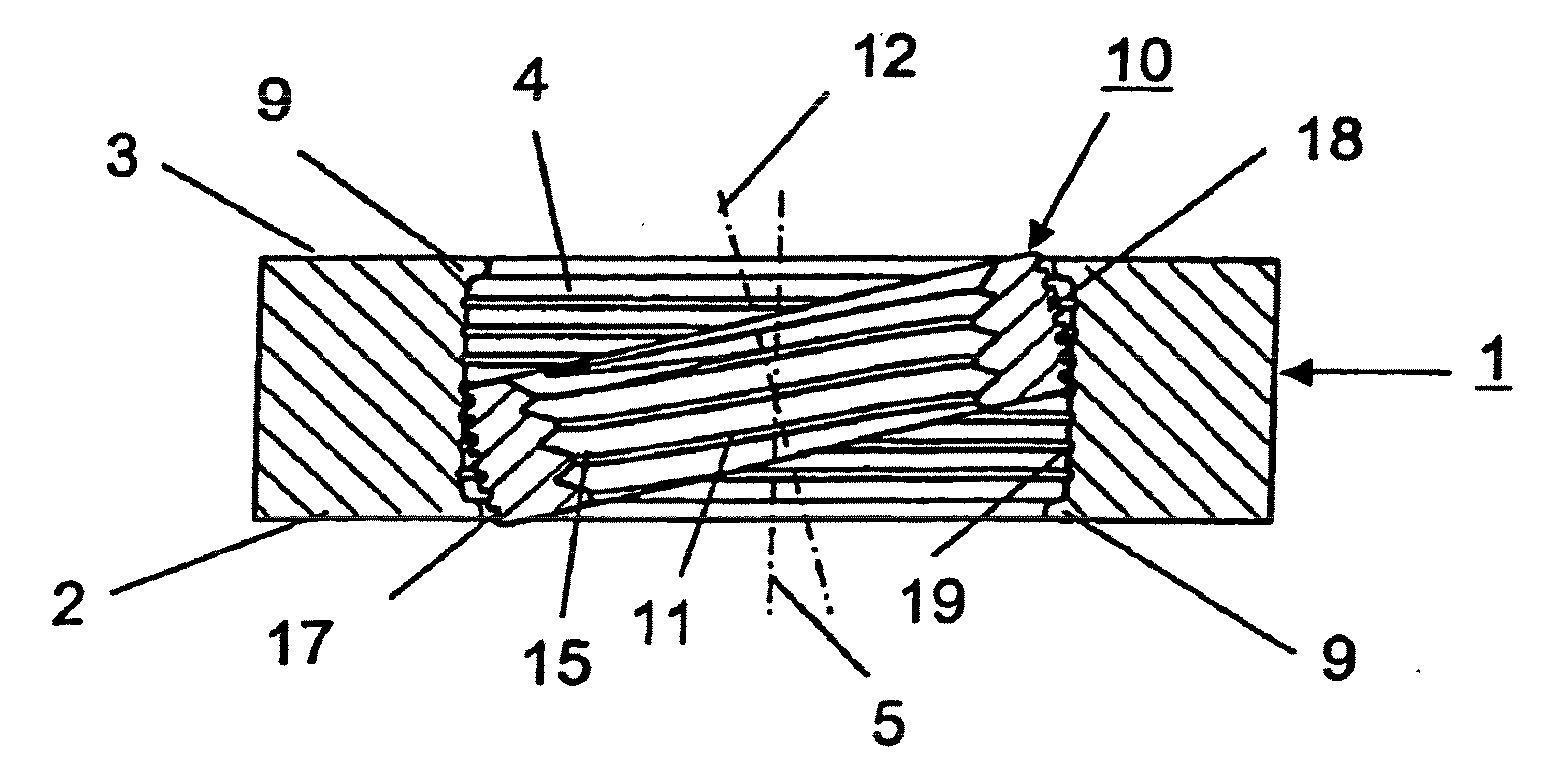

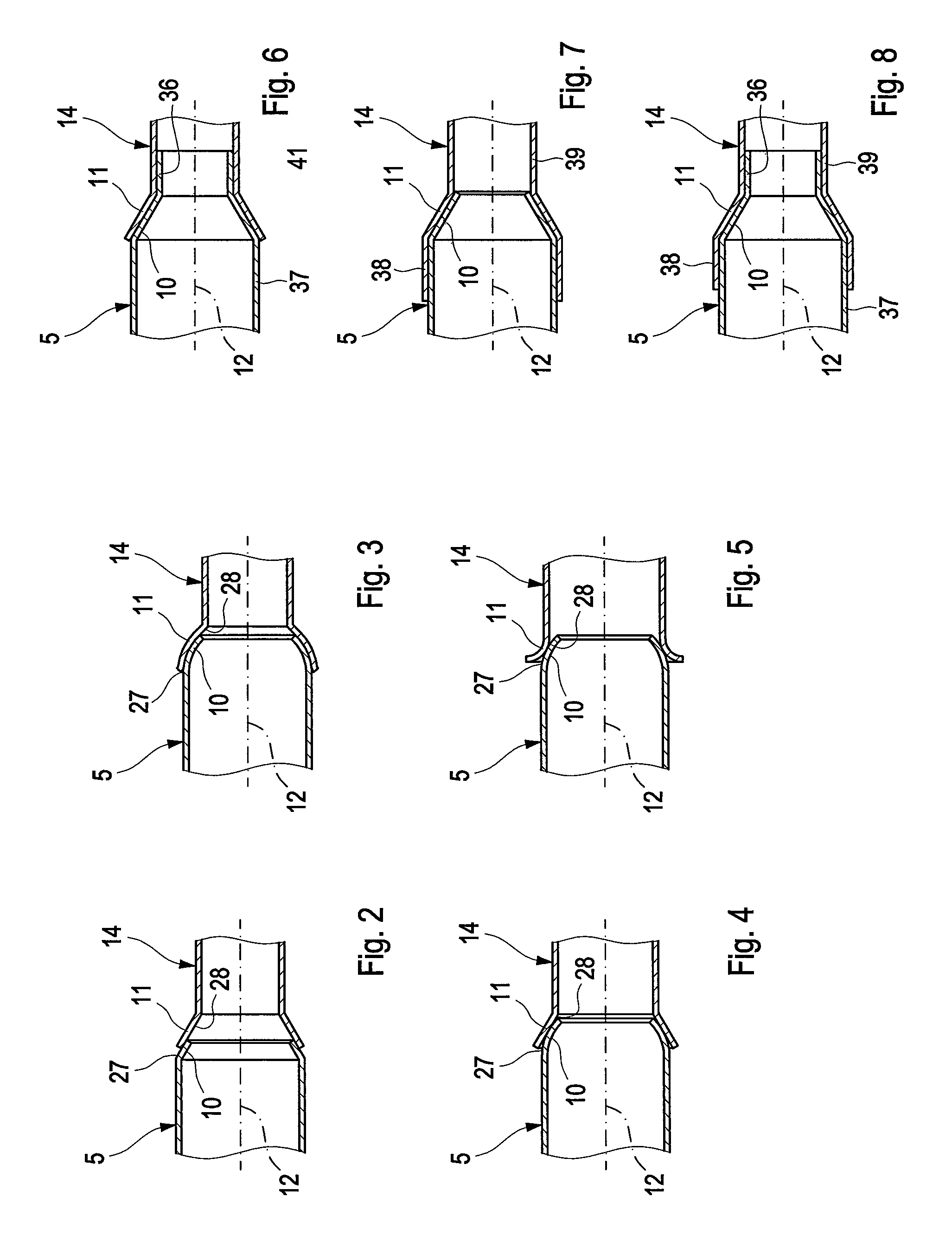

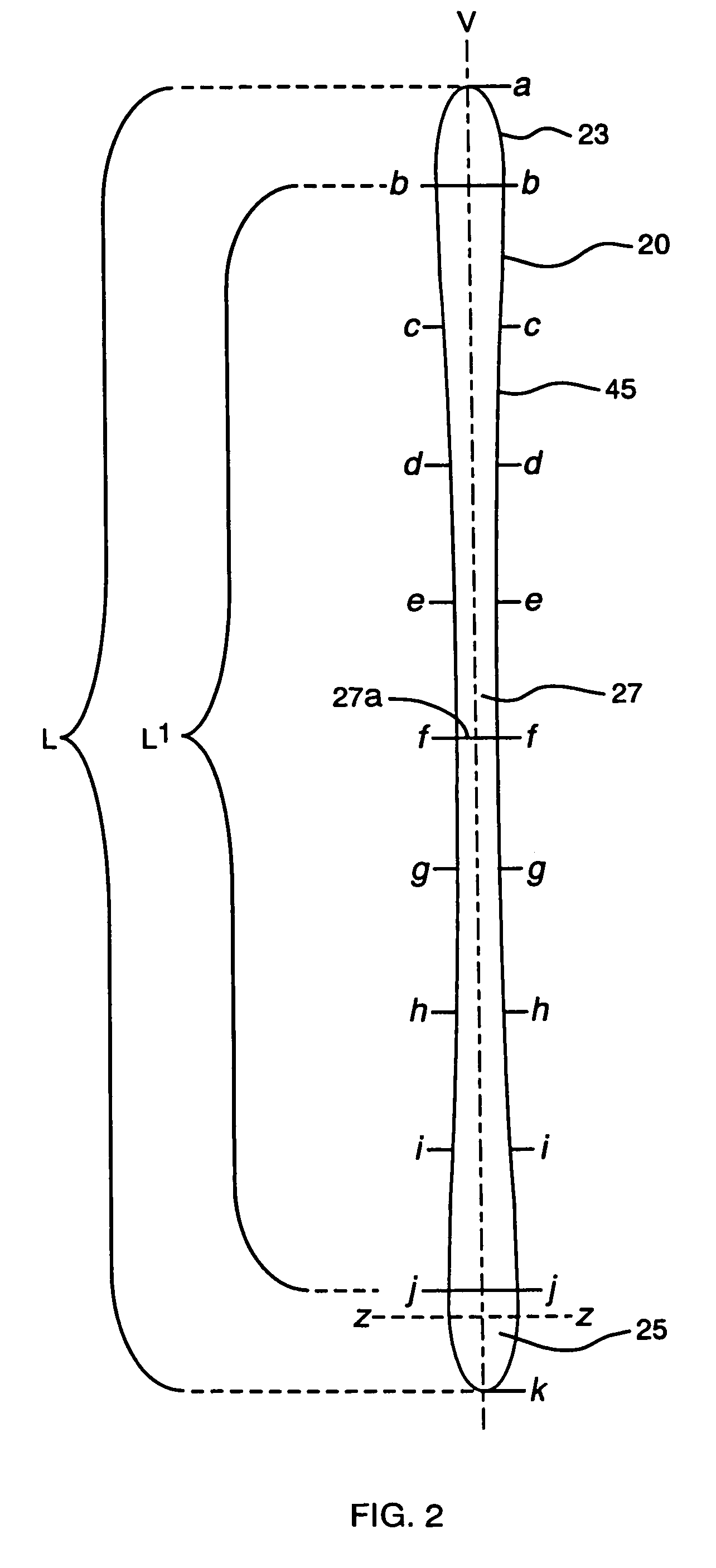

Undercut anchor element that can be mounted with positive engagement

An undercut anchor element comprising a shank of an anchor bolt. The shank passes through a base part, which is provided for effecting an anchoring, passes through a spacer sleeve, and at the end thereof is provided with a tightening head. The tightening head can be pulled inside the base part, which is subdivided into anchoring segments by slots provided over a portion of the length of the base part. The slots lead from the front free end of the base part up and into the area of an encircling groove. The anchoring segments have the outer shape of two truncated cones which coincide with their ends that have a smaller diameter. The truncated cone that is located in front in a direction of mounting has an obtuse cone angle of greater than 150° and the adjoining truncated cone has an acute cone angle of less than 30°.

Owner:SIMPSON STRONG TIE IRELAND

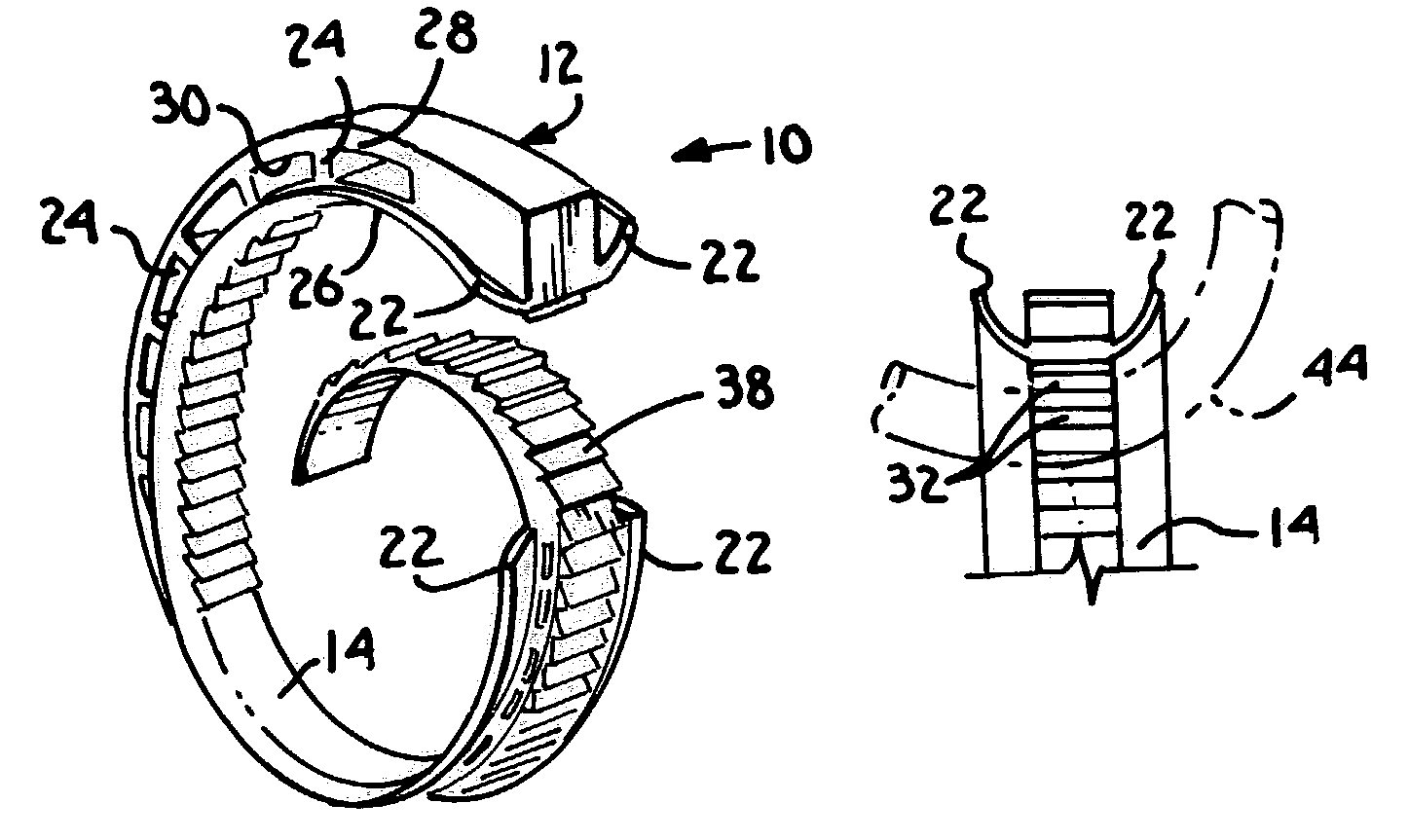

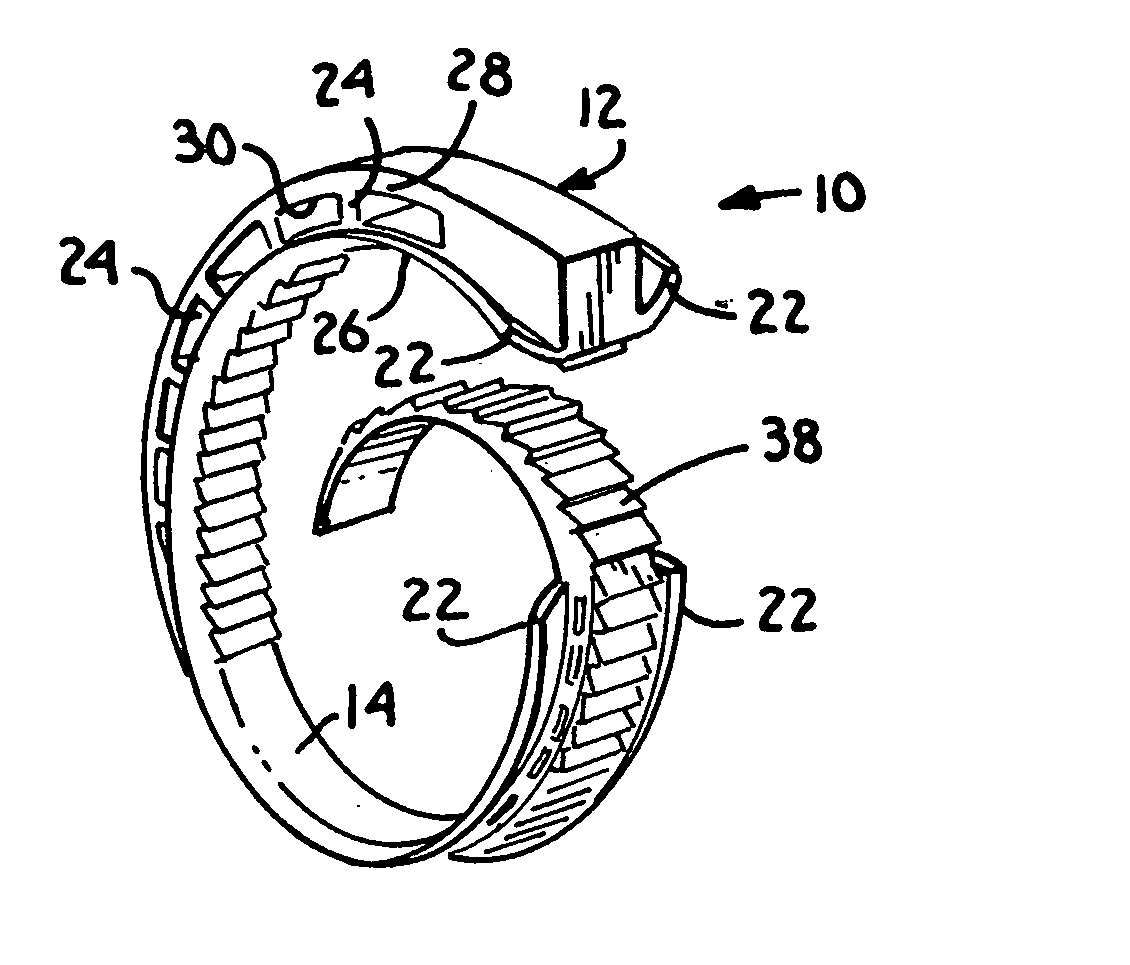

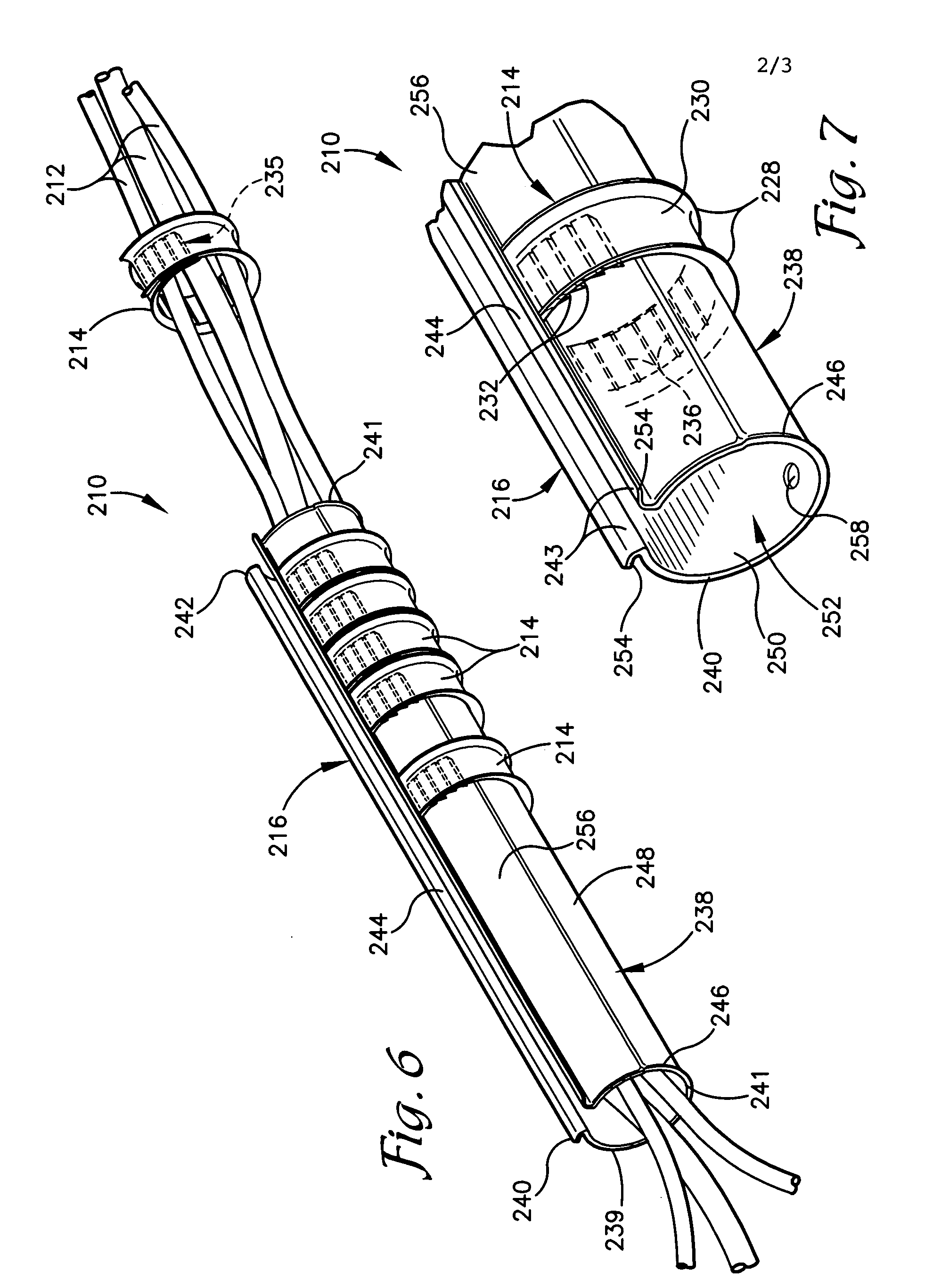

Cable retention device

InactiveUS7107653B2Overcome disadvantagesInhibit bindingSnap fastenersStands/trestlesClosed loopEngineering

A tie for bundling a plurality of elongated objects is formed in a generally arcuate configuration from a material having shape retaining memory properties. Complemental teeth on two opposed surface lock the two surfaces together to form a closed loop.

Owner:DT SEARCH & DESIGNS

Device for osteosynthesis

InactiveUS20080172094A1Reduced cross sectionPositive engagementSuture equipmentsLigamentsEngineeringBone screws

A device for osteosynthesis that includes a fixation element having at least one through hole designed to receive a pivotable bushing for a bone screw. The through hole has a central axis and a cross-section extending orthogonally to the central axis defined by two incomplete semicircles connected to each other by at least two non-circular cut outs forming grooves in the fixation element. The device also includes at least one bushing insertable in the through hole. The bushing has top and bottom surfaces, a longitudinal axis, a central bore designed to receive a bone screw, and a peripheral outside face having at least two outwardly extending protrusions defining an axis of rotation of the bushing extending through the protrusions. A cross section of the bushing orthogonal to the longitudinal axis is shaped such that the bushing is pivotable about the axis of rotation defined by the protrusions.

Owner:SYNTHES USA

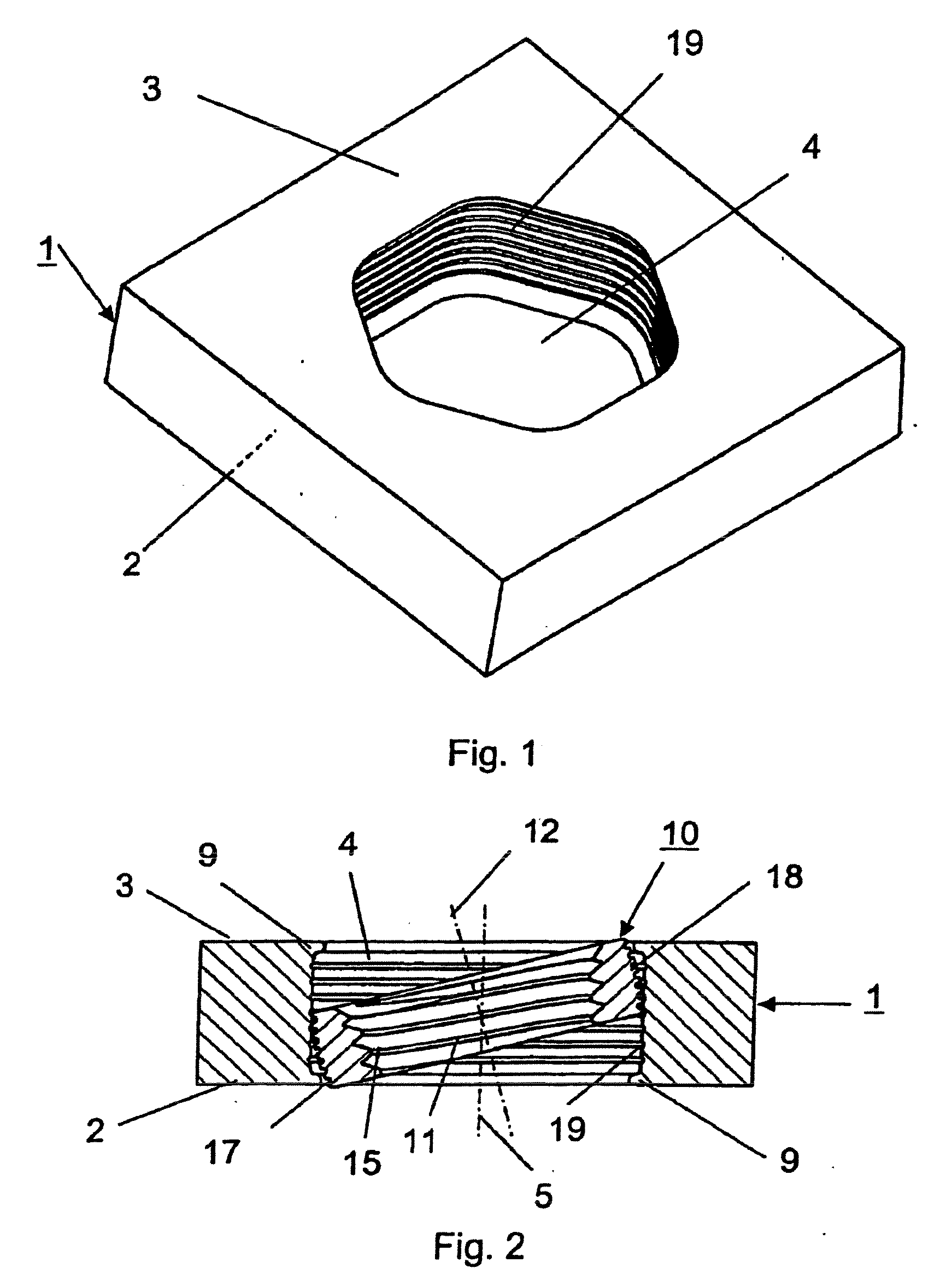

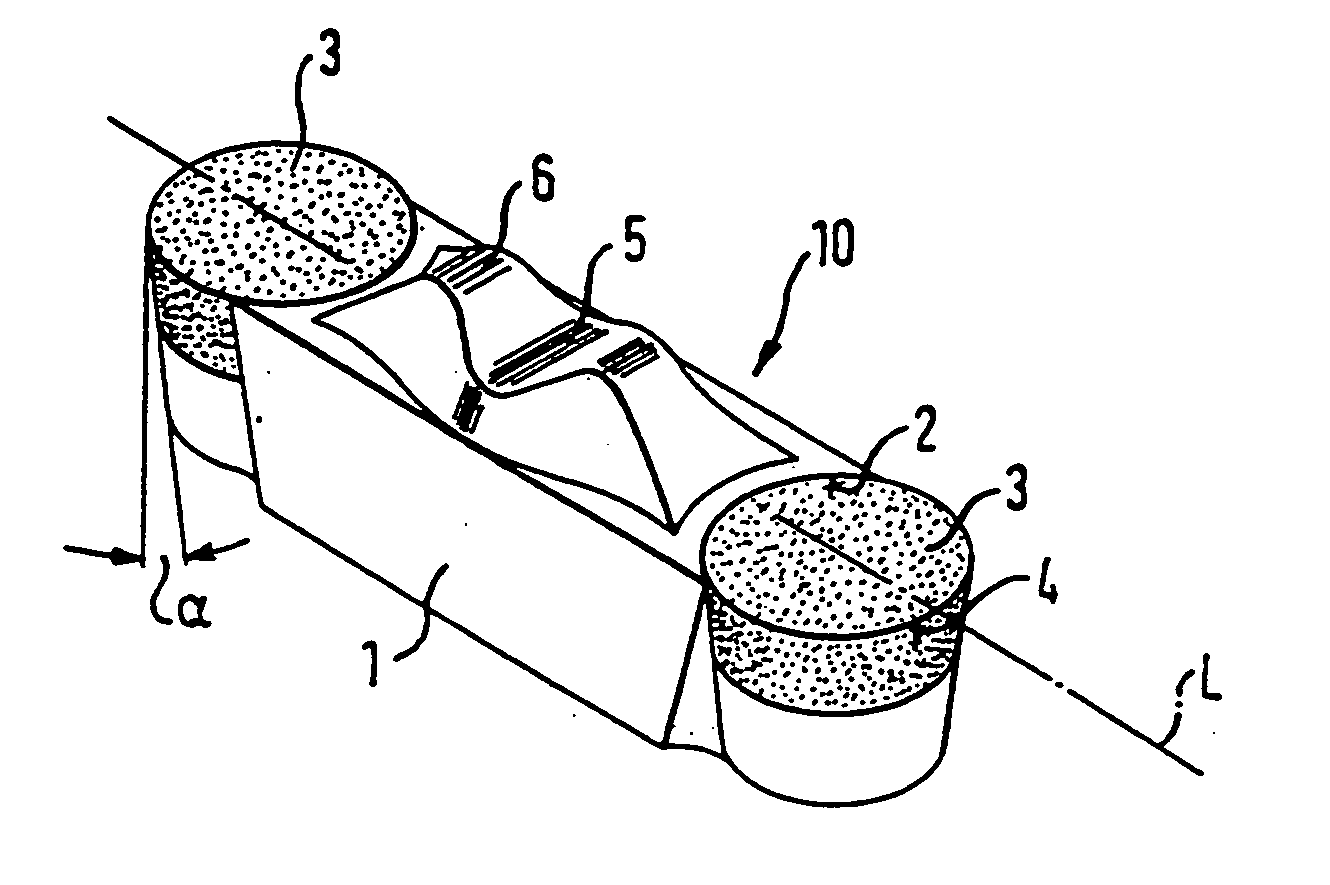

Cutting insert and use thereof

InactiveUS7313991B2High mechanical strengthSmall widthTool workpiece connectionWorkpiecesEngineeringCemented carbide

A cutting insert made of cemented carbide and the use thereof for recessing or copy-turning, preferably at a high rotating speed. The cutting insert has at least one recess for insertion therein of a cutting body of a material other than cemented carbide, such as a ceramic material.

Owner:KENNAMETAL INC

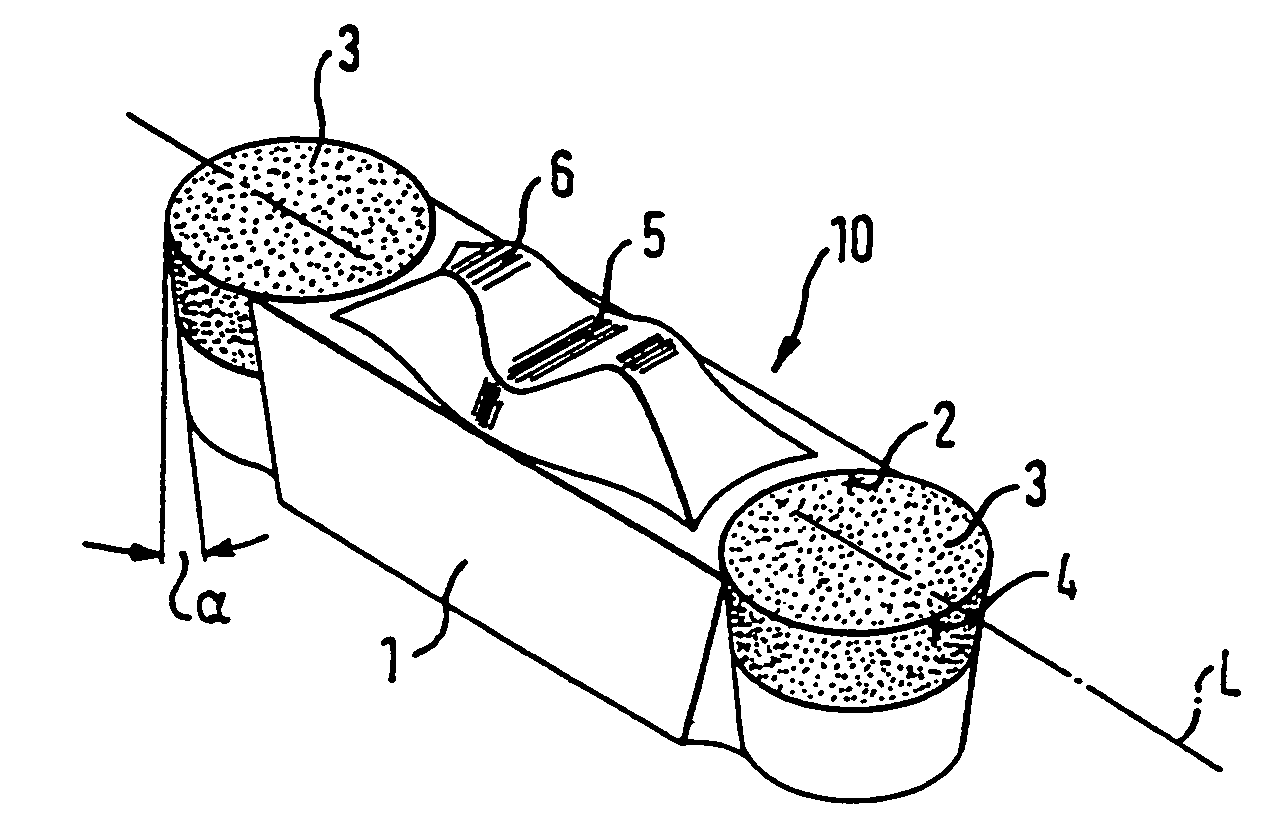

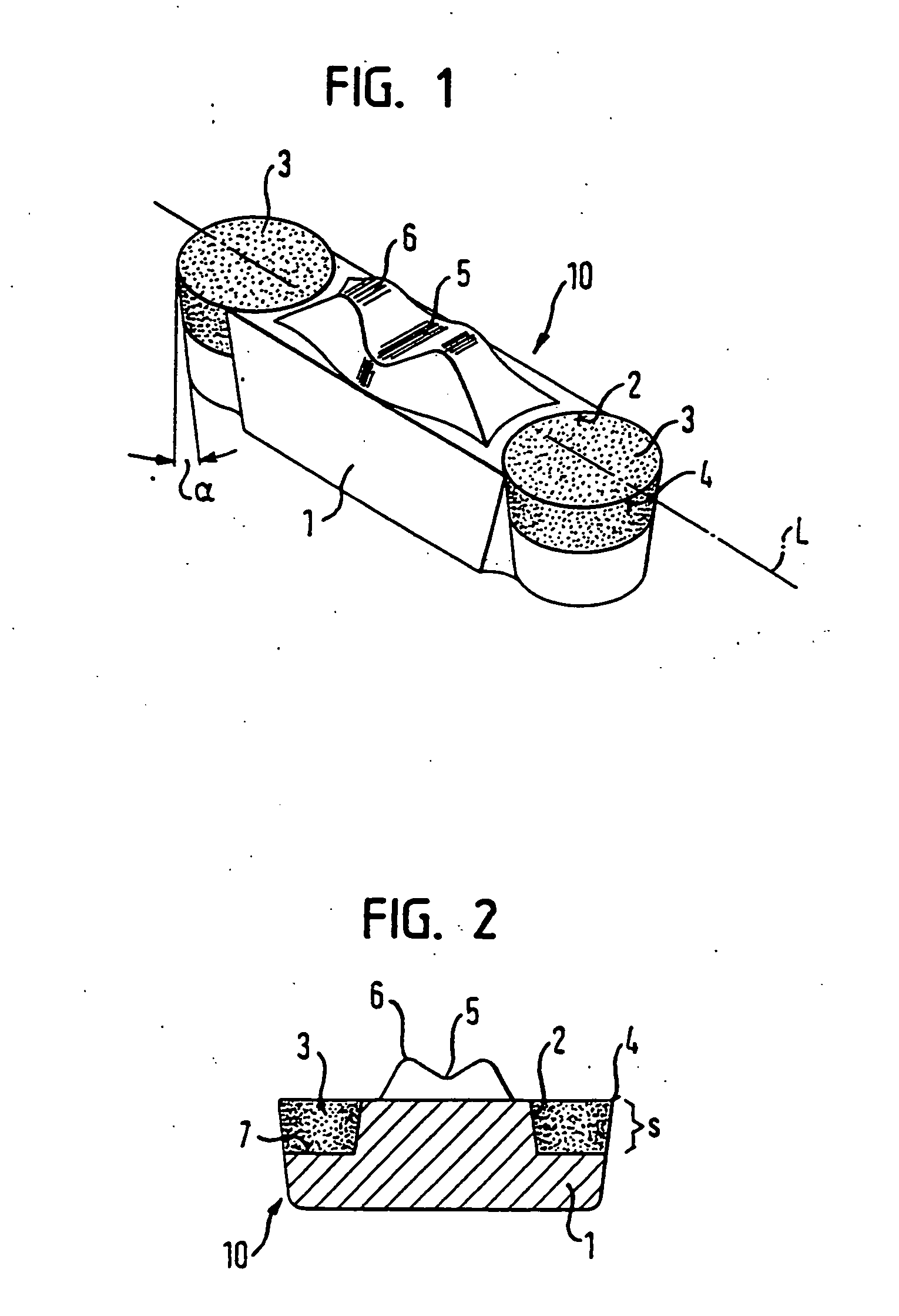

Silencer

ActiveUS8292026B2Improve stabilityPositive engagementSilencing apparatusThermometers using physical/chemical changesCombustionEngineering

A silencer for an exhaust system of a combustion engine, more preferably of a motor vehicle, has two end face bottoms facing away from each other, a closed circumferential jacket, at least one silencer insert, at least one inlet pipe and at least one outlet pipe. At least one of the pipes extends through the jacket into the silencer interior and is fastened to the jacket. The manufacture can be simplified if the pipe extending through the jacket has a cone, if the silencer insert on an intermediate pipe has a mating cone which engages in the cone.

Owner:PUREM GMBH

Cutting insert and use thereof, and a cutting insert especially for turning aluminum

InactiveUS20040258491A1High mechanical stiffnessImprove applicabilityTool workpiece connectionWorkpiecesCemented carbideTrademark

A cutting insert made of cemented carbide and the use thereof for recessing or copy-turning, preferably at a high rotating speed. The cutting insert has at least one recess for insertion therein of a cutting body comprising a cutting material different from cemented carbide to form a firm connection, the cutting body having a cutting edge formed thereon. The cutting insert has high mechanical strength even with small dimensions in the high-temperature range because the cutting body comprises a ceramic cutting material and has a geometric shape at least a portion of which is congruent with the geometric shape of the recess. The abstract of the disclosure is submitted herewith as required by 37 C.F.R. §1.72(b). As stated in 37 C.F.R. §1.72(b): "A brief abstract of the technical disclosure in the specification must commence on a separate sheet, preferably following the claims, under the heading "Abstract of the Disclosure." The purpose of the abstract is to enable the Patent and Trademark Office and the public generally to determine quickly from a cursory inspection the nature and gist of the technical disclosure. The abstract shall not be used for interpreting the scope of the claims."Therefore, any statements made relating to the abstract are not intended to limit the claims in any manner and should not be interpreted as limiting the claims in any manner.

Owner:KENNAMETAL INC

Decorative wall covering with improved interlock system

ActiveUS20080098683A1Easy and engagementHelp positioningRoof covering using tiles/slatesCovering/liningsEngineeringFlange

A roof or wall covering comprising a plurality of horizontal courses of molded plastic panels each formed with a single row of simulated shake shingles. The panels have a continuous upper interlock flange that facilitates inner-engagement of the panels of overlying courses without cumbersome handling of numerous small interlock fingers which can be missed during installation. Cooperating detents are provided between the overlying lower and upper marginal edge regions which facilitate proper positioning of the panels and which support the weight of the panel during securement to a wall surface. A bottom interlock flange is supported transversely across a rear side of the panel by vertically-spaced support plates which facilitate both liquid drainage and air circulation through the installed wall covering. In the preferred embodiment, the panels in alternate courses are identically formed with different shake patterns for enhancing the natural appearance of the wall covering.

Owner:NOVIK INC

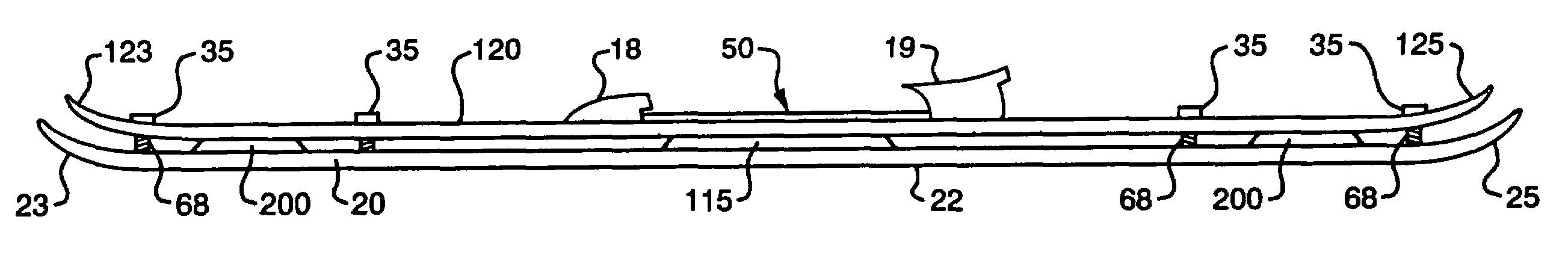

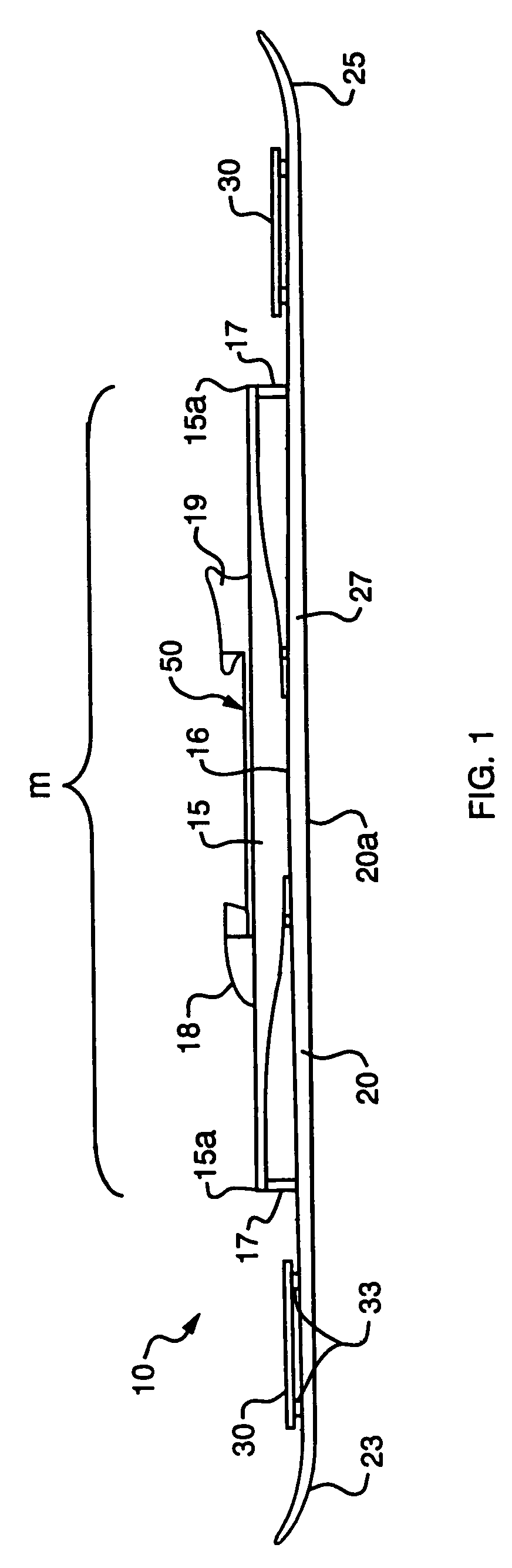

Gliding skis

A snow glider is provided having a design that facilitates gliding through snow rather than skidding. The snow glider may have a narrow waist width combined with an elevated binding assembly to promote positive engagement with a skiing surface during use. A method of skiing includes skiing downhill on a skiing surface using glider skis, wherein each ski has a ski base and a pair of edges extending along opposite sides of the base. While skiing downhill, the method of skiing also includes changing direction without skidding the skis on the skiing surface.

Owner:WILSON ANTON F

Method for joining metal and plastic workpieces

ActiveUS20110131784A1Efficient use ofBetter candidateNutsLarge fixed membersBiomedical engineeringMetal

The present invention relates to a method for connecting a metal workpiece and a plastic workpiece by means of a joining tool, including positioning the metal workpiece and the plastic workpiece, bringing the front end of the pin, the sleeve and the clamping ring in contact with an outer surface of the metal workpiece, rotating the sleeve and the pin so as to generate friction between the front ends of the sleeve and the pin and the outer surface of the metal workpiece, and moving the pin and the sleeve in the axial direction while both are rotated, one of the sleeve and the pin penetrating into the metal workpiece and the other of the sleeve and the pin being retracted from the outer surface thereof. The axial movement into the metal workpiece is stopped before the one of the sleeve and the pin reaches the contact surface and after stopping the axial movement the one of the sleeve and the pin is retracted from the metal workpiece and the other is moved towards the outer surface of the metal surface until the front ends of the pin and the sleeve are on the same level.

Owner:HELMHOLTZ ZENT GEESTHACHT ZENT FUER MATERIAL UND KUESTENFORSCHUNG

Cable actuator for lumbar support

InactiveUS7007568B2Easy to operateLarge range of motionControlling membersBack restsEngineeringActuator

The actuator has a housing with a longitudinal passage between a first end and an opening at a second end. A spindle, supported and moveable in the passage, has oppositely handed, first and second threaded portions each nearer a respective end of the housing. A first nut fixed relative to the housing is engaged with the first threaded portion. The spindle is rotated and moved relative to the first nut by a handle at the housing first end. A second nut fixed against rotation relative to the housing and engaged with the second threaded portion moves relative to and in the same direction as the spindle as the spindle rotates. The second nut is connectable through the opening to a device, and the spindle is rotatable by the handle for adjusting the device by movement of the spindle and the second nut.

Owner:HENDERSONS IND PTY LTD

Silencer

ActiveUS20110272209A1Increased radial spring elasticitySimplifies insertion operationSilencing apparatusThermometers using physical/chemical changesInternal combustion engineCombustion

A silencer for an exhaust system of a combustion engine, more preferably of a motor vehicle, has two end face bottoms facing away from each other, a closed circumferential jacket, at least one silencer insert, at least one inlet pipe and at least one outlet pipe. At least one of the pipes extends through the jacket into the silencer interior and is fastened to the jacket. The manufacture can be simplified if the pipe extending through the jacket has a cone, if the silencer insert on an intermediate pipe has a mating cone which engages in the cone.

Owner:PUREM GMBH

Cable retention system

InactiveUS20060265840A1Inhibit bindingPositive engagementElectrical apparatusFlexible elementsEngineeringMechanical engineering

A cable retention system includes a cable tie and a storage and installation tool. The cable tie includes an elongated band having head and tail ends. The inner surface of the band includes spaced grooves offset toward the tail end to render it more flexible than the head end. Teeth along the inner surface of the band adjacent the head end and along the outer surface of the band adjacent the tail end engage in a circumferential direction when the head end overlaps the tail end. The tool has an annular configuration with an elongated longitudinal opening and an inner raceway for receiving cables. The opening enables the tube to be slipped over a group of cables and moved along the cables. As the tube is moved along the cables, the ties are slipped off and onto the cables at selected spaced locations for securing the cables into a bundle.

Owner:DT SEARCH & DESIGNS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com