Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

77results about How to "Play the role of water stop" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

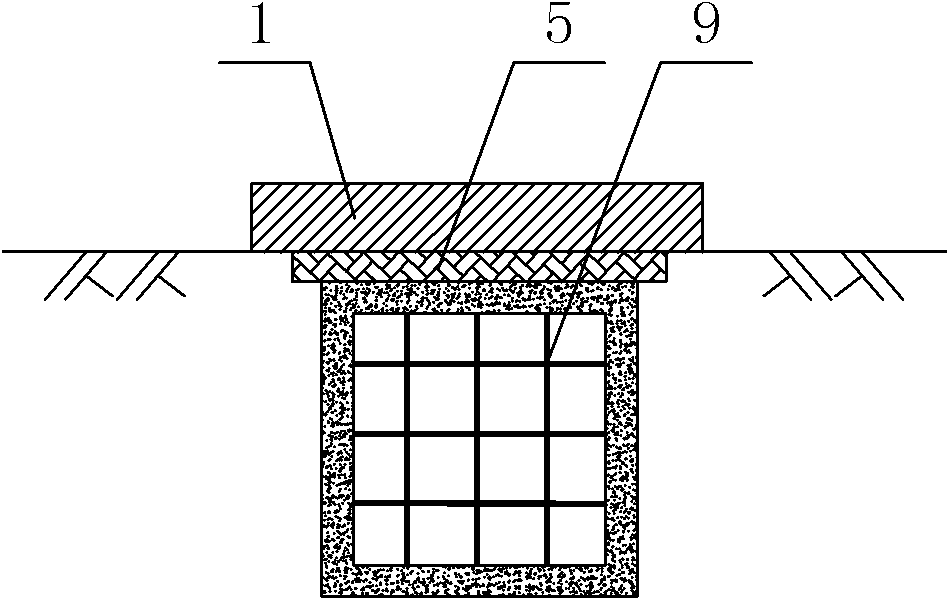

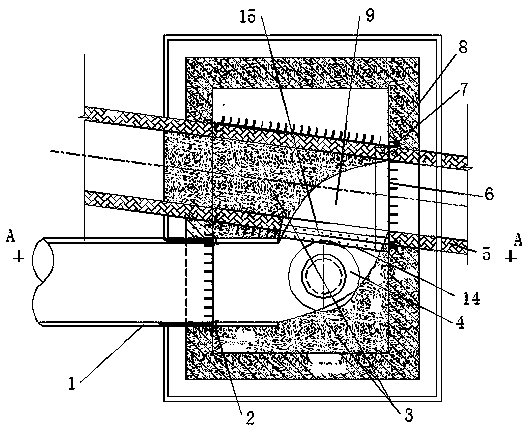

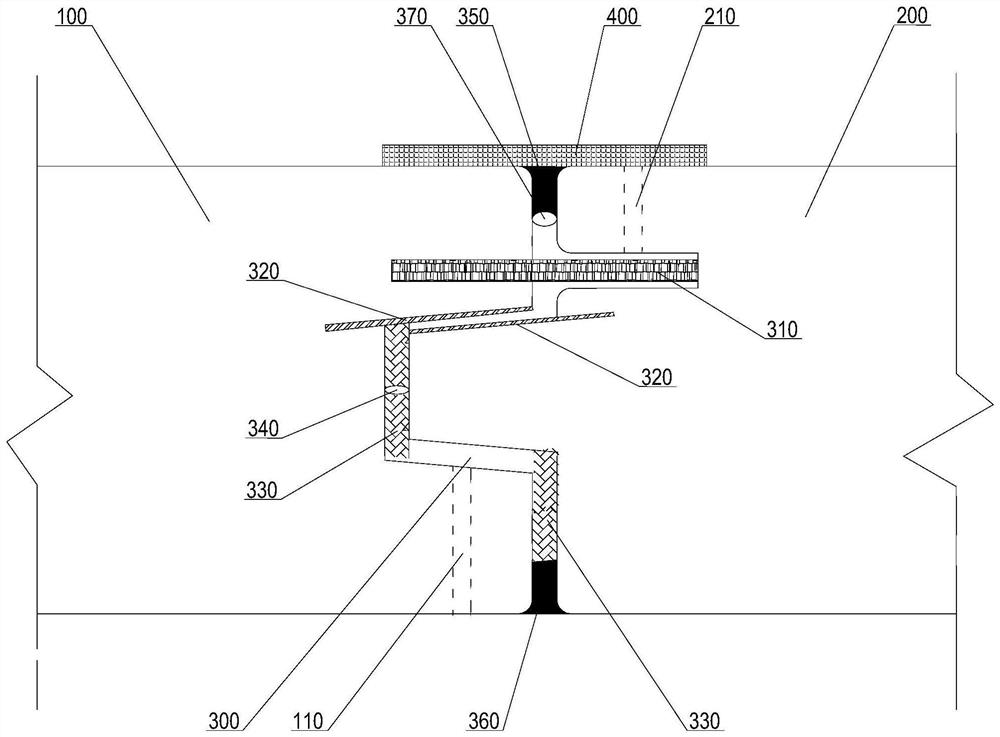

Base pit dewatering and water saving device and construction method thereof

InactiveCN101768976ASolve the precipitation problemEfficient use ofProtective foundationExcavationsWater savingBaseboard

The invention relates to a base pit dewatering and water saving device and a construction method thereof. The middle part of the base pit of a baseboard structure is provided with a well pit; the well pit is internally and vertically provided with a no-sand tube; pebbly sand is filled between the bottom and periphery of the no-sand tube; the top of the no-sand tube is higher than the top surface of the well pit; a water pump is arranged in the no-sand tube; blinding layer concrete is poured at the top surface of the well pit which is at the periphery of the no-sand tube and the side wall of the base pit of the baseboard structure; and the top elevation of the no-sand tube is flush with the elevation of a blinding layer; a dewatering conduit is pre-buried in a base pit baseboard right above the no-sand tube, a waterproof layer is paved on the blinding layer concrete, a layer of waterproof and protective concrete is poured on the waterproof layer, and the base pit baseboards are poured above the waterproof and protective concrete and at the periphery of the dewatering conduit. The method of the invention has lower investment, saved cost and less amount of dewatering amount, thereby reducing the loss of underground water and protecting water resource; and the method can be adopted for a project in which the well point dewatering method is not ideal for dewatering or a project in which the underground water is near the base pit elevation.

Owner:CSCEC CITY CONSTR DEV +1

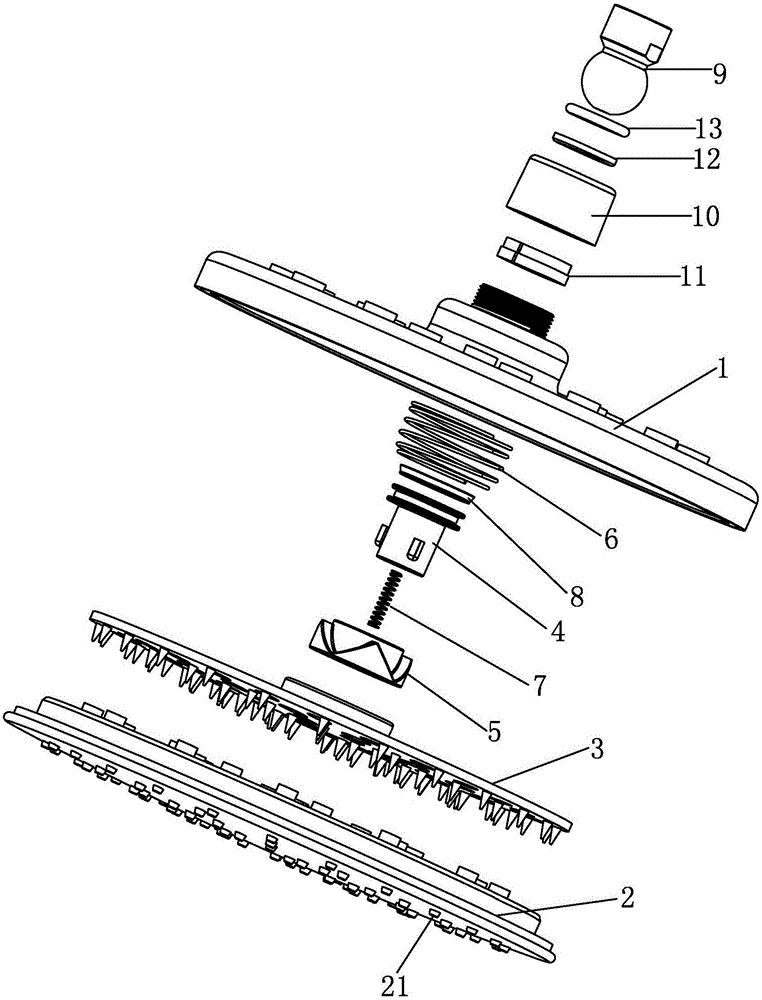

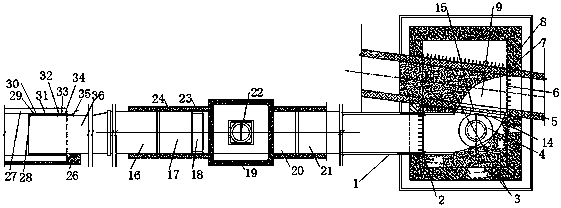

Automatic descaling sprinkler and automatic descaling method for sprinkler

The invention discloses an automatic descaling sprinkler and an automatic descaling method for the sprinkler. The automatic descaling sprinkler comprises a sprinkler body, a water outlet face cover, a descaling plate and an automatic control mechanism. The descaling plate can be vertically and movably arranged between the sprinkler body and the water outlet face cover, and descaling needles in one-to-one correspondence with all or part of water outlet holes in the water outlet face cover are distributed on the bottom face of the descaling plate. The automatic control mechanism comprises a driving part movably arranged between the sprinkler body and the water outlet face cover and impacted by water flow to achieve the movement, a transmission part which is rotatably arranged on the inner side of the water outlet face cover and is matched with the driving part in a linkage manner, and a reset device used for driving any one or more of the descaling plate, the transmission part and the driving part to reset, wherein the driving part moves to drive the transmission part to rotate by a preset angle, the transmission part and the descaling plate are matched with a first transmission structure, the transmission part rotates to drive the descaling plate to move upwards, and therefore the descaling needles of the descaling plate can retreat from the water outlet holes. The automatic descaling sprinkler is small in number of parts, simple in structure, easy to assemble, low in cost and obvious in descaling effect.

Owner:JOMOO KITCHEN & BATHROOM

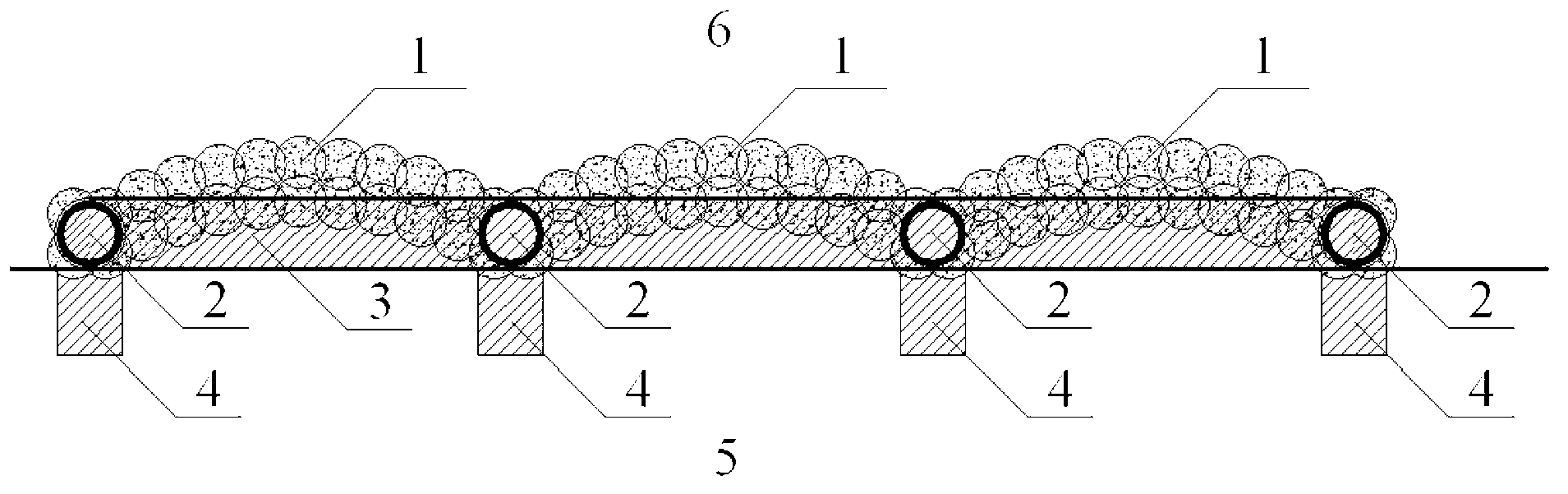

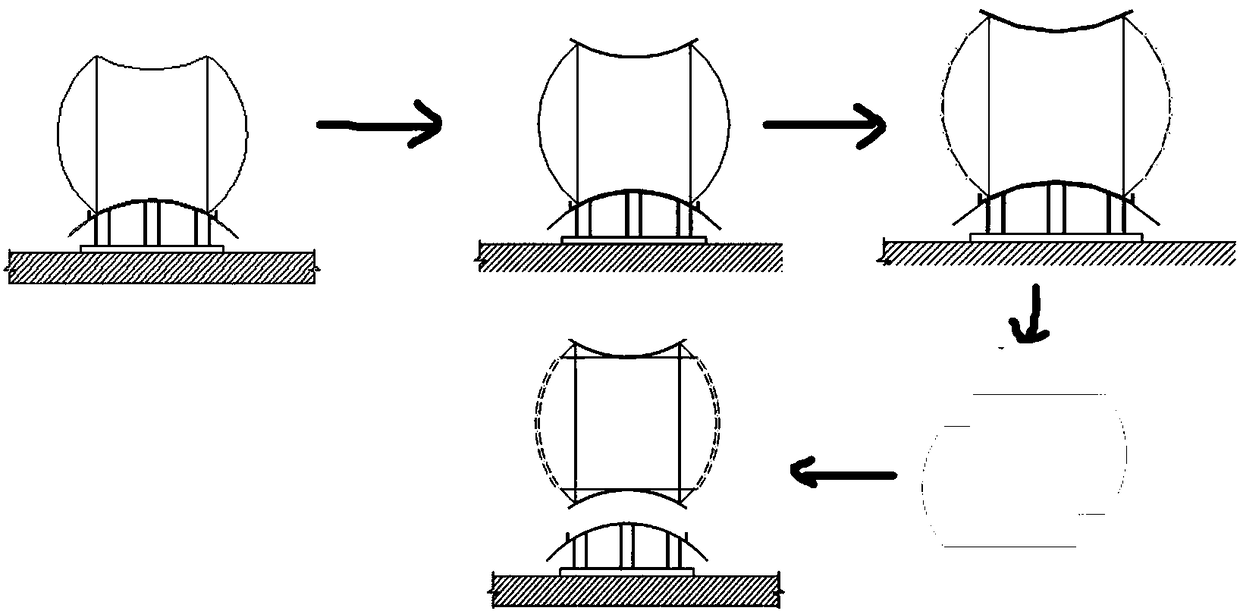

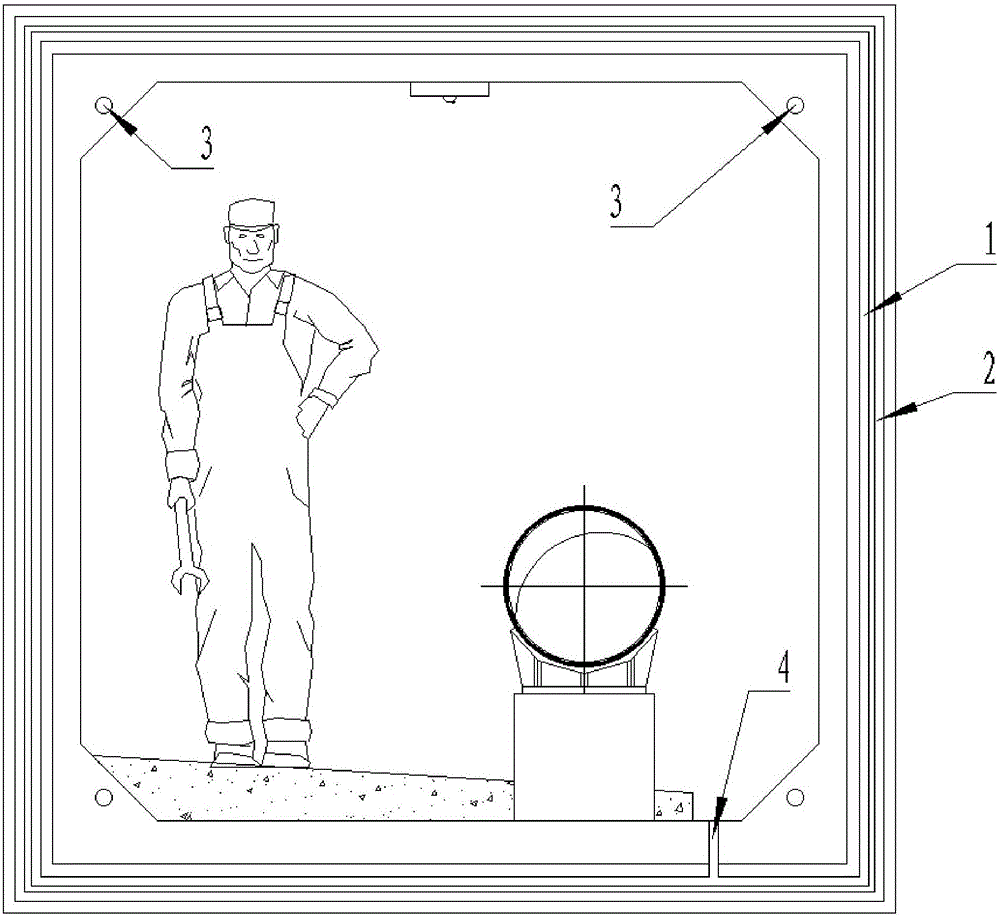

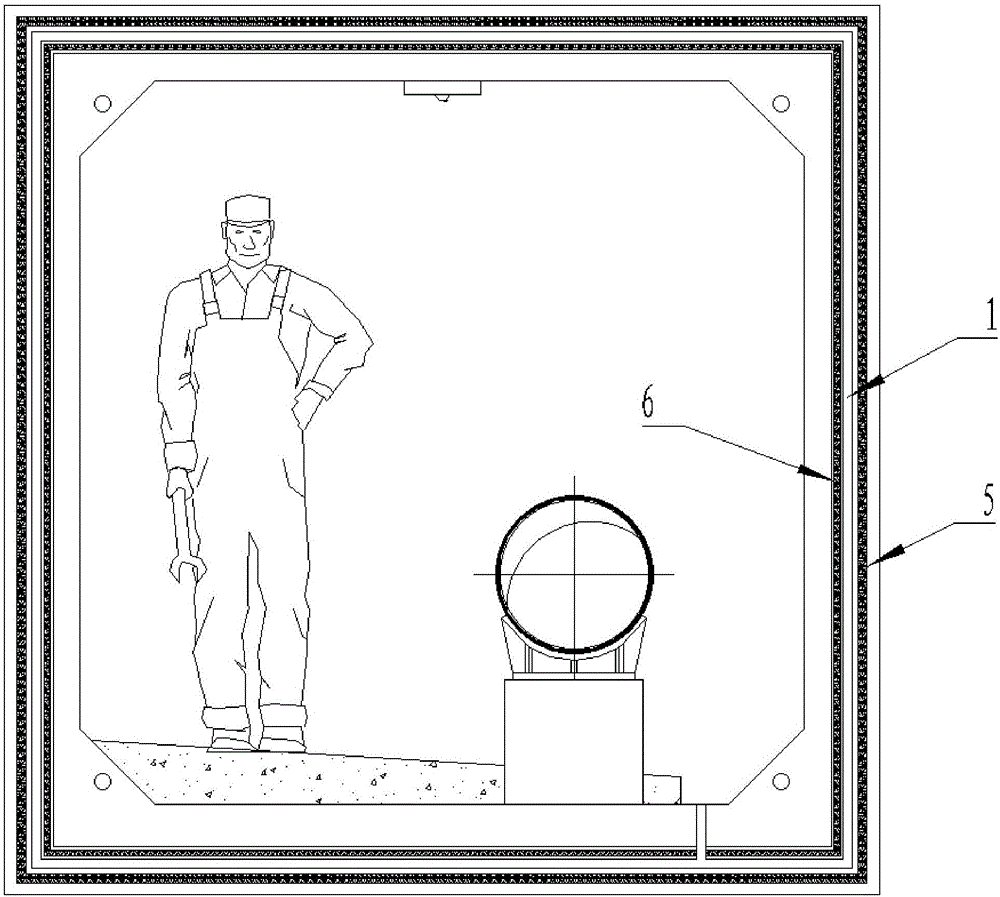

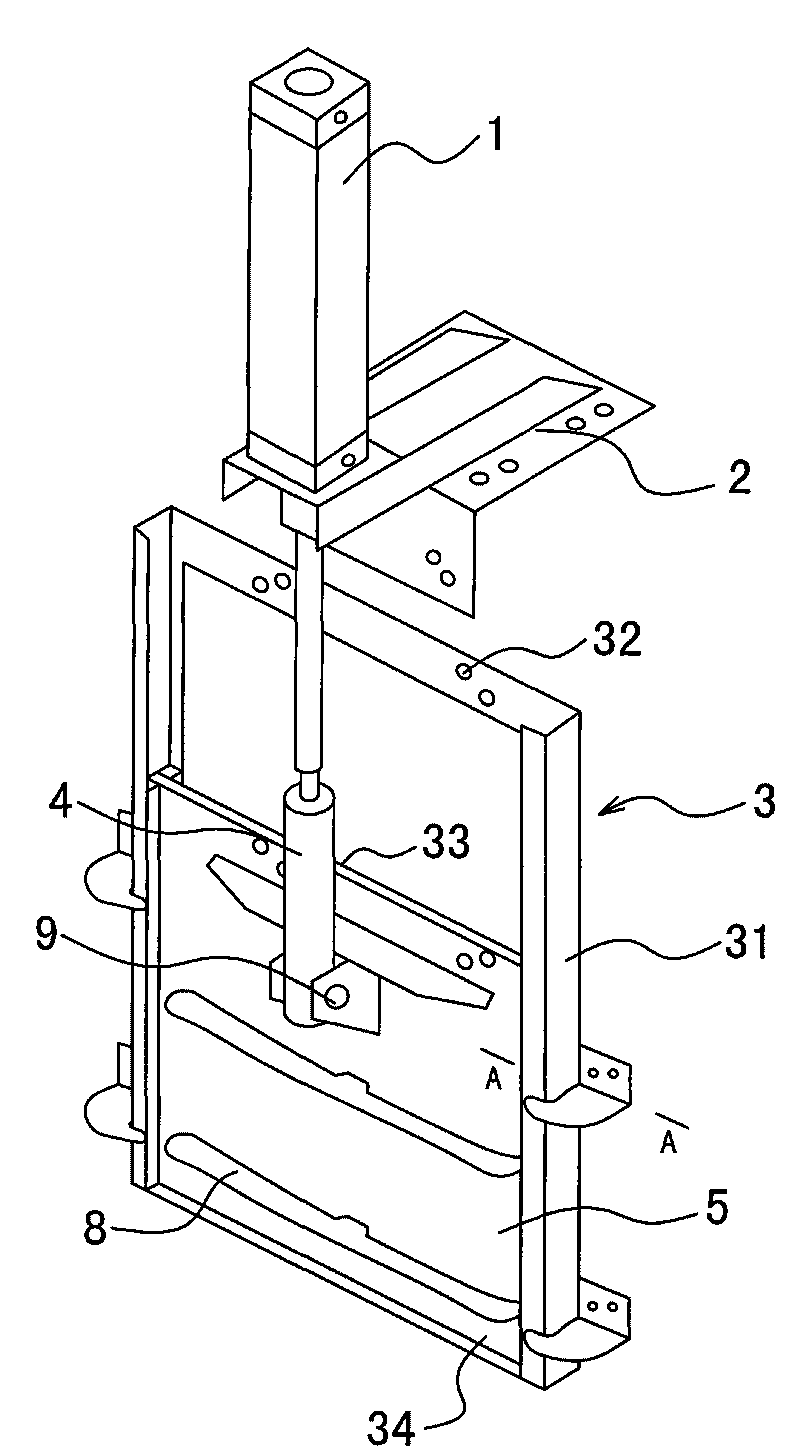

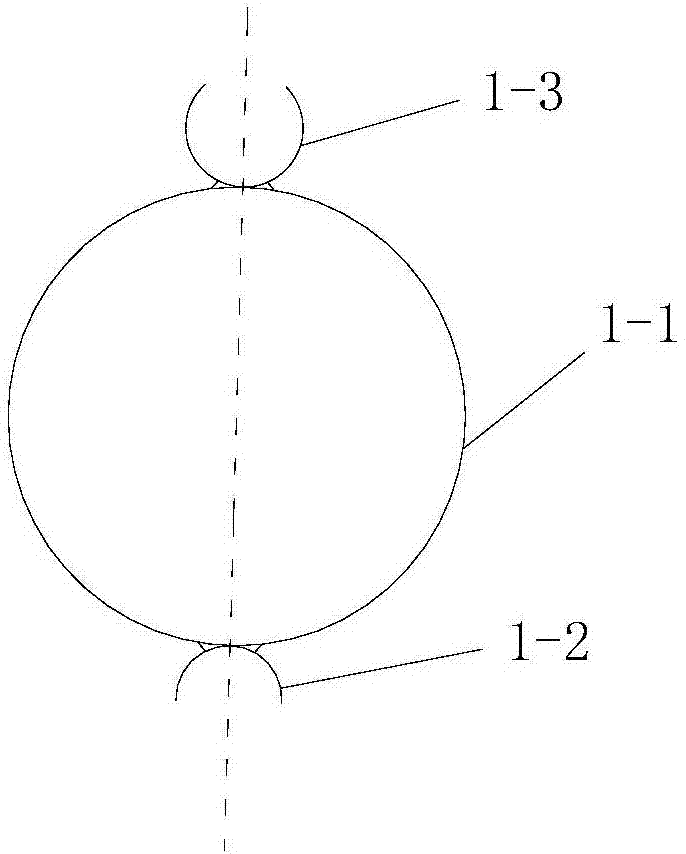

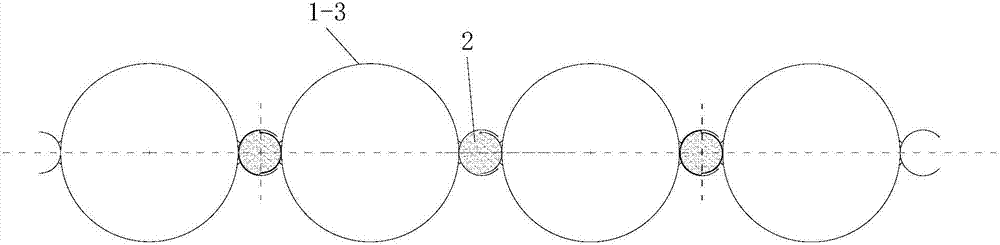

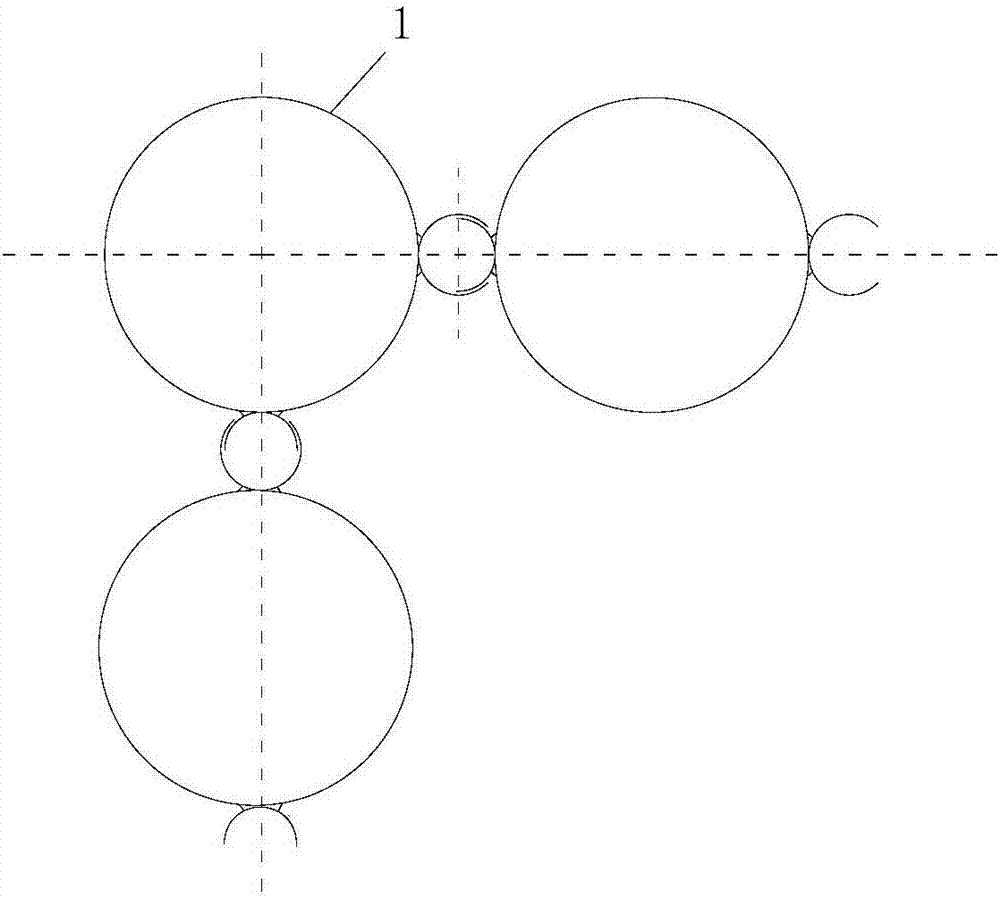

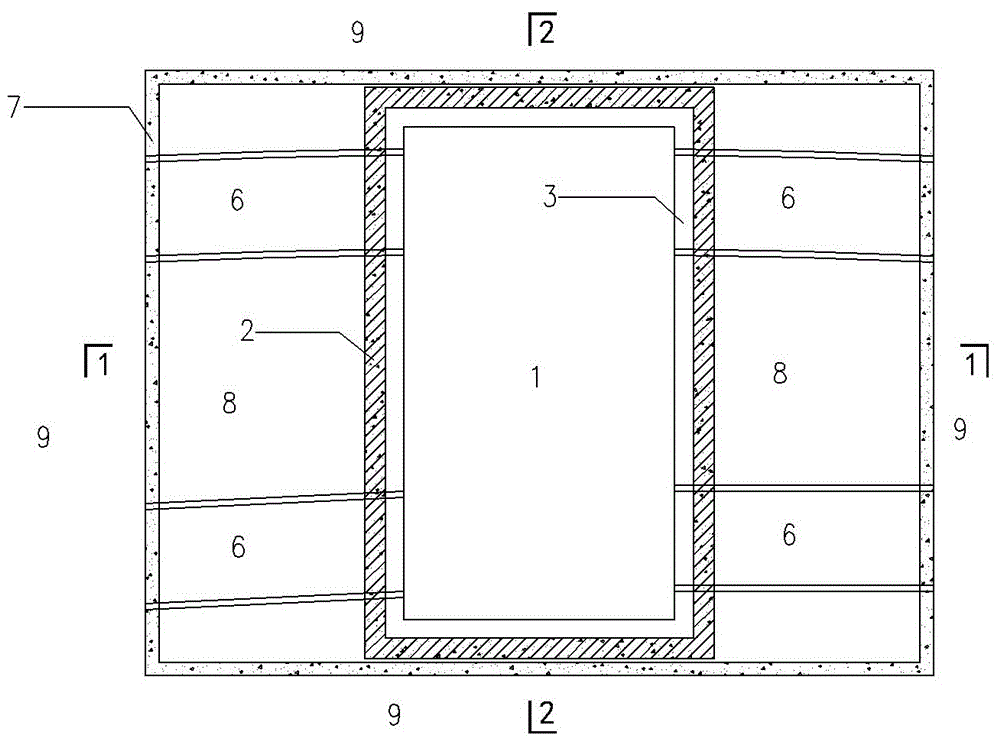

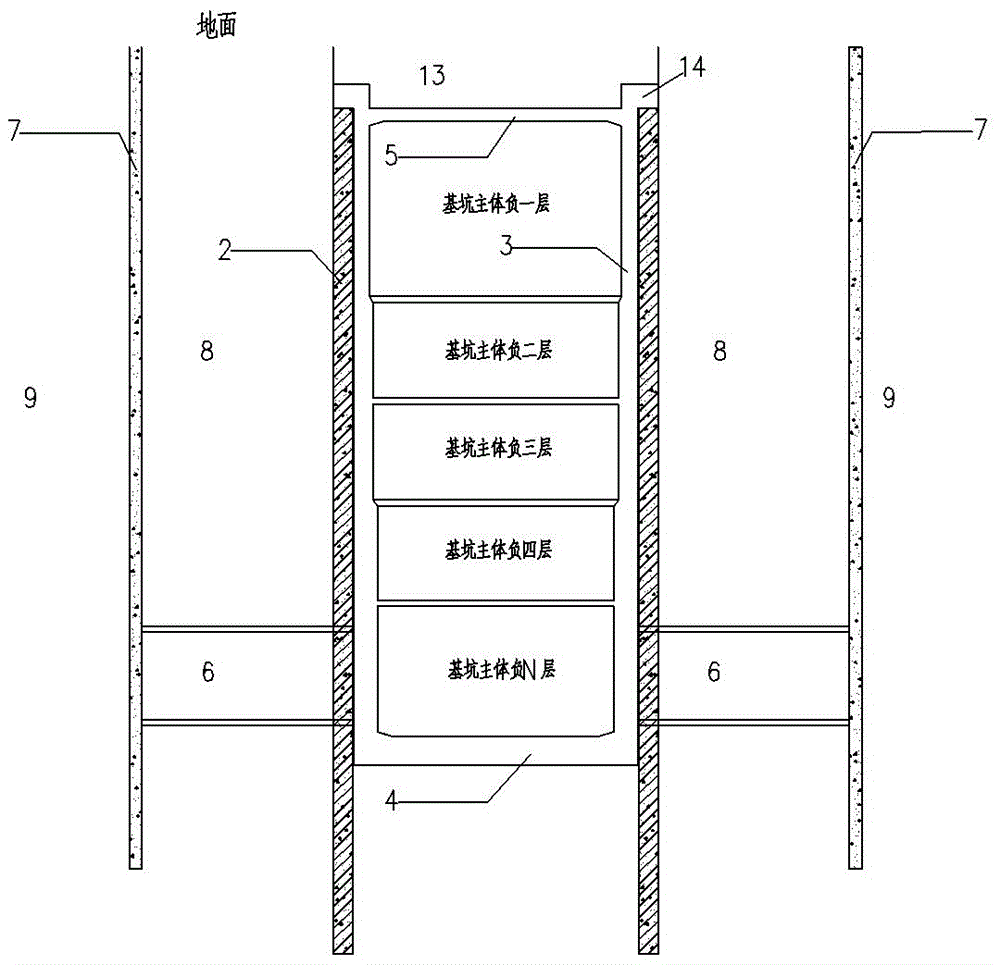

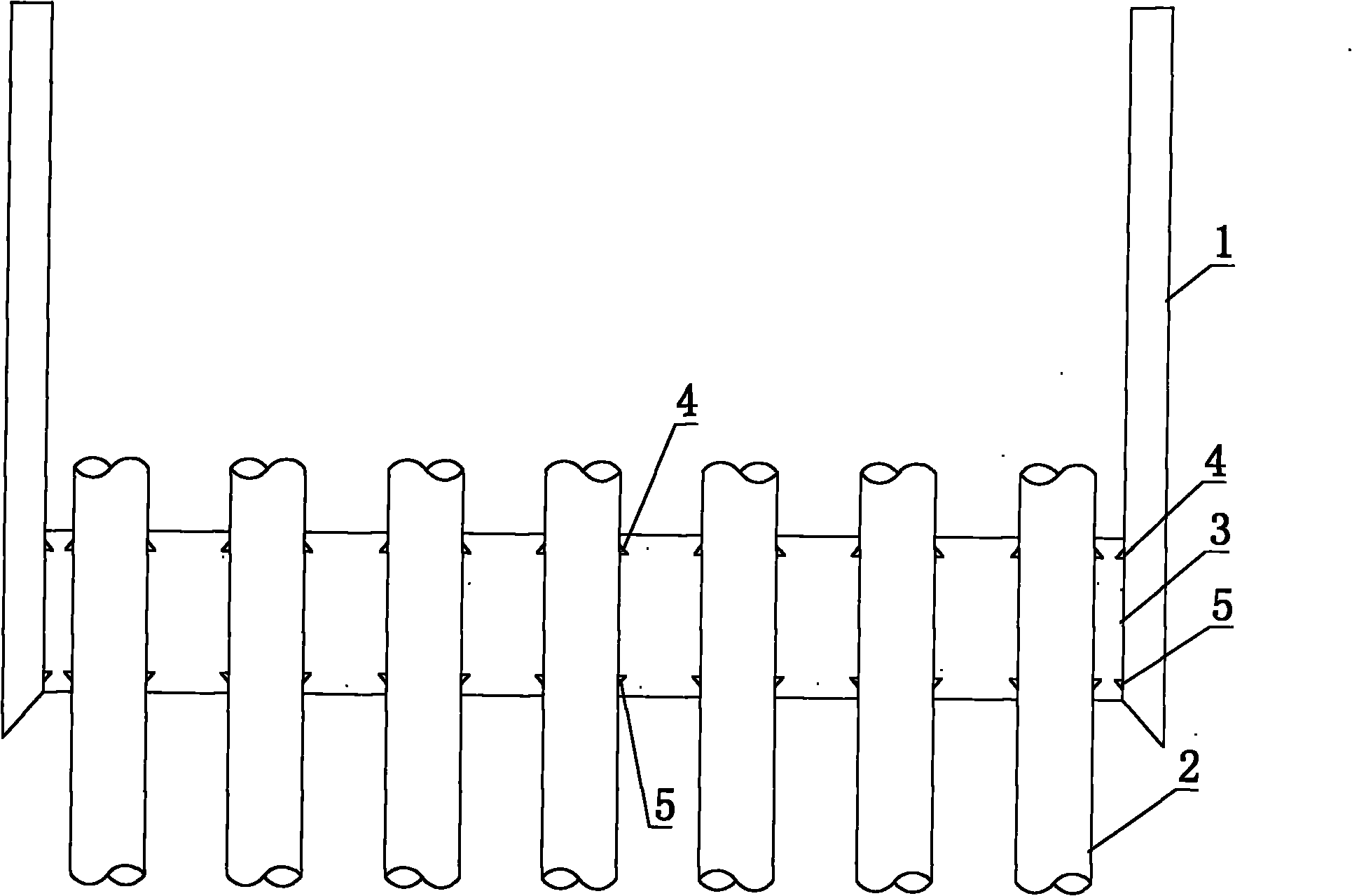

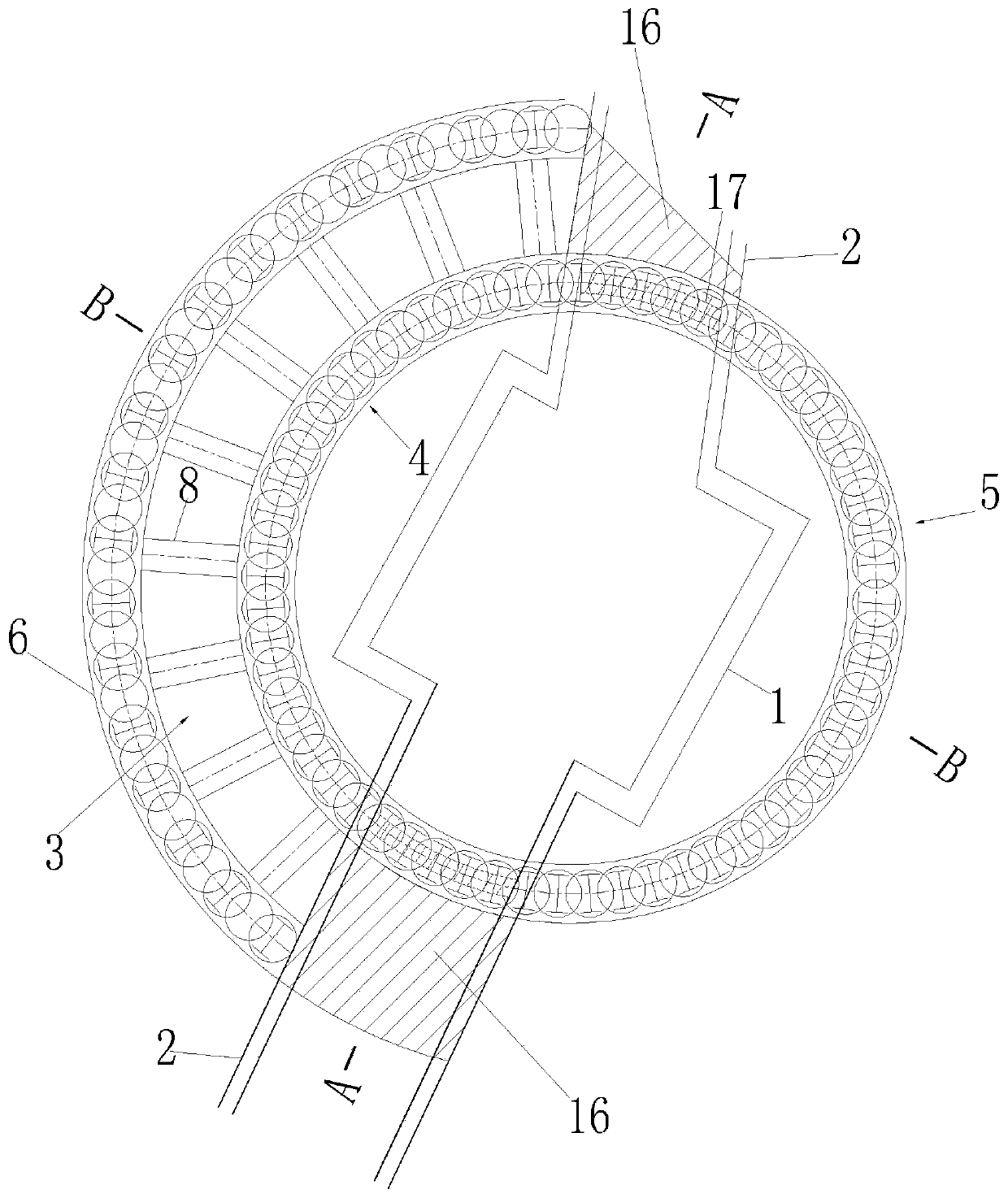

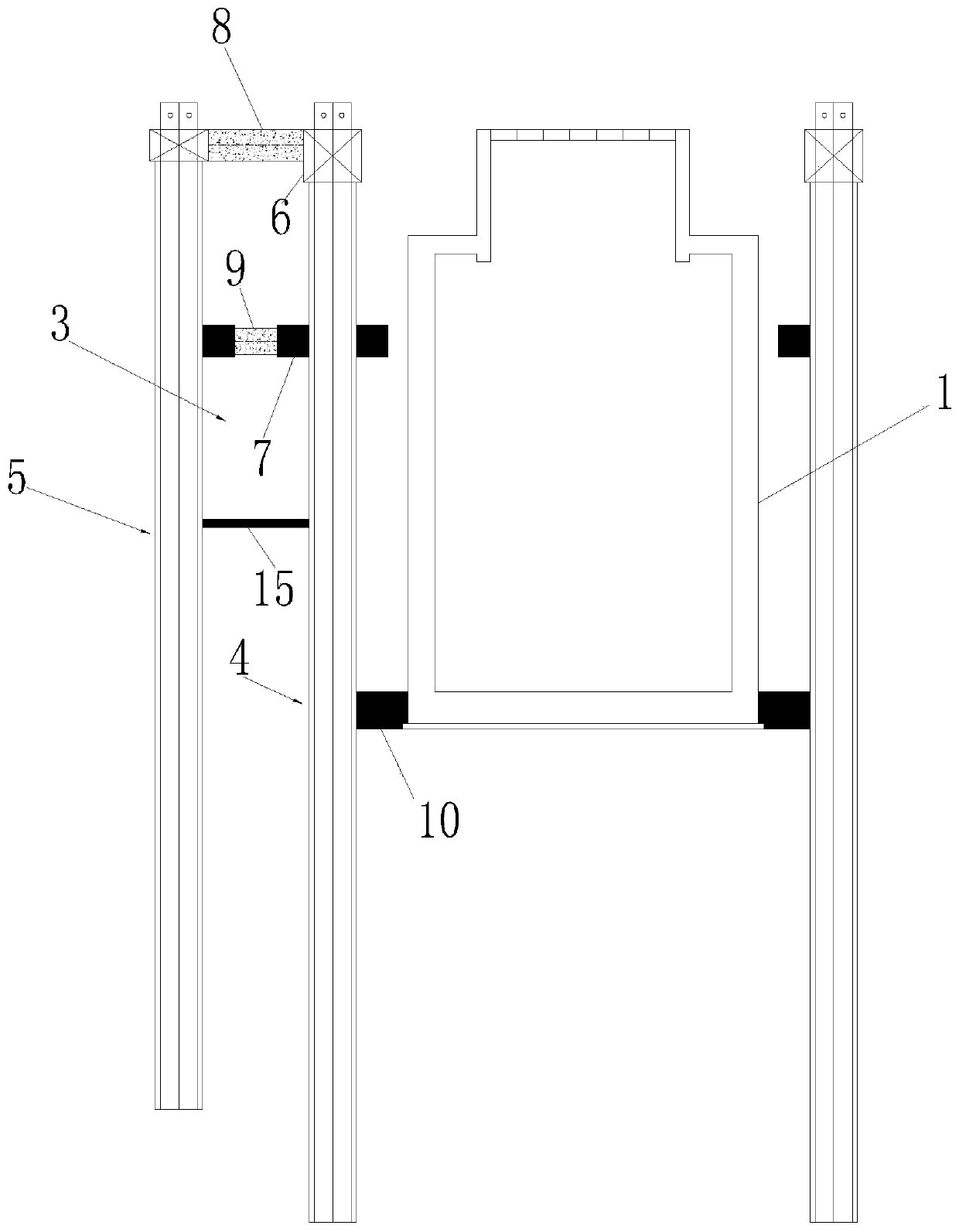

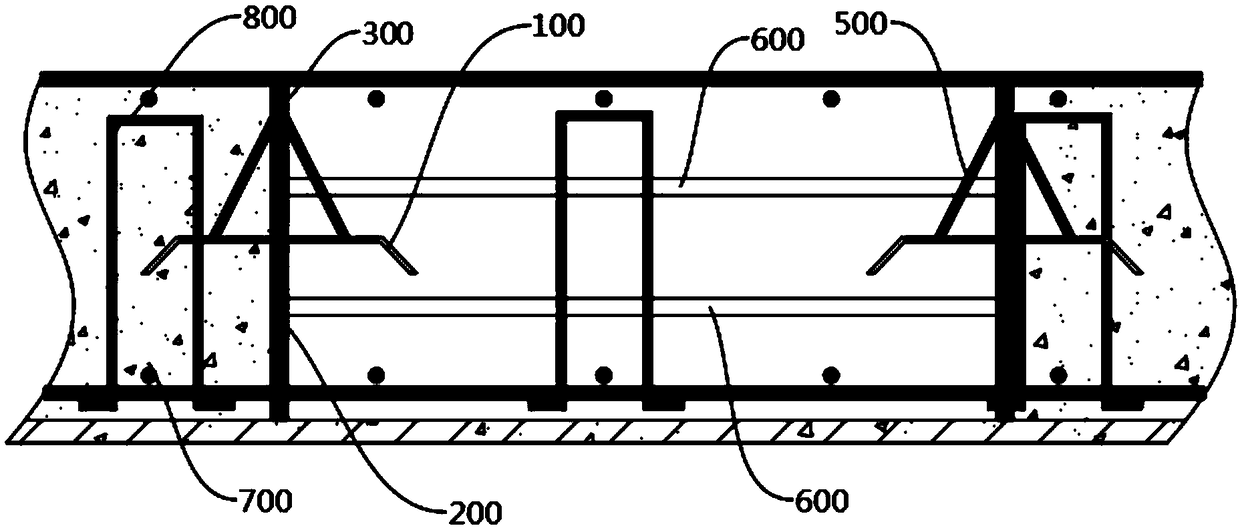

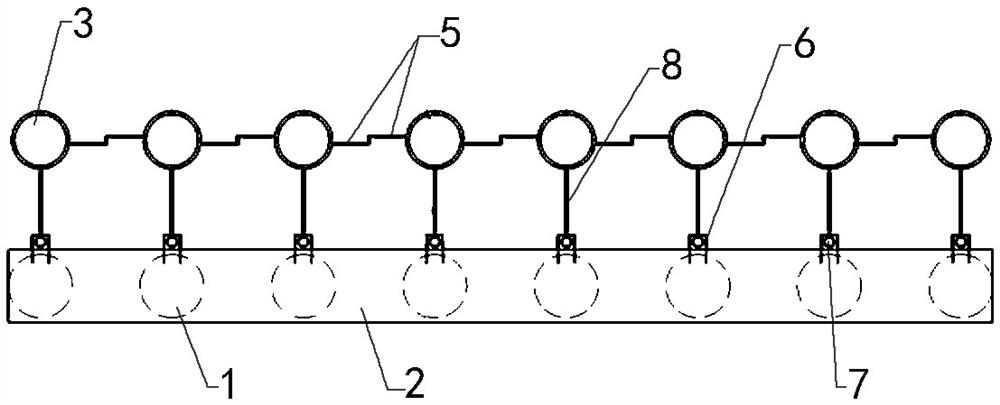

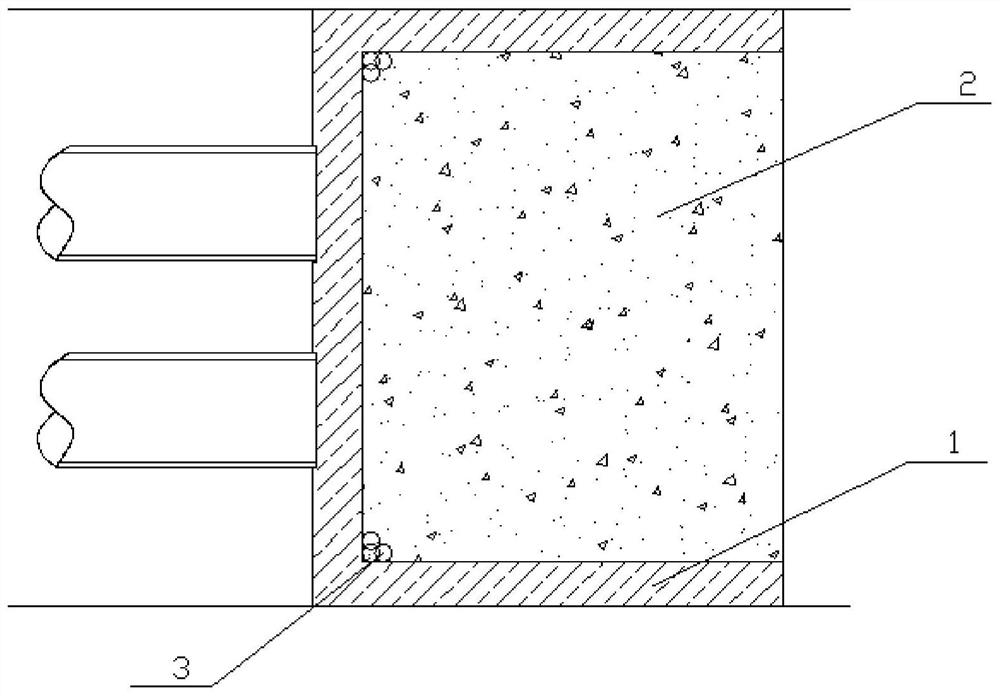

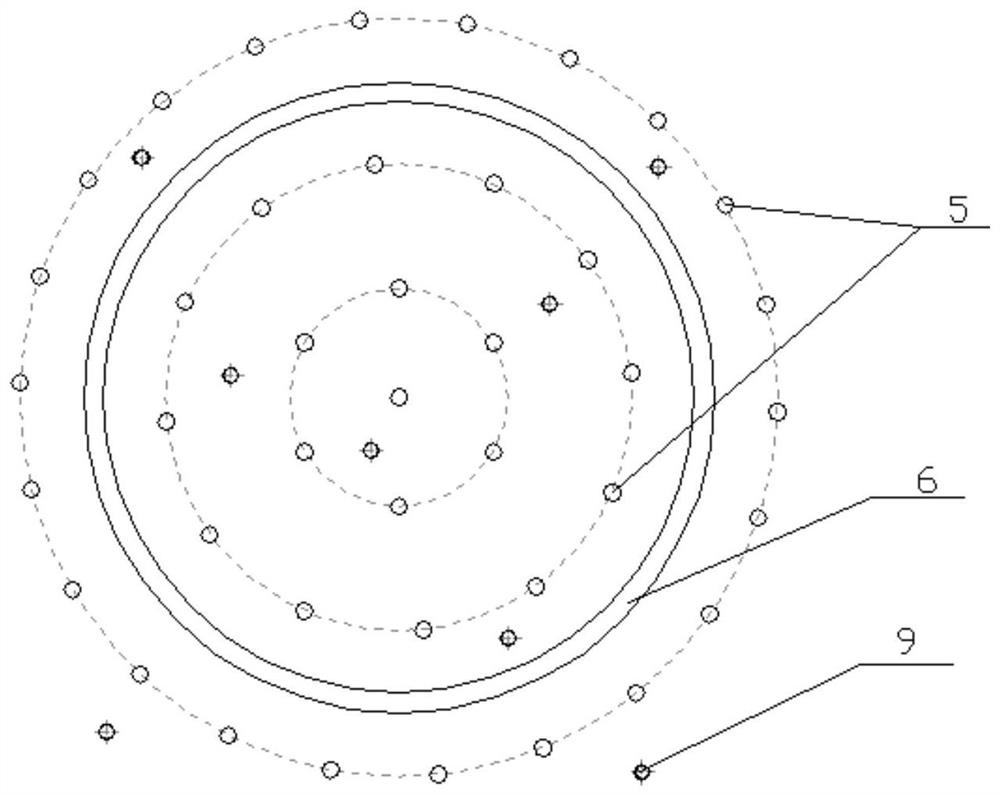

Arch combination foundation pit retaining and protection system and construction method thereof

InactiveCN103290850APlay the role of water stopGive full play to the resistance to pressureExcavationsHigh strength concreteSoil mixing

The invention relates to an arch combination foundation pit retaining and protection system and a construction method of the arch combination foundation pit and protection system, and provides a combination foundation pit retaining and protection system which is simple in structural style, fast in construction method, capable of sufficiently utilizing property advantages of materials and combining the soil blocking function and waterproof function, and suitable for an arch-shaped cement soil mixing pile large in excavating depth and prefabrication of a high-strength concrete thin-wall steel tube pile, and the construction method of the combination foundation pit retaining and protection system. The arch combination foundation pit retaining and protection system comprises arch-shaped cement soil mixing pile walls (1), high-strength concrete thin-wall steel pipe piles (2), pile top beams (3) and inner supports (4), wherein the high-strength concrete thin-wall steel pipe piles (2) are arranged inside the foundation pit in a scattered mode, the pile top beams (3) connect the high-strength concrete thin-wall steel pipe piles into a whole, each inner support (4) is arranged on the outer side of each high-strength concrete thin-wall steel pipe pile (2), each arch-shaped cement soil mixing pile wall (1) is arranged between two high-strength concrete thin-wall steel pipe pile (2) and the arch-shaped cement soil mixing pile walls (1) to be connected into a whole, and the arch-shaped foundation pit retaining and protection system is formed.

Owner:THE CITY VOCATIONAL COLLEGE OF JIANGSU

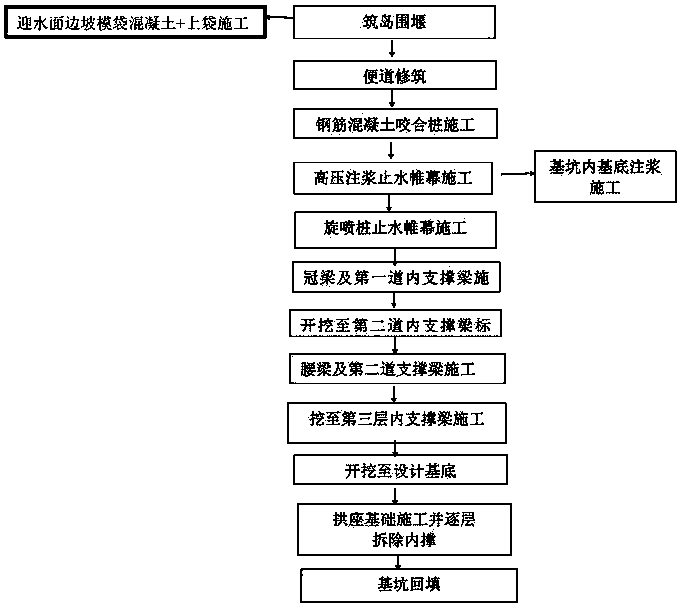

Construction method of large-scale arch bridge foundation on water-permeable geology

ActiveCN108316339AReduce Engineering Oversquare ProblemsPrevent landslidesFoundation engineeringBridge erection/assemblyBasementReinforced concrete

The invention discloses a construction method of a large-scale arch bridge foundation on the water-permeable geology. The construction method of the large-scale arch bridge foundation on the water-permeable geology is characterized by comprising the following steps of conducting island and cofferdam construction, constructing a shortcut, constructing reinforced concrete secant piles, conducting high-pressure grouting waterproof curtain construction and foundation pit inner basement grouting construction at the same time, constructing a jet grouting pile waterproof curtain, constructing a top beam and a first inner support beam, conducting excavation to the elevation of a second inner support beam, constructing a waist rail and the second inner support beam, conducting excavation to the elevation of a third inner support beam and constructing a third-layer inner support beam, conducting excavation to the designed basement, constructing an arch support foundation and detaching inner support layer by layer and backfilling the foundation pit. According to the construction method, the construction progress is rapid, the construction quality is stable, the waterproof curtain outside thepit enables the outer side of the foundation pit to form an annular closed seepage-proof structure layer; and meanwhile, the high-pressure jet grouting piles on the top enable the soil layer outside support piles to be hardened, the soil layer outside the foundation pit is further strengthened, and the situation that the cofferdam landslides and collapses due to flood scouring is effectively prevented. In addition, a special-shaped steel reinforcement cage saves concrete materials.

Owner:SHANGHAI CIVIL ENG GRP FIFTH

Construction structure and construction method of channel structure

InactiveCN102182464AAvoid back soil effectReduce construction riskTunnelsSoil preservationArchitectural engineeringEngineering

The invention discloses a construction structure of a channel structure. A box culvert is adopted to construct a soil mass for building the channel structure so as to form the channel structure, a pushing area and a receiving area are respectively arranged at the two ends of the soil mass for building the channel structure, and a composite rebar adding curtain is arranged at the outer side of the soil mass for building the channel structure. The invention also discloses a construction method of the channel structure. Due to the additional arrangement of the composite rebar adding curtain, an original soil mass around the box culvert can be isolated, thereby avoiding the generation of a back earth effect of the box culvert during jacking, and effectively reducing the influence to a neighboring environment. Furthermore, when a circle of closed composite rebar adding curtain is formed at the periphery of the mass body for building the channel structure, the composite rebar adding curtain can play a role of stopping water, thus effectively reducing construction risk caused by underground water. In addition, the composite rebar adding curtain can be constructed by adopting conventional methods such as horizontal reinforcement, consolidated grouting and the like, thus having low requirements on construction technology; and the construction can be conducted by adopting conventional equipment, and special construction equipment is not needed, thus having good economical efficiency.

Owner:SHANGHAI CONSTRUCTION GROUP

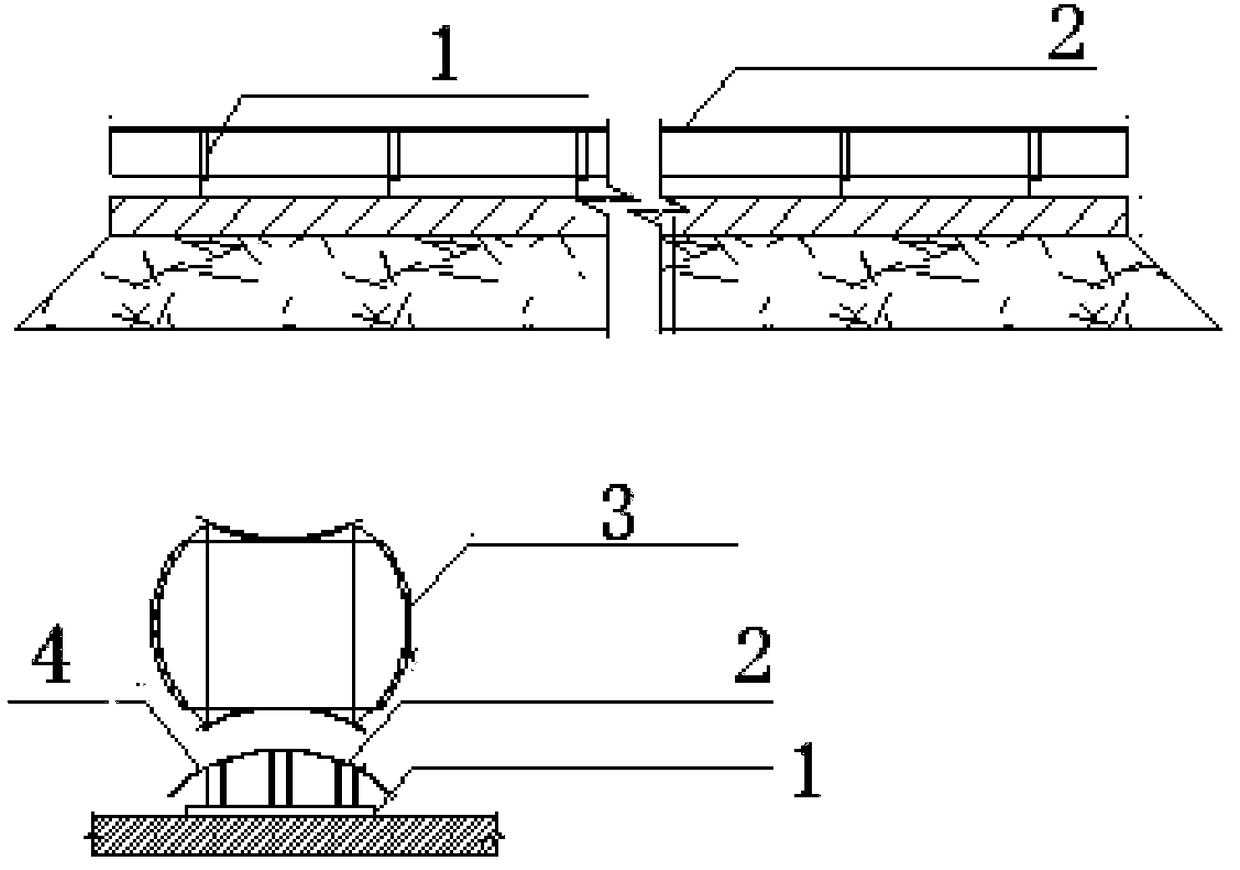

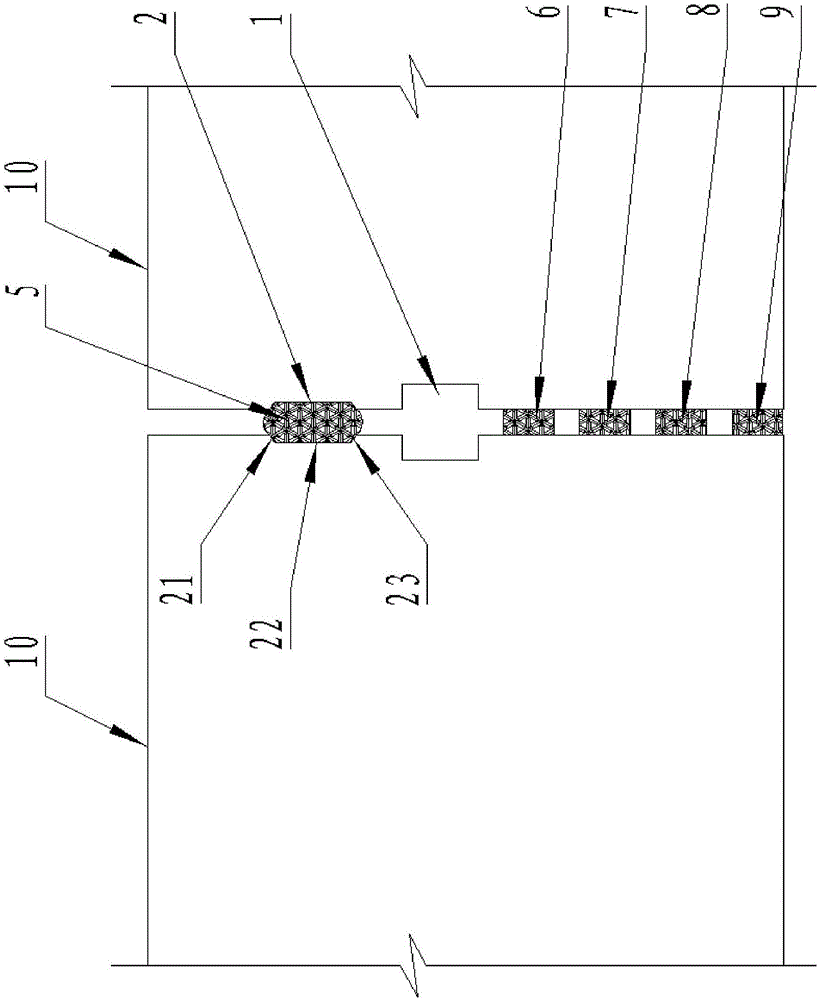

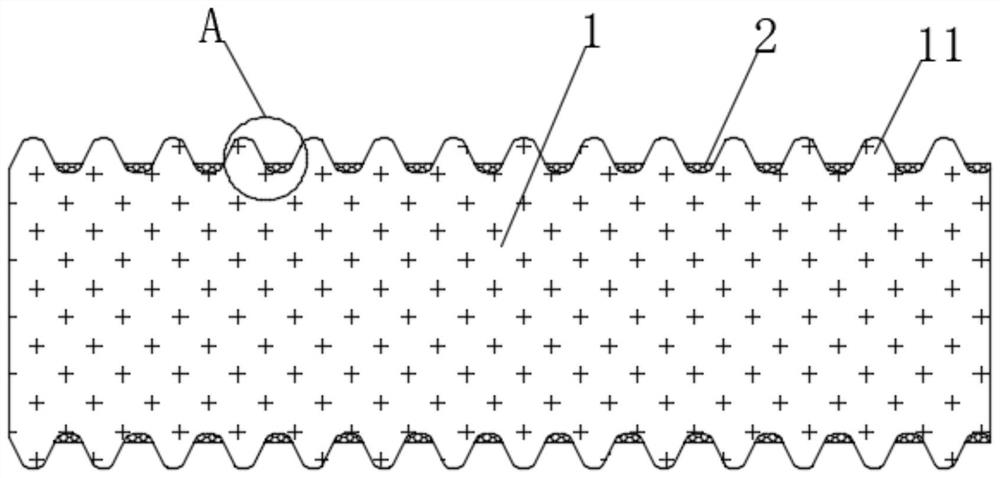

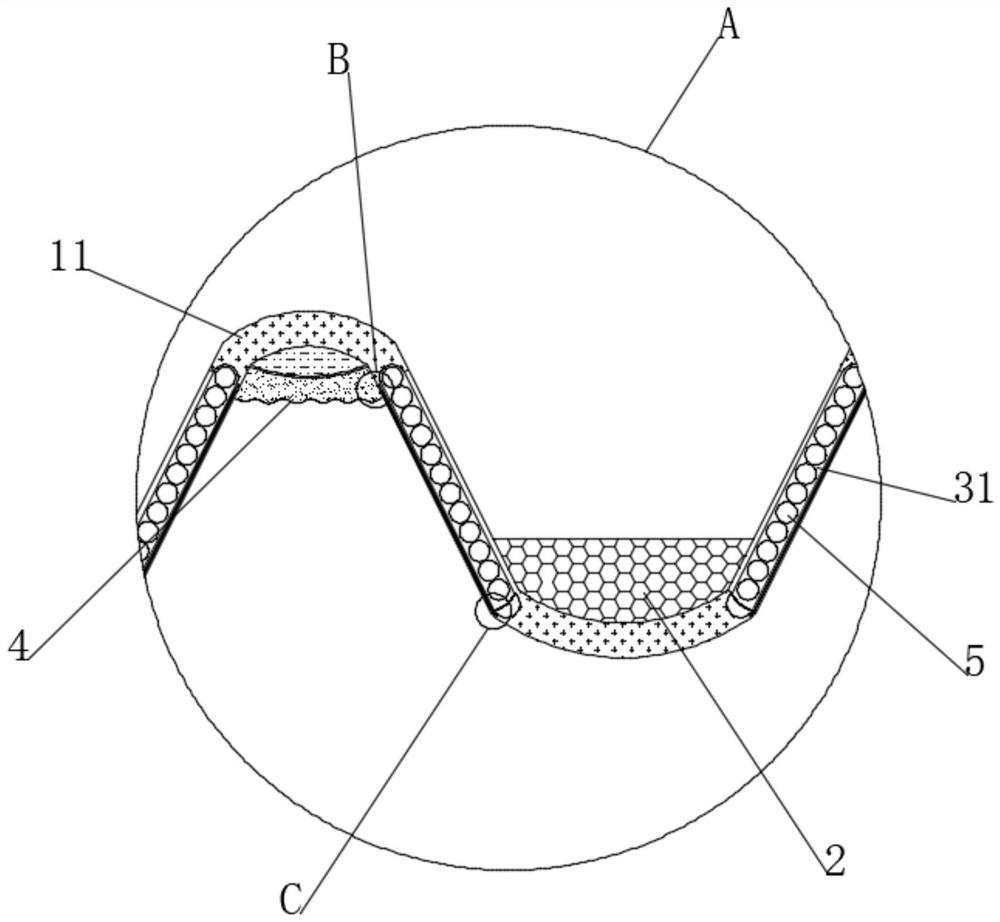

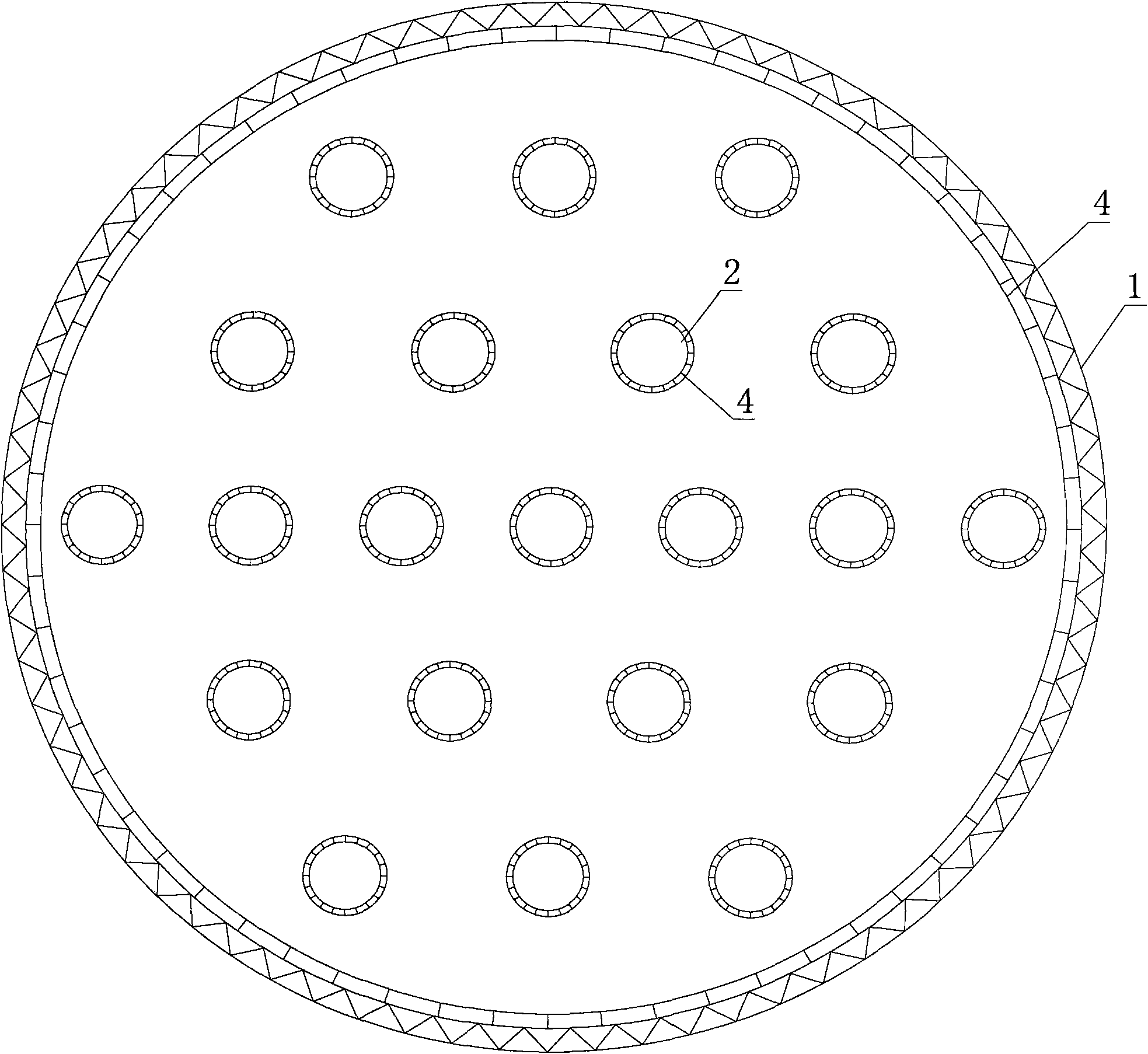

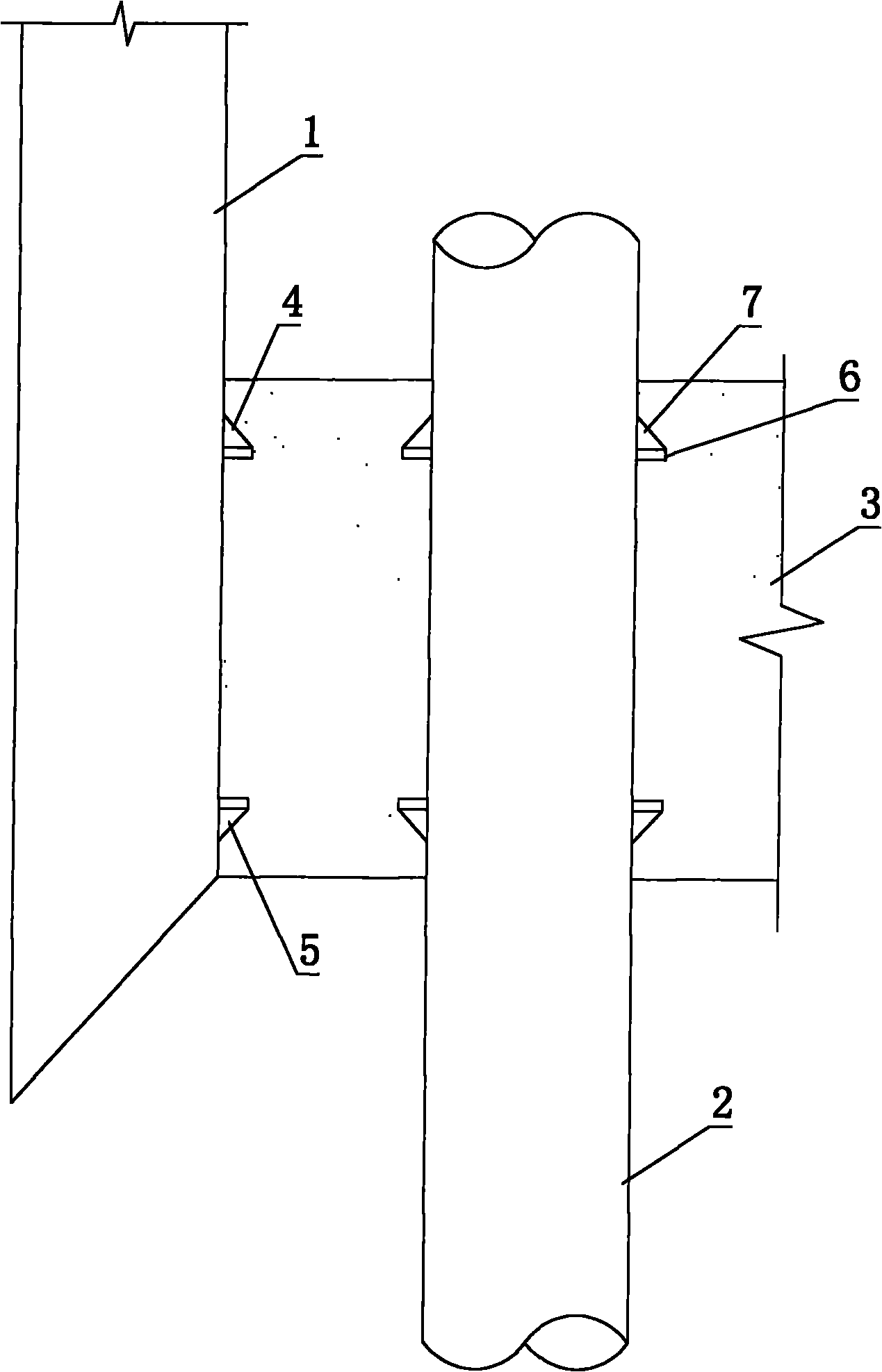

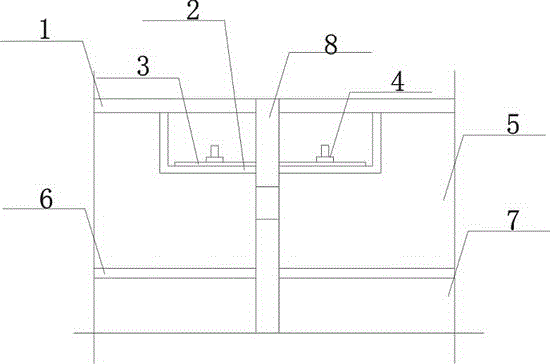

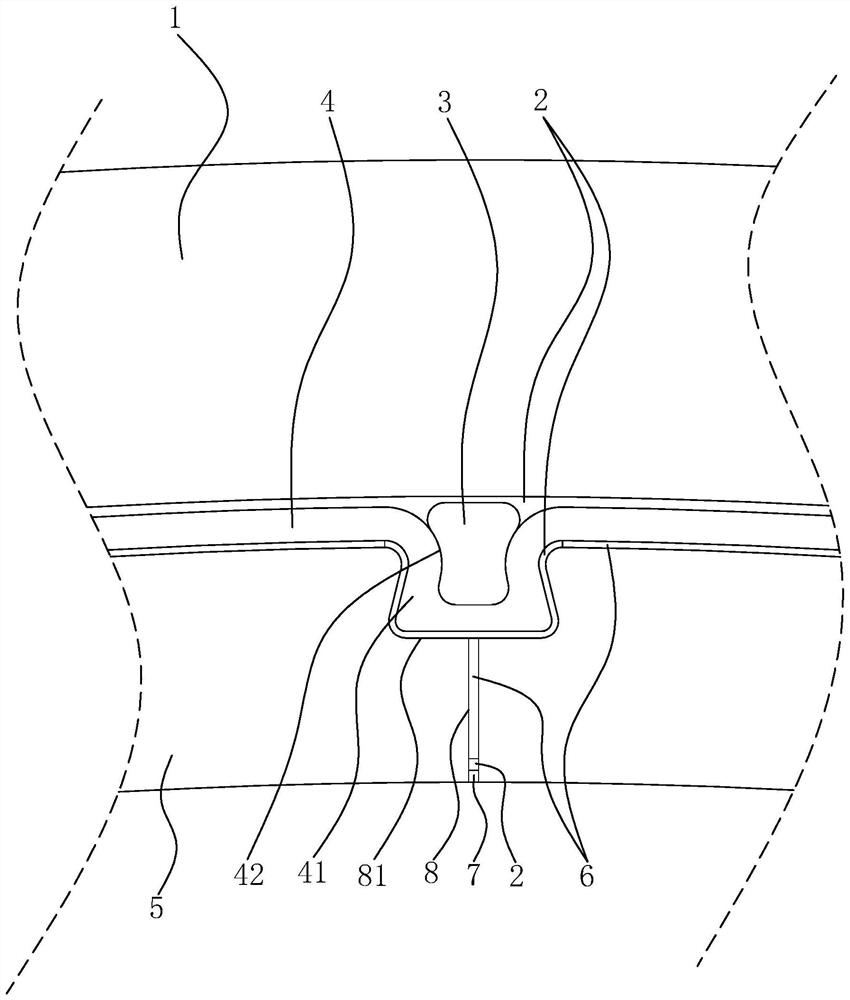

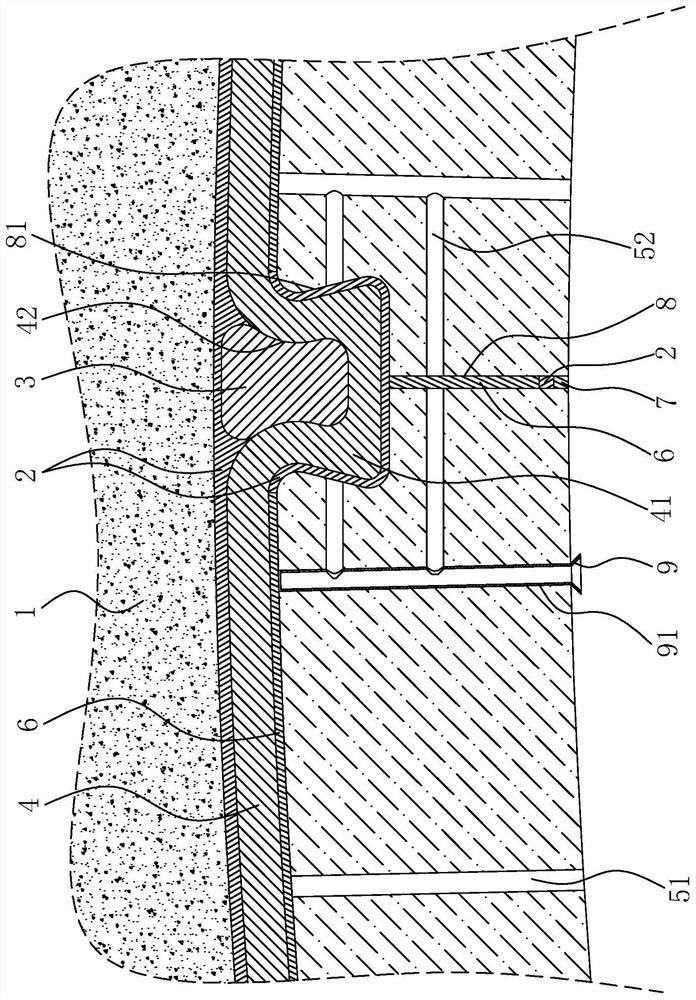

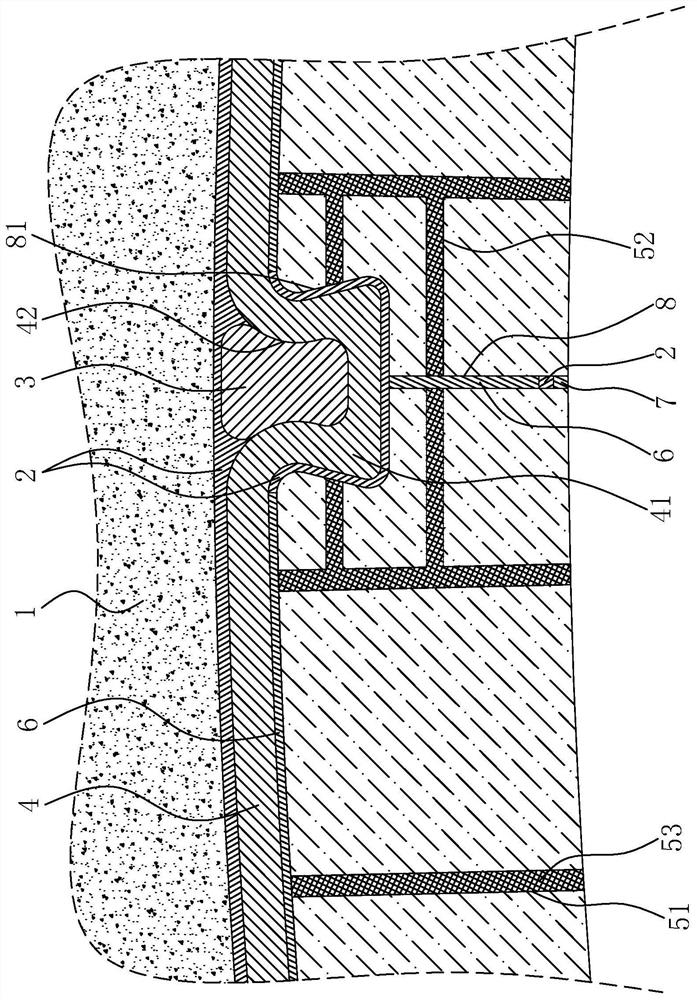

Precast concrete culvert pipe, precast utility tunnel and maintenance method of utility tunnel

ActiveCN106638337AHave a water-stopping effectPlay the role of water stopArtificial islandsGround-workUtility tunnelEngineering

The invention provides a precast concrete culvert pipe, a precast utility tunnel and a maintenance method of the utility tunnel. Annular end faces at the two ends of the precast concrete culvert pipe are both provided with a waterproof drainage structure. Each waterproof drainage structure comprises a drainage channel (1) and a sealing rubber strip installation groove (2), wherein the sealing rubber strip installation groove (2) is located between the drainage channel (1) and the outer surface of the precast concrete culvert pipe, the distance from the drainage channel (1) to the outer surface of the precast concrete culvert pipe is smaller than that from the drainage channel (1) to the inner surface of the precast concrete culvert pipe. The precast concrete culvert pipe, the precast utility tunnel and the maintenance method of the utility tunnel solve the waterproof problem of a splicing part, the combination of prevention, drainage and plugging is achieved, after the material comes to the end of the service life, the waterproof joints can be further repaired, and the waterproof effect is ensured.

Owner:MCC CAPITAL ENGINEERING & RESEARCH

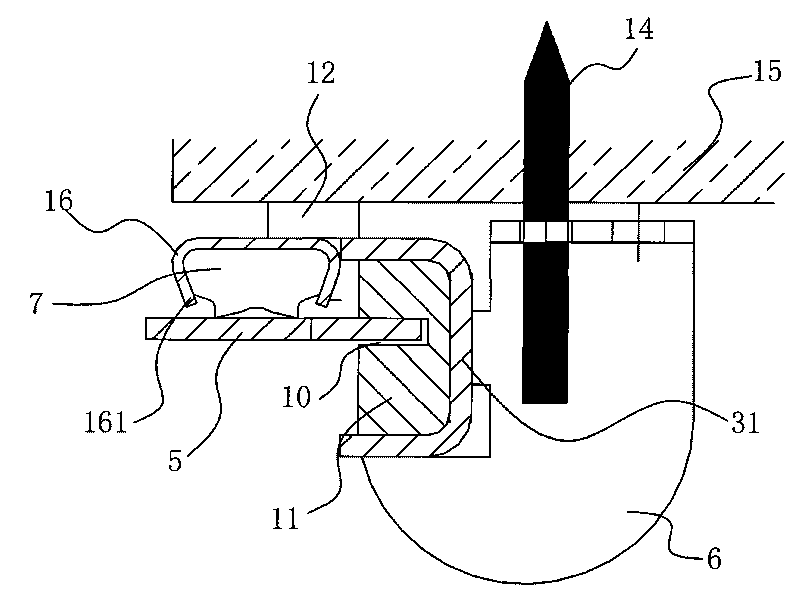

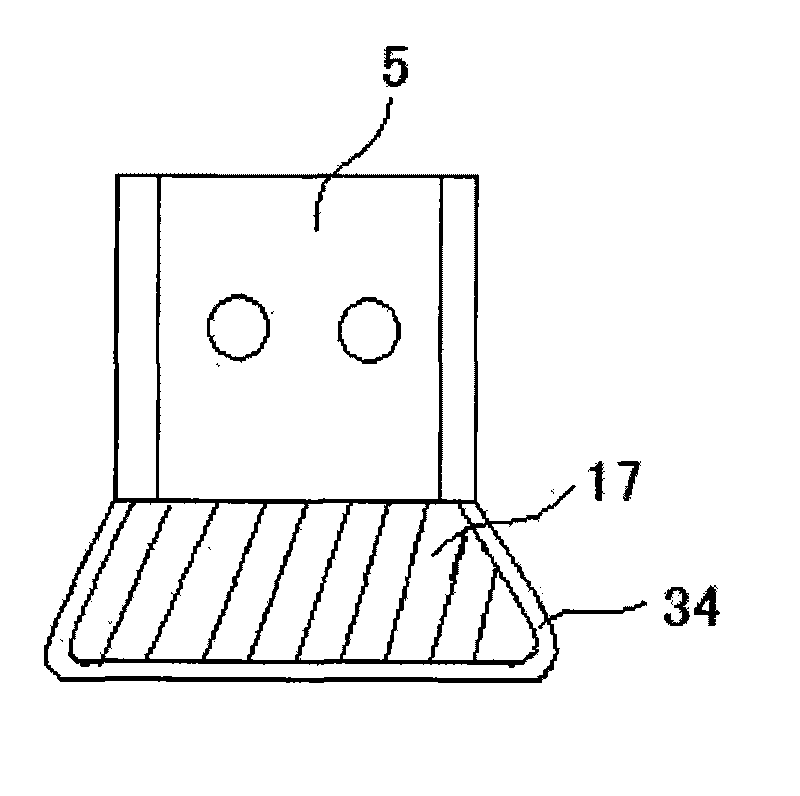

Paddle valve

InactiveCN101713469ARealize the water stop effectPlay the role of water stopSlide valveEngineeringUltimate tensile strength

The invention discloses a GLP03 type paddle valve comprising a floodgate frame and a flashboard; a seal valve buckle is fixed on the floodgate frame; the seal valve buckle is in a U-shaped structure which is arranged between the flashboard and an installation wall surface; the opening of the U-shaped structure is towards the flashboard; a double lip-shaped rubber sealing strip is installed in the sealing floodgate frame; and the lip-shaped part of the double lip-shaped rubber sealing strip is contacted with the flashboard, which plays a seal function. Interference close fit is formed between the lip-shaped part of the double lip-shaped rubber sealing strip and the flashboard, thus preventing fluid medium at the internal direction and the external direction of the paddle valve from passing through, and realizing bidirectional water stopping effect. Foamed rubber sealing strips are arranged between the floodgate frame and the installation wall surface and between the sealing valve frame and the installation surface, which play the function of water stop. The paddle valve of the invention has simple and lightweight design structure, high strength, convenient installation and maintenance and good bidirectional water stopping effect; compression resisting safety factor is larger than 6; and the highest adaptive water pressure can reach 10 water heads.

Owner:郭华为

C-C type interlocking steel pipe pile cofferdam and construction method

The invention discloses a C-C type interlocking steel pipe pile cofferdam and a construction method. The cofferdam is encircled by a plurality of C-C type interlocking steel pipe piles which are closely connected in sequence, wherein each C-C type interlocking steel pipe pile comprises a vertical steel pipe as well as a male lock catch and a female lock catch which are distributed at the outer side of the vertical steel pipe, and each two adjacent vertical steel pipes are connected through an interlocking structure composed of the corresponding male lock catch and female lock catch; and each interlocking structure is internally densely filled with an interlocking filling structure, and each interlocking filling structure comprises a cloth bag, heating resistance wires distributed in the cloth bag, and a mortar filling structure formed by sulphur mortar filled in the cloth bag. The construction method comprises the following steps: 1. surveying and setting out; 2. steel pipe pile inserting piling and closure construction; 3. interlocking structure filling; 4. cofferdam construction completion; and 5. cofferdam removal. The cofferdam disclosed by the invention is reasonable in design, simple and convenient to disassemble and assemble, safe and reliable, good in water-stopping effect, and capable of effectively achieving the engineering purposes of interlocking connection, water-stopping and rapid removal of the steel pipe pile cofferdam.

Owner:CHINA RAILWAY FIRST GRP CO LTD

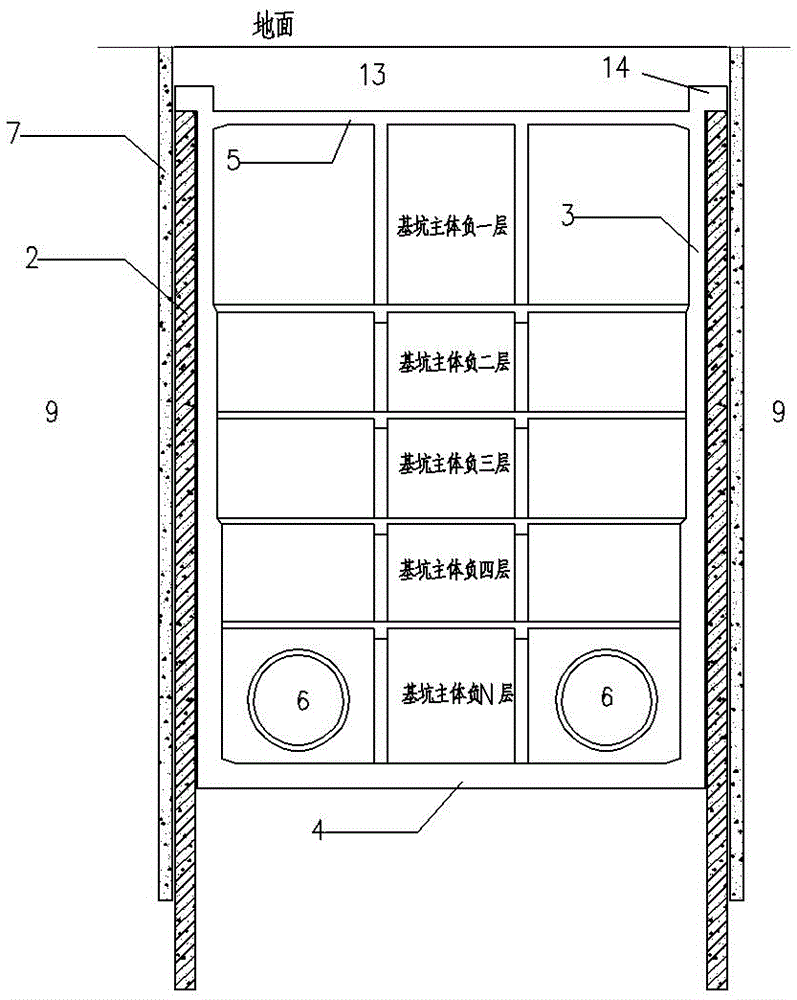

Multi-underground-diaphragm-wall combined stratum strengthening precipitation foundation pit enclosure structure

InactiveCN106759380AImprovePlay the role of water stopExcavationsBulkheads/pilesSlurry wallReinforced concrete

The invention relates to a multi-underground-diaphragm-wall combined stratum strengthening precipitation foundation pit enclosure structure. A reinforced concrete underground diaphragm wall which is closed to form a ring outside the excavation scope inside a foundation pit is included, a reinforced concrete body structure wall is tightly attached to the inner circumference of the reinforced concrete underground diaphragm wall, an outer ring of the reinforced concrete underground diaphragm wall is provided with an outer circumference plain concrete underground diaphragm wall closed to form a ring, stratums between the underground diaphragm walls are strengthened, and precipitation wells are distributed on the outer circumference of the plain concrete underground diaphragm wall on the outmost side, the positions between the underground diaphragm walls and the interior of the foundation pit. The multi-underground-diaphragm-wall combined stratum strengthening precipitation foundation pit enclosure structure is reasonable is stress, obvious in effect and good in implementation, the engineering problem about deep and large foundation pit building in high-permeable stratums, water-rich stratums, stratums close to water areas and other stratums can be effectively solved, the measures are safe and reliable, and the construction efficiency is improved.

Owner:CHINA RAILWAY FIRST SURVEY & DESIGN INST GRP

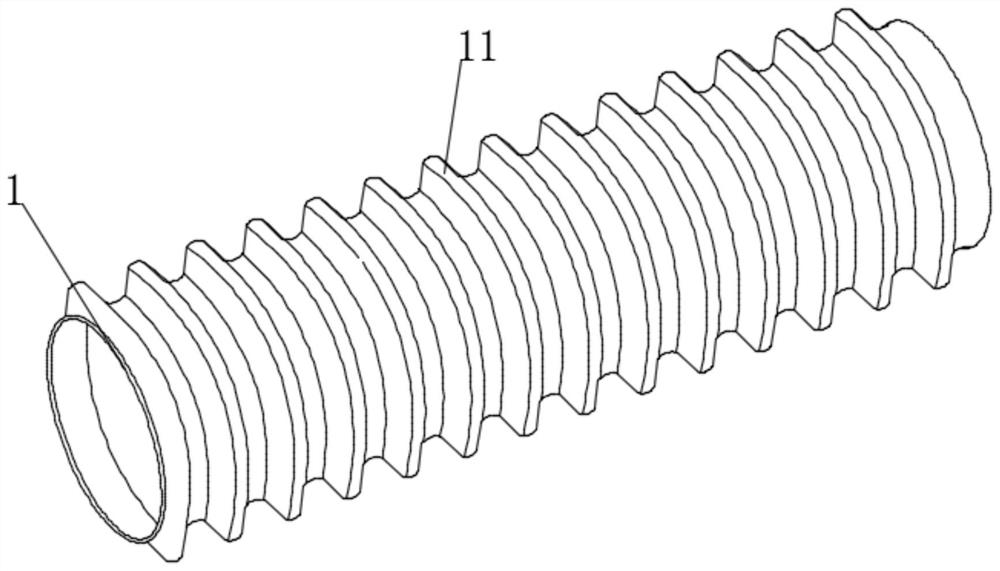

Air contact type self-condensation repaired electric corrugated pipe

ActiveCN112186665AHigh strengthPlay the role of water stopApparatus for repairing insulation/armouring cablesBending forceElectric power

The invention discloses an air contact type self-coagulation repair electric power corrugated pipe, belongs to the field of electric power pipes, and provides the air contact type self-coagulation repair electric power corrugated pipe with the advantages that through the arrangement of an air contact layer, on one hand, a certain anti-seismic force unloading effect is realized, and the partial extrusion force can be effectively protected; on the other hand, when the bamboo-shoot-shaped convex joints are subjected to large bending force, the air contact layer is extruded, so that the embedded extending pieces are extruded to a certain extent, the sides, facing the inner liquid storage ball, of the embedded extending pieces expand and deform, and the folded parts of the embedded extending pieces are unfolded, so that the bamboo-shoot-shaped convex joints are prevented from being broken. The inner contact pricking point can make contact with the inner liquid storage ball and prick the inner liquid storage ball, a repairing agent in the inner liquid storage ball overflows, and when the bamboo-shoot-shaped convex joint is locally broken, the repairing agent can flow out along the brokenposition in time, so that self-repairing of the broken position or the cracked position is achieved, and the situation of electric leakage caused by breaking is remarkably reduced.

Owner:成得建设集团有限公司

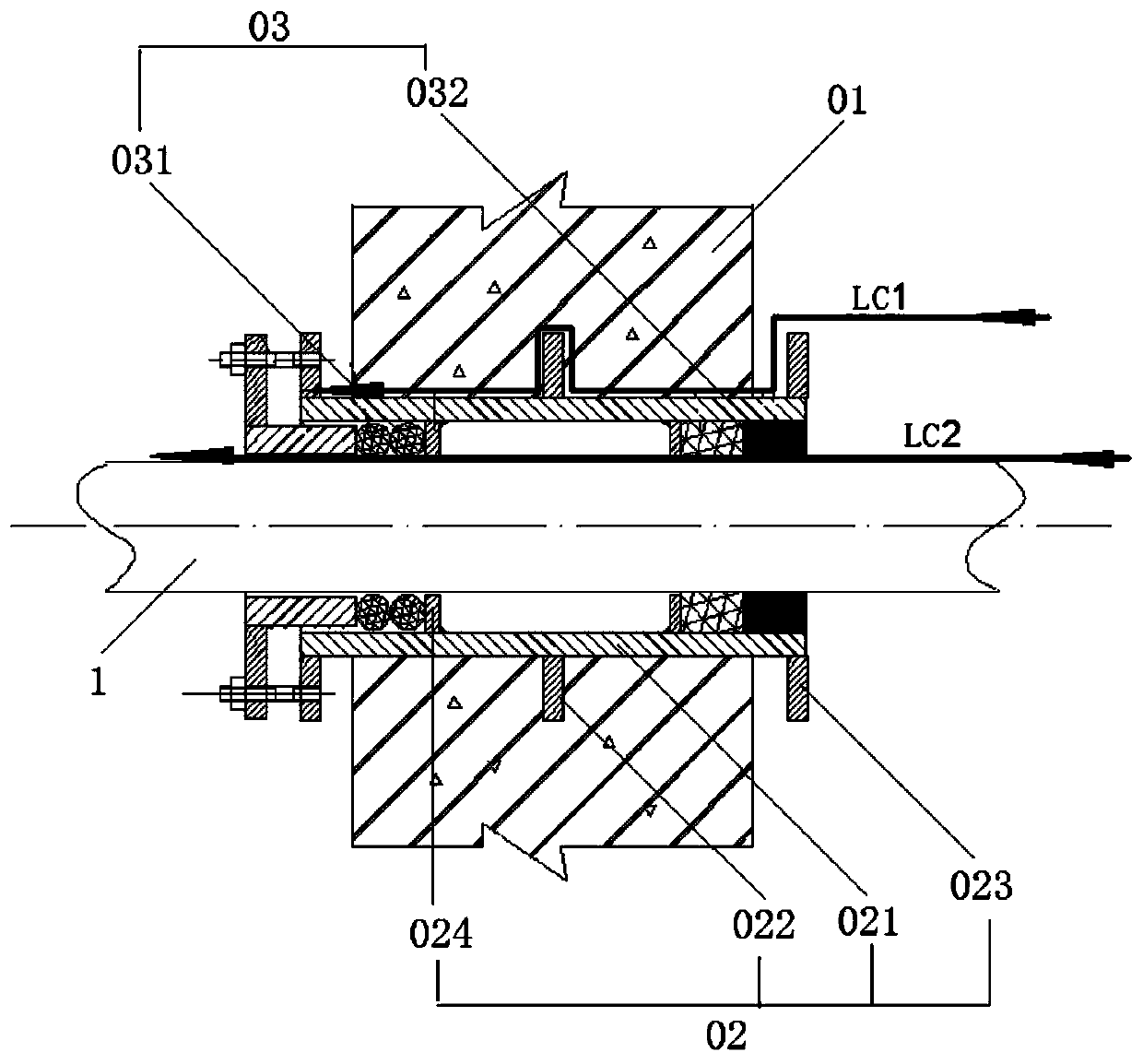

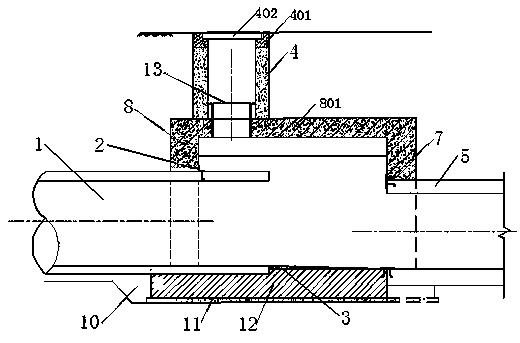

Vibration-damping waterproof wall-penetrating pipe structure and construction method thereof

PendingCN110985764AOvercome separate settingsOvercoming structural complexityPipeline expansion-compensationThermal insulationClassical mechanicsEngineering

The invention provides a vibration-damping waterproof wall-penetrating pipe structure and a construction method thereof. The wall-penetrating pipe structure comprises a wall-penetrating pipe and vibration-damping corrugated compensators arranged at two ends of the wall-penetrating pipe; the wall-penetrating pipe is embedded into a wall body; the two ends of the wall-penetrating pipe extend out ofthe wall body; and a medium pipeline communicate with the wall-penetrating pipe in a sealed mode through the vibration-damping corrugated compensators on the upstream face and the downstream face. According to the invent vibration-damping waterproof wall-penetrating pipe structure and the construction method thereof ion, the rigid through-wall pipe with a labyrinth type water stop plate and the vibration-damping corrugated compensator structure is adopted to realize the sealing structure with both rigid and flexible functions, the through-wall pipe replaces an existing waterproof wall-penetrating sleeve, a flexible sealing assembly between the wall-penetrating sleeve and the medium pipeline is removed, a leakage channel is reduced, the structure is simplified, and the defects that an existing flexible waterproof sleeve and a rigid waterproof sleeve are separately arranged, the structure is complex, the construction is inconvenient and the like are overcome. The anti-leakage performanceequivalent to that of the wall-penetrating pipe and the wall body is realized, the sealing structure is simplified, and the processing and construction cost is reduced.

Owner:BEIJING TRIUMPH INT ENG +1

Method for reducing thickness of subsealing concrete of steel cofferdam and preventing seepage

ActiveCN102094428APlay the role of water stopImprove carrying capacityFoundation engineeringTransfer modeCofferdam

The invention discloses a method for reducing the thickness of subsealing concrete of a steel cofferdam and preventing seepage, comprising the following steps of: a. assembling the steel cofferdam and welding an upper circle of shearing resistant structure and a lower circle of shearing resistant structure along the inner wall of the steel cofferdam; b. feeding the steel cofferdam in water; c. welding an upper circle of shearing resistant structure and a lower circle of shearing resistant structure on the outer wall of each steel protecting tube and sequentially punching the steel protecting tubes into a foundation in the steel cofferdam; d. constructing all drilling piles; e. cleaning the foundation in the steel cofferdam and flushing the steel cofferdam and the shearing resistant structures underwater on the steel protecting tubes; f. pouring the subsealing concrete to be combined with the steel protecting tubes, the steel cofferdam and the shearing resistant structure into a whole; and g. pumping water from the steel cofferdam and constructing a bearing platform. According to the method, by arranging the shearing resistant structures, after water in the steel cofferdam is pumped, the force transfer mode of the subsealing concrete and the inner wall of the steel cofferdam and the outer walls of the steel protecting tubes is converted into a bonding force and a shearing force from the mutual bonding force, so that the dereference of the concrete bearing capacity accords with the reliable basis and the thickness of the subsealing concrete can be reduced; and the water seepagae in the steel cofferdam can be prevented.

Owner:CHINA RAILWAY MAJOR BRIDGE ENG GRP CO LTD

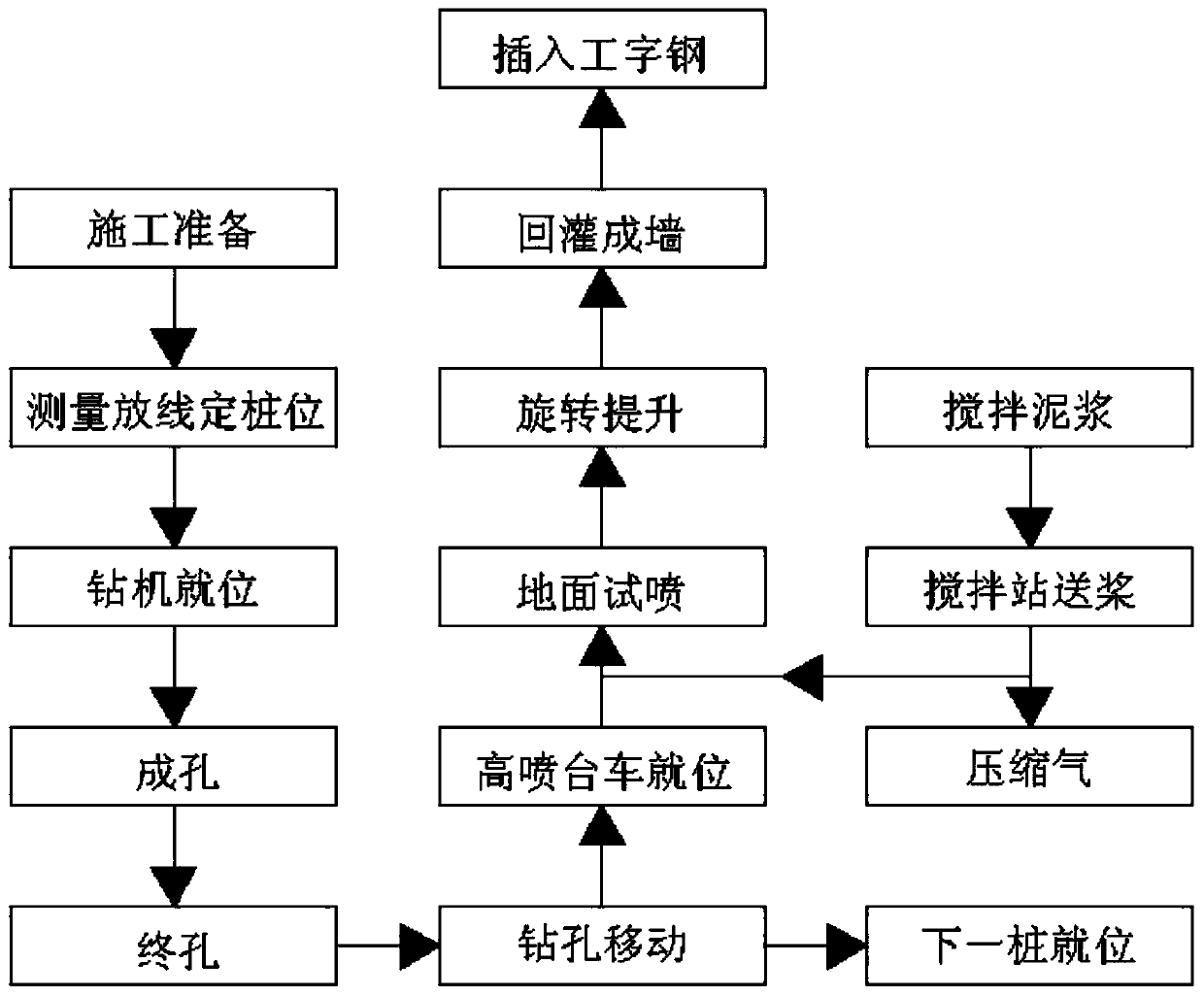

Hard cutting type construction method of secant pile in karst region

InactiveCN108625369AEliminate the problem of non-continuous operationNo pollution in the processBulkheads/pilesReinforced concreteKarst

The invention provides a hard cutting type construction method of a secant pile in a karst region, and belongs to the field of urban mass transit construction. The method specifically comprises the processes of preparing for constructing; paying off in pile positions; constructing a guide wall; arranging a drilling machine in place; drilling and removing ballast; cleaning a hole; examining the finished hole; displacing the drilling machine; arranging a reinforcement framework; pre-preparing for concrete pouring; pouring concrete; drawing out a sleeve; chiseling a pile head, and cleaning; detecting a pile body; and constructing a top beam, wherein pure concrete piles and reinforced concrete piles are sequentially alternatively arranged at the pile positions; the secant pile is constructed by the steps of sequentially constructing the pure concrete piles at regular intervals of every three concrete piles; sequentially constructing the rest pure concrete piles; sequentially constructing the reinforced concrete piles at regular intervals of every three concrete piles; and the constructing the rest reinforced concrete piles. With the adoption of the method, a plurality of problems in secant pile construction in karst developed old cities can be solved.

Owner:CHINA RAILWAY ERJU 1ST ENG

Construction method for combination of water swelling sealing rod and water swelling glue

ActiveCN107143046ARepair operation is simpleQuality improvementArtificial islandsUnderwater structuresSocial benefitsBuilding construction

The invention discloses a construction method for combination of water swelling sealing rod and water swelling glue, which relates to the technological field of waterproof construction. In the construction method for combination of water swelling sealing rod and glue, the water swelling sealing rod is used as a main water stopping material and the water swelling glue is used as a bonding and fixing material as well as an auxiliary water stopping material on a lap joint. At the same time, the combination of water swelling rod and water swelling glue is applied to the construction of the waterproof part in a building. The construction method for combination of swelling sealing rod and water swelling glue can be extensively applied to concrete construction joints, late poured bands, wall pipes, pile crowns in underground projects and other joints which is suitable for the waterproof method. The construction method for combination of water swelling sealing rod and water swelling glue has much more polarization and application value. Besides, the economic and social benefits of the construction method for combination of water swelling rod and water swelling glue are extremely notable.

Owner:王军

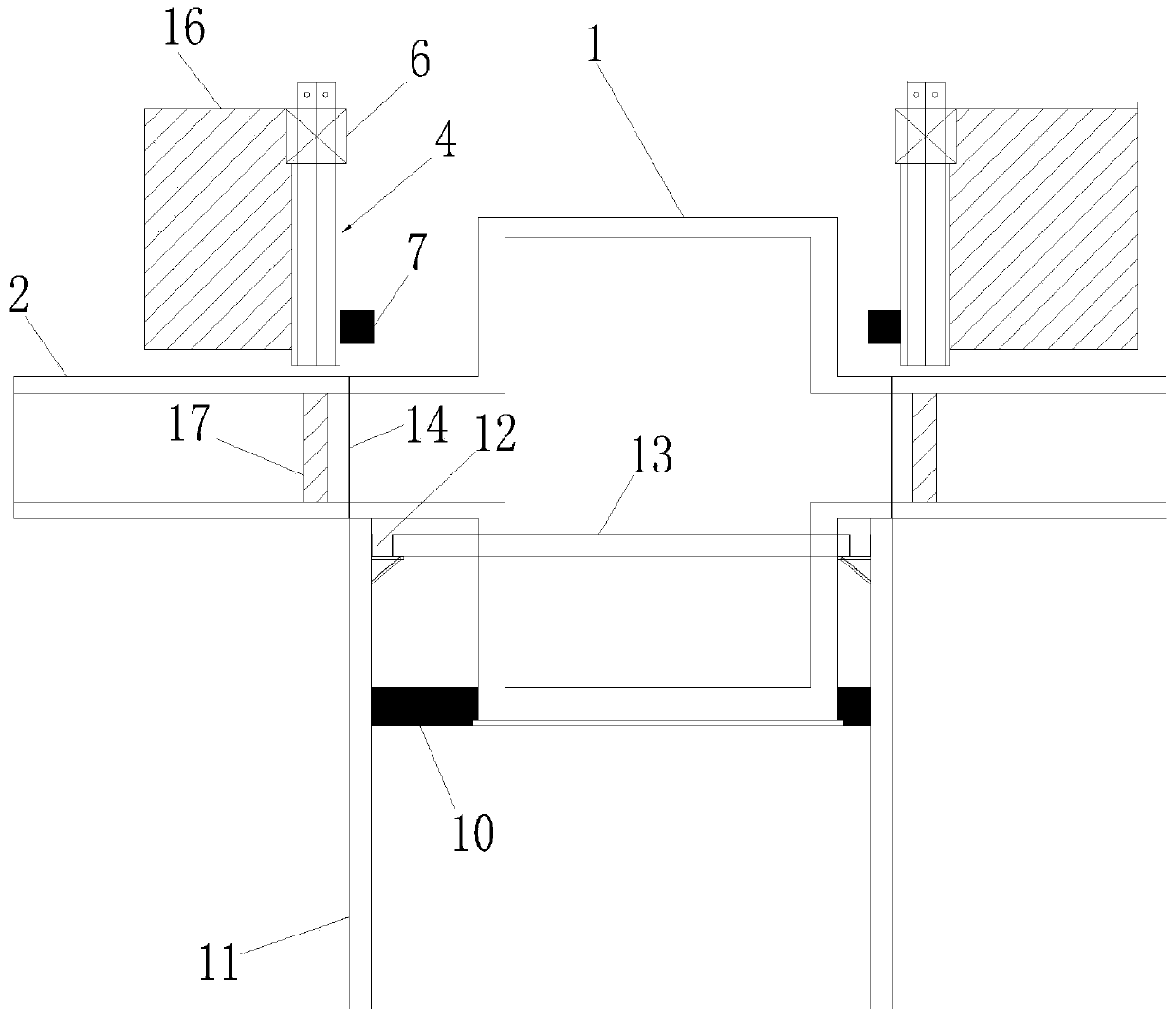

Multiple water stop belt, waterproof structure and construction method of waterproof structure

InactiveCN105821908AGuaranteed water stop effectPlay the role of water stopArtificial islandsProtective foundationEconomic benefitsEngineering

The invention discloses a multiple water stop belt, a waterproof structure and a construction method of the waterproof structure. The multiple water stop belt comprises a metal water stop plate and at least one water stop strip fixedly connected to the surface of the metal water stop plate. The water stop strips are arranged in the length direction of the metal water stop plate in a through-length manner. The water stop strips are located on the upper side and / or the lower side of the metal water stop plate. The waterproof structure comprises multiple water stop belts, structural reinforcing steel bars, fore-poured concrete and post-poured concrete. A fore-poured concrete water stop strip body of each multiple water stop belt is embedded in the fore-poured concrete, and a post-poured concrete water stop strip body of each multiple water stop belt is embedded in the post-poured concrete. The construction method of the waterproof structure includes the construction steps that the multiple water stop belts are machined, the structural reinforcing steel bars are bound, the multiple water stop belts are fixed, a formwork is erected, and the concrete is poured. A water stop function of the concrete can be achieved, a waterproof effect is ensured, the water stop belts release stress under the dead load of concrete pouring, water can be stopped effectively, and therefore economic benefits are improved.

Owner:姚攀峰

Construction method for connecting new and old sewage pipes during sewage pipe shifting transformation

The invention discloses a construction method for connecting new and old sewage pipes during sewage pipe shifting transformation. The construction method includes carrying out construction for connecting side surface PCCP (prestressed concrete cylinder pipes) with original three-pollution communicating pipes and connecting PCCP with three-pollution communicating pipes of square canals and carryingout construction for connecting the adjacent PCCP with inspection wells. Section construction can be simultaneously carried out or can be carried out step by step. The construction method has the advantages that non-intersection zones, the inspection wells and package wells are constructed in integral foundation pits at first according to actual plane intersection conditions of the new and old three-pollution communicating pipes, then cutover construction processes for the new and old three-pollution communicating pipes are further carried out, the construction method includes simple and convenient construction processes and is suitable for popularization and application, and the obtained new and old sewage pipes are stable in connection structure.

Owner:HANGZHOU MUNICIPAL CONSTR GRP CO LTD

Guiding device for supporting construction of foundation pit in narrow zone and construction method

PendingCN110700280APlay the role of water stopResistance to deformationExcavationsBulkheads/pilesReinforced concreteArchitectural engineering

The invention provides a guiding device for supporting construction of a foundation pit in a narrow zone and a construction method. The structure is as the follows that an original box culvert is cutinto two sections of a front section and a rear section by an intercepting well; an inner circle and an outer circle of high-pressure jet grouting piles are constructed at the periphery of an intercepting well foundation pit; H-shaped steels are interpolated in modes of closely inserting and inserting one by one with one interval; the outer circle of high-pressure jet grouting pile is arc-shaped,and the positions, the right above the front section and the rear section of the original box culvert, of two ends of the outer circle of high-pressure jet grouting pile are connected with the inner circle of high-pressure jet grouting pile through full reinforcement of the high-pressure jet grouting pile; a reinforced concrete inner support is arranged between the inner circle and the outer circle of high-pressure jet grouting piles, and a guide groove foundation pit is excavated between piles; and the front and rear sections of the original box culvert are respectively provided with holes inthe side wall and the holes communicate with the guide grooves; and the front section and the rear section of the original box culvert respectively use the positions corresponding to the right lowerparts of the H-shaped steels inserted into the inner circle of high-pressure jet grouting pile as a plugging part, a temporary plugging wall is formed between the underwater concrete and the intercepting well, and bidirectional steel bars are configured in the wall. The device meets the requirement of foundation pit supporting and simultaneously has construction diversion capability.

Owner:ANHUI SHUIAN CONSTR GRP CO LTD

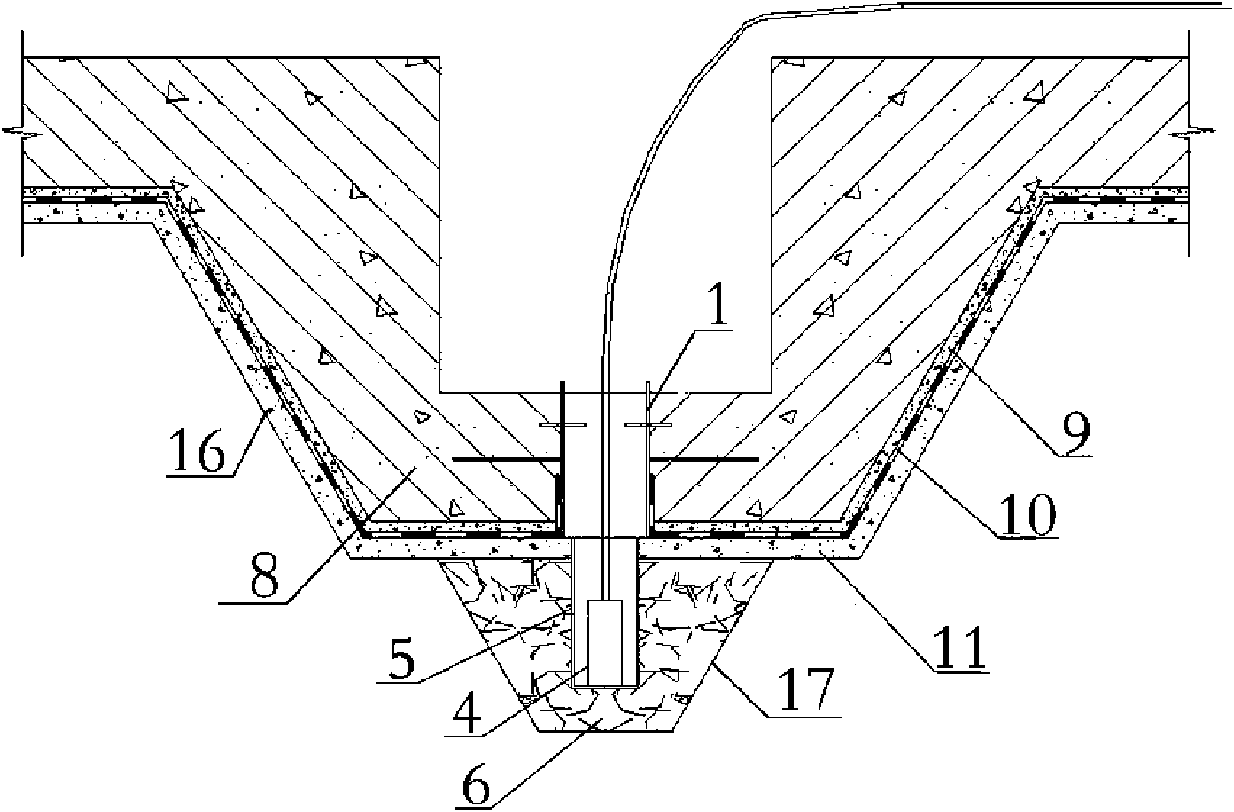

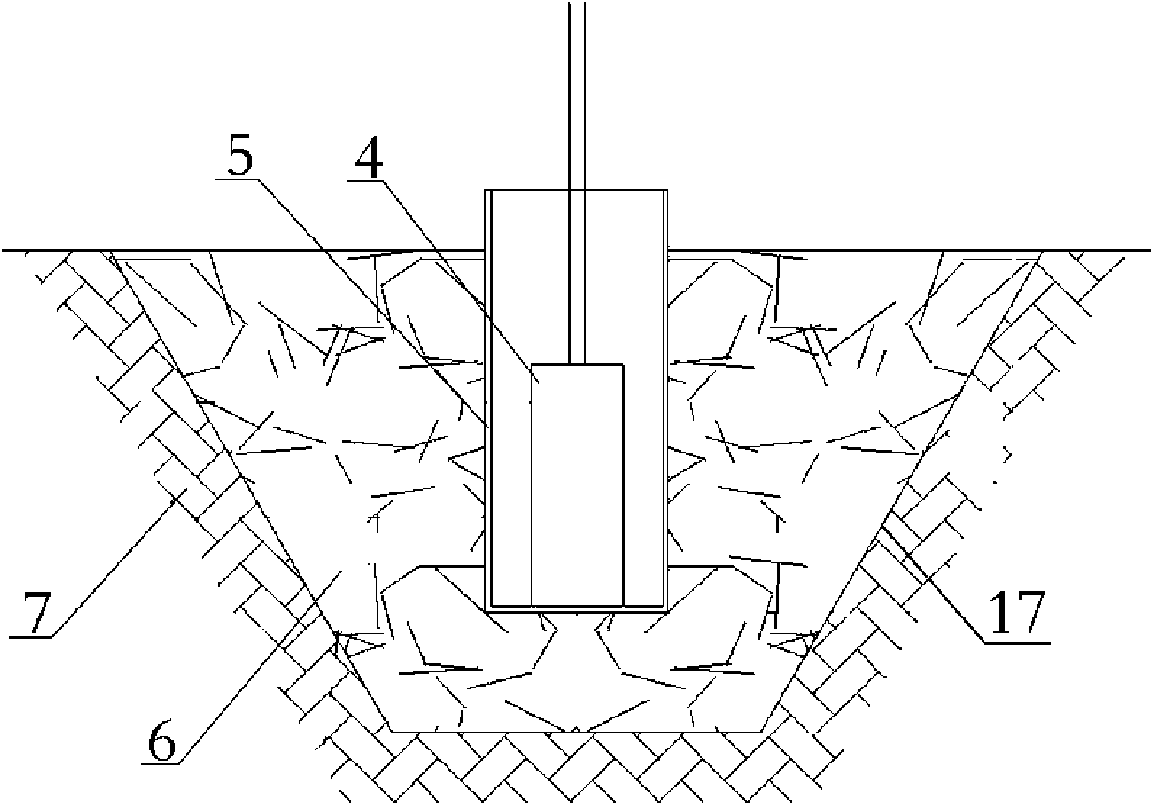

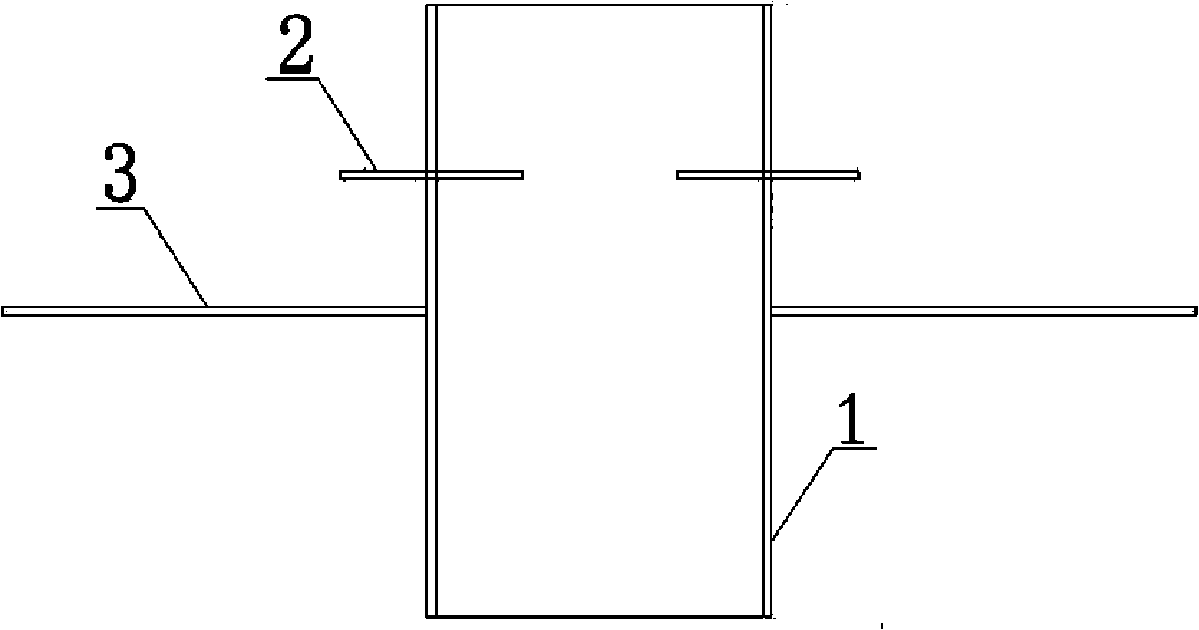

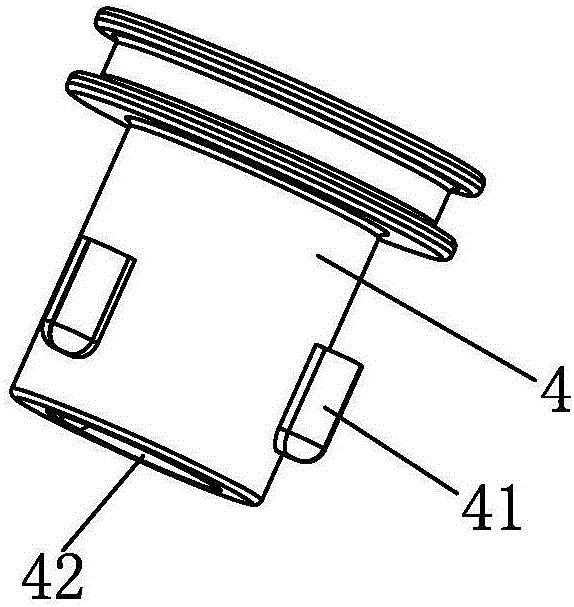

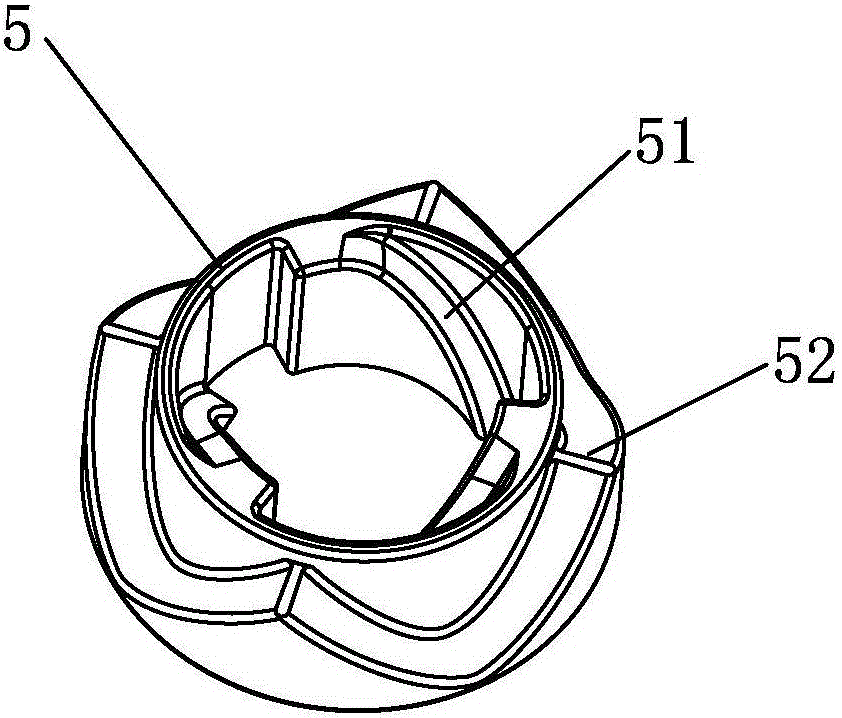

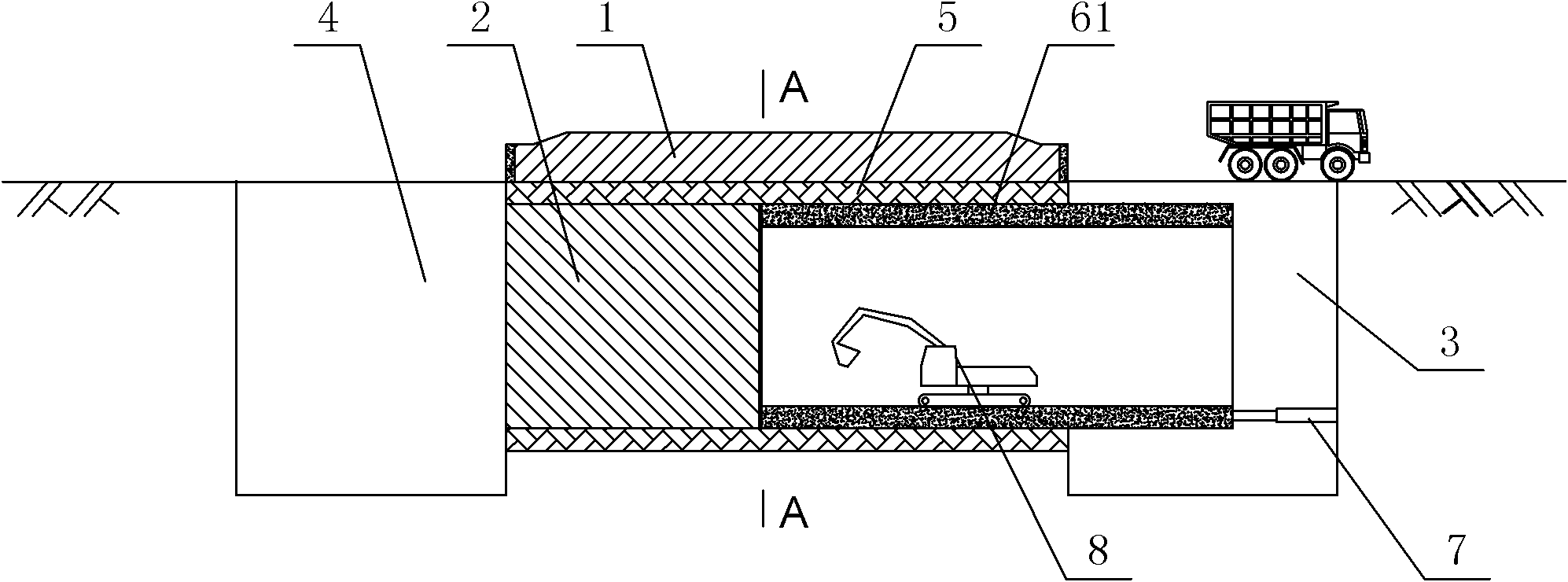

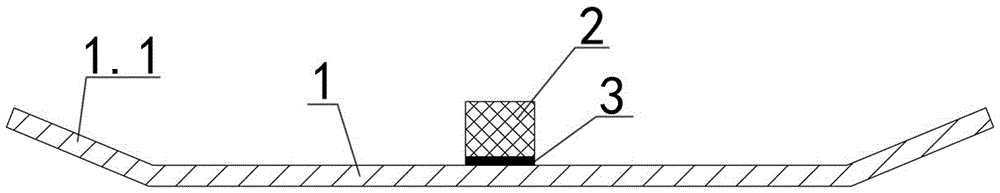

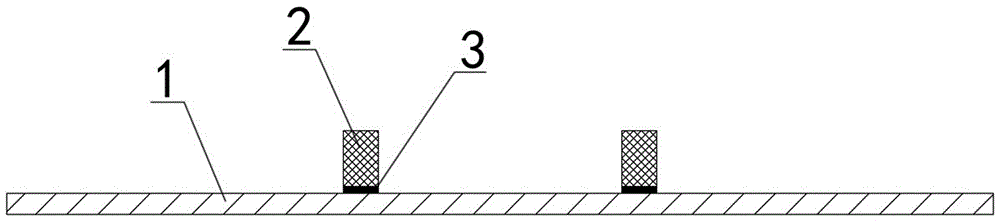

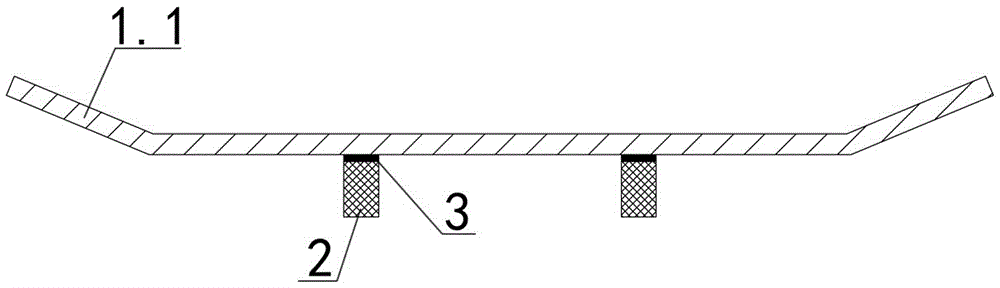

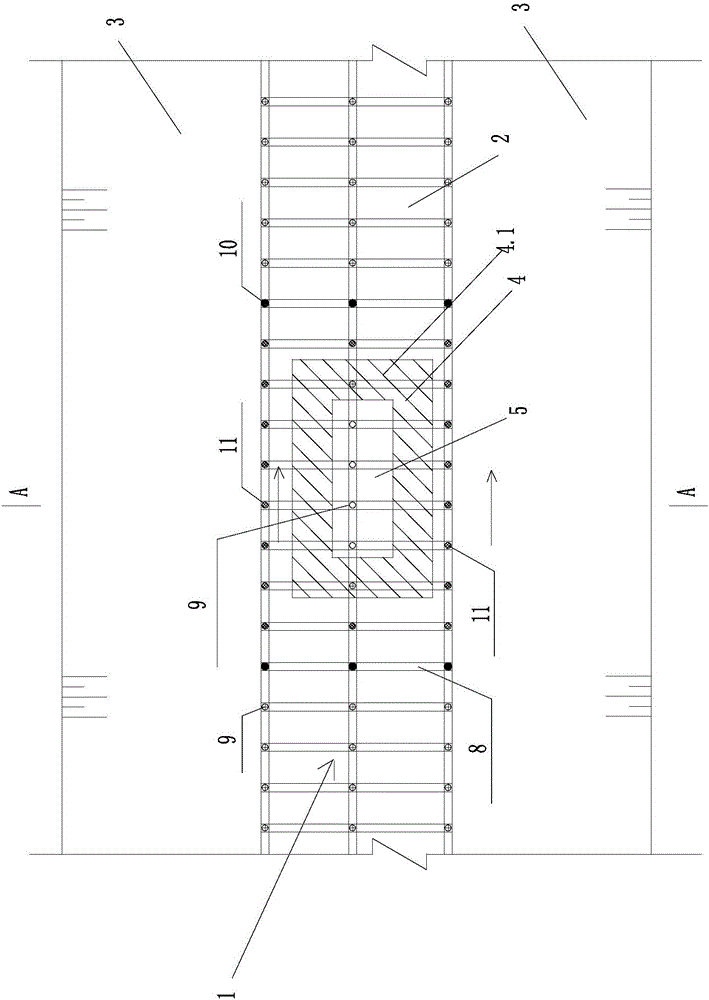

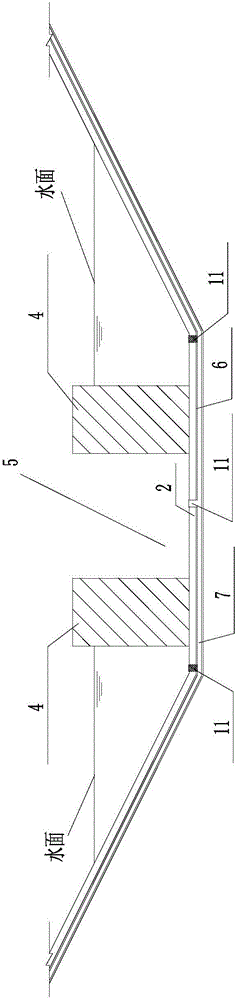

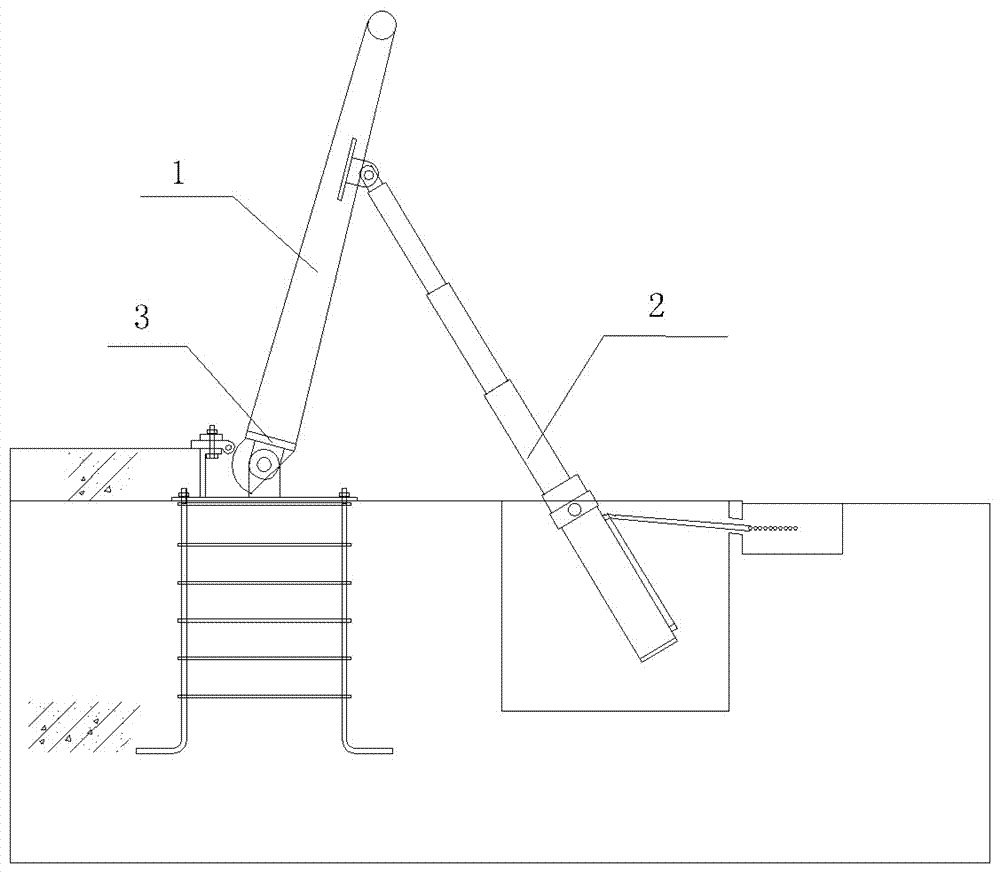

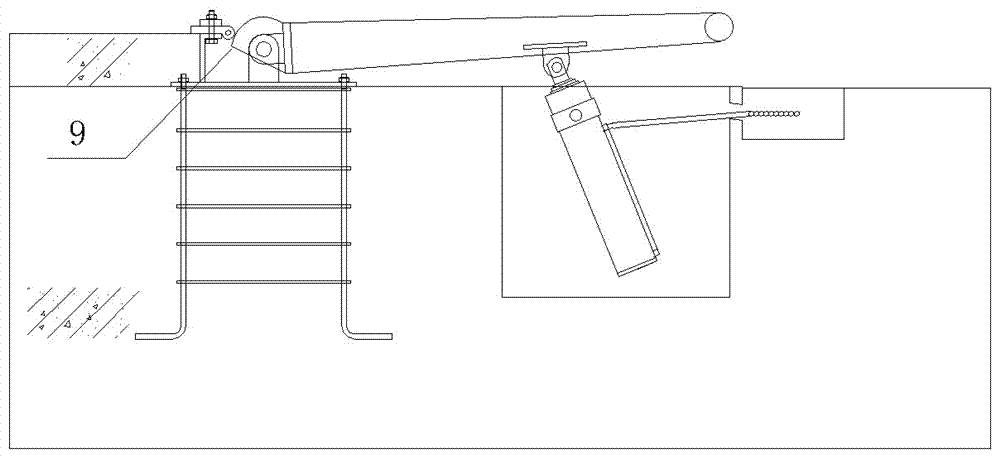

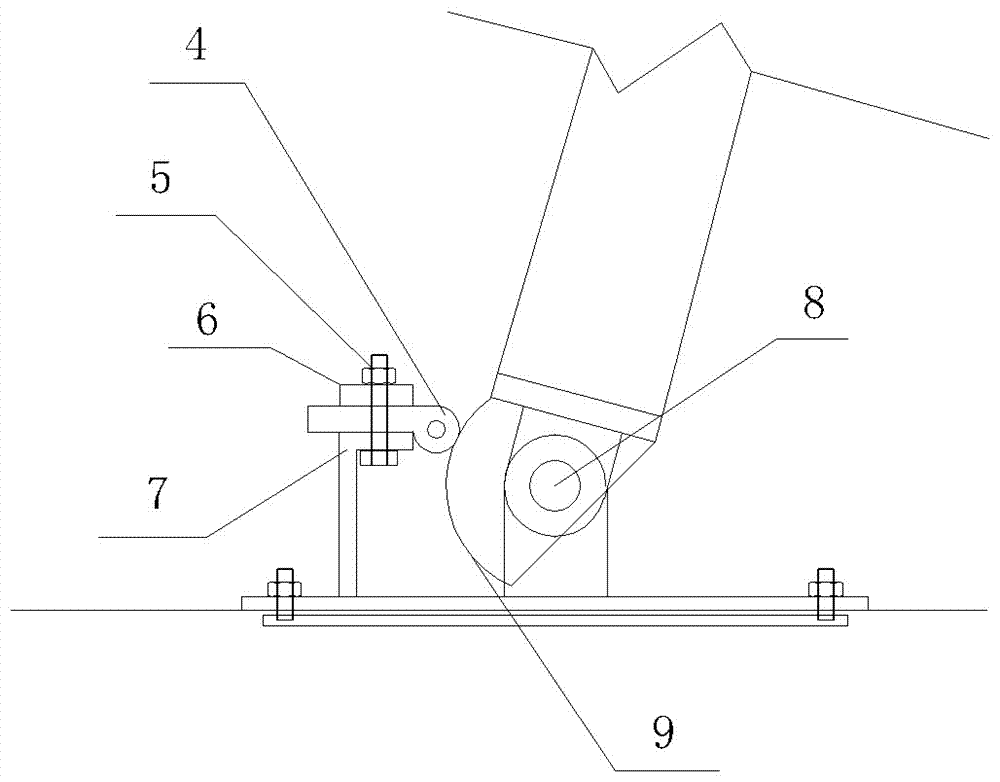

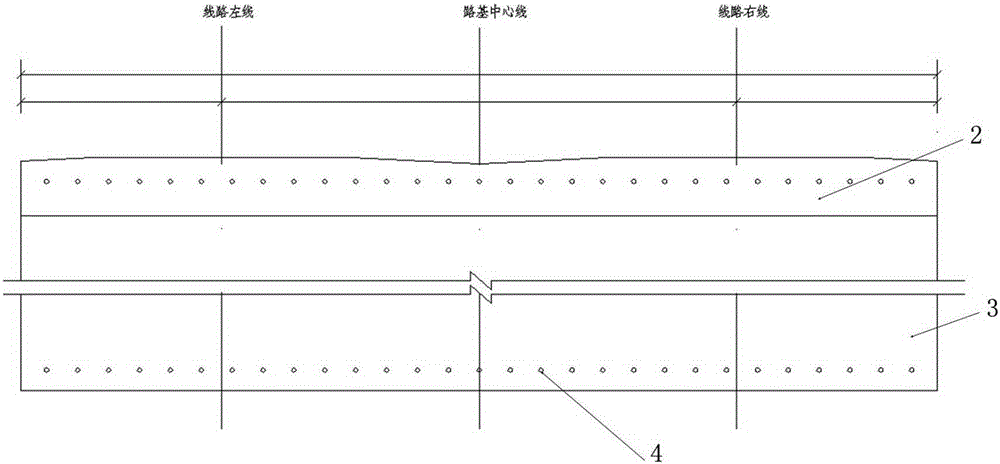

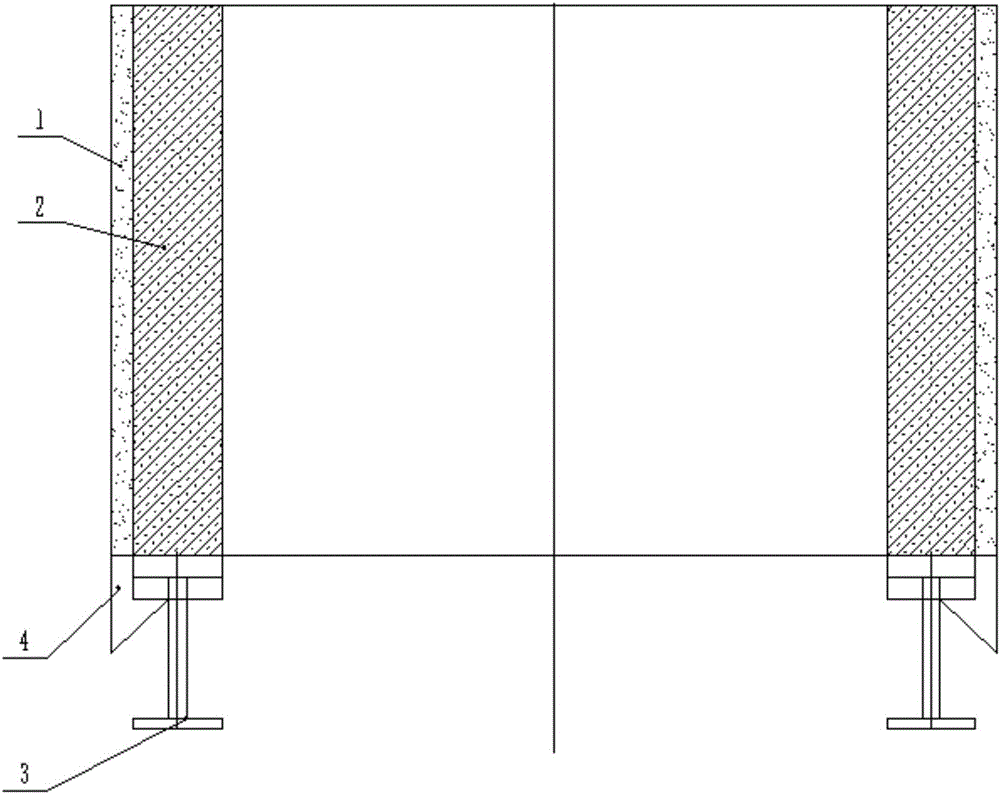

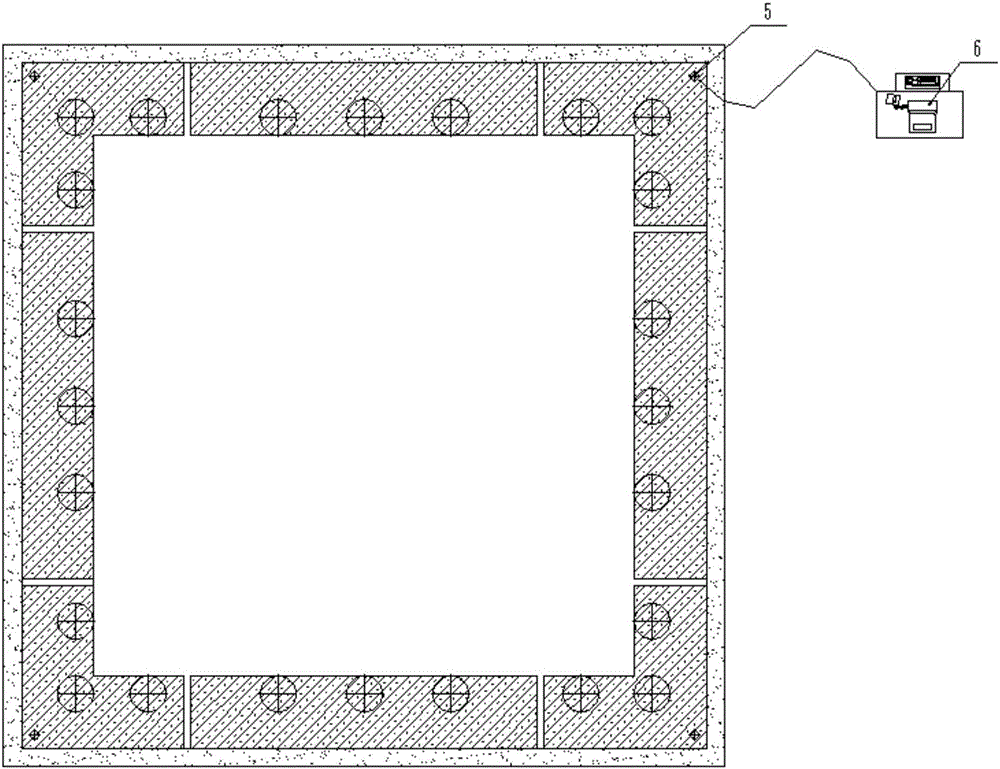

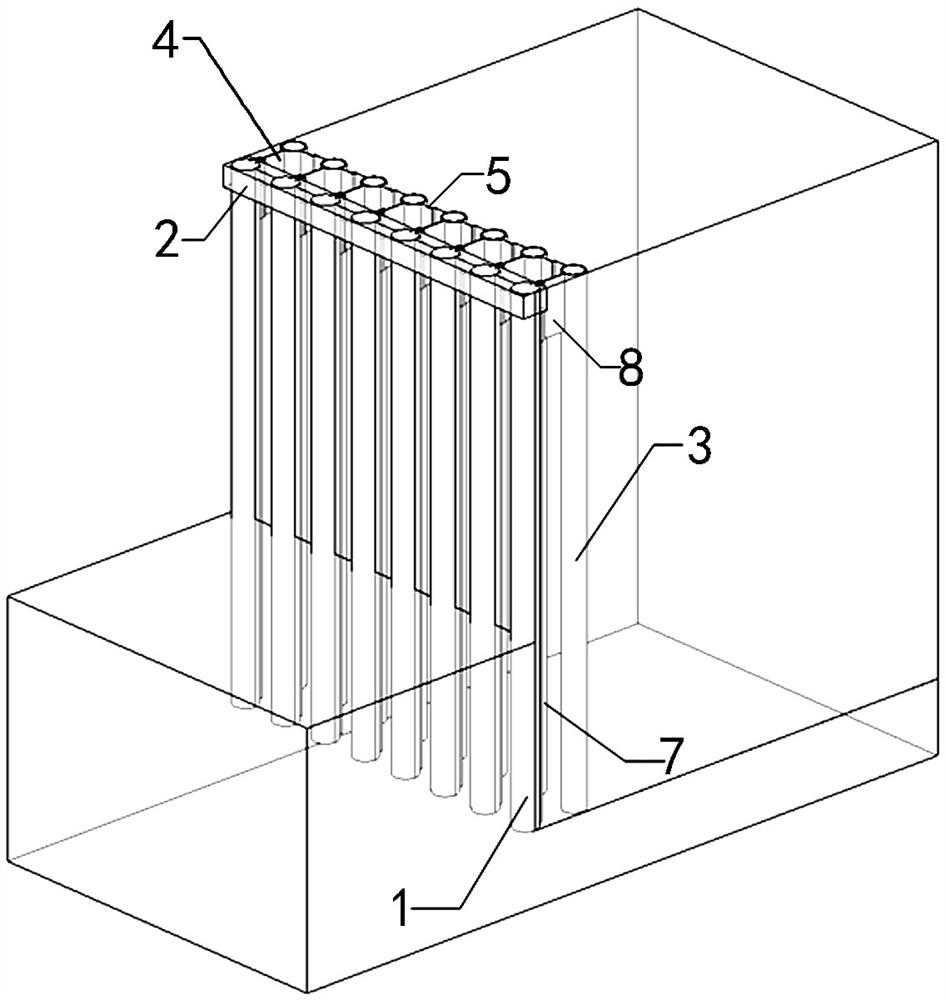

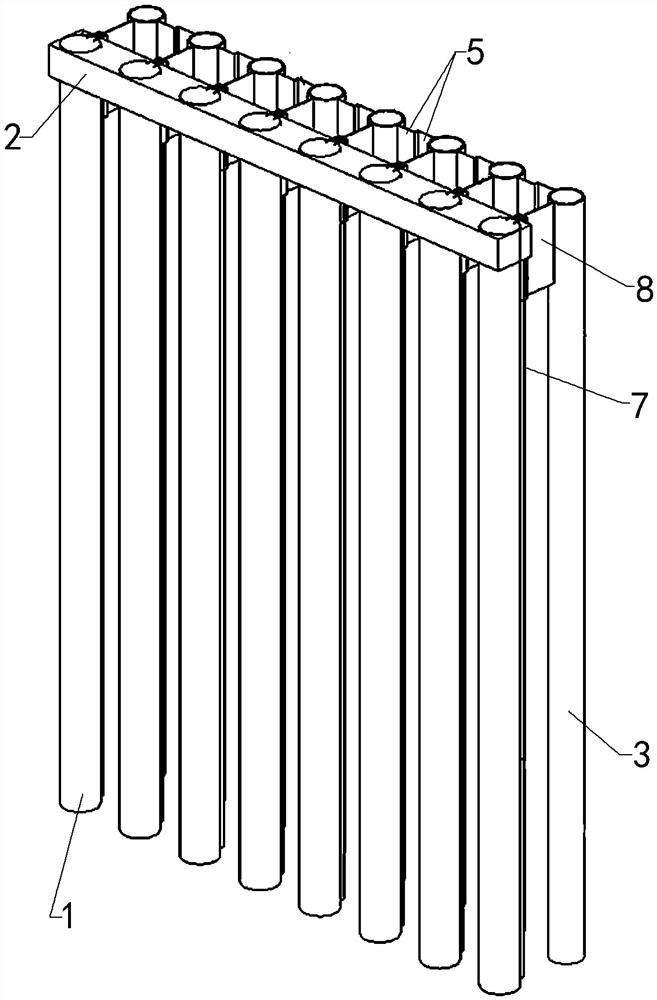

Cofferdam island type foundation pit structure and method for canal lining repairing under condition of uninterrupted water delivery

ActiveCN106545022AAchieve ups and downsConducive to underwater constructionArtificial water canalsFoundation engineeringWater dischargeUplift pressure

The invention discloses a cofferdam island type foundation pit and method for canal lining repairing under the condition of uninterrupted water delivery. The cofferdam island type foundation pit and method are characterized in that a water canal (1) comprises a lining plate (2) arranged in the water delivery direction and inclined canal slopes (3) arranged symmetrically along with the lining plate (2); a cofferdam (4) is arranged on the water canal (1), the cofferdam (4) is located in the middle of the water canal (1), and the lower end of the cofferdam (4) and the canal slopes (3) are fixed together; the lower portion of the cofferdam (4) and the water canal (1) form a dry ground foundation pit (5); and the cofferdam (4) is of a module type buoyancy tank steel structure, and an air and water discharging structure (4.1) is arranged inside the cofferdam (4). The defect that a canal structure can be damaged by a cofferdam in the prior art is overcome. The cofferdam island type foundation pit and method have the advantages that the water head in the foundation pit is reduced greatly, and the uplift pressure borne by the lining in the foundation pit is reduced effectively.

Owner:CHANGJIANG SURVEY PLANNING DESIGN & RES

Anti-seepage structure for basement

The invention discloses an anti-seepage structure for a basement. The anti-seepage structure comprises a concrete slab, wherein a connecting plate is mounted on the upper surface of the concrete slab; the connecting plate is connected with the concrete slab through pins; a U-shaped water storage tank is arranged between the concrete slab and the connecting plate; the U-shaped water storage tank is sunken into the concrete slab; the U-shaped water storage tank is fixed on the concrete slab; expansion water stopping adhesive tapes are mounted on the internal bottom surface of the U-shaped water storage tank, and mounting bolts are connected between the expansion water stopping adhesive tapes and the U-shaped water storage tank; a polyethylene plastic waterproof rod is further arranged between the connecting plate and the concrete slab; the top part of the polyethylene plastic waterproof rod is arranged on the connecting plate; the bottom of the polyethylene plastic waterproof rod penetrates through a flow guiding pipe to be connected with the lower surface of the concrete slab; the flow guiding pipe is communicated with the polyethylene plastic waterproof rod. The anti-seepage structure for the basement overcomes the defects in the prior art, can effectively solve the problem of basement water leakage, is simple and firm in structure, quite convenient for construction and high in pertinence, and can achieve better effect of flow guiding and water stopping.

Owner:CHENGDU JIAMEIJIA SCI & TECH

Retaining dam bottom waterstop mechanism

The invention relates to a water stop mechanism at the bottom of a river dam. The dam face plate and the dam foundation are connected by bolts, and the bottom of the water retaining face face facing the water is welded into a whole with a piece of arc material greater than 90 degrees. At the same time, the P-type water-stop rubber is always tightly pressed on the arc, so that no matter the water-blocking panel stops at any water-blocking height, it can play a role in water-stopping. The invention is simple in structure, economical and durable, safe and reliable, solves most of the defects of the traditional bottom water-stop structure, and has great practical value in the field of retaining dams.

Owner:宗泽群

Roadbed concrete bed structure and construction method

The invention discloses a roadbed concrete bed structure and a construction method. The roadbed concrete bed structure is provided with a plurality of sections of concrete beds and ballastless tracks arranged on the concrete beds, wherein each concrete bed is divided into a C35 concrete layer, a C20 concrete layer, 5% cement mixed graded broken stone layer and a packing layer from the top down sequentially; the ballastless tracks are laid on the concrete beds through a plurality of sections of base plates; an expansion joint is arranged between every two adjacent concrete beds; the expansion joints are fit with gaps between adjacent base plates; and each concrete bed is aligned to one base plate correspondingly. Free extension of bed concrete and the stability in a freezing and thawing state in an alpine region can be ensured, and a situation that no geometrical states of the ballastless tracks are changed due to temperature change can be finally guaranteed.

Owner:CHINA RAILWAY NO 9 GRP

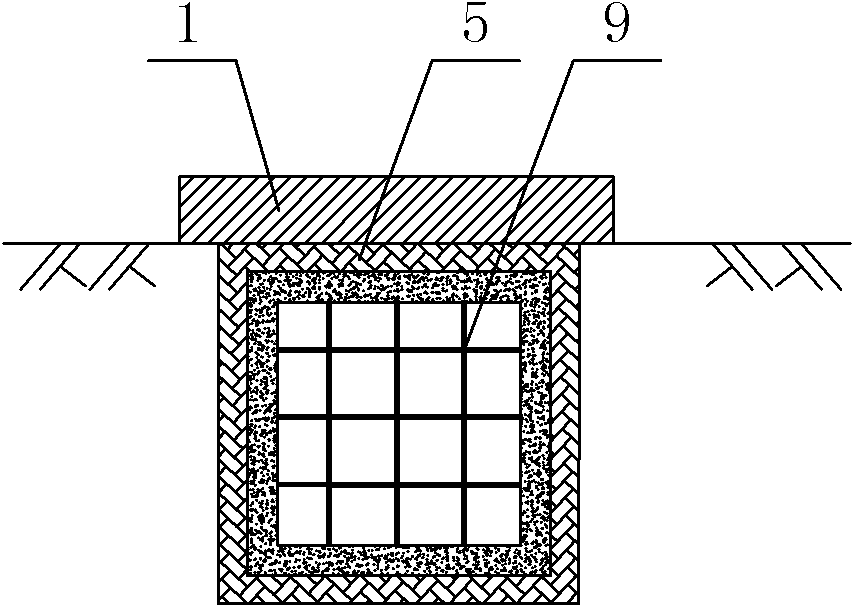

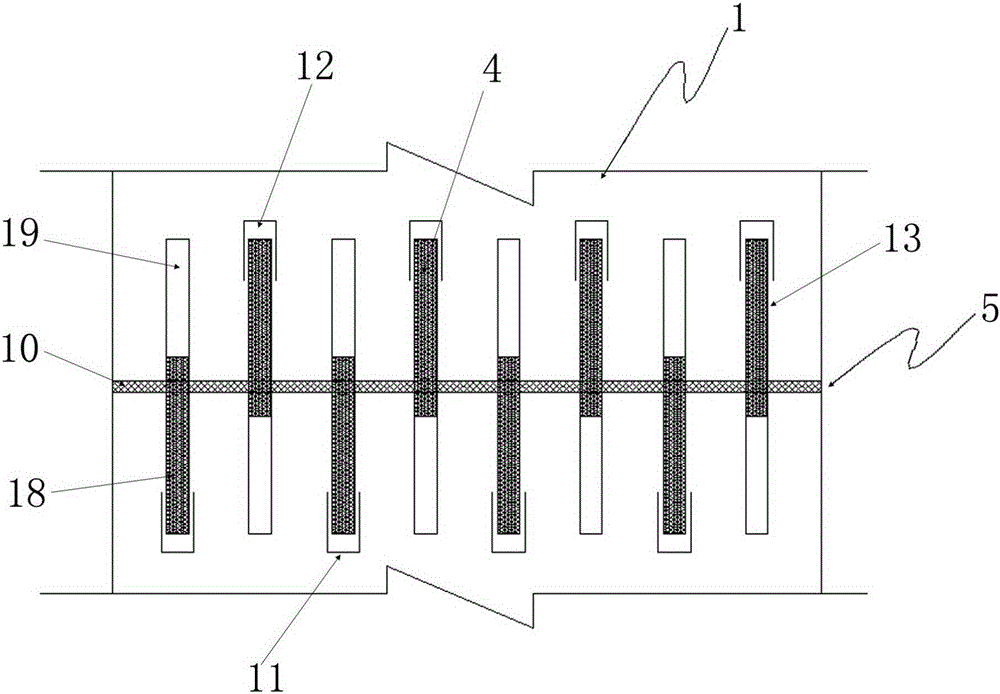

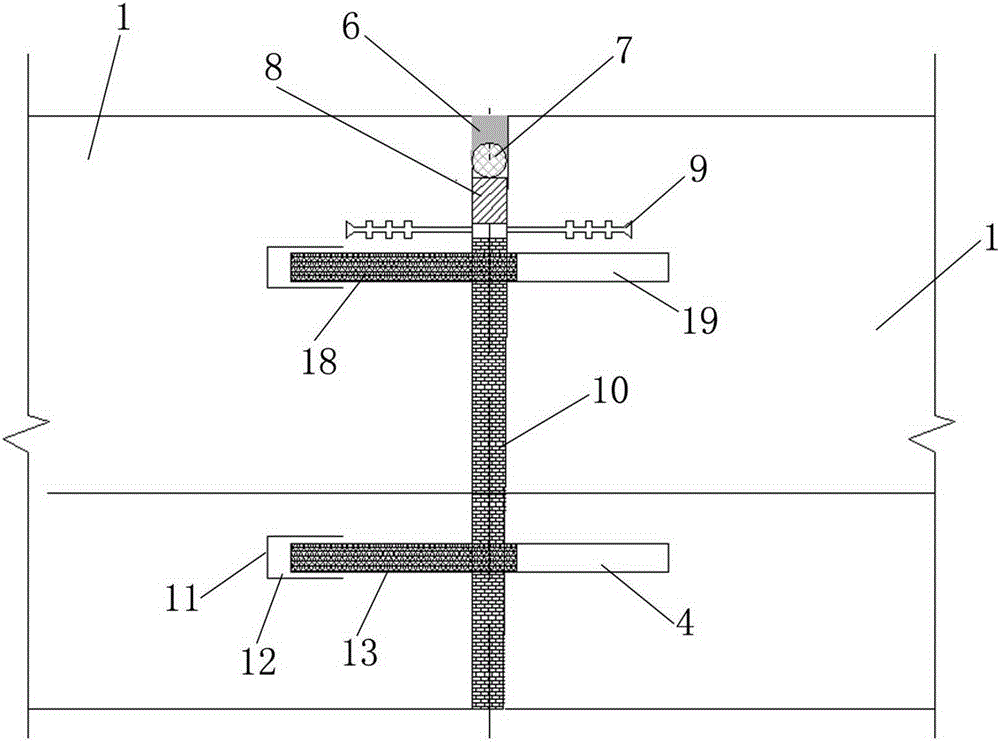

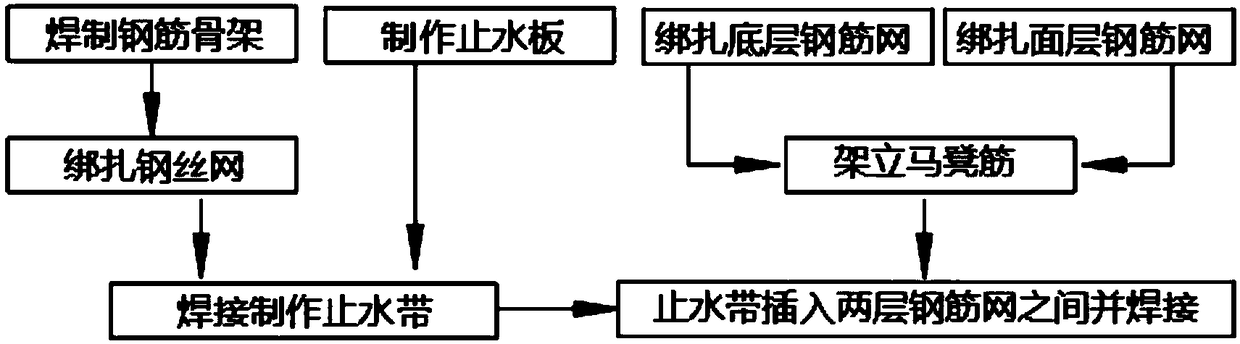

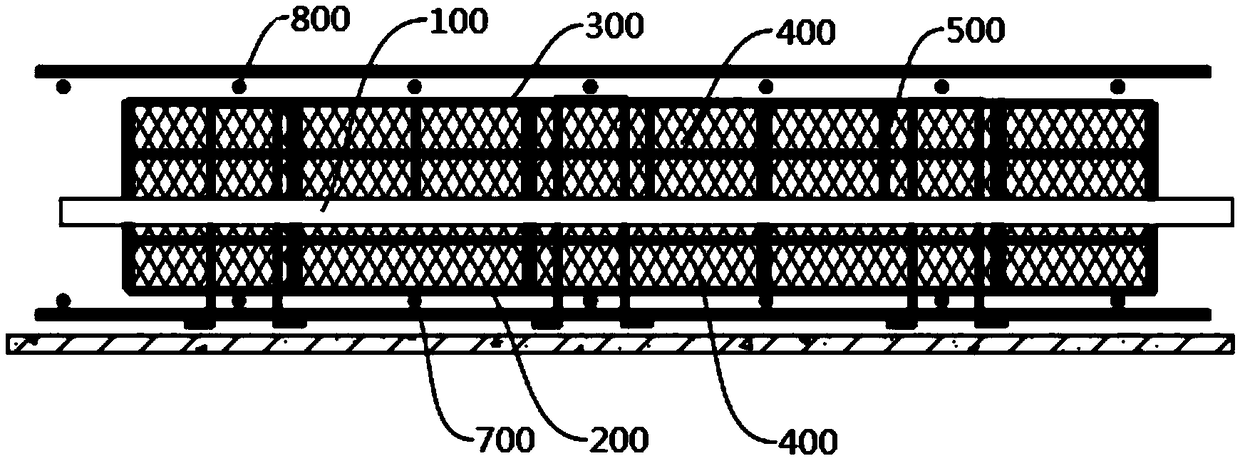

Integral water stopping system and manufacturing method thereof

ActiveCN109024699AShorten the construction scheduleShort timeArtificial islandsProtective foundationEngineeringRebar

The invention relates to the field of expansion joint post-cast strip water stopping systems, in particular to an integral water stopping system and a manufacturing method thereof. The integral waterstopping system is used for being arranged at the position of a post-cast strip to achieve a water stopping effect. The manufacturing method of the water stopping system mainly includes the steps thatrectangular reinforcement frameworks are manufactured; the two reinforcement frameworks are welded to the two faces of a water stopping plate, the water stopping plate and the reinforcement frameworks are inserted between a bottom-layer reinforcement net and a face-layer reinforcement net, the reinforcement frameworks on the two faces of the water stopping plate are fixedly connected with the bottom-layer reinforcement net and the face-layer reinforcement net, and the length of the water stopping plate is larger than or equal to the lengths of the reinforcement frameworks. The two steps of manufacturing a water stopping belt and manufacturing structural reinforcements can be carried out simultaneously and do not interfere each other, thus, the construction period is shortened, the construction progress is accelerated, and as the water stopping belt is manufactured in advance, a large amount of time can be saved when the water stopping system is manufactured on site.

Owner:广东蕉岭建筑工程集团有限公司

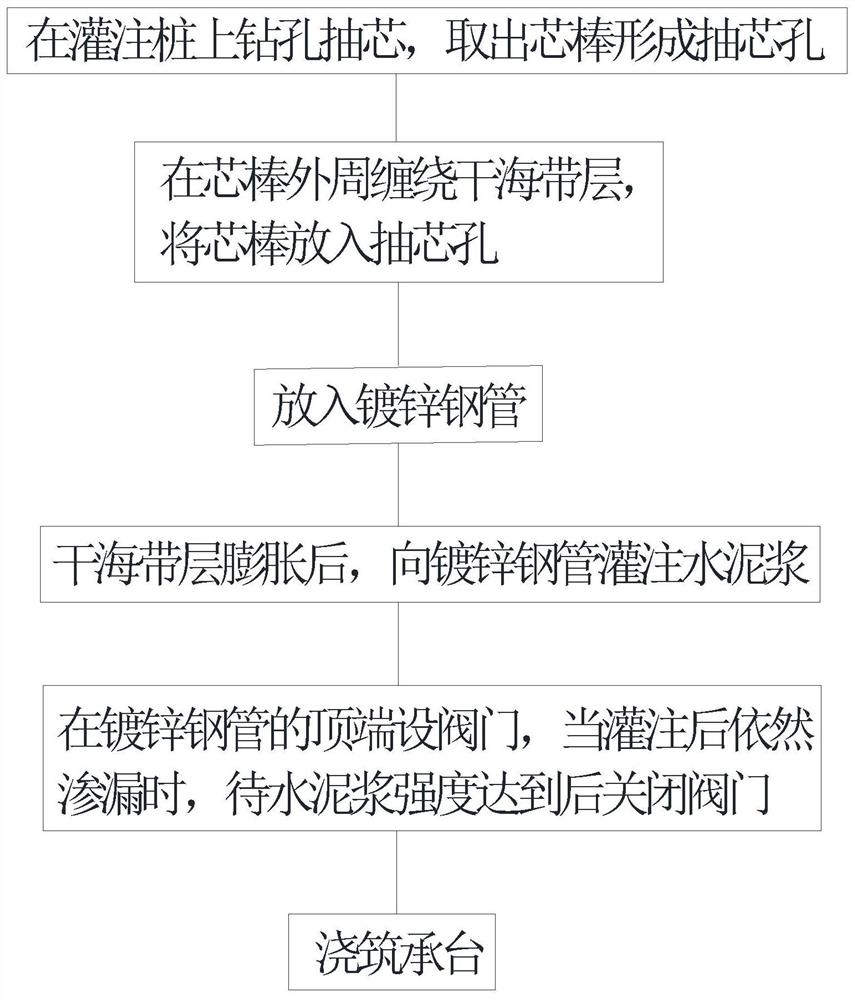

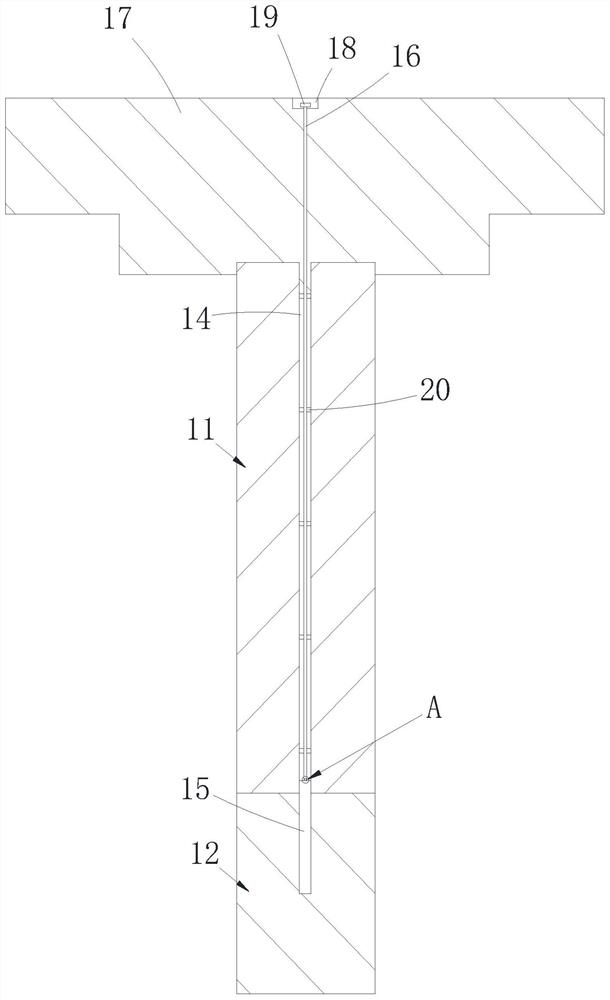

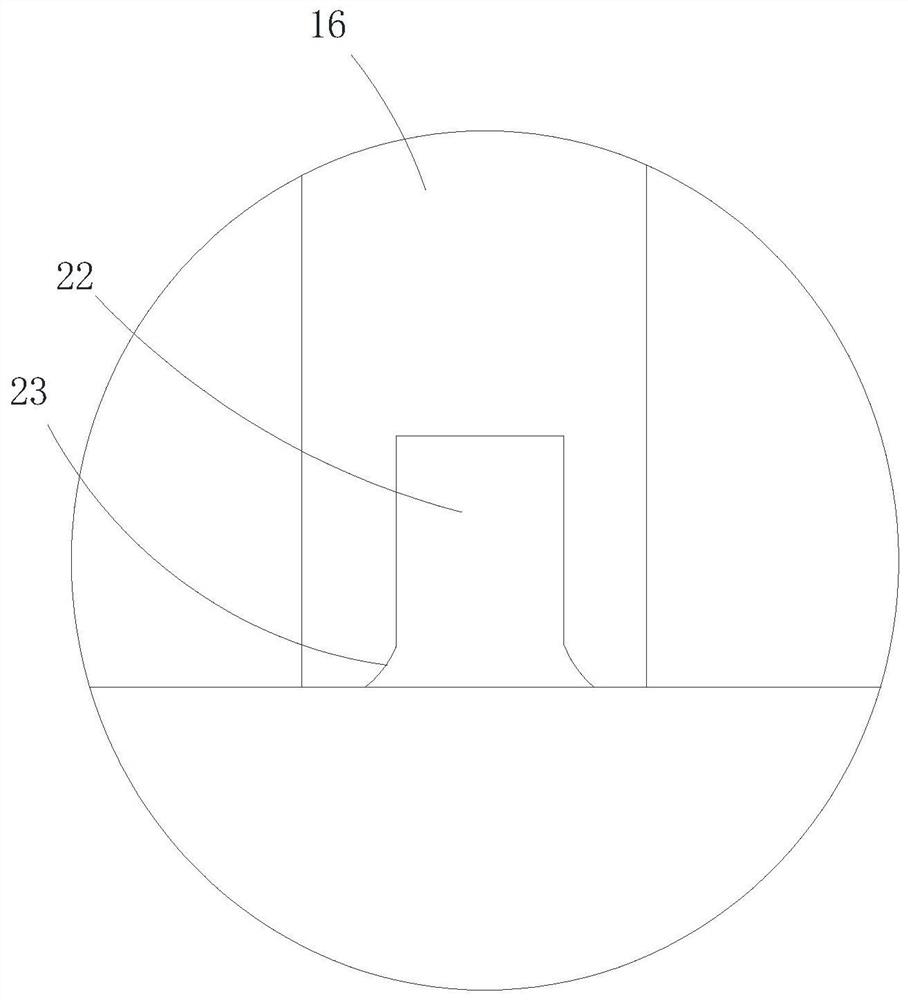

Rotary excavating cast-in-place pile hole water leakage plugging method

ActiveCN111691414AQuality improvementSolve the leakFoundation testingProtective foundationWater leakageCement paste

The invention relates to the technical field of rotary excavating cast-in-place pile construction, and discloses a rotary excavating cast-in-place pile hole water leakage plugging method. The method comprises the following construction steps that S1, core pulling is conducted on a cast-in-place pile, and a core rod is taken out to form a core pulling hole; S2, the core rod with the length of 1 m is taken, and a dry kelp layer is wound around the core rod and is put into the core pulling hole; S3, a galvanized steel pipe is placed in the core pulling hole, and the bottom end of the galvanized steel pipe abuts against the upper end of the core rod; S4, the dry kelp layer absorbs water and expands, so that the core pulling hole stops water, and then expansion cement paste is injected throughthe galvanized steel pipe; S5, a valve is arranged at the top end of the galvanized steel pipe, and when leakage still exists after the cement paste is injected into the core pulling hole, the valve is closed after the strength of the cement paste is reached; and S6, concrete is poured above the cast-in-place pile to form a bearing platform, the upper surface of the bearing platform is sunken downwards to form a groove, and the top end of the galvanized steel pipe is exposed in the groove. According to the rotary excavating cast-in-place pile hole water leakage plugging method, the filling work after core pulling is completed, the problem of leakage of the core pulling hole is solved, the problem of high construction difficulty caused by compensation work after occurrence of leakage in subsequent construction is solved, and the construction cost is reduced.

Owner:深圳市建工集团股份有限公司

Open caisson construction technology

InactiveCN106812148AImprove the construction environmentSimple caisson constructionCaissonsComputer monitoringEngineering

The invention relates to an open caisson construction technology, a jack set is placed into a foundation pit, a concrete plate is placed at the upper end of the jack set, and the periphery of the foundation pit is filled with a lubrication water-stop agent which has the functions of reducing displacement of peripheral soil, increasing concrete sinking power and stopping water; the jack set has the function of adjusting the perpendicularity; the blade foot has the cut soil sinkingfunction; a computer monitoring system monitors the perpendicularity of the open caisson in real time by a perpendicularity monitoring point. According to the open caisson construction technology, the problems that in the conventional construction technologies the sinking speed cannot be controlled, the peripheral sinking is large, damage to the peripheral environment is large, the perpendicularity adjustment is inconvenient and inflexible and the construction quality cannot be guaranteed are solved, the construction is easy, and the cost is saved.

Owner:BEIJING ZHONGYAN DADI TECH CO LTD

Double-row pile structure with water stopping function and construction method thereof

InactiveCN112227382AReduce wasteRecyclable and reusableExcavationsBulkheads/pilesWater stopArchitectural engineering

The invention relates to the technical field of double-row pile supporting, and discloses a double-row pile structure with a water stopping function and a construction method thereof. The double-row pile structure comprises front-row cast-in-place concrete piles, a concrete top beam, rear-row steel pipe piles and a waterproof curtain located between the cast-in-place concrete piles and the steel pipe piles. The cast-in-place concrete piles are connected through the top beam. The steel pipe piles are detachably connected through L-shaped connecting buckle plates, locking opening assemblies arearranged on the side walls of the cast-in-place concrete piles in the pile axial direction, and grouting pipes are arranged between the locking opening assemblies and the cast-in-place concrete piles.Connecting short plates are arranged between the cast-in-place concrete piles and the steel pipe piles which are opposite front and back. The steel pipe piles cooperate with the concrete piles, excellent water stopping performance is achieved, construction is easy, convenient and efficient, and part of the structure can be detached and recycled.

Owner:CHINA CONSTR FIRST DIV GROUP CONSTR & DEV

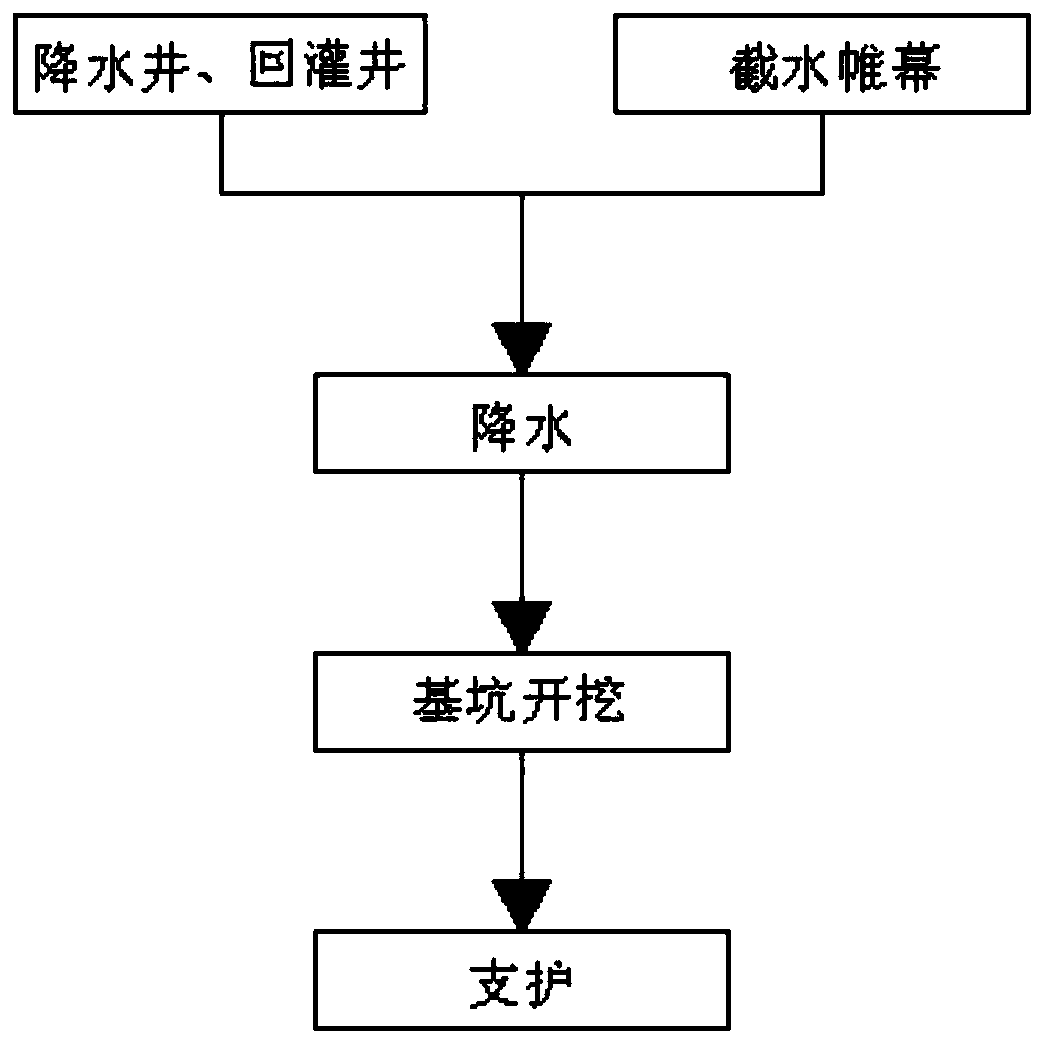

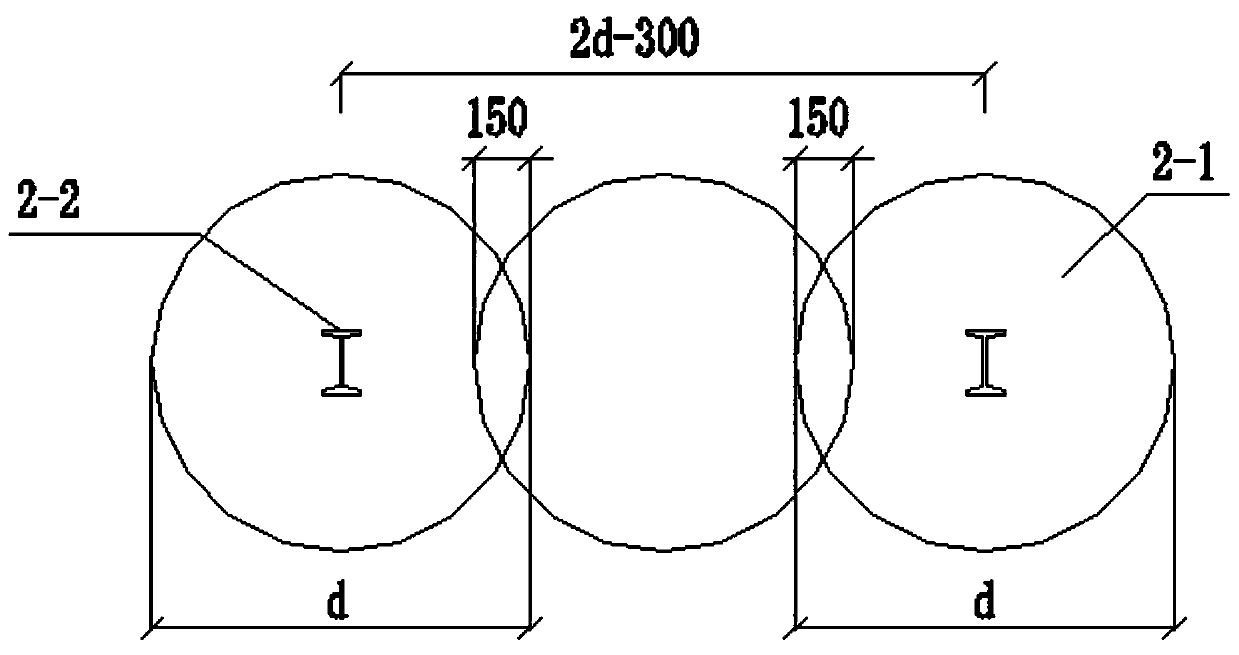

Construction method for combined supporting of deep foundation pits under complex environments

InactiveCN109881681AReduction of precipitationSmall footprint for excavationArtificial islandsExcavationsSmall footprintEngineering

The invention discloses a construction method for combined supporting of deep foundation pits under complex environments, and relates to the technical field of building construction. The constructionmethod for combined supporting of the deep foundation pits under the complex environments is characterized by comprising the following steps: a waterproof curtain of a high pressure jet grouting pileis constructed through a two-tube method, and according to an adopted two-tube method high pressure jet grouting construction process, two media of high pressure cement paste and compressed air are conveyed to the design depth to be cut, stirred and replaced to form a cement soil impermeable wall to reinforce a foundation and stop water. According to the construction method for combined supportingof the deep foundation pits under the complex environments, rainfall around the foundation pits can be reduced and avoided, negative influences such as sedimentation and cracking caused by rainfall to surrounding buildings are prevented, meanwhile the occupied area of foundation pit excavation is small, excavation can be conducted without sloping, the I-shaped steel waterproof curtain is additionally inserted in the adopted high pressure jet grouting pile, the water stopping effect is achieved, the purpose of reinforcing slopes of the foundation pits is also achieved, at present, mature implementation processes and equipment exist, a technology is feasible, and economical and practical effects are achieved.

Owner:CHINA MCC17 GRP

Socket and spigot structure for prefabricated assembly pipe gallery and construction method

InactiveCN112144578AAvoid docking misalignmentImprove docking accuracyArtificial islandsProtective foundationRubber ringButt joint

The invention discloses a socket and spigot structure for a prefabricated assembly pipe gallery and a construction method. The socket and spigot structure comprises a socket and a spigot which are inbutt joint, wherein the socket and the spigot are spliced through a rabbet, a splicing seam is reserved between the socket and the spigot, waterproof slurry is poured into the splicing seam, and the two ends of the splicing seam are blocked; a PC steel bar transversely penetrating through the splicing seam is arranged above the rabbet, and a water stop belt tightly attached to the inclined face isarranged at the inclined face above the rabbet; and the middle section of the rabbet and the lower portion of the rabbet are filled with joint filling plates, and a water-swelling rubber ring is arranged in the joint filling plate at the middle section of the rabbet. According to the socket and spigot structure, butt joint dislocation can be avoided, and the butt joint precision and the butt joint efficiency are effectively improved; uneven settlement of a foundation can be effectively prevented, and the anti-seismic and waterproof effects are achieved; and sealing and waterproof measures canbe achieved for the spigot, combination of working face compression rubber ring sealing and series connection compression can be formed by means of the PC steel bar, and the anti-seepage sealing andstress requirements can be met.

Owner:CHINA 19TH METALLURGICAL CORP

Segment caulking plugging structure and plugging process

PendingCN113586083APlay the role of water stopReduce exudationUnderground chambersTunnel liningStructural engineeringSealant

The invention relates to the field of tunnel segment construction, in particular to a segment caulking plugging structure and a plugging process. The segment caulking plugging structure comprises a waterproof adhesive tape, wherein the waterproof adhesive tape is tightly arranged between a segment and the inner wall of a tunnel, both sides of the waterproof adhesive tape extend towards both sides of a caulking respectively, a sealing groove is formed in the end, close to the inner wall of the tunnel, of the caulking, the middle of the waterproof adhesive tape is bent towards the side close to the sealing groove to form a protrusion, the protrusion is tightly attached to the interior of the sealing groove, a groove is formed in the protrusion, a water swelling strip is arranged in the groove and is tightly attached to the interior of the groove, the side, away from the segment, of the water swelling strip is tightly abutted with the inner wall of the tunnel, and polyurethane sealants fills up the space between the water swelling strip and the inner wall of the groove as well as the space between the water swelling strip and the inner wall of the tunnel as well as the space between the waterproof adhesive tape and the inner wall of the tunnel. The segment caulking plugging structure has the effects that the phenomenon that underground water seeps from the caulking is reduced, and the waterproof performance of the caulking is improved.

Owner:北京隧盾市政建设有限公司

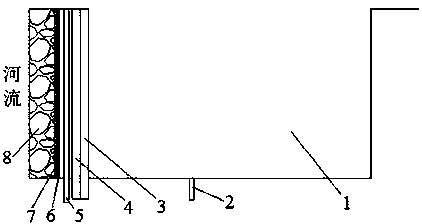

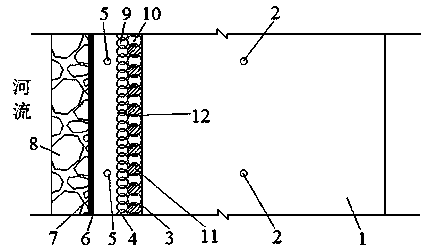

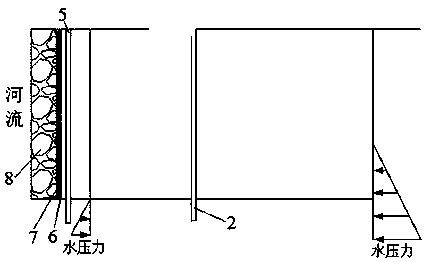

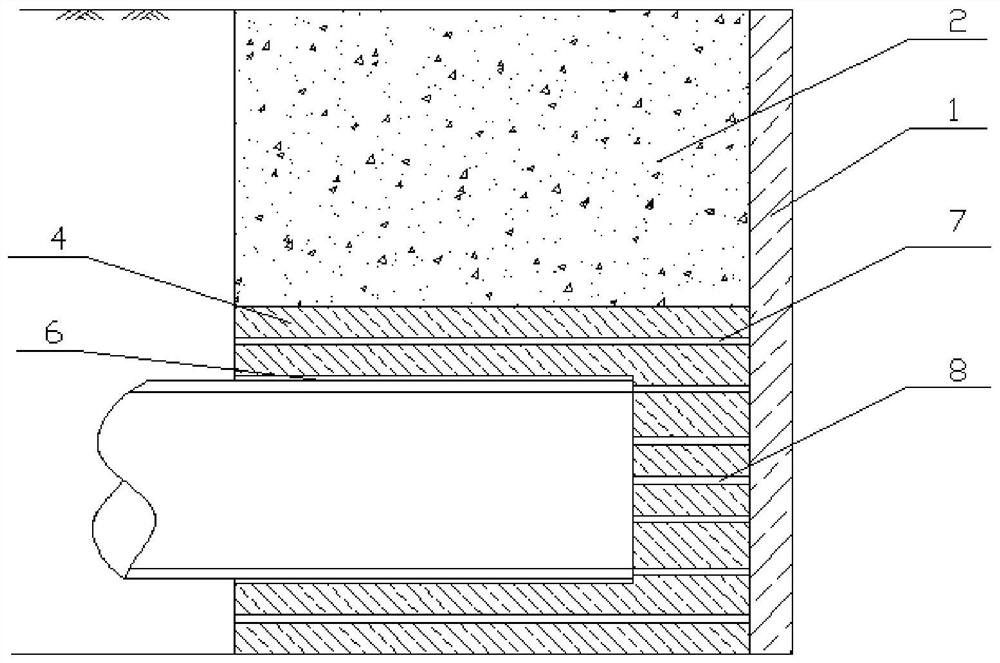

Foundation pit water stop system adjacent to river permeable stratum and construction process thereof

The invention provides a foundation pit water stop system adjacent to a river permeable stratum and a construction process thereof. A cofferdam, a protective wall, a waterproof wall, a second precipitation well, a clay bite pile group and a first bite pile group which are sequentially arranged are included; and the bottoms of all precipitation wells, clay bite piles, plain concrete piles and reinforced concrete piles enter an impervious layer. According to the scale of a foundation pit, engineering geology and hydrogeological conditions, the scope and scale of the cofferdam are determined; theprotective wall is constructed in a stacking manner, waterproof geotextile is laid, the cofferdam is piled up, the precipitation wells are drilled, water suction pumps are mounted in all the precipitation wells, and the water level of the precipitation wells on the side far from a river is made be higher than the water level in the precipitation wells near the river; the clay bite pile group is built; a bite pile group of the reinforced concrete piles and the plain concrete piles is built; and the adjacent reinforced concrete piles and plain concrete piles are wrapped with one-way grouting sleeve valve tubes, and the foundation pit water stop system adjacent to the river permeable stratum is built. By means of the water stop system, surrounding and intercepting of water is formed throughmultiple water-stopping lines, and the needs of project water stopping are effectively met.

Owner:中铁科学研究院有限公司

Reinforcing method and reinforcing structure for water-rich sand layer geological shield receiving end

PendingCN113530559AHigh strengthAvoid reinforcement effectsUnderground chambersTunnel liningSoil scienceStructural engineering

The invention discloses a reinforcing method and a reinforcing structure for a water-rich sand layer geological shield receiving end. The reinforcing method and the reinforcing structure are used for carrying out layered reinforcement on a soil body around the shield receiving end and comprise the following steps of firstly, designing a horizontal freezing reinforcement mode, and freezing the soil body around the shield receiving end into a freezing reinforcement area with a concave structure by utilizing the matching of a long freezing pipe and a short freezing pipe so as to improve the strength of the surrounding soil body, achieve a water stop effect and help to improve a grouting or jet grouting reinforcement effect, therefore a three-shaft stirring pile reinforcing area is arranged above the freezing reinforcement area, the shield end is further reinforced, and the situation that the reinforcing effect of the shield end is affected again by water in soil after freezing is completed is avoided. The construction of the three-shaft stirring pile reinforcing area on the upper layer and the construction of the horizontal freezing reinforcing area do not influence each other, compared with a vertical freezing reinforcing mode, the reinforcing effect is higher, the reinforcing efficiency is higher, and safe receiving of a shield tunneling machine is ensured.

Owner:CCCC TUNNEL ENG +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com