Retaining dam bottom waterstop mechanism

A dam and bottom water stop technology, which is applied in water conservancy projects, sea area projects, coastline protection, etc., can solve the problems of long service life, difficulty in waterproofing, inability to disassemble, etc., and achieve increased service life, high practical value, and waterproof effect Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to understand the technical solution of the present invention more clearly, the present invention will be further described below in conjunction with the accompanying drawings.

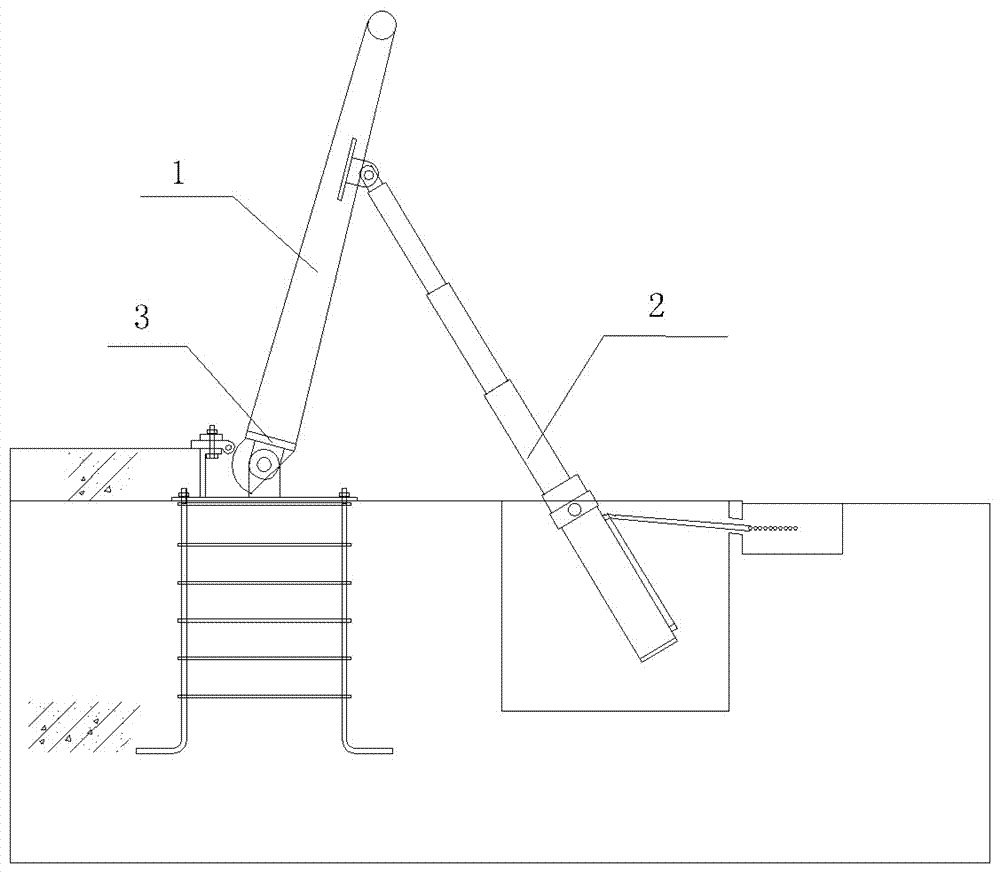

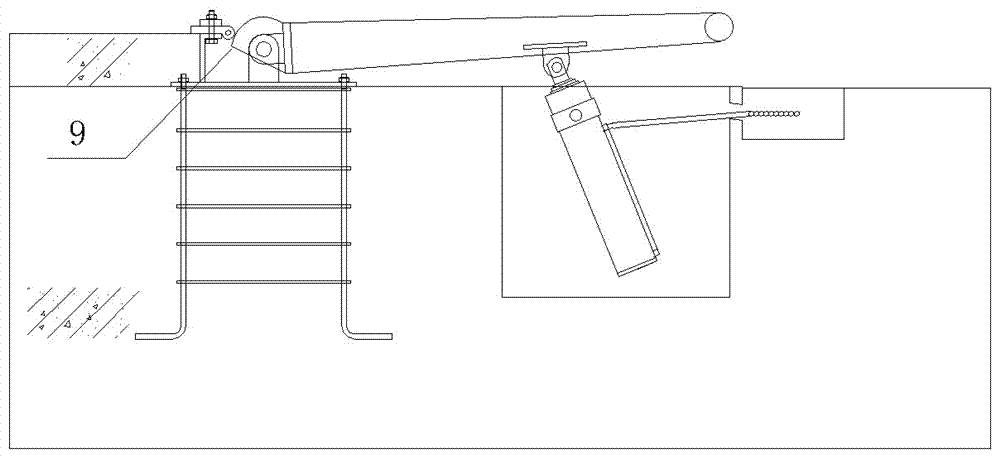

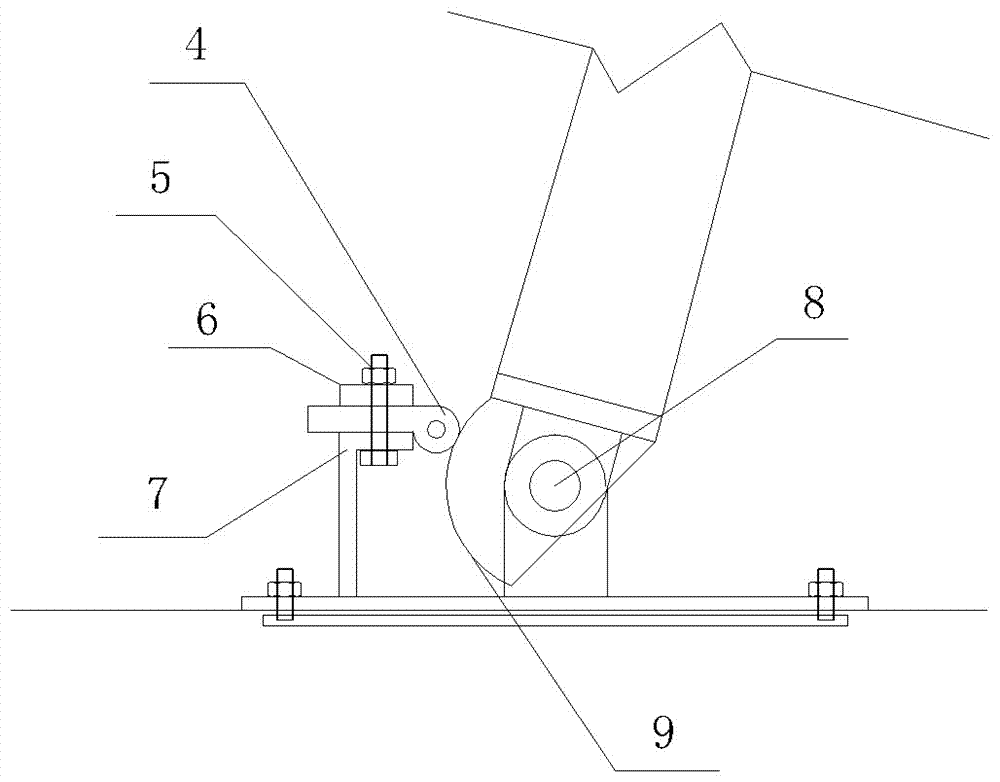

[0021] see figure 1 — Figure 4 , a water stop mechanism at the bottom of a dam, including a P-type water stop rubber part and a dam face part, the dam face plate 1 and the dam foundation are connected by bolts, and the bottom of the water retaining face plate 1 facing the water is more than 90 degrees The circular arc material 9 is welded into a whole. The P-type water-stop rubber part includes P-type water-stop rubber 4, fastening screws 5, flat bead 6, and L-shaped angle steel 7. The L-shaped angle steel 7 is fixed On the dam foundation, the P-shaped water-stop rubber 4 and the flat bead 6 are fixed on the L-shaped angle steel 7 by fastening screws 5. Rotating around the flat bottom shaft 3, the P-type water-stop rubber 4 is always tightly pressed on the arc material 9, no matter ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com