Automatic descaling sprinkler and automatic descaling method for sprinkler

An automatic descaling and shower technology, applied in the direction of spraying device, spraying device, etc., can solve the problems of poor descaling effect, scattered impact force of water flow, high process requirements, etc., achieve remarkable descaling effect, stable working state, and overall The effect of flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

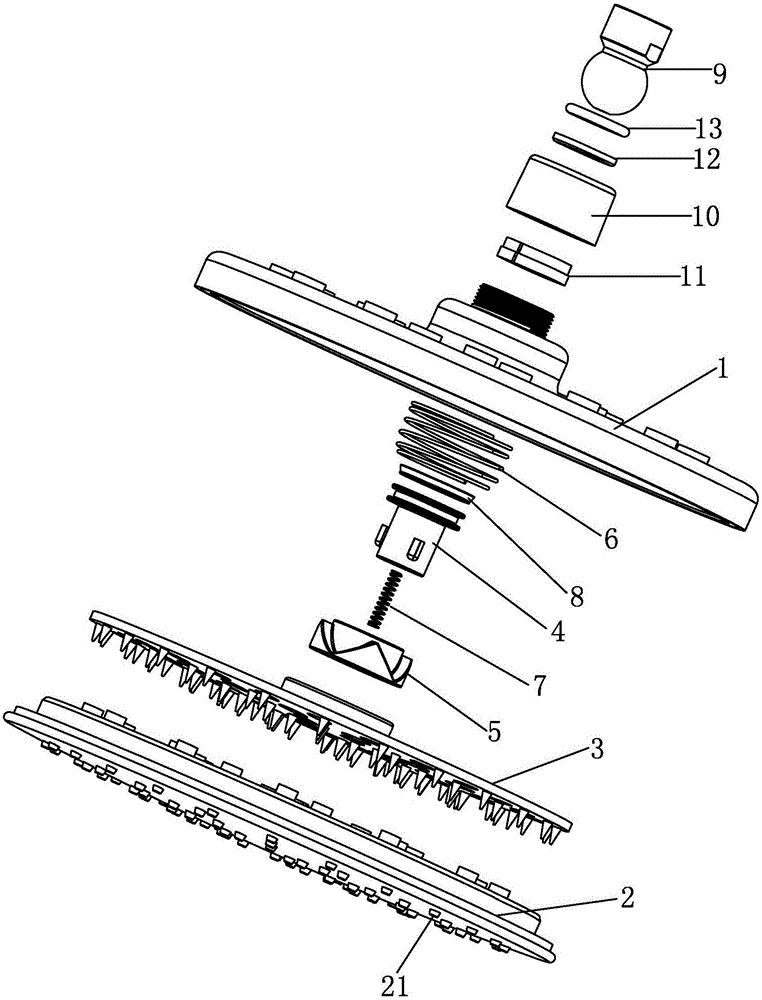

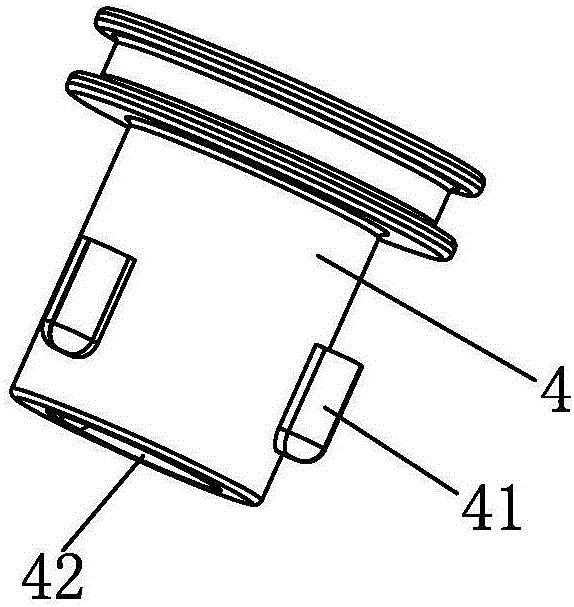

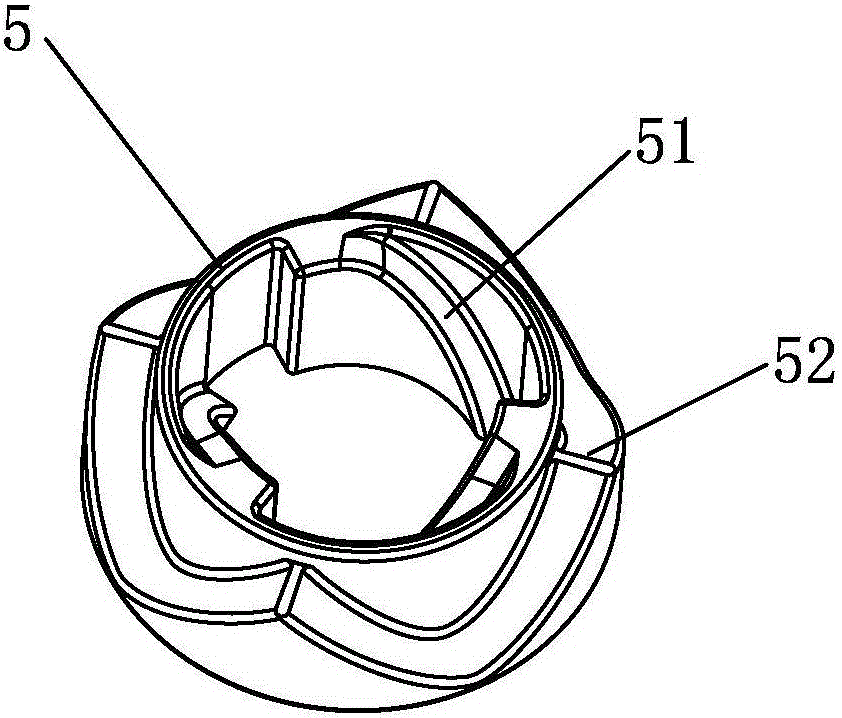

[0032] Examples, see Figure 1-Figure 8 As shown, an automatic descaling shower of the present invention is a top spray shower (the shower of the present invention is not limited to a top spray shower, and may also be a hand-held shower, etc.), including a shower body 1, an outlet The water surface cover 2, the descaling plate 3, the automatic control mechanism for driving the descaling plate 3 to move up and down, the descaling plate 3 is arranged between the shower body 1 and the water outlet cover 2 so that The bottom surface is provided with descaling needles 31 that correspond one-to-one to the water outlet holes 21 on the water outlet cover 2 . A water inlet is arranged on the top of the shower body 1, and a ball head 9 is installed with a nut 10, a backing ring 12, and a bushing 11, and a sealing ring 13 is fitted between the ball head 9 and the inner wall of the shower body 1. Automatic control mechanisms include:

[0033] The driving part is movable between the show...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com