Socket and spigot structure for prefabricated assembly pipe gallery and construction method

A prefabricated assembly and socket technology, which is applied in infrastructure engineering, underwater structures, artificial islands, etc., can solve problems such as rubber gasket aging, corrosion of pipe gallery equipment, and concrete cracks, so as to improve water-stop performance and improve The effect of docking accuracy and improving docking efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to facilitate understanding of the present invention, the present invention will be further described below in conjunction with the accompanying drawings.

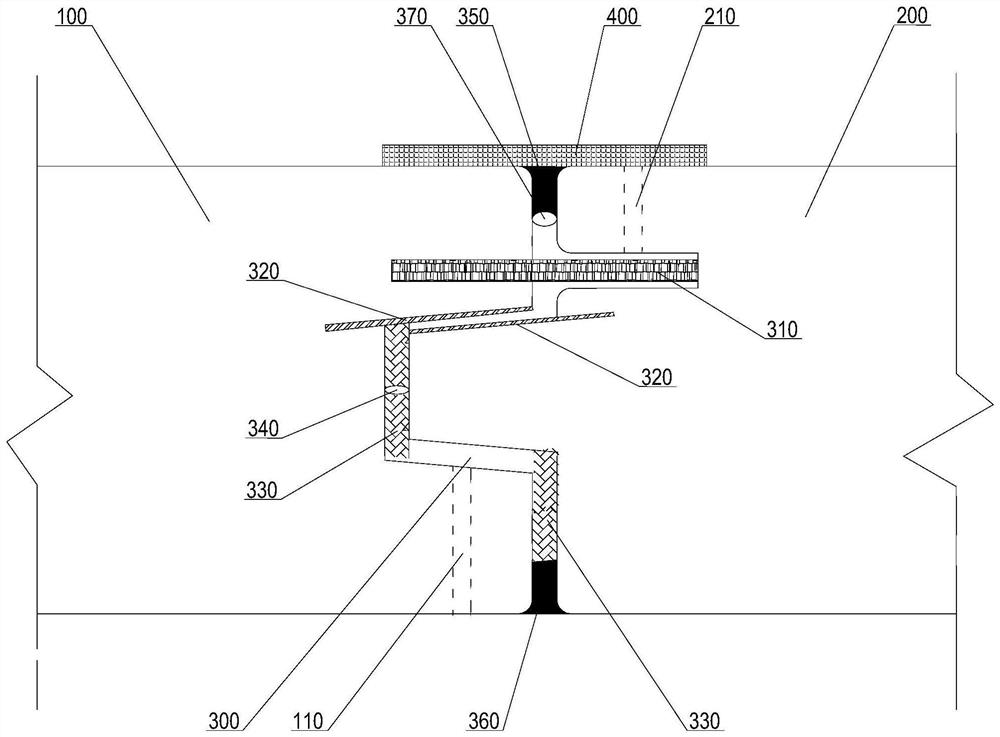

[0031] Such as figure 1 As shown, the socket structure disclosed in the present invention for the prefabricated assembled pipe gallery is butted through the socket 100 and the socket 200, and the socket 100 and the socket 200 are butted by tongue-and-groove splicing, and the middle part of the socket 100 is concave , the middle part of the socket 200 protrudes outward, and the socket 200 is inserted into the socket 100 to form a tongue and groove when docking. A seam 300 is left between the butt surfaces of the socket 100 and the socket 200 , and sealing is achieved by pouring waterproof grout into the seam 300 and sealing both ends of the seam 300 . The present invention pours waterproof grout into the splicing joint 300 through the grouting hole 210 , and the grouting hole 210 is connected to the splicin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com