An automobile workpiece coating production line

A coating production line and production line technology, applied in the direction of transportation and packaging, mechanical conveyors, conveyors, etc., can solve the problems affecting the normal operation of the power-taking mechanism, large deformation of structural parts, and mobile power supply interference, etc., to achieve good practical promotion and The effect of application value, low installation accuracy requirements, and exquisite structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

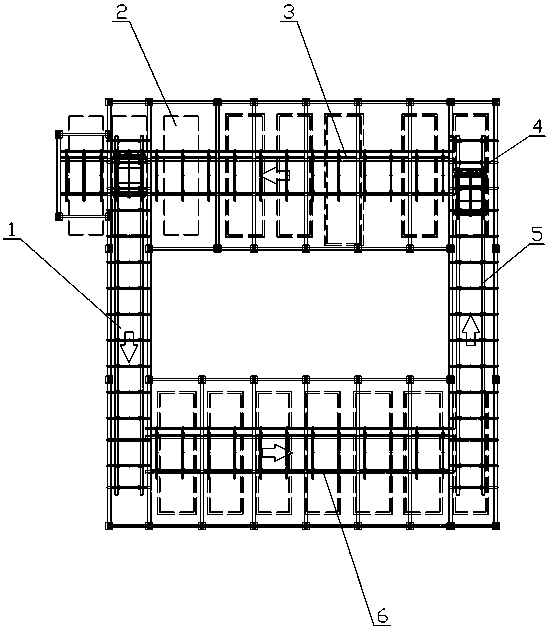

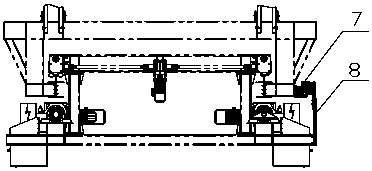

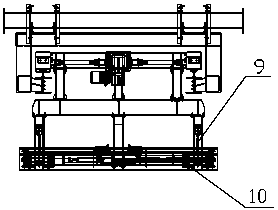

[0018] see Figure 1-Figure 4 , the present invention is an automobile workpiece coating production line, which has a production line frame, and the left and right sides of the production line frame are arranged with a moving track A1 and a moving track B5, and the front and rear sides of the production line frame are arranged with a process track A6 and a process track B3 , the moving track A and the moving track B are respectively equipped with a moving trolley 4, and a double-track trolley is arranged on the process track A or the process track B, and the double-track trolley forms a rectangular one-way running circuit through the transfer of the two transition trolleys. The bottom of the double-track trolley is equipped with a chain lifting device, and the chain lifting device is connected with a workpiece spreader. A number of process pools 2 are arranged below the process track A and process track B. The moving track A, moving track B, process track A and The process tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com