Integral water stopping system and manufacturing method thereof

A production method and integrated technology, applied in water conservancy projects, underwater structures, artificial islands, etc., can solve the problems of long time and slow progress in the construction of waterstops, and achieve shortened construction progress, reduced time consumption, and convenient installation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039]The utility model relates to an integral water-stop system, which is used for water-stop at the post-pouring belt, and is easy to install and can speed up the construction progress.

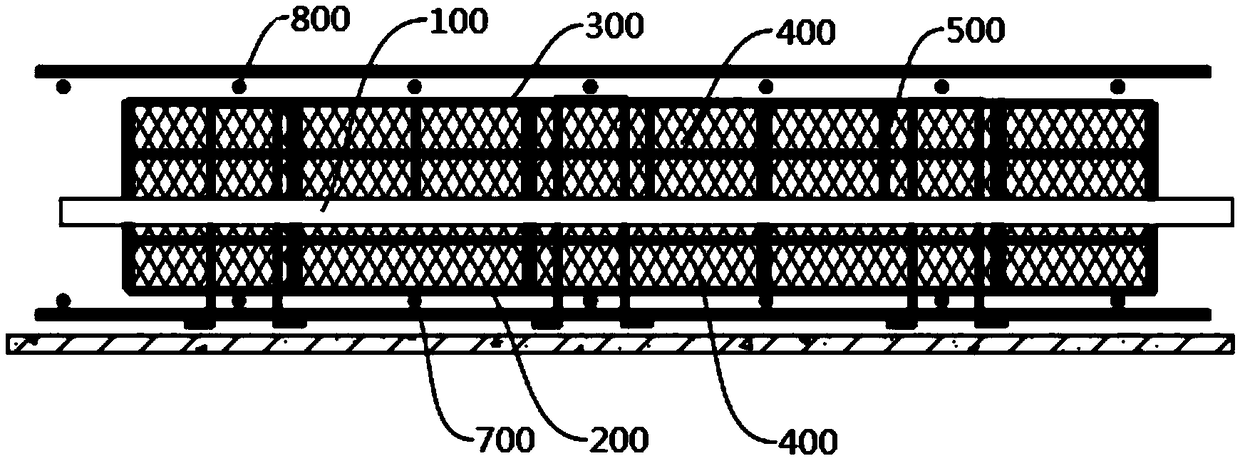

[0040] Please refer to the attached Figure 4 And attached Figure 5 , The integral water stop system includes a water stop strip composed of a steel frame, a water stop plate 100 and a steel wire mesh 400 .

[0041] Please refer to the attached Figure 6 , the overall steel frame is rectangular, and the two ends of the steel bars of the steel frame are bent back to form rounded corners.

[0042] Please refer to the attached Figure 6 , the steel wire mesh 400 is arranged on the steel bar skeleton, and is used as a formwork for pouring cast-in-place components. The density of the steel wire mesh 400 is based on the fact that the coarse aggregate of concrete corresponding to the cast-in-place component cannot pass through.

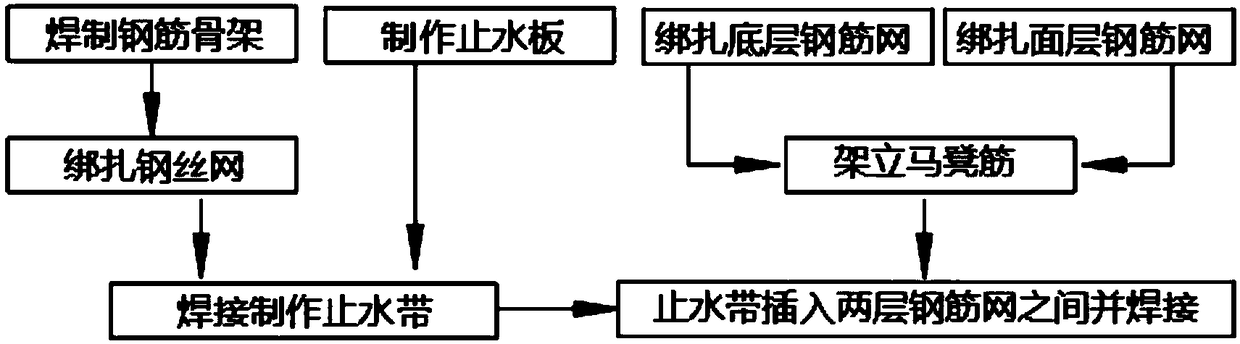

[0043] Refer to attached figure 1 As shown, the manufacturing ...

Embodiment 2

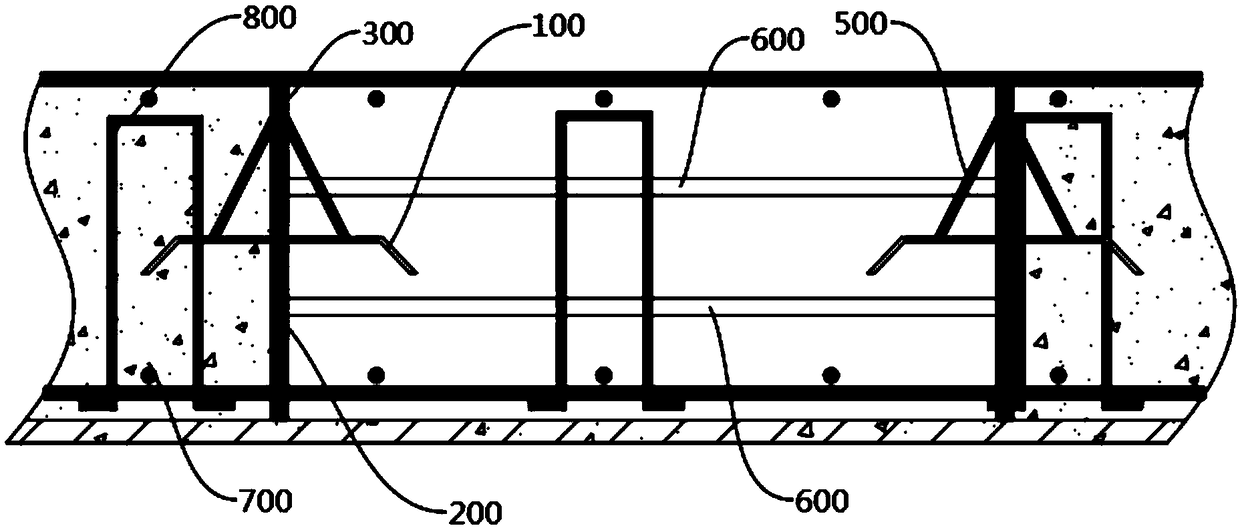

[0062] On the basis of embodiment 1, with reference to the attached Figure 7 As shown, in order to strengthen the anti-seepage effect, the post-casting belt of the present invention is set as follows:

[0063] The steel skeleton is staggered, the steel skeleton connected to the bottom steel mesh 700 is close to the post-cast belt, and the steel skeleton connected to the surface layer steel mesh 800 is far away from the post-cast belt, so that the end face of the cast-in-place component is stepped, and the post-cast belt is close to the surface layer It is wide at the bottom and narrow near the bottom layer. Even if a cold joint is formed between the cast-in-place component and the post-casting belt, the path of the cold seam from the bottom layer to the outer layer is curved and does not directly lead to the bottom layer, so it can further prevent water seepage from the surface layer. .

[0064] In order to further enhance the anti-seepage effect, the number of water stop bo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bending angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com