Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

33results about How to "Play the role of axial positioning" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

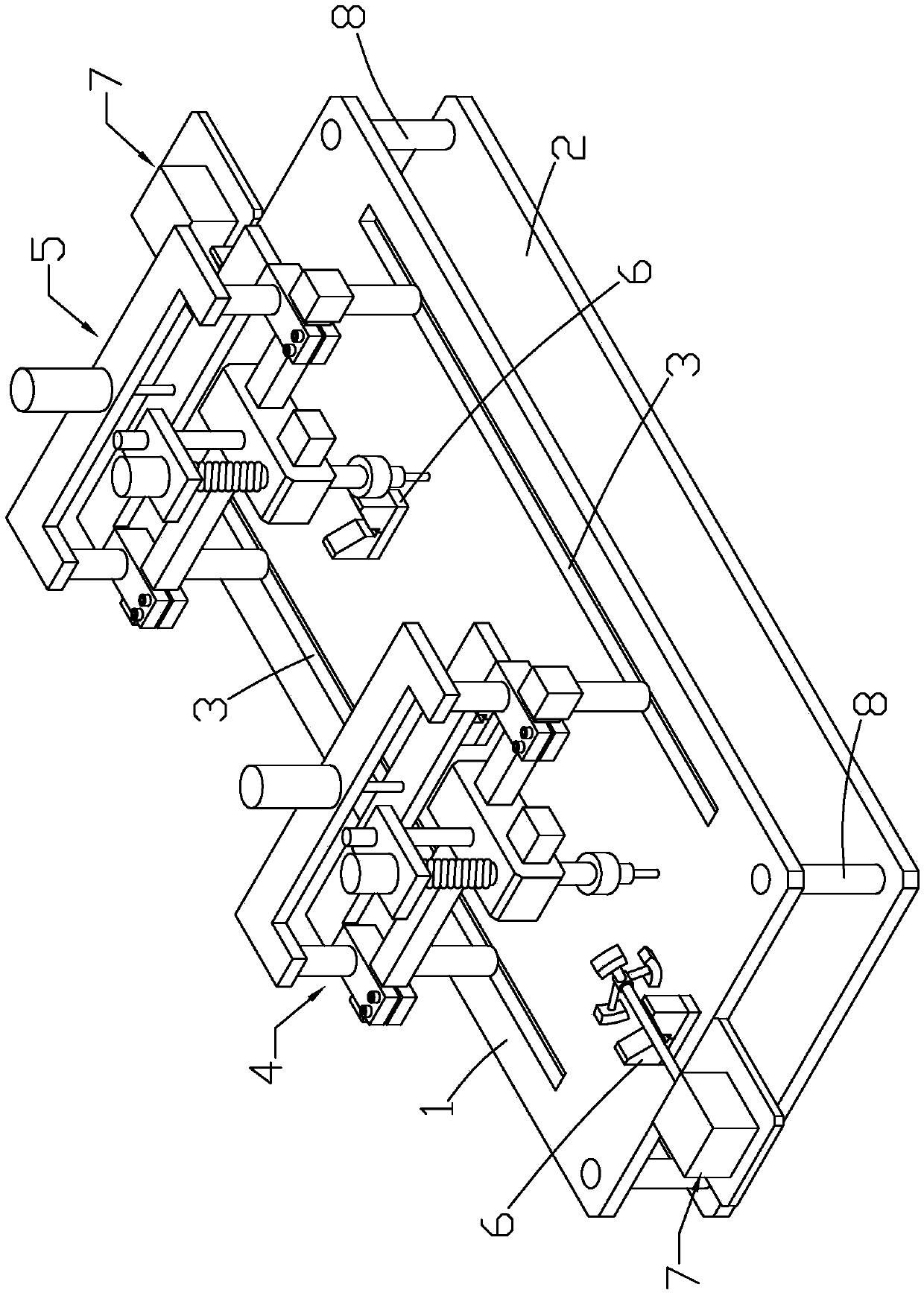

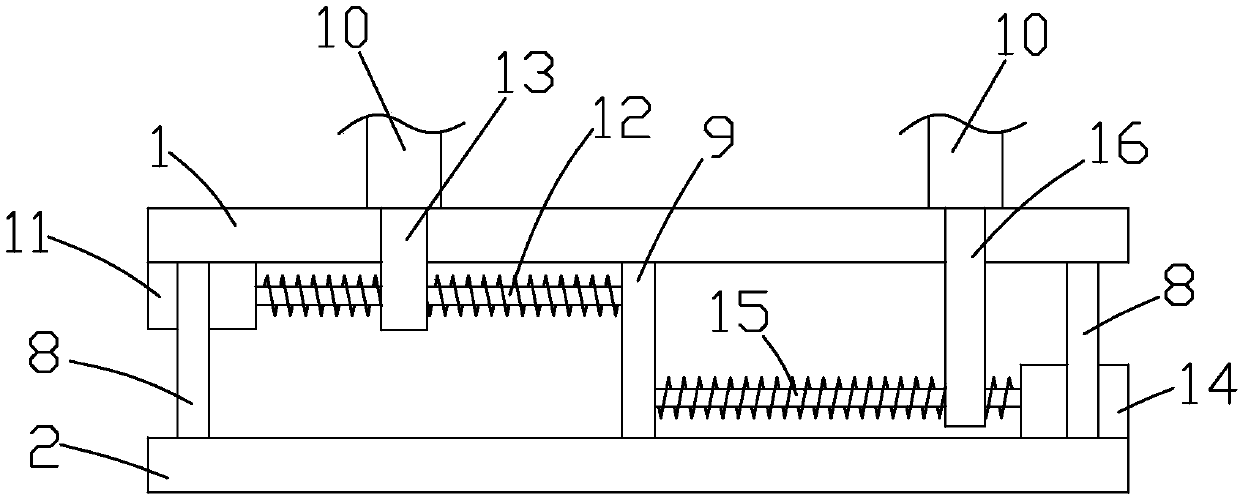

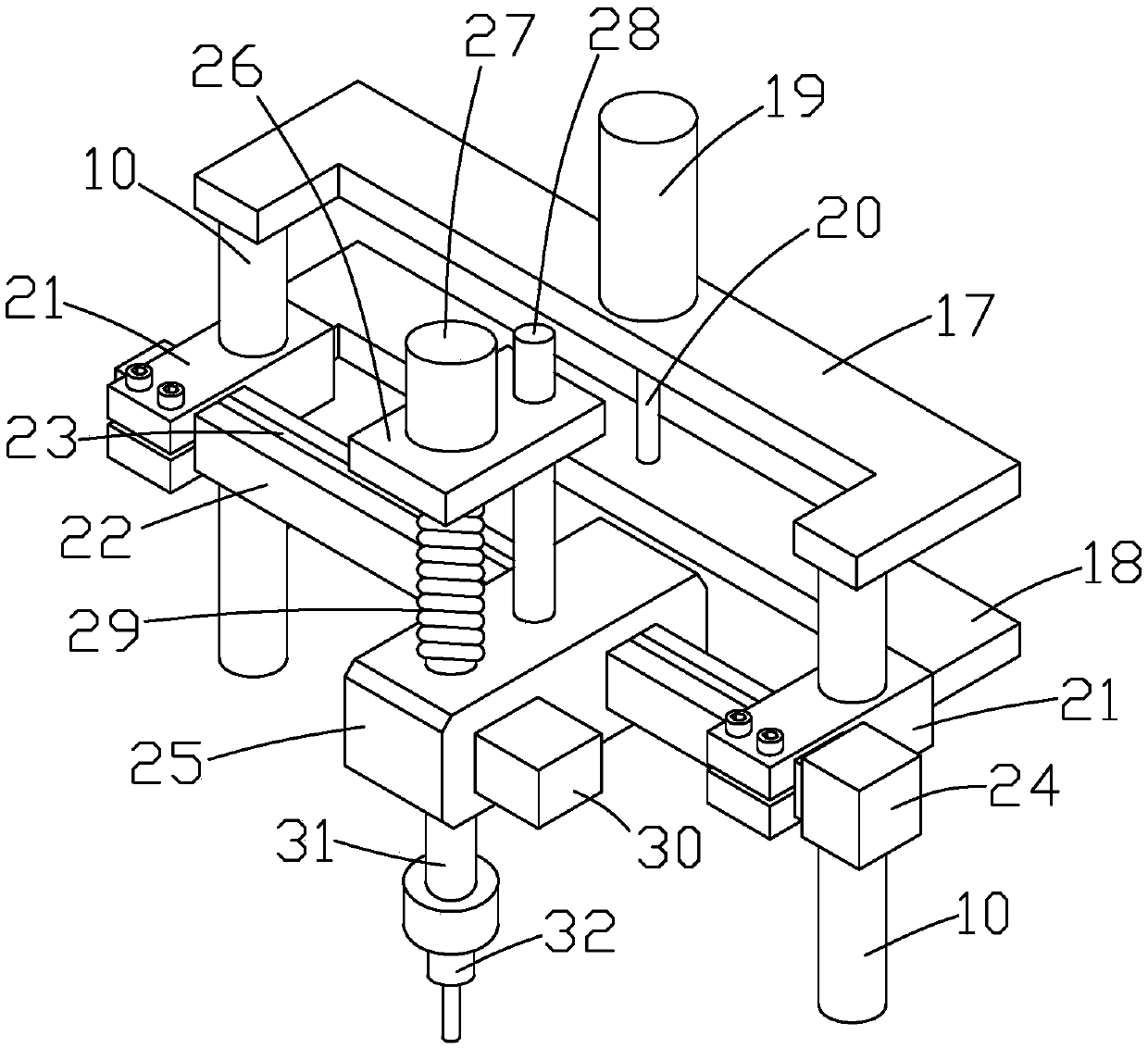

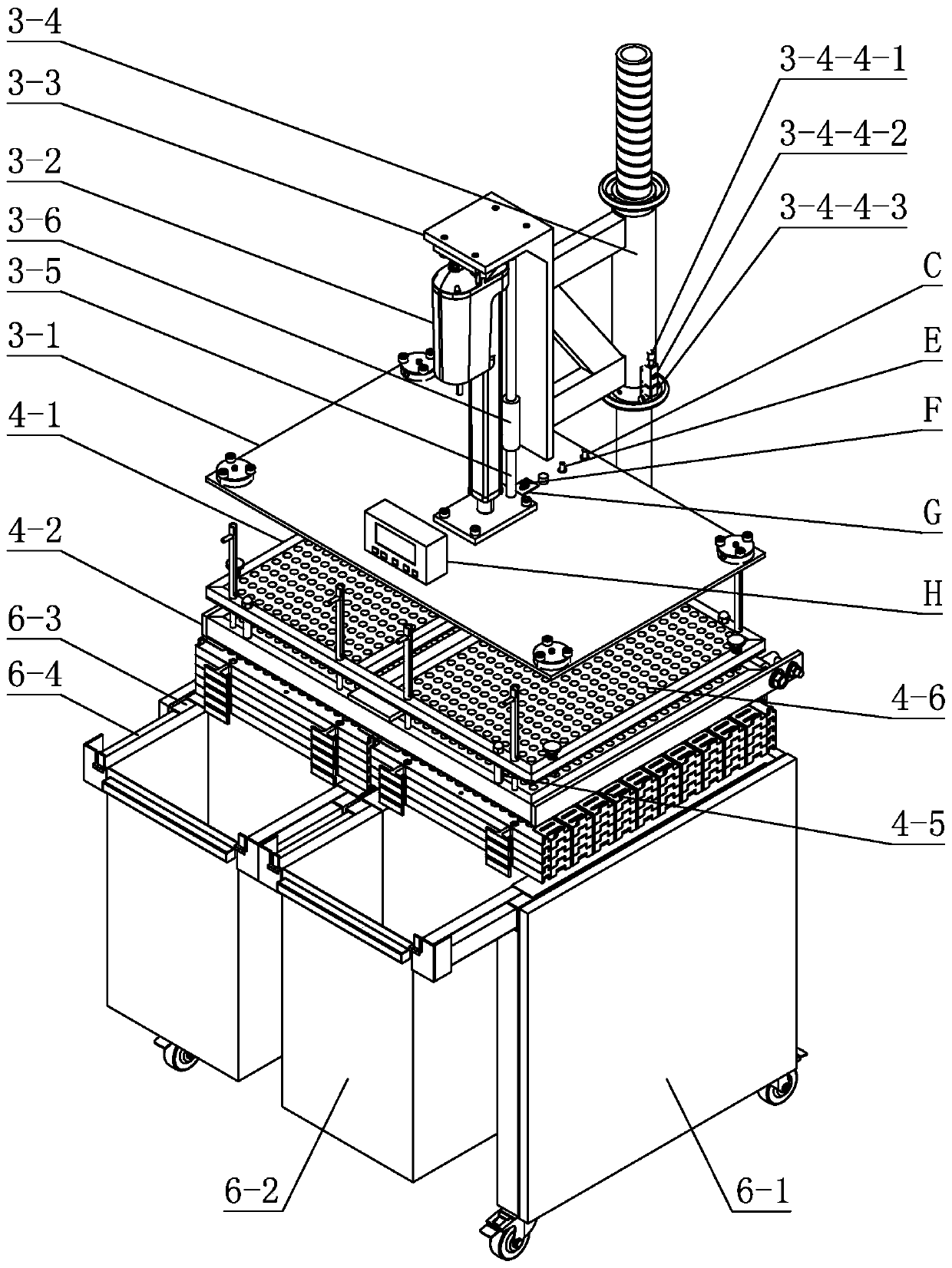

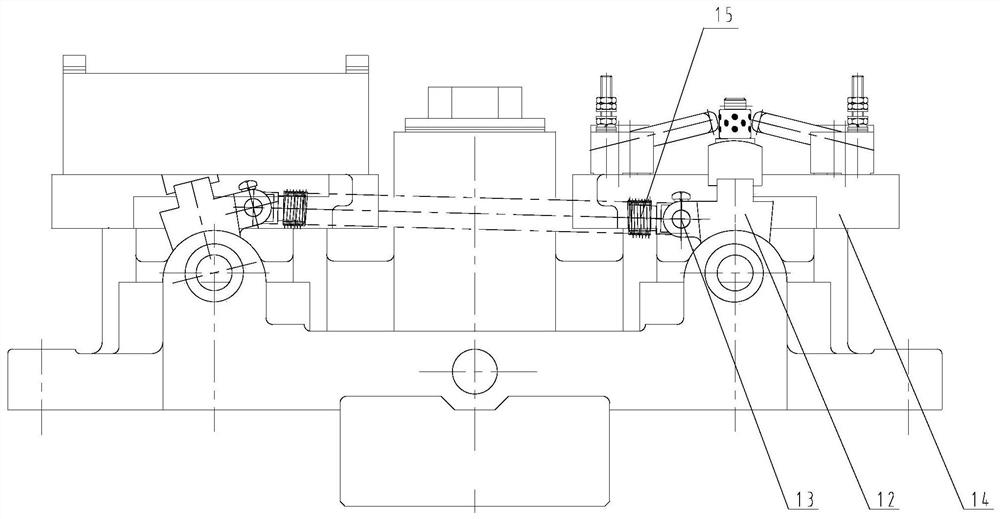

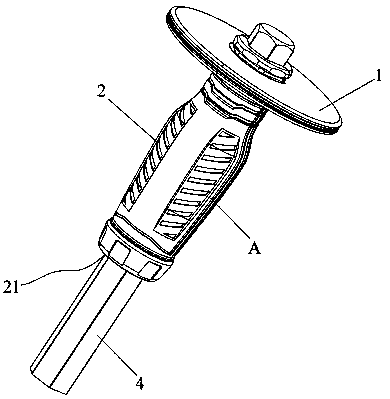

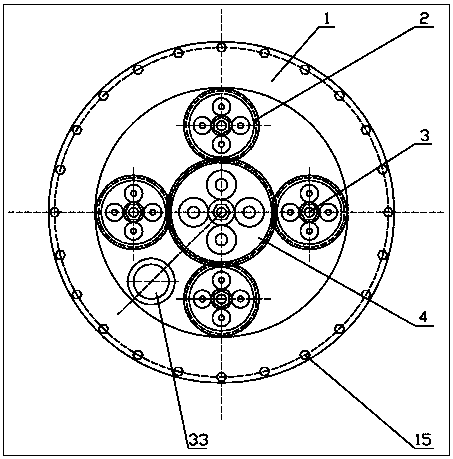

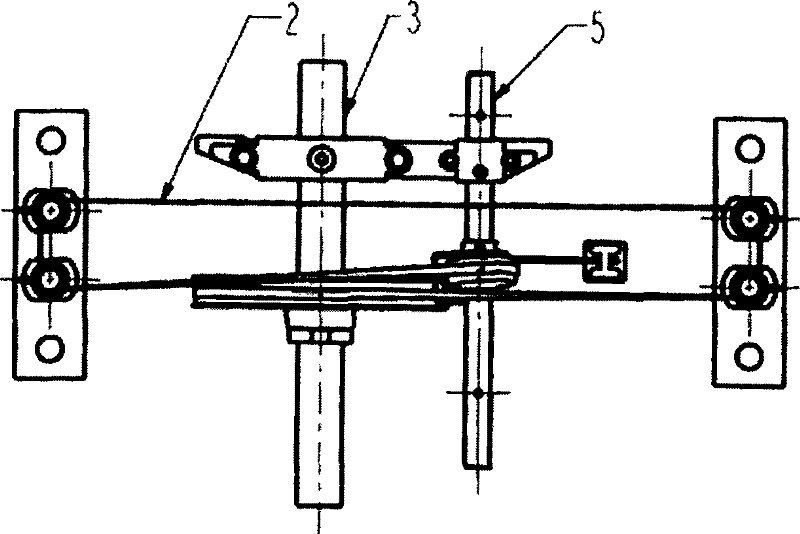

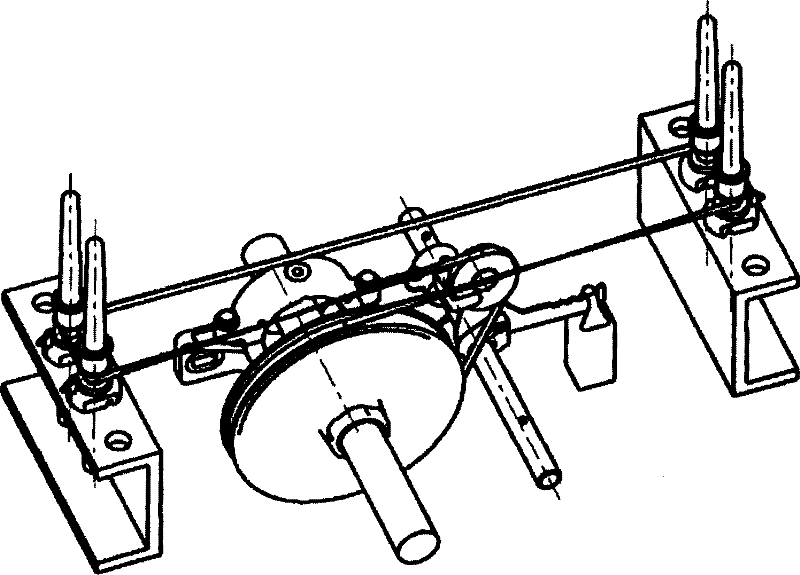

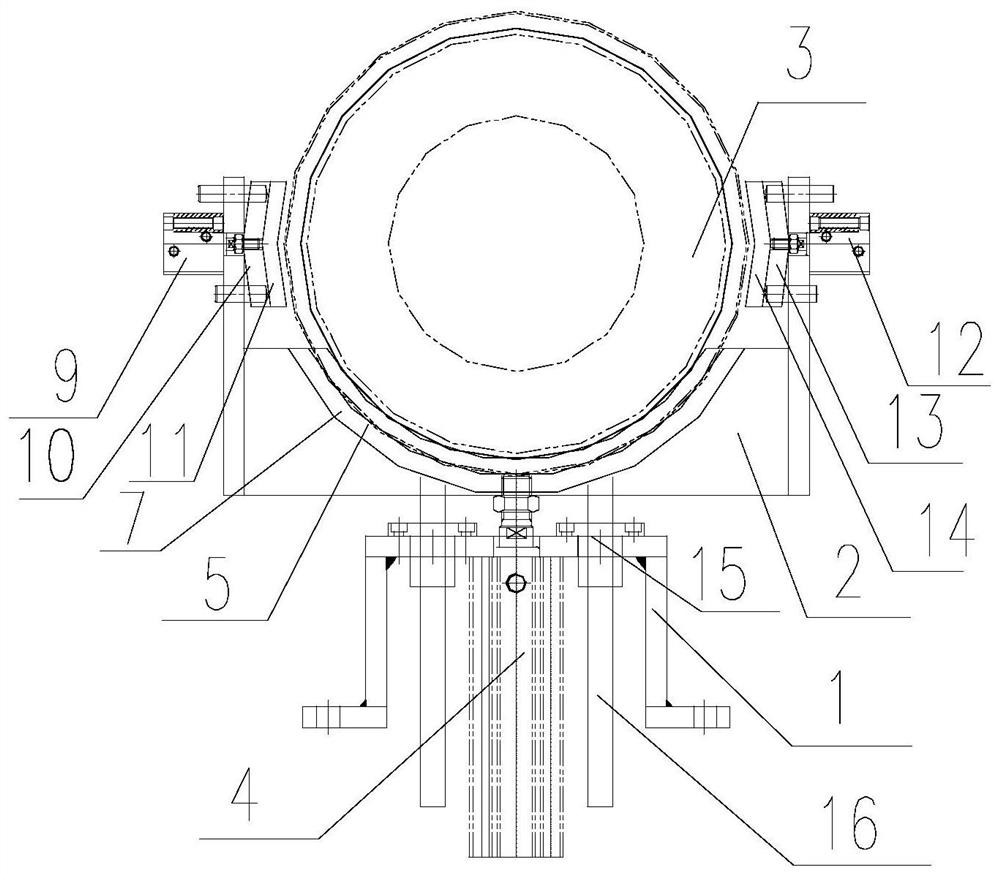

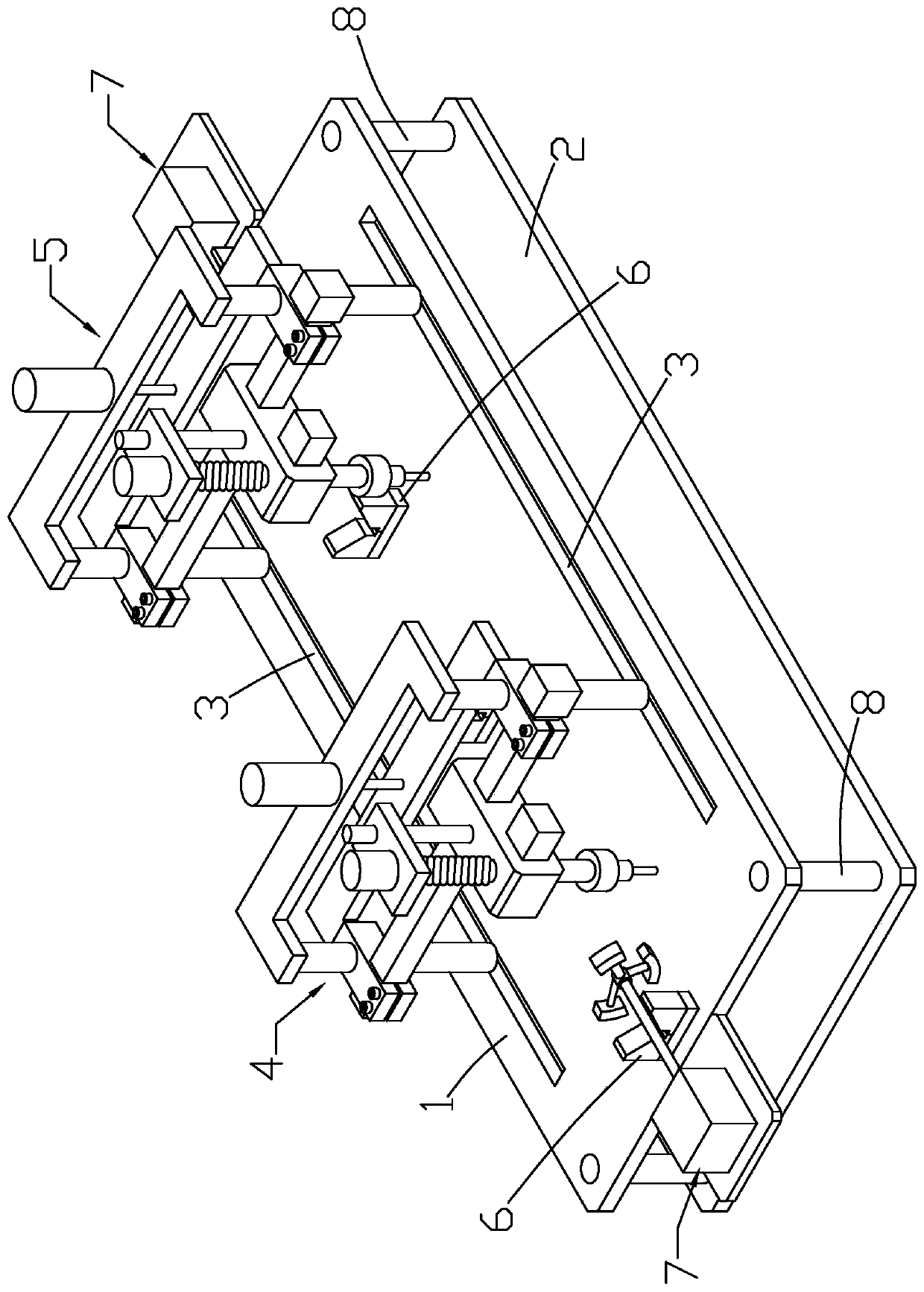

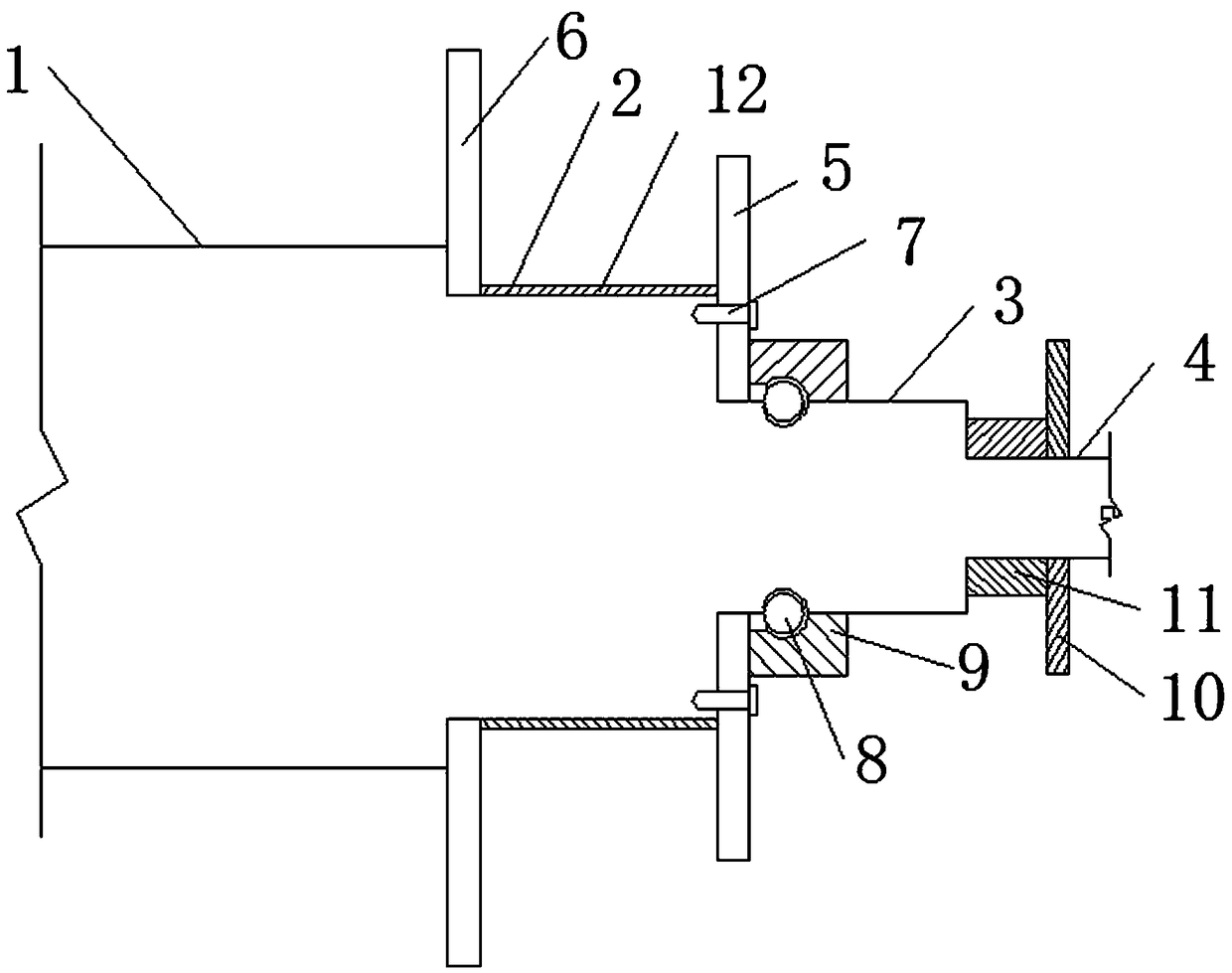

Surface hole drilling device for non-excavation construction pipelines

ActiveCN109570557AImprove drilling efficiencyIncrease flexibilityLarge fixed membersPositioning apparatusArchitectural engineeringPipe support

The invention discloses a surface hole drilling device for non-excavation construction pipelines. The device comprises a base board, a bottom board, a first hole drilling machine, a second hole drilling machine and pipeline rotary mechanisms; the bottom board is located below the base board; the base board is fixedly connected with the bottom board through a supporting rod; two guide grooves are formed in the top face of the base board in parallel; the first hole drilling mechanism and the second hole drilling mechanism are movably connected to the guide groove; a drive mechanism is arranged between the base board and the bottom board and is connected with the first hole drilling mechanism and the second hole drilling mechanism; pipeline supporting mechanisms are arranged on the center straight line of the top face of the base board at equal intervals; and the two pipeline rotary mechanisms are symmetrically arranged on two sides of the base board. The surface hole drilling device fornon-excavation construction pipelines is simple in structure and high in practicability, not only can achieve single-hole or dual-hole machining for construction pipelines and improve the hole drilling efficiency, but also can clamp and position construction pipelines, rotates construction pipelines at the constant speed according to hole drilling needs at the same time, and greatly improves the hole drilling precision and quality.

Owner:嵊州市越通非开挖建设有限公司

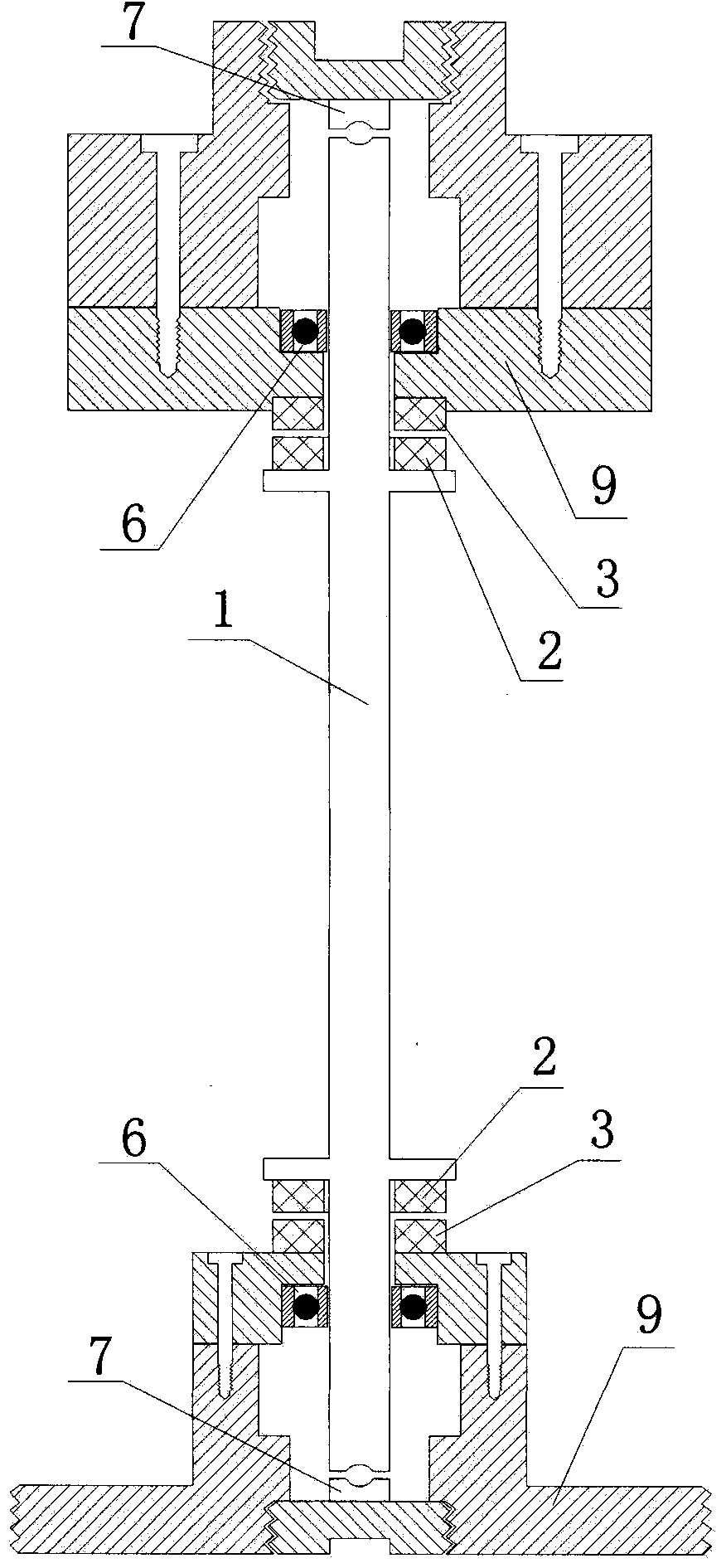

Magnetic push suspension bearing unit

InactiveCN103790962AReduce frictionPrevent mutual friction and fireBearingsBearing load reliefElectrical polarityEngineering

The invention discloses a magnetic push suspension bearing unit, comprising a shaft, an inner magnetic ring, an outer magnetic ring, an auxiliary bearing, a limiting block and a bracket, wherein the inner magnetic ring is arranged at the near end part of the shaft; the corresponding outer magnetic ring is arranged on the bracket; the adjacent surfaces of the two magnetic rings are the same in polarity; an inner magnetic barrel for magnetizing in a radial manner is arranged on the shaft; the inner magnetic barrel is sleeved with an outer magnetic barrel for magnetizing in the radial manner, and the outer magnetic barrel is fixedly arranged on the bracket; the adjacent surfaces of the two magnetic barrels are the same in polarity; the auxiliary bearing is also arranged between the shaft and the bracket; corresponding limiting block and limiting ball are arranged at the end of the shaft; a direct contact rolling body is not formed between the shaft and the bracket; the shaft and the bracket form a suspension state by virtue of a magnetic push shaft; the shaft and the bracket are free of friction, free of abrasion, high in transmission efficiency, free of cooling and lubricating, and long in service life, and the magnetic push suspension bearing unit has high applicable value in high-speed fields of aerospace and the like.

Owner:BEIJING LIANGMING TONGCHUANG WATER TREATMENT EQUIP DEV CENT

Split combined type outer casing of engine oil filter

InactiveCN101469621ASimple structureLow costPressure lubricationLubricant mounting/connectionConvex structureScrew thread

The present invention relates to a split combination type engine oil filter housing, aims to stop housing from rotating together with the engine oil filter when replacing filter element. The Audi cars engine oil filter housing in the invention includes a upper bowl (1) and a lower bowl (2) that connected through screw threads; the upper bowl (1) passes through the central hole on the heat radiator and connects with output pipeline of Audi cars engine oil base plate through screw threads by a nut (3); the outer surface of a outlet (11) on the upper bowl (1) is provided with a tapered cylinder convex structure (12) that can limit radial rotate between the upper bowl (1) and the heat radiator on Audi cars engine oil base plate; a hole with taper is set on the center of the tapered cylinder convex structure and two side of the hole is provided with a shallow slot openings; the shape of the tapered cylinder centre hole fits with Audi cars engine oil base plate heat radiator convex area. The present invention is provided with simple structure, low cost, convenient operation, secure and reliable operation, and has a broad application foreground.

Owner:环节安(北京)滤清器技术研究所有限公司

Tool set for changing downhole damaged casing and cementing

PendingCN109763786AGuaranteed coaxialityReduce the risk of accidentsDrilling rodsSealing/packingButt jointWell cementing

The invention relates to a tool set for changing a downhole damaged casing and cementing. The tool set comprises a hydraulic internal cutter, a downhole junk fishing tool, a remaining casing milling tool and an external insertion butt joint cementing tool, an external insertion guiding shoe is arranged at the lower end of the external insertion butt joint cementing tool, an extension cylinder is rotatably connected at the upper end of the external insertion guiding shoe, a circulating cylinder is rotatably connected at the upper end of the extension cylinder, a plurality of rows of ash injection holes are arranged on the peripheral wall on the middle section of the circulating cylinder, a sealing cylinder is rotatably connected at the upper end of the circulating cylinder, an R-shaped sealring is embedded at the upper part of a female thread at the lower end of the sealing cylinder, a barb faces upwards, a butt joint is rotatably connected in the female thread at the upper end of thesealing cylinder, a conical female thread is arranged at the upper end of the butt joint, an inner chamfer of the butt joint is arranged on a lower port of the butt joint, the upper part of the innerchamfer is narrow, and the lower part of the inner chamfer is wide; and the inner diameters of the sealing cylinder, the circulating cylinder, the extension cylinder and the external insertion guidingshoe are adaptive to the outer diameter of the casing. The tool set for changing the downhole damaged casing and cementing is simple in structure and is convenient to operate, the production cost andthe downhole risk are low, the operations of butt jointing and setting are simple, and the sealing reliability is high.

Owner:中石化石油工程技术服务有限公司 +1

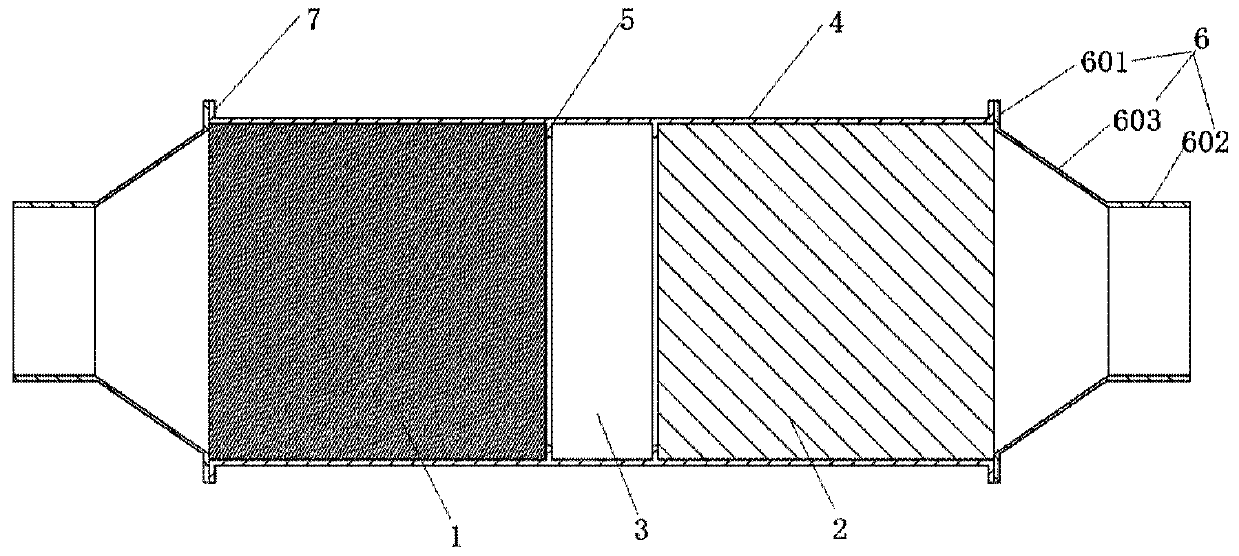

Sectional type filter element and engine particle catcher thereof

PendingCN110159396AIncrease the chance of being caughtImprove capture efficiencyExhaust apparatusSilencing apparatusParticulatesCordierite

The invention discloses a sectional type filter element and an engine particle catcher thereof. The sectional type filter element comprises a first filter element body and a second filter element body, which have different catching efficiency as well as a turbulent-flow interval layer which is formed between the first filter element body and the second filter element body. Compared with a pure cordierite material wall-flow type filter element, the sectional type filter element can effectively reduce gas exhaust pressure drop, and improves fuel oil economical efficiency; compared with a pure metal foam material filter element, the sectional type filter element can effectively improve particle catching efficiency; and the turbulent-flow interval layer is arranged between the two sections ofthe filter element bodies, so that particles are in turbulent-flow motion in the turbulent-flow interval layer, and therefore, motion track of the particles generates relatively great fluctuation, particle catching efficiency is improved, and the purpose of reducing back pressure by improving catching efficiency is achieved.

Owner:TIANJIN UNIV

Stator core, stator, manufacturing method thereof, motor and household appliance

InactiveCN109120078AIncrease full rateImprove work performanceMagnetic circuit stationary partsManufacturing stator/rotor bodiesElectric machineryEngineering

The invention provides a stator core, a stator, a manufacturing method thereof, a motor and a household appliance. The stator core comprises a yoke portion, a plurality of tooth portions and a plurality of shoe portions, wherein the plurality of tooth portions are arranged along the circumferential direction of the yoke portion, one shoe is disposed on one end of the tooth portion corresponding tothe shoe portion, wherein the one end of the tooth portion is far away from the yoke portion; at least two splicing modules are spliced to form the stator core; the shoe portions and the yoke portionare respectively located on the two splicing modules; and the splicing modules comprise a first splicing module and a second splicing module; the first splicing module and the second splicing moduleare detachably connected with each other; positioning slots are formed in one of the first splicing module and the second splicing module, and the other splicing module is provided with matching protrusions; the matching protrusions are inserted in the positioning slots; the first splicing module and the second splicing module are spliced along the radial direction of the yoke portion; and the length of the positioning slot is smaller than the length of the yoke portion along an axial direction parallel to the yoke portion. The stator core has the advantages of simple structure, convenient assembly and accurate positioning.

Owner:GREE ELECTRIC APPLIANCES INC +1

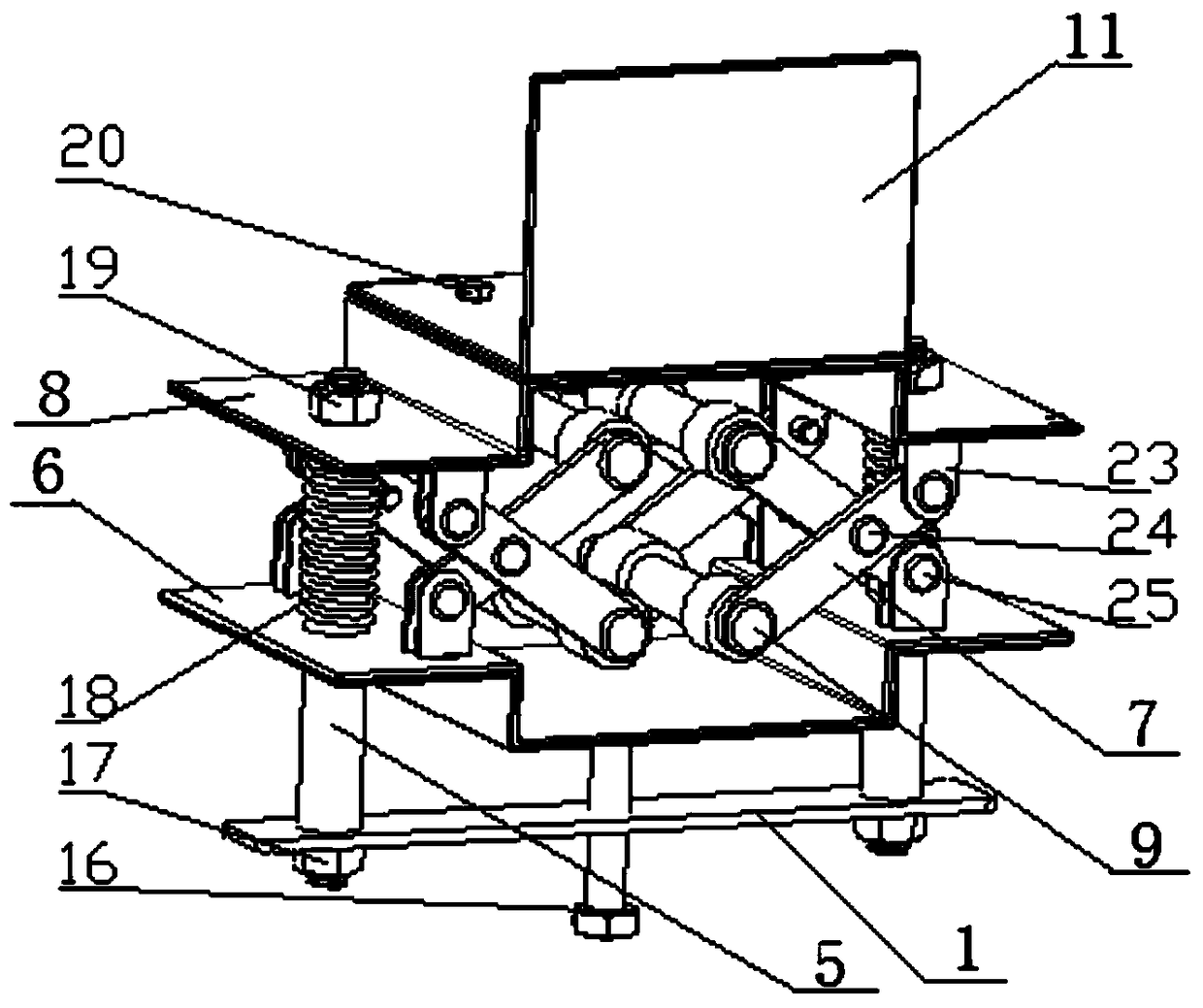

Automatic batch kebab penetration machine

PendingCN110786362ALarge operating spacePlay the role of axial positioningConfectionerySweetmeatsManufacturing engineeringFood processing

The invention discloses an automatic batch kebab penetration machine, and relates to the field of food processing. The automatic batch kebab penetration machine solves the problems that the penetration of kebab products of different length specifications can not be adapted since a material placement operation space and a stick placement operation space of an existing kebab penetration machine arerestricted and a stick folding phenomenon is likely to happen since the perpendicularity of a kebab stick is poor. A machine head optical axis stand column is fixed on the rear side wall of a machinebody supporting frame along a vertical direction, and a material placement plate group is horizontally arranged on the machine body supporting frame; a finished product collection box is arranged justbelow the material placement plate group; a stick pressing component and a stick spacing component are arranged just above the material placement plate group from top to bottom in sequence and are independently rotatably connected with the machine head optical axis stand column; the upper part of the machine head optical axis stand column is provided with a first external thread; multiple groupsof material placement plates of the material placement plate group are overlaid and distributed in sequence from top to bottom; a plurality of material placement modules of each group of material placement plates are arranged on the same horizontal plane in parallel from front to back; and adjacent material placement modules are connected in a pulling and drawing way. The automatic batch kebab penetration machine is used for the mass production of kebab products.

Owner:王海石

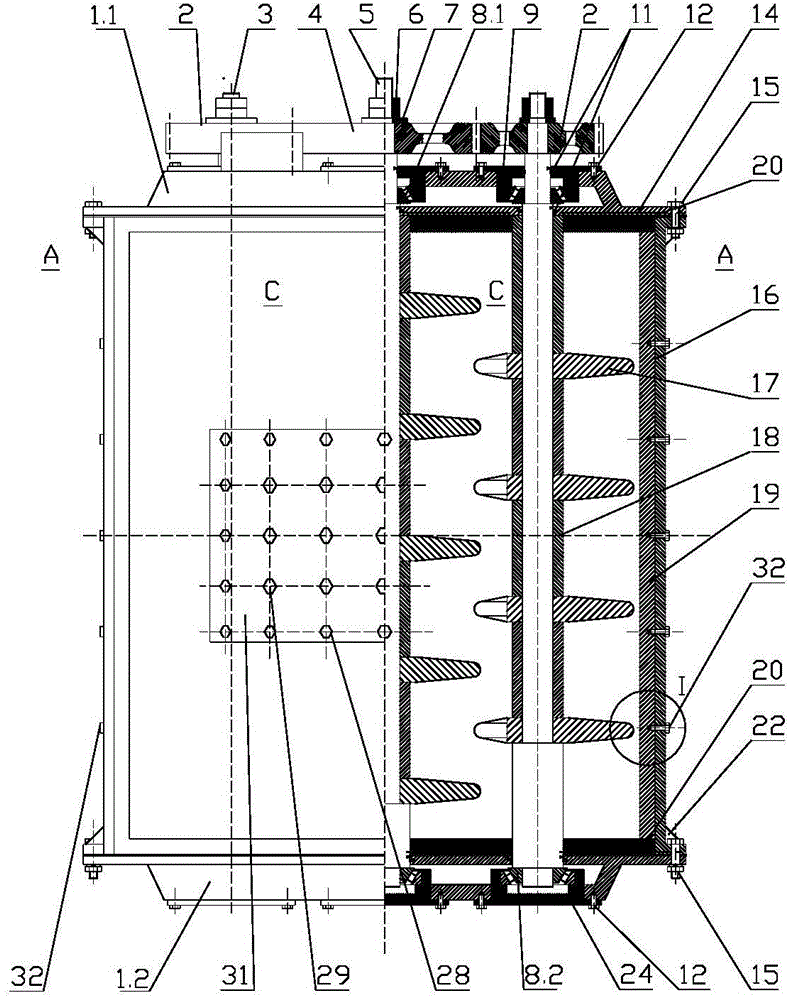

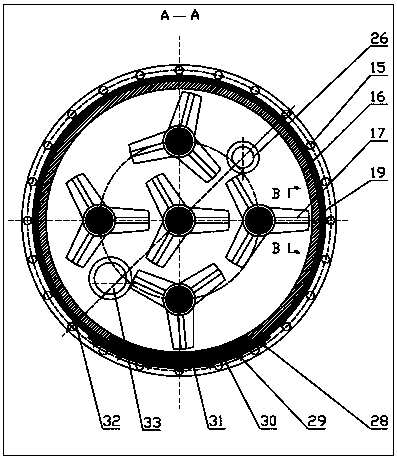

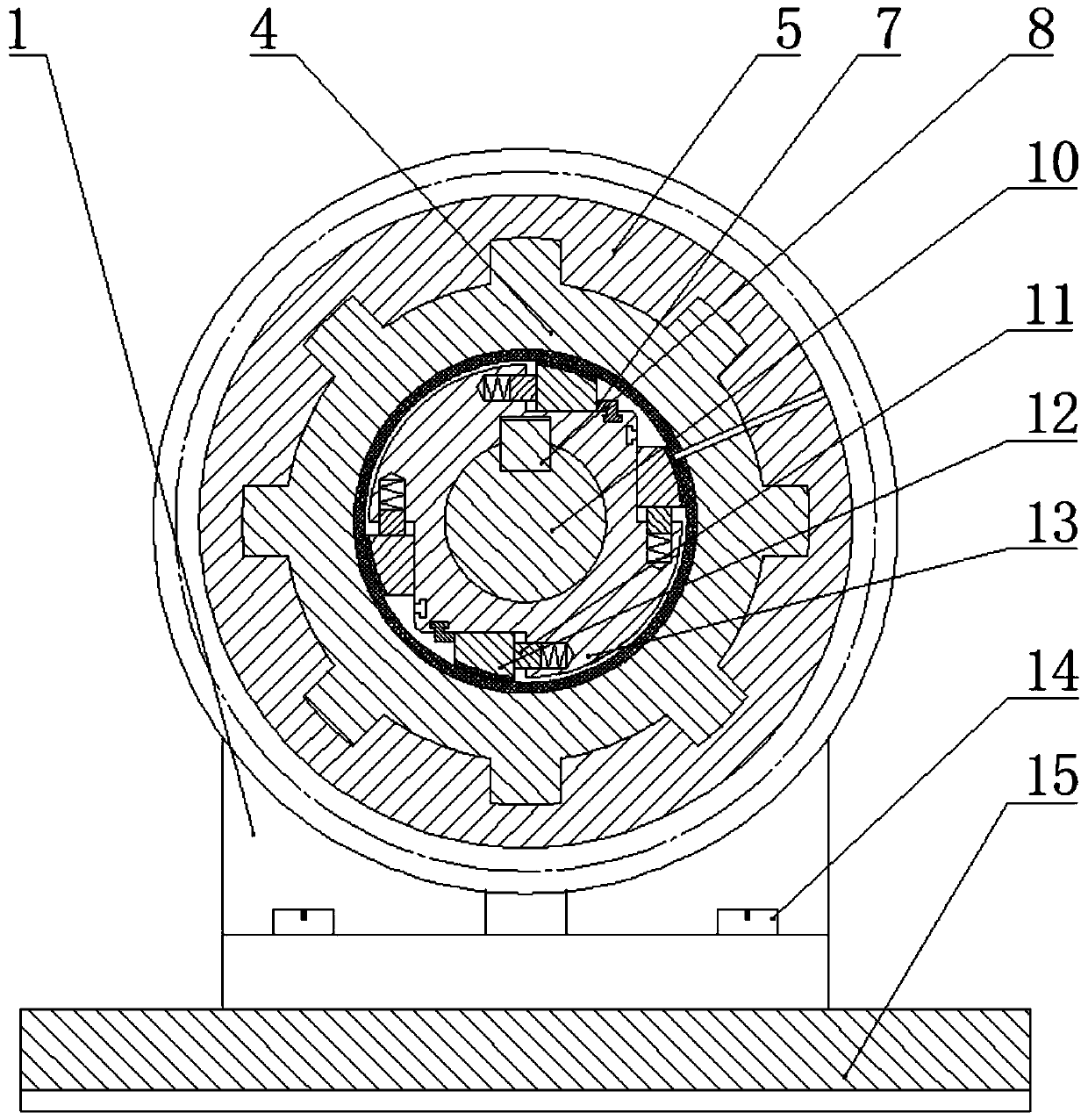

Multi-purpose reverse mineral grain crusher

InactiveCN104785323AReduce energy consumptionImprove work efficiencyGrain treatmentsDrive shaftEngineering

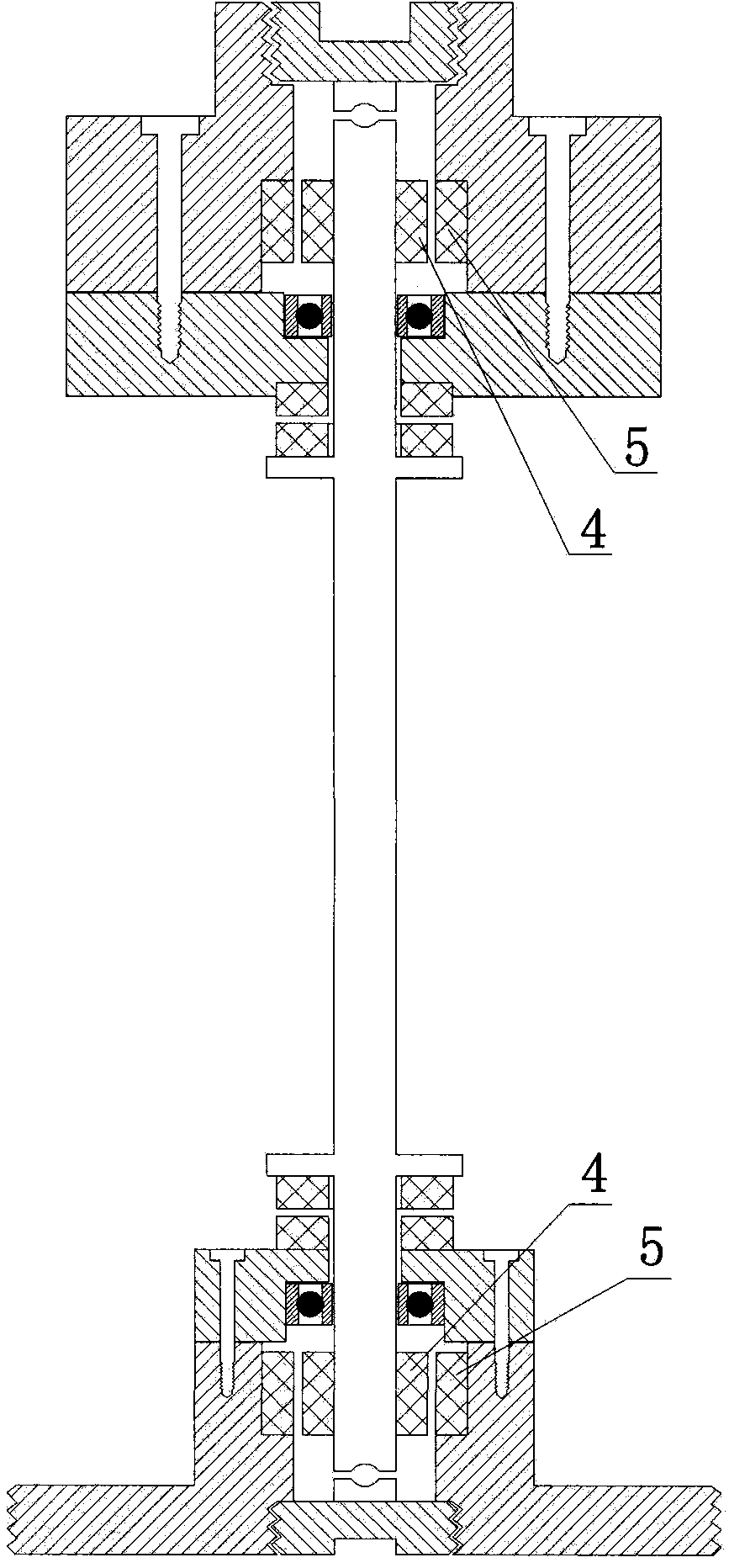

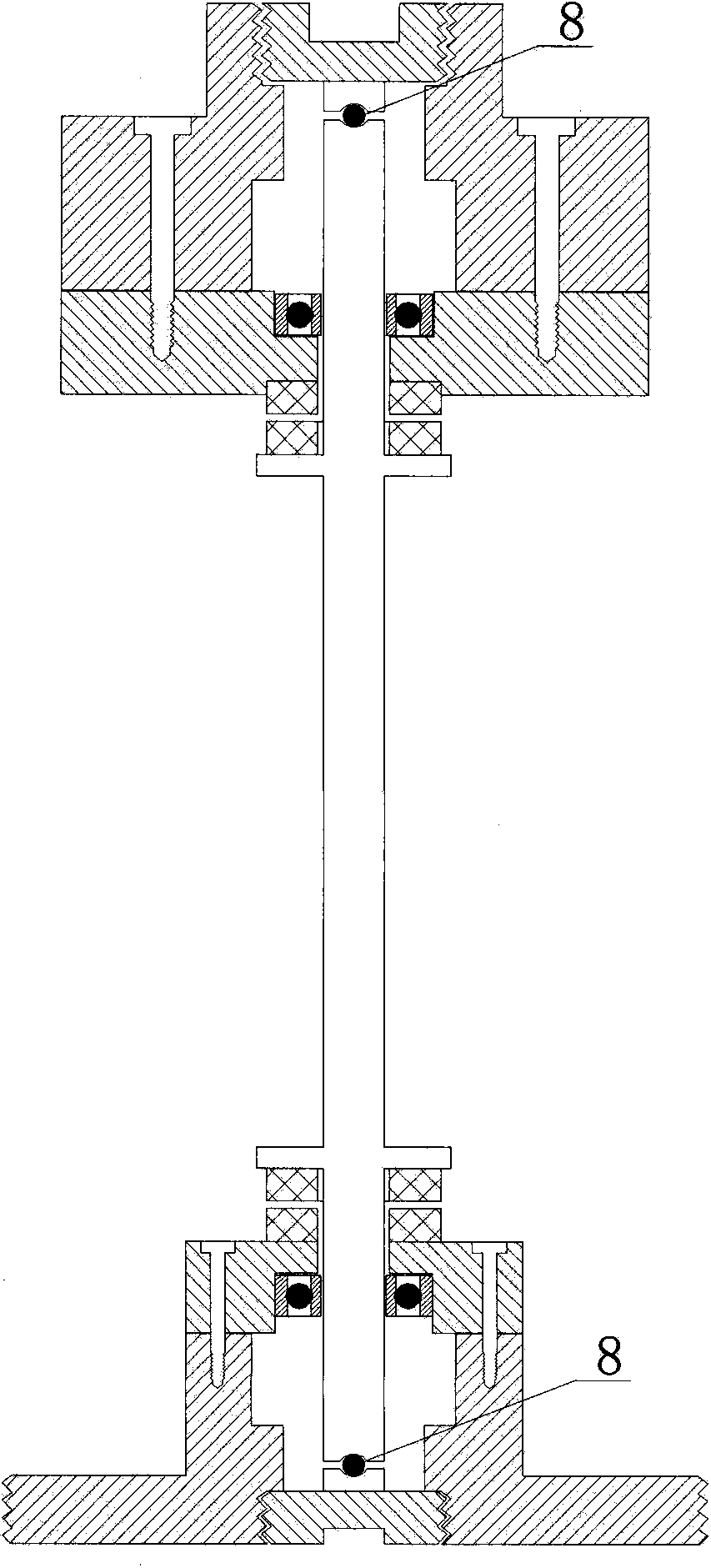

A multi-purpose reverse mineral grain crusher is characterized in that a crusher cylinder is cylindrical, an upper bearing box is mounted at the upper part of the crusher cylinder, and a lower bearing box is mounted at the lower part of the crusher cylinder; a bearing block through cover is connected onto the upper bearing box, and a bearing block airtight cover is connected with the lower bearing box; upper and lower conical roller bearings are mounted in the upper bearing box and the lower bearing box; the upper bearing box is located at the upper part of the crusher cylinder, and the lower bearing box is located at the lower part of the crusher cylinder; a driving gear and a driven gear are located at the top of the upper bearing box, and a driving transmission shaft and a driven transmission shaft are transmission shafts of the driving gear and driven gear respectively; in order to prevent the axial movement of the driving transmission shaft and the driven transmission shaft, both the driving transmission shaft and the driven transmission shaft adopt stepped shafts and penetrate through the bearing block through cover, middle parts are located in the crusher cylinder, and bottom parts are connected with the bearing block airtight cover; sanding vanes are mounted on the driving transmission shaft and the driven transmission shaft. The multi-purpose reverse mineral grain crusher has the characteristics of high efficiency, environmental pollution reduction and energy consumption reduction.

Owner:薛应东

Vibration arm connecting structure

Owner:CHINA TOBACCO HENAN IND

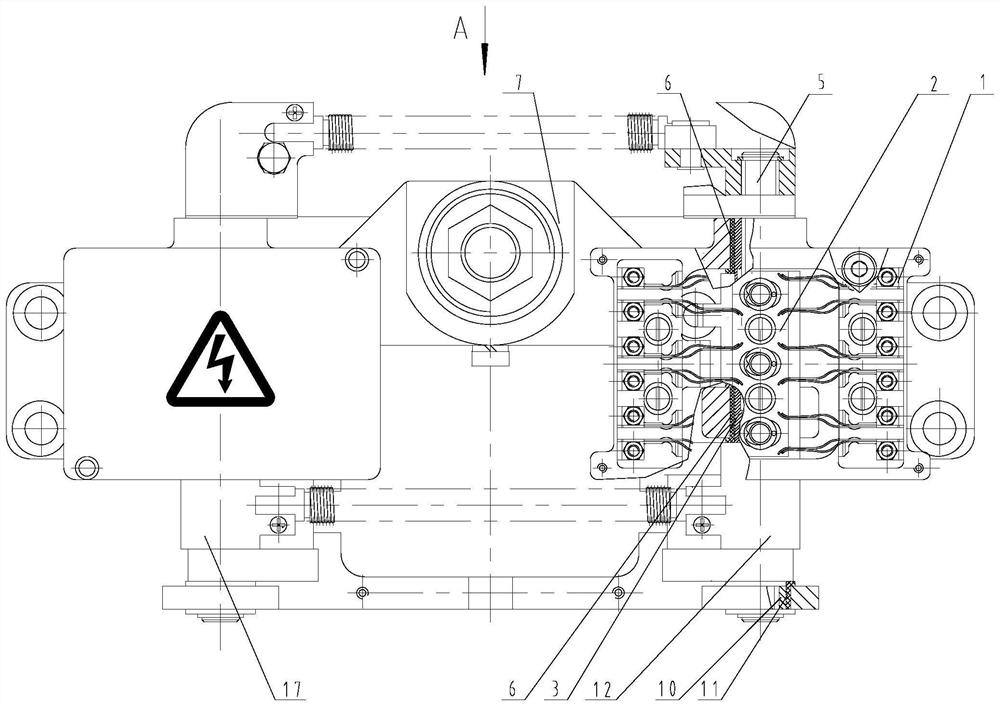

Contact seat for electric switch machine

PendingCN111605579ARealize location movementPrevent obstacles that prevent proper conversionContact driving mechanismsElectric devices for scotch-blocksStructural engineeringMachine

The invention provides a contact seat for an electric switch machine. The contact seat comprises a contact seat base body, fixing plates used for assembling a static contact set and a support used forassembling a movable contact set. The support comprises a left support and a right support which are symmetrically connected to the contact seat base body through movable contact shafts respectively;a tension spring is arranged between the left support and the right support; fixing plates corresponding to the positions of the left support are arranged on the two sides of the left support respectively; fixing plates corresponding to the positions of the right support are respectively arranged on two sides of the right support; one end of the movable contact shaft is provided with an adjustingplate capable of rotating relative to the contact seat base body; and a tension spring is arranged between the right adjusting plate and the left adjusting plate. According to the contact seat for the electric switch machine, the tension spring between the left adjusting plate and the right adjusting plate and the tension spring between the left support and the right support form a double-tension-spring system, conversion power of the movable contact set is improved, and conversion stability of the movable contact set is improved.

Owner:TIANJIN RAILWAY SIGNAL

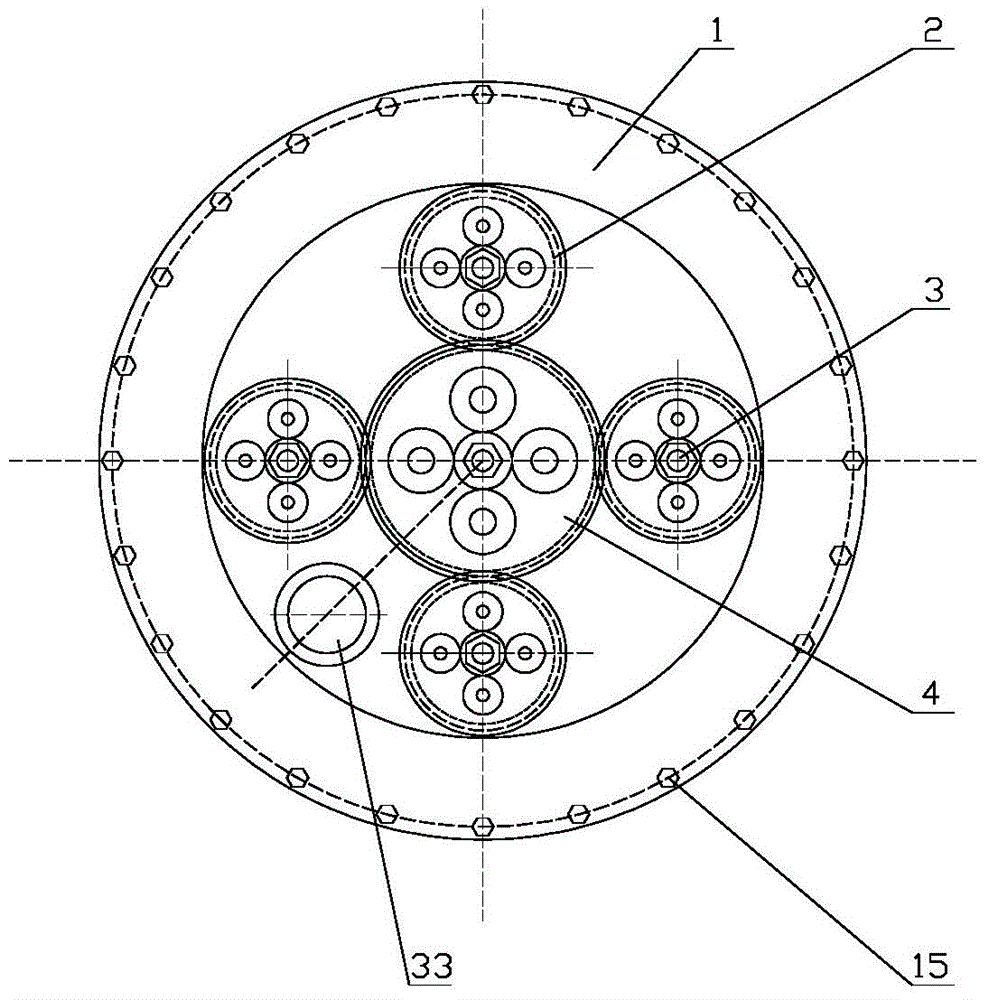

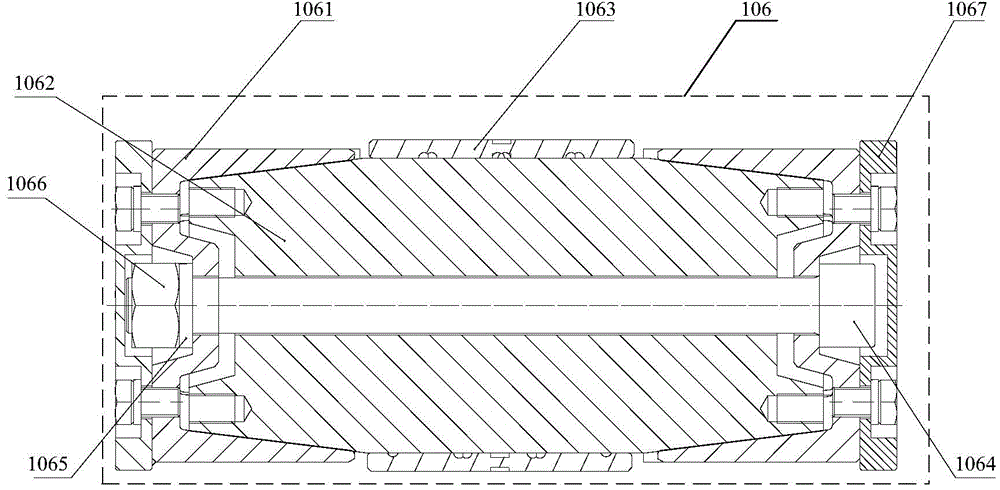

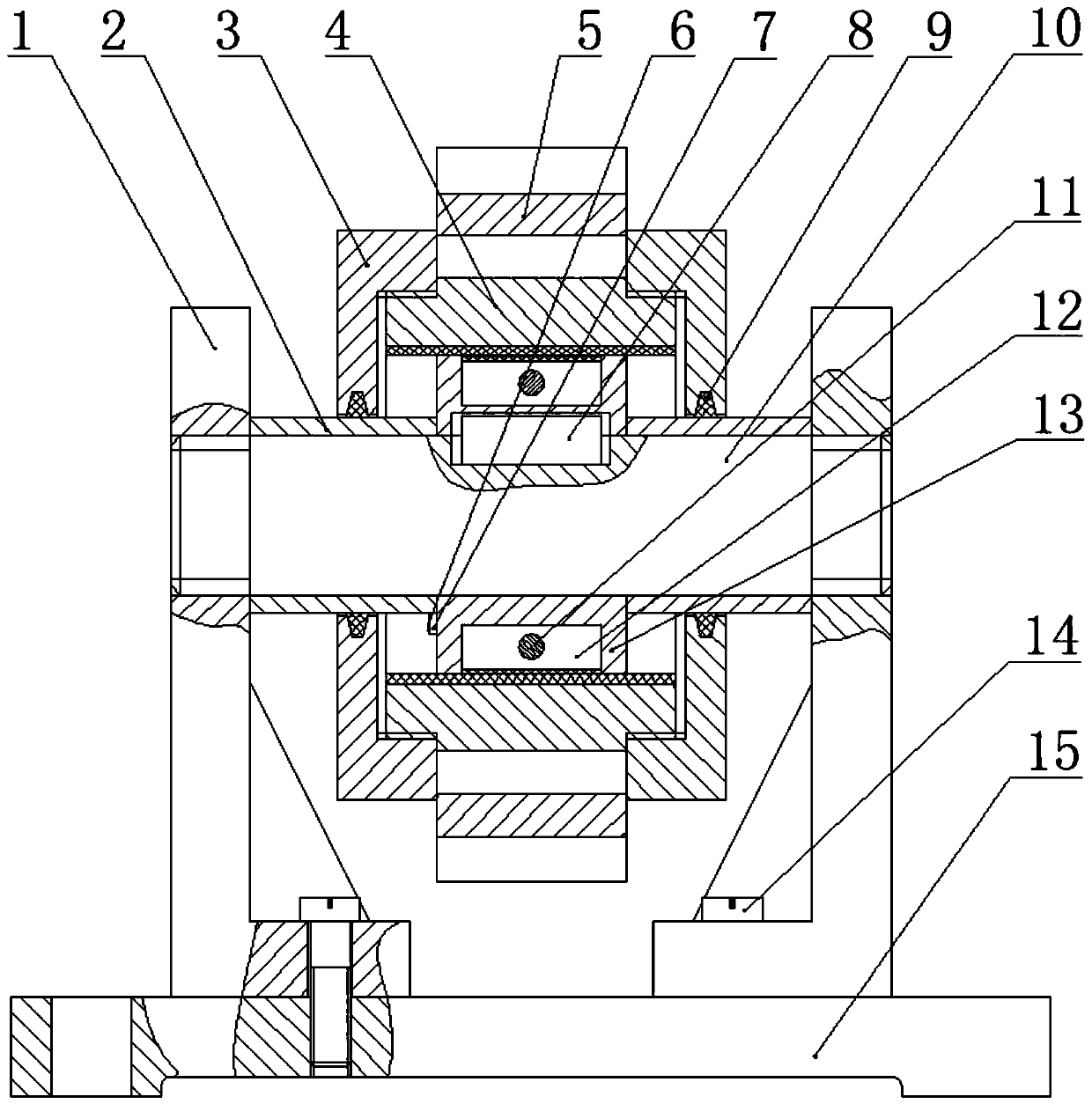

Spray water type screw compressor

PendingCN109058103AGood axial positioningWell balanced axial forceRotary piston pumpsRotary piston liquid enginesEngineeringFuselage

The invention discloses a spray water type screw compressor. The spray water type screw compressor comprises a machine body, wherein a negative rotor and a positive rotor are arranged in the machine body; a negative row end sliding bearing is arranged at the row end of the negative rotor; a positive row end sliding bearing is arranged at the row end of the positive rotor; a first axial limiting cavity and a second axial limiting cavity are formed in the row end of the machine body, the negative row end sliding bearing is arranged in the first axial limiting cavity, and the positive row end sliding bearing is arranged in the second axial limiting cavity; negative water injection tanks are separately arranged at two ends of the negative row end sliding bearing and between two side walls of the first axial limiting cavity; and positive water injection tanks are separately arranged at two ends of the positive row end sliding bearing and between two side walls of the second axial limiting cavity. The spray water type screw compressor can enable the negative and positive rotors to bear more axial force, the structure is simple, and installation and manufacture are convenient.

Owner:NINGBO BAOSI ENERGY EQUIP

Hinge pin device and coal mining machine

InactiveCN104806236AGuaranteed to workEnsure normal lubrication operationSlitting machinesCutting machinesWorking environmentEngineering

The invention provides a hinge pin device and a coal mining machine. The hinge pin device is applied to the coal mining machine and comprises taper sleeves and a hinge pin, wherein the taper sleeves are mounted at two ends of the hinge pin. The hinge pin device is characterized by further comprising a shaft sleeve connected onto the hinge pin in a sleeving manner, and lubricant accommodating holes are formed in the shaft sleeve. With adoption of the technical scheme, on the one hand, by means of the lubricant accommodating holes formed in the shaft sleeve of the hinge pin device, normal lubrication and operation of the hinge pin can be guaranteed effectively for a long time, and a manual oil injection link is omitted; on the other hand, a dust ring is mounted on the shaft sleeve of the hinge pin device, so that the working environment between the hinge pin and the shaft sleeve can be improved effectively, and the service life of the hinge pin device is prolonged; further, openings and steps are formed on the taper sleeves of the hinge pin device, accordingly, displacement of the hinge pin can be prevented effectively, and an axial positioning function is realized.

Owner:SANY HEAVY EQUIP

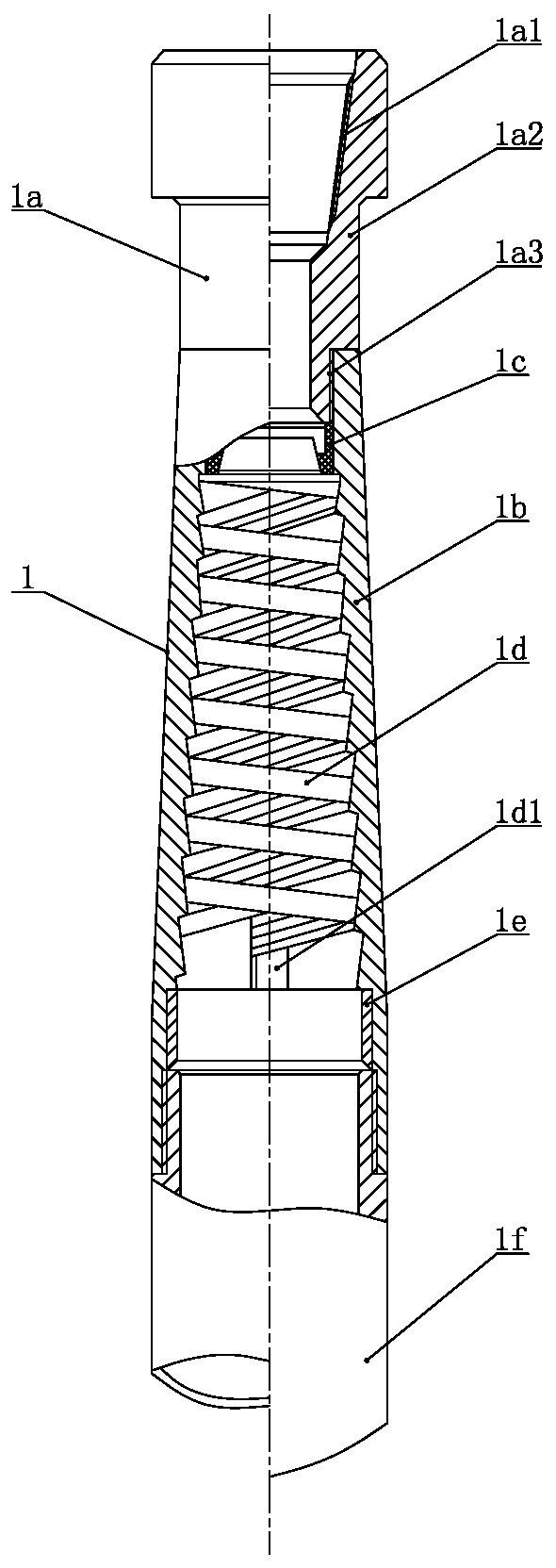

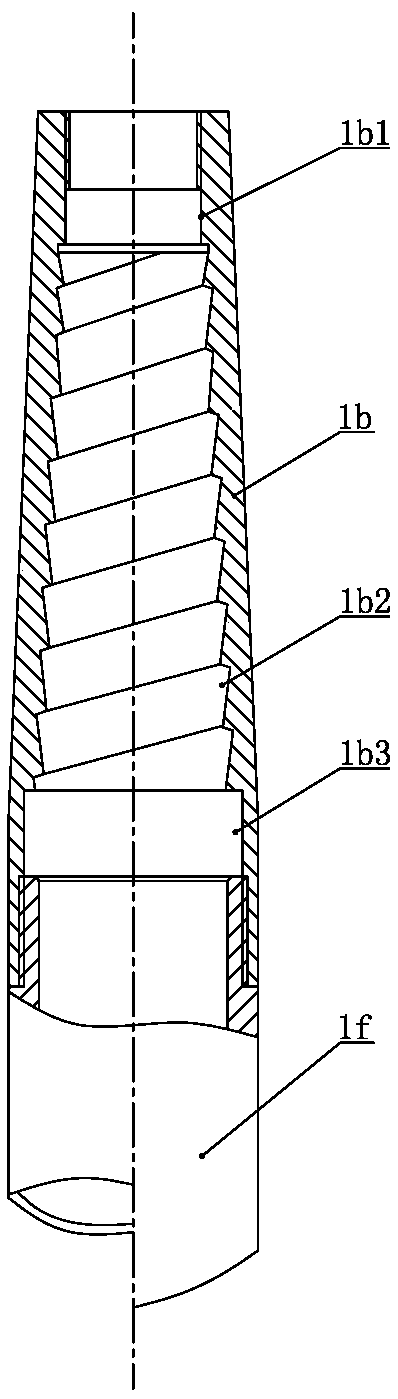

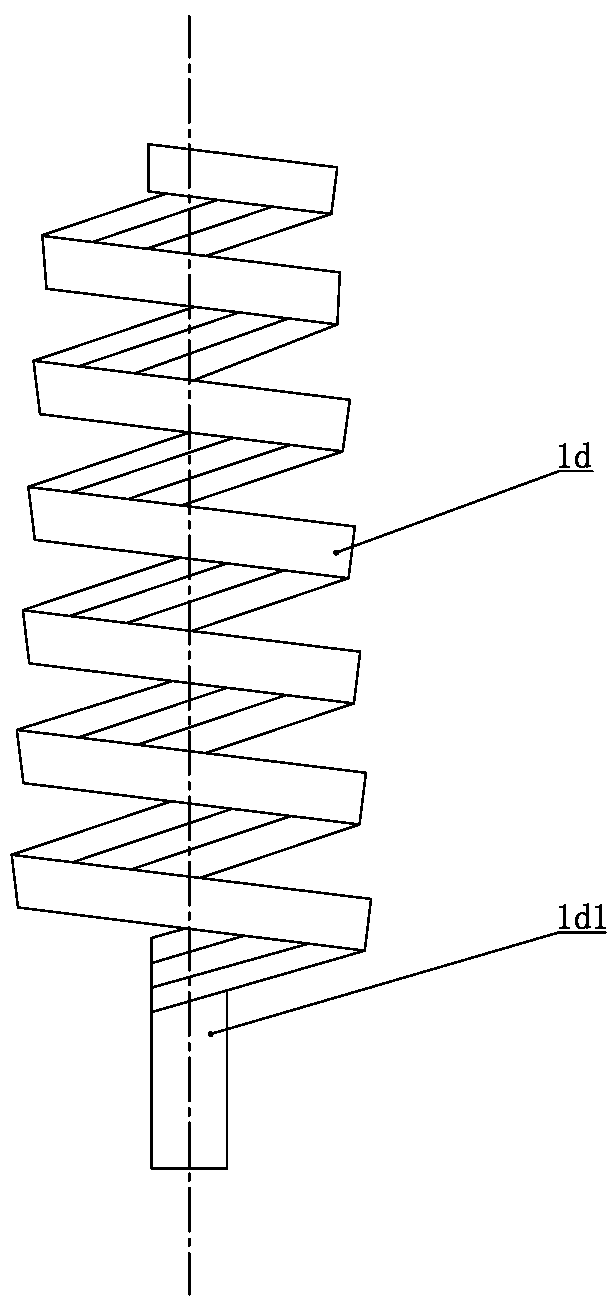

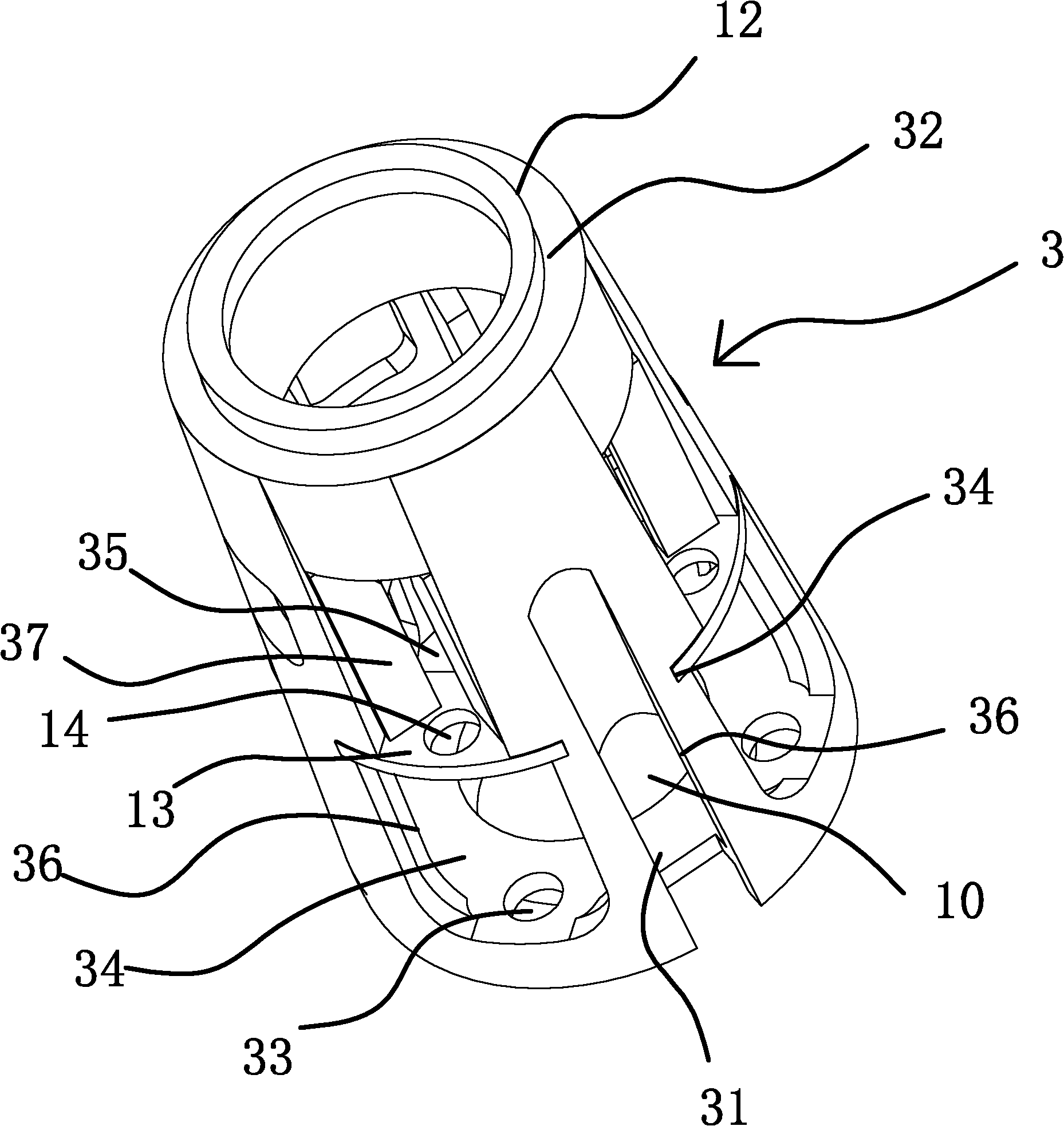

Rotary type cutting and fishing integral fisher

InactiveCN105781465APrevent chargebackThe effect of structure anti-regression is obviousBorehole/well accessoriesNeedle roller bearingEngineering

The invention discloses a rotary type cutting and fishing integral fisher. The rotary type cutting and fishing integral fisher comprises an upper connector provided with an internal thread. The upper connector is connected with a lower connector provided with an external thread. The inner side of the lower end of the upper connector is provided with L-shaped tracks. The lower connector is sequentially sleeved with an upper bearing ring, a slip cone body and a lower bearing ring from top to bottom. The part between the slip cone body and the lower connector is sequentially sleeved with an upper roller pin sealing sleeve, an upper roller pin bearing, a lower roller pin bearing and a lower roller pin sealing sleeve from top to bottom. The upper end and the lower end of the upper roller pin bearing are provided with upper roller pin bearing spacer rings correspondingly. The upper end and the lower end of the lower roller pin bearing are provided with lower roller pin bearing spacer rings correspondingly. The slip cone body is sleeved with a slip. The outer side of the upper end of the slip is provided with L-shaped keys. The rotary type cutting and fishing integral fisher is simple in structure, convenient to use, long in service life, capable of descending a well along with a cutter and conducting one time of cutting milling and fishing operation on a pipe column to be cut and milled, and suitable for cutting milling and fishing of the pipe column.

Owner:CHINA NAT OFFSHORE OIL CORP +1

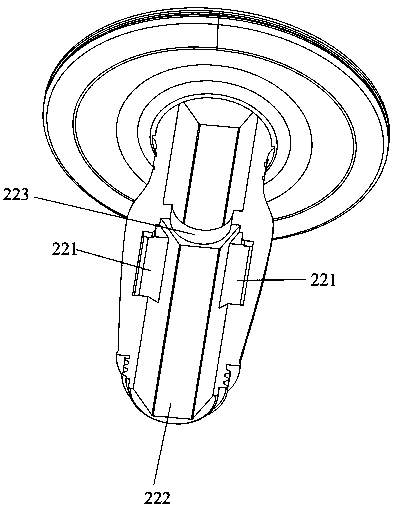

Masonry chisel sheath, masonry chisel and quick disassembly and assembly method of masonry chisel

PendingCN110625830ALow costLow processing and manufacturing costsStone-like material working toolsEngineeringStructural engineering

The invention relates to a masonry chisel sheath, a masonry chisel and a quick disassembly and assembly method of the masonry chisel. The masonry chisel sheath includes a hand protecting plate and a handle. The hand protecting plate is installed on the handle, and the handle is provided with a mounting hole for inserting a chisel rod of the masonry chisel. The handle is divided into two parts which are a left half handle and a right half handle. The left half handle and the right half handle are connected together by a fastening sleeve to form the handle. The masonry chisel includes the chiselrod of the masonry chisel, a chisel head is arranged at the lower end of the chisel rod of the masonry chisel, and the masonry chisel sheath is installed at the upper end of the chisel rod of the masonry chisel. A circle of concave positioning groove is machined in the chisel rod of the masonry chisel in the circumference direction of the chisel rod. A left half mounting hole of the left half handle is internally provided with a positioning protrusion matched with the concave positioning groove and playing an axial positioning role on the chisel rod of the masonry chisel. The rapid disassembly, assembly and replacement of the masonry chisel sheath and the chisel rod of the masonry chisel are realized, from the perspective of a user, all the masonry chisels with the same shapes of the chisel rods of the masonry chisels need only be equipped with one masonry chisel sheath, and the cost is saved.

Owner:杭州萧山佳佳工具有限公司

Pump shaft sleeve for double suction pump

InactiveCN107701490AExtended service lifeReduce adverse effectsPump componentsRadial flow pumpsImpellerCavitation

The invention discloses a pump shaft sleeve for a double suction pump. The pump shaft sleeve comprises a shaft sleeve body. A cylindrical cavity structure is arranged in the shaft sleeve body. An annular groove is formed in the inner wall of the left side of the shaft sleeve body. An arc structure smoothly connected with the shaft sleeve body is arranged on the outer side of the right end of the shaft sleeve body. An annular step is arranged at the position, corresponding to the arc structure, of the inner wall of the shaft sleeve body. Multiple through holes are evenly formed in the peripheryof the shaft sleeve body. Compared with the prior art, the pump shaft sleeve has the following beneficial effects that the annular groove of the shaft sleeve cooperates with a pump shaft to form a closed oil cavity, the lubricating time of the shaft and a bearing can be effectively increased, and the service life of the shaft can be prolonged; the through holes are formed in the shaft sleeve body, and therefore concentration of bubbles on the surface of the shaft sleeve can be reduced, and the bad influence generated by cavitation on the shaft sleeve is avoided; and a part matched with the step formed by an impeller and the pump shaft is arranged at the right end of the shaft sleeve, the axial locating function can be achieved on the impeller, the outer side of the shaft sleeve and the impeller are in smooth transition, resistance to water flow is reduced, and the work efficiency of the double suction pump is improved.

Owner:ANHUI TENGLONG PUMP VALVE MFG CO LTD

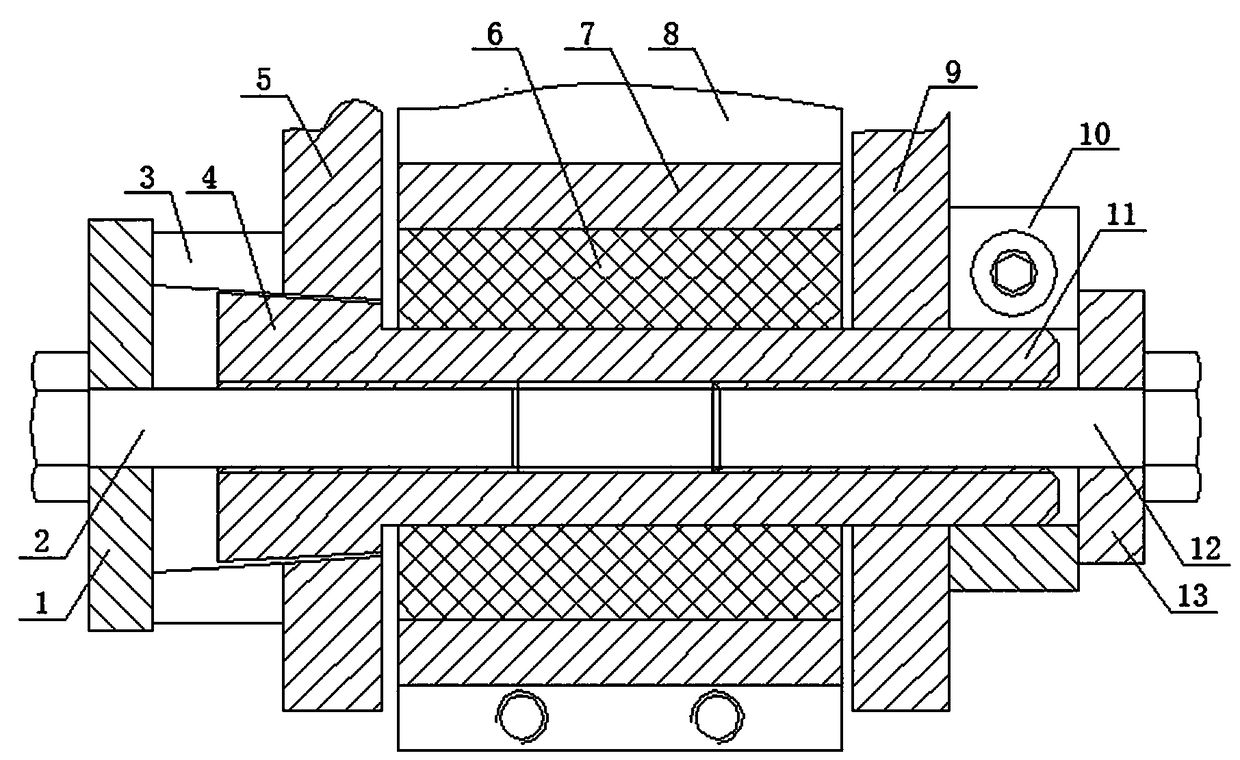

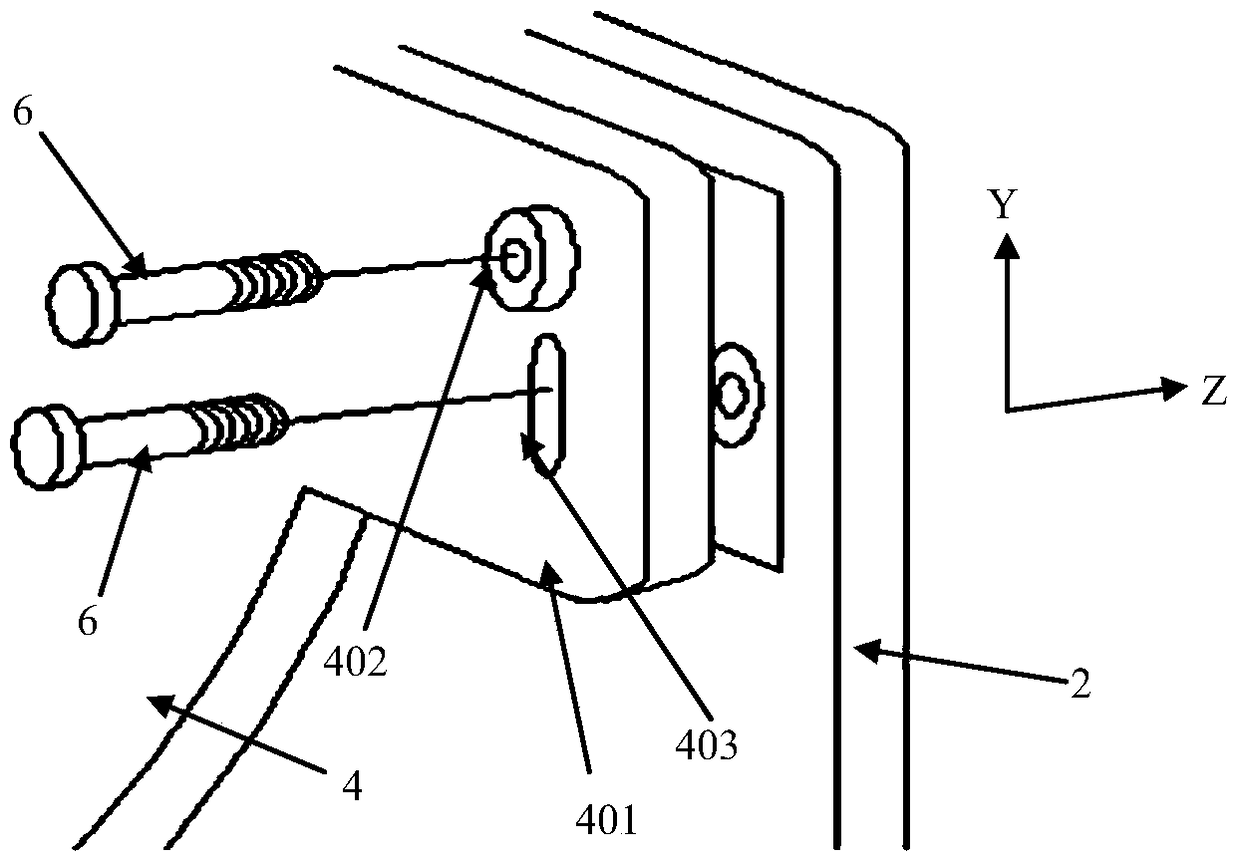

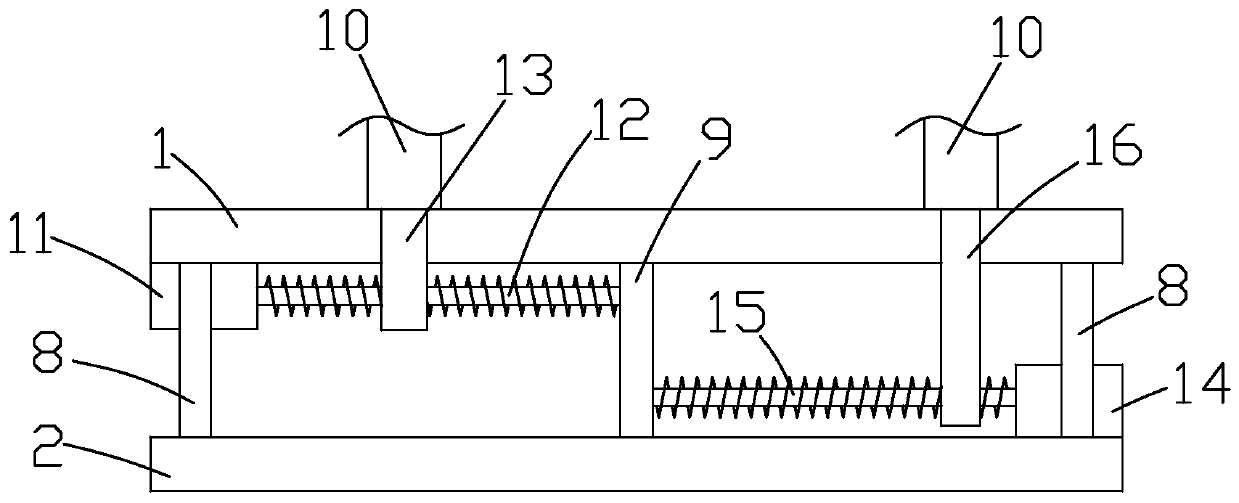

Corrugated pipe forming device

InactiveCN106825167AAvoid displacement deviationPlay the role of axial positioningEconomic benefitsElectrical and Electronics engineering

The invention discloses a bellows forming device, which comprises a forming workbench and a supporting base plate. The forming workbench is arranged on the supporting base plate. A driving mechanism and a positioning seat are respectively arranged on the forming workbench. The driving mechanism is located on one side of the positioning seat. An adjustment mechanism is provided between the positioning seat and the forming workbench, a support frame is provided on the support base plate, a first transmission mechanism and a second transmission mechanism are respectively provided on the support frame, and a first transmission roller group is provided on the first transmission mechanism. The first transmission roller set is provided with an upper pressure roller, and two adjacent upper pressure rollers are connected end to end. The second transmission mechanism is provided with a second transmission roller set, and the second transmission roller set is provided with a lower pressure roller. The two lower pressure rollers are connected end to end, and the upper pressure roller is in contact with the lower pressure roller. The invention has stable molding, good molding effect, high product quality, long service life, automatic safety, high production efficiency, simple structure, low manufacturing cost and remarkable economic benefits.

Owner:全南县智护力工业产品设计有限公司

A large-section wire stripper

ActiveCN104993429BReduce crimp qualityFlat sectionLine/current collector detailsApparatus for removing/armouring cablesMechanical engineering

Owner:CHINA ELECTRIC POWER RES INST +2

A fan blade pre-embedded root flange device

Owner:SINOMATECH WIND POWER BLADE +1

Multi-reverse granular mineral crusher

InactiveCN108393142AReduce energy consumptionImprove work efficiencyGrain treatmentsBlade plateDrive shaft

A multi-reverse granular mineral crusher is characterized in that a crusher barrel is a cylindrical barrel, the upper part of the crusher barrel is provided with an upper bearing box, and the lower part of the crusher barrel is provided with a lower bearing box; an upper bearing box is connected with a bearing seat unclosed cover, and a lower bearing box is connected with a bearing seat closed cover; an upper tapered roller bearing is arranged in the upper bearing box, and a lower tapered roller bearing is arranged in the lower bearing box; the upper bearing box is arranged at the upper part of the crusher barrel and the lower bearing box is arranged at the lower part of the crusher barrel; a driving gear and driven gears are both located at the top of the upper bearing box, a driving transmission shaft is a transmission shaft of the driving gear, and driven transmission shafts are transmission shafts of the driven gears; in order to prevent the axial movement of the driving transmission shaft and the driven transmission shafts, both the driving transmission shaft and the driven transmission shafts are stepped shafts, the driving transmission shaft and the driven transmission shafts both pass through the bearing seat unclosed cover, the middle parts are in the crusher barrel, and the bottom parts are connected with the bearing seat closed cover; and sanding blade plates are correspondingly arranged on the driving transmission shaft and the driven transmission shafts. The multi-reverse granular mineral crusher has the beneficial effects of being high in efficiency and capable of lowering the environmental pollution and lowering the energy consumption.

Owner:HEFEI RUIHONG HEAVY MACHINERY

Auxiliary device for controlling one-way transmission of gear train structures

ActiveCN110645287APlay the role of axial positioningEasy to controlFreewheel clutchesSet screwFrictional coefficient

The invention discloses an auxiliary device for controlling one-way transmission of gear train structures. The auxiliary device comprises side vertical plates, positioning sleeves, sealing covers, spline sleeves, the gear train structures, positioning screws, sliding blocks, flat keys, sealing rings, a shaft, spring ejector rods, friction pieces, star wheels, slotted screws and a fixing base. Theauxiliary device does not directly participate in transmission, the rotation and the stop of the gear train structures are realized by controlling the friction between the friction pieces and inner rings of the spline sleeves by using a friction principle, the transmission direction of the gear train structure transmission device is effectively controlled, the problems of transmission direction failure and working safety are solved, meanwhile, the working noise is reduced through rotation and stopping of the friction control gear train structures, and the working environment is optimized; a high friction coefficient material is adopted, reticulated mottles are arranged on the friction surface to increase friction force, and the sliding blocks are used for controlling whether the friction pieces can participate in working to realize unidirectional rotation control in two different directions; and meanwhile, the auxiliary device is convenient to disassemble, and has strong practical value and application prospects.

Owner:SOUTHWEST JIAOTONG UNIV

Inverted vertical roller for ship

InactiveCN104816811AAccurate scrollingAvoid axial misalignmentPower plants using positive-displacement steam enginesBall bearingPulp and paper industry

The invention mainly relates to an inverted vertical roller for a ship and belongs to the technical field of ships. The inverted vertical roller for the ship comprises a shaft, a check ring, a roller, a first bearing, a bearing seat and a second bearing, wherein the roller is sleeved outside the shaft, two ends of the shaft extend outside the roller, the check ring is arranged at the free end of the shaft, the first bearing is the single direction thrust ball bearing, the first bearing and the bearing seat are arranged between the roller and the shaft, the bearing seat is screwed on the shaft and the outer wall of the bearing seat and a gap is formed between the inner wall of the hole of the roller, and the first bearing is arranged between the end face of the bearing seat and the inner end face of the hole of the roller. After by adopting the structure, compared with the prior art, the inverted vertical roller for the ship has following advantages: possible axial direction dislocation between the roller and the shaft can be avoided after that the roller is used for a long time, the roller can roll accurately and convenience is met for practical use.

Owner:ZHEJIANG OCEAN UNIV

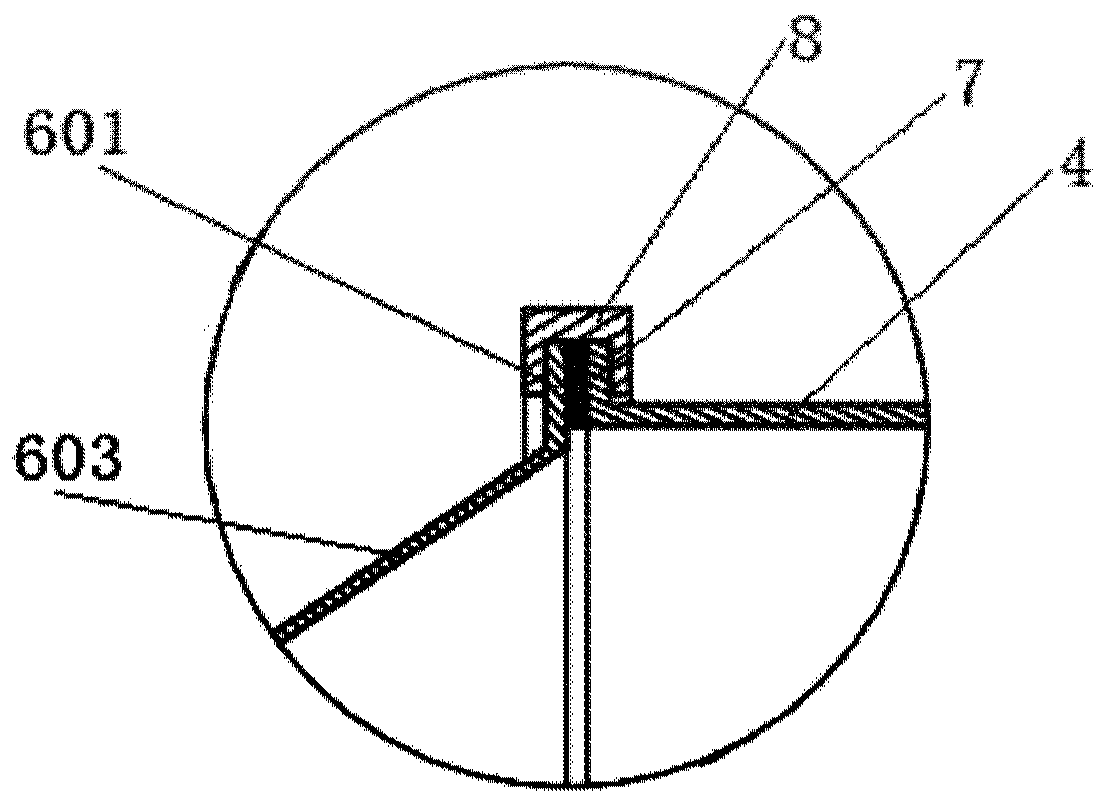

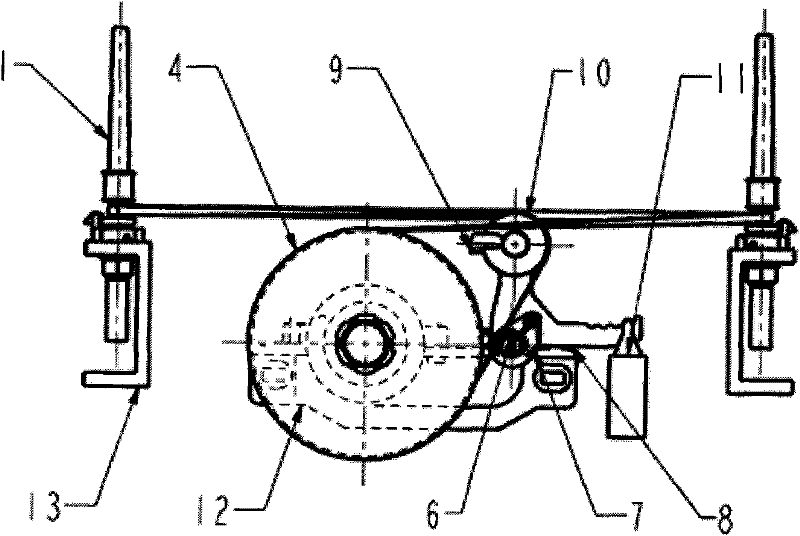

Spindle tape tension device of ring spinning frame

The invention relates to a spindle tape tension device of a ring spinning frame, wherein a main shaft (3) and a tension pulley shaft (5) are arranged on a main shaft bearing seat (12); a rolling disc (4) is arranged on the main shaft (3); a positioning pin (6) is arranged on the tension pulley shaft (5); a support ring (7) is arranged on the tension pulley shaft (5) and a positioning pin (6); a bracket (8) is arranged on the support ring (7); a heavy punch (11) is arranged at one end of the bracket (8); the tension pulley frame (9) and a spindle tape tension pulley (10) are arranged at the other end of the bracket (8); a spindle (1) is arranged on a keel (13); and a spindle tape (2) is arranged on the rolling disc (4), the spindle tape tension pulley (10) and four spindles (1). With the adoption of the spindle tape tension device, the requirements on tension stabilization and consistence of the spindle tape of the spinning frame can be met.

Owner:JINGWEI TEXTILE MASCH CO LTD

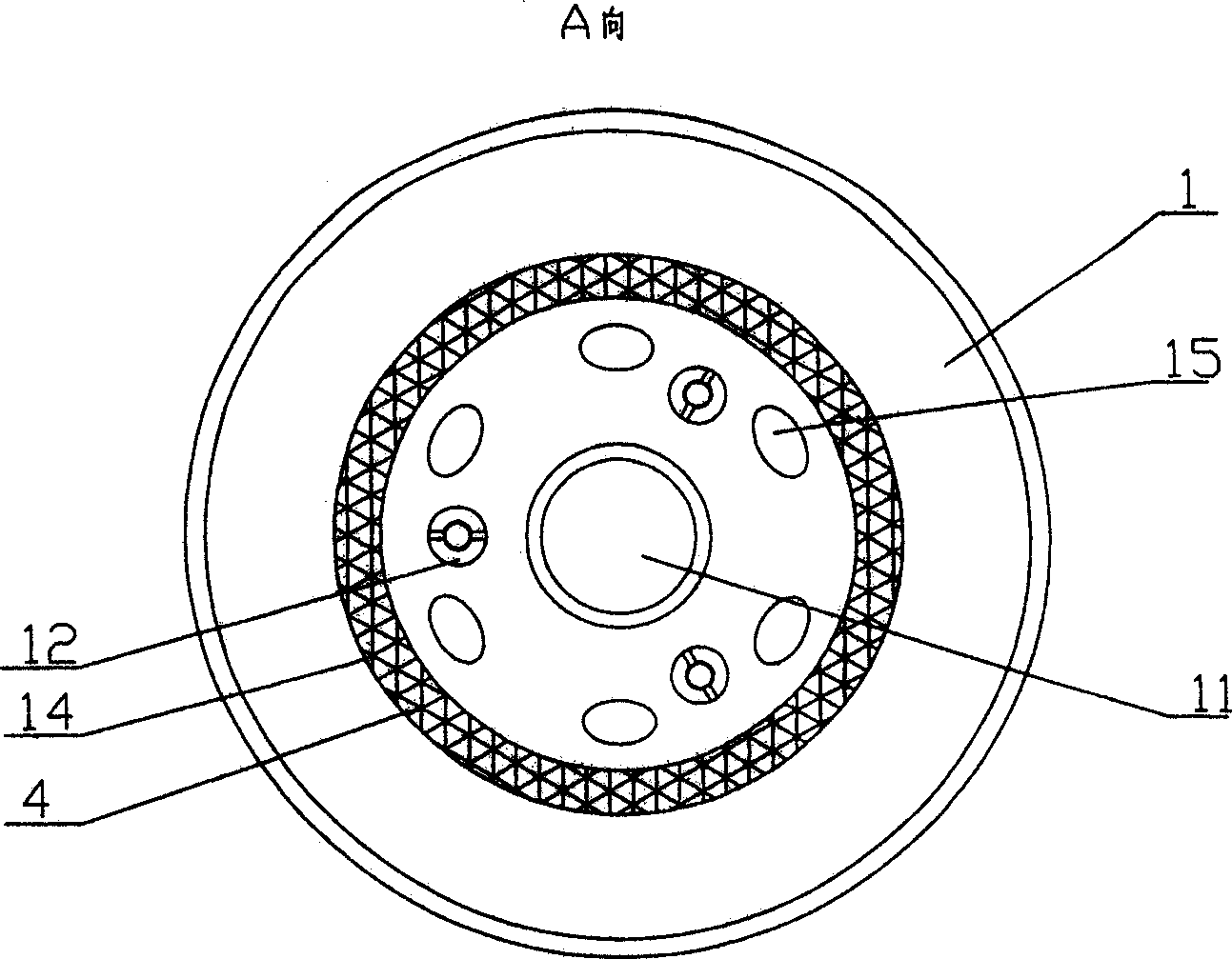

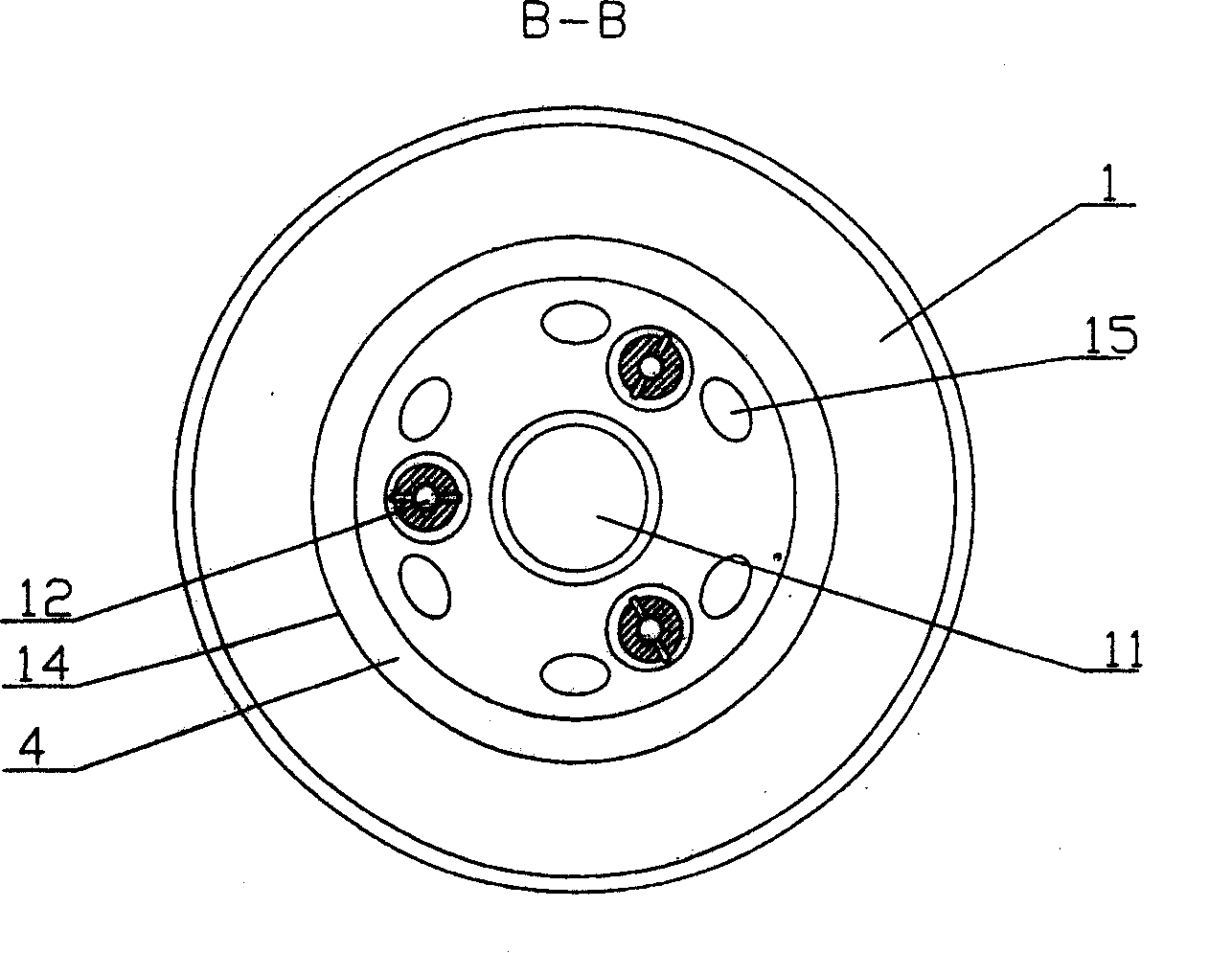

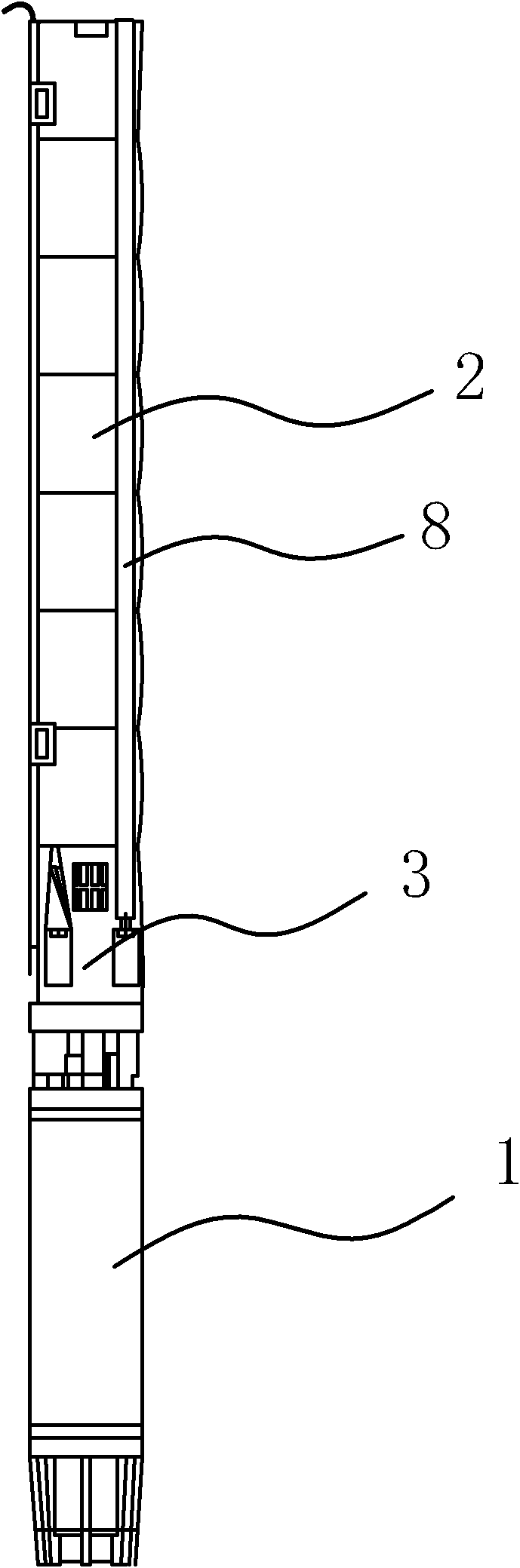

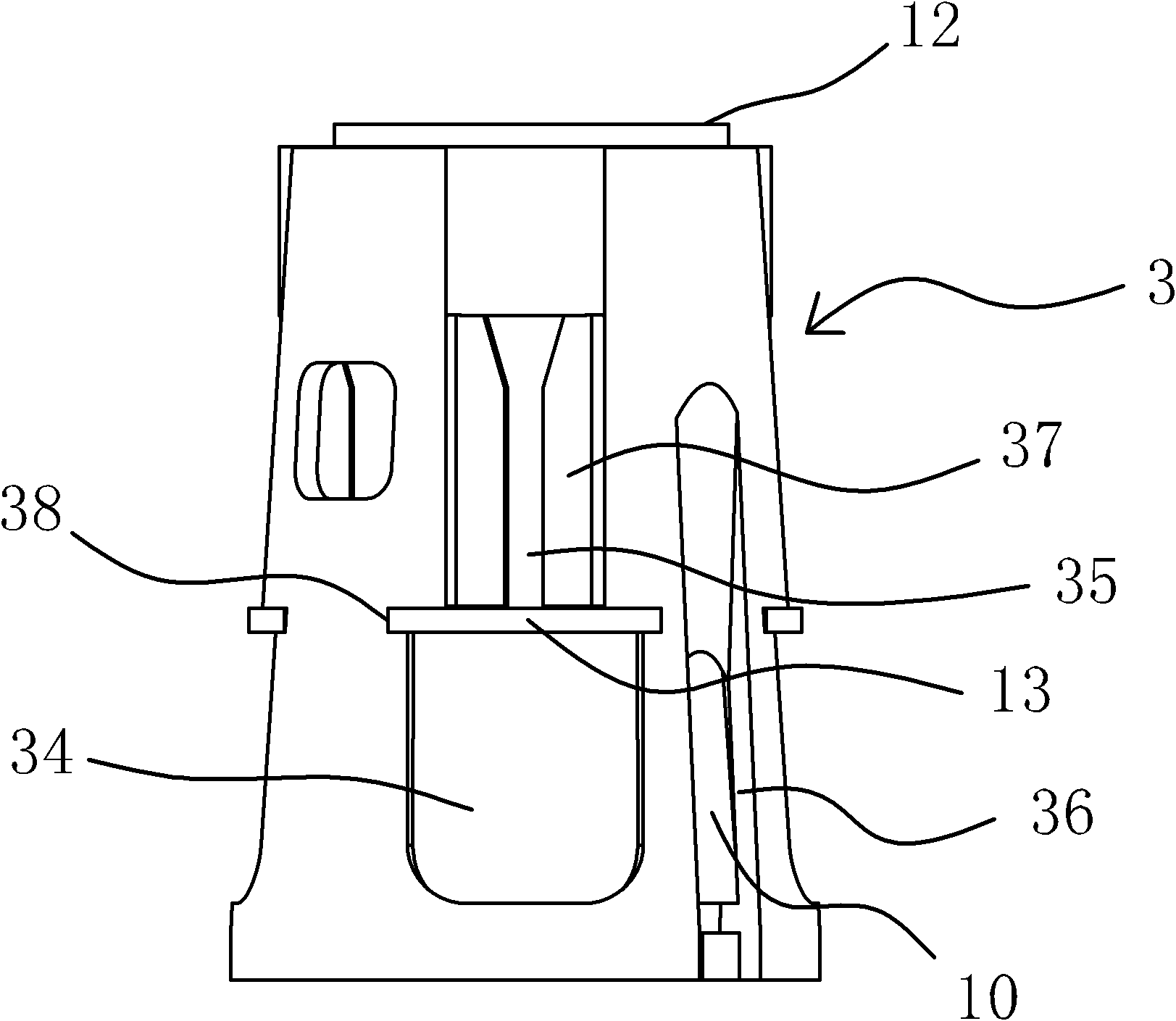

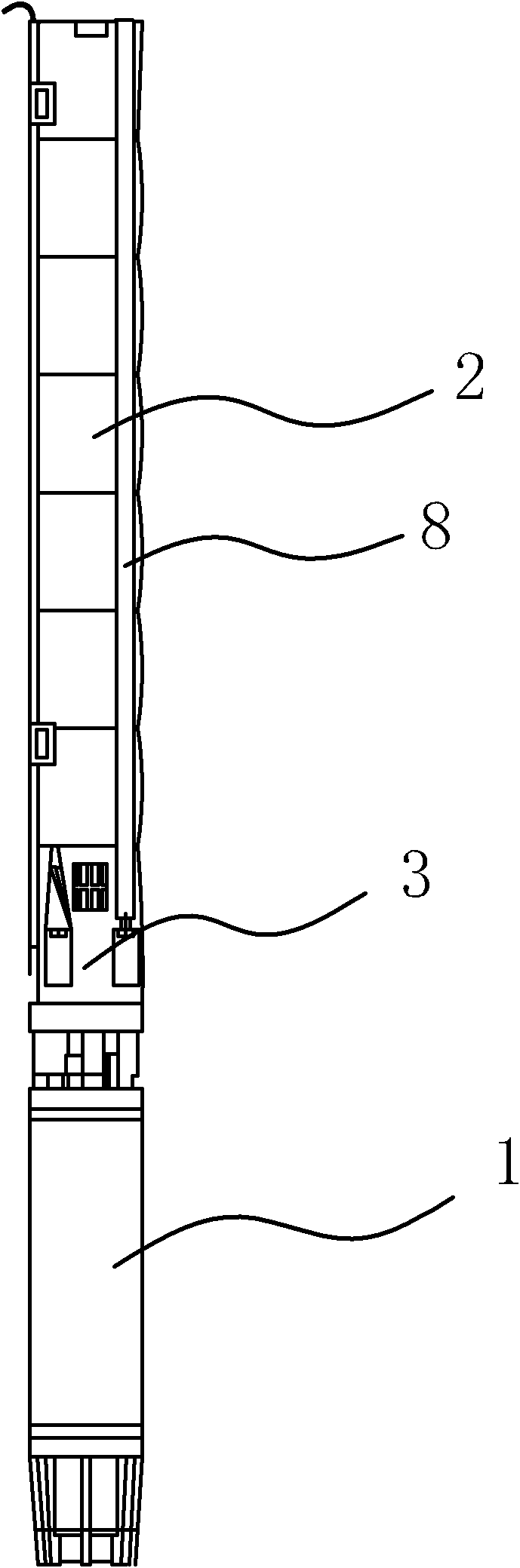

Submerged electric pump for well

ActiveCN102094833BImprove bearing capacityHigh mechanical strengthPump componentsPump installationsImpellerNitrile rubber

Owner:TAIZHOU YONGXIN PUMP IND

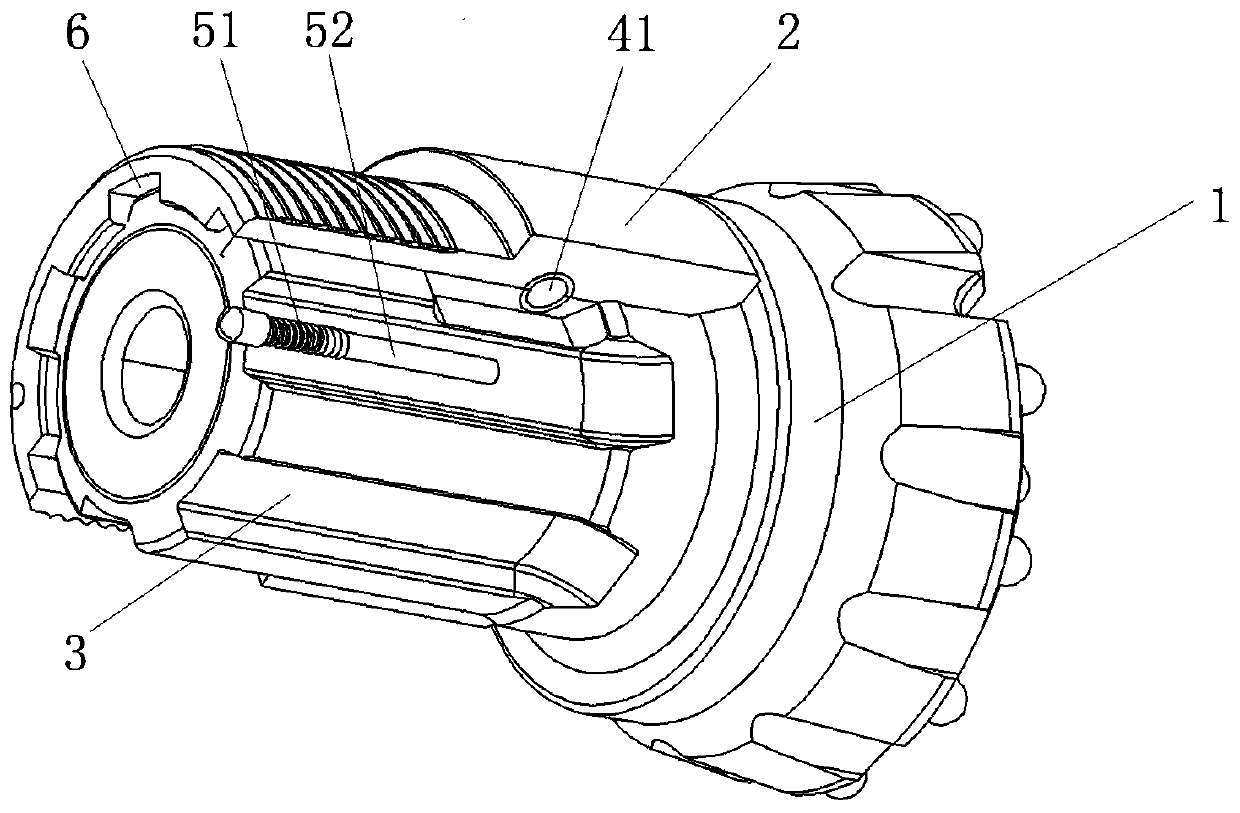

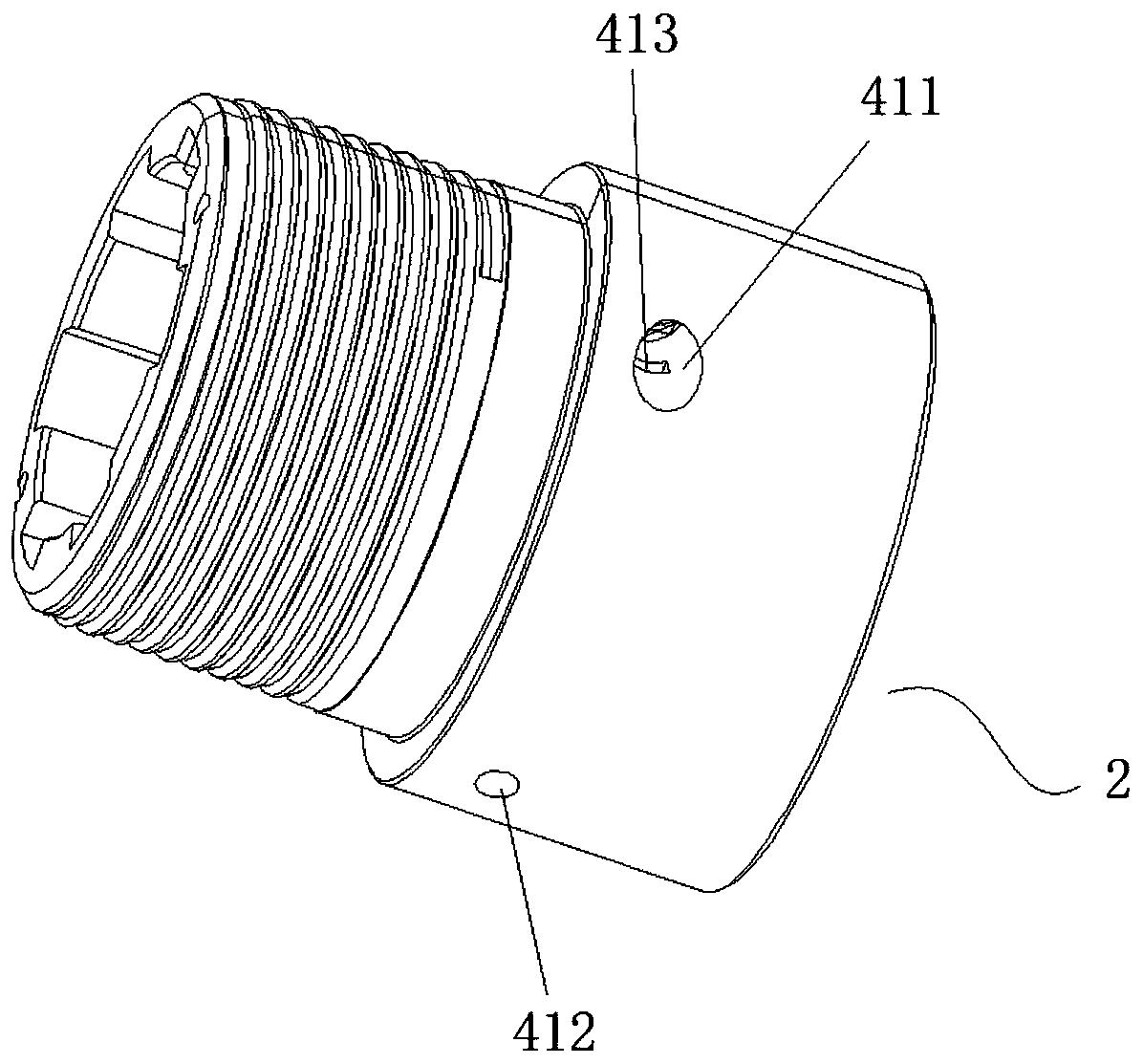

Impactor with quick-change structure

PendingCN110847808ATo achieve a fixed connectionPlay the role of axial positioningBorehole drivesDrill bitFiber

The invention discloses an impactor with a quick-change structure. The impactor comprises a drill bit and a clamping fiber sleeve, wherein the end of the drill bit is sleeved with the end of the clamping fiber sleeve; a guide groove, a guide key and a locking part are arranged between the attaching faces of the drill bit and the clamping fiber sleeve; the guide groove and the guide key extend in the axial direction; and the locking part is used for achieving axial positioning. According to the impactor with the quick-change structure, the guide groove, the guide key and the locking part are used for replacing clamping ring connection in the prior art, when the impactor is disassembled, the locking part is unlocked, the drill bit and the clamping fiber sleeve are pulled in the extending direction of the guide groove and the guide key, namely the axial direction of the drill bit, the drill bit and the clamping fiber sleeve are separated in the axial direction, and disassembly is achieved. In the process, the step that a clamping ring is taken down by disassembling an outer cylinder and the clamping fiber sleeve in the prior art does not exist, and therefore the outer cylinder and theclamping fiber sleeve are prevented from being disassembled, and the problem that the drill bit is difficult to disassemble due to the fact that threads of the outer cylinder and the clamping fiber sleeve are too locked is solved.

Owner:CHANGSHA HEIJINGANG IND CO LTD

Circuit breaker moving contact with arc contact

PendingCN110676133AEffective protectionExtend your lifeCircuit-breaking switch contactsBreaking capacityHigh voltage

The invention relates to the technical field of circuit breakers, and especially discloses circuit breaker moving contact with an arc contact. The circuit breaker moving contact comprises a contact system, a contact support, contact springs, a connecting shaft and a flexible connector, wherein the contact system comprises a plurality of contact pieces, the contact pieces are all sleeved on the connecting shaft, the end parts, which are located at two sides of the connecting shaft, of each contact piece are respectively a butt joint end abutted against the contact spring and a connecting end connected with the flexible connector, the side edge of each connecting end is provided with a limiting rod for the butt joint of the connecting end, the middle part of the limiting rod is provided witha concave cavity, the bottom surface of the concave cavity is lower than the surface of the other positions of the limiting rod, the connecting end of at least one contact piece is in butt joint withthe bottom surface of the concave cavity to form an arc contact, the other contact pieces form a main contact, and the butt joint end of the arc contact protrudes out of the butt joint end of the main contact. By adopting the structure, the circuit breaker moving contact with the arc contact which can effectively protect the main contact and can provide reliable high breaking capacity and long electric service life under high voltage.

Owner:DELIXI ELECTRIC

Heavy-duty warehouse gate opening and closing machine

PendingCN111456580ALower height requirementSave spacePower-operated mechanismBlock and tackleMachine

The invention provides a heavy-duty warehouse gate opening and closing machine which comprises a rack. A drive piece is fixed onto the rack and is fixedly connected with one end of a pulley block through a connecting piece; the pulley block is connected with a deflecting pulley through a rope; one end of the rope is fixed onto the pulley block; the other end of the rope is fixedly connected with one end of a gate body; and the other end of the gate body is hinged to the left side of a groove on the ground surface through a hinge support. The heavy-duty warehouse gate opening and closing machine provided by the invention is simple in structure, ingenious in design, low in cost, safe and stable; in the gate opening and closing process, the space required for rotating the gate body is small,so that the requirement on the height of a warehouse is low; and an oil cylinder drives the gate body to rotate around the hinge seat so as to open and close the gate through two groups of pulley blocks, so that the gate body opening speed is fast, the efficiency is high, the time is saved, a horizontal space is saved, and the heavy-duty warehouse gate opening and closing machine is particularly suitable for occasions with low height of a warehouse and a small horizontal space.

Owner:浙江机电职业技术学院

Floating disc mechanism

PendingCN111824853APlay the role of axial positioningSave spaceFilament handlingEngineeringWire wrap

Owner:张家港市瑞昌智能机器系统有限公司

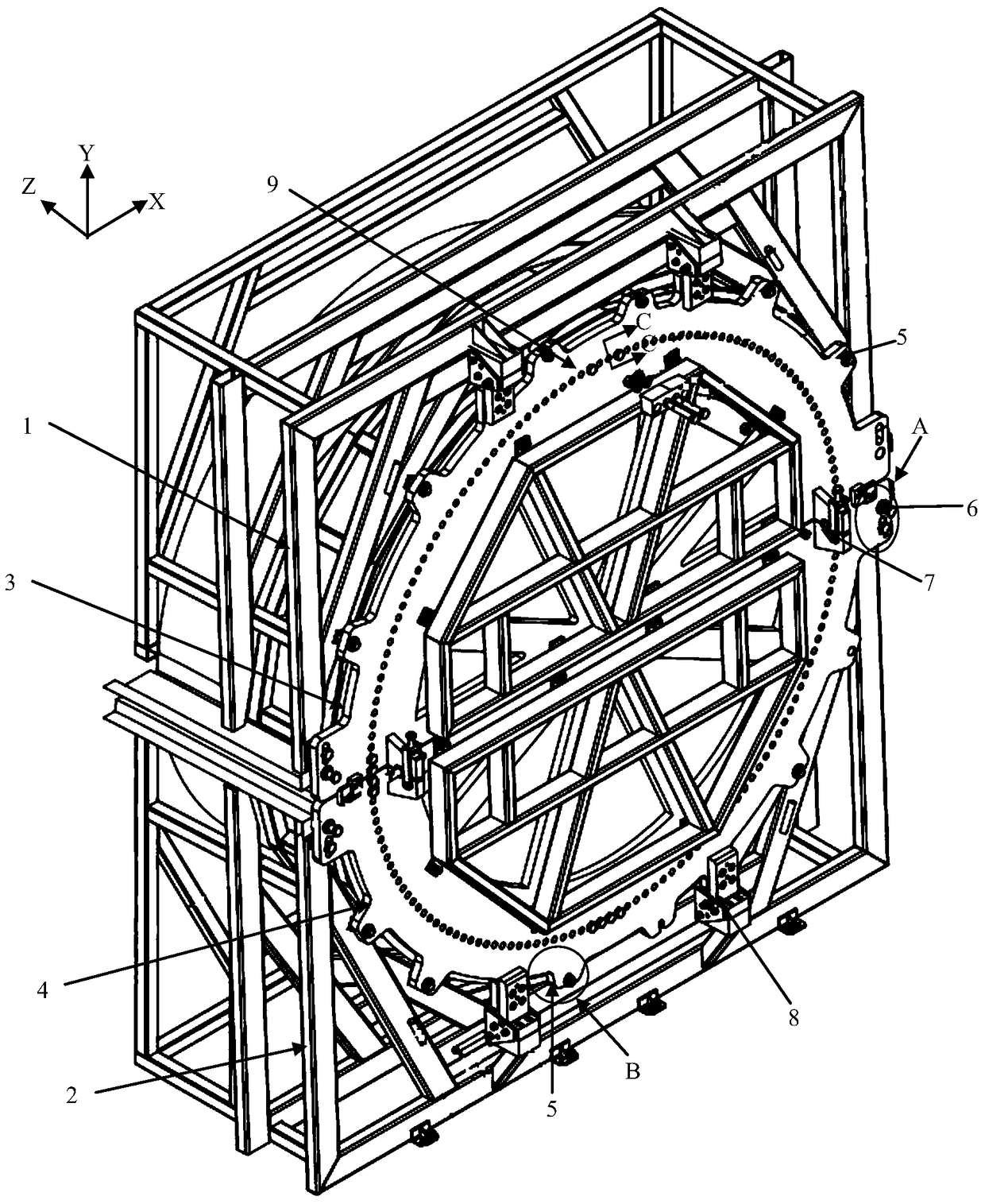

A surface drilling device for trenchless construction pipelines

ActiveCN109570557BImprove drilling efficiencyIncrease flexibilityLarge fixed membersMetal working apparatusClassical mechanicsEngineering

The invention discloses a surface hole drilling device for non-excavation construction pipelines. The device comprises a base board, a bottom board, a first hole drilling machine, a second hole drilling machine and pipeline rotary mechanisms; the bottom board is located below the base board; the base board is fixedly connected with the bottom board through a supporting rod; two guide grooves are formed in the top face of the base board in parallel; the first hole drilling mechanism and the second hole drilling mechanism are movably connected to the guide groove; a drive mechanism is arranged between the base board and the bottom board and is connected with the first hole drilling mechanism and the second hole drilling mechanism; pipeline supporting mechanisms are arranged on the center straight line of the top face of the base board at equal intervals; and the two pipeline rotary mechanisms are symmetrically arranged on two sides of the base board. The surface hole drilling device fornon-excavation construction pipelines is simple in structure and high in practicability, not only can achieve single-hole or dual-hole machining for construction pipelines and improve the hole drilling efficiency, but also can clamp and position construction pipelines, rotates construction pipelines at the constant speed according to hole drilling needs at the same time, and greatly improves the hole drilling precision and quality.

Owner:嵊州市越通非开挖建设有限公司

Submerged electric pump for well

ActiveCN102094833AImprove bearing capacityHigh mechanical strengthPump componentsPump installationsImpellerNitrile rubber

The invention provides a submerged electric pump for a well, and belongs to the technical field of machinery. The submerged electric pump provided by the invention is used for solving the problems of less bearing capacity, low efficiency and high production cost of the existing submerged electric pump for a well. The submerged electric pump for the well comprises a shell, a motor, a main shaft and a pump body, wherein the main shaft is connected with a motor rotary shaft; the pump body consists of a plurality of pump units, and a connecting seat is connected between the pump body and the shell; one end surface of the connecting seat is provided with bolt holes, and the side wall of the connecting seat is provided with first mounting holes which are corresponding to the bolt holes; third mounting holes are arranged between any two adjacent first mounting holes; each pump unit is composed of a guide blade shell of a tubular integral structure and a vane wheel which is placed in the guide blade shell; the guide blade shell is provided with a shaft sleeve which is made of a nitrile rubber buna material; and two long side edges of each first mounting hole and each third mounting hole are provided with reinforcing ribs which are bent toward the interior of the connecting seat. The submerged electric pump for the well has the advantages of great bearing capacity, high efficiency and low production cost.

Owner:TAIZHOU YONGXIN PUMP IND

Thrust plate assembly for turbo compressor

PendingCN109209983ANot easy to looseGuaranteed stabilityPump componentsPumpsDISC assemblyRetaining ring

The present invention relates to a turbo compressor, and more particularly to a thrust plate assembly for a turbo compressor. The thrust disk assembly comprises a thrust plate and a rotating shaft, wherein the rotating shaft is a stepped shaft including a first stepped shaft, a second stepped shaft, and a third stepped shaft and a fourth stepped shaft. The thrust plate includes a main thrust plateand a secondary thrust plate, wherein the auxiliary thrust plate is located on the second stepped shaft, and the auxiliary thrust plate is integrally formed with the rotating shaft; the main thrust plate is located on the third stepped shaft and fixed with the rotating shaft through a screw, the third stepped shaft is further provided with a positioning collar, an annular retaining ring abuttingagainst the positioning collar, and the fourth stepped shaft is sleeved with a bearing. The thrust disc assembly can effectively solve the problem that the thrust plate is easy to wear and loose in the prior art. The assembly efficiency of a thrust plate assembly is improved, and the service life of the thrust plate assembly is prolonged.

Owner:四川聚亿重工有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com