Auxiliary device for controlling one-way transmission of gear train structures

A technology of one-way transmission and auxiliary devices, which is applied in the direction of one-way clutches, clutches, mechanical equipment, etc., can solve the problems of lack of transmission direction control devices, etc., achieve strong practical value and application prospects, high reliability, and reduce working noise Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

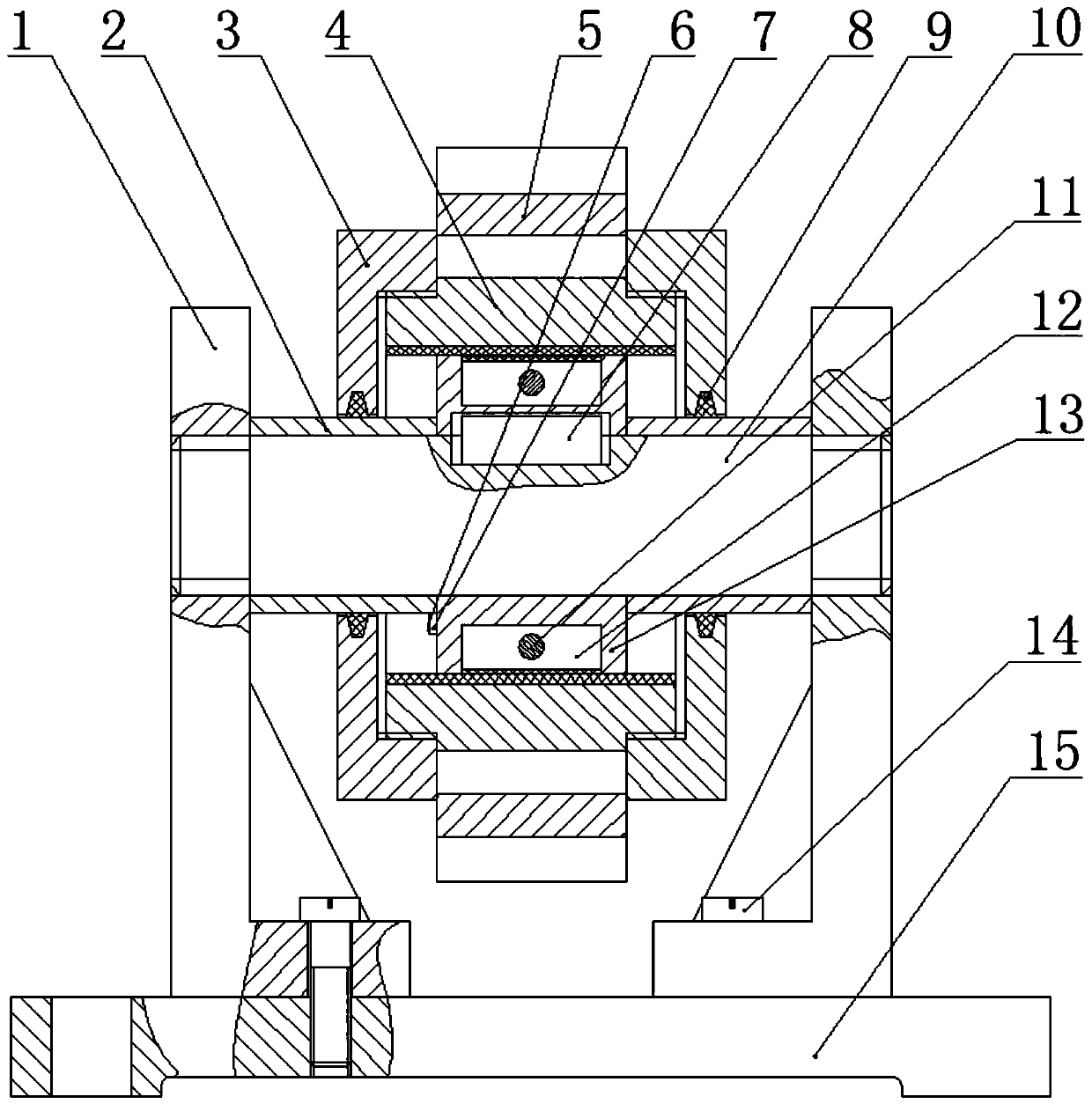

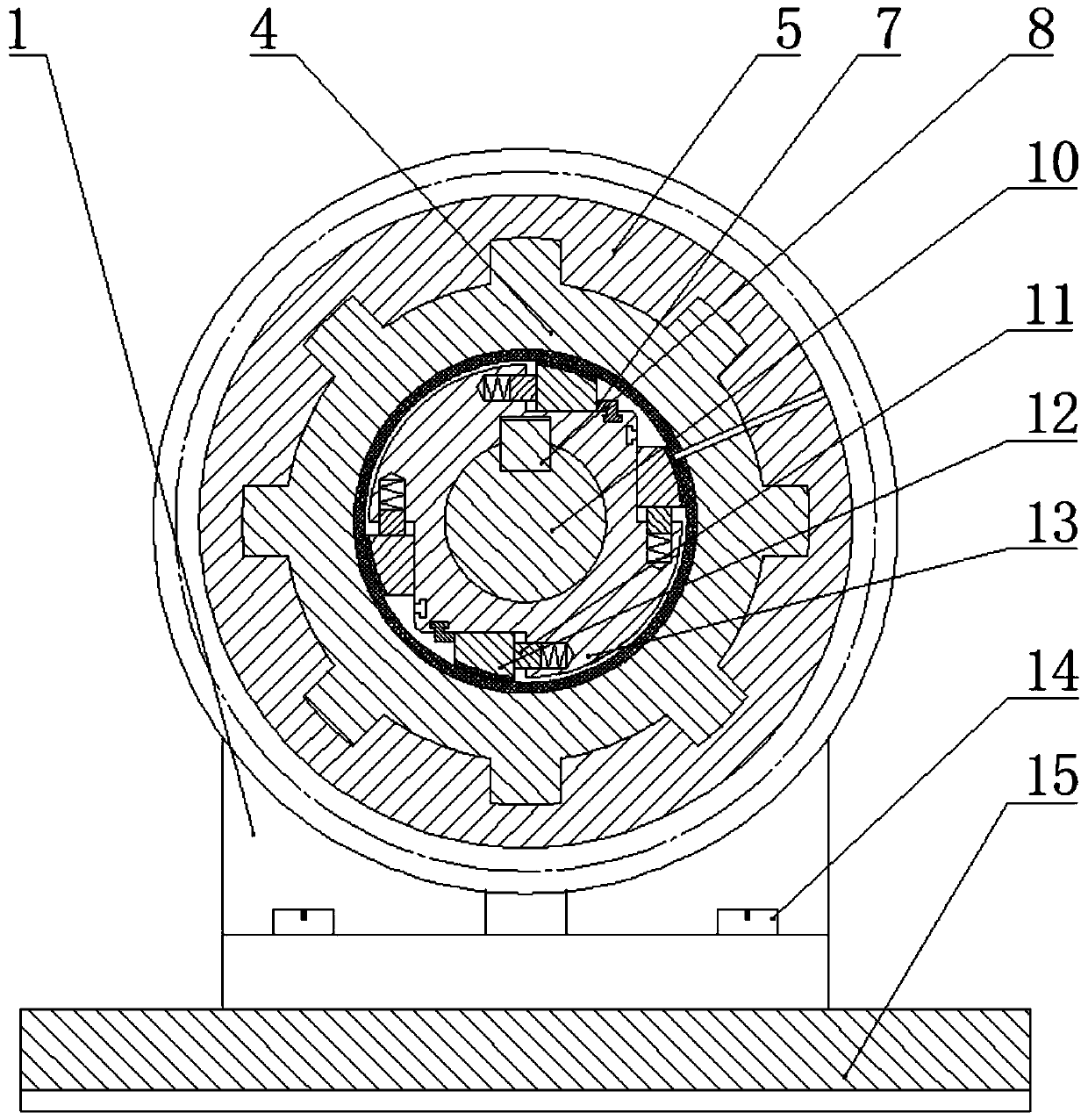

[0034] Please refer to figure 1 and figure 2 , the present embodiment provides an auxiliary device for controlling the one-way transmission of the gear train structure 5, which includes: a fixed base 15, a side vertical plate 1, a positioning sleeve 2, a sealing cover 3, a spline sleeve 4, a gear train Structure 5, slider 7, shaft 10, spring ejector rod 11, friction member 12, star wheel 13, set screw 6, flat key 8, sealing ring 9 and slotted screw 14, fixed base 15 is fixed on the existing On the device platform, the side vertical plate 1 is connected to the fixed base 15 through the slotted screw 14, and there are two sealing covers 3, which are respectively connected with the spline sleeve 4 to realize sealing. Or the ring-shaped structure of the pulley, the wheel train structure 5 and the spline sleeve 4 are connected through the set spline structure, the star wheel 13 is axially positioned through the positioning sleeve 2, and the slider 7 is in the T-shaped groove of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com