Split combined type outer casing of engine oil filter

A kind of oil filter, split type technology, applied in the installation/connection of lubricant purification device, lubricating parts, pressure lubricant, etc., can solve the problems such as the inability to complete the core replacement work, and achieve simple structure, reliable operation, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

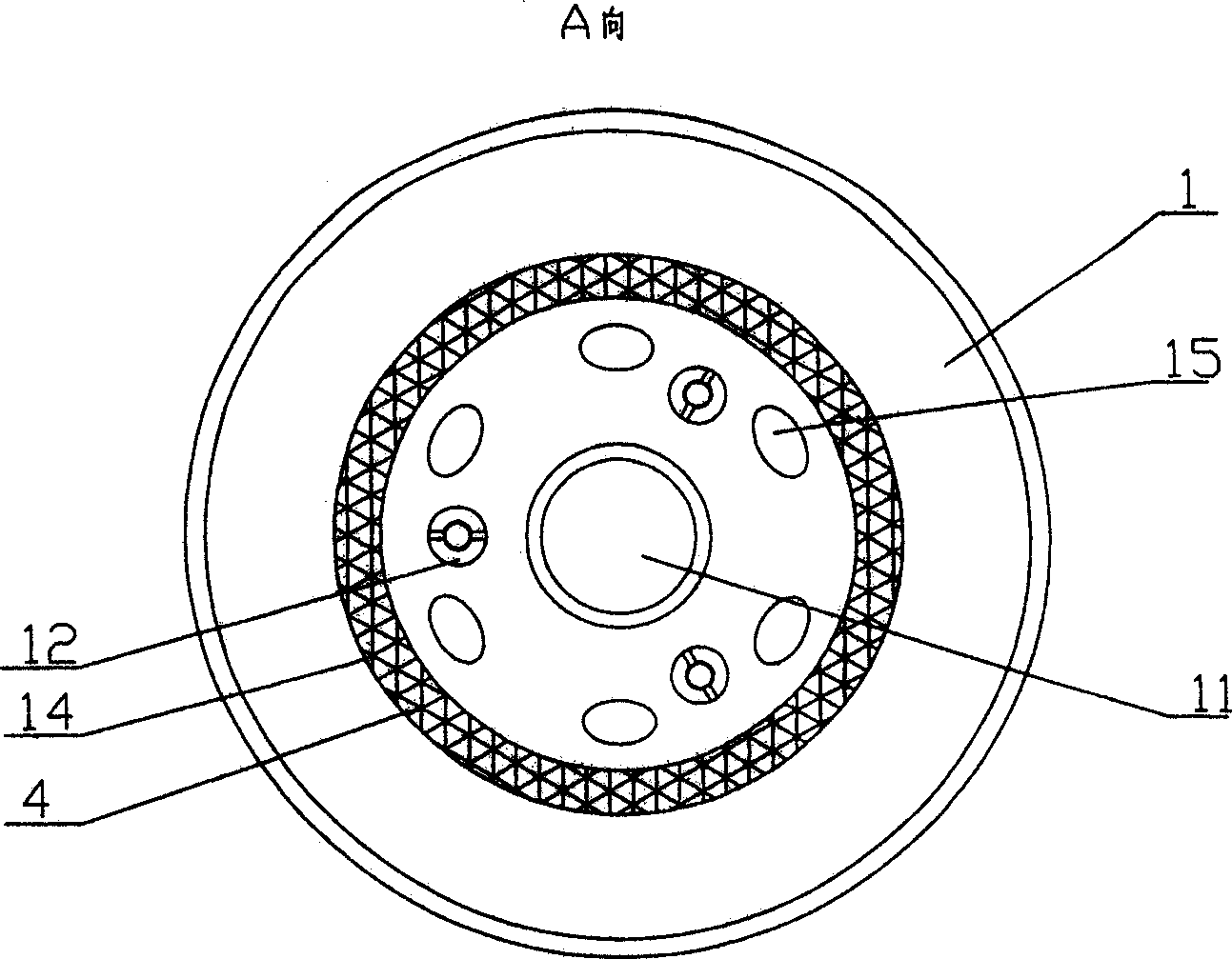

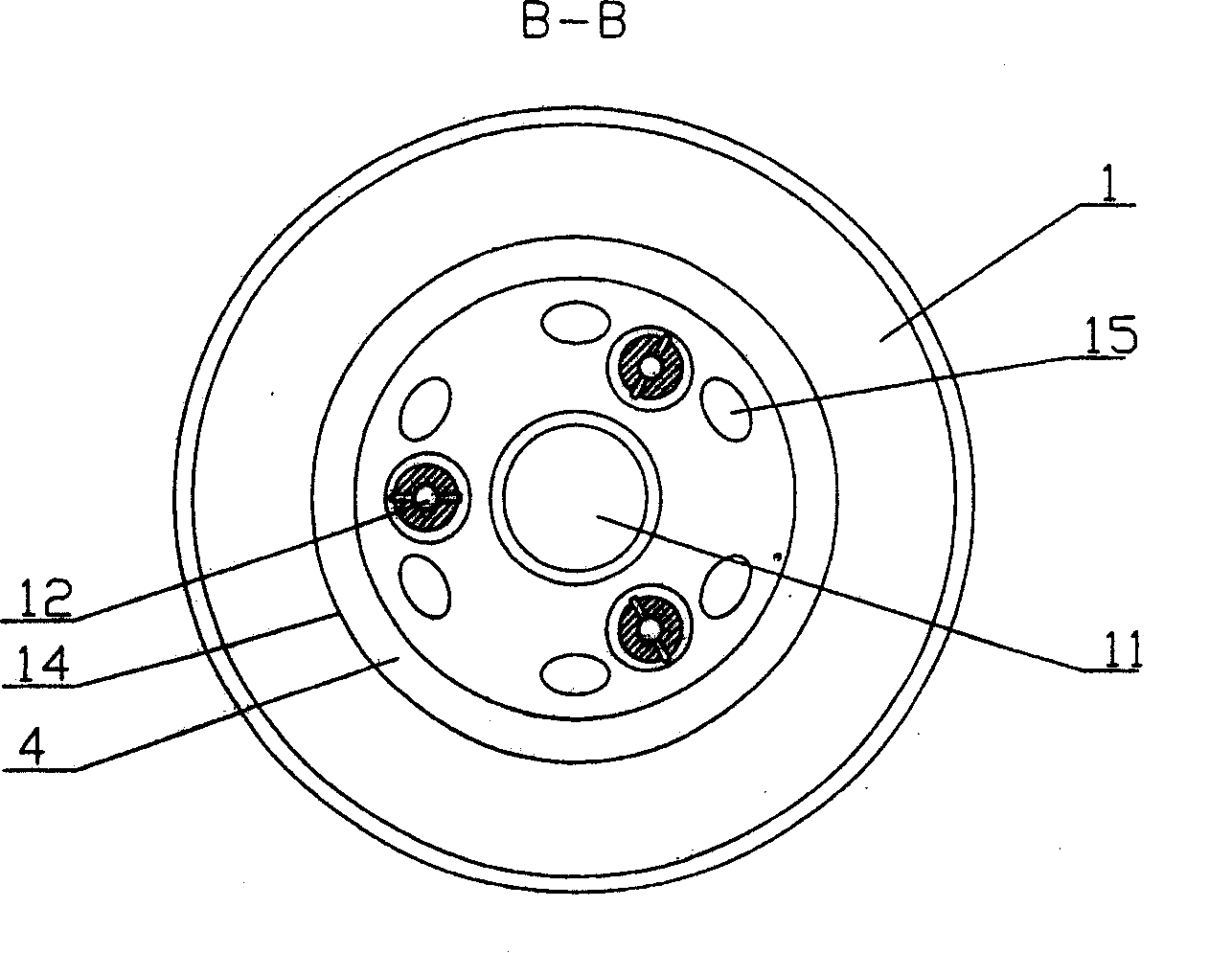

[0014] Preferred embodiments of the present invention will be specifically described below in conjunction with the accompanying drawings.

[0015] Such as figure 1 and figure 2 As shown, the present embodiment comprises an upper bowl (1) and a lower bowl (2) connected by the housing, and the upper bowl (1) passes through the central hole of the radiator and the oil outlet pipe of the oil base of the Audi car through the nut (3) threaded connection, the outer surface of the periphery of the oil outlet (11) on the upper bowl (1) is provided with a tapered cylinder for radial rotation between the upper bowl (1) and the Audi engine oil base radiator Body convex structure (12), the center of the tapered cylinder convex structure is provided with a round hole with a tip, and the two sides of the hole are provided with shallow openings. The protrusions fit together.

[0016] The central hole of the conical cylinder protrusion structure (12) is adapted to the specific structure of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com