Multi-reverse granular mineral crusher

A crusher and particle technology, applied in grain processing and other directions, can solve the problems of unfavorable environmental protection, high noise and high energy consumption, and achieve the effects of increasing service life, improving work efficiency and improving reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

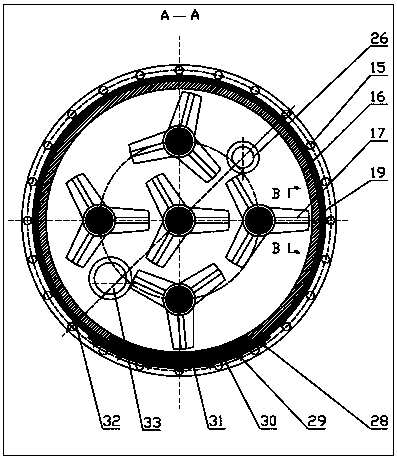

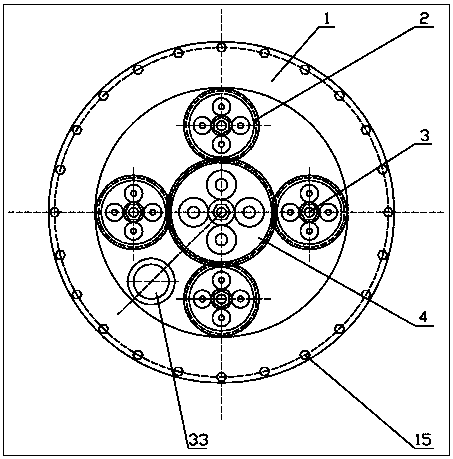

[0056] 1. Multiple reverse particle mineral crusher, characterized in that it includes: upper bearing box 1.1, lower bearing box 1.2, driven gear 2, driven transmission shaft 3, driving gear 4, driving transmission shaft 5, gear compression nut 6. Gear compression cover 7, upper tapered roller bearing 8.1, lower tapered roller bearing 8.2, bearing seat through cover 9, sealing packing 11, bearing seat cover mounting nut 12, cylinder gasket 14, box mounting bolt 15 , Pulverizer barrel 16, sanding blade 17, blade axial positioning sleeve 18, wear-resistant lining 19, wear-resistant lining end plate 20, rib plate 22, bearing seat cover 24, discharge port 26 , Inspection door installation bolt 28, inspection door wear-resistant lining board installation bolt 29, inspection door wear-resistant lining board 30, inspection door 31, bolt assembly 32, material inlet 33;

[0057] The pulverizer cylinder 16 is a cylindrical cylinder, the upper part of the pulverizer cylinder 16 is equipp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com