Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

61results about How to "Not prone to deviation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

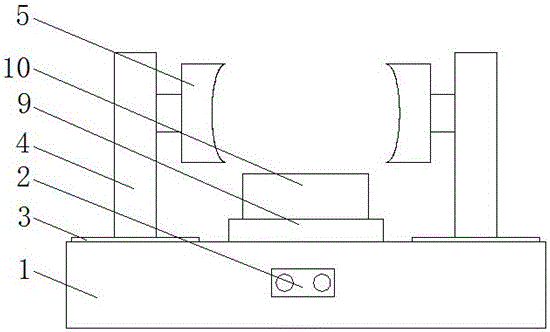

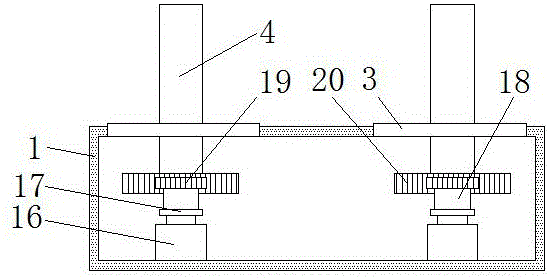

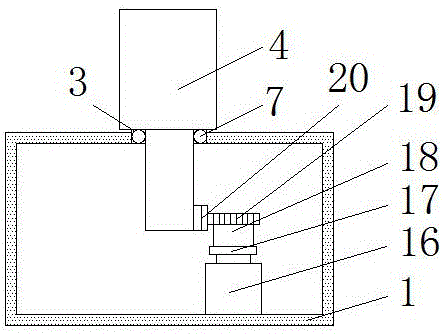

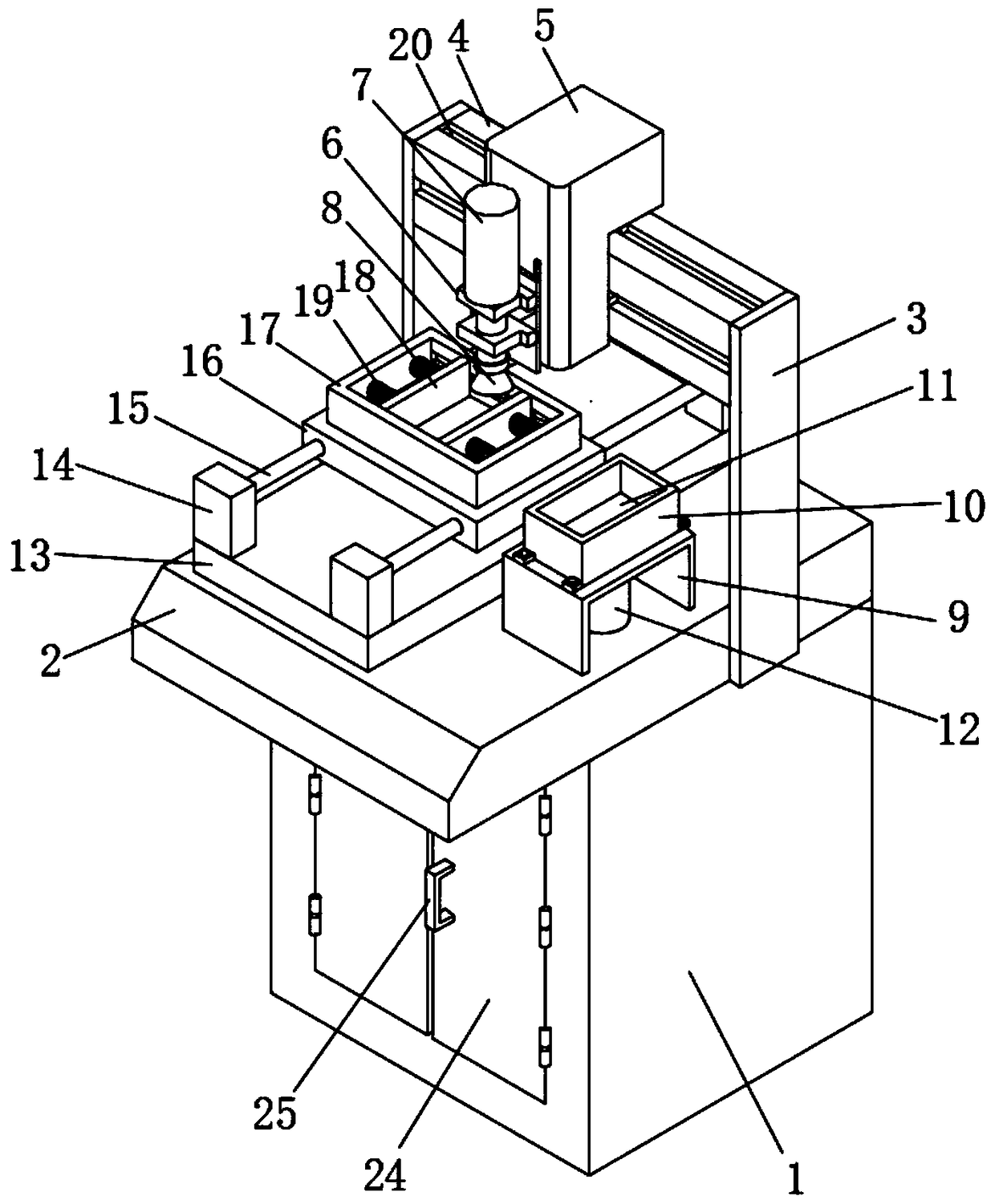

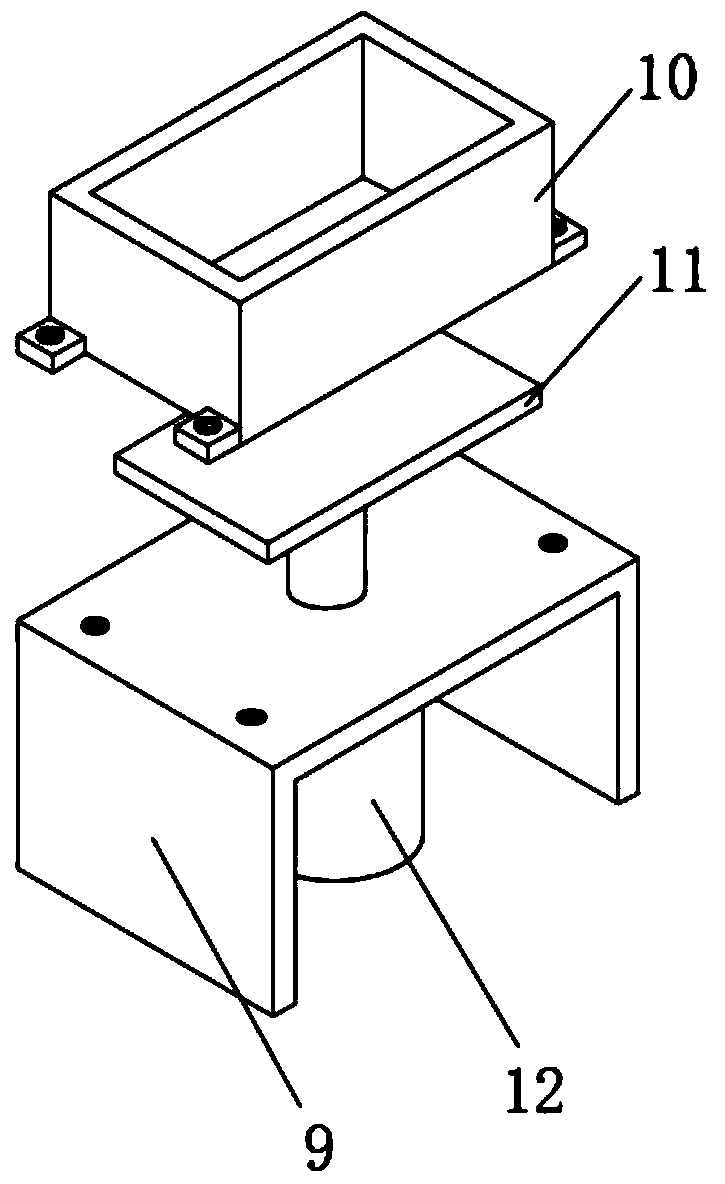

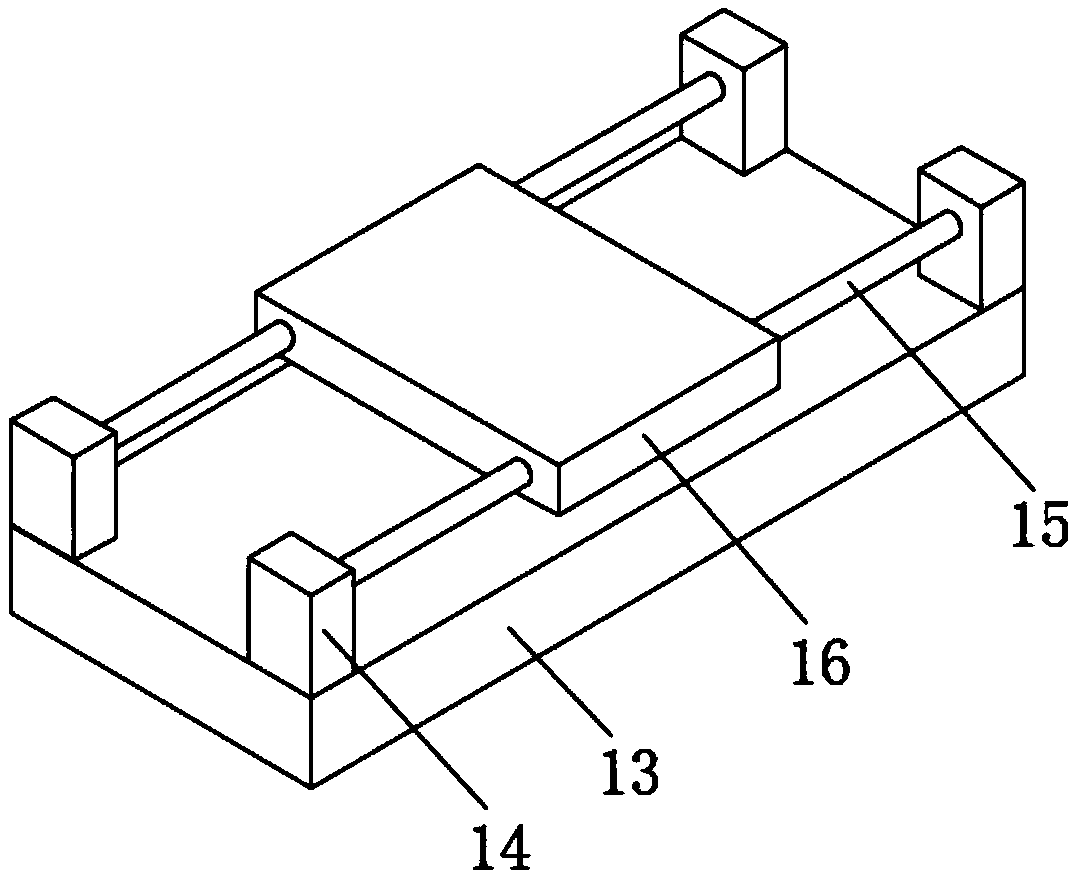

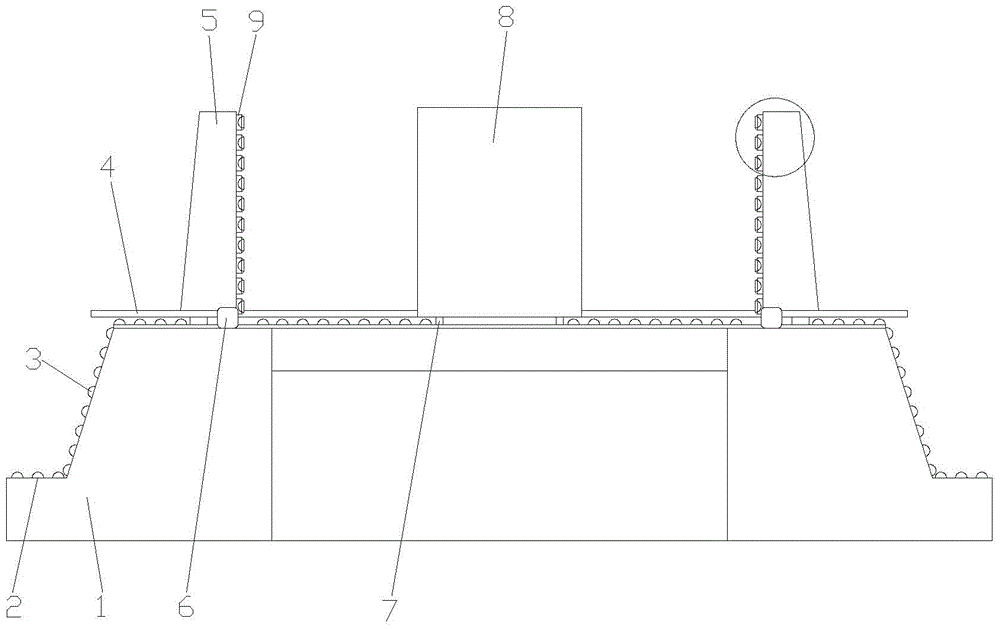

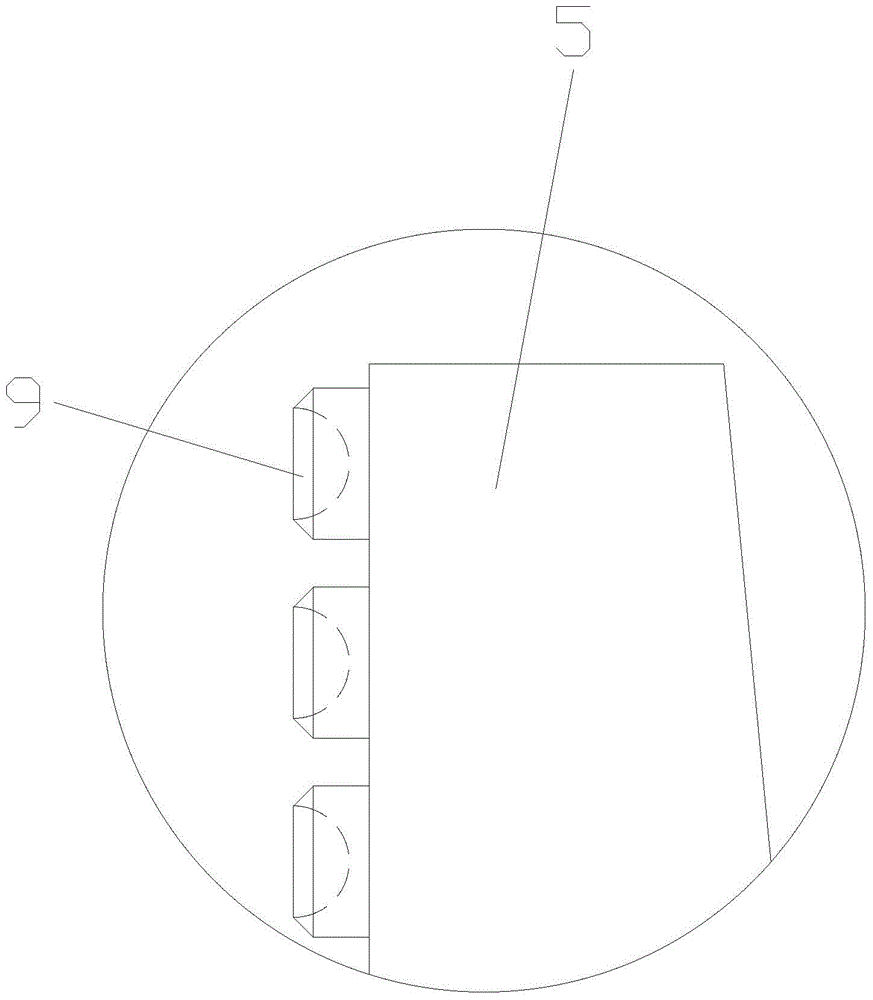

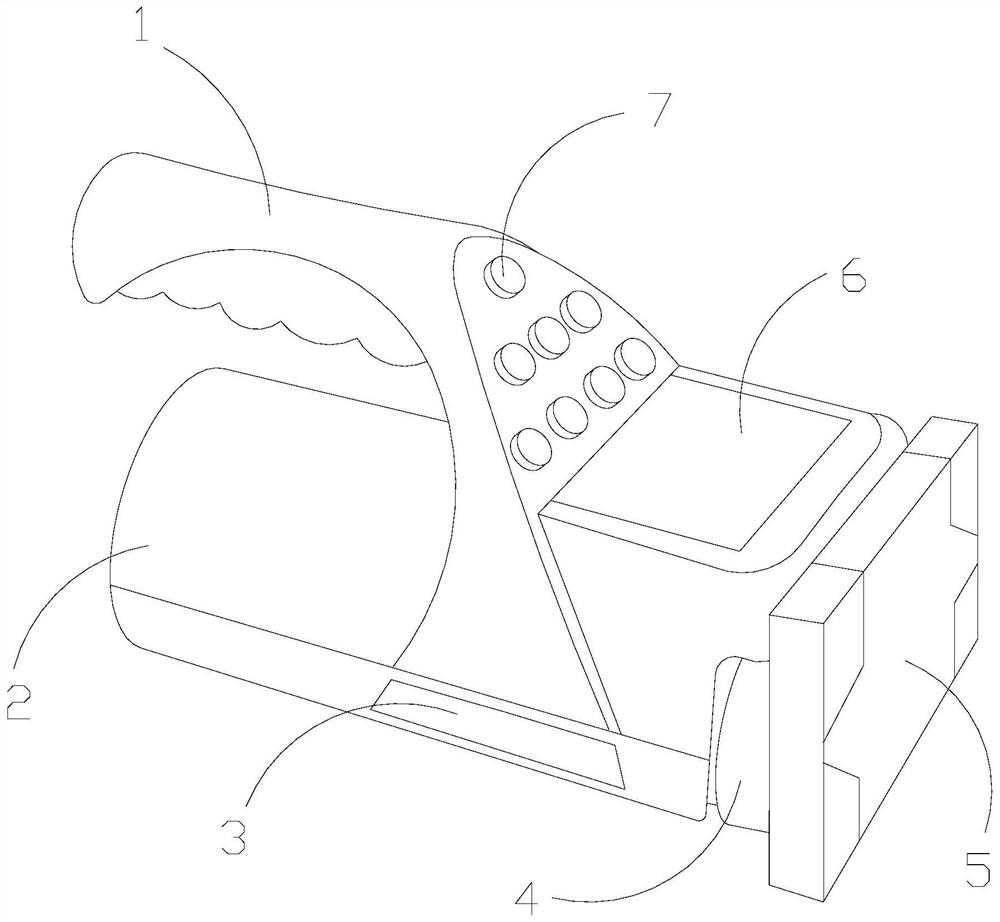

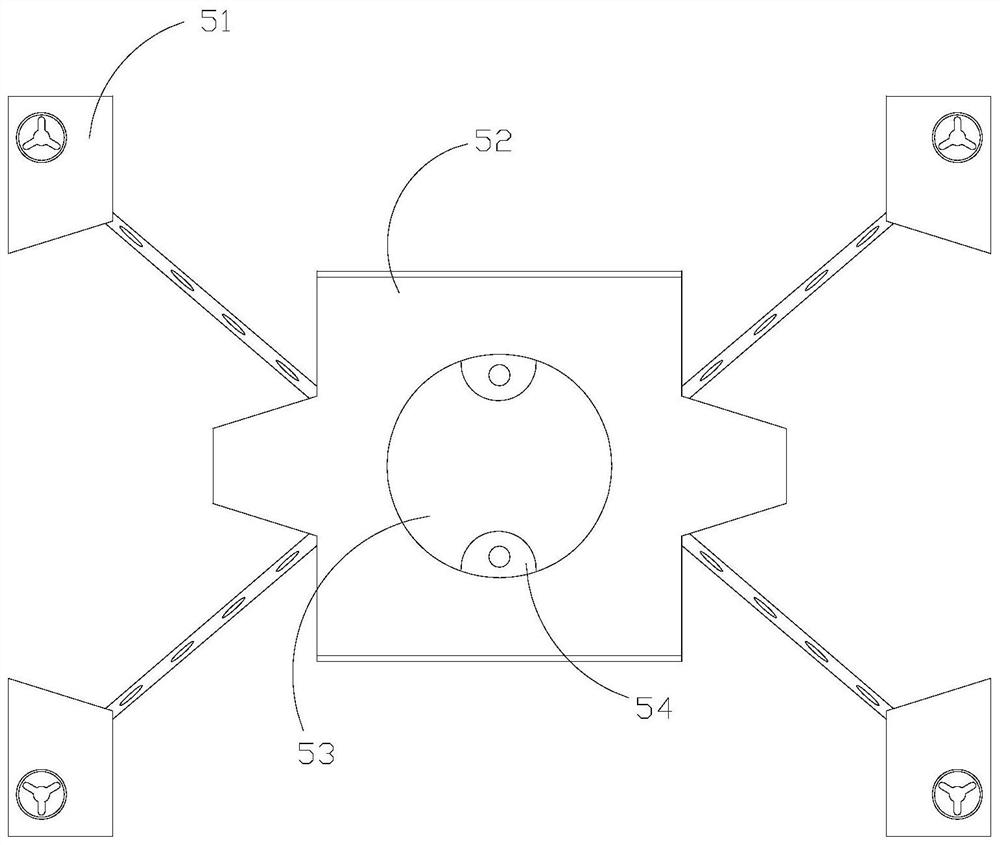

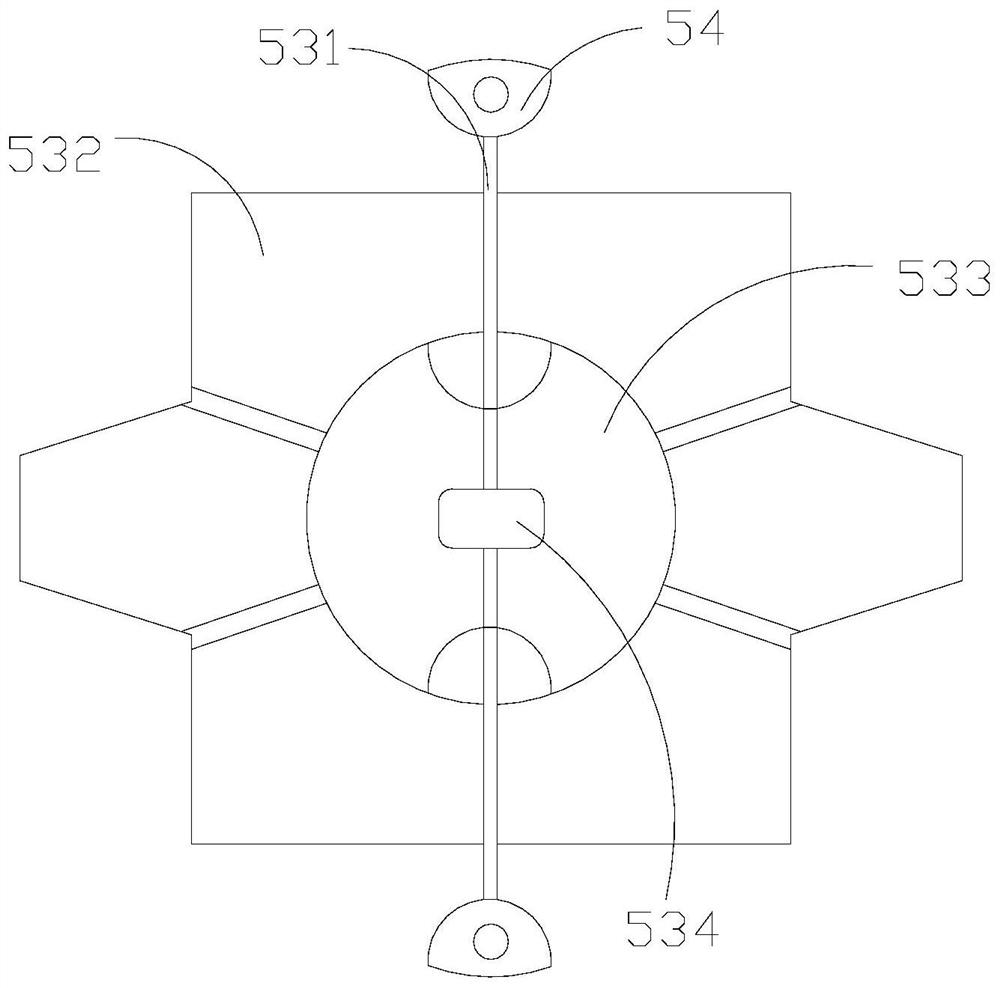

Hardware processing and clamping device

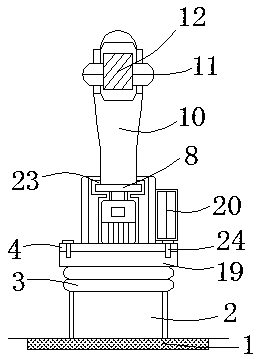

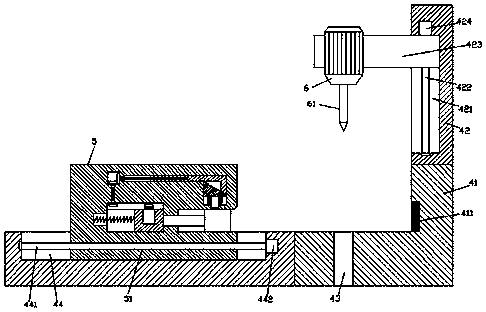

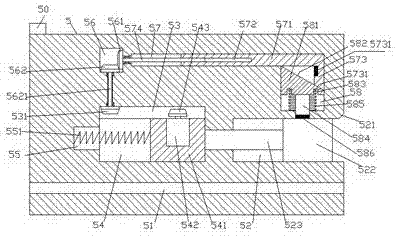

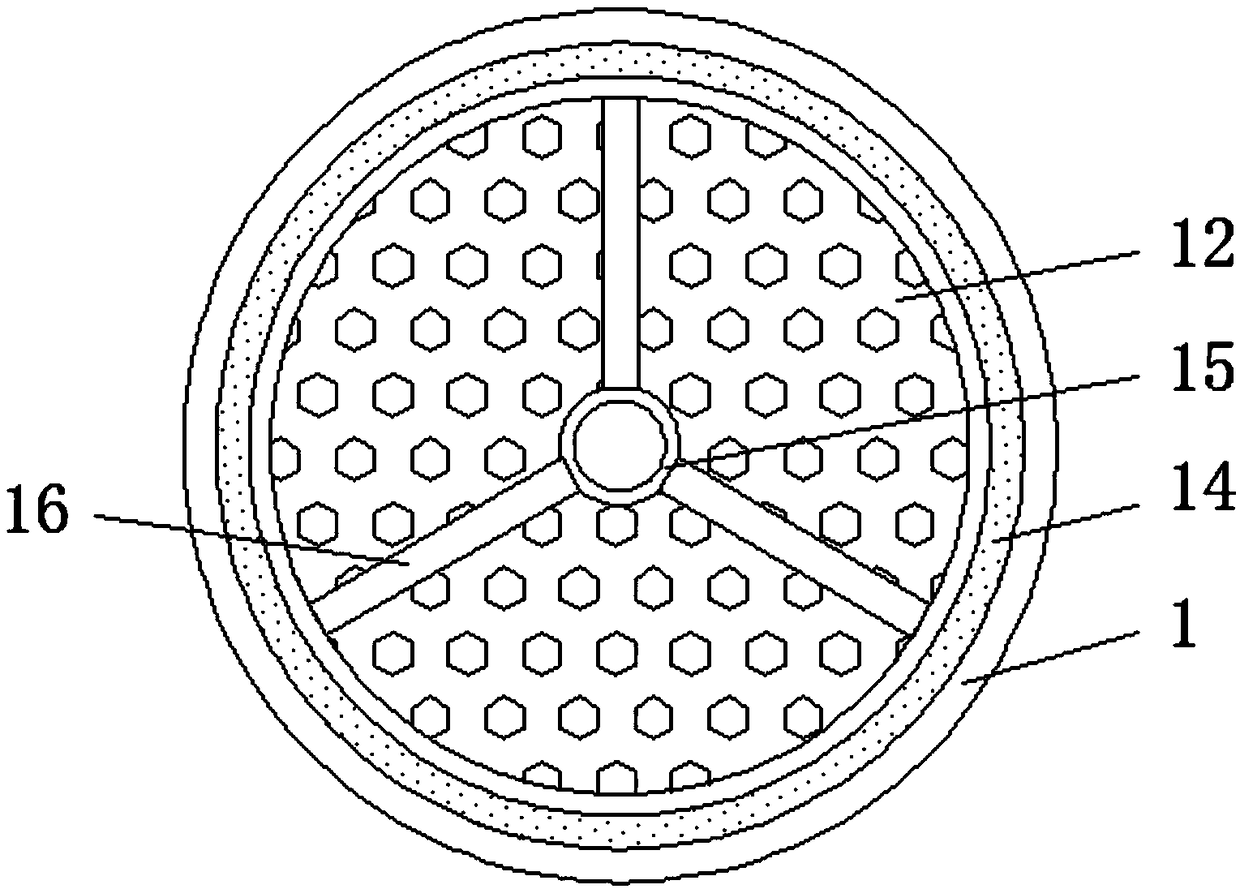

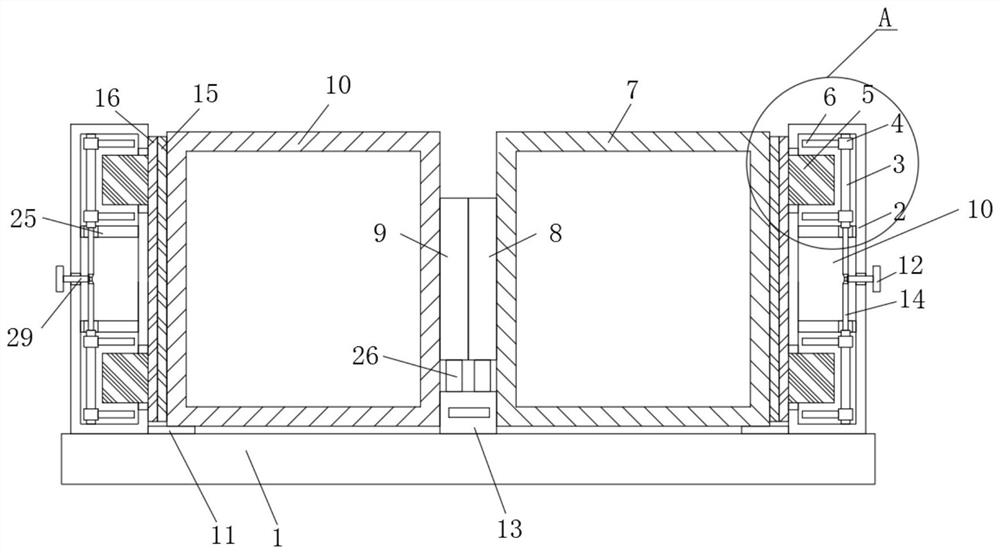

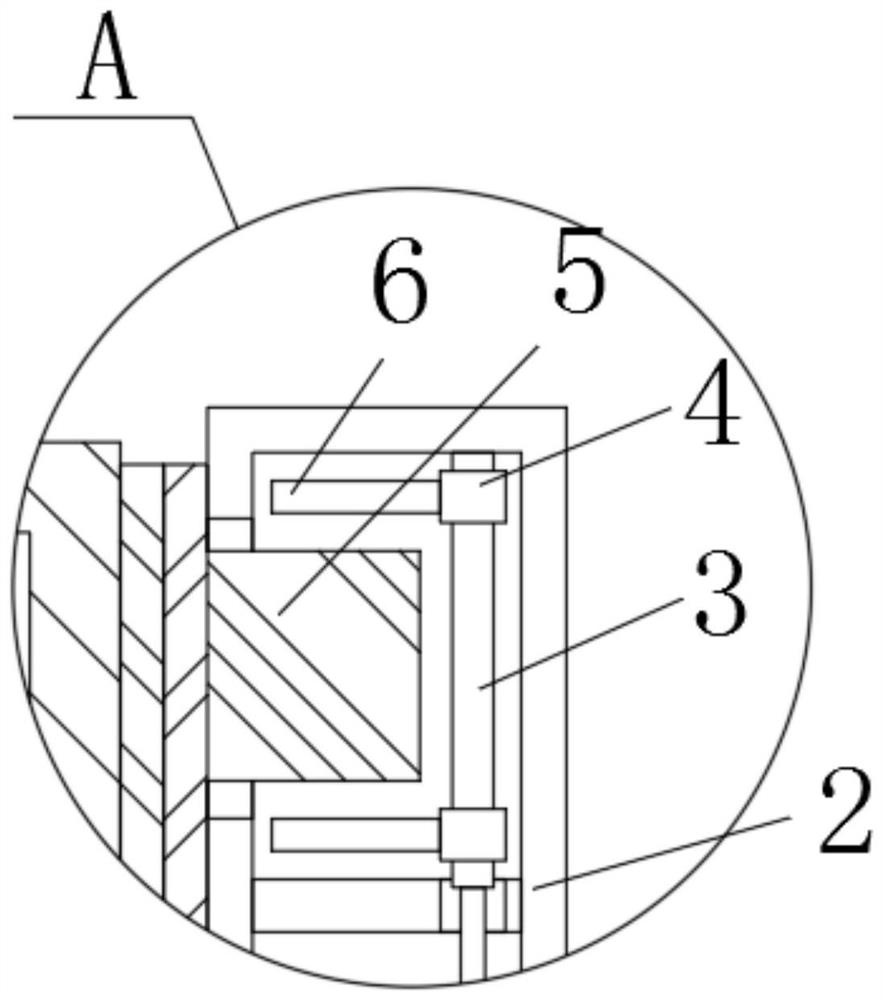

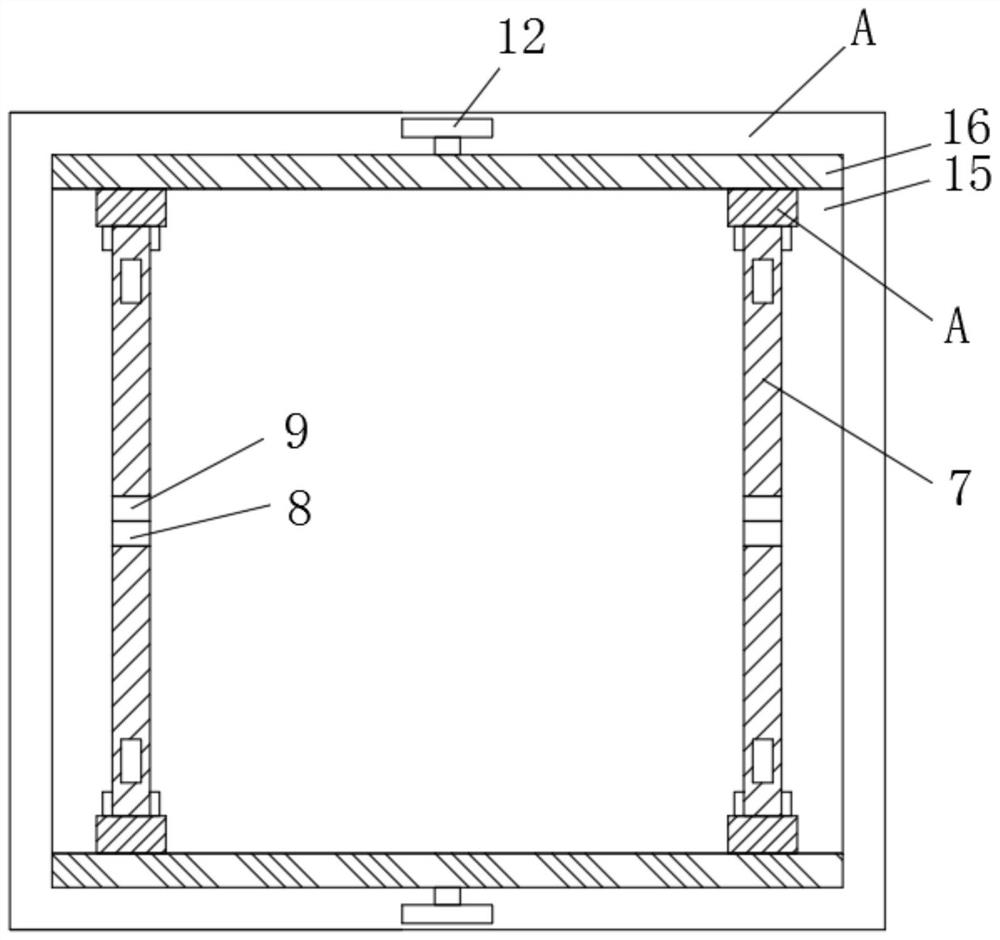

The invention discloses a hardware processing and clamping device. The hardware processing and clamping device comprises a base, wherein a controller is arranged on the front surface of the base; slide chutes are embedded into two sides of the top part of the base; a support plate is arranged at the top part of each slide chute, passes through the corresponding slide chute and extends to the inside of the base; a clamping plate is arranged at the inner side of the support plate; a buffer spring is arranged in the clamping plate; balls are arranged at two sides in each slide chute, and are partitioned by a limiting block; a damping device is also arranged at the top part of the base; and a worktable is arranged at the top part of the damping device. By the hardware processing and clamping device, when a hardware part is processed, the support plate can move left and right through the arranged slide chutes; the size of a clamp can be changed; the hardware processing and clamping device can be suitable for processing of most hardware parts; the cost is reduced; the work efficiency is improved; the worktable is in a stable state through the arranged damping device; the condition that the hardware part does not easily deviate in the machining process is ensured; and the machining quality is improved.

Owner:CHANGZHOU JINHAILONG MACHINE MFG

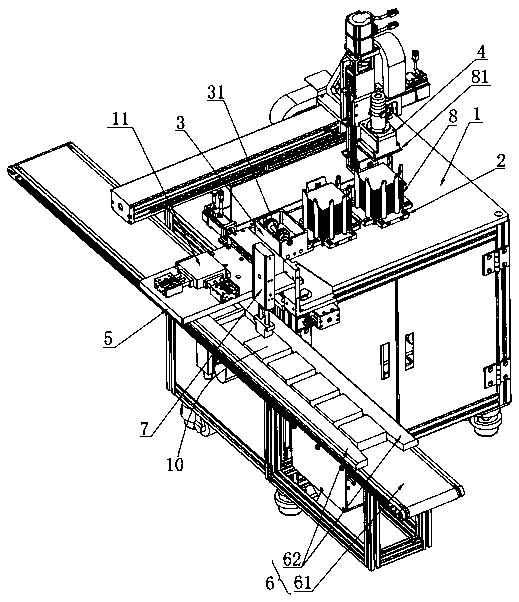

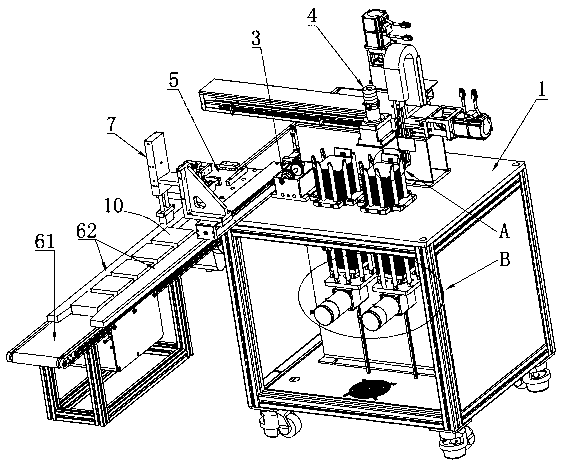

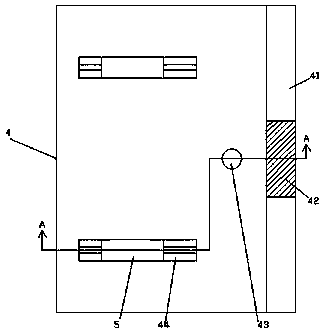

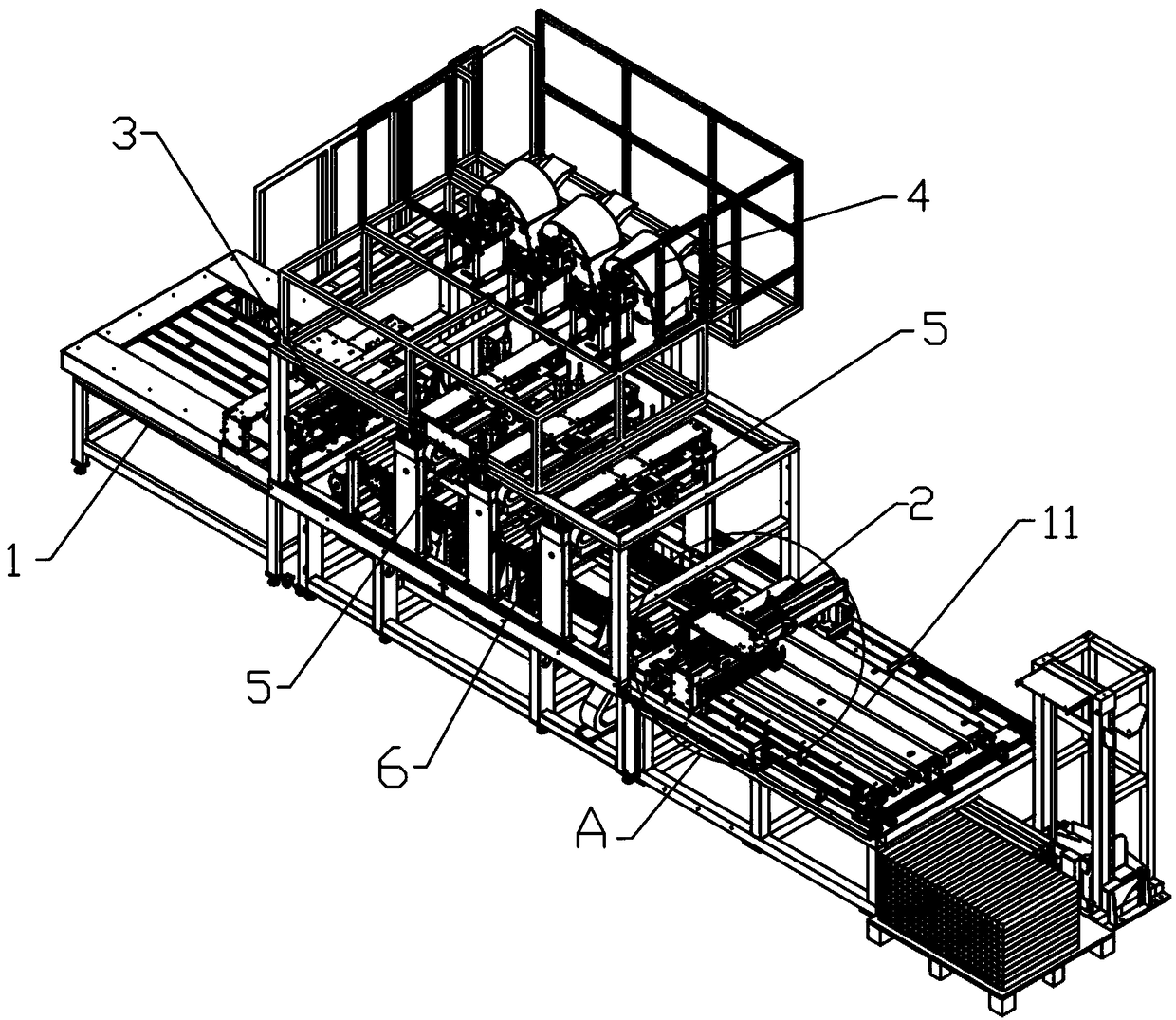

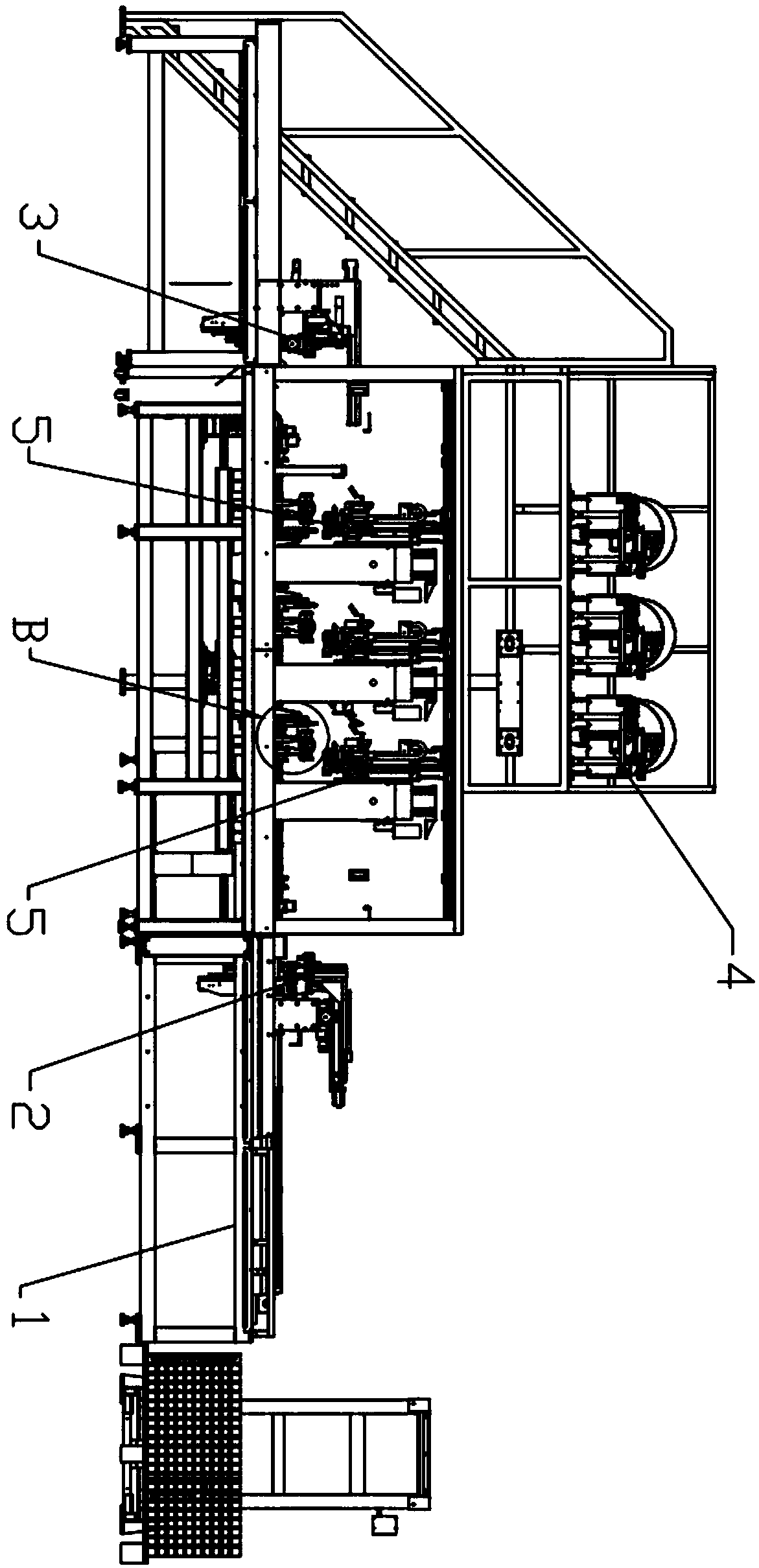

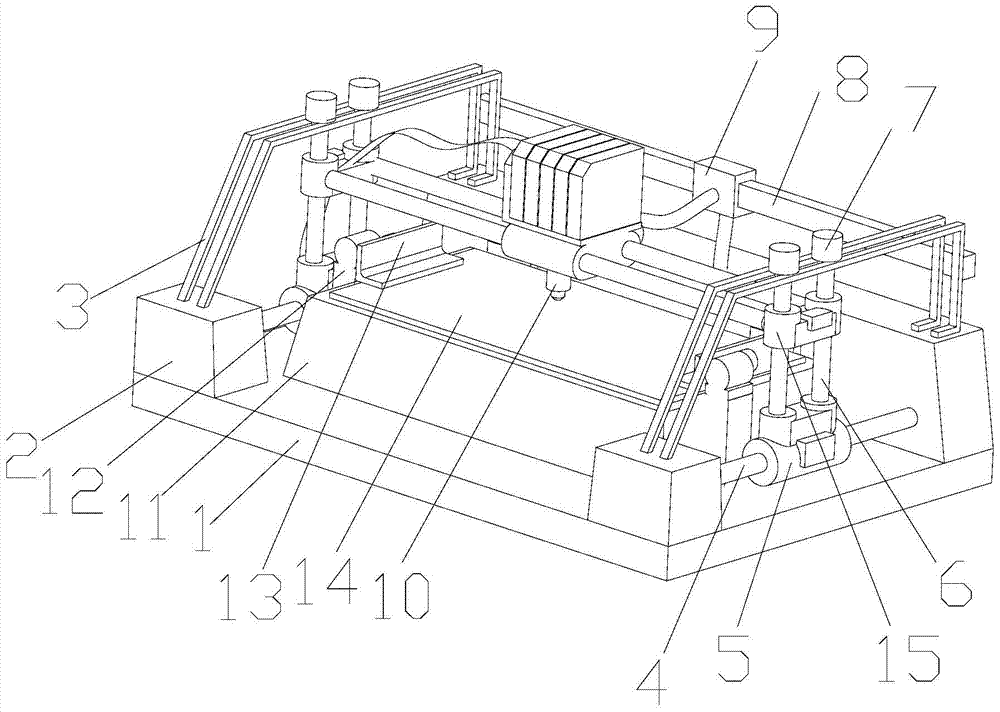

Automatic folding and gluing apparatus for packing boxes

PendingCN105500772AReduce labor costsQuality improvementPaper-makingBox making operationsManipulatorPackaging Case

The invention relates to the technical field of packing equipment, in particular to an automatic folding and gluing apparatus for packing boxes, comprising a frame, a feeding device, a transfer manipulator, a glue box, a packing table, a feeding manipulator and a conveyer, the feeding device comprises a bottom plate, a plurality of fences and a lifting mechanism, the lifting mechanism comprises a lifting motor, a lifting bar and a lifting plate, the top end of the lifting bar is fixed to the lifting plate, top stickers are neatly stacked on the lifting plate, the lifting bar is connected with the lifting motor, the limiting motor can drive the lifting bar to move up, the lifting bar drives the lifting plate to move up, and thus the top stickers stacked on the lifting plate are lifted. A whole folding and gluing process is automated without manual operation, saving labor cost; the transfer manipulator sticks the top stickers to packing boxes with rarity of error occurrence, ensuring that the top stickers are stuck to same positions on each packing box and improving sticking quality of the top stickers.

Owner:DONGGUAN HUAZHI COLOR PRINTING PACKAGING CO LTD

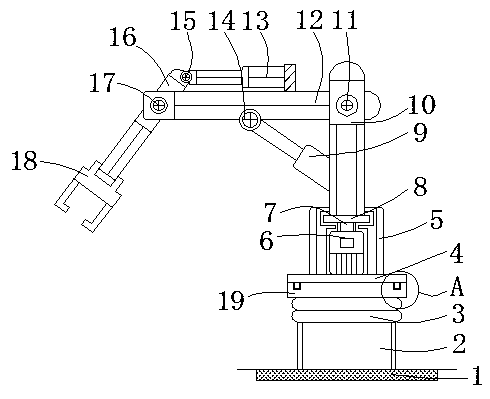

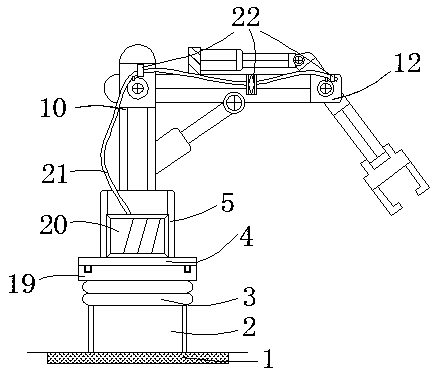

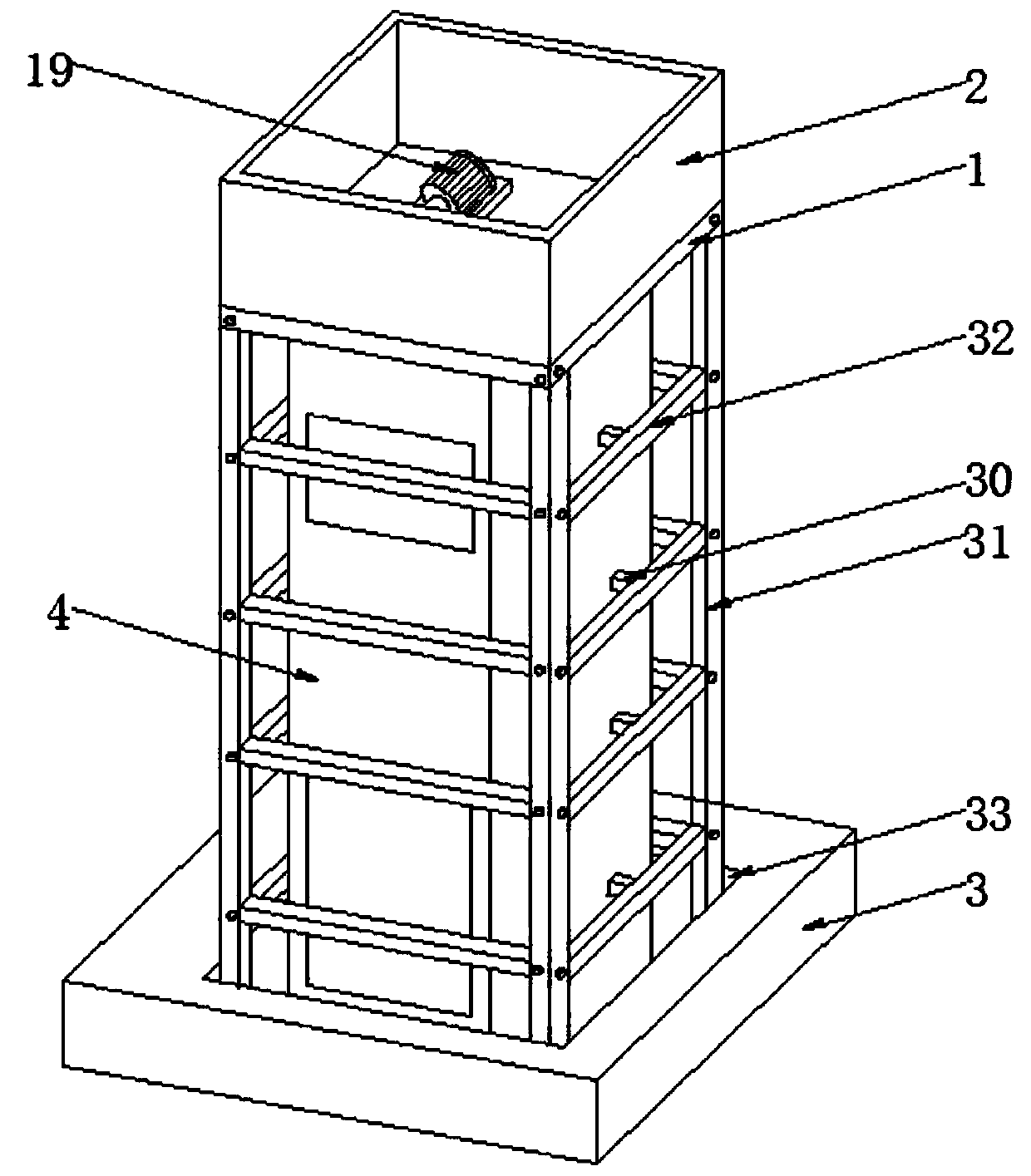

Lifting manipulator providing convenience for multi-directional fixation for gear processing

InactiveCN109227204AEasy to fix in multiple directionsImprove processing efficiencyProgramme-controlled manipulatorMetal working apparatusManipulatorMachine tool

The invention discloses a lifting manipulator providing convenience for multi-directional fixation for gear processing, and relates to the technical field of gear production. The lifting manipulator comprises a machine tool board and an operation box, wherein the top of the machine tool board is provided with a base, the operation box is arranged above the base, the base is connected to the machine tool board through screws, and the top end of the base is connected with a spring piece. The lifting manipulator providing convenience for the multi-directional fixation for gear processing has theadvantages that a clamping block, a clamping groove, a supporting plate and a supporting frame are arranged, and the outer side of the clamping block fits the inner wall of the clamping groove, so that when a device needs to be connected and fixed, the clamping block at the bottom of a bottom plate is inserted into the clamping groove to prefix the device; the multi-directional fixation is carriedout from the two sides of the top ends of the bottom plate and supporting plate through bolts, so that the stability of the device is improved when auxiliary operation is performed on gear processing, a traditional integrated welding method is replaced, and the difficult maintenance phenomenon is avoided.

Owner:DONGGUAN UNIV OF TECH

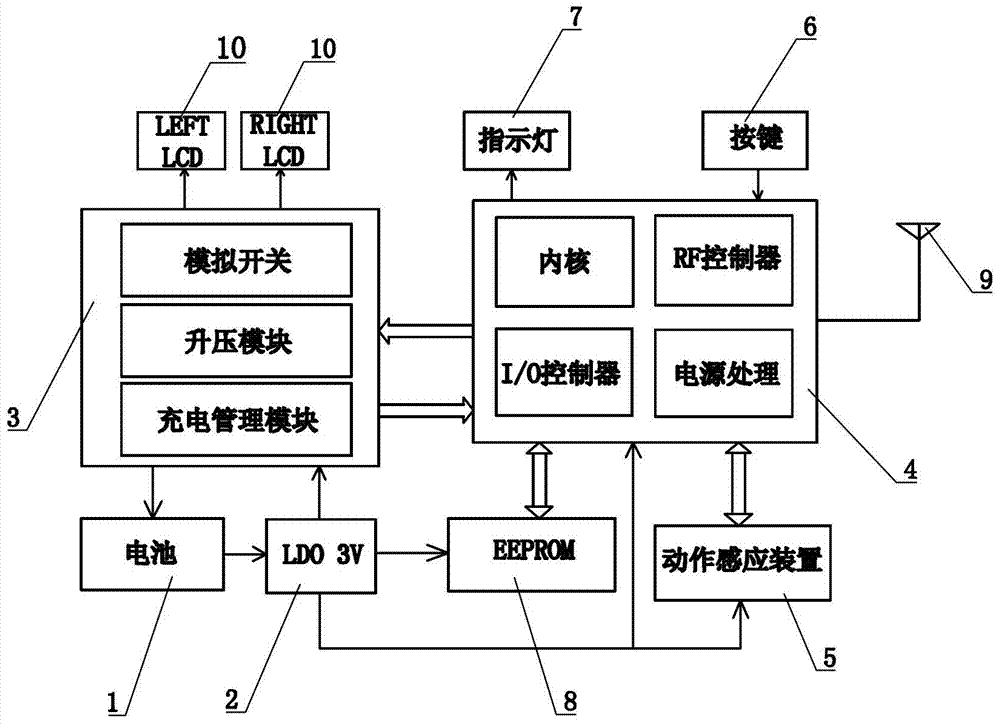

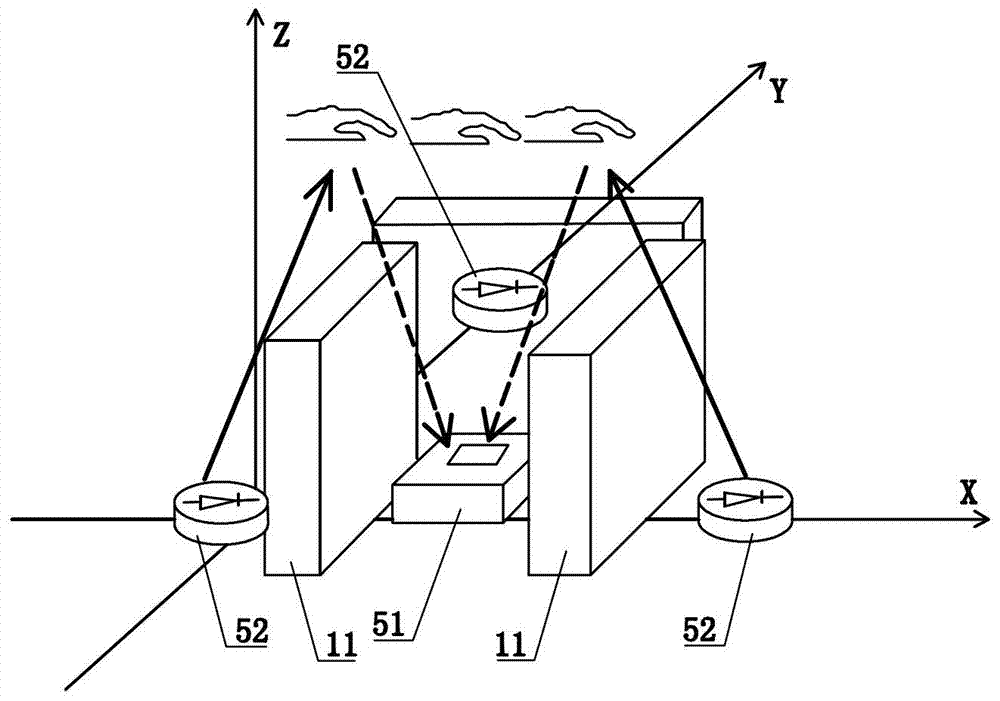

3D spectacles with gesture control function and gesture control method thereof

ActiveCN103246070AAvoid unclearPrevent the situationSelective content distributionSteroscopic systemsControl systemRadio frequency signal

The invention discloses a pair of 3D spectacles with the gesture control function, which includes a spectacle frame, eyeglasses and a battery, as well as a gesture control system arranged on the spectacle frame, wherein the gesture control system includes a pressure-stabilizing chip, an action induction device and a master controller; the pressure-stabilizing chip is electrically connected with the battery, and is used for providing a stable direct-current main; the action induction device is used for inducting gesture action of an operator, and converting the action into an electrical signal, and sending the electrical signal to the master controller; the master controller is electrically connected with the action induction device; the master controller is in wireless communication connection with a terminal of projection equipment, and is used for receiving an electric signal sent by the action induction device, processing the electric signal into a radio-frequency signal, and transferring the radio-frequency signal to the terminal of the projection equipment in a wireless manner. The invention further discloses a gesture control method for a pair of 3D spectacles. The pair of 3D spectacles with the gesture control function and the gesture control method for the pair of 3D spectacles, provided by the invention, enable gesture action induction to be clear when gesture control is performed to the projection equipment, and enable deviation to be scarcely caused.

Owner:QINGDAO GOERTEK

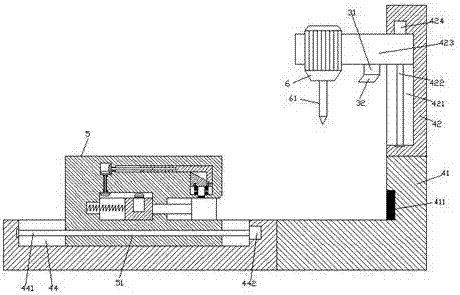

Adjustable plate perforating device

InactiveCN107696174ARealize automatic controlAchieve horizontal lockDrilling machinesWorking accessoriesElectric machineryEngineering

The invention discloses an adjustable plate perforating device. The adjustable plate perforating device comprises a machine body, wherein first sliding grooves are symmetrically formed in the end surfaces of the front top and rear top of the machine body; the interior of each first sliding groove is connected to a clamping mechanism with the top sticking out of the end surface of the top of the machine body in a sliding fit manner; a first screw hole which extends left and right is formed in the clamping mechanism located in the first sliding groove; a first sliding cavity is formed in the clamping mechanism above the first screw hole; a first transmission cavity is formed in the top of the first sliding cavity in a connection manner; the interior of the first sliding cavity is in slip connection with a sliding block; a clamping sliding groove is formed in the end surface of the right side of the clamping mechanism located at the right side of the first sliding cavity; the interior ofthe clamping sliding groove is in slip connection with a push block; a locking motor is fixedly arranged in the end surface of the top of the sliding bock; the top of the locking motor is connected toa first conical wheel extending to the interior of the first transmission cavity in a matching manner; and a second transmission cavity is arranged in the clamping mechanism located above the left side of the first transmission cavity. The adjustable plate perforating device is simple in structure, time-saving and labor-saving, is less likely to cause a deviation and improves production efficiency.

Owner:南宁市博腾安防科技有限公司

Three-dimensional printing method with arrangement of reference point

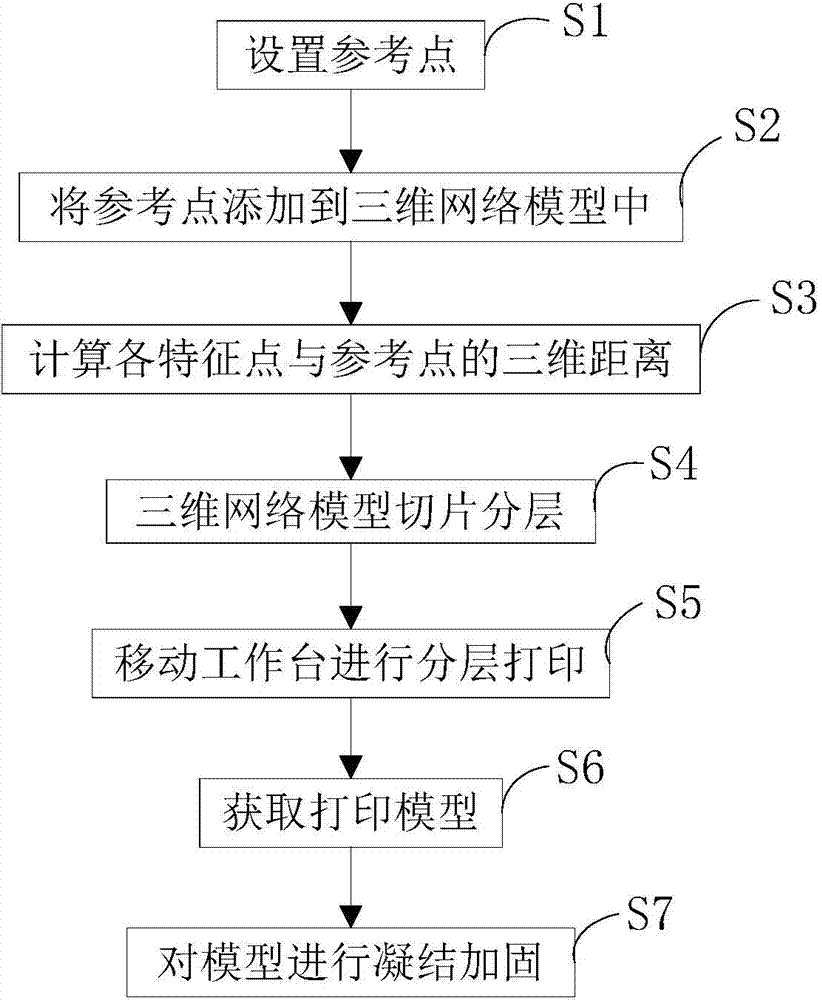

InactiveCN104290324AImprove pass rateGood for controlling printing accuracyNetwork modelComputer science

The invention brings forward a three-dimensional printing method with the arrangement of a reference point. A print head operates in a static state, and a workbench carries out three-dimensional motion and can rotate. Specific work steps are as follows: selecting a point which always remains motionless relative to the workbench as a reference point; adding the reference point into a three-dimensional network model; computing three-dimensional distance from each feature point in the three-dimensional network model to the reference point; slicing the three-dimensional network model for layering and acquiring molding information at each layer; moving the workbench to adjust relative position between the workbench and the print head, and carrying out layered printing; and acquiring a printing model. The invention brings forward the three-dimensional printing method with the arrangement of a reference point. By the method, printing deviation can effectively be reduced and printing precision and efficiency can be raised.

Owner:HEFEI SKE INTELLIGENT TECH

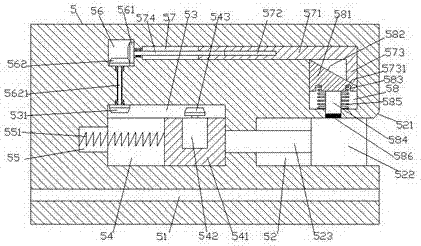

Auxiliary device for printer

InactiveCN105437552AAffect qualityEasy to printAdditive manufacturing apparatusDrive shaftEngineering

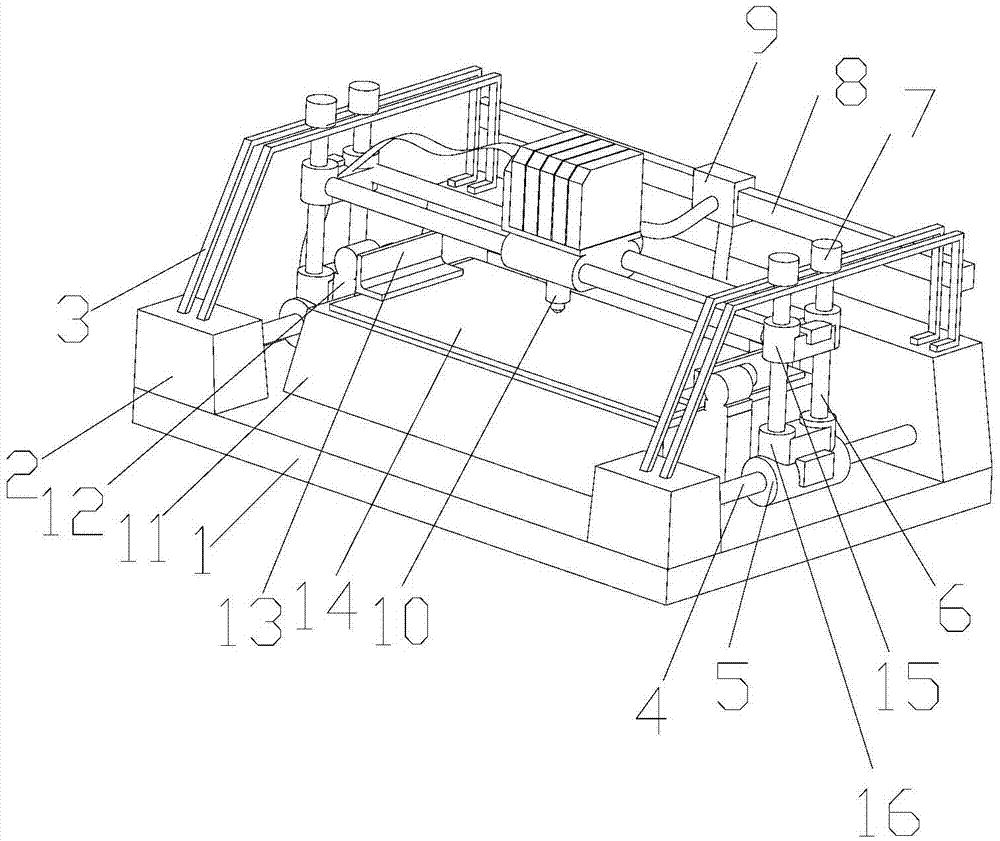

The invention discloses an auxiliary device for a printer. The auxiliary device for the printer comprises a baseplate, a material change mechanism, a fixing mechanism, a support mechanism, multiple cross bars, and printing mechanisms on the multiple cross bars; the material change mechanism includes a material change base fixedly connected to the baseplate, driving devices fixedly connected to the two ends of the material change base, connecting blocks rotationally connected to driving shafts of the driving devices, and material change plates detachably connected to the connecting blocks; when the driving shafts of the driving devices rotate, the material change plates can rotate; printing heads are towards the material change plates; a support base includes lantern rings slidingly sleeved on the support rods, and multiple sleeves matched with the lantern rings; vertical rods are vertically arranged; the bottom ends of the vertical rods are arranged in the sleeves; and when the lantern rings rotate, the positions of the sleeves are invariable. The auxiliary device for the printer can print models according to actual shaping requirements more precisely.

Owner:ANHUI CHUNGU 3D PRINTING INTELLIGENT EQUIP IND TECH RES INST CO LTD

Welding device

InactiveCN106956056ARealize automatic stable locking and driving workRealize automatic controlSoldering auxillary devicesPulleyElectric motor

The invention discloses a welding device. The welding device comprises a basal body, wherein first sliding slots are formed in the top surface of the basal body in front-and-back symmetrical arrangement; a clamping mechanism of which the top stretches out of the top surface of the basal body is connected into each first sliding slot in a sliding and matching manner; a first screw hole extending left and right is formed in the clamping mechanism in the first sliding slot; a first sliding cavity is formed in the clamping mechanism above the first screw hole; a first converting cavity is formed in the top of the first sliding cavity in a running-through way; a sliding block is connected into the first sliding cavity in a sliding manner; a clamping sliding slot is formed in the right side surface of the clamping mechanism on the right side of the first sliding cavity; a pushing block is connected into the clamping sliding slot in a sliding manner; a locking motor is fixedly arranged inside the top surface of the sliding block; a first cone pulley stretching into the first converting cavity is connected to the top of the locking motor in a matching manner; a second converting cavity is formed in the clamping mechanism above the left side of the first converting cavity. The welding device is simple in structure, time-saving and labor-saving, is unlikely to generate offset, and improves the production efficiency.

Owner:冯斌斌

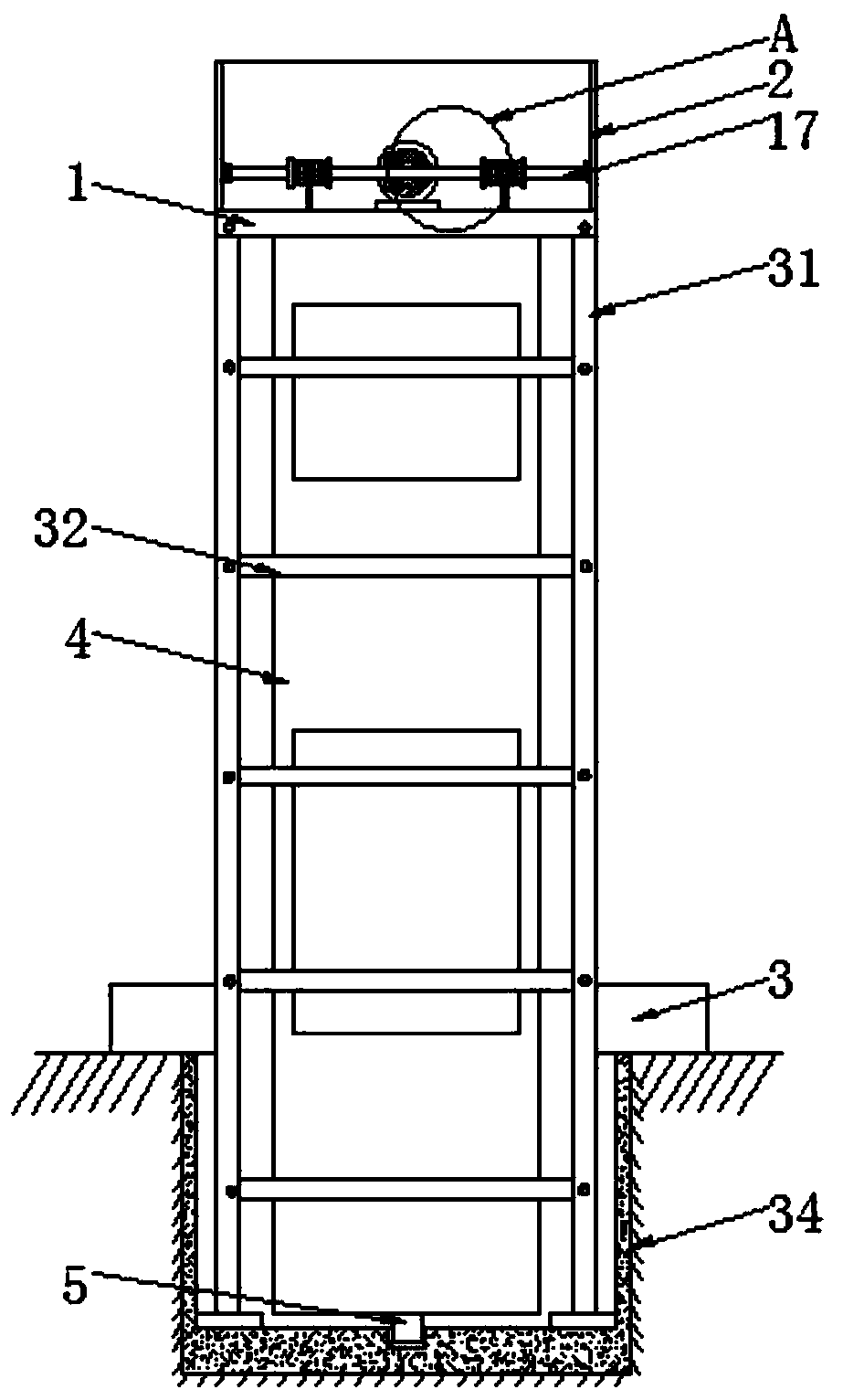

Novel free fall test system

InactiveCN110319996AHigh precisionImprove stabilityShock testingStrength propertiesEngineeringFree falling

The invention discloses a novel free fall test system, comprising a top plate, a rectangular frame and a fixing seat, wherein the rectangular frame is fixedly connected to the top of the top plate, acylinder is fixedly connected to the bottom of the top plate, an upright post is fixedly connected to a position at the bottom of the top plate located at the middle of the cylinder, a balancing weight matching the cylinder is movably connected to the top of the surface of the upright post, and the invention relates to the technical field of mine equipment. In the novel free fall test system, shells are movably connected to both sides of the top of the balancing weight and the both sides of the upright post, thereby facilitating the free fall of the balancing weight, the operation is simple, the reactive force is small, a free fall test can be conveniently carried out, a rotating rod is rotationally connected between the both sides of an inner wall of the rectangular frame, so that the fall height of the balancing weight can be conveniently adjusted according to the test requirements, and the balancing weight is unlikely to generate an offset phenomenon during the free fall, such thata derrick is not affected by the balancing weight, and potential safety hazards are reduced.

Owner:WUHAN YUNZHU ELECTROMECHANICAL NEW TECH DEV CO LTD

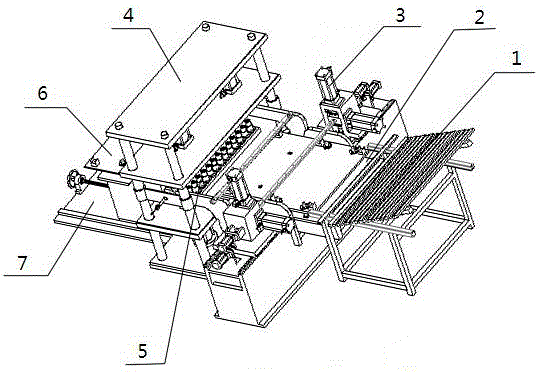

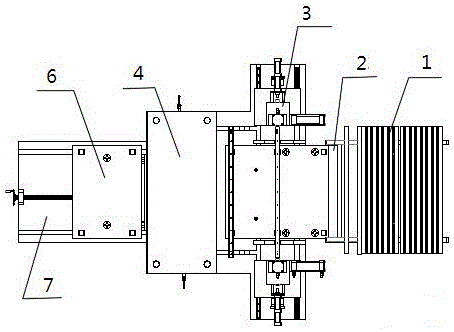

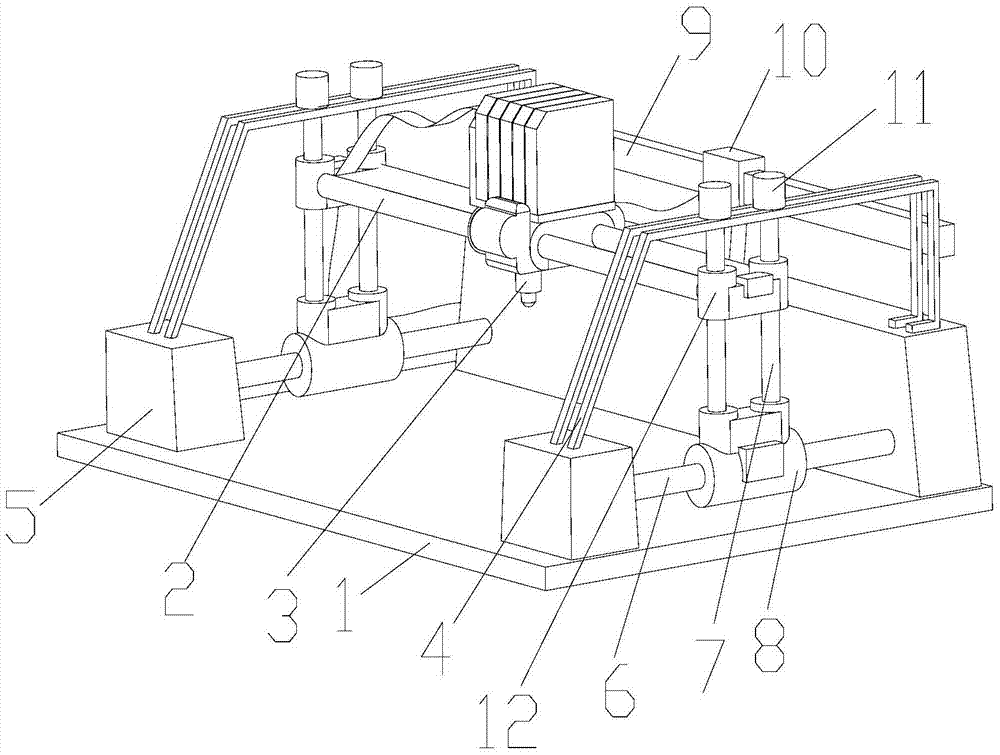

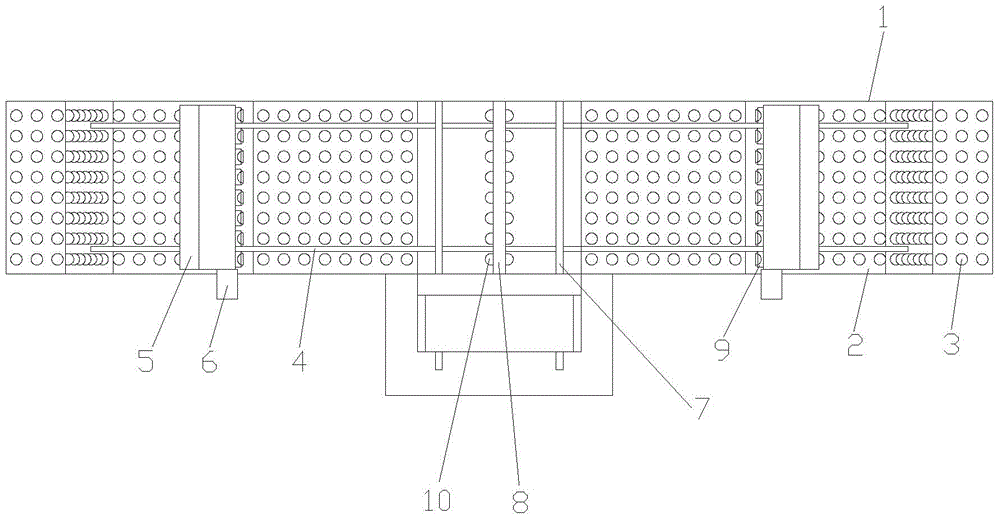

Chain feeding square tube punching machine

InactiveCN105013937APrecise positioningEnsure safetyPerforating toolsMetal-working feeding devicesPunchingEngineering

The invention provides an automatic square tube punching machine with high production efficiency. To solve the technical problem, the invention adopts a technical scheme that the square tube punching machine is characterized by comprising a material stacking area, a material arrangement structure, end punching mechanisms, a punching hydraulic rack, a punching die, a finished product discharging movable frame and a die replacement movable frame; a PLC is arranged, and is provided with a touch screen; a chain feeding mechanism is arranged in the material stacking area and comprises a feeding table and an arrangement chain; a floating air cylinder is arranged below the right end of the feeding table, and a first blocking plate is arranged at the left end of the feeding table; a motor is further arranged, and controls the arrangement chain to rotate; a conveying chain is arranged at the left end of the feeding table, and a second blocking plate is arranged above the middle of the conveying chain. The square tube punching machine has the beneficial effects that the machine can arrange the square tubes automatically, orderly, and regularly; precise locating of the punching mechanisms is achieved, and the deviation is not prone to occur; the automatic production is achieved, the management is facilitated, the efficiency is high, and the safety of operators is guaranteed.

Owner:苏州金牛精密机械有限公司

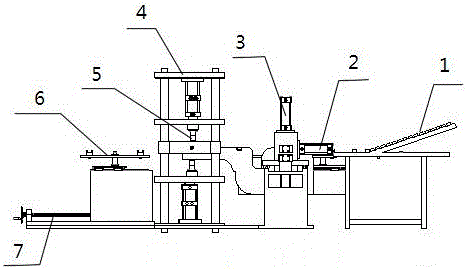

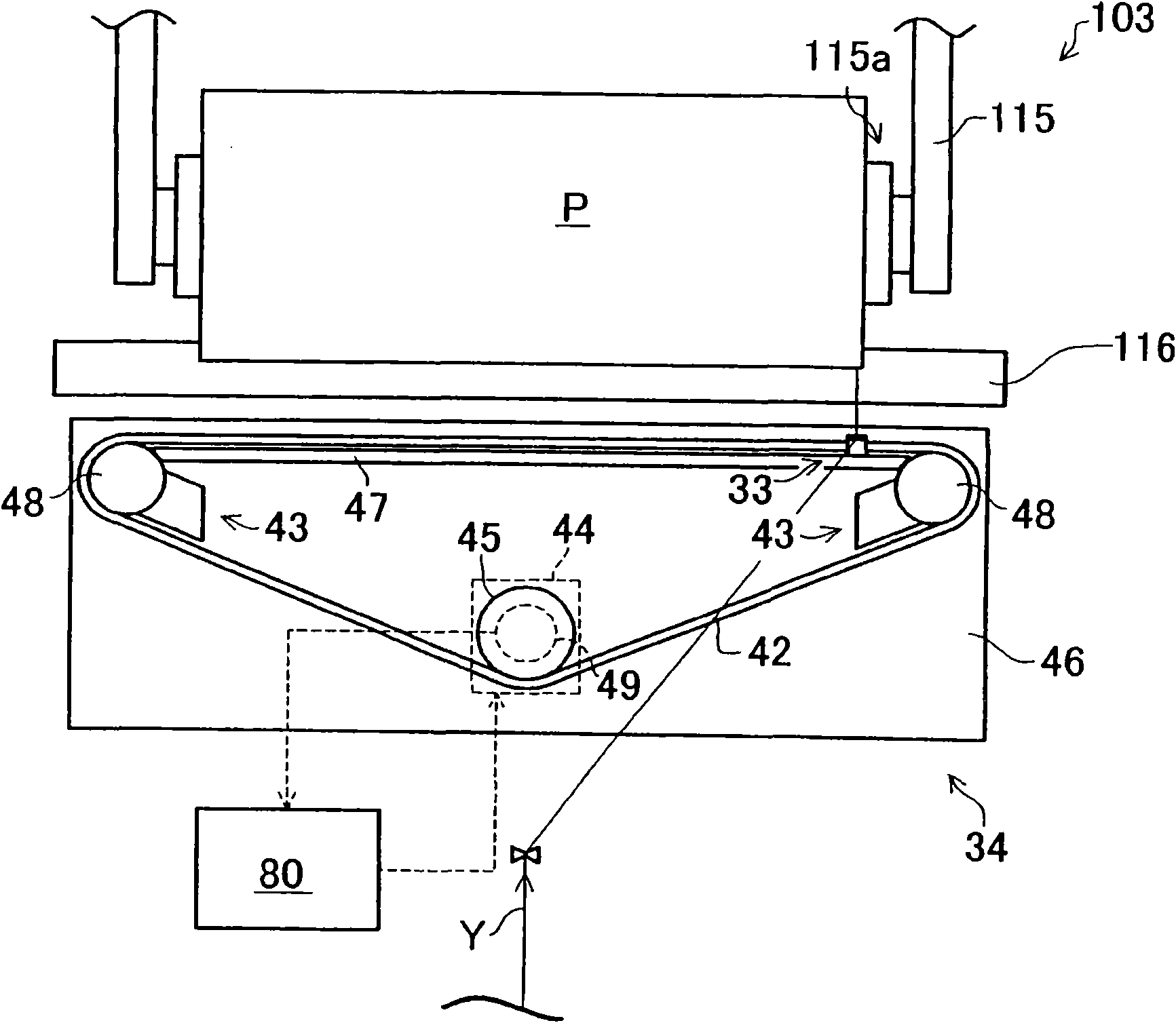

Control device of a transversing gear

ActiveCN101962136ANot prone to deviationEliminate biasFilament handlingTextiles and paperYarnVolumetric Mass Density

The invention relates to a control device of a transversing gear capable of eliminating the axial nonuniformity of the package density. A transversing control part (80) of the transversing gear (34) comprises a position-speed mode generation part (60) for supplying the relation between the position of a yarn guide (33) and the walking speed of the yarn guide (33) at the position, namely position-speed mode; an object speed calculation part (61) for calculating the object walking speed of the yarn guide (33) based on the position-speed mode supplied by the position-speed mode generation part (60) and the current position of the yarn guide (33) detected by a coder (49); and a drive control unit for controlling the action of a drive unit of the yarn guide based on the walking speed calculated by the object speed calculation part (61).

Owner:TMT MACHINERY INC

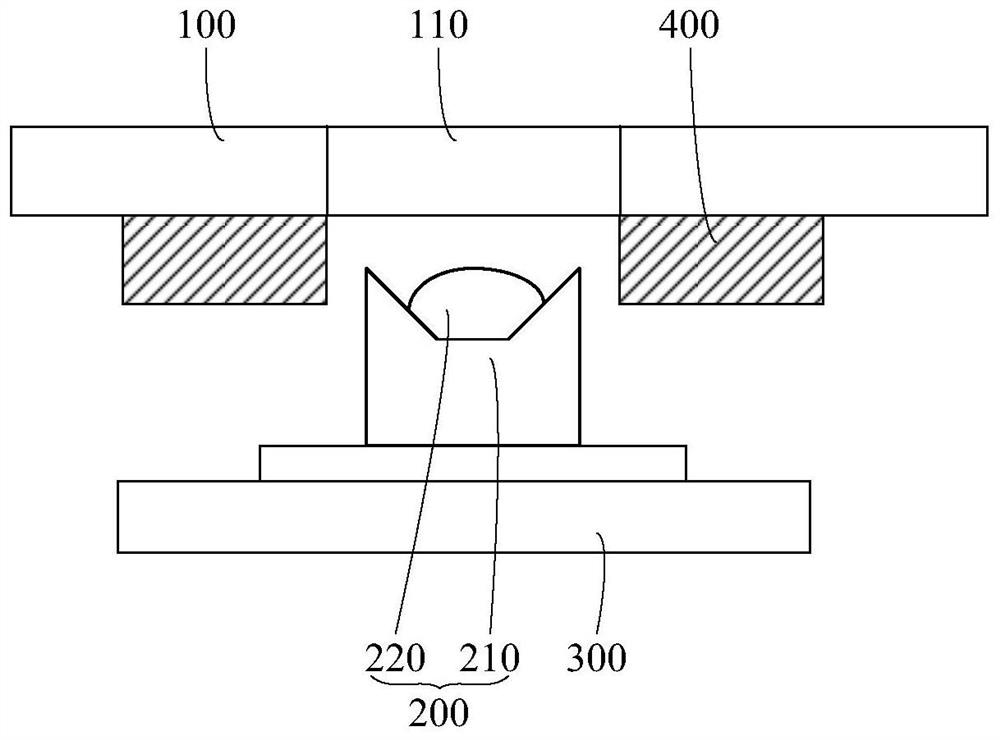

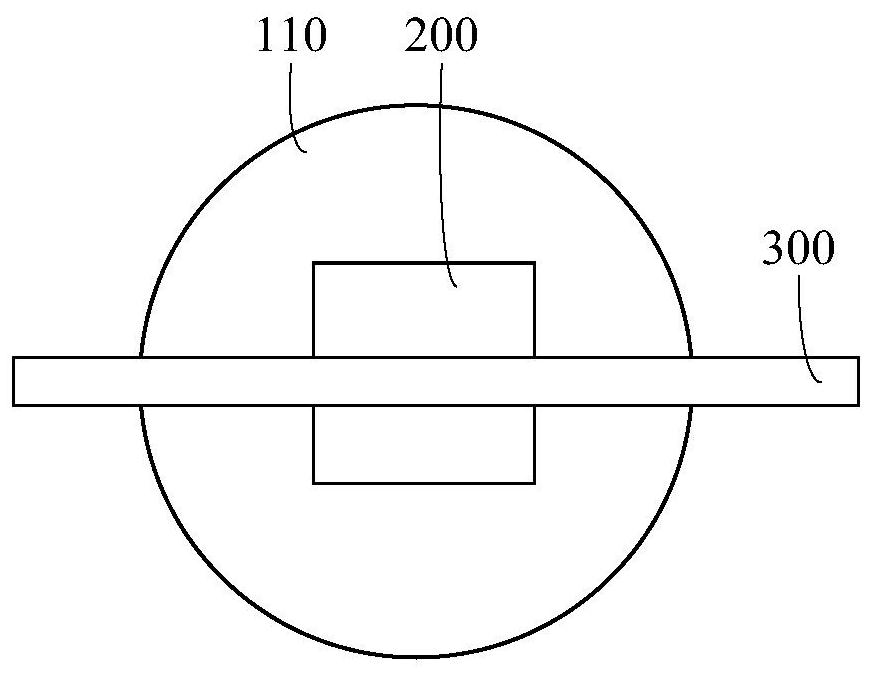

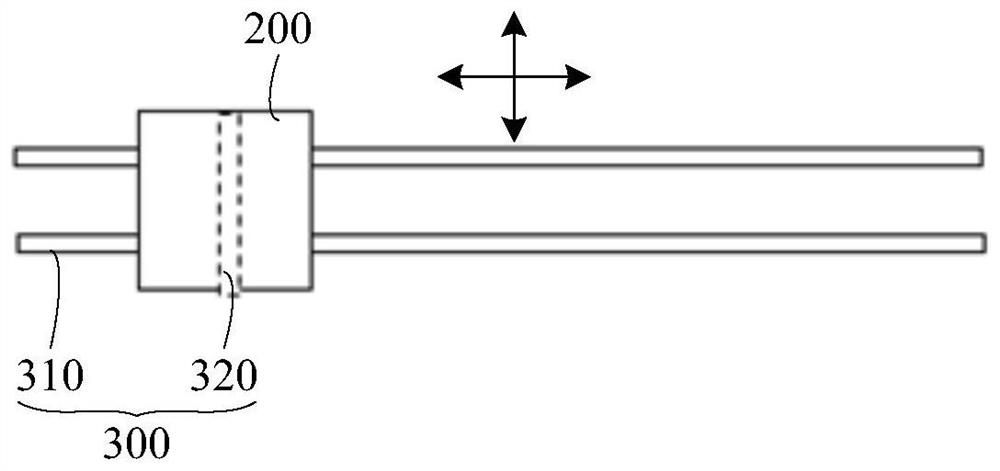

Electronic equipment and control method and control device thereof

ActiveCN113206901AAccurateImprove the shooting effectDigital data processing detailsTelephone set constructionsCamera moduleControl theory

The invention discloses electronic equipment, and belongs to the technical field of communication equipment. The electronic equipment comprises an equipment main body, a camera module and a first driving mechanism, wherein the equipment main body is provided with a light-transmitting area; the camera module is arranged in the equipment main body and moves along a first plane in the equipment main body, and the first plane is parallel to the plane where the light-transmitting area is located; and the first driving mechanism is arranged in the equipment main body, the first driving mechanism is connected with the camera module, and the first driving mechanism can drive the camera module to move along the first plane so as to adjust the relative position of the camera module and the light-transmitting area, and therefore, the center of a lens of the camera module coincides with the center of the light-transmitting area. According to the electronic equipment, the problem that the shooting performance of the electronic equipment is poor can be solved. The invention discloses a control method and a control device of the electronic equipment, and a readable storage medium.

Owner:VIVO MOBILE COMM CO LTD

Stable 3D printer

ActiveCN106956429ASimple structureImprove stabilization effectManufacturing platforms/substrates3D object support structuresEngineering3d printer

Owner:荟源(青海)数字科技有限公司

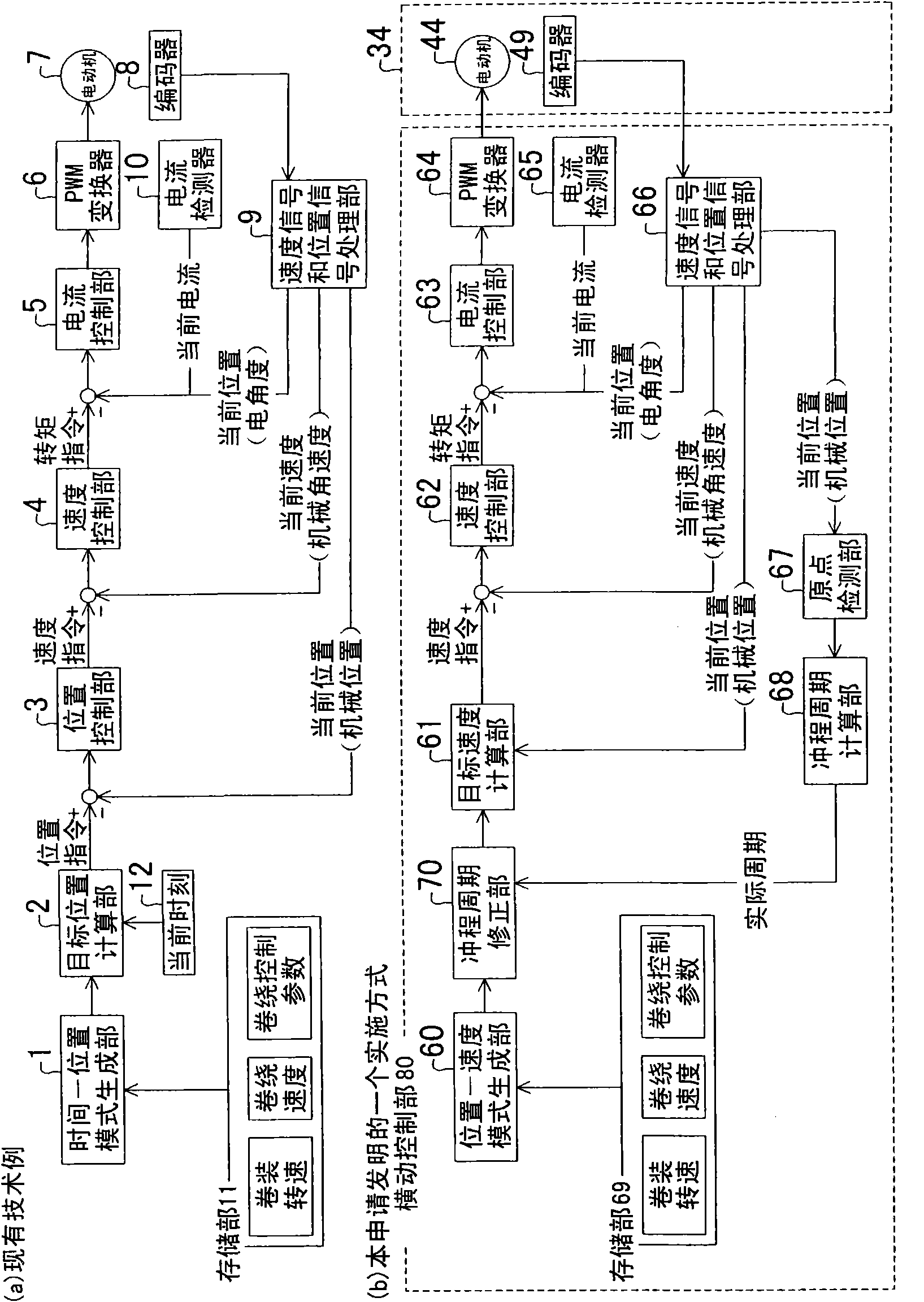

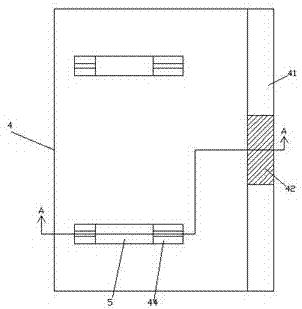

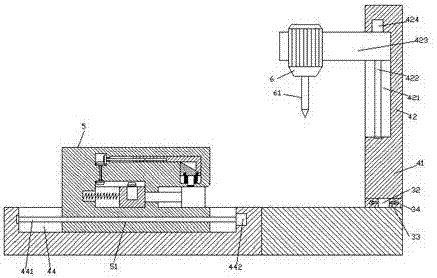

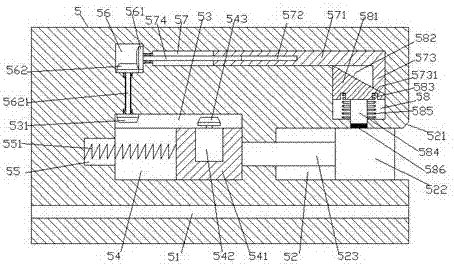

Section bar screw pull-riveting machine

PendingCN108502467AAvoid it happening againImprove processing efficiencyConveyor partsRotary conveyorsEngineeringSmall footprint

The invention provides a section bar screw pull-riveting machine. The section bar screw pull-riveting machine comprises a rack and is characterized in that the rack is provided with multiple moving chains used for conveying section bars in parallel, the rack has two layers, the top layer is provided with multiple screw discharging mechanisms, a feeding mechanism, multiple screw pull-riveting mechanisms, a discharging mechanism and a positioning mechanism are arranged on the bottom layer from right to left, the positioning mechanism is arranged under the screw pull-riveting mechanisms, and thestructure of the feeding mechanism is the same as that of the discharging mechanism. According to the section bar screw pull-riveting machine, continuous operation is achieved through cooperation of the mechanisms, therefore, the machining efficiency is high, machining deviation is not prone to occurring the machine is compact in structure and small in occupation area, unqualified screws are directly pushed out from a material receiving device, and generation of unqualified products is avoided.

Owner:广东港古工业自动化有限公司

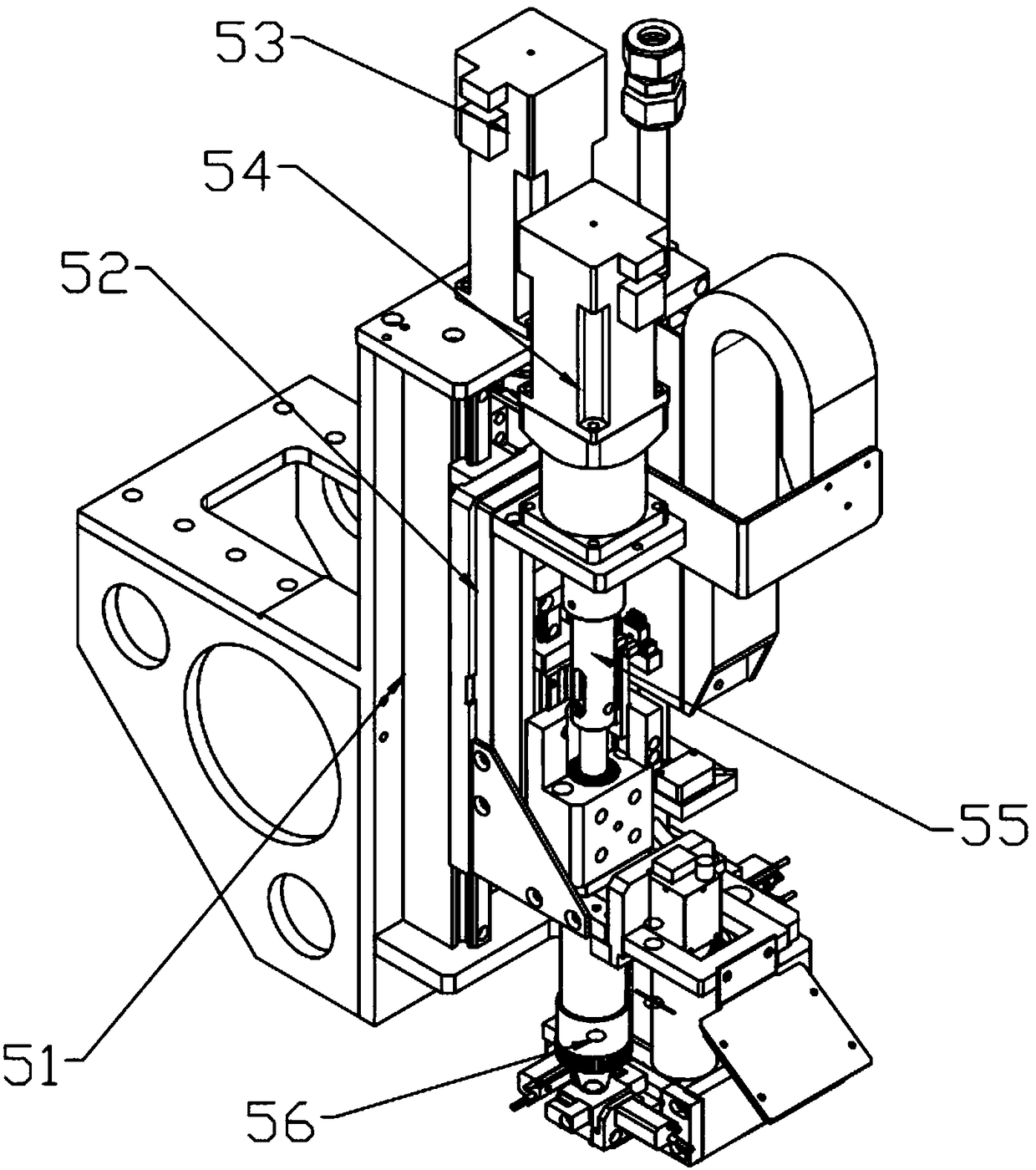

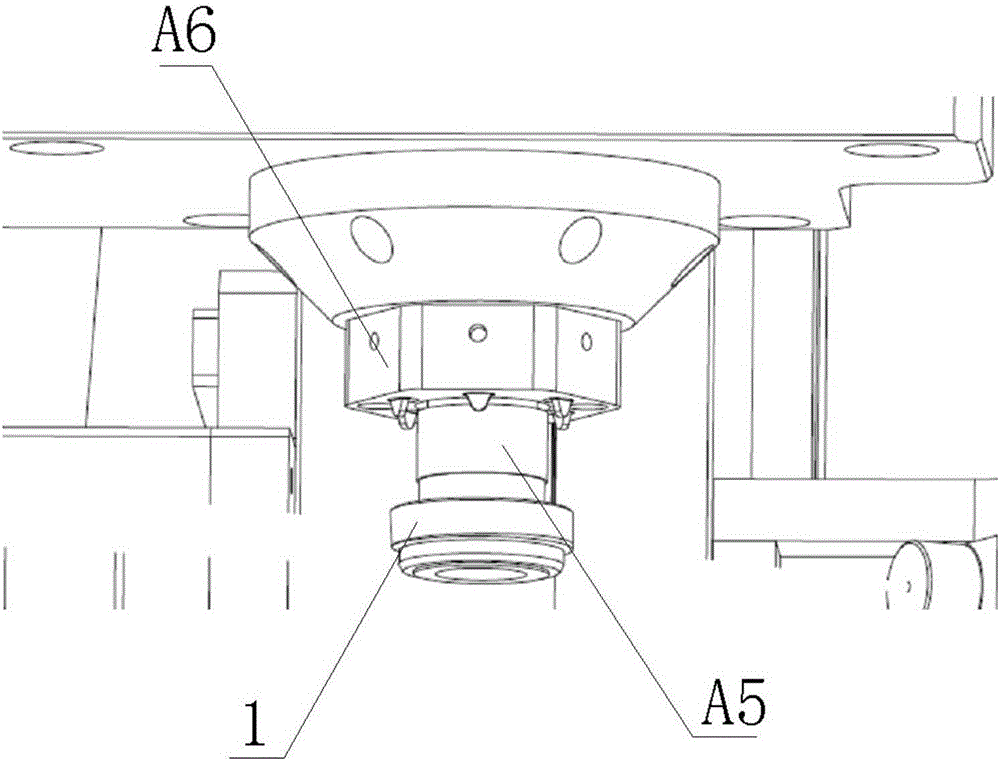

Integrated screwing and riveting mechanism for steering engine adjusting nut and application method of integrated screwing and riveting mechanism

ActiveCN106584087ASave station beatsCompact structureMetal working apparatusMachine toolProduction quality

The invention discloses an integrated screwing and riveting mechanism for a steering engine adjusting nut and an application method of the integrated screwing and riveting mechanism. The integrated screwing and riveting mechanism comprises the adjusting nut. The adjusting nut is arranged in a set machine tool limiting position where in the adjusting nut is screwed into a shell. An integrated screwing and riveting mechanism assembly is arranged on the adjusting nut. The screwing axis and the riveting pressure axis of the assembly coincide in the same axis. The integrated screwing and riveting mechanism assembly can move up and down. After the adjusting nut arranged under the assembly and the shell are screwed, the adjusting nut is subjected to riveting pressure through the integrated screwing and riveting mechanism assembly. The screwing and riveting mechanism is optimized into an integrated structure, compared with traditional two mechanisms and two processes of screwing and riveting, a set of sliding table air cylinder is omitted, due to the fact that the mechanism is compact, the station beat can be shortened by 6 S, and the production efficiency is greatly improved; and the integrated screwing and riveting mechanism is free of secondary positioning, so that the riveting point position is not liable to go away during riveting, and the finished production quality is greatly improved.

Owner:BOSCH HUAYU STEERING SYST CO LTD

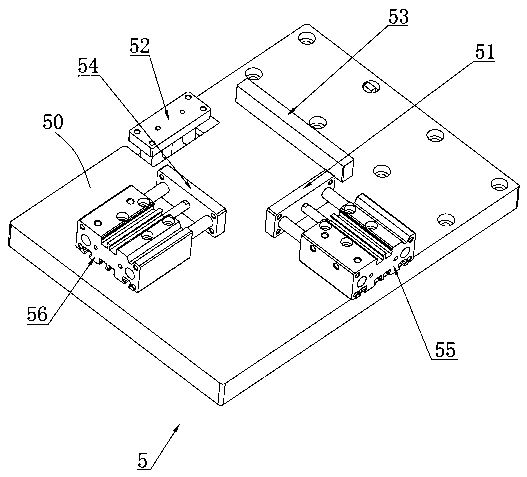

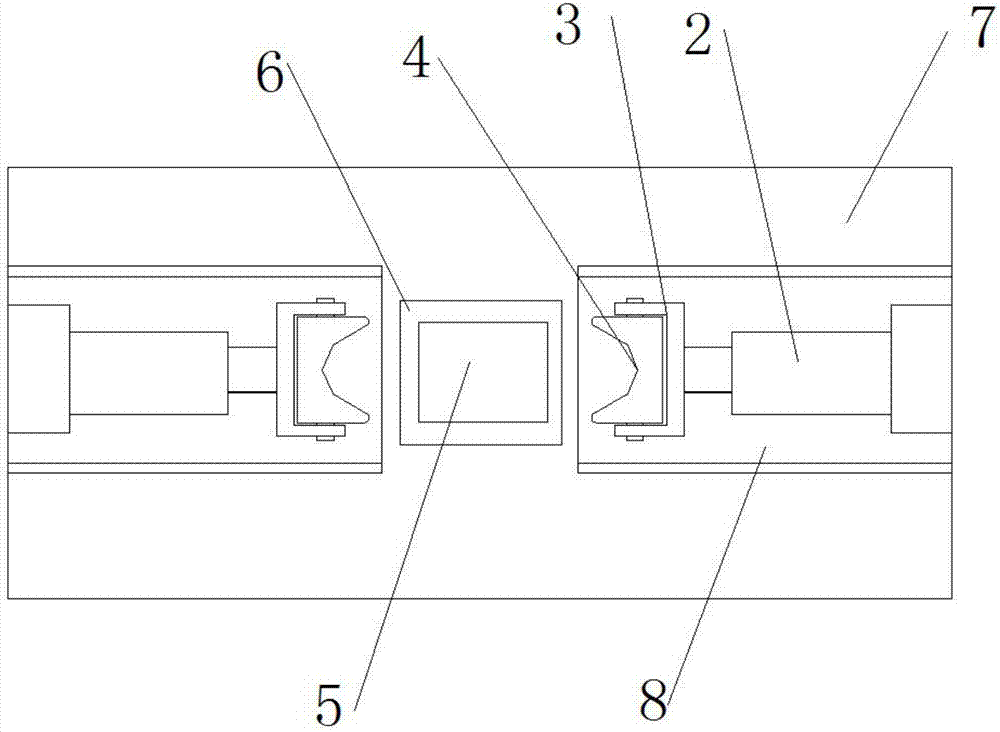

Mobile phone screen assembling device

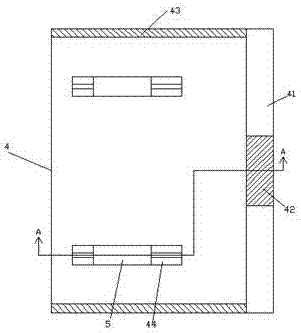

PendingCN109175943AGood assembly effectNot prone to deviationMetal working apparatusMobile phoneAutomation

The invention discloses a mobile phone screen assembling device. The mobile phone screen assembling device comprises a bottom plate; a worktable is arranged at the top of the bottom box; a supportingplate is arranged on each of the two sides of the worktable; a sliding way is arranged at the top ends of the inner sides of the supporting plates; one side of the sliding way is connected with a transmission block in a sliding manner; and a connecting seat is arranged on one side of the transmission block. According to the mobile phone screen assembling device, a material placement box is arranged; a mobile phone screen can be placed in the material placement box first; the transmission block drives a first air cylinder to move to the position above the material placement box; the first air cylinder extends downwards, so that a sucking nozzle is in contact with the mobile phone screen; under the action of the sucking nozzle, the mobile phone screen is adsorbed on the sucking nozzle, and then the first air cylinder retracts to complete material taking; a second air cylinder pushes the mobile phone screen in the material placement box upwards through a pushing plate so as to facilitatematerial taking next time; then the transmission block drives the first air cylinder to move to the position above a fixed seat; the first air cylinder extends downwards to make the mobile phone screen correspond to a mobile phone shell; the sucking nozzle stops adsorbing; the assembling is completed; and automation is realized.

Owner:漳州高新区远见产业技术研究有限公司

B-ultrasound probe positioning device

InactiveCN111407319AEasy to adjustImprove practicalityOrgan movement/changes detectionSurgeryAcousticsComputer science

The invention discloses a B-ultrasound probe positioning device. The device comprises a limit device, and the left end of the limit device is provided with a storage device. The B-ultrasound probe positioning device can be converted between a working state and a storage state through the limit device; the storage device is convenient for people to adjust the B-ultrasound probe positioning device to the working state; a marking pen and the ultrasound probe are fixed together through the cooperation of the storage device and a circle-drawing device, so as to solve the problem that the marking pen is easy to lose; and through the cooperation of the storage device, the circle-drawing device, a transmission device and a fixing device, the B-ultrasound probe positioning device can automaticallydraw circles to mark lesion positions, so that deviation is not prone to appear, the accuracy is high, and the practicability of the B-ultrasound probe positioning device is improved.

Owner:王雪

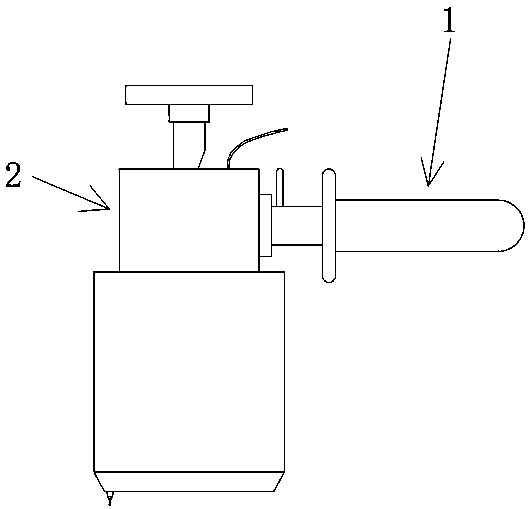

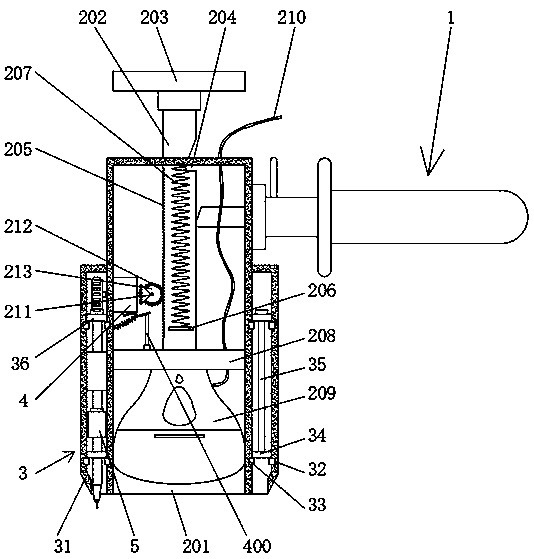

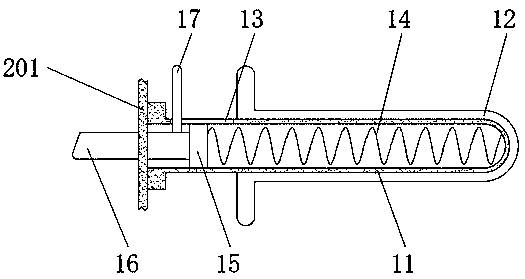

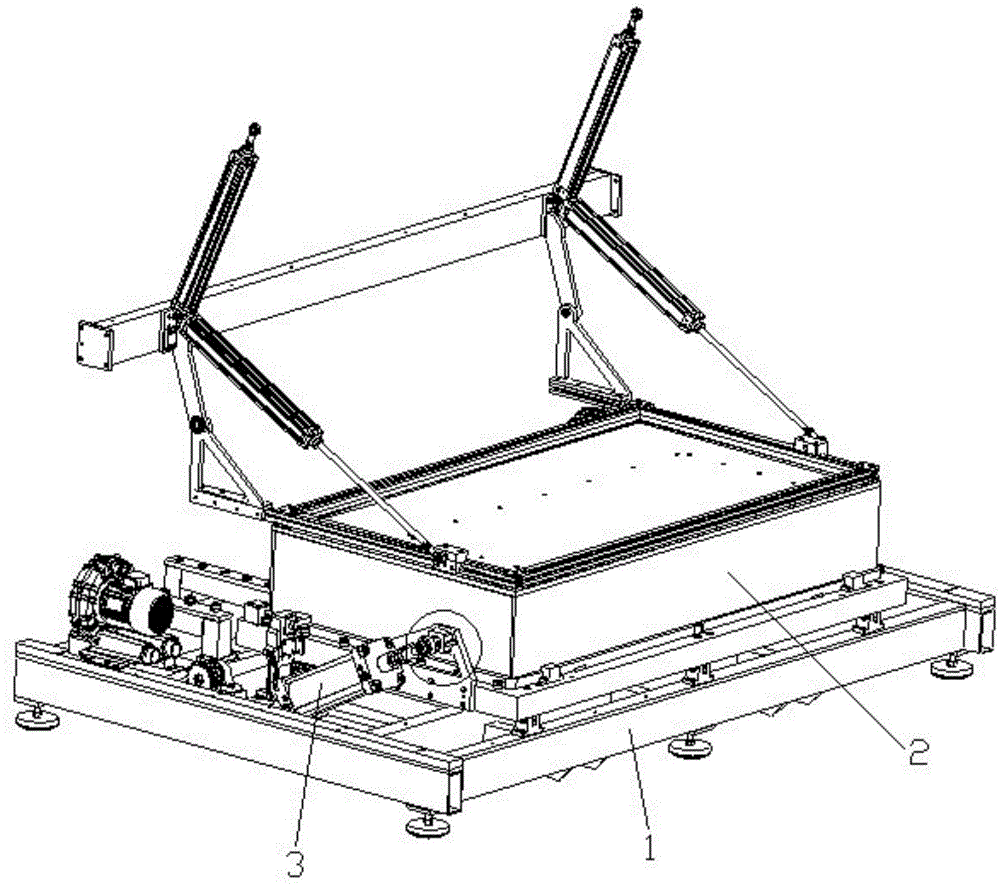

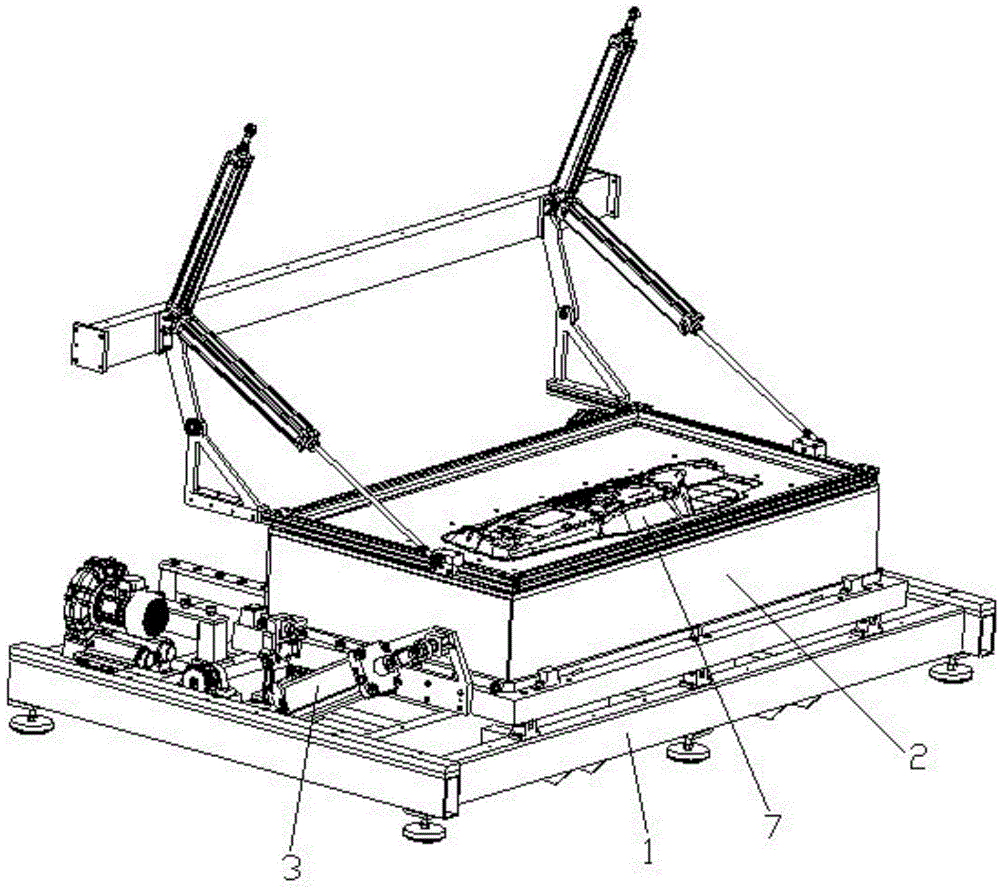

Overturning worktable for activating equipment

Owner:SUZHOU KEBER PRECISION MACHINERY

Cable outer mold glue injection frame

ActiveCN104252923AGuaranteed qualityProvides productivityInsulating conductors/cablesEngineeringMechanical engineering

The invention provides a cable outer mold glue injection frame, and relates to the technical field of cable processing. The cable outer mold glue injection frame comprises a bottom plate, an outer mold fixing frame and at least one cable end fixing frame, wherein the outer mold fixing frame is used for fixing an outer mold, the cable end fixing frame is used for fixing the end part of a core wire of a cable, the outer mold fixing frame and the at least one cable end fixing frame are connected onto the bottom plate in a side by side way at the left side and the right side, each cable end fixing frame has a preset distance from the outer mold fixing frame, the outer mold fixing frame and the cable end fixing frame are adopted for respectively fixing the positions of the outer mold and the end part of the core wire, the outer mold can be positioned in a correct position only through setting the distance between the outer mold fixing frame and the cable end fixing frame to be the preset distance in advance and directly and respectively fixing the outer mold and the end part of the core wire onto the outer mold fixing frame and the cable end fixing frame before the outer mold glue injection, then, glue materials are injected into the outer mold, and the outer mold glue injection work procedure is completed, convenience and high speed are realized, the production efficiency is improved, and meanwhile, the outer mold position cannot easily generate the deviation, so the cable quality is also ensured.

Owner:GUANGDONG ZHONGDE CABLE

Water power generation pipeline water filtering device

InactiveCN109289271AComprehensive cleaningGuaranteed cleanlinessStationary filtering element filtersWater filterDifferential pressure

The invention discloses a water power generation pipeline water filtering device, which comprises a filter tank. One end of the filter tank is connected with an inlet pipe, and a coarse filter net anda fine filter net are arranged inside the filter tank. A waterproof bearing seat is arranged at the center of both the coarse filter net and the fine filter net. A control line is fixed at the top ofthe filter tank. The control line is equipped with a differential pressure switch. Three blow-off pipes are arranged at the bottom of the filter tank. A Y-160M 2-2 motor is fixed at the other end ofthe filter tank. An output end of the Y-160M 2-2 motor is connected with a rotating spindle, one end of which penetrates through the two waterproof bearing seats. Four triangular stirring rods are fixed at one end of the rotating spindle. According to the invention, a protective cover wraps the rotating spindle and a grinding head, and residues generated by processed metal tableware are collectedby the protective cover. The splash of the residues is also avoided, the use safety of workers is ensured, and the polishing device is cleaner.

Owner:合肥先杰新能源科技有限公司

High-altitude operation protection device for building construction

InactiveCN112225141AImprove stabilityAffects protectionSafety devices for lifting equipmentsArchitectural engineeringBuilding construction

The invention discloses a high-altitude operation protection device for building construction comprising a platform. Two fixed columns are symmetrically and fixedly connected to the top end surface ofthe platform; two second partition plates are symmetrically arranged in each fixed column; fixing mechanisms are arranged on the other opposite sides of the two second partition plates; two fences are symmetrically arranged between the two fixed columns; a first limiting plate and a second limiting plate are arranged between the two fences, respectively; the bottom end of the first limiting plateand the bottom end of the second limiting plate are fixedly connected with insertion rods, respectively; and fixed boxes are arranged at the bottom of the first limiting plate and the bottom of the second limiting plate. The high-altitude operation protection device for building construction achieves the beneficial effects that the effect of conveniently disassembling and assembling a fence can be achieved, disassembling and assembling are convenient and rapid, the situation that if the platform is impacted during high-altitude operation, the fence is inconvenient to replace or maintain, thenthe protection performance of the fence is reduced, and subsequent work is affected is avoided, and through a secondary limiting and fixing mode, fixed connection is more stable.

Owner:苏州荔记得机械工程科技有限公司

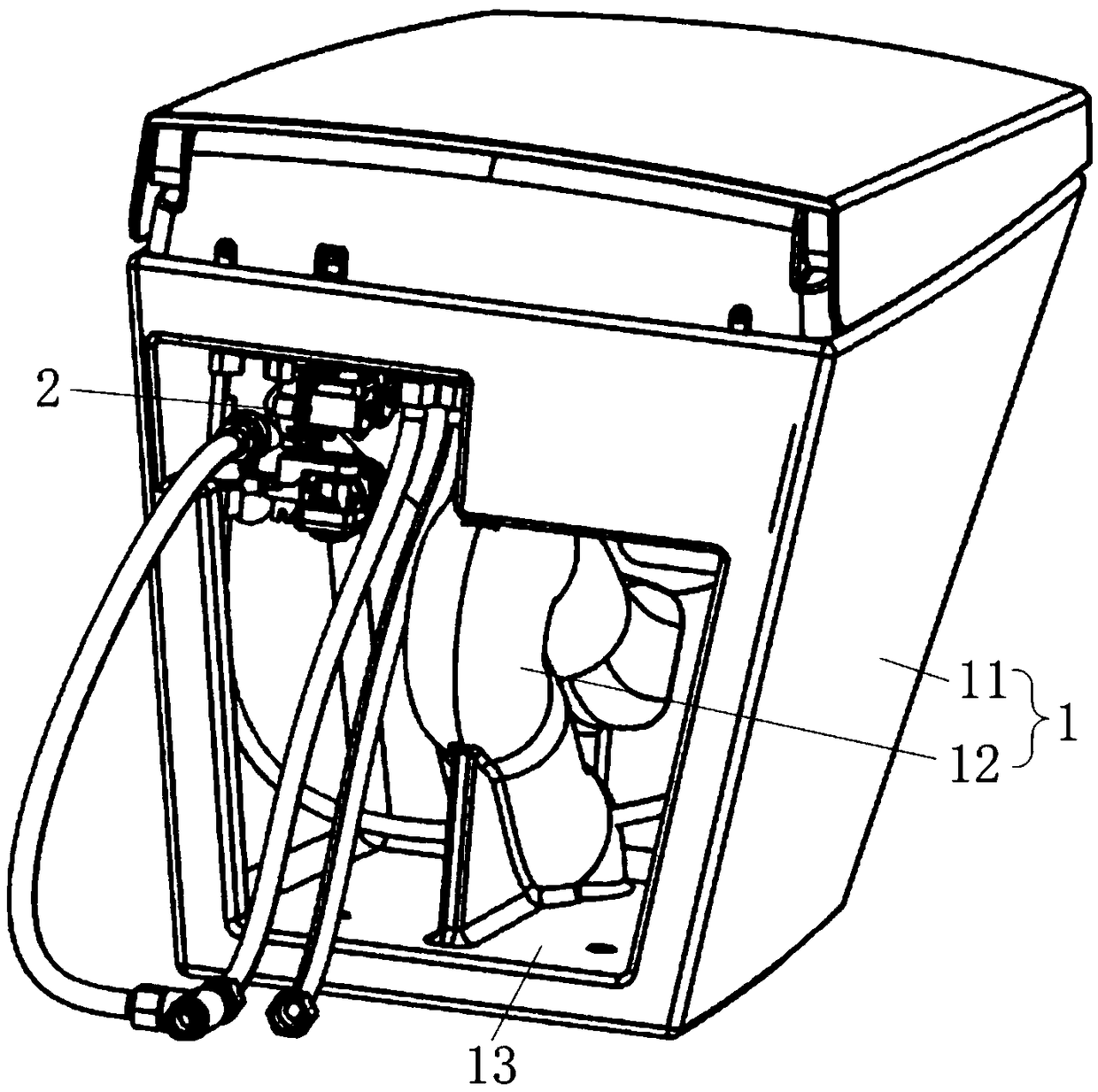

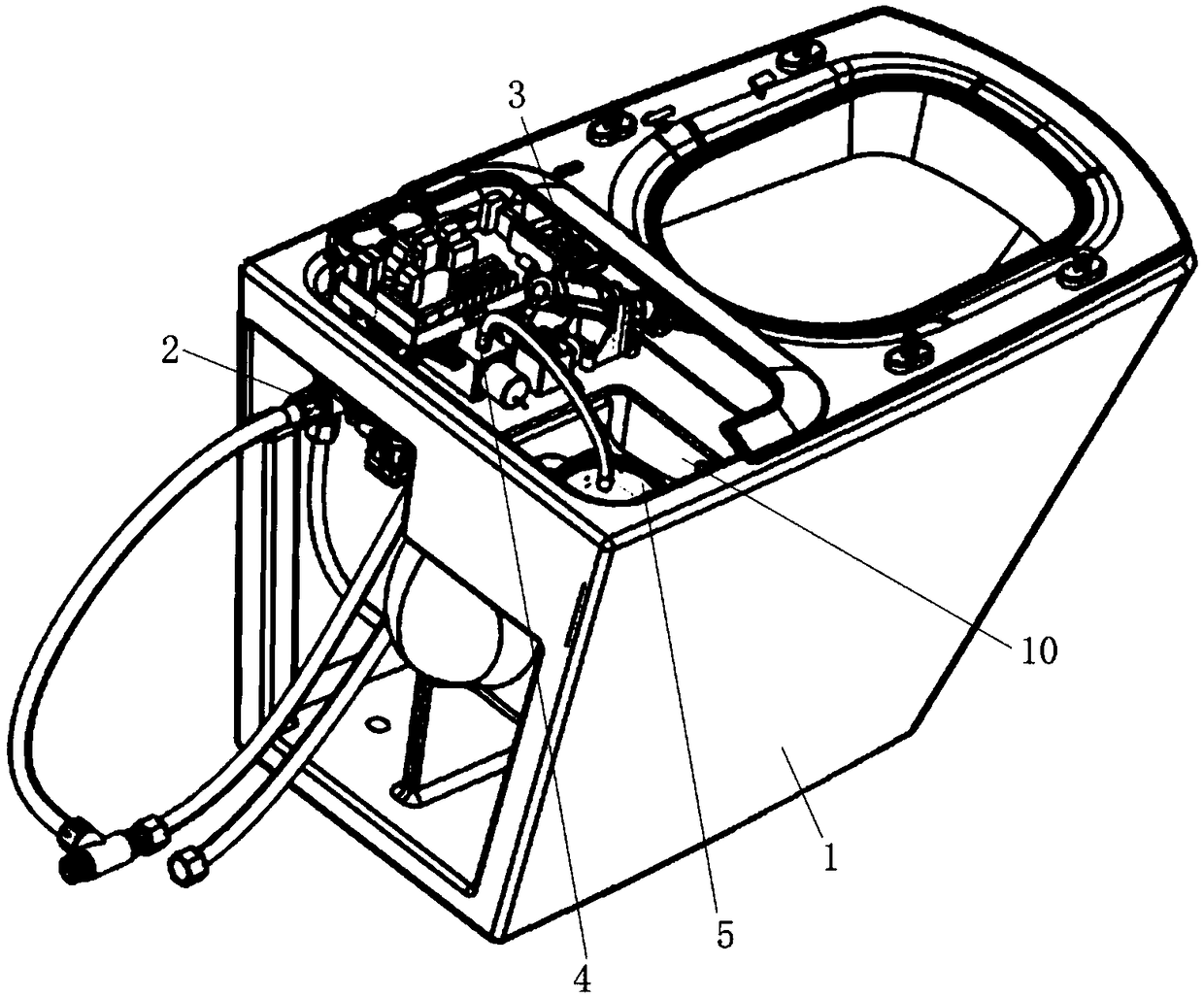

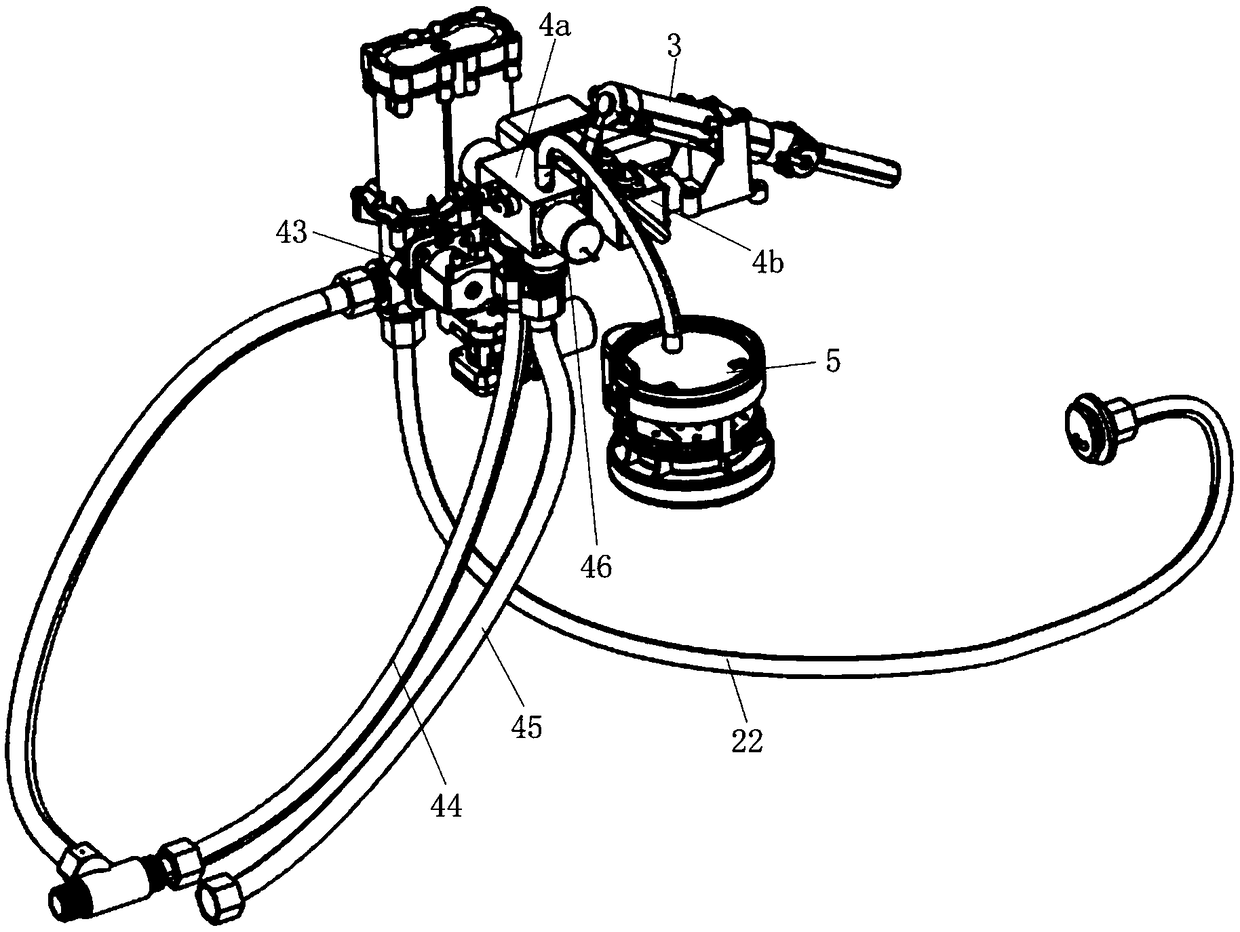

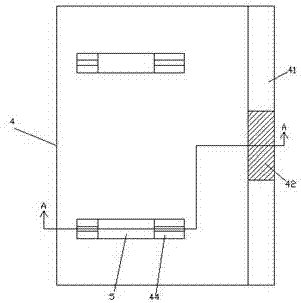

Low-voltage smart toilet bowl and control method thereof

InactiveCN109056946AImprove securityTo achieve the purpose of saving waterLavatory sanitoryTemperature controlLow voltage

The invention discloses a low-voltage smart toilet bowl. The low-voltage smart toilet bowl includes a toilet bowl main body; the toilet bowl main body is provided with a flushing water channel, a washing assembly, a water temperature adjusting device and a cold water storing chamber; the water temperature adjusting device includes a water inlet control part and a temperature control part, the temperature control part includes a first temperature detection part, a water flow control assembly and a main part which is provided with a mixed water channel, the main part is provided with a cold water inlet, a hot water inlet and a mixed water outlet, the mixed water outlet is communicated with the washing assembly, and the first temperature detection part is used for detecting the temperature ofwater inside the main part; the water inlet control part includes a cold water pipe, a hot water pipe, a hot water control part and a second temperature detection part, the cold water pipe is communicated with the cold water inlet, the hot water pipe is connected with an external heating module, and the second temperature detection part is used for detecting the temperature of water inside the hot water pipe. The invention further discloses a control method of the low-voltage smart toilet bowl. The usage safety of the low-voltage smart toilet bowl is high, and it is convenient to control thetemperature of the water for cleaning the body.

Owner:梁子明

Carving machine

ActiveCN107031250ASimple structureImprove stabilization effectModel makingEngravingEngineeringLocking mechanism

The invention discloses a carving machine which comprises a machine base. First sliding grooves are equally arranged in the front and back top faces of the machine base, a locking mechanism with the top extending outside the top face of the machine base is connected into each first sliding groove in a slide fit manner, a first spiral hole arranged in a left-and-right extending manner is formed inside the locking mechanism of each first sliding groove, a first sliding cavity is arranged in the position, above the corresponding first spiral hole, of each locking mechanism, and a first conveying cavity is arranged at the top of each first sliding cavity in a through manner; a sliding block is connected into each first sliding cavity in a slide fit manner, a locking sliding groove is formed on the right side of each first sliding cavity and on the right side face of the corresponding locking mechanism, and a push sliding block is connected into each locking sliding groove in a sliding fit manner; and a locking driving device is fixedly arranged in the top face of each sliding block, a first taper wheel extending into the corresponding first conveying cavity is connected to the top of each locking driving device in a matched manner, and a second conveying cavity is arranged in the position, above the left side of the corresponding first conveying cavity, in each locking mechanism. The carving machine is simple in structure, time and labor are saved, deviation is not prone to being generated, and the production efficiency is improved.

Owner:东莞市东尚木业有限公司

Device for printer

InactiveCN105437554ANot prone to deviationAccurate printingAdditive manufacturing apparatusEngineeringElectrical and Electronics engineering

Owner:ANHUI LANWA ELECTRONICS TECH CO LTD

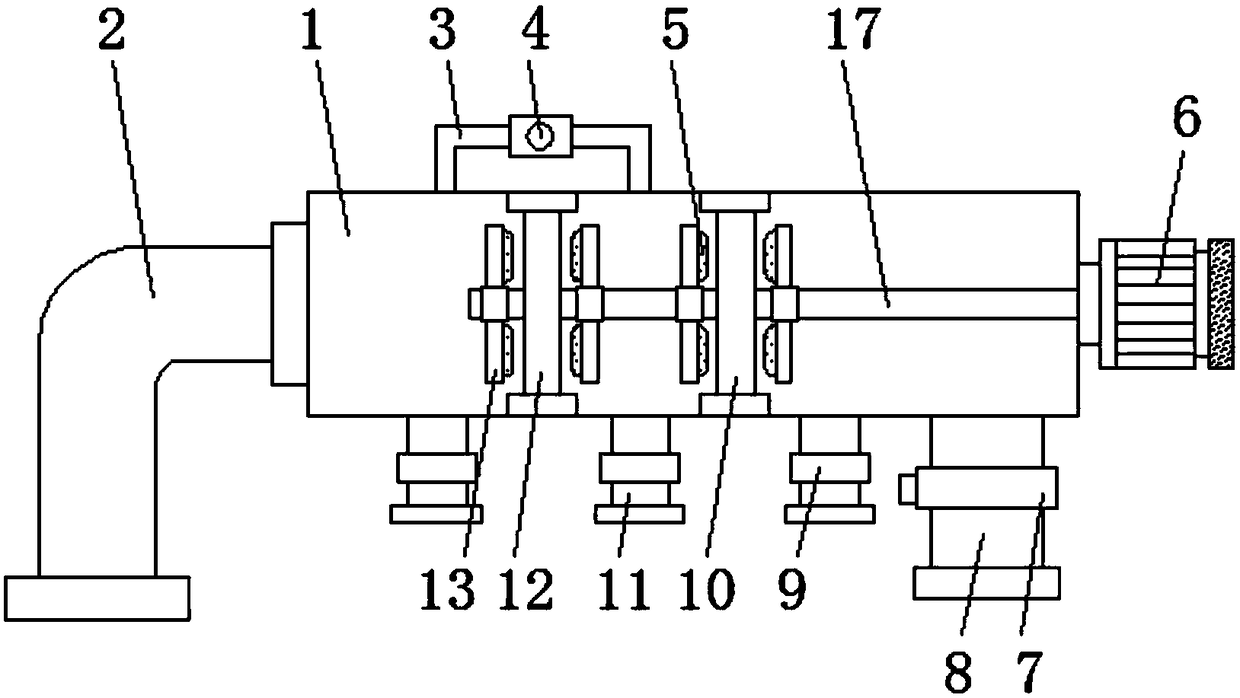

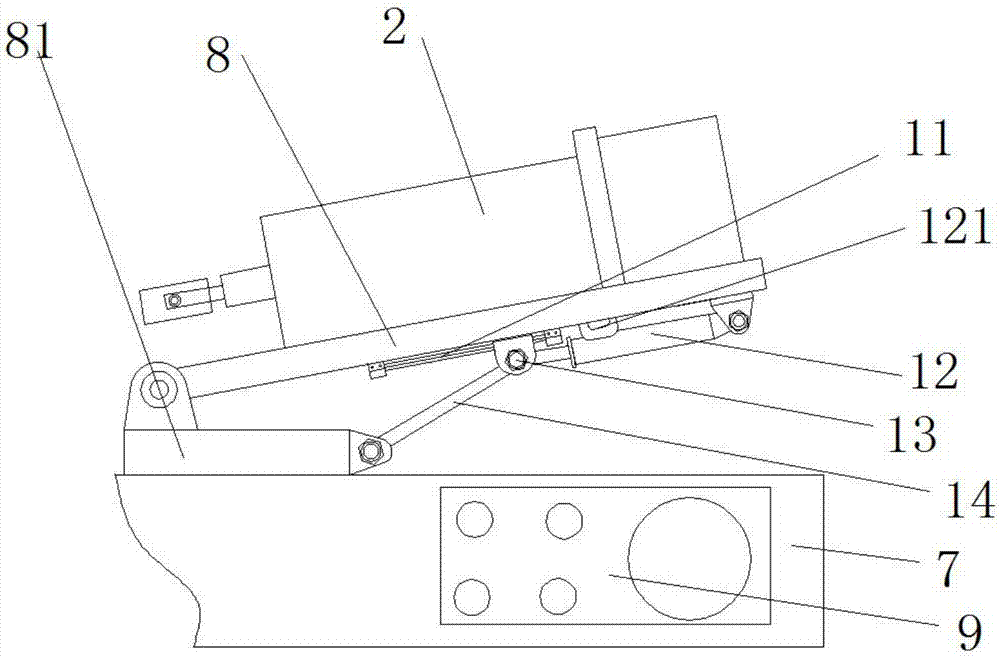

Hardware machining device

PendingCN107309691ANot prone to deviationSimple structurePositioning apparatusMetal-working holdersStructural engineeringMachining

The invention relates to a hardware machining device which comprises a machining base. One end of the machining base is hinged to a rotary shaft fixed to a bottom plate. The machining base is provided with a clamping device, and tilting devices are arranged at the bottom of the machining base. Each tilting device comprises a sliding rail, a lifting air cylinder and a supporting rod, wherein limiting blocks are arranged at the two ends of the sliding rail; a connecting part is arranged at the tail end of a cylinder barrel of the lifting air cylinder; the air cylinder base connecting part is connected with an air cylinder base through a pin rod, and the air cylinder base is arranged at the bottom of the machining base; a sliding block connected with a piston rod of the lifting air cylinder is arranged on the sliding rail in a sliding mode and hinged to the supporting rod; and the other end of the supporting rod is hinged to a connecting part through pin rods, and the connecting part is fixed to the rear end of the bottom plate. The hardware machining method has the advantages of simple structure, safety, reliability, good stability and the like.

Owner:江苏迎燕紧固系统科技有限公司

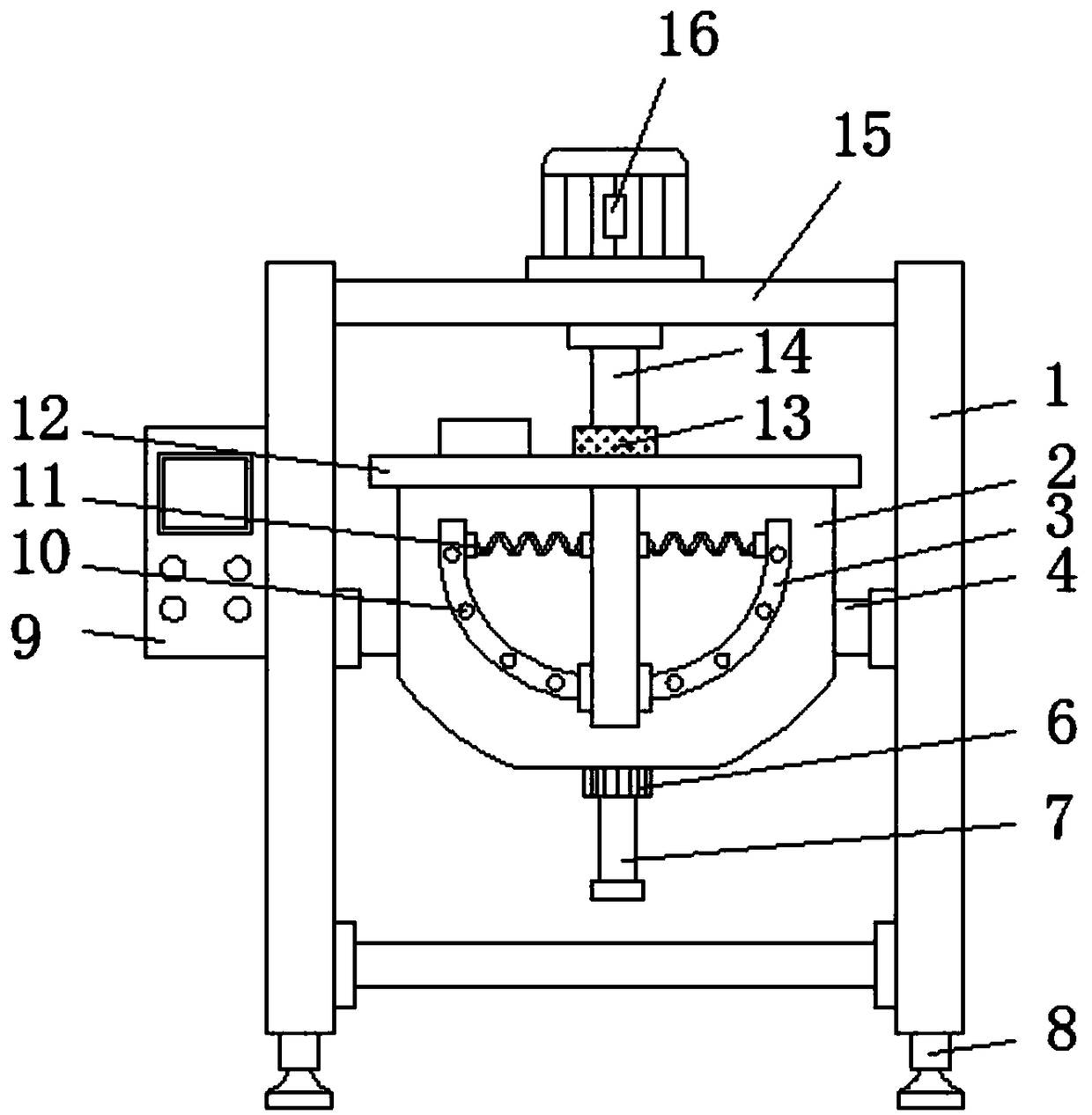

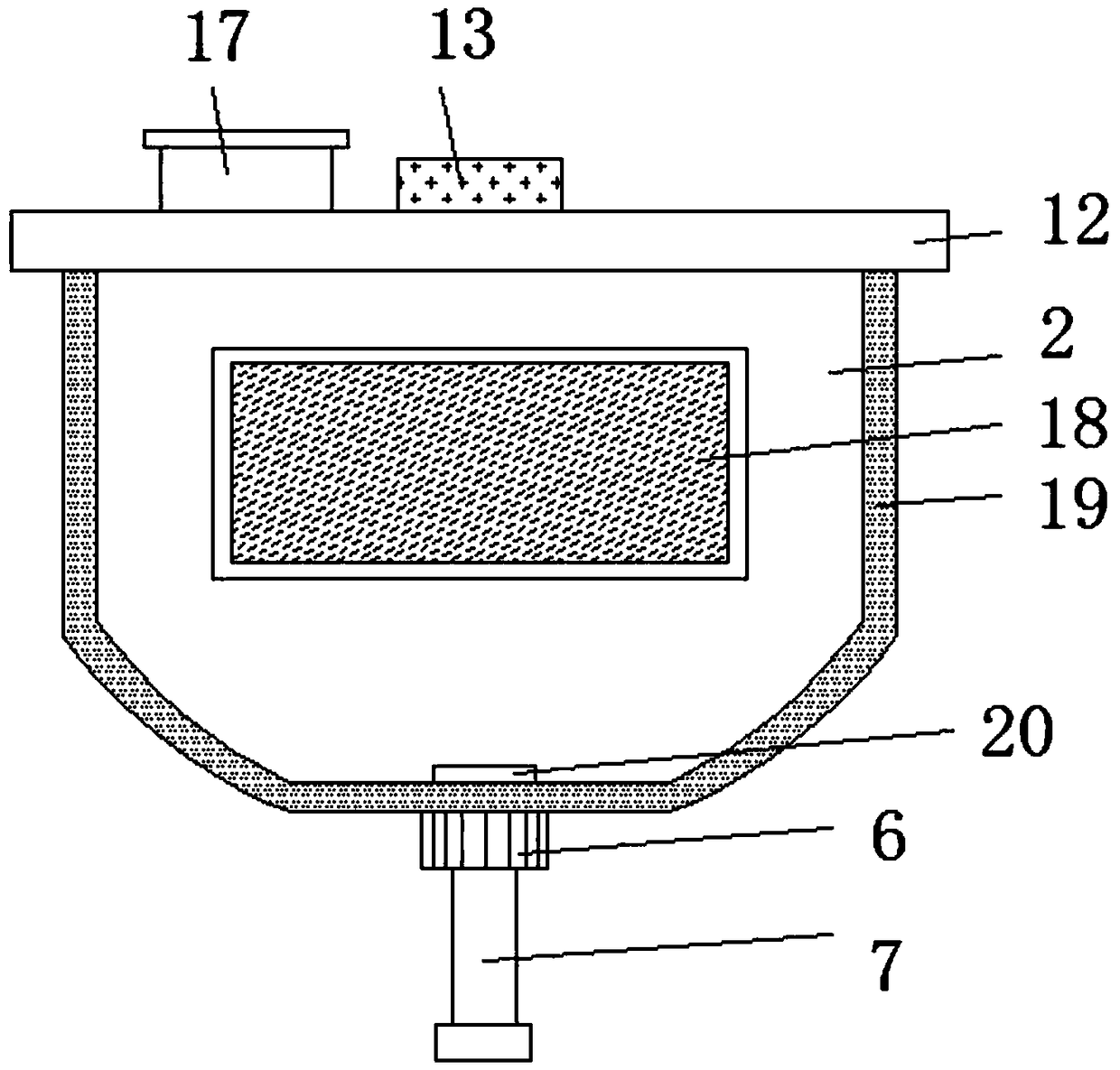

Groove-shaped stirring mixing machine for pharmacy

InactiveCN108786639AHigh mixing precisionIntegrity guaranteedRotary stirring mixersTransportation and packagingPharmacyMotor drive

The invention discloses a groove-shaped stirring mixing machine for pharmacy. The groove-shaped stirring mixing machine comprises fixed frames and locking bolts, wherein a top plate is arranged at thetop ends of the fixed frames; a Y-160M 2-2 stirring motor is arranged at the center of the top plate, and the output end of the Y-160M 2-2 stirring motor is connected with a rotary main shaft; the fixed frames are provided with a mixing groove; a bearing seat is arranged at the center of a sealing cover; screw rods are arranged between one end of a curved stirring rod and the rotary main shaft; both ends of the screw rods are connected with the curved stirring rod and the rotary main shaft by welding; the center of the top end of the mixing groove is provided with a material outlet; an electromagnetic valve is fixedly arranged on the material outlet, and is connected with a material discharge pipe; a PLC (programmable logic controller) is arranged at one end of the fixed frames. The groove-shaped stirring mixing machine has the advantage that the Y-160M 2-2 stirring motor drives the rotary main shaft to uniformly rotate, so that the material is fully mixed and uniformly shaken by thecurved stirring rod and the screw rods, and the mixing precision of the material is improved.

Owner:倪菁菁

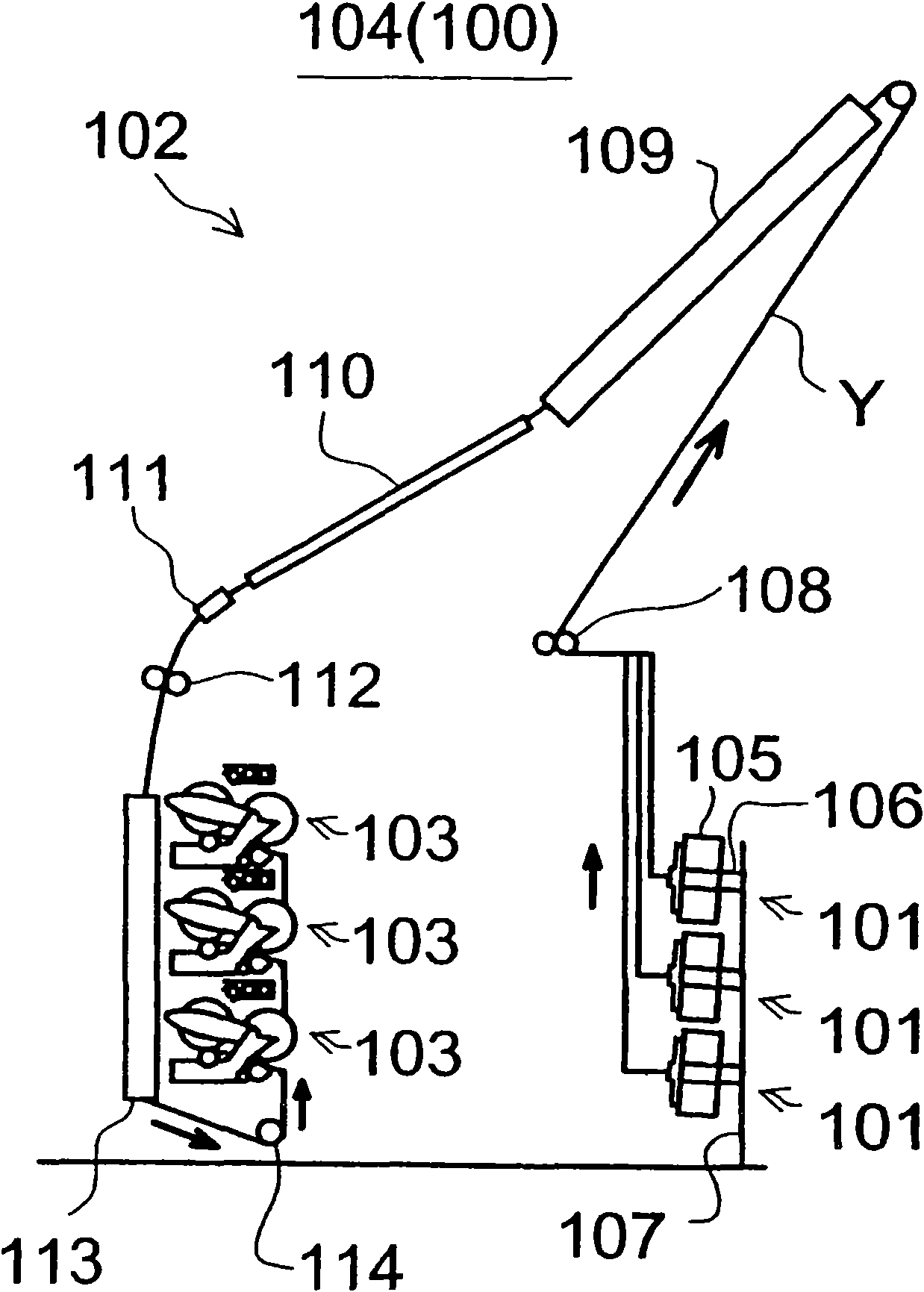

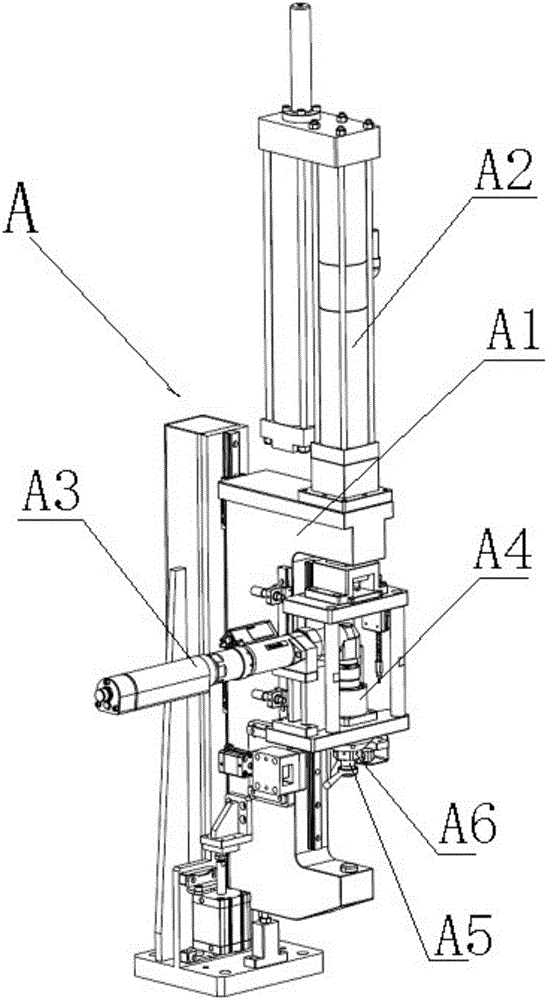

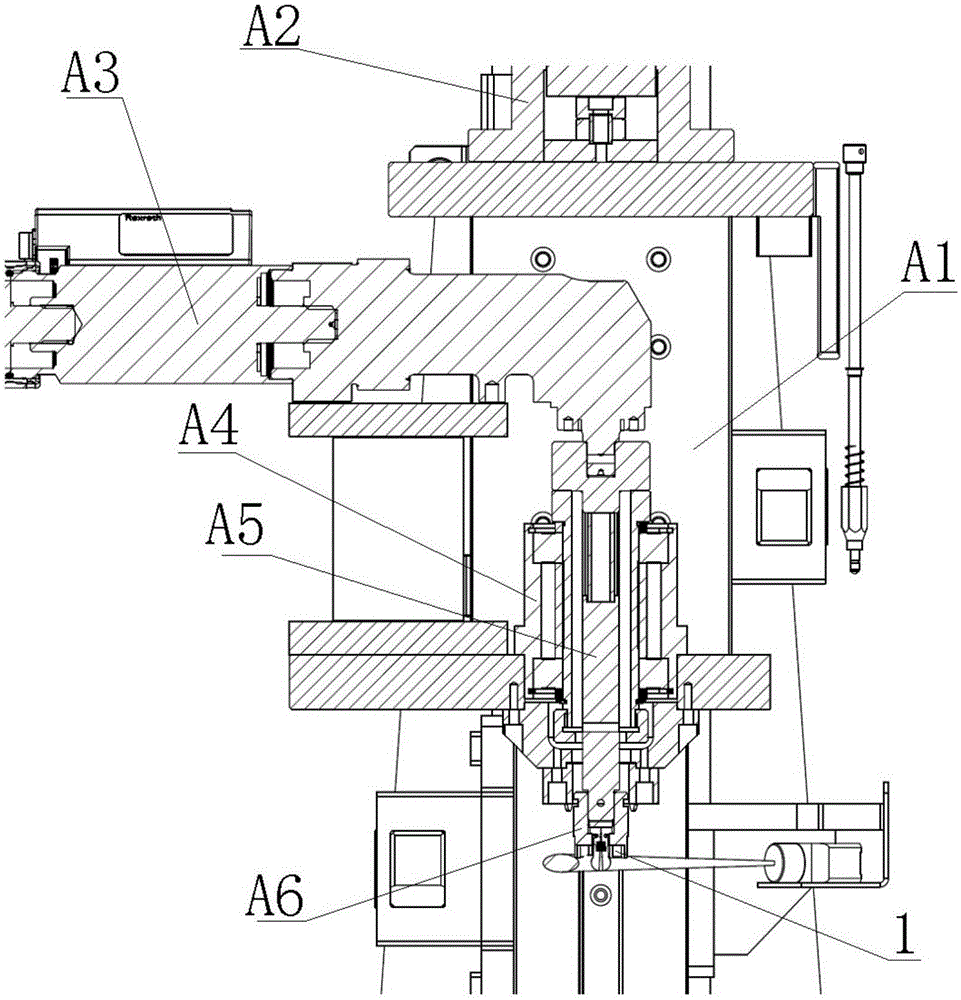

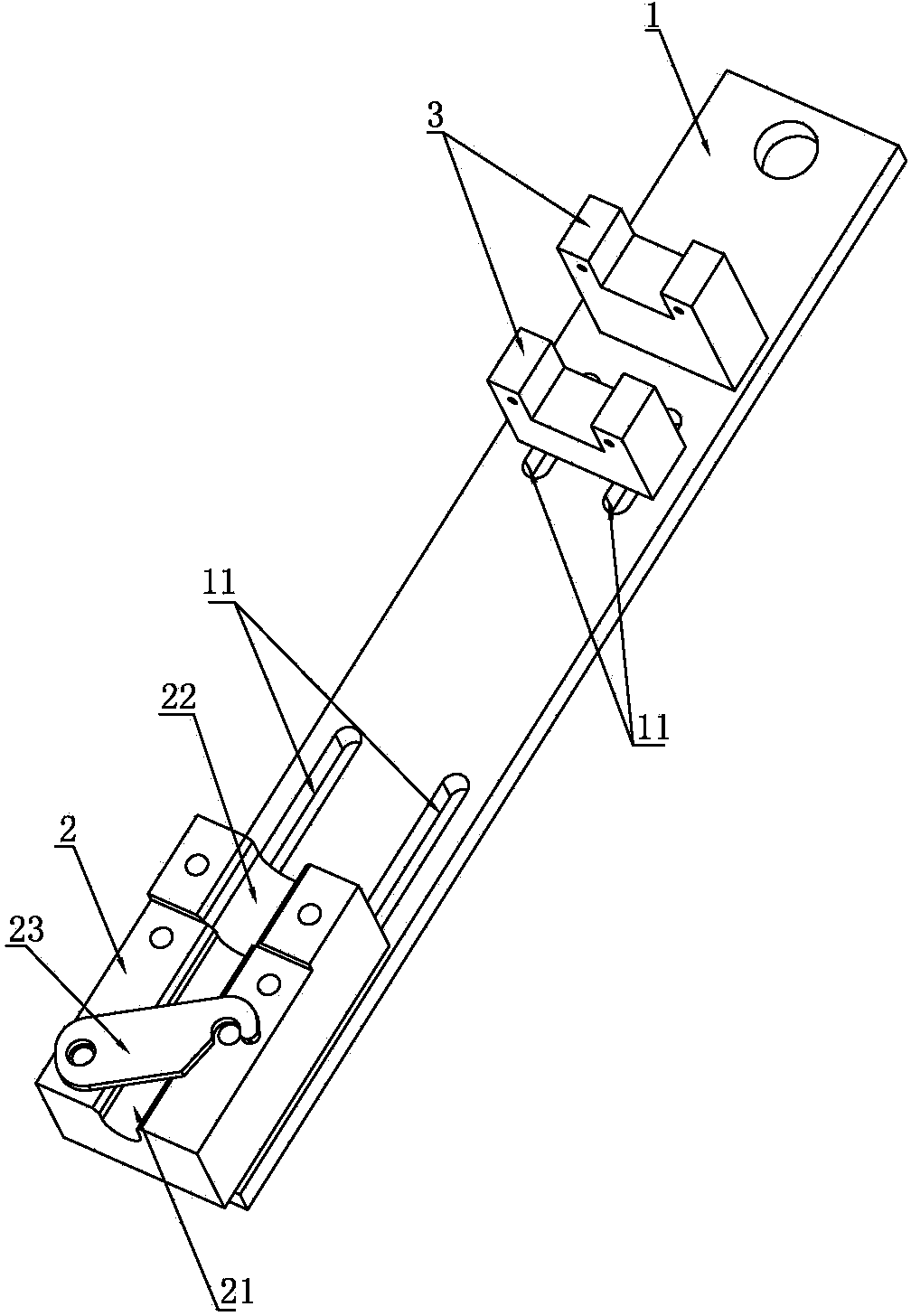

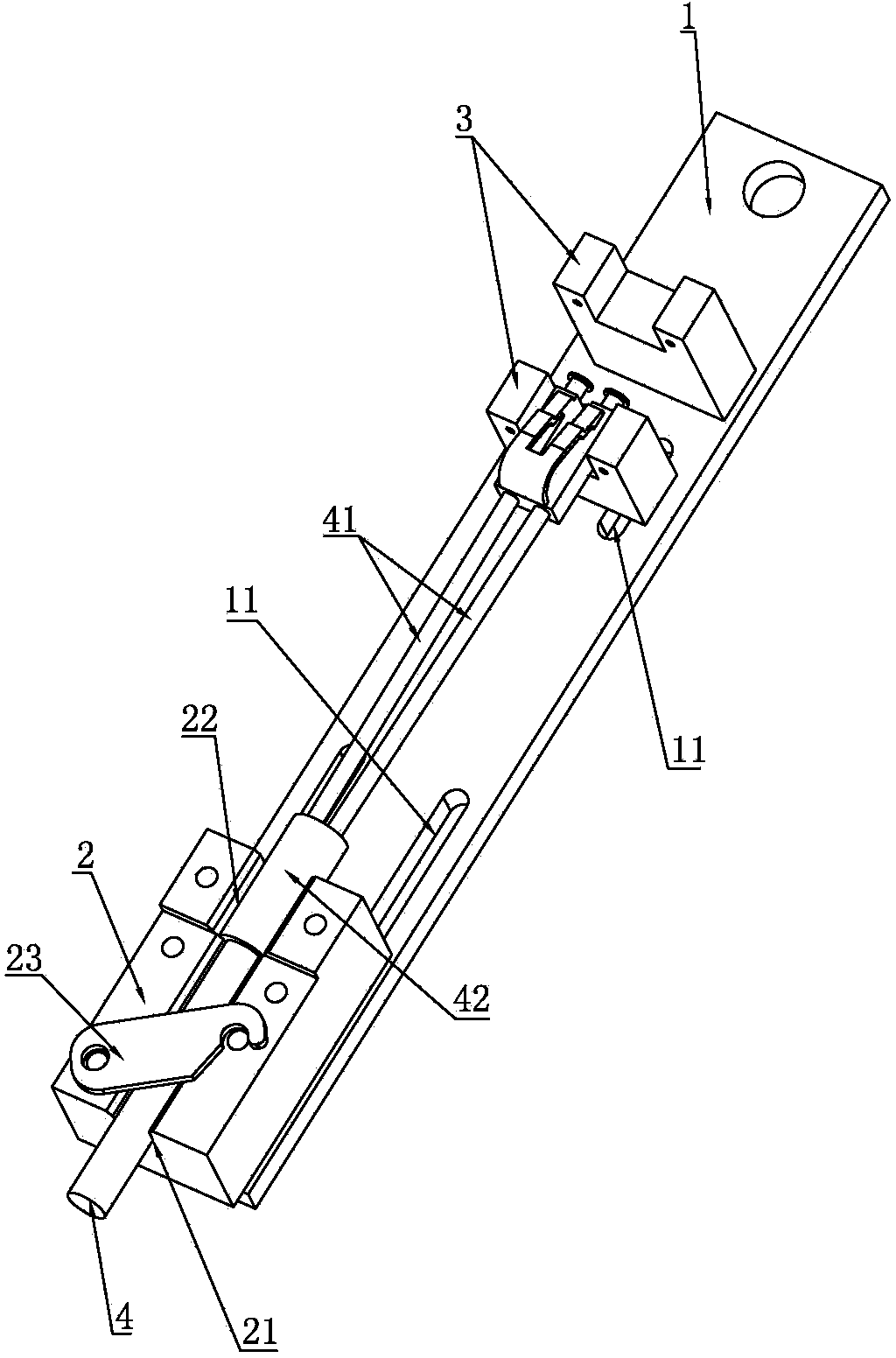

Feeding device applicable to infrared plastic ball welding machine

The invention discloses a feeding device applicable to an infrared plastic ball welding machine. The feeding device comprises a feeding table, a material conveying device and a material transmitting device, wherein the material conveying device and the material transmitting device are arranged at the feeding table. Through the feeding device applicable to the infrared plastic ball welding machine, the original manual feeding is replaced by mechanical feeding, thus greatly reducing the labor strength and improving the accuracy of placing products; the feeding device has small possibility of causing deviation and is capable of more accurately welding the products, thereby avoiding the defective products.

Owner:SUZHOU KEBER PRECISION MACHINERY

printing device

InactiveCN105437551BAffect qualityEasy to printAdditive manufacturing apparatus3D object support structuresDrive shaftTransducer

The invention discloses a printing device, which comprises a base plate, a refueling mechanism arranged on the base plate, a fixing mechanism set on the base plate, a support mechanism slidably connected to the fixing mechanism, a A plurality of horizontal bars arranged in parallel on the support mechanism and a printing mechanism slidingly connected to the plurality of the horizontal bars; When sliding in the vertical direction, the printing mechanism can follow the support seat to move in the second direction; the refueling mechanism includes a refill seat fixed on the bottom plate, a drive device fixed to both ends of the refill seat and rotatably connected to the The connection block on the drive shaft of the drive device and the refill plate detachably connected to the connection block; so that when the drive shaft of the drive device rotates, the refill plate can rotate; and the The print head faces the refill plate. The printing device can more accurately print the model according to the actual modeling requirements.

Owner:ANHUI LANWA ELECTRONICS TECH CO LTD

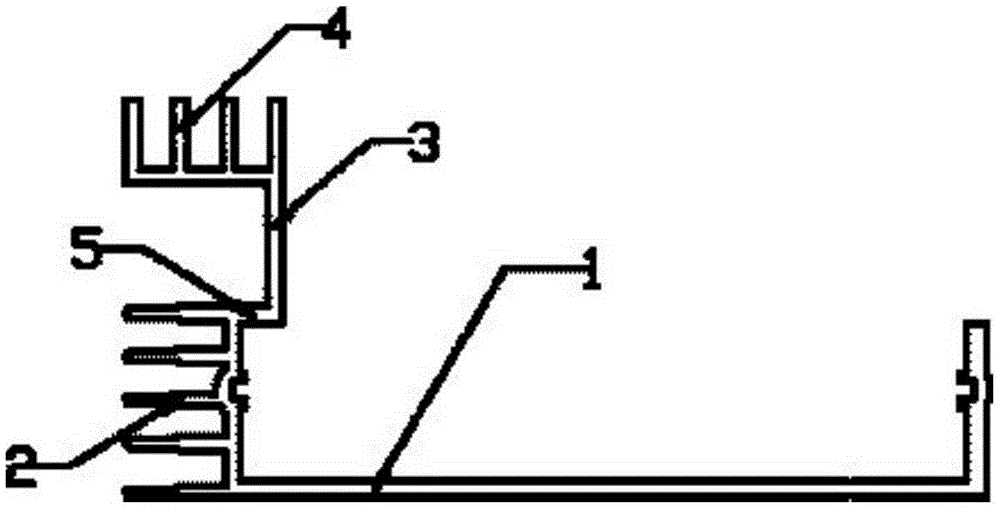

Energy-saving radiator proximate matter

InactiveCN106686941AReduce dosageImprove conductivityModifications by conduction heat transferProximateEngineering

The invention discloses a radiator, specifically to an energy-saving radiator proximate matter. The energy-saving radiator proximate matter comprises a substrate with a groove-structured section, wherein cooling fins which extend to the outside of the substrate are arranged on one lateral side of the substrate; an extension sheet which extends upwardly is arranged above one lateral side of the cooling fins; upper sheet materials which are arranged in parallel are arranged at the upper end of the extension sheet; and the upper sheet materials are positioned outside the substrate. By virtue of the structure, the conductivity can be improved while material usage amount is lowered; meanwhile, adverse factors in the installation process of aluminum proximate matter are solved; an effect of energy saving, consumption reducing, cost lowering, and working efficiency improving is also achieved; and in addition, requirement of the existing market is satisfied while demands of clients are also satisfied.

Owner:NINGXIA QIKAI ENERGY SAVING EQUIP

A building floor thickness detector

ActiveCN111561886BAccurate thickness detectionNot prone to deviationUsing wave/particle radiation meansFloor slabDisplay device

Owner:江西润洋工程检测有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com