Feeding device applicable to infrared plastic ball welding machine

A technology of plastic balls and feeding devices, applied in the field of welding, can solve the problems of reducing the accuracy of product placement, inaccurate product welding, and increasing labor intensity, achieving the effects of not easy deviation, avoiding defective products, and reducing labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

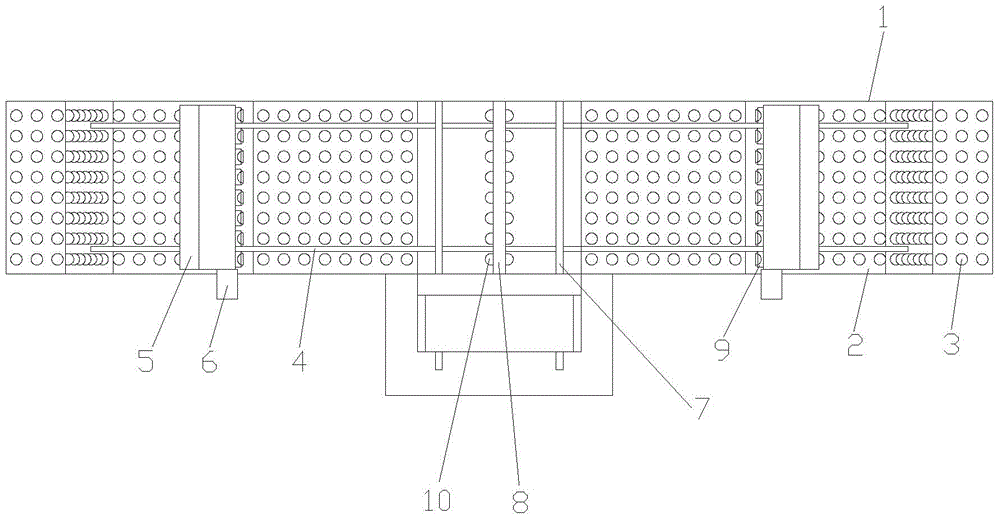

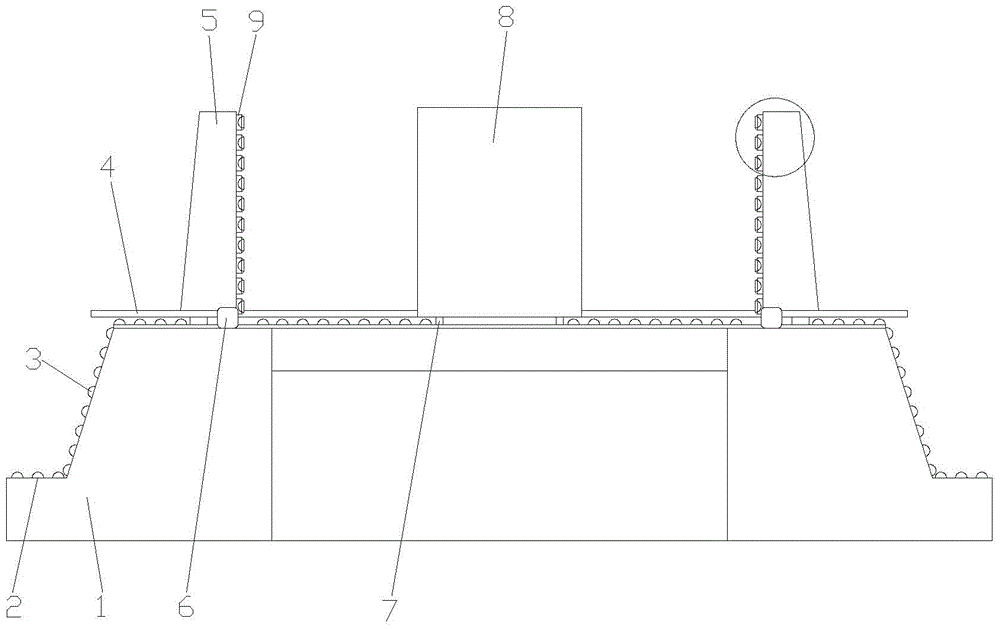

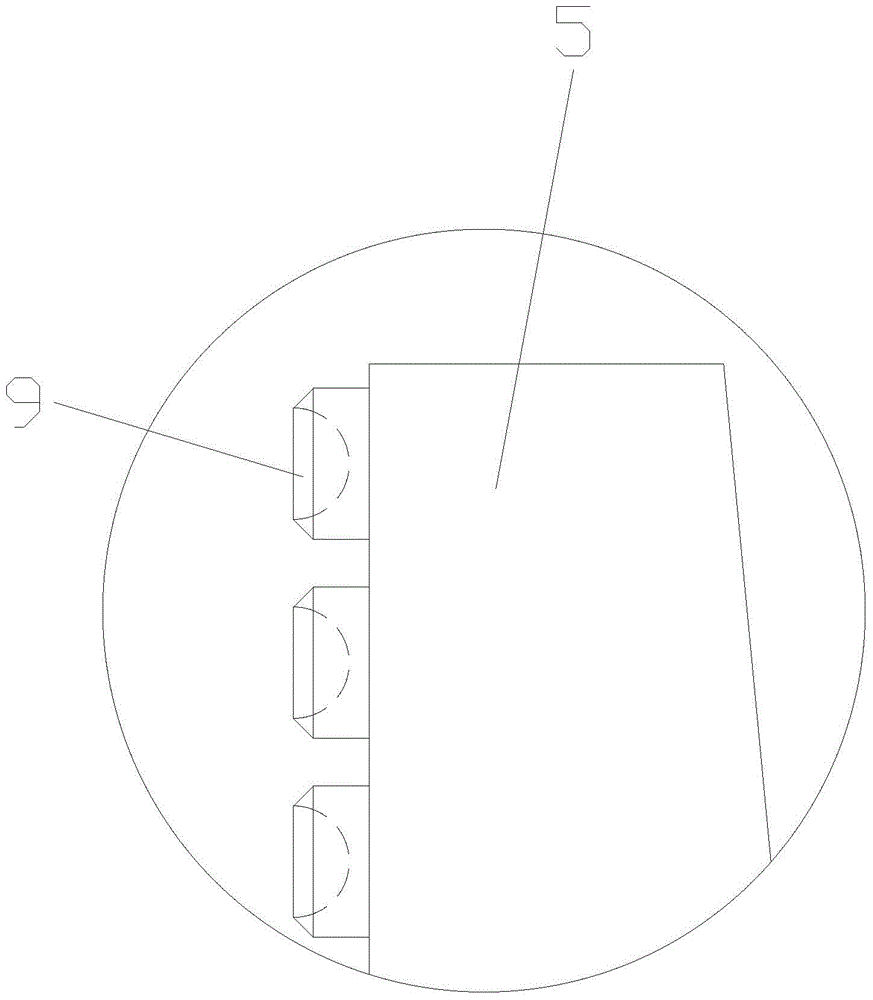

[0017] The present invention is described below in conjunction with accompanying drawing.

[0018] as attached Figure 1-3 The shown present invention includes a feeding machine platform 1, a feeding device and a feeding device; the feeding device and the feeding device are arranged on the feeding machine table 1; the feeding device is a conveyor belt 2; Two conveyor belts 2 are symmetrically arranged on the left and right; a plurality of first hemispherical protrusions 3 are arranged in an array on the conveyor belt 2; The moving slide rail 7 and the material transfer fixed module 8; the first moving slide rail 4 is horizontally arranged on the feeding machine platform 1; the taking-up fixed module 5 can be moved left and right and arranged on the first moving slide rail 4; There are two fixed modules 5 for taking materials left and right symmetrically arranged; the fixed module 5 for taking materials is provided with a motor 6; Two moving slide rails 7 are vertically arran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com