Chain feeding square tube punching machine

A punching machine and punching technology, applied in the field of machinery, can solve the problems of irregular material, short die life, difficult to arrange neatly, etc., and achieve the effect of neat and regular arrangement, high production efficiency, and easy management.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

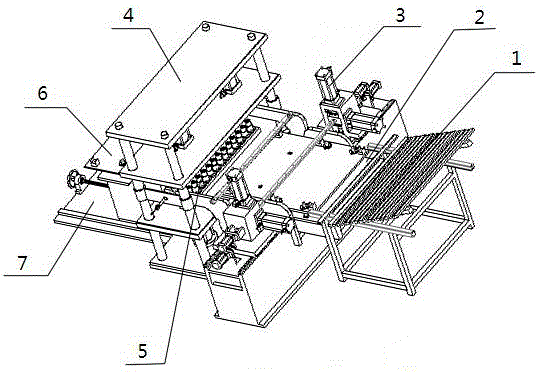

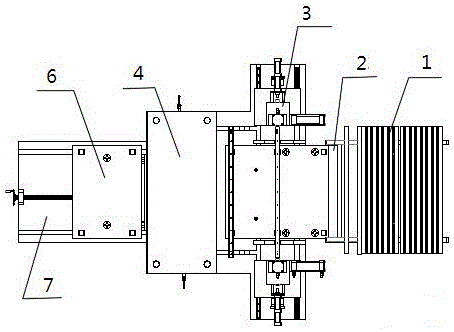

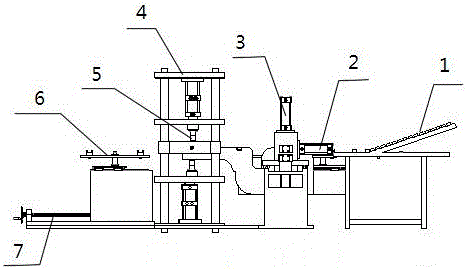

[0017] The present invention will be further described below in conjunction with accompanying drawing:

[0018] A square tube punching machine, characterized in that it includes a material accumulation area 1, a material finishing structure 2, an end punching mechanism 3, a punching hydraulic frame 4, a punching die 5, a moving frame for unloading finished products 6, and a moving frame for changing molds 7. Equipped with a PLC controller and equipped with a touch screen, and the material accumulation area 1 is equipped with a chain feeding mechanism, the chain feeding mechanism includes a feeding table 8, a finishing chain 9, a floating cylinder 10 is set under the right end of the feeding table 8, and a floating cylinder 10 is set at the left end of the feeding table 8 The first material retaining plate 11; also comprise motor 12, motor control finishing chain 9 rotates; Feeding platform 8 left ends are provided with conveying chain 13, conveying chain 13 middle part tops are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com