Section bar screw pull-riveting machine

A riveting machine and screw technology, applied to conveyors, conveyor objects, rotary conveyors, etc., can solve the problems of lack of automation in production, failure to meet production requirements, and increase labor intensity of workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The technical solutions of the present invention will be described below in conjunction with the accompanying drawings and embodiments.

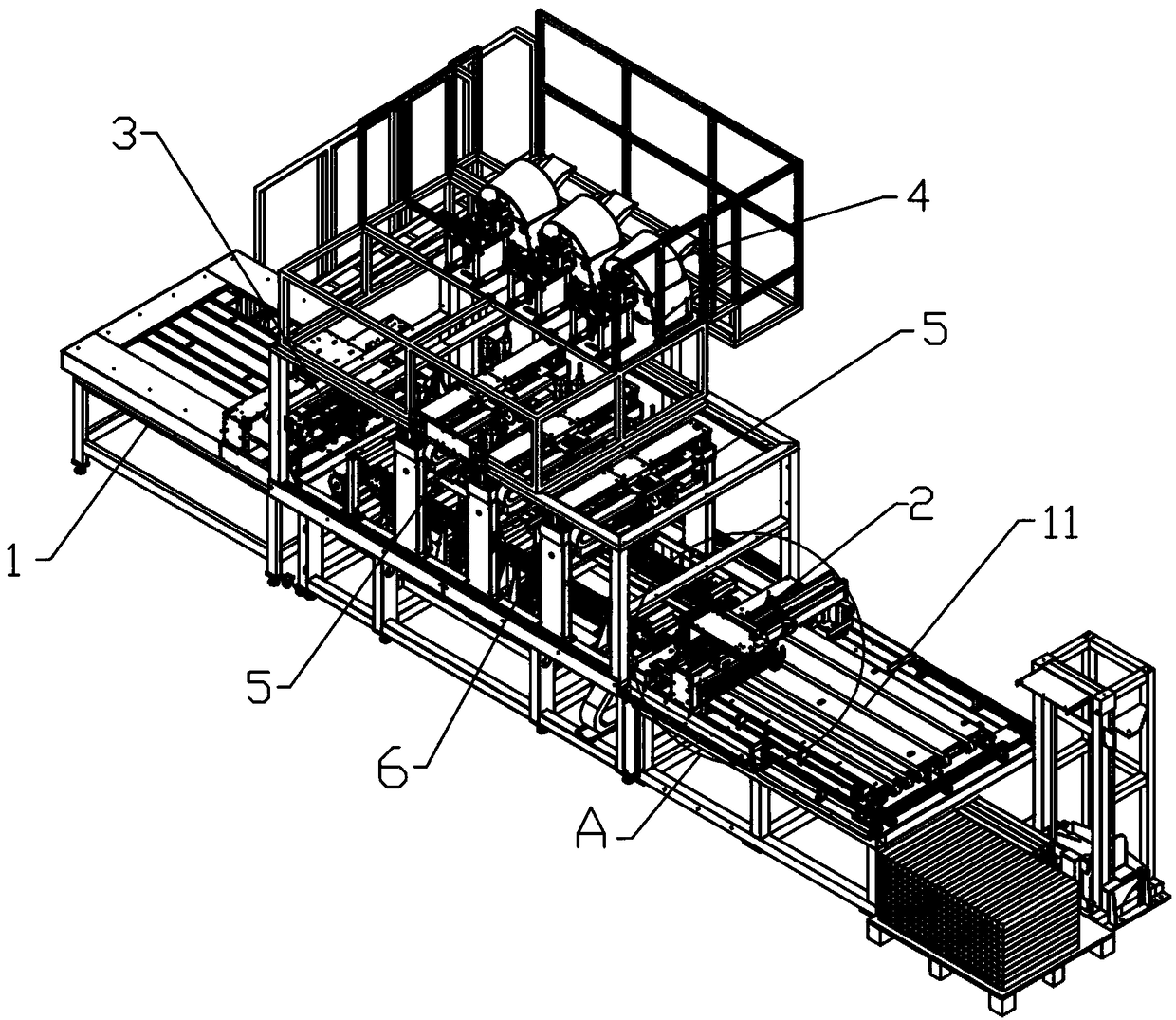

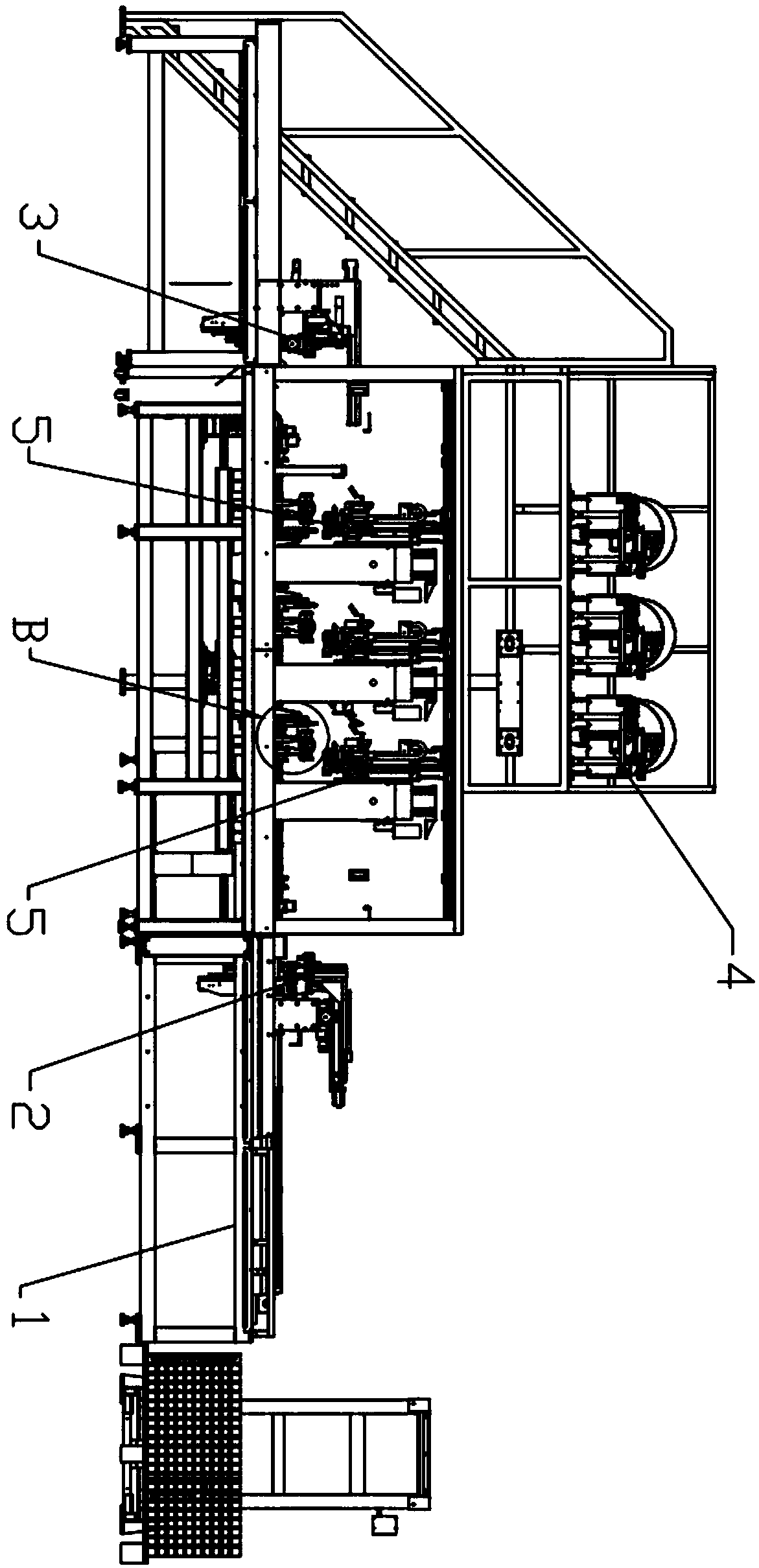

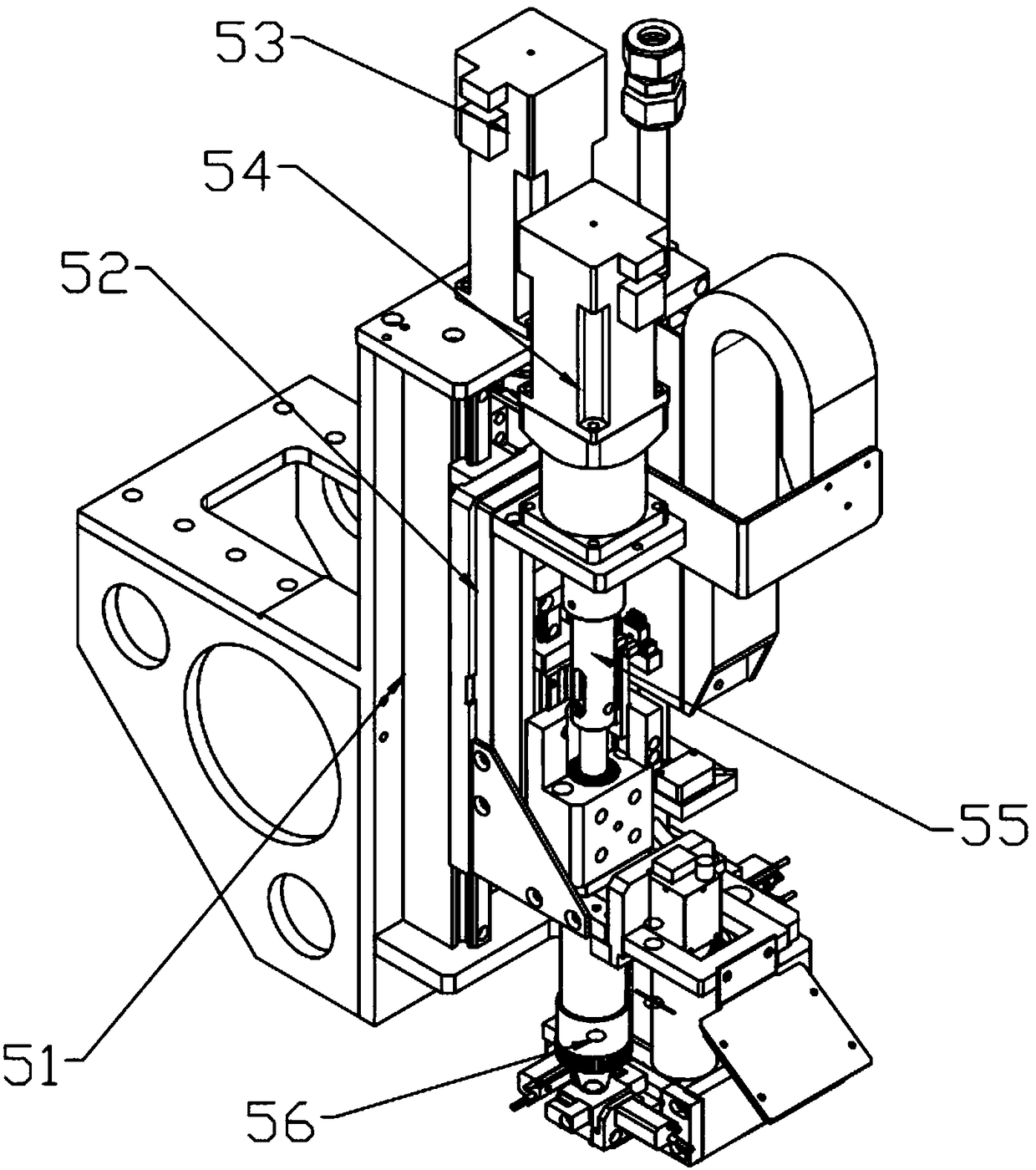

[0031] Such as Figure 1 to Figure 11 As shown, a profile screw riveting machine according to the present invention includes a frame 1, on which a plurality of moving chains 11 are arranged in parallel for conveying profiles, and the frame has two layers, The top layer is provided with a plurality of screw blanking mechanisms 4, and the bottom layer is respectively provided with a loading mechanism 2, a plurality of screw riveting mechanisms 5, a blanking mechanism 3 and a positioning mechanism 6 from right to left, and the positioning mechanism 6 is located on the screw pulling mechanism. Below the riveting mechanism 5, the loading mechanism 2 has the same structure as the unloading mechanism 3; wherein, the screw riveting mechanism 5 includes a riveting frame 51, and the riveting frame 51 is slidingly connected with a Sliding seat ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com