Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

31results about How to "Maximum cleaning" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Steam nozzle attachment for use with steam cleaner

Owner:SHARKNINJA OPERATING LLC

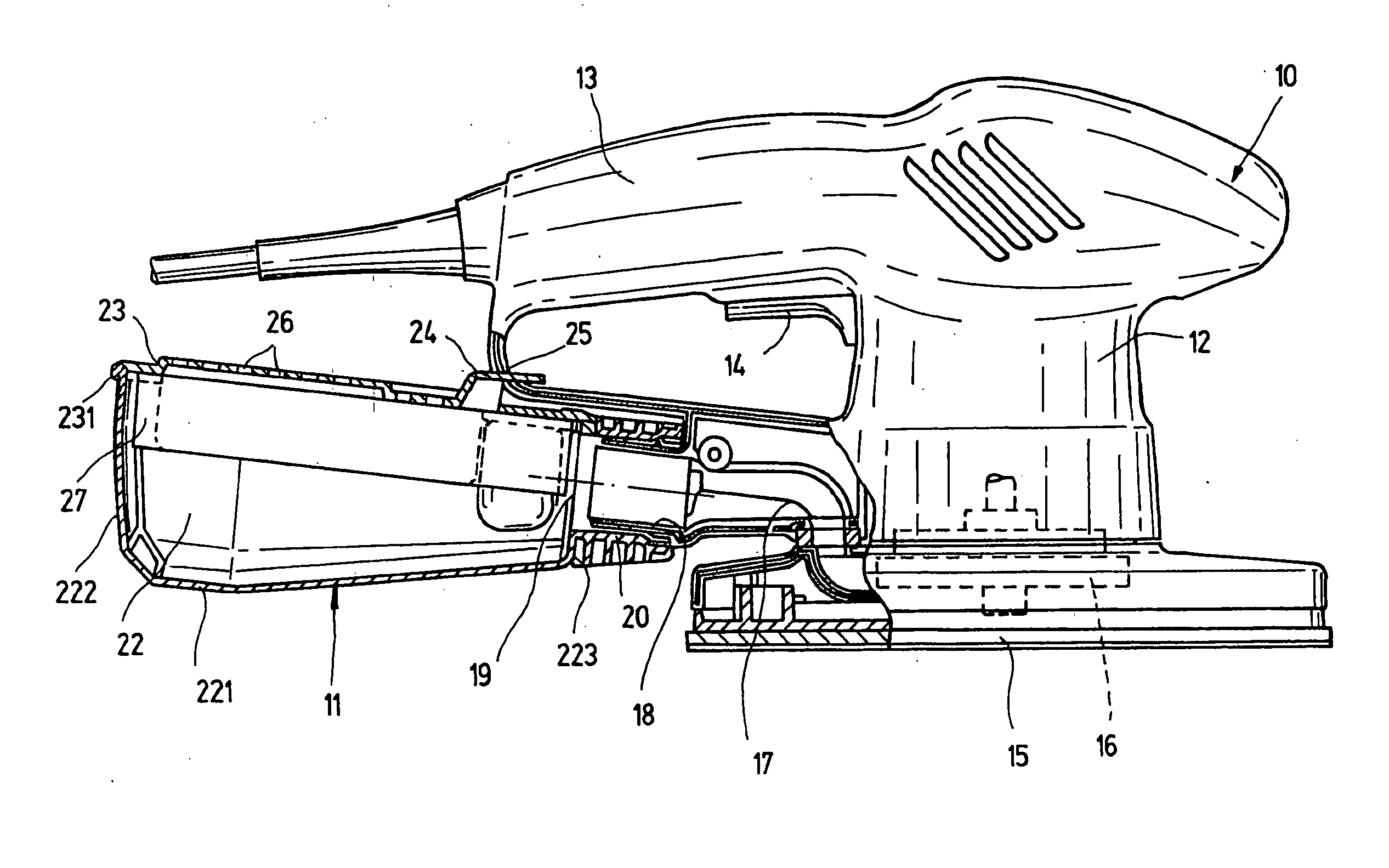

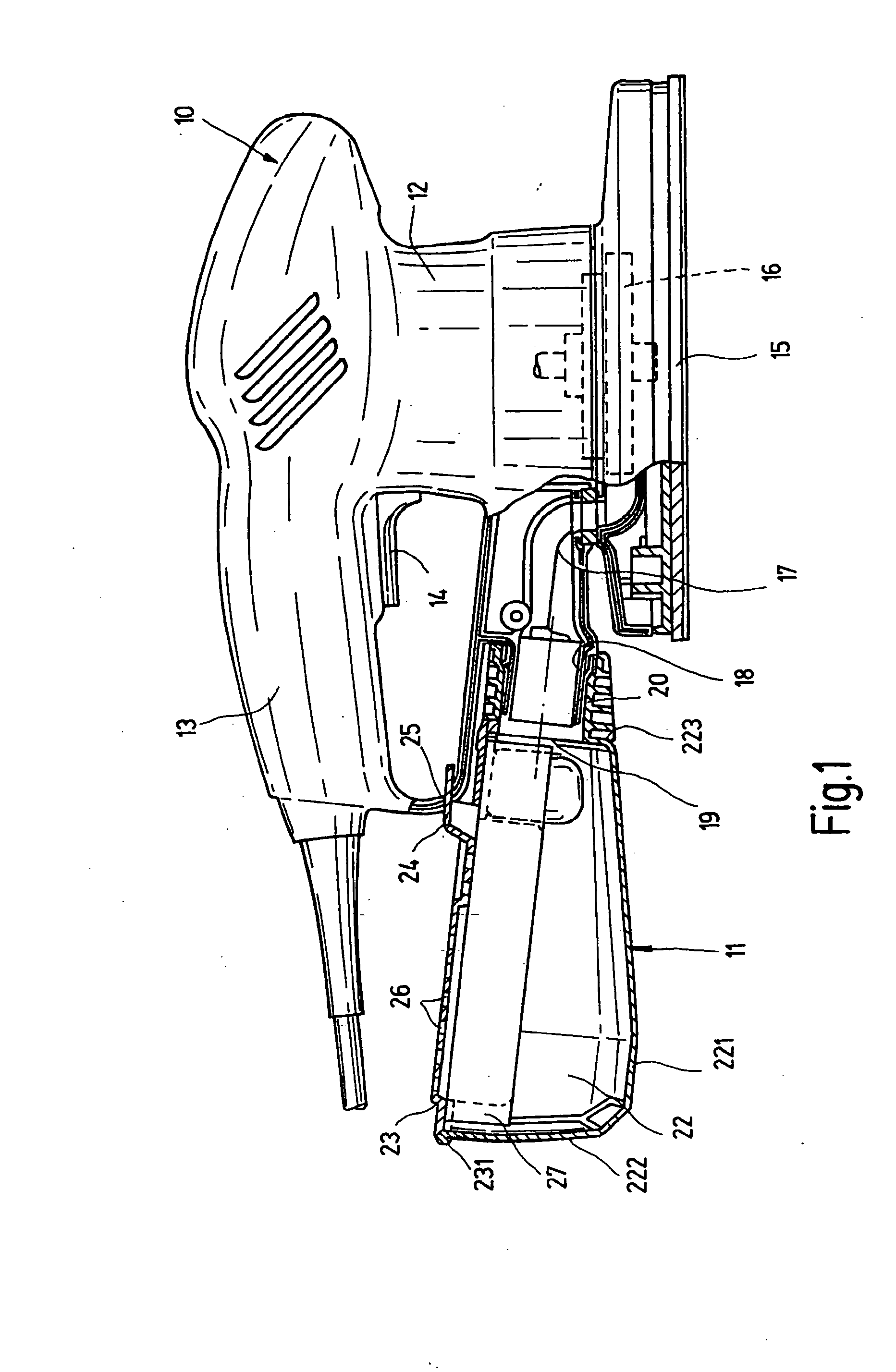

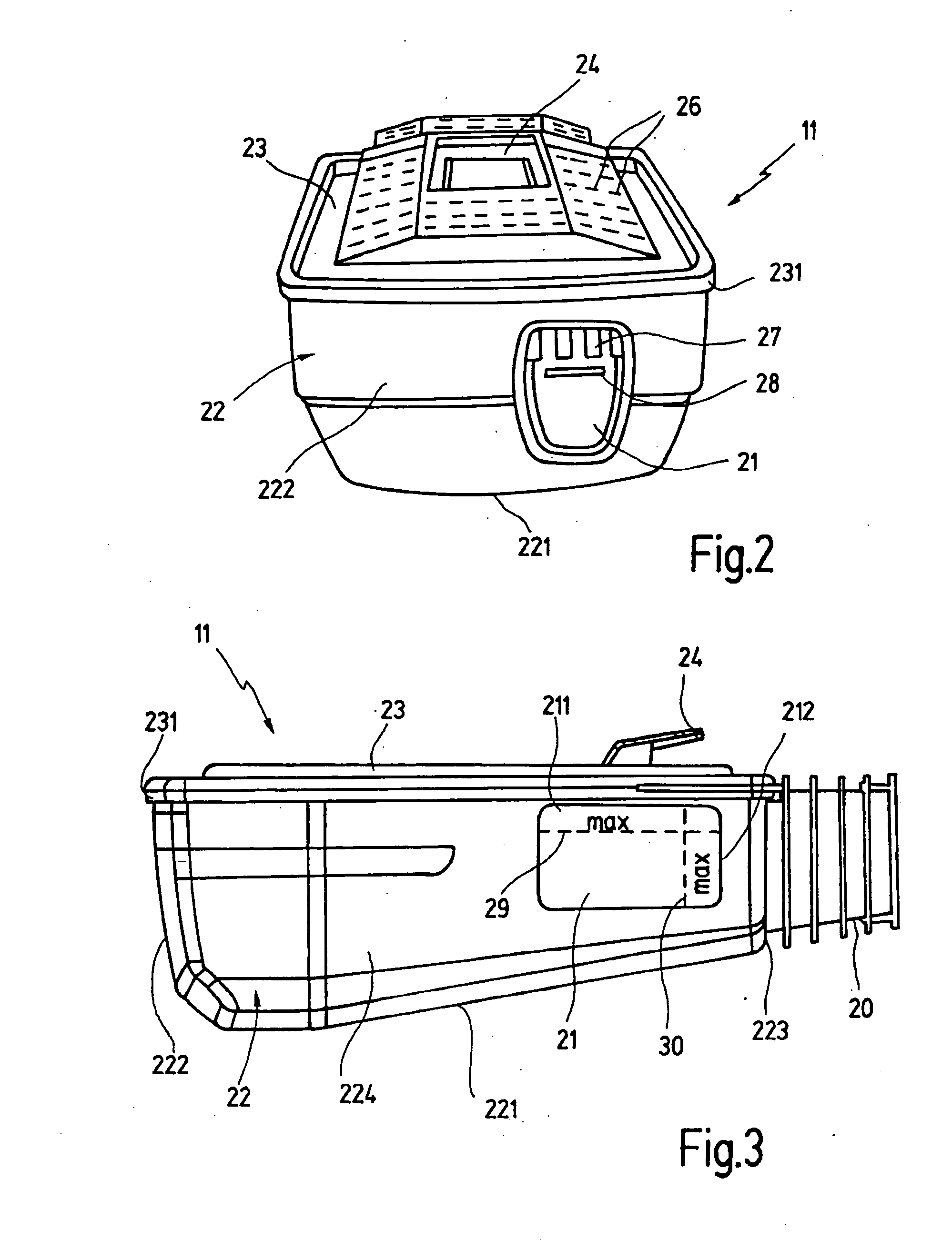

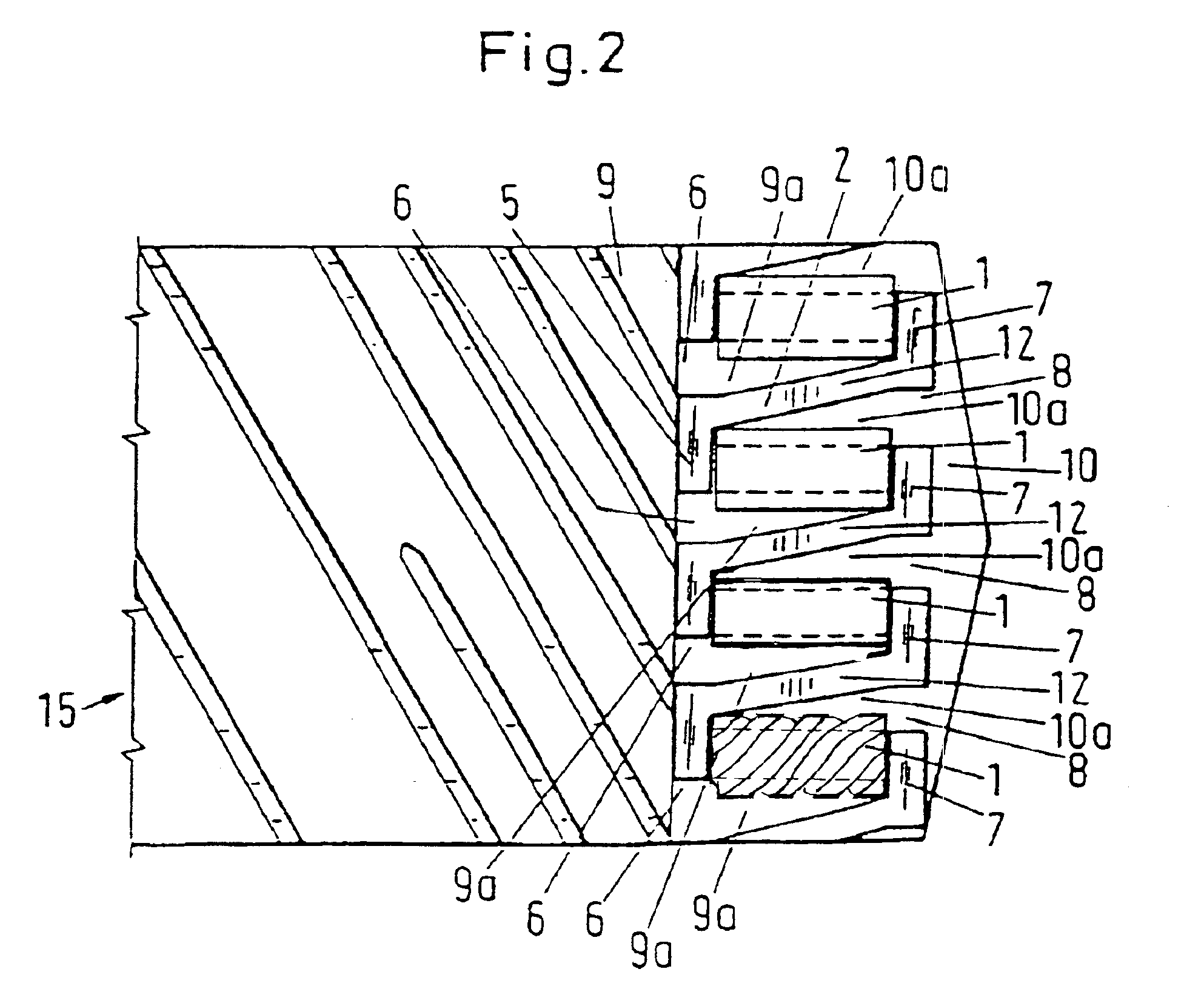

Dust collecting container for a hand-held machine tool

InactiveUS20060276116A1High trafficMaximum cleaningSuction filtersPortable grinding machinesHand heldPower tool

A dust-collection container (11) for a hand-held power tool with a dust-extraction device is indicated that has a container wall that encloses a dust-collection volume and a dust-intake opening (19) for connection to a dust-discharge adapter of hand-held power tools. To ensure timely emptying of the full dust-collection container (11) when working with the hand-held power tool, a viewing window (21) is provided in the container wall, through which the dust fill level can be visually determined.

Owner:ROBERT BOSCH GMBH

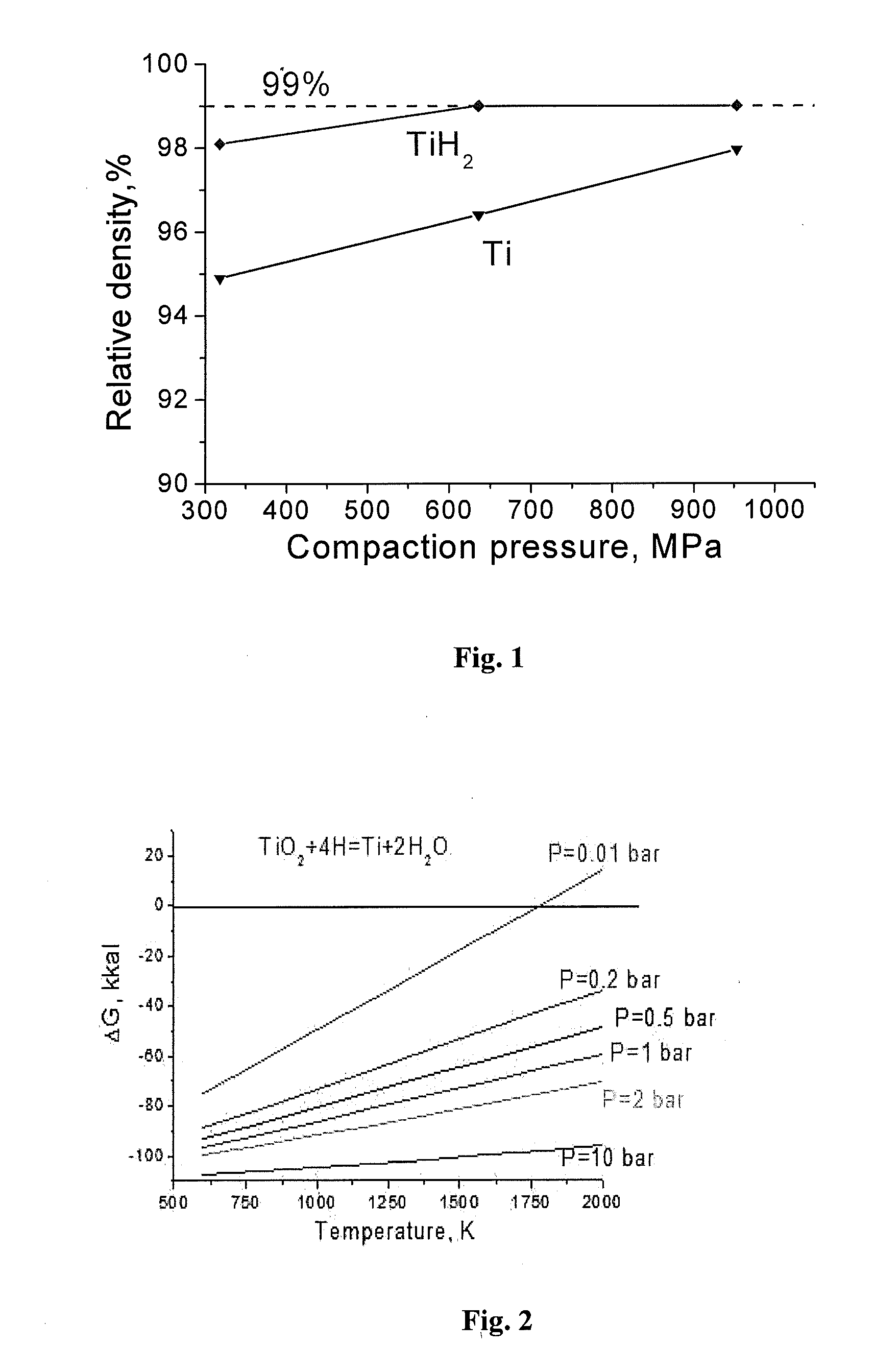

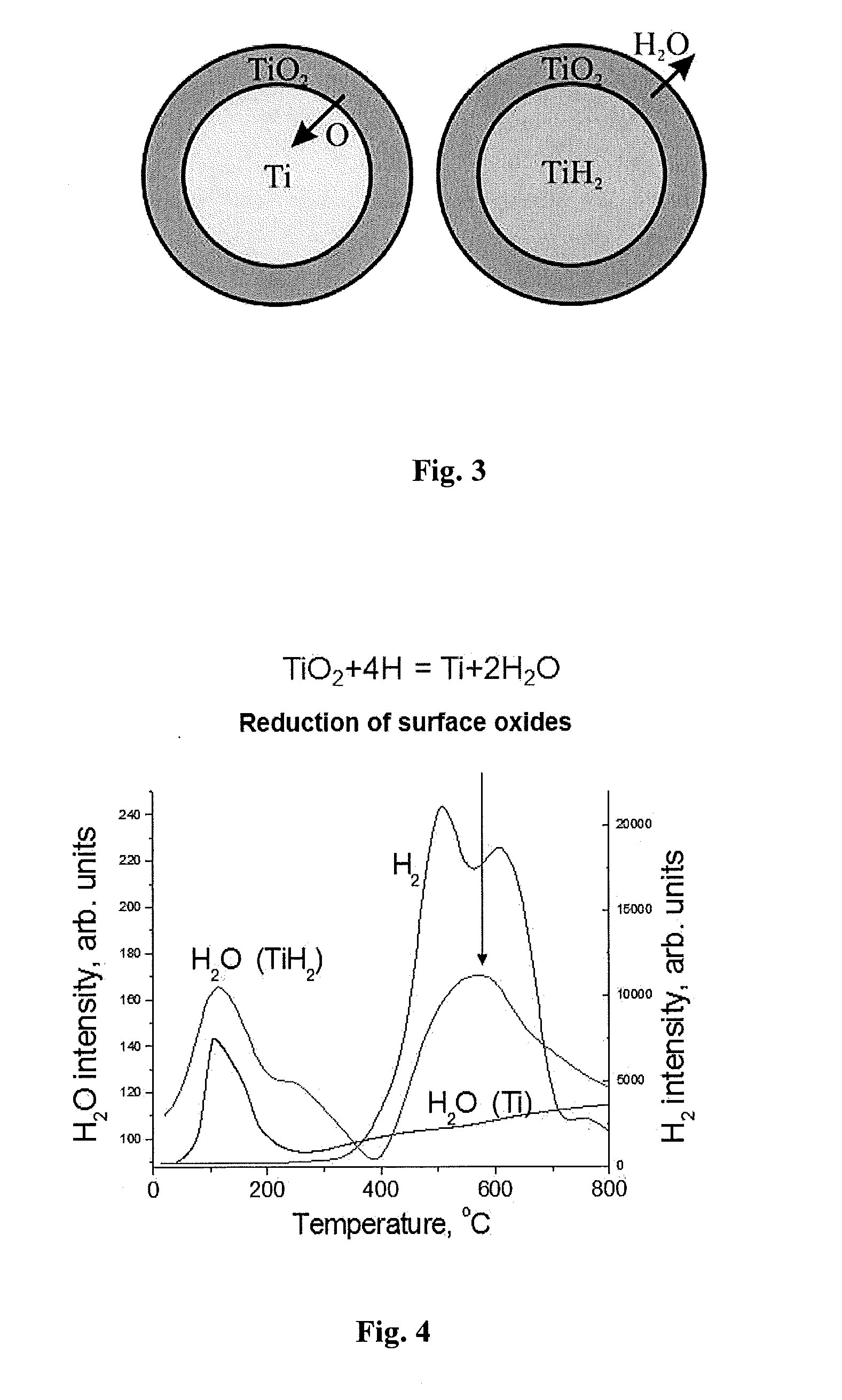

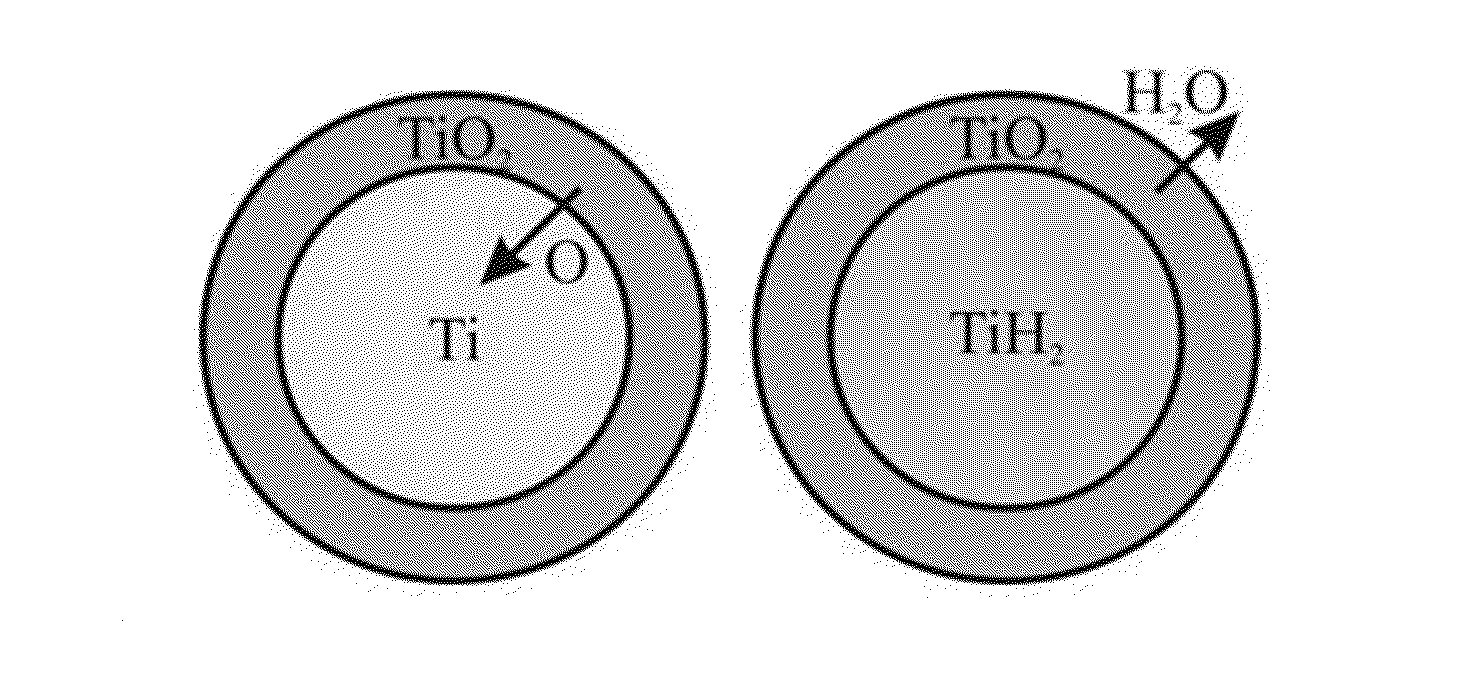

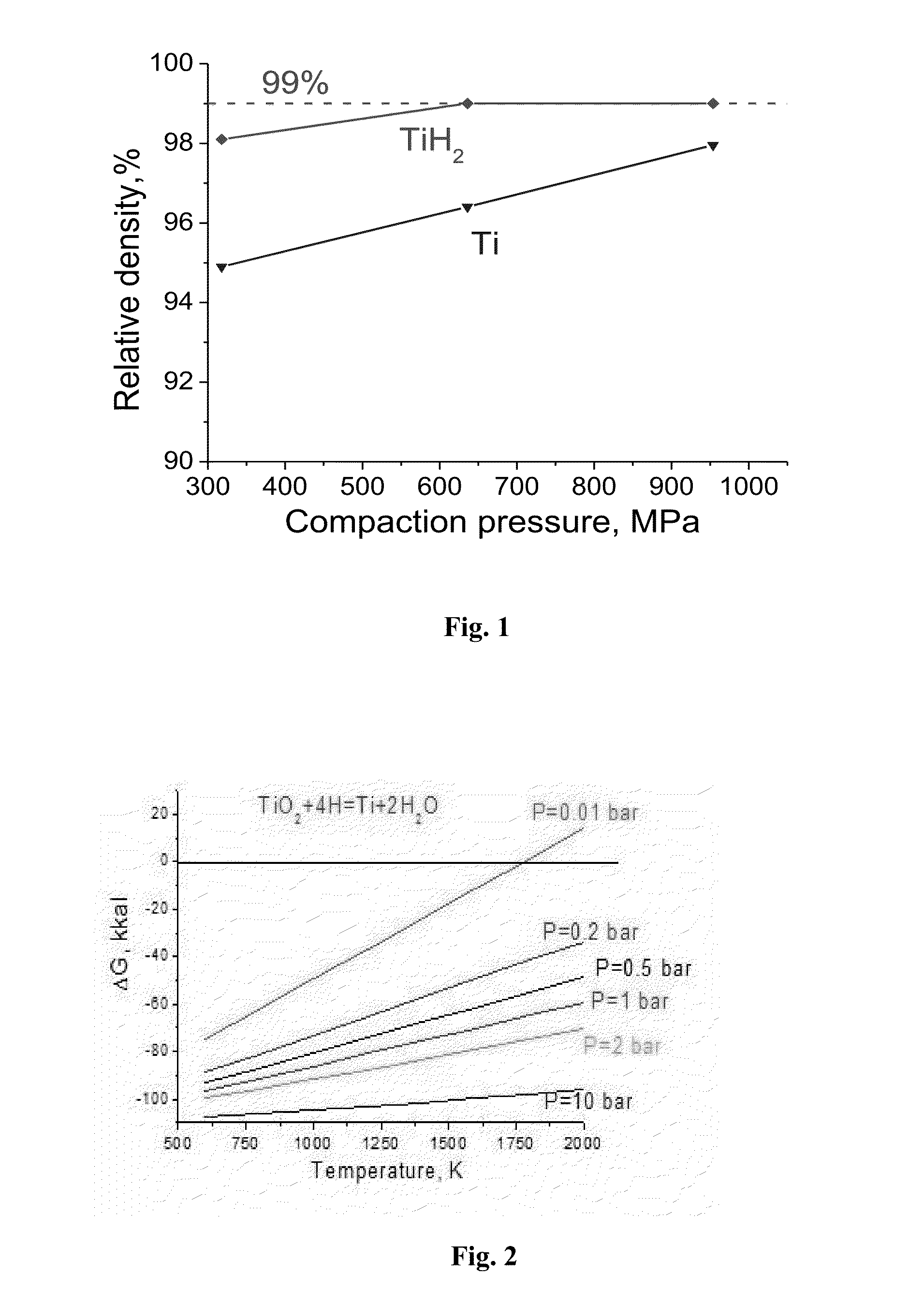

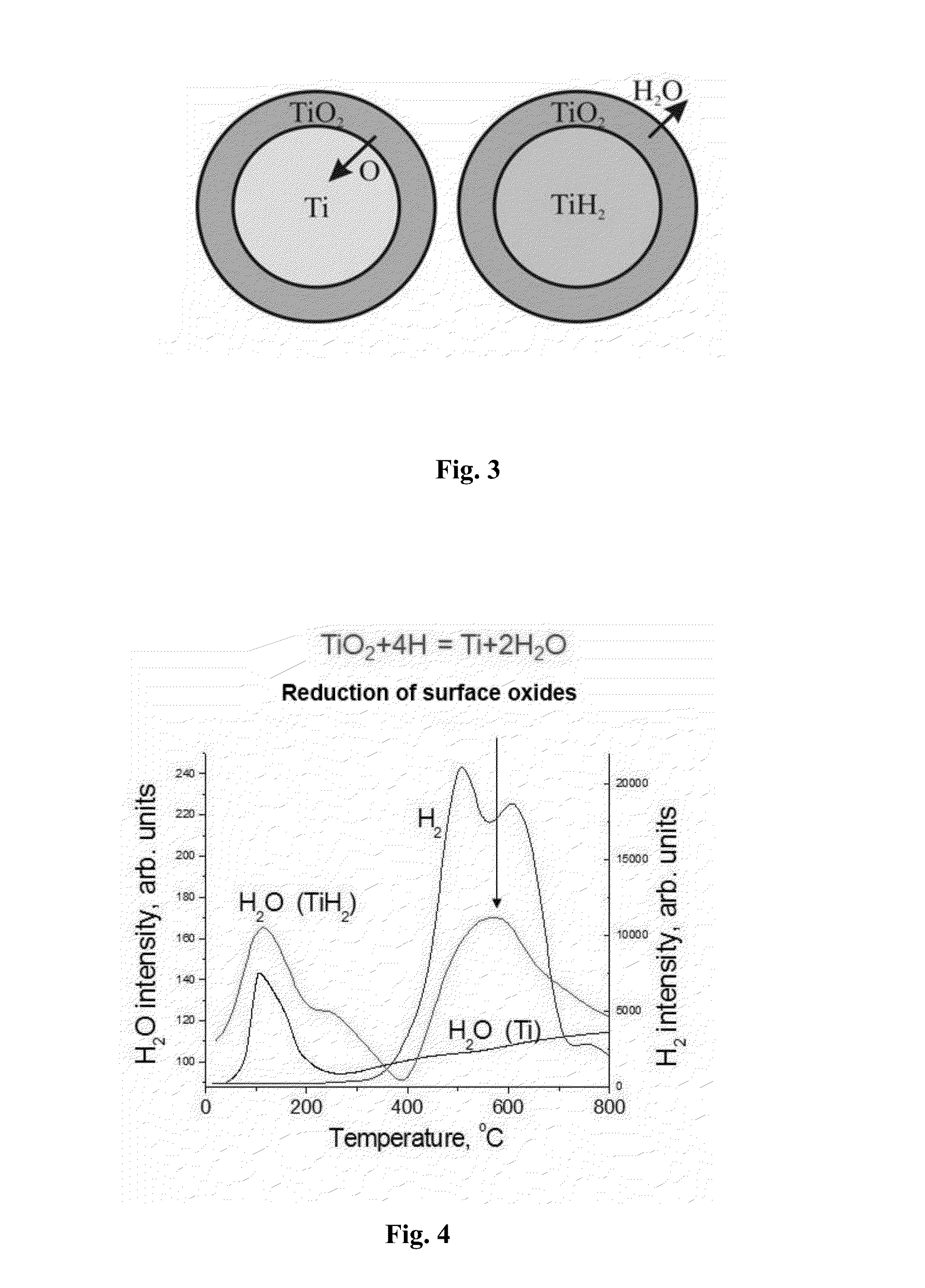

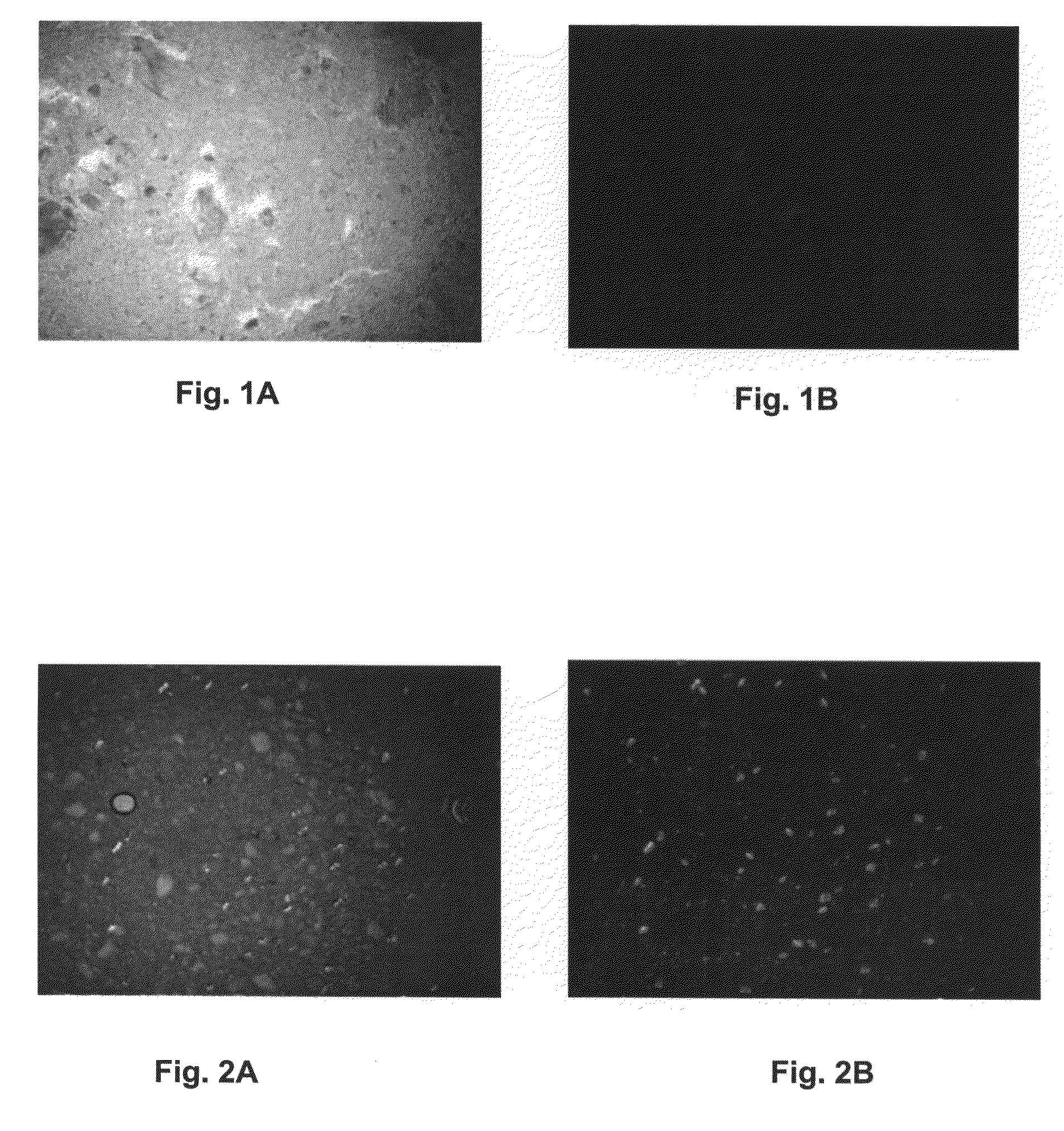

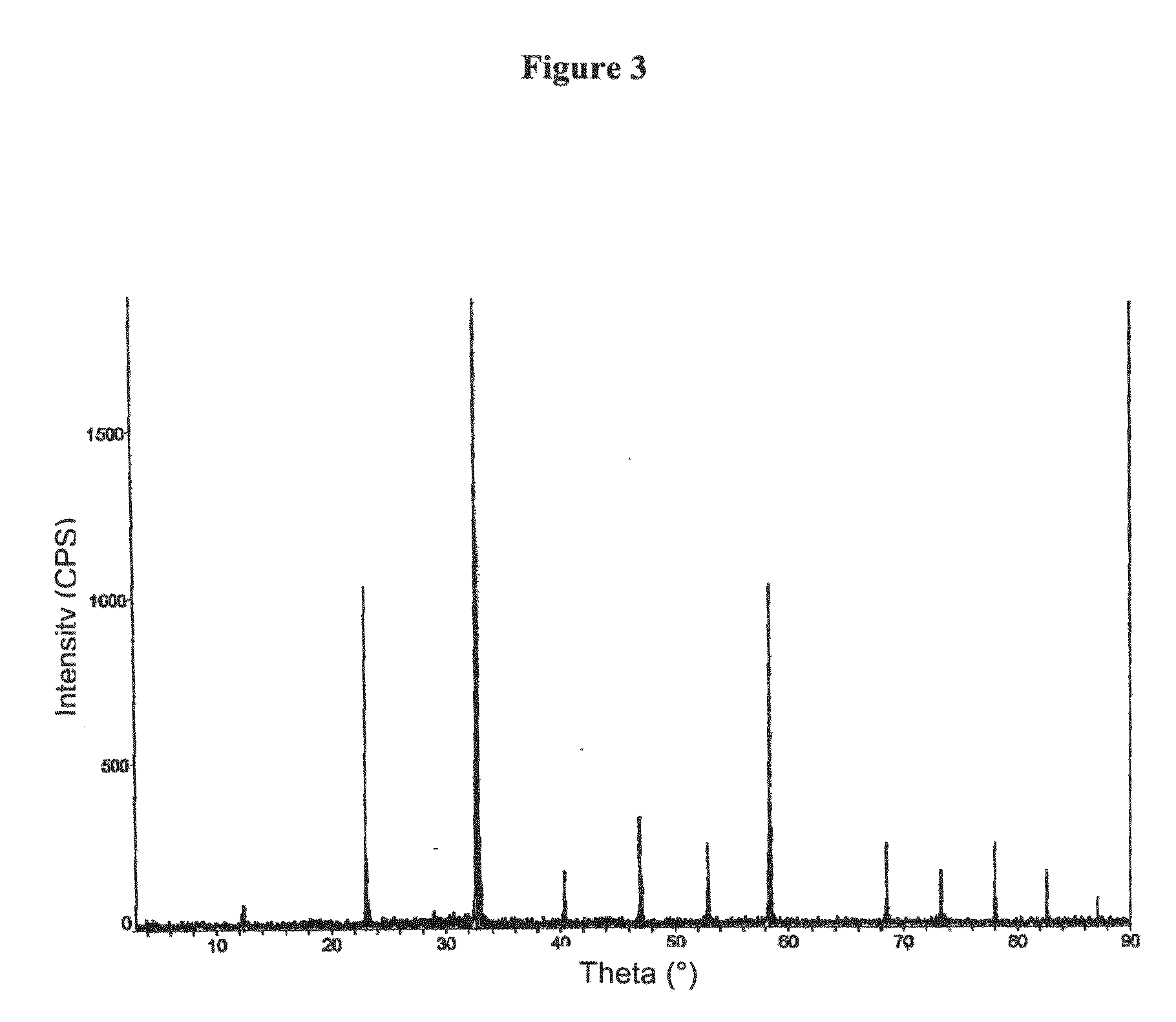

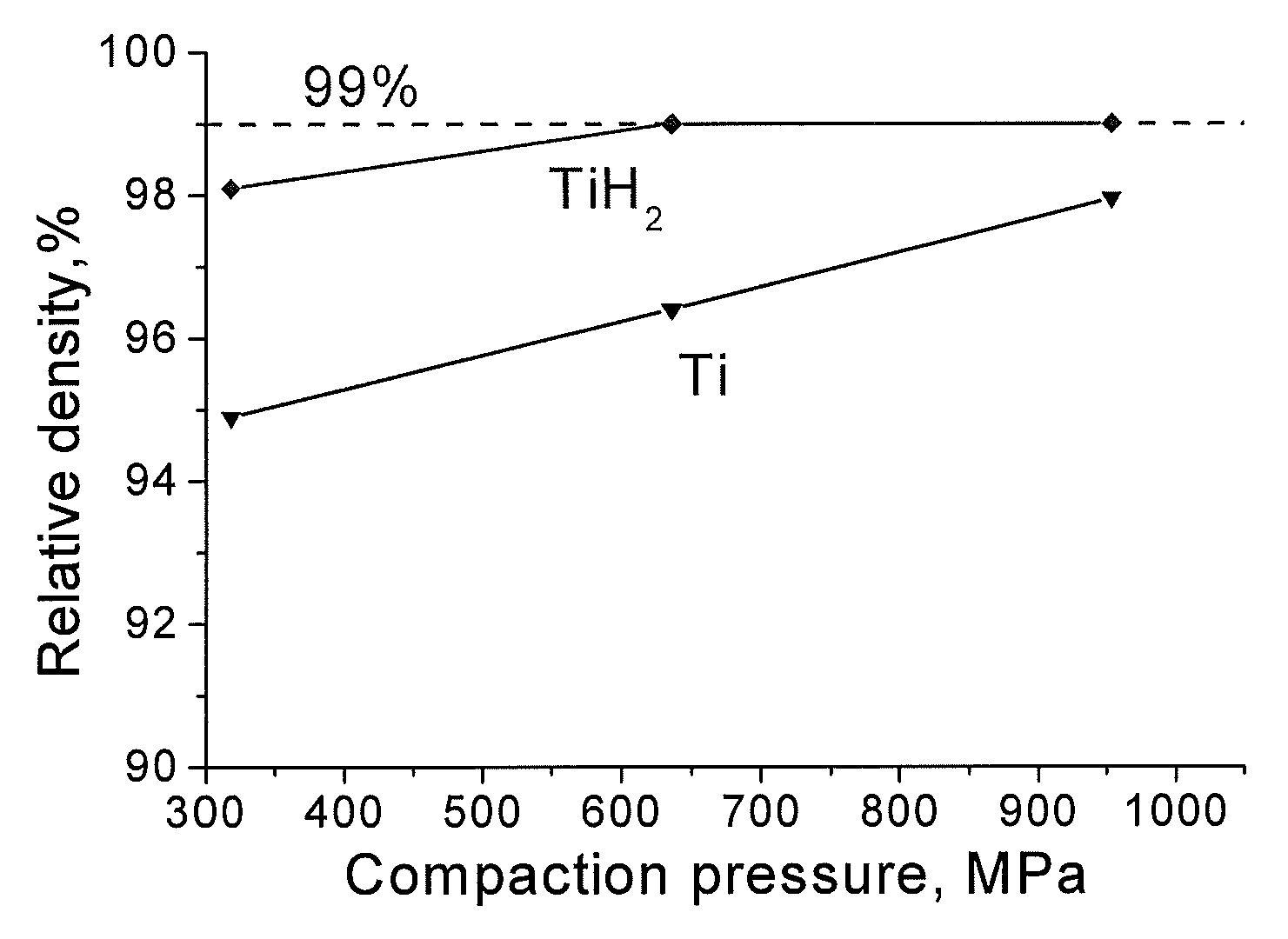

Manufacture of near-net shape titanium alloy articles from metal powders by sintering with presence of atomic hydrogen

ActiveUS20120058002A1Cost-effective manufacturingImprove mechanical propertiesCoatingsDehydrogenationTitanium alloy

A process including:(a) forming a powder blend by mixing titanium powders,(b) consolidating the powder blend by compacting to provide a green compact,(c) heating the green compact thereby releasing absorbed water from the titanium powder,(d) forming β-phase titanium and releasing atomic hydrogen from the hydrogenated titanium by heating the green compact in an atmosphere of hydrogen emitted by the hydrogenated titanium,(e) reducing surface oxides on particles of the titanium powder with atomic hydrogen released by heating of the green compact,(f) diffusion-controlled chemical homogenizing of the green compact and densification of the green compact by heating followed by holding resulting in complete or partial dehydrogenation to form a cleaned and refined compact,(g) heating the cleaned and refined green compact in vacuum thereby sintering titanium to form a sintered dense compact, and(h) cooling the sintered dense compact to form a sintered near-net shaped article.

Owner:ADVANCE MATERIAL PRODS ADMA PRODS

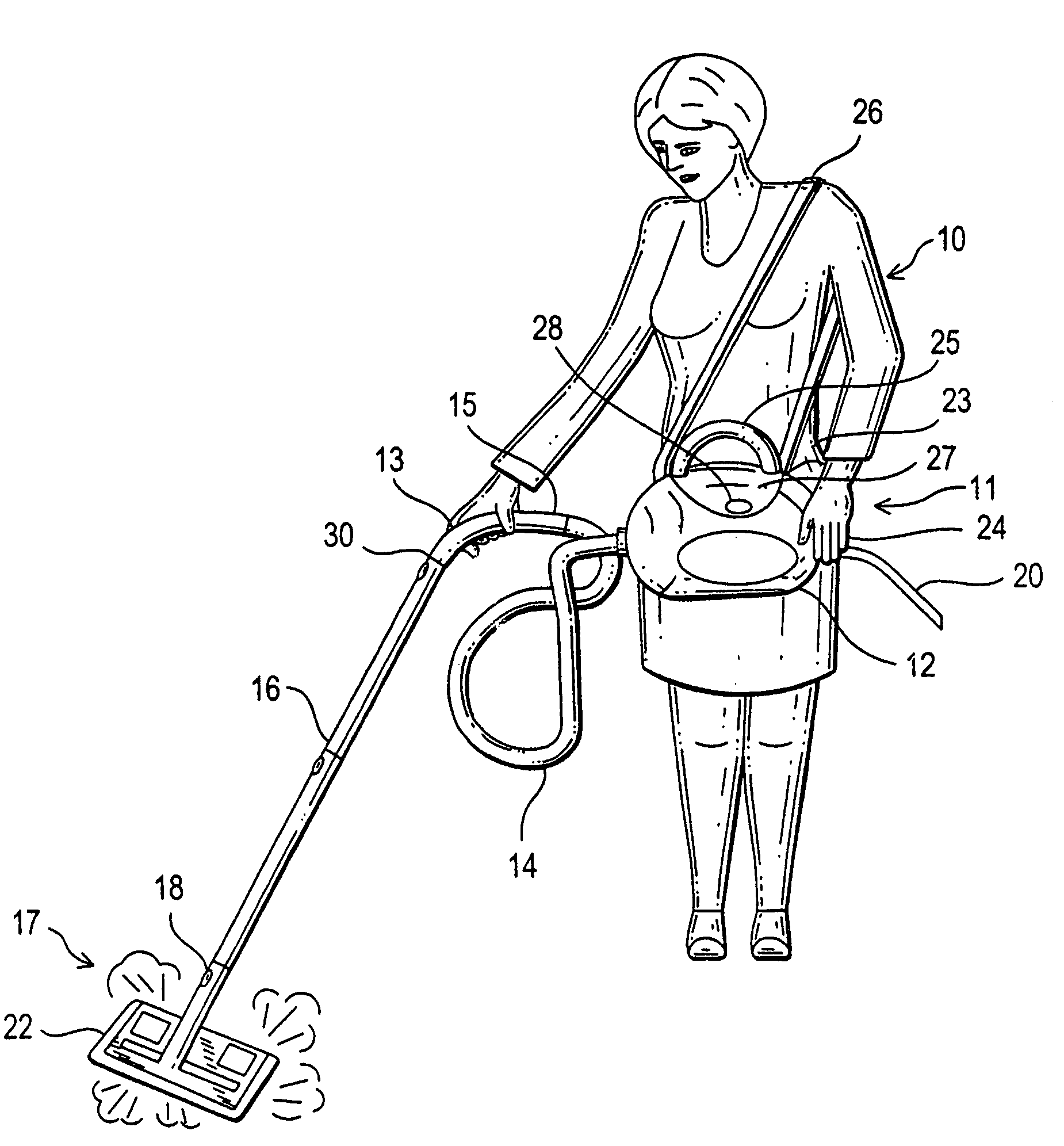

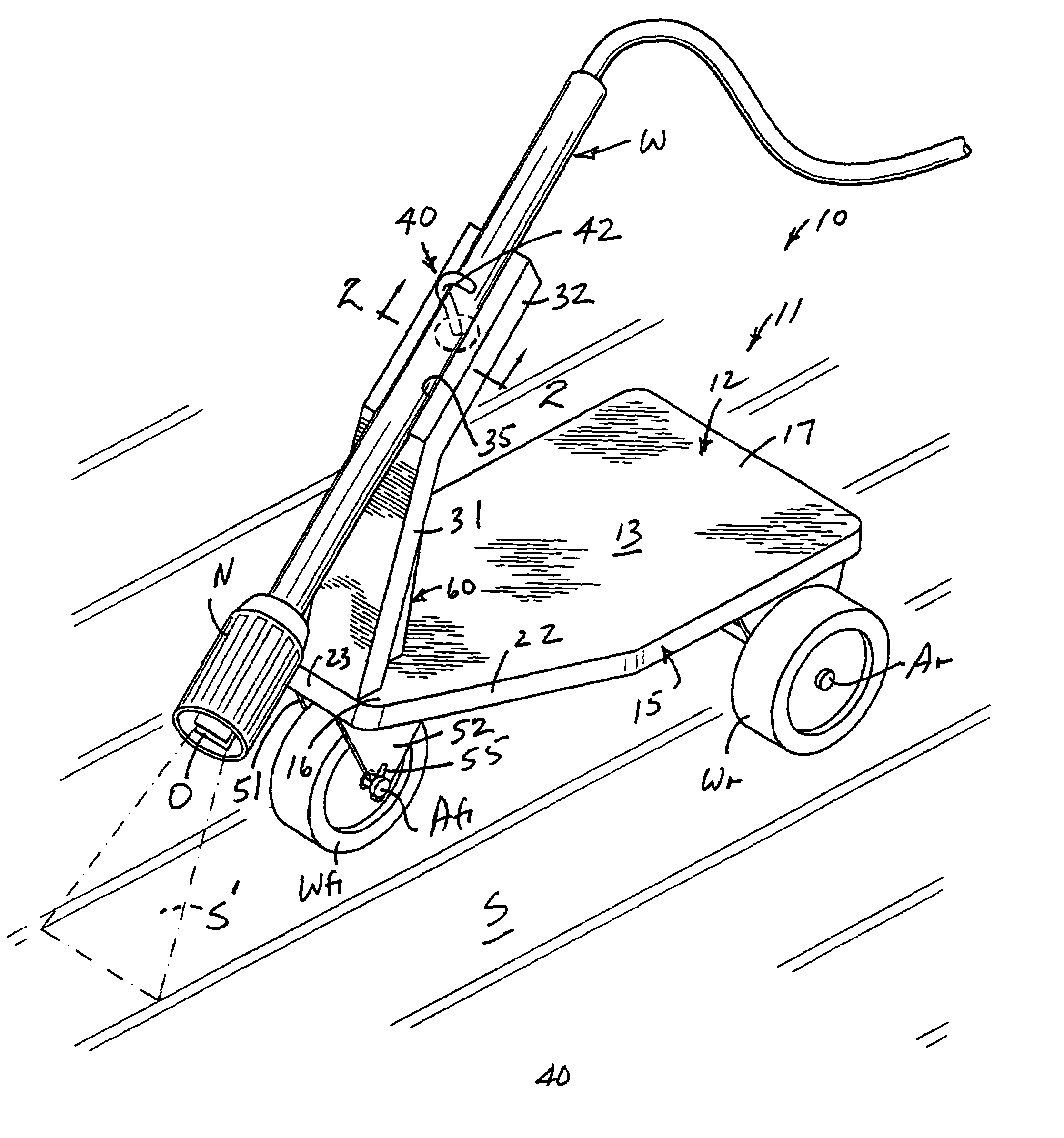

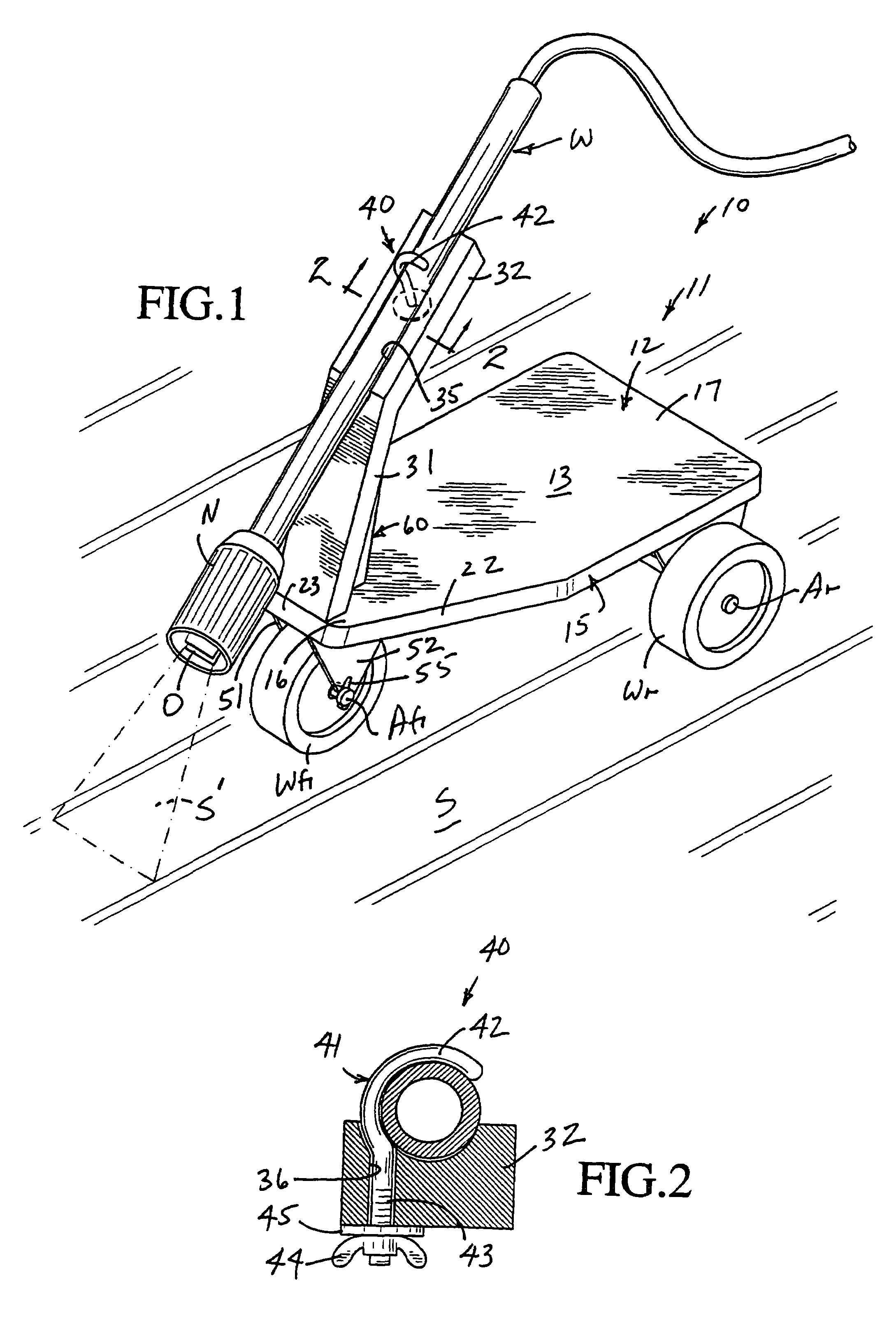

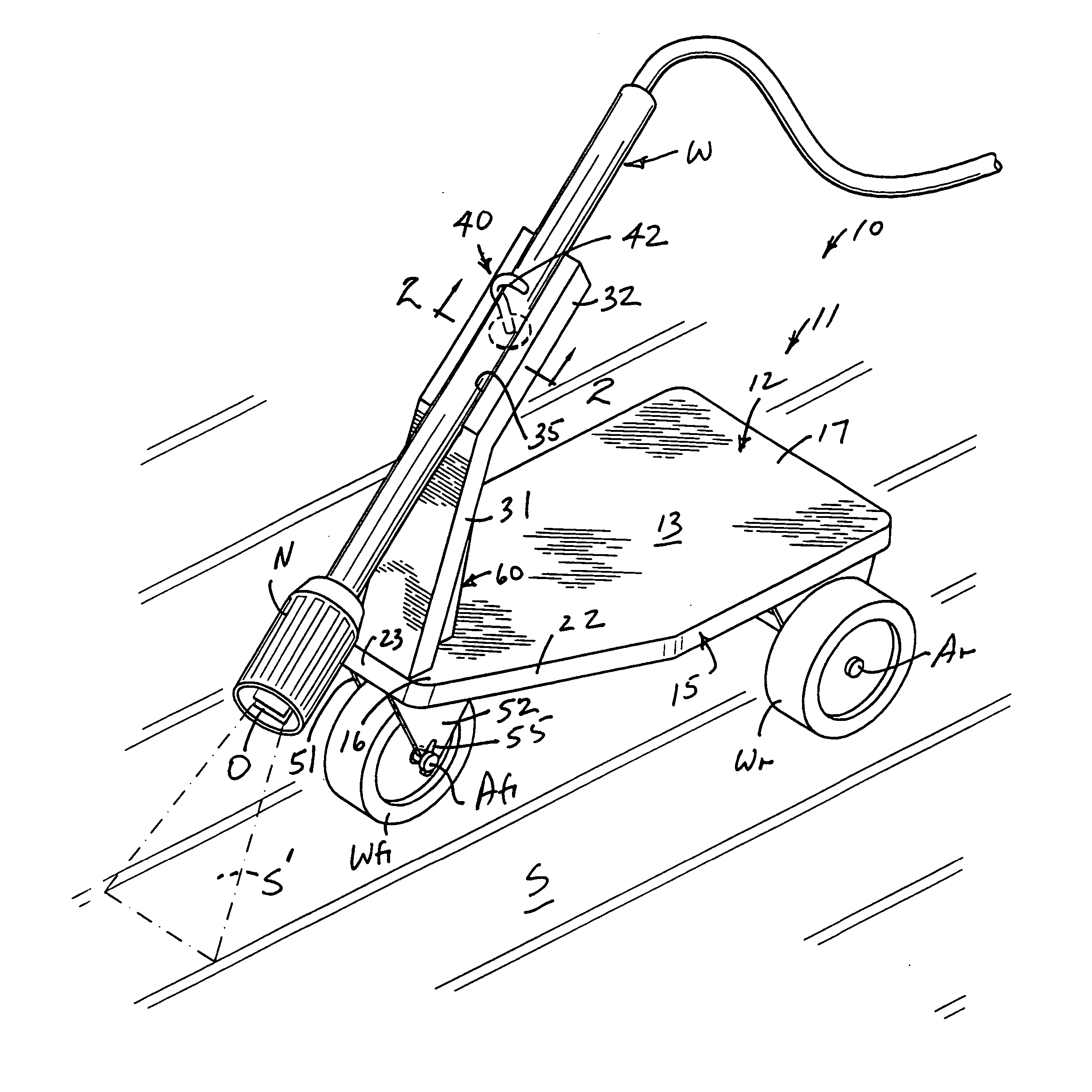

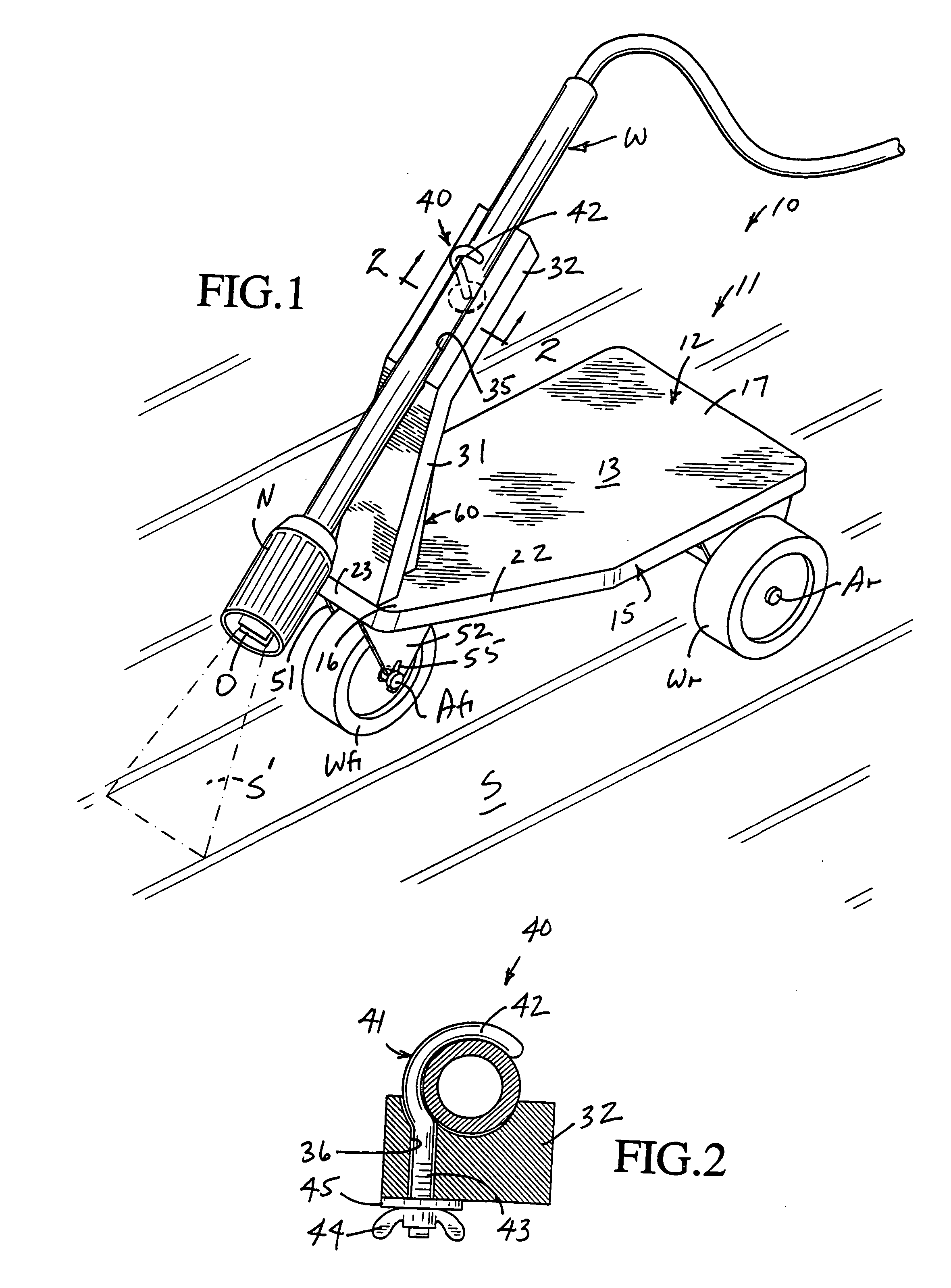

Carriage for a power washer wand

InactiveUS7121484B2Eliminate disadvantagesAugments easeWatering devicesMovable spraying apparatusNosePlastic materials

A carriage designed for supporting a power washer wand and its nozzle a predetermined, though adjustable, distance from a surface which is to be cleaned by high velocity water exiting a discharge orifice of the nozzle. The carriage is defined by a one-piece body molded from substantially high strength synthetic polymeric / copolymeric plastic material. The carriage body includes a platform having a converging front end nose upwardly from which projects a wand support having a channel in which a power washer wand is located and adjustably clamped. The platform includes two wheels at a rear end thereof and a single wheel beneath the front end nose.

Owner:DALEY HOWARD

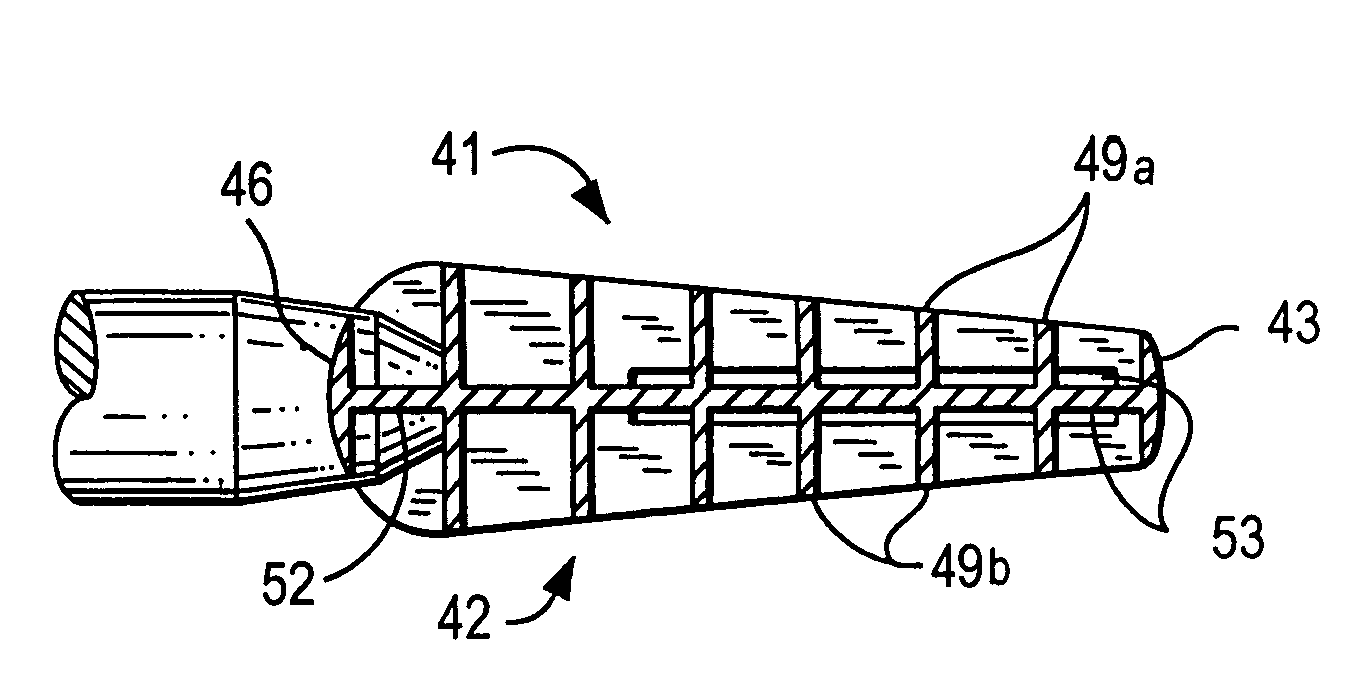

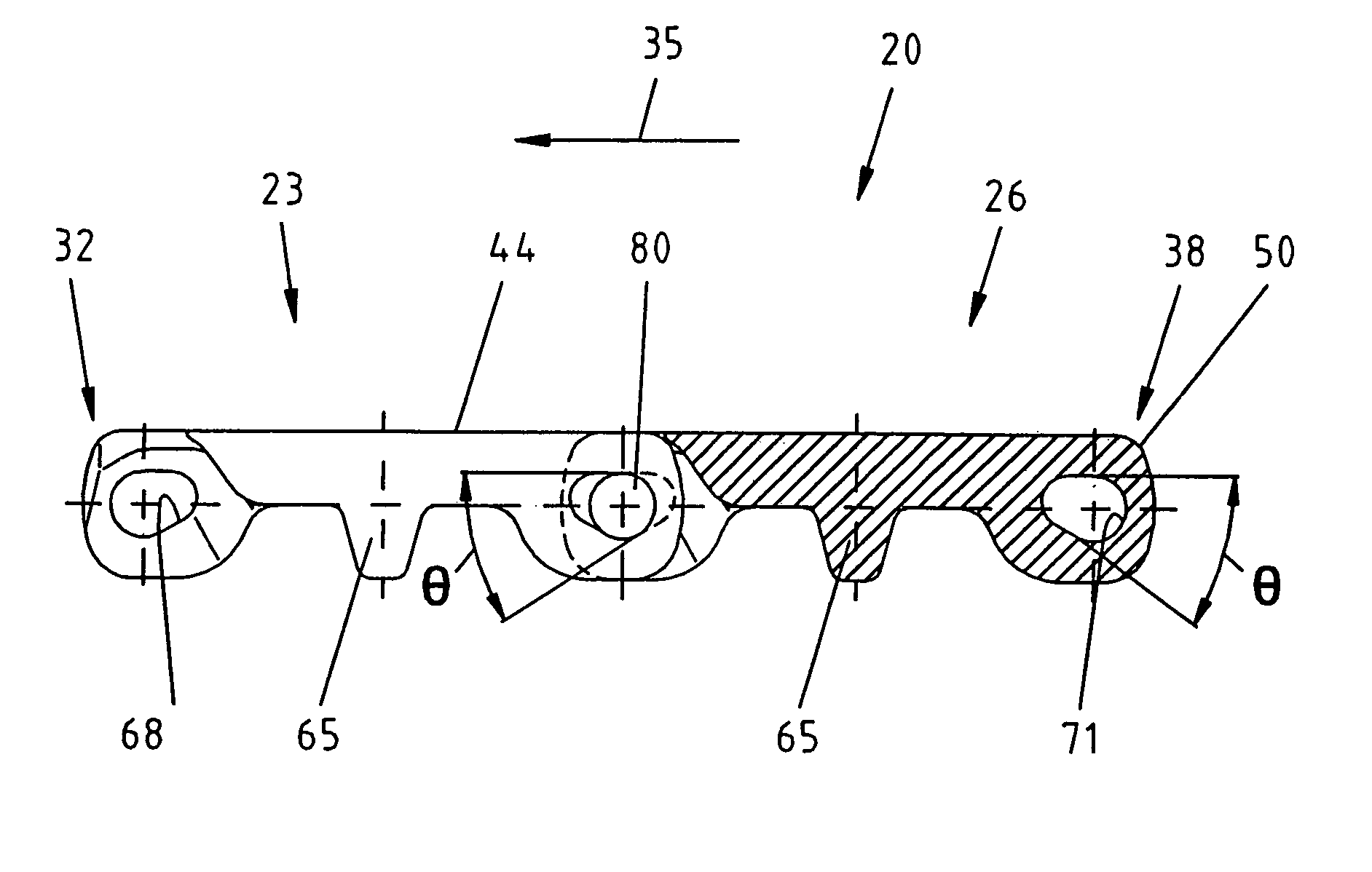

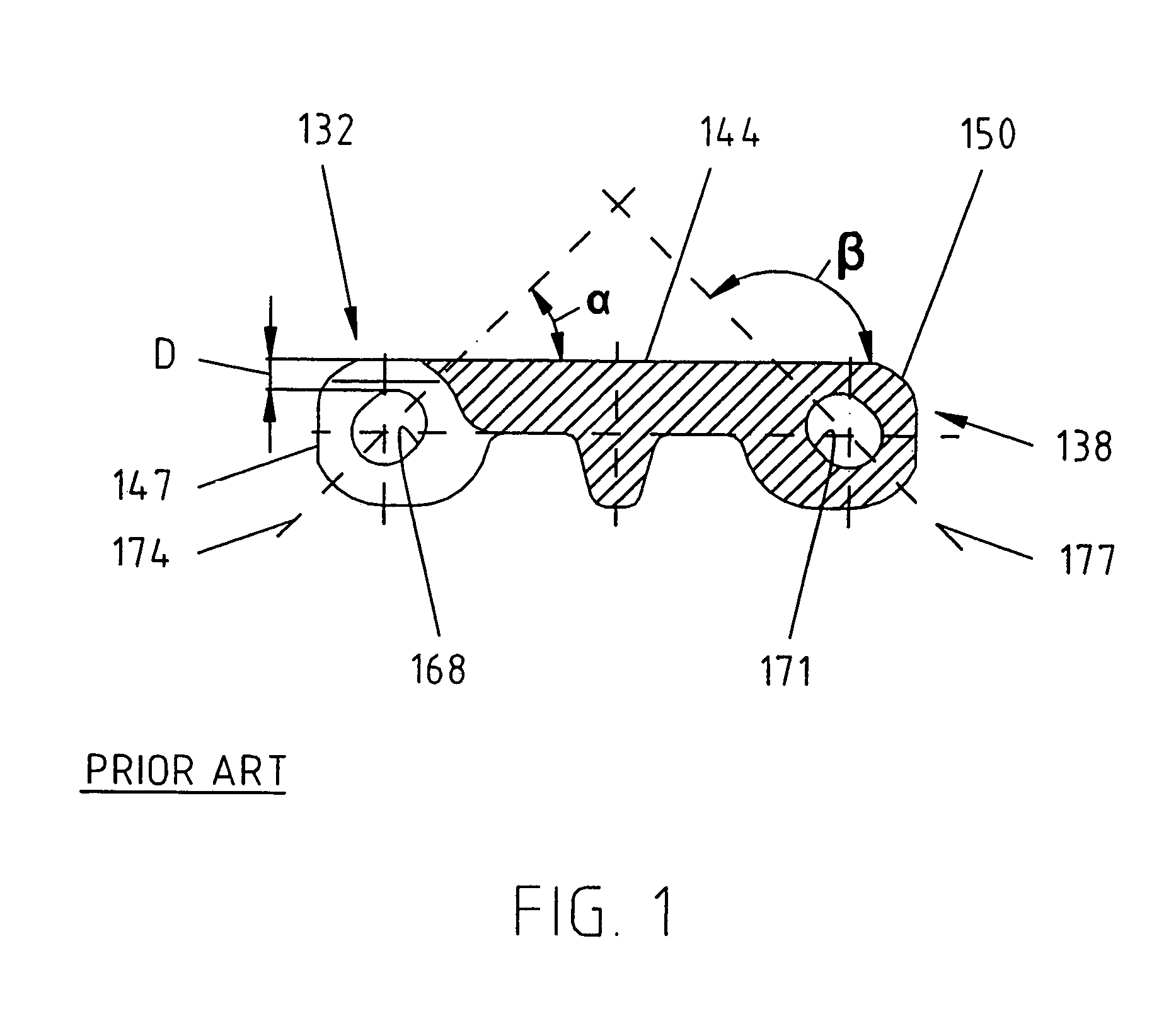

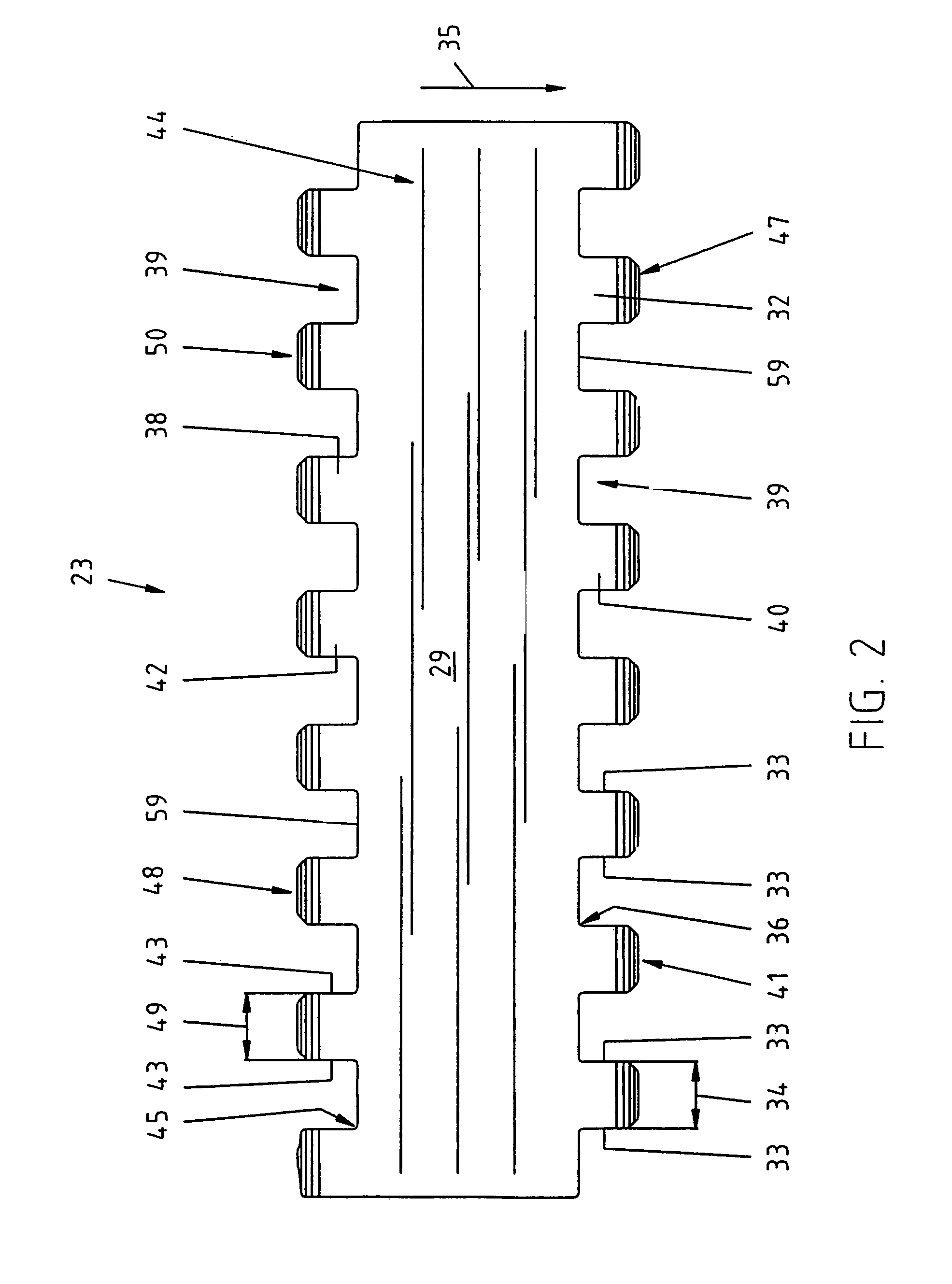

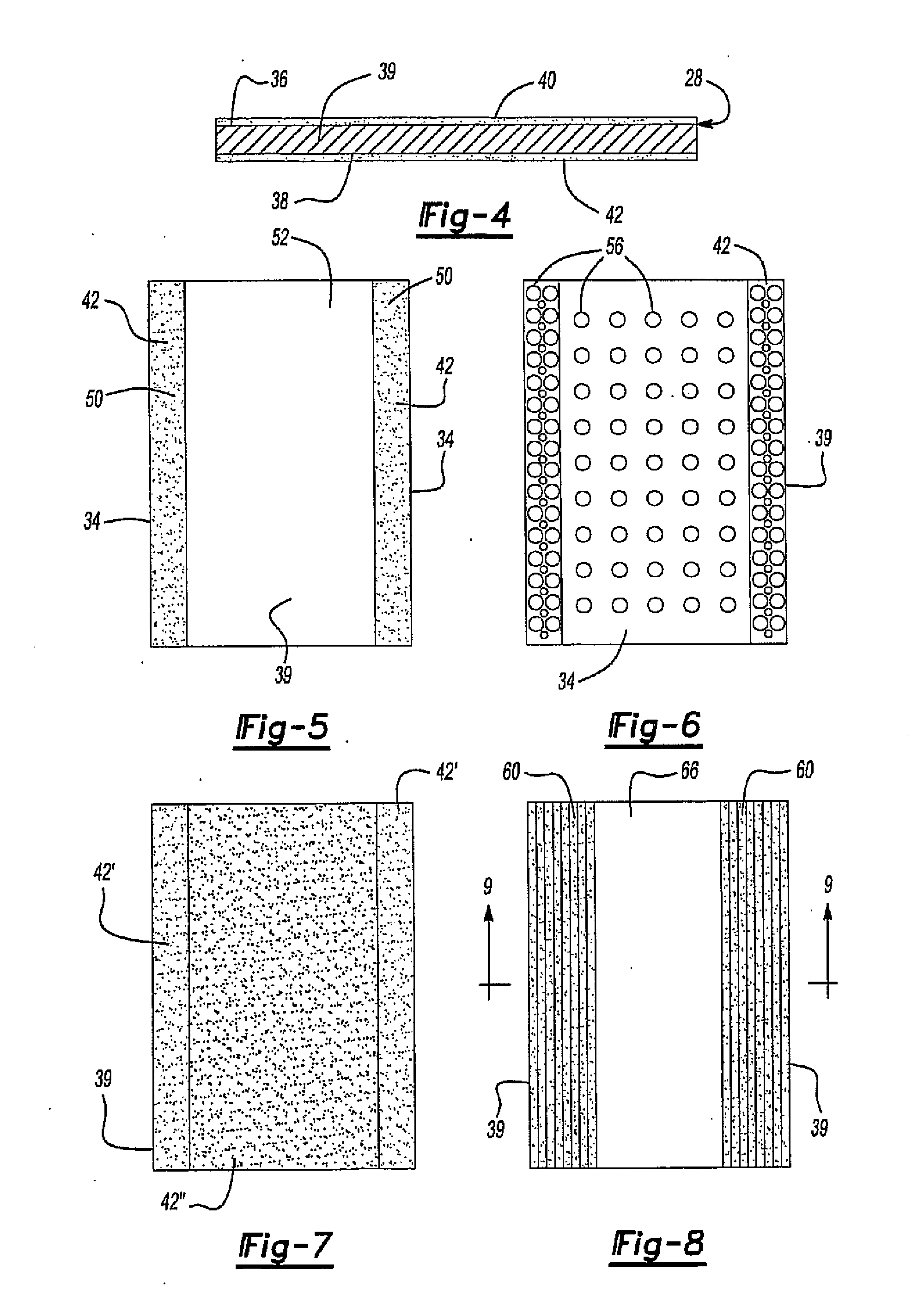

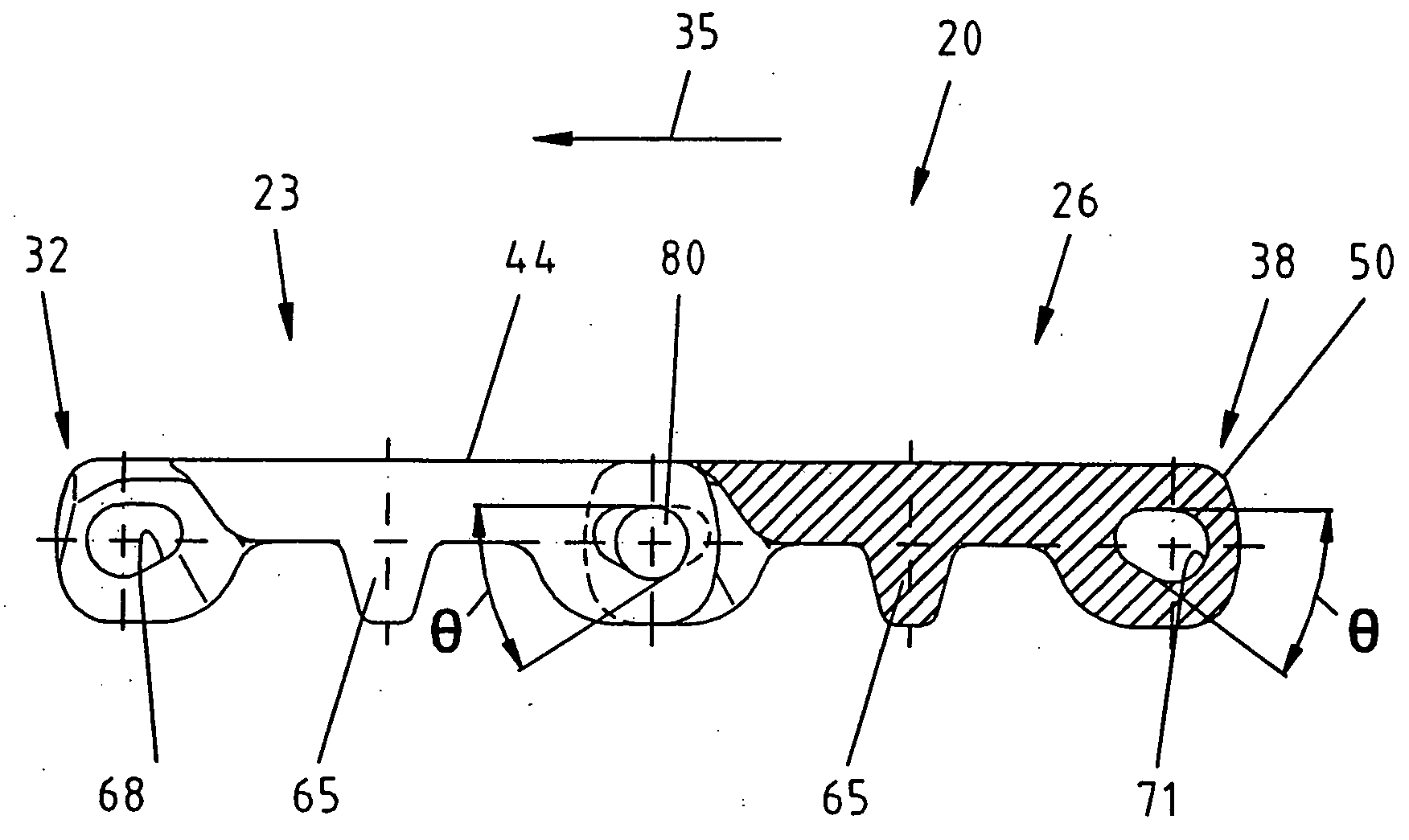

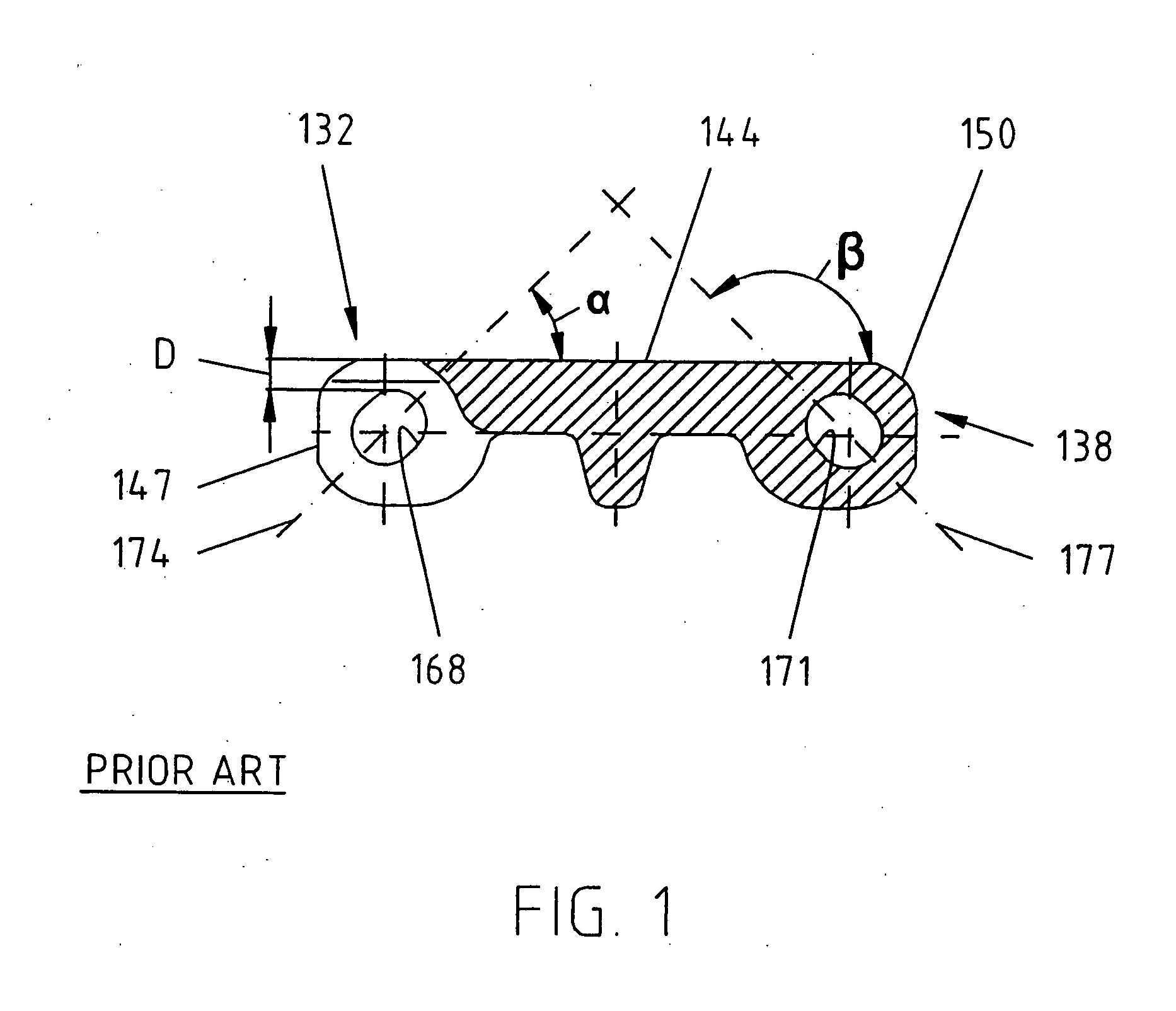

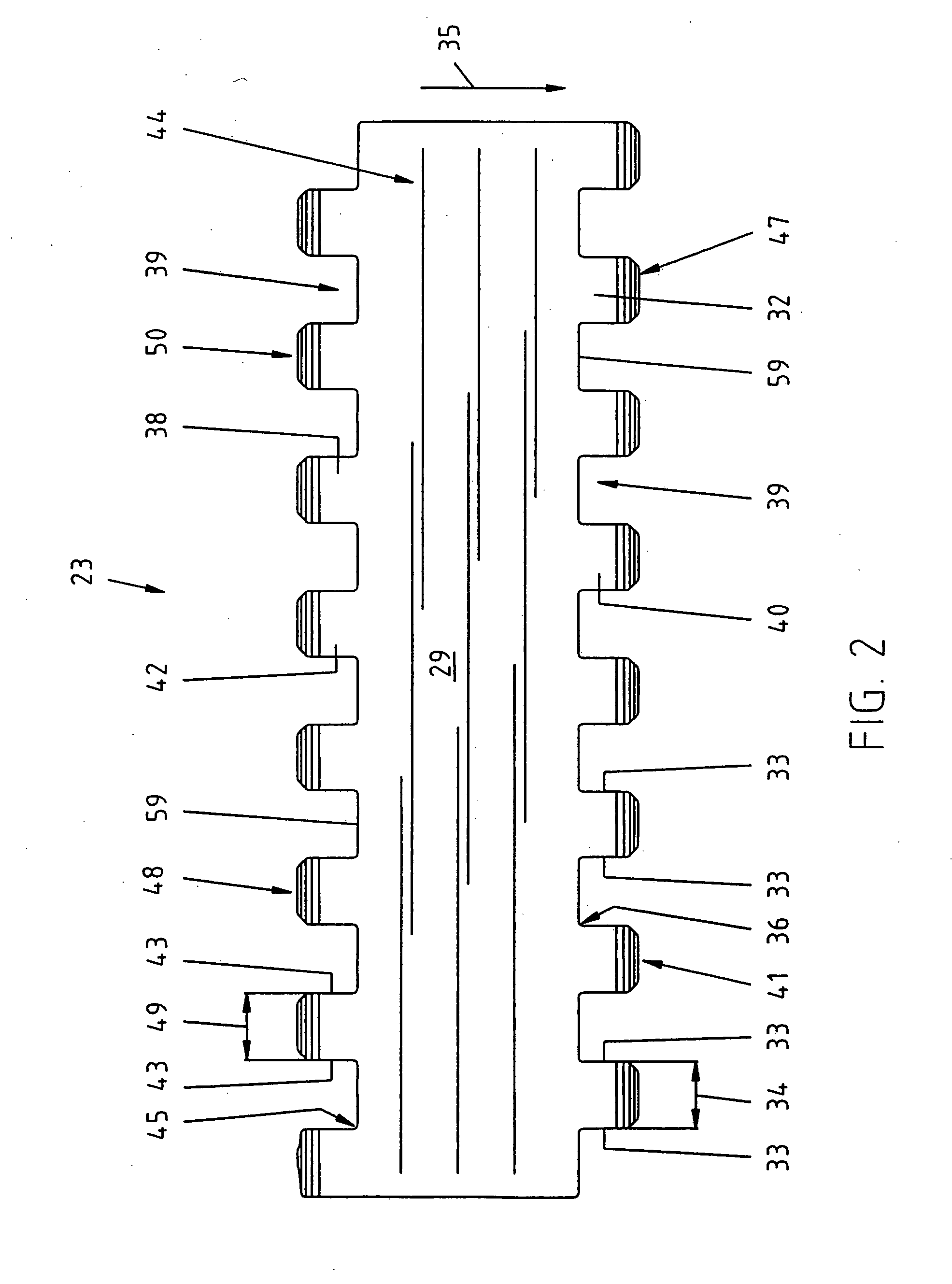

Belt module with oblong pivot hole

A modular conveyor belt formed of rows of belt modules pivotally interlinked by transverse pivot rods. The modules include a top, product conveying surface and a bottom, sprocket-driven surface. The belt modules have a plurality of first link ends disposed in the direction of travel of the conveyor belt and a plurality of second link ends disposed in the opposite direction. Transverse holes in the link ends are aligned to accommodate a pivot rod. When the link ends of the consecutive rows of side by side modules are intercalated, the pivot rod serves as a hinge pin in a hinged joint between consecutive interlinked rows. The transverse holes are disposed at an angle relative to the top surface of the belt module such that when the belt modules are connected to form a belt the transverse holes in adjacent link ends are disposed at opposite angles.

Owner:HABASIT AG

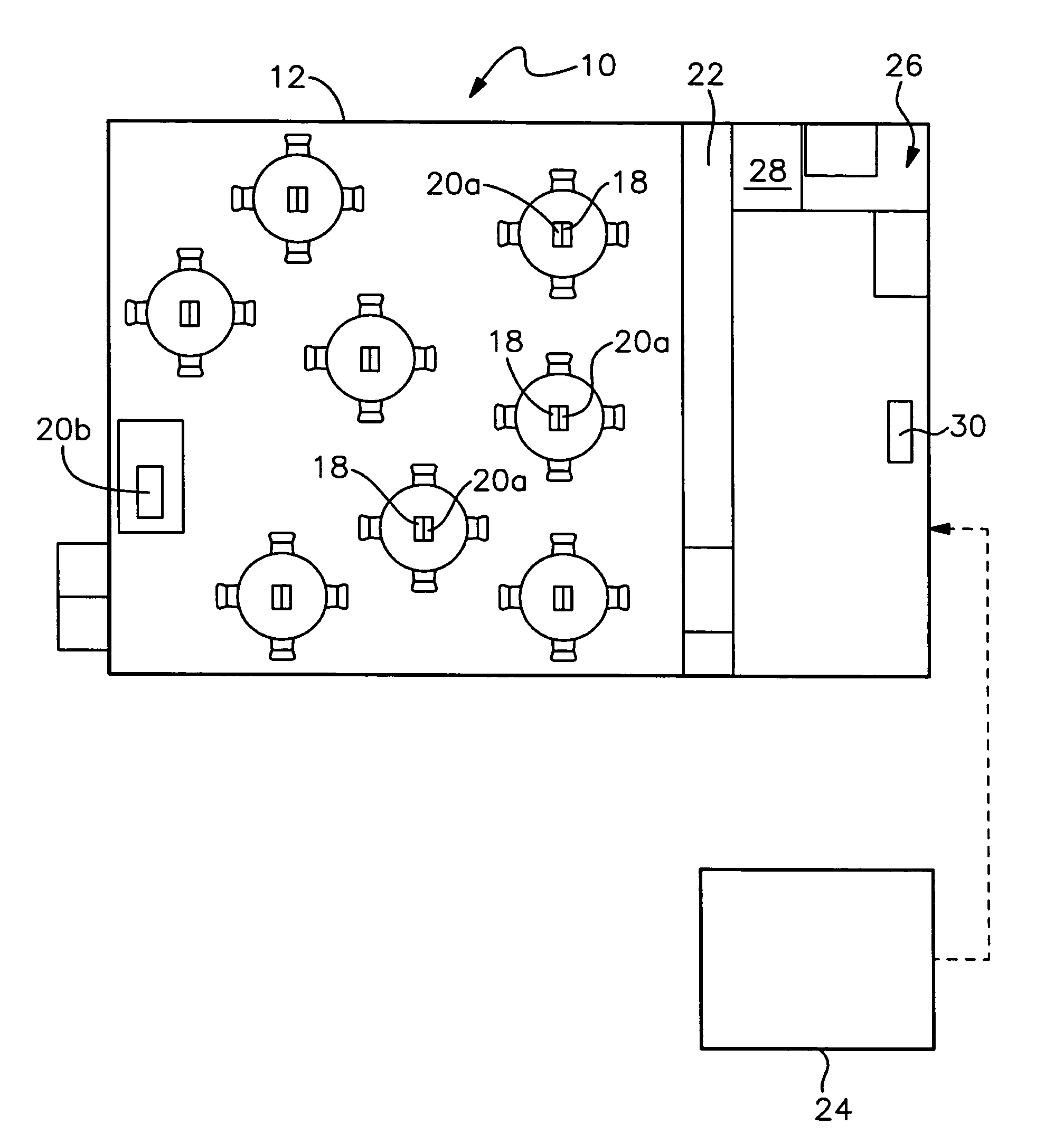

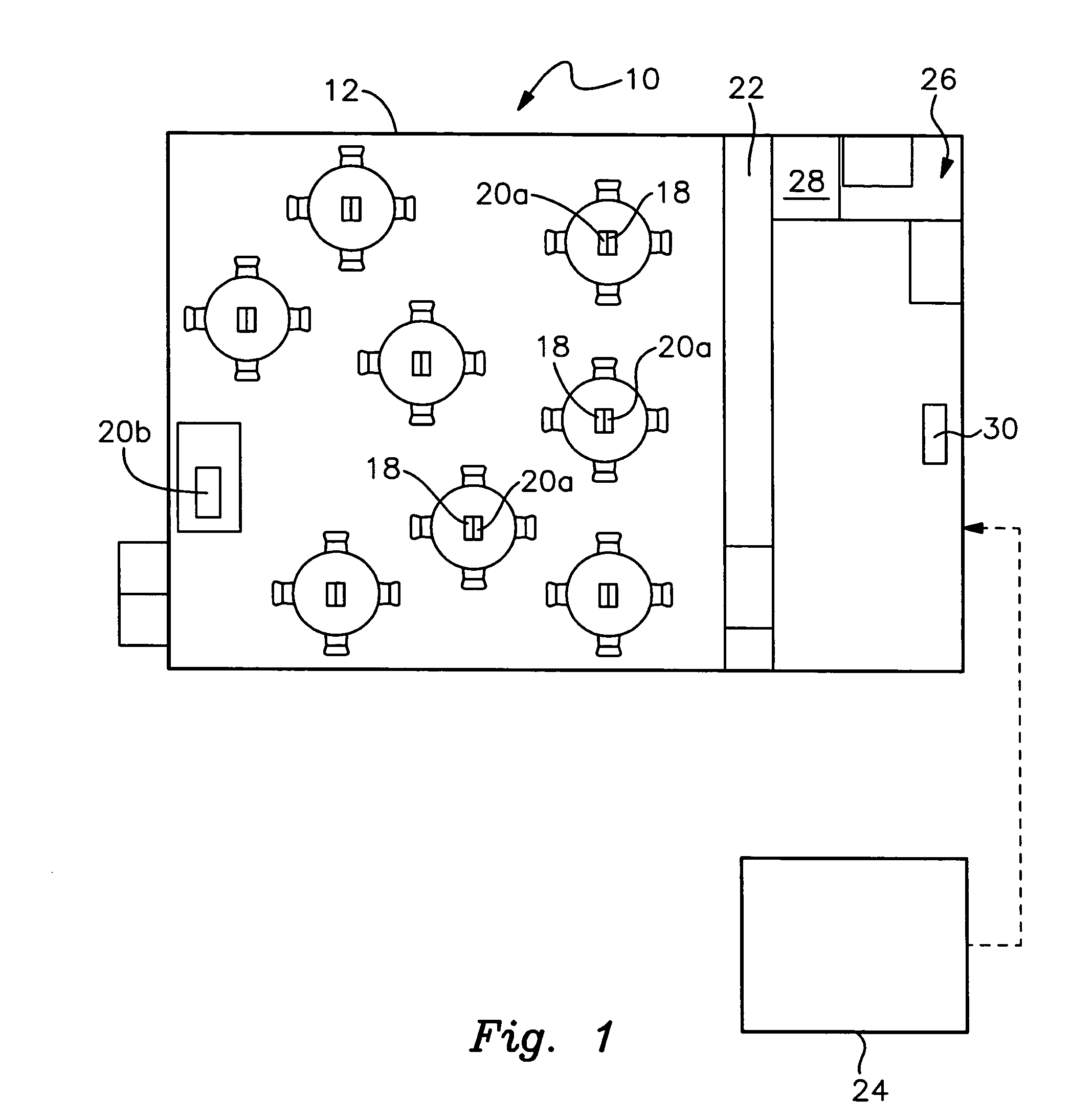

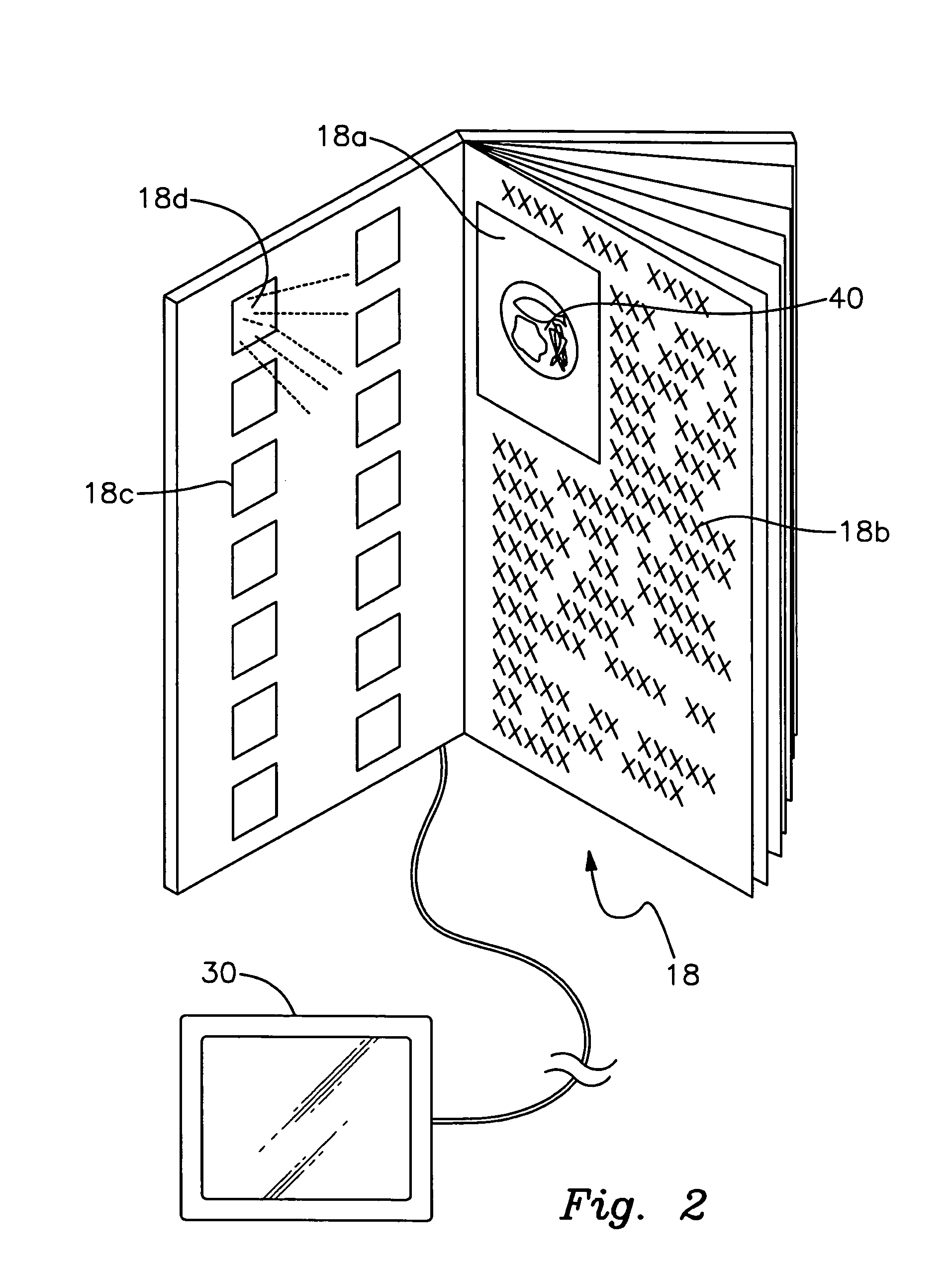

World gourmet fast health food facility

A method for providing quality exotic foods or foods from a variety of countries at prices comparable to fast food restaurants where the restaurant includes a menu selection book used to pick a food item. The table area includes the ability to order the food. Payment for the food can be made from a self-pay station at the table or at a self-pay cashier station exiting the facility. The restaurant facility specializes in international gourmet foods representative of popular foods typically found in various countries around the world. The menu book includes informational data related to a food item being considered for selection including one of pictures of the food item, seasonings in the food item, history of the food item, ingredients within the food item, nutritional data and any combination thereof.

Owner:FEIERTAG DAVID M

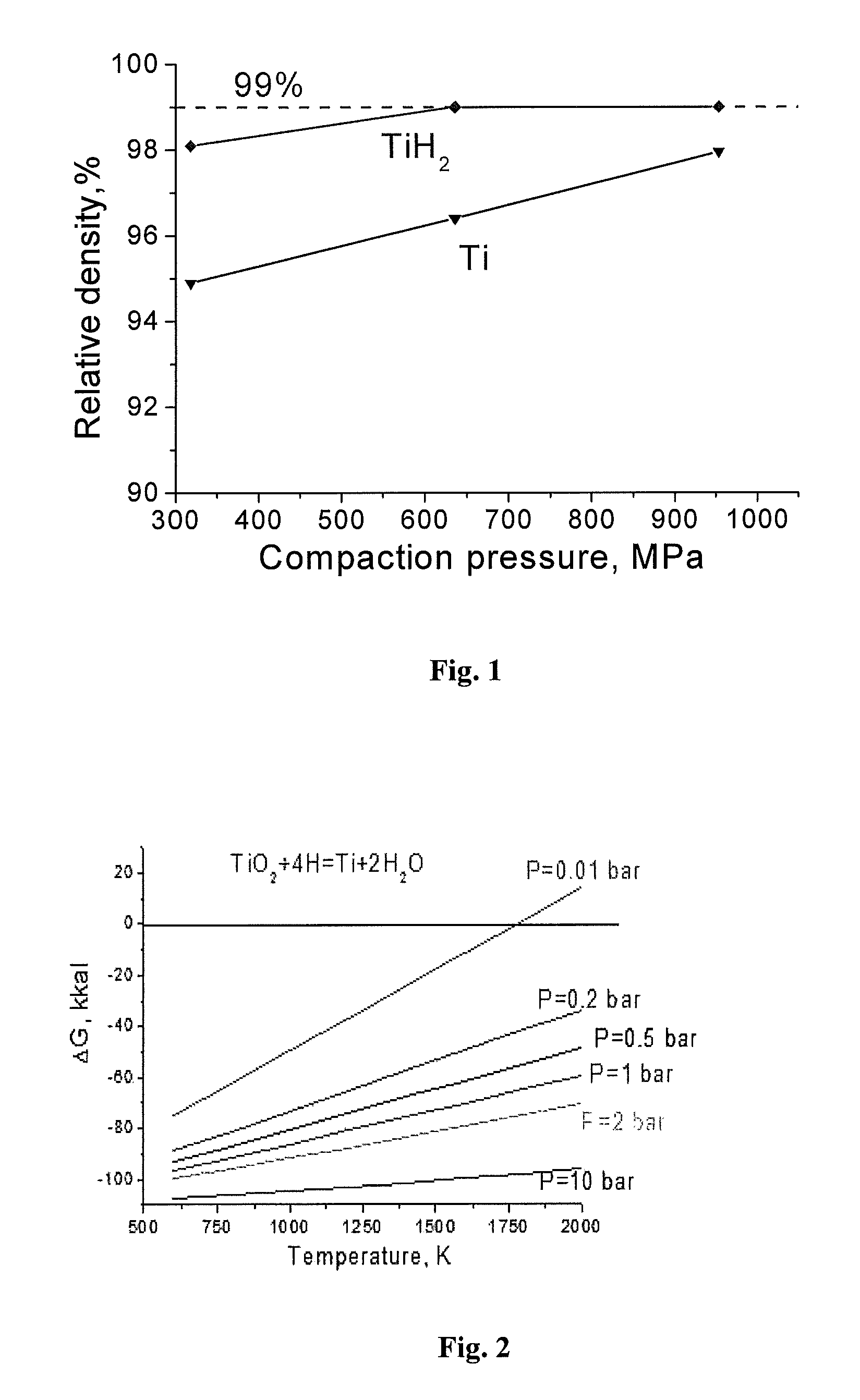

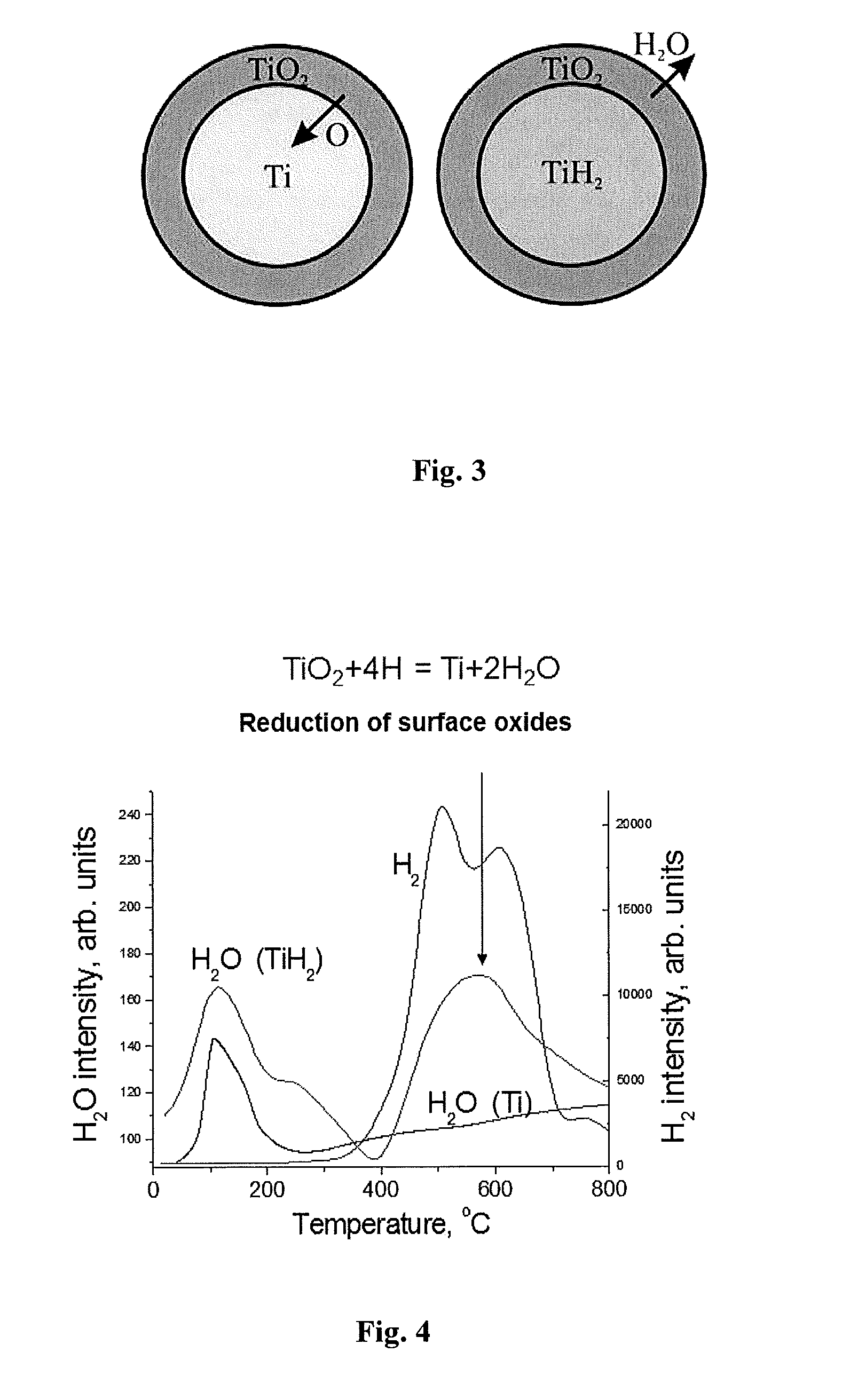

Manufacture of near-net shape titanium alloy articles from metal powders by sintering with presence of atomic hydrogen

InactiveUS20160243617A1Improve mechanical propertiesImprove the level ofPowder mixtureVolumetric Mass Density

Disclosed herein is a process that includes:(a) forming a powder blend by mixing Commercially Pure (C.P.) titanium powder, one or more hydrogenated titanium powders containing around 3.4 to around 3.9 weight % of hydrogen (e.g., hydrogenated titanium powders available or referred to nominally as “titanium hydride” or TiH2), and one or more hydrogenated titanium powders containing around 0.2 to around 3.4 weight % of hydrogen, or a mixture of the hydrogenated titanium powders without the C.P. titanium powder,(b) consolidating the powder blend by either compacting the powder blend using die pressing, direct powder rolling, cold isostatic pressing, impulse pressing, metal injection molding, other room temperature consolidation method, or combination thereof, at a pressure in the range of around 400 to around 960 MPa, or loose sintering, to provide a green compact having a density lower than that of a green compact formed from only C.P. titanium powder, such that the subsequent sintering of said green compacts is promoted by an increased hydrogen content retained in the green compact which provides emission of hydrogen and a high partial pressure during subsequent cleaning and sintering steps,(c) heating the green compact to a temperature ranging from around 100° C. to around 250° C. at a heating rate≦around 15° C. / min, thereby releasing absorbed water from the titanium powder, and holding the green compact at this temperature for a holding time ranging from around 10 to around 360 min, wherein the holding time and a thickness of the green compact are such that there is around 20 to around 24 min of holding time per every 6 mm of the thickness of the green compact,(d) forming β-phase titanium and releasing atomic hydrogen from the hydrogenated titanium by heating the green compact to a temperature of around 400 to around 600° C. in an atmosphere of hydrogen emitted by the hydrogenated titanium and holding the green compact at this temperature for around 5 to around 30 min thereby forming and releasing reaction water from the hydrogenated titanium powder,(e) reducing surface oxides on particles of the titanium powder by contact with atomic hydrogen released by heating of the green compact to a temperature of around 600 to around 700° C. and holding at this temperature for a holding time of around 30 to around 60 min sufficient to transform β-phase titanium into α-phase titanium while preventing dissolution of oxygen in the metallic body of the titanium particles and simultaneously providing maximum cleaning of titanium powders before forming closed pores,(f) diffusion-controlled chemical homogenizing of the green compact and densification of the green compact by heating to around 800 to around 850° C. at a heating rate of around 6 to around 8° C. / min, followed by holding at this temperature for 30-40 min resulting in complete or partial dehydrogenation and more active shrinkage of titanium powder formed from the initial hydrogenated titanium powder to form a cleaned and refined compact,(g) heating the cleaned and refined green compact in vacuum at a temperature in the range of around 1000 to around 1350° C., and holding the cleaned and refined green compact at such temperature for at least around 30 minutes, thereby sintering titanium to form a sintered dense compact, and(h) cooling the sintered dense compact to form a sintered near-net shaped article.

Owner:ADVANCED MATERIALS PRODS

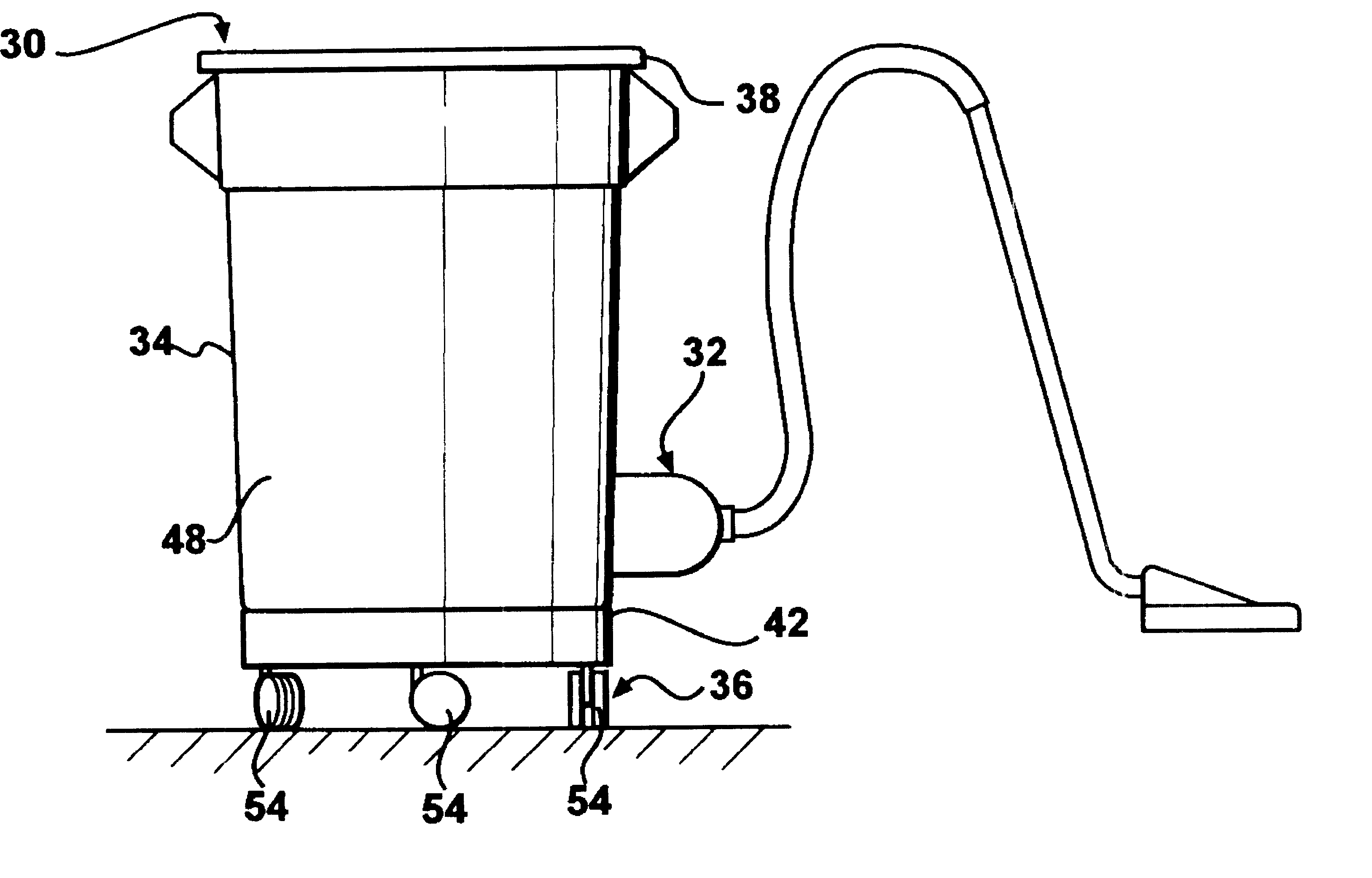

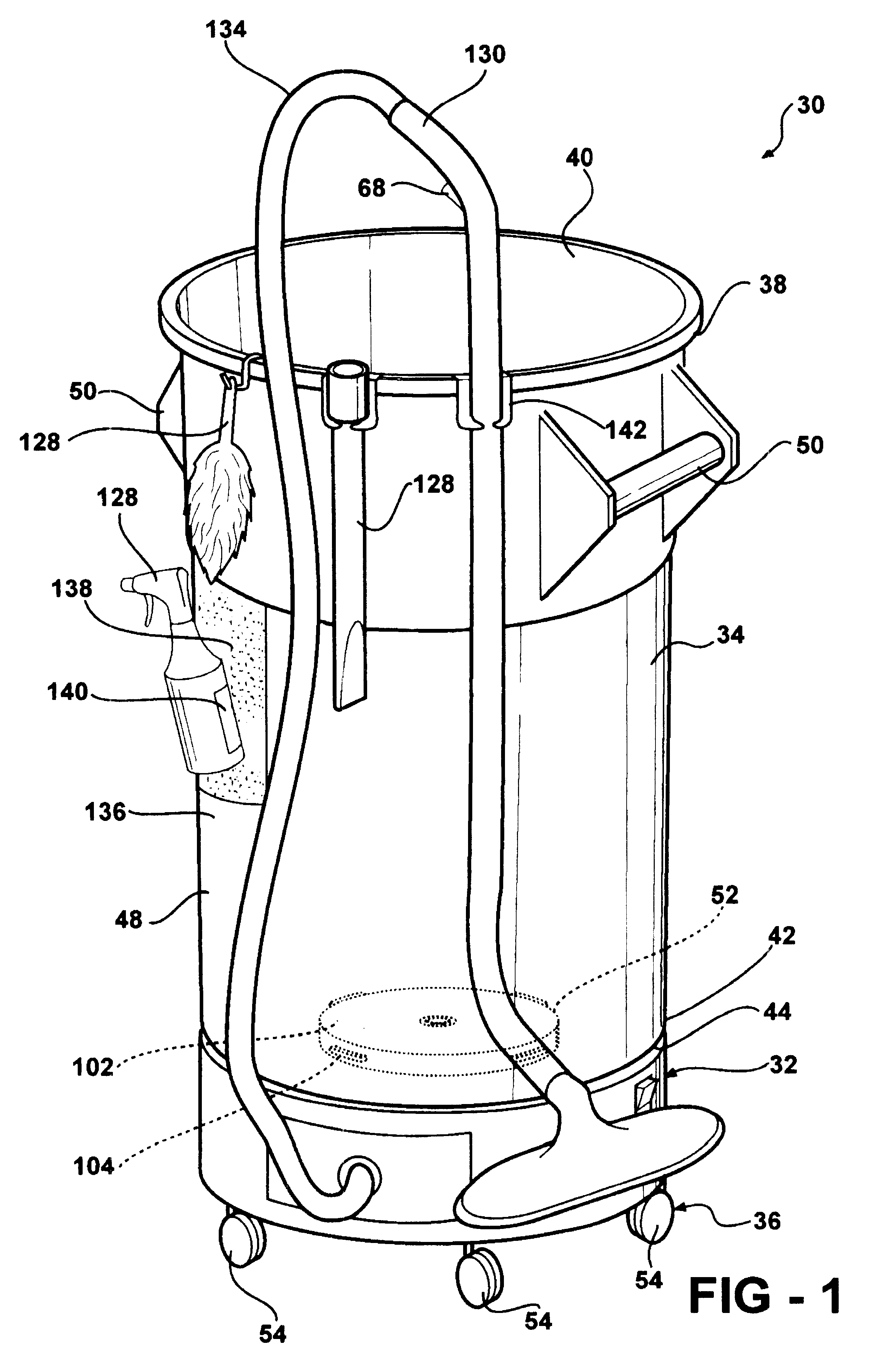

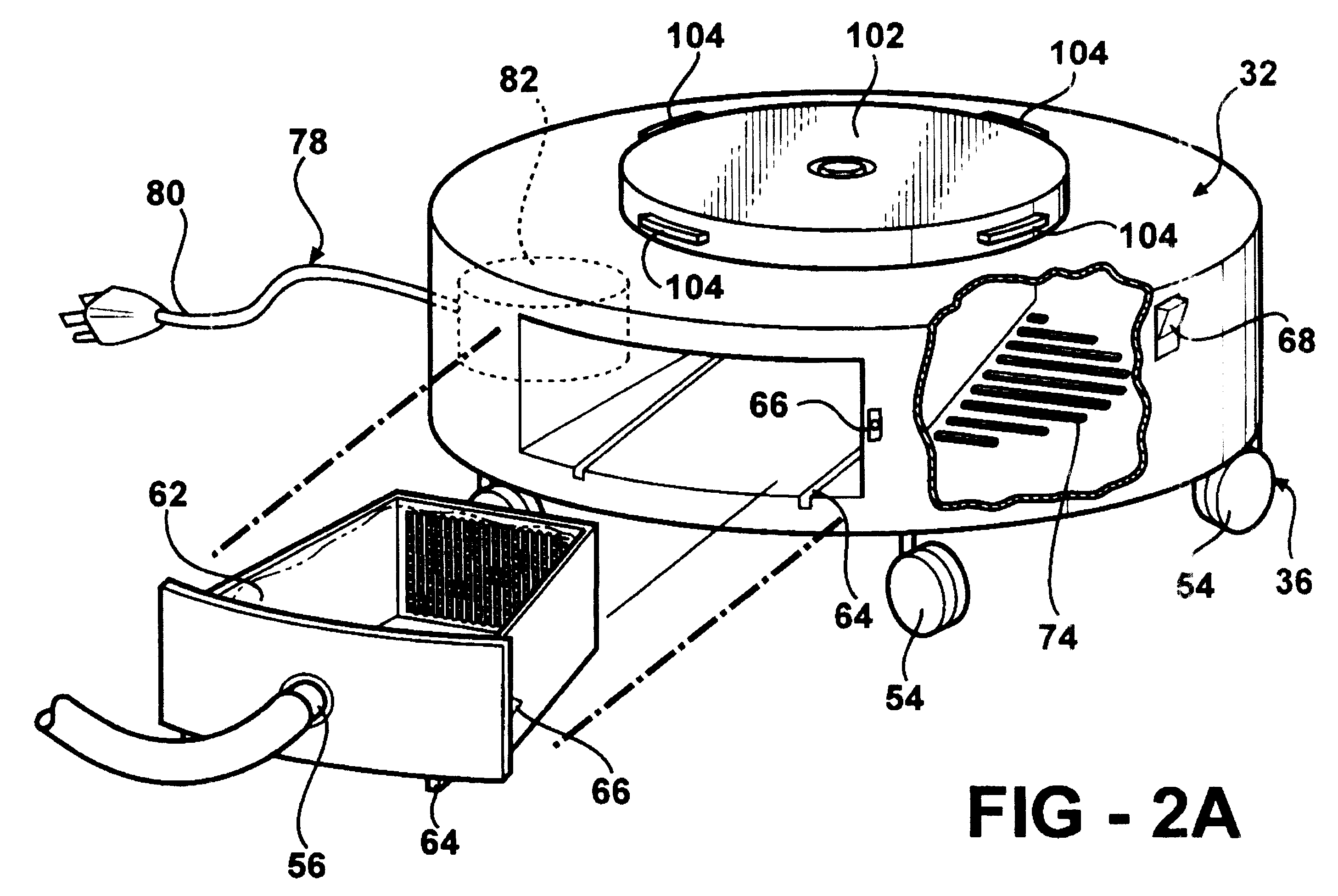

Portable cleaning assembly

InactiveUS7210193B2Efficient transportOvercome deficienciesCleaning filter meansSuction filtersWaste management

Owner:VACBARREL

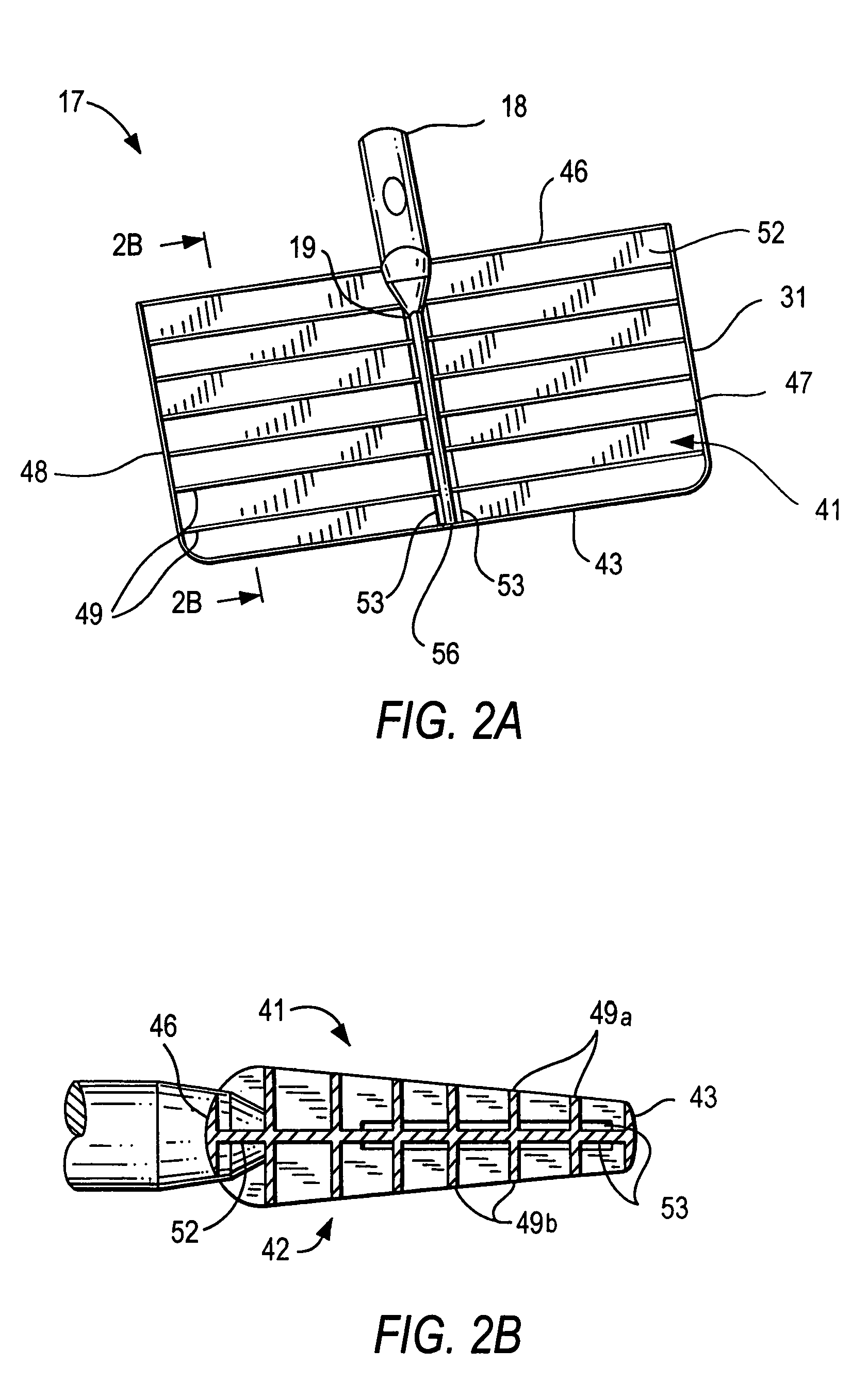

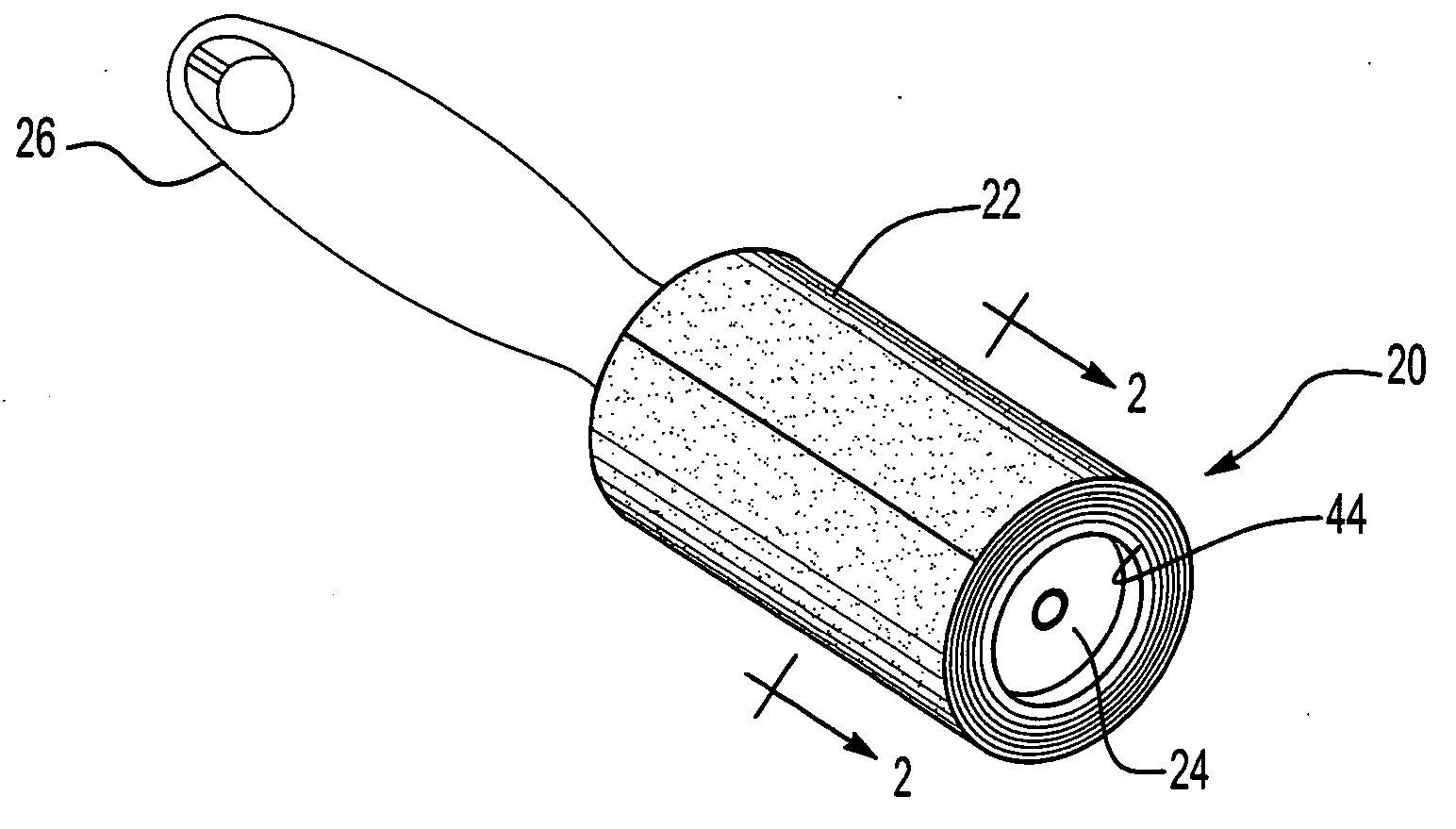

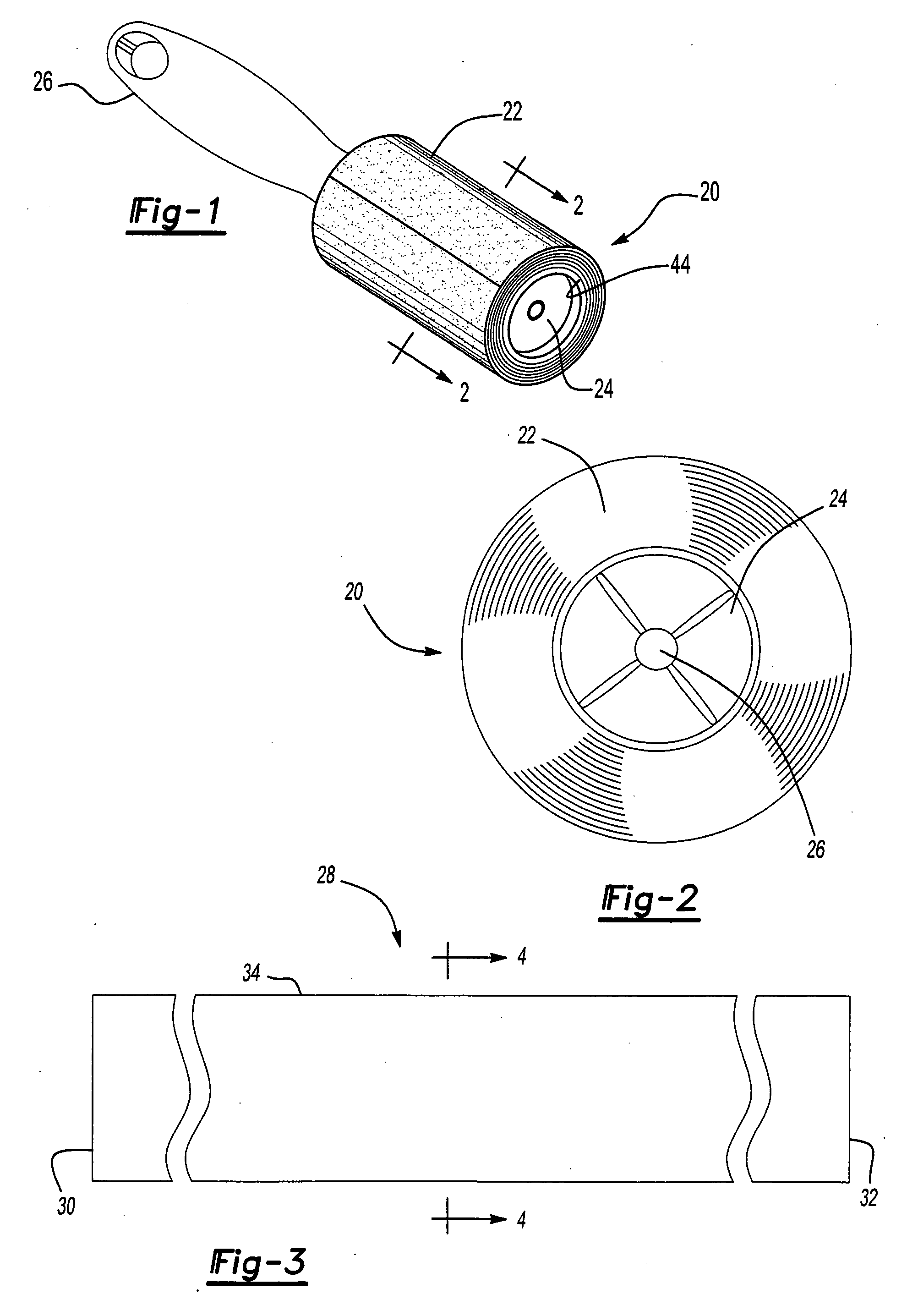

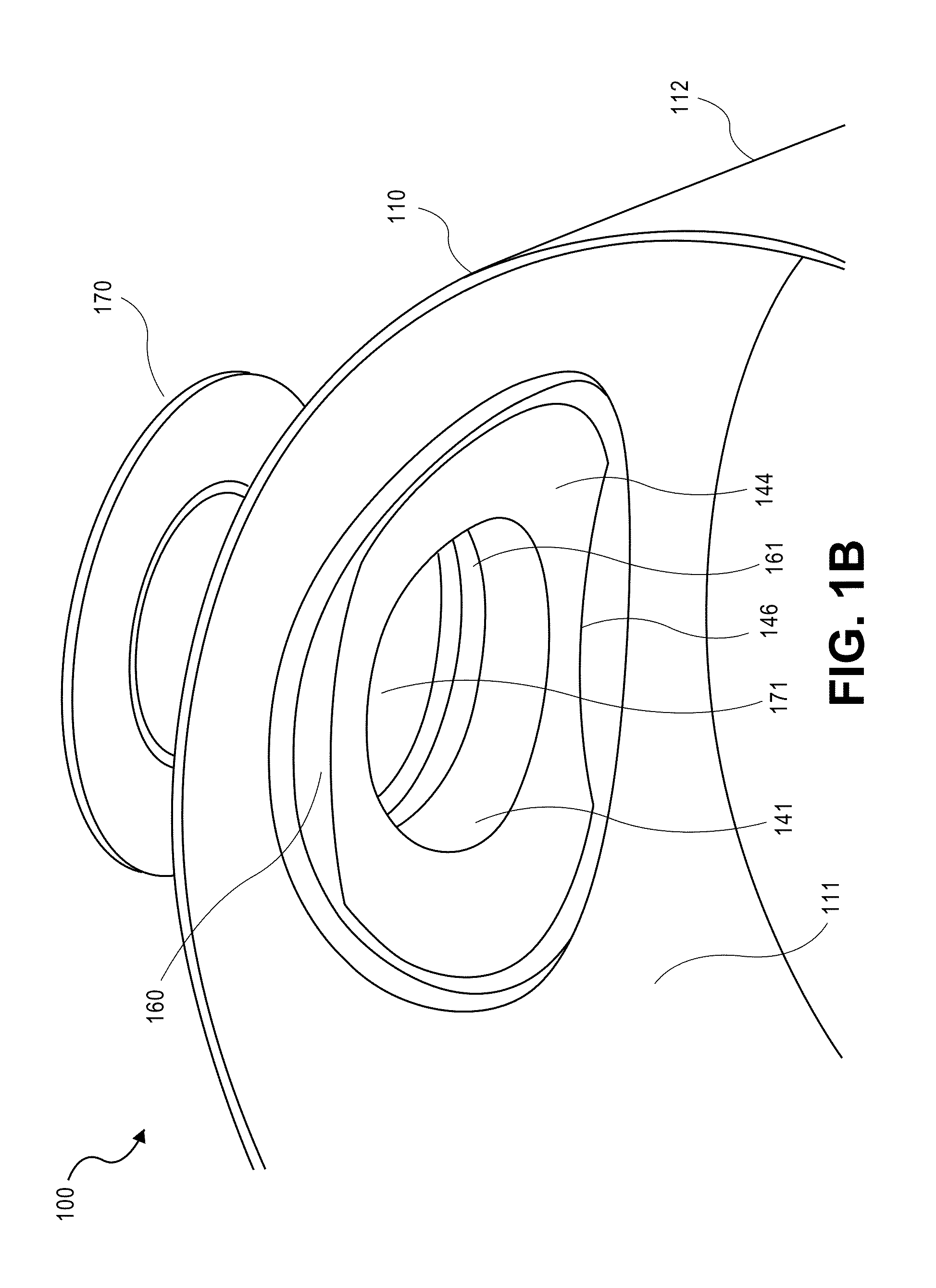

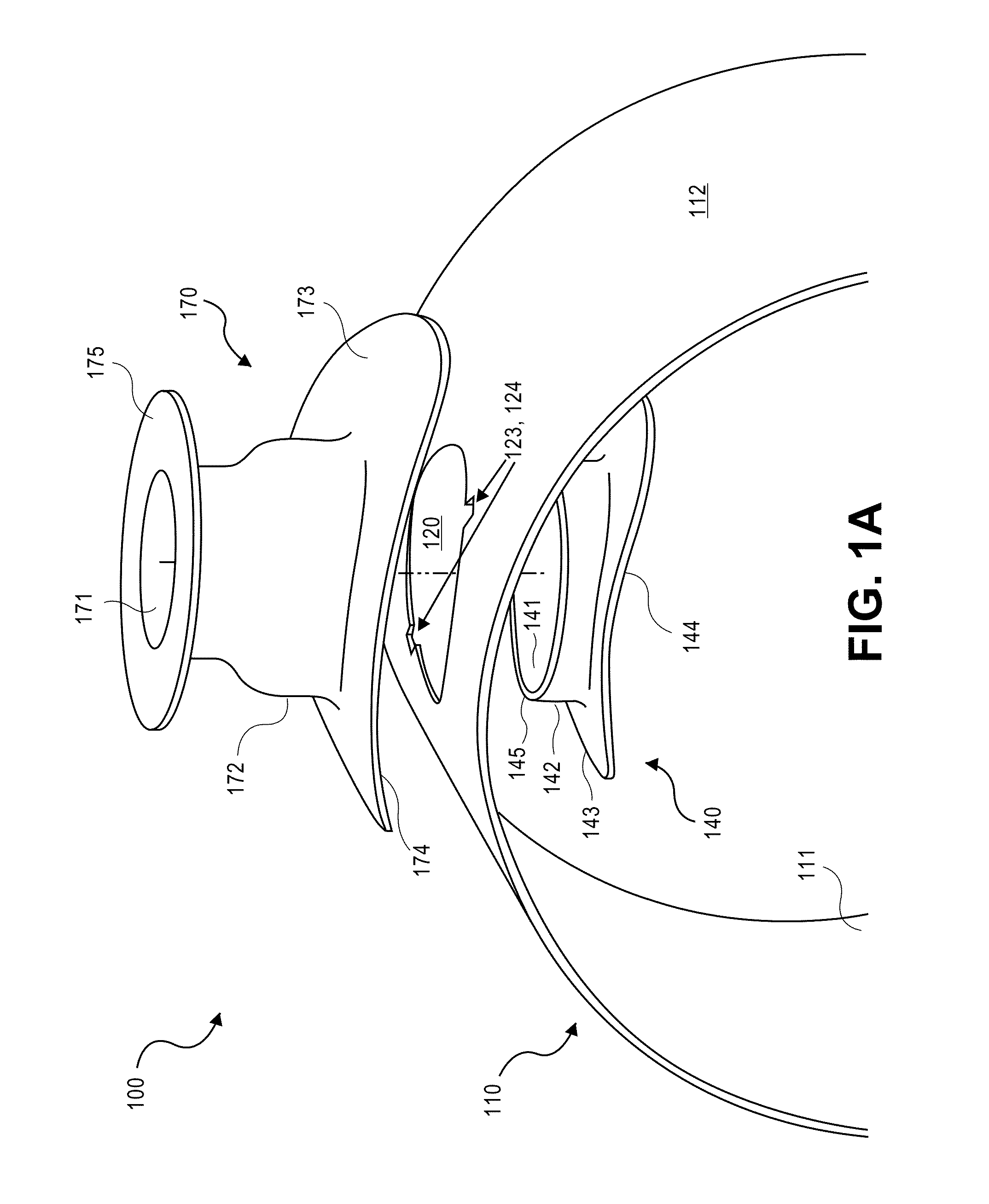

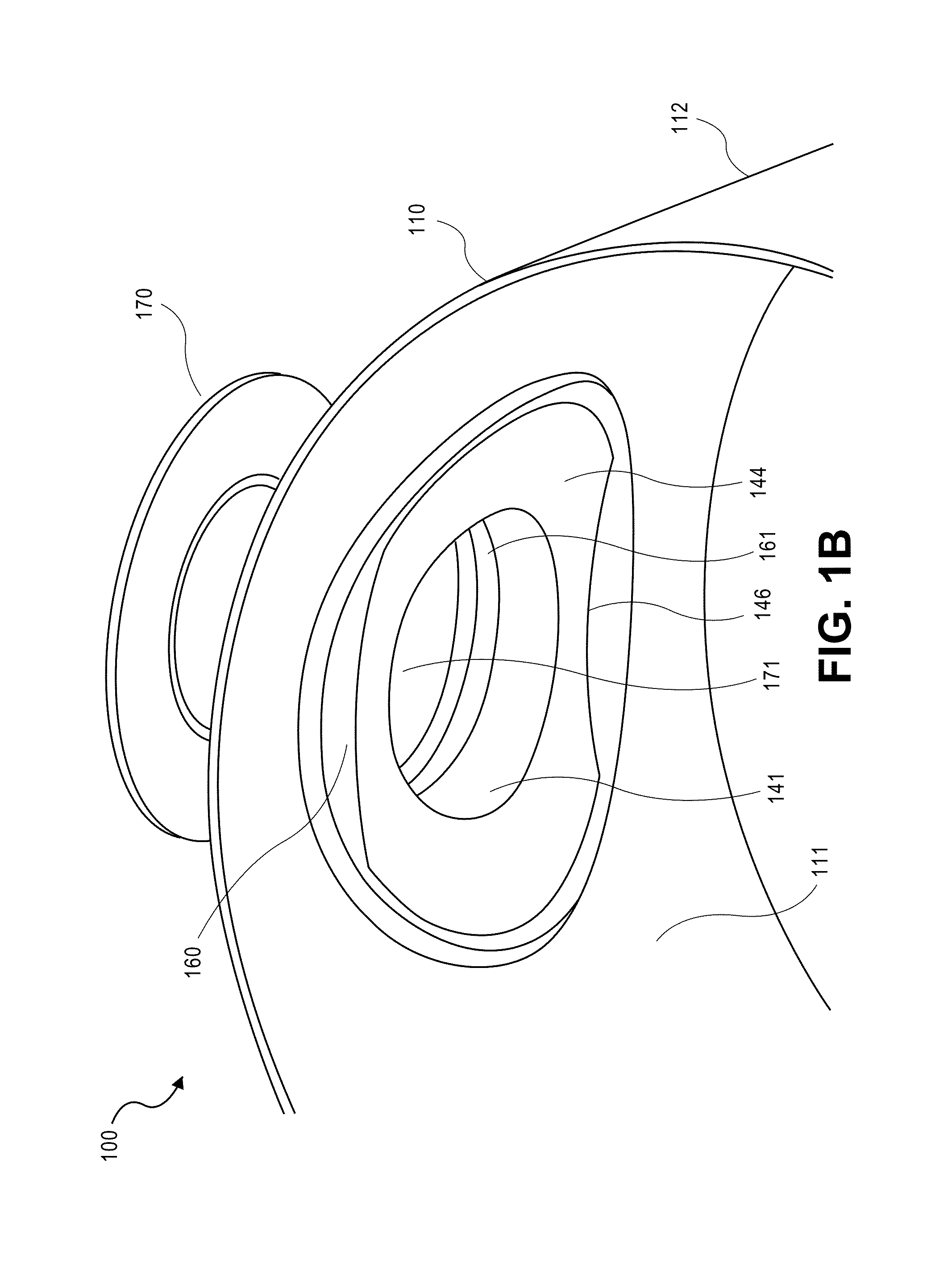

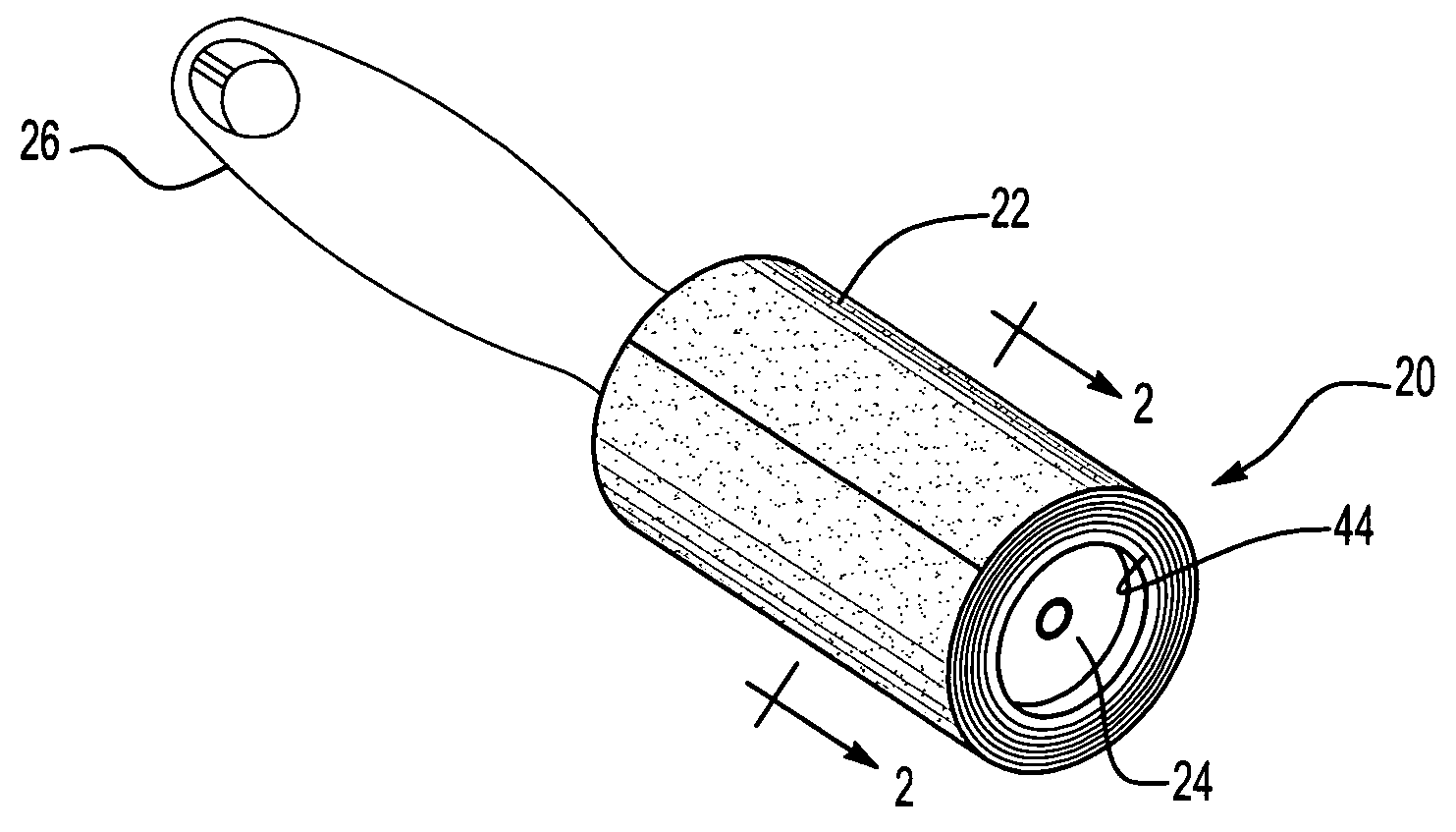

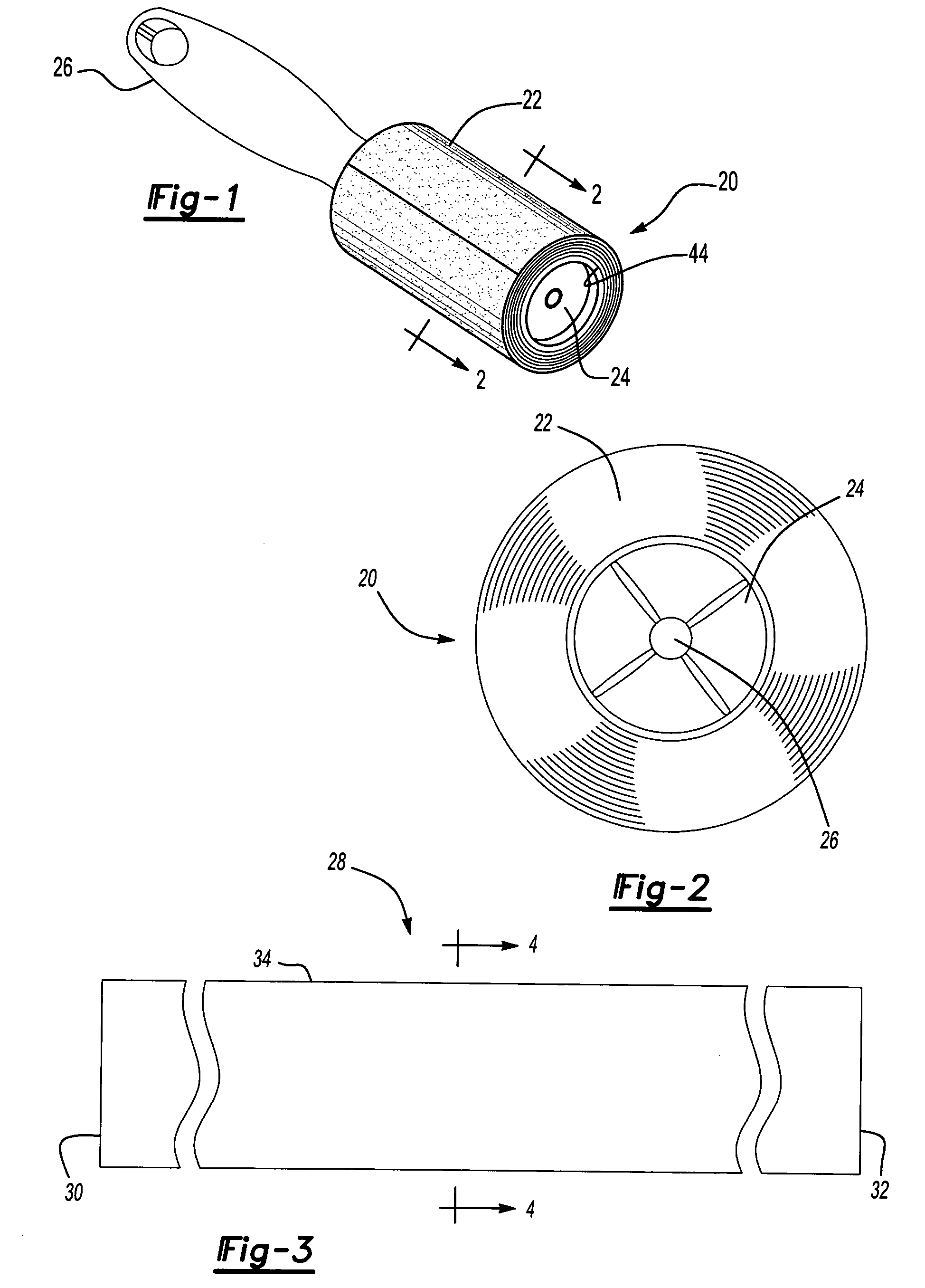

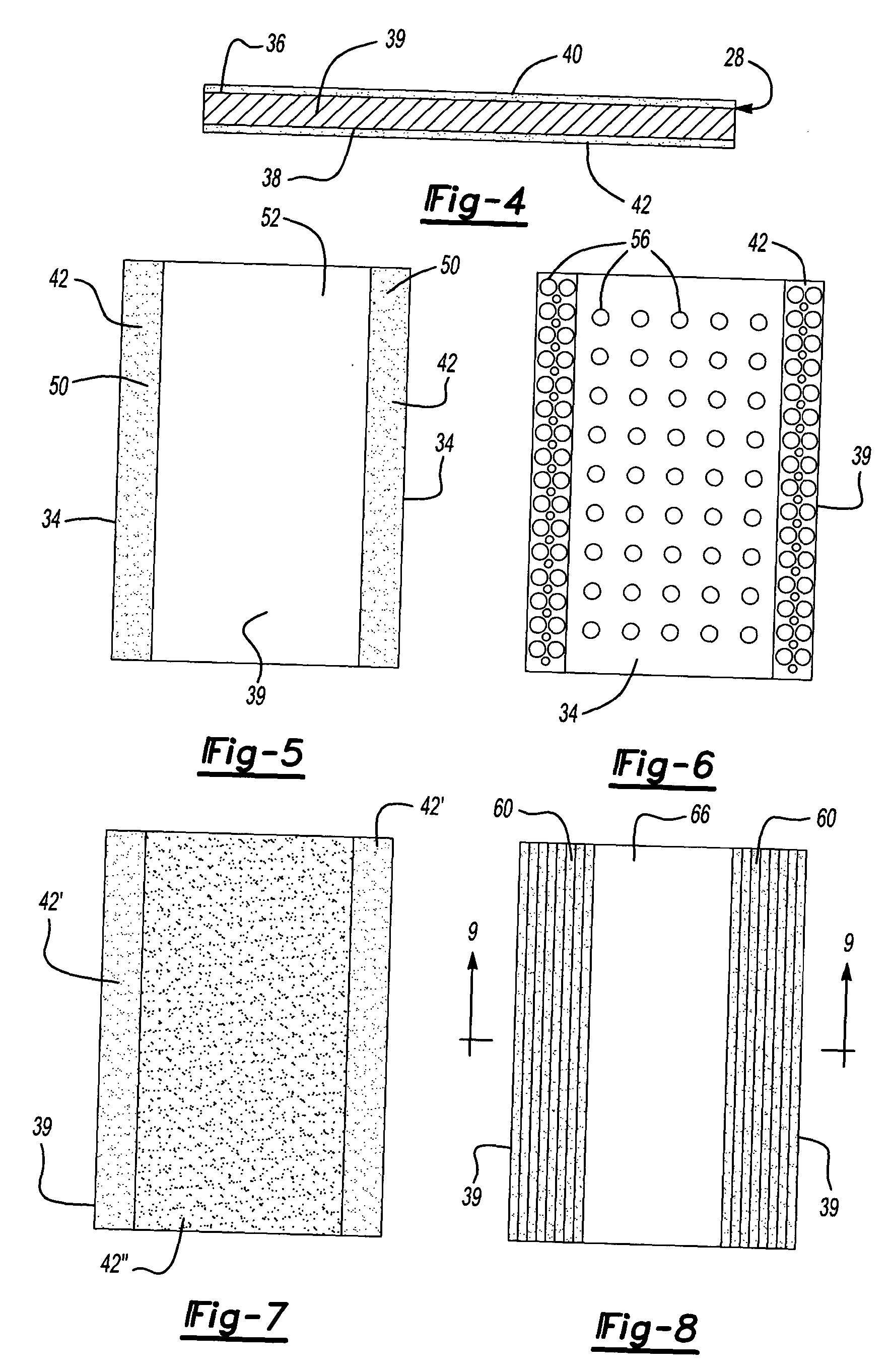

Adhesive roller

ActiveUS20050050661A1Easy to separateReduce adhesionCarpet cleanersLayered productsSolid substrateCoating

An adhesive roller for detritus removal having an elongated strip where the strip has both a backing layer and an adhesive layer overlying and covering a first side of the backing layer. The strip also has a first end, a second end and two spaced apart sides. The strip is wound from its first end and to its second end into a tubular cylindrical roller with the adhesive layer facing outwardly. An adhesive release coating also overlies at least a portion of a second side of the backing layer. The adhesive release coating may be either applied as a liquid coating, or may be a solid substrate. This adhesive release coating facilitates removal of individual sheets from the roller. Alternatively, a portion of the backing layer is crimped to form alternating peaks and valleys along at least a portion of the backing layer. These alternating peaks and valleys limit the amount of areal contact between the backing layer and the next inner adhesive layer of the roller to facilitate removal of individual sheets from the roller.

Owner:BUTLER HOME PRODUCTS LLC

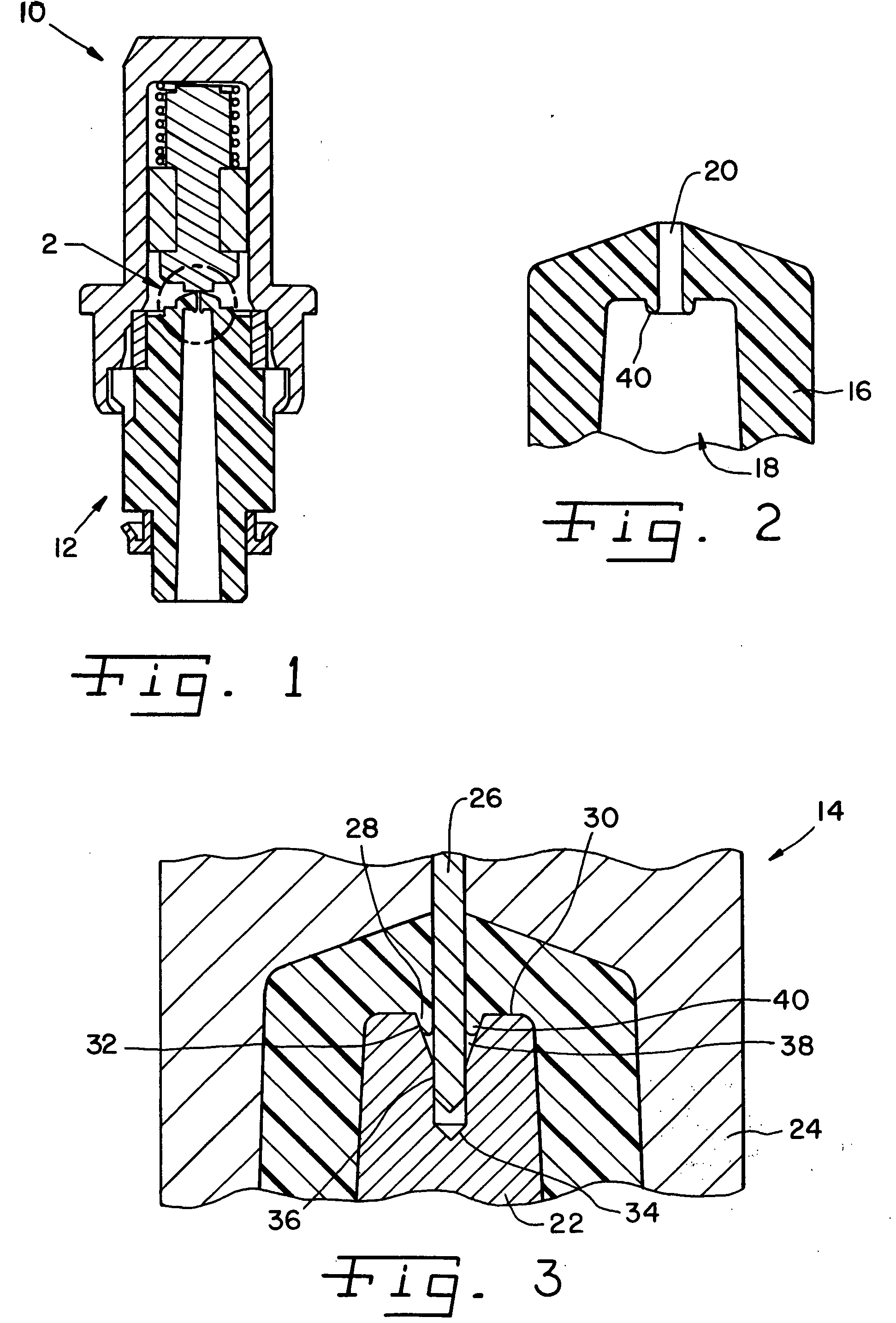

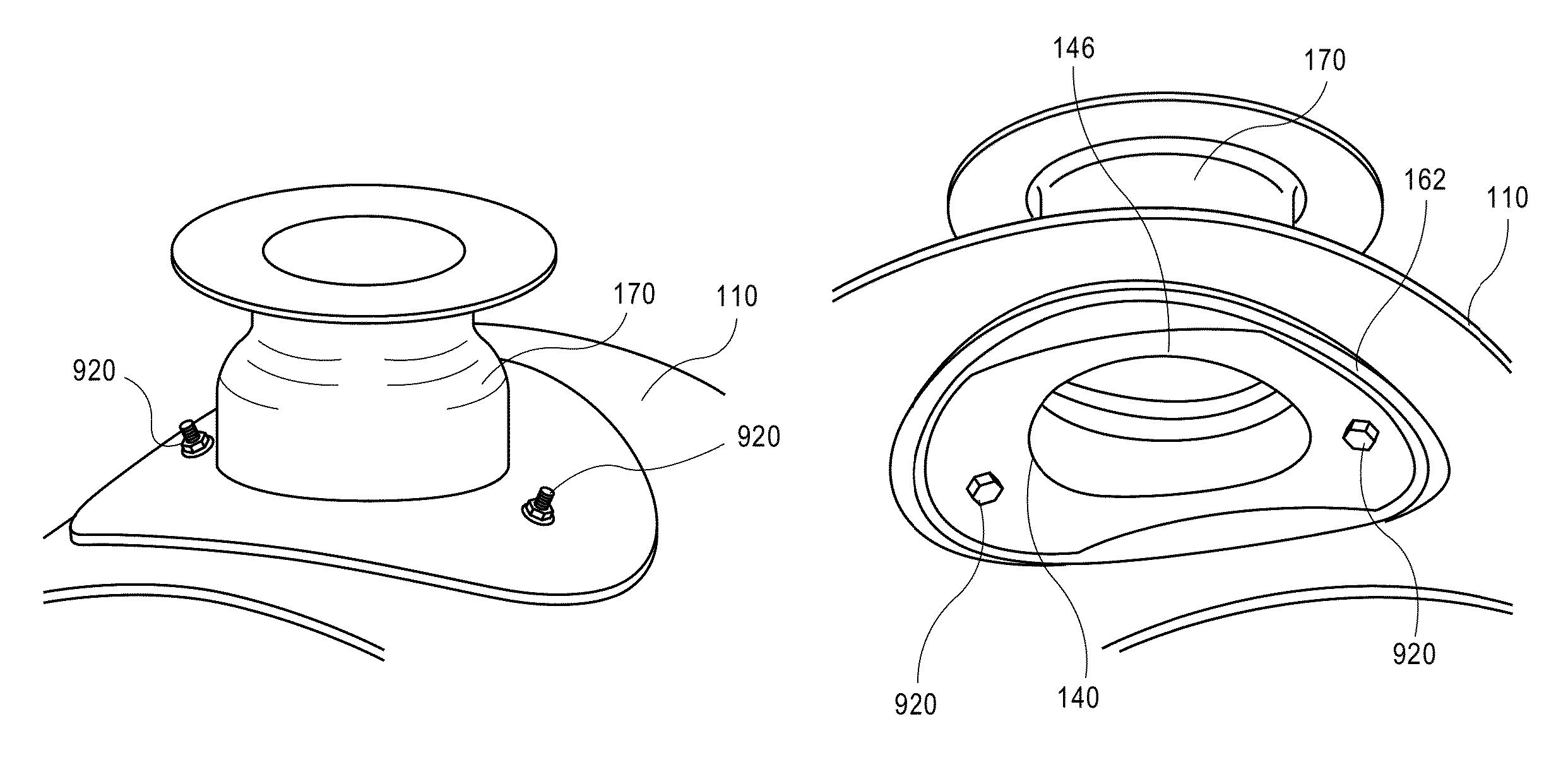

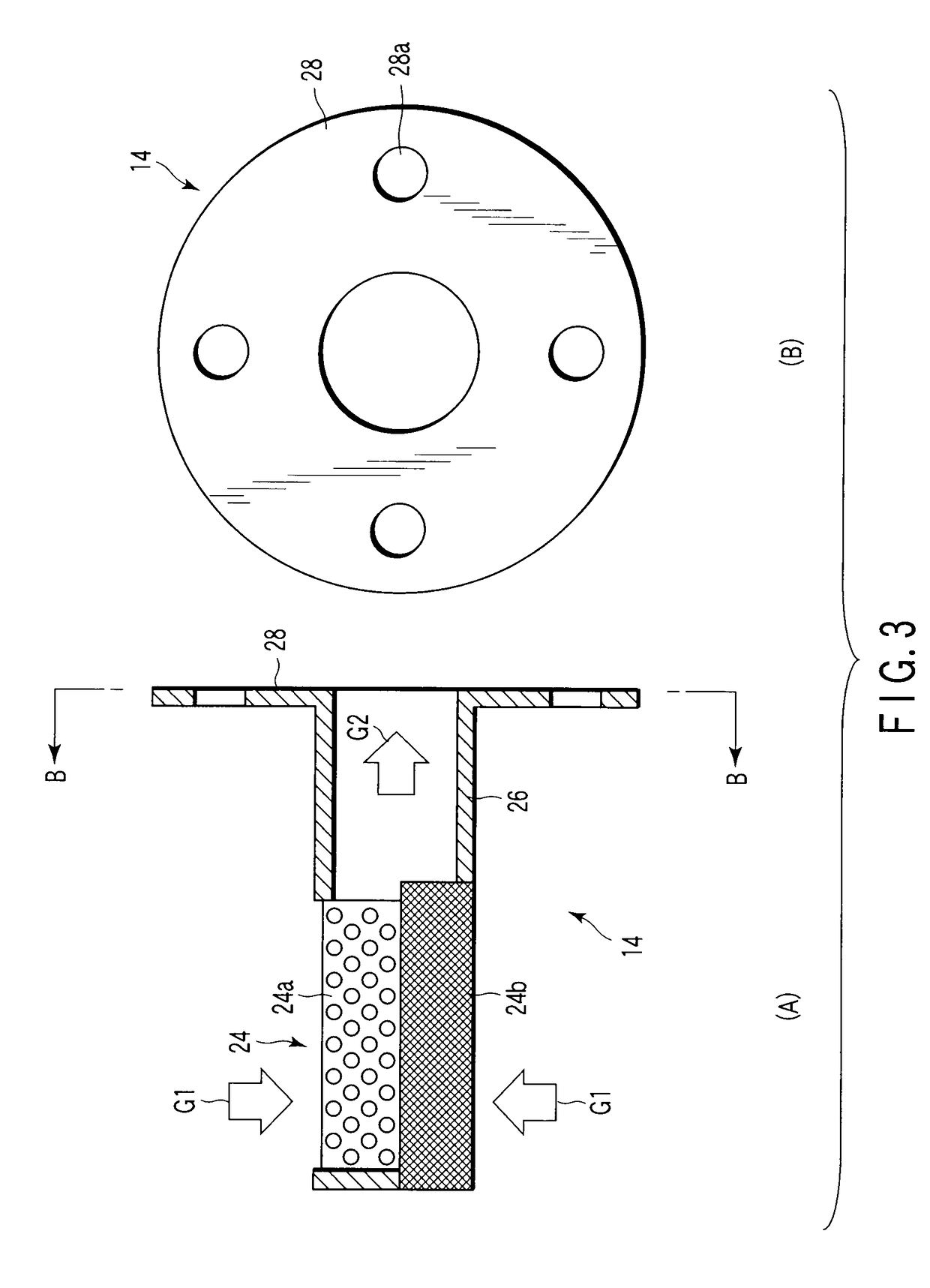

Saddle tap connection and installation device

InactiveUS20130187376A1Maximum cleaningSafely and efficiently installValve arrangementsContainer filling methodsCost effectivenessAdhesive

Saddle tap assemblies comprising internal collars and external saddle taps are disclosed. A saddle tap assembly may include an external slip tap, internal tap collar, a duct section, and adhesive. The external slip tap and the internal tap collar may each have a flange. The flanges may be curved. The flange of the internal collar may have a sheared portion permitting the flange of the internal collar to pass through an opening in a section of duct. The installation of saddle tap assemblies according to embodiments of the present invention is more cost-effective and less time consuming than conventional methods. Moreover, the seals and bonds formed using embodiments of the present invention provide for several layers of chemical protection and structural stiffening wherever the saddle tap assemblies are located.

Owner:ATS PRODS

Carriage for a power washer wand

InactiveUS20060038033A1Augments easeMaximum cleaningWatering devicesWriting implementsVehicle frameEngineering

A carriage designed for supporting a power washer wand and its nozzle a predetermined, though adjustable, distance from a surface which is to be cleaned by high velocity water exiting a discharge orifice of the nozzle. The carriage is defined by a one-piece body molded from substantially high strength synthetic polymeric / copolymeric plastic material. The carriage body includes a platform having a converging front end nose upwardly from which projects a wand support having a channel in which a power washer wand is located and adjustably clamped. The platform includes two wheels at a rear end thereof and a single wheel beneath the front end nose.

Owner:DALEY HOWARD

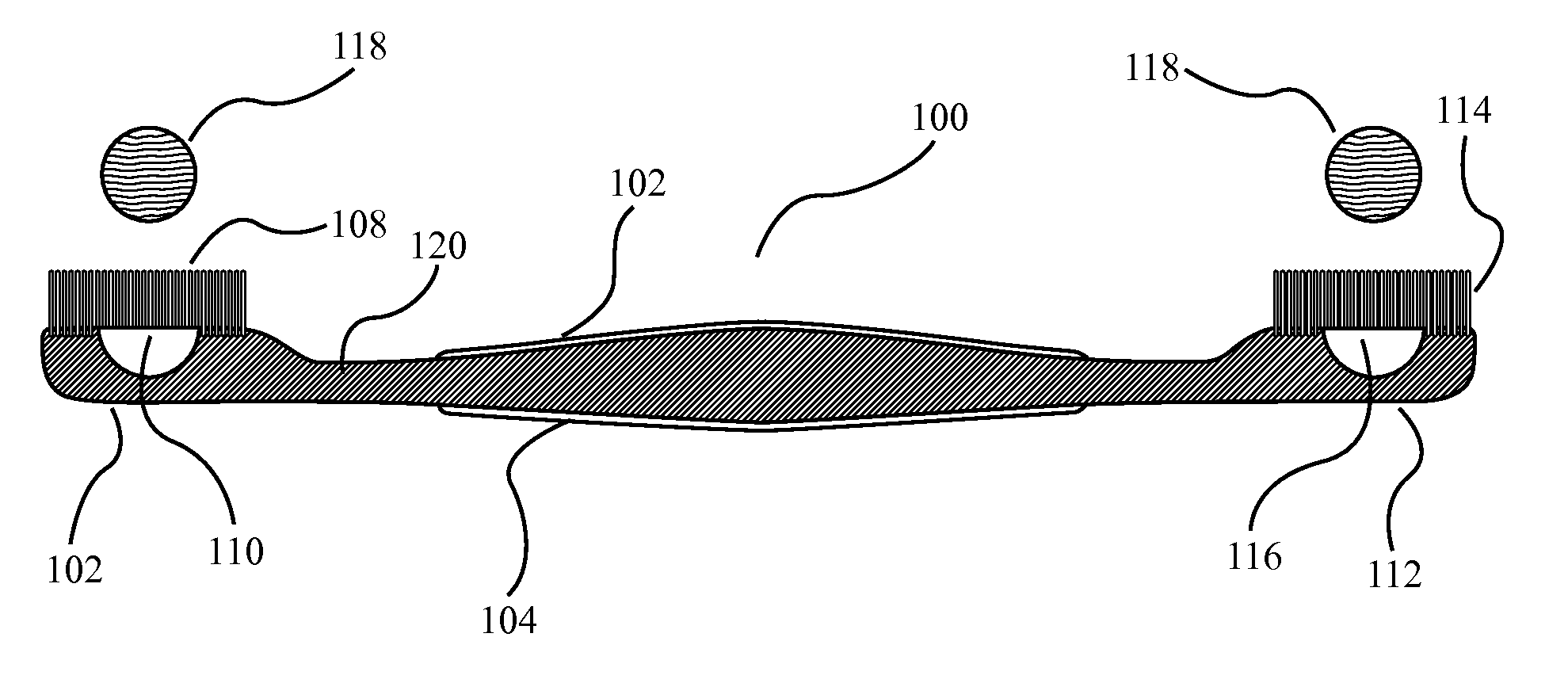

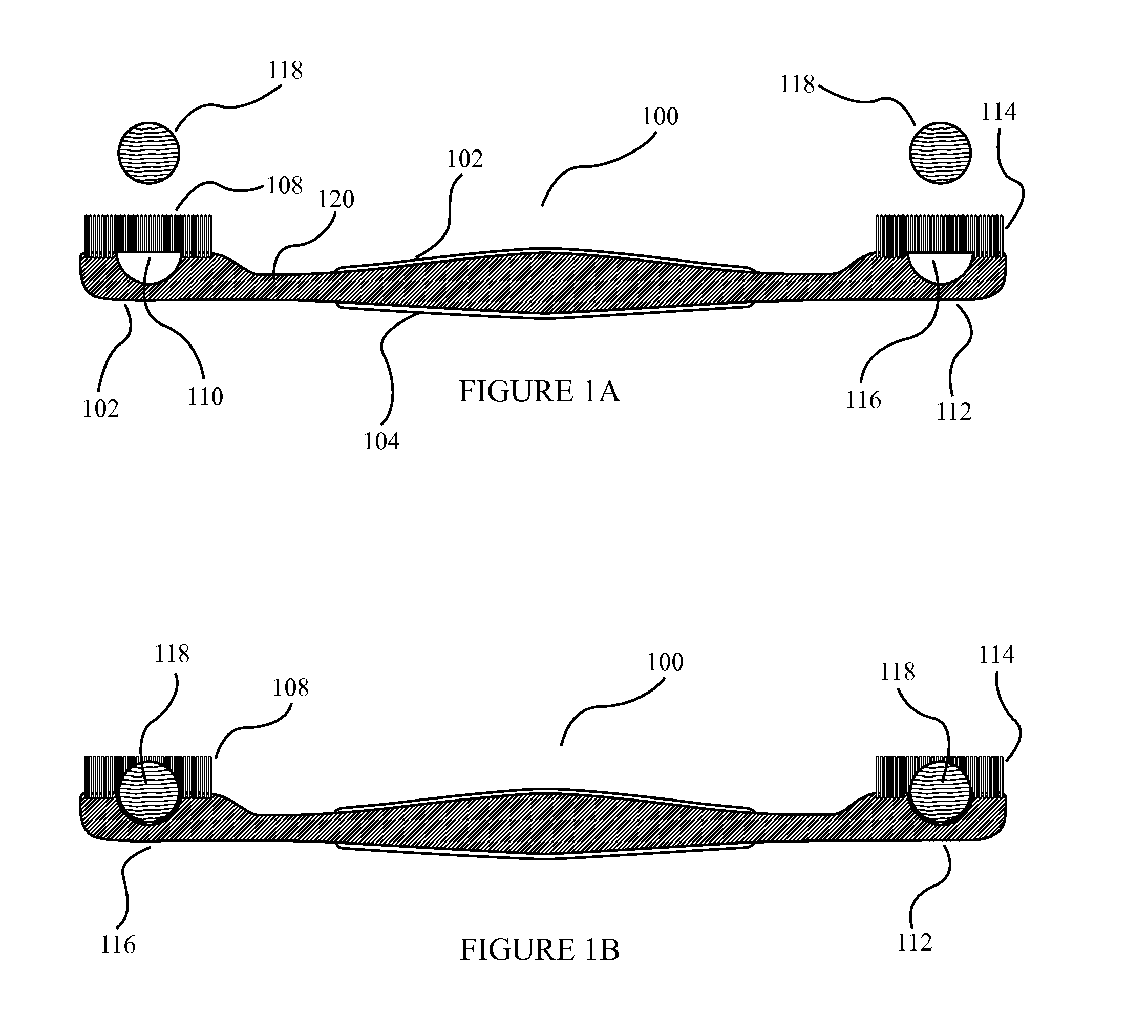

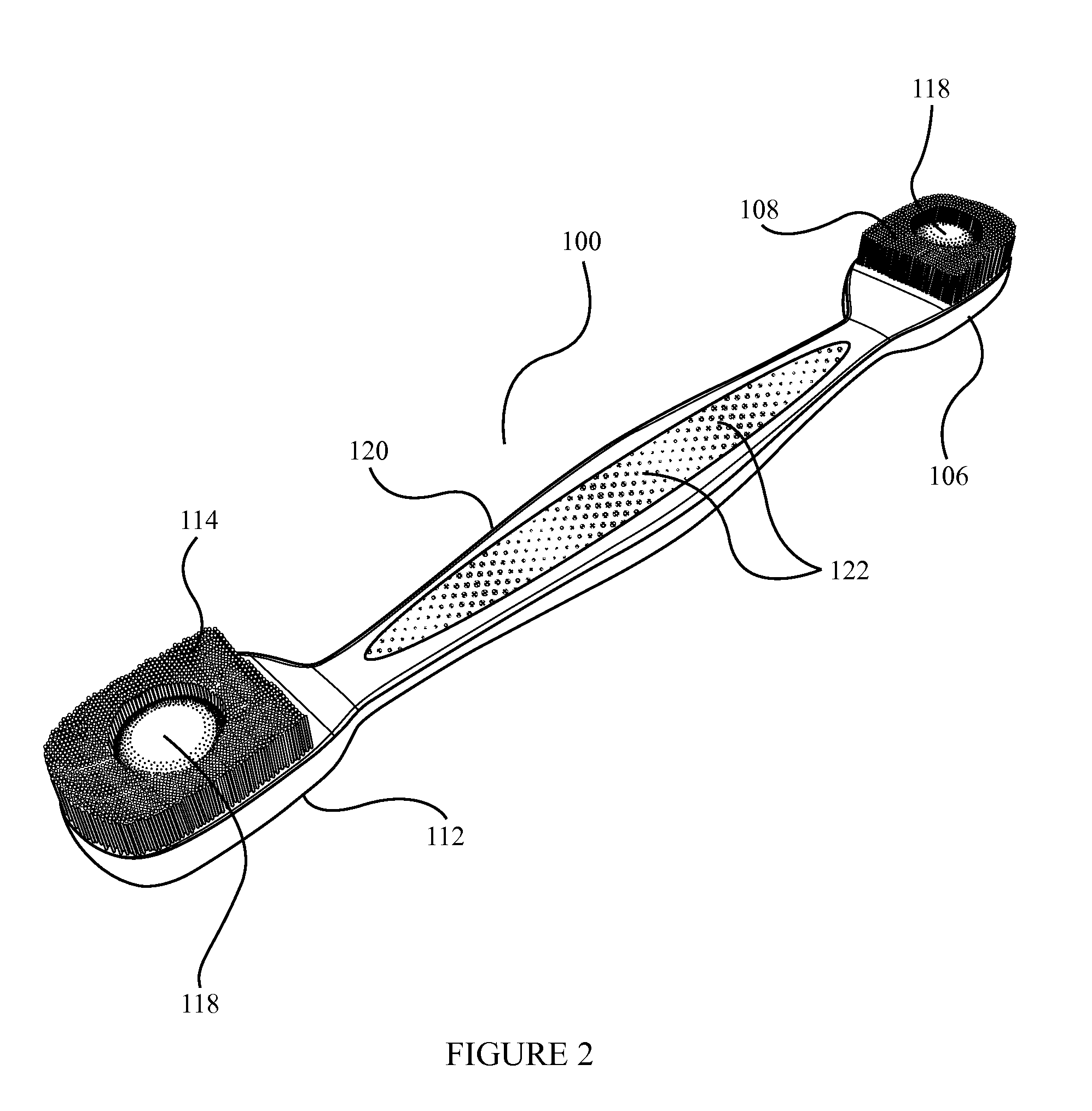

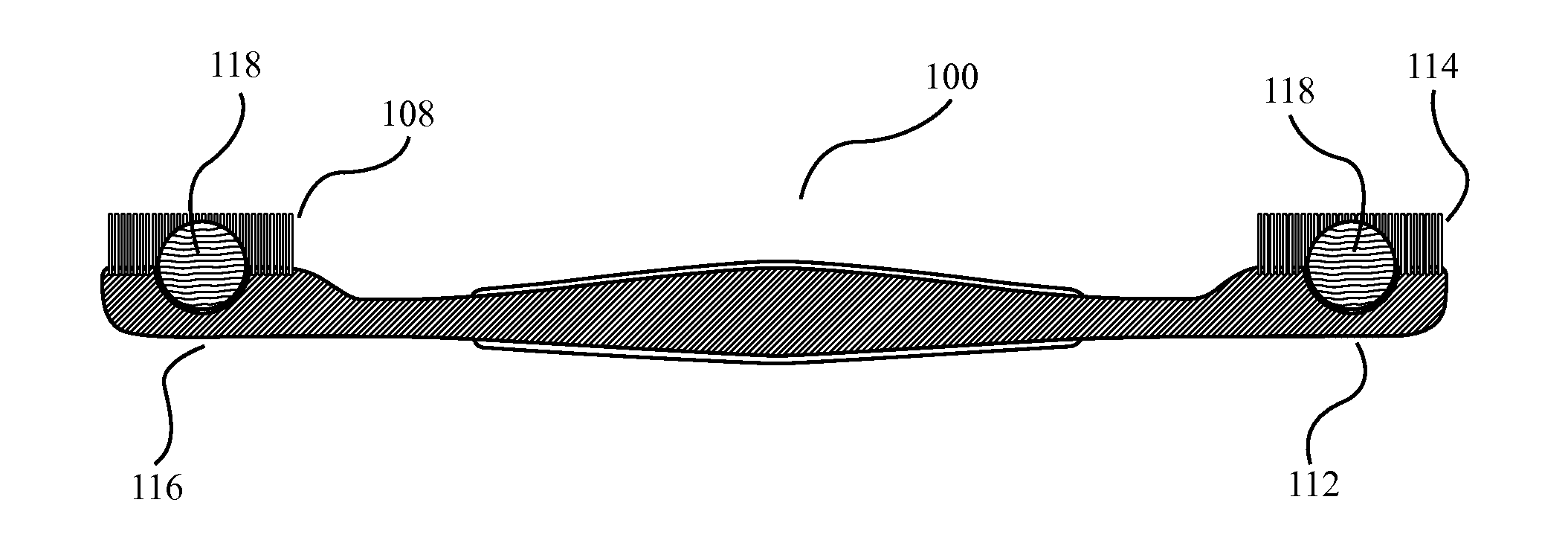

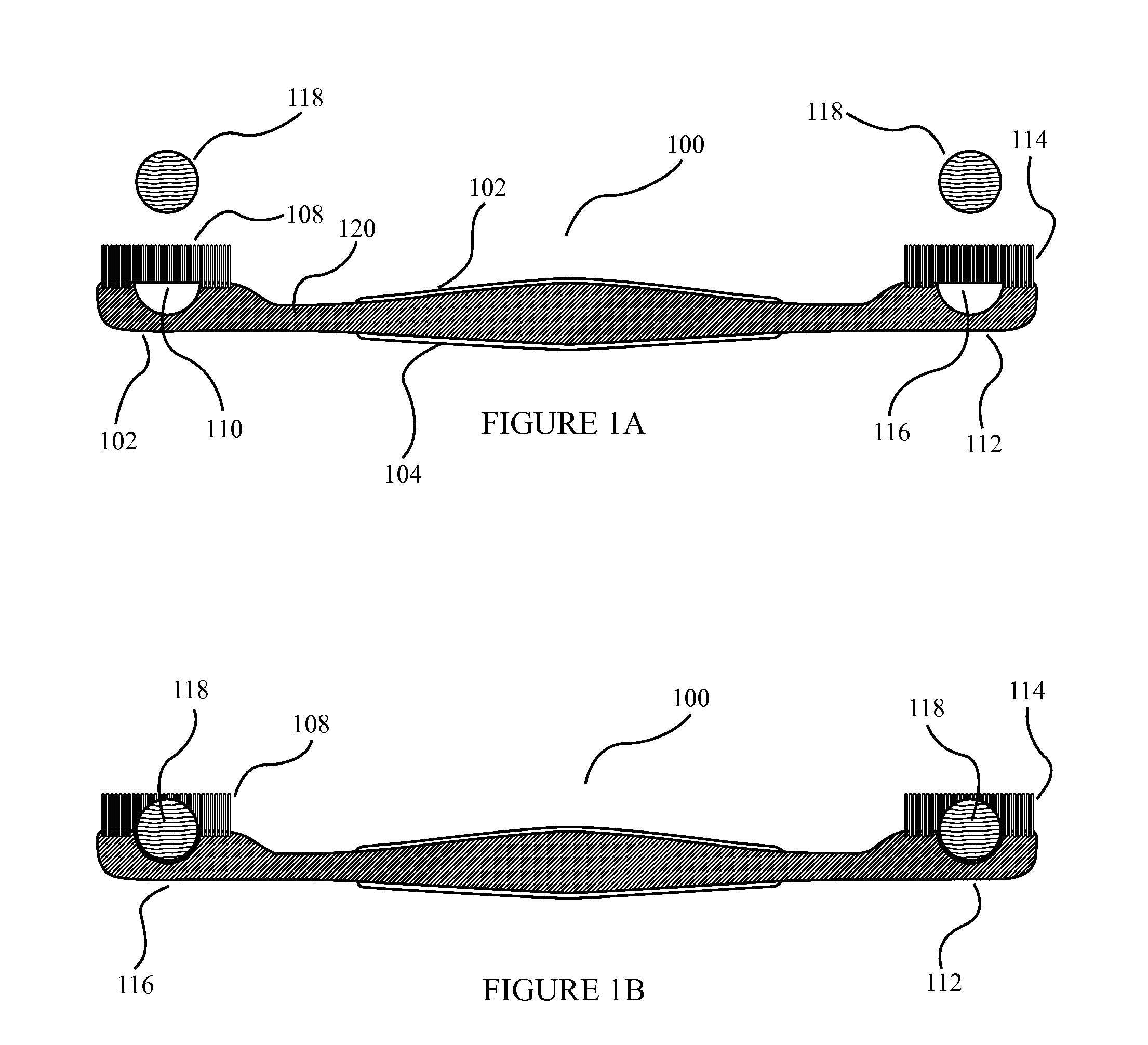

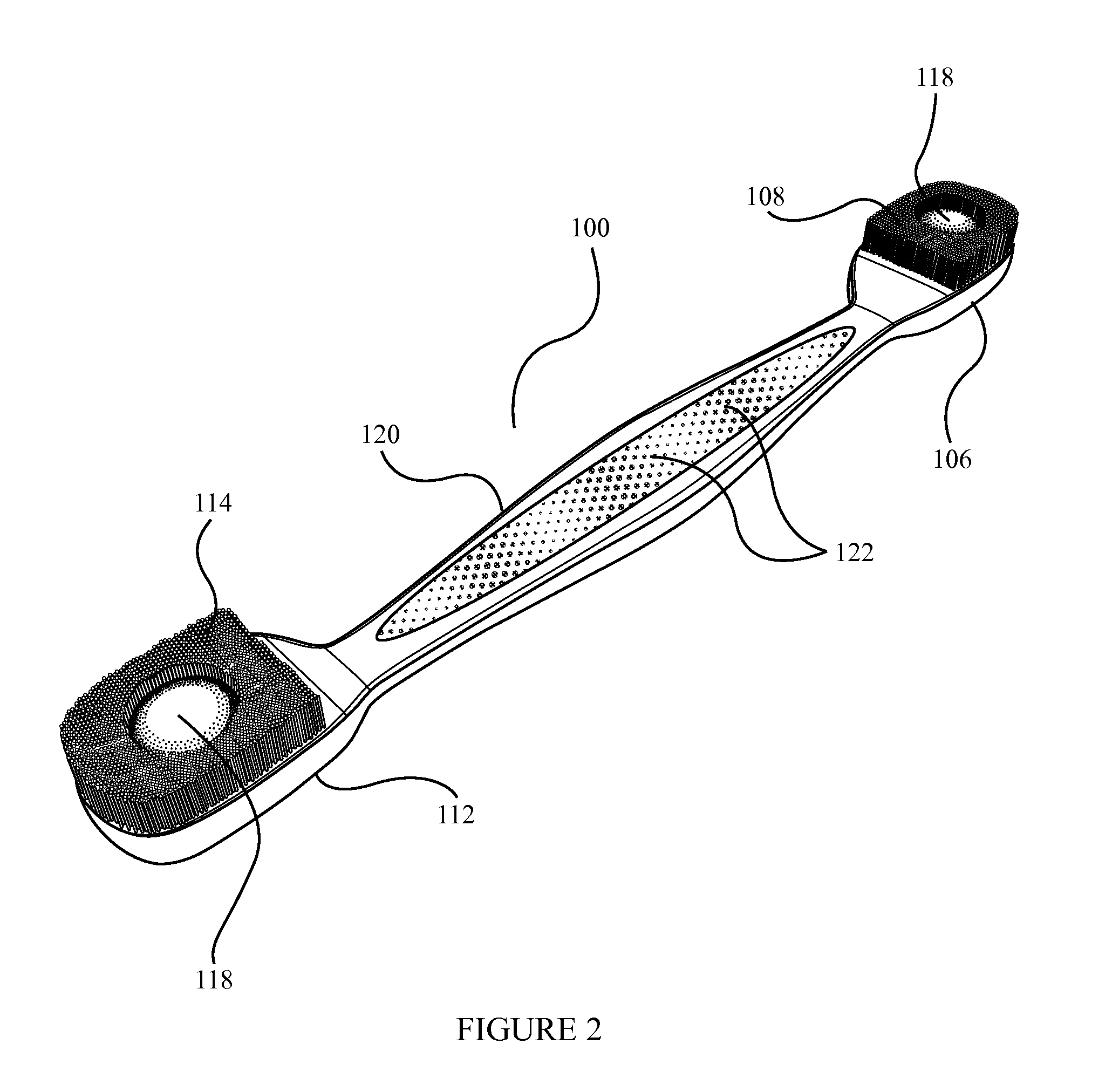

Oral hygiene implement and method of use

InactiveUS20120054974A1Easy to cleanMaximum cleaningBrush bodiesBristleOral hygieneBiomedical engineering

Oral hygiene implement including a handle, a first head mounted to the first end of the handle, a second head mounted to the second end of the handle, including a plurality of cleaning elements extending from the first head and the second head wherein the cleaning elements can exhibit releasable dentifrice retained in the cleaning elements.

Owner:HURWITZ MARNI MARKELL

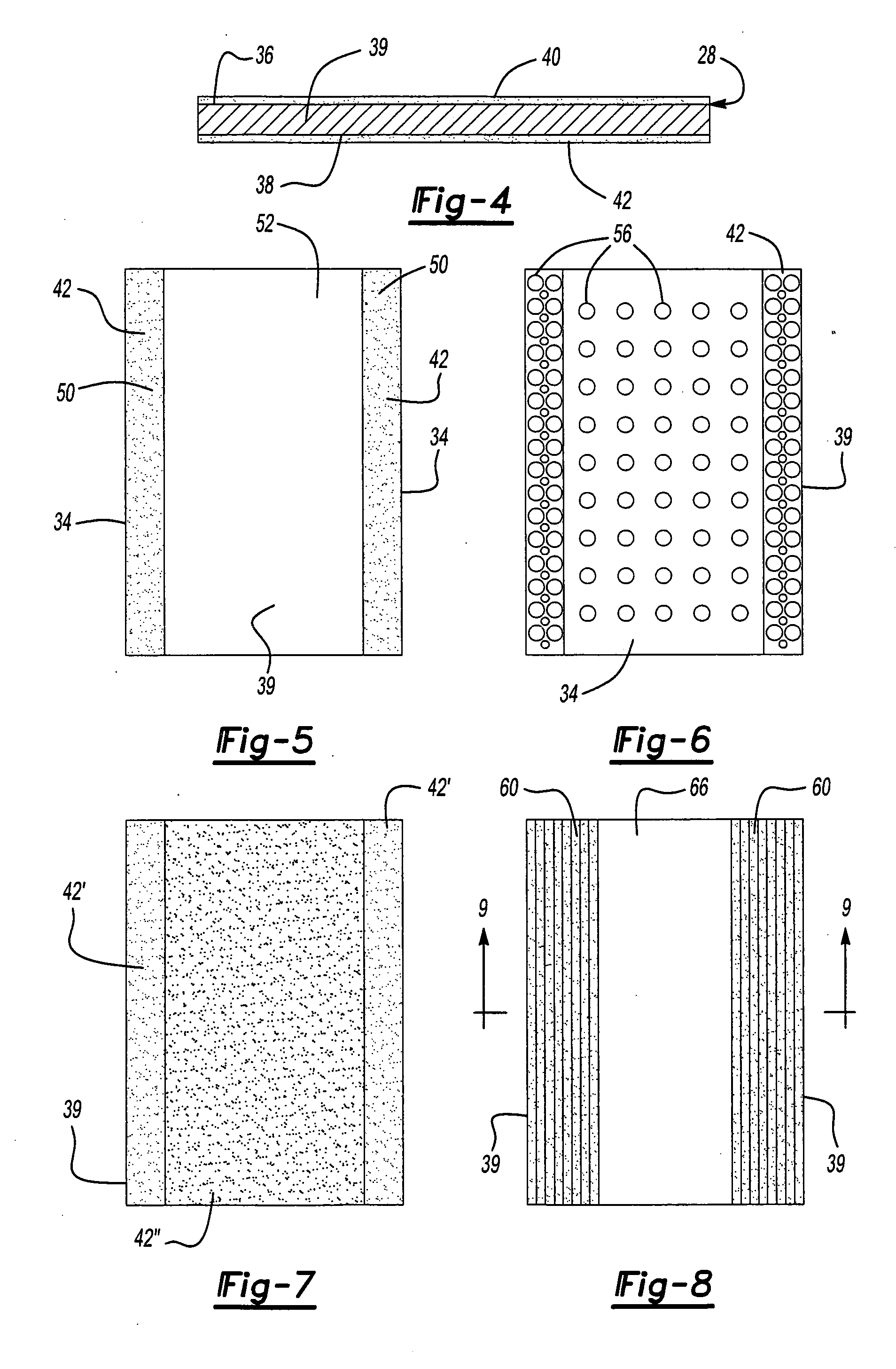

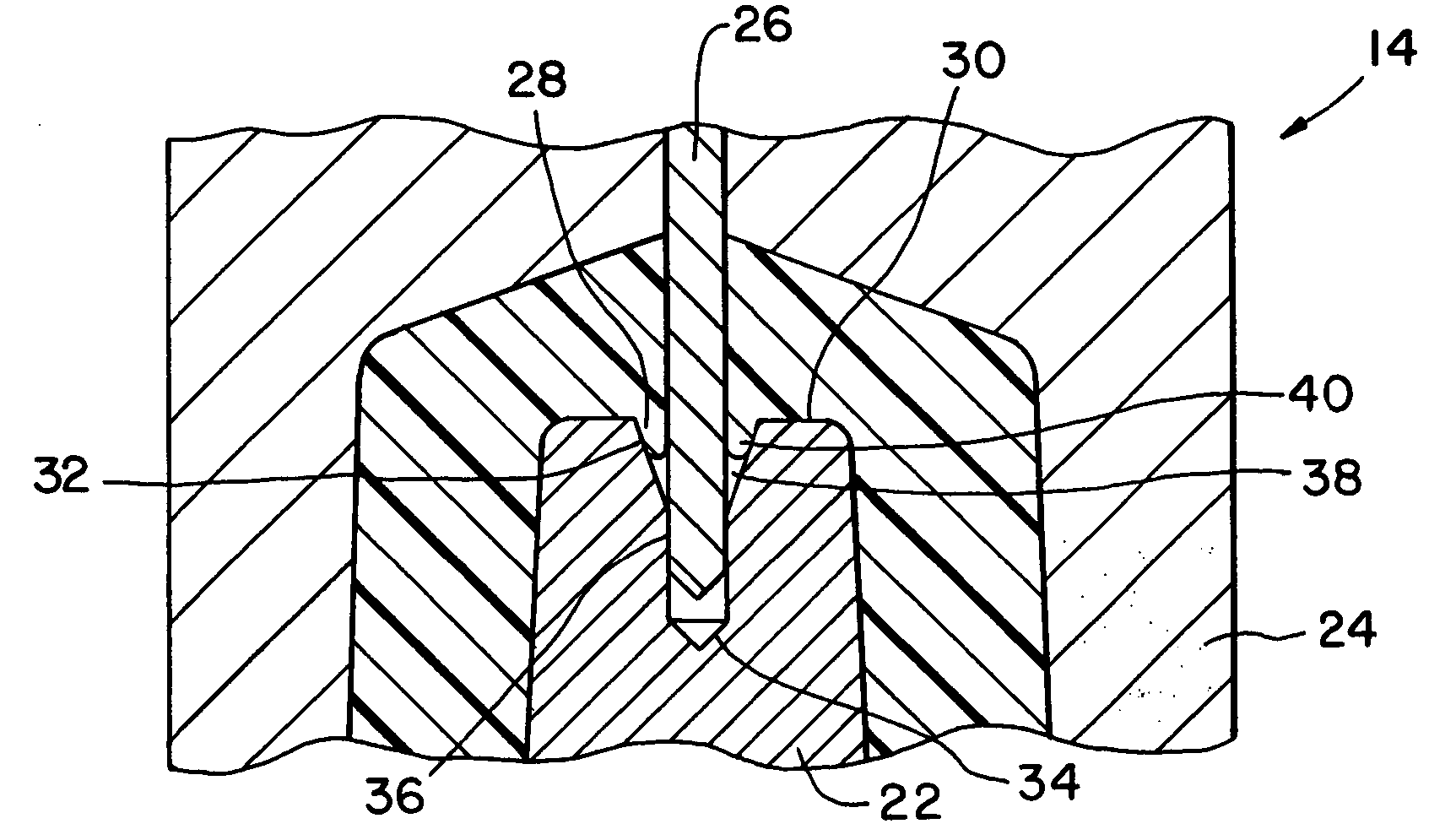

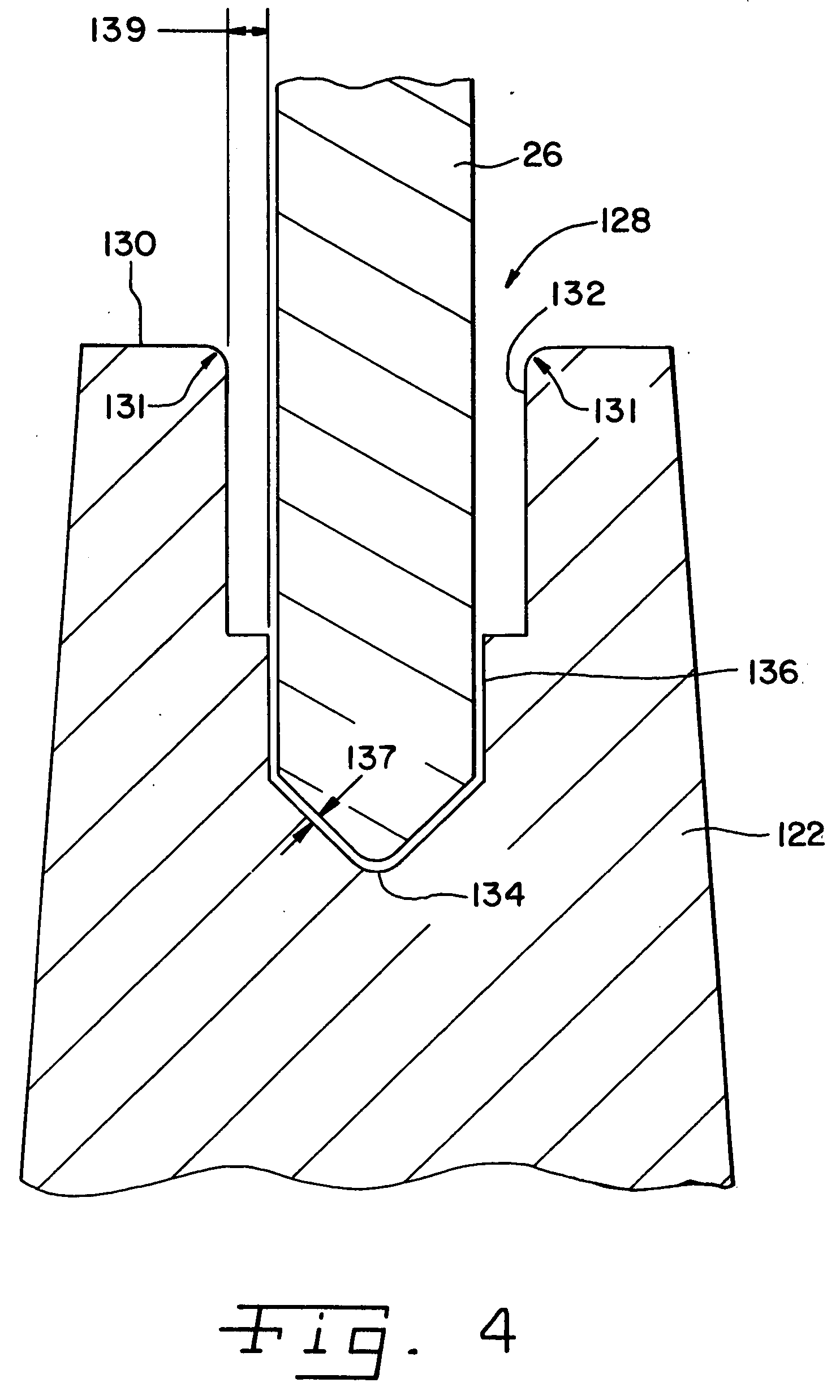

Mold flash trap, process using and parts made thereby

InactiveUS20060099298A1Lower potentialHighly precise moldedFood shapingMaterials scienceInternal cavity

A mold for forming a part, a part formed in the mold and processes for using the mold and forming the part. The mold includes inner and outer mold pieces and a pin extending between the mold pieces to form the part having an internal cavity and an orifice extending into the cavity. The inner mold piece defines a pocket for receiving the pin. The pocket enables the formation of an annular donut-like projection around the orifice within the cavity.

Owner:ILLINOIS TOOL WORKS INC

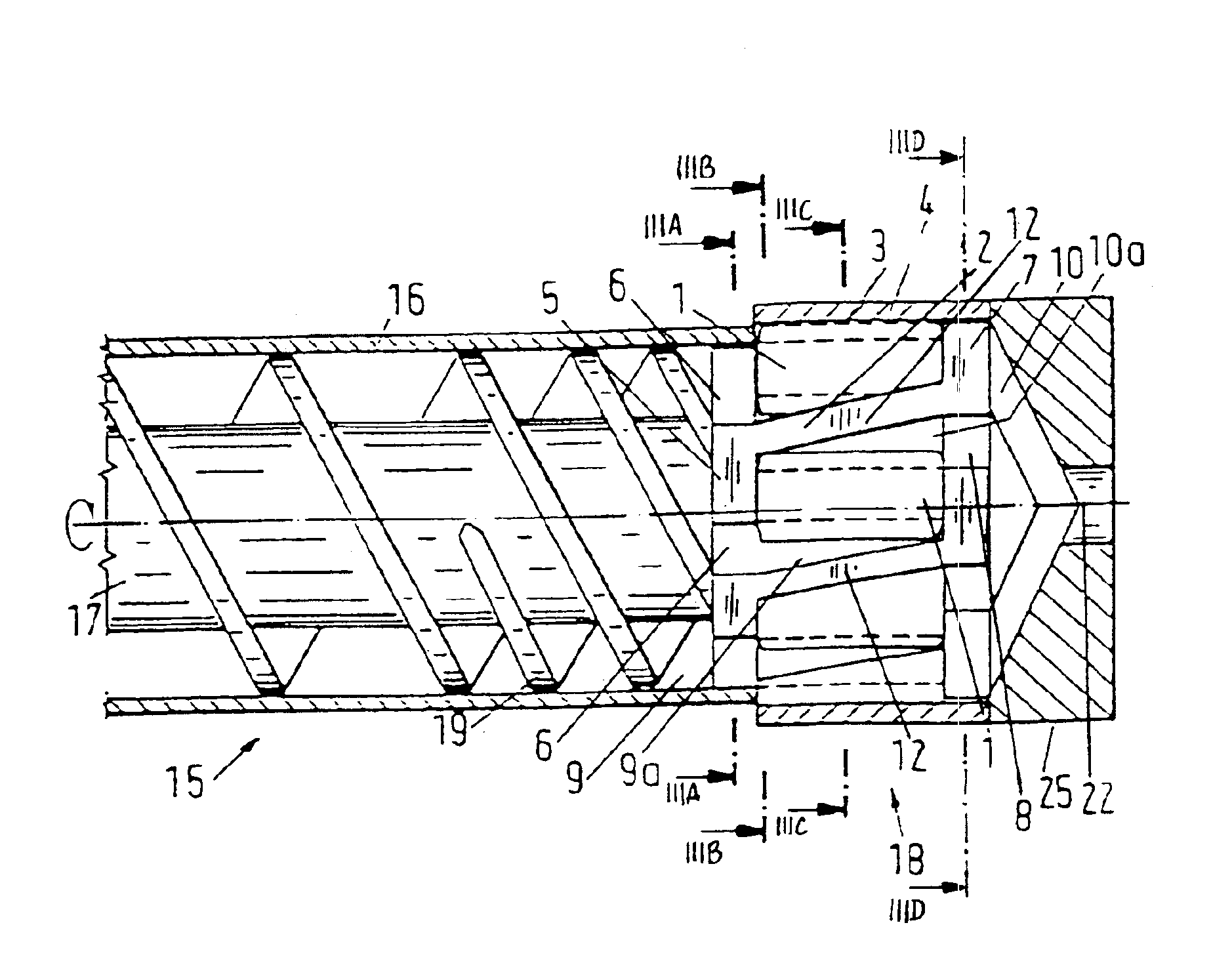

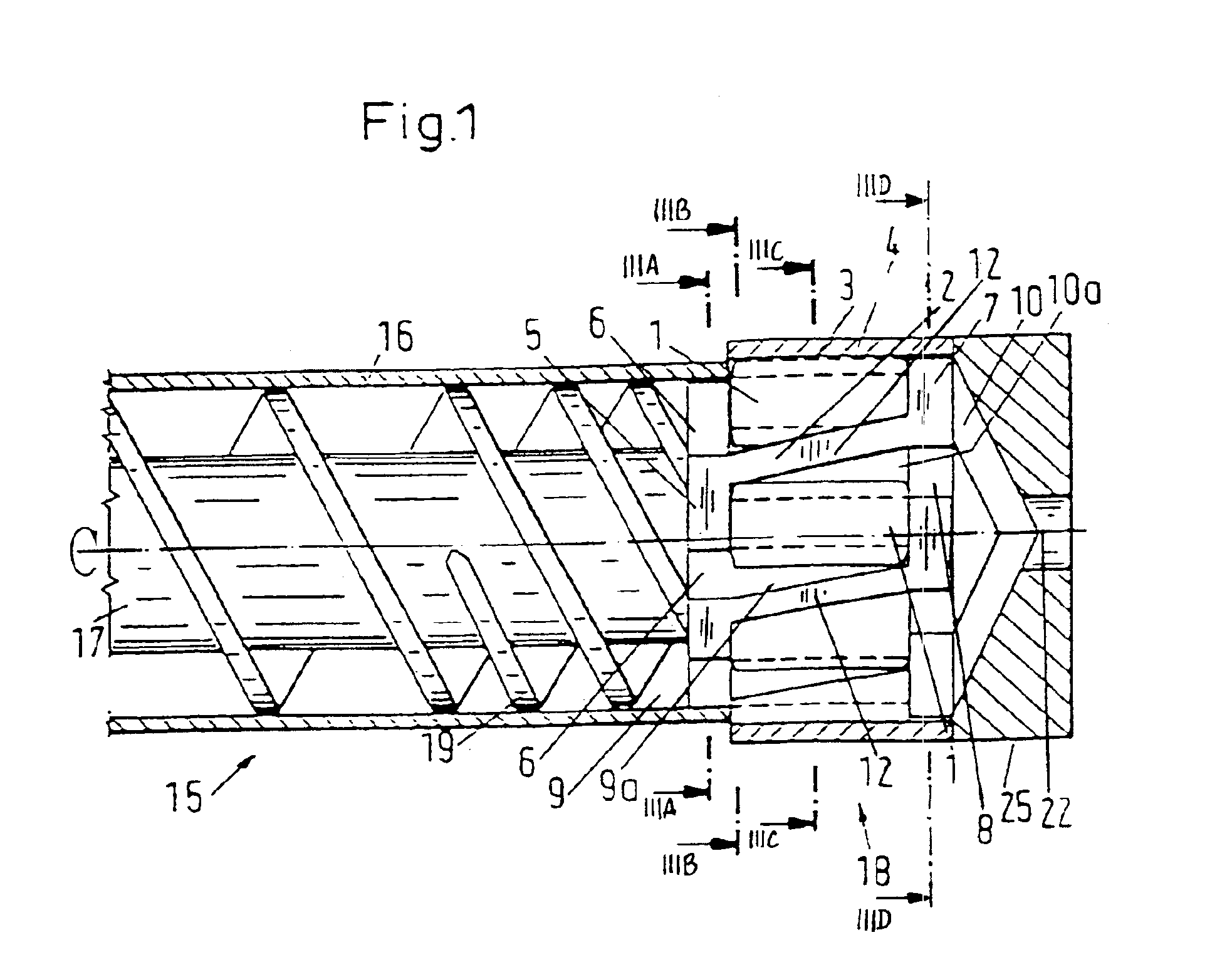

Screw extruder and gear pump arrangement for highly viscous media

InactiveUS6974310B2Good pressure build-upShort designEngine of arcuate-engagement typeOscillating piston enginesGear pumpGear wheel

A screw extruder and gear pump arrangement for highly viscous media includes a screw shaft and a gear pump operatively coupled to the screw shaft. A planet carrier is operatively engaged with at least one rotatably mounted planet gear, a first functional element that is cooperatively engaged with planet gear as a sun wheel, and a second functional element that is cooperatively engaged with the planet gear as an outer ring. One of the first functional element or the second functional element includes gear teeth for meshing with the planet gear and the other includes a sealing region for bearing in a sliding and sealing manner over part of the circumference and length of the planet gear. A pump casing surrounds the planet carrier.

Owner:TKH DEUTSCHLAND GMBH & CO KG

Washing-fast smoldering-suppressing compositions

ActiveUS20090117797A1Non-damaging to aestheticalNon-damaging to textural propertyPhosphatesPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesHigh phosphateNuclear chemistry

Novel smoldering suppressing compositions containing a metal complex of ammonium superphosphoric acid and having a high phosphate content, and processes for their preparation, are disclosed. Further disclosed are formulations containing these compositions and articles-of-manufacture having these formulations applied thereon. These novel formulations are particularly effective as smoldering suppressants for textiles, and are characterized by a high washing fastness.

Owner:BROMINE COMPOUNDS

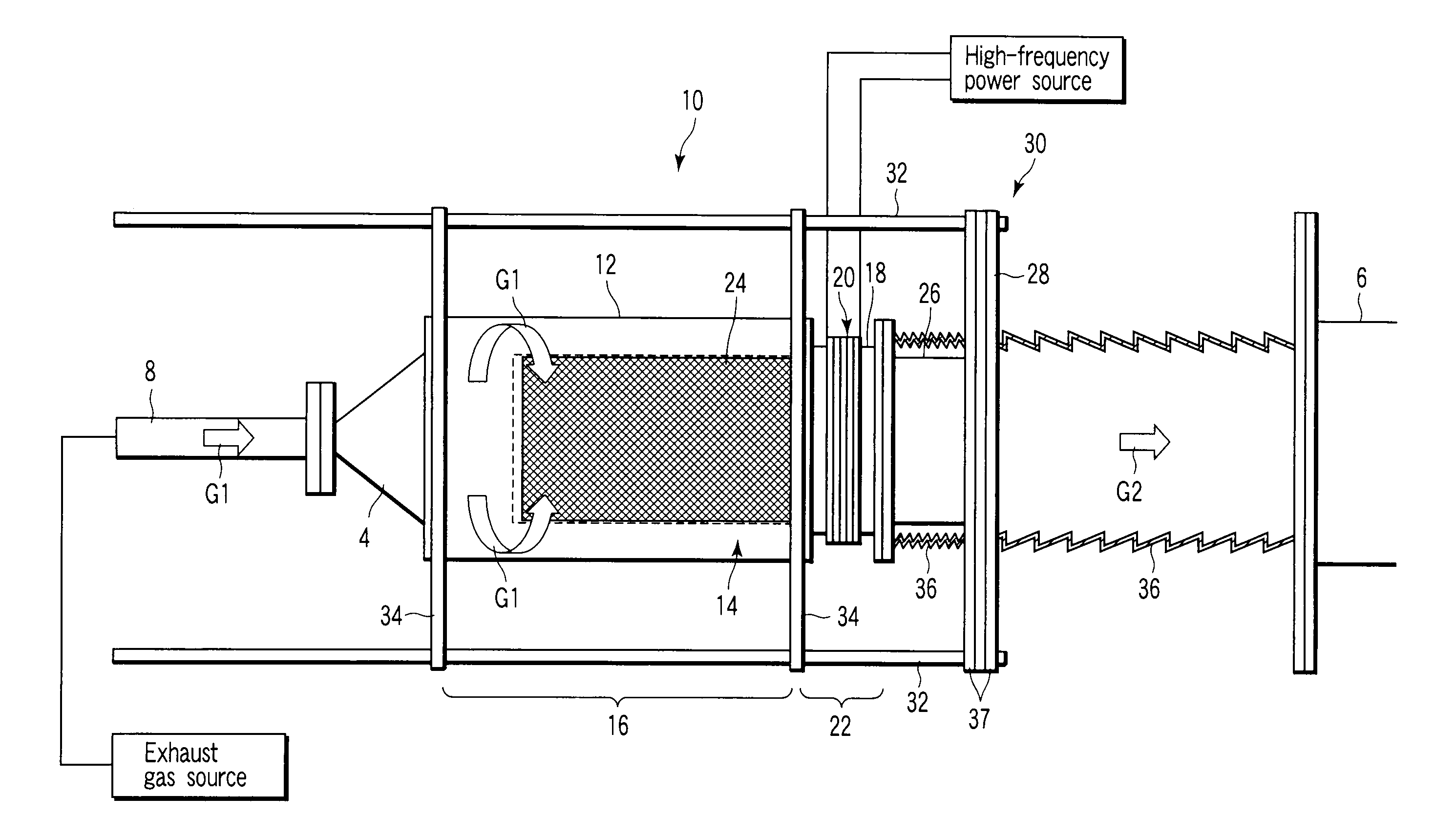

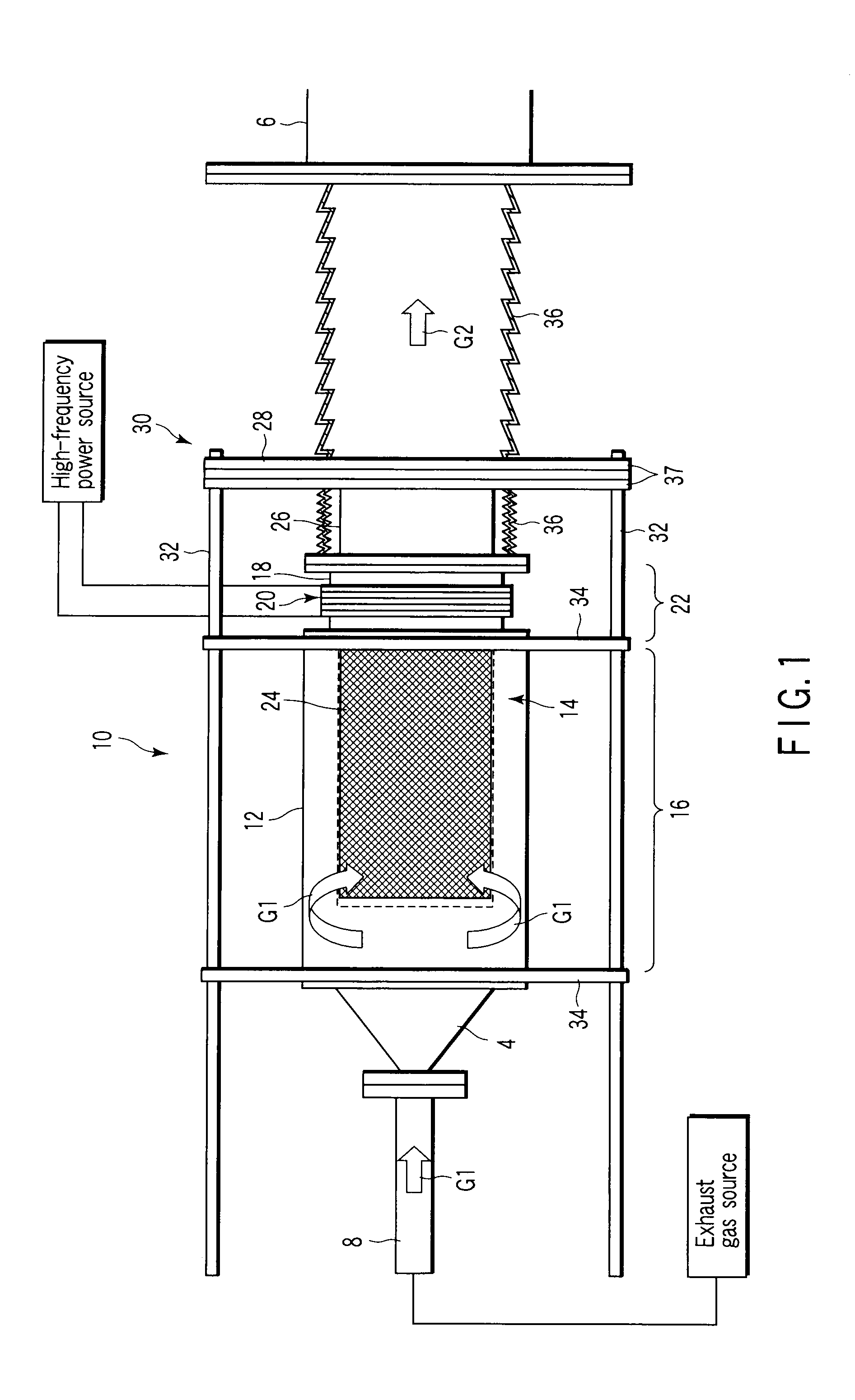

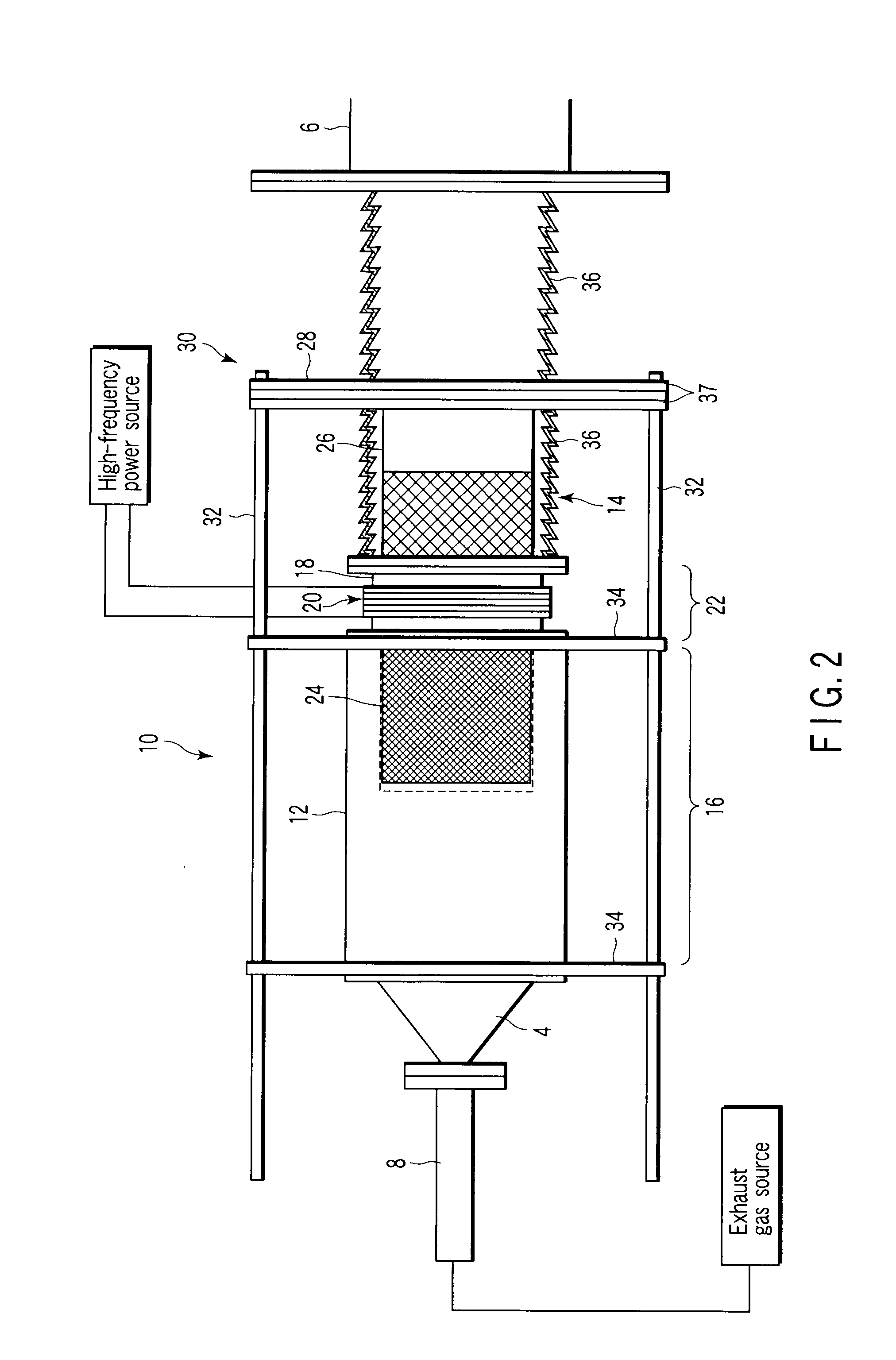

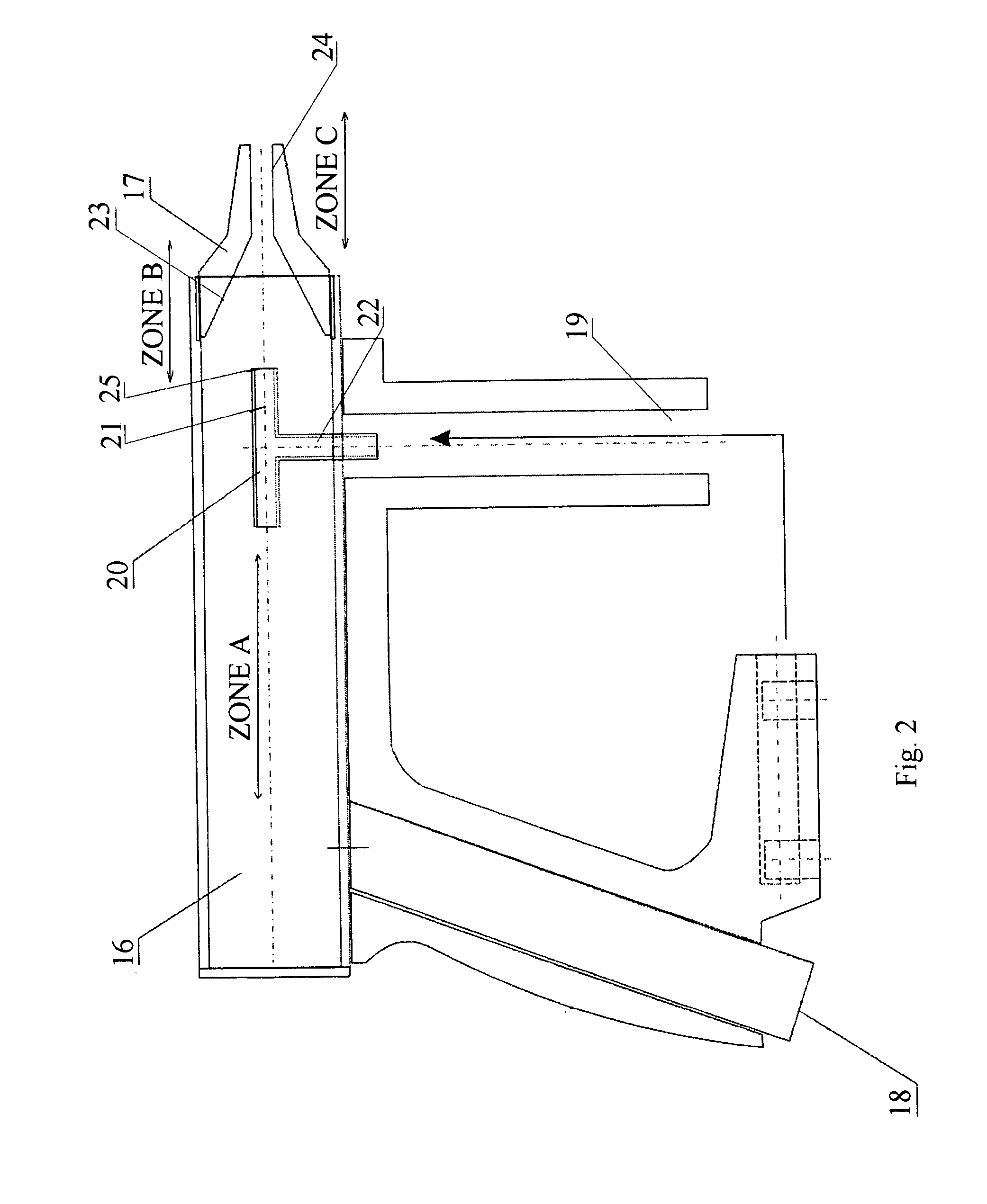

Exhaust gas purifier and filter regenerator

InactiveUS20090084077A1Compact and durableEfficiently gathering particulateCombination devicesAuxillary pretreatmentExhaust gasEngineering

An exhaust gas cleaning apparatus and a filter regeneration apparatus that are capable of cleaning a large volume of exhaust gas without any increase in size of a nonmagnetic member around which a working coil for induction heating is wound. The exhaust gas cleaning apparatus includes a particulate collecting section and a filter regenerating section placed next to each other in the flow direction of an exhaust gas, and a movable frame. The movable frame holds an extension of a filter unit extending from a casing of the particulate collecting section beyond the support frame of the filter regenerating section, and can move the filter unit in the axial direction of the casing. When the filter unit moved by the movable frame passes through the filter regenerating section, a corresponding part of a holding frame disposed in the filter unit is continuously induction-heated to burn collected particulates, such that the filter unit can be regenerated.

Owner:TOKYO UNIV OF MANNE SCI & TECH

Saddle tap connection and installation device

InactiveUS8936280B2Maximum cleaningSafely and efficiently installLamination ancillary operationsLaminationCost effectivenessAdhesive

Saddle tap assemblies comprising internal collars and external saddle taps are disclosed. A saddle tap assembly may include an external slip tap, internal tap collar, a duct section, and adhesive. The external slip tap and the internal tap collar may each have a flange. The flanges may be curved. The flange of the internal collar may have a sheared portion permitting the flange of the internal collar to pass through an opening in a section of duct. The installation of saddle tap assemblies according to embodiments of the present invention is more cost-effective and less time consuming than conventional methods. Moreover, the seals and bonds formed using embodiments of the present invention provide for several layers of chemical protection and structural stiffening wherever the saddle tap assemblies are located.

Owner:ATS PRODS

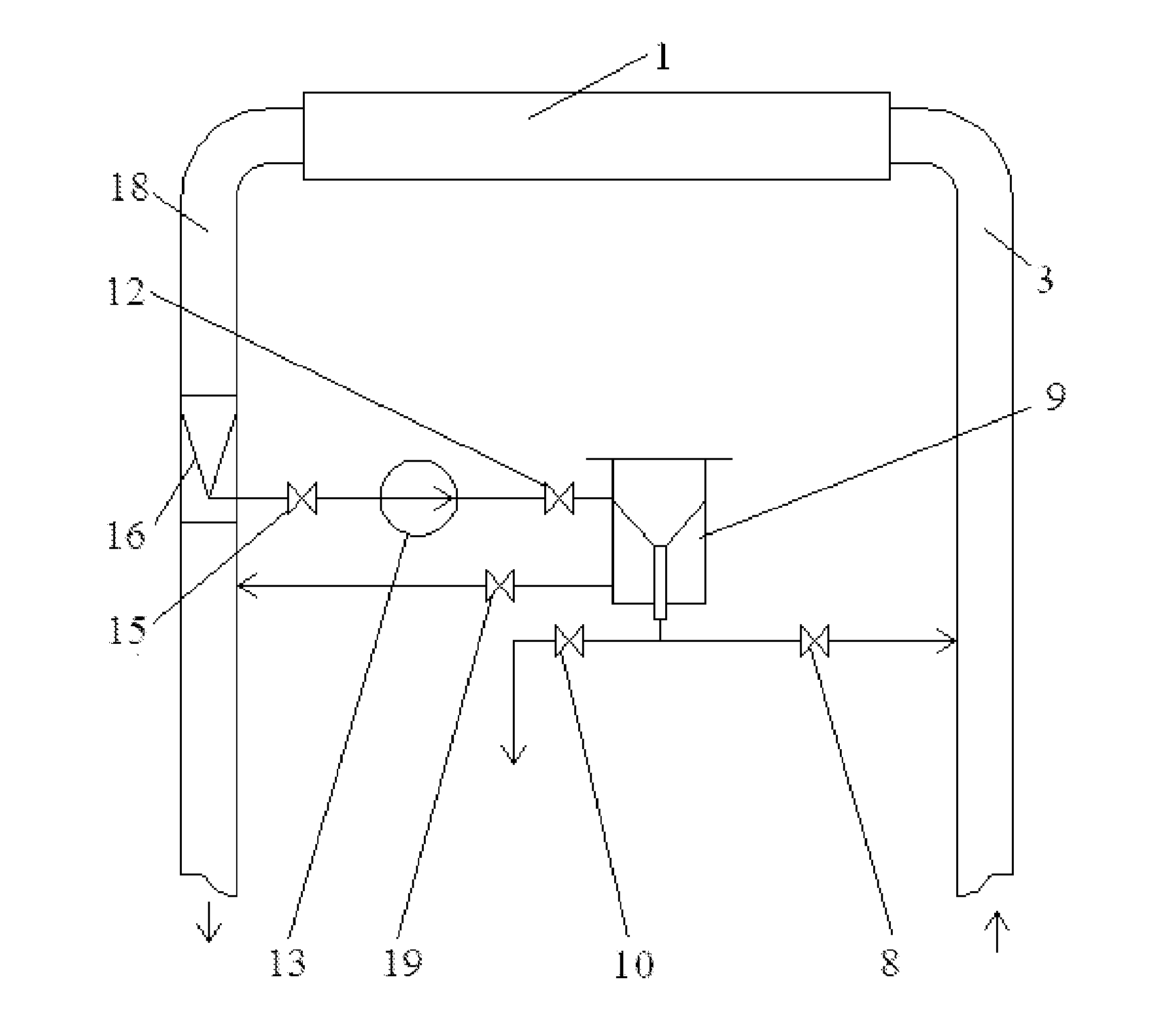

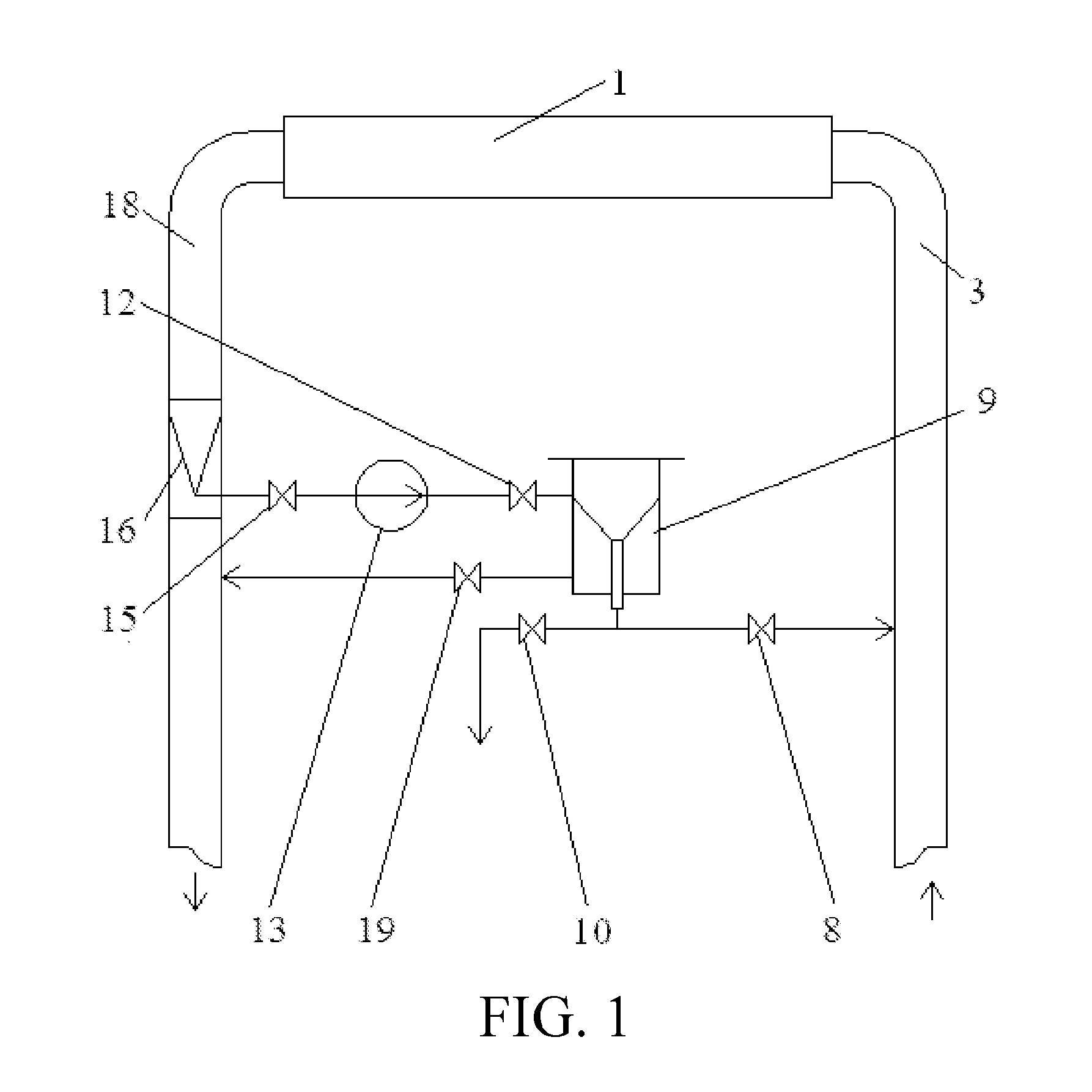

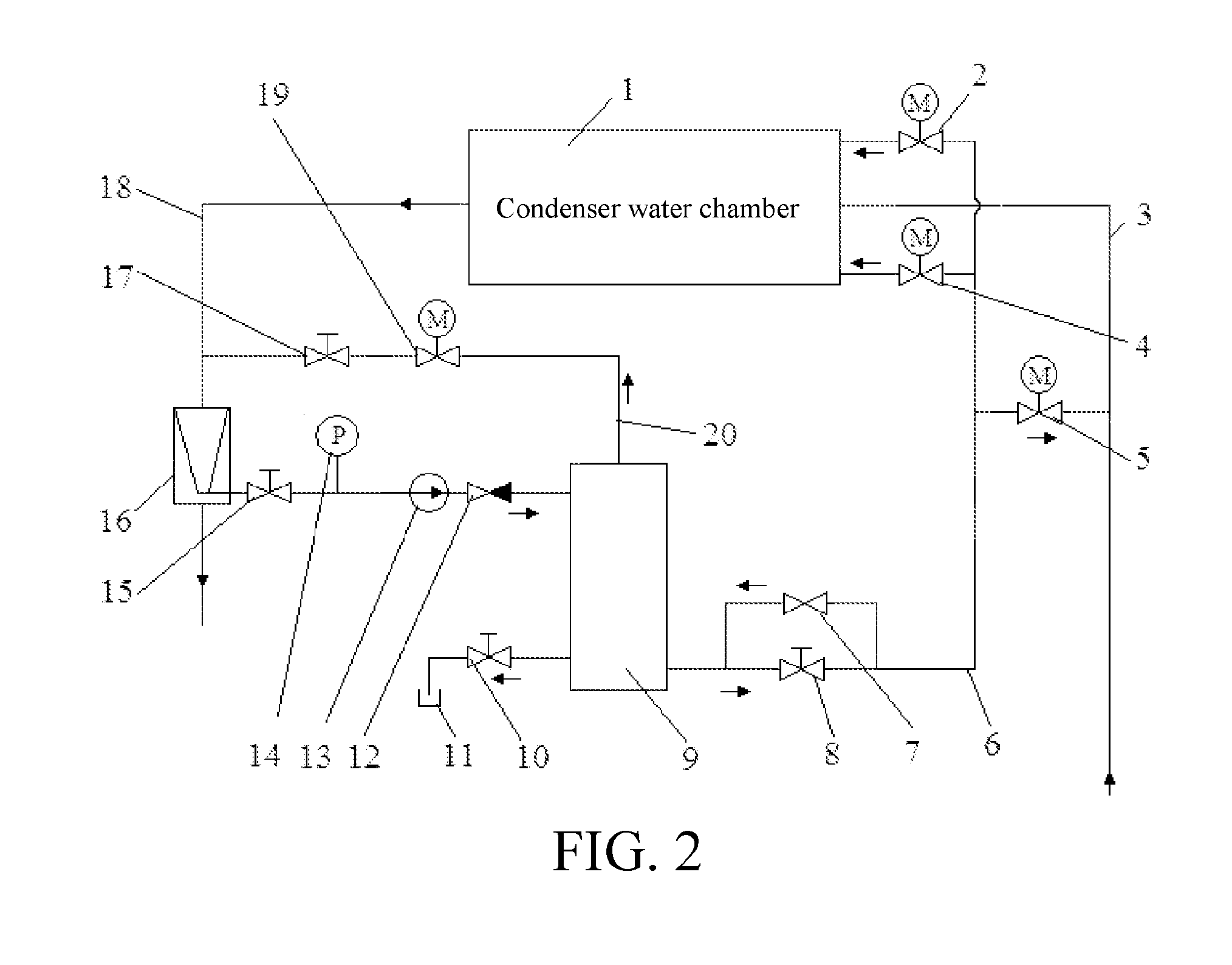

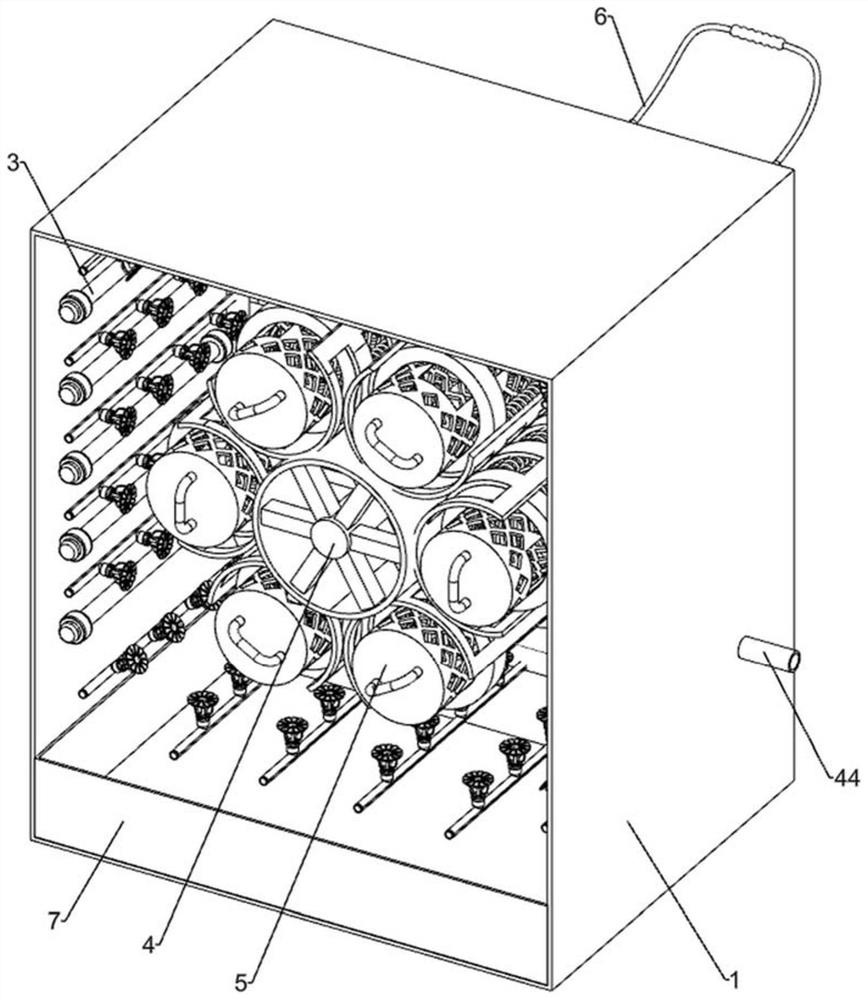

Rubber ball cleaning multipoint centralized ball serving system for condenser

InactiveUS20160084594A1Improve cooling effectReduce in quantityHollow article cleaningNon-rotary device cleaningIsolation valveCooling effect

A rubber ball cleaning multipoint centralized ball serving system for a condenser includes a condenser water chamber, a cooling water outlet pipe, a cooling water inlet pipe, a ball recovery net, a second isolating valve, a rubber ball pump, and a check valve. A water inlet end of the condenser water chamber is connected to a plurality of pulse ball serving valves. The plurality of pulse ball serving valves is connected to a ball adding chamber via a rubber ball transfer pipe. The rubber ball transfer pipe is connected to the cooling water inlet pipe via another pulse ball serving valve. The ball adding chamber is connected to the circulating cooling water outlet pipe via a hot water discharging pipe. The hot water discharging pipe is provided with a third isolating valve and a hot water discharging valve. A lower portion of the ball adding chamber is provided with a rubber ball discharge valve. The present system can reduce a quantity of the circulating cooling water that is heated during running of the rubber ball system and again enters the water inlet pipe of the circulating cooling water system, thereby improving a condenser circulating cooling effect. By oppositely and correspondingly operating a pulse ball serving valve and a hot water discharging valve to open or close, a great number of rubber balls are enabled to centrally enter the circulating cooling water inlet pipe and the condenser water chamber within a short time, thereby cleaning the condenser heat exchange pipe in full coverage.

Owner:SHANXI HANDE ENERGY SAVING ENVIRONMENTAL PROTECTION TECH CO LTD

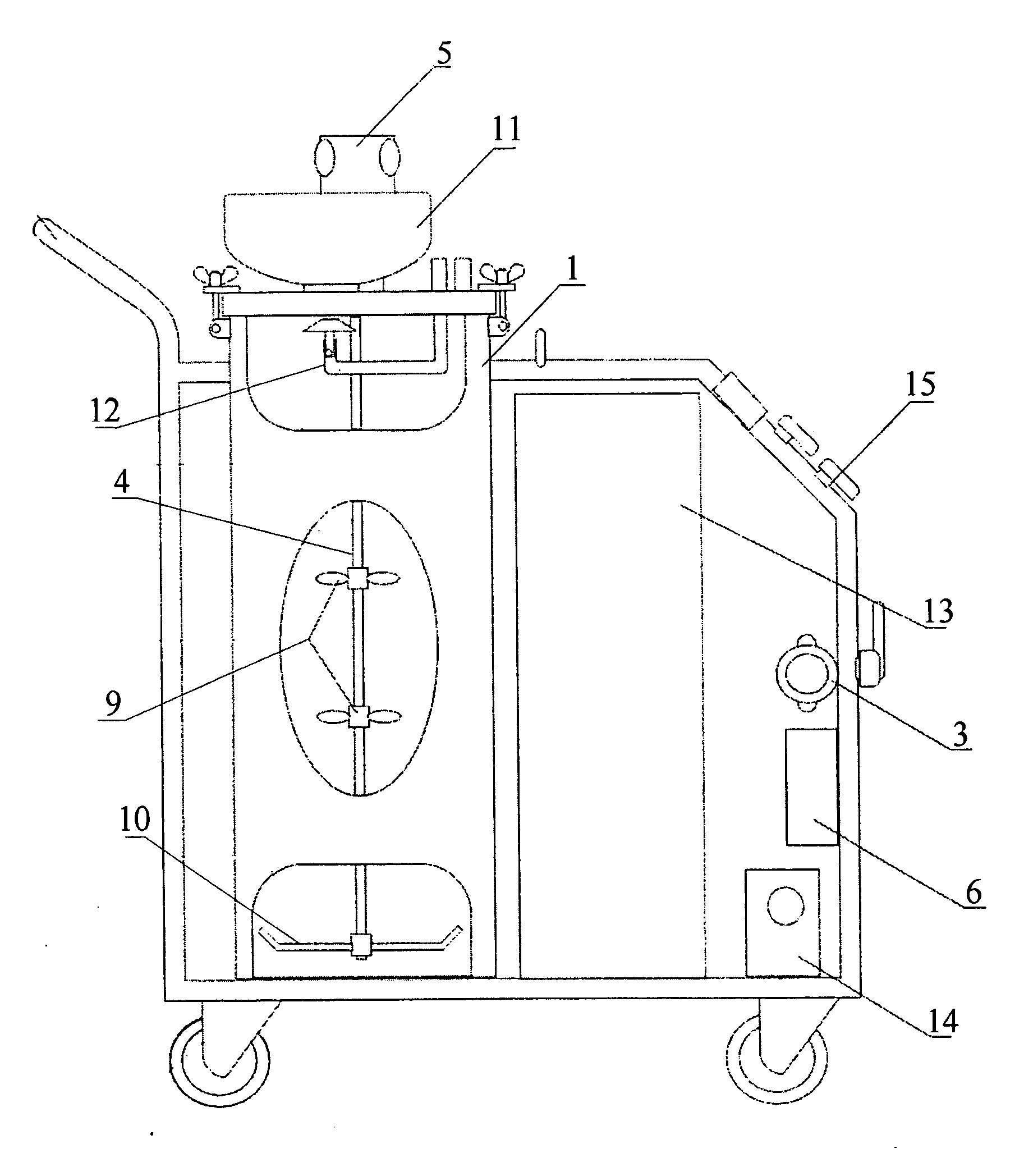

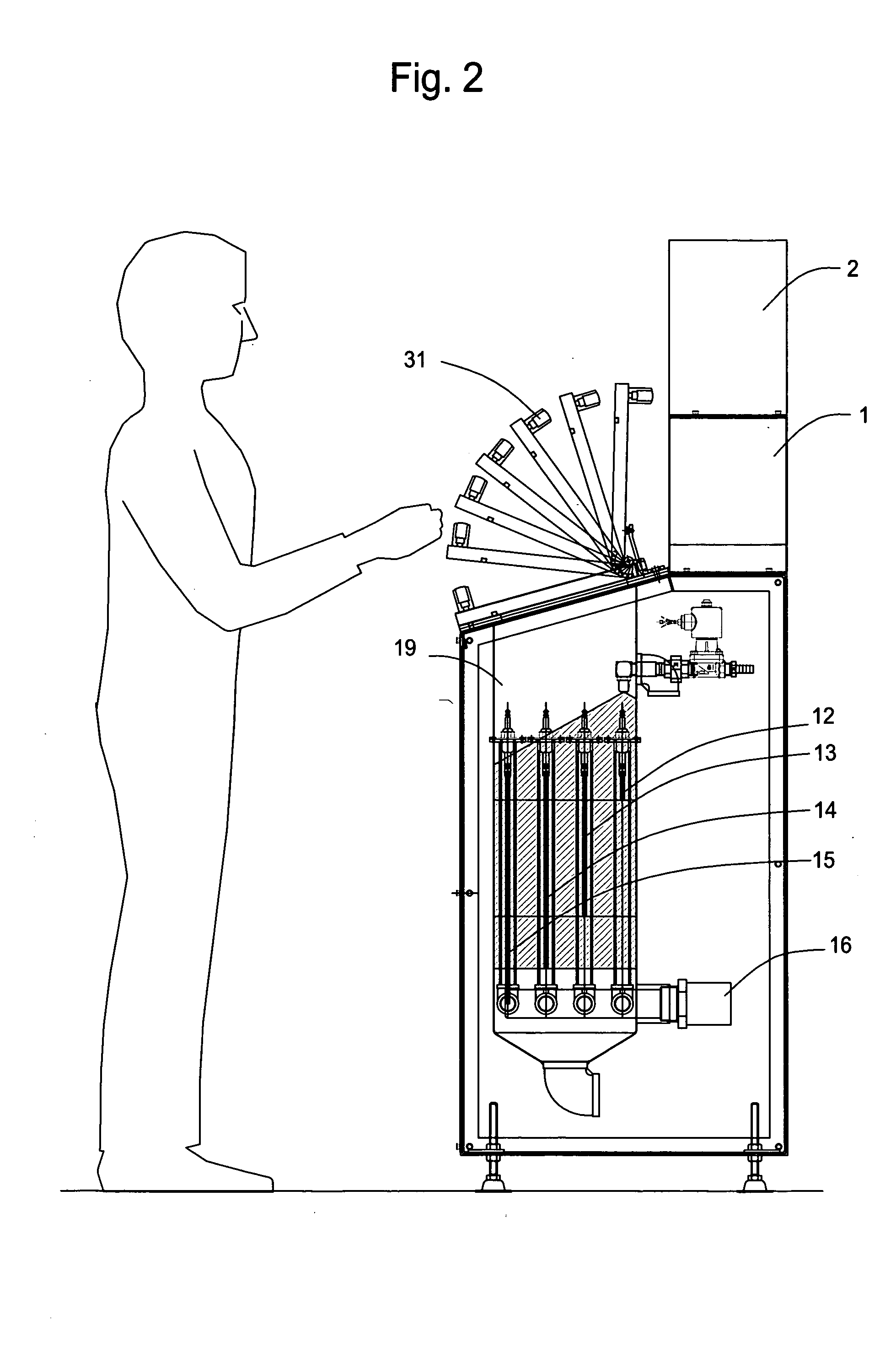

Apparatus for aerohydrodynamic abrasive cleaning of surfaces, sprayer for the same, and method for aerohydrodynamic abrasive cleaning of surfaces

InactiveUS20110237162A1High outputImprove efficiencyAbrasive feedersAbrasive blasting machinesSprayerEngineering

An apparatus for mechanical spray treatment of materials has a container for preparing an abrasive suspension, the container having a stirring mechanism including a stirrer provided with at least one blade, and a sprayer for spraying the abrasive suspension connected to the container and a compressed gas supply device. The stirrer of the stirring mechanism has a comminuting cutter provided thereon in the bottom part of the container. The method for aerohydrodynamic abrasive cleaning of surfaces includes entraining the abrasive suspension flow in compressed gas to produce aerosol particles and directing the stream of aerosol particles from the sprayer nozzle to a surface. Moreover, after aerosol particles have been formed they are accelerated owing to the sprayer design within the sprayer before they are ejected from the nozzle. The method and device help improve the output, efficiency, and quality of cleaning by improving the uniformity of abrasive material grains used and imparting a high velocity to the suspension spray, expanding the area of effective cleaning, and distributing the aerosol particles therein in an optimal proportion.

Owner:KOSTEVICH ALEXANDR VIKTOROVICH

Adhesive roller

InactiveUS20050050660A1Easy to separateReduce adhesionHousehold cleanersPipe units with cleaning aperturesEngineeringSolid substrate

An adhesive roller for detritus removal having an elongated strip where the strip has both a backing layer and an adhesive layer overlying and covering a first side of the backing layer. The strip also has a first end, a second end and two spaced apart sides. The strip is wound from its first end and to its second end into a tubular cylindrical roller with the adhesive layer facing outwardly. An adhesive release coating also overlies at least a portion of a second side of the backing layer. The adhesive release coating may be either applied as a liquid coating, or may be a solid substrate. This adhesive release coating facilitates removal of individual sheets from the roller. Alternatively, a portion of the backing layer is crimped to form alternating peaks and valleys along at least a portion of the backing layer. These alternating peaks and valleys limit the amount of areal contact between the backing layer and the next inner adhesive layer of the roller to facilitate removal of individual sheets from the roller.

Owner:THE EVERCARE

Apparatus for dissolving filth treatment bags formed by water soluble film

InactiveUS20070144951A1Minimize timeRelease problematicalOther chemical processesSettling tanks feed/dischargeWastewaterWater soluble

An apparatus for dissolving filth treatment bags formed by hot water soluble films in a dissolving tub is disclosed. The apparatus includes a pipe for inputting hot water for dissolving the filth bag storing filth by stirring action of the hot water therefrom, a pipe for outputting vapor including odor generated by a mixture of the filth and the hot water in the dissolving tub, the vapor being generated on a shifting process from a state where the film is divided and collapsed to a stage where the film is dissolved, and a mechanism for cooling the heated wastewater including the dissolved filth bag and the hot water in the dissolving tub and outputting the wastewater into a sewer pipe from the dissolving tub.

Owner:MATSUOKA KIKAI

Manufacture of near-net shape titanium alloy articles from metal powders by sintering with presence of atomic hydrogen

ActiveUS8920712B2Improve mechanical propertiesImprove the level ofCoatingsDehydrogenationTitanium alloy

A process including:(a) forming a powder blend by mixing titanium powders,(b) consolidating the powder blend by compacting to provide a green compact,(c) heating the green compact thereby releasing absorbed water from the titanium powder,(d) forming β-phase titanium and releasing atomic hydrogen from the hydrogenated titanium by heating the green compact in an atmosphere of hydrogen emitted by the hydrogenated titanium,(e) reducing surface oxides on particles of the titanium powder with atomic hydrogen released by heating of the green compact,(f) diffusion-controlled chemical homogenizing of the green compact and densification of the green compact by heating followed by holding resulting in complete or partial dehydrogenation to form a cleaned and refined compact,(g) heating the cleaned and refined green compact in vacuum thereby sintering titanium to form a sintered dense compact, and(h) cooling the sintered dense compact to form a sintered near-net shaped article.

Owner:ADVANCE MATERIAL PRODS ADMA PRODS

Adhesive roller

InactiveUS20080193694A1Easy to separateReduce adhesionCarpet cleanersFilm/foil adhesivesEngineeringSolid substrate

An adhesive roller for detritus removal having an elongated strip where the strip has both a backing layer and an adhesive layer overlying and covering a first side of the backing layer. The strip also has a first end, a second end and two spaced apart sides. The strip is wound from its first end and to its second end into a tubular cylindrical roller with the adhesive layer facing outwardly. An adhesive release coating also overlies at least a portion of a second side of the backing layer. The adhesive release coating may be either applied as a liquid coating, or may be a solid substrate. This adhesive release coating facilitates removal of individual sheets from the roller. Alternatively, a portion of the backing layer is crimped to form alternating peaks and valleys along at least a portion of the backing layer. These alternating peaks and valleys limit the amount of areal contact between the backing layer and the next inner adhesive layer of the roller to facilitate removal of individual sheets from the roller.

Owner:BUTLER HOME PRODUCTS LLC

Belt module with oblong pivot hole

A modular conveyor belt formed of rows of belt modules pivotally interlinked by transverse pivot rods. The modules include a top, product conveying surface and a bottom, sprocket-driven surface. The belt modules have a plurality of first link ends disposed in the direction of travel of the conveyor belt and a plurality of second link ends disposed in the opposite direction. Transverse holes in the link ends are aligned to accommodate a pivot rod. When the link ends of the consecutive rows of side by side modules are intercalated, the pivot rod serves as a hinge pin in a hinged joint between consecutive interlinked rows. The transverse holes are disposed at an angle relative to the top surface of the belt module such that when the belt modules are connected to form a belt the transverse holes in adjacent link ends are disposed at opposite angles.

Owner:HABASIT AG

Oral hygiene implement and method of use

InactiveUS20120272984A1Easy to cleanMaximum cleaningBrush bodiesBristleOral hygieneBiomedical engineering

Oral hygiene implement including a handle, a first head mounted to the first end of the handle, a second head mounted to the second end of the handle, including a plurality of cleaning elements extending from the first head and the second head wherein the cleaning elements can exhibit releasable dentifrice retained in the cleaning elements.

Owner:HURWITZ MARNI MARKELL

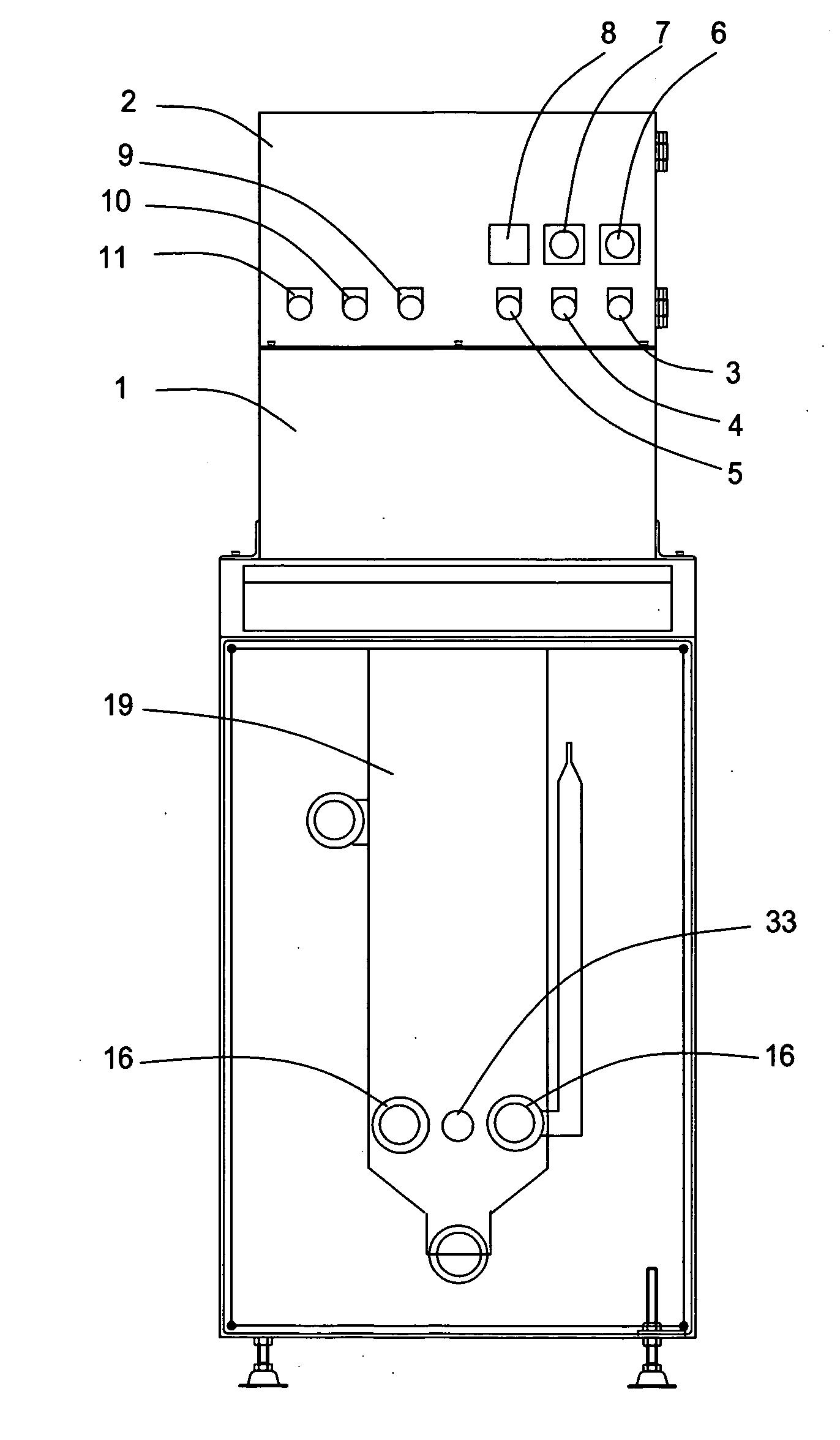

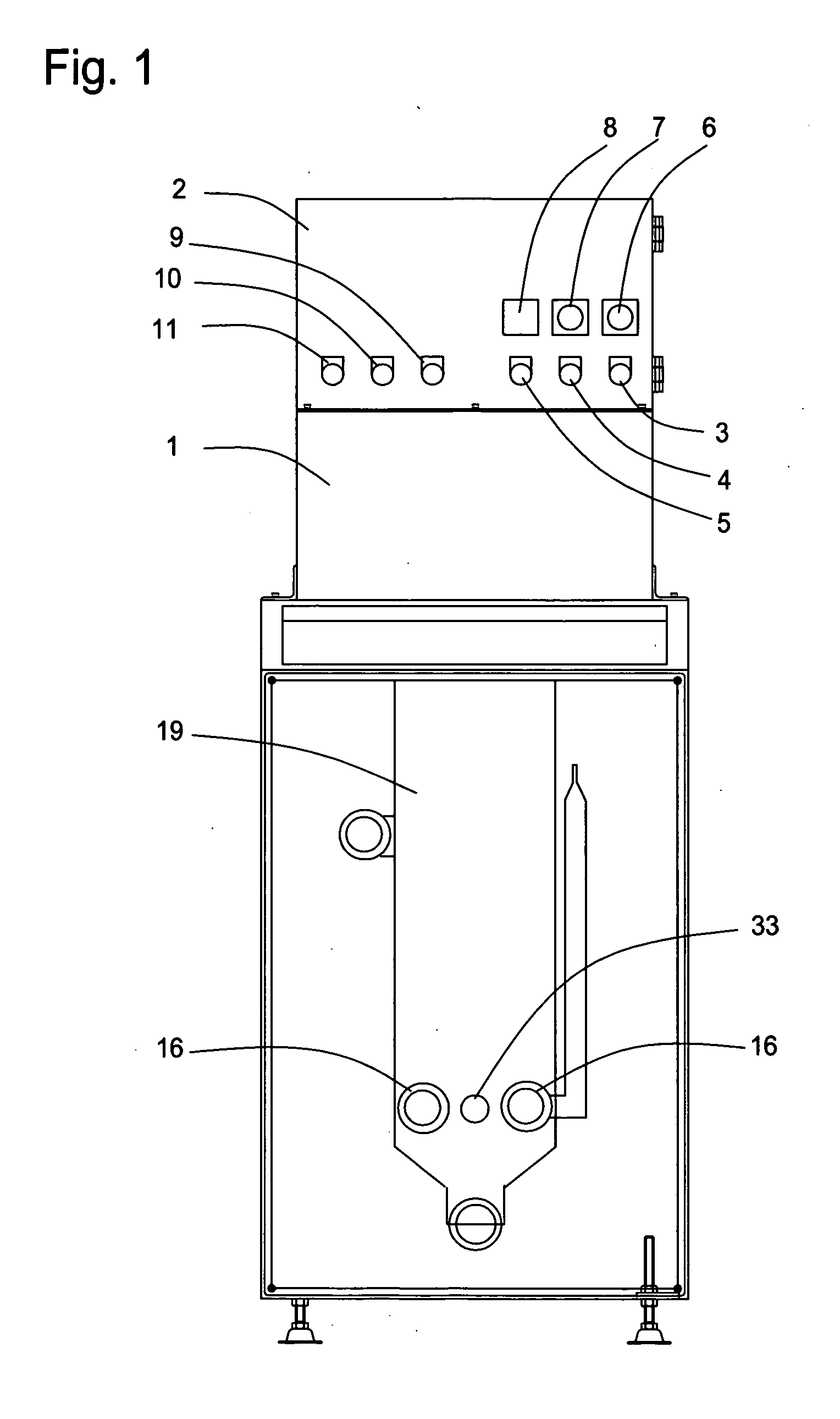

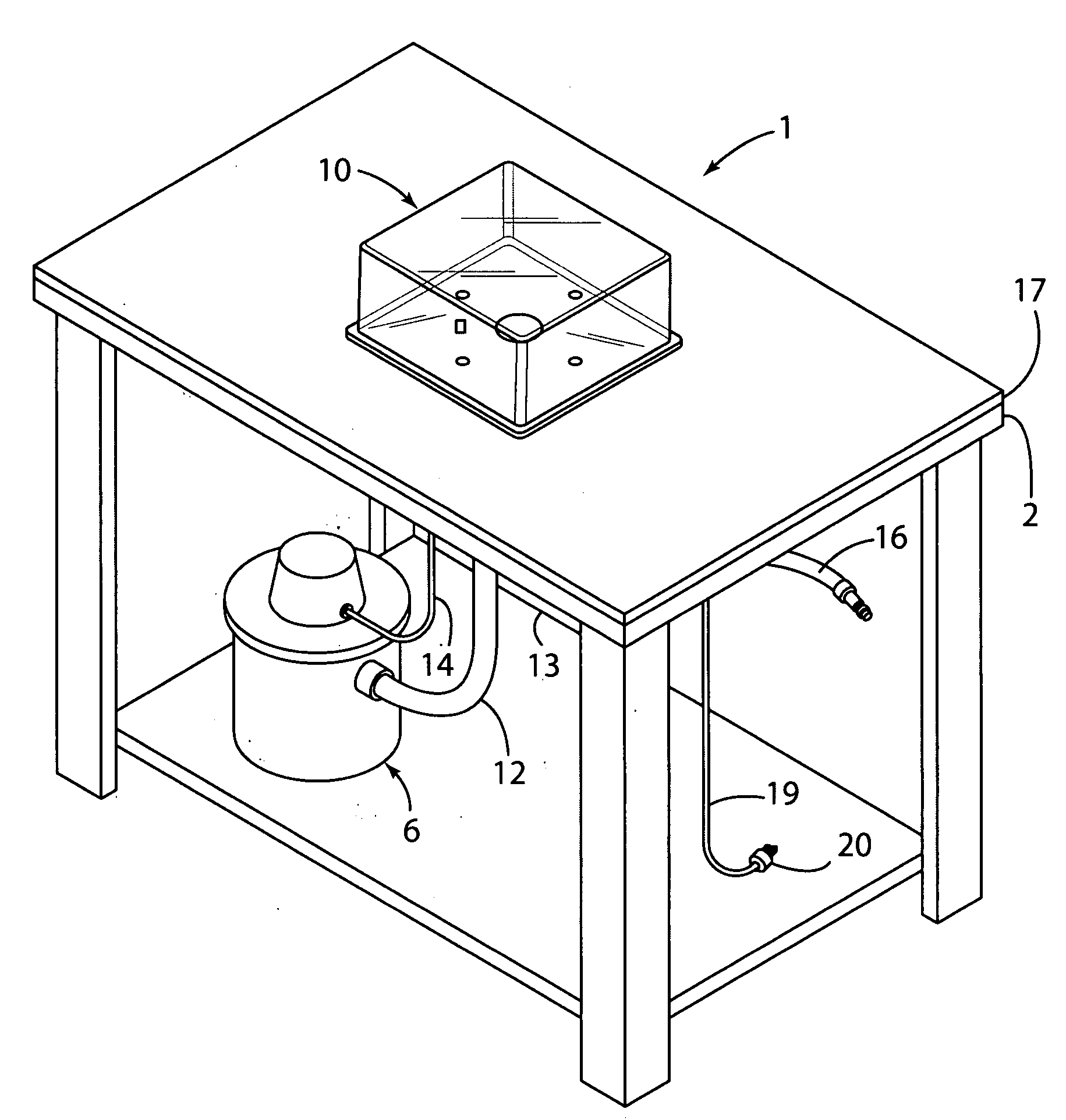

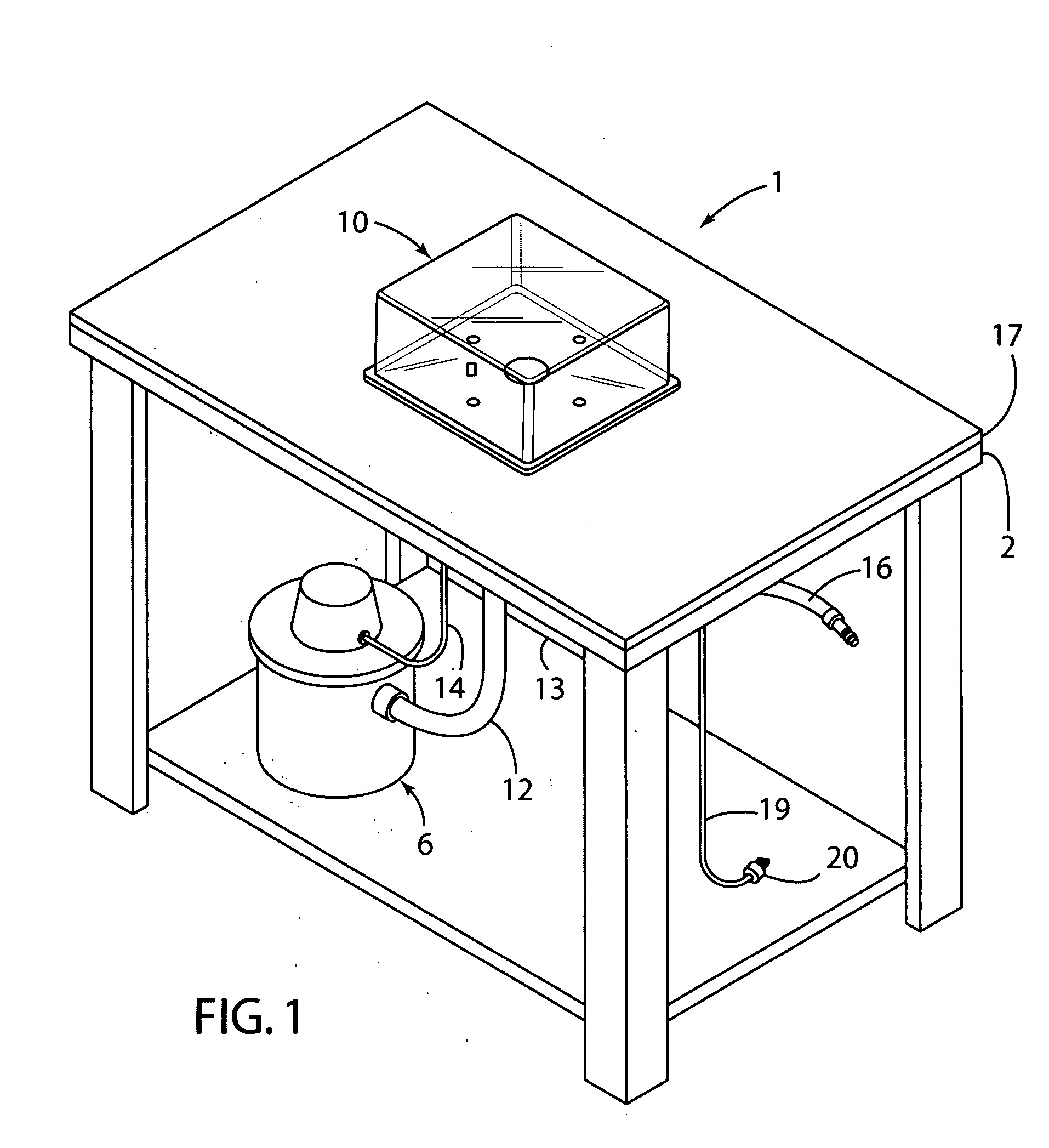

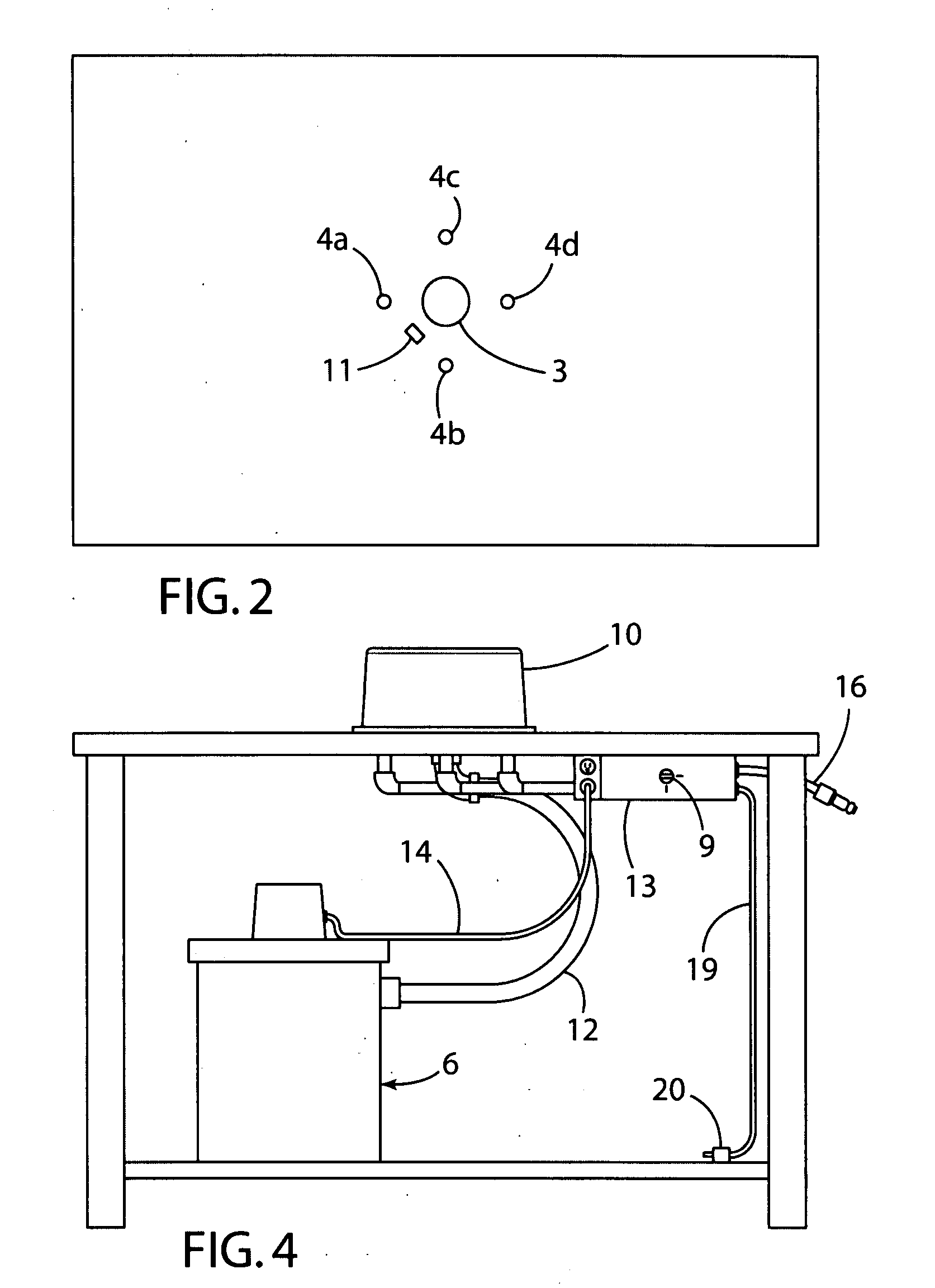

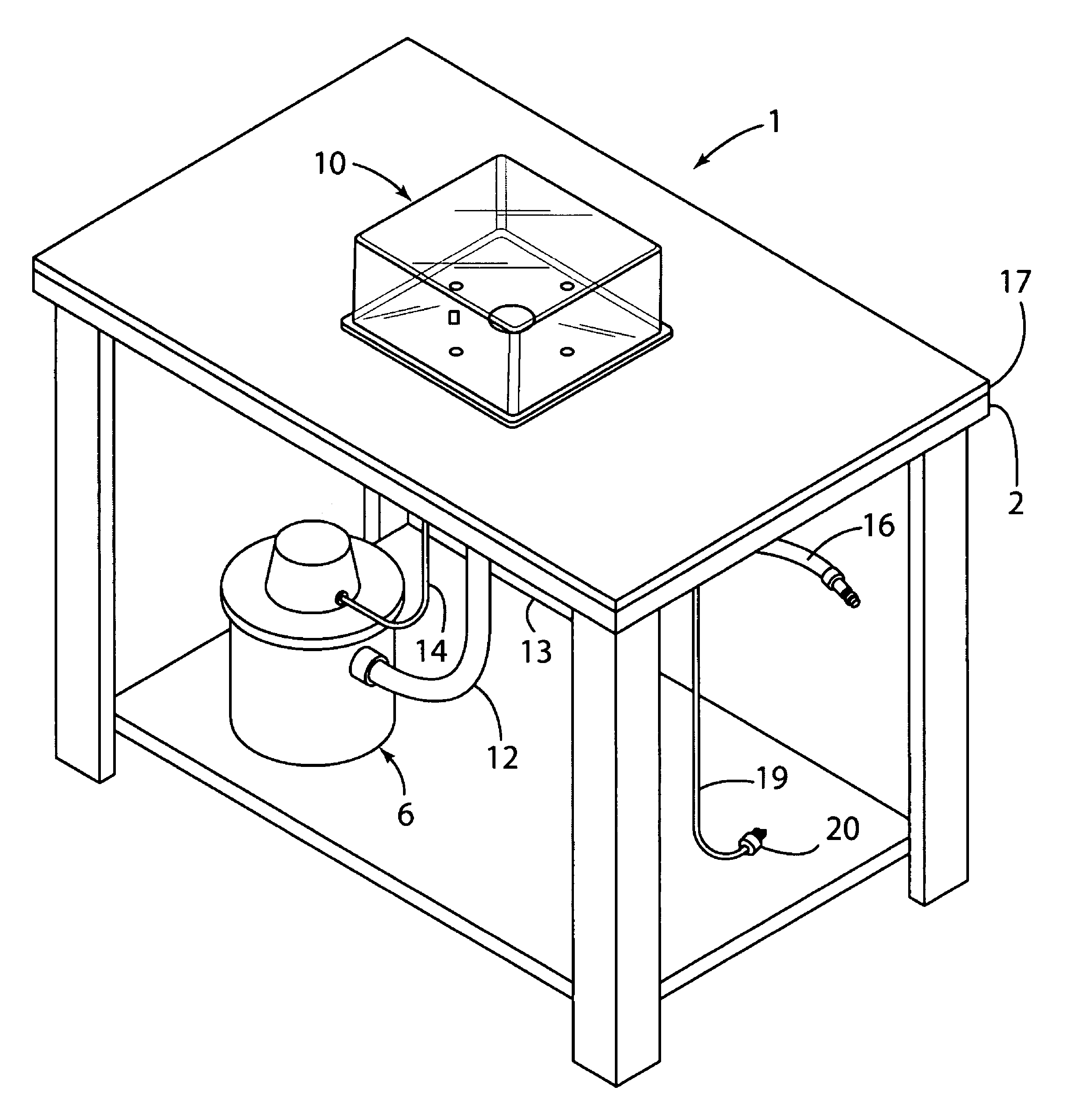

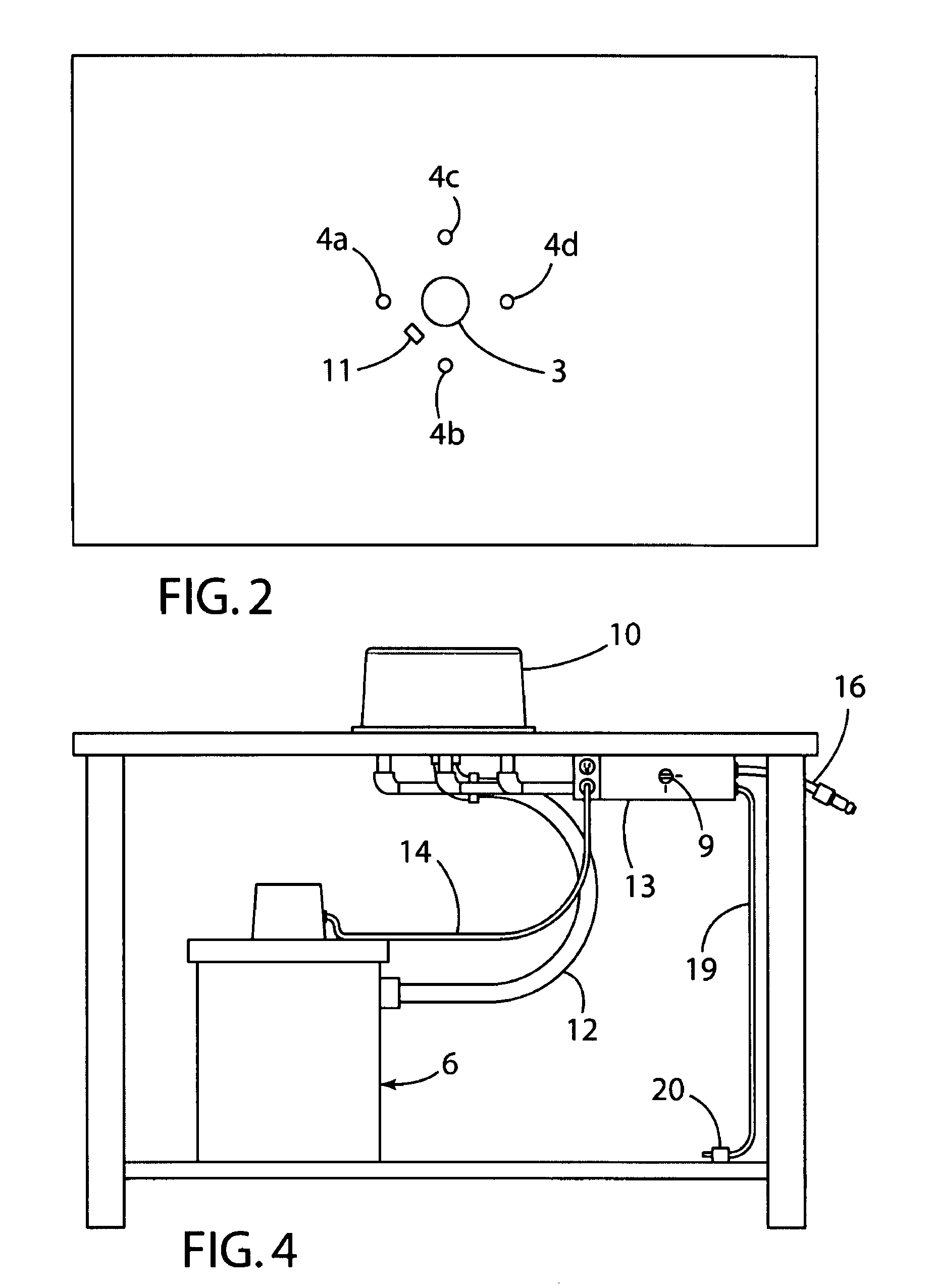

Container cleaning machine

InactiveUS20080066256A1Operate efficiently and effectivelyFacilitates placement and movementSuction cleanersHollow article cleaningEngineeringCompressed air

A container cleaning apparatus comprising a table having holes in the top surface suitably arranged to deliver compressed air and a vacuum substantially simultaneously into the open top of an inverted reusable container placed on the table top and thereby remove debris from the inside of the container.

Owner:RIGGS MARK AARON

Container cleaning machine

InactiveUS7937799B2Operate efficiently and effectivelyFacilitates placement and movementSuction cleanersHollow article cleaningEngineeringCompressed air

A container cleaning apparatus comprising a table having holes in the top surface suitably arranged to deliver compressed air and a vacuum substantially simultaneously into the open top of an inverted reusable container placed on the table top and thereby remove debris from the inside of the container.

Owner:RIGGS MARK AARON

Exhaust gas purifier and filter regenerator

InactiveUS7905933B2Efficiently gathering particulateEasy to useCombination devicesAuxillary pretreatmentParticulatesMechanical engineering

An exhaust gas cleaning apparatus and a filter regeneration apparatus that are capable of cleaning a large volume of exhaust gas without any increase in size of a nonmagnetic member around which a working coil for induction heating is wound. The exhaust gas cleaning apparatus includes a particulate collecting section and a filter regenerating section placed next to each other in the flow direction of an exhaust gas, and a movable frame. The movable frame holds an extension of a filter unit extending from a casing of the particulate collecting section beyond the support frame of the filter regenerating section, and can move the filter unit in the axial direction of the casing. When the filter unit moved by the movable frame passes through the filter regenerating section, a corresponding part of a holding frame disposed in the filter unit is continuously induction-heated to burn collected particulates, such that the filter unit can be regenerated.

Owner:TOKYO UNIV OF MANNE SCI & TECH

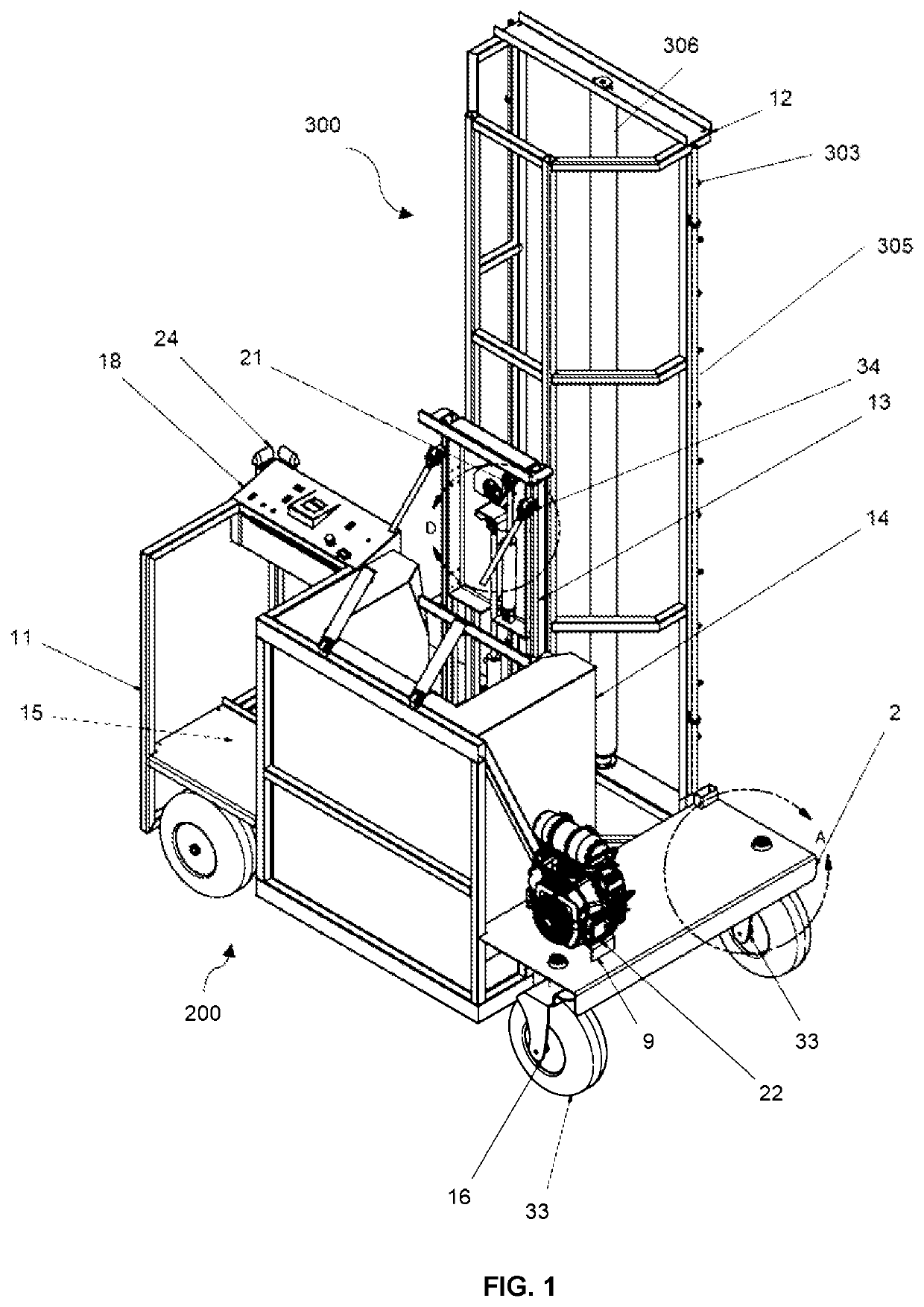

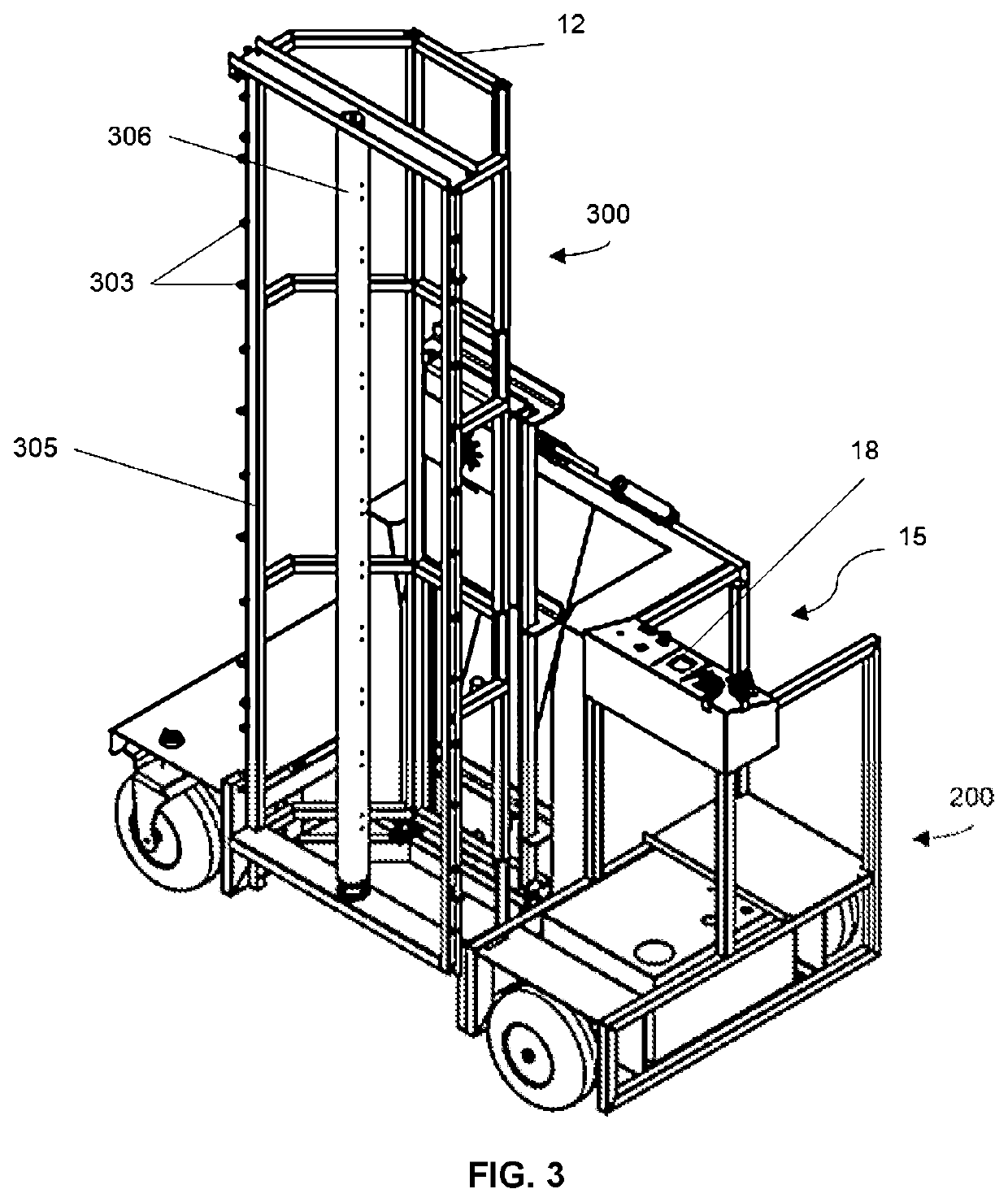

Semi-Automated, Self-Contained Mobile Wash System

PendingUS20210394718A1Easy to operateMaximum cleaningCleaning apparatus for vehicle exteriorsEnvironmental engineeringMobile device

A mobile cleaning system has a mobile unit allowing for movement of the cleaning system to and around a static vehicle for cleaning, a main cleaning assembly for applying cleaning fluids to a surface of the static vehicle and for scrubbing the surface of the static vehicle (where the cleaning assembly has the ability to pivot, rotate, and / or tilt for various cleaning purposes), a self-contained fluid supply system providing the cleaning fluids used by the cleaning assembly, and a operator control assembly allowing an operator to ride the mobile unit and selectively operate the components of the cleaning system.

Owner:NASH IND SOLUTIONS

Cleaning and disinfecting equipment for tools for food production

InactiveCN111822425ACleaning and disinfection work savingsDisinfection work savingsCleaning using liquidsHeatHeater RodElectric machinery

The invention relates to cleaning and disinfecting equipment, in particular to cleaning and disinfecting equipment for tools for food production. The cleaning and disinfecting equipment for the toolsfor food production aims to avoid carrying by workers, reduce the operation process, improve the working efficiency and automatically clean and disinfect the tools. In order to achieve the technical aims, the cleaning and disinfecting equipment for the tools for food production comprises a high-temperature box with one side provided with a gear motor, at least one heating rod connected with two sides of the interior of the high-temperature box, a cleaning assembly installed inside the high-temperature box, and a fixing assembly connected with the cleaning assembly. By the cooperation of the cleaning assembly and the fixing assembly, the cleaning and disinfecting work of the tools for food production is completed, the cleaning and disinfecting are integrated, the manual cleaning work is saved, and the working efficiency is improved.

Owner:江西谷纬科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com