Adhesive roller

a technology of adhesive rollers and rollers, which is applied in the direction of cleaning apertures in pipes, household cleaners, and domestic applications, can solve the problems of affecting the cleaning effect, so as to achieve the effect of maximizing cleaning efficiency and easy separation from the roller

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

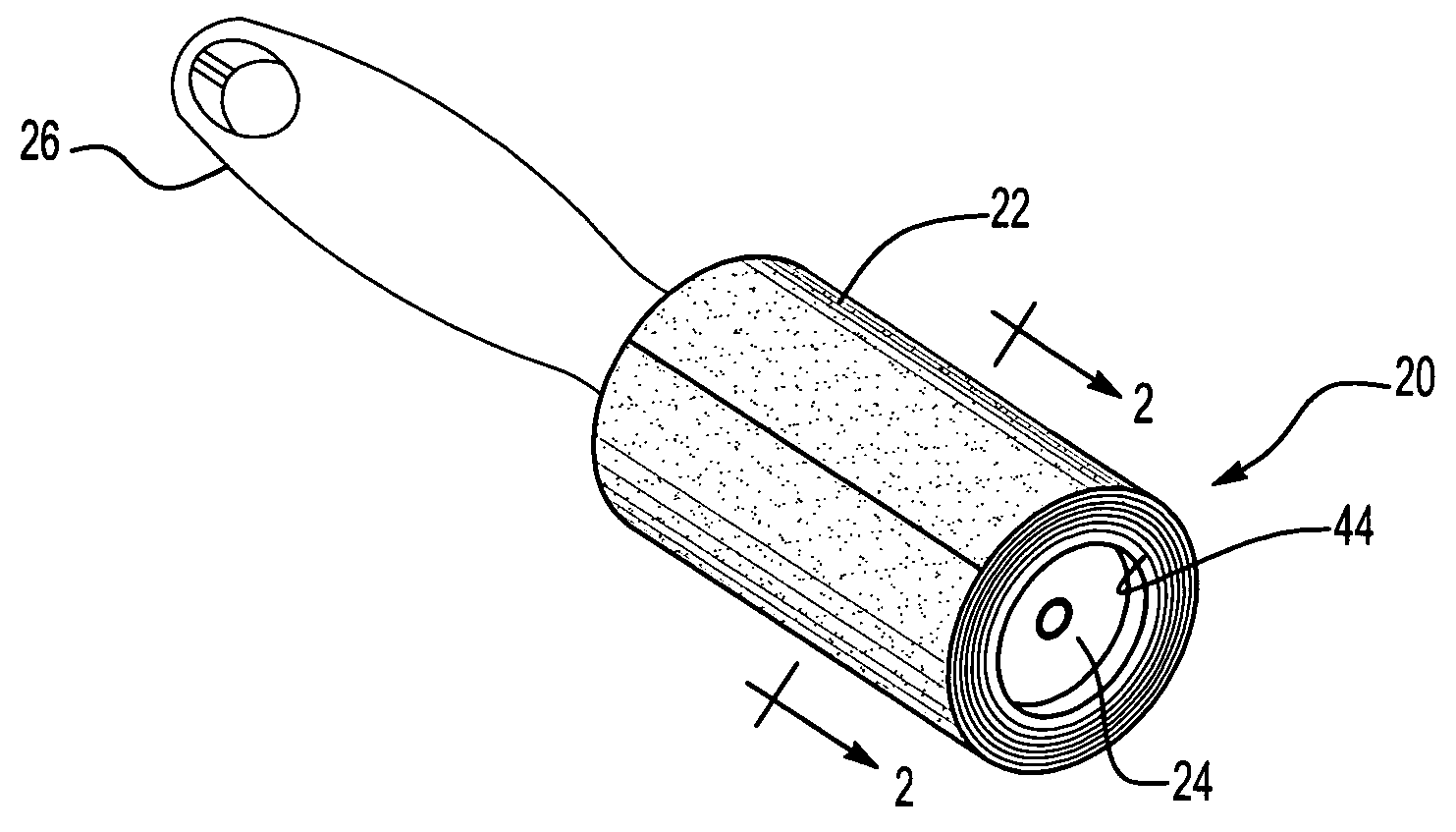

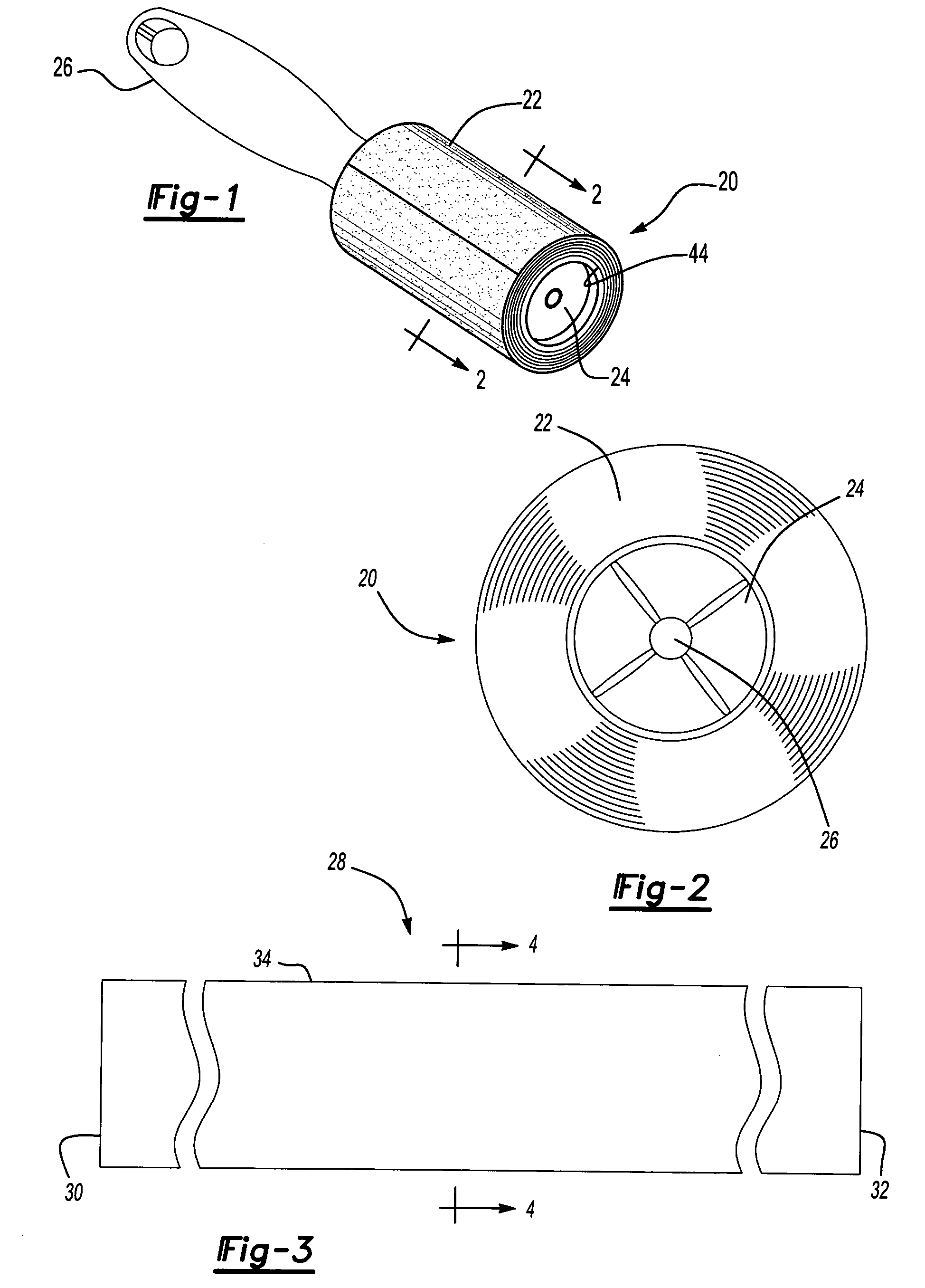

[0035] With reference first to FIGS. 1 and 2, a first preferred embodiment of the adhesive roller 20 of the present invention is shown in which the roller 20 is tubular and cylindrical in shape. The roller 20 preferably includes a tubular and cylindrical core 24 made of cardboard, plastic or other suitable material. The core 24 is then mounted on a handle 26 (FIG. 1) so that the adhesive roller 20 rotates freely with respect to the handle 26.

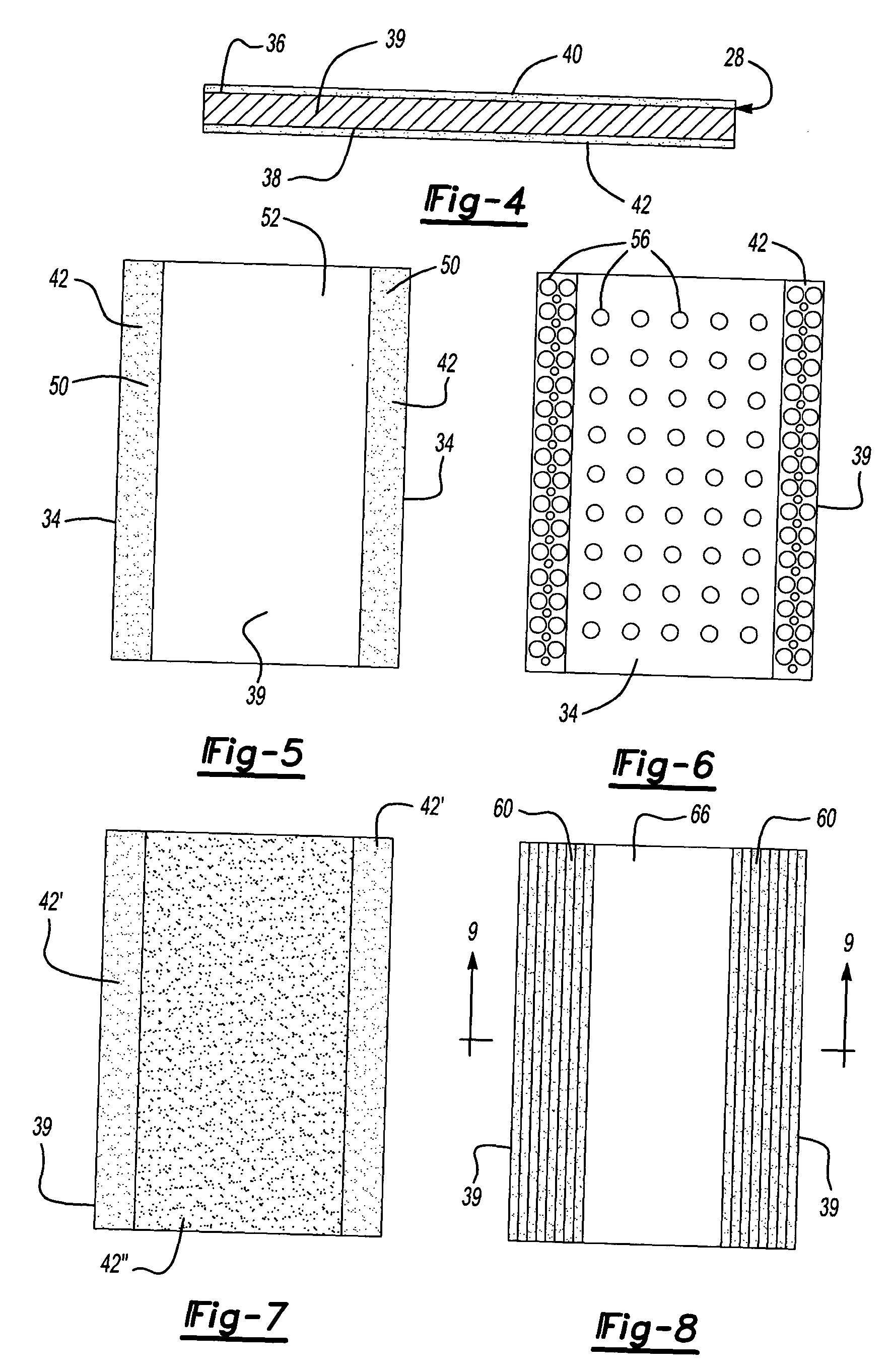

[0036] With reference now to FIGS. 3 and 4, the adhesive roller 20 comprises an elongated strip 28 having a first end 30, a second end 32, and two spaced apart and generally parallel sides 34. As best shown in FIG. 4, the strip 28 includes a backing layer 39 having a first or outer side 36 and second or inner side 38. The backing layer 39 may be constructed of any conventional material, such as paper. Additionally, the backing layer 39 may be made of paper, film, cloth, foam as well as other materials and mixtures thereof. In the event that the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com