Cleaning and disinfecting equipment for tools for food production

A technology for cleaning and disinfecting tools, applied in cleaning methods and utensils, cleaning methods using liquids, heating, etc., and can solve problems such as troublesome operation and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

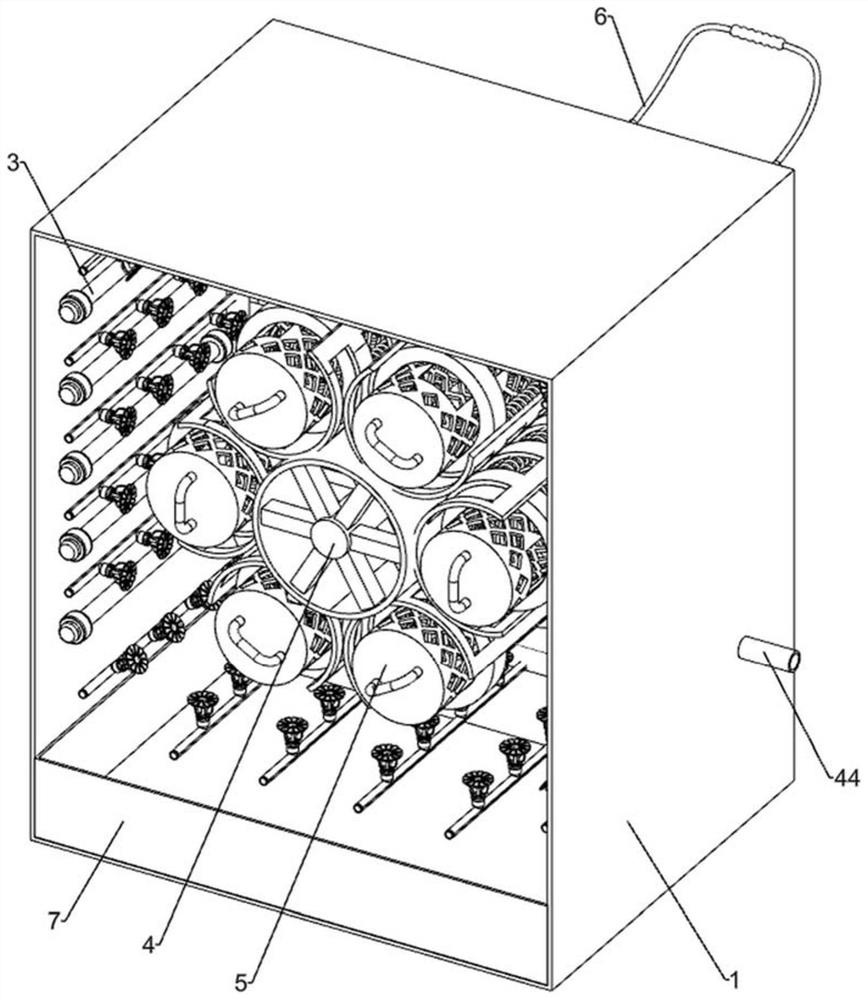

[0026] A food production tool cleaning and disinfection equipment, such as Figure 1-5 As shown, it includes a high-temperature box 1, a geared motor 2, a heating rod 3, a cleaning component 4 and a fixed component 5. A geared motor 2 is installed on the rear side of the high-temperature box 1, and multiple heaters are evenly spaced on the left and right sides of the high-temperature box 1. Rod 3, a cleaning component 4 is installed inside the high temperature box 1, and a fixing component 5 is connected to the cleaning component 4.

[0027] The cleaning assembly 4 includes a hexagonal telescopic rod 41, a connecting cylinder 42, an arc-shaped fixed plate 43, a water inlet pipe 44, a main water pipe 45, a branch water pipe 46 and a nozzle 47. The rear side of the high temperature box 1 is connected with a hexagonal telescopic Rod 41, the tail end of the hexagonal telescopic rod 41 is connected with the output shaft of the reduction motor 2, the front end of the telescopic rod ...

Embodiment approach 2

[0031] On the basis of Example 1, such as Figure 6 As shown, a rotating assembly 6 is also included. The rotating assembly 6 includes a push rod 61, a gear ring 62 and a gear 63. The rear side of the high temperature box 1 is slidably connected to the push rod 61, and the front end of the push rod 61 is connected to the gear ring 62. , the rear end of the rear limiting sleeve 52 is connected with a gear 63 , and the gear ring 62 and the gear 63 mesh with each other.

[0032] When the tools for food production to be cleaned and disinfected need to be put into the limit sleeve 52, the push rod 61 is pushed, and the limit sleeve 52 and the connecting cylinder 42 are pushed through the gear ring 62 to move, and the entire fixing assembly 5 is pushed to more than the limit sleeve 52. When the width of the food production tool is different, the food production tool to be cleaned and disinfected is put into the limit sleeve 52, and the connecting sleeve 42 is pushed back to the orig...

Embodiment approach 3

[0034] On the basis of Example 2, such as figure 1 and figure 2 As shown, it also includes a water collection tank 7 and a water outlet pipe 8. The bottom side of the high temperature box 1 is connected with a water collection tank 7, and the left side of the high temperature box 1 is connected with a water outlet pipe 8, and the right end of the water outlet pipe 8 is connected with the water collection tank 7.

[0035] A large amount of waste water generated during the cleaning process will be collected into the sump 7 and then discharged through the outlet pipe 8, which is convenient for workers to centrally treat the waste water and reduces the trouble of cleaning the waste water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com