Pre-heating warmer of diesel engine exhaust aftertreatment device and warming method

A technology for after-treatment of exhaust and diesel engines, which is applied in the direction of exhaust devices, engine components, machines/engines, etc. It can solve problems such as ignition failure, poor ignition reliability, and secondary environmental pollution, so as to avoid interference and influence, Simplified ignition device and low regenerative energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

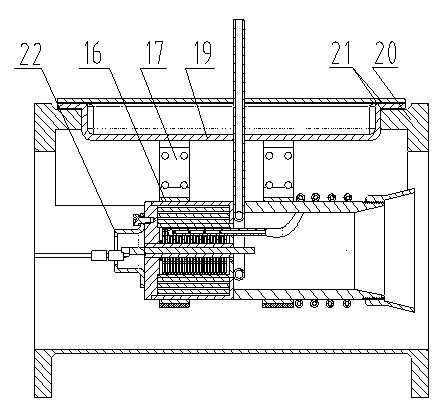

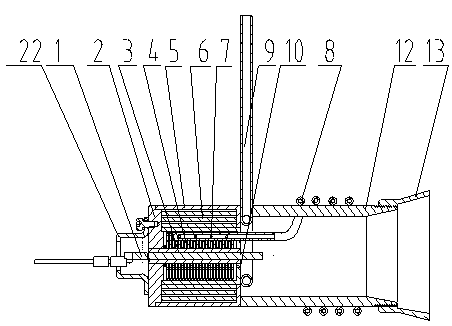

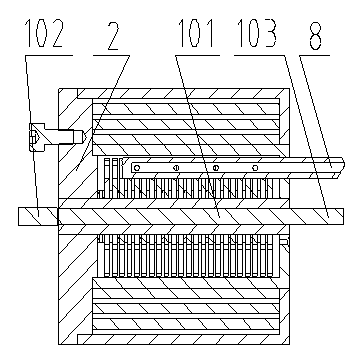

[0016] Embodiment 1: with reference to attached Figure 1-4 and Figure 7. A heating device for a diesel engine exhaust post-processing device. The mandrel 3 (sleeve 3) is set on the heating rod 1 and one end of the heating rod 1 is exposed outside the mandrel 3 and constitutes a high-temperature ignition head 103. The heating rod 103 is another One end is connected to the power supply and is provided with a ceramic sheath 22, and the two ends of the mandrel 3 are sealed and connected with the end covers of the diesel gasification chamber 2, such as welding sealing, sintering sealing and many other ways. The regenerator 4 is set on the mandrel 3 and is located in the diesel gasification chamber 2. One end of the combustion chamber 12 is connected to the diesel gasification chamber 2 and covered on the high-temperature ignition head 103. The oil delivery pipe 8 is placed on the wall of the combustion chamber 12. The fuel injection pipe part in the fuel delivery pipe 8 passes ...

Embodiment 1-1

[0017] Embodiment 1-1: On the basis of Embodiment 1, the length of the heating rod exposed outside the mandrel 3 is less than 15 mm, but it is not limited thereto.

Embodiment 1-2

[0018] Embodiment 1-2: On the basis of Embodiment 1, the heat accumulator 4 is formed by stacking fins with different diameters, one large and one small.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com