Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

32results about How to "Maximize signal to noise" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

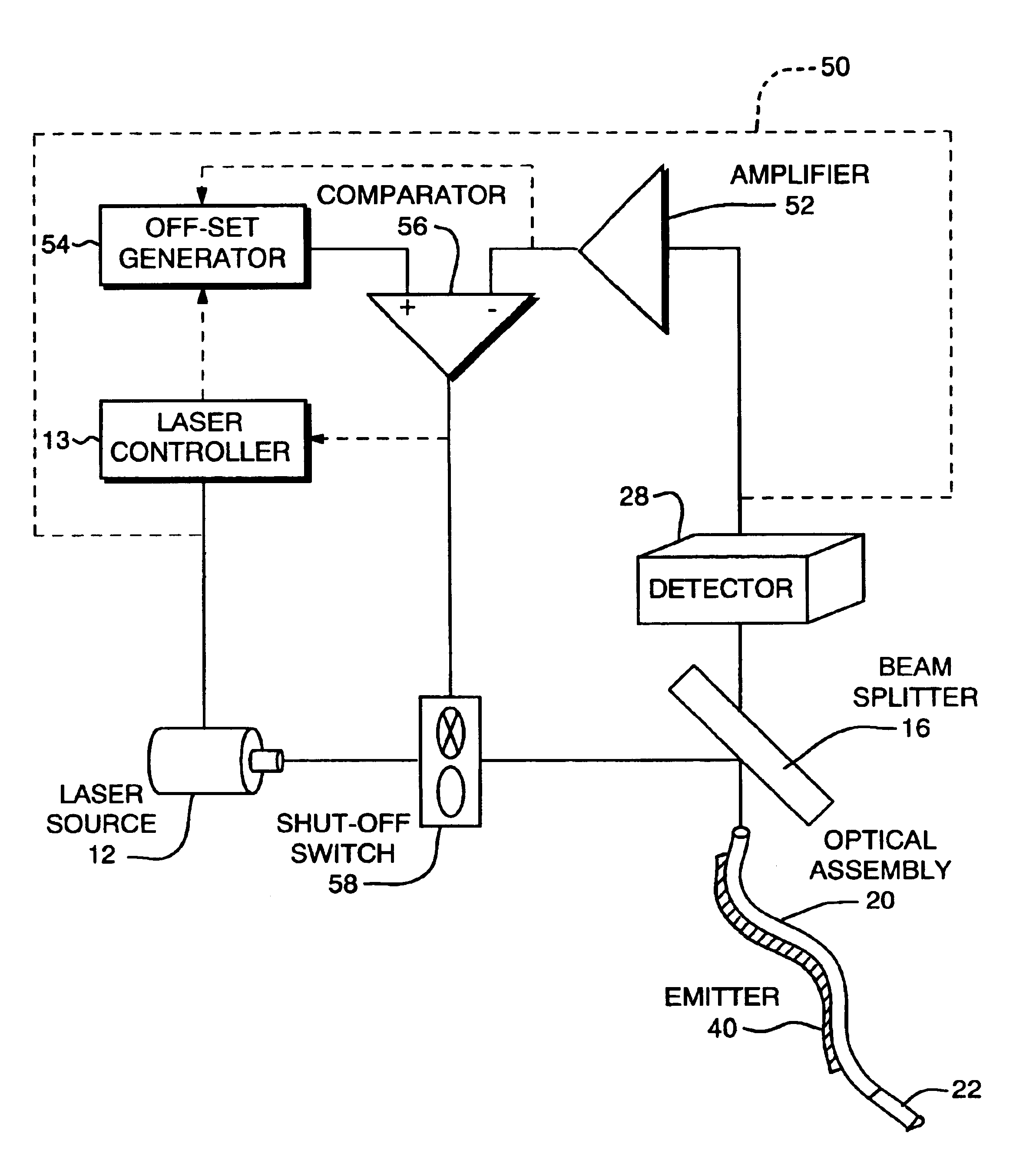

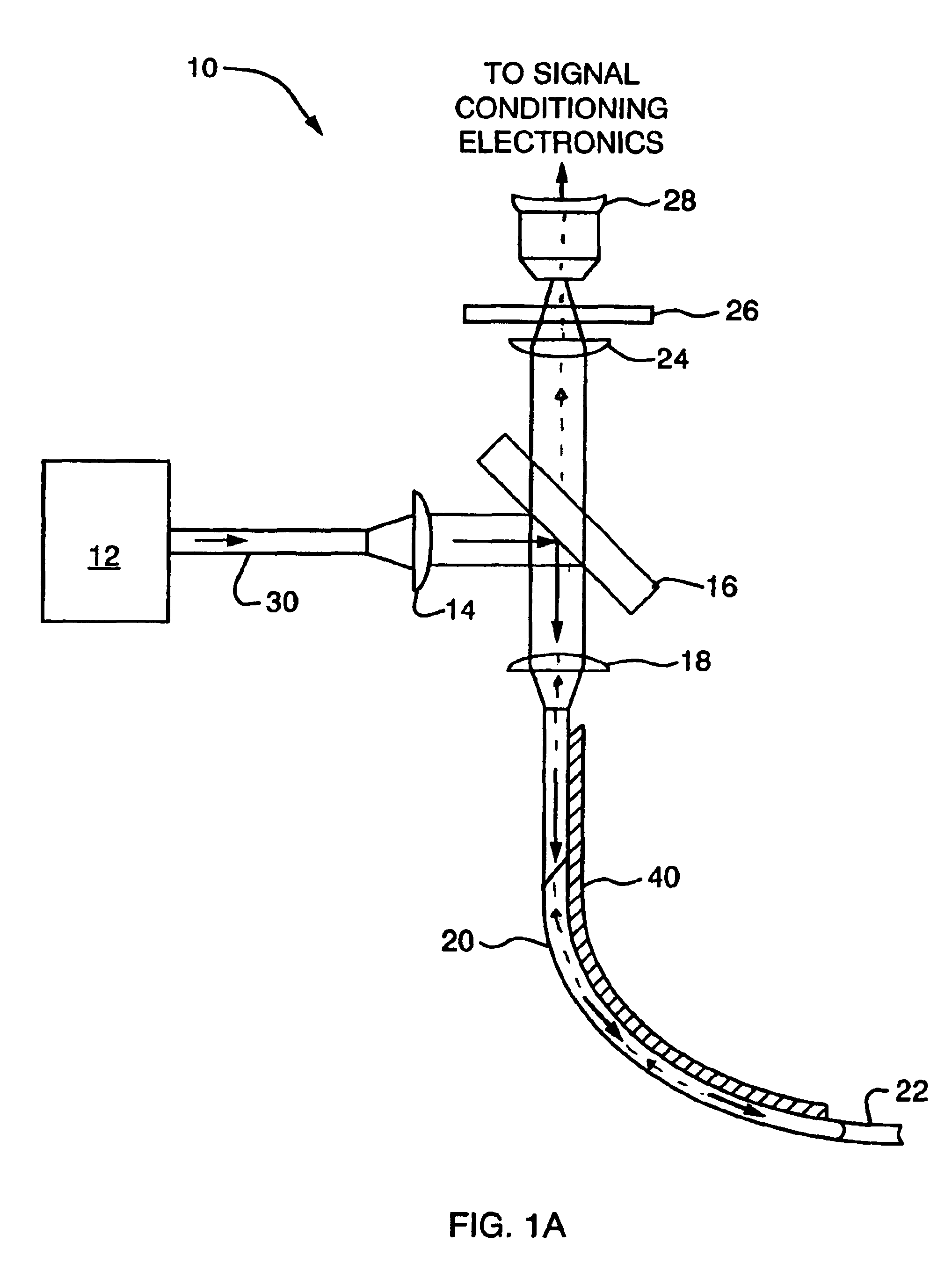

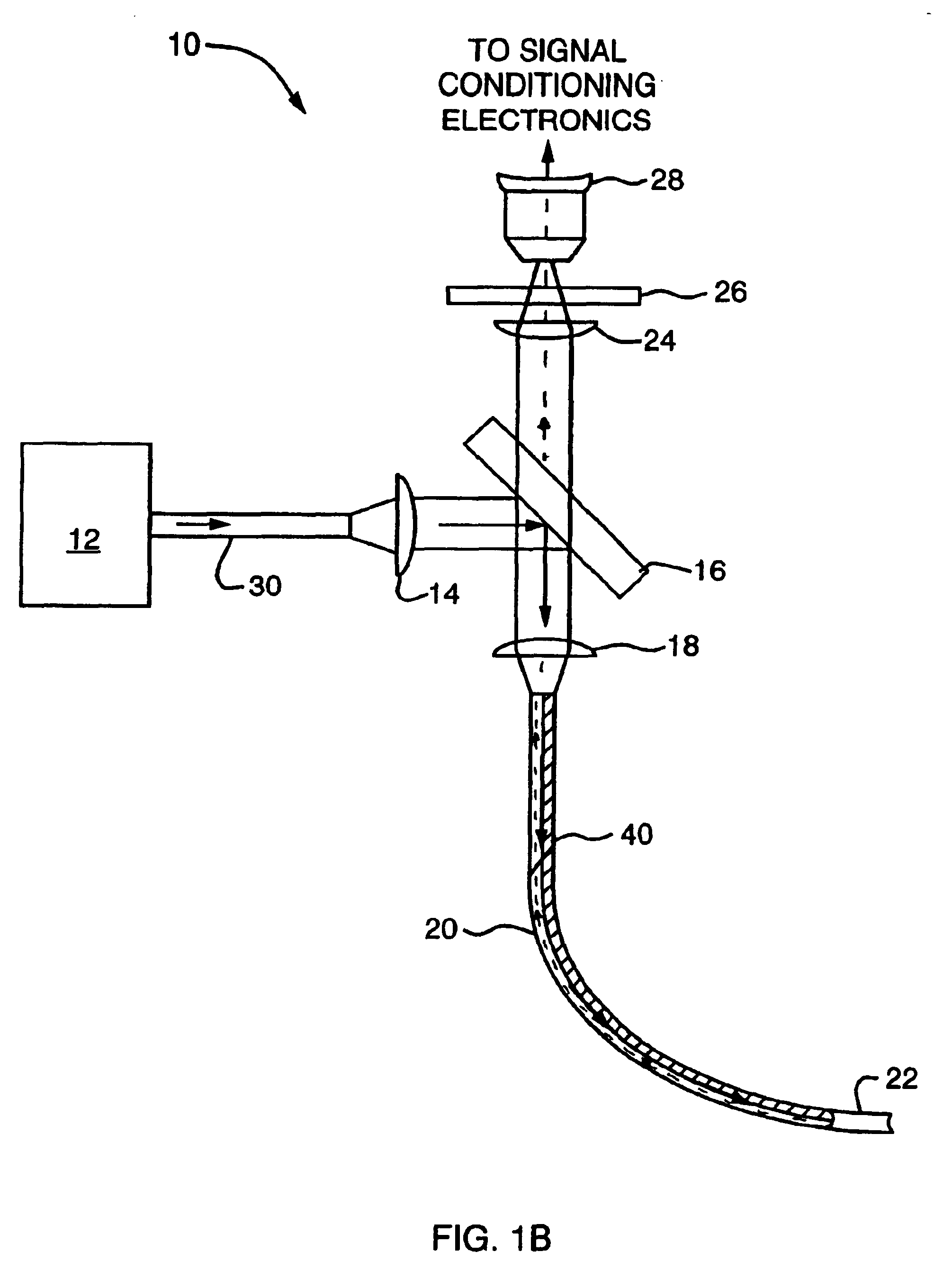

Safety shut-off device for laser surgical instruments employing blackbody emitters

InactiveUS6932809B2High detection sensitivityHigh strengthThermometer detailsPhotometry using reference valueInfraredTherapeutic radiation

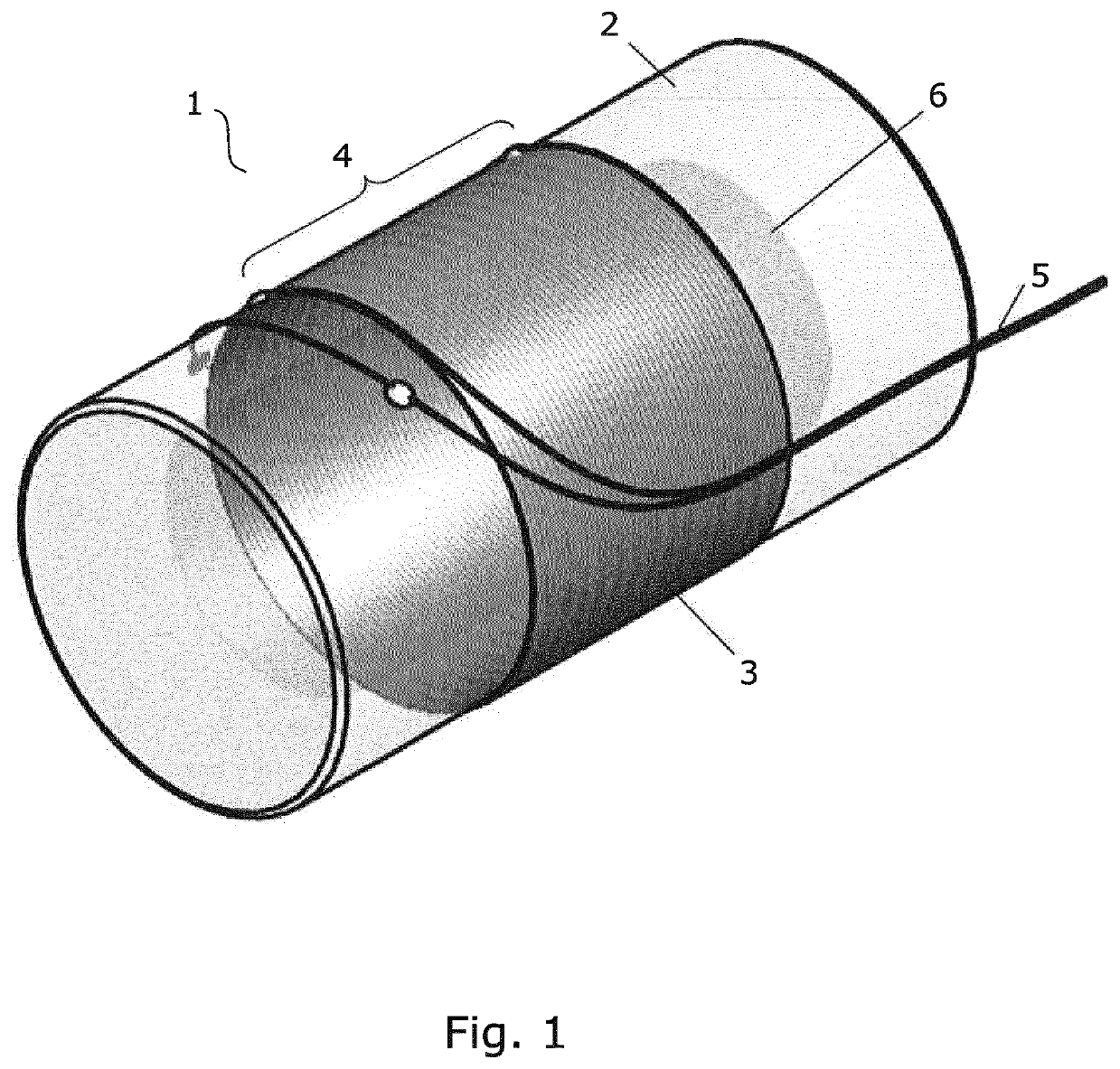

Methods and systems are disclosed for detecting overheating in an optical device before harmful consequences, such as severe local heating, can result. In one embodiment of the invention, a blackbody emitter is disposed in close proximity to a therapeutic optical fiber to absorb therapeutic radiation at a fault and re-emit blackbody (infrared) radiation. The emitter can be coupled to the fiber but, during normal operation, lies outside the optical path between the output of the laser radiation and the site of treatment. Systems and catheters incorporating such emitters are also described for effective monitoring of the laser power transmitted along the optical fiber within the phototherapy device.

Owner:CARDIOFOCUS INC

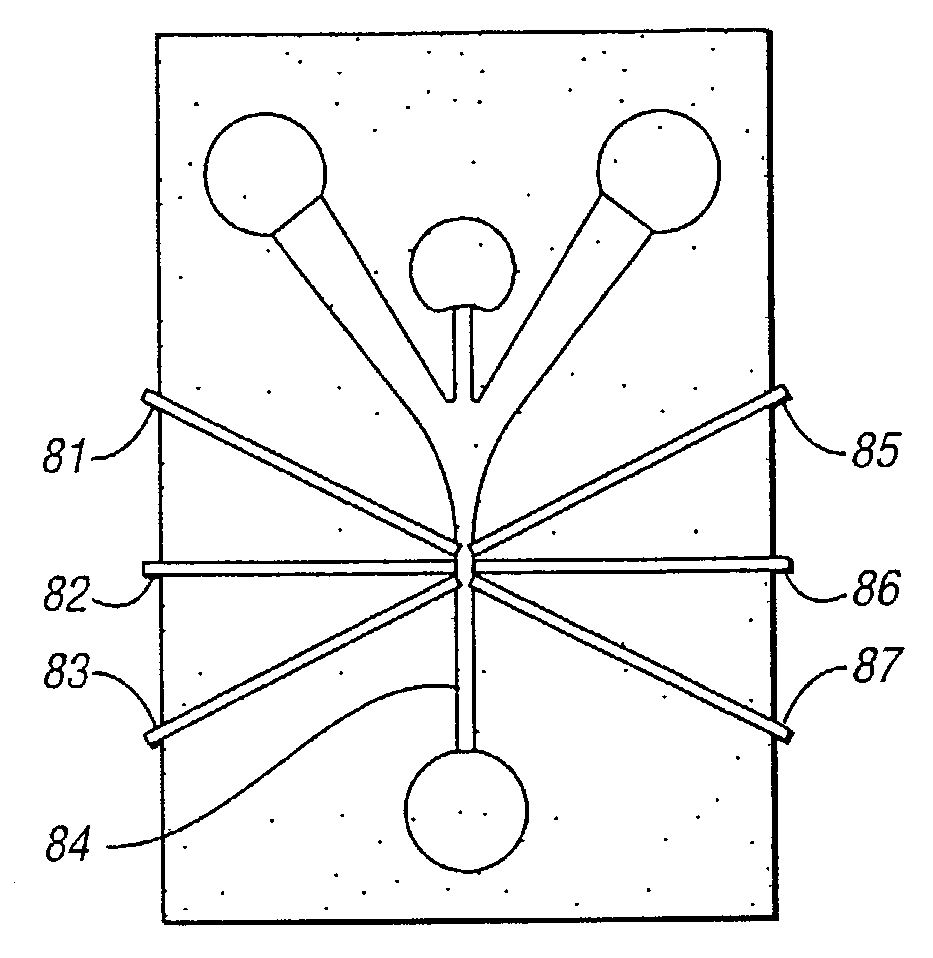

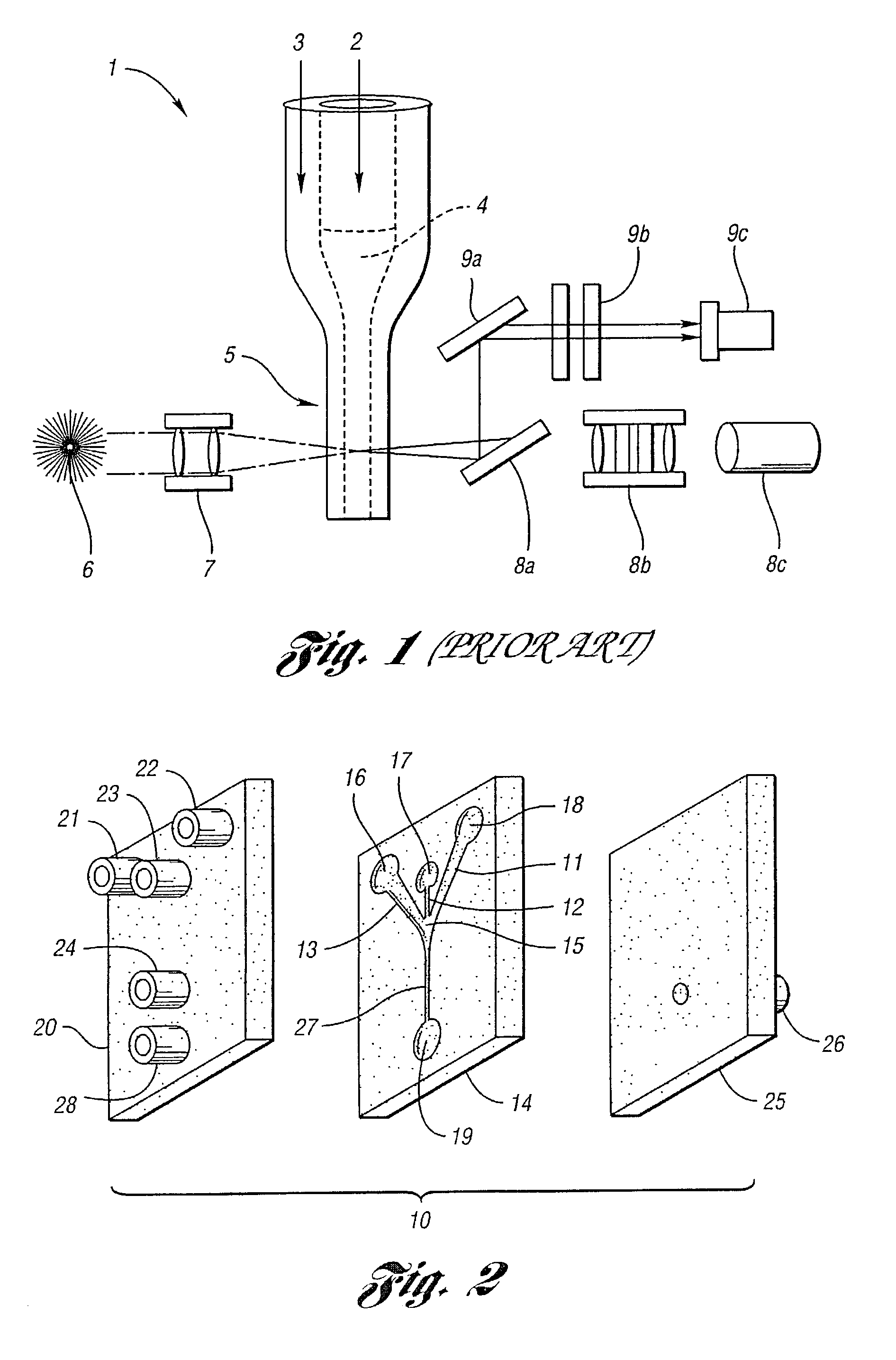

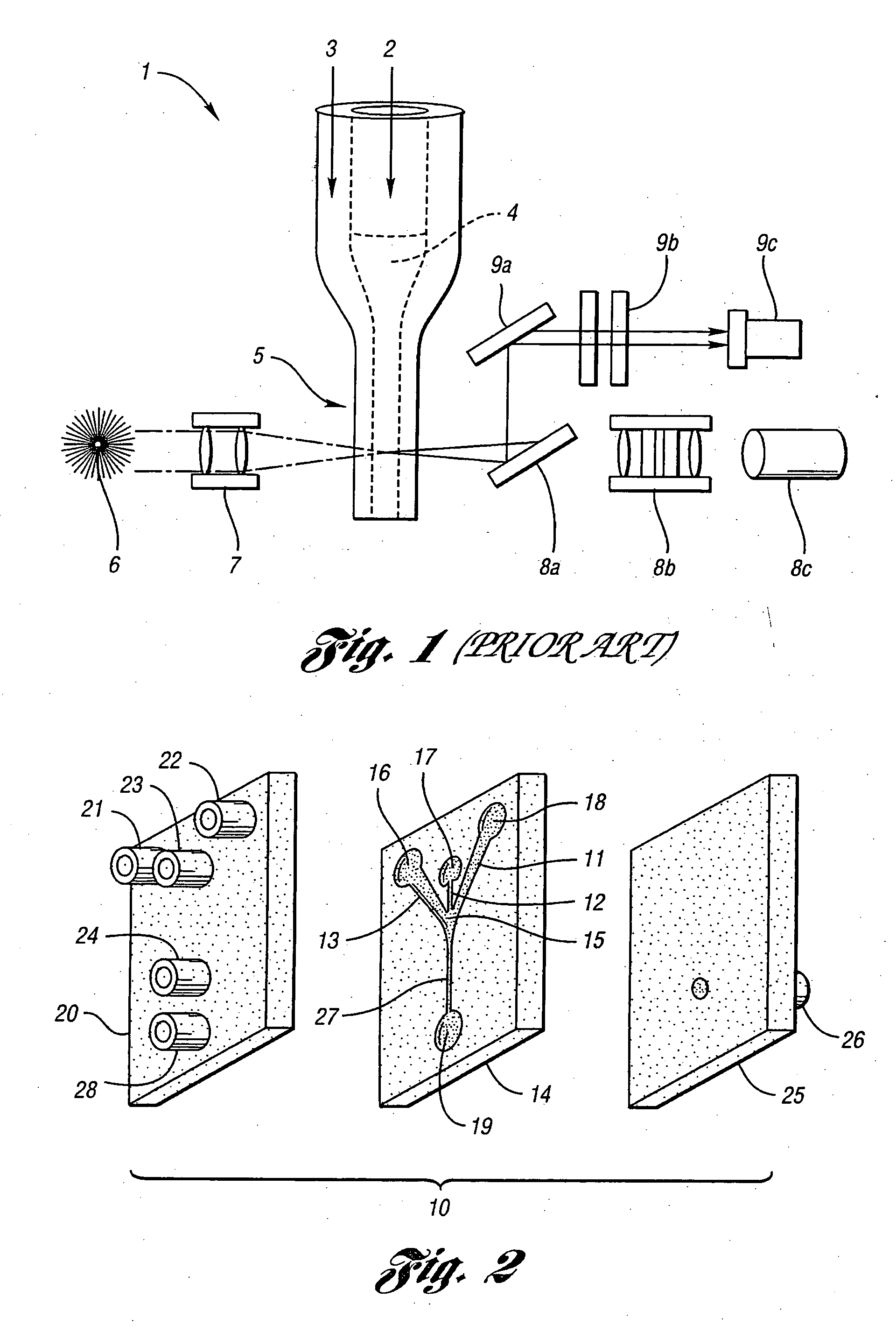

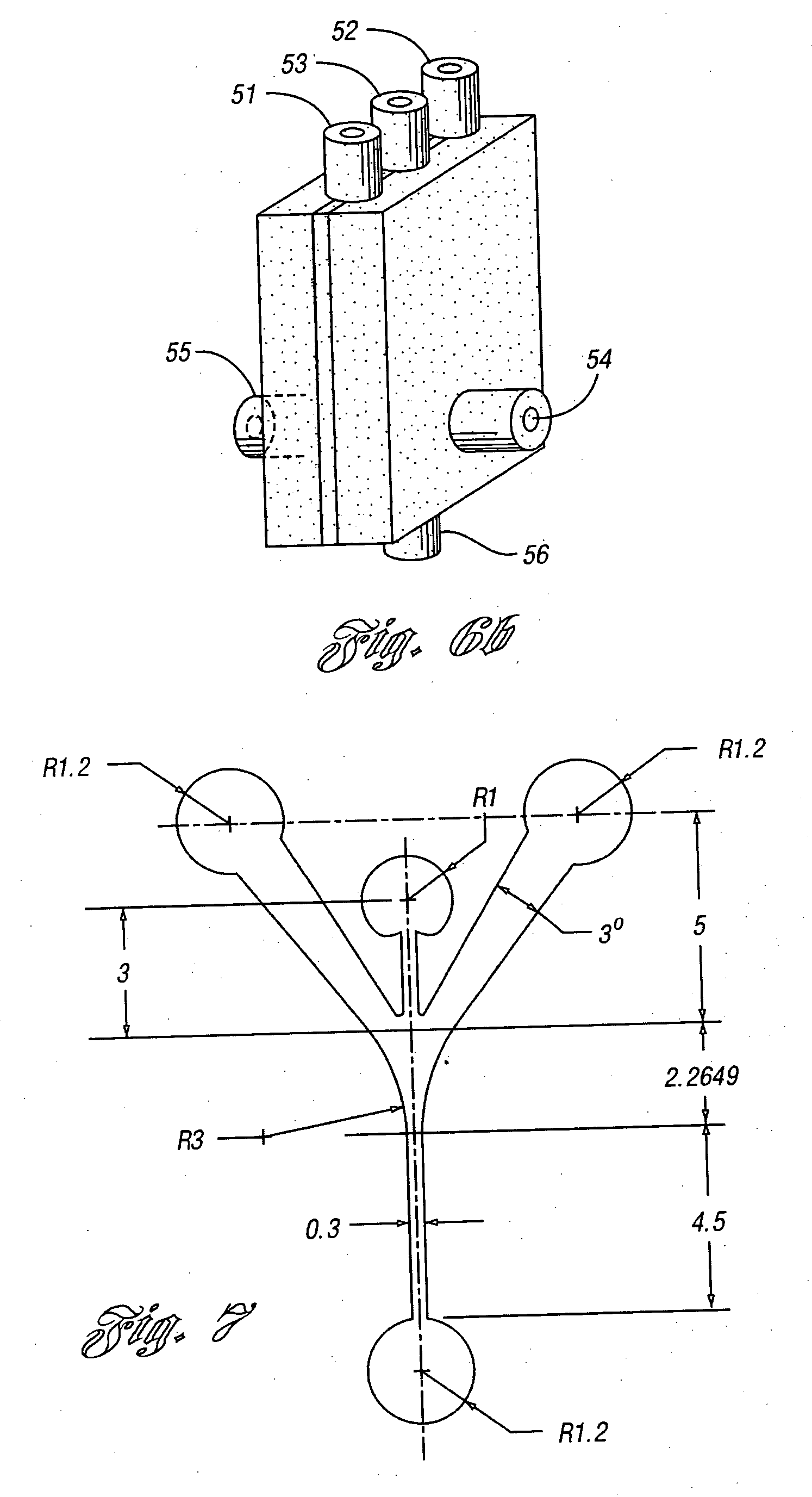

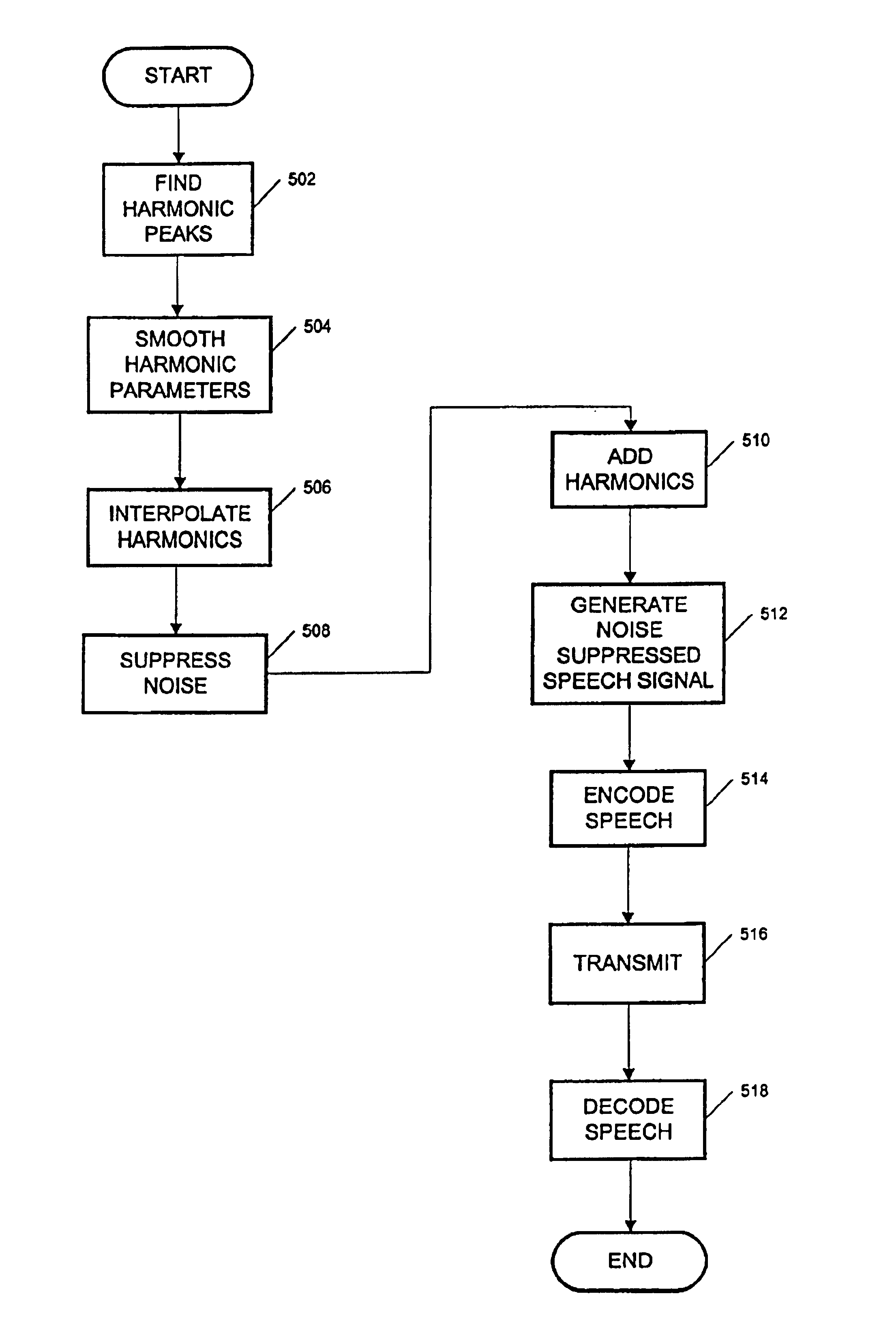

Flow cytometers and detection system of lesser size

InactiveUS7105355B2Increase the number ofMaximize signal to noiseWithdrawing sample devicesAnalysis by material excitationFiberManufacturing technology

Gas focusing flow cytometers are fabricatable employing simple and inexpensive manufacturing techniques. When such cytometers or conventional cytometers are combined with fiber optical light paths and laser diode and semiconductor photodetectors, light weight and handheld, optionally disposable devices which maintain high performance are possible.

Owner:RGT UNIV OF MICHIGAN

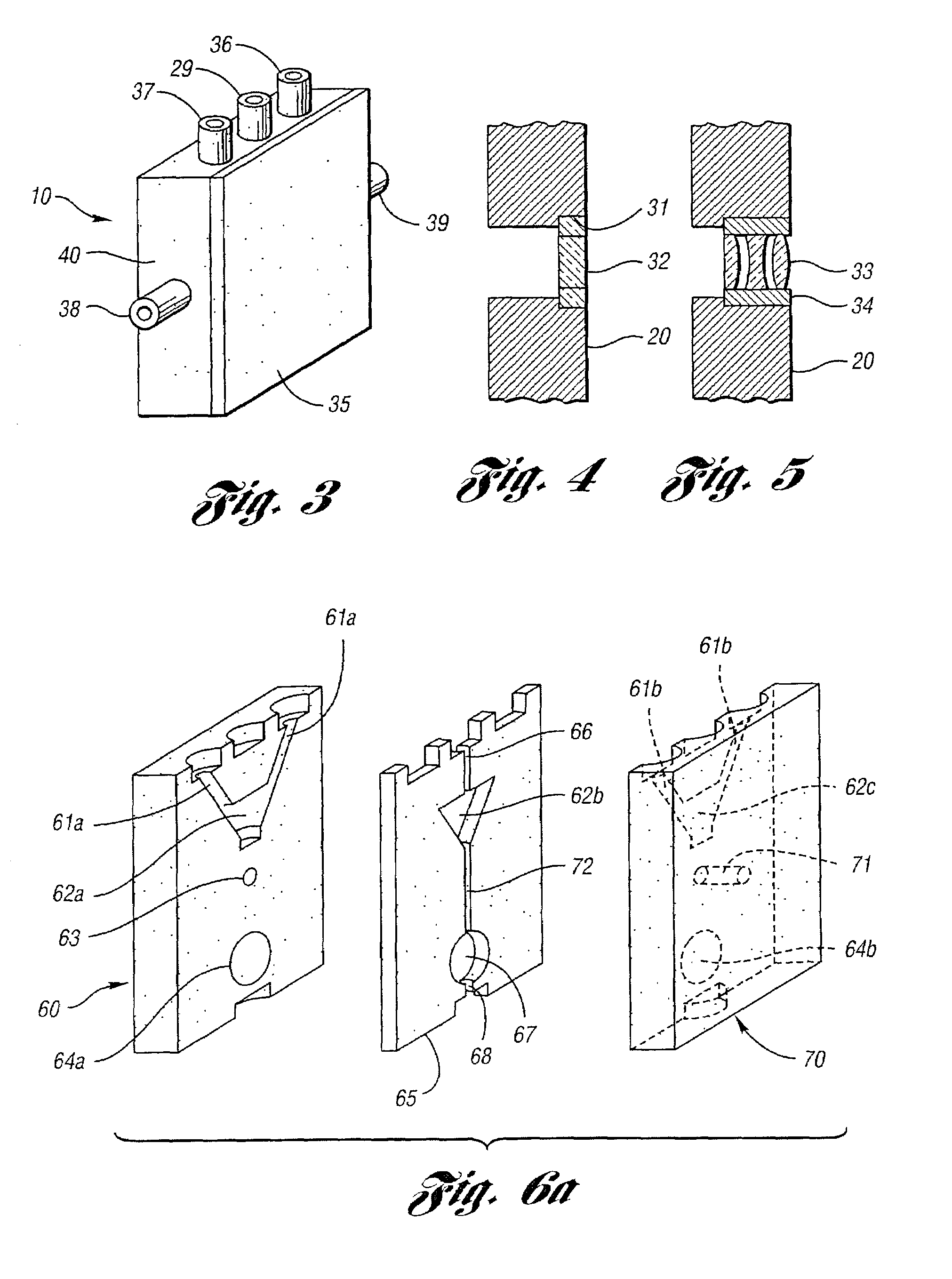

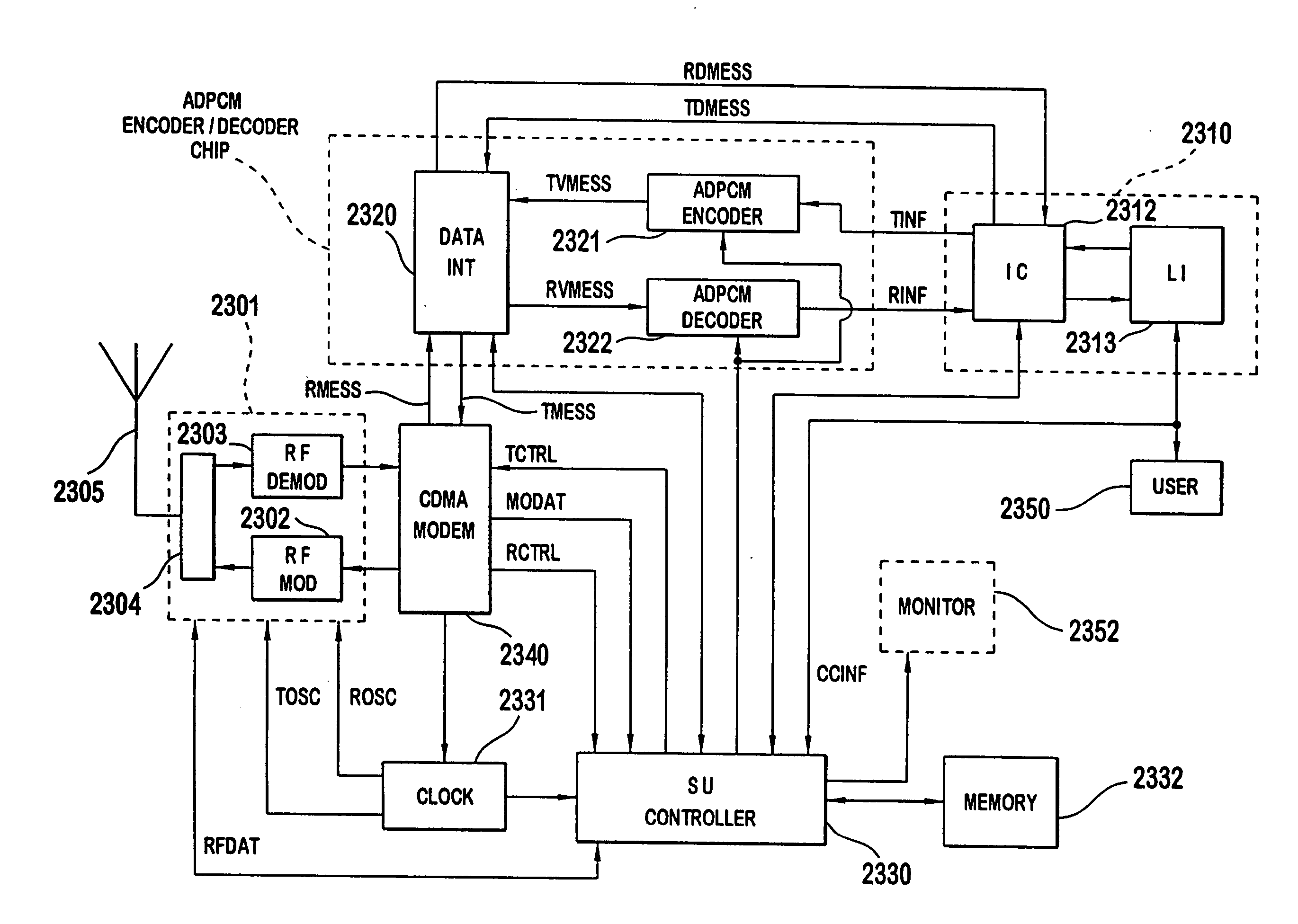

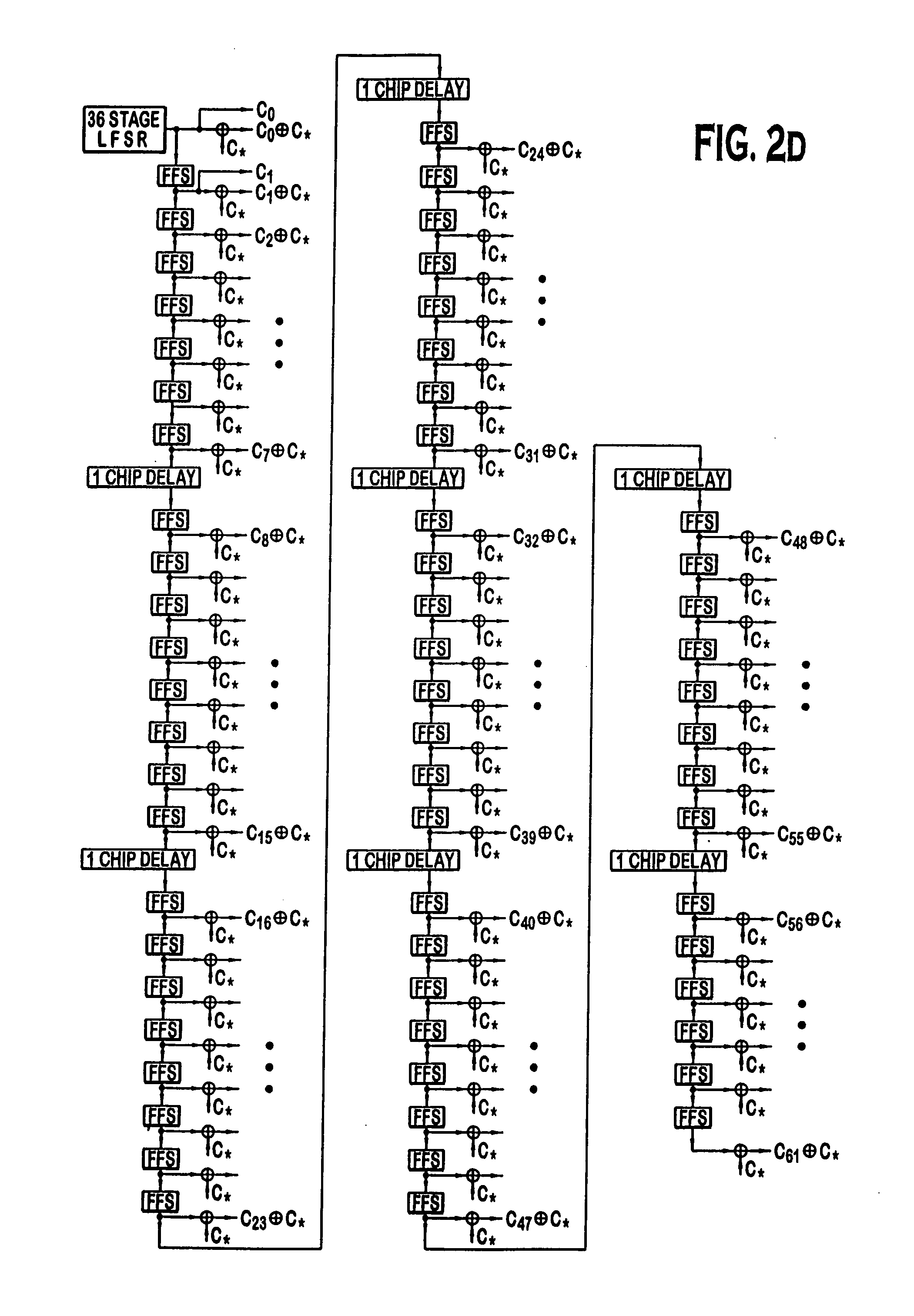

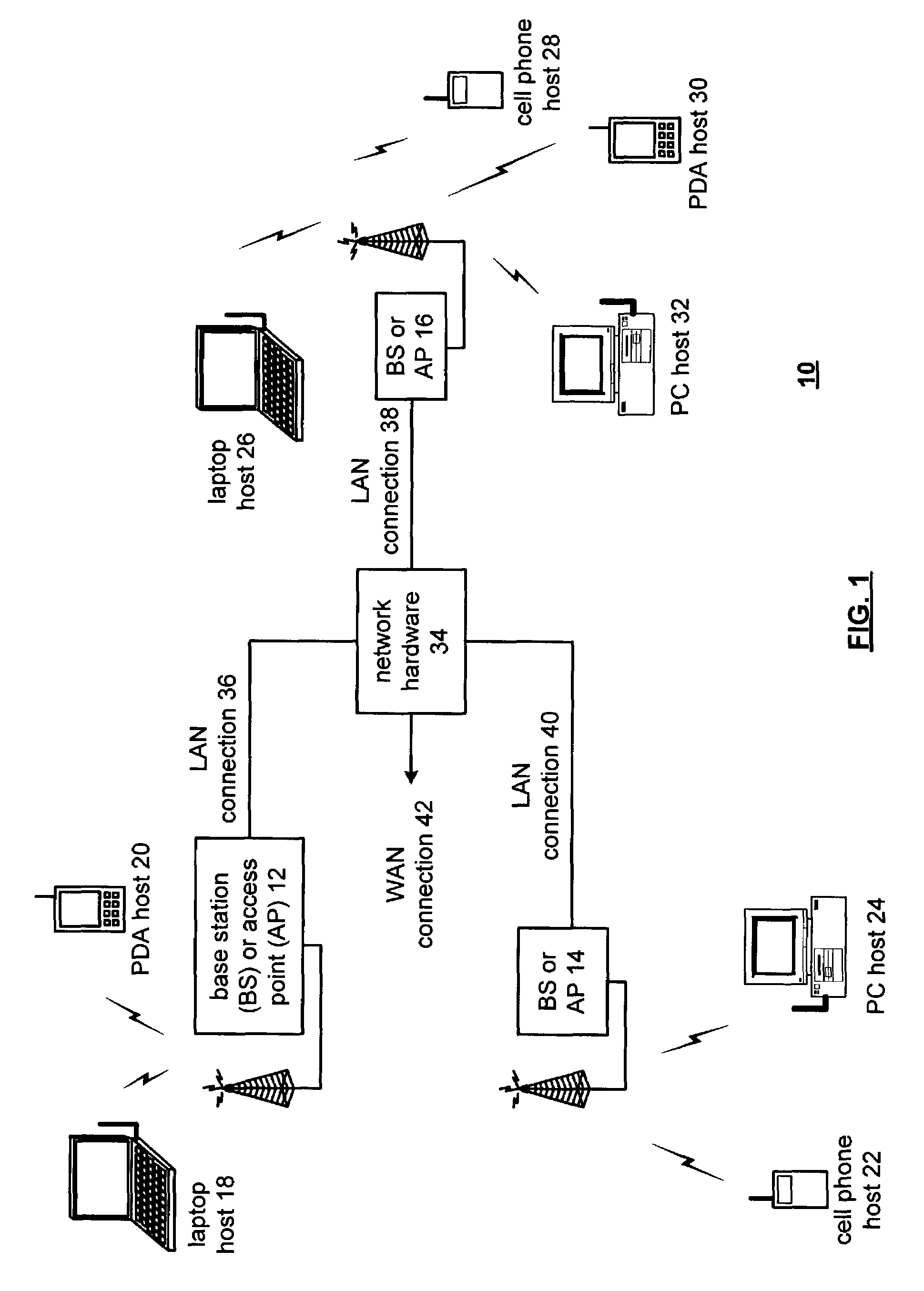

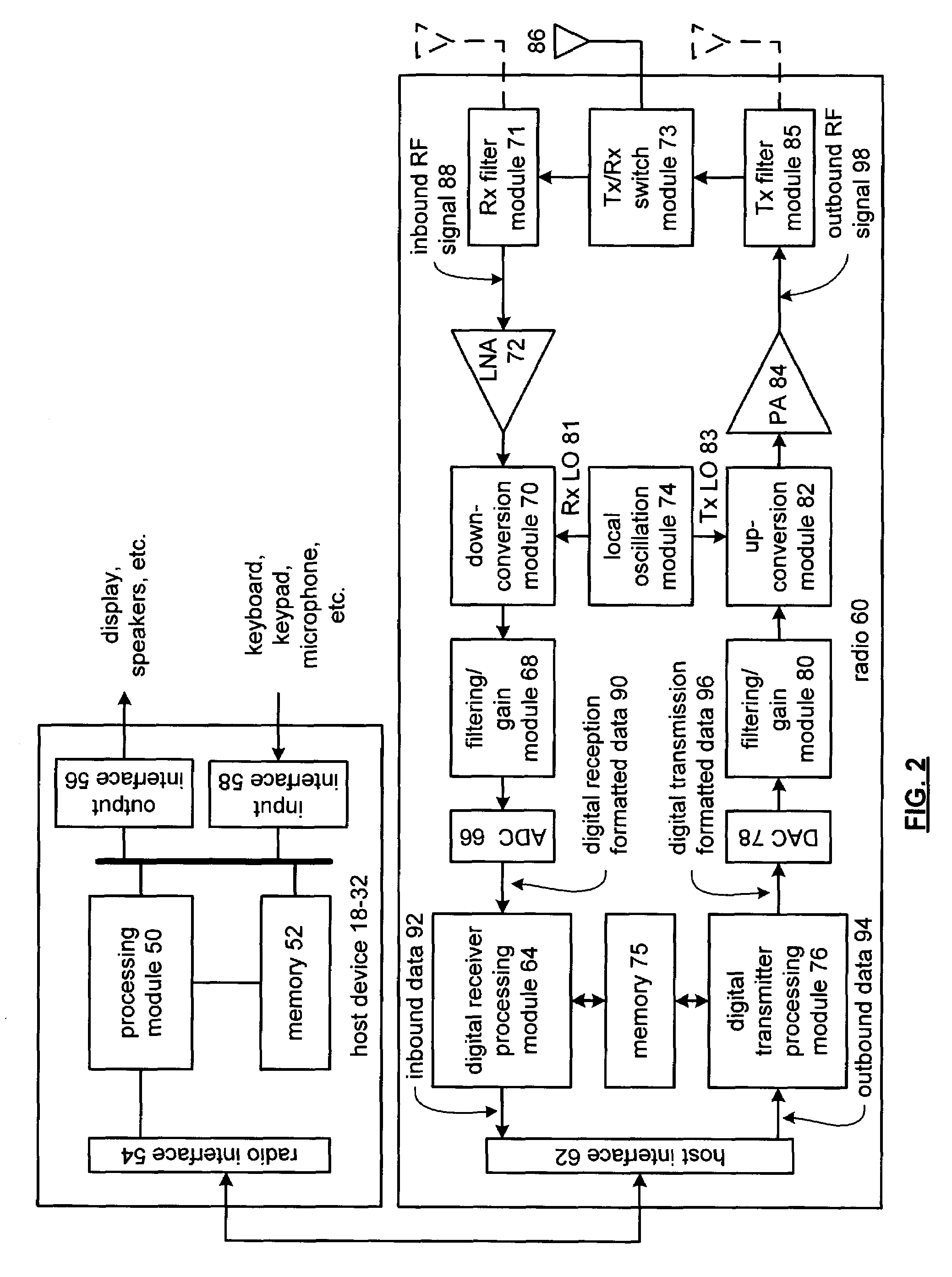

Code division multiple access (CDMA) communication system

InactiveUS20040252668A1Easy to liftMaximize signal to noisePower managementBaseband system detailsSystem capacityCode division multiple access

A subscriber unit for use in a multiple access spread-spectrum communication system includes a spread spectrum radio interface, responsive to a rate function signal from a base station, and first and second despreaders. The base station assigns the rate function spread-spectrum message channels and the first despreader recovers and modifies an information signal one of the spread spectrum message channels. The information channel mode is then modified for processing by the second despreader, with the second despreader supporting a different information signal rate. The subscriber unit has a capability of communicating with a dynamically changing a transmission rate of an information signal which includes multiple spread spectrum message channels. The system includes a closed loop power control system for maintaining a minimum system transmit power level for a radio carrier station and the subscriber units, and system capacity management for maintaining a maximum number of active subscriber units for improved system performance.

Owner:INTERDIGITAL TECH CORP

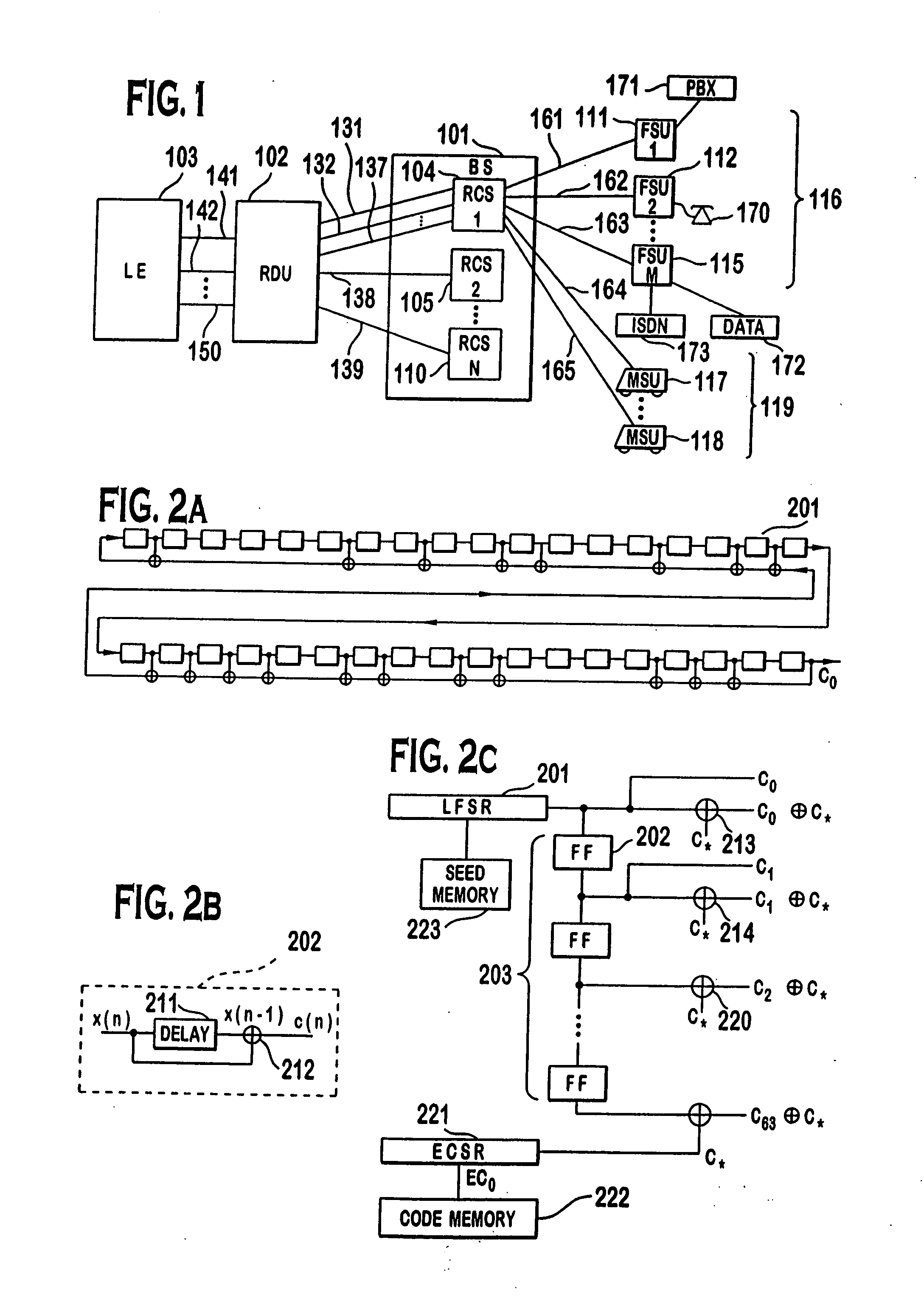

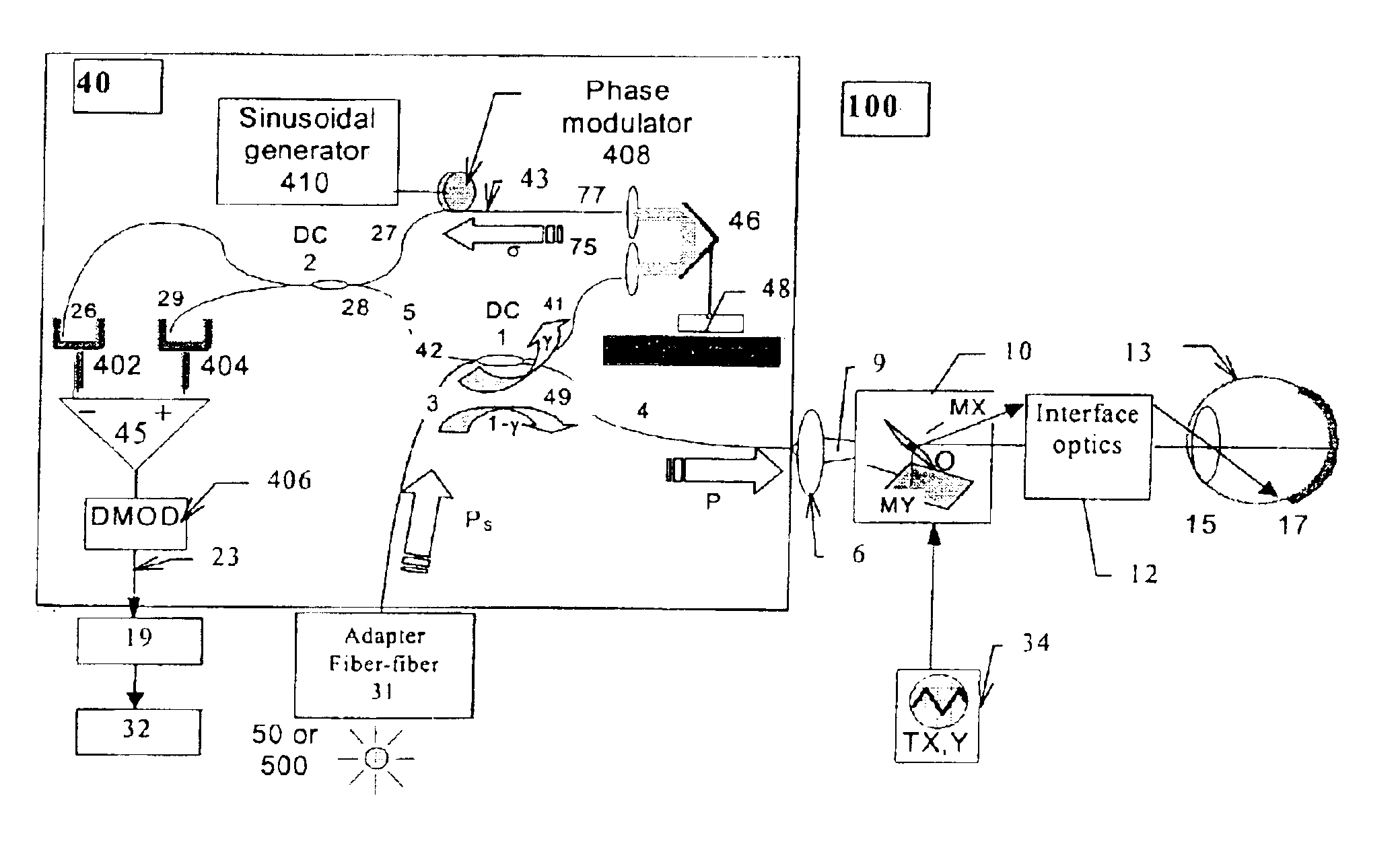

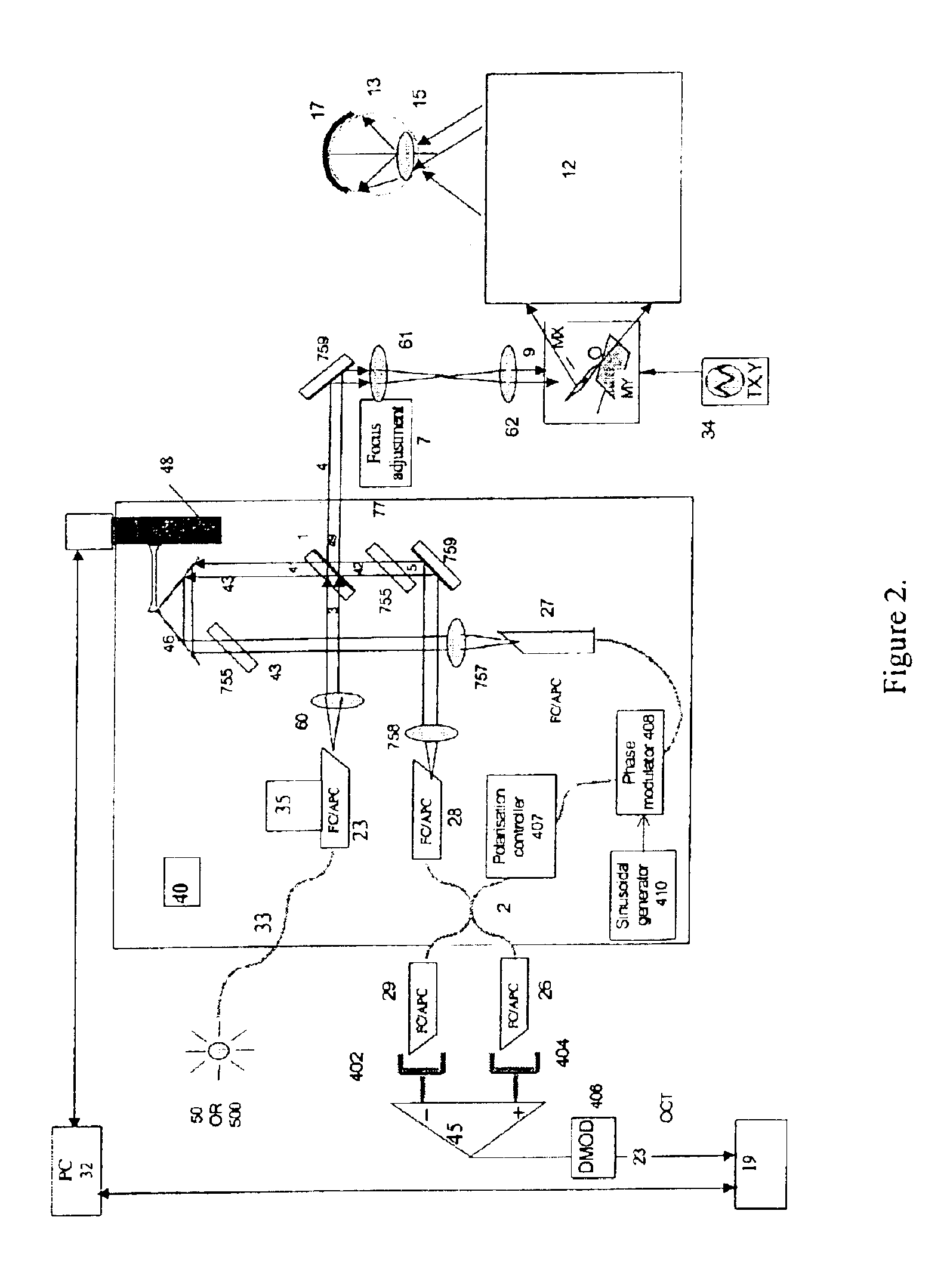

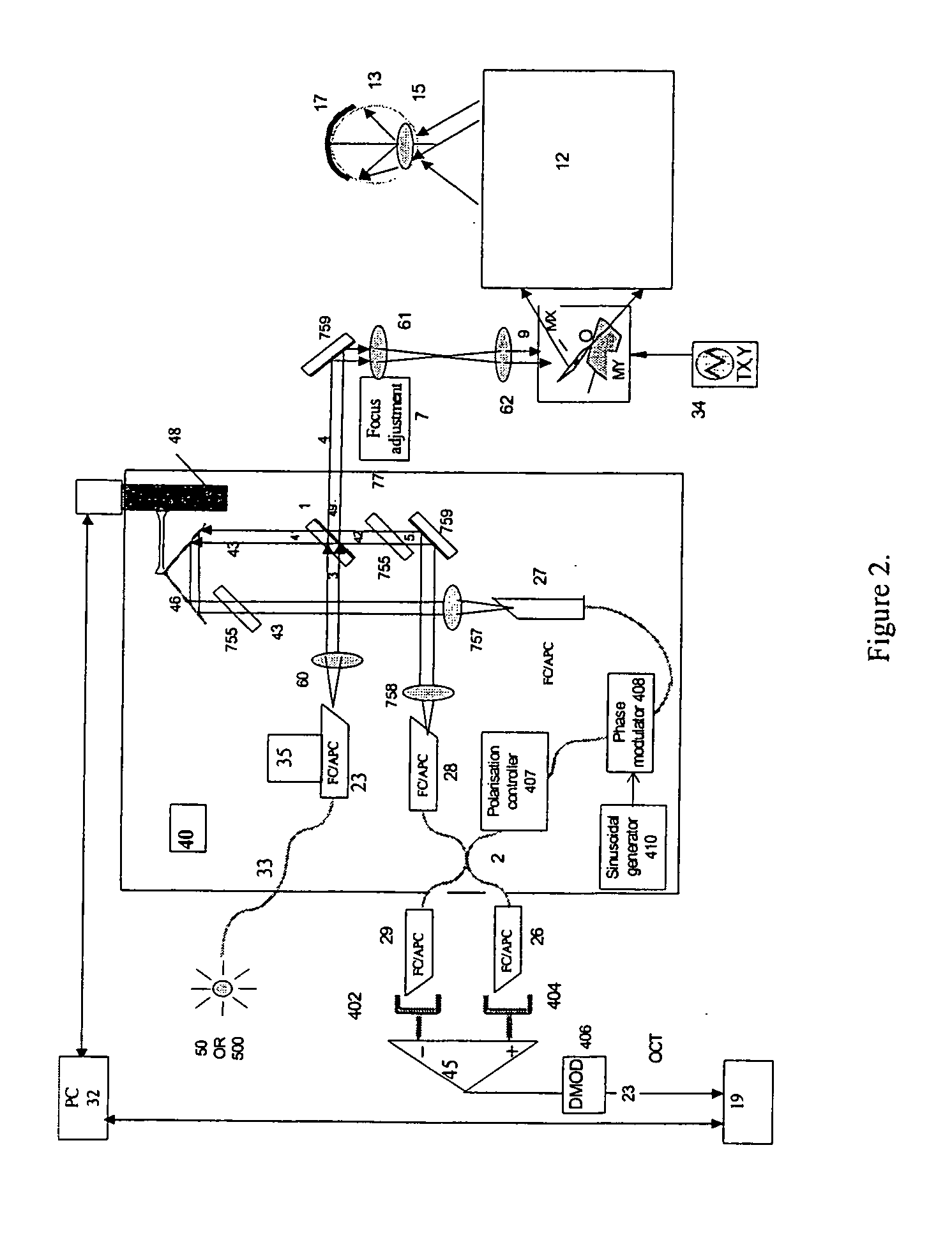

Optical mapping apparatus with optimized OCT configuration

InactiveUS6927860B2Reduce the amount requiredReduce the amount of solutionInterferometersScattering properties measurementsFace scanningBeam splitter

OCT apparatus includes an interferometer, having an input beam splitter and a 50 / 50 output splitter. The splitting ratio of the input splitter may be optimized depending on the source power of light source and on the mismatch of the balanced receiver. The input splitter is a plate beam-splitter to minimize the stray reflected light in the interferometer and allow sequential operation of the apparatus in the OCT or in the confocal regime. The switching between the two regimes may be at will, or synchronous with the en-face scanning which results in quasi-simultaneous OCT / confocal imaging or in alternatives frames, confocal and OCT. By using polarization sensitive elements, two channels are provided in each regime, OCT and confocal. The two confocal polarization sensitive channels may allow adjustments of compensators prior to OCT measurements or OCT imaging.

Owner:OPTOS PLC

Flow cytometers and detection system of lesser size

InactiveUS20060177937A1Maximize signal to noise ratioIncrease the number ofWithdrawing sample devicesAnalysis by subjecting material to chemical reactionFiberPhotodetector

Gas focusing flow cytometers are fabricatable employing simple and inexpensive manufacturing techniques. When such cytometers or conventional cytometers are combined with fiber optical light paths and laser diode and semiconductor photodetectors, light weight and handheld, optionally disposable devices which maintain high performance are possible.

Owner:RGT UNIV OF MICHIGAN

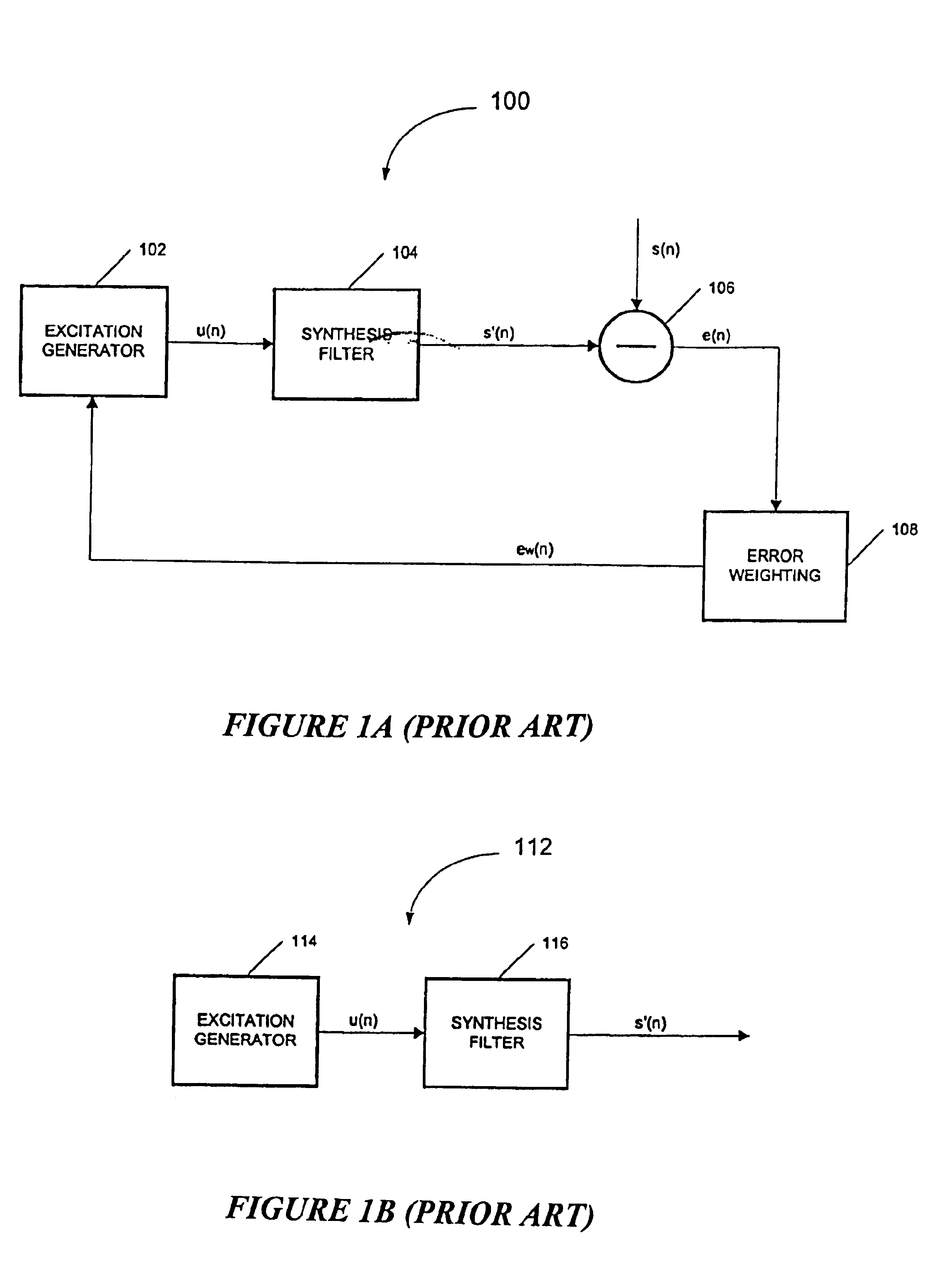

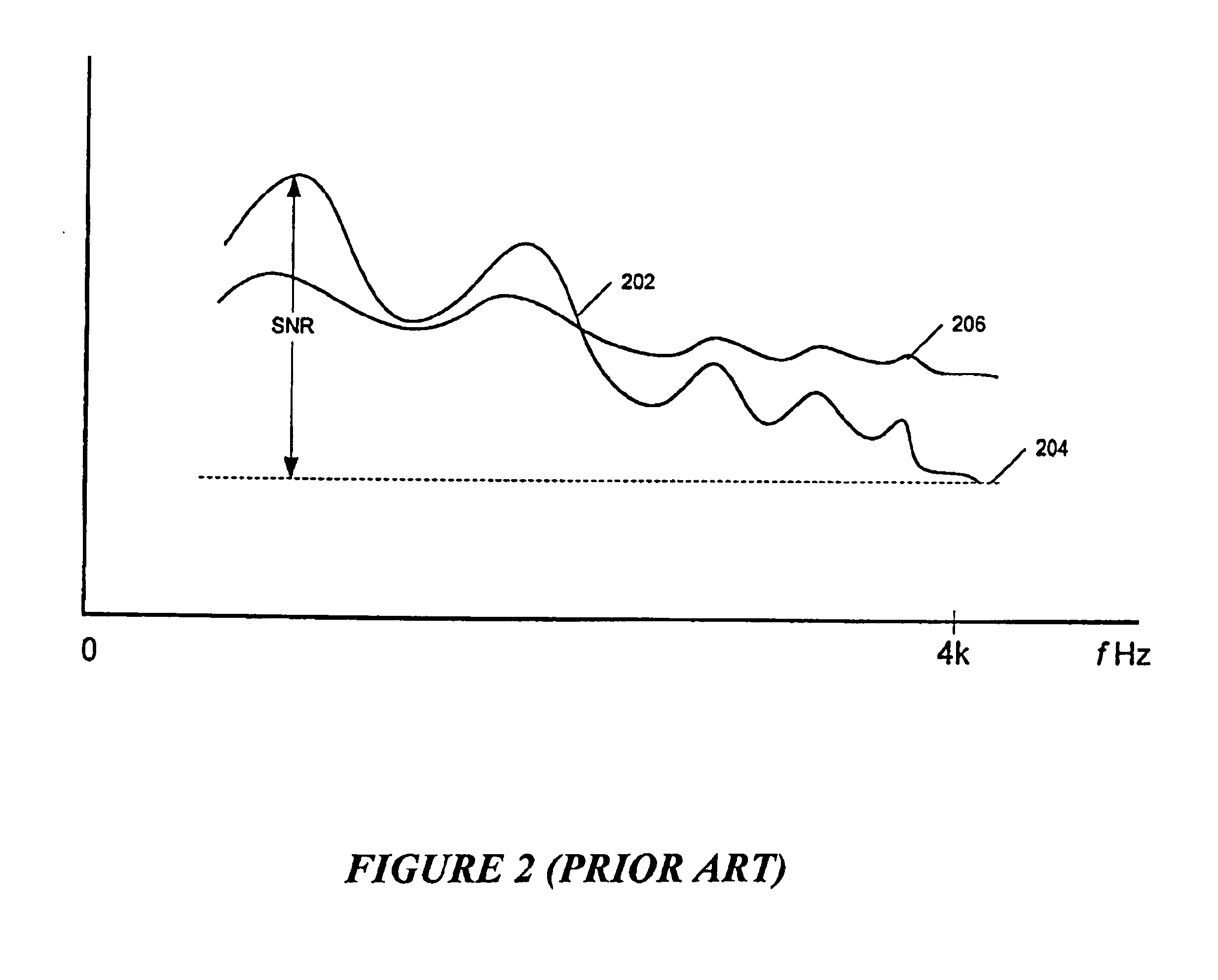

Method and apparatus for improved noise reduction in a speech encoder

InactiveUS6925435B1Eliminate noise componentEliminate noiseSpeech analysisSignal-to-noise ratio (imaging)Speech sound

A speech encoder comprises an encoding element for encoding a noise reduced speech signal, and a noise suppression element that takes a noisy speech signal and generates the noise reduced speech signal by maximizing the signal to noise ratio (SNR) of the noisy speech signal without suppressing the voiced speech components of the noisy speech signal. The noise suppression element may use harmonic modeling techniques that maximize the SNR in each sub-band of the noisy speech signal by reconstructing the voiced speech components of the noisy voiced speech signal emphasizing harmonic frequencies within each sub-band. The SNR is further maximized by eliminating noise components between signal peaks at the harmonic frequencies, and eliminating noise at signal peaks at the harmonic frequencies by smoothing harmonic parameters generated by the reconstruction of the voiced speech components of the noisy speech signal.

Owner:WIAV SOLUTIONS LLC +1

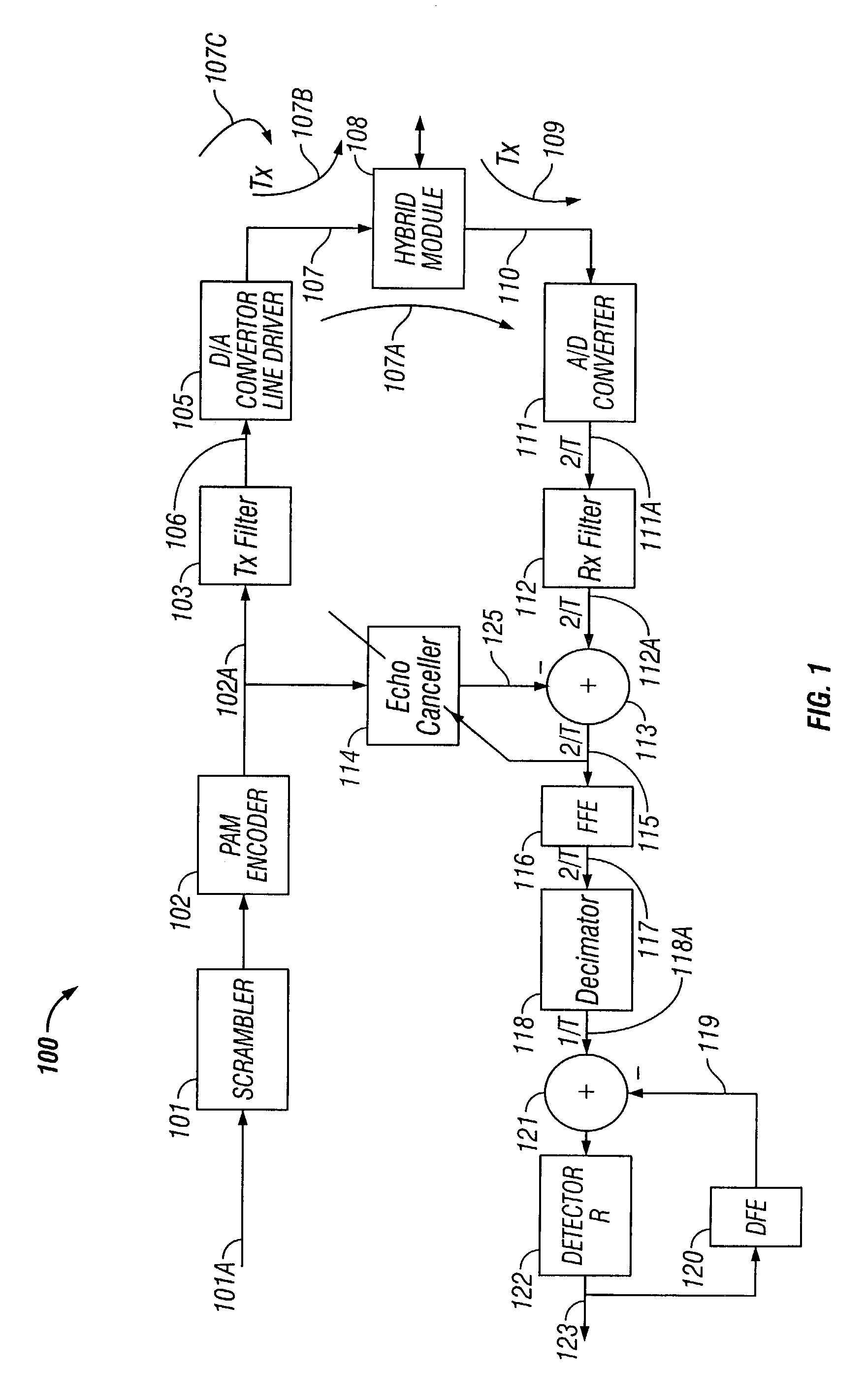

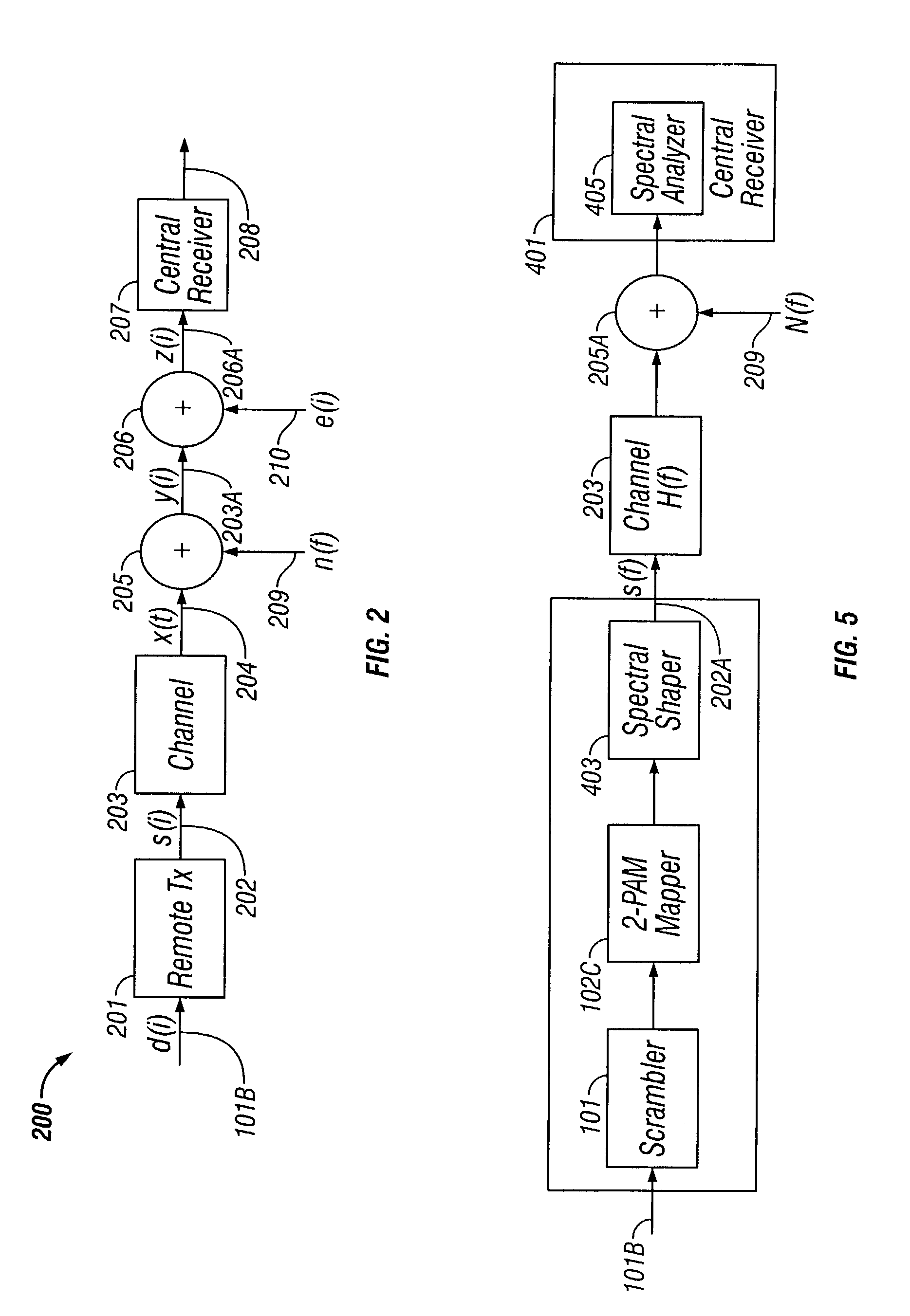

Method and system for data rate optimization in a digital communication system

InactiveUS7187719B2Large bit rateEasy to operatePower managementTransmission control/equalisingNoise power spectrumSignal-to-quantization-noise ratio

A method and for optimizing bit rate throughput in a digital communication system is provided. The method includes establishing a relationship between signal to noise ratio and plural symbol rates for a particular constellation size. The method also includes determining noise power spectral density (N(f)), wherein N(f) is determined during a silent period of line probing; determining Xk(f), wherein Xk(f) is determined by turning on a remote station transmit signal, after N(f) has been measured and determining residual echo Ek(f), wherein Ek(f) is determined by turning on a central station echo canceller.

Owner:MACOM TECH SOLUTIONS HLDG INC

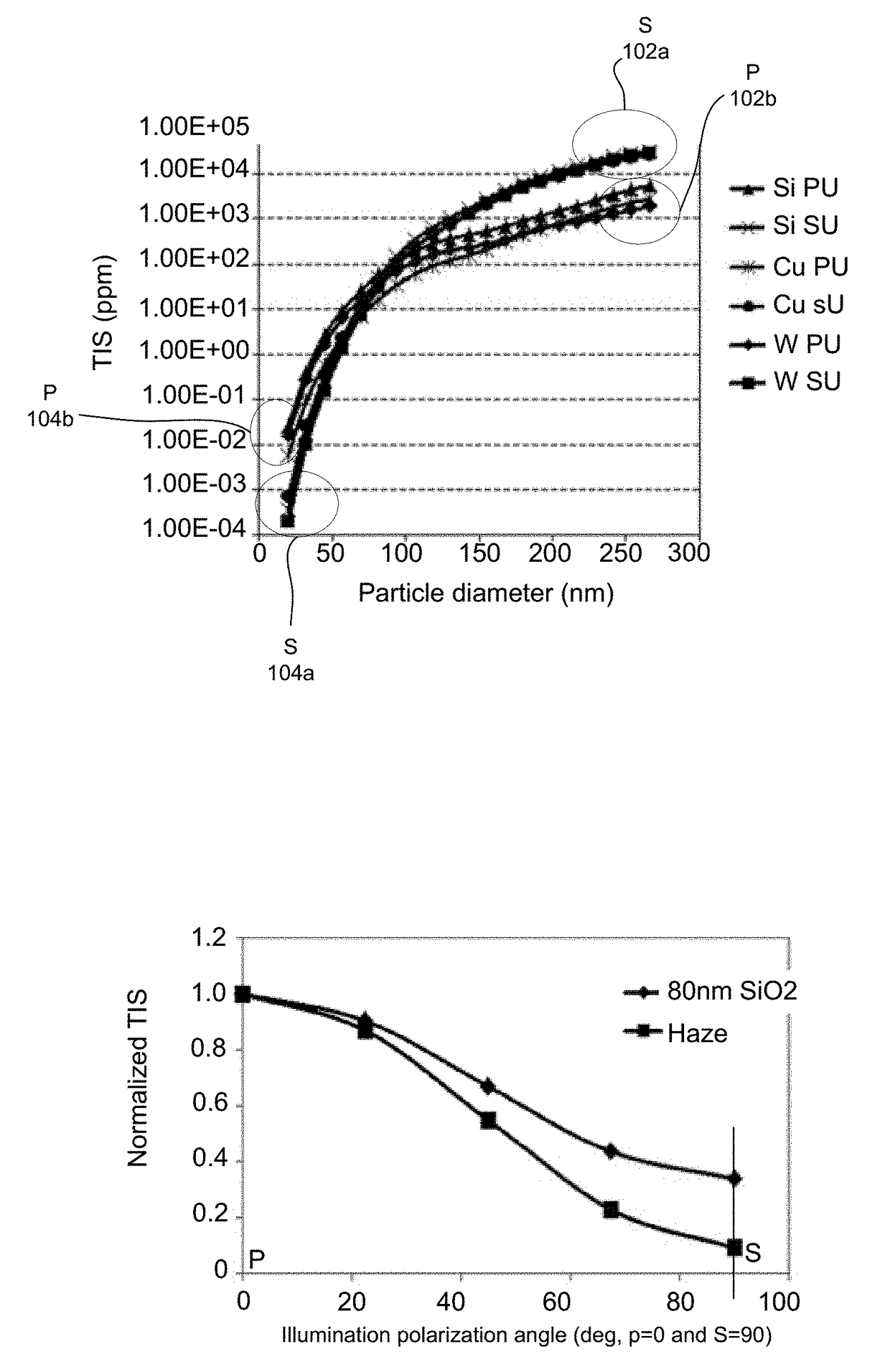

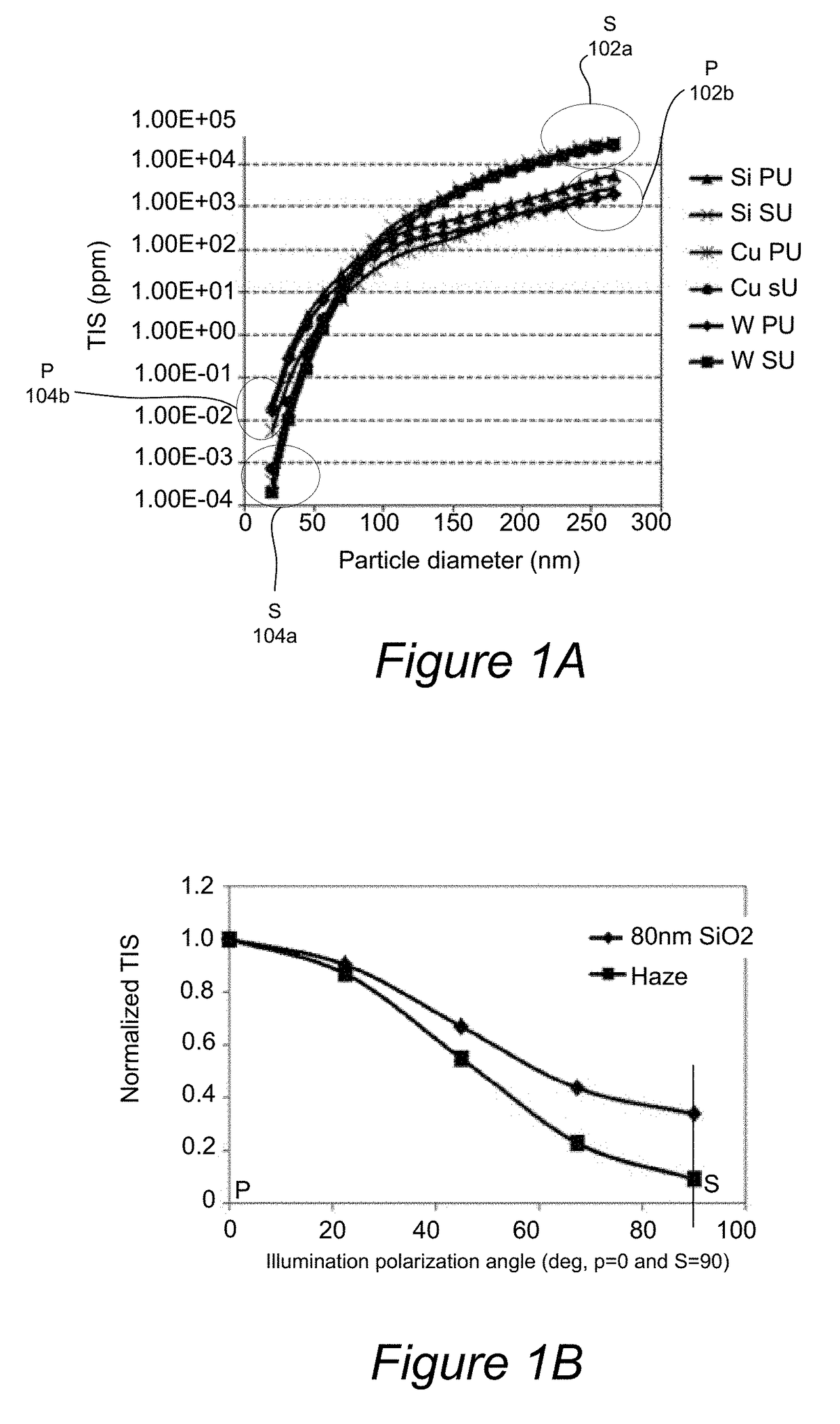

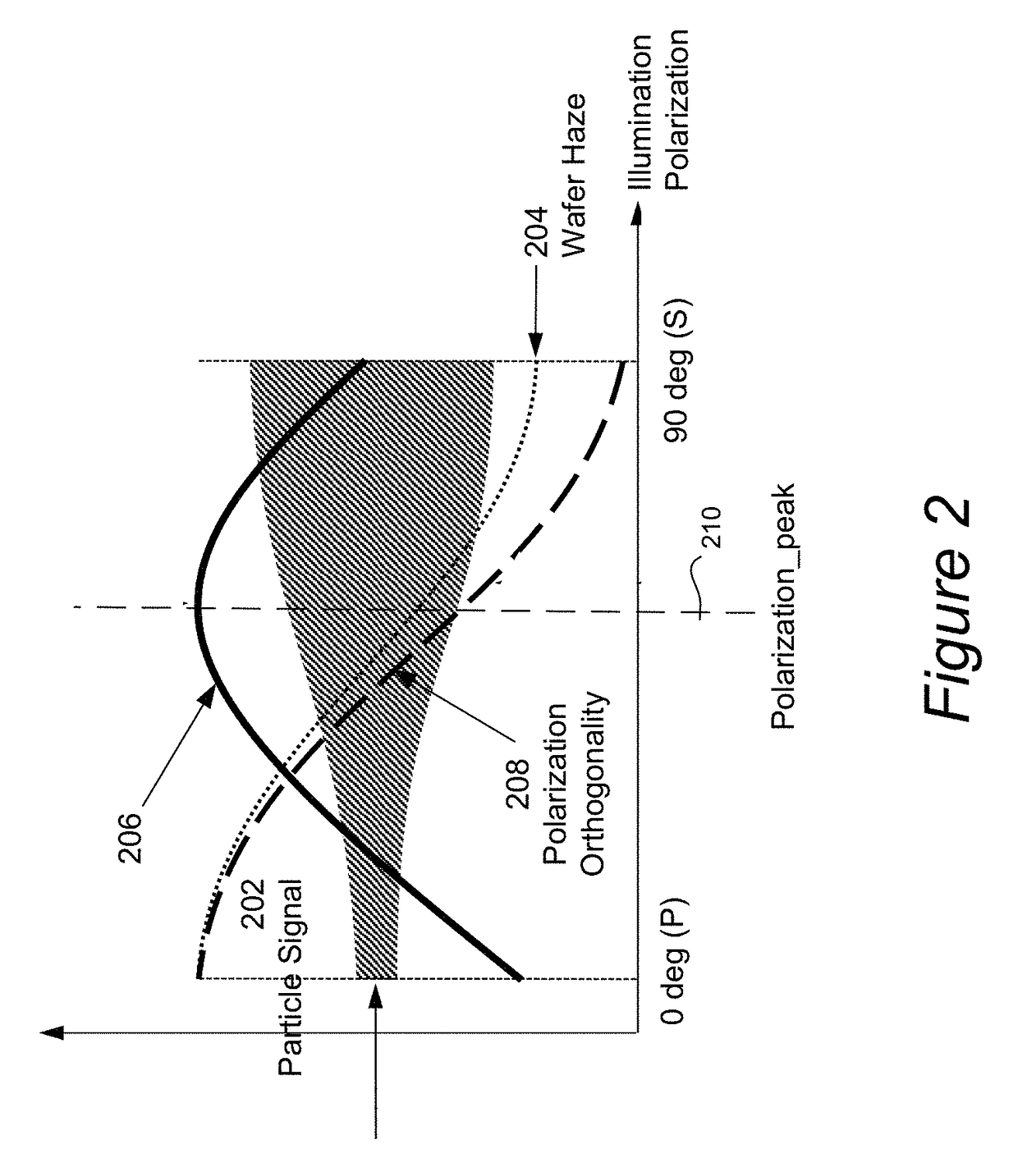

Methods and apparatus for polarized wafer inspection

ActiveUS20170276613A1Maximize signal to noiseSemiconductor/solid-state device testing/measurementPolarisation-affecting propertiesPhase differenceLight beam

Disclosed are methods and apparatus for inspecting a semiconductor sample. This system comprises an illumination optics subsystem for generating and directing an incident beam towards a defect on a surface of a wafer. The illumination optics subsystem includes a light source for generating the incident beam and one or more polarization components for adjusting a ratio and / or a phase difference for the incident beam's electric field components. The system further includes a collection optics subsystem for collecting scattered light from the defect and / or surface in response to the incident beam, and the collection optics subsystem comprises an adjustable aperture at the pupil plane, followed by a rotatable waveplate for adjusting a phase difference of electric field components of the collected scattered light, followed by a rotatable analyzer. The system also includes a controller that is configured for (i) selecting a polarization of the incident beam, (ii) obtaining a defect scattering map, (iii) obtaining a surface scattering map, and (iv) determining a configuration of the one or more polarization components, aperture mask, and rotatable ¼ waveplate, and analyzer based on analysis of the defect and surface scattering map so as to maximize a defect signal to noise ratio,

Owner:KLA CORP

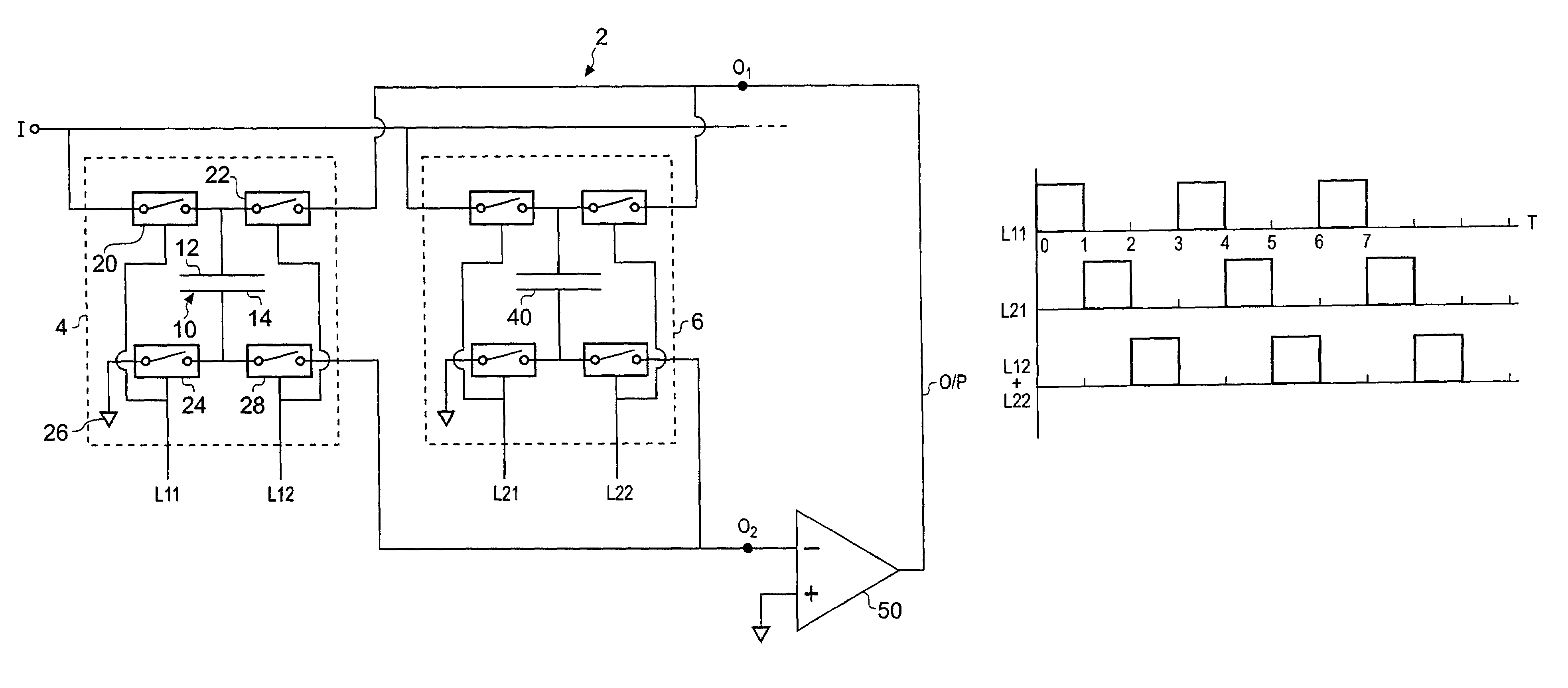

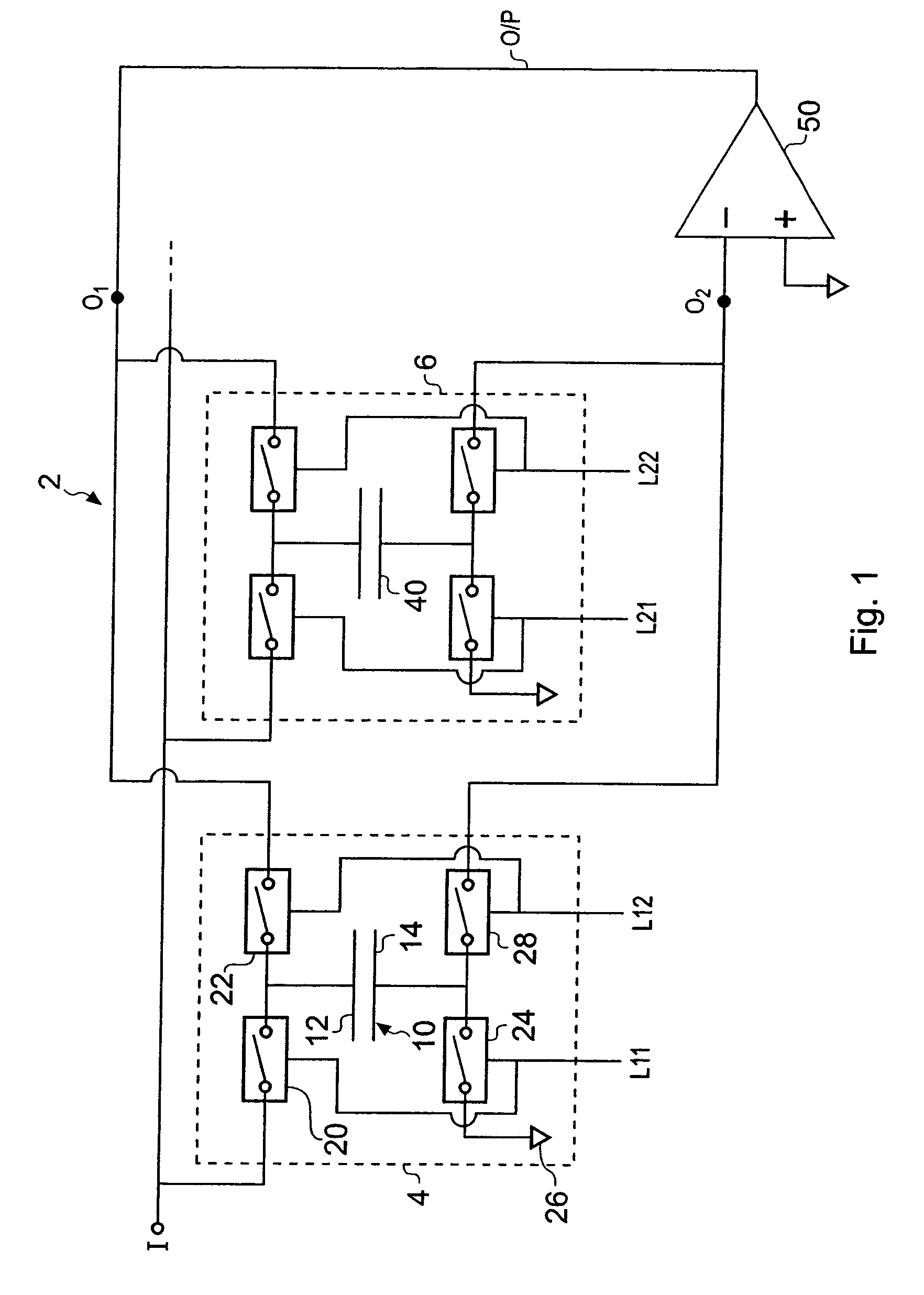

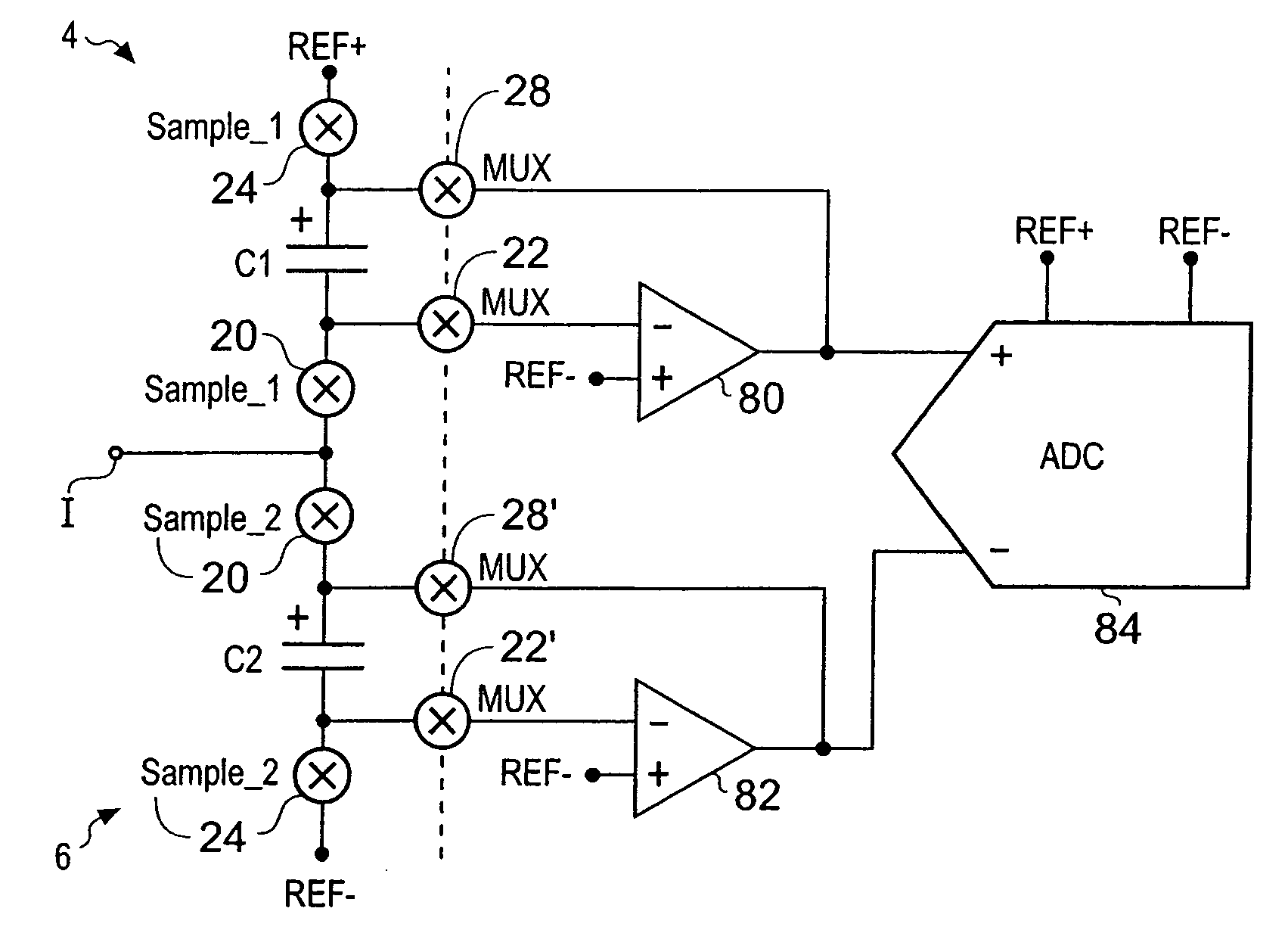

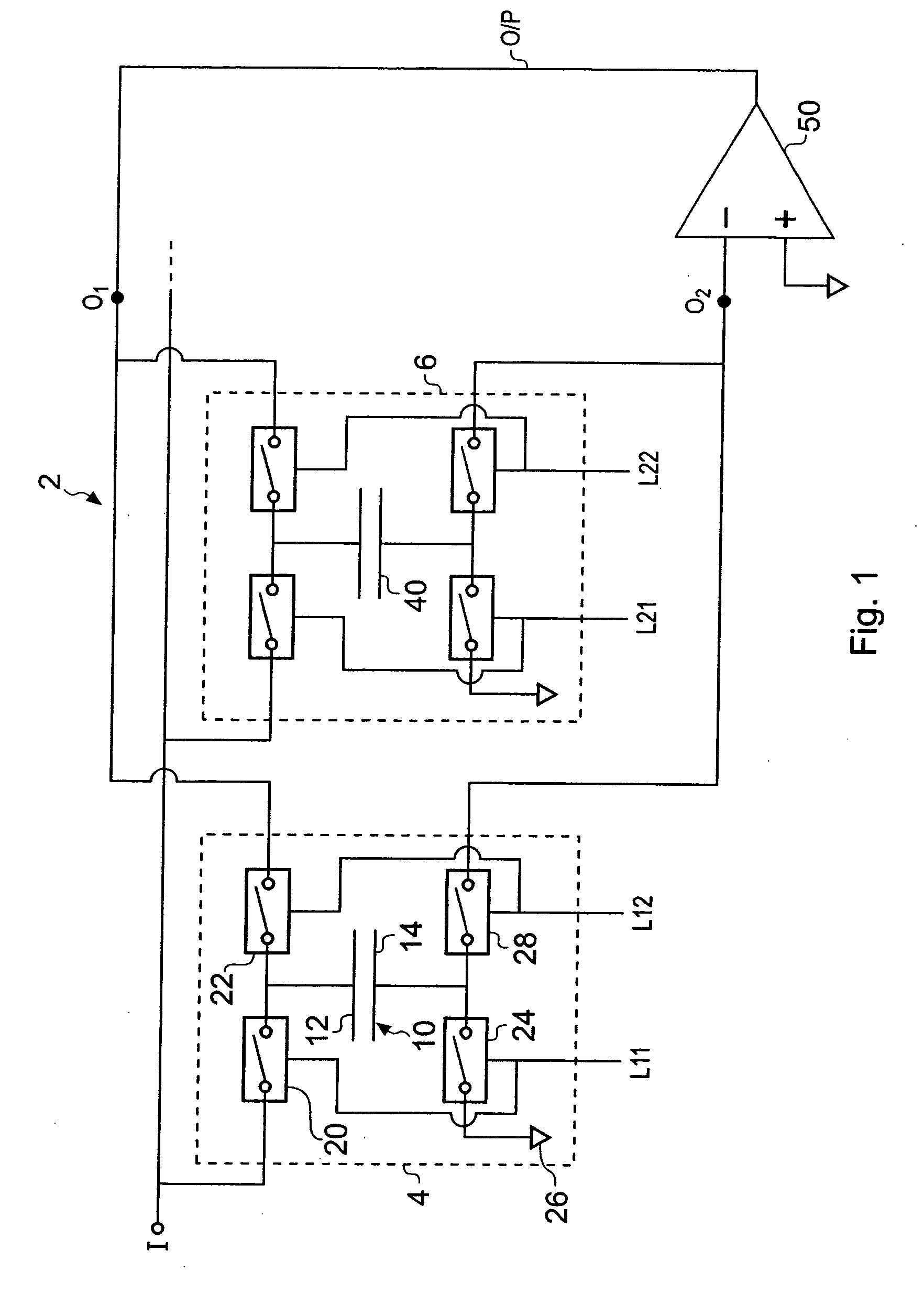

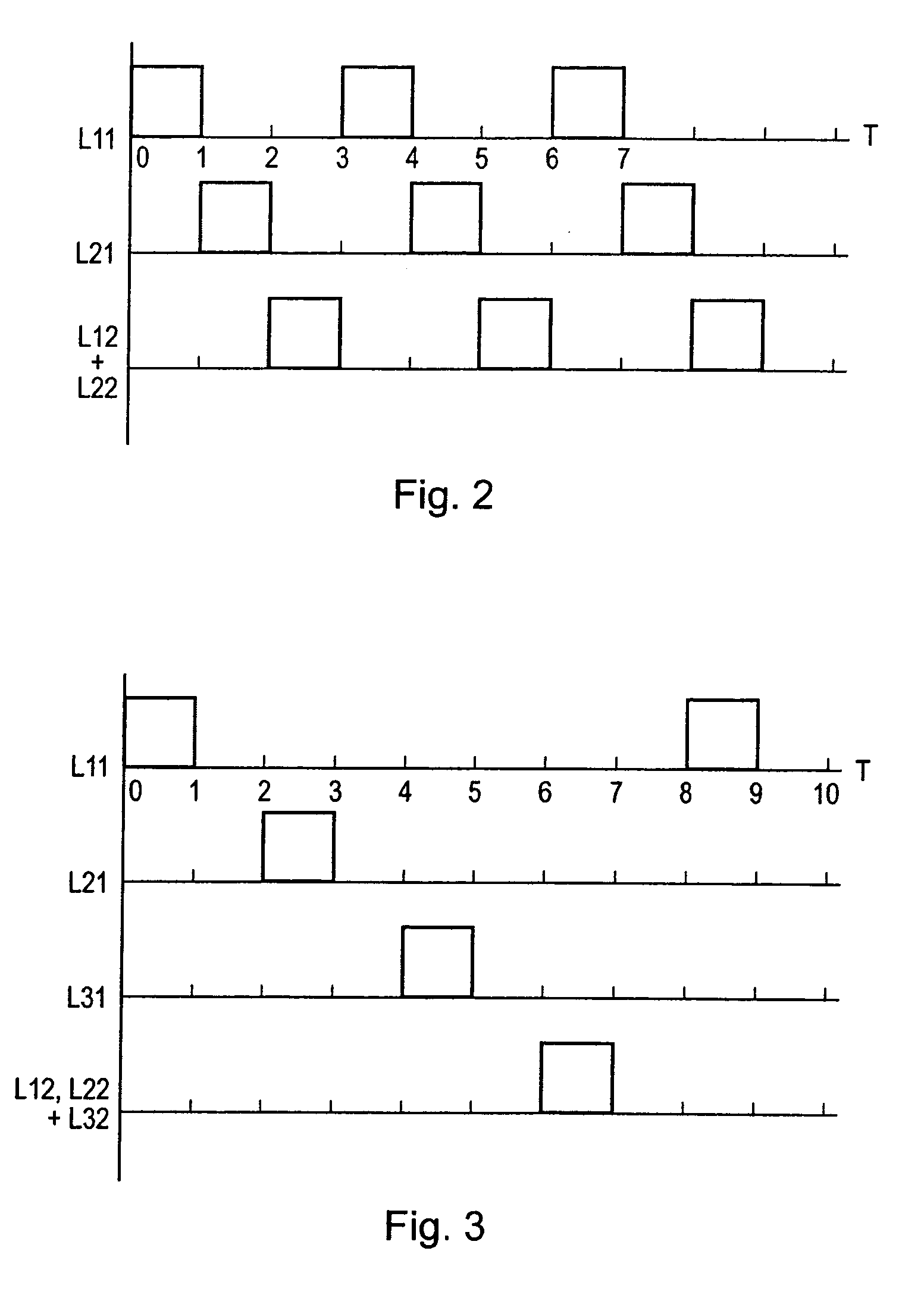

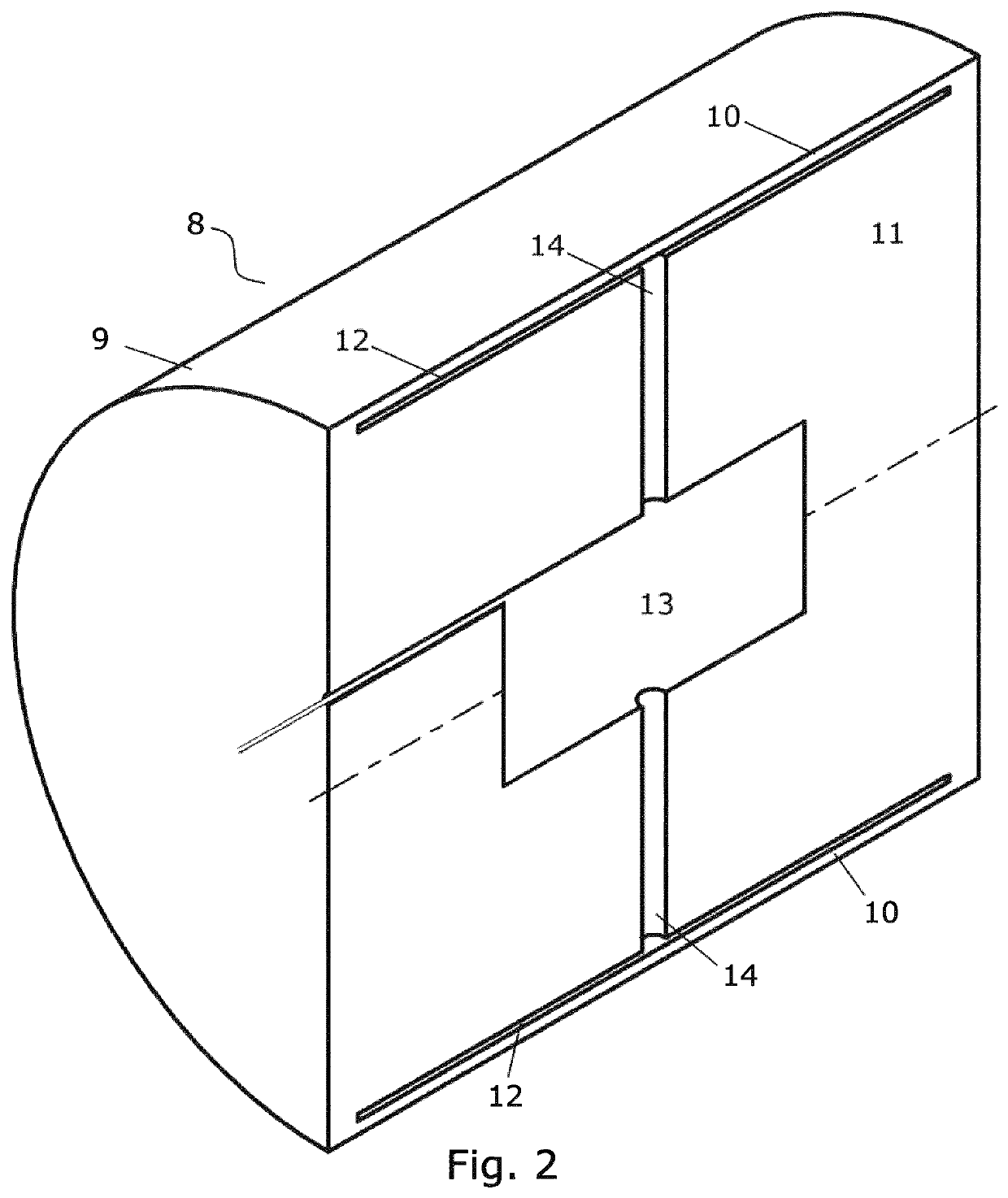

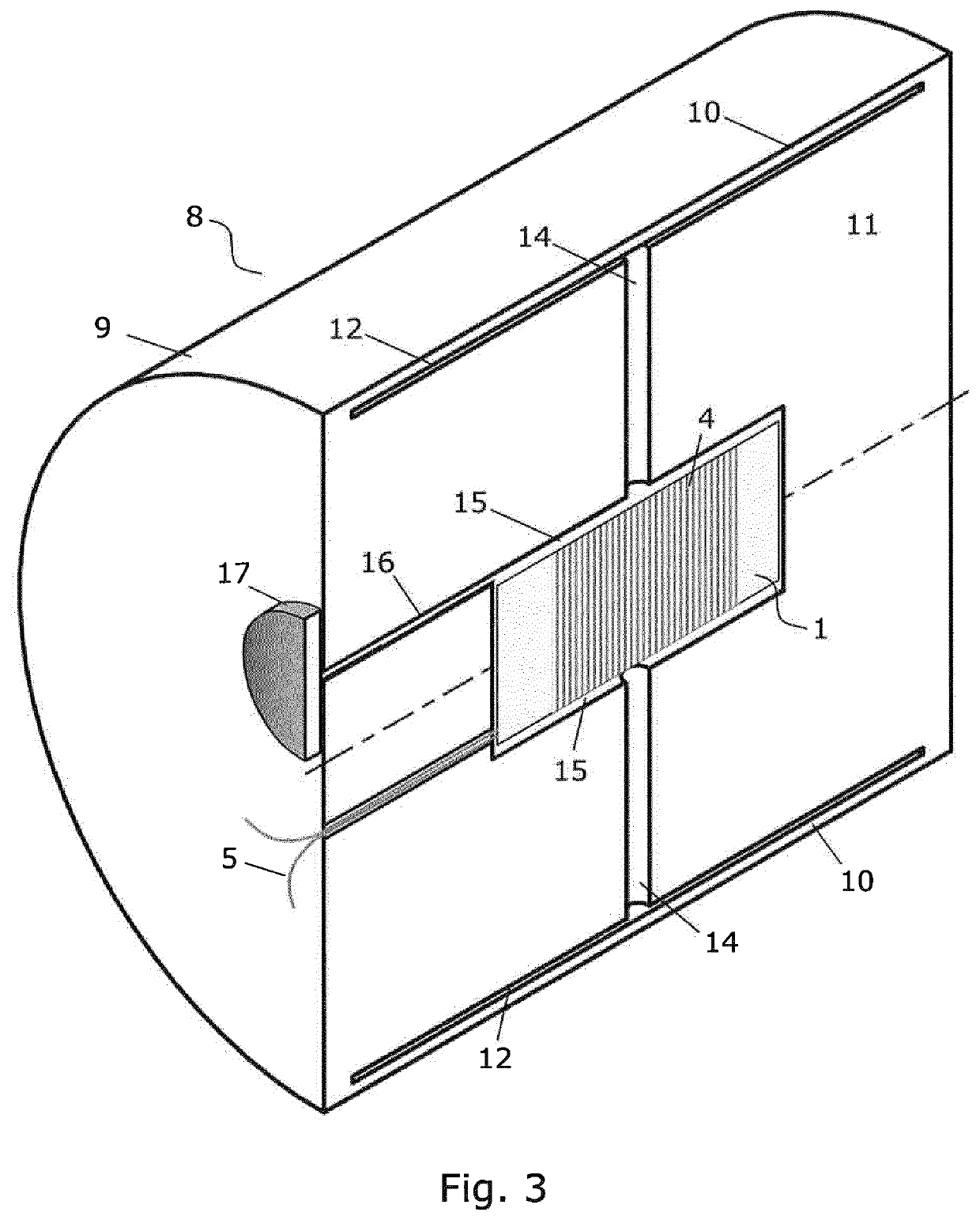

Sample and hold apparatus

ActiveUS7113116B2Effectively signal voltageMaximize signal to noiseElectric signal transmission systemsElectric analogue storesEngineeringCapacitor

An acquisition and averaging circuit is provided in which, during a sampling phase capacitors in sample blocks 4 and 6 are sequentially connected to the input signal to sample it and are then isolated so as to hold the sample. The capacitors are then connected to a combining / averaging arrangement such that an average of the sample values is formed.

Owner:ANALOG DEVICES INC

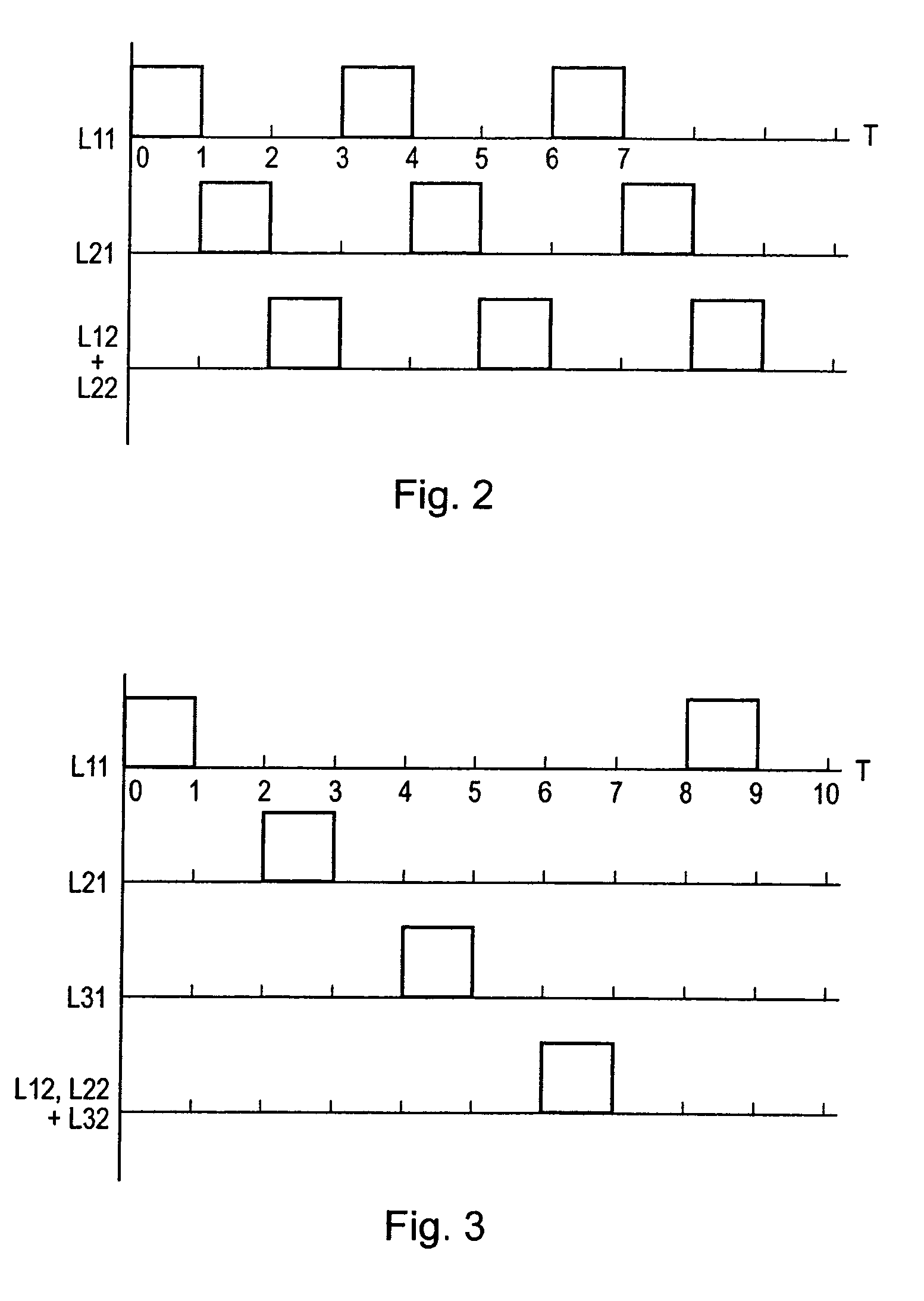

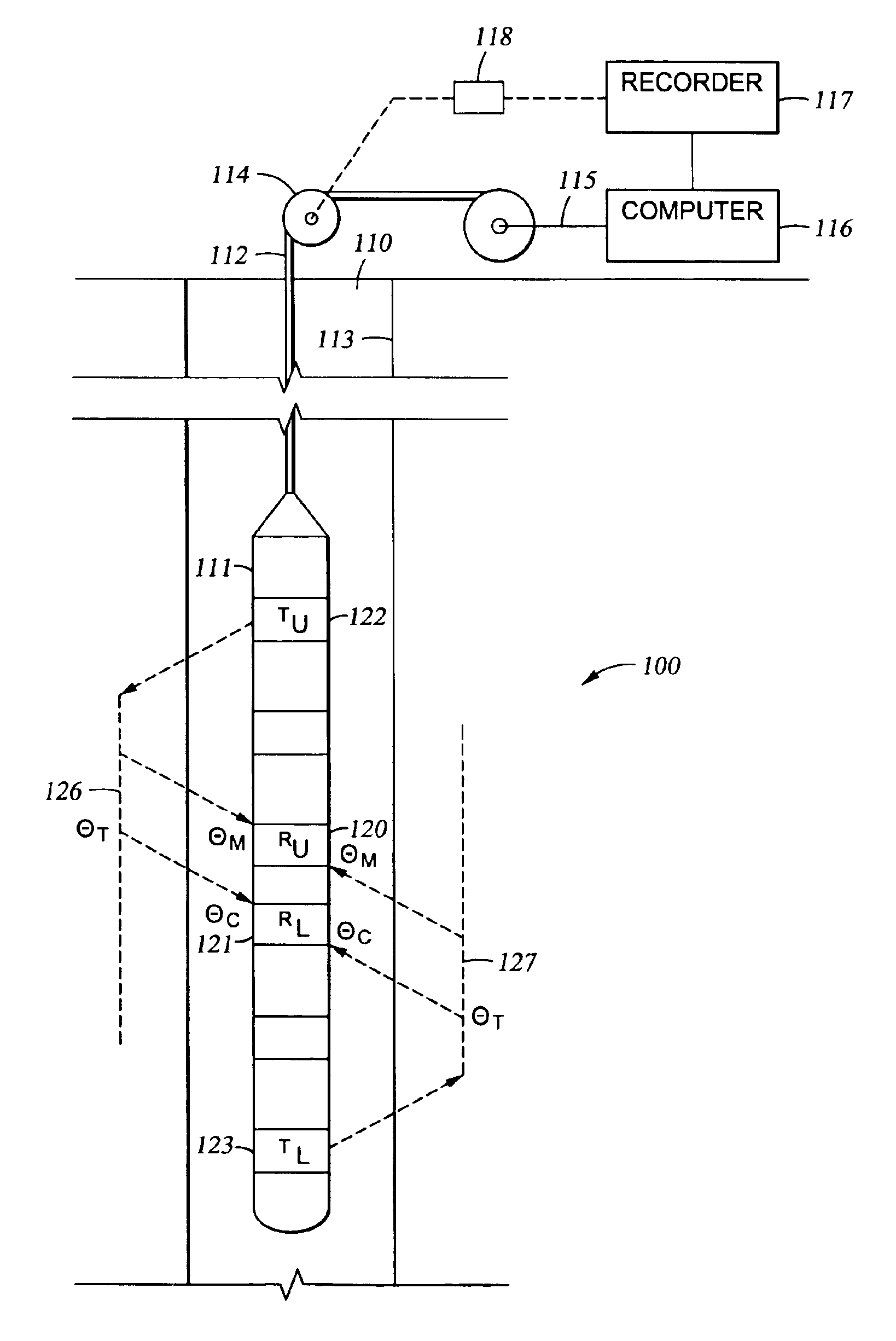

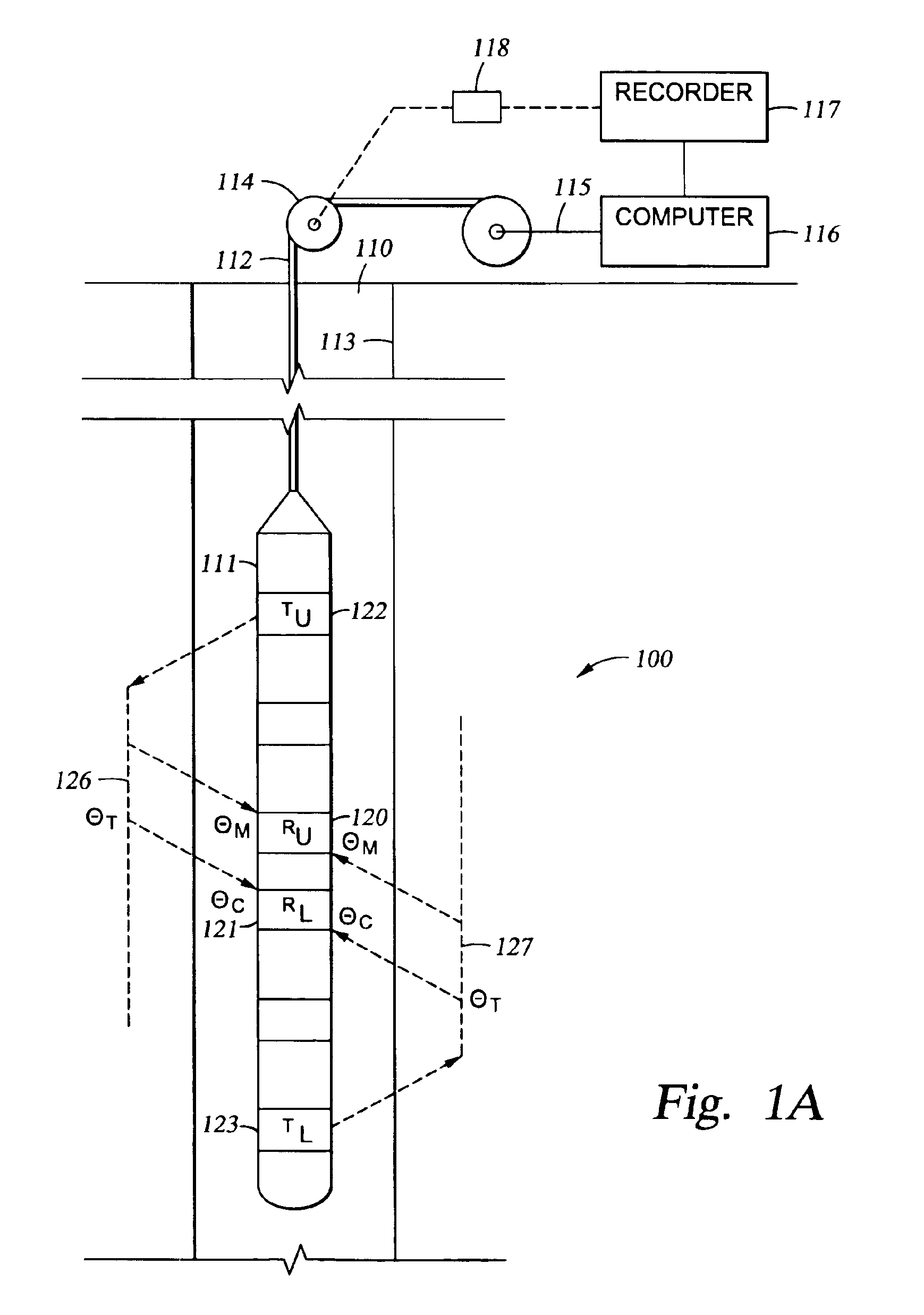

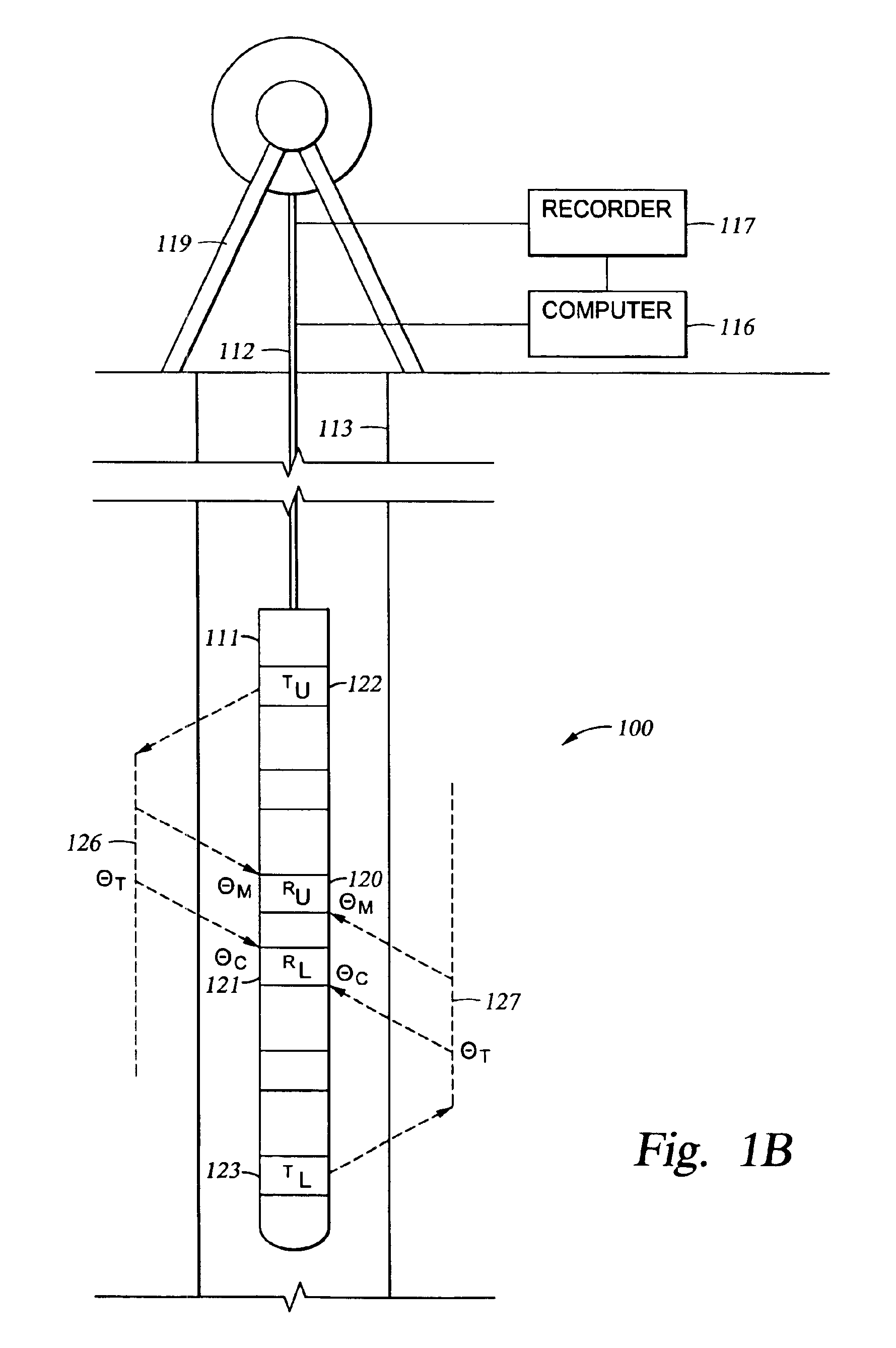

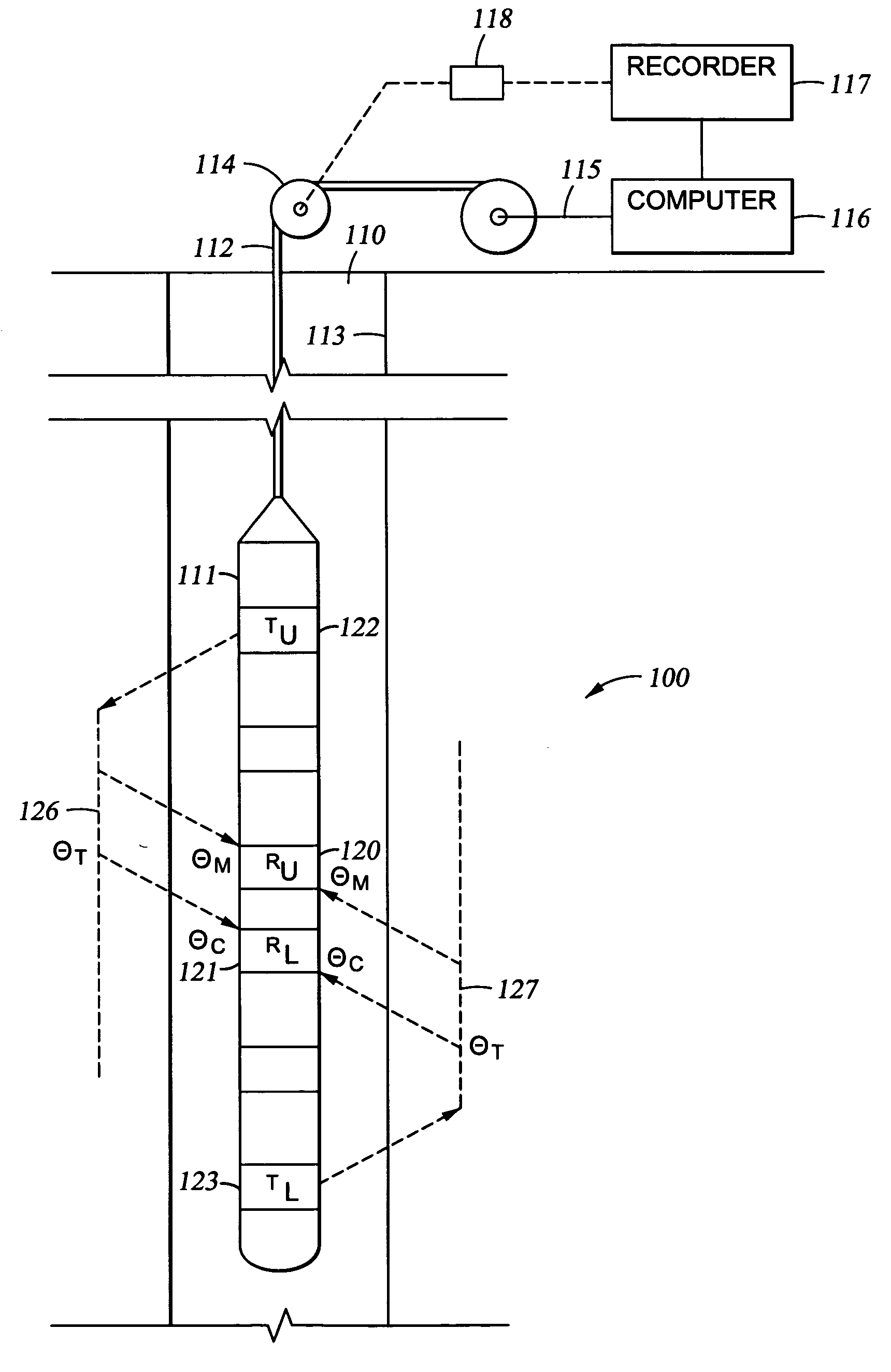

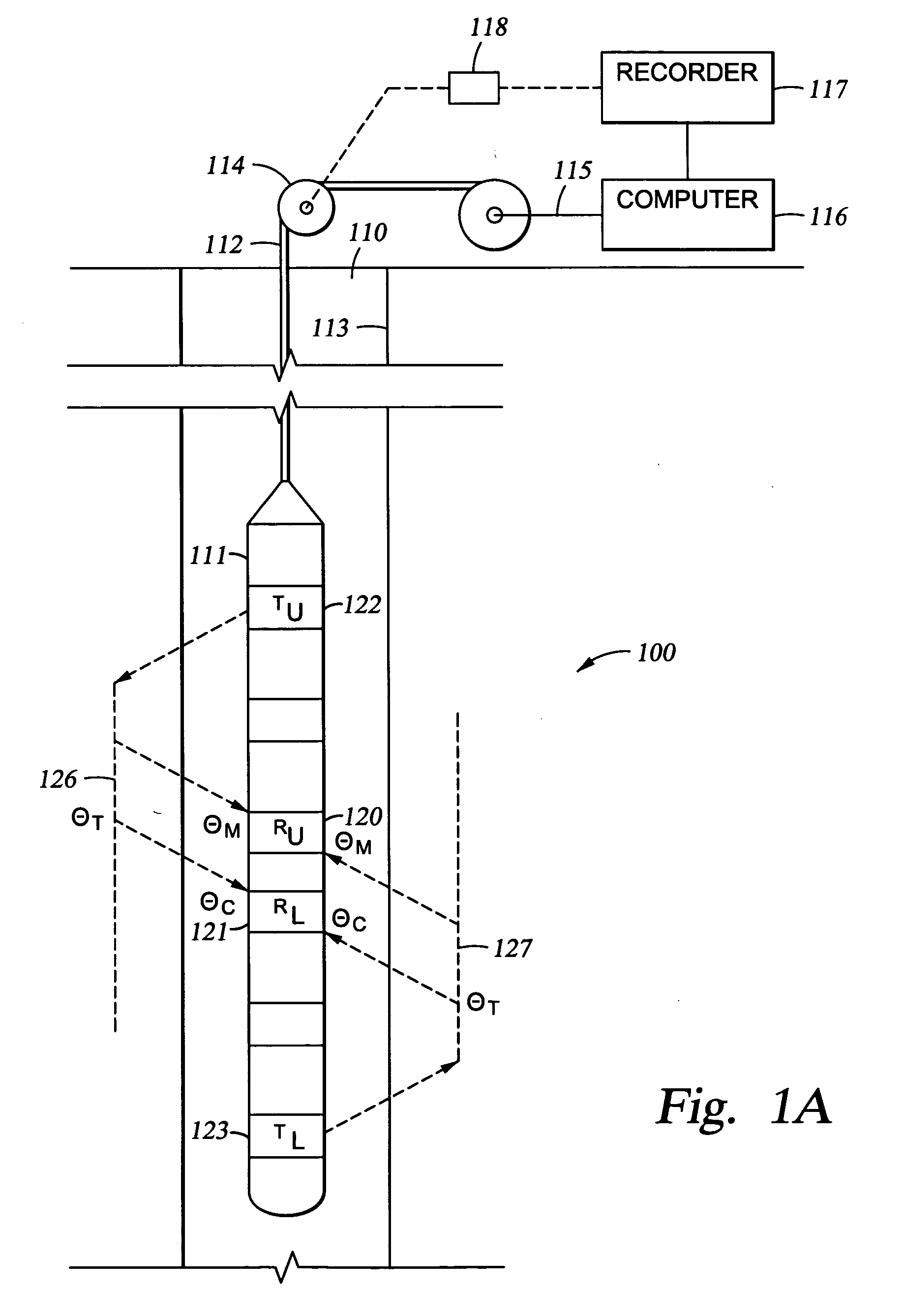

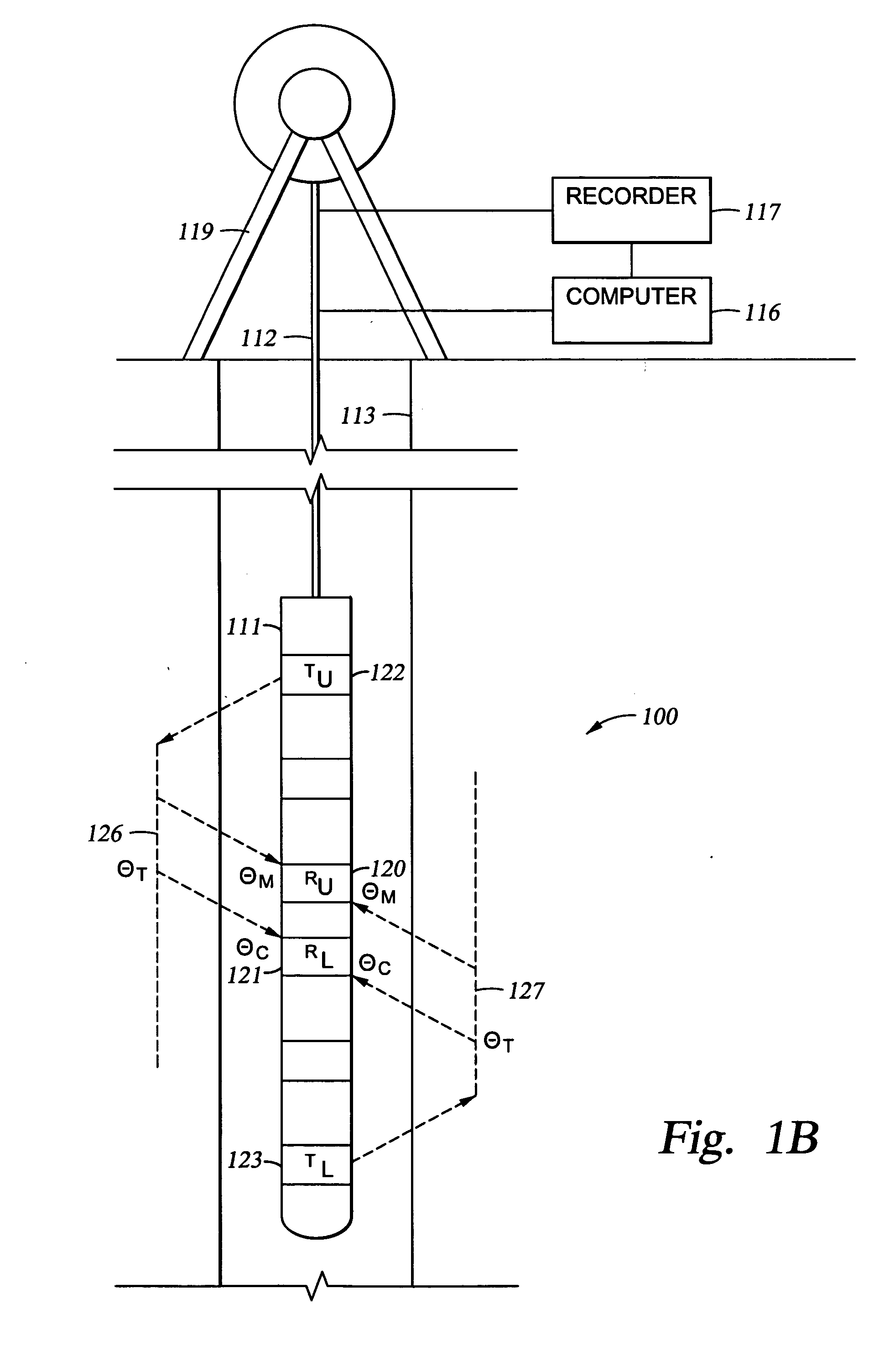

Borehole compensation system and method for a resistivity logging tool

InactiveUS6961663B2Increase ratingsMaximize signal to noiseElectric/magnetic detection for well-loggingSeismology for water-loggingUltrasound attenuationPhase difference

System and method for borehole compensation. The method includes simultaneously transmitting at least two modulated signals from one or more transmitters; receiving the at least two modulated signals by at least one receiver; and processing the received at least two modulated signals to determine a phase difference and an amplitude attenuation of the transmitted modulated signals, the processing providing borehole compensated data.

Owner:WEATHERFORD TECH HLDG LLC

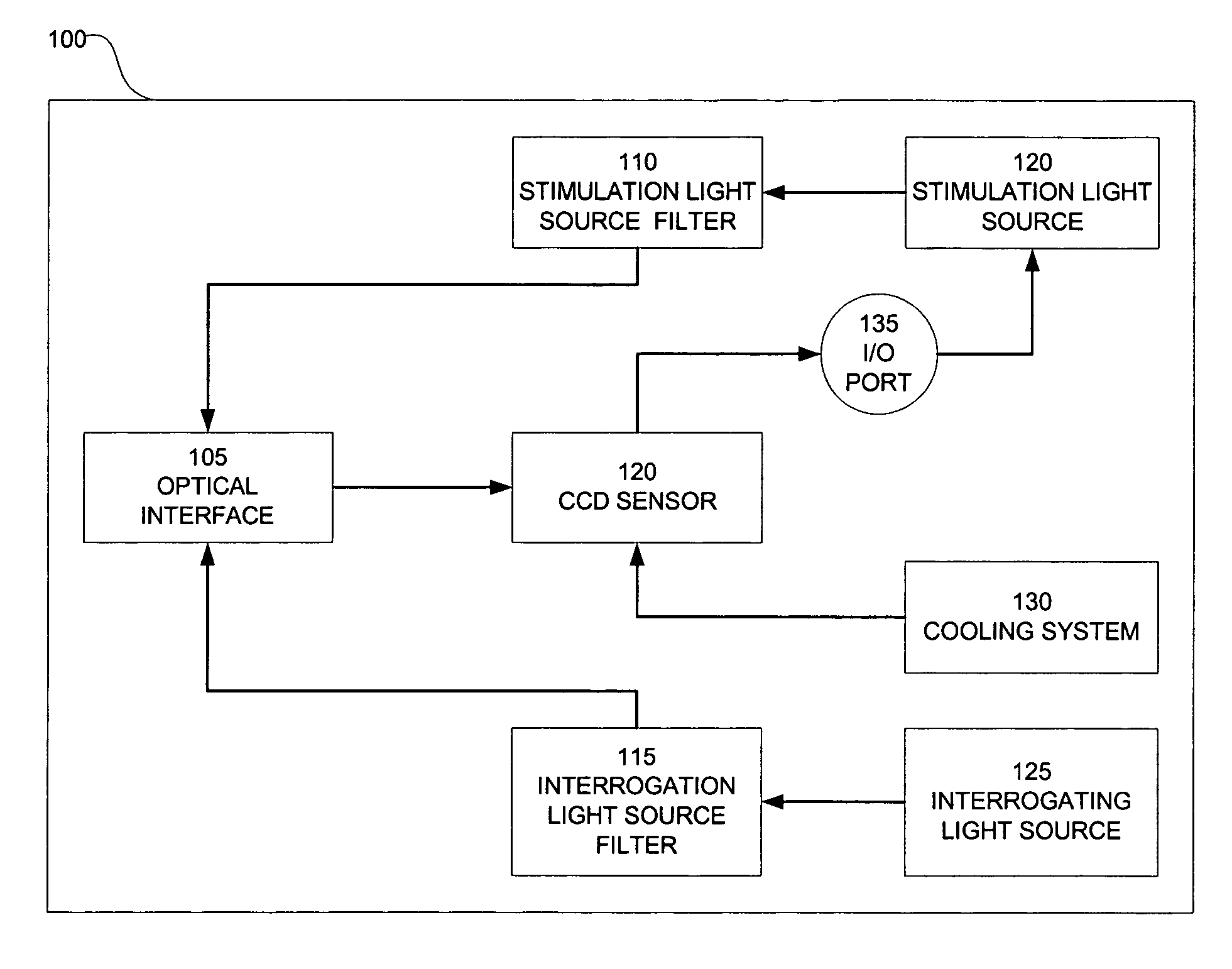

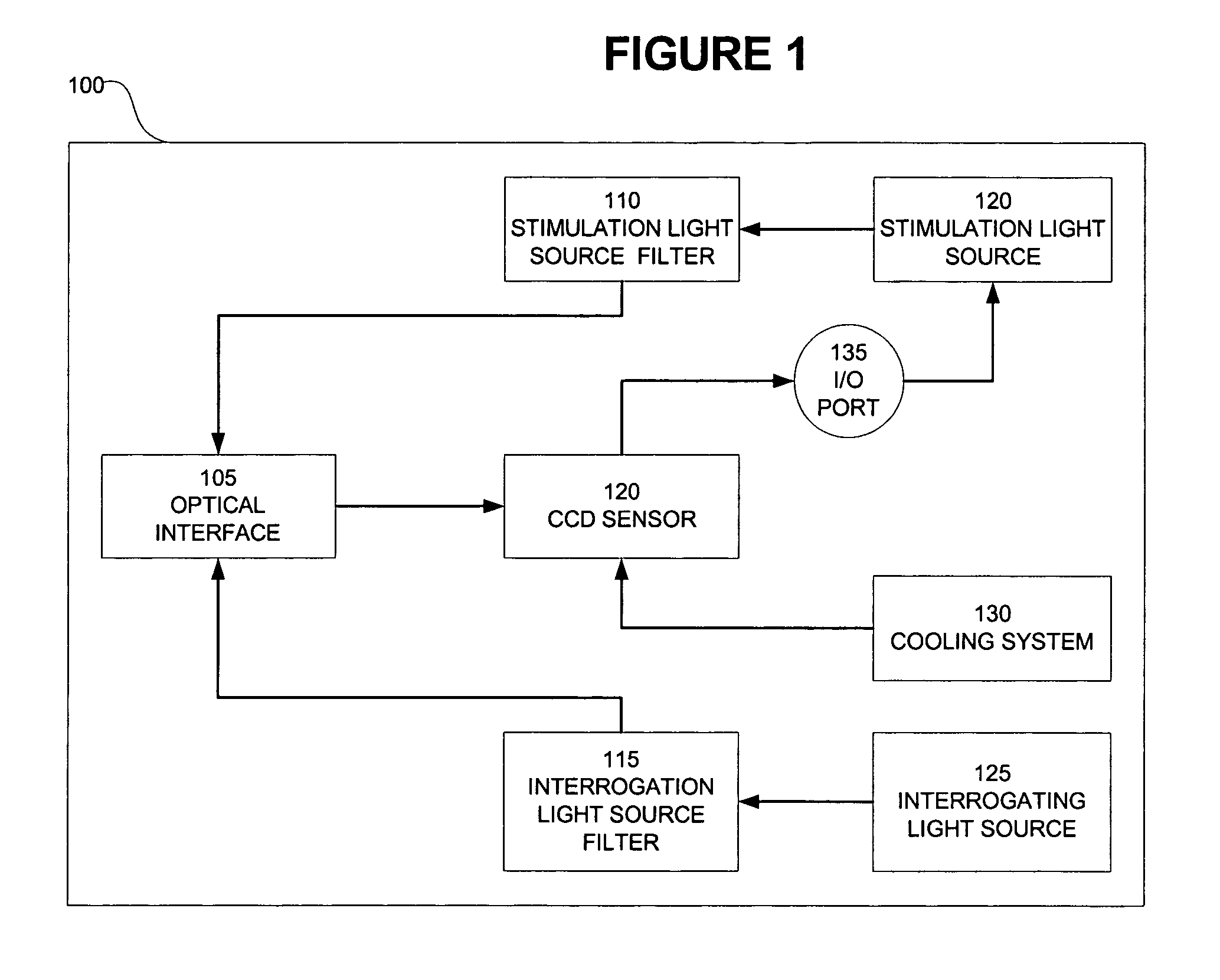

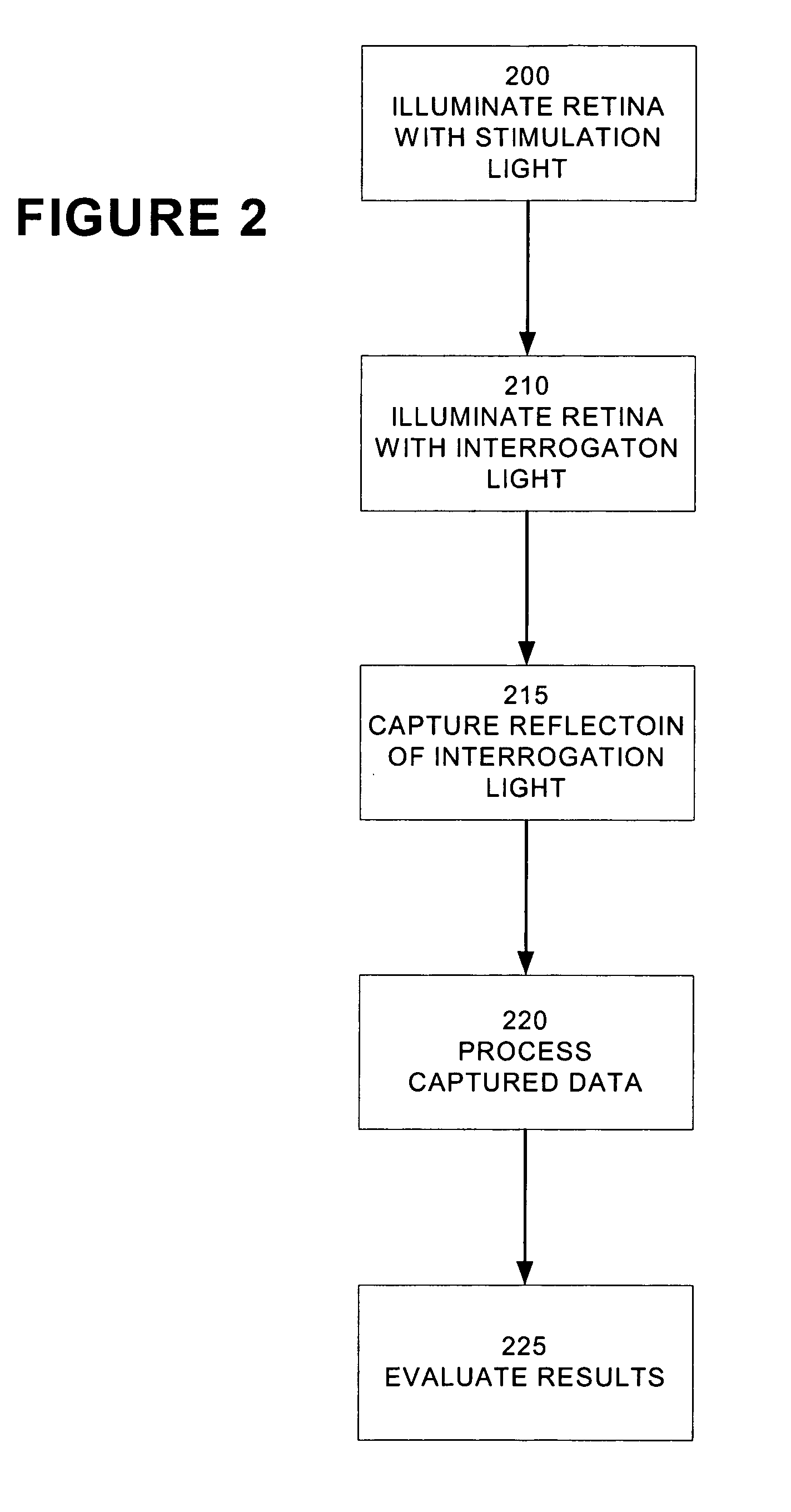

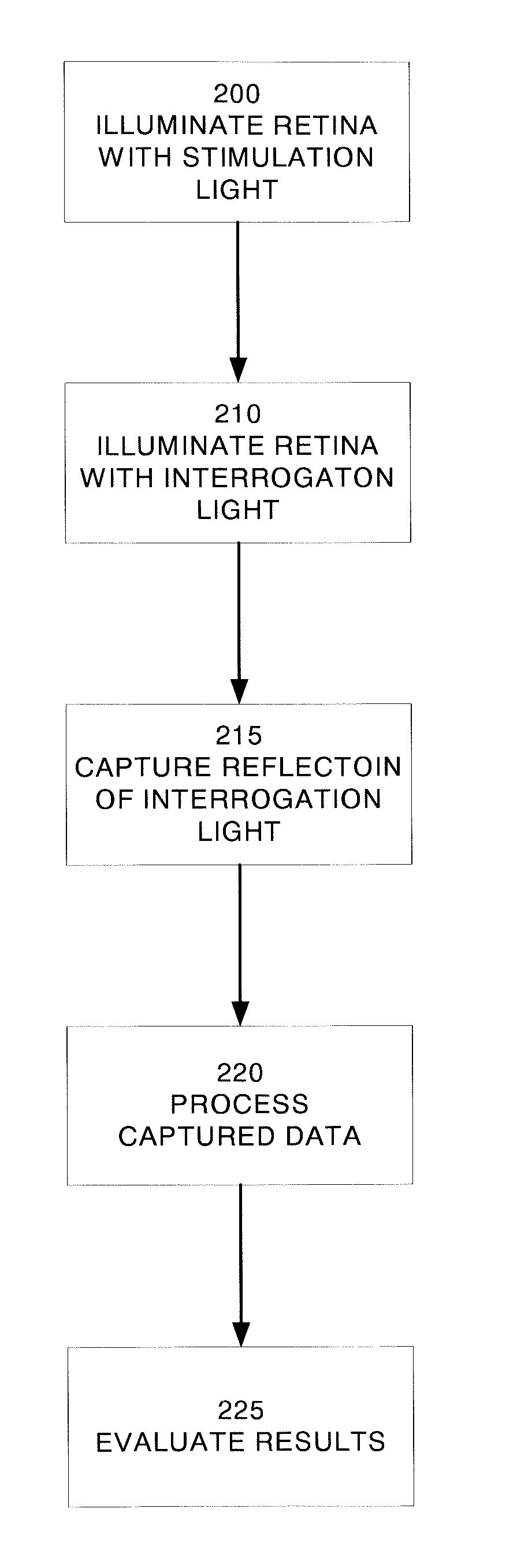

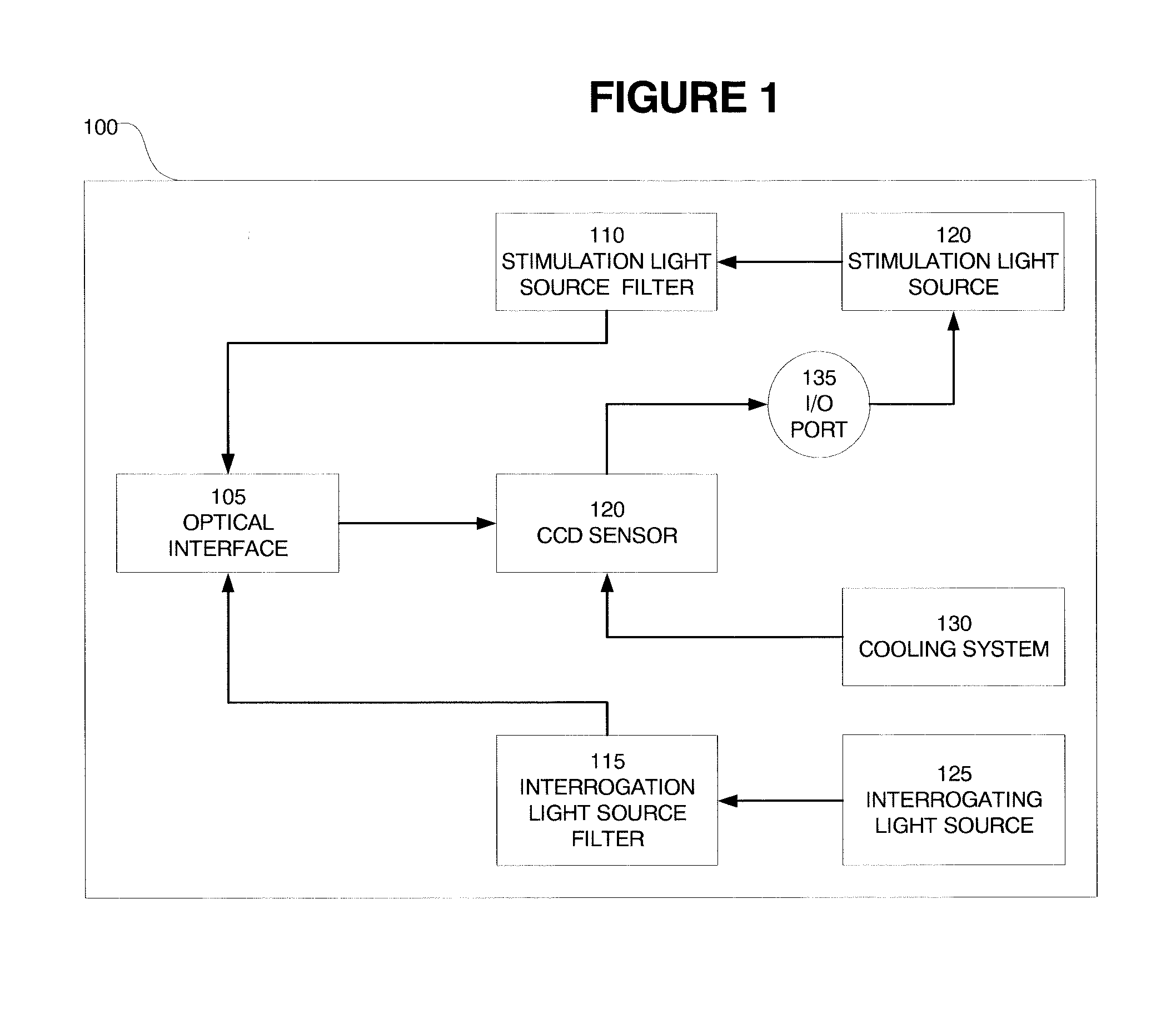

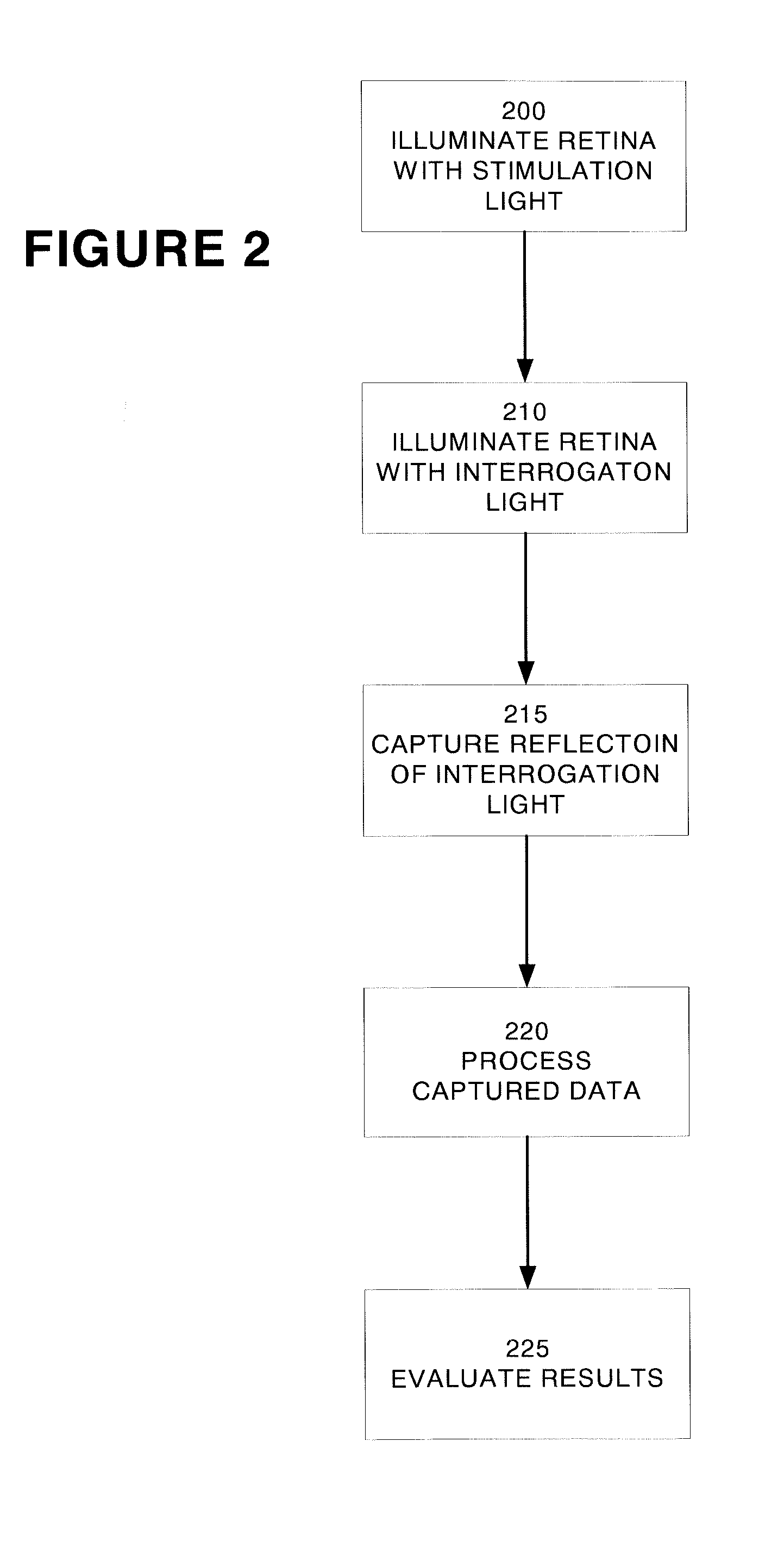

Method for detecting a functional signal in retinal images

InactiveUS7222961B2Cancel noiseUnwanted artifactDiagnostics using lightSensorsSpectral bandsPrincipal component analysis

A system and method for detecting a functional signal in retinal images. An optical imaging device comprises a stimulation light source, an interrogating light source, and a detector. The retina is stimulated by the stimulation light source. The retina is then illuminated by an interrogation light, and the reflected intensity from the retina is measured at an interrogating spectral band that indicates the state of hemoglobin saturation before and after visual stimulation. The optical changes that result from retinal neuronal activity are captured by the detector. The signal representing the state of hemoglobin saturation before and after visual stimulation is isolated. In an embodiment of the present invention, this signal is isolated using principle components analysis (PCA). In another embodiment of the present invention, blind source separation (BSS) and independent component analysis (ICA) algorithms such as extended spatial decorrelation and fast-ICA are used to isolate the functional signal from the retinal videos.

Owner:KESTREL CORP

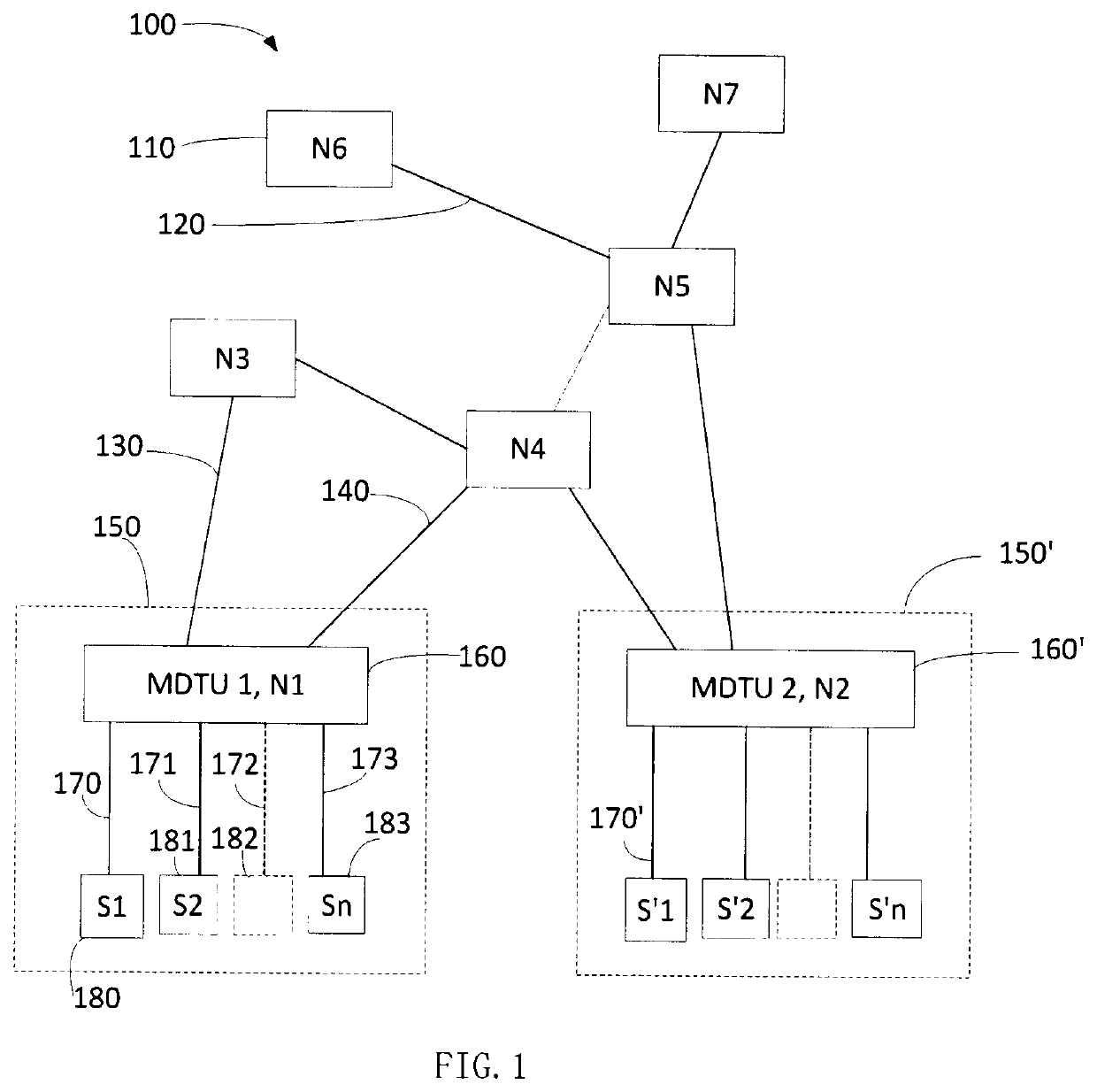

Multimode Heterogeneous IOT Networks

InactiveUS20200145493A1Minimize network induced noiseMaximize signal to noiseKey distribution for secure communicationEncryption apparatus with shift registers/memoriesComputer networkStructure and function

Owner:INNOVATION SCI LLC

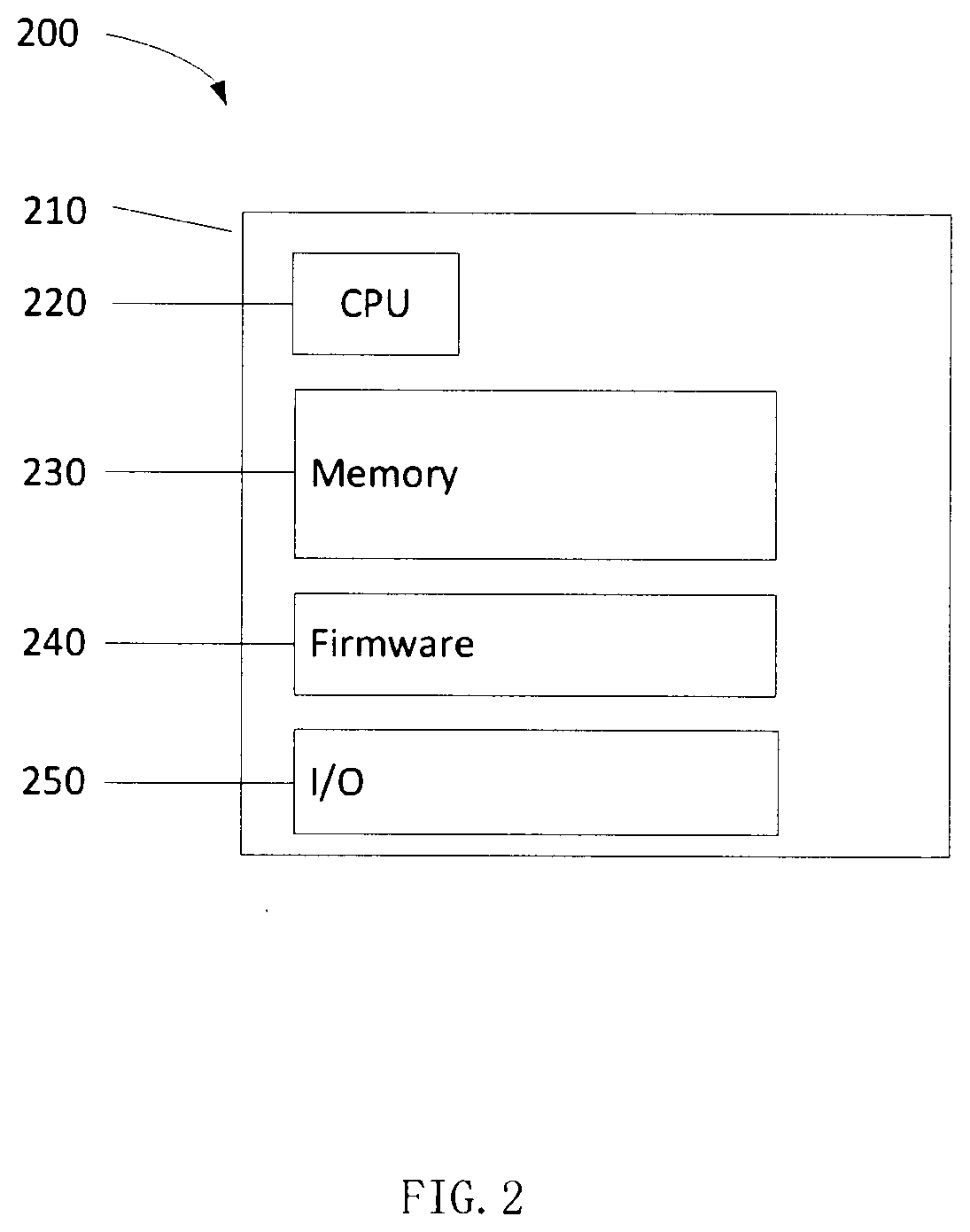

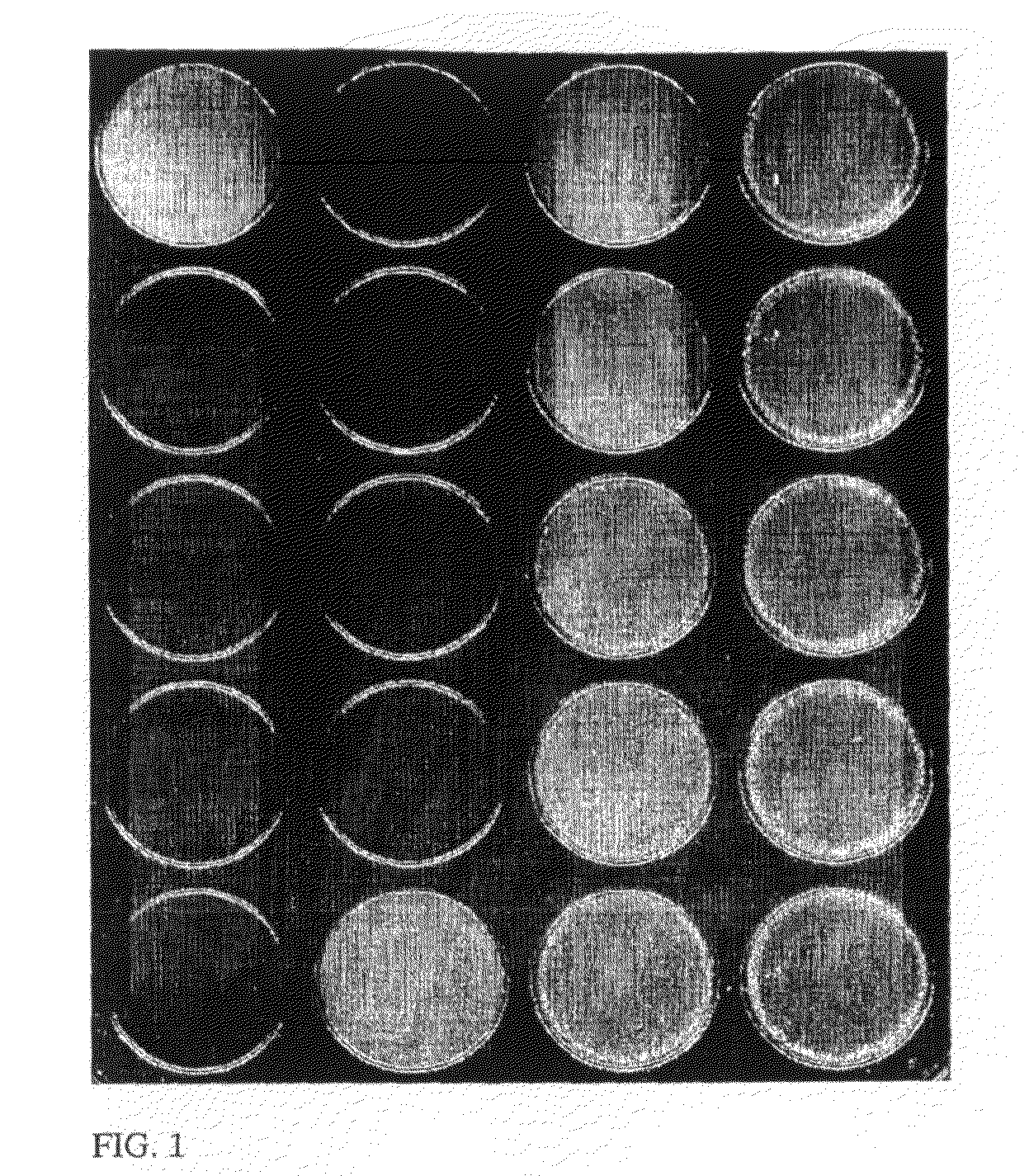

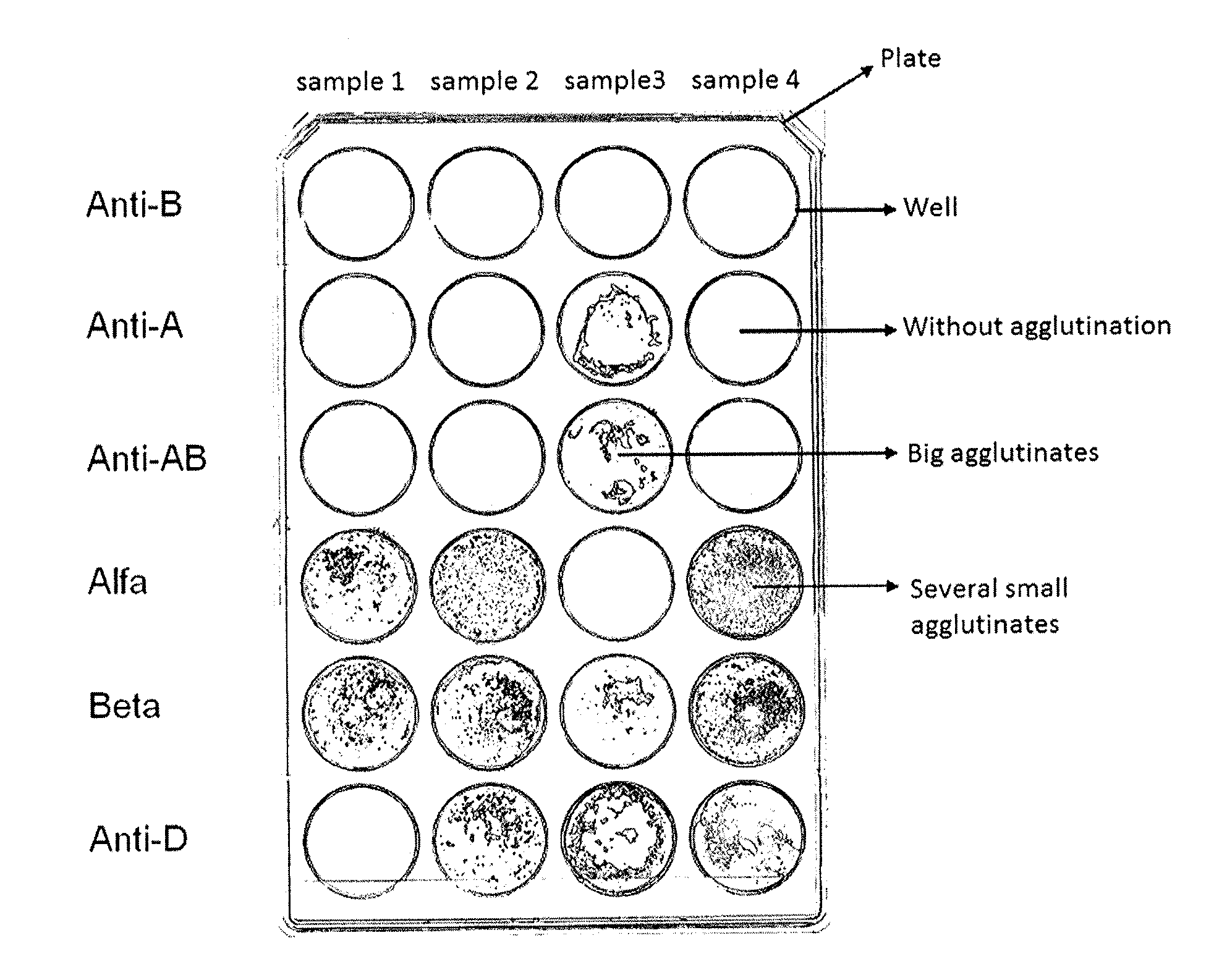

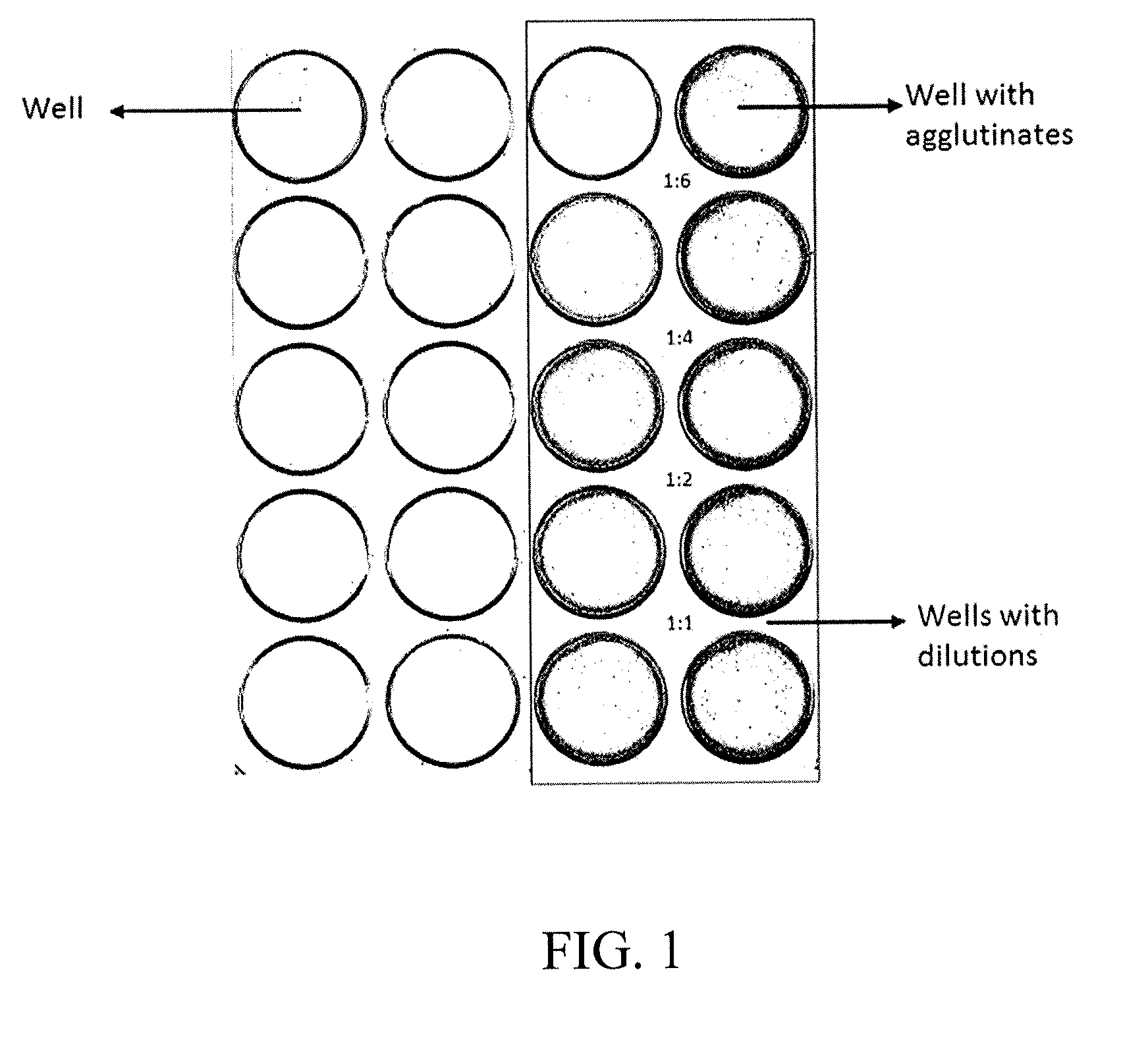

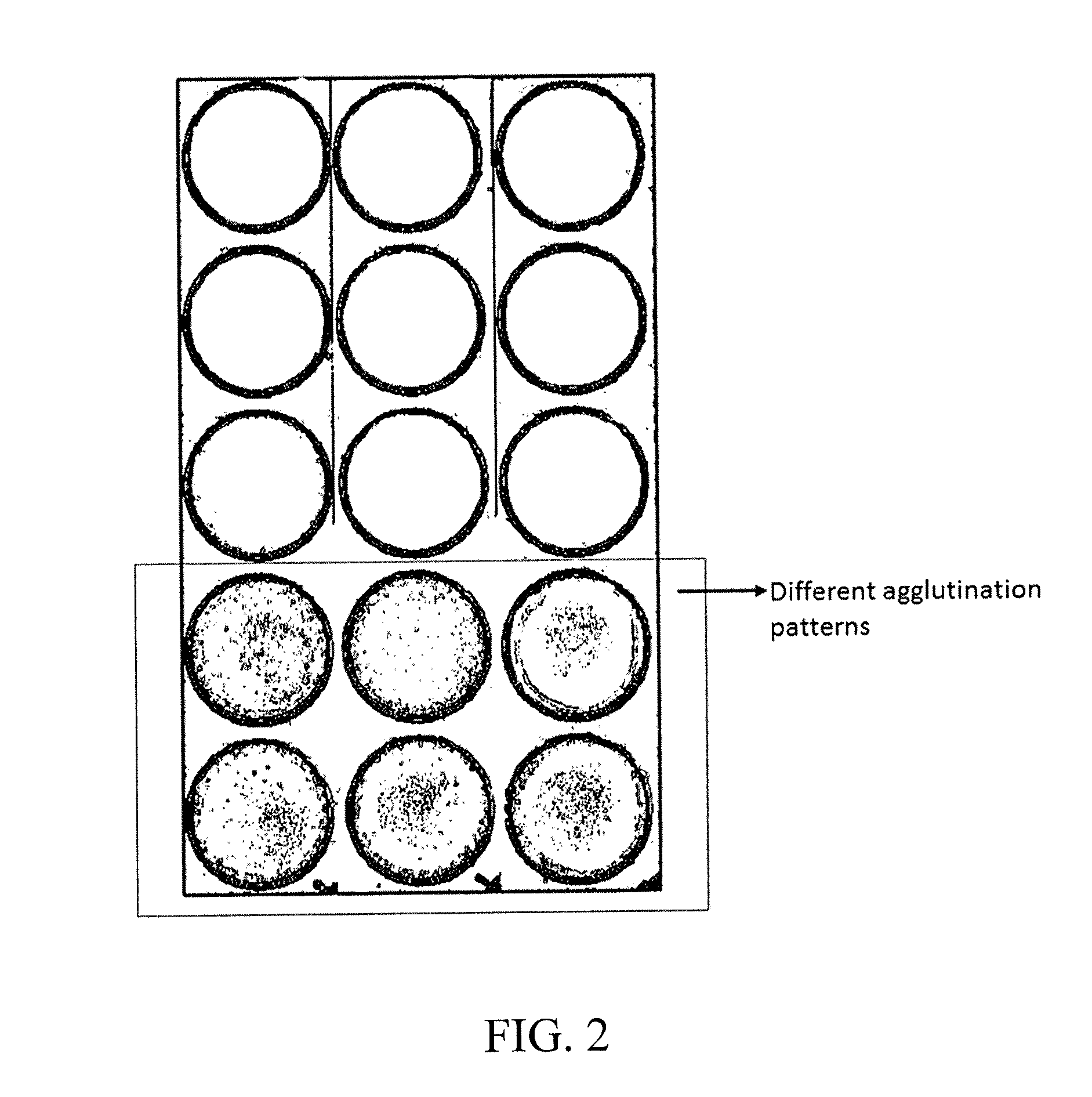

Method for analyzing image data relating to agglutination assays

InactiveUS20090324036A1Maximize signal to noiseEnhances agglutinatesMaterial analysis by observing effect on chemical indicatorCharacter and pattern recognitionPattern recognitionSignal-to-noise ratio (imaging)

A method for acquiring a digital image of an agglutination result comprising performing an agglutination assay on a reaction substrate having a set of dimensions and characteristics which permit a pattern of agglutination in a result of said assay. The image of the result is developed. The image has a colored background which maximizes a signal to noise ratio. Further, the image has been passed through a filter that complements an action of the colored background and enhances the agglutinates in the image while additionally increasing the signal to noise ratio.

Owner:LAB CELSIUS

Sample and hold apparatus

ActiveUS20060164279A1Effectively signal voltageMaximize signal to noise ratioElectric signal transmission systemsElectric analogue storesEngineeringCapacitor

An acquisition and averaging circuit is provided in which, during a sampling phase capacitors in sample blocks 4 and 6 are sequentially connected to the input signal to sample it and are then isolated so as to hold the sample. The capacitors are then connected to a combining / averaging arrangement such that an average of the sample values is formed.

Owner:ANALOG DEVICES INC

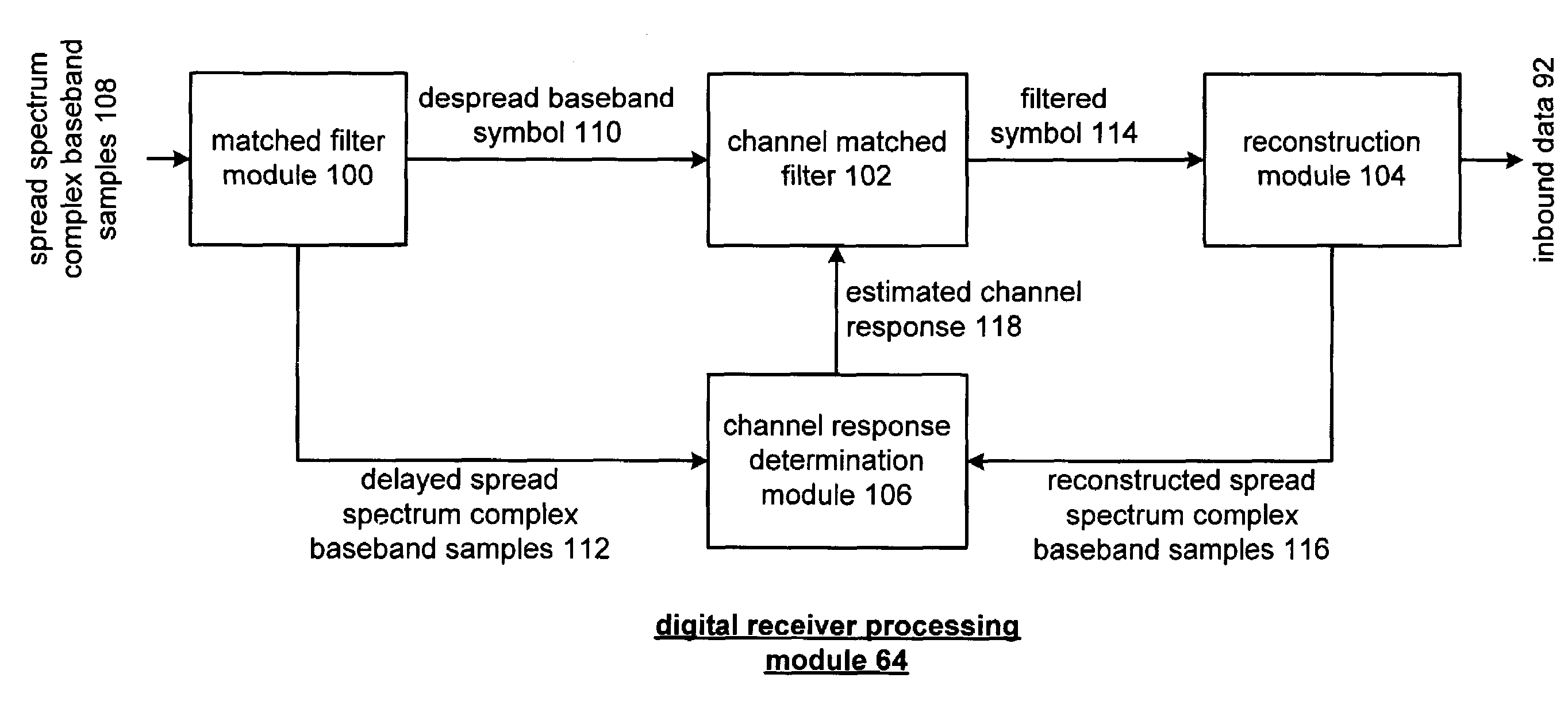

Channel estimation in a spread spectrum receiver

InactiveUS7301993B2Accurately determineMaximize signal to noiseBaseband system detailsSpread spectrumBaseband

A method and apparatus for channel estimation in a spread spectrum receiver include processing that begins by despreading a received spread spectrum complex baseband sample utilizing a pseudorandom spreading sequence to produce a despread baseband symbol. The processing continues by filtering the despread baseband symbol to attenuate adverse channel effects based on a channel response estimate to produce a filtered despread baseband symbol. The processing then continues by decoding the filtered despread baseband symbol to produce recaptured data. The processing continues by modulating the recaptured data to produce a remodulated symbol. The processing then continues by producing a reconstructed spread spectrum complex baseband sample from the remodulated symbol based on the pseudorandom spreading sequence. The processing then continues by generating the channel response estimate such that a convolution of the channel response estimate with the reconstructed spread spectrum complex baseband sample substantially emulates the received spread spectrum complex baseband sample.

Owner:AVAGO TECH WIRELESS IP SINGAPORE PTE

Borehole compensation system and method for a resistivity logging tool

InactiveUS20050046424A1Increase ratingsMaximize signal to noise ratioElectric/magnetic detection for well-loggingSeismology for water-loggingUltrasound attenuationDrill hole

System and method for borehole compensation. The method includes simultaneously transmitting at least two modulated signals from one or more transmitters; receiving the at least two modulated signals by at least one receiver; and processing the received at least two modulated signals to determine a phase difference and an amplitude attenuation of the transmitted modulated signals, the processing providing borehole compensated data.

Owner:WEATHERFORD TECH HLDG LLC

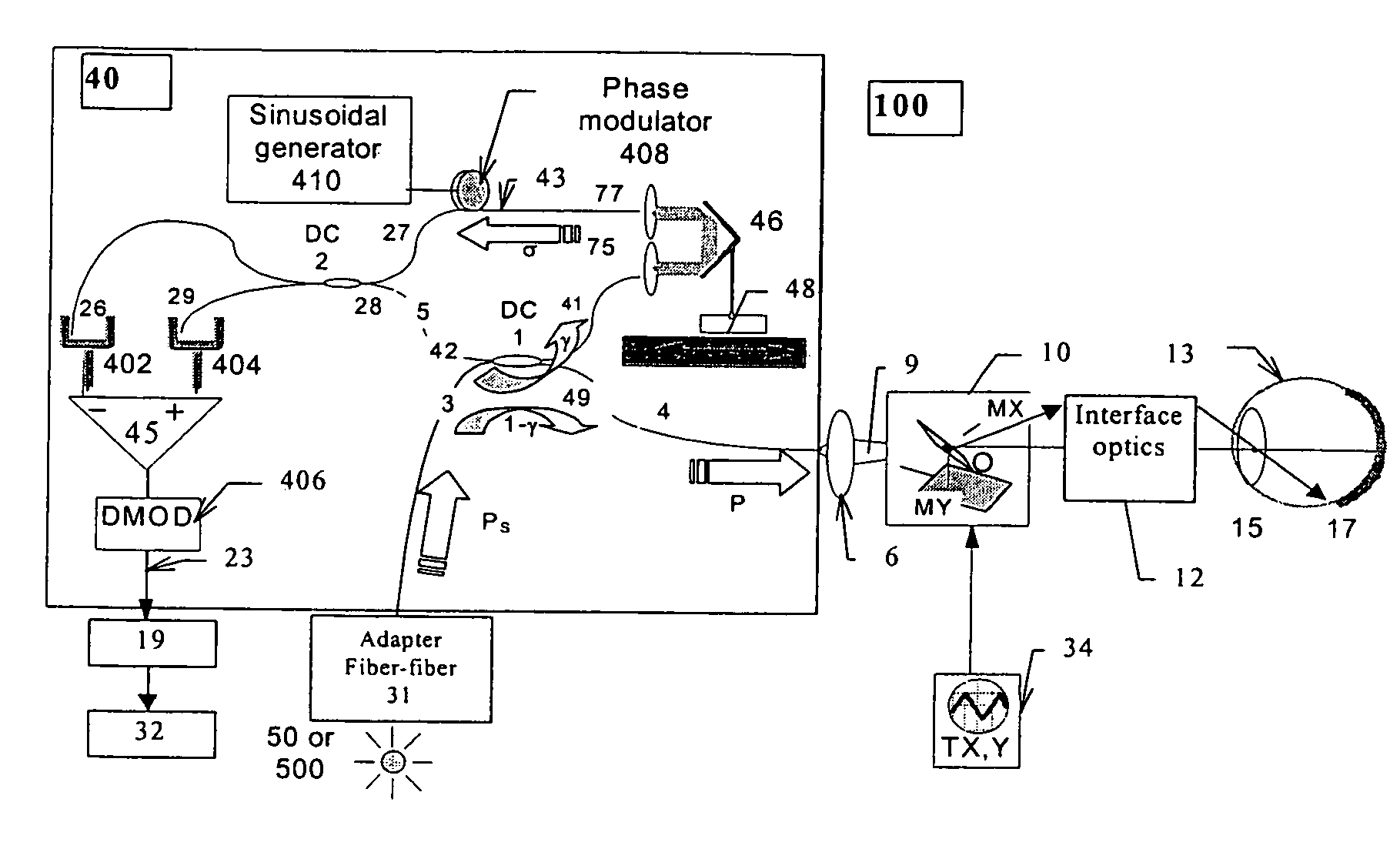

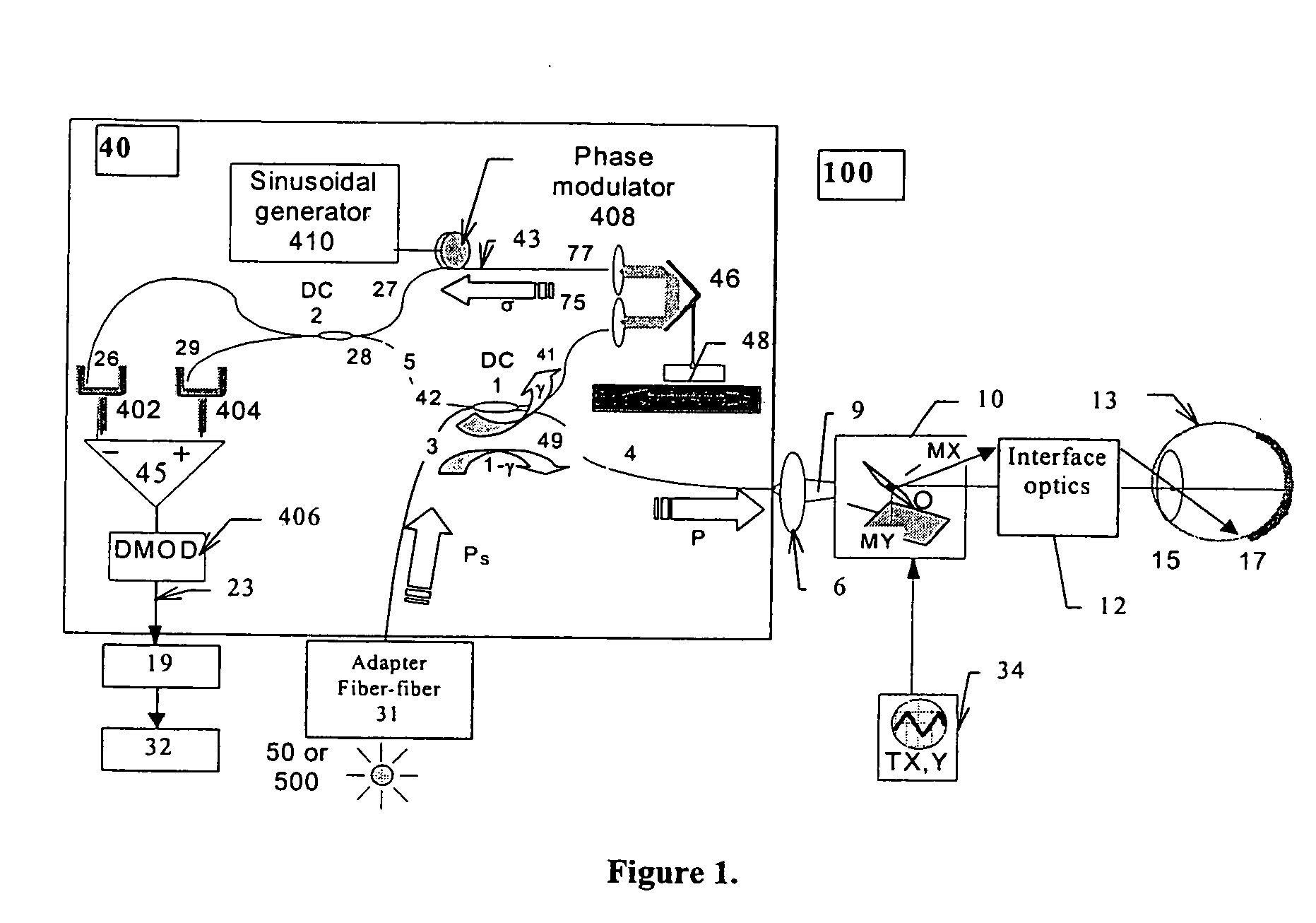

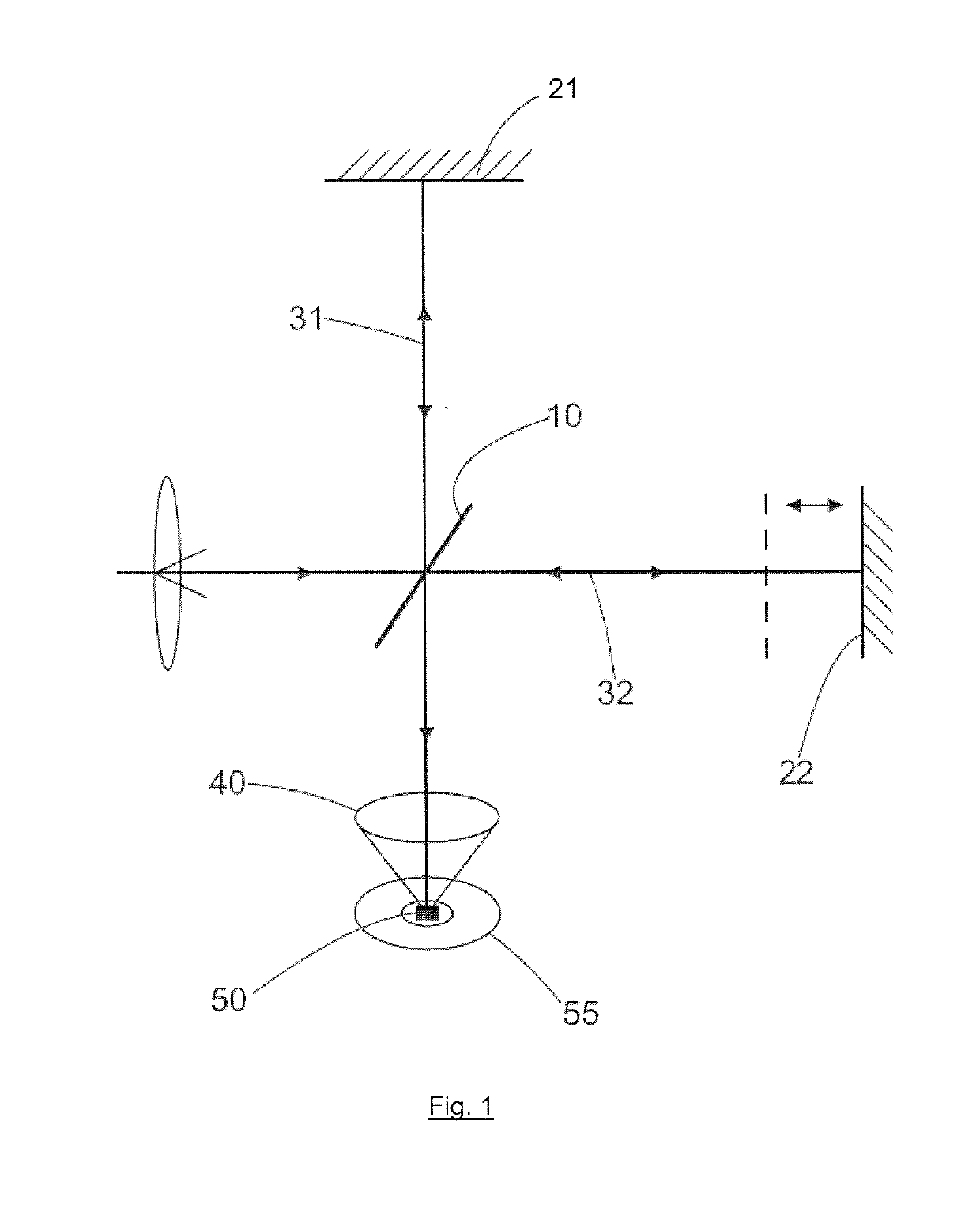

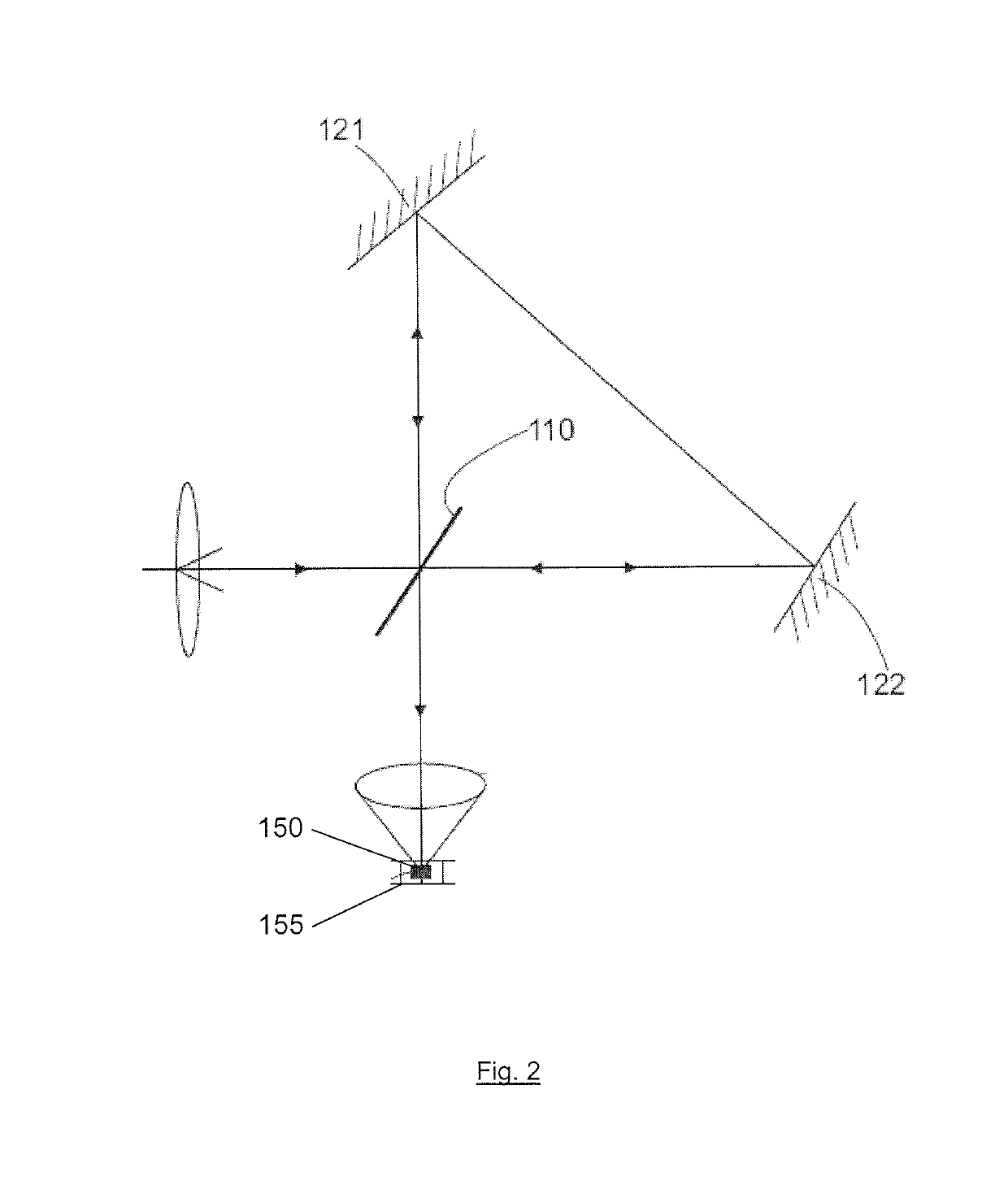

Optical mapping apparatus with optimized OCT configuration

InactiveUS20050264820A1Maximize signal to noiseReduce the required powerInterferometersScattering properties measurementsFace scanningBeam splitter

OCT apparatus includes an interferometer, having an input beam splitter and a 50 / 50 output splitter. The splitting ratio of the input splitter may be optimized depending on the source power of light source and on the mismatch of the balanced receiver. The input splitter is a plate beam-splitter to minimize the stray reflected light in the interferometer and allow sequential operation of the apparatus in the OCT or in the confocal regime. The switching between the two regimes may be at will, or synchronous with the en-face scanning which results in quasi-simultaneous OCT / confocal imaging or in alternatives frames, confocal and OCT. By using polarization sensitive elements, two channels are provided in each regime, OCT and confocal. The two confocal polarization sensitive channels may allow adjustments of compensators prior to OCT measurements or OCT imaging.

Owner:OPTOS PLC

Method for detecting a functional signal in retinal images

InactiveUS20070211211A1Maximize signal to noiseDifference in absorptionDiagnostics using lightSensorsSpectral bandsOphthalmology

A system and method for detecting a functional signal in retinal images. An optical imaging device comprises a stimulation light source, an interrogating light source, and a detector. The retina is stimulated by the stimulation light source. The retina is then illuminated by an interrogation light, and the reflected intensity from the retina is measured at an interrogating spectral band that indicates the state of hemoglobin saturation before and after visual stimulation. The optical changes that result from retinal neuronal activity are captured by the detector. The signal representing the state of hemoglobin saturation before and after visual stimulation is isolated. In an embodiment of the present invention, this signal is isolated using principle components analysis (PCA). In another embodiment of the present invention, blind source separation (BSS) and independent component analysis (ICA) algorithms such as extended spatial decorrelation and fast-ICA are used to isolate the functional signal from the retinal videos.

Owner:KESTREL CORP

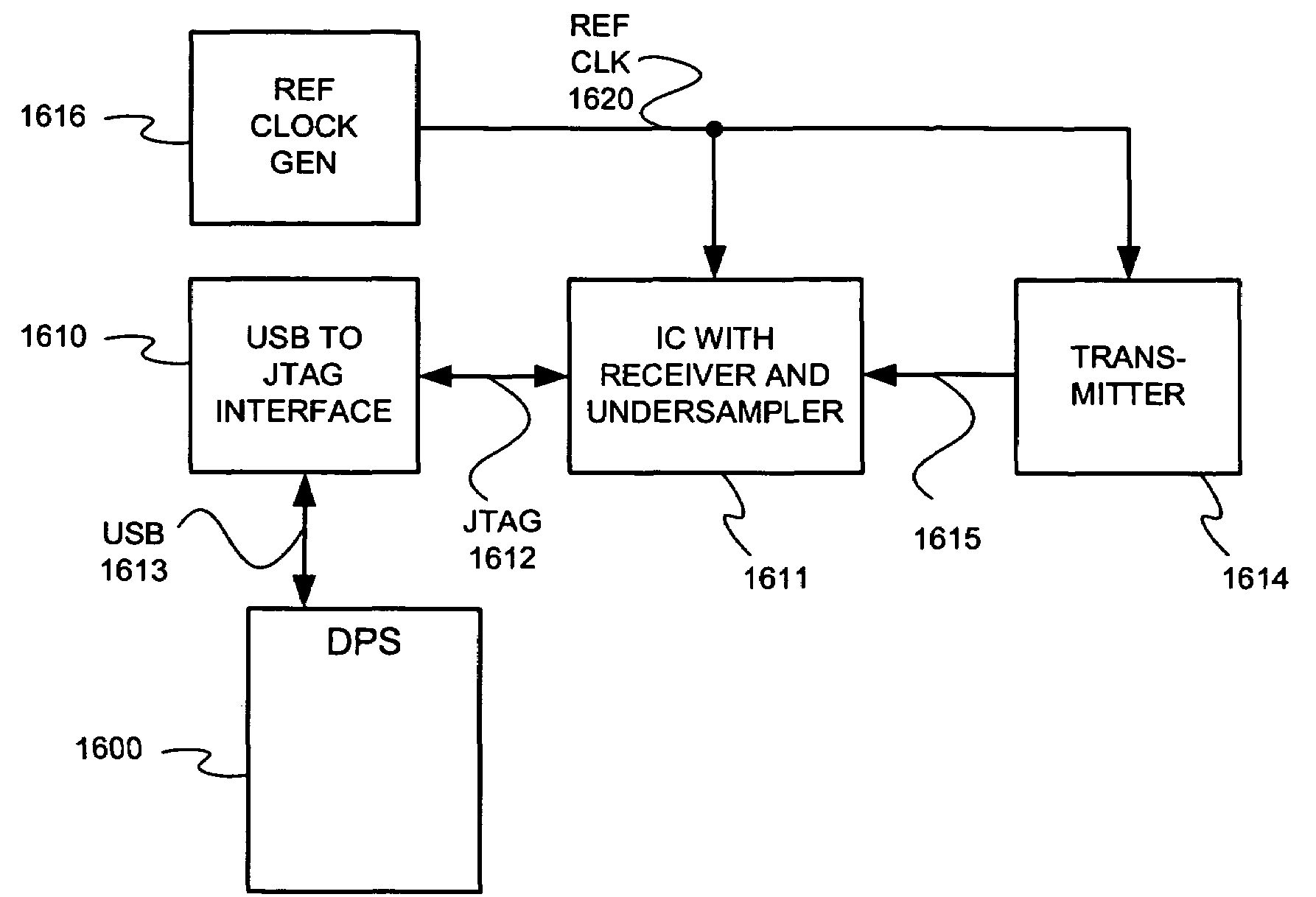

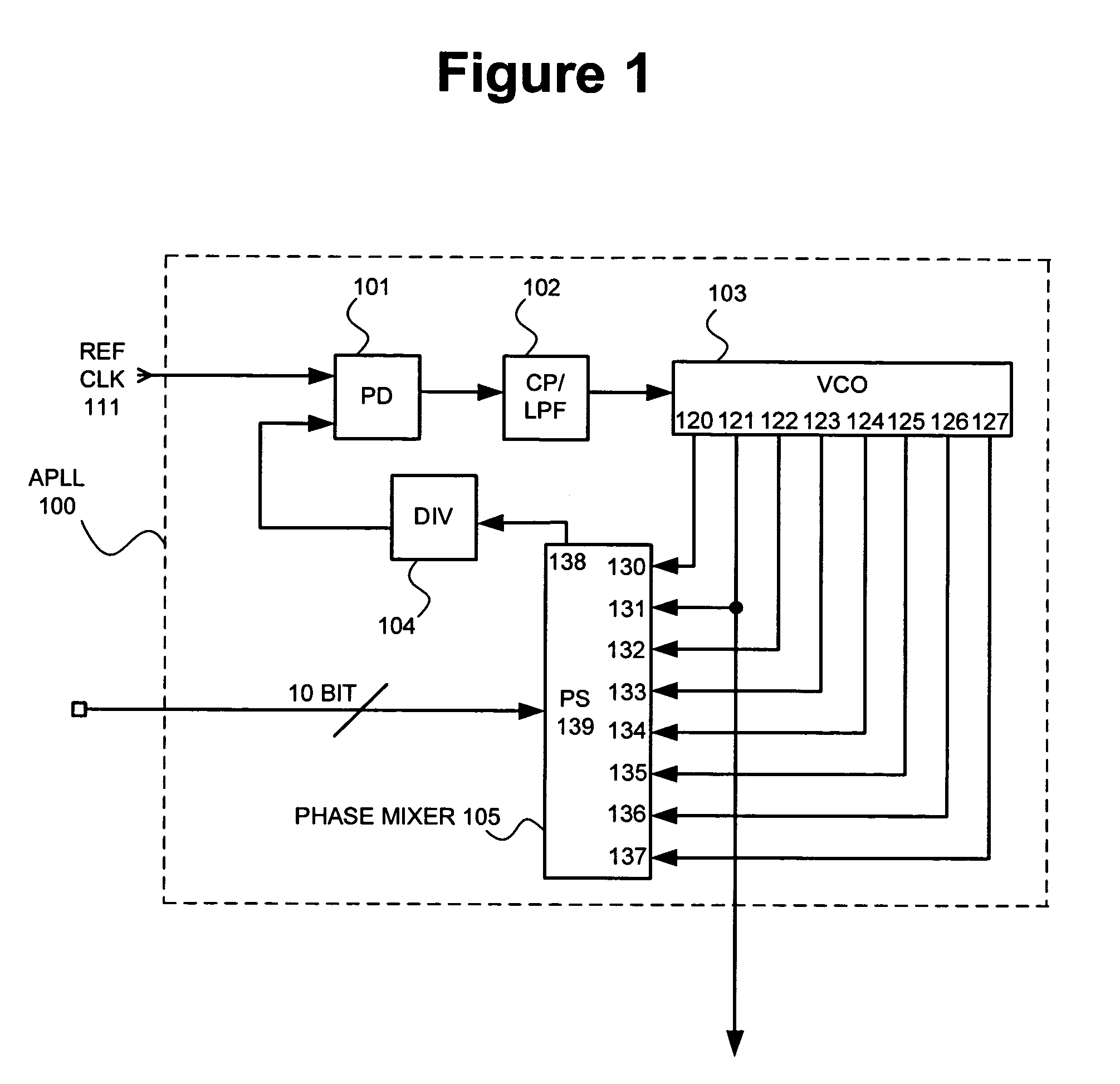

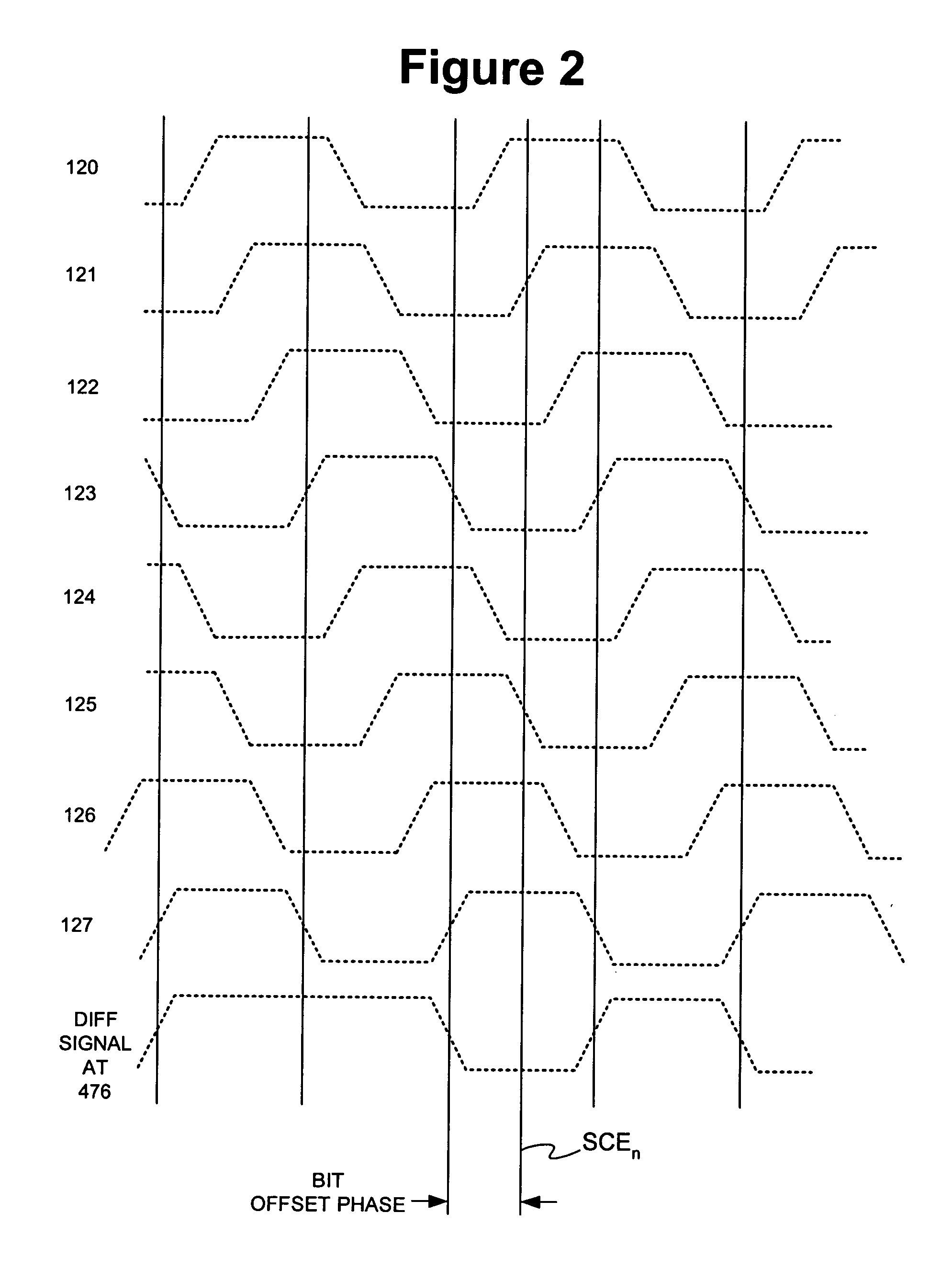

Method and apparatus for integrated channel characterization

ActiveUS7382825B1Maximizes minimum powerMaximize signal to noiseTransmission monitoringLine-transmission monitoring/testingSignal-to-noise ratio (imaging)Engineering

A periodic broadband signal can be used to determine the S21 measurement for a channel by stimulating the channel across a spectrum of interest. The channel response to such broadband signal can be measured from undersampled data captured at the receiver. The Fourier transform of the broadband signal as received, divided by the Fourier transform of broadband signal as transmitted, constitutes the S21. A physically contiguous IC can integrate both a receiver circuit, at which S21 is to be measured, along with an undersampler for sampling the received broadband signal. To maximize signal to noise, a pattern for the broadband signal can be selected to maximize the minimum power across the spectrum of interest. A pattern generator for the broadband signal can be integrated on the same physically contiguous IC with a multiplexer that can select either the pattern generator, or a typical source of data, for transmission into the channel.

Owner:SYNOPSYS INC

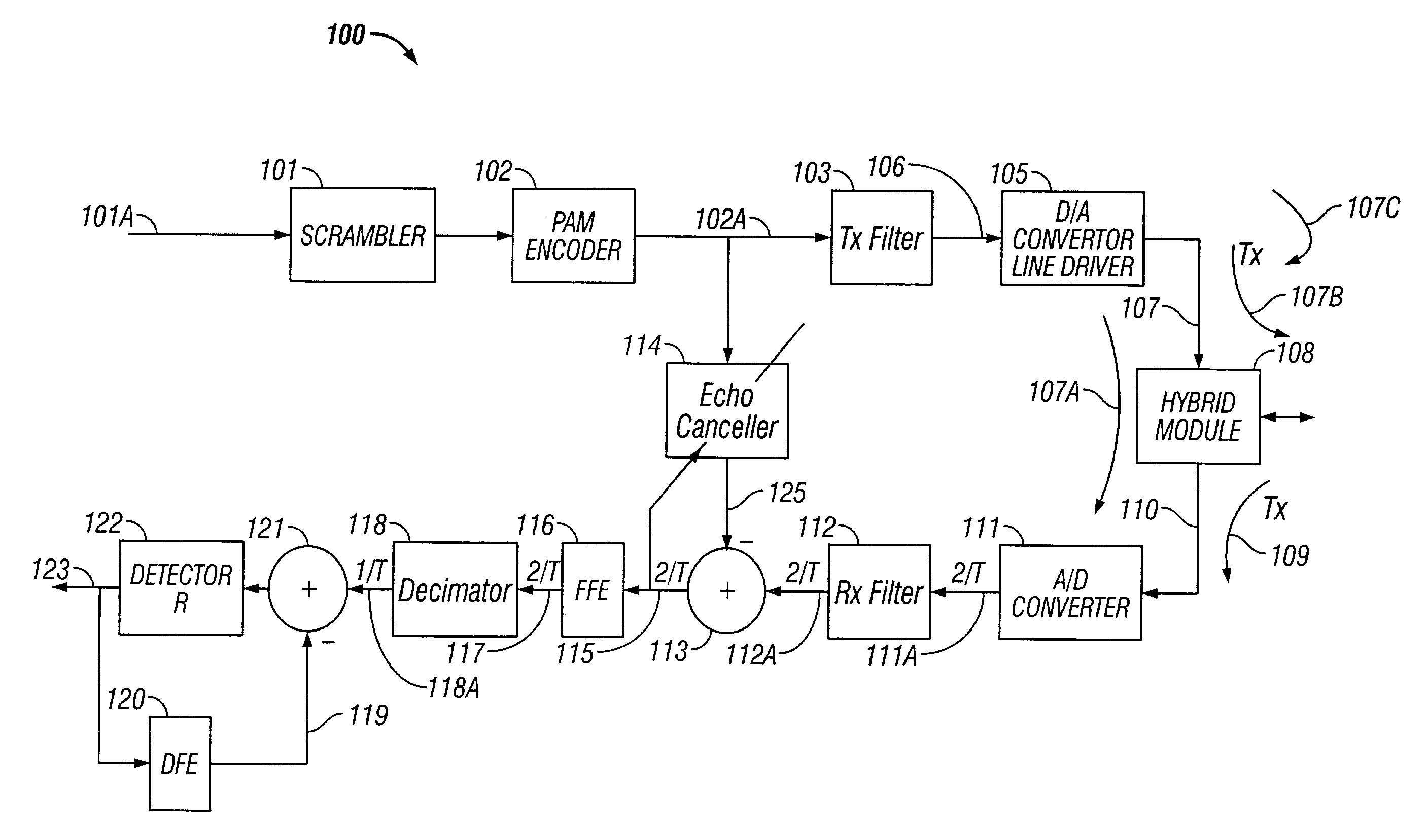

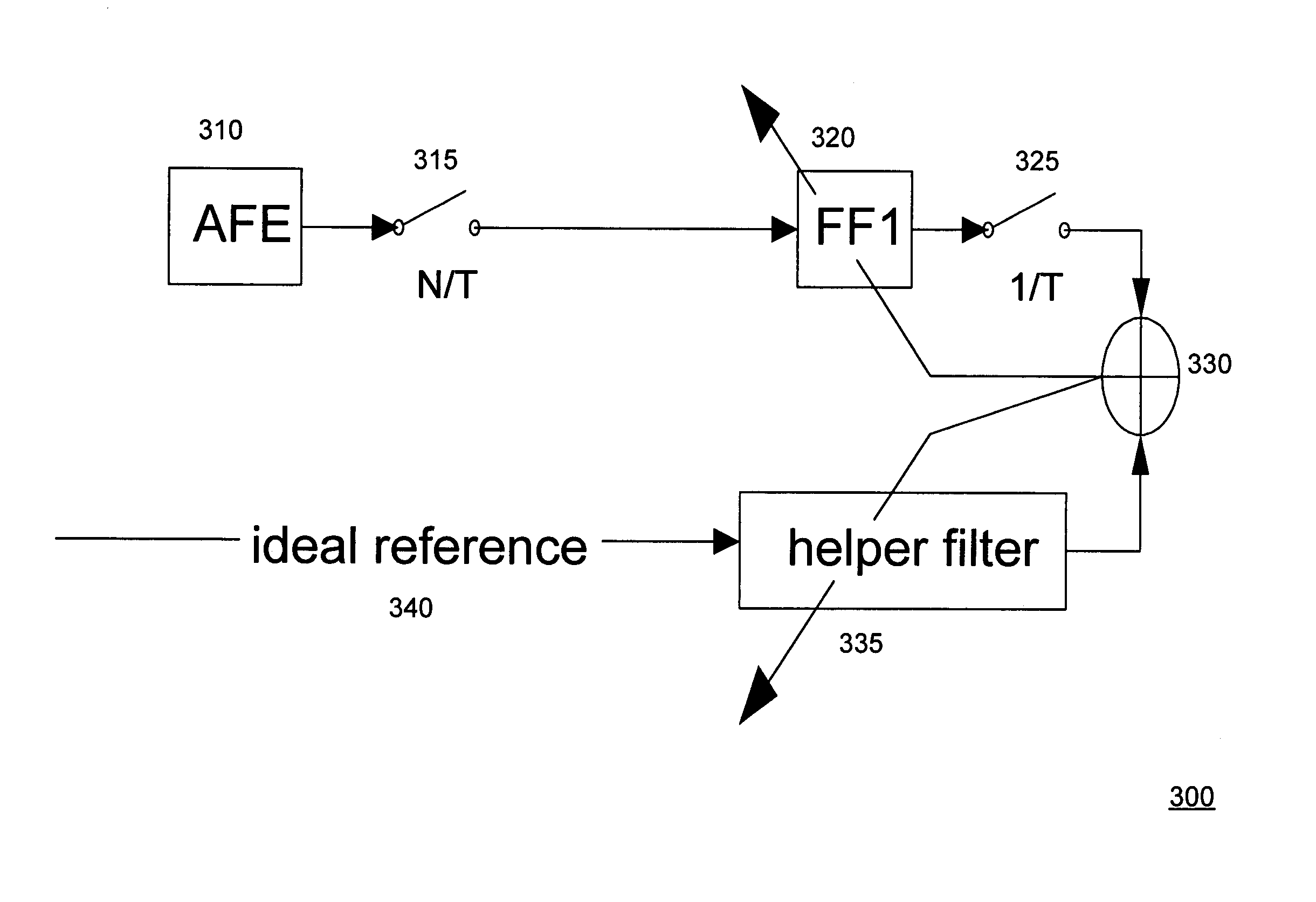

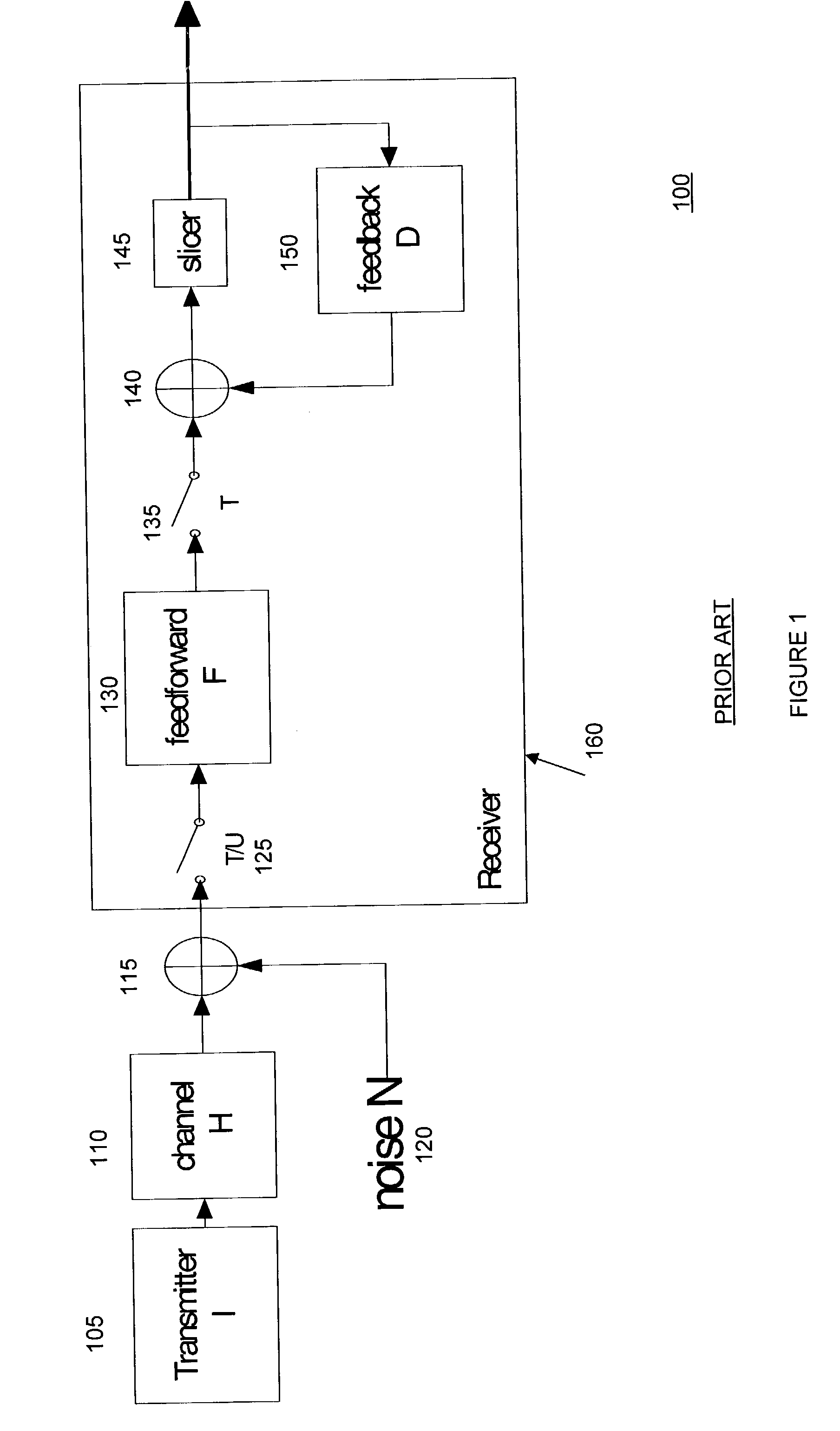

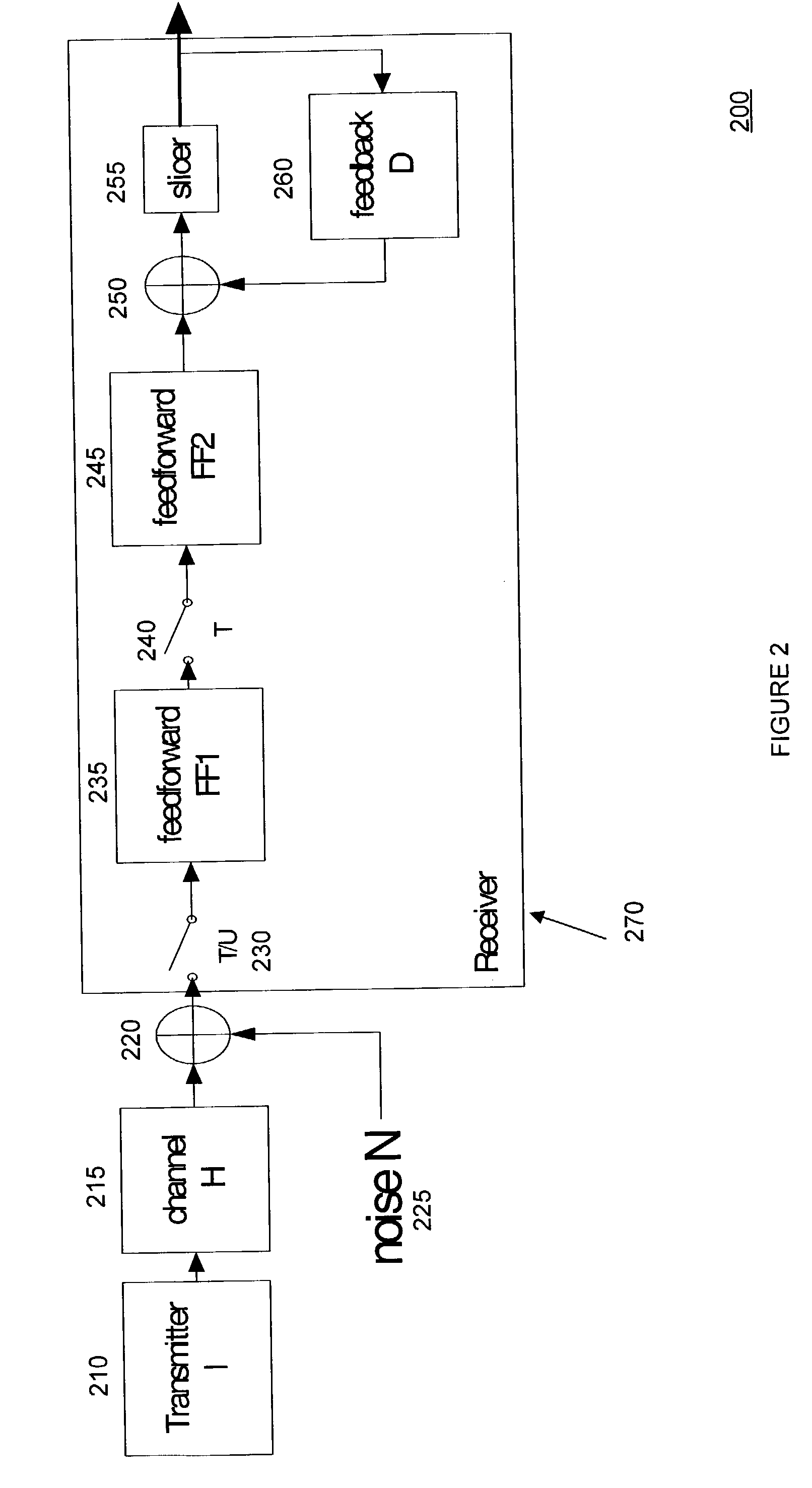

Combined feedforward filter for a decision feedback equalizer

ActiveUS7031414B2Reduce Intersymbol InterferenceReduce in quantityMultiple-port networksTelevision system detailsCommunications systemSignal-to-noise ratio (imaging)

A method and apparatus for mitigating for inter-symbol interference in a communication system using a multi-rate adaptive decision feedback equalizer (DFE) with a feedforward filter which is a combination of a first feedforward filter (FF1) that performs match filtering and a second feedforward filter (FF2) which runs at a lower sampling rate than first feedforward filter (FF1), thereby, reducing the total the number of computation done at the receiver, and removes ISI and white noise.The present invention also employs a method and apparatus where the initial training is done separately for the first feedforward filter (FF1) and the second feedforward filter (FF2). An approximate solution of the optimal receiver has the first feedforward filter (FF1) maximize the output signal to noise ratio (SNR) which is used to train first feedforward filter (FF1).

Owner:SYNAPTICS INC

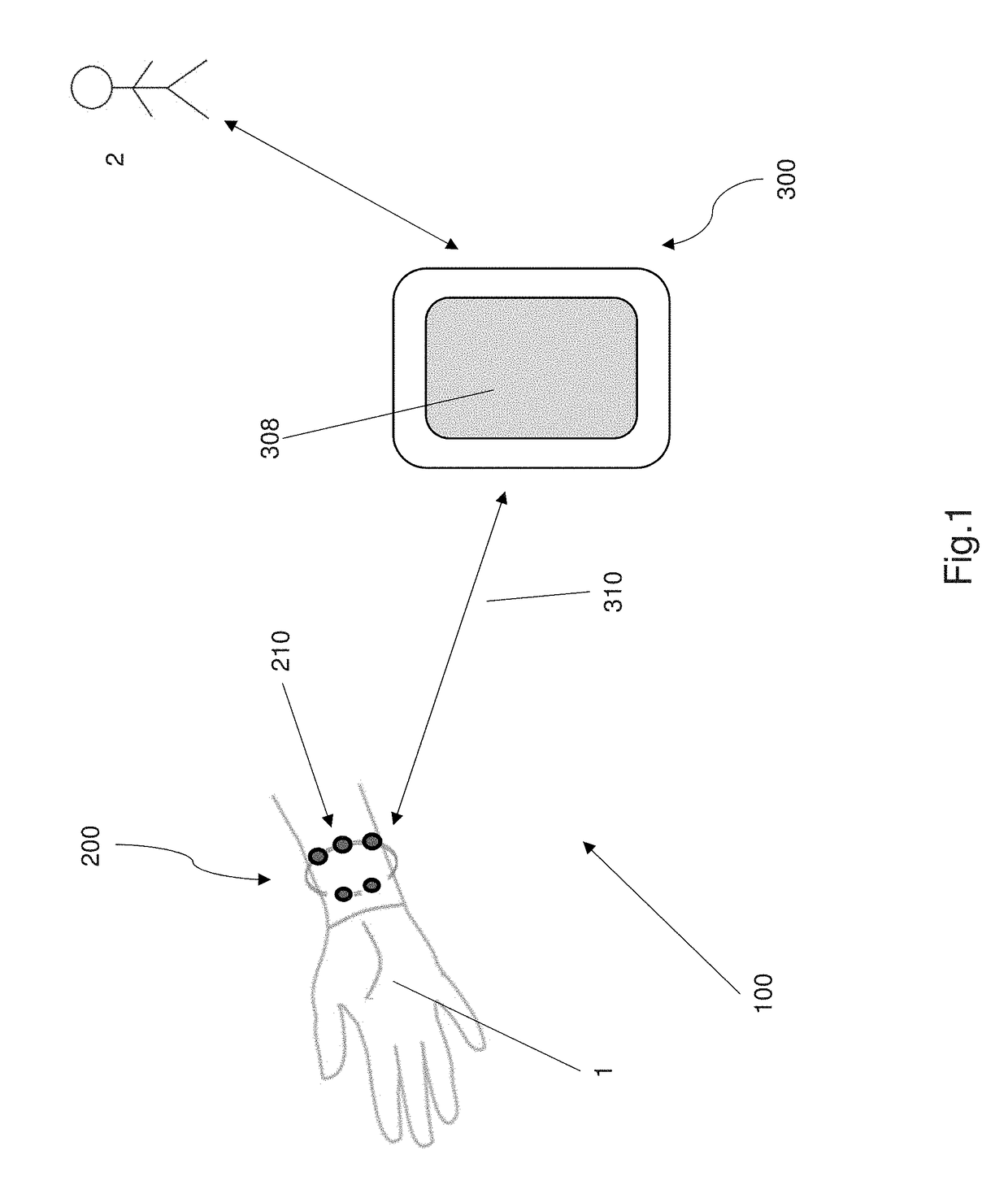

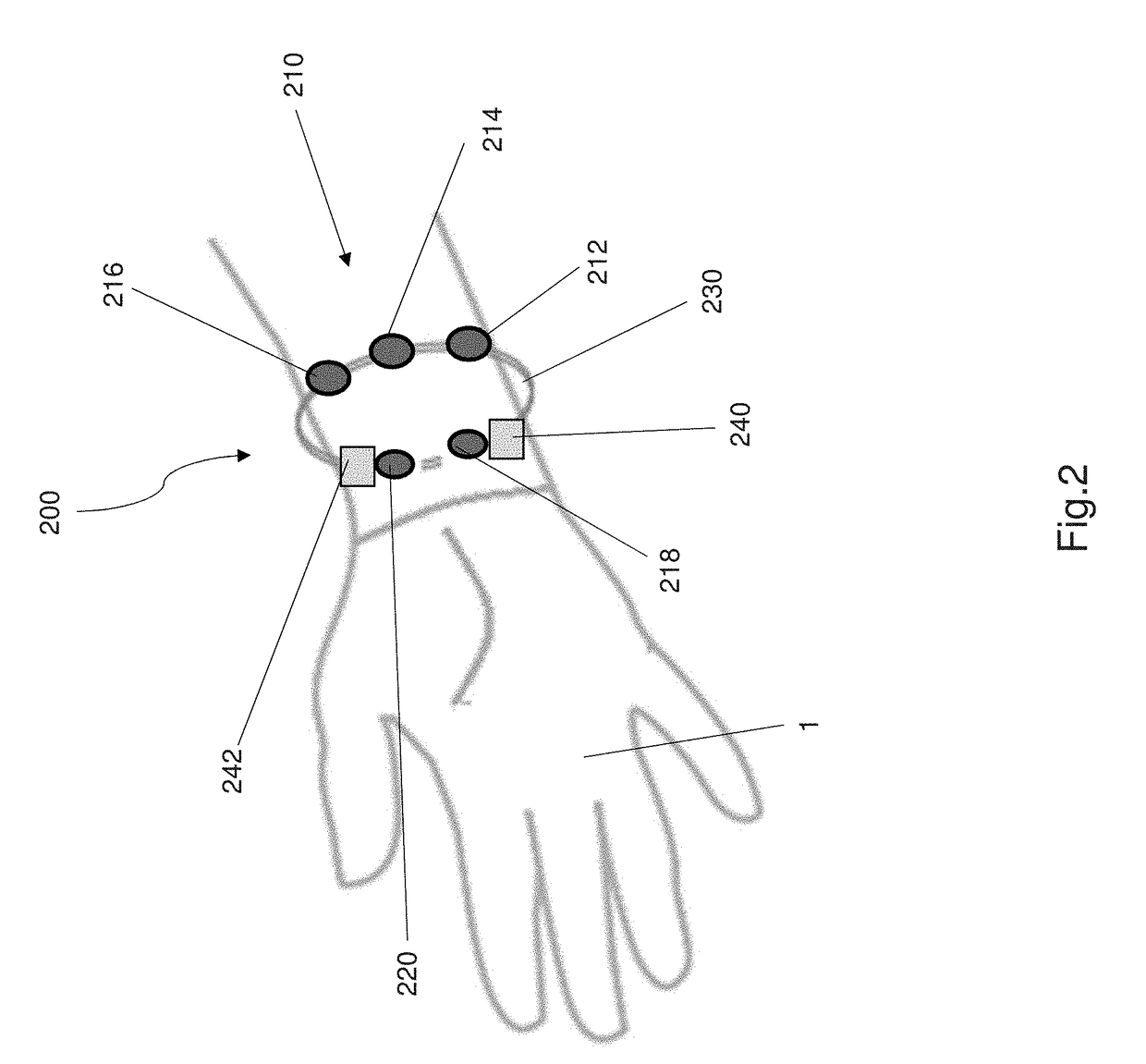

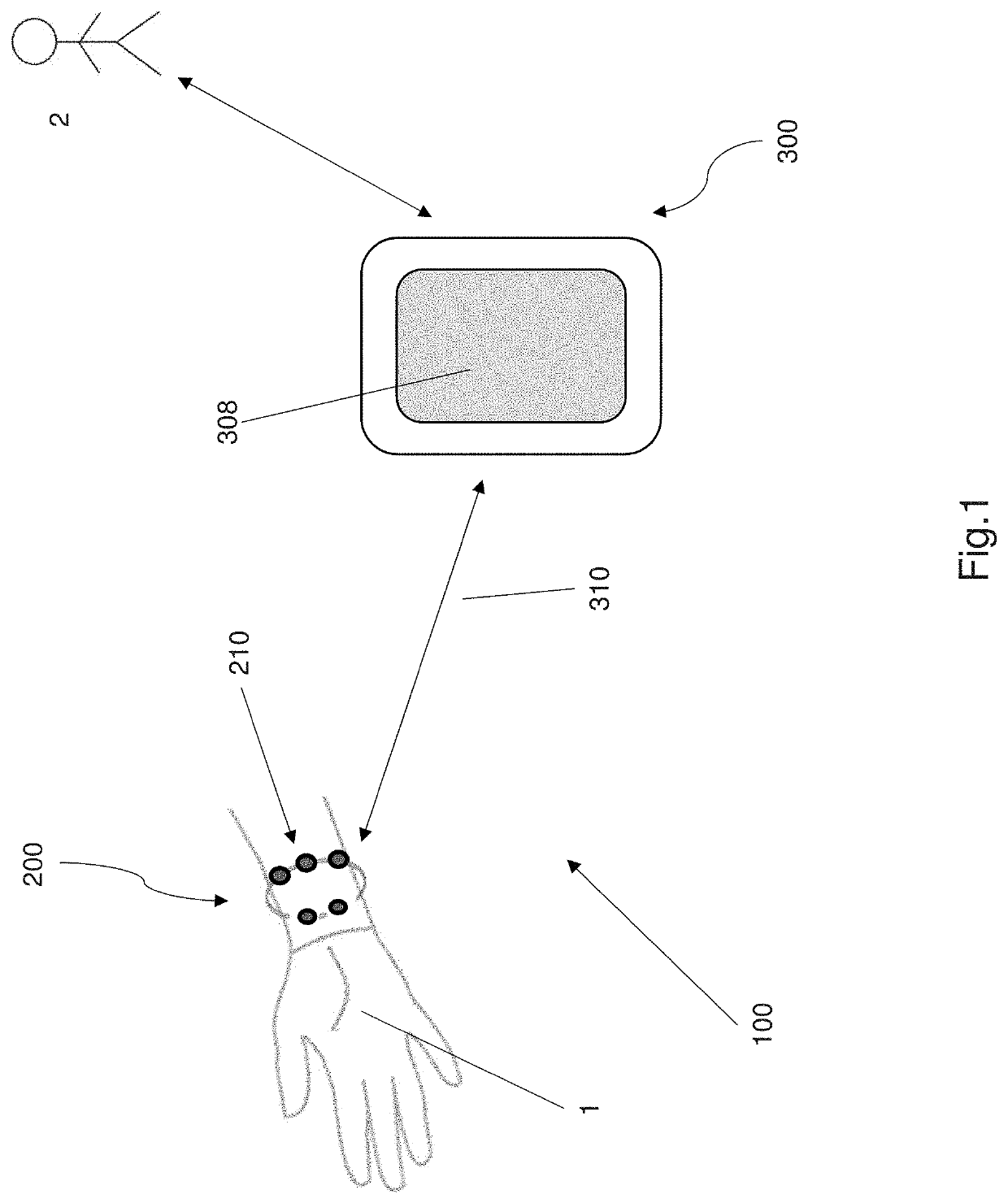

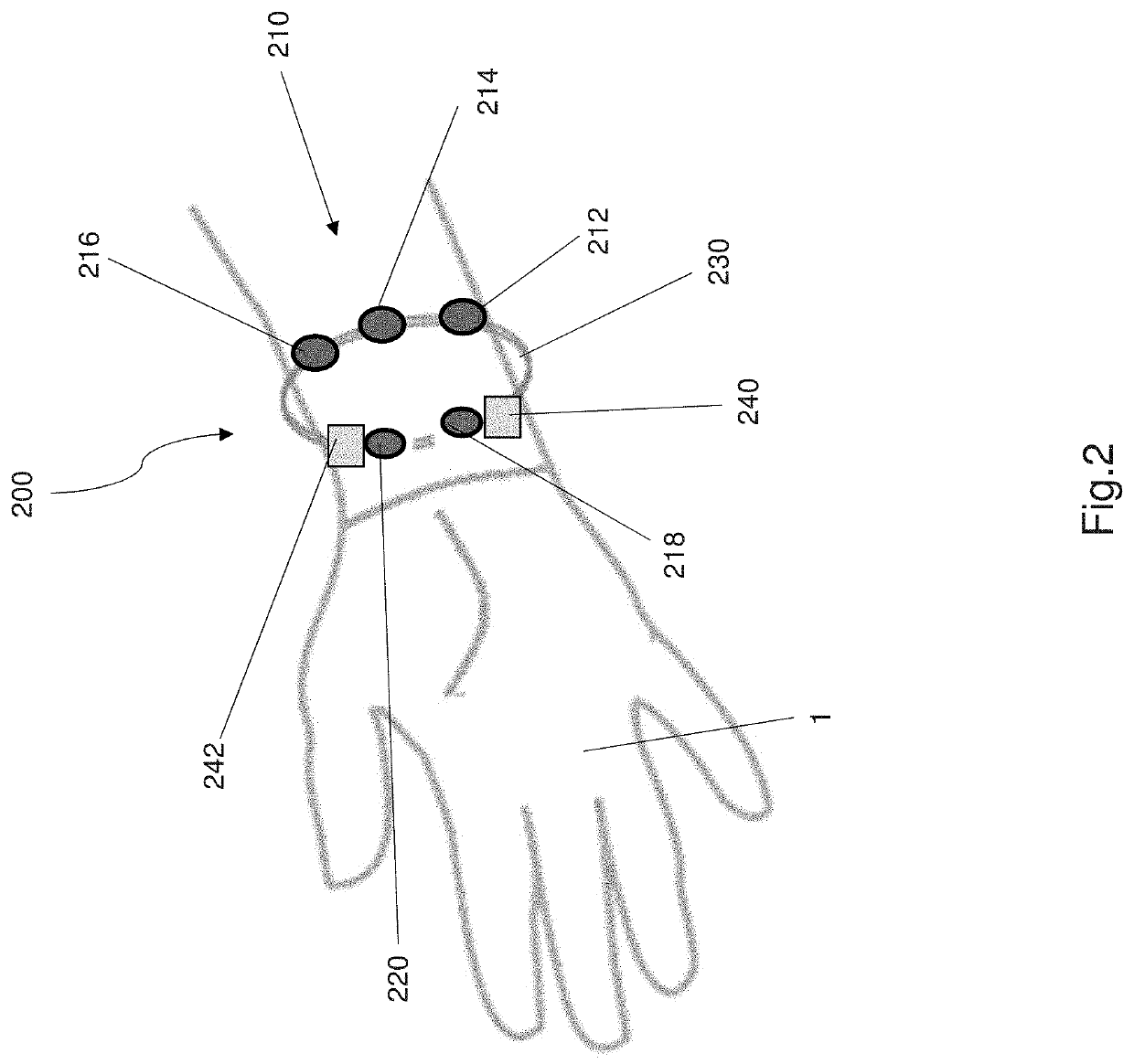

Gesture recognition apparatus and components thereof

ActiveUS20180348877A1Improve disadvantagesMaximize signal to noiseInput/output for user-computer interactionPiezoelectric/electrostrictive microphonesHuman–computer interactionGesture recognition

A gesture recognition apparatus includes a sensor unit configured to be worn by a user on a user's body part. The sensor unit includes one or more sensors, a processor unit, the processor unit and the sensor unit are arranged in communication with each other, the processor unit receiving acoustic data from the one or more sensors, wherein the acoustic data corresponds to a gesture performed by a user, and the processor unit is configured to process the acoustic data received from the one or more sensors to determine a gesture performed by the user.

Owner:CITY UNIVERSITY OF HONG KONG

Amplified photoconductive gate

InactiveUS6936821B2Lower impedanceMinimal RC time constantSolid masersSolid-state devicesAudio power amplifierSemiconductor

The present invention includes a semiconductor epitaxial structure optimized for photoconductive free space terahertz generation and detection; and amplifier circuits for photoconductively sampled terahertz detection which may employ the optimized epitaxial structures.

Owner:LUNA INNOVATIONS

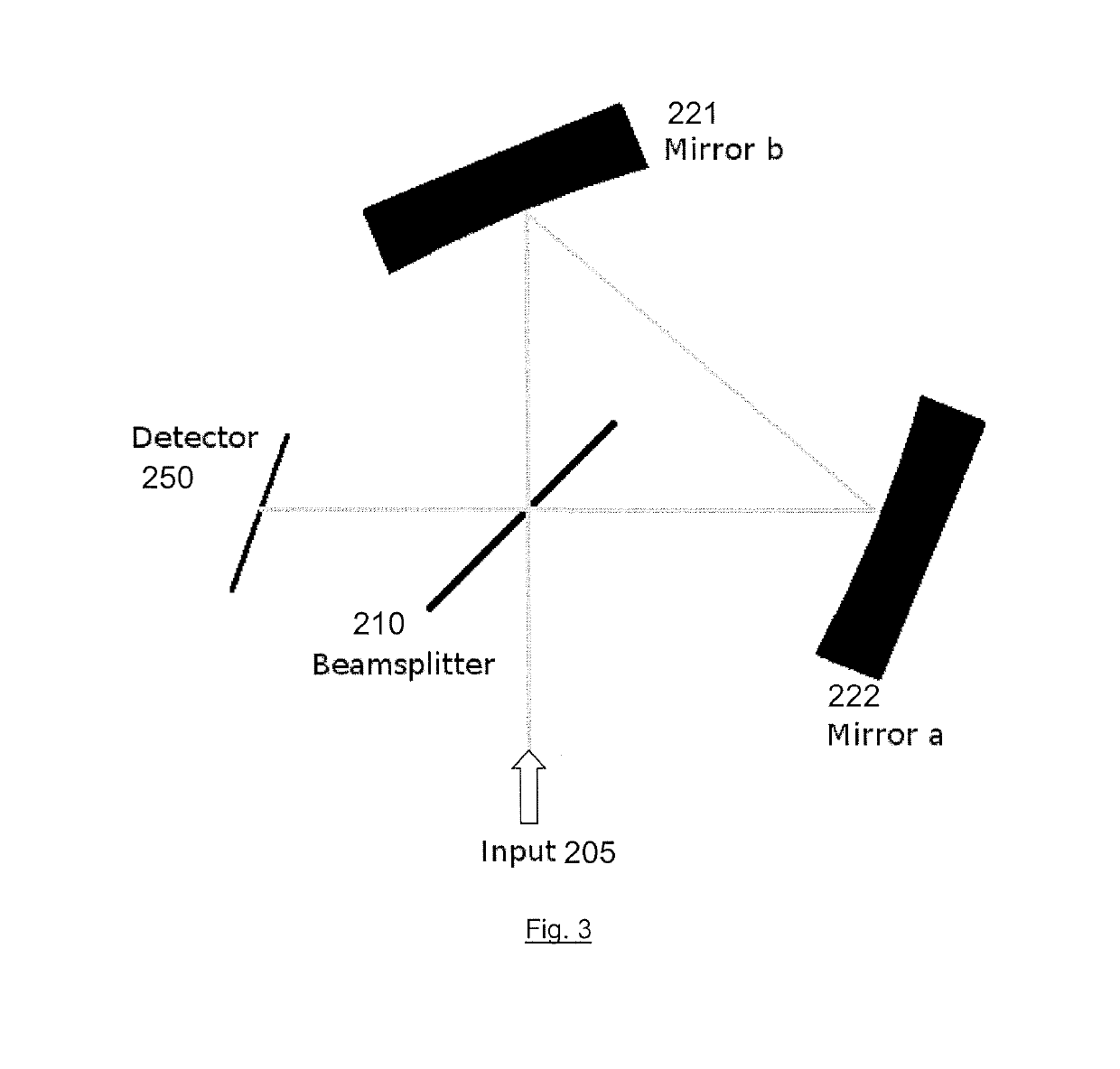

Compact Interferometer Spectrometer

ActiveUS20190178715A1Compact size and stabilityArea of detector can be bestRadiation pyrometrySpectrometry/spectrophotometry/monochromatorsLight beamOptoelectronics

A common path interferometer is disclosed. The interferometer is arranged to divide an input beam into first and second beam portions directed in opposite directions around a cyclic path to form an interference pattern at a detector. The cyclic path is defined by at least two mirror regions curved in the plane of the cyclic path, such that the interference pattern represents path difference variations between the first and second beam portions. The interferometer further includes an input optic arranged in the beam path before division of the input beam into the beam portions. The input optic is configured to provide convergence to reduce the extent transversely to the plane of the cyclic path of the interference pattern at the detector. The beam and beam portions have different convergence requirements in the plane of, and transverse to the plane of, the cyclic path, which are addressed separately by the mirror regions and the input optic.

Owner:KEIT

Method for analyzing image data relating to agglutination assays

InactiveUS8417002B2Enhances agglutinatesMaximize signal to noiseMaterial analysis by observing effect on chemical indicatorCharacter and pattern recognitionSignal-to-noise ratio (imaging)Assay

A method for analyzing a digital image containing the result of an agglutination assay to generate a quantitative result value representative of the degree of agglutination of the sample is provided. The method for analyzing the digital image includes: applying a filter to extract a component of the image or portion of a spectrum where a signal to noise ratio between agglutinated and background is maximized; extracting a set of features that characterize the agglutination pattern, obtaining a quantification function which maps measured features to the actual concentration of the sample and computing a quantitative result for each sample in the assay.

Owner:LAB CELSIUS

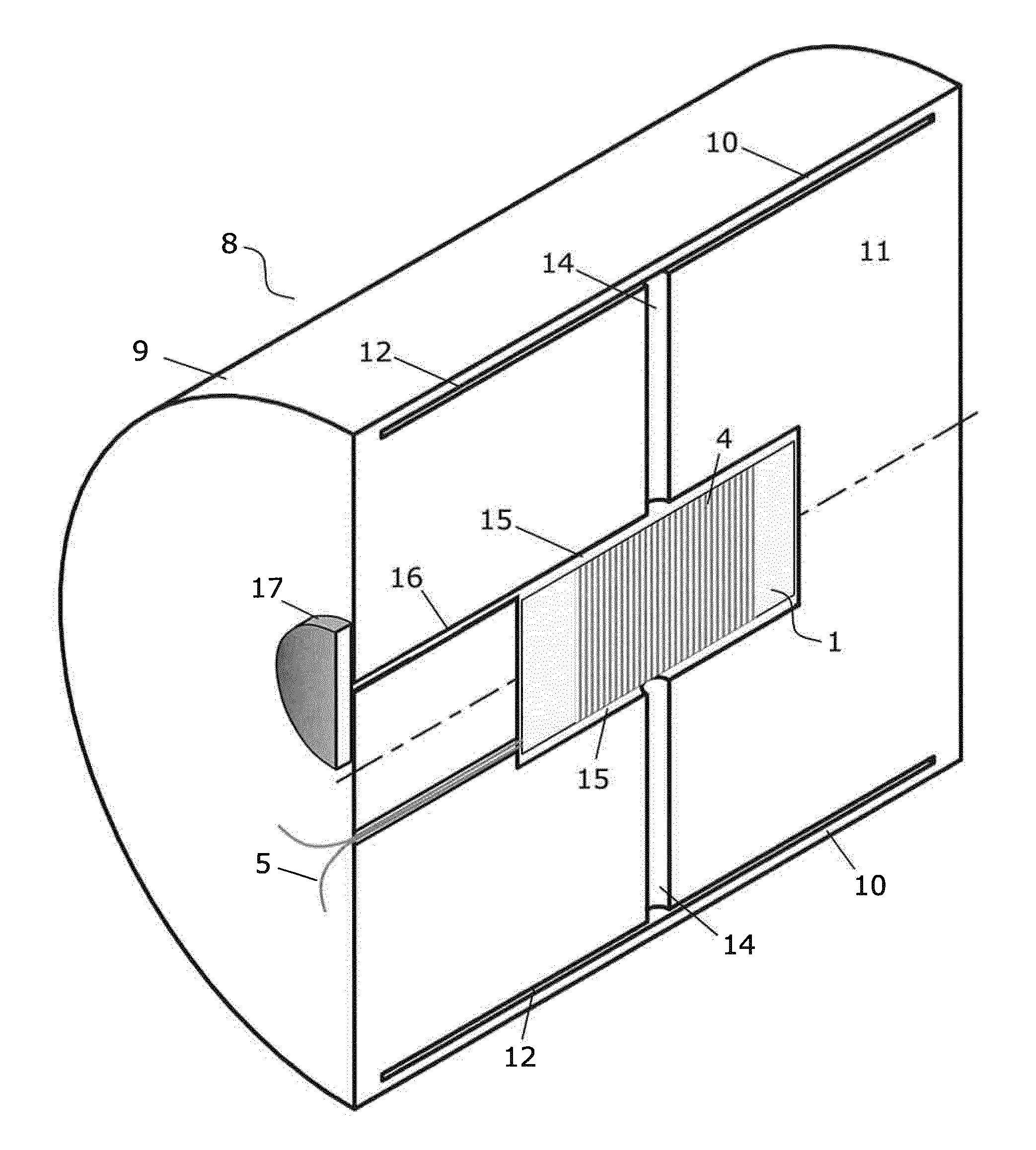

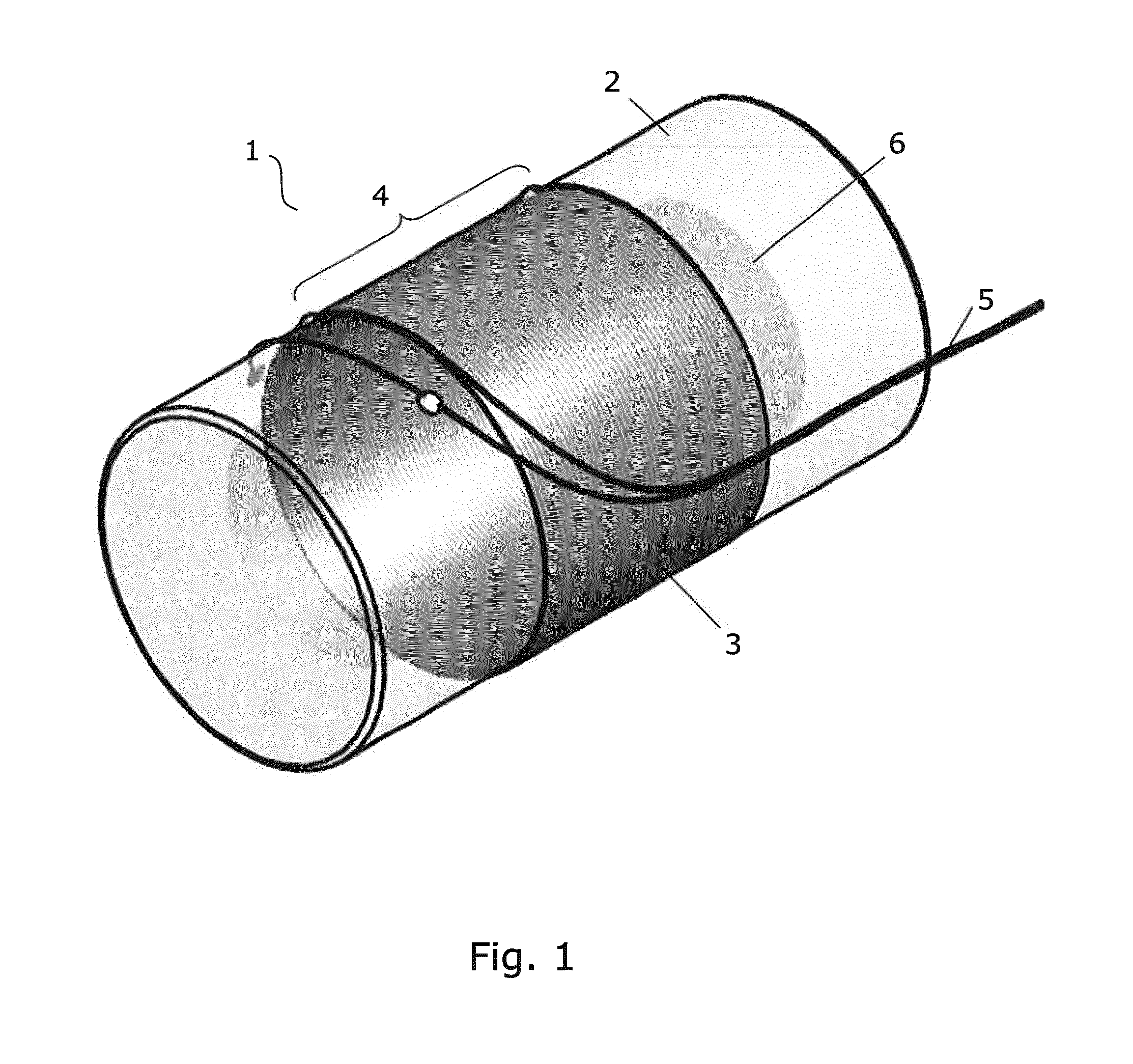

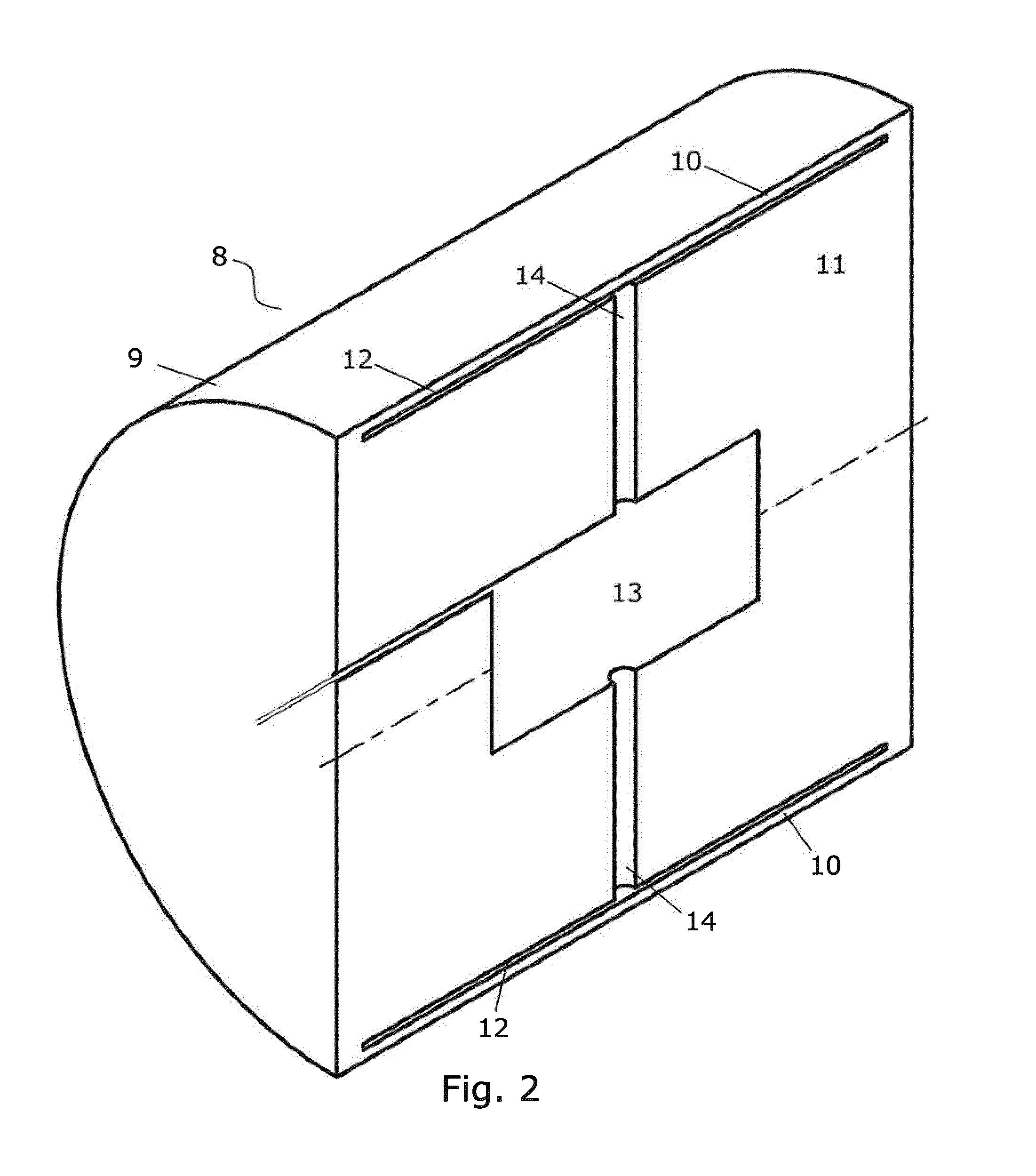

Hydrophone housing

ActiveUS20150085618A1High sensitivityLower requirementSubsonic/sonic/ultrasonic wave measurementSeismic signal receiversHydrophoneCoupling

The invention relates to a hydrophone housing. The housing comprises an outer casing with an exterior shape being in close contact with sediment when buried therein and having a deflectable wall part. Solid material partly fills the casing to define an outer chamber behind the deflectable wall part, a cavity shaped so that an inner chamber is defined immediately surrounding a hydrophone sensing element held therein, and a first duct for liquid flow communication between the outer chamber and the cavity or an internal volume of the hydrophone sensing element. Thereby, a hydraulic coupling is provided so that an acoustic pressure causing small radial displacements of outer surface of the housing will, via liquid in the first duct, cause large radial displacements of the hydrophone sensitive element. The area of the deflectable wall part is much larger than the area of the sensitive element so that only small displacements of the housing are required to cause large displacements at the hydrophone sensing element.

Owner:OPTOPLAN

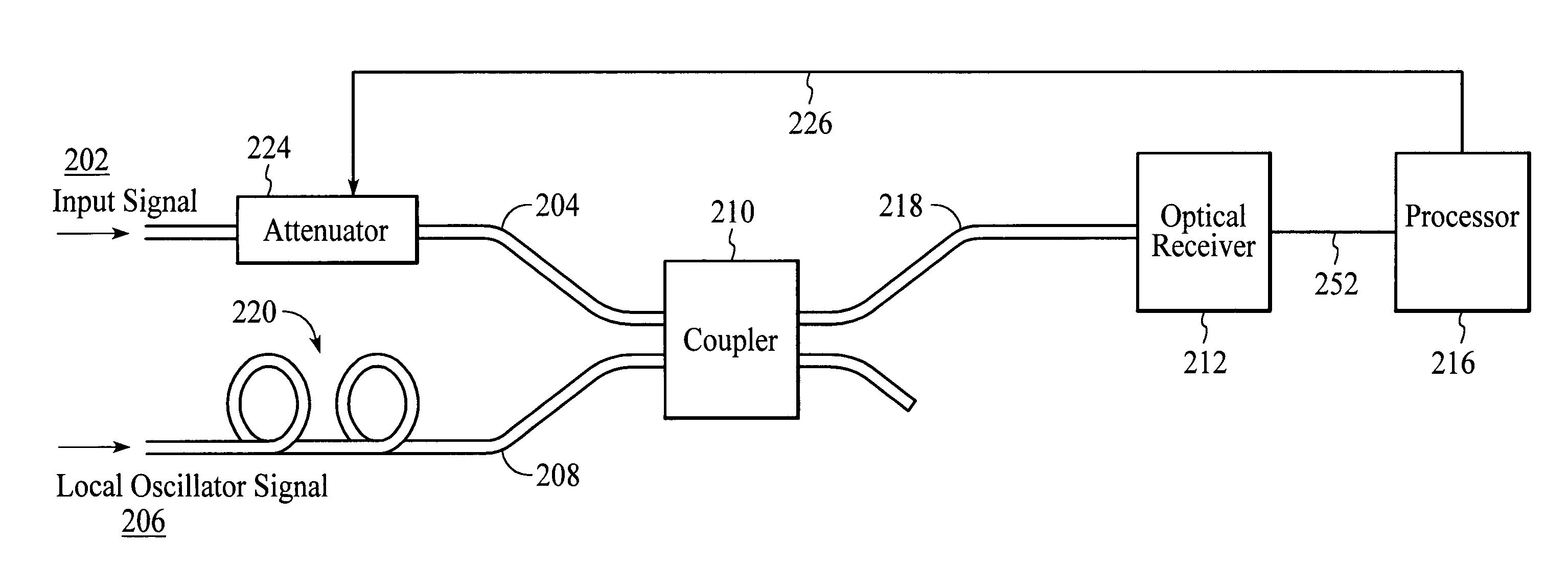

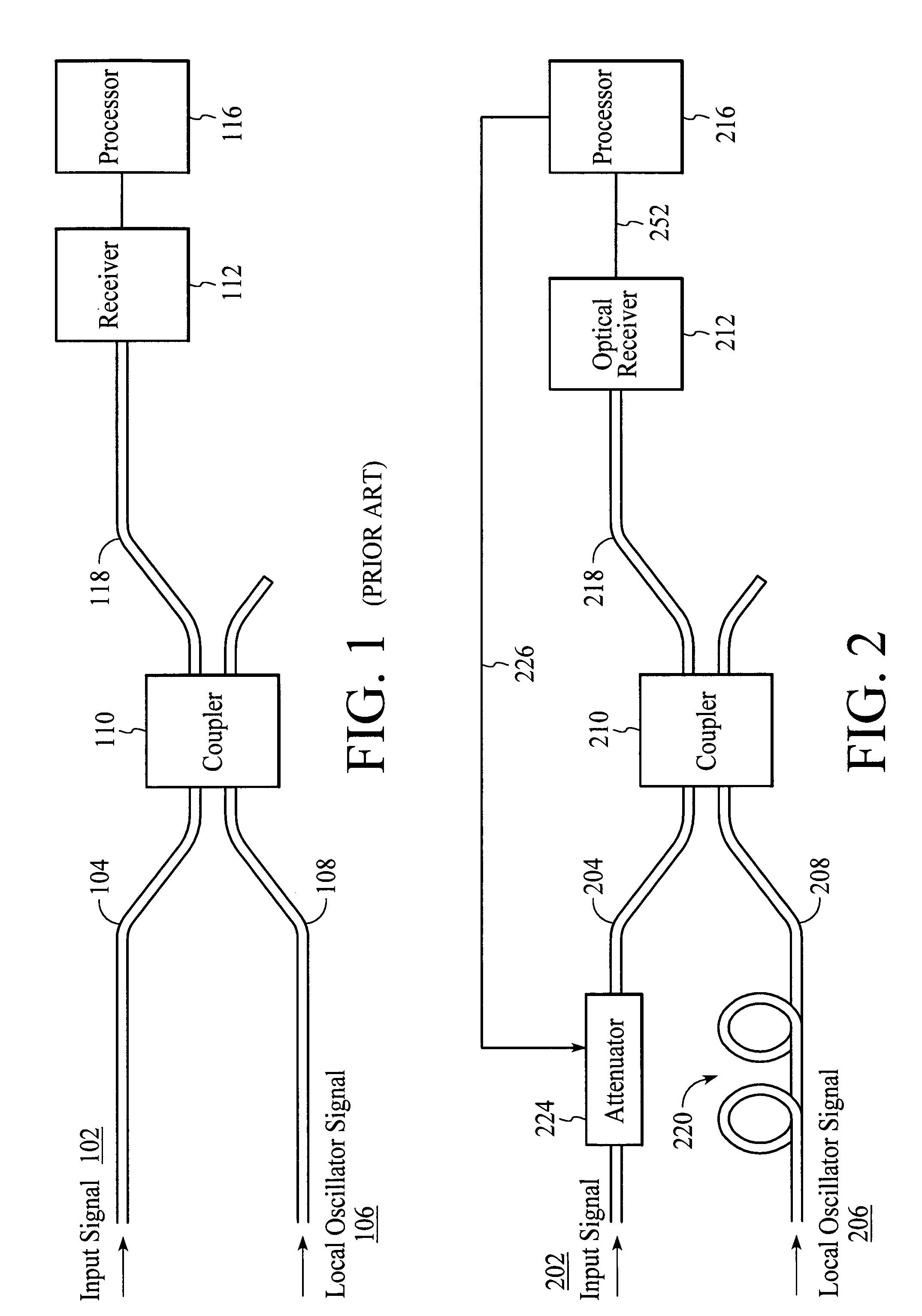

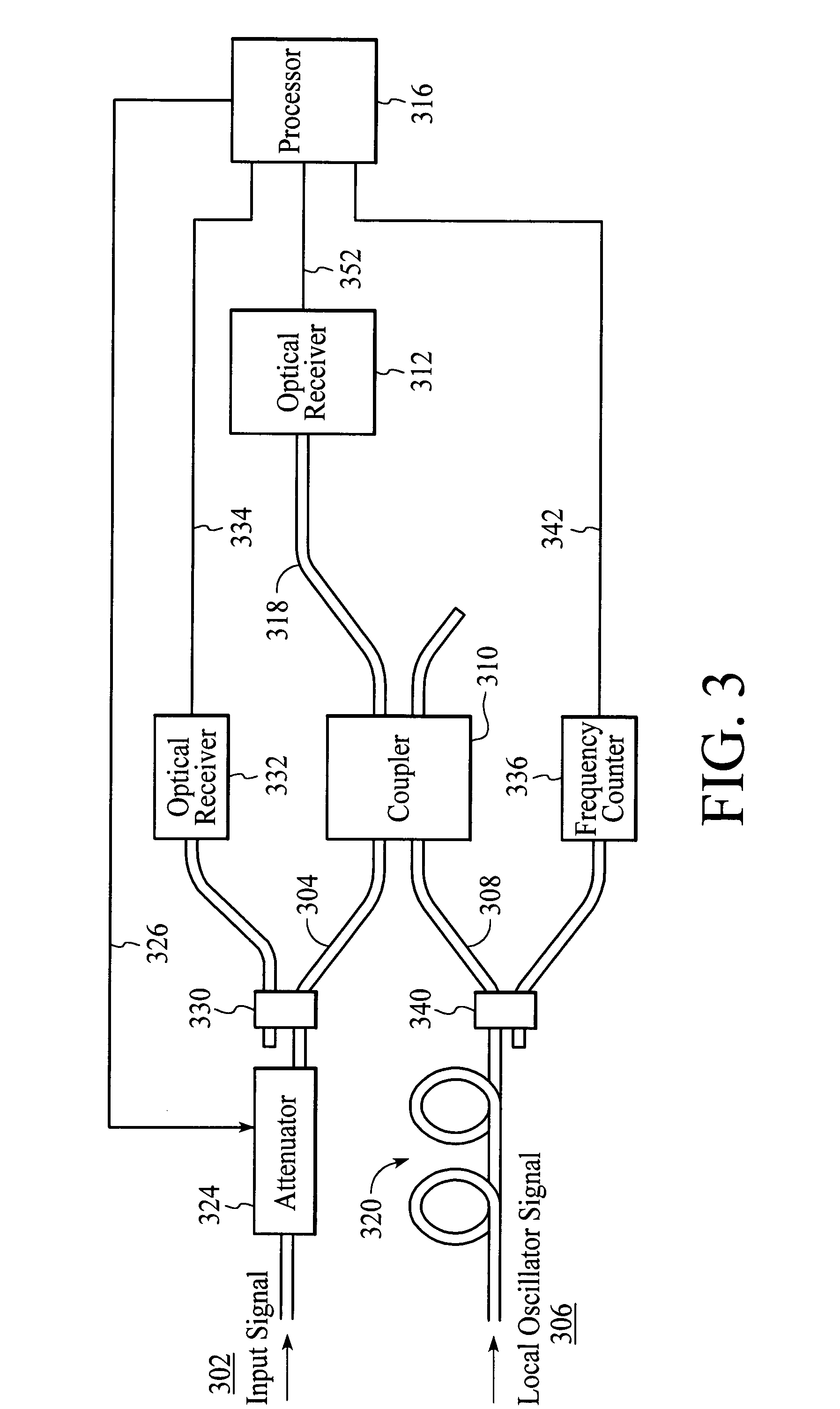

Method and system for optical heterodyne detection of an optical signal that utilizes optical attenuation

InactiveUS6970250B1Improve signal to noiseImprove signal to noise ratioOptical measurementsUsing optical meansSignal-to-noise ratio (imaging)Physics

Monitoring an optical signal utilizing optical heterodyne detection involves attenuating an input signal before the input signal is combined with a local oscillator signal. The input signal is attenuated in order improve the signal to noise ratio of the heterodyne signal that is generated when the input signal and the local oscillator signal are combined. The signal to noise ratio of the heterodyne signal improves with attenuation of the input signal, specifically in the case where the intensity noise from the input signal is the dominant noise source, because the heterodyne signal and the intensity noise of the input signal scale differently with attenuation of the input signal.

Owner:AGILENT TECH INC

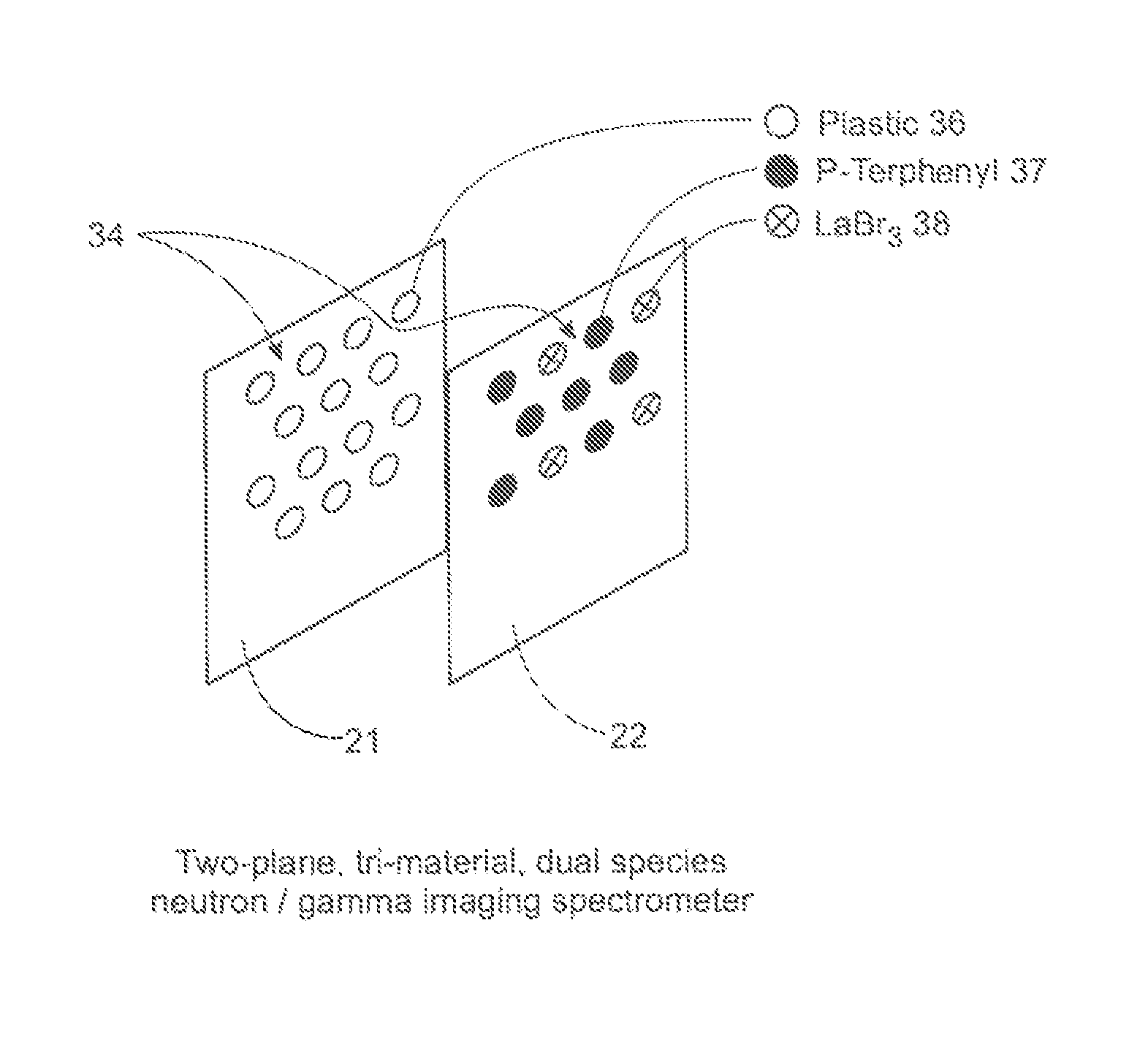

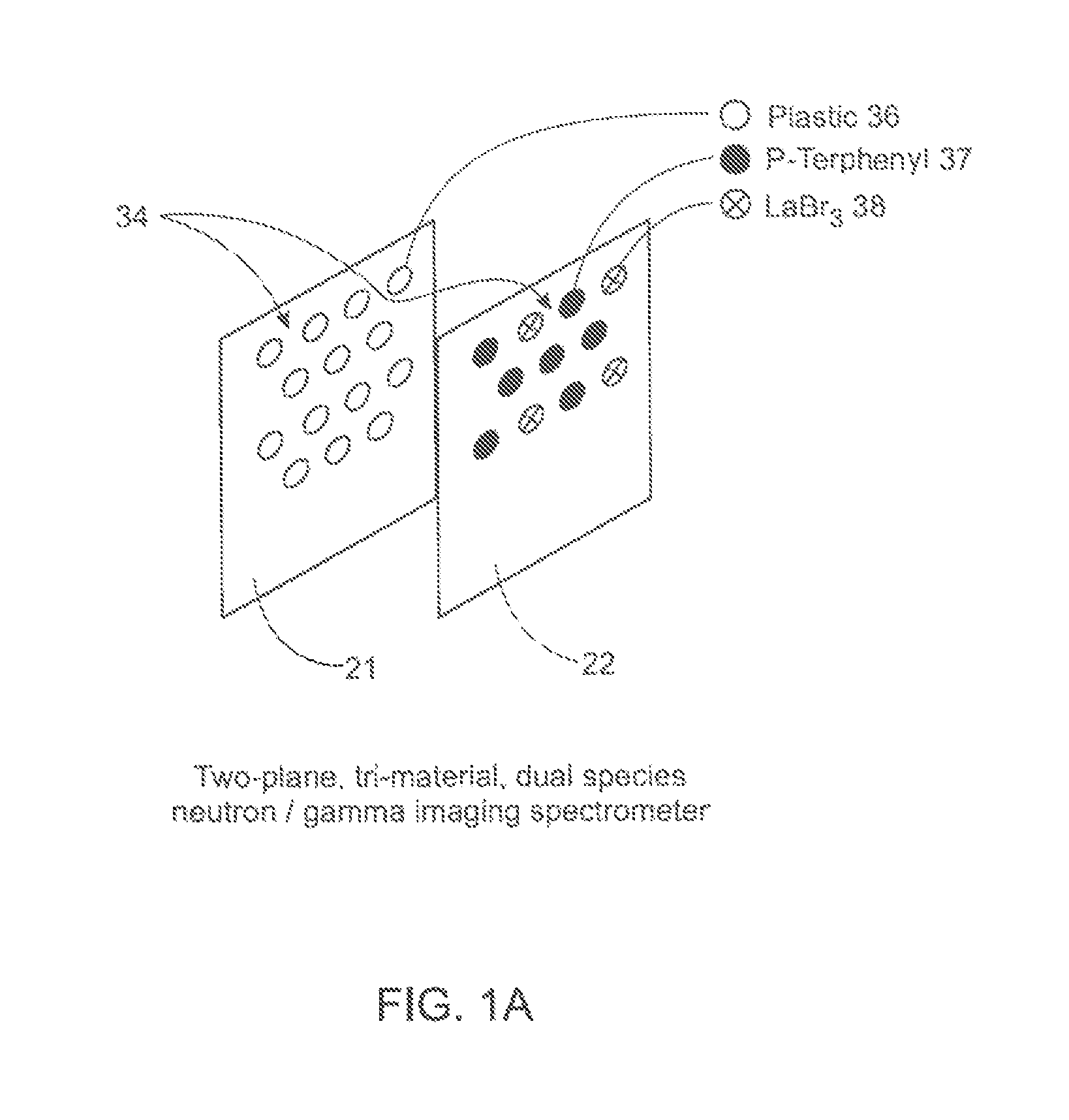

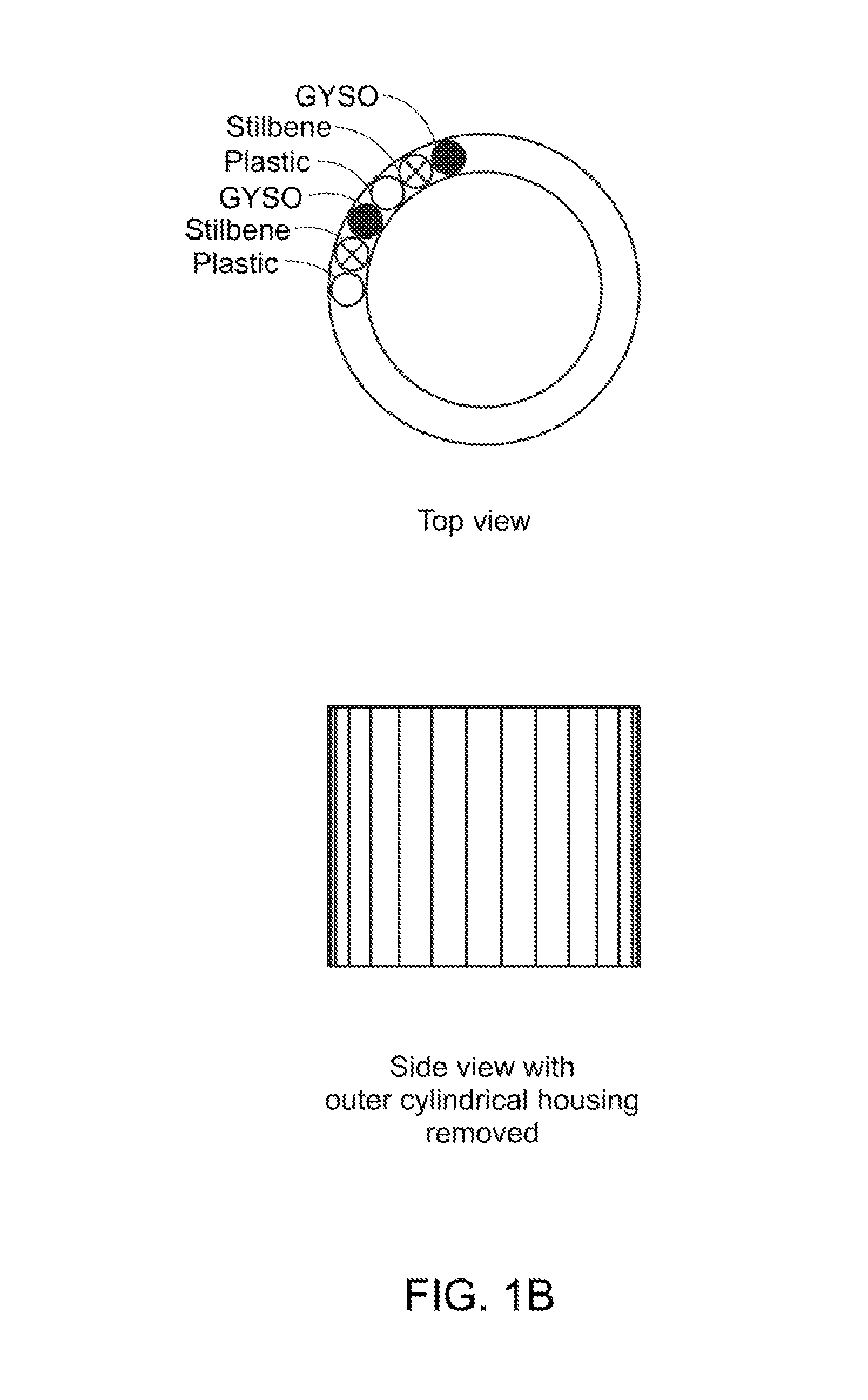

Tri-material dual-species neutron/gamma spectrometer

ActiveUS9507035B2Maximize signal to noiseMeasurement with scintillation detectorsRadiation intensity measurementParallel plateGamma ray

A system of the present invention is capable of detecting, imaging and measuring both neutrons and gamma rays. In some cases, the system has a plurality of parallel plates each containing a plurality of detectors. The plates comprise non-PSD organic scintillation detectors, scintillation detectors having pulse-shape discrimination (PSD) properties, and inorganic scintillation detectors. In some other cases, the system has a plurality of scintillation rods radially distributed about a central axis, and the scintillation rods comprise non-PSD organic scintillation detectors, scintillation detectors having pulse-shape discrimination (PSD) properties, and inorganic scintillation detectors. A first plate or rod and a second plate or rod are used in connection to detect, image and measure neutrons and / or gamma rays.

Owner:UNIVERSITY OF NEW HAMPSHIRE

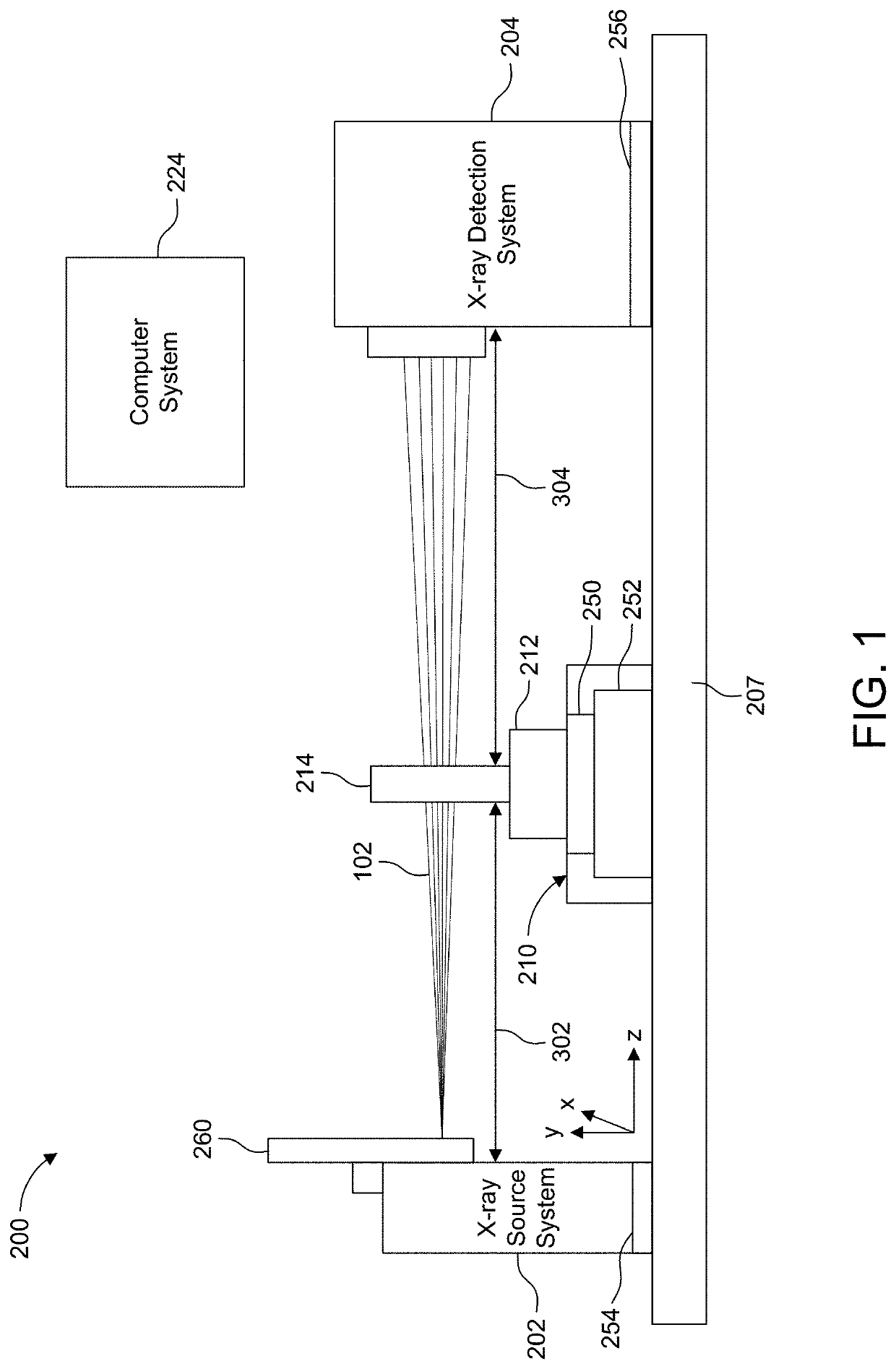

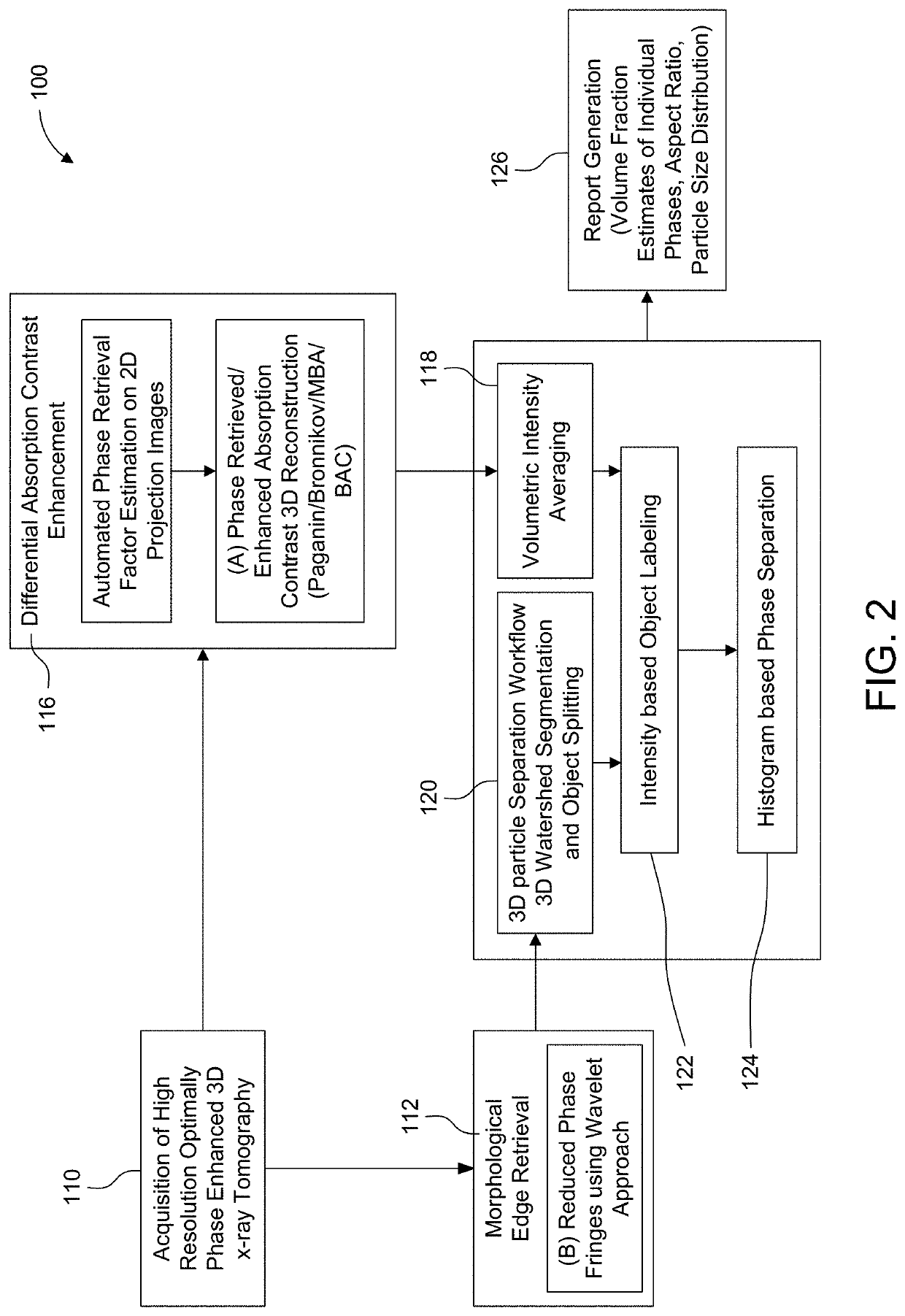

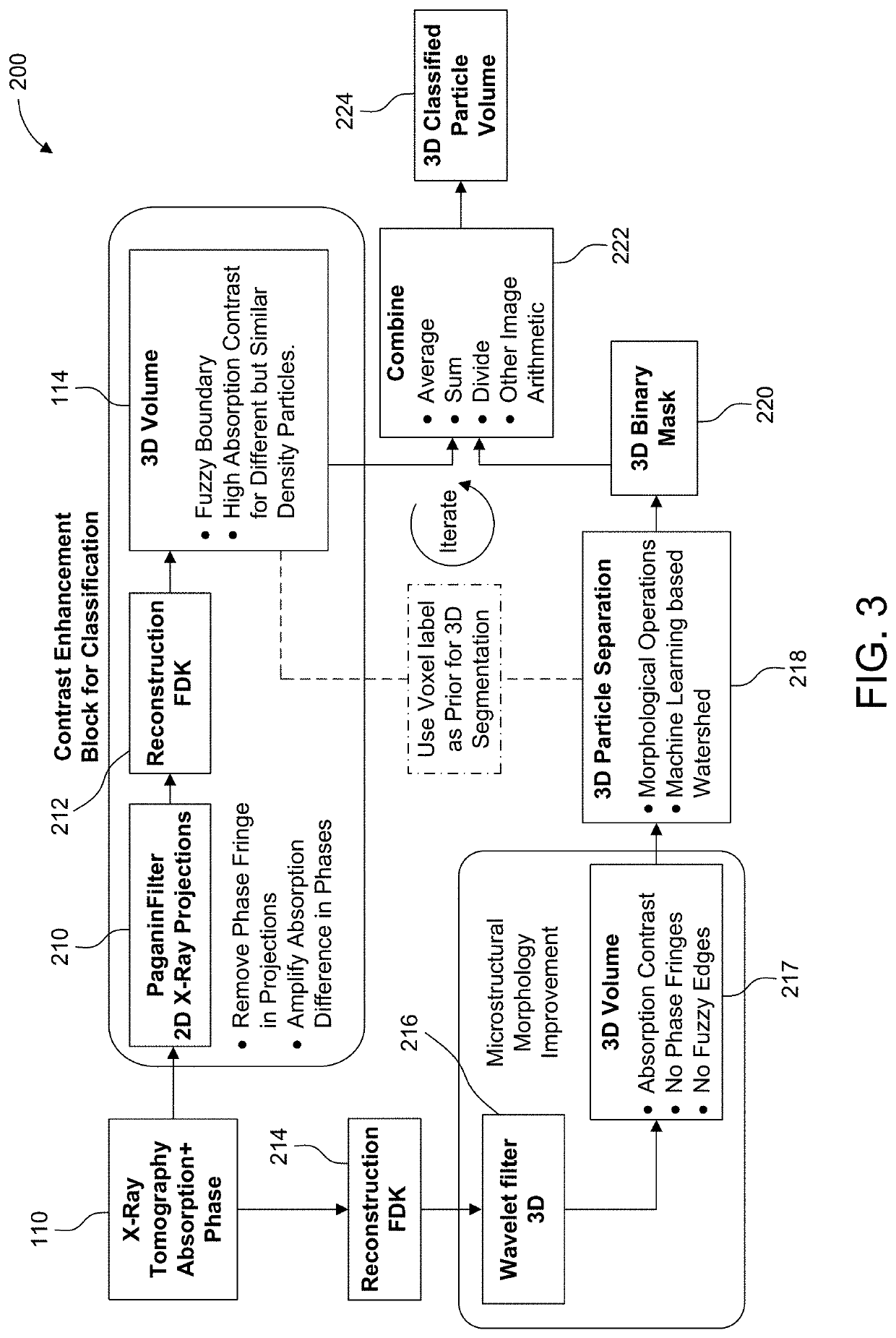

Edge Phase Effects Removal Using Wavelet Correction and Particle Classification Using Combined Absorption and Phase Contrast

ActiveUS20220366620A1Fast volumetric classificationMaximize signal to noiseImage enhancementReconstruction from projectionImaging processingAbsorption contrast

An x-ray microscopy method that obtains a classification of different particles by distinguishing between different material phases through a combination of image processing involving morphological edge enhancement and possibly resolved absorption contrast differences between the phases along with optional wavelet filtering.

Owner:CARL ZEISS X RAY MICROSCOPY

Gesture recognition apparatus and components thereof

ActiveUS10691218B2Improve disadvantagesMaximize signal to noiseInput/output for user-computer interactionPiezoelectric/electrostrictive microphonesComputer hardwareEngineering

A gesture recognition apparatus includes a sensor unit configured to be worn by a user on a user's body part. The sensor unit includes one or more sensors, a processor unit, the processor unit and the sensor unit are arranged in communication with each other, the processor unit receiving acoustic data from the one or more sensors, wherein the acoustic data corresponds to a gesture performed by a user, and the processor unit is configured to process the acoustic data received from the one or more sensors to determine a gesture performed by the user.

Owner:CITY UNIVERSITY OF HONG KONG

Hydrophone housing

ActiveUS10677945B2Stress minimizationLow loss transfer of pressure energySubsonic/sonic/ultrasonic wave measurementSeismic signal receiversHydrophoneEngineering

The invention relates to a hydrophone housing. The housing comprises an outer casing with an exterior shape being in close contact with sediment when buried therein and having a deflectable wall part. Solid material partly fills the casing to define an outer chamber behind the deflectable wall part, a cavity shaped so that an inner chamber is defined immediately surrounding a hydrophone sensing element held therein, and a first duct for liquid flow communication between the outer chamber and the cavity or an internal volume of the hydrophone sensing element. Thereby, a hydraulic coupling is provided so that an acoustic pressure causing small radial displacements of outer surface of the housing will, via liquid in the first duct, cause large radial displacements of the hydrophone sensitive element. The area of the deflectable wall part is much larger than the area of the sensitive element so that only small displacements of the housing are required to cause large displacements at the hydrophone sensing element.

Owner:OPTOPLAN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com