Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

33results about How to "Less packaging" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

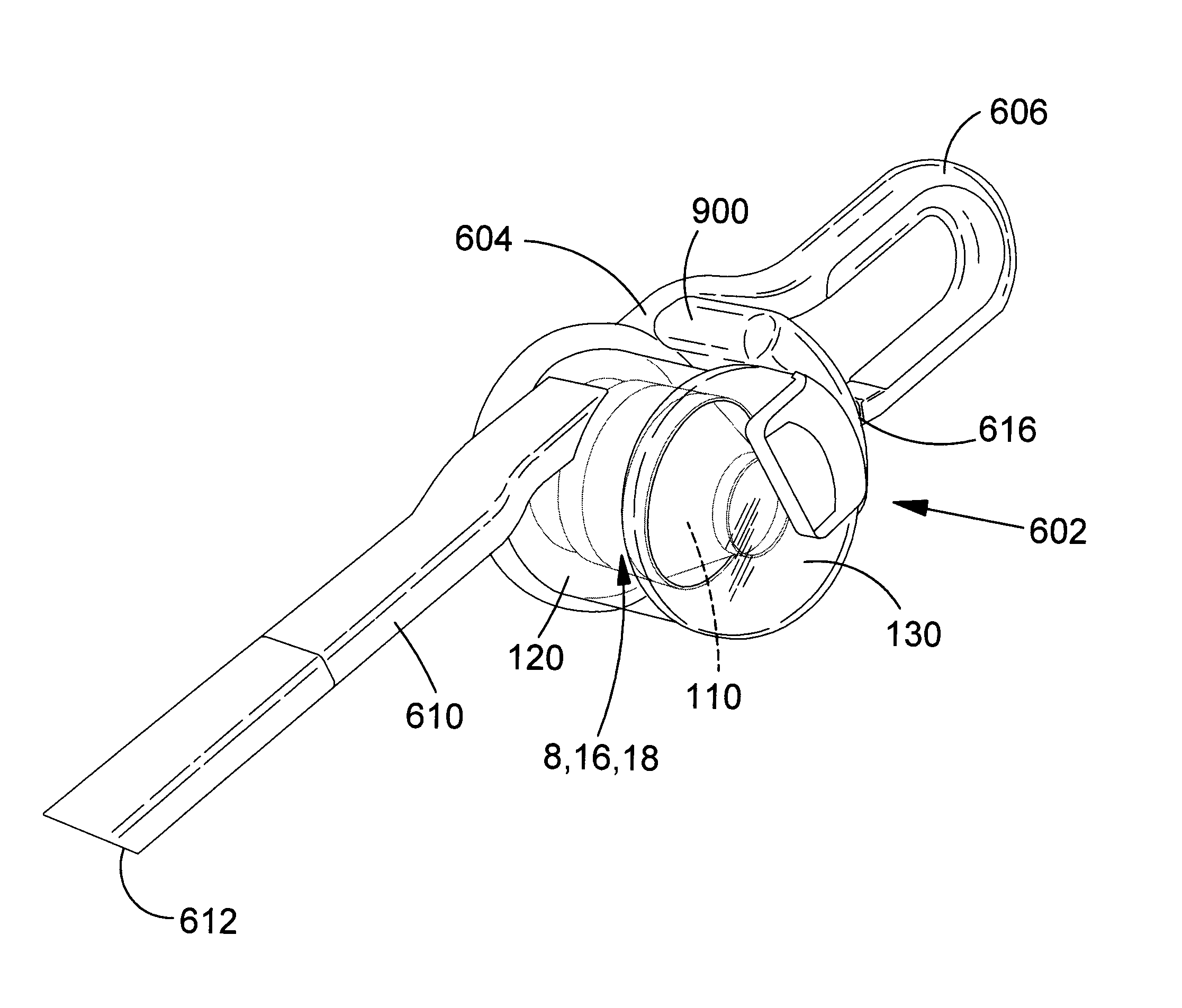

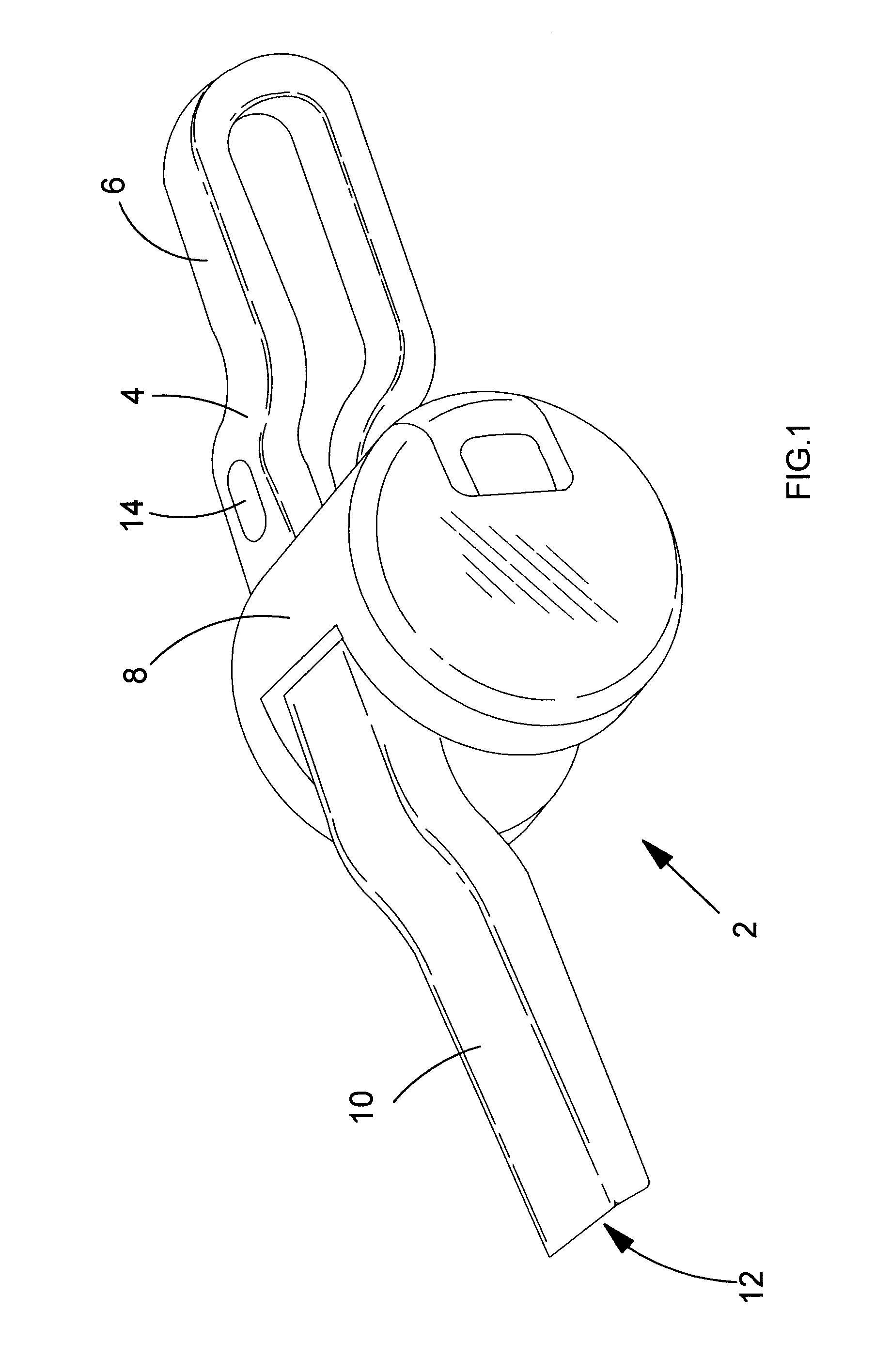

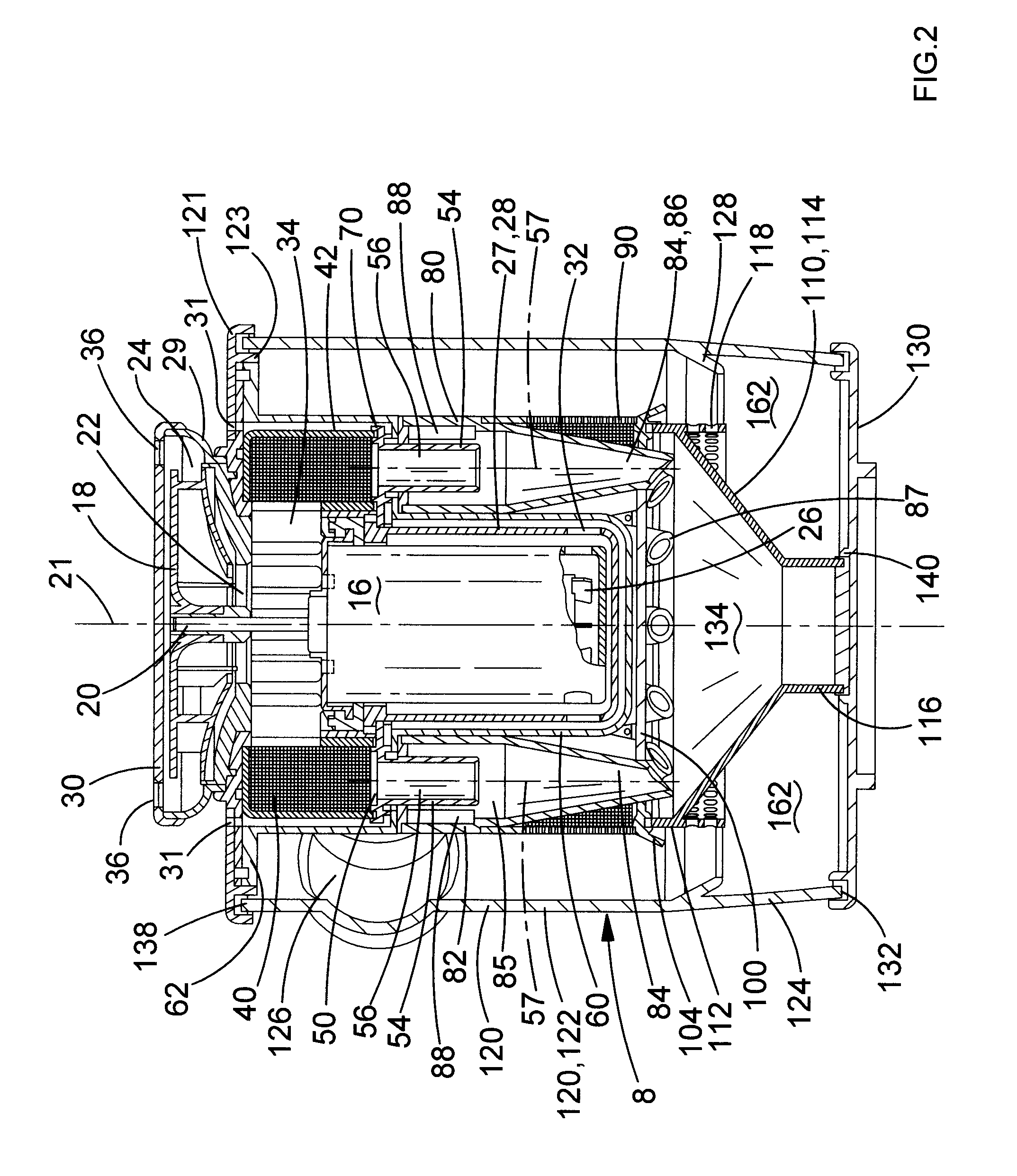

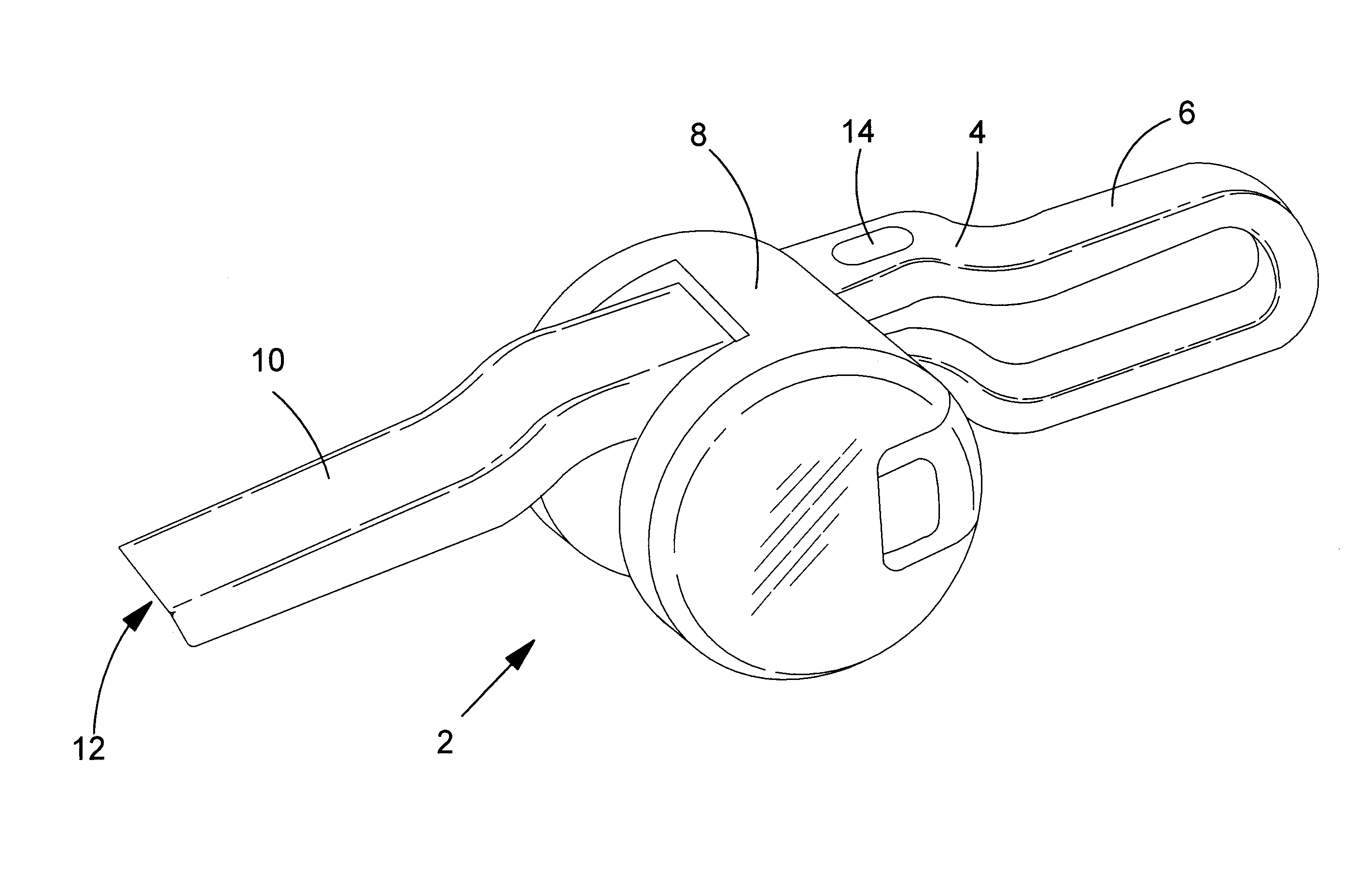

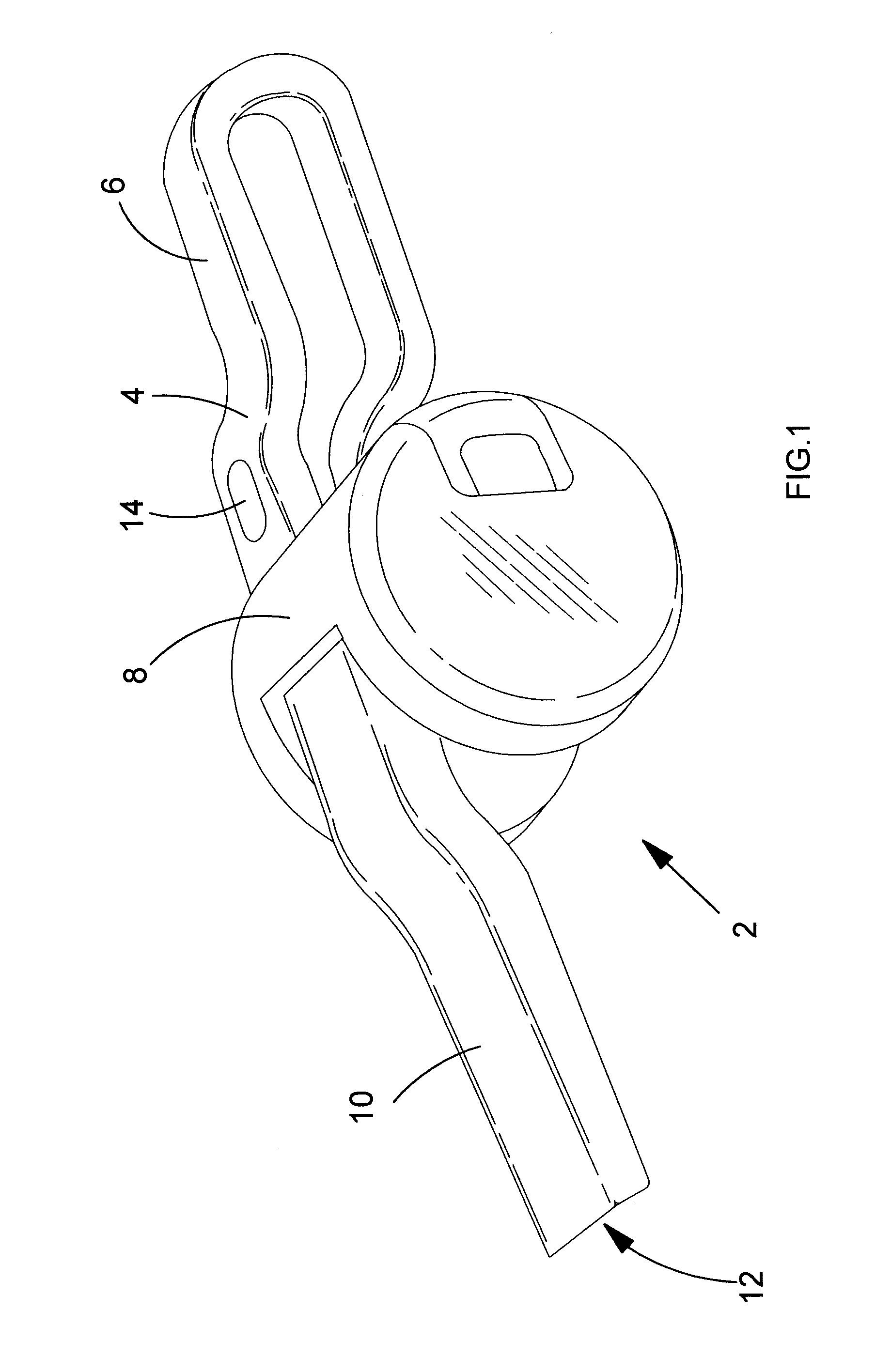

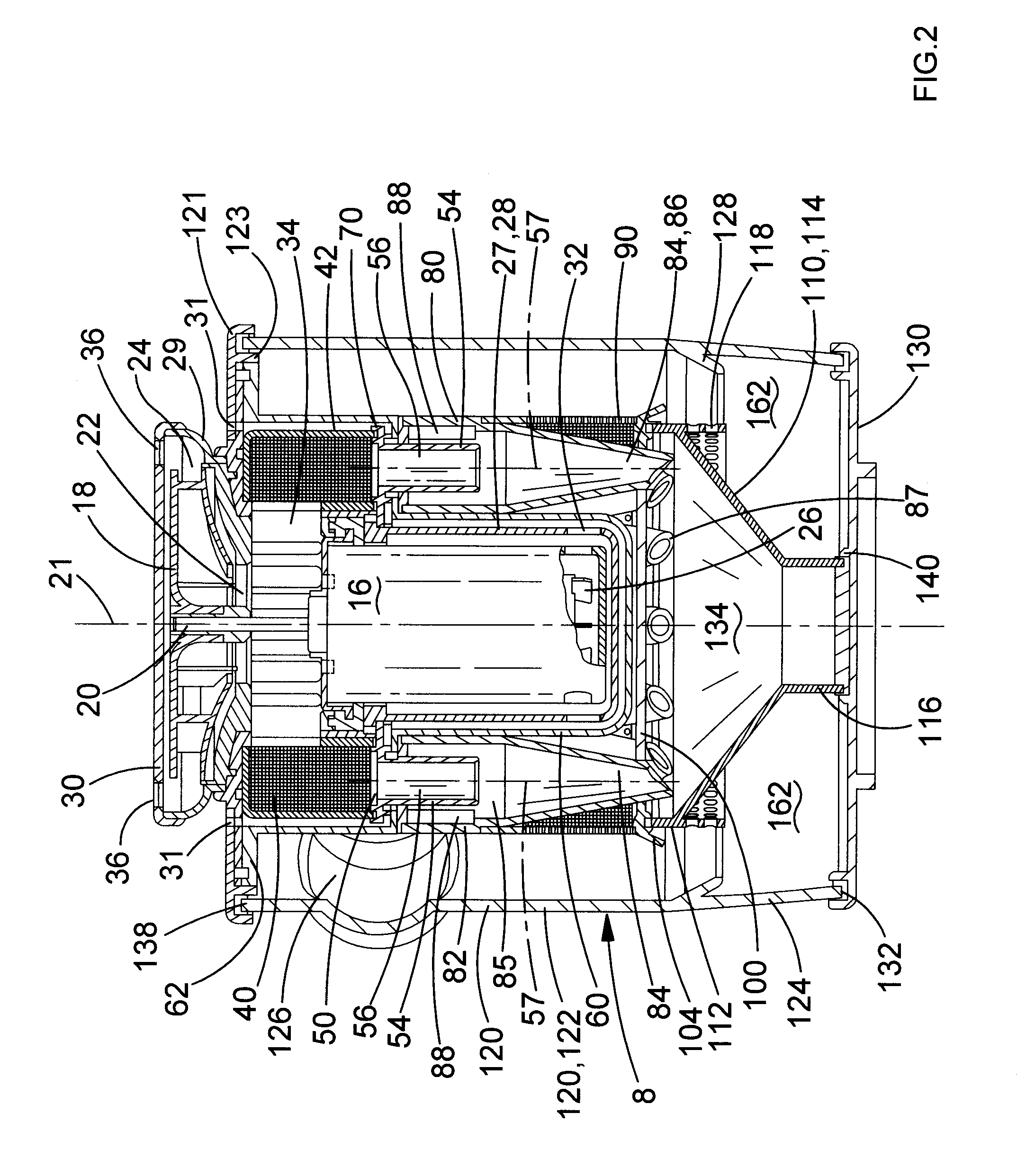

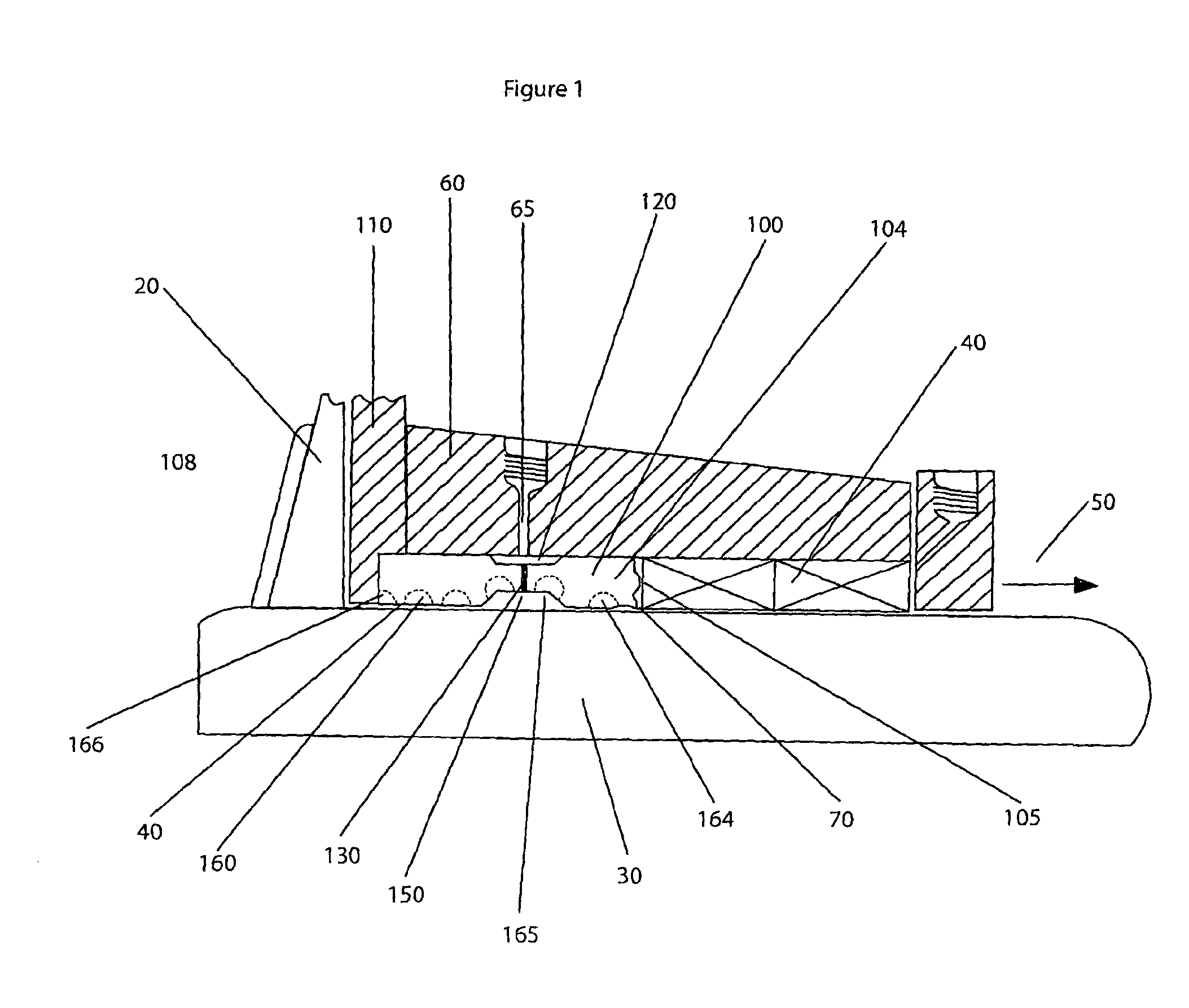

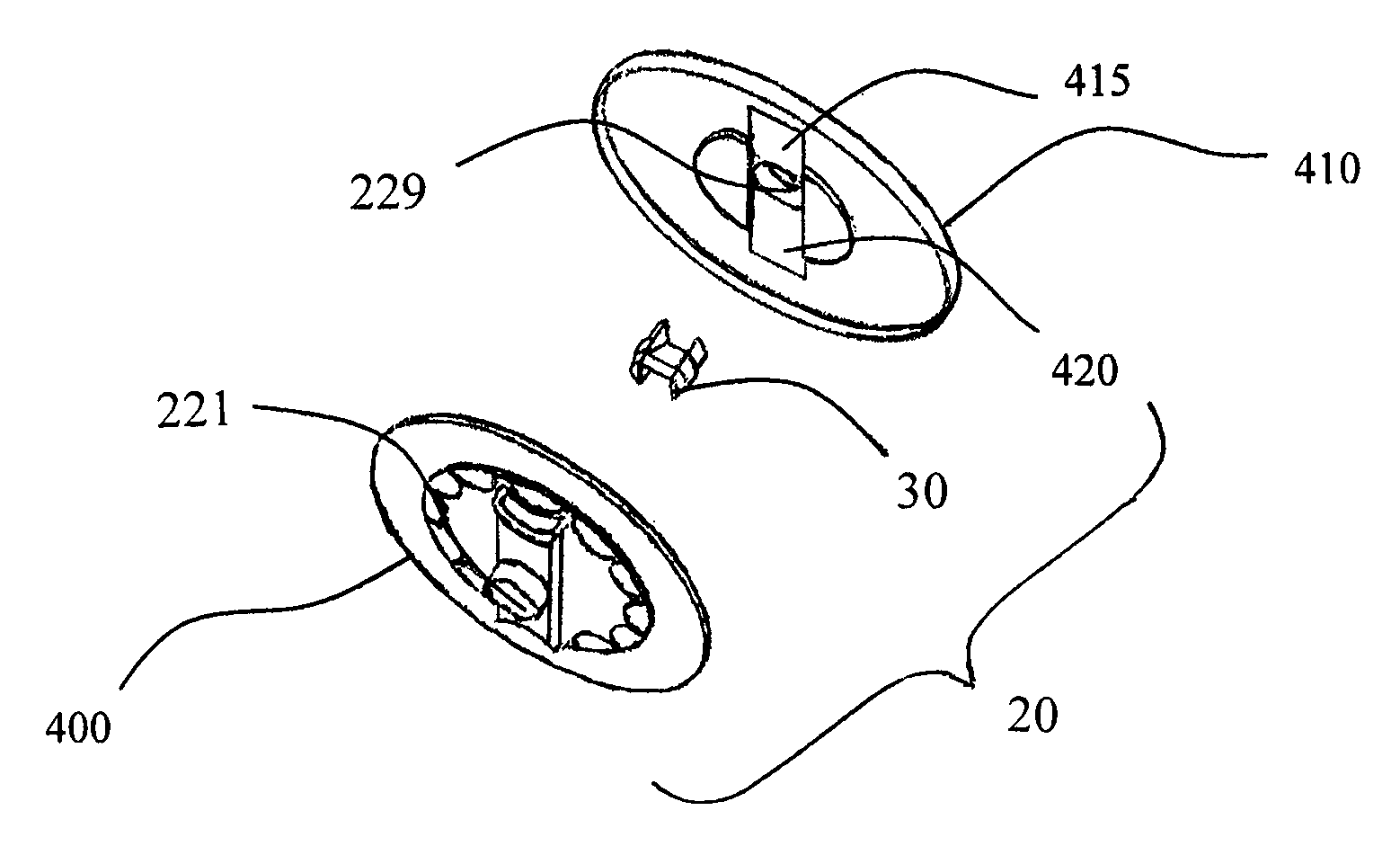

Battery-powered vacuum cleaner

ActiveUS8549703B2Smoother profileEasily includedCleaning filter meansSuction filtersRechargeable cellEngineering

A vacuum cleaner comprising: a motor coupled to a fan for generating air flow; a body with a handle; a dirty air duct with a dirty air inlet; a battery pack housing at least one rechargeable cell for powering the motor; and a dirt separating means located in a path of the air flow generated by the fan, wherein the dirt separating means comprises: a hollow substantially cylindrical dirt container with a longitudinal central axis; and an air inlet port to the dirt container, wherein the air inlet port is in communication with the dirty air duct and wherein the battery pack has a curvilinear or annular cross-sectional profile transverse to the central axis and a curvilinear inner wall embracing the dirt container.

Owner:BLACK & DECKER INC

Battery-powered vacuum cleaner

ActiveUS20130091657A1Separation efficiency can be improvedLess spaceCleaning filter meansSuction filtersAirflowEngineering

A vacuum cleaner comprising: a motor coupled to a fan for generating air flow; a body with a handle; a dirty air duct with a dirty air inlet; a battery pack housing at least one rechargeable cell for powering the motor; and a dirt separating means located in a path of the air flow generated by the fan, wherein the dirt separating means comprises: a hollow substantially cylindrical dirt container with a longitudinal central axis; and an air inlet port to the dirt container, wherein the air inlet port is in communication with the dirty air duct and wherein the battery pack has a curvilinear or annular cross-sectional profile transverse to the central axis and a curvilinear inner wall embracing the dirt container.

Owner:BLACK & DECKER INC

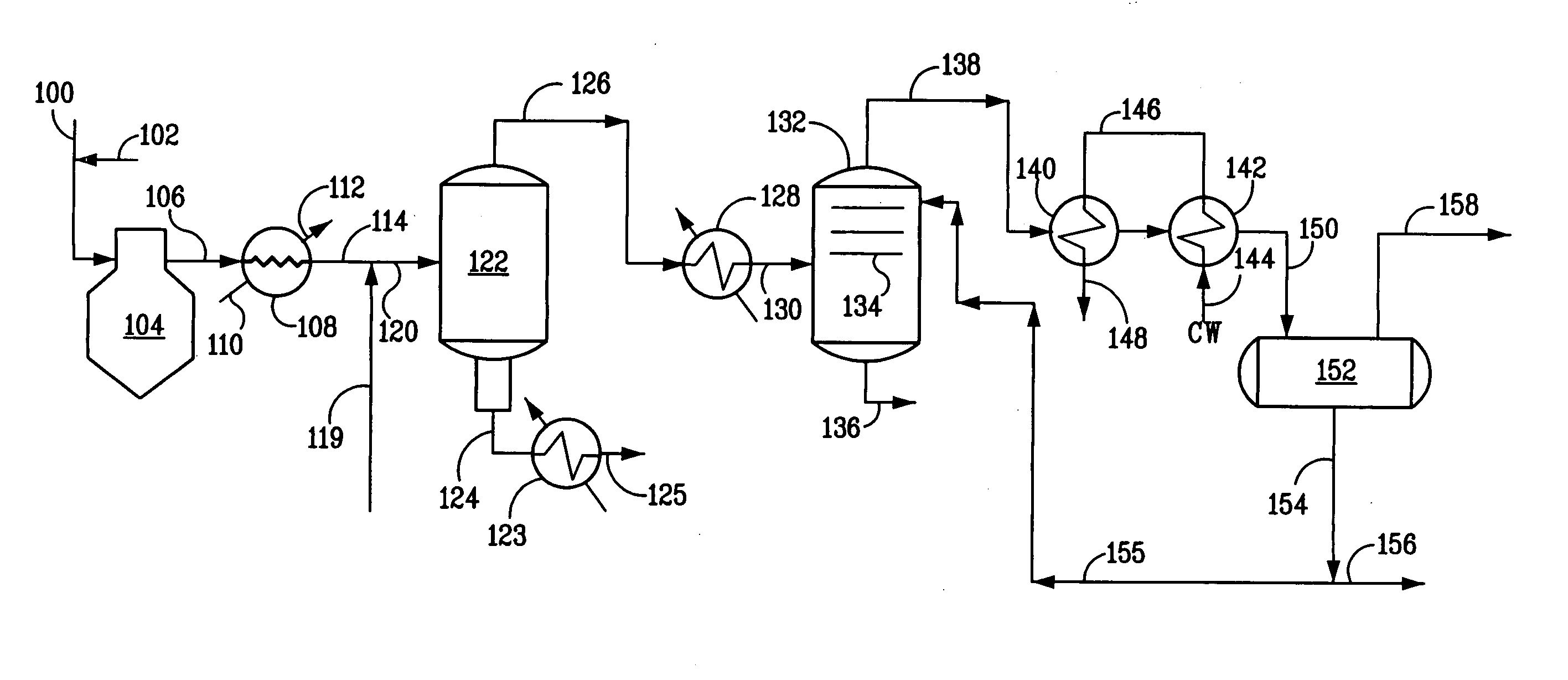

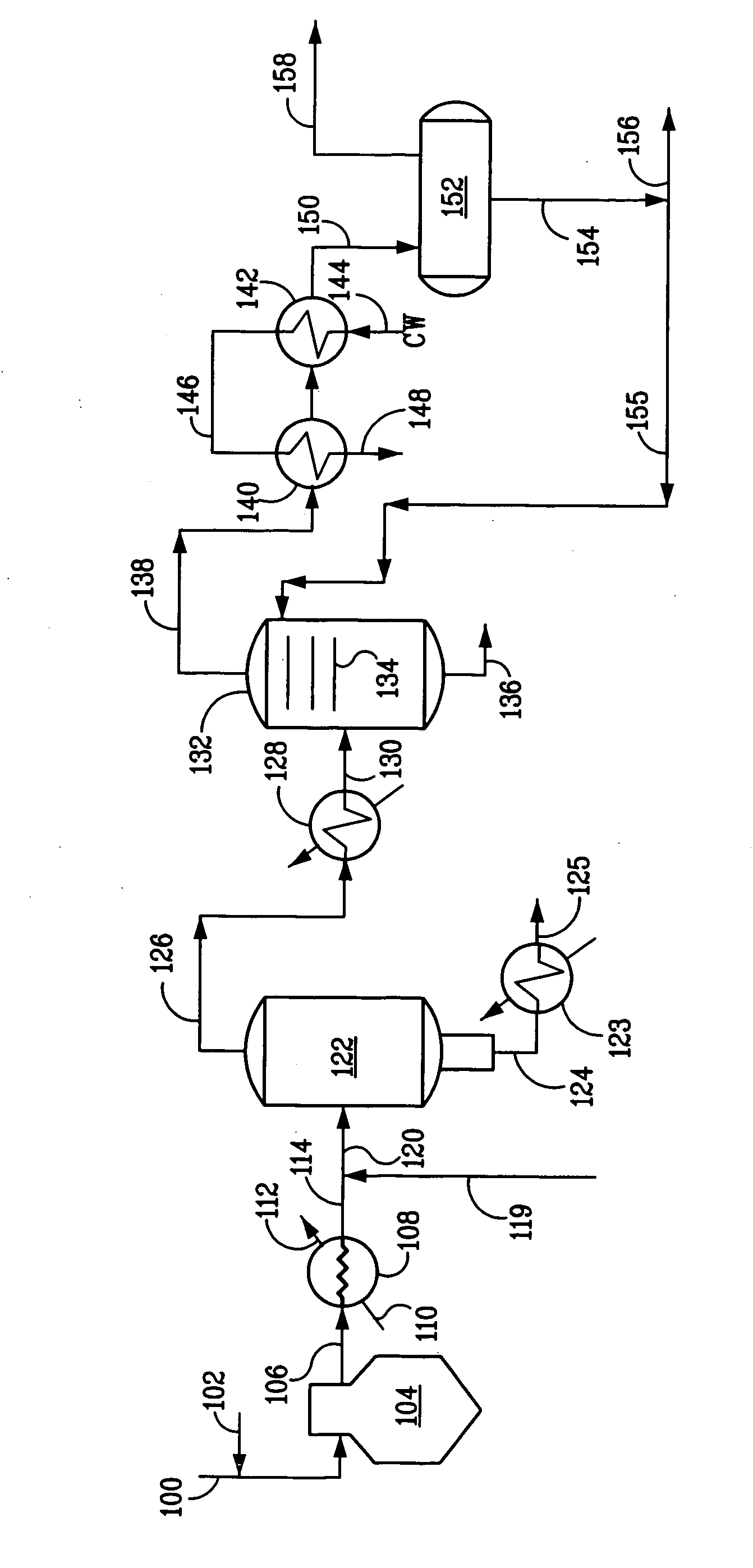

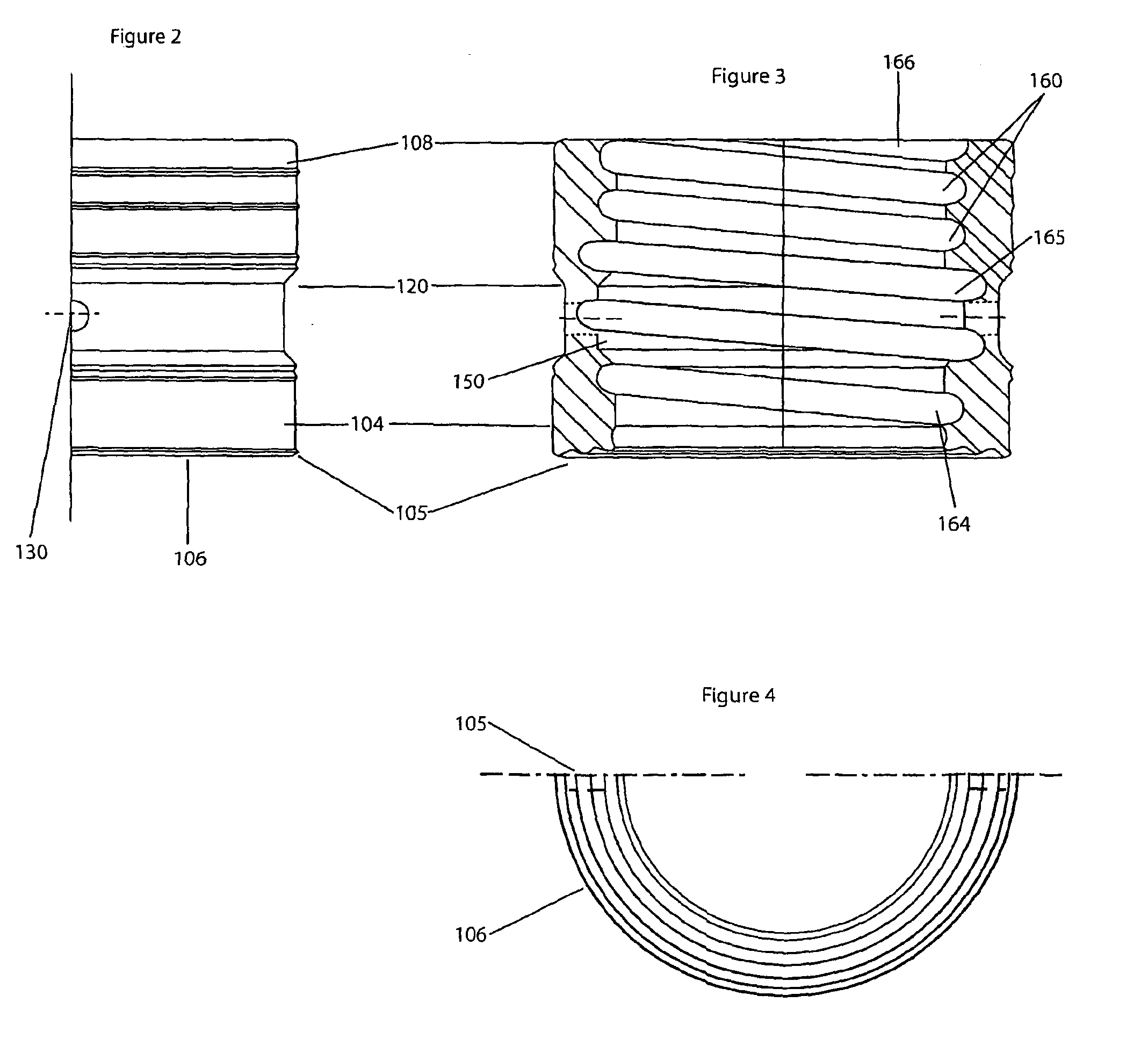

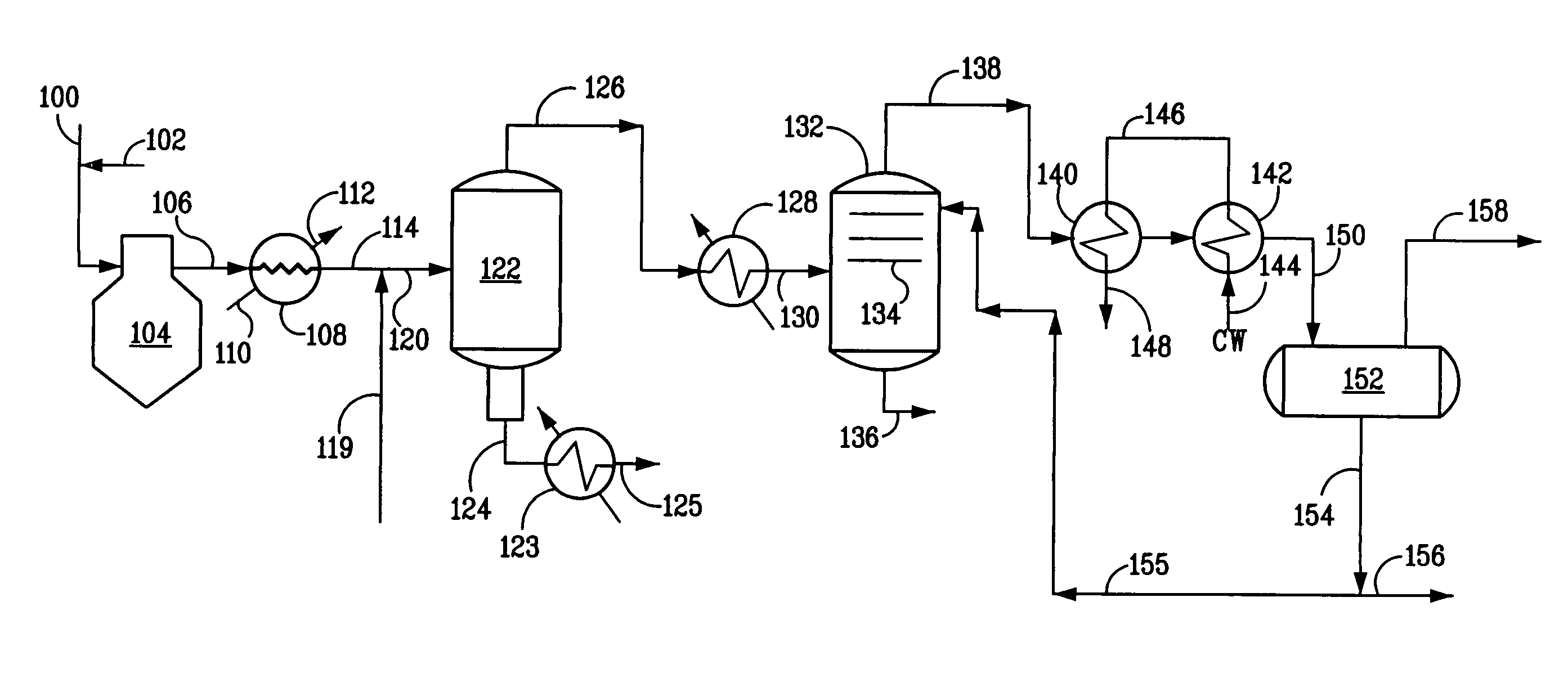

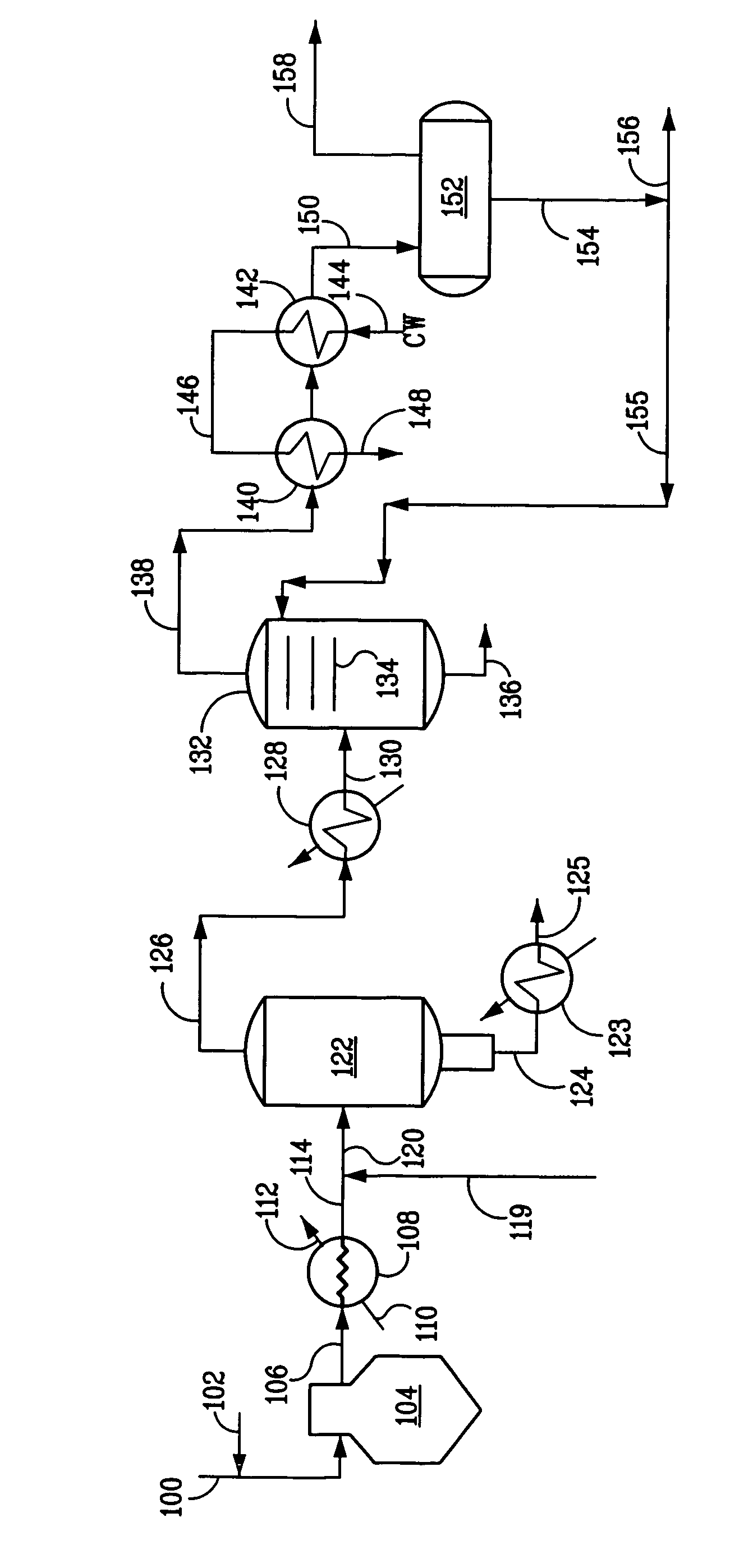

Method for processing hydrocarbon pyrolysis effluent

InactiveUS20070007174A1Value maximizationReduced susceptibility to foulingThermal non-catalytic crackingHydrocarbon oil cracking processProcess engineeringEnvironmental engineering

A method and apparatus are disclosed for treating the effluent from a hydrocarbon pyrolysis unit employing a small primary fractionator, i.e., a rectifier. The method comprises cooling the gaseous effluent, e.g., by direct quench and / or at least one primary heat exchanger, and then cooling the gaseous effluent to a temperature at which tar, formed by reactions among constituents of the effluent, condenses, e.g., in a secondary exchanger. The resulting mixed gaseous and liquid effluent is passed through a rectifier, to cleanly separate quench oil from the gaseous effluent comprising a pyrolysis gasoline fraction, whose boiling point can be lowered as a result of the rectifier treatment. The effluent is then cooled to condense a liquid effluent comprising pyrolysis gasoline and water condensed from steam, which fractions are separated in a distillate drum. The cooled gaseous effluent is directed to a recovery train to recover light olefins. At least a portion of the pyrolysis gasoline-containing fraction can be recycled to the rectifier to enhance separation of the quench oil from the pyrolysis gasoline fraction.

Owner:EXXONMOBIL CHEM PAT INC

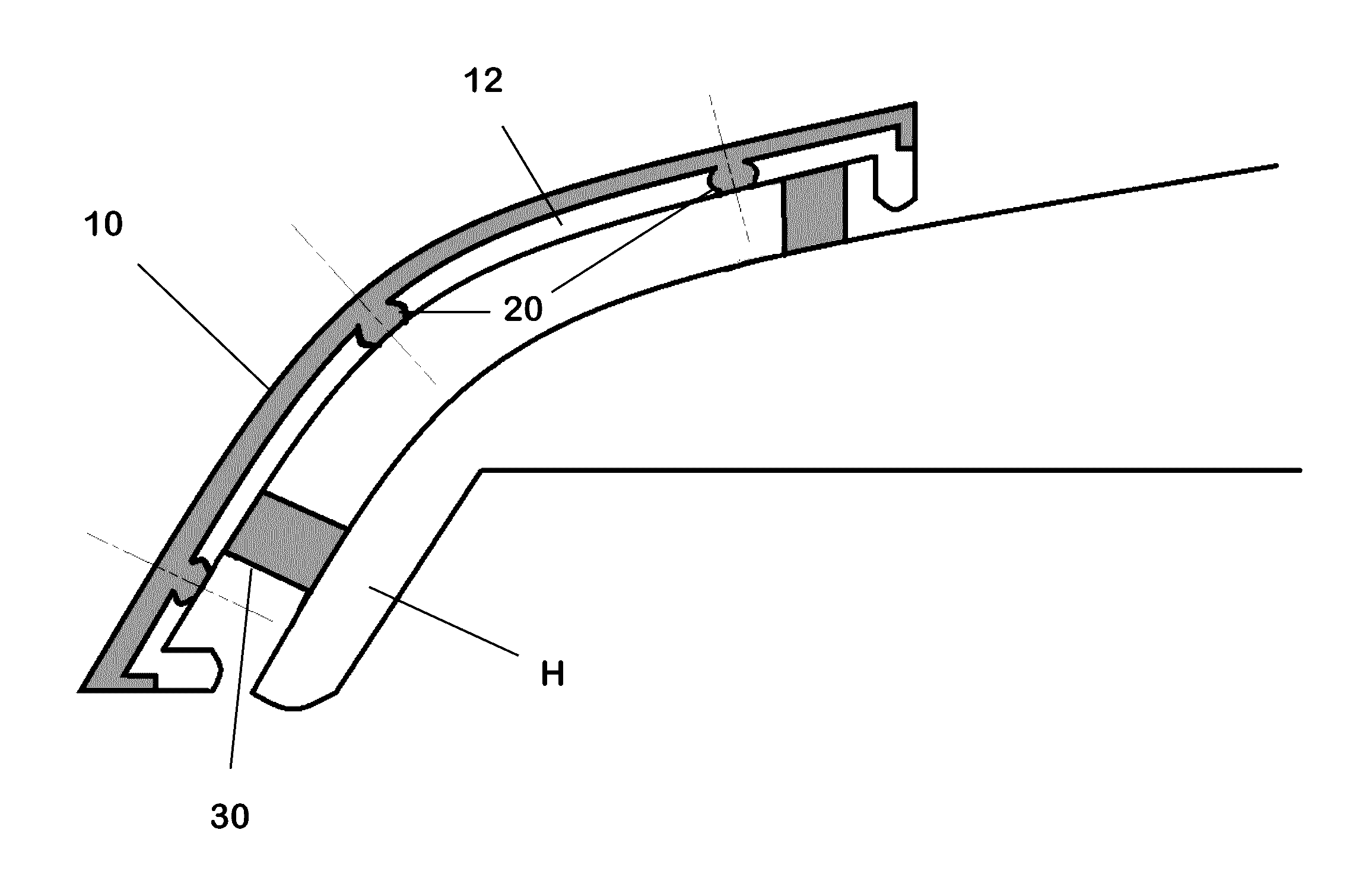

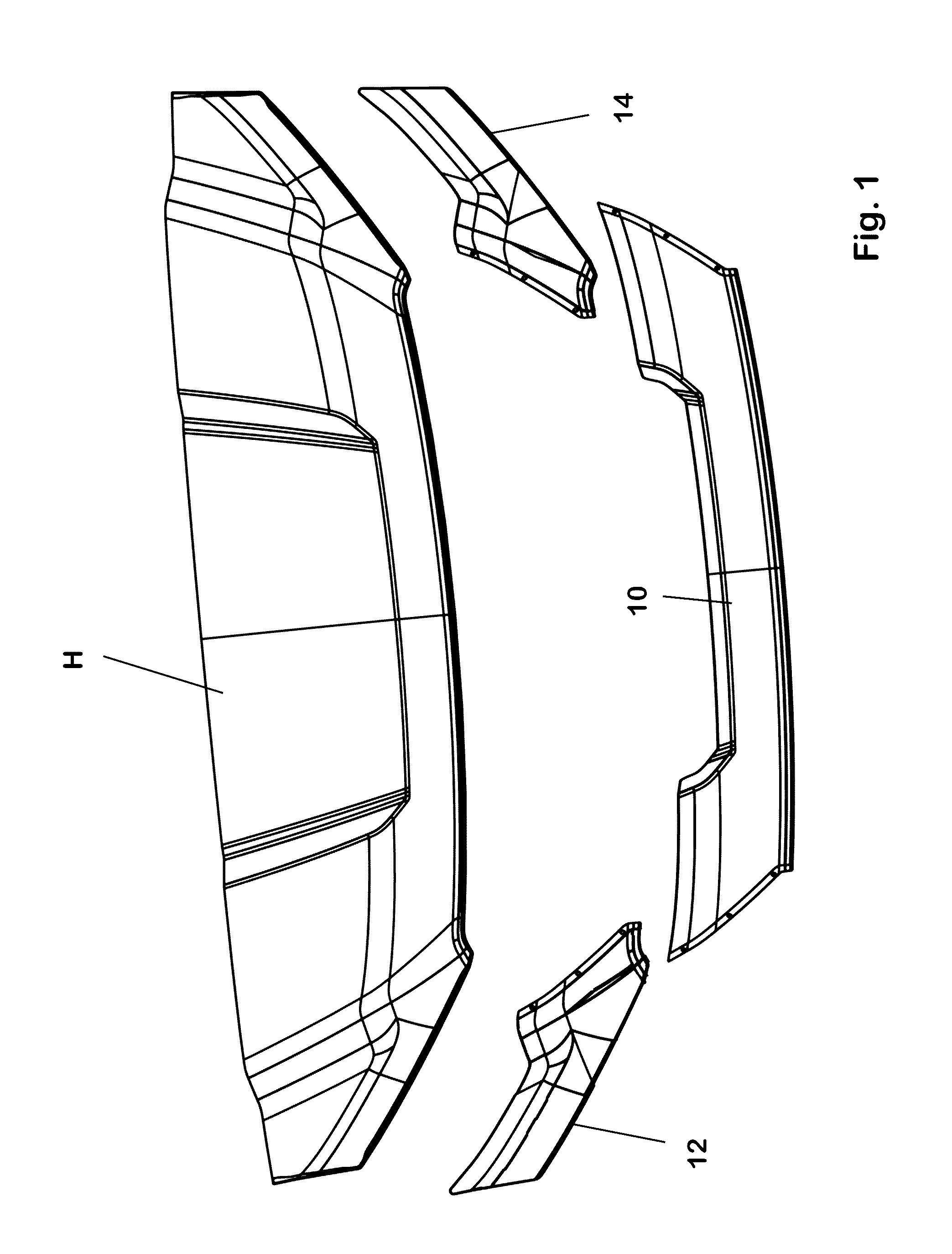

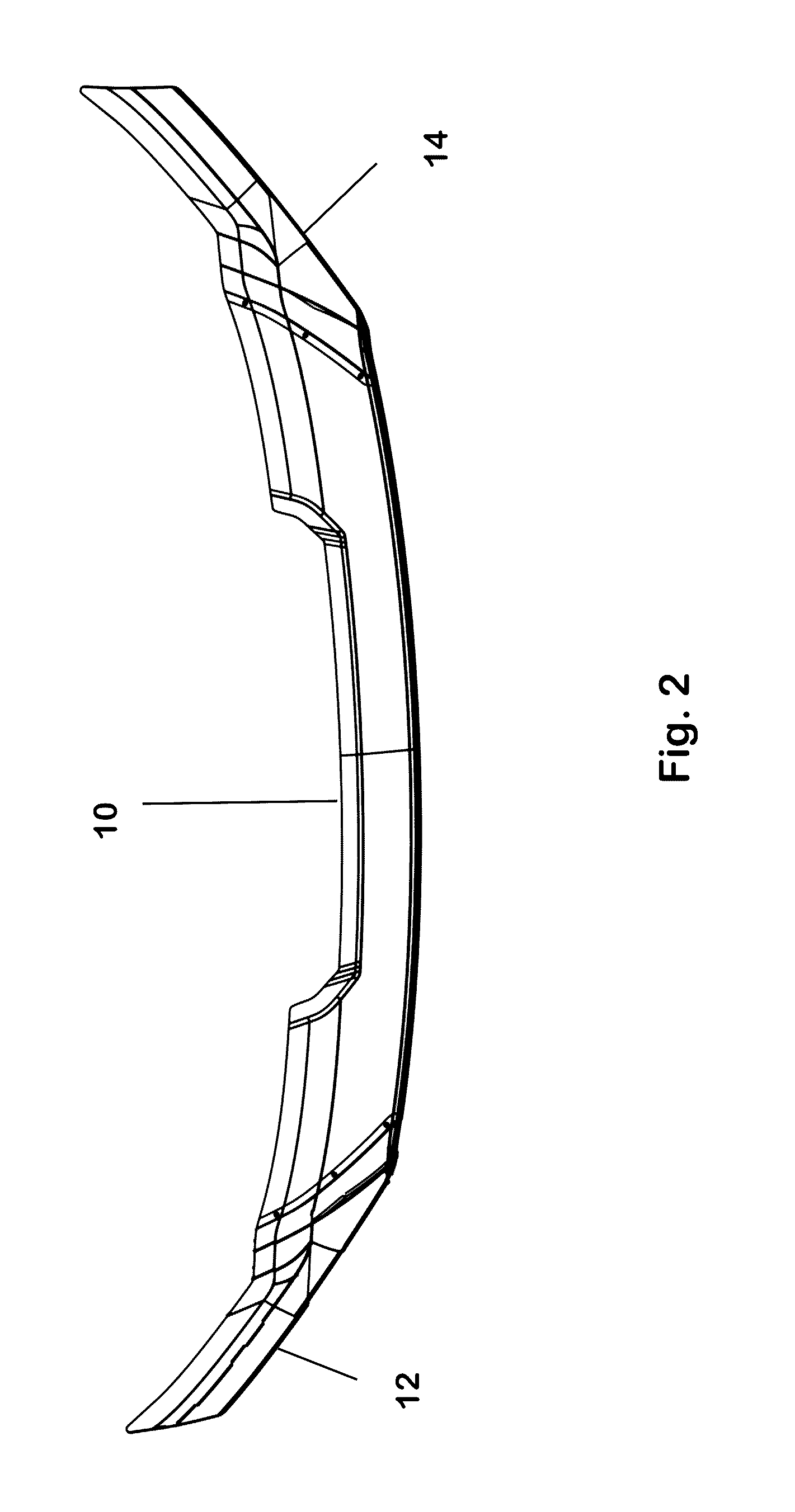

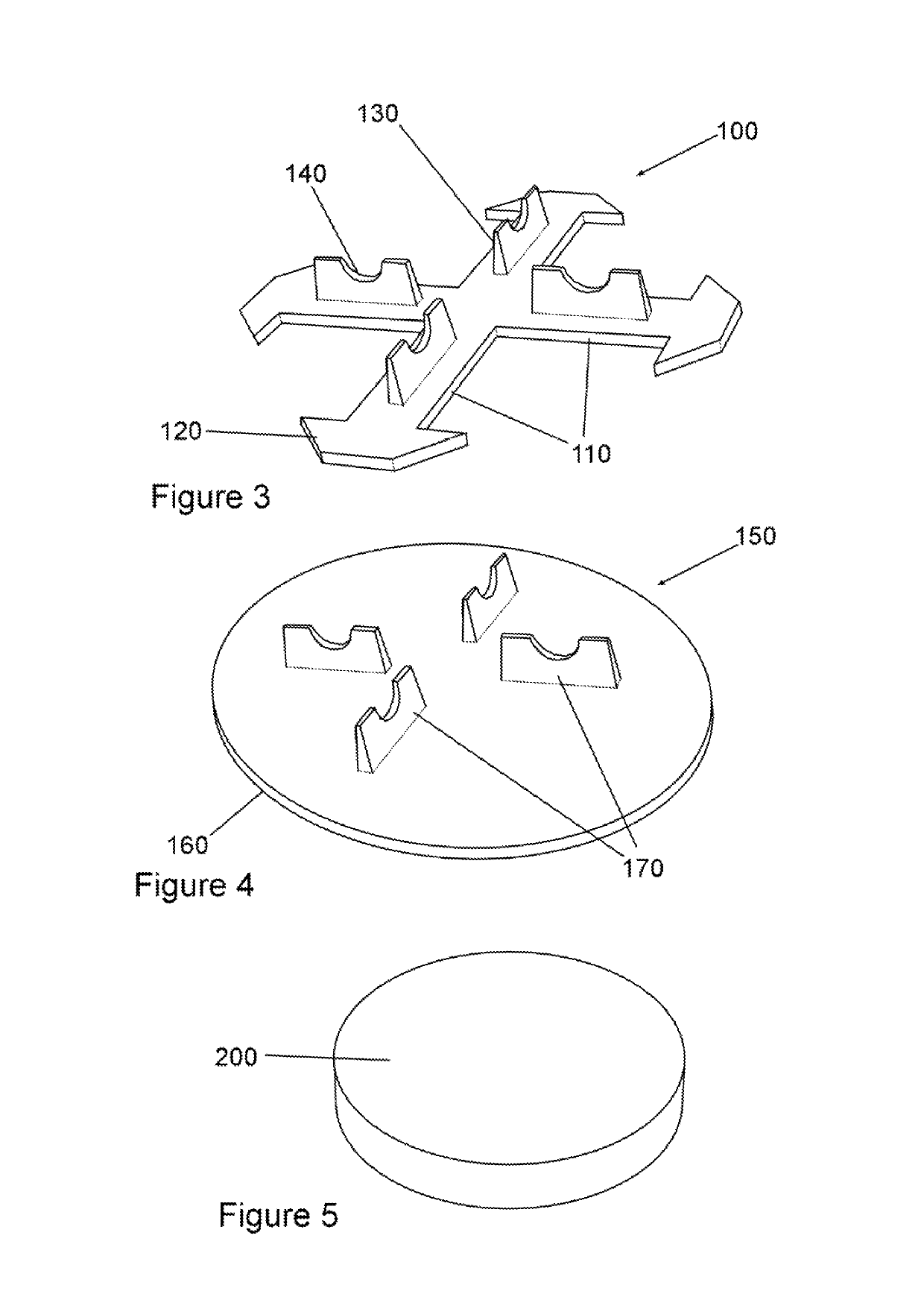

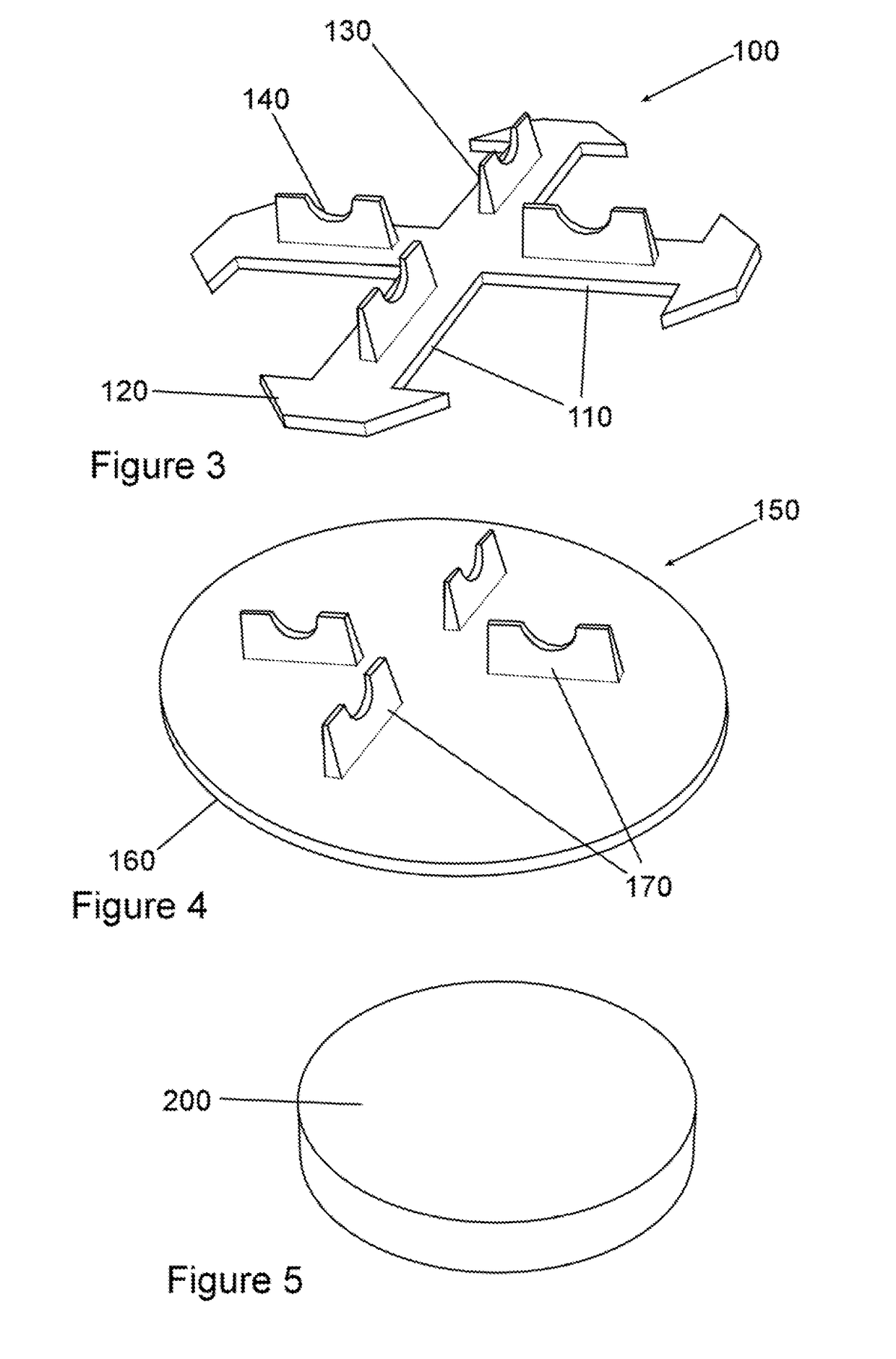

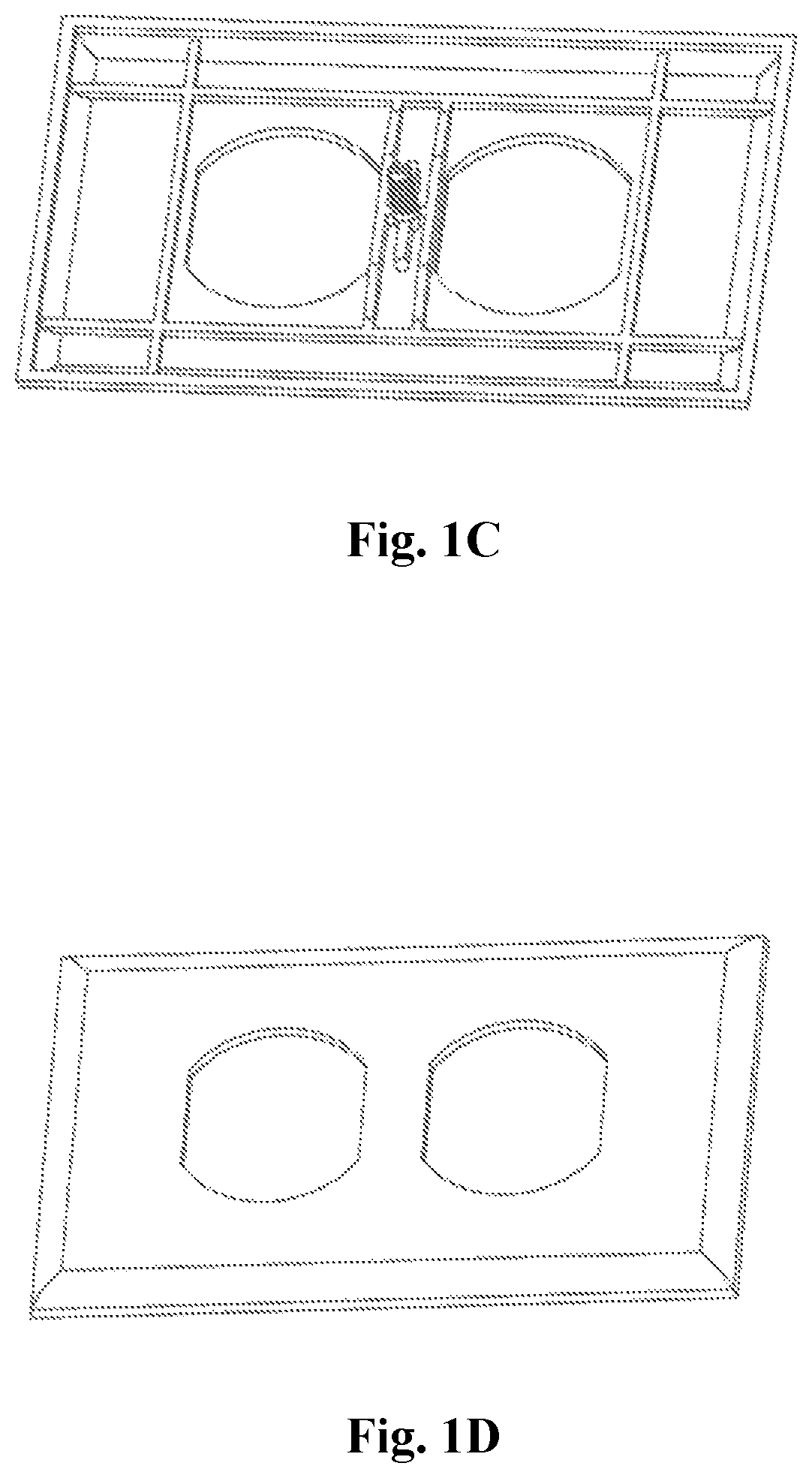

Interlocking multipiece vehicle front end protective device

InactiveUS20170021786A1Less packagingReduce environmental impactBumpersVehicle body streamliningMechanical engineeringEngineering

An interlocking multipiece vehicle shield is assembled from plural pieces which are joined edgewise, for example by studs and apertures having a snap-together feature. The pieces are designed so that the assembled shield conforms to the shape of the front end of a particular vehicle. The shield is secured to the vehicle by adhesive tape applied around the periphery of the shield.

Owner:AUTOMOTIVE ACCENTS LLC

Seal cavity throat protectors

Rotary shaft (220), housing (250) and packaging type seal (230) together form seal cavity (260). Seal cavity throat protector (200) in cavity (260) protects seal (230) against damaging materials from the region of impeller (210). Such material is directed away from seal (230) along spiral groove(s) (280) on inner surface of protector (200) with the assistance of flushing fluid entering cavity (260) via bore (270) and passing to inner surface of protector (200) via radial bores therethrough.

Owner:PRINZ GMBH & CO KG

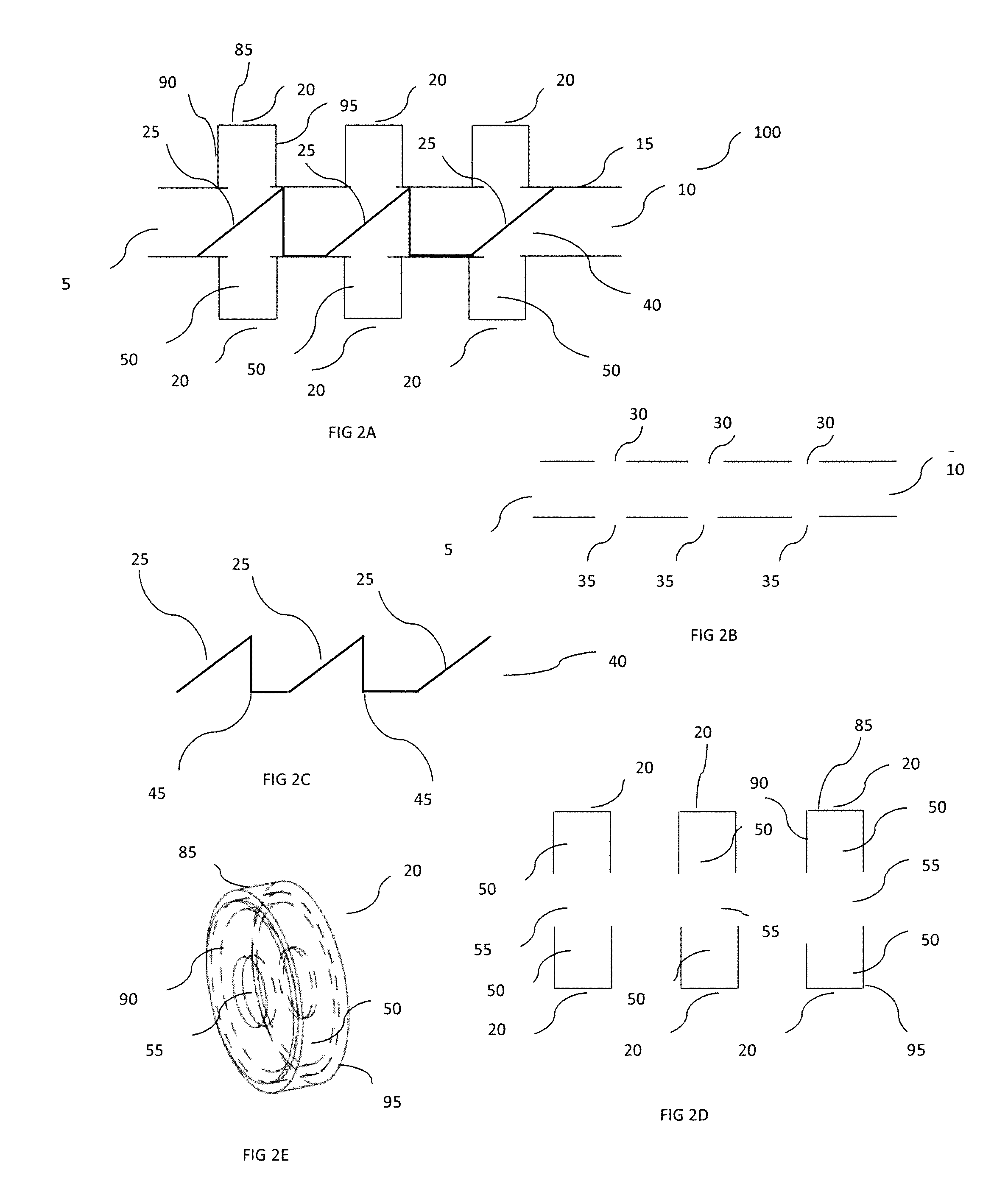

Heat Exchanger with heat exchange chambers and plate members utilizing respective medium directing members and method of making same

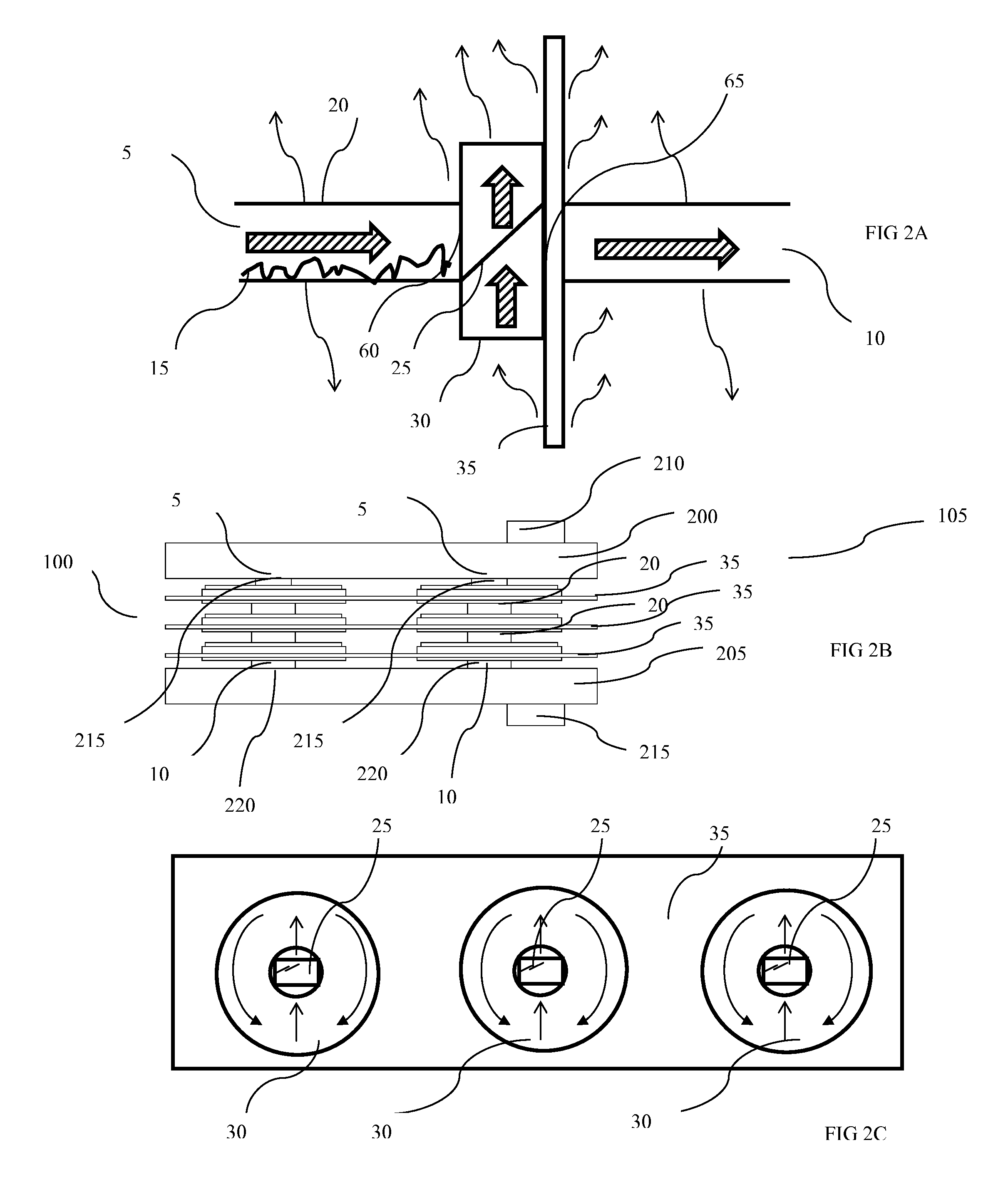

InactiveUS20130098590A1Increase surface areaMaximize heat exchanging capability of heat exchangerHeat exhanger conduitsMetal-working apparatusEngineeringInlet flow

A heat exchange unit having a plurality of chamber assembly coupled to a plate member, said chamber assembly including an inlet flow tube, an outlet flow tube, and a plurality of walls defining a chamber interior. Disposed within the chamber interior is a medium-directing member, having an inclined surface, diverting the heat exchange medium from the initial flow direction so that it disperses within the chamber interior, in to at least two distinct flow patterns. The heat exchange medium exits the chamber, via the outlet, in the initial line of flow. The chambers are interconnected by tubes to form assemblies. A plurality of plate member having plurality of chamber assembly is arranged on a spaced relation between manifolds to complete the medium flow.

Owner:MIKUTAY CORP

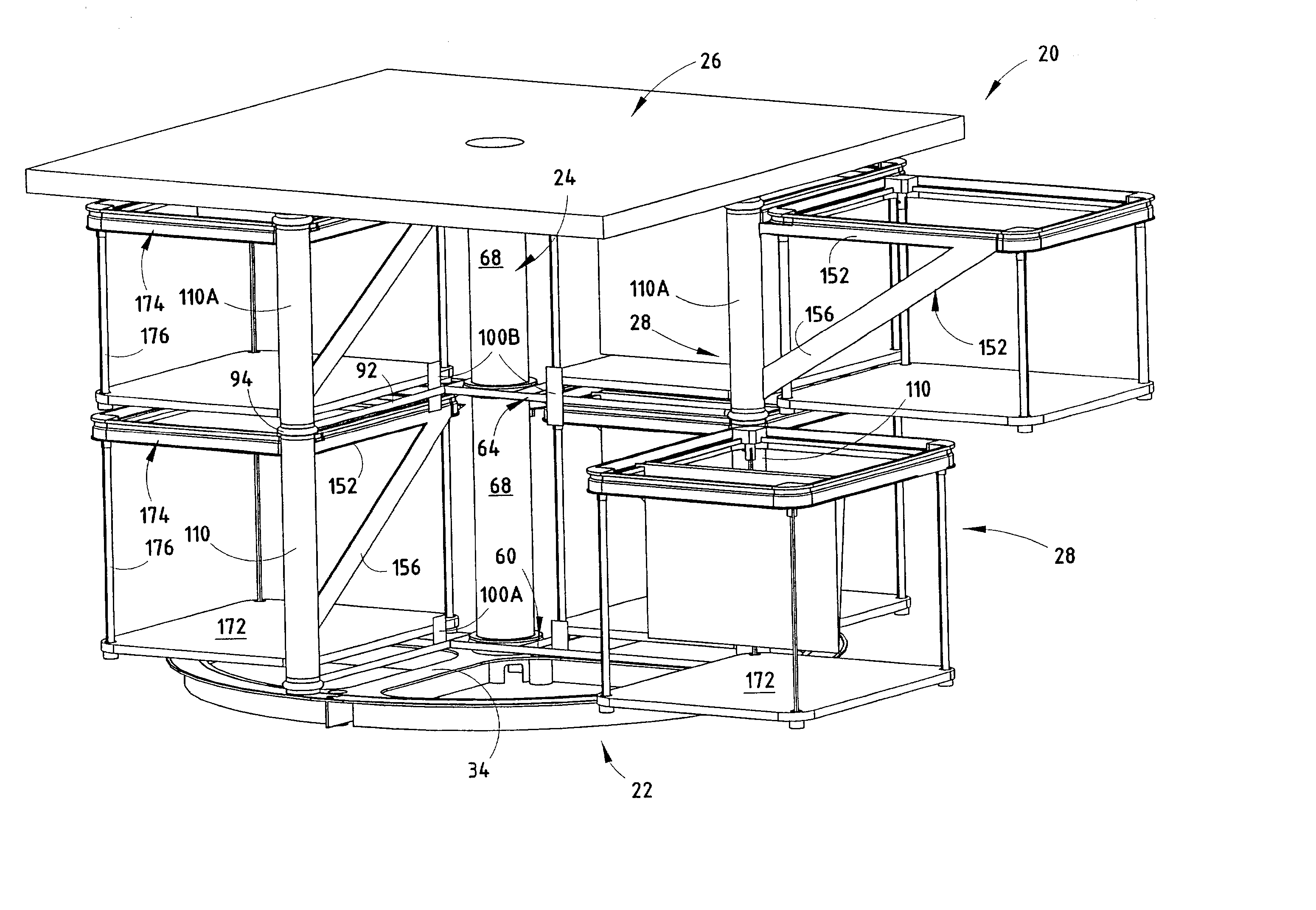

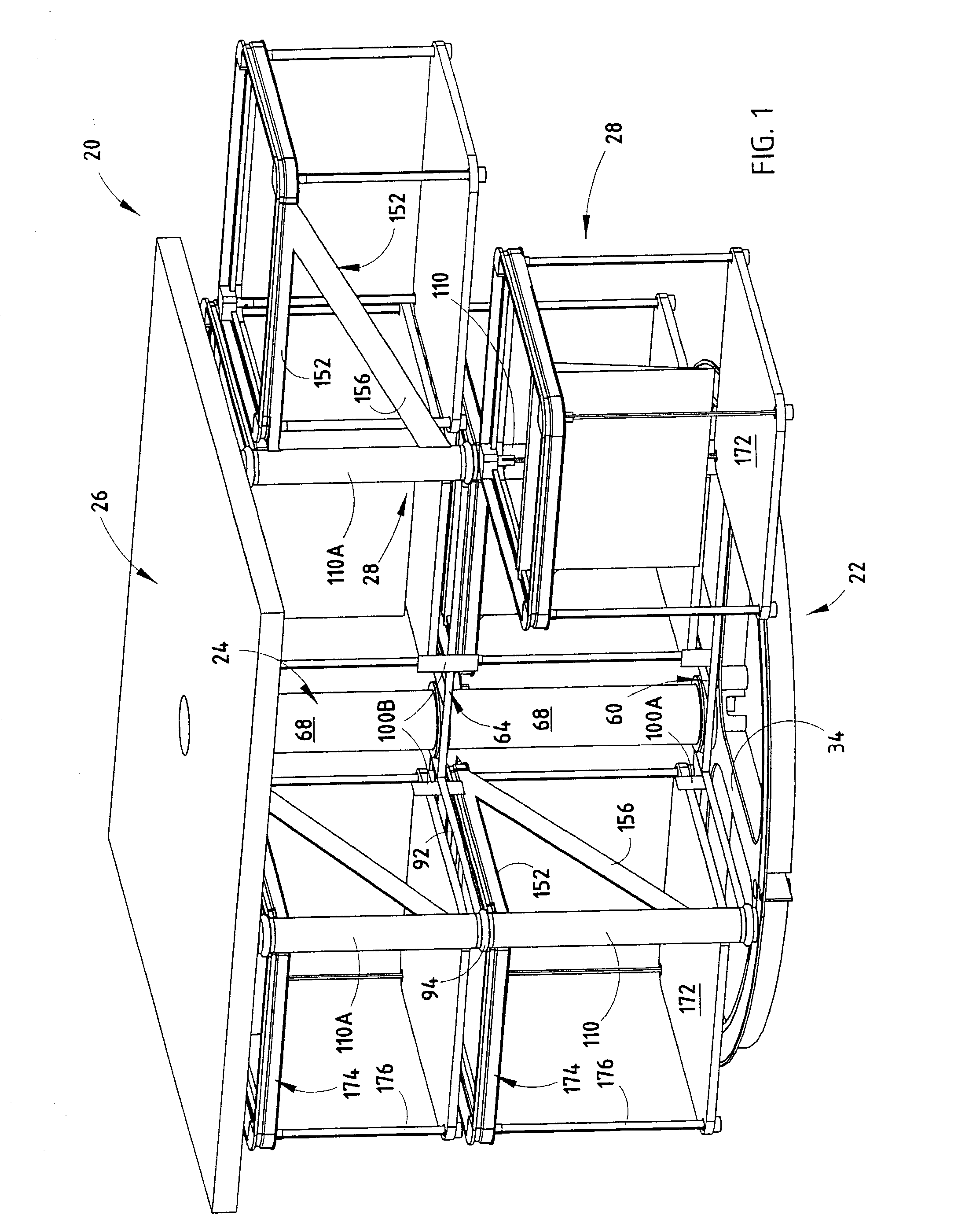

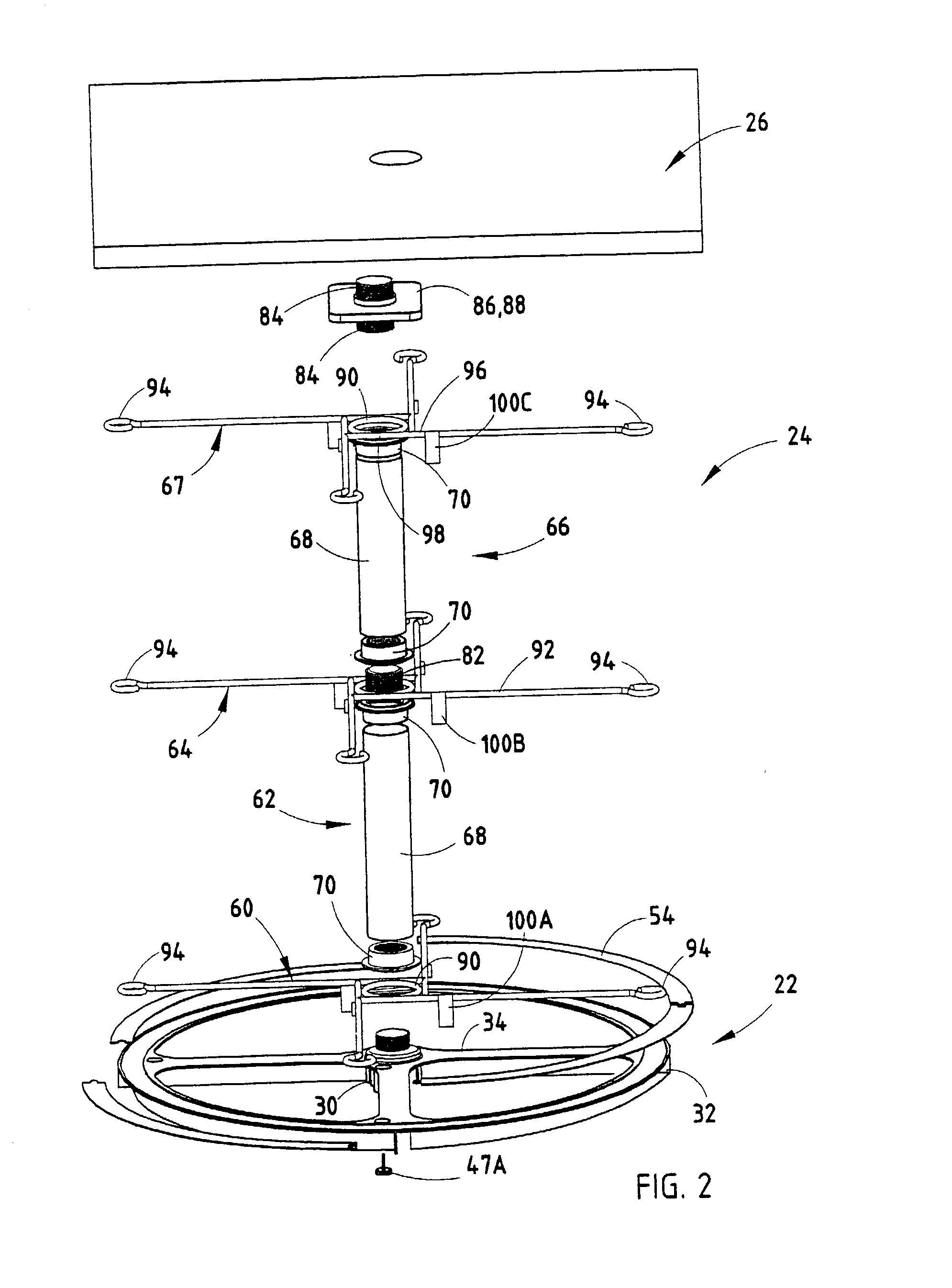

Carrousel file cabinet

InactiveUS20030034718A1Less packagingLess shipping spaceBook cabinetsSuspended filingsVertical axisOperating system

A file cabinet providing access to files from substantially all sides, and having one or more rotatable tiers, each tier containing a plurality of file containers. Each tier includes a central carrousel having a plurality of radially extending arms. Mounted to the outer terminus of each arm is a file support assembly, each configured to rotate about a vertical axis between a retracted position and an extended position. Each file support assembly is adapted to suspend a file container thereon to provide detachable storage. The detachable file containers each include a box having an upper frame which suspends the container from the file support assemblies. A top may be provided to close each container in a secure manner to protect the container's contents.

Owner:HARBOR STEEL & SUPPLY

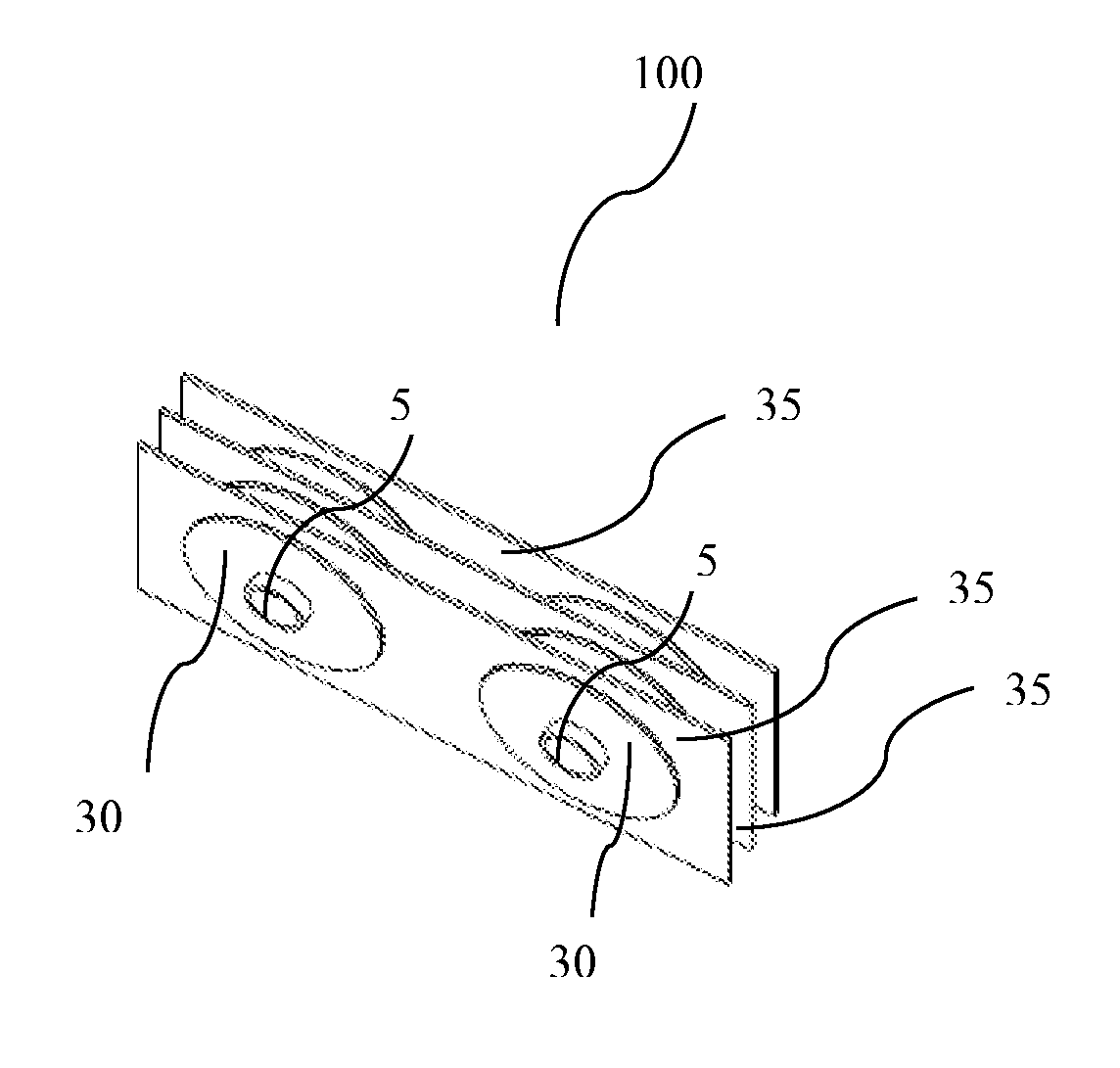

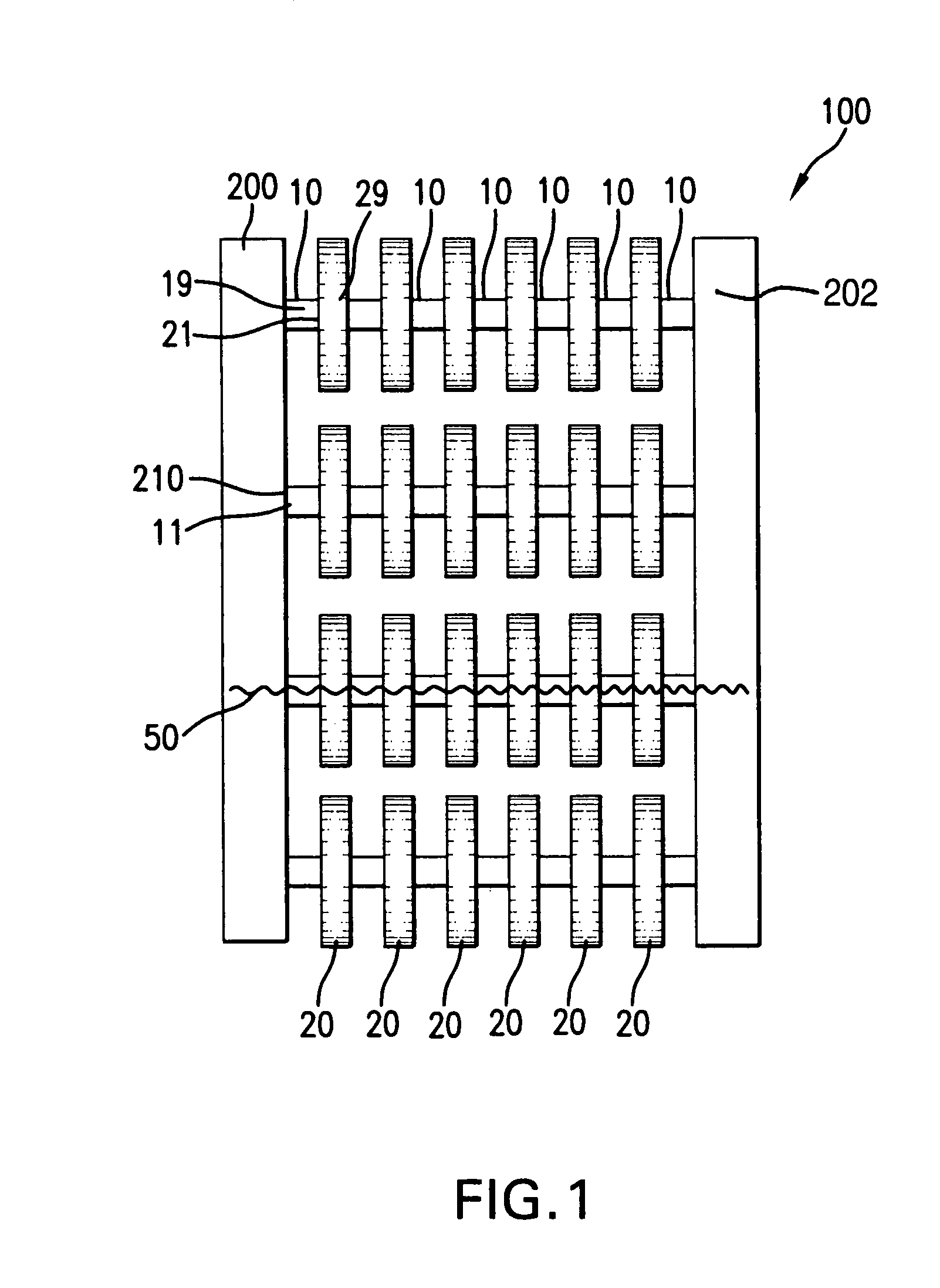

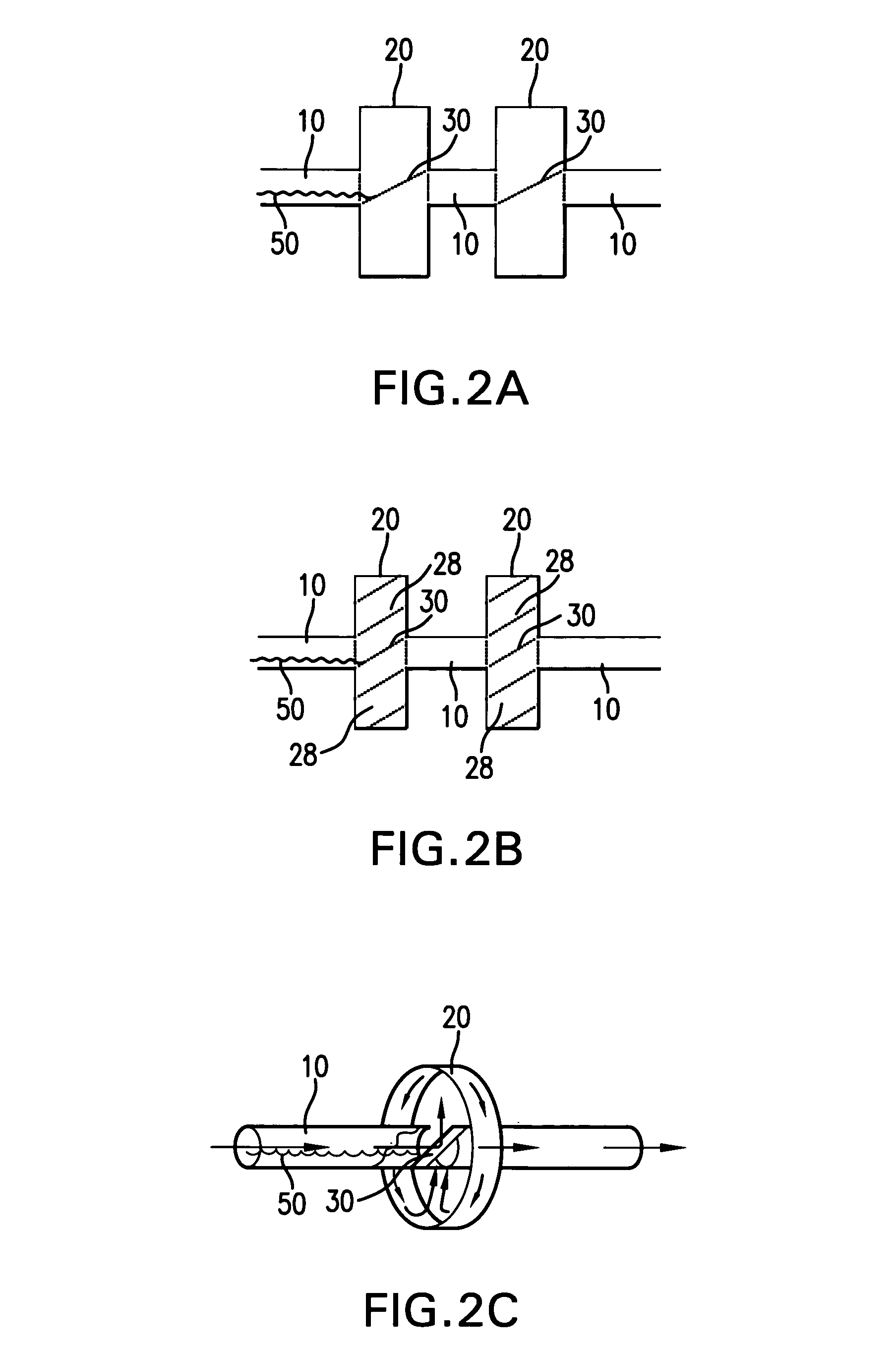

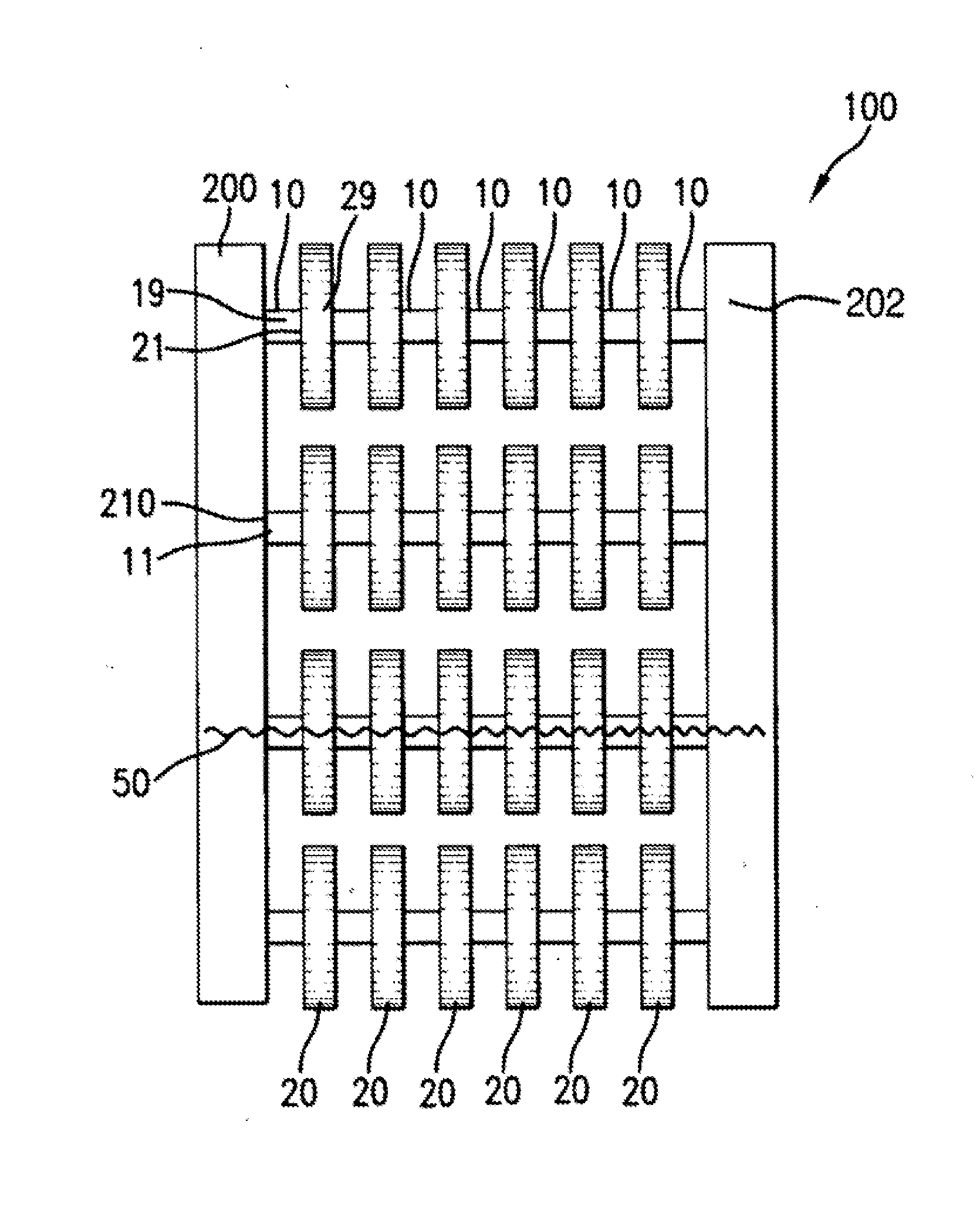

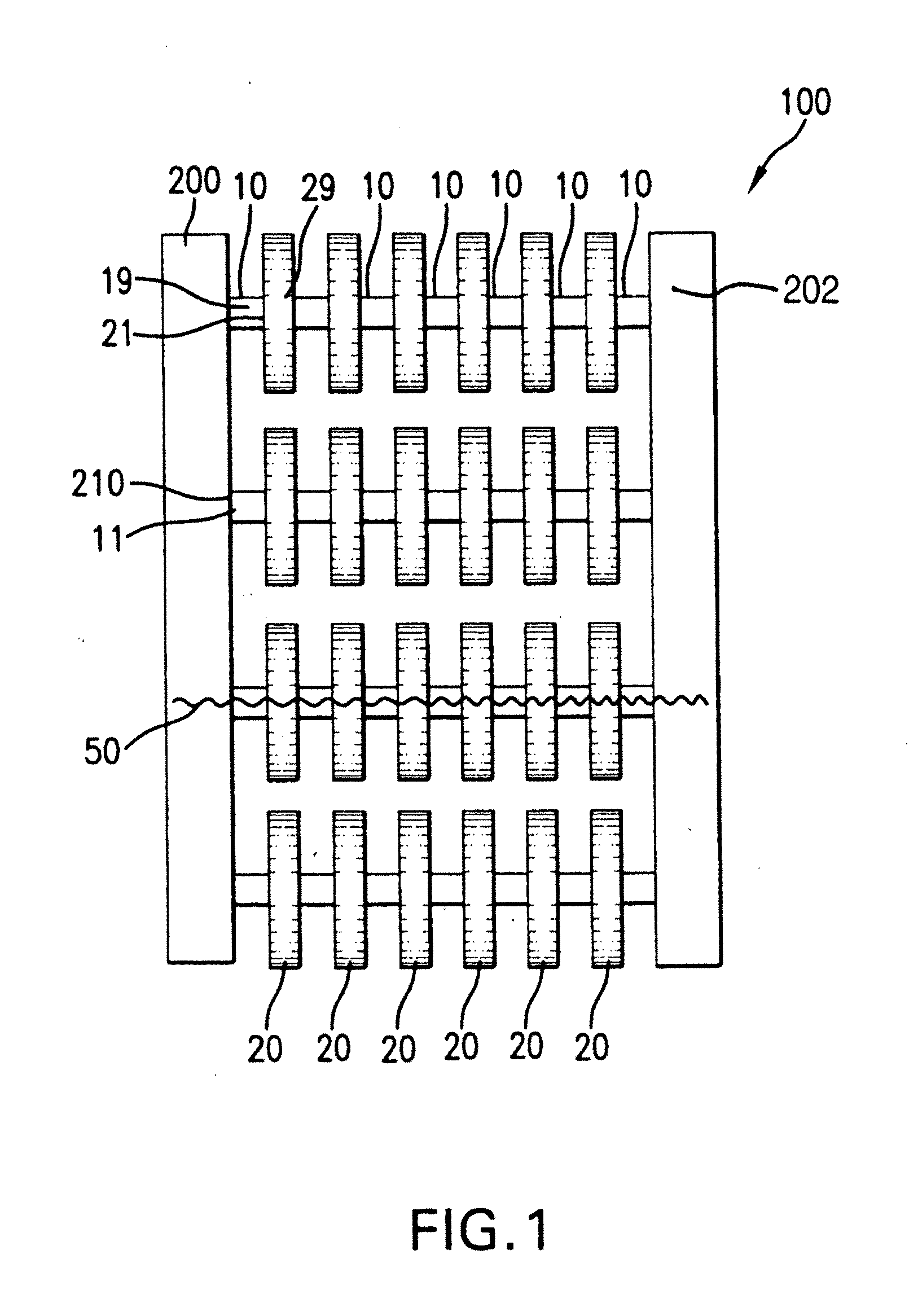

Heat exchanger with heat exchange chambers utilizing respective medium directing members

ActiveUS7987900B2Improve heating efficiencyIncrease the lengthHeat exchanger casingsHeat transfer modificationEngineeringMicro heat exchanger

A heat exchange chamber includes an inlet, an outlet and a plurality of walls defining a chamber interior. The inlet receives a heat exchange medium flowing in a first flow direction in an initial line of flow. Disposed within the chamber interior is a medium directing member, having an inclined surface, which diverts the medium from the initial flow direction so that it disperses within the chamber interior. The medium exits the chamber, via the outlet, in the initial line of flow. The chambers are interconnected by tubes to form assemblies. Plural sets of chamber and tube assemblies are arranged between manifolds to provide a heat exchanger.

Owner:MIKUTAY CORP

Tube for a heat exchanger

ActiveUS20090260788A1Improve heating efficiencyIncrease the lengthHeat exchanger casingsHeat transfer modificationNuclear engineeringHeat exchanger

A tube for a heat exchanger includes a first segment that couples to a chamber for transportation of heat exchange media. The chamber receives the heat exchange media that disperses throughout the chamber and mixes within the chamber. The heat exchange media is then transported from the chamber. The chamber may include redirection members for controlling the direction in which the heat exchange media travels throughout the chamber. The tube may be connected to a header or manifold. The tube and chamber combination alone may be used as a heat exchanger.

Owner:MIKUTAY CORP

Method for processing hydrocarbon pyrolysis effluent

InactiveUS8524070B2Value maximizationReduced susceptibility to foulingThermal non-catalytic crackingCatalytic crackingBoiling pointTar

A method and apparatus are disclosed for treating the effluent from a hydrocarbon pyrolysis unit employing a small primary fractionator, i.e., a rectifier. The method comprises cooling the gaseous effluent, e.g., by direct quench and / or at least one primary heat exchanger, and then cooling the gaseous effluent to a temperature at which tar, formed by reactions among constituents of the effluent, condenses, e.g., in a secondary exchanger. The resulting mixed gaseous and liquid effluent is passed through a rectifier, to cleanly separate quench oil from the gaseous effluent comprising a pyrolysis gasoline fraction, whose boiling point can be lowered as a result of the rectifier treatment. The effluent is then cooled to condense a liquid effluent comprising pyrolysis gasoline and water condensed from steam, which fractions are separated in a distillate drum. The cooled gaseous effluent is directed to a recovery train to recover light olefins. At least a portion of the pyrolysis gasoline-containing fraction can be recycled to the rectifier to enhance separation of the quench oil from the pyrolysis gasoline fraction.

Owner:EXXONMOBIL CHEM PAT INC

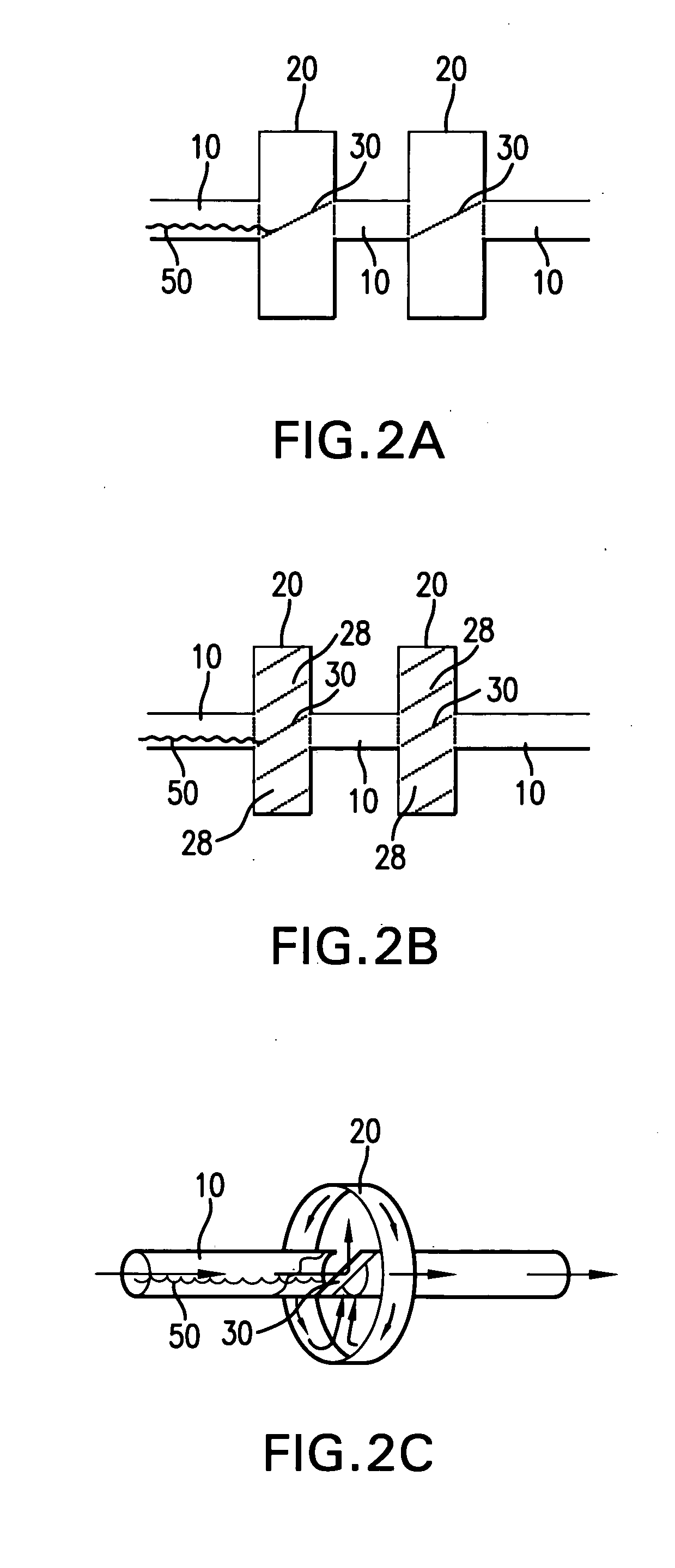

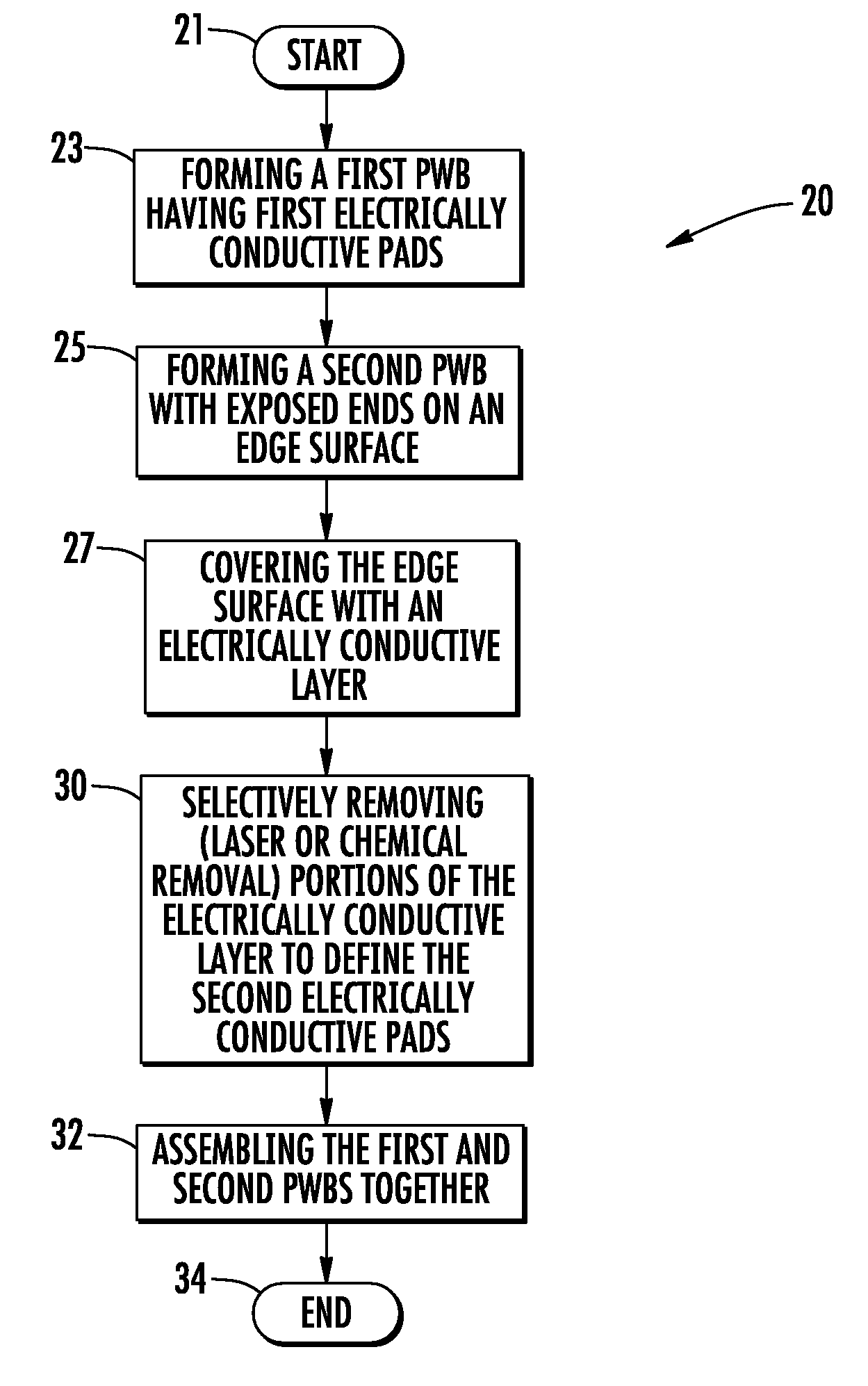

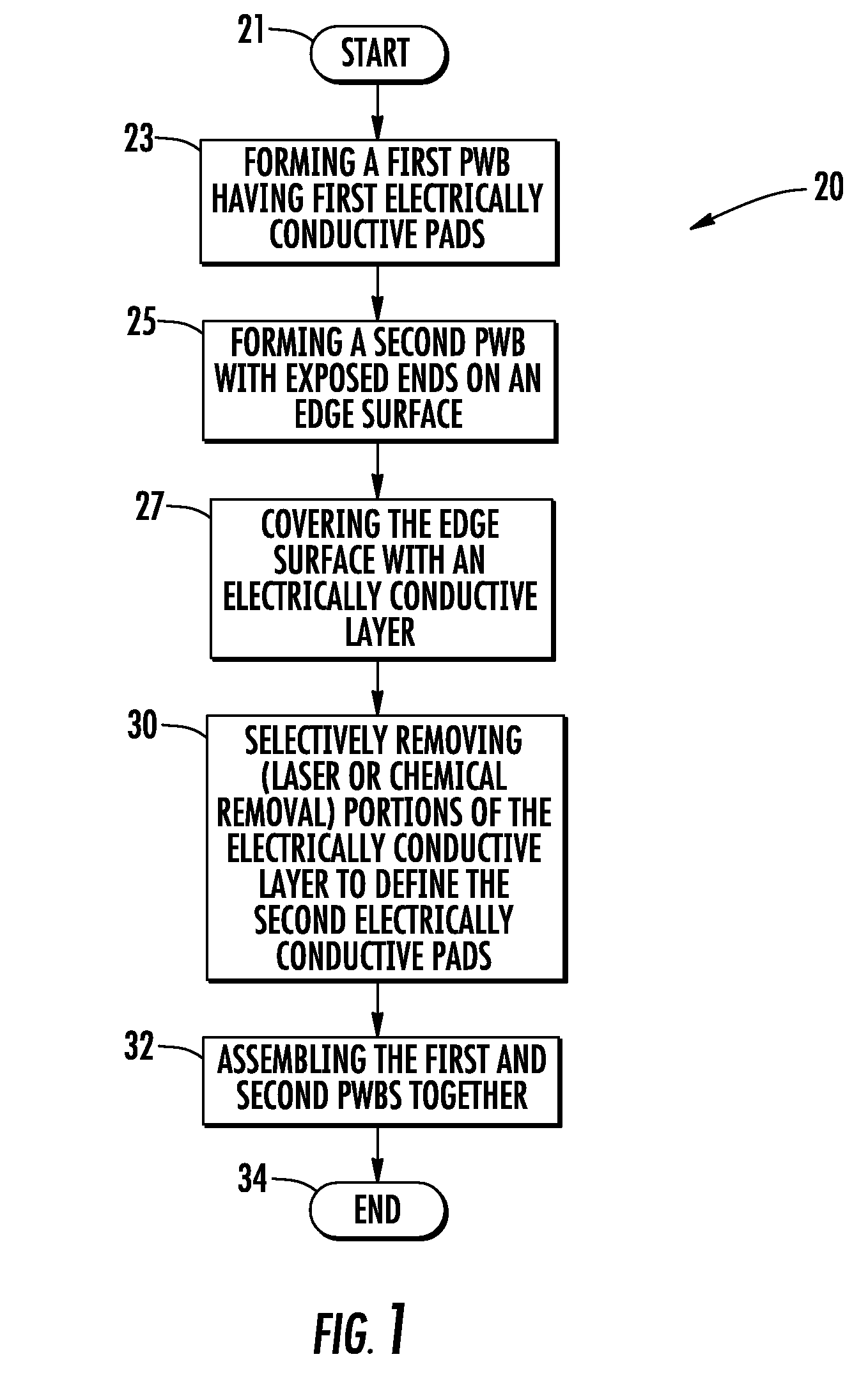

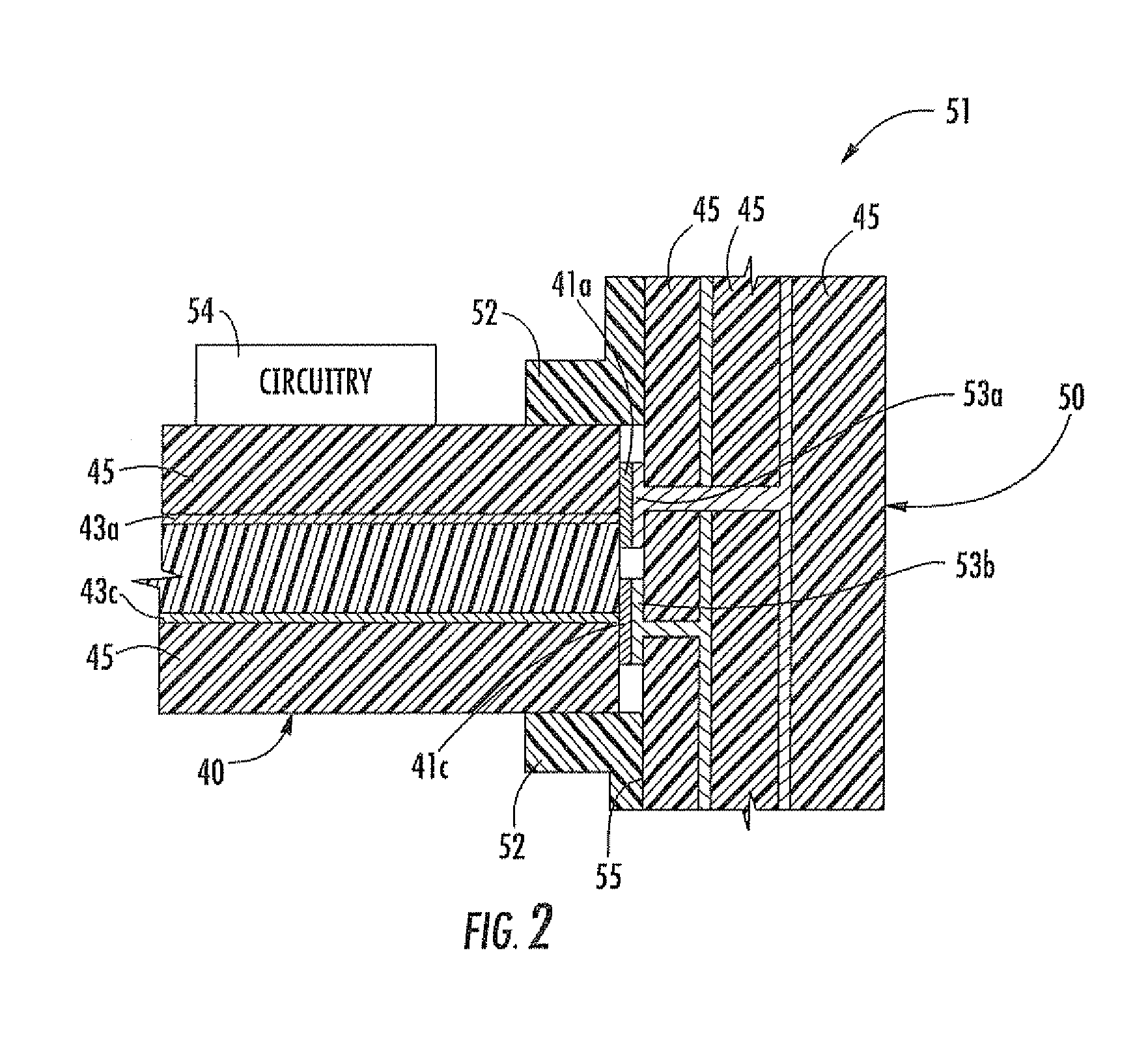

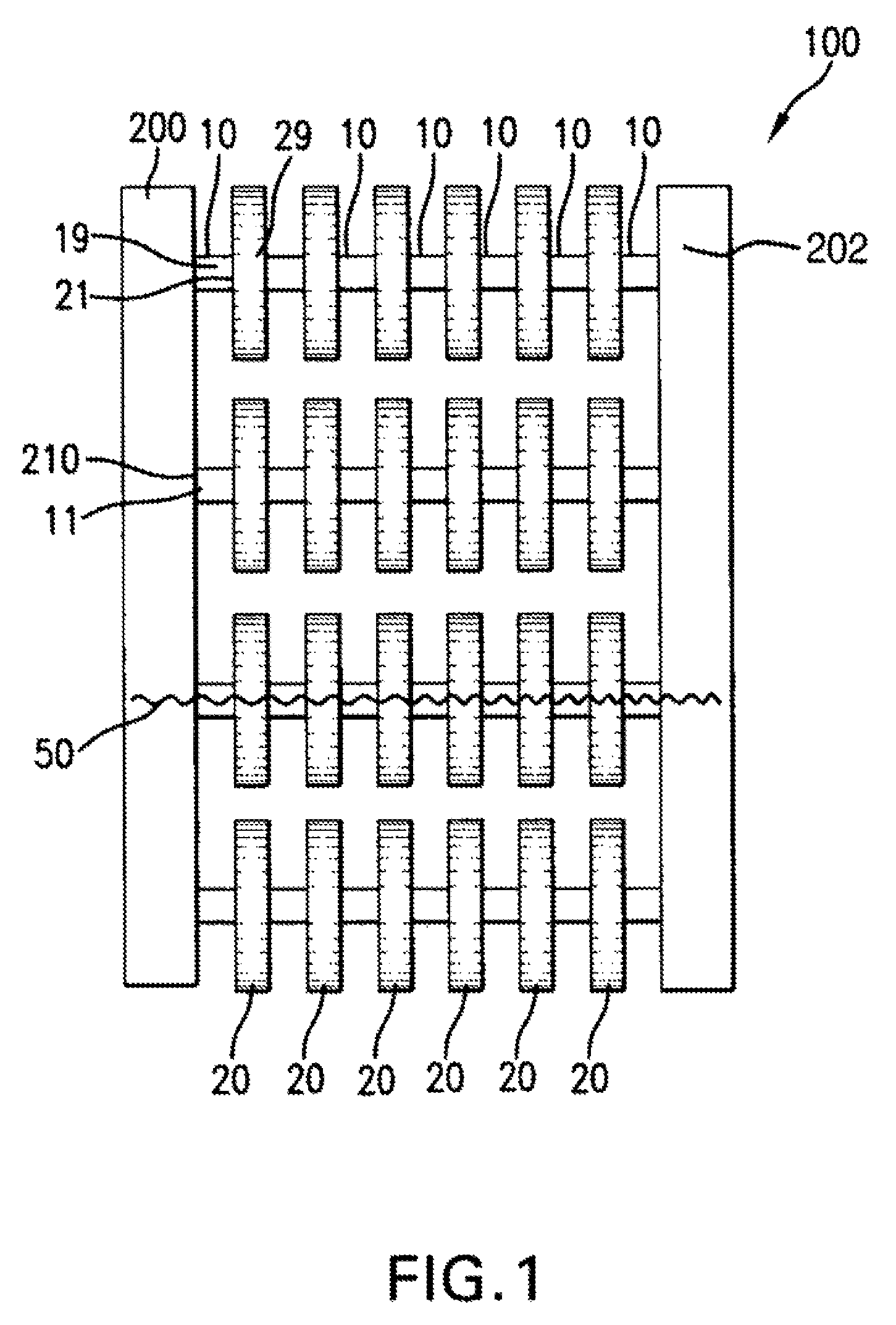

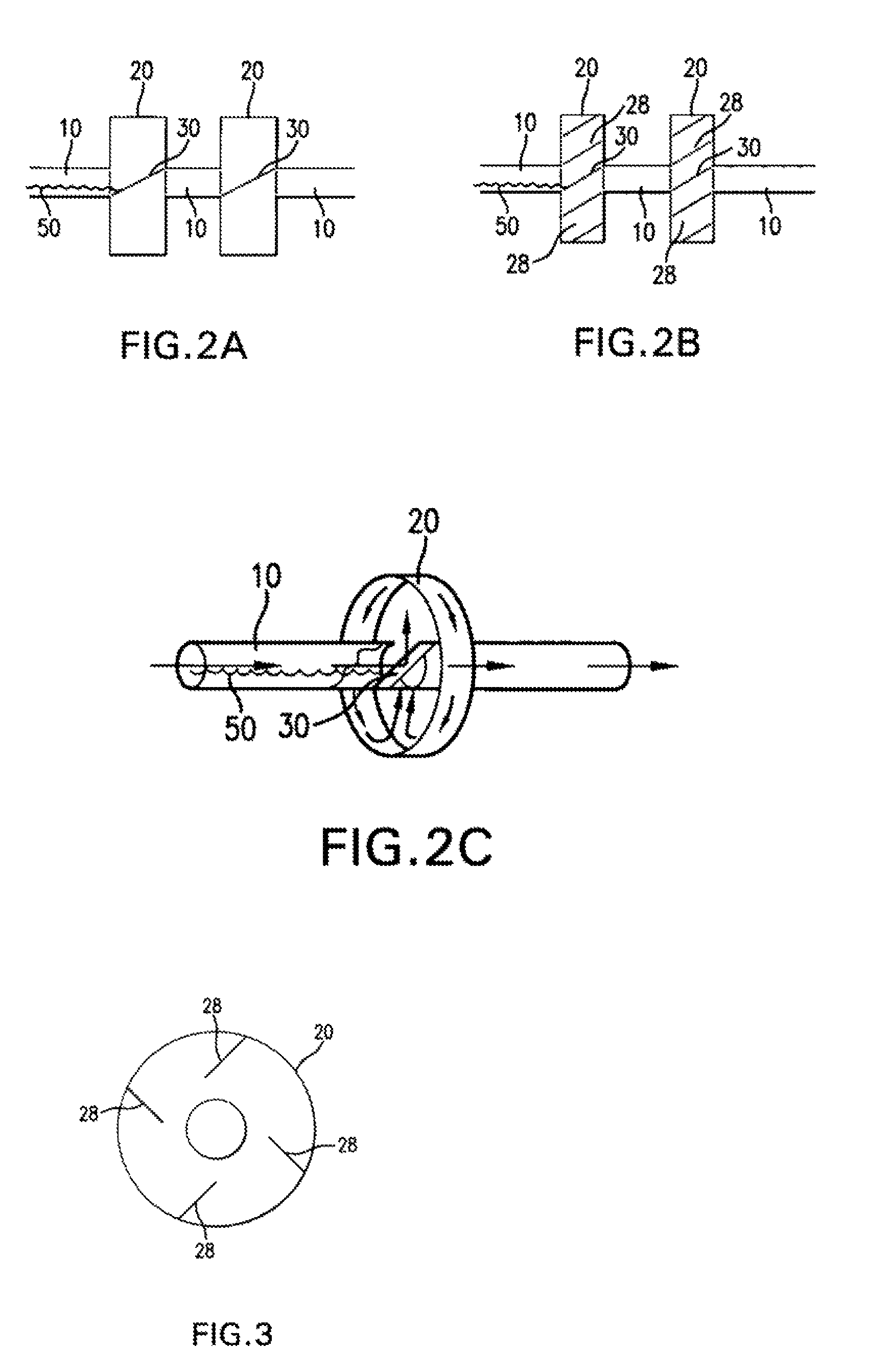

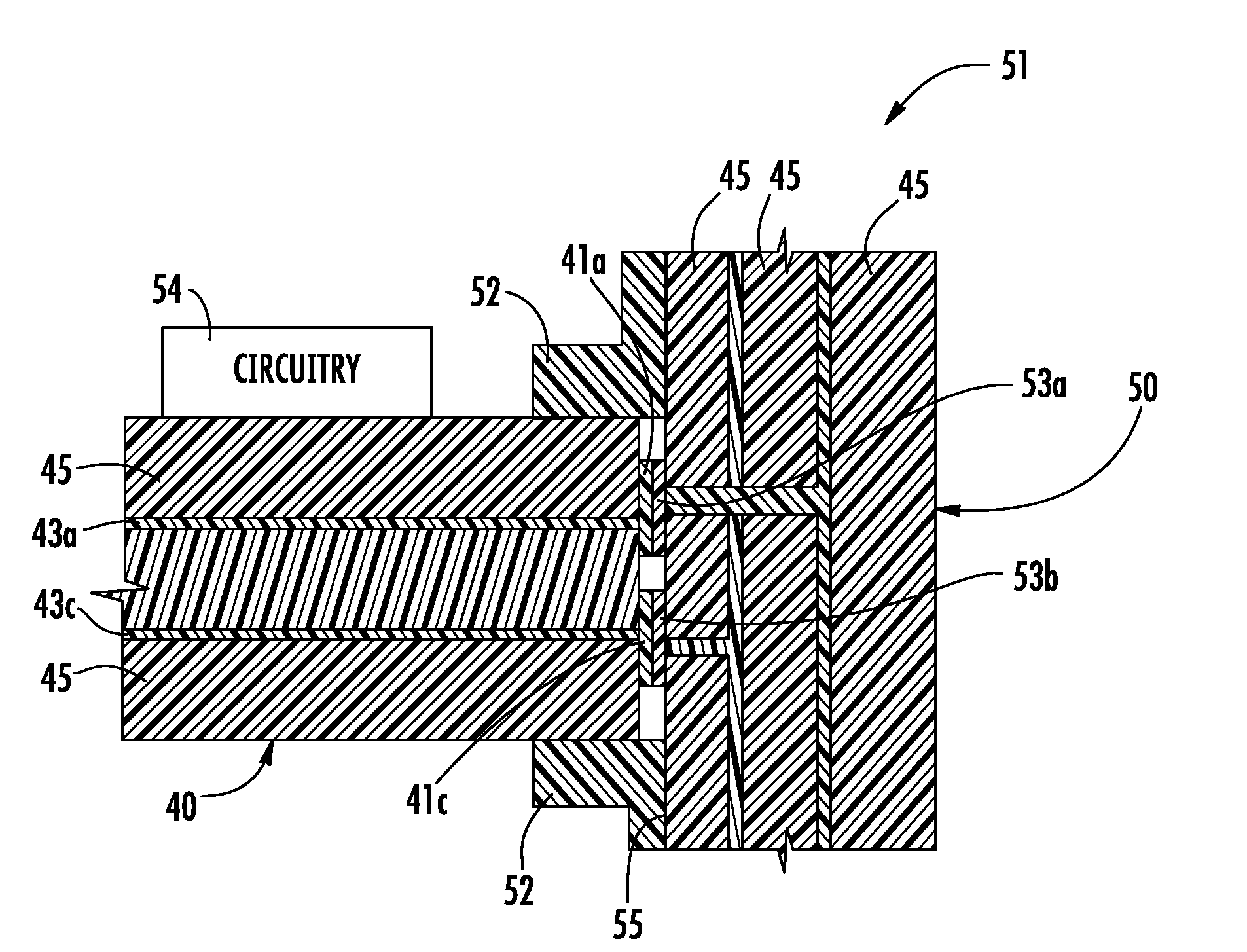

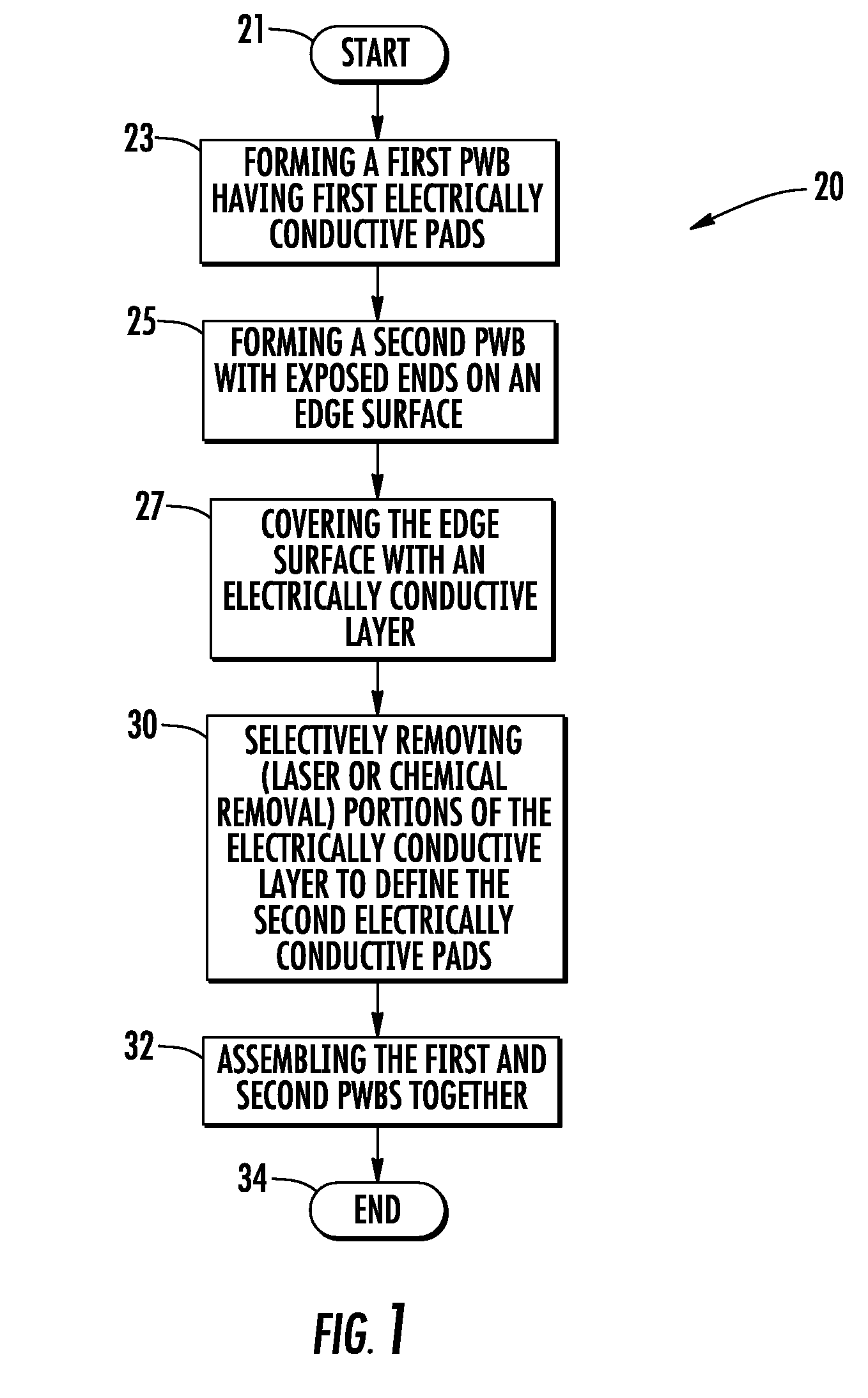

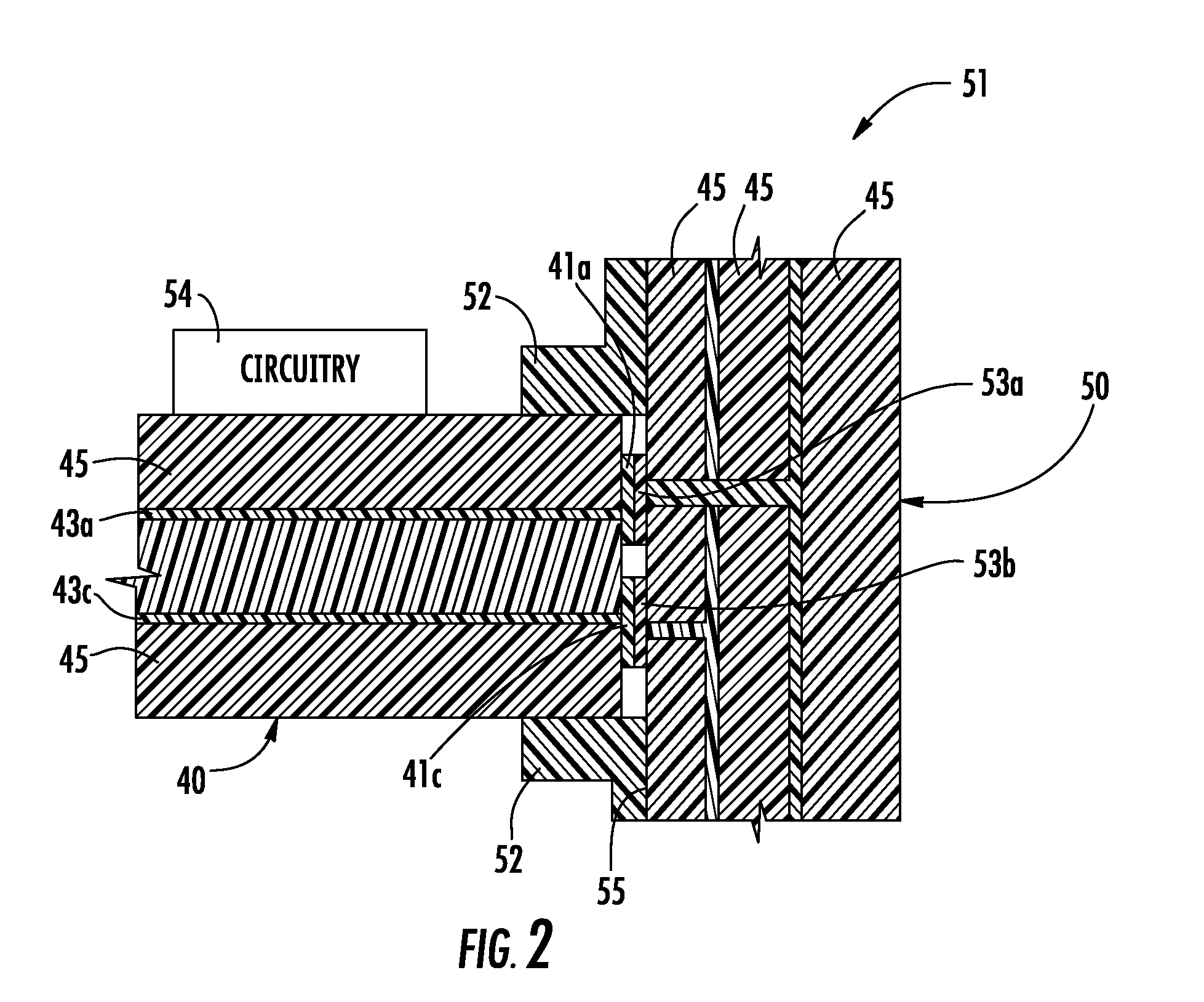

Printed wiring board assembly and related methods

ActiveUS8572841B2Cost effectiveEfficient preparationPrinted circuit assemblingPrinted electric component incorporationEdge surfaceElectrical and Electronics engineering

A method is for making a printed wiring board (PWB) assembly. The method may include forming a first PWB having a plurality of first electrically conductive pads, forming a second PWB including a plurality of electrically conductive traces having exposed ends on an edge surface of the second PWB, and covering the edge surface of the second PWB with an electrically conductive layer. The method may also include selectively removing portions of the electrically conductive layer to define a plurality of second electrically conductive pads electrically connected to corresponding ones of the exposed ends of the electrically conductive traces, and assembling the first and second PWBs together so that the first and second electrically conductive pads are electrically coupled together to define the PWB assembly.

Owner:HARRIS CORP

Heat exchanger with heat exchange chambers utilizing protrusion and medium directing members and medium directing channels

InactiveUS8584741B2Improve heating efficiencyIncrease the lengthStationary conduit assembliesHeat exchanger casingsEngineeringMicro heat exchanger

A heat exchanger has a plurality of chamber units. The chamber units include an inlet orifice, an outlet orifice, and a plurality of walls defining a chamber interior. The inlet receives a heat exchange medium flowing in a first flow direction in an initial line of flow. Disposed within the chamber interior is a medium directing member, having an inclined surface, which diverts the heat exchange medium from the initial flow direction so that it disperses within the chamber interior in at least two distinct flow patterns. Directional flow of the medium may be facilitated by two medium directing channels disposed within one or more of the chamber walls. Protrusion members on one or more chamber walls enhance dispersion of the heat exchange medium, causing a turbulent flow pattern within the chamber interior. The heat exchange medium exits the chamber, via the outlet, in the initial line of flow. The chambers are interconnected to form assemblies. Plural assemblies are arranged between manifolds to complete the heat exchanger.

Owner:MIKUTAY CORP

Printed wiring board assembly and related methods

ActiveUS20090236139A1Efficient preparationEfficient and cost-effective manufacturingPrinted circuit assemblingCross-talk/noise/interference reductionEdge surfaceElectrical and Electronics engineering

A method is for making a printed wiring board (PWB) assembly. The method may include forming a first PWB having a plurality of first electrically conductive pads, forming a second PWB including a plurality of electrically conductive traces having exposed ends on an edge surface of the second PWB, and covering the edge surface of the second PWB with an electrically conductive layer. The method may also include selectively removing portions of the electrically conductive layer to define a plurality of second electrically conductive pads electrically connected to corresponding ones of the exposed ends of the electrically conductive traces, and assembling the first and second PWBs together so that the first and second electrically conductive pads are electrically coupled together to define the PWB assembly.

Owner:HARRIS CORP

Heat Exchanger with heat exchange chambers utilizing respective medium directing members

InactiveUS20110290466A1Increase surface areaImprove heat exchange capacityStationary conduit assembliesHeat exchanger casingsEngineeringHeat exchanger

Owner:MIKUTAY CORP

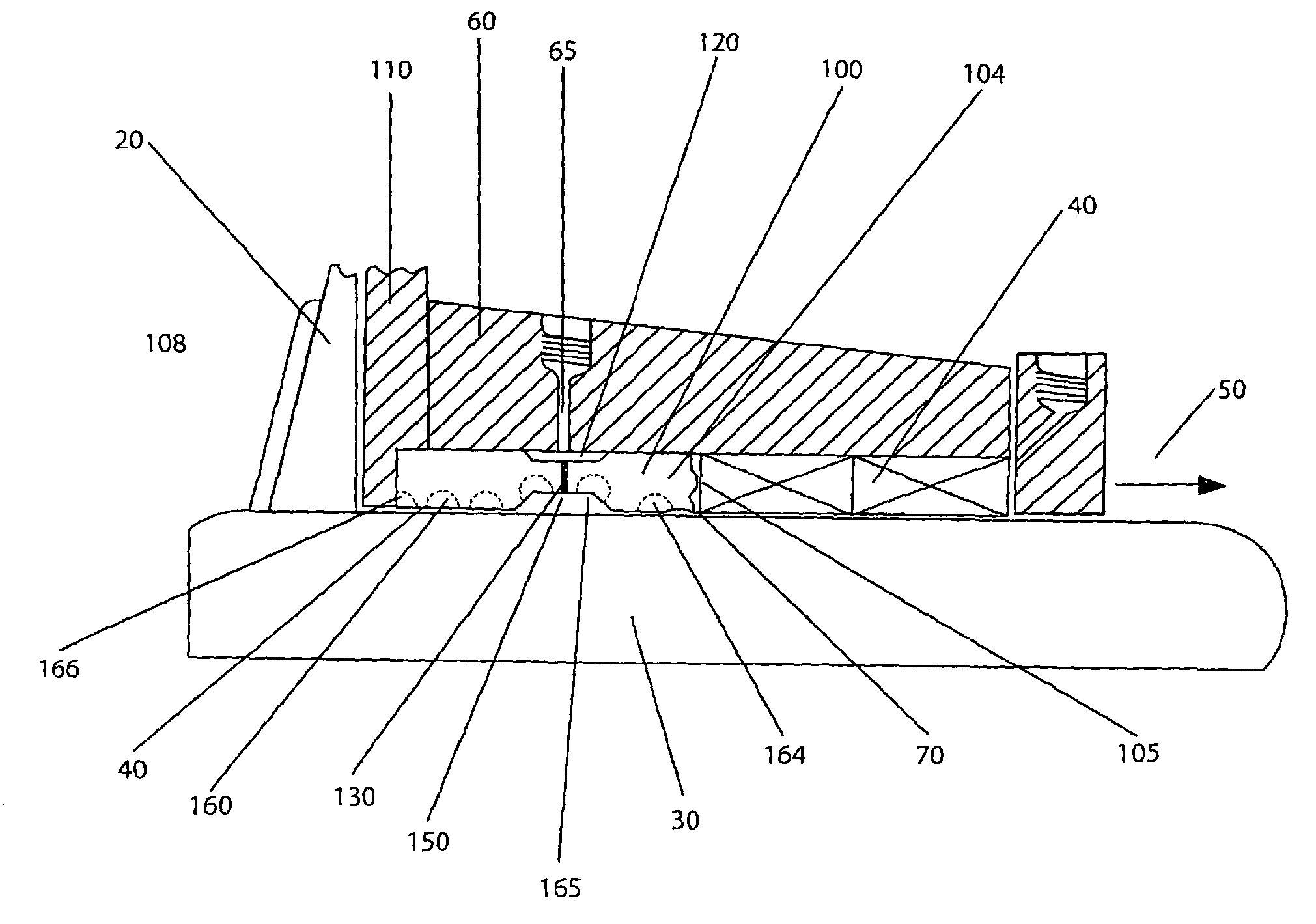

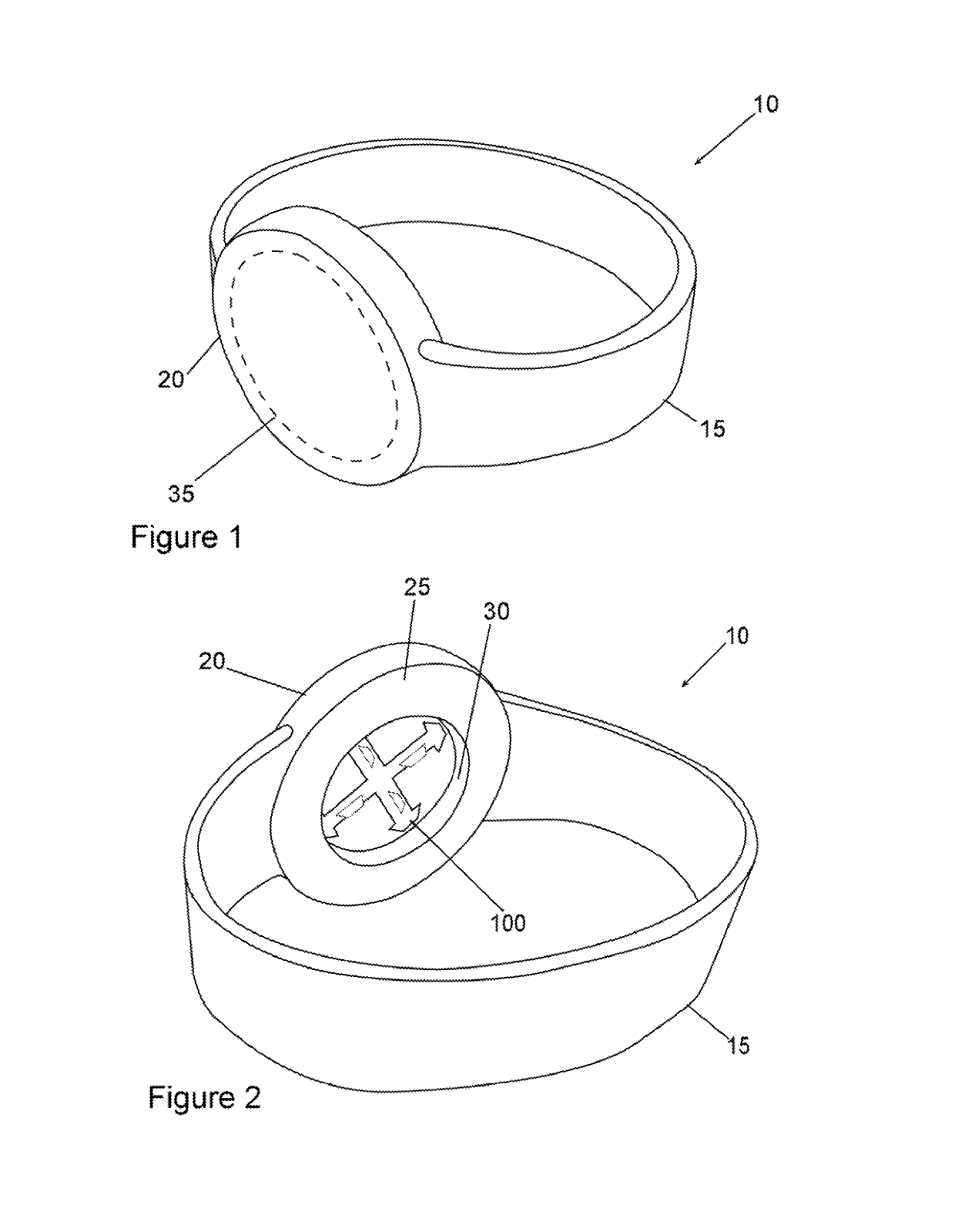

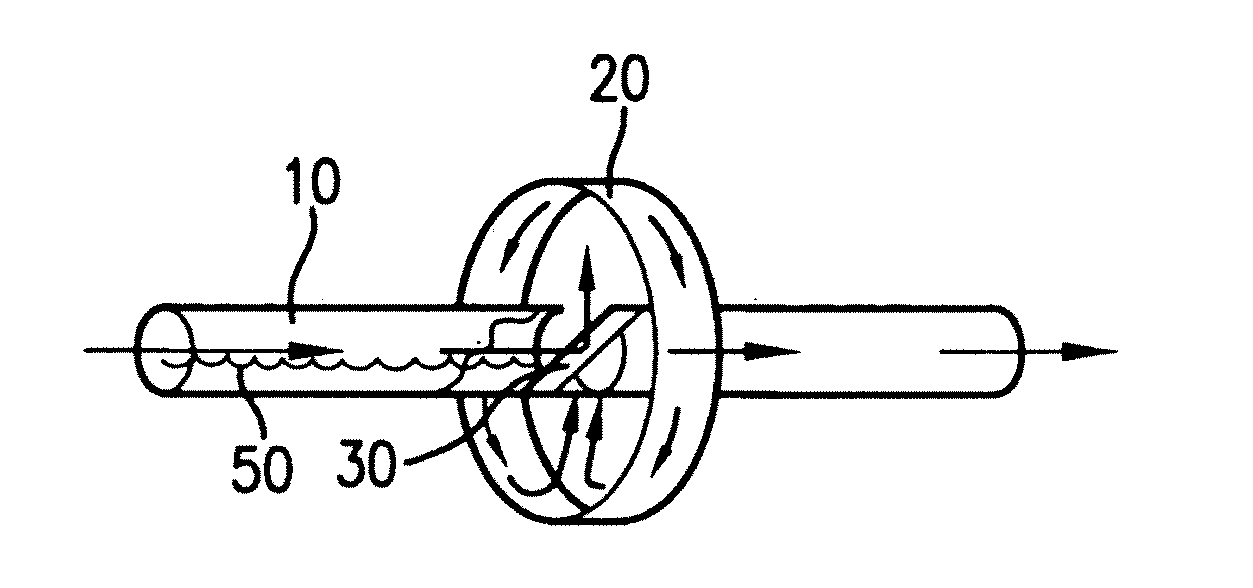

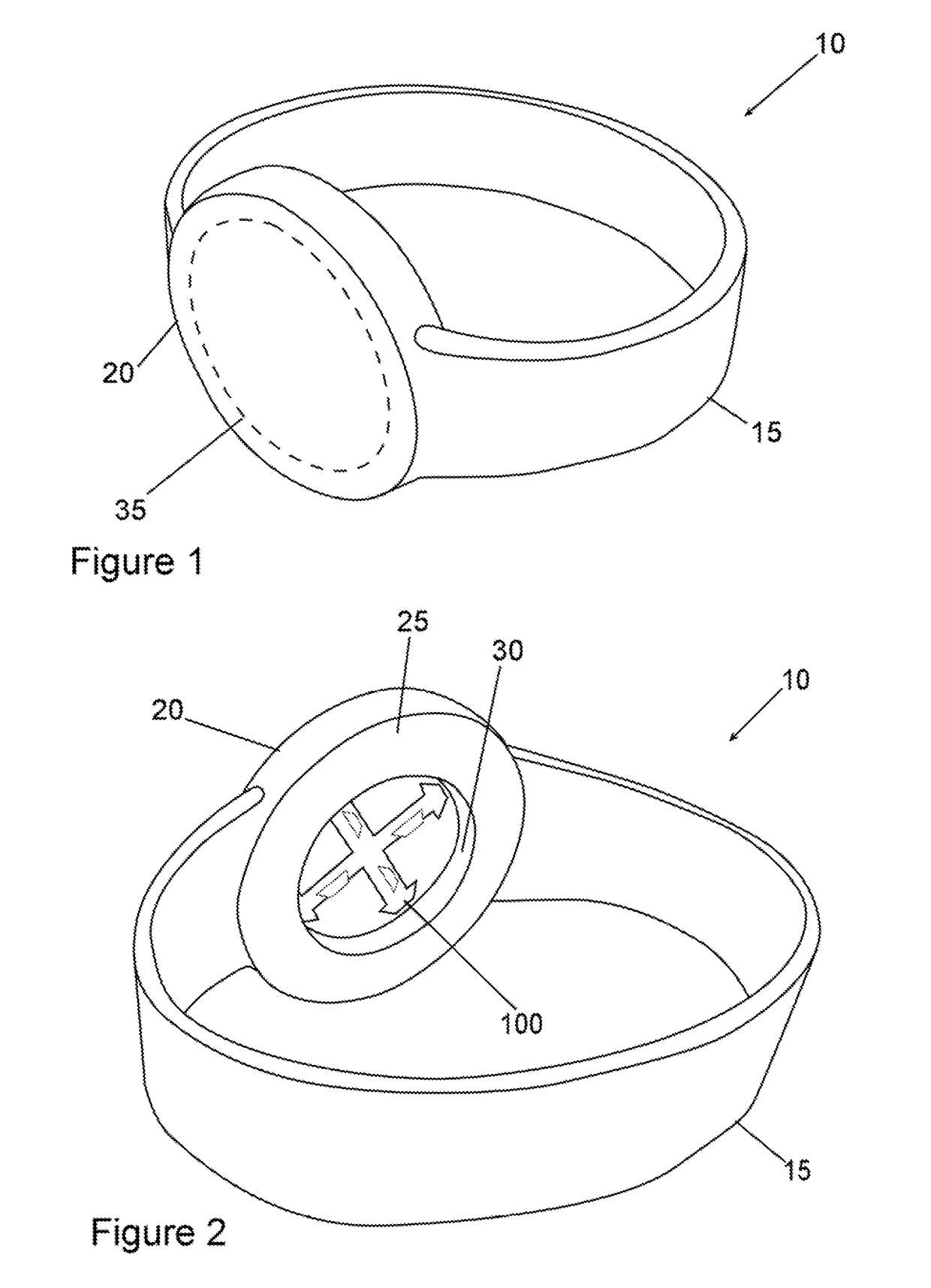

Solid soap holder

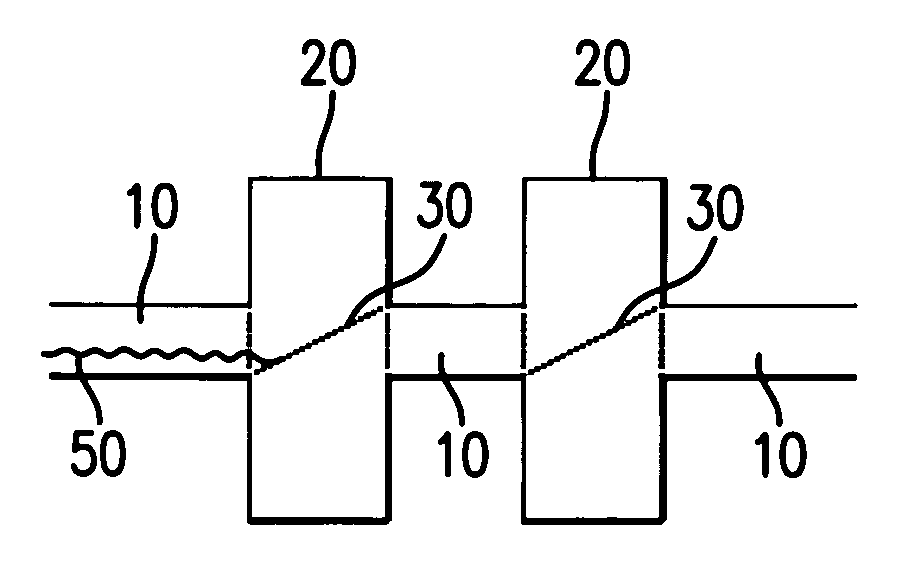

ActiveUS10362907B2Less convenientGood choice environmentallyTravelling carriersMechanical clocksEngineeringSOAP

A soap holder 10 comprises a reversible elastic wristband having a dual-sided face 20. A first side of the face 20 has an indentation 30 for receiving a piece of solid soap. A second side of the face is provided with a waterproof watch or other functional device, or a decorative surface. In normal wear, the soap holder 10 is worn on the wrist of a user with the second side facing outwards. When the user wishes to wash, the wristband is reversed so that the first side faces outwards. The face 20 is moved to the palm of the user. A piece of soap is pressed into the indentation 30 and the user is conveniently able to wash themselves.

Owner:HOLLERON SHAUN

Heat exchanger with heat exchange chambers utilizing respective medium directing members

InactiveUS20140041842A1Improve heating efficiencyIncrease the lengthStationary conduit assembliesHeat exchanger casingsPlate heat exchangerNuclear engineering

A heat exchange chamber includes an inlet, an outlet and a plurality of walls defining a chamber interior. The inlet receives a heat exchange medium flowing in a first flow direction in an initial line of flow. Disposed within the chamber interior is a medium directing member, having an inclined surface, which diverts the medium from the initial flow direction so that it disperses within the chamber interior. Exposure to the contact surfaces provided by the chamber walls causes the medium to exchange heat with the chamber and the external environment. The medium exits the chamber, via the outlet, in the initial line of flow. The chambers are interconnected by tubes to form assemblies. Plural sets of chamber and tube assemblies are arranged between manifolds to provide a heat exchanger.

Owner:MIKUTAY CORP

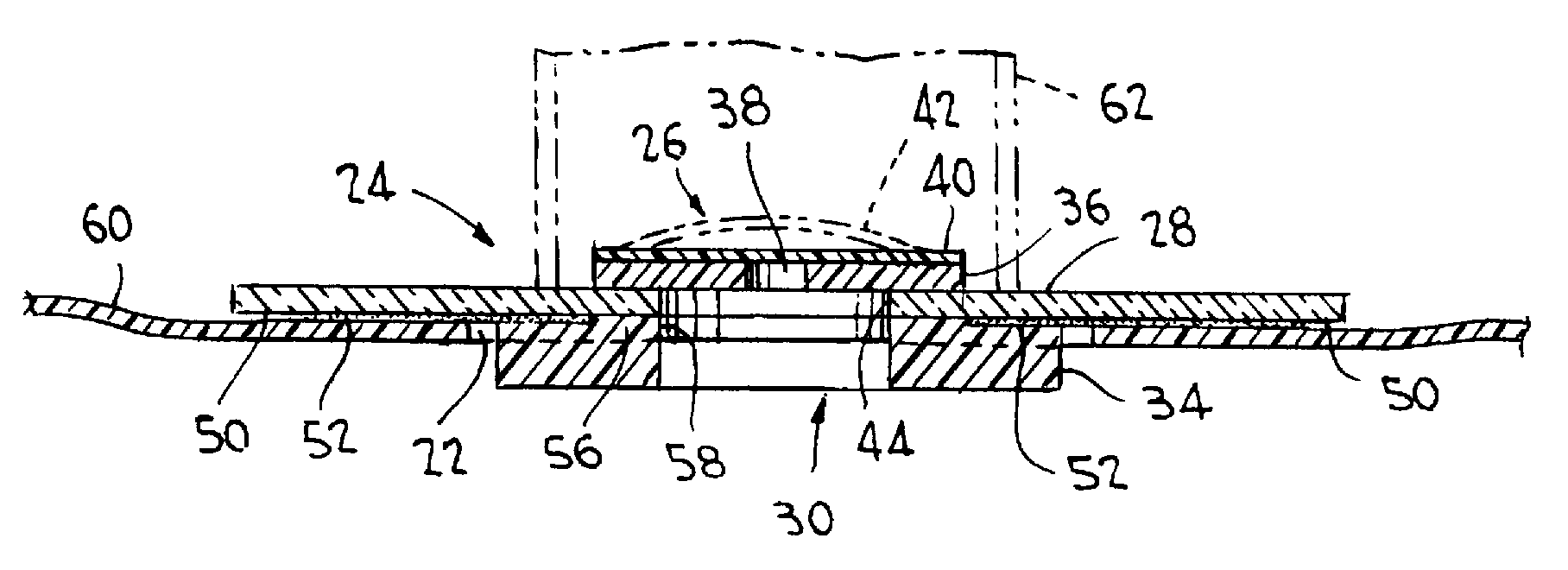

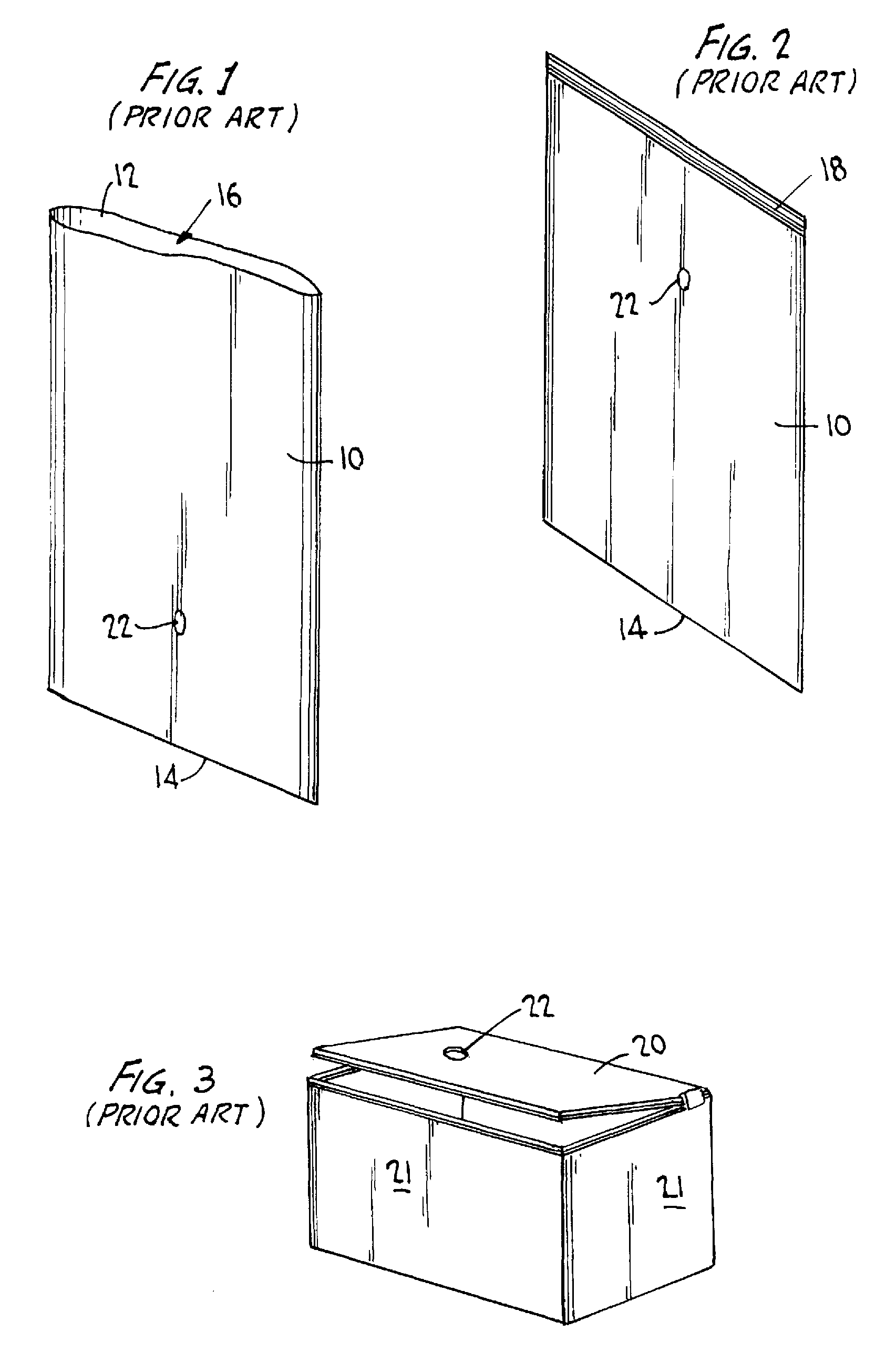

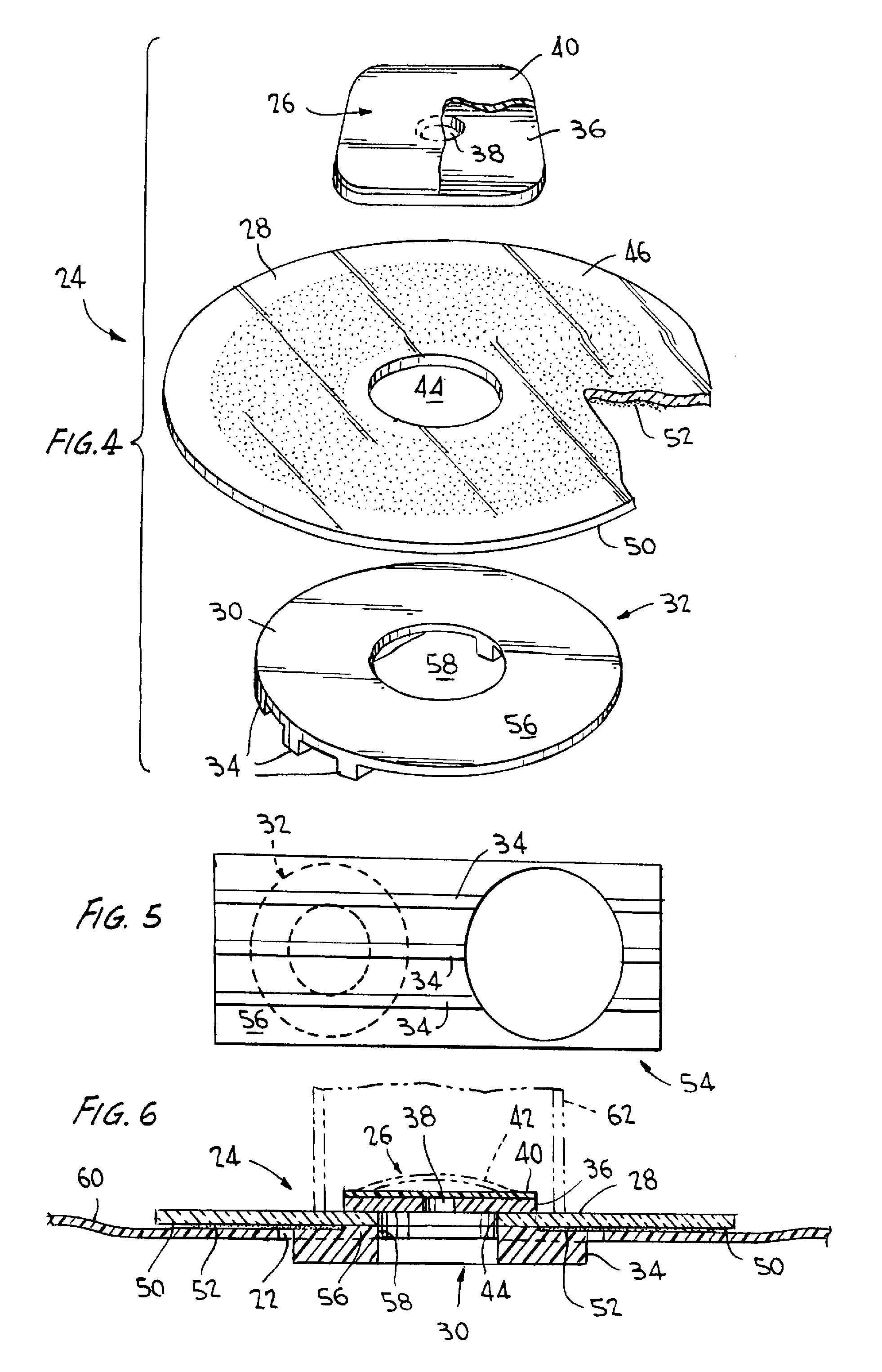

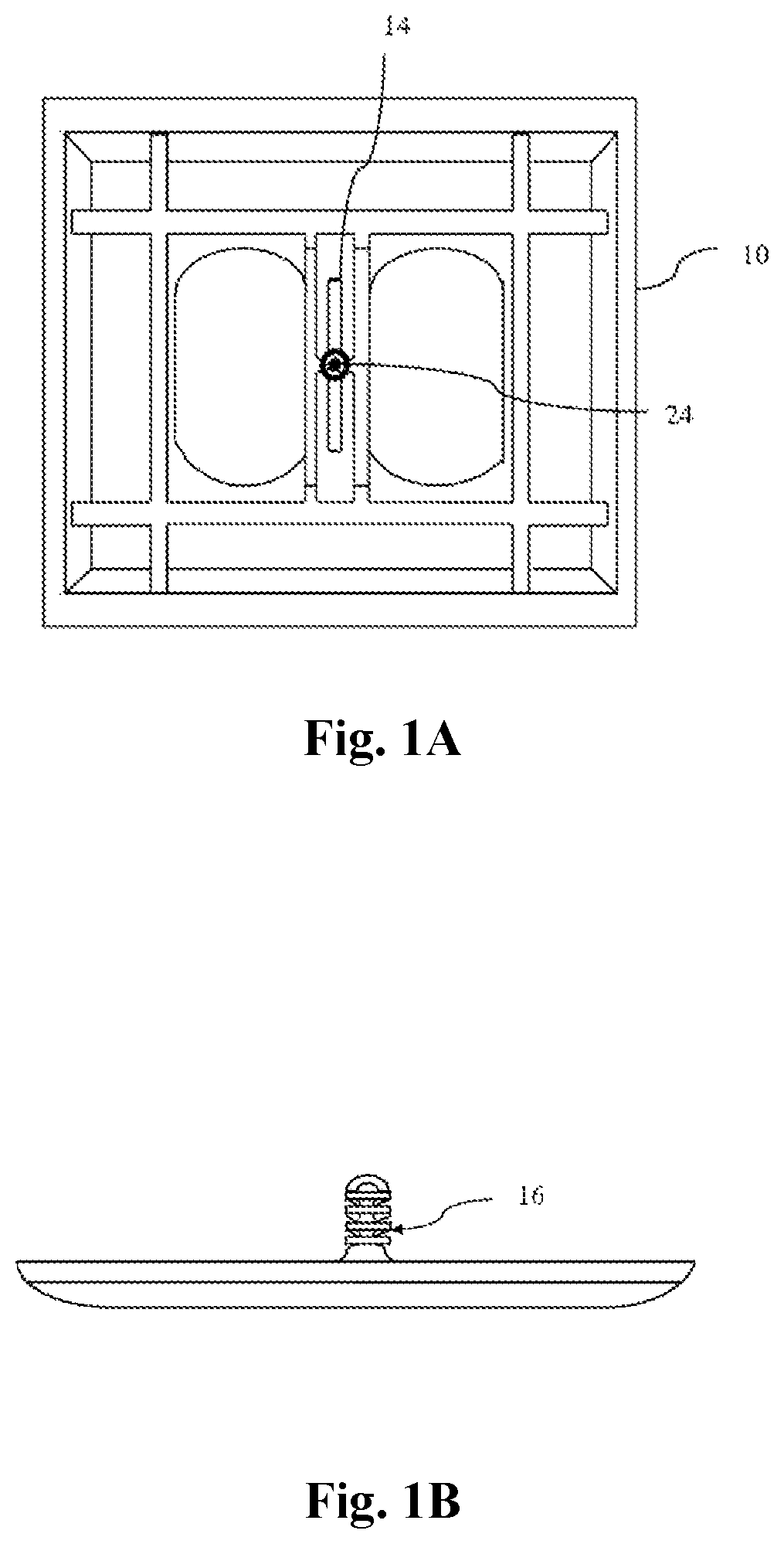

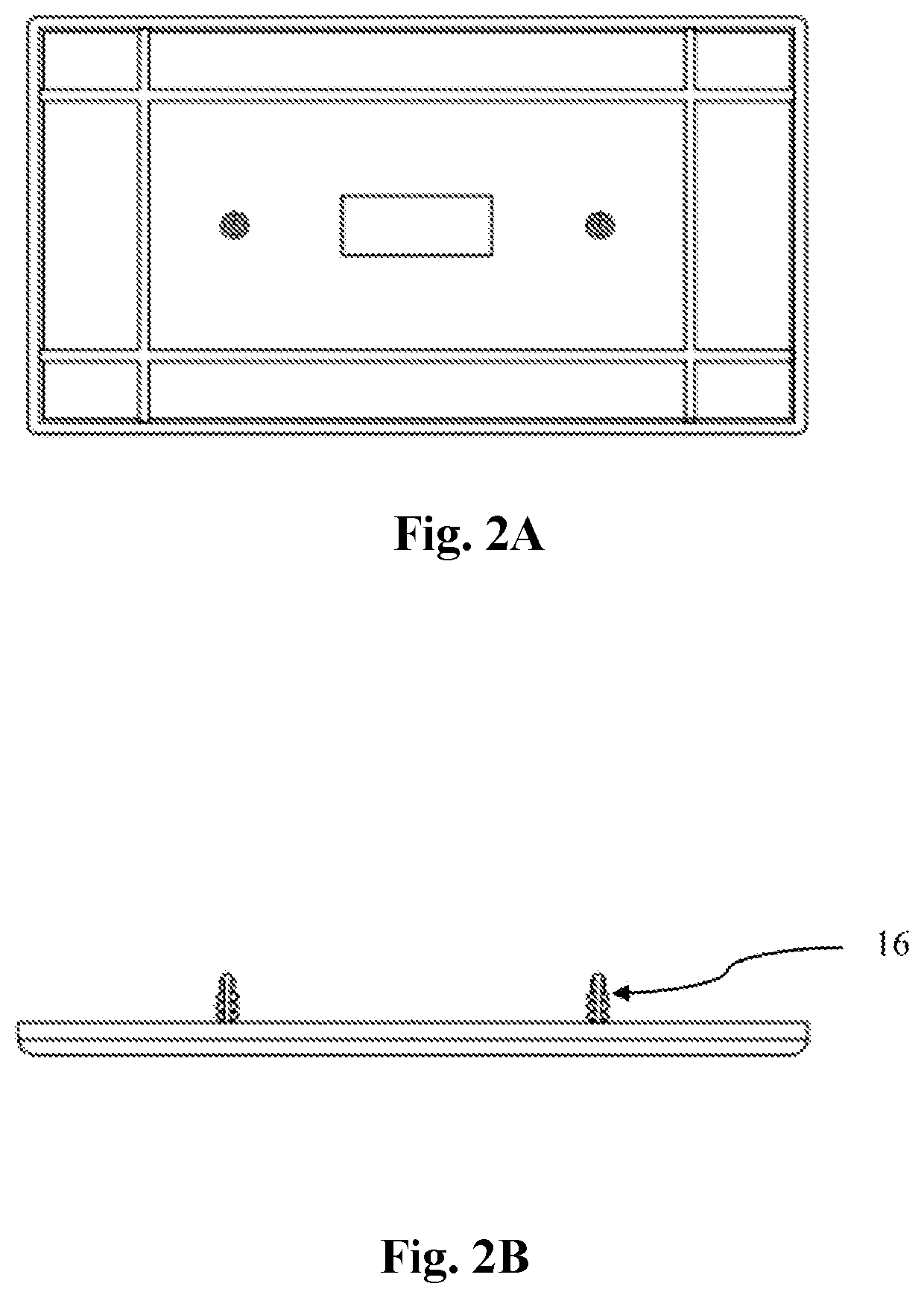

Vacuum valve and compression storage bags including the valve

ActiveUS9296541B2Simple and inexpensive to manufactureLess packagingDiaphragm valvesEngine diaphragmsAdhesiveEngineering

Valves useful in vacuum compression storage bags are described. The valve includes a check valve, a carrier film having adhesive on a surface thereof, and a plastic stand-off with projecting protrusions. The check valve, carrier film and stand-off each have an opening therethrough which when affixed together align to provide a passageway through the valve. When used with a vacuum compression storage bag, the valve is aligned with a hole through a wall of the bag to provide an air flow passageway through the aligned holes from the interior of the bag through the valve when vacuum force is applied over the valve and the bag sealed. The stand-off extends inside the bag to prevent contents therein from blocking air flow from inside the bag through the valve during vacuum evacuation of air from the bag. The stand-off has a rigidity to prevent collapse of the valve under vacuum force.

Owner:SC JOHNSON & SON INC

Solid soap holder

ActiveUS20190038087A1Less convenientGood choice environmentallyMechanical clocksTravelling carriersEngineeringSOAP

A soap holder 10 comprises a reversible elastic wristband having a dual-sided face 20. A first side of the face 20 has an indentation 30 for receiving a piece of solid soap. A second side of the face is provided with a waterproof watch or other functional device, or a decorative surface. In normal wear, the soap holder 10 is worn on the wrist of a user with the second side facing outwards. When the user wishes to wash, the wristband is reversed so that the first side faces outwards. The face 20 is moved to the palm of the user. A piece of soap is pressed into the indentation 30 and the user is conveniently able to wash themselves.

Owner:HOLLERON SHAUN

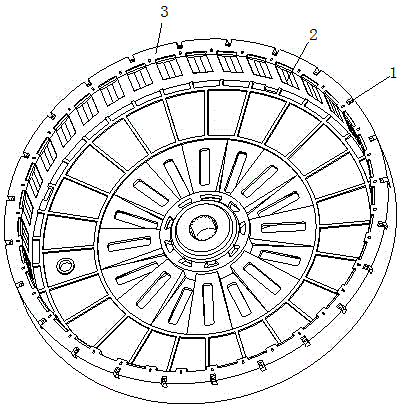

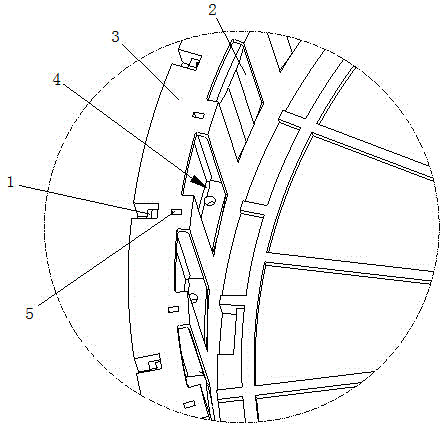

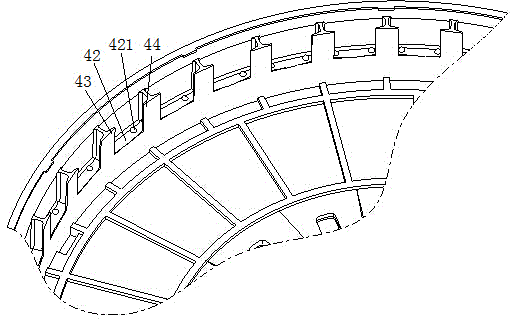

Magnetic steel fixing structure of permanent magnet motor

InactiveCN104410189AAvoid crackingReduce usageMagnetic circuit rotating partsPermanent magnet motorMaterials science

The invention relates to a magnetic steel fixing structure of a permanent magnet motor. The magnetic steel fixing structure of the permanent magnet motor comprises rotor cores and a plurality of magnetic steels uniformly arranged along inner circles of the rotor cores at intervals, excircles of the magnetic steels are tightly adhered to the inner circles of the rotor cores, injection molding units filling and integrally injection molding the rotor cores and the magnetic steels are arranged between the rotor cores and the magnetic steels, the position where the injection molding units is matched with the magnetic steels is provided with magnetic steel grooves for accommodating the magnetic steels, and the magnetic steel grooves wrap up and locate the magnetic steels. By means of the above technical scheme, the magnetic steel fixing structure of the permanent magnet motor is small in package material portions of the magnetic steel through the fixing structure of the magnetic steel slots to the magnetic steels, avoids drawing breakage caused when the magnetic steels are wrapped by a large area of materials but the materials shrink, and reduces material use and uniform in appearance.

Owner:WHIRLPOOL CHINA

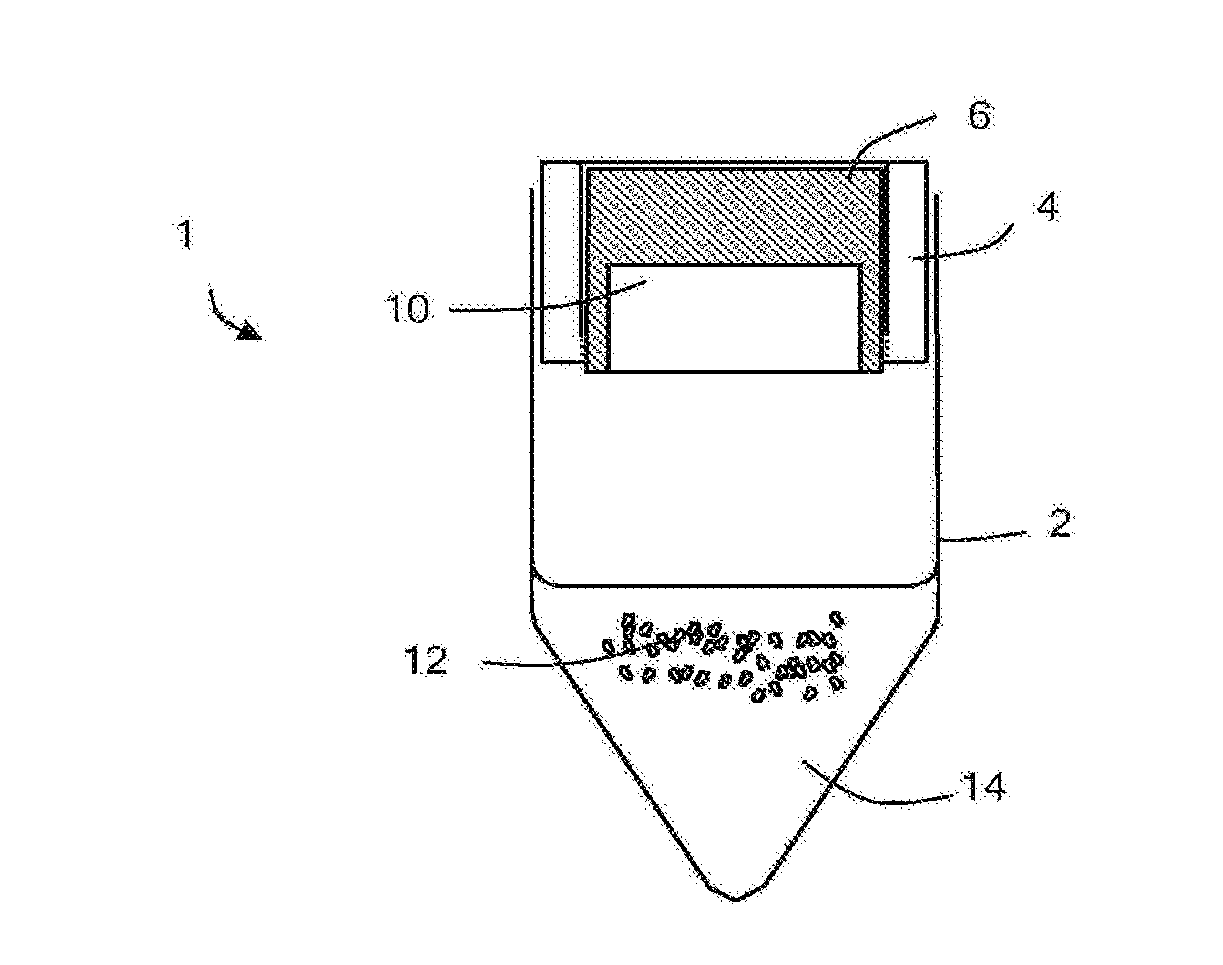

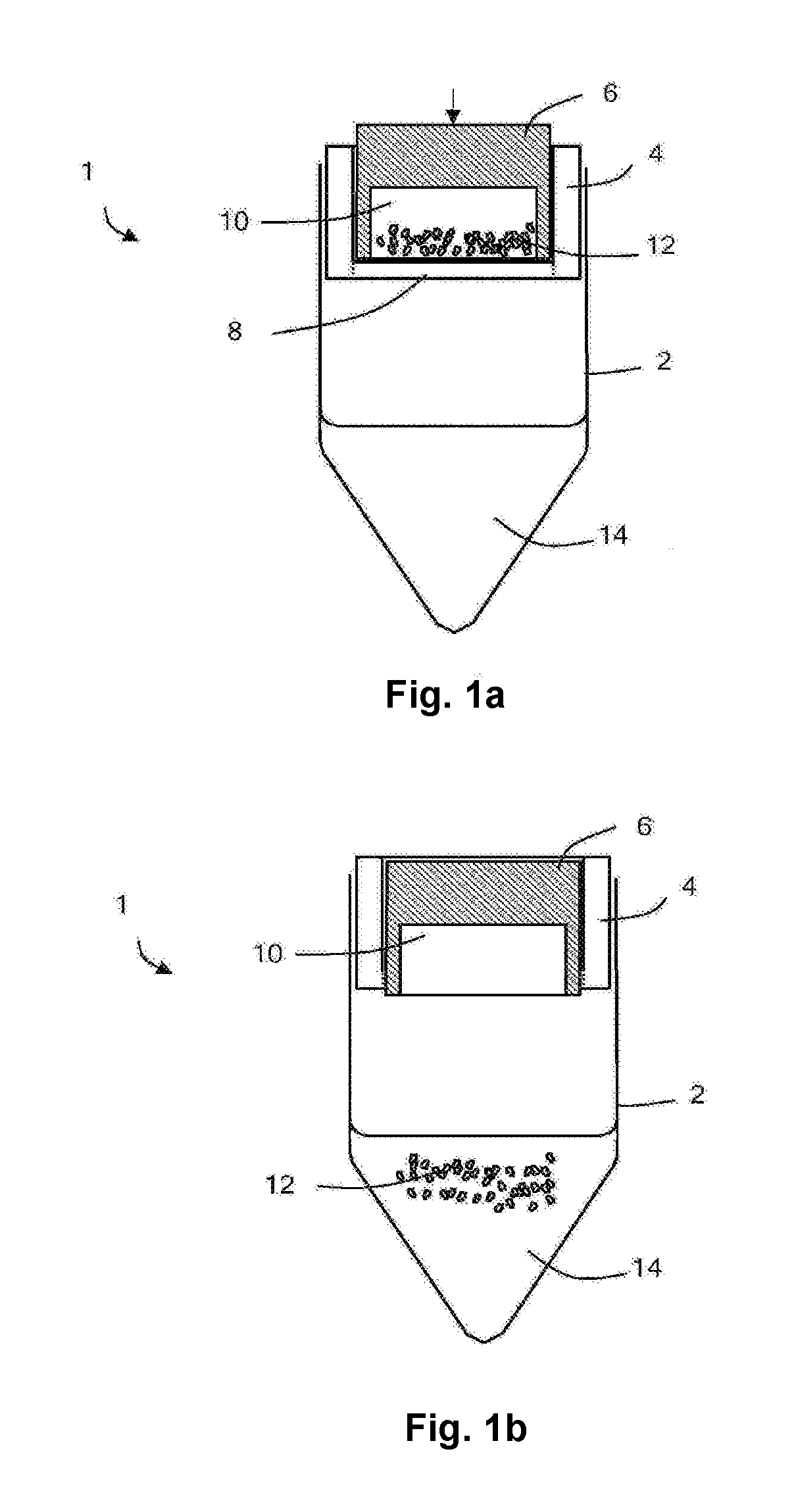

Container and method of manufacture of container

InactiveUS20170224586A1Easy to useLess packagingClosures with freeze-dryingPharmaceutical containersActive agentDiluent

Owner:EULYSIS UK

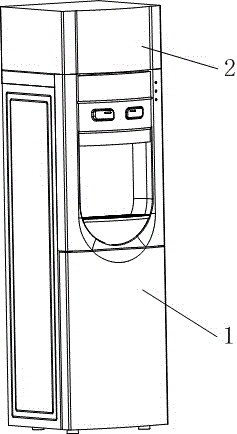

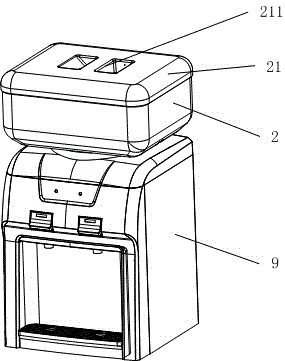

Water dispenser with bagged water

PendingCN106618193AAvoid secondary pollutionNo cross contaminationBeverage vesselsEnvironmental engineeringPollution

The invention provides a water dispenser with bagged water. The water dispenser with bagged water comprises a water dispenser body, an external water tank and a smart block are arranged at the top of the water dispenser body and connected into a whole, a jacking rod is arranged in the center of the bottom inside the smart block, a water bag is put inside the external water tank, the lower portion of the water bag is connected with a puncturing device which is arranged inside the smart block, and the puncturing device punctures the water bag to take water. The water bag of the water dispenser is put into the external water tank, the external water tank is used for supporting the water bag, external air directly acts on the outer surface of the water bag, and therefore the water inside the water bag can flow into the water dispenser depending on self weight. By the utilization of a jacking core and self weight of the water bag, the water bag is automatically punctured, the punctured position can automatically form stable sealing with the conical surface of a jacking needle, the water in the bag under the sealed state is guided to flow into the water dispenser, no air is allowed to enter the water dispenser, and secondary pollution is avoided.

Owner:QINGDAO HAIER STRAUSS WATER EQUIP CO LTD

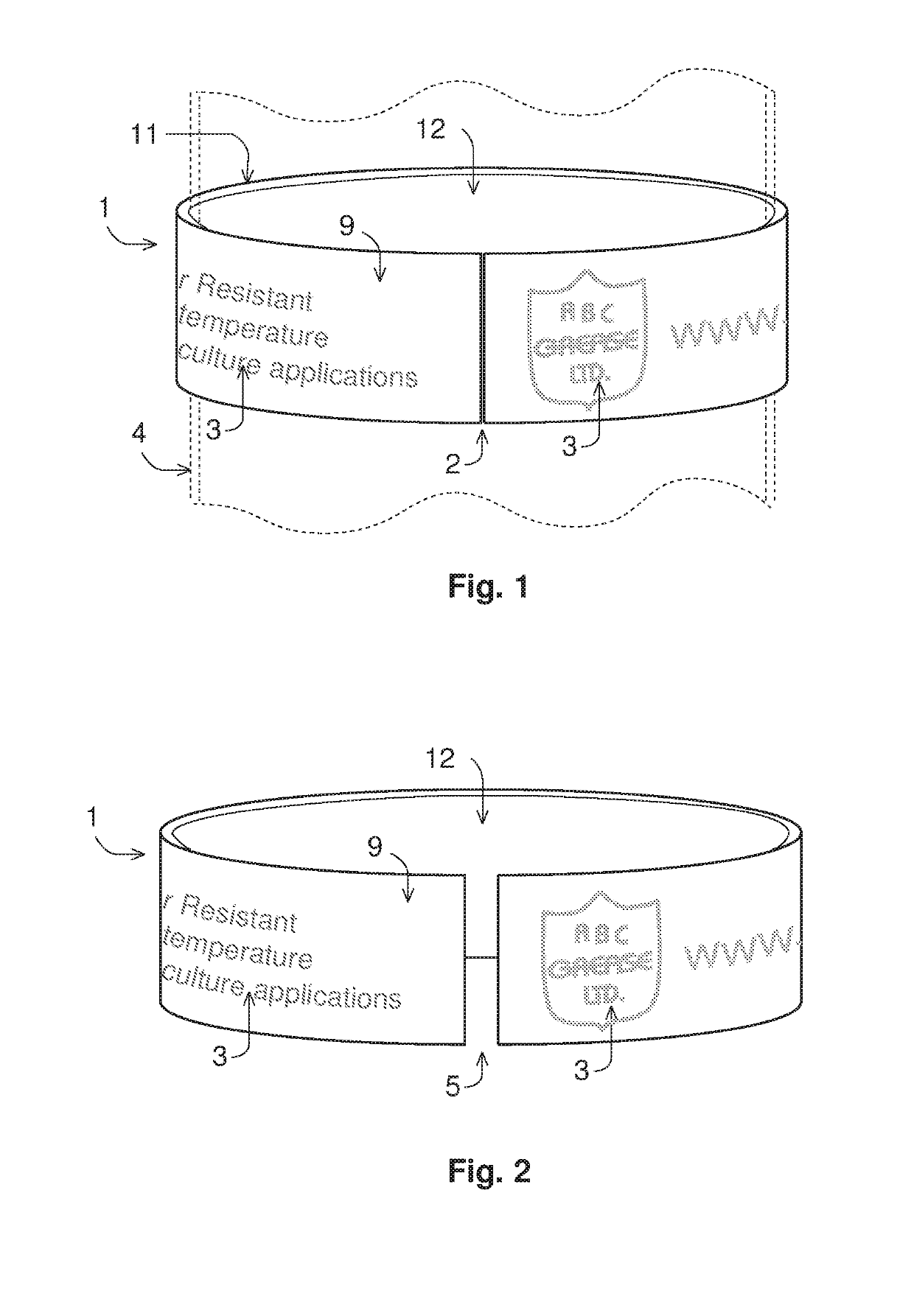

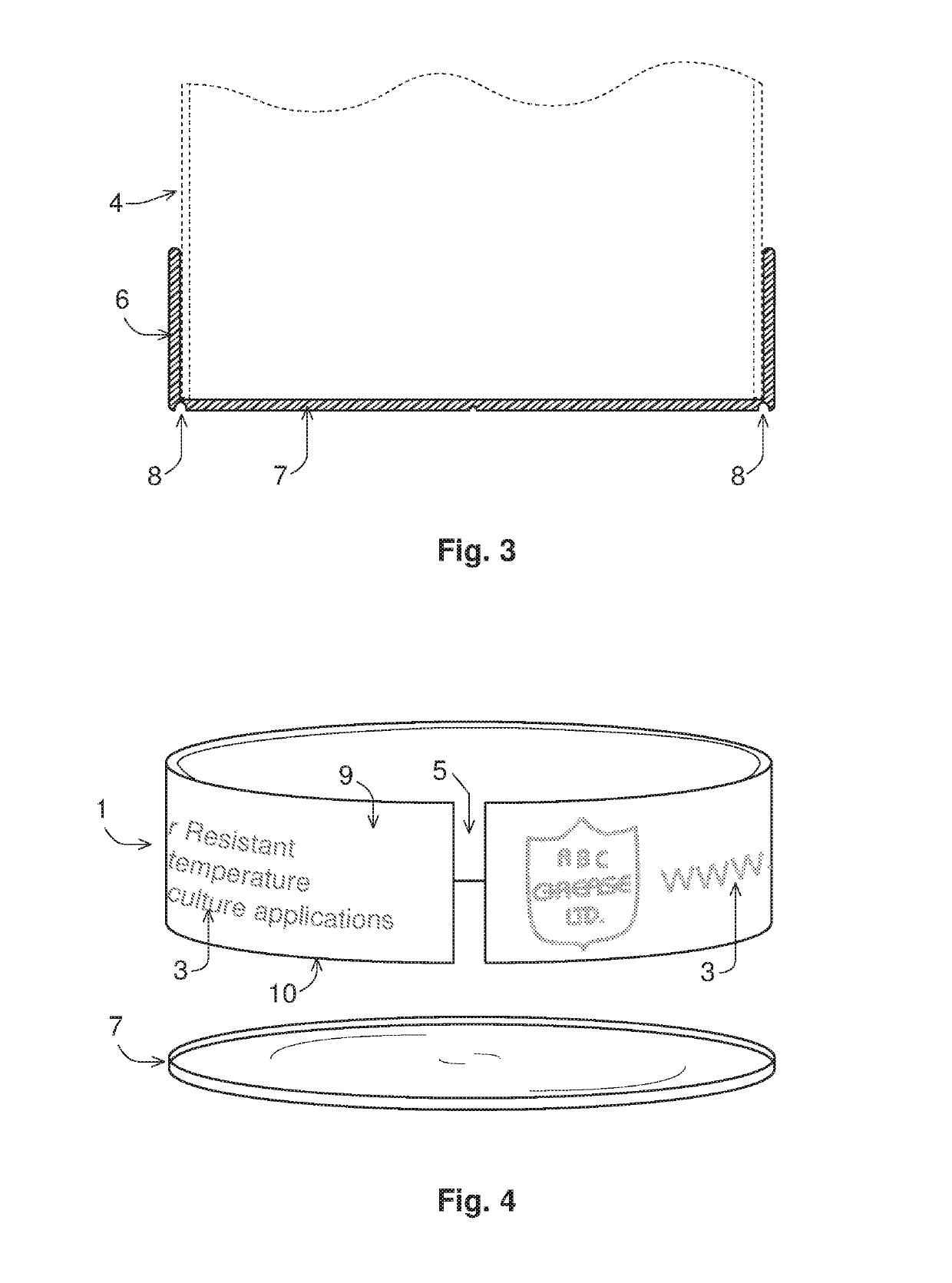

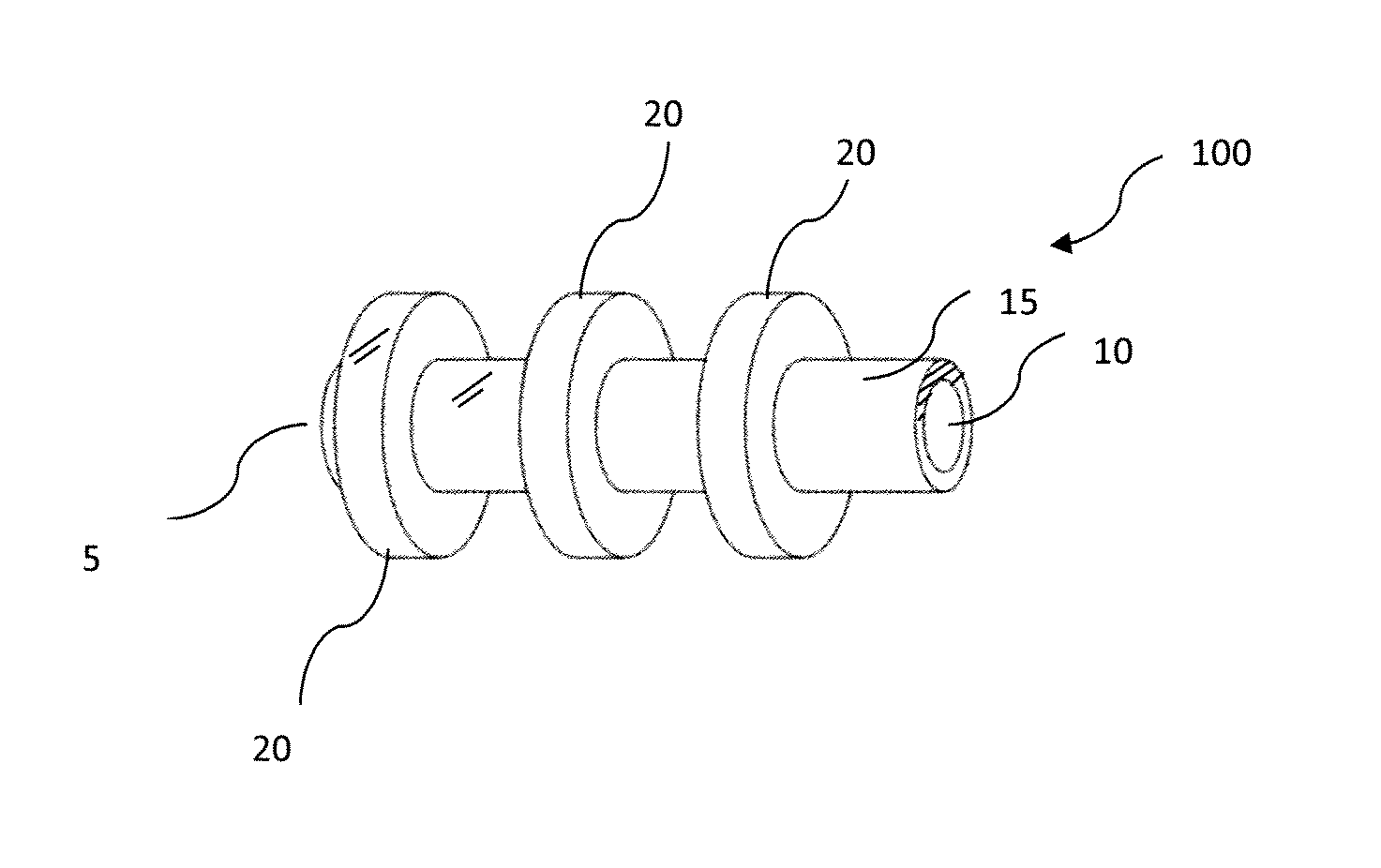

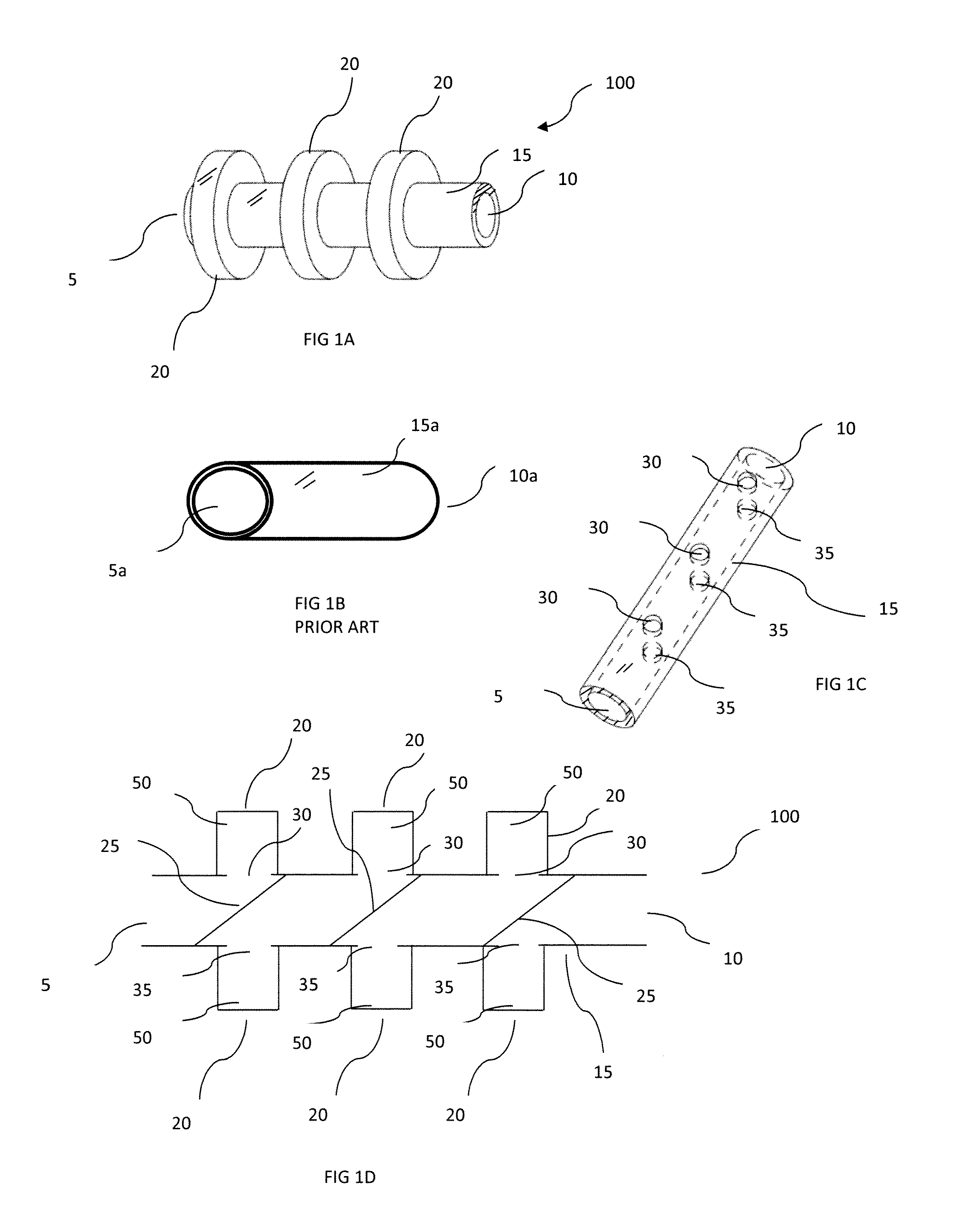

Split ring information tag

InactiveUS20190279537A1Increase awarenessConveniently formedStampsClosure with auxillary devicesSplit ringEngineering

An information baring tag providing the means of conveying product information, concerning a product filled cartridge inserted into its dispensing device, to the user of said device. The tag is detachably attached to the cartridge and consists of an inner and outer circular plane surface that forms a cylindrical ring. A single weakened line extends from the top circular plane edge to bottom circular plane edge which can be broken, either by hand or mechanical cutting appliance, to form a split across the circular plane surface. This split enables the tag to be expanded, allowing for placement onto a dispensing device and is held in place by the tags natural tendency to return to its original shape, thereby gripping the dispensing device. Once placed, the tag can be referenced by the user for product identification and important information which would otherwise have been concealed.

Owner:HEINZLMEIR DANNY

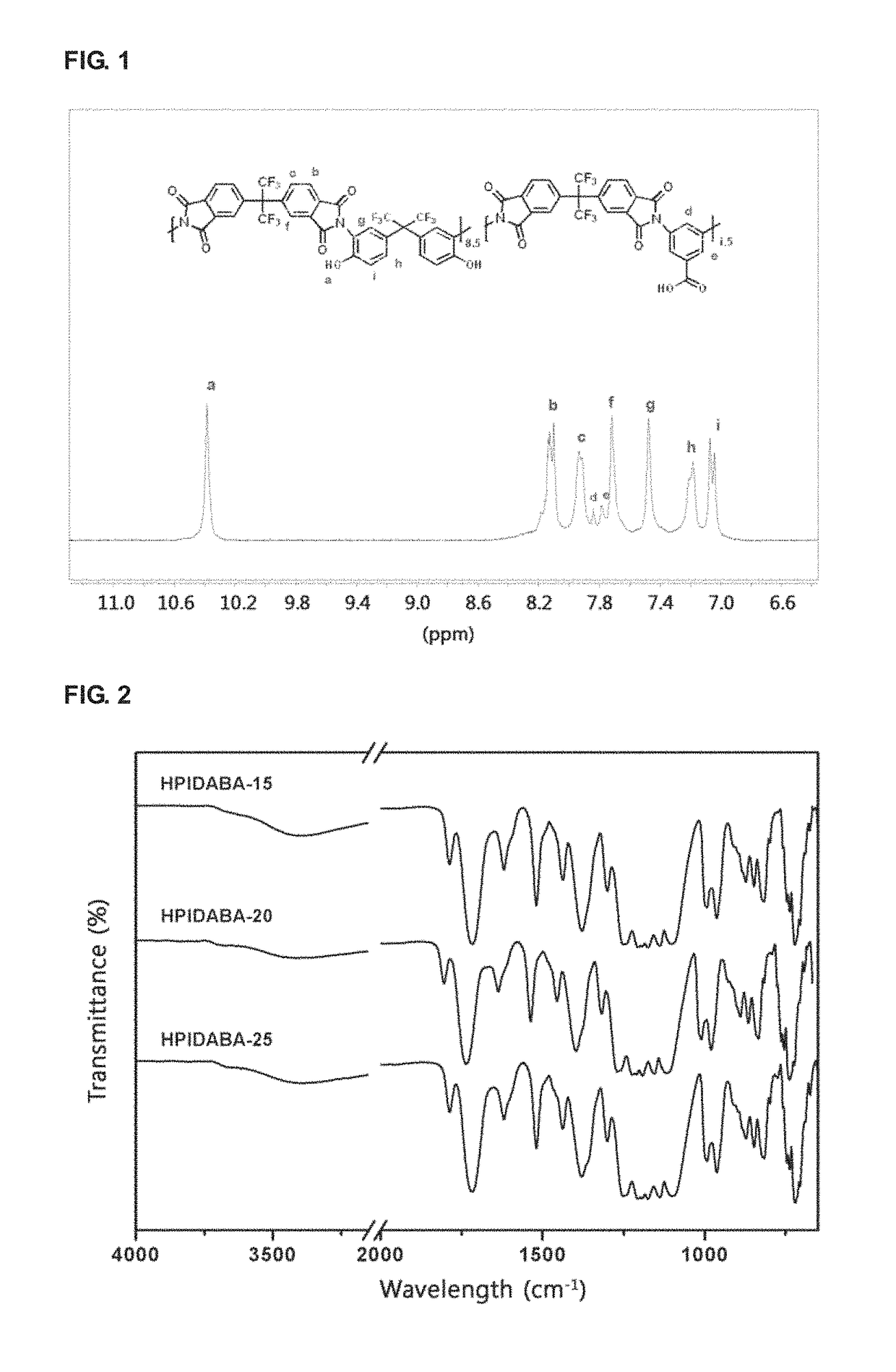

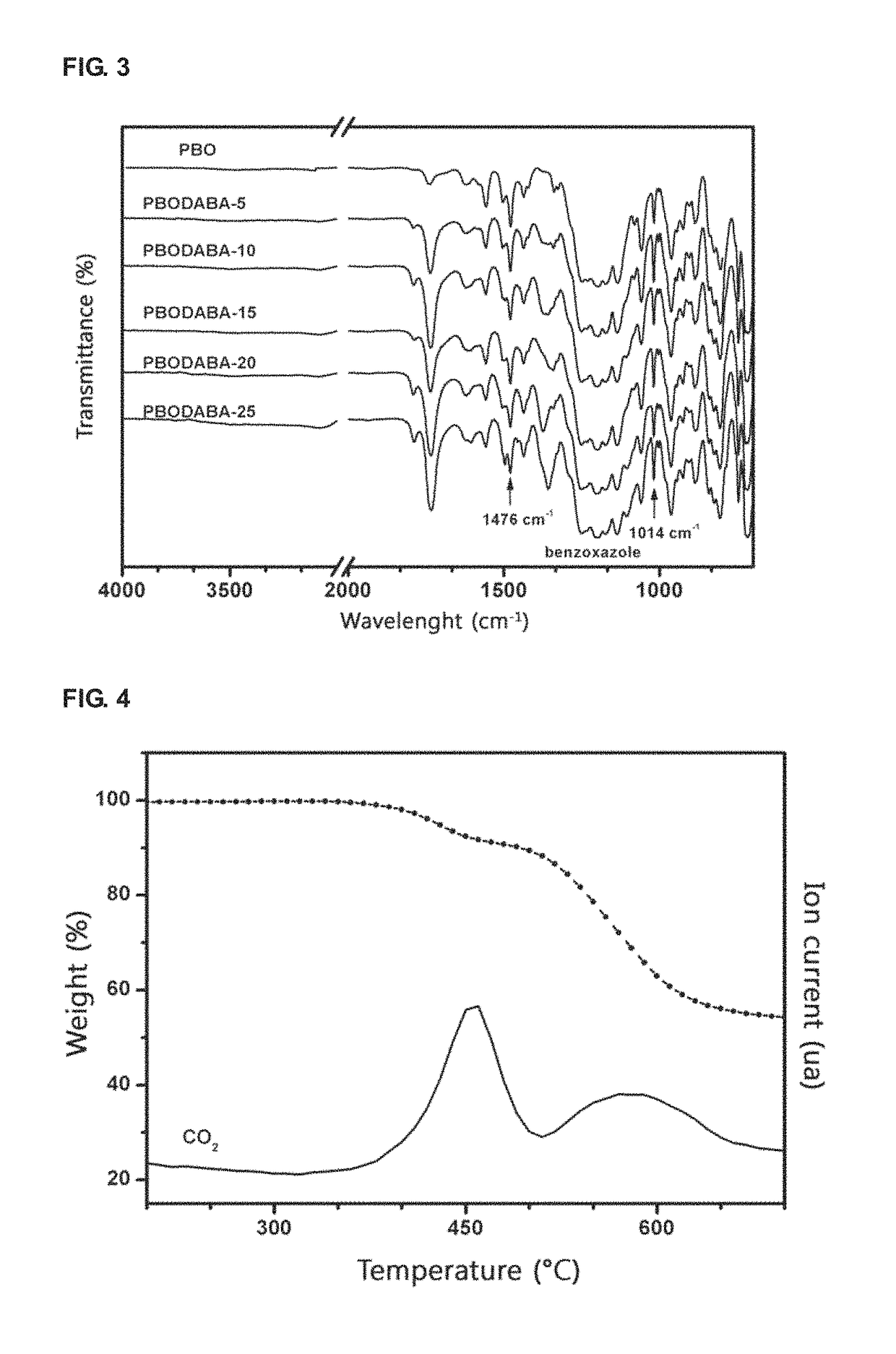

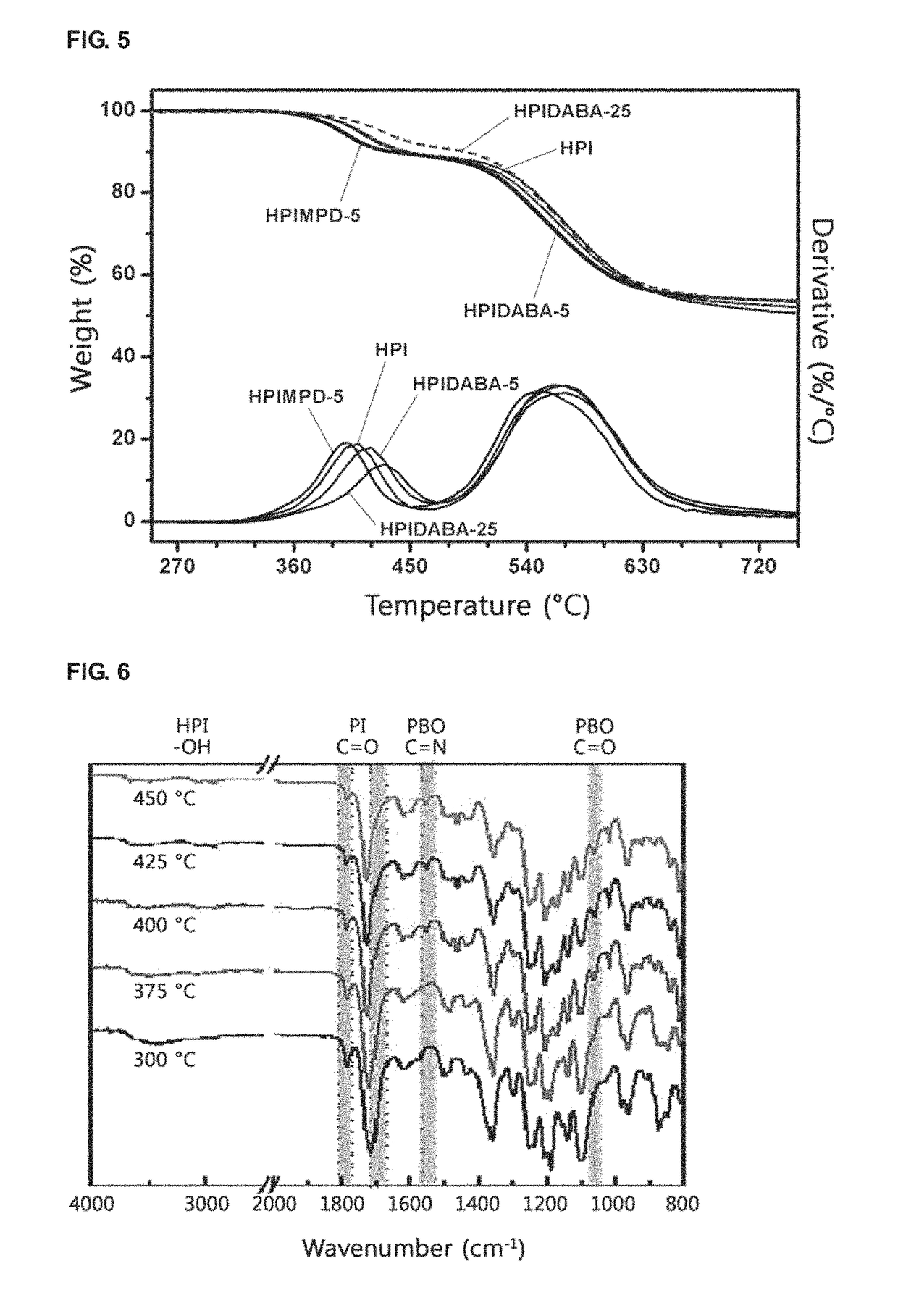

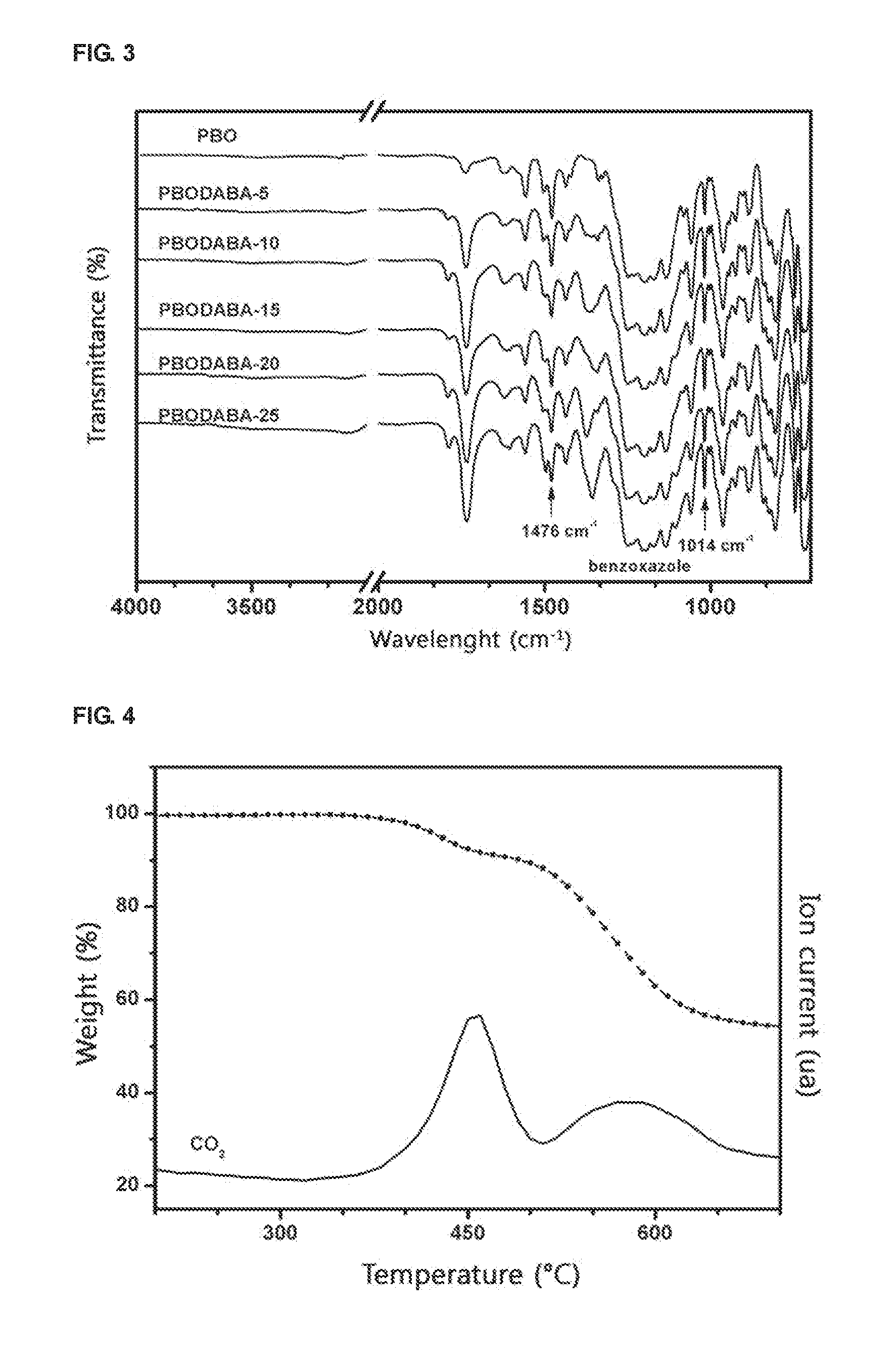

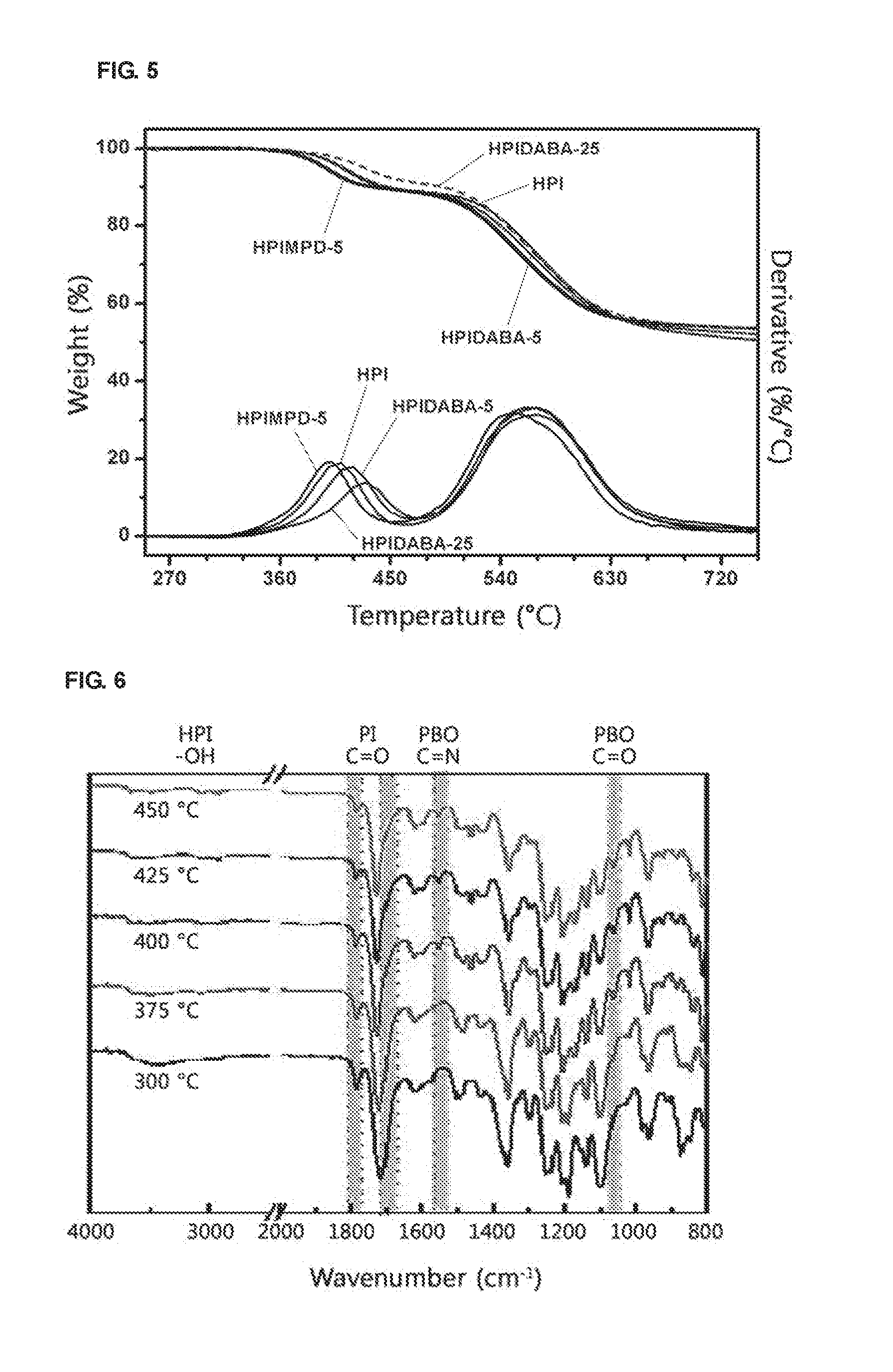

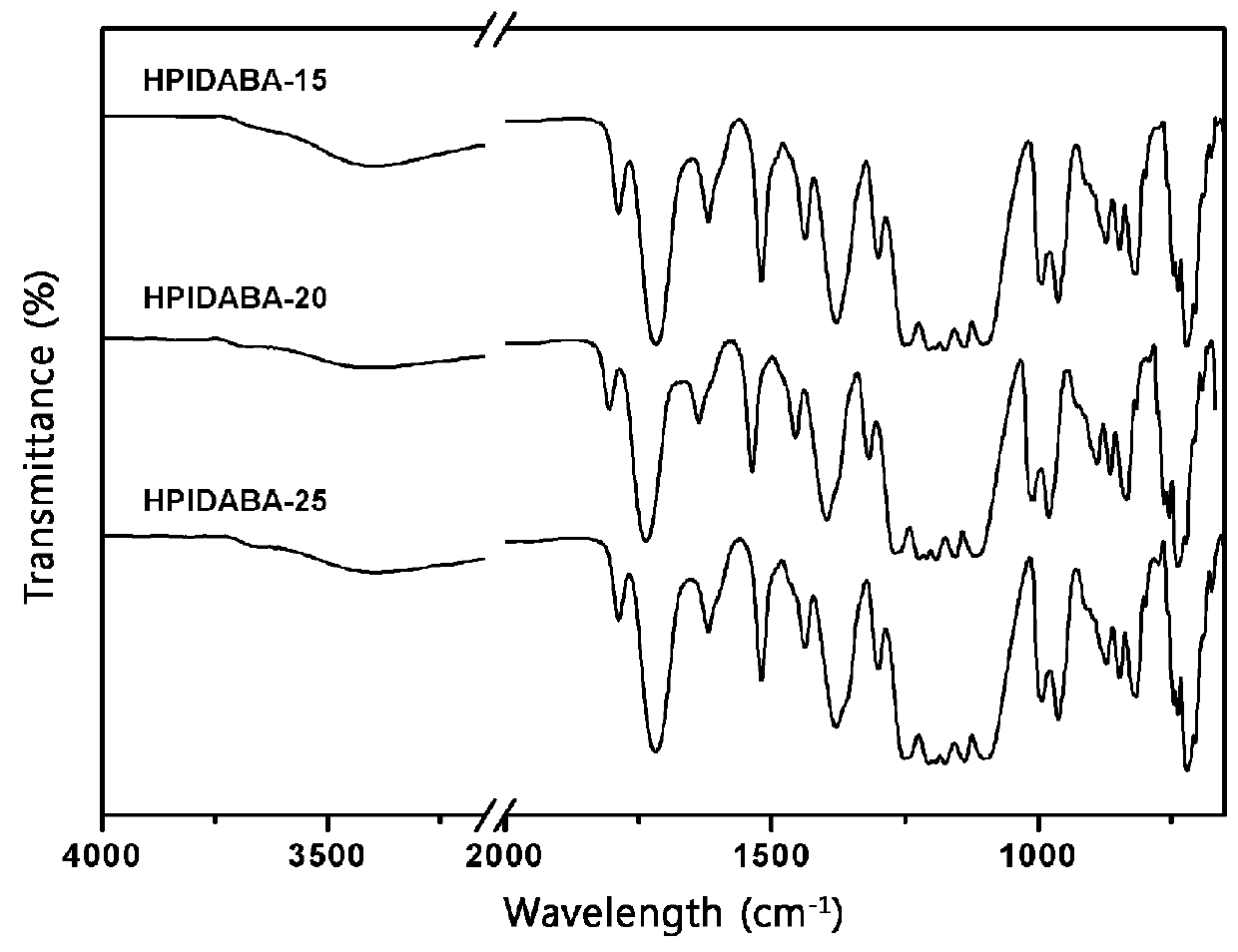

Crosslinked, thermally rearranged poly(benzoxazole-co-imide), gas separation membranes comprising the same and preparation method thereof

InactiveUS10035109B2Improve permeabilityHigh selectivitySemi-permeable membranesMembranesBenzoxazoleCarboxylic acid

The present disclosure relates to a crosslinked, thermally rearranged poly(benzoxazole-co-imide) copolymer membrane prepared simply by heat-treating a membrane prepared from an o-hydroxypolyimide copolymer having carboxylic acid groups such that thermal crosslinking and thermal rearrangement occur simultaneously or a gas separation membrane containing a crosslinked, thermally rearranged poly(benzoxazole-co-imide) copolymer having a benzoxazole group content of less than 80% in the polymer chain, prepared from transesterification crosslinking of an o-hydroxypolyimide copolymer having carboxylic acid groups and a diol-based compound followed by thermal rearrangement, and a method for preparing the same (a membrane for flue gas separation is excluded).In accordance with the present disclosure, a crosslinked, thermally rearranged poly(benzoxazole-co-imide) copolymer membrane for gas separation can be prepared simply through heat treatment without requiring a complicated process such as chemical crosslinking, UV irradiation, etc. for forming a crosslinked structure and a gas separation membrane (a membrane for flue gas separation is excluded) prepared therefrom exhibits superior permeability and selectivity. Also, the method is applicable to commercial-scale production because the preparation process is simple.

Owner:IUCF HYU (IND UNIV COOP FOUND HANYANG UNIV)

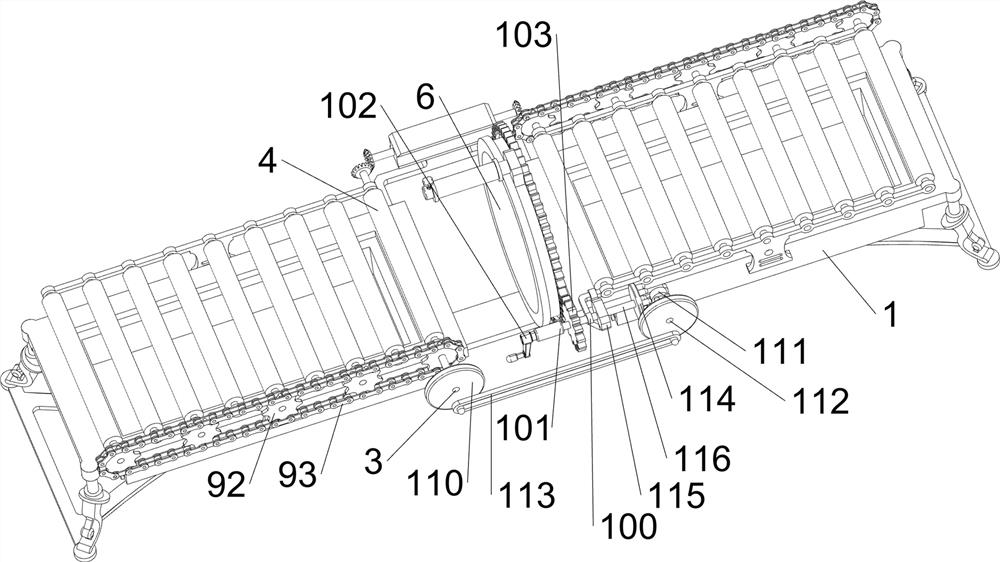

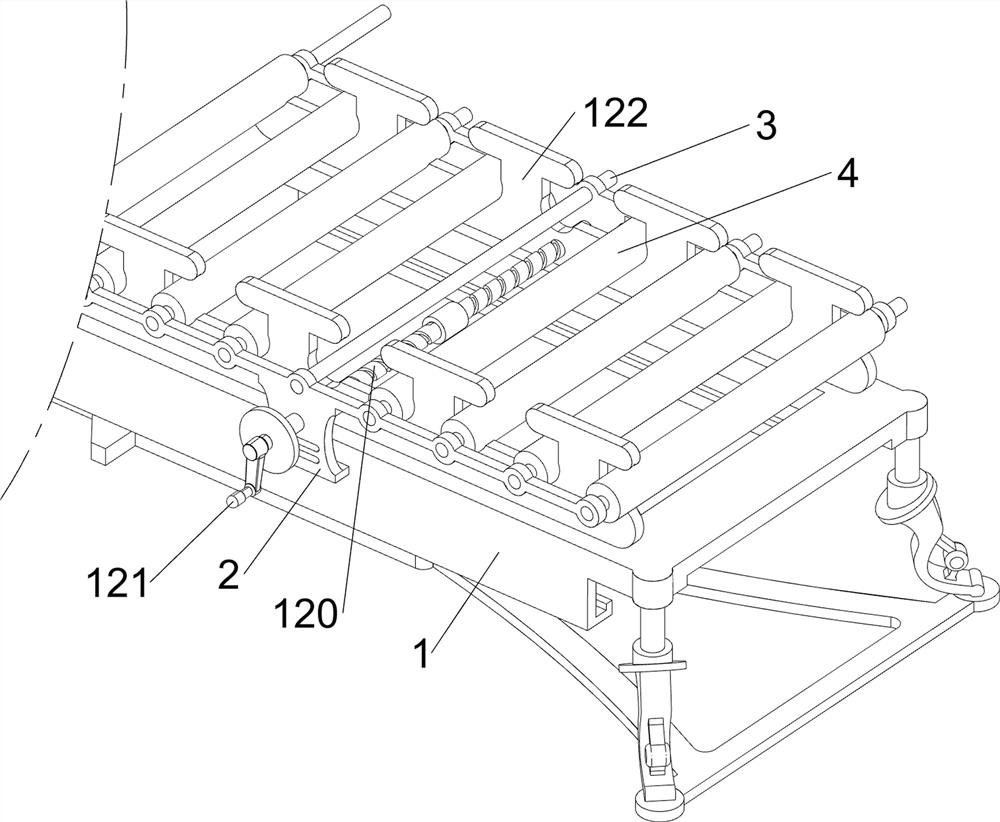

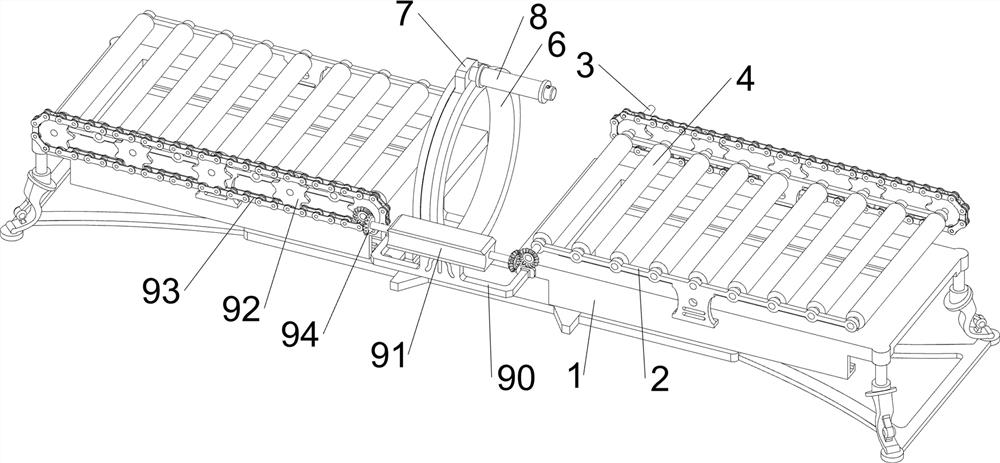

Logistics transportation household appliance packaging device

PendingCN114194476AAvoid displacementReduce handlingWeb rotation wrappingElectric machineryStructural engineering

The invention relates to a packaging device, in particular to a logistics transportation household appliance packaging device. The invention provides a logistics transportation household appliance packaging device capable of packaging goods and reducing manual operation. According to the logistics transportation household appliance packaging device, first supporting rods are arranged on the left side, the right side, the front side and the rear side of a base; nine first rotating shafts are rotationally arranged between every two adjacent first supporting rods at equal intervals; the conveying rollers are arranged on the eighteen first rotating shafts; the curved supporting seats are arranged on the front side and the rear side of the left end of the base. The double-shaft motor serves as driving force to drive the bevel gear to rotate, the bevel gear drives the first rotating shaft to rotate, the first rotating shaft drives the conveying rolling wheels to rotate, the conveying rolling wheels rotate so that goods can be conveyed, and manual goods carrying is reduced.

Owner:刘旭

Membranes for flue gas separation comprising crosslinked, thermally rearranged poly(benzoxazole-co-imide) and preparation method thereof

InactiveUS20160296893A1Improve permeabilityHigh selectivityMembranesSemi-permeable membranesBenzoxazoleImide

The present disclosure relates to a membrane for flue gas separation containing a crosslinked, thermally rearranged poly(benzoxazole-co-imide) copolymer prepared simply by heat-treating a membrane prepared from an o-hydroxypolyimide copolymer having carboxylic acid groups such that thermal crosslinking and thermal rearrangement occur simultaneously or a membrane for flue gas separation containing a crosslinked, thermally rearranged poly(benzoxazole-co-imide) copolymer having a benzoxazole group content of less than 80% in the polymer chain, prepared from transesterification crosslinking of an o-hydroxypolyimide copolymer having carboxylic acid groups and a diol-based compound followed by thermal rearrangement, and a method for preparing the same.In accordance with the present disclosure, a crosslinked, thermally rearranged poly(benzoxazole-co-imide) copolymer membrane for flue gas separation can be prepared simply through heat treatment without requiring a complicated process such as chemical crosslinking, UV irradiation, etc. for forming a crosslinked structure and a membrane for flue gas separation prepared therefrom exhibits superior permeability and selectivity. Also, the method is applicable to commercial-scale production because the preparation process is simple.

Owner:IUCF HYU (IND UNIV COOP FOUND HANYANG UNIV)

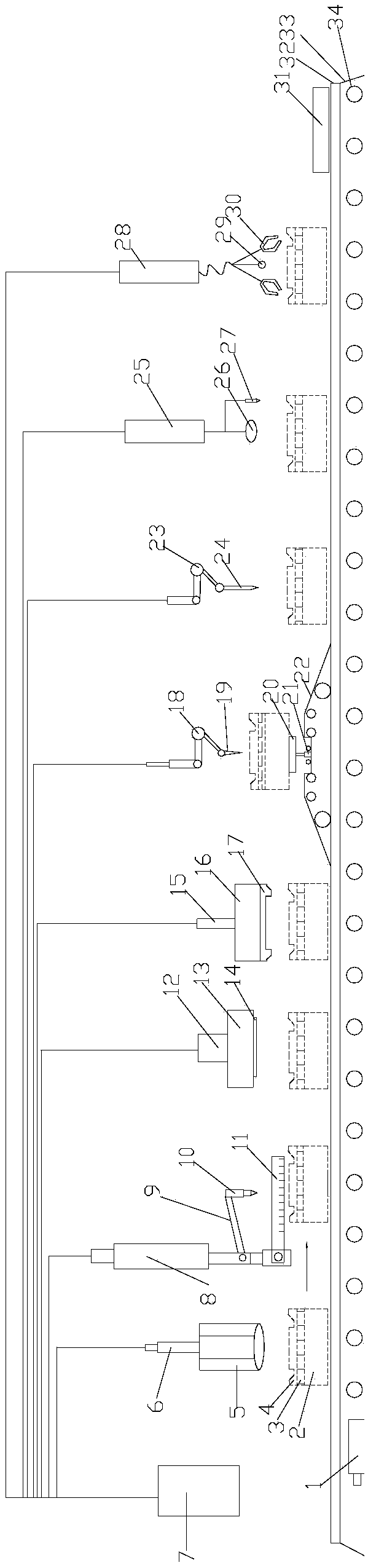

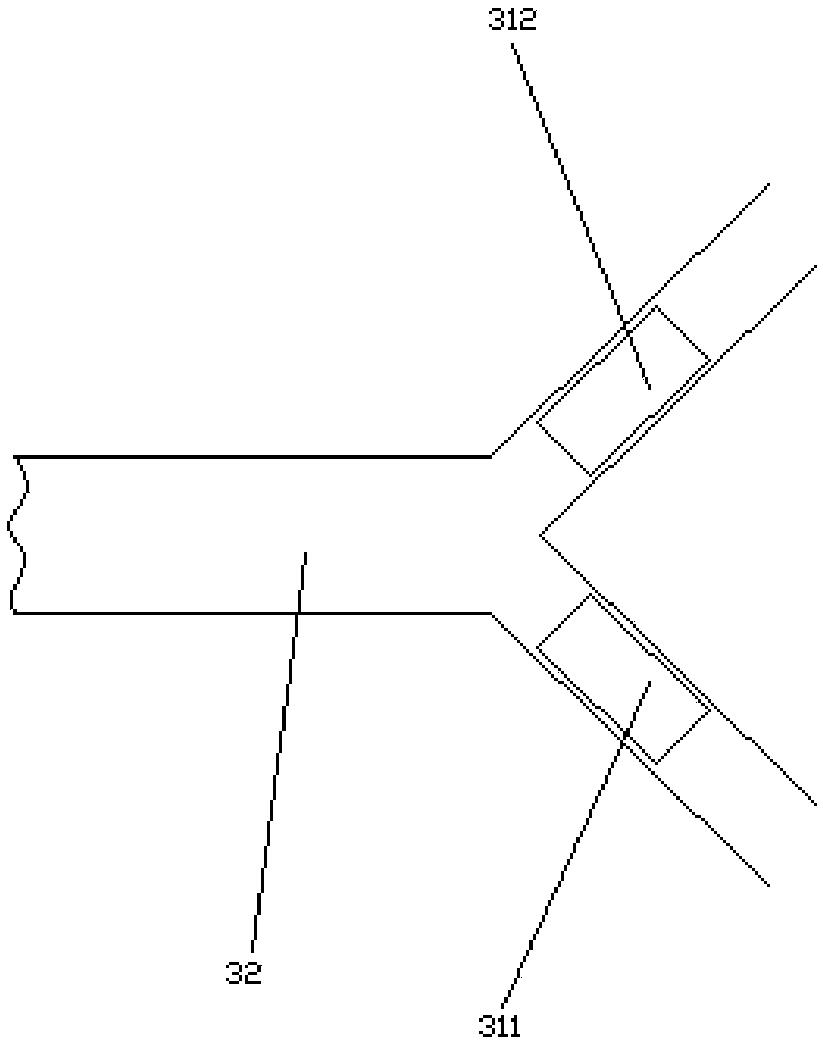

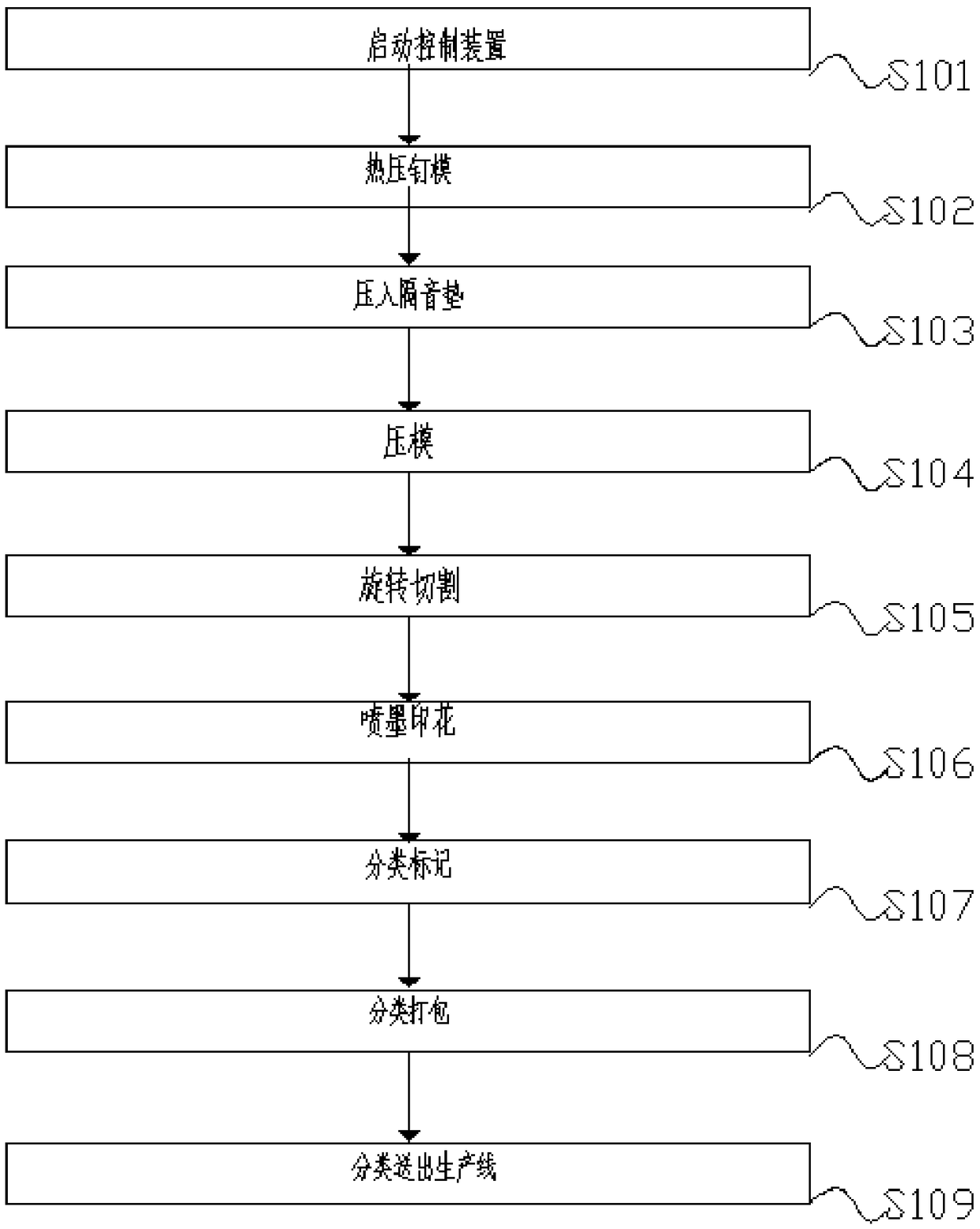

Fully automatic car carpet production line and production method

ActiveCN106585461BImprove efficiencyAvoid wastingVehicle arrangementsLaser beam welding apparatusProduction lineRobotic arm

The invention provides a full-automatic automotive carpet production line and a production method. The full-automatic automotive carpet production line comprises a rack and a control table, wherein an emptying device, a hot-pressing device, a pressure pad device, a pressure mold device, a laser cutting device, an inkjet printing device, a detection device and a packing device are sequentially arranged above the rack; an emptier is arranged on the emptying device; a hot-pressing plate is hinged onto the lower end of the hot-pressing device; a first mold is arranged on the pressure pad device; a second mold is arranged on the pressure mold device; a laser cutter is arranged on the laser cutting device; the upper end of the laser cutter is connected with a first mechanical arm; a rotary worktable is arranged just under the laser cutting device and mounted on the rack; an inkjet printing machine is arranged on the inkjet printing device; a camera is arranged on the detection device; a marking instrument is arranged beside the camera; an image analyzer is connected to the upper side of the marking instrument; a manipulator is arranged on the packing device; a packing controller is arranged above the manipulator.

Owner:桐乡市瑞炬纺织品有限公司

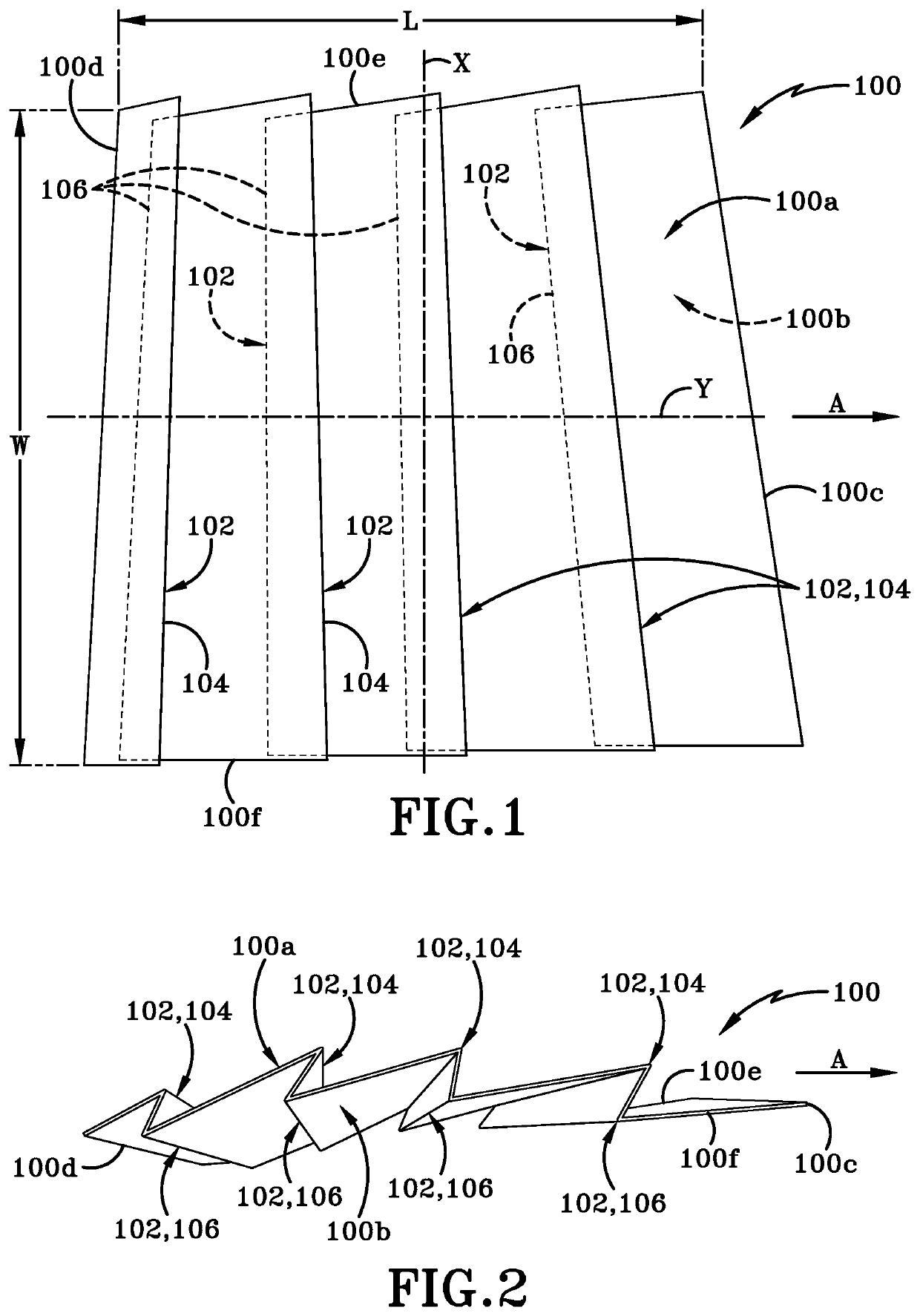

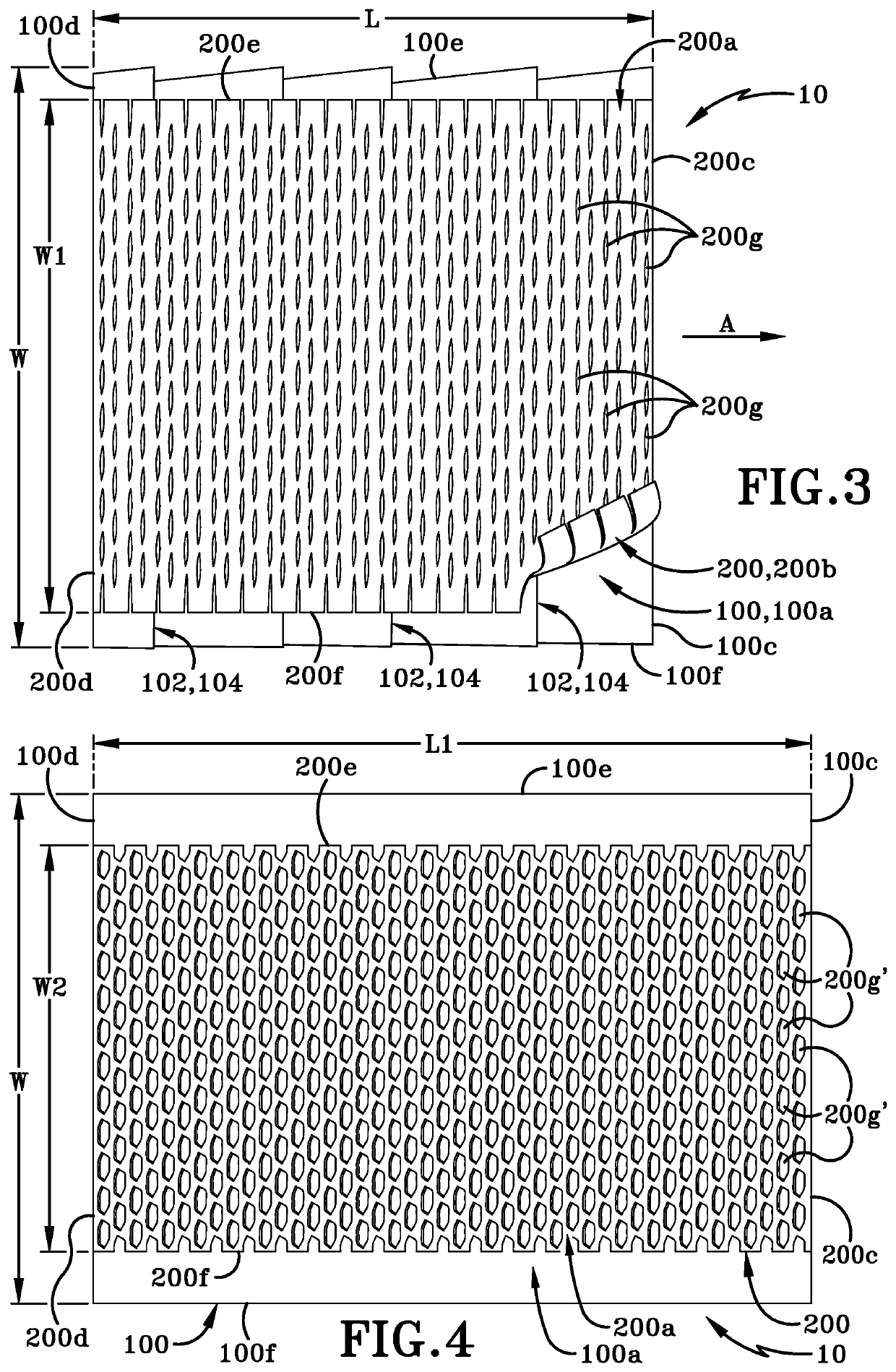

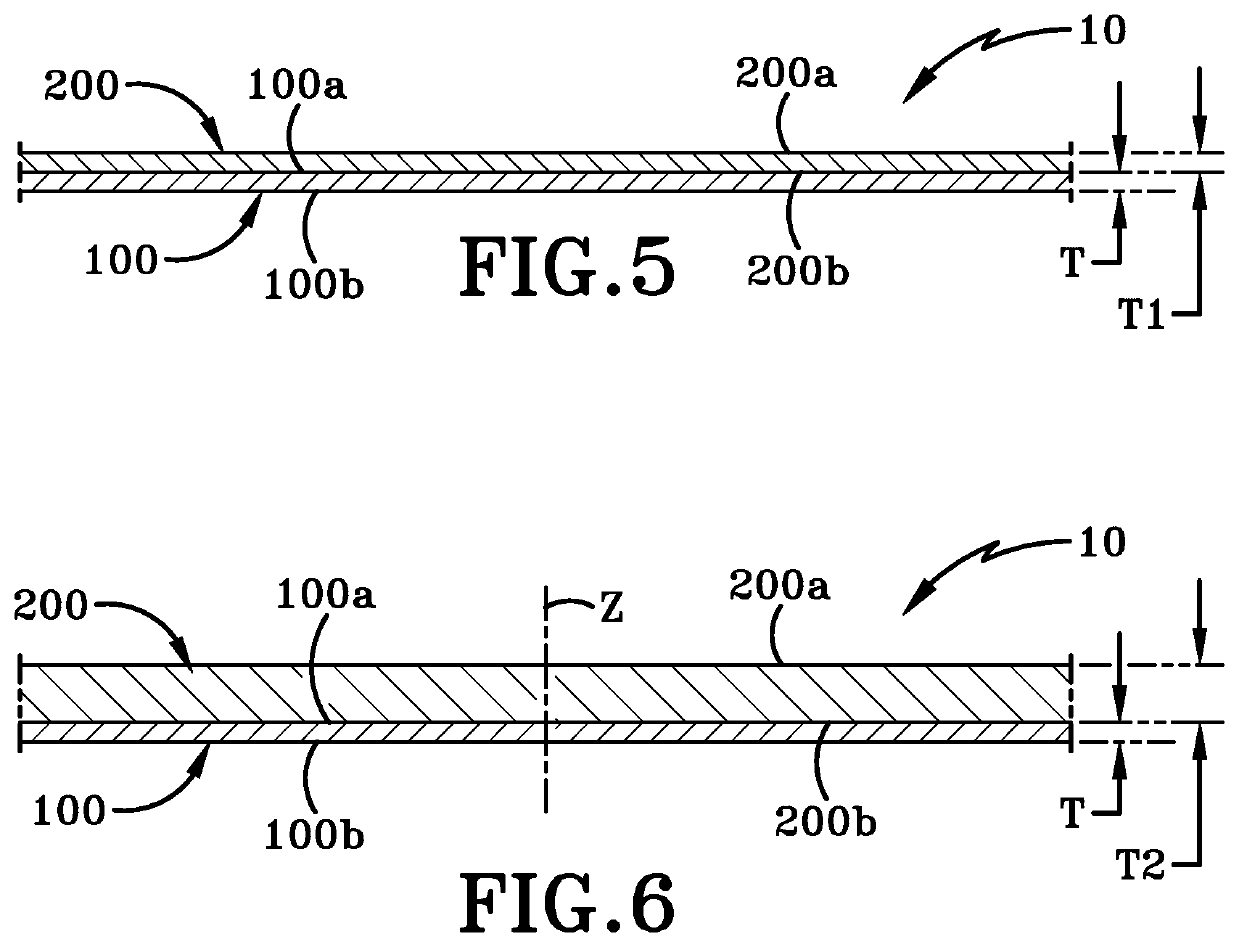

Packaging material with expanding layer and packaging enclosure formed therewith

PendingUS20220143946A1Creating structural strengthLess overall consumptionPaper/cardboard articlesUsing shock-absorbing mediaPack materialMechanical engineering

A packaging material including one or more expandable layers that provide protection to contents of a packaging enclosure formed with the packaging material. The packaging material includes at least a first layer and a second layer bonded to one another. The first layer is pulled or extended in a first direction that is effective to cause the second layer to expand in a second direction. The second layer is a cut-patterned layer which creates structural strength in the packaging material when expanded.

Owner:IOW LLC

Screw less cover plate for electrical fixtures

ActiveUS10742012B2Easy to installSustained coverageElectrical apparatusClassical mechanicsScrew thread

Owner:DJW DEV LLC

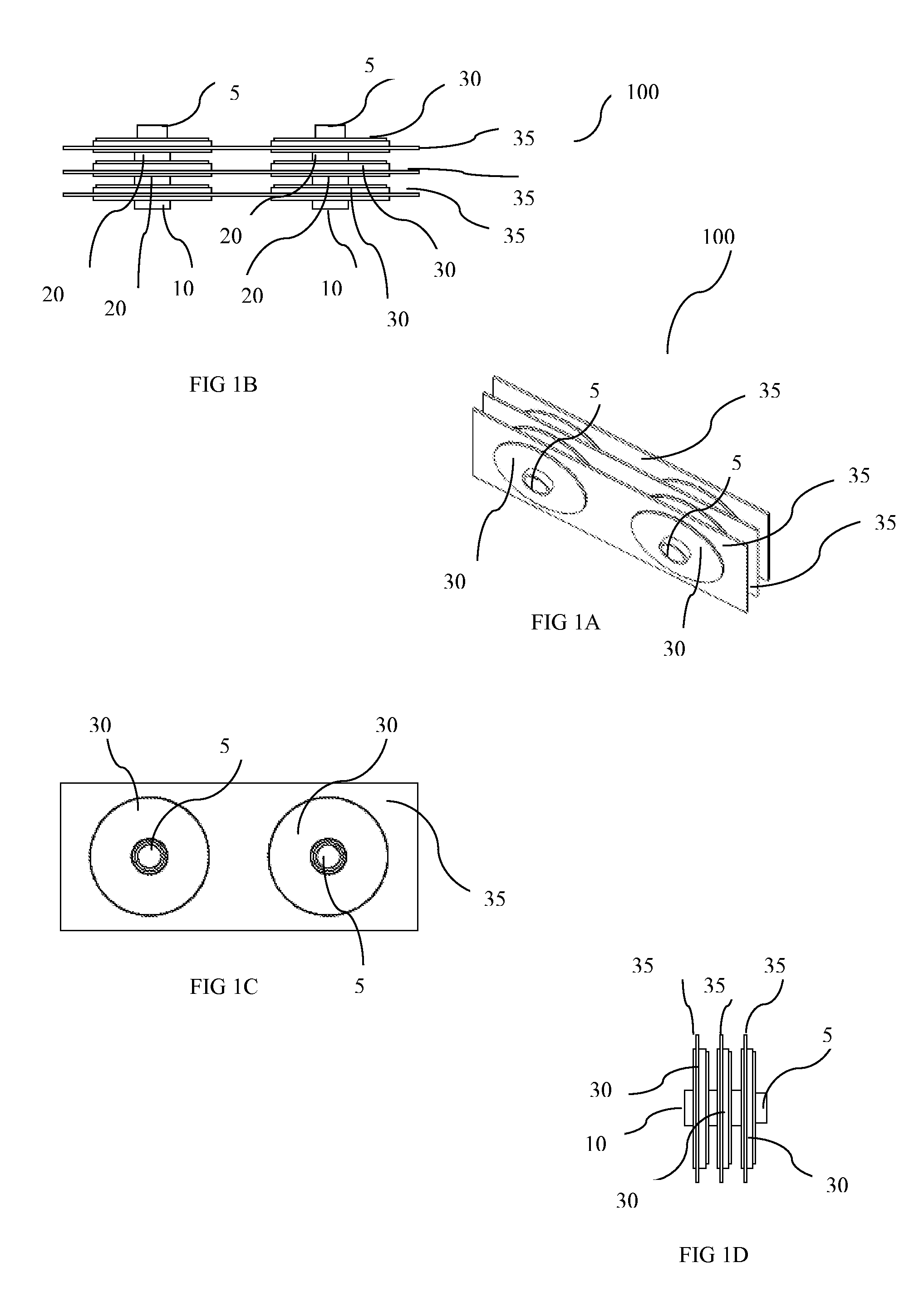

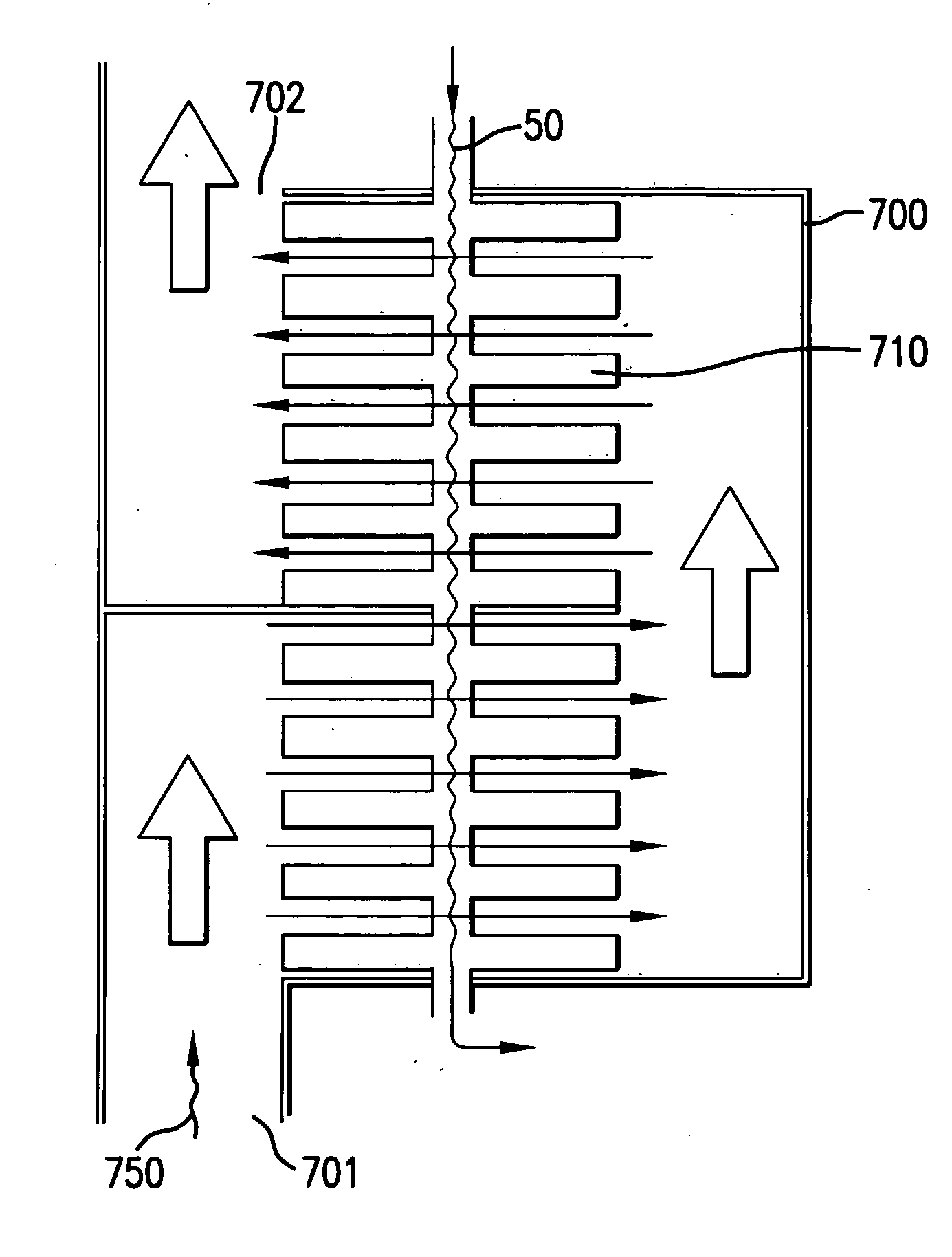

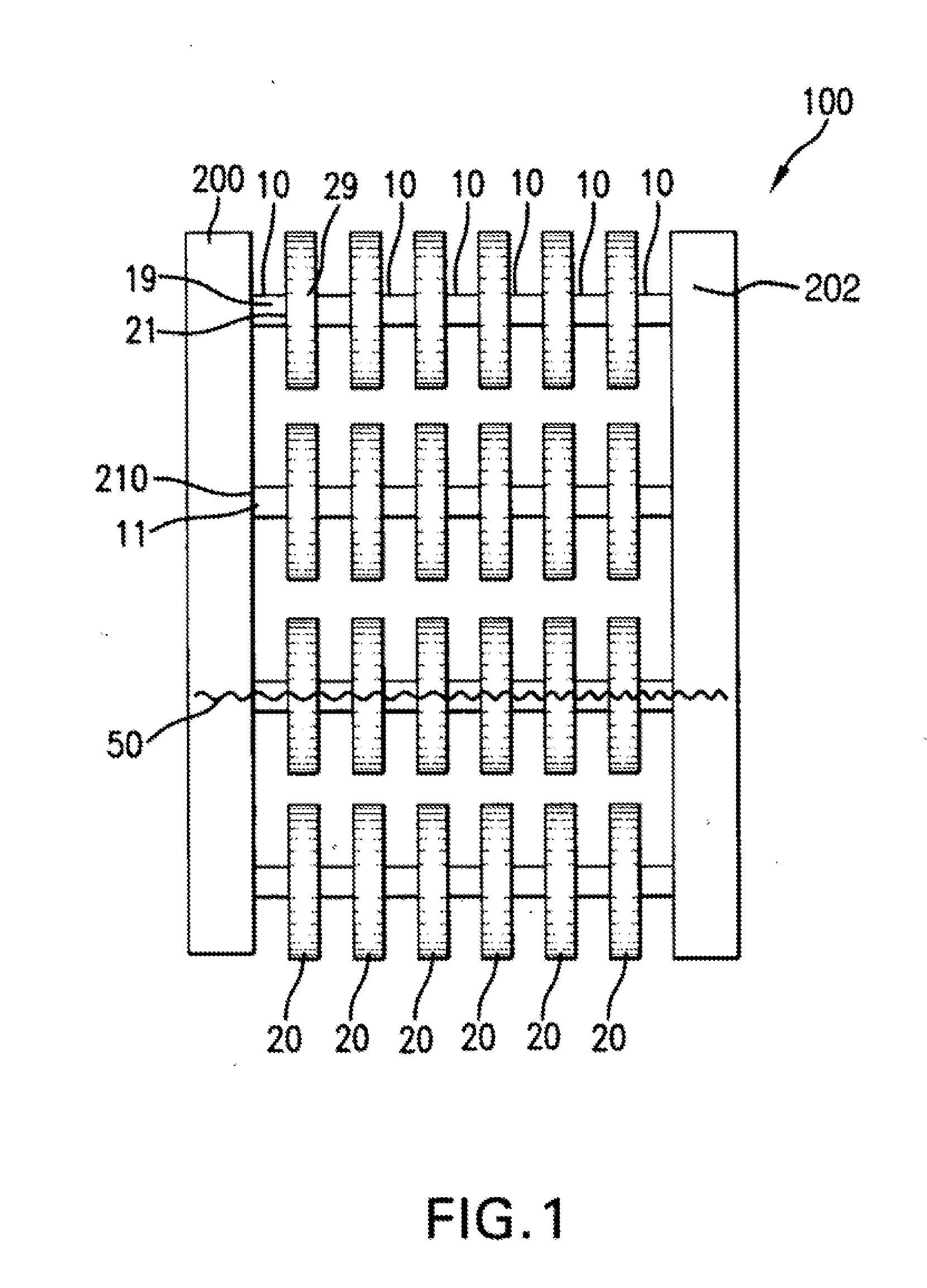

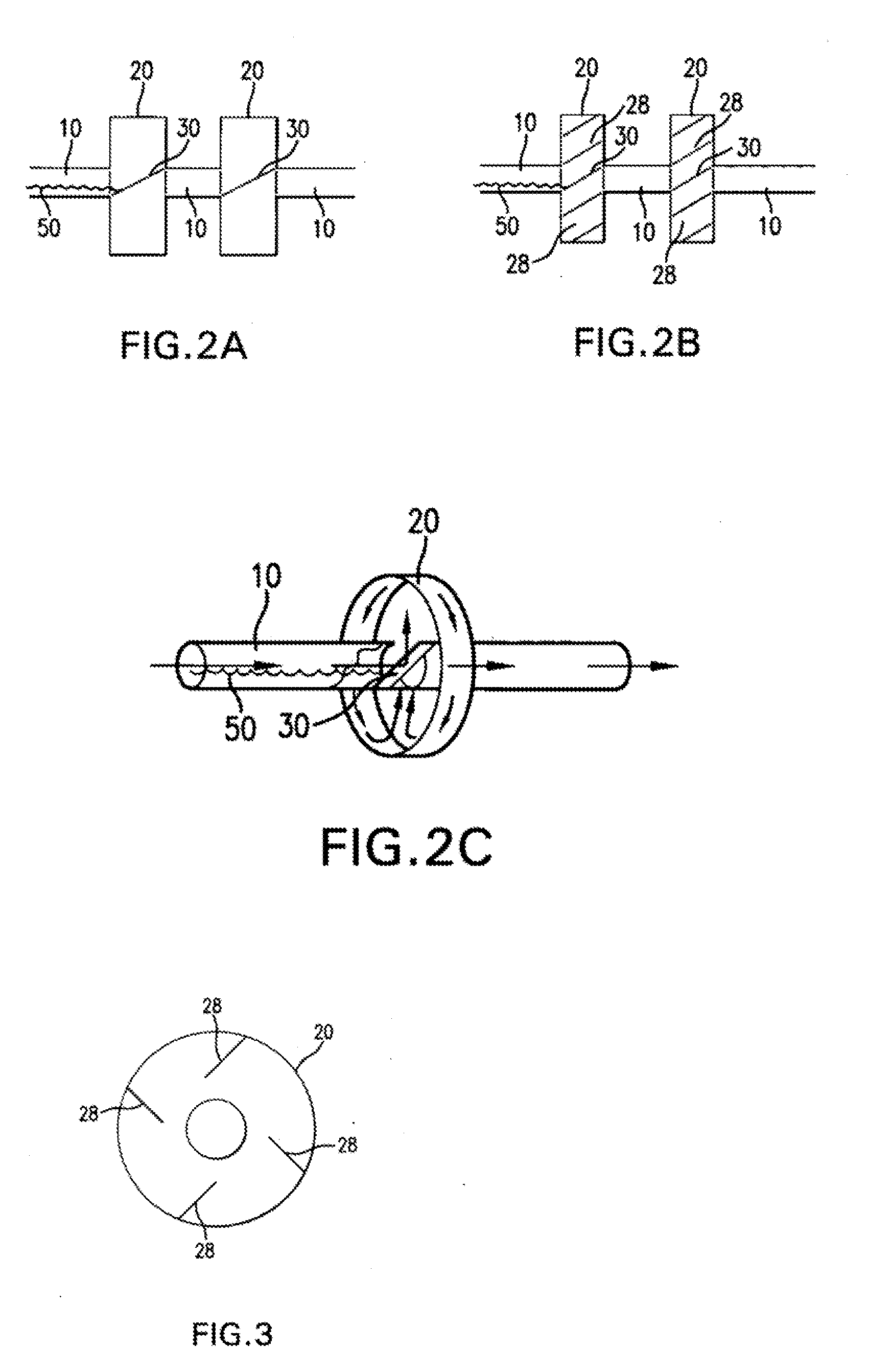

Heat exchanger utilizing tubular structures having internal flow altering members and external chamber assemblies

InactiveUS20150219409A1Increase surface areaImprove heating efficiencyCleaning heat-transfer devicesHeat exchanger casingsMechanical engineeringHeat exchanger

A heat exchanger includes at least one cylindrical tubular member formed from a tubular structure and chamber assemblies. A plurality of flow altering members are coupled at predetermined intervals within the tubular structure. The flow altering members have an angled surface on their respective sides facing the flow of a heat exchange medium. Pairs of inlet orifices and outlet orifices are formed on the wall of the tubular structure at the same intervals as the flow altering members. Chamber assemblies are coupled as a full or partial collar on the exterior of the tubular structure. Each chamber assembly is hollow, permitting fluid flow within, and is in fluid communication with a corresponding inlet orifice, outlet orifice pair so that the heat exchange medium repeatedly flows out of the tubular structure into a chamber assembly and back into the tubular structure. Multiple cylindrical tubular members may be coupled between manifolds.

Owner:MIKUTAY CORP

Membranes for flue gas separation comprising crosslinked, thermally rearranged poly(benzoxazole-co-imide) and preparation method thereof

InactiveUS10040034B2Improve permeabilityHigh selectivityMembranesSemi-permeable membranesBenzoxazoleImide

The present disclosure relates to a membrane for flue gas separation containing a crosslinked, thermally rearranged poly(benzoxazole-co-imide) copolymer prepared simply by heat-treating a membrane prepared from an o-hydroxypolyimide copolymer having carboxylic acid groups such that thermal crosslinking and thermal rearrangement occur simultaneously or a membrane for flue gas separation containing a crosslinked, thermally rearranged poly(benzoxazole-co-imide) copolymer having a benzoxazole group content of less than 80% in the polymer chain, prepared from transesterification crosslinking of an o-hydroxypolyimide copolymer having carboxylic acid groups and a diol-based compound followed by thermal rearrangement, and a method for preparing the same.In accordance with the present disclosure, a crosslinked, thermally rearranged poly(benzoxazole-co-imide) copolymer membrane for flue gas separation can be prepared simply through heat treatment without requiring a complicated process such as chemical crosslinking, UV irradiation, etc. for forming a crosslinked structure and a membrane for flue gas separation prepared therefrom exhibits superior permeability and selectivity. Also, the method is applicable to commercial-scale production because the preparation process is simple.

Owner:IUCF HYU (IND UNIV COOP FOUND HANYANG UNIV)

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com