Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

62results about How to "Improve stack stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

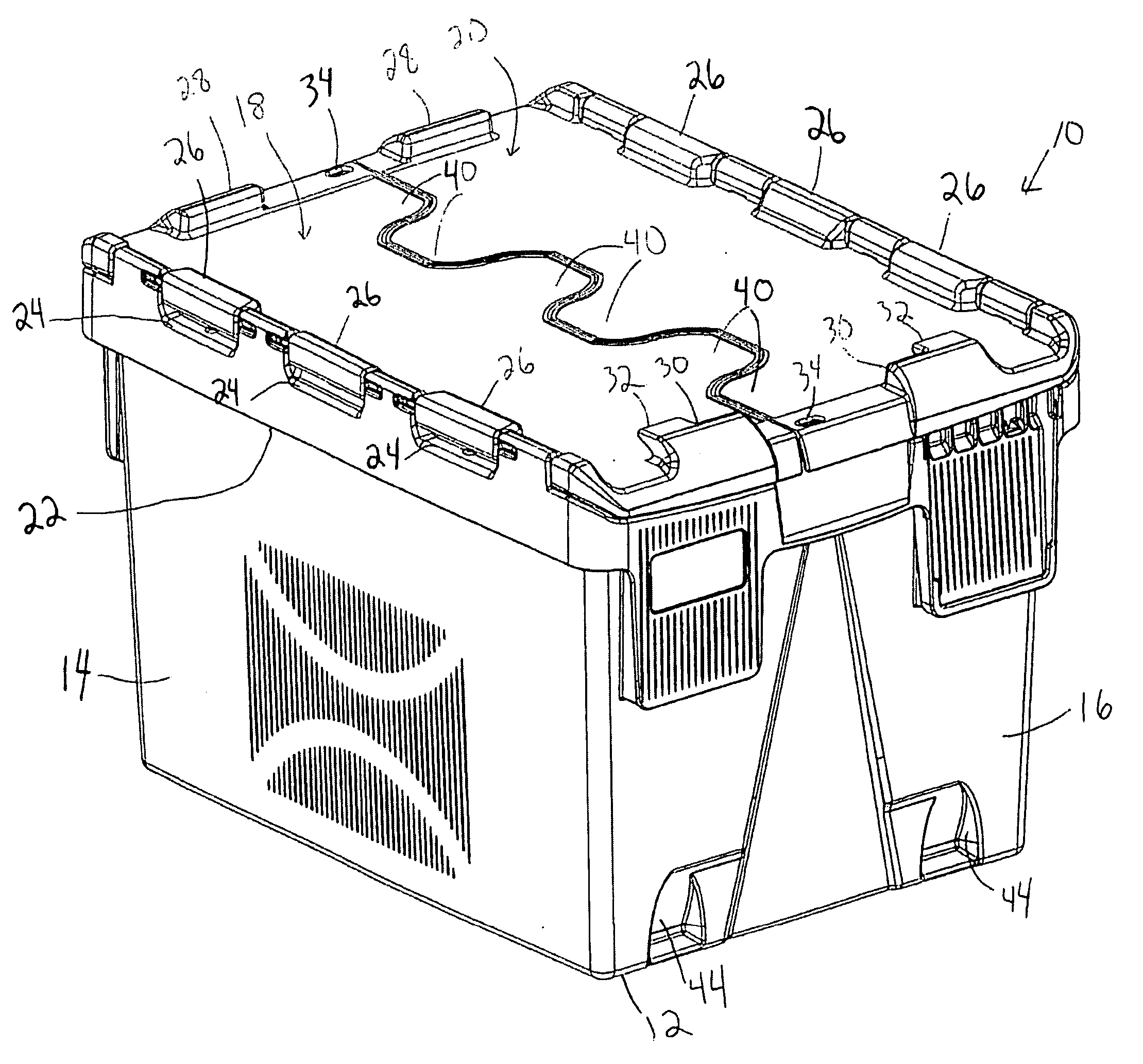

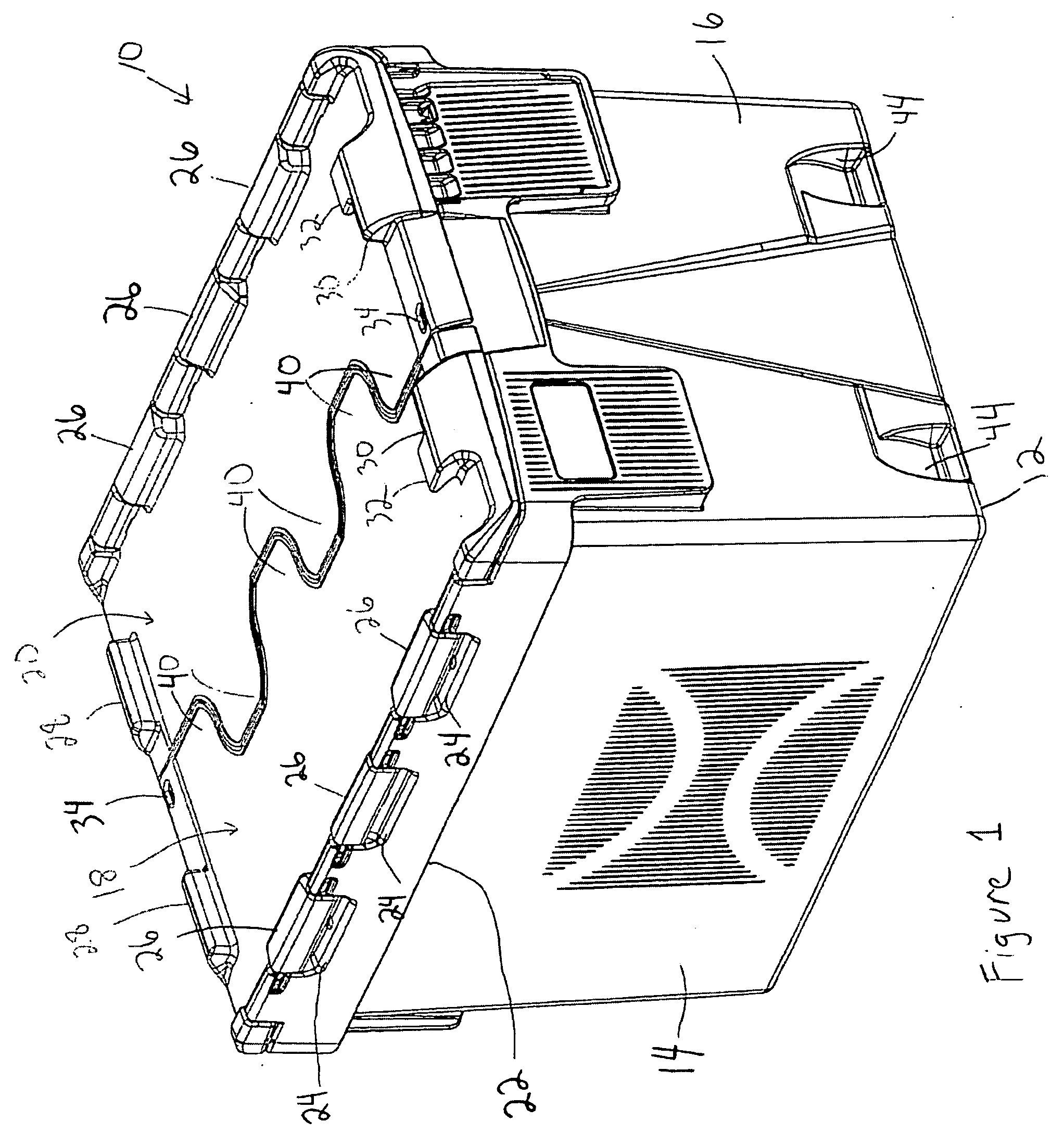

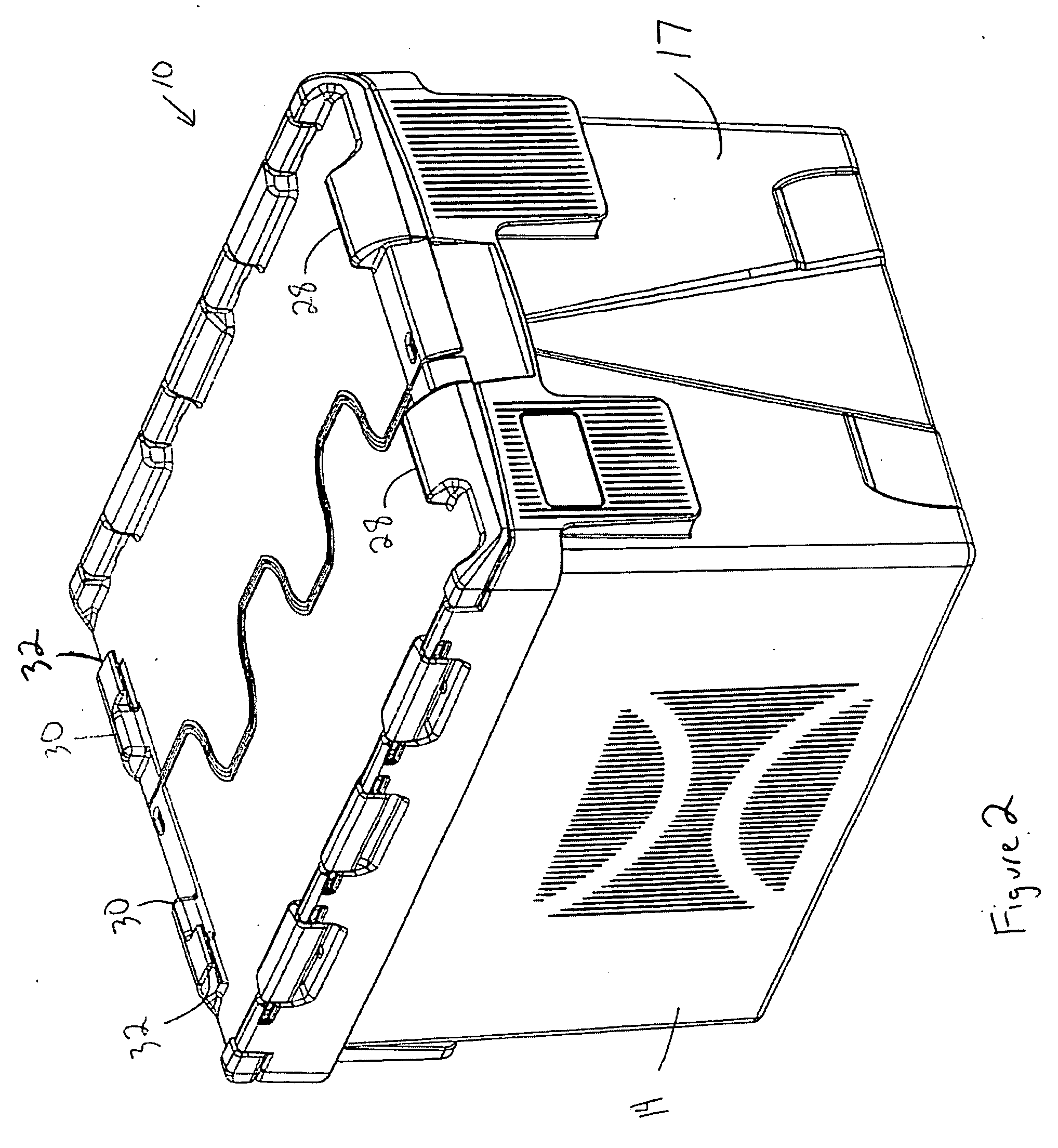

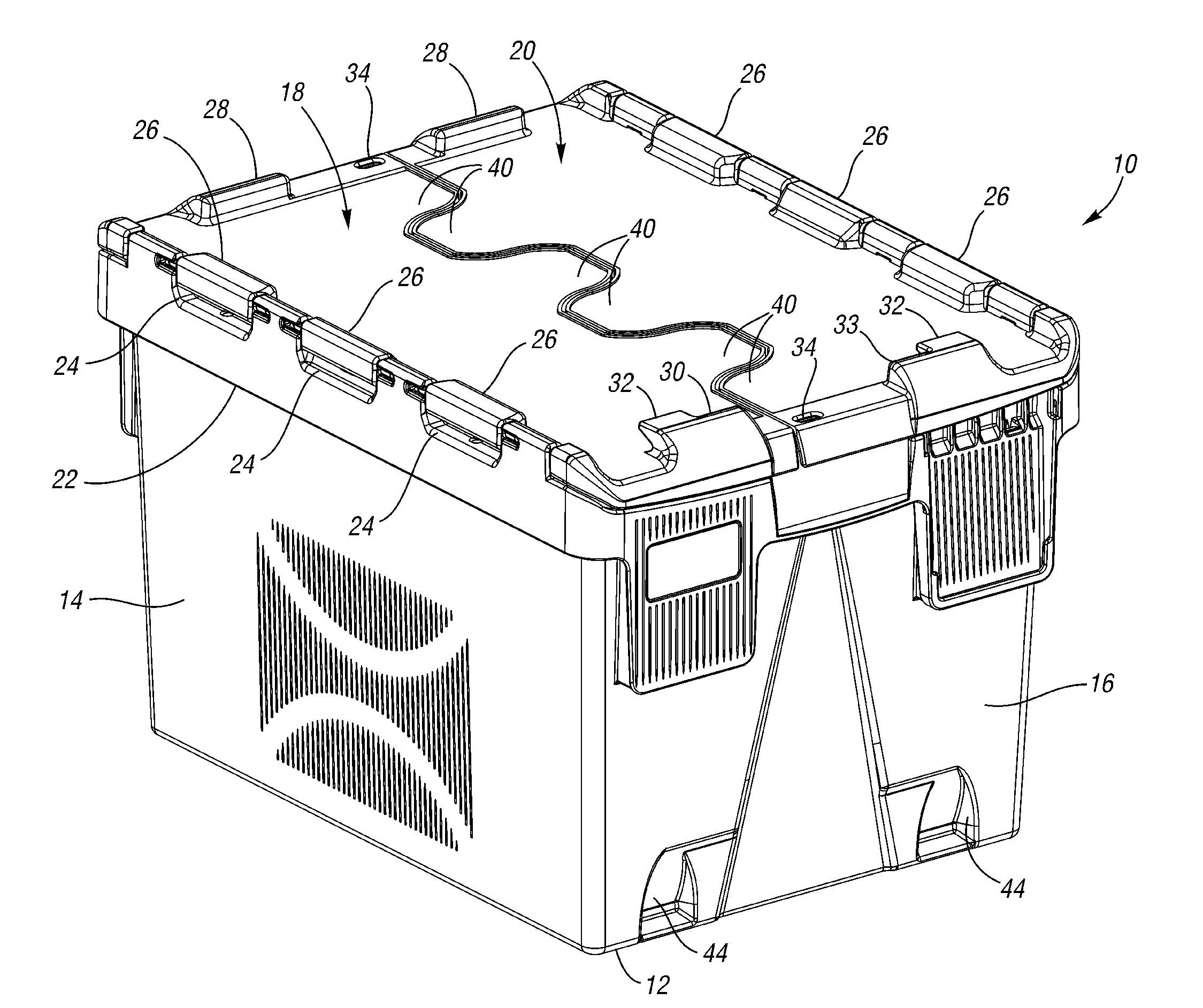

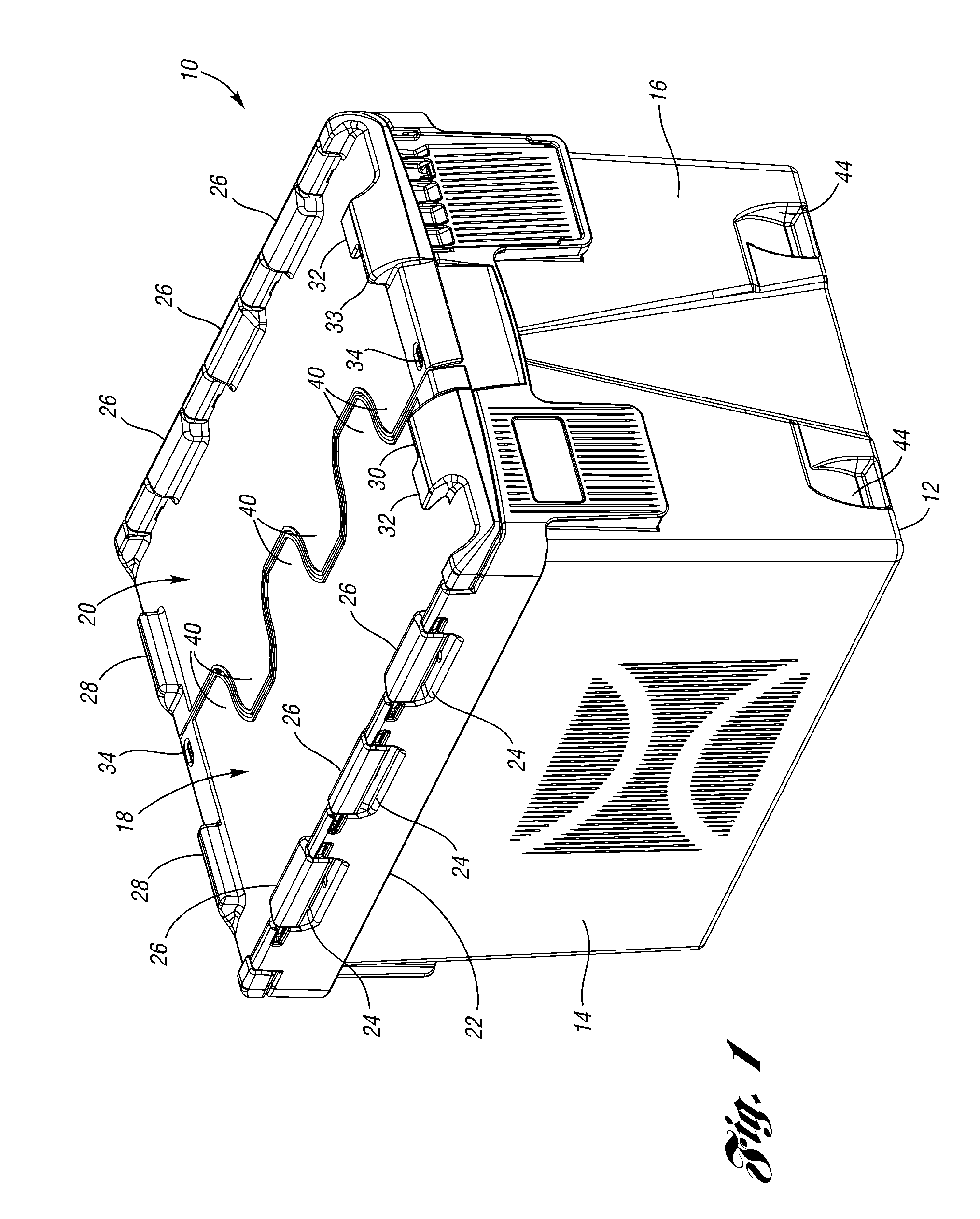

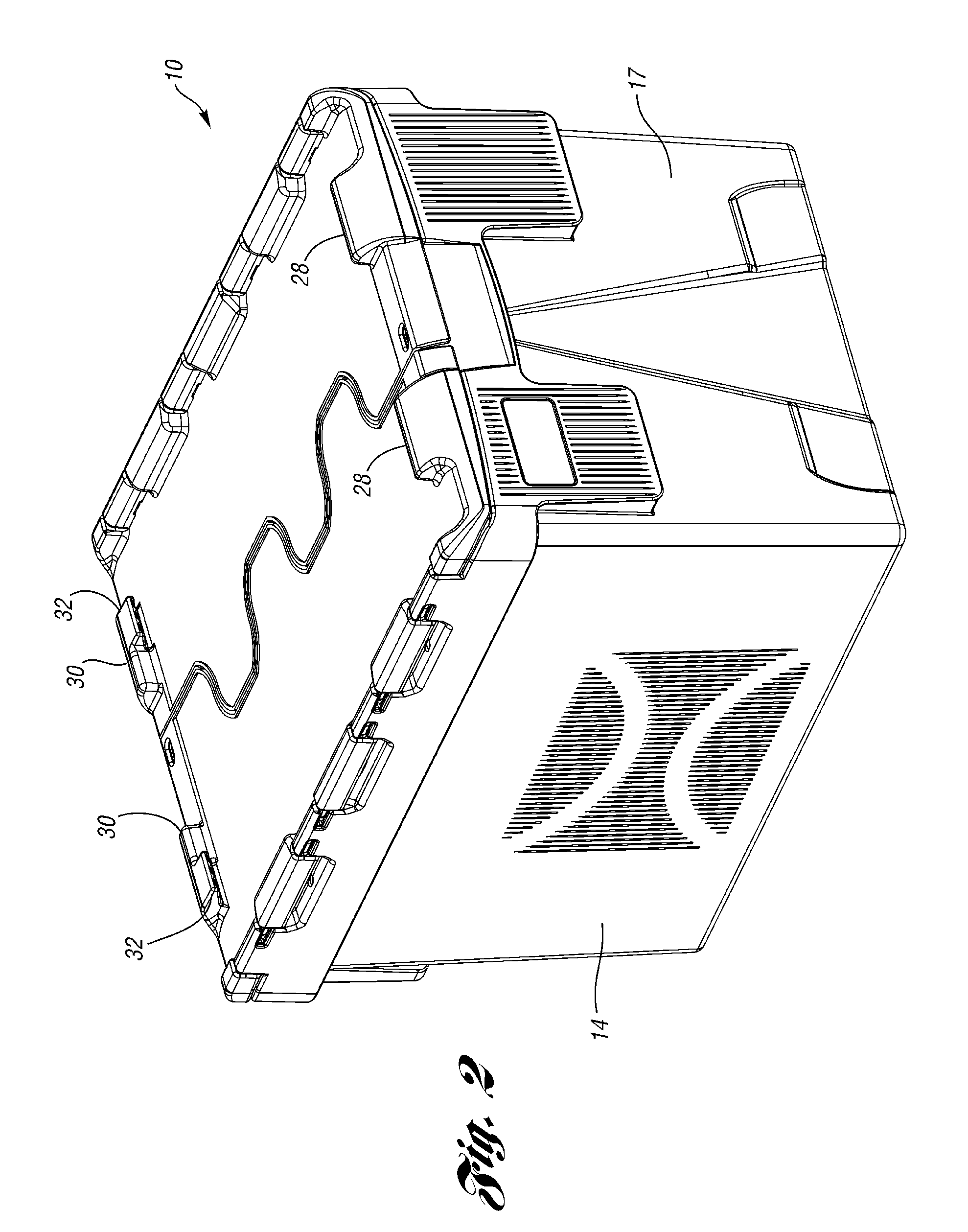

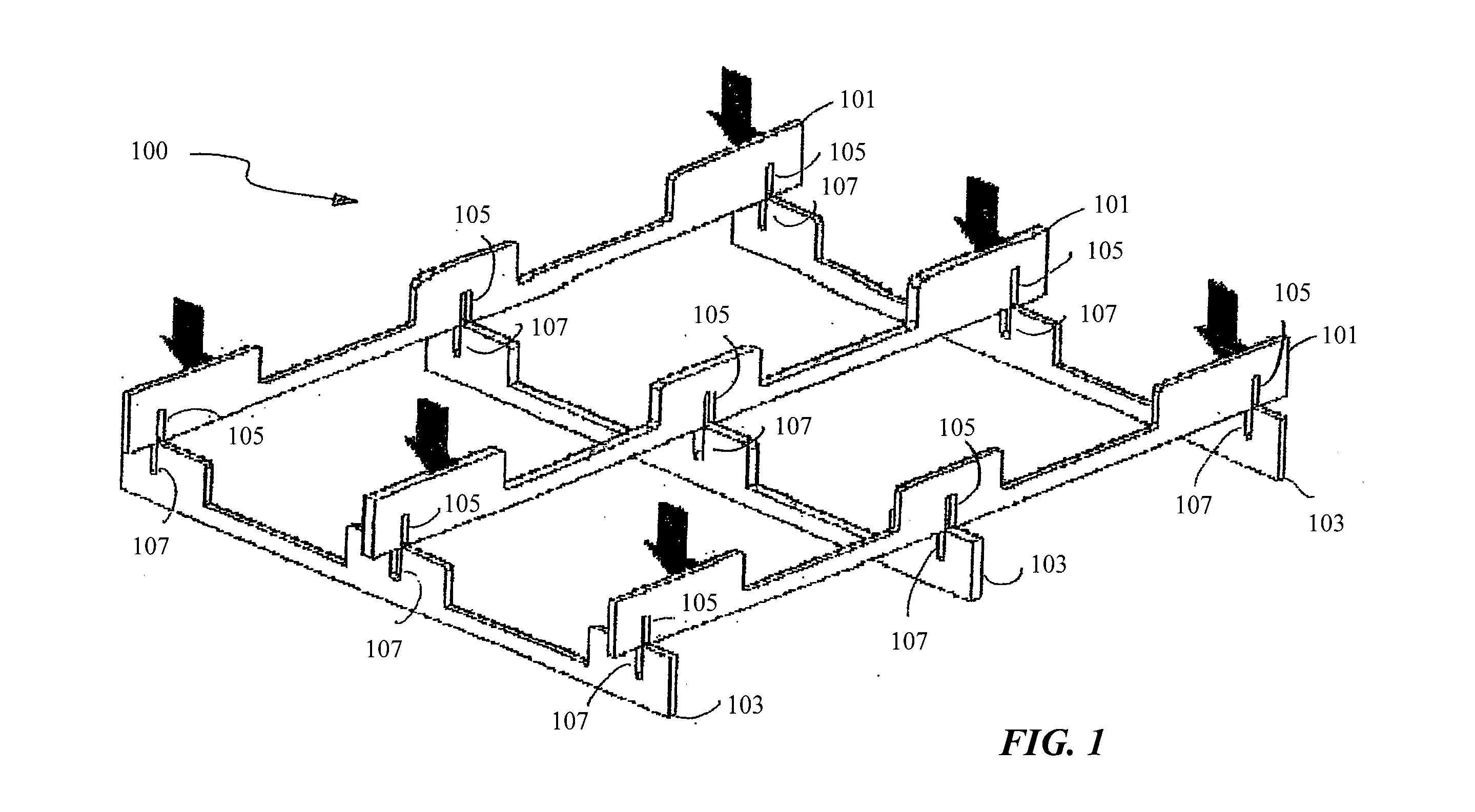

Storage container

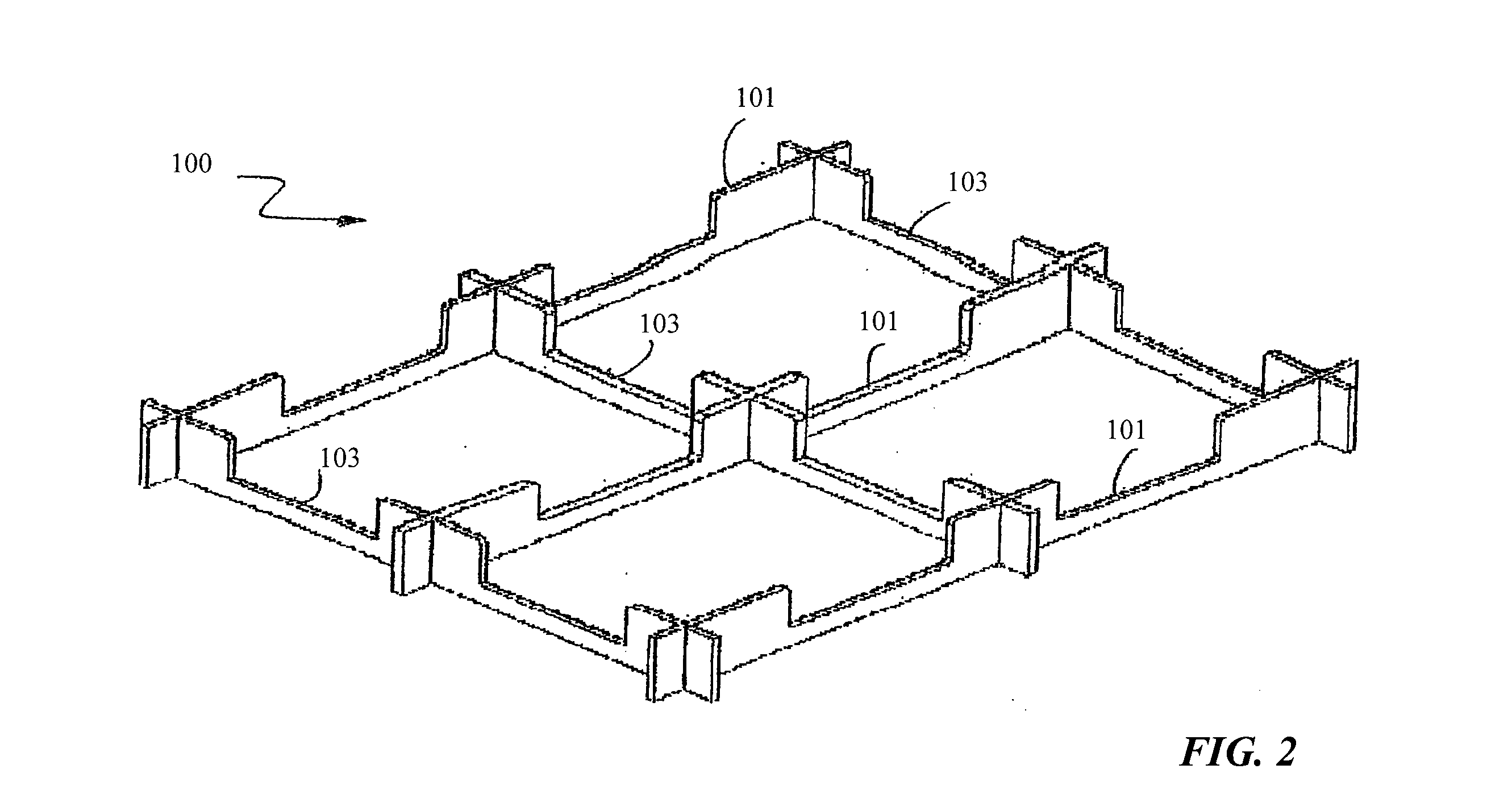

ActiveUS20060186123A1Improve stack stabilityAvoid vertical movementWing accessoriesLidsEngineeringMechanical engineering

A storage container includes a base having side walls and end walls extending upwardly from the base. Lid halves are hingeably connected to upper edges of the side walls. A security recess is formed in the side walls adjacent to each hinge and corresponds with a security tab projecting from the lid halves preventing vertical movement of the outer edge of the lid half when the lid is in the closed position. The lid halves also include a lip adjacent to the hinge and upper and lower leaves that overlap with the opposing lid half to prevent moisture from seeping into the storage container.

Owner:REHRIG PACIFIC CO INC

Storage container with hinged lid

ActiveUS8066143B2Improve stack stabilityAvoid vertical movementWing accessoriesBoxesEngineeringMechanical engineering

A storage container includes a base having side walls and end walls extending upwardly from the base. Lid halves are hingeably connected to upper edges of the side walls. A security recess is formed in the side walls adjacent to each hinge and corresponds with a security tab projecting from the lid halves preventing vertical movement of the outer edge of the lid half when the lid is in the closed position. The lid halves also include a lip adjacent to the hinge and upper and lower leaves that overlap with the opposing lid half to prevent moisture from seeping into the storage container.

Owner:REHRIG PACIFIC CO INC

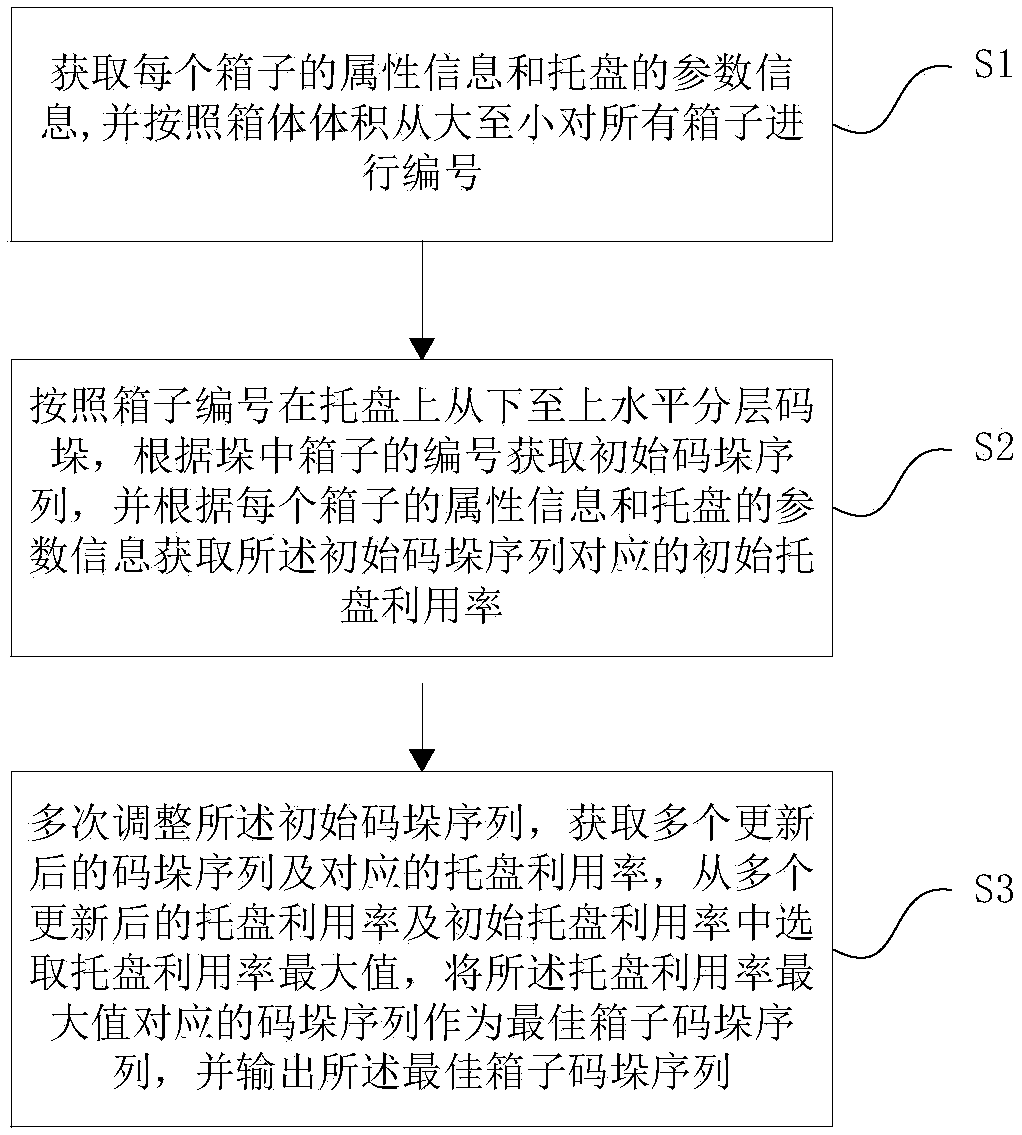

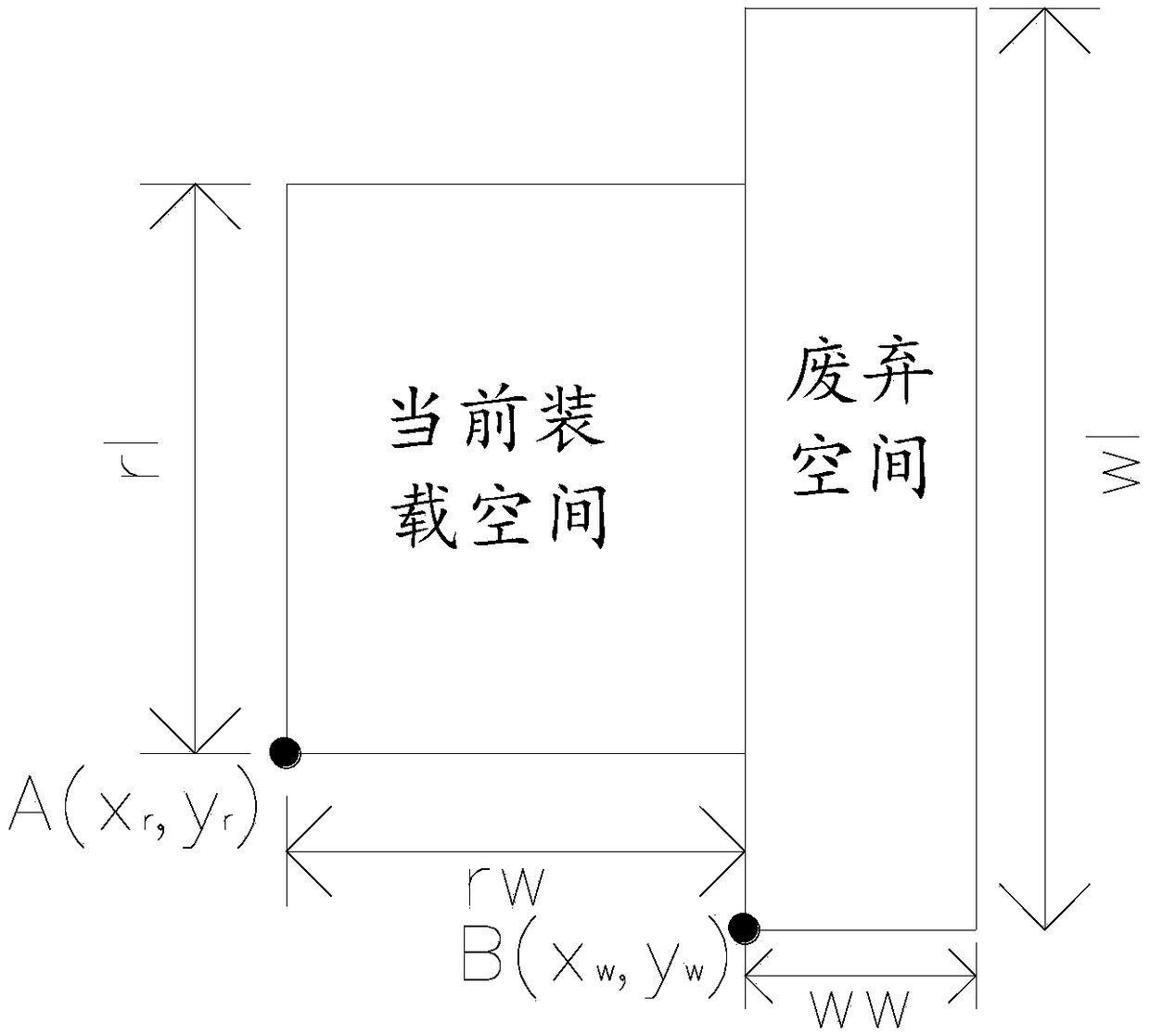

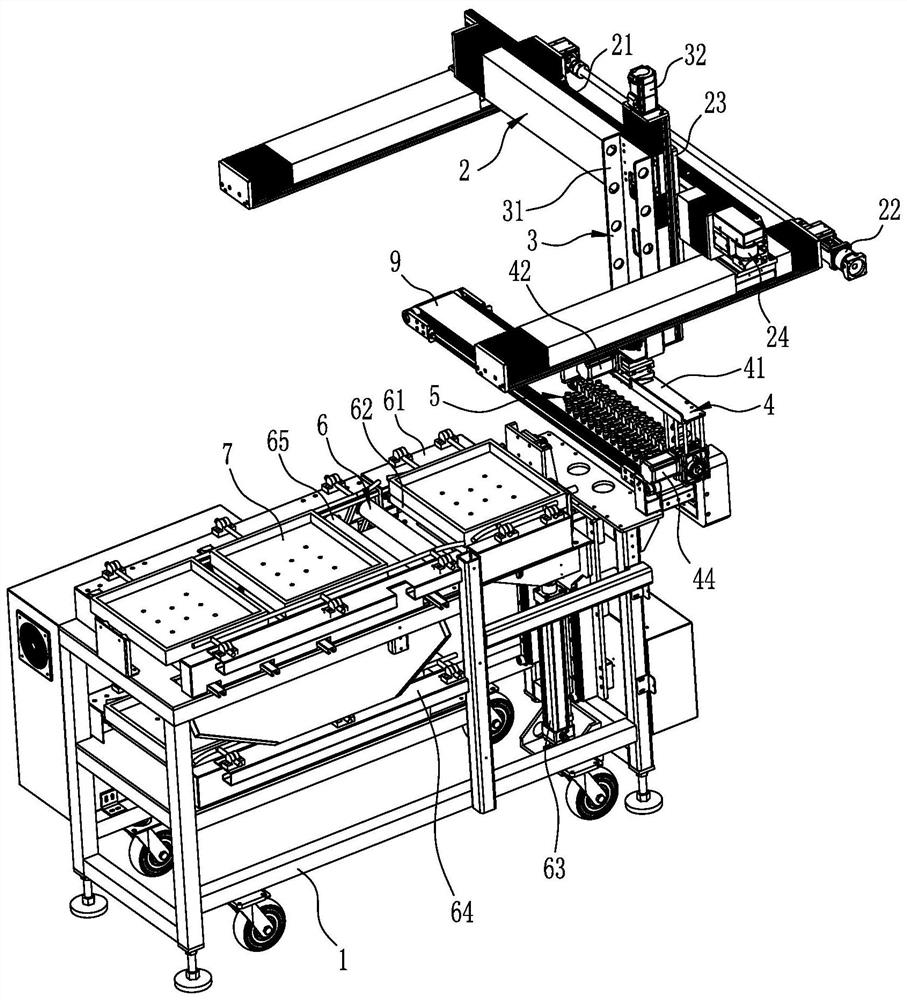

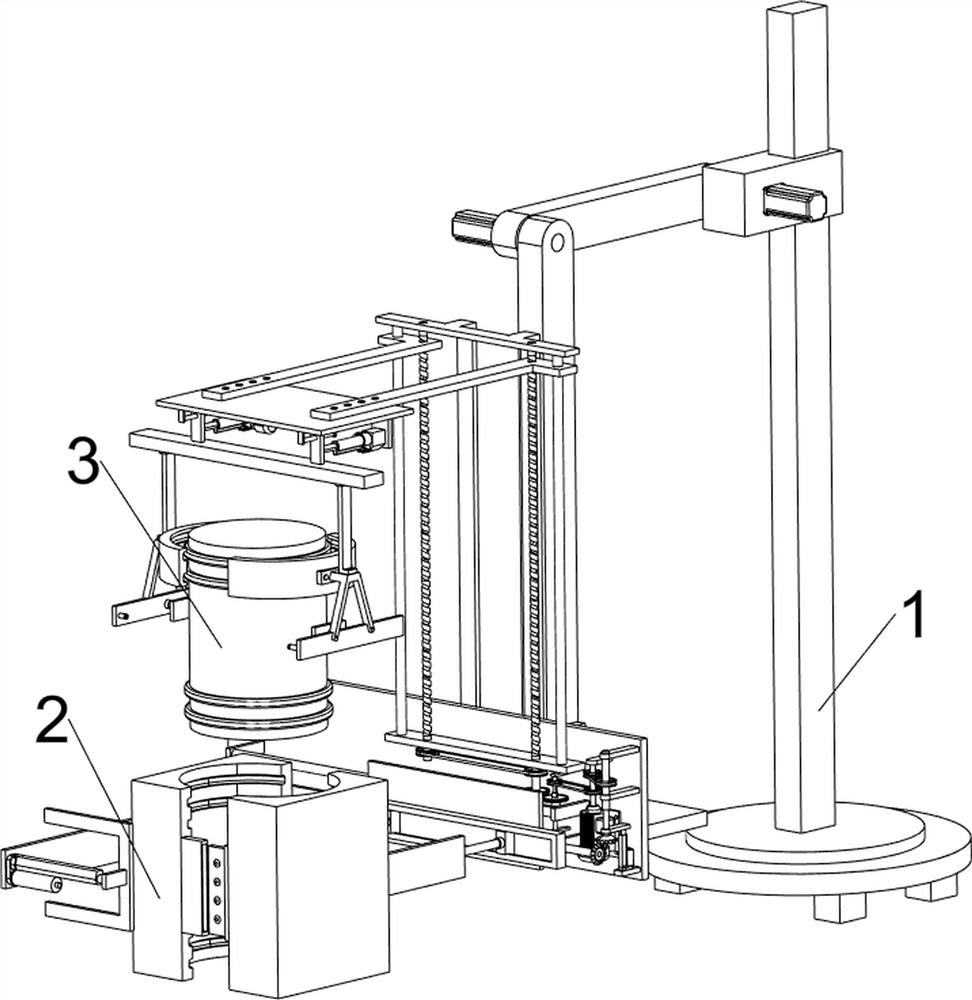

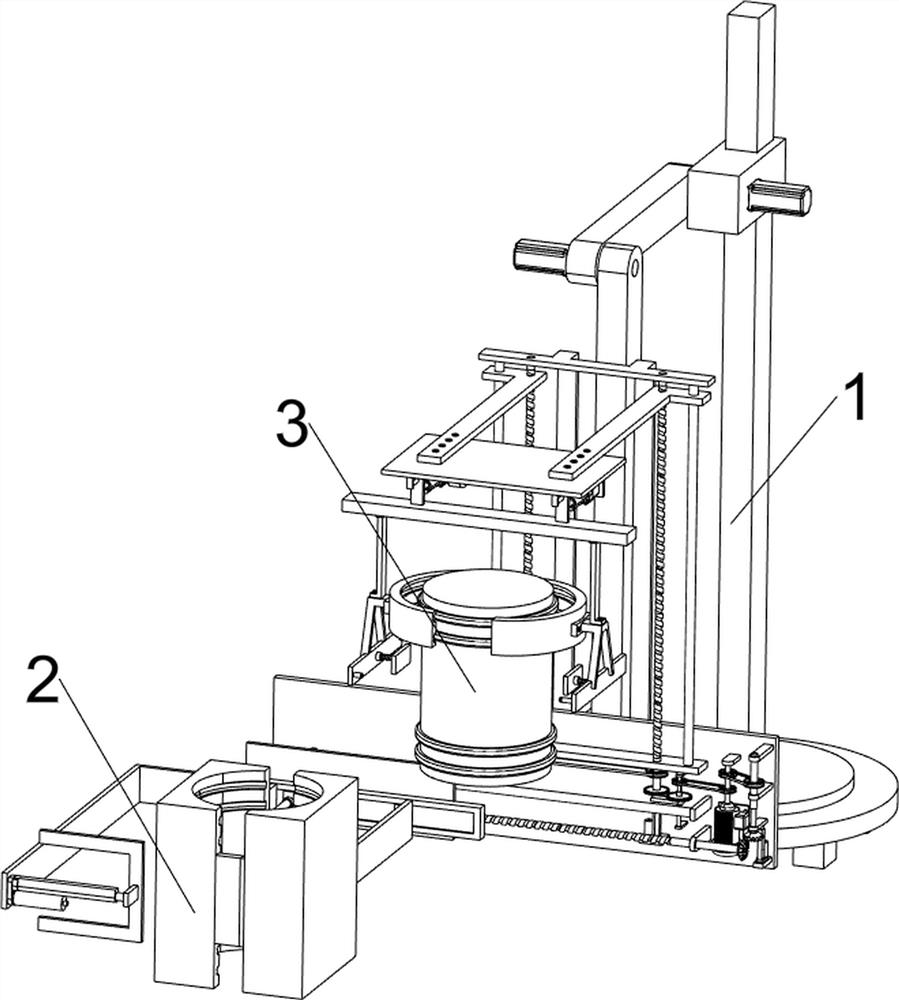

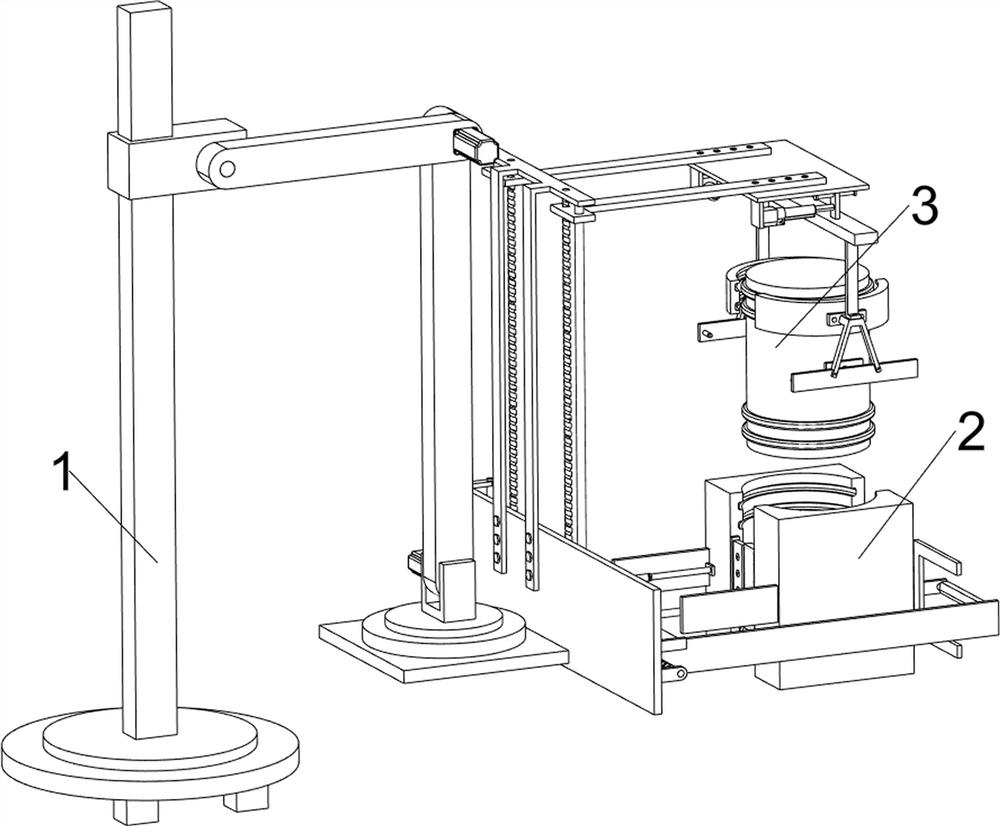

Offline hybrid stacking method and system

ActiveCN108750685AEnsure stack stabilityRealize horizontal layered palletizingConveyorsStacking articlesEngineeringUtilization rate

The invention relates to an offline hybrid stacking method and system. The method comprises the steps of acquiring the attribute information of each box and the parameter information of a tray, and numbering all boxes according to the volumes of the boxes from big to small; stacking the boxes on the tray from bottom to top according to the number of the boxes in a layered manner, and acquiring aninitial stacking sequence and the utilization rate of a corresponding initial tray; regulating the initial stacking sequence for many times, and acquiring the maximum value of the tray utilization rate; and taking the stacking sequence corresponding to the maximum value of the tray utilization rate as the optimal stacking sequence of the boxes, and output the optimal stacking sequence. According to the offline hybrid stacking method, cuboid boxes of different sizes can be stacked in a hybrid manner, and the stacking stability can be ensured; the horizontal layered stacking is achieved, and theoffline hybrid stacking method has the advantages that the stacking stability is high, and the stacking by a robot is facilitated; the utilization rate of the tray is high, etc., and the automation and intelligence of the hybrid stacking process are achieved.

Owner:哈尔滨库柏特科技有限公司

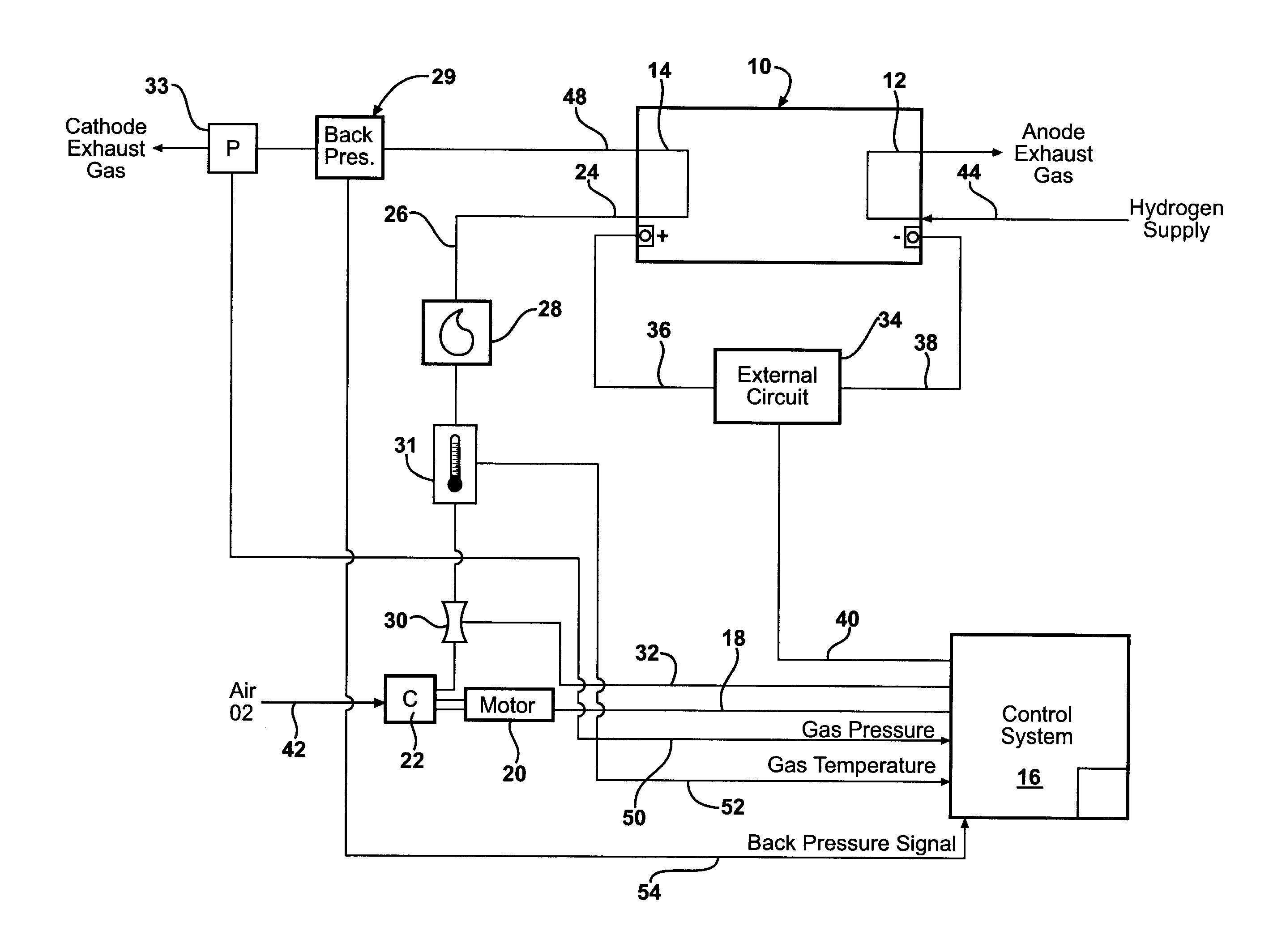

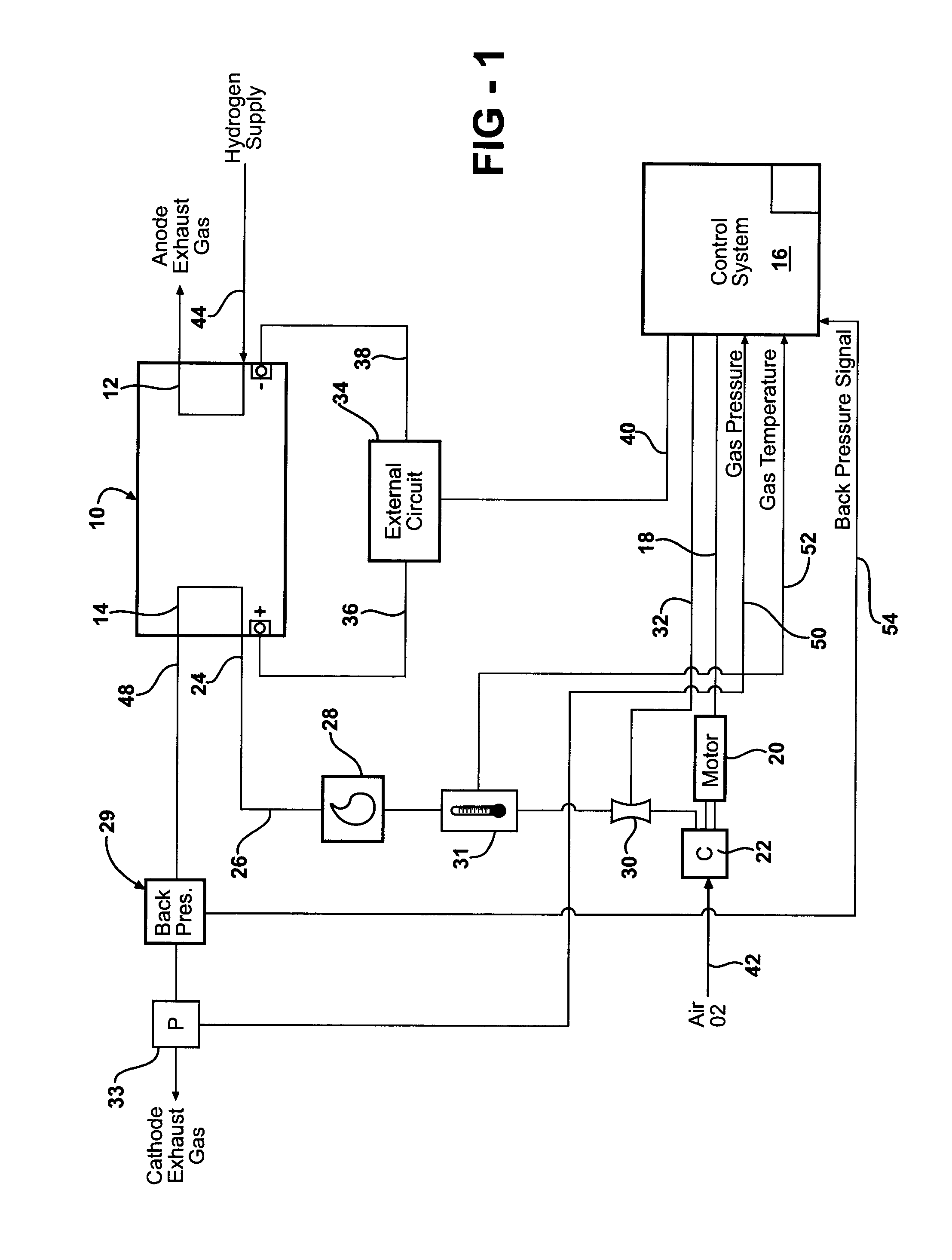

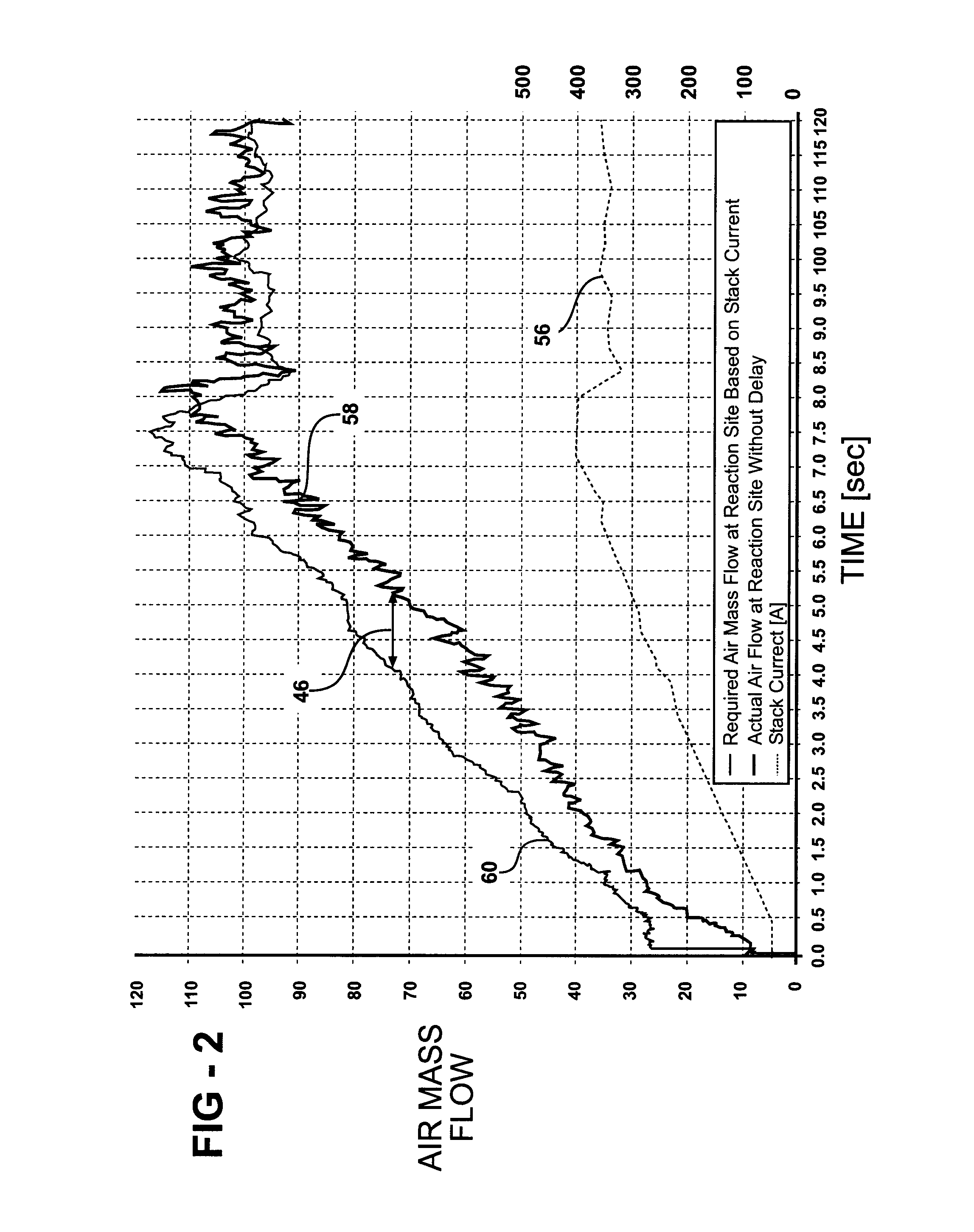

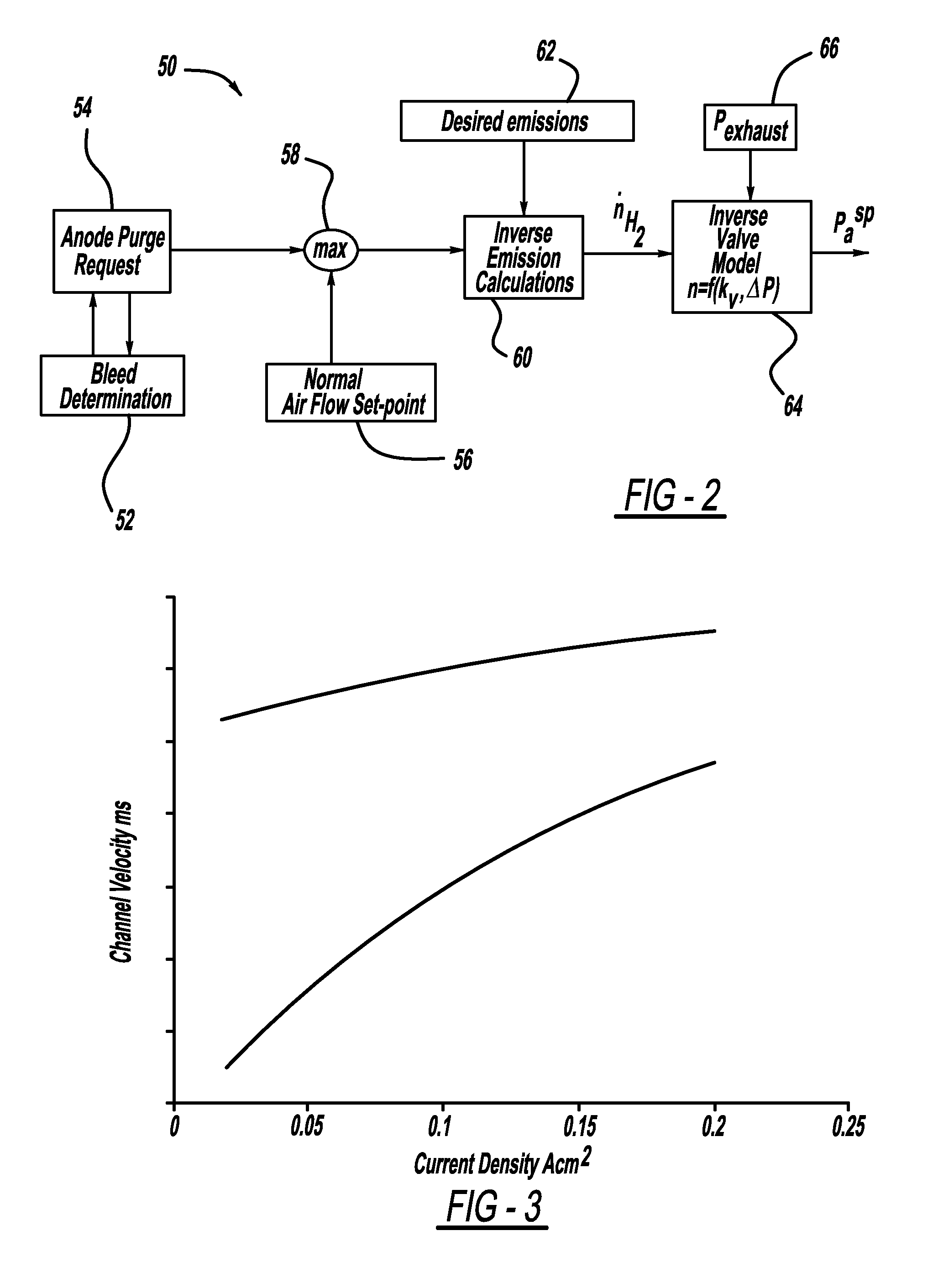

Method for managing fuel cell power increases using air flow feedback delay

ActiveUS20080081225A1Improve stack stabilityFuel cells groupingFuel cell auxillariesFuel cellsExternal circuit

A method for managing fuel cell power increases in a fuel cell system using an air flow feedback delay. The method comprises the steps of determining a required air mass flow rate at a predetermined point in the fuel cell system, determining an actual air mass flow at a predetermined point in the fuel cell system, calculating an air flow feedback delay as a function of the required air mass flow rate and the actual air mass flow, and delaying an external circuit from increasing current draw from the fuel cell stack by the magnitude of the air flow feedback delay.

Owner:GM GLOBAL TECH OPERATIONS LLC

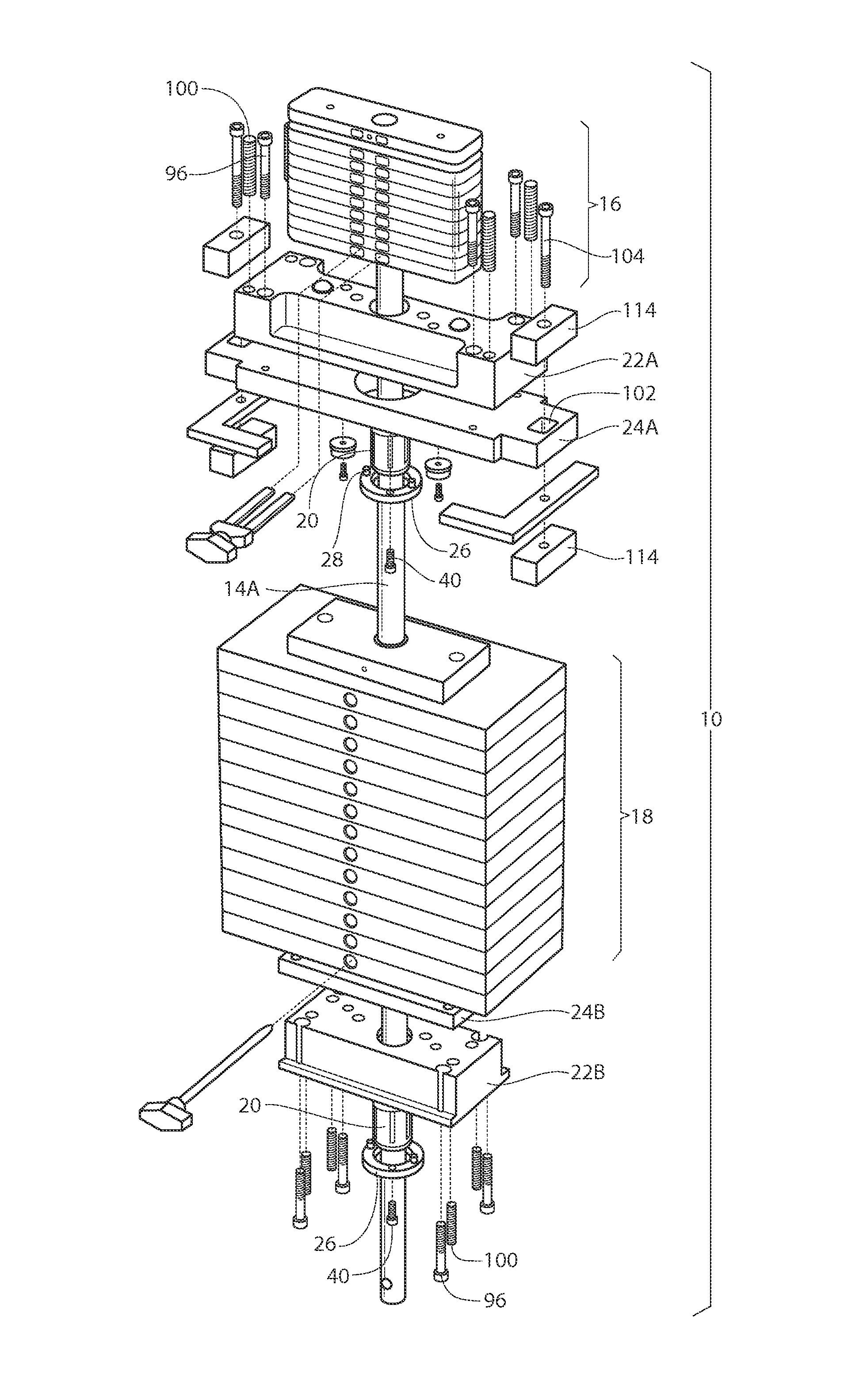

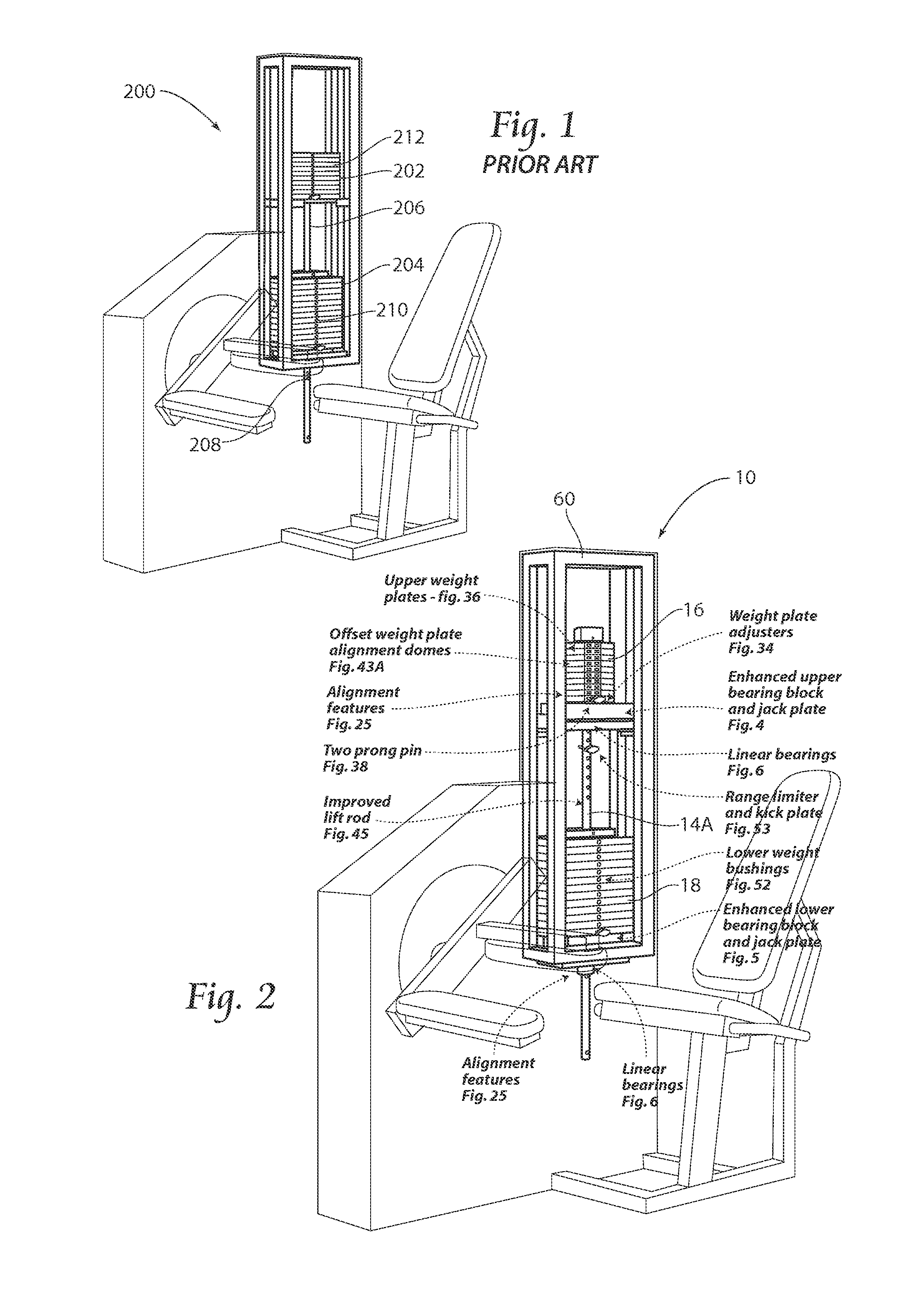

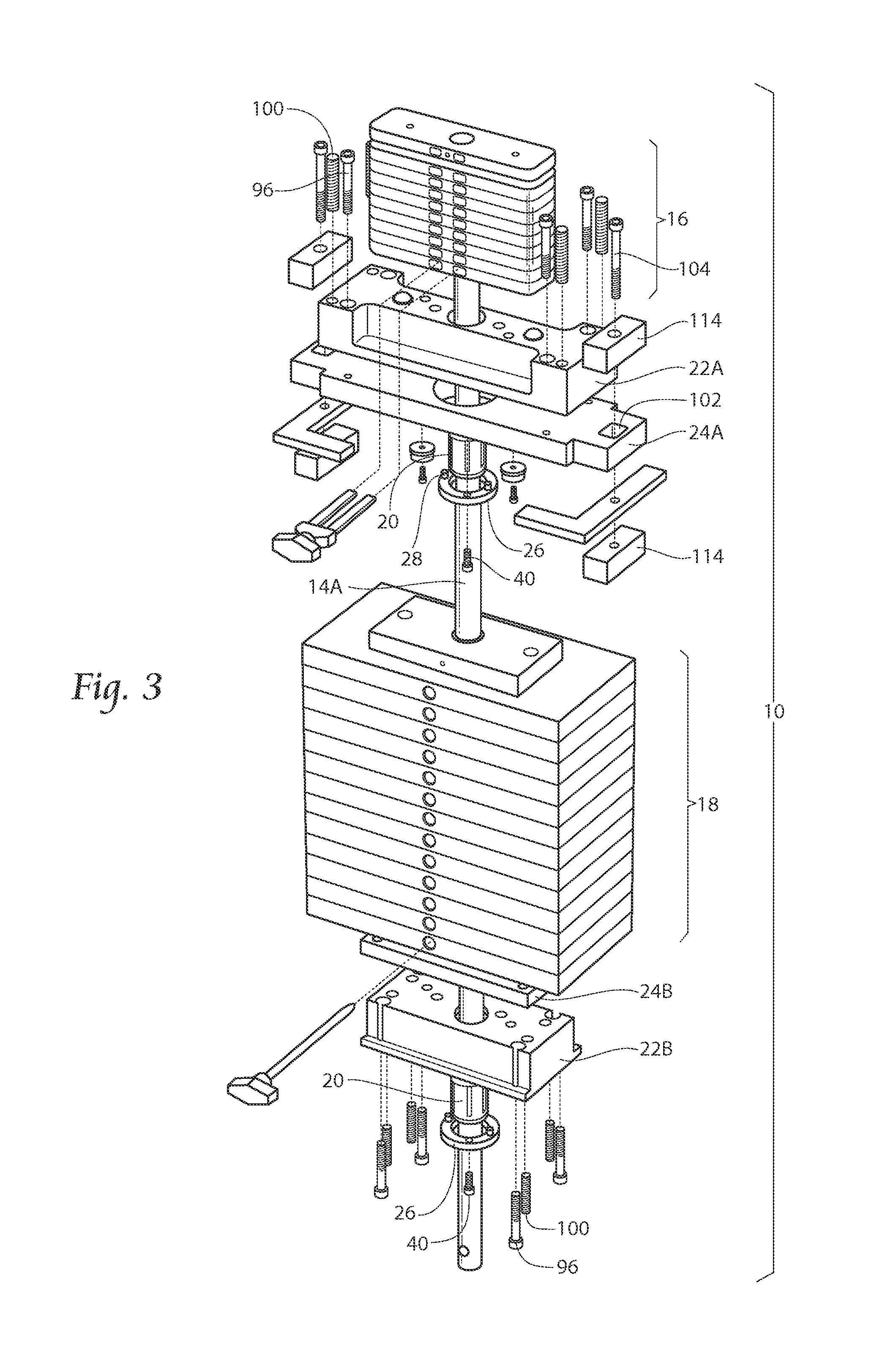

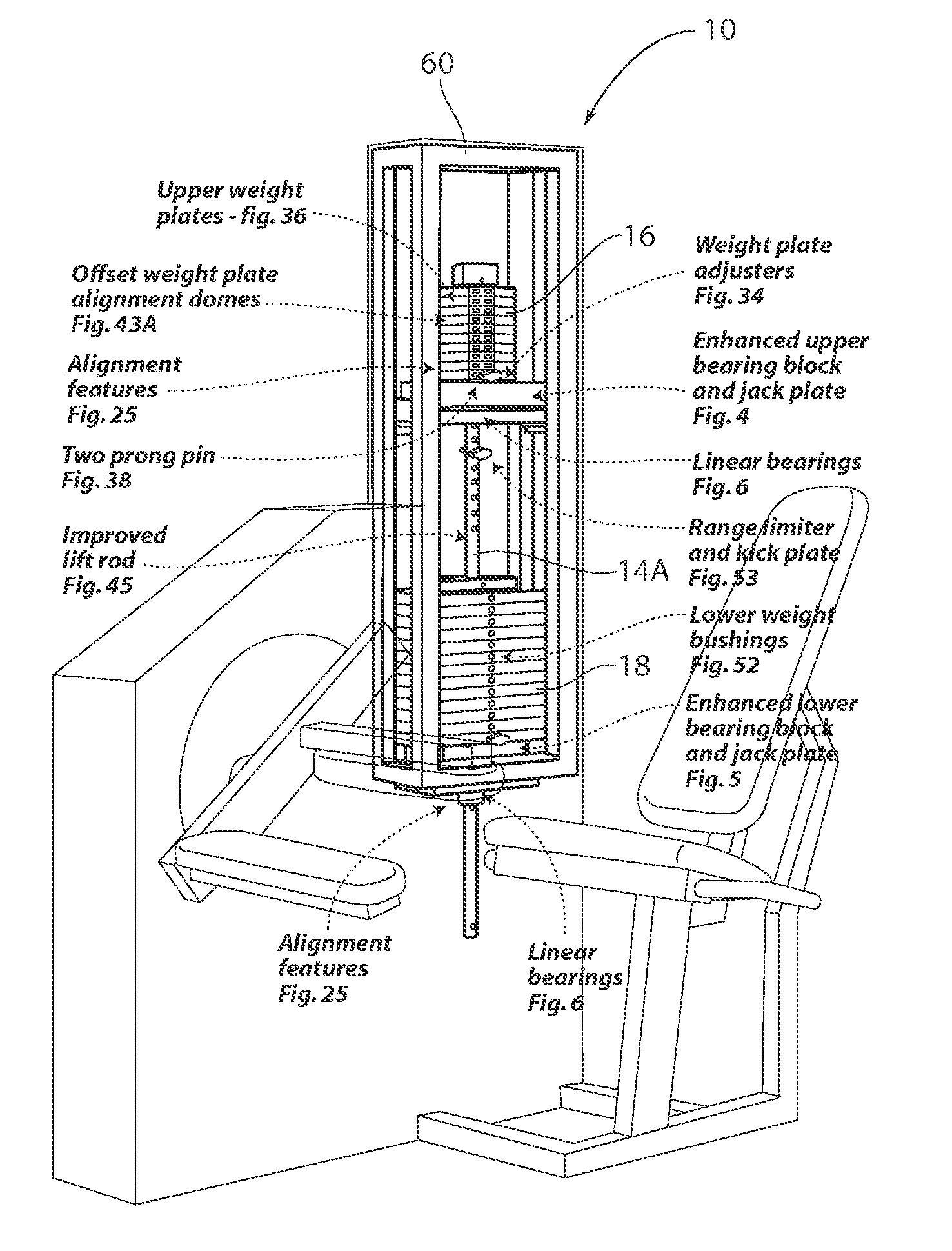

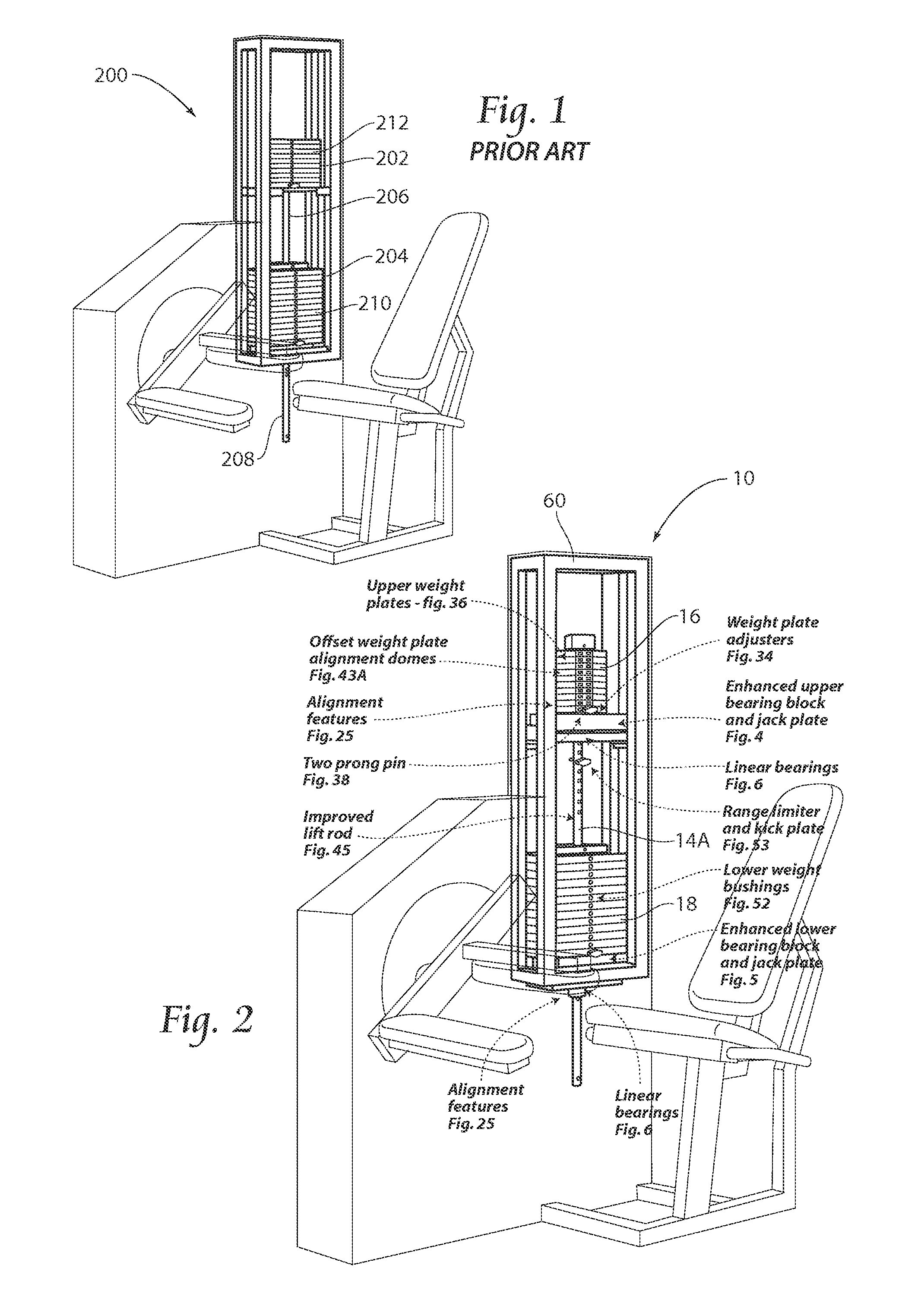

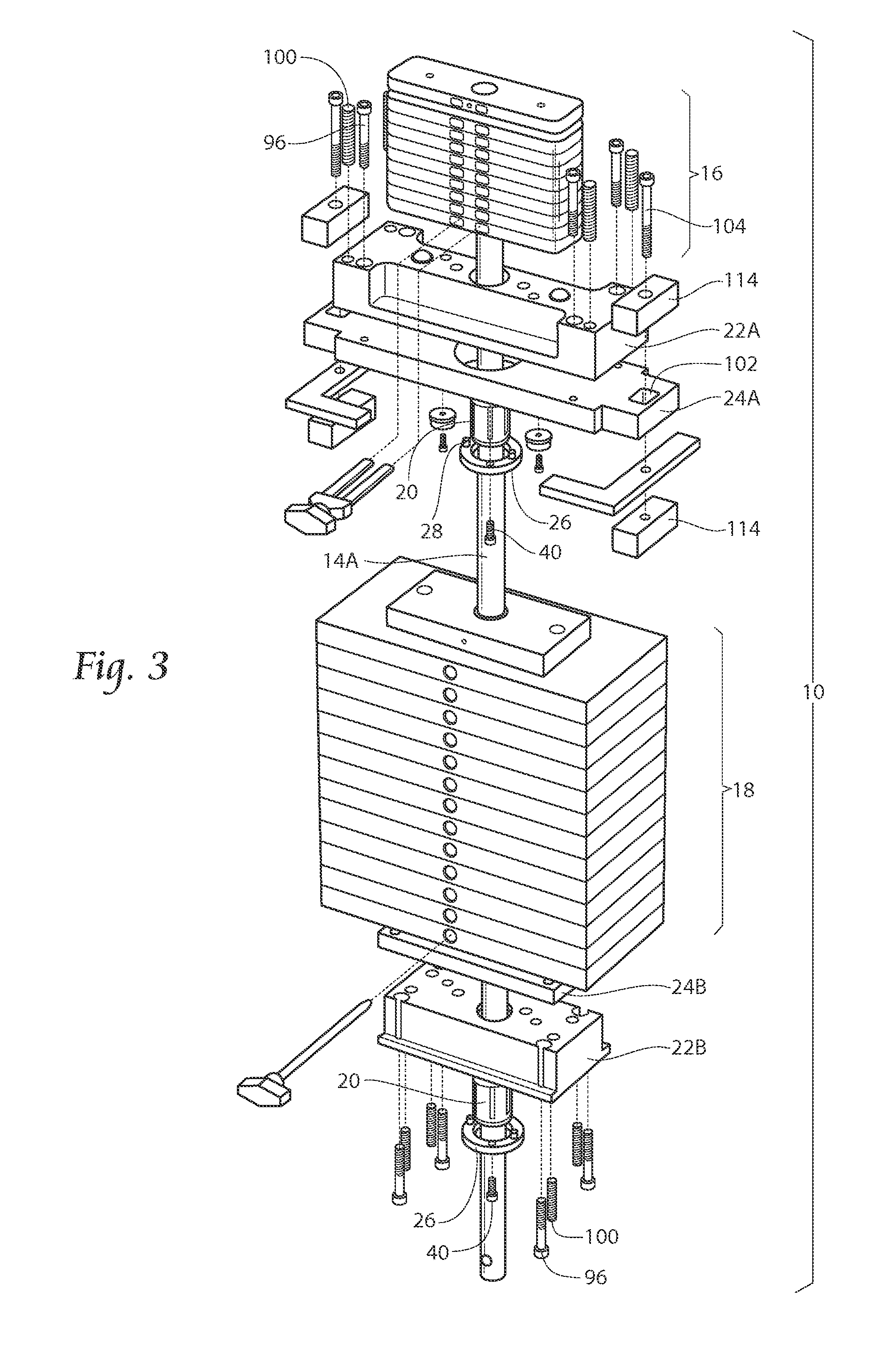

Linear bearings and alignment method for weight lifting apparatus

ActiveUS9079068B2Reduce frictionImprove stack stabilityMuscle exercising devicesEngineeringWeight lifting

A weight system having at least one weight stack moveable in a vertical direction on a lift rod, and a bearing block for housing a linear bearing. The invention further includes a method and apparatus for aligning the linear bearing.

Owner:WHITEROCK EXERCISE

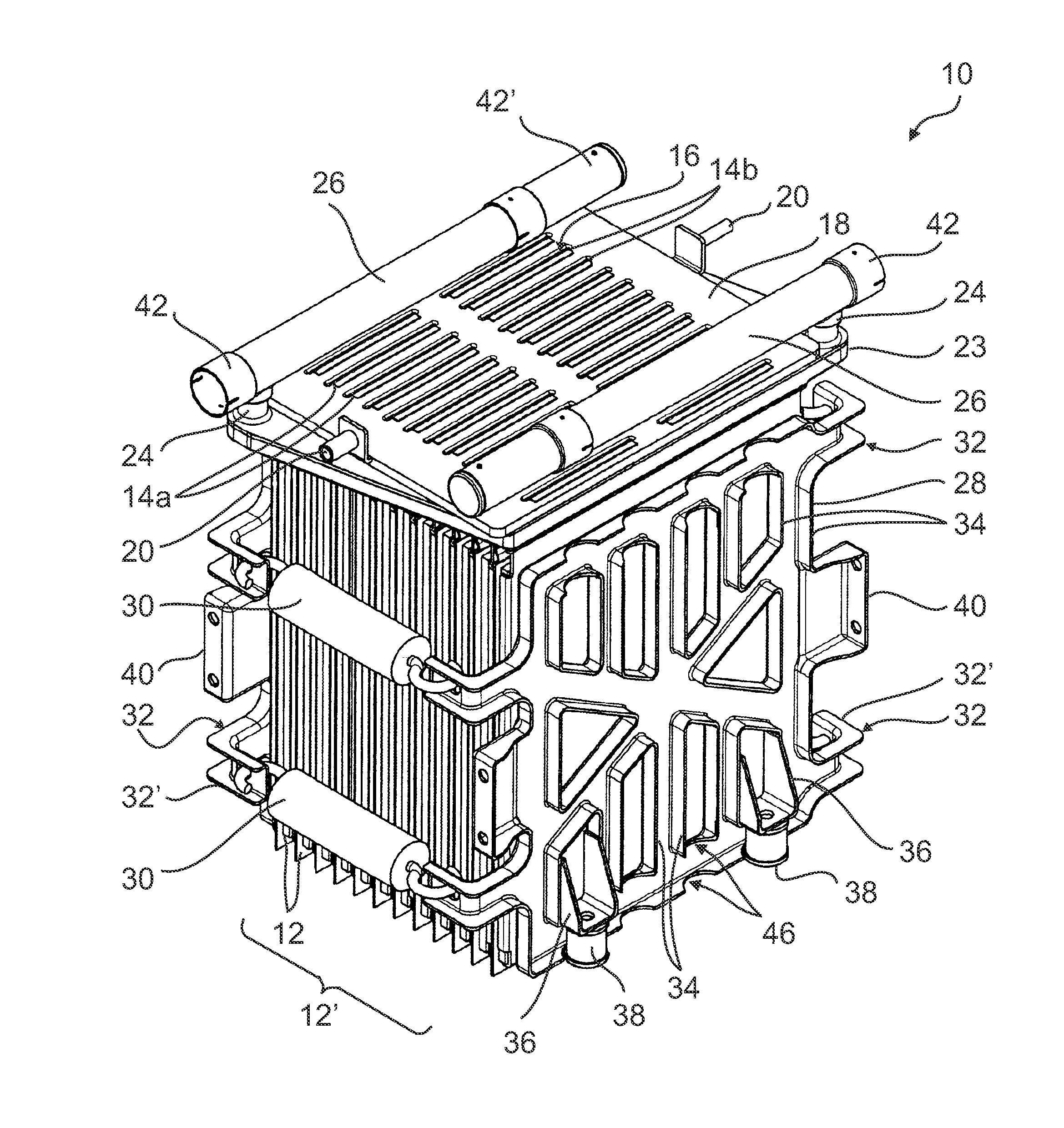

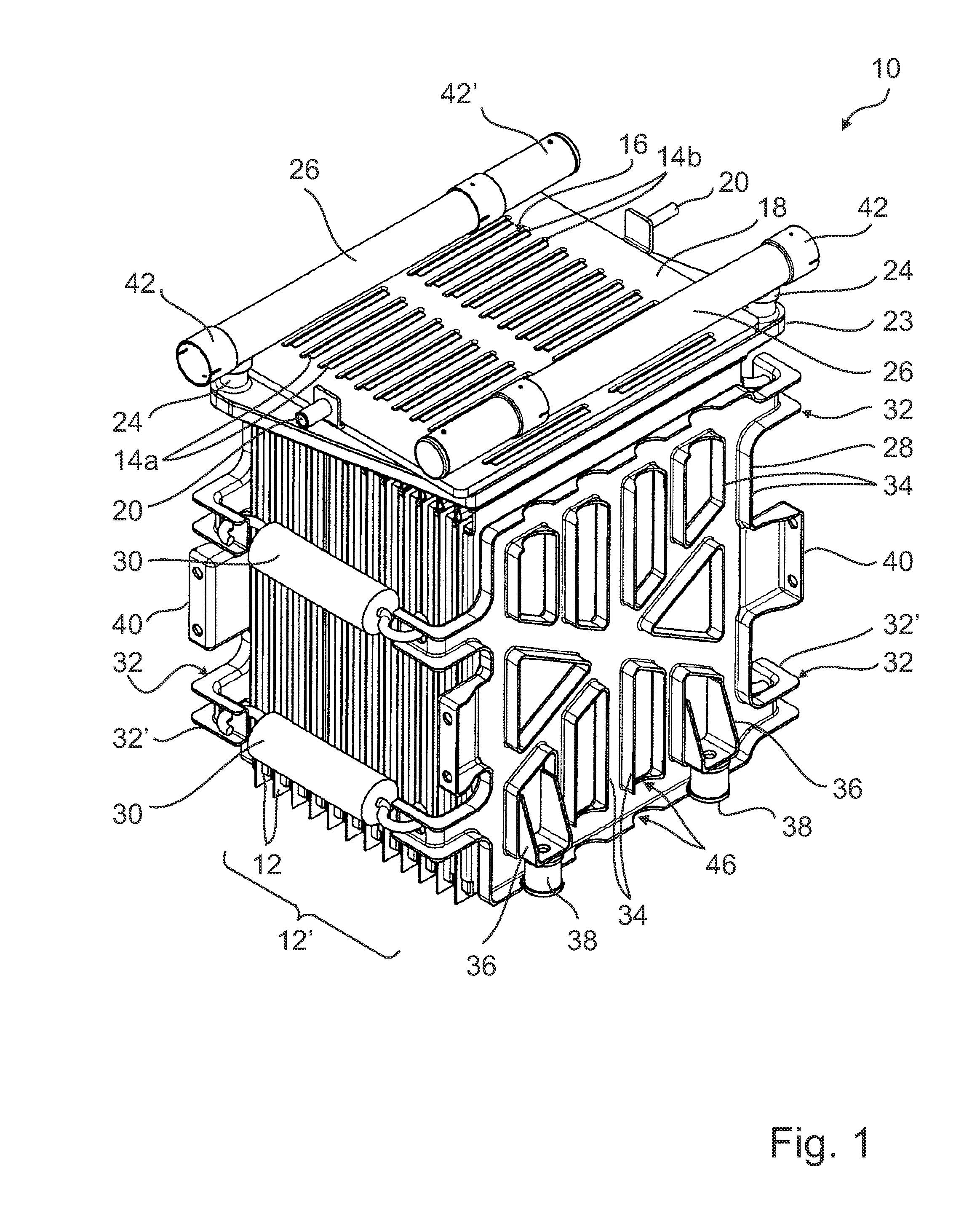

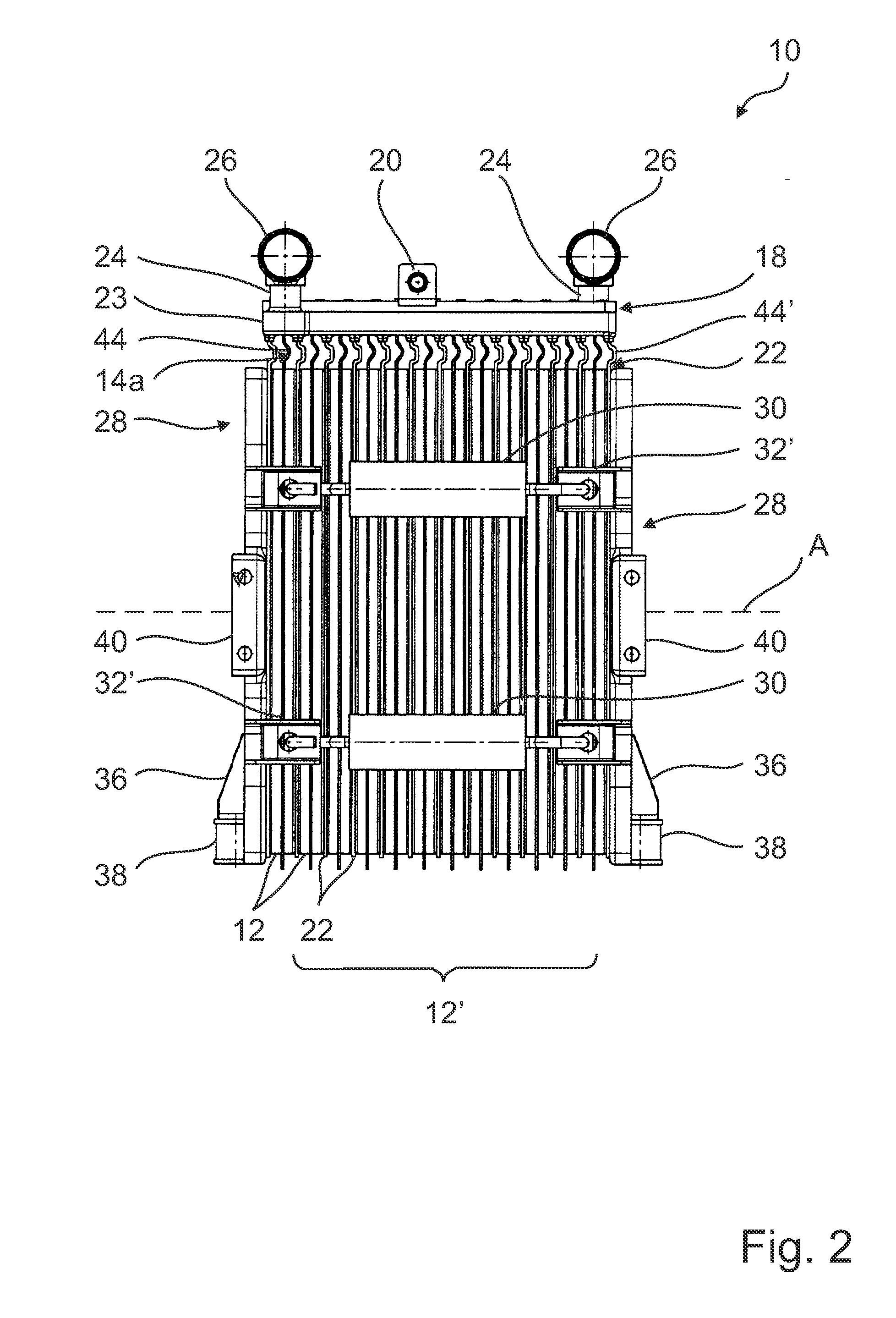

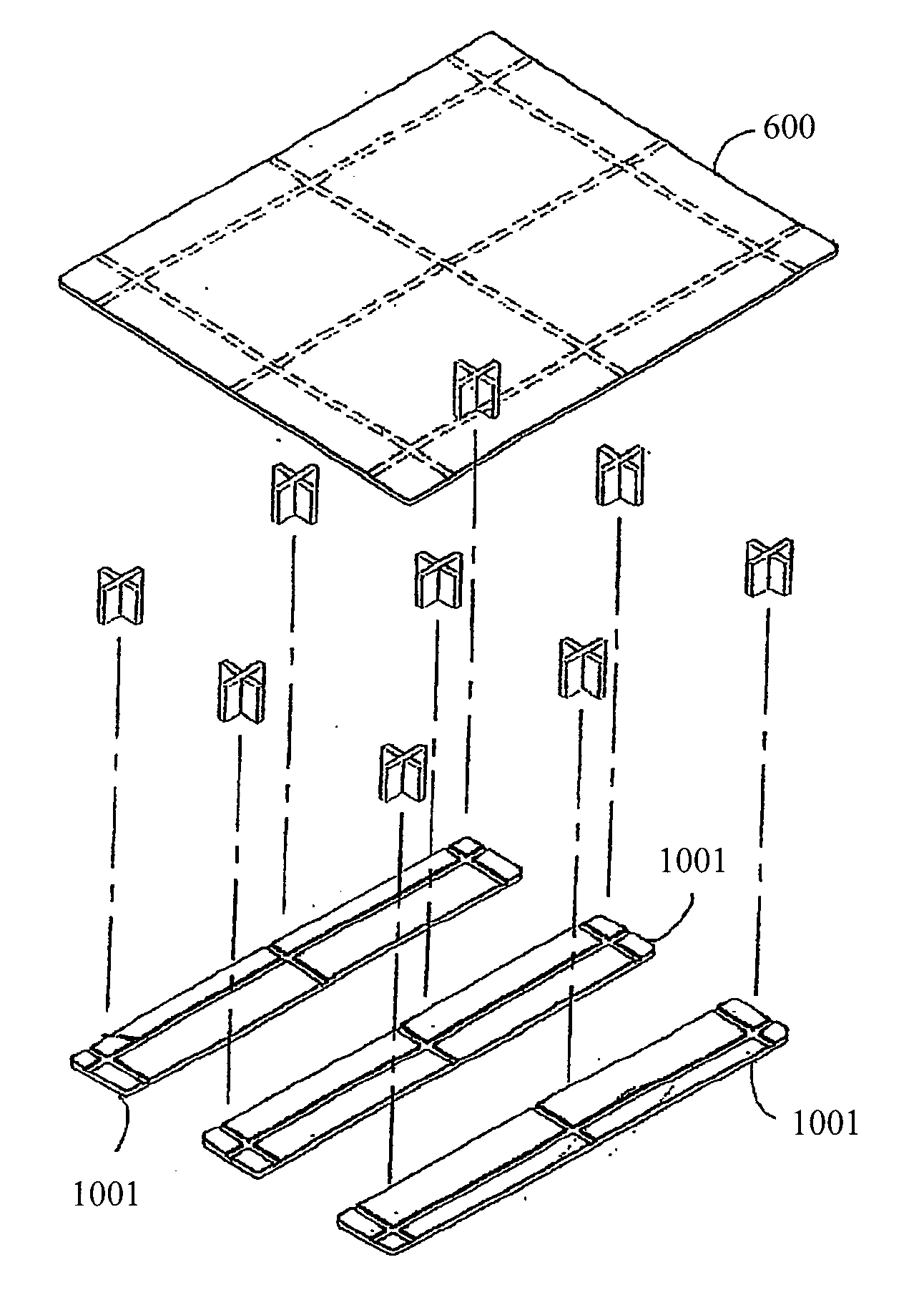

Energy accumulator module

InactiveUS20110189527A1Easy to assembleLower assembly costsFinal product manufactureCell temperature controlInterconnectionEnergy storage

An energy storage module having a plurality of stacked flat cells. The energy storage module has an interconnection formed in such a way that the energy storage module can be connected mechanically, electrically and / or for exchanging coolant with at least one other energy storage module of the same kind.

Owner:MAGNA E CAR SYSEMS & OG

Linear bearings and alignment method for weight lifting apparatus

ActiveUS20130217548A1Reduce frictionIncrease weight stack stabilityMuscle exercising devicesEngineeringWeight lifting

A weight system having at least one weight stack moveable in a vertical direction on a lift rod, and a bearing block for housing a linear bearing. The invention further includes a method and apparatus for aligning the linear bearing.

Owner:WHITEROCK EXERCISE

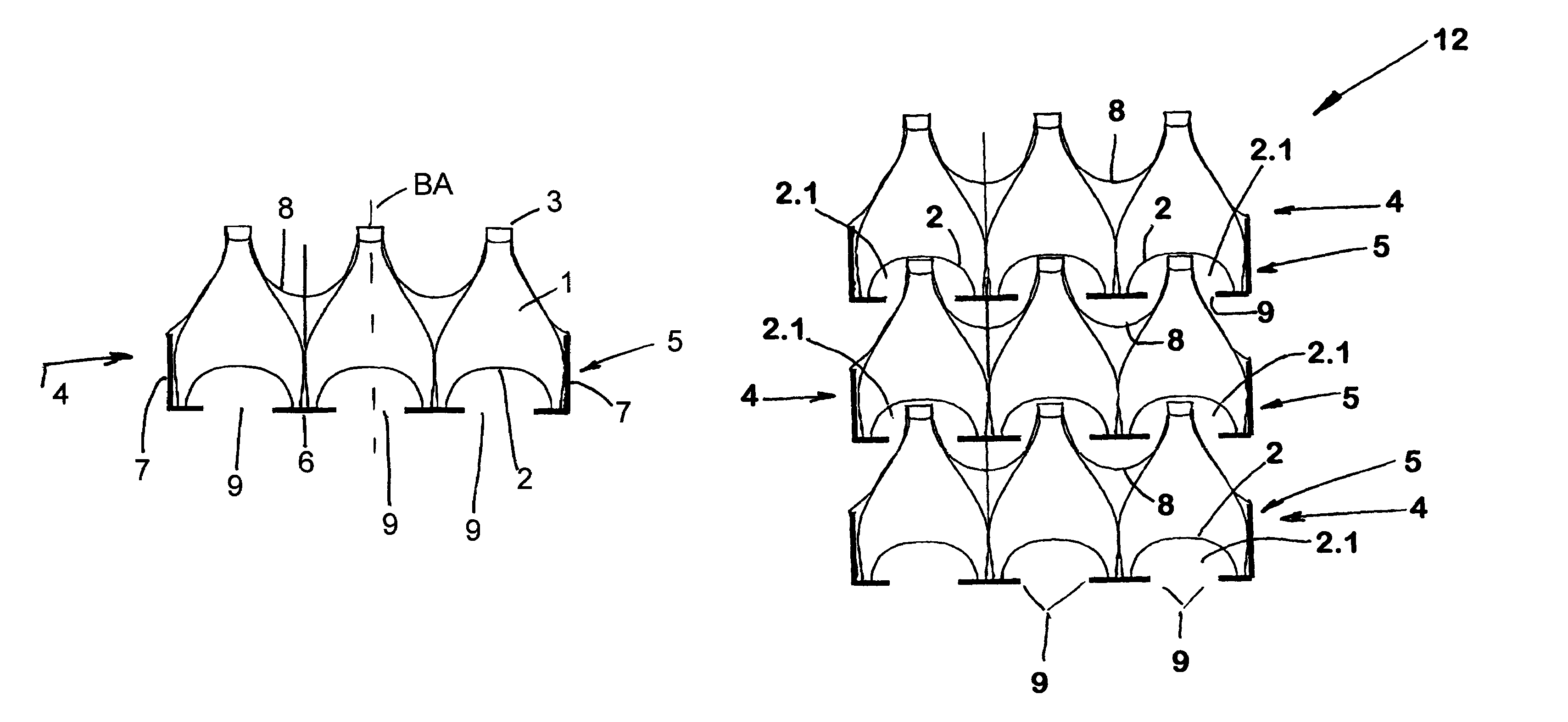

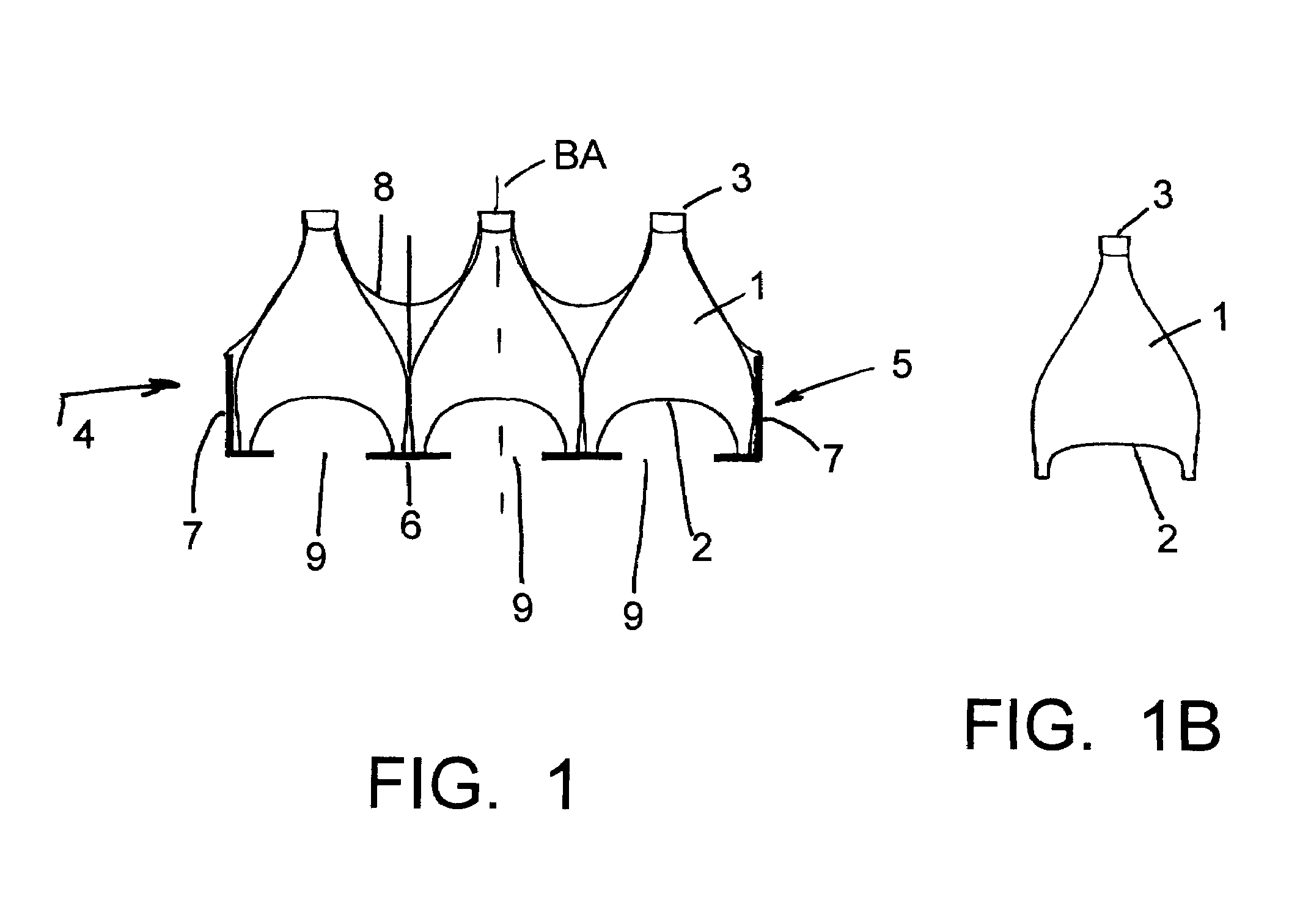

Method of manufacturing and stacking packaging units with increased stability

InactiveUS7574843B2Improve stack stabilityPrevents or essentially prevents the lateral slippage of the individual packaging unitsWrappers shrinkageLiquid materialProcess engineeringBottle

A beverage bottling plant for filling beverage bottles with a liquid beverage material with a packing apparatus for packing filled bottles and a method of operation thereof. Further, a method of manufacturing and stacking packaging units with increased stability is performed.

Owner:KHS MASCHEN UND ANALAGENBAU AKTIENGES

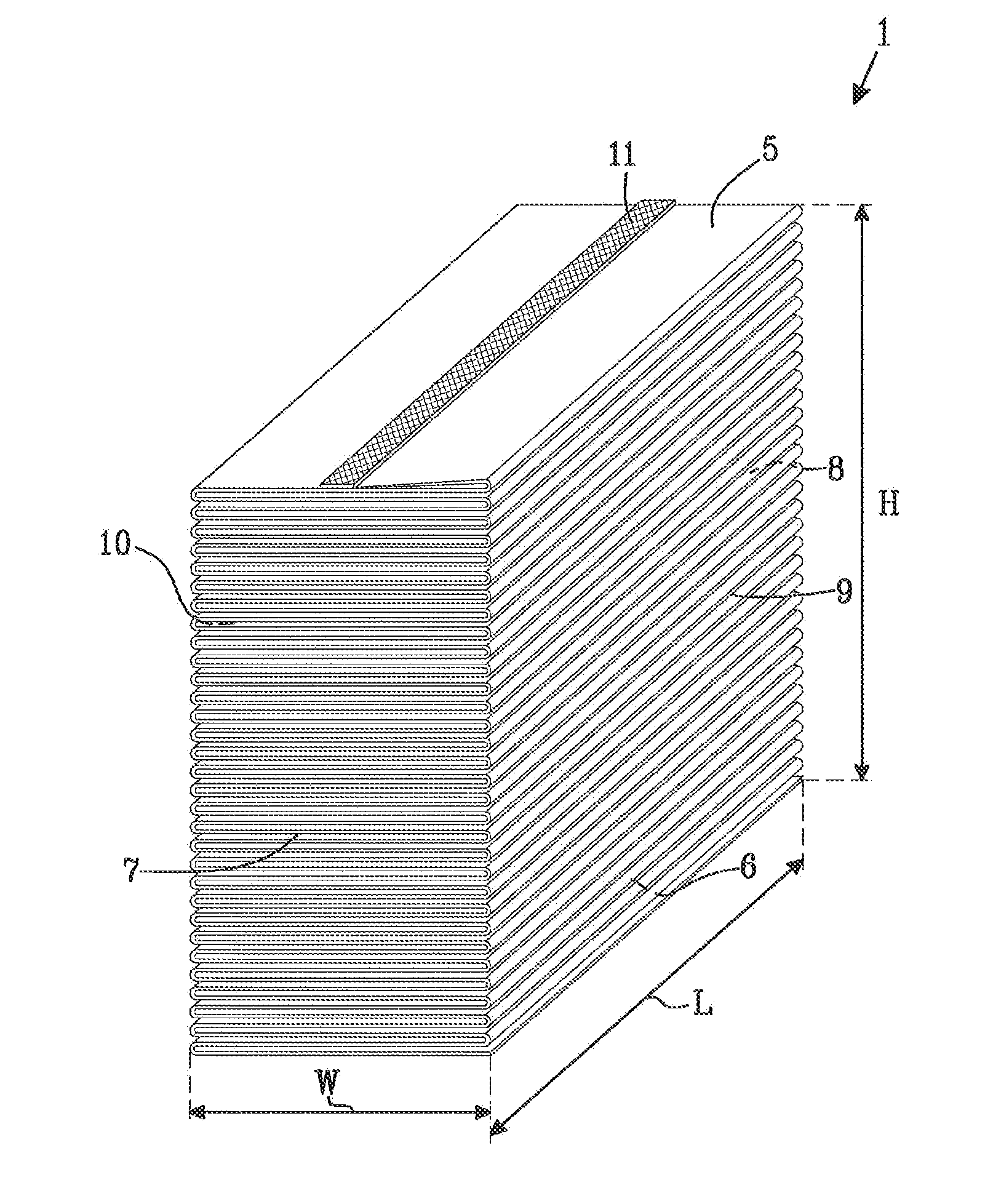

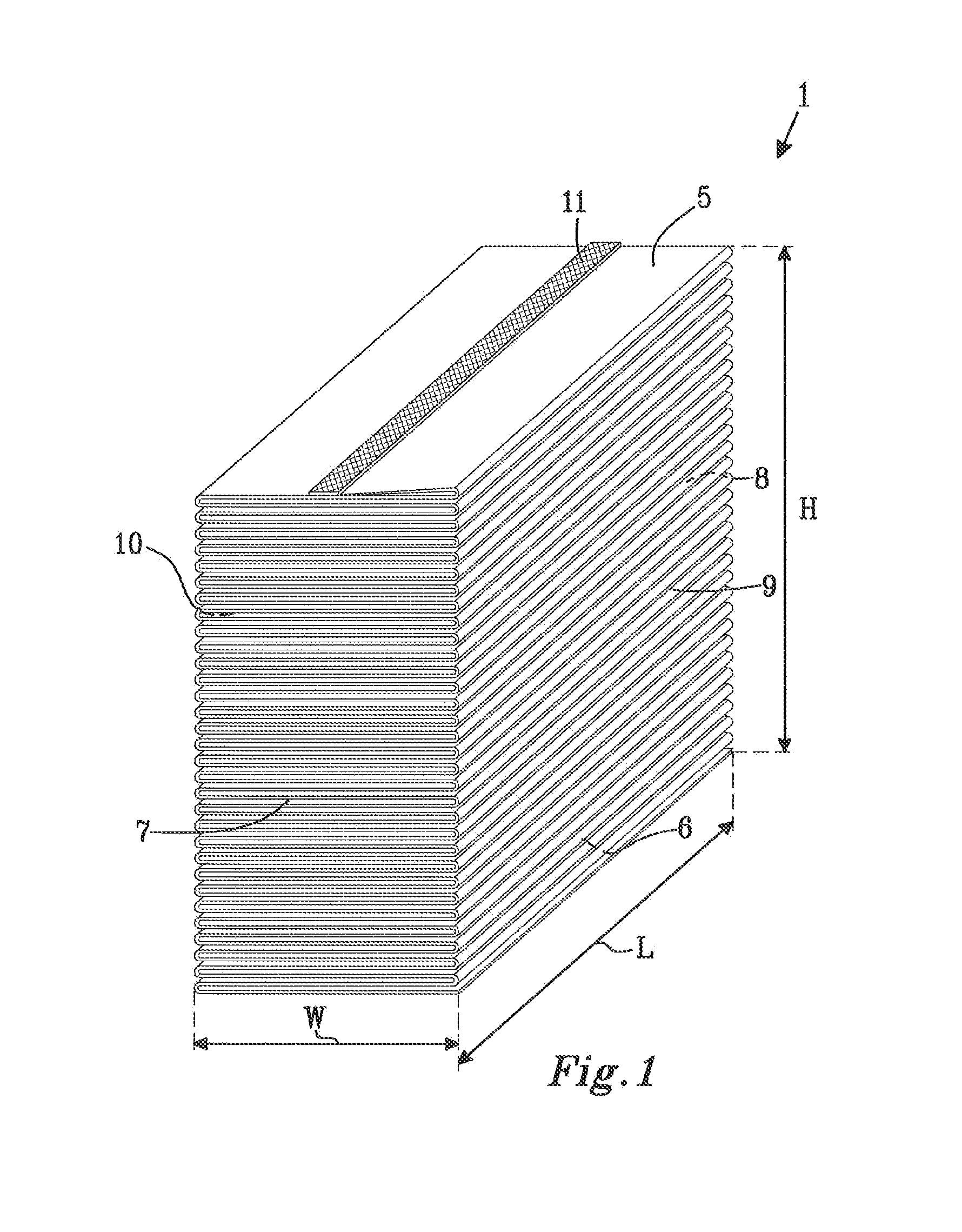

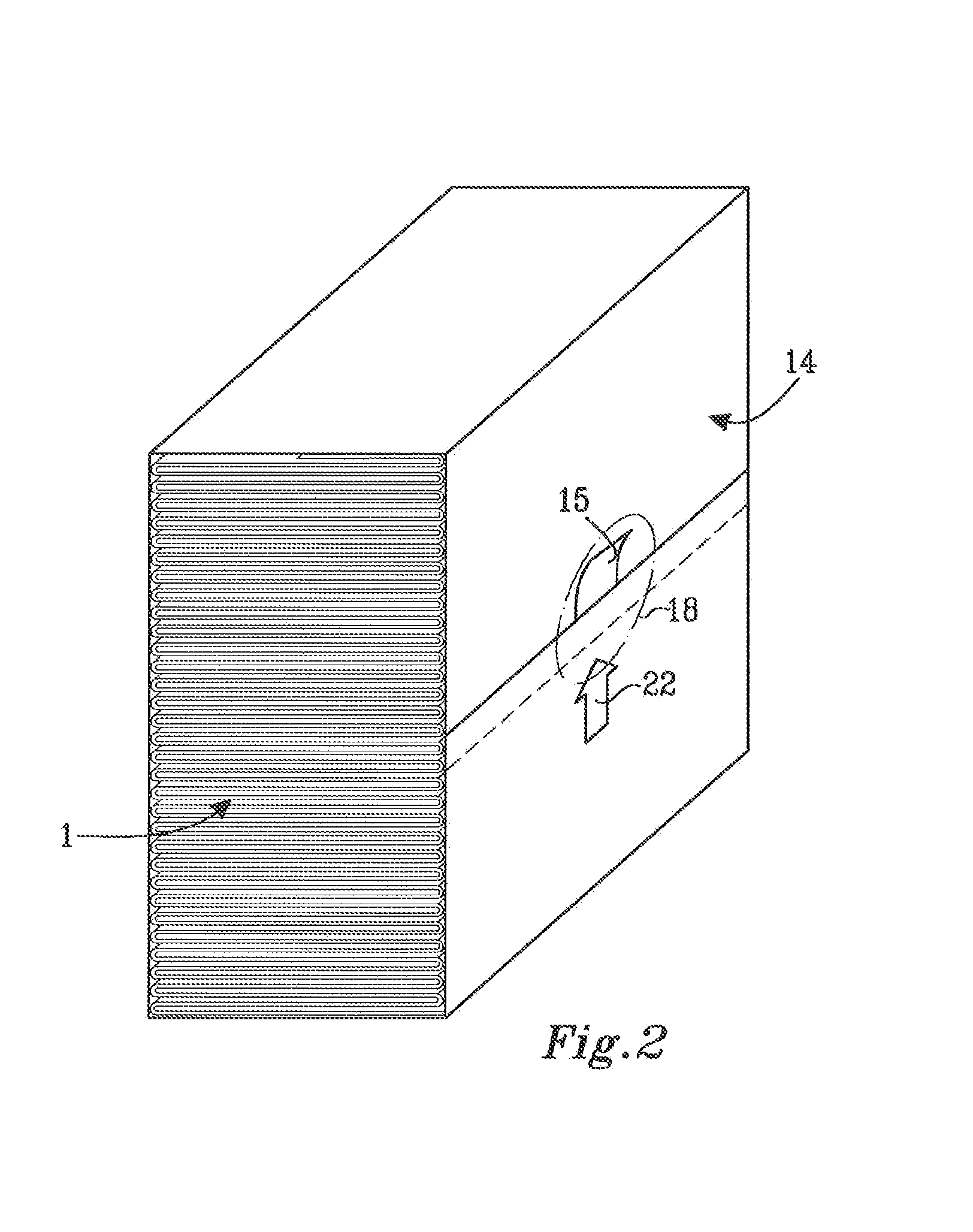

Package comprising a stack of z-folded web material

InactiveUS20160022097A1Maintain integrityImprove stack stabilityOpening closed containersBottle/container closureEngineeringClassical mechanics

A package of web material for hygiene products, for use in a dispenser, including: a stack including web material being folded about transverse folding lines, thereby providing panels having a length along said folding lines, and a width perpendicular to said folding lines, said panels being piled on top of each other to form a height of said stack, such that said stack outlines a rectangular parallelepiped, and forming six outer surfaces, including the folded edges of the web material, and a wrapper extending at least over said height direction, so as to maintain the integrity of the stack during transport and storage thereof. The wrapper includes an opening feature for predetermined opening of the package, and said package is configured to be openable such that the wrapper is removable from the integrity of the stack while the stack is resting on an outer surface thereof.

Owner:SCA HYGIENE PROD AB

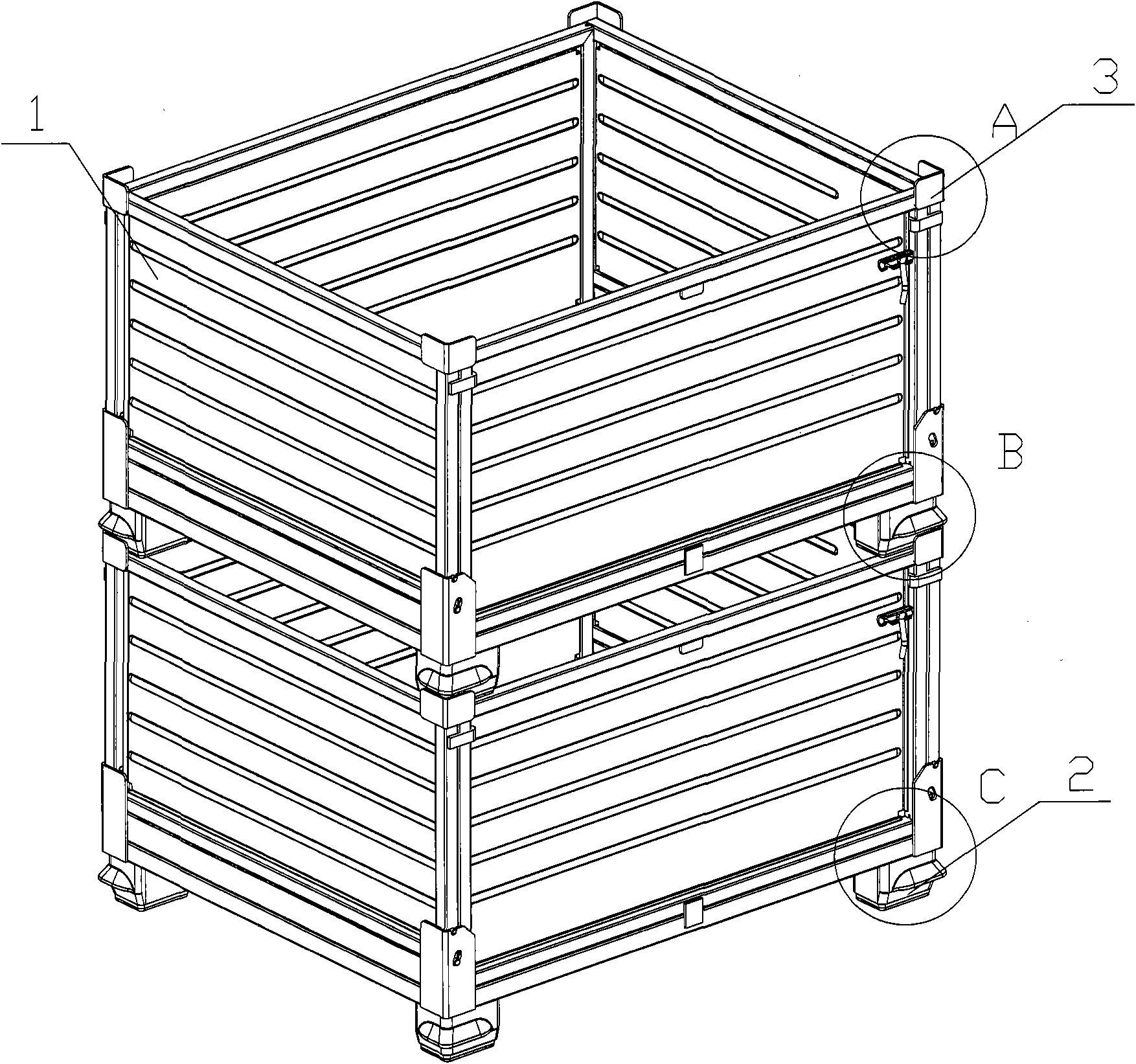

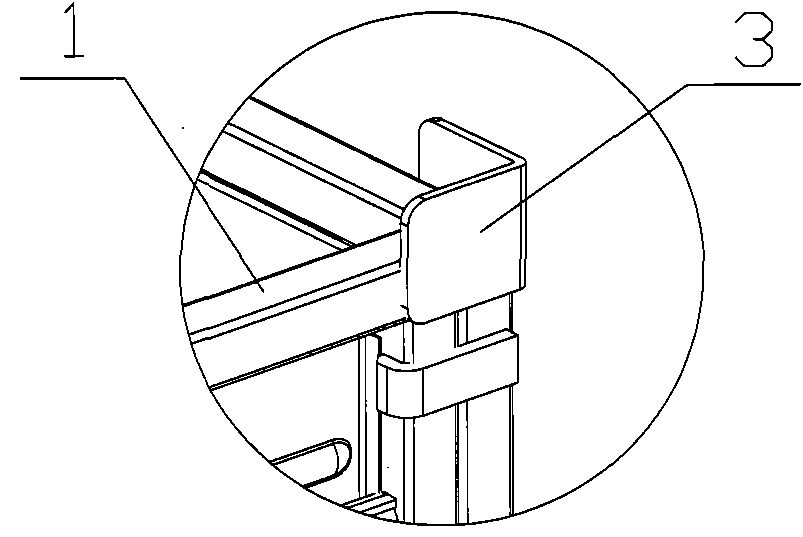

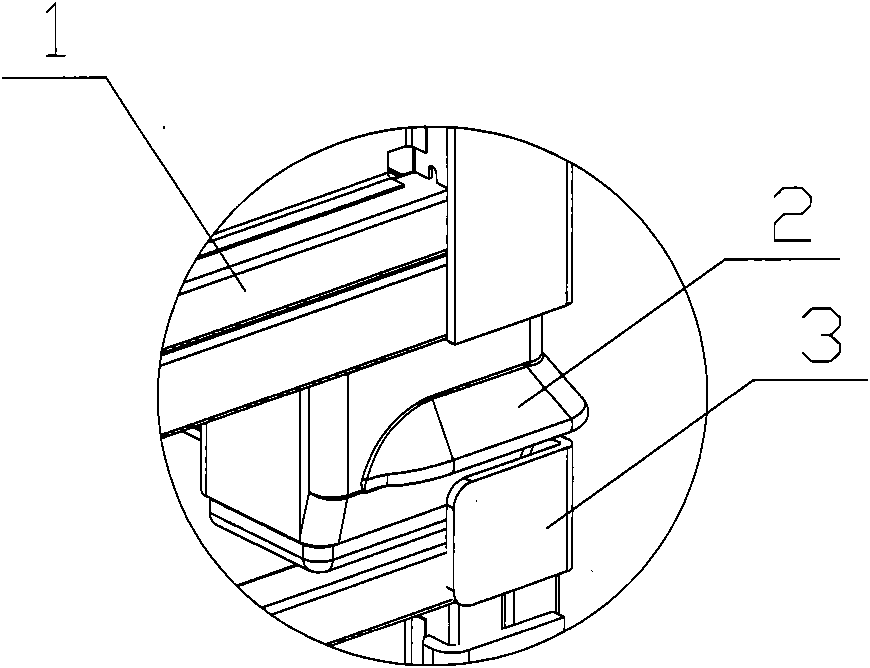

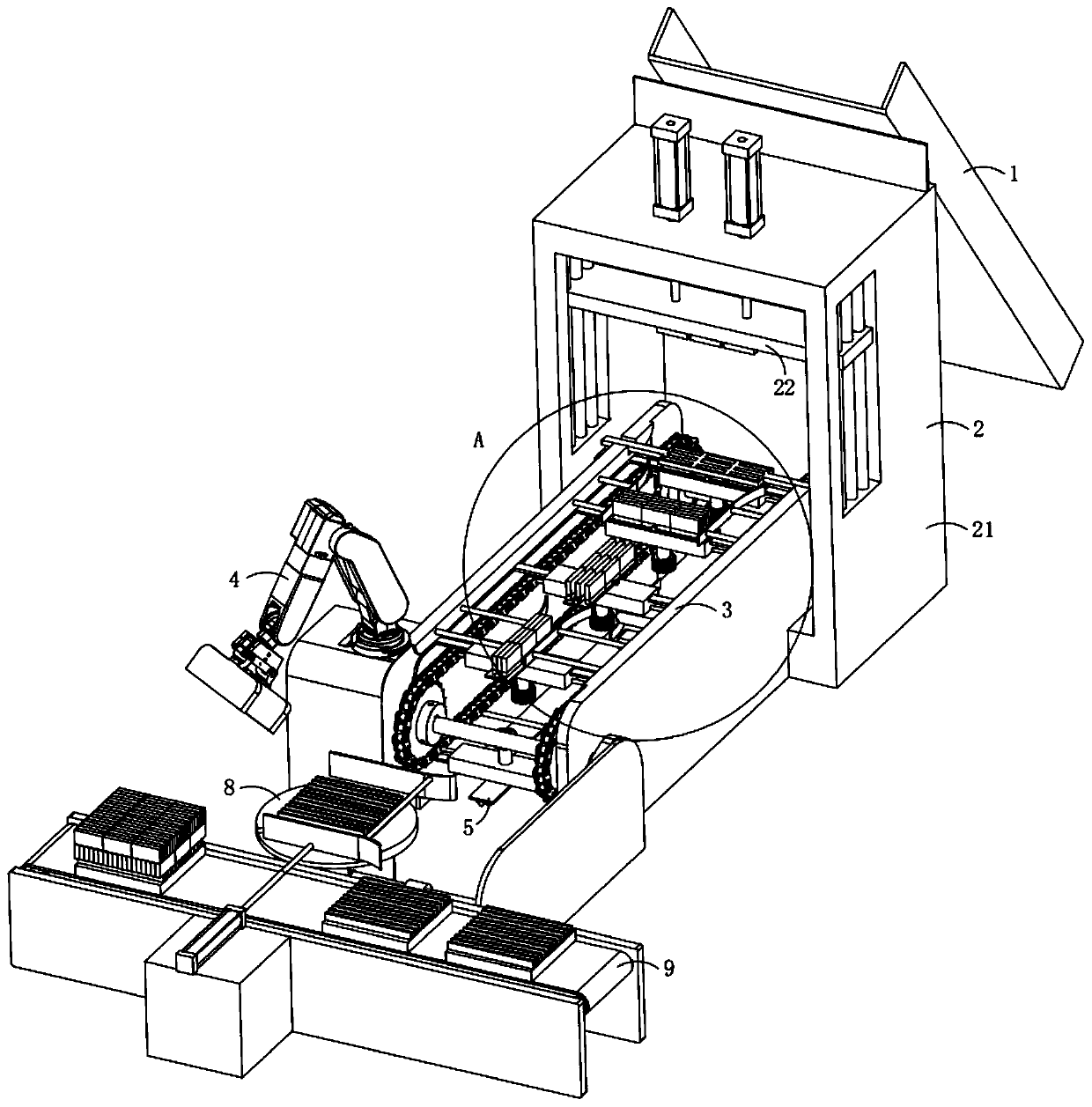

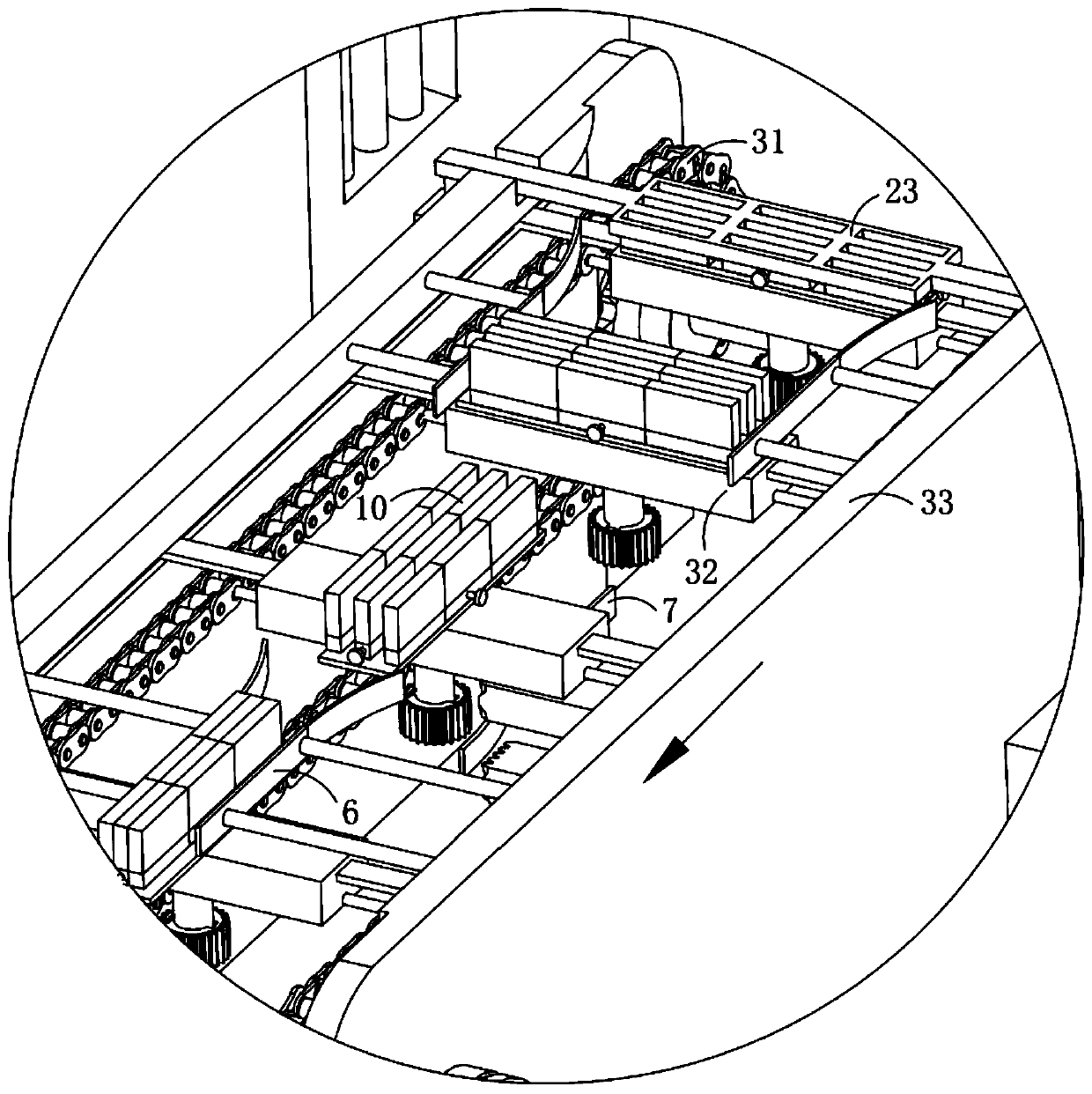

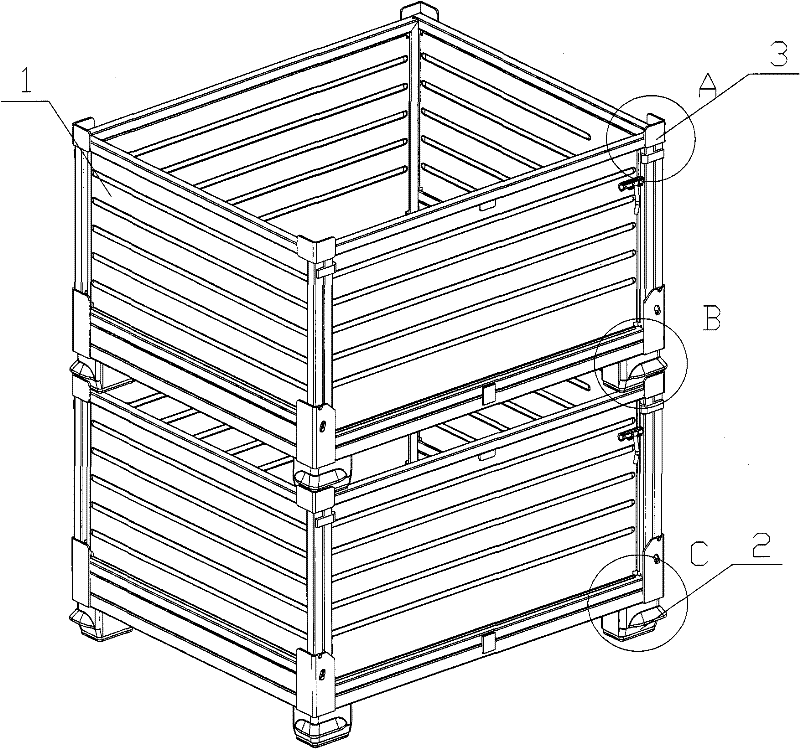

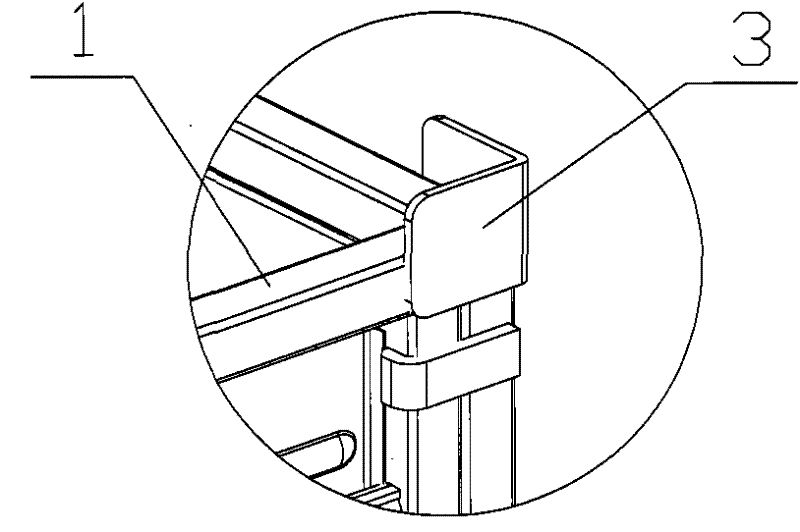

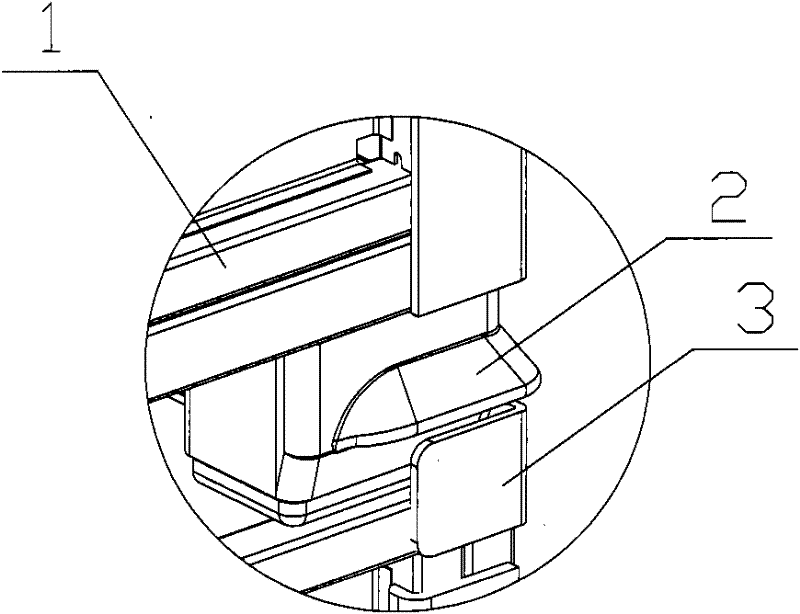

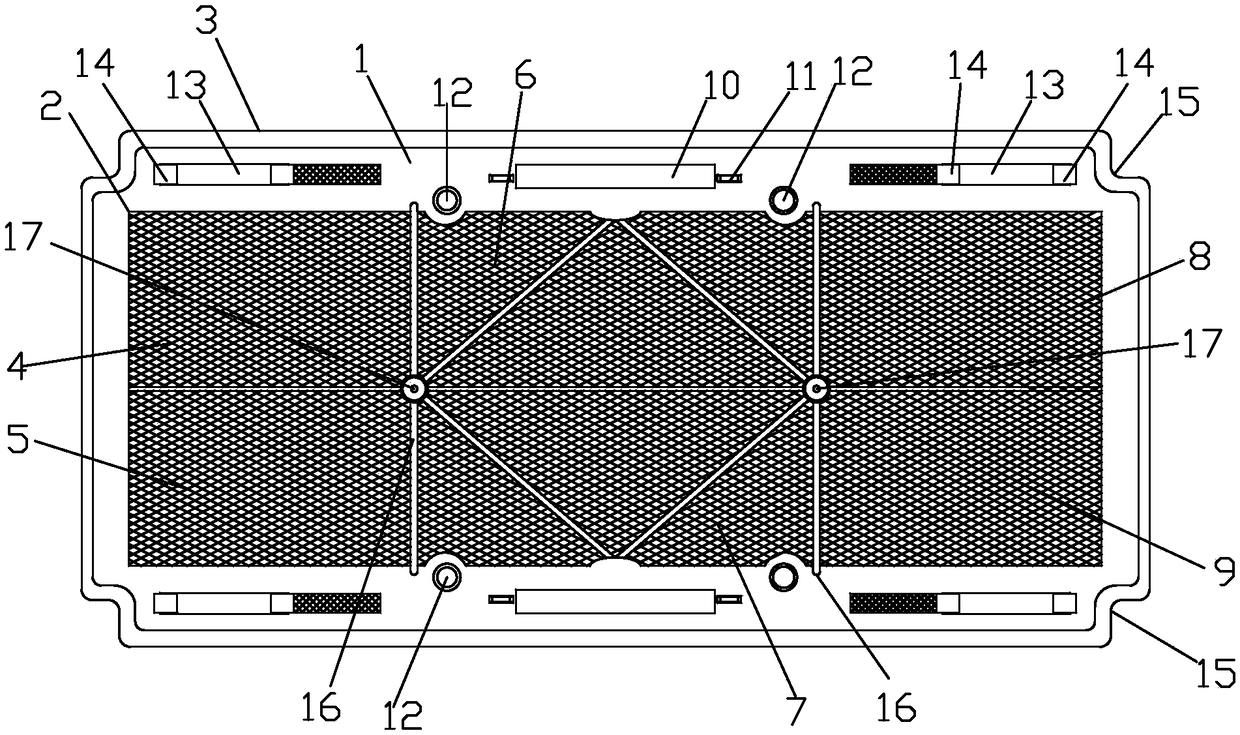

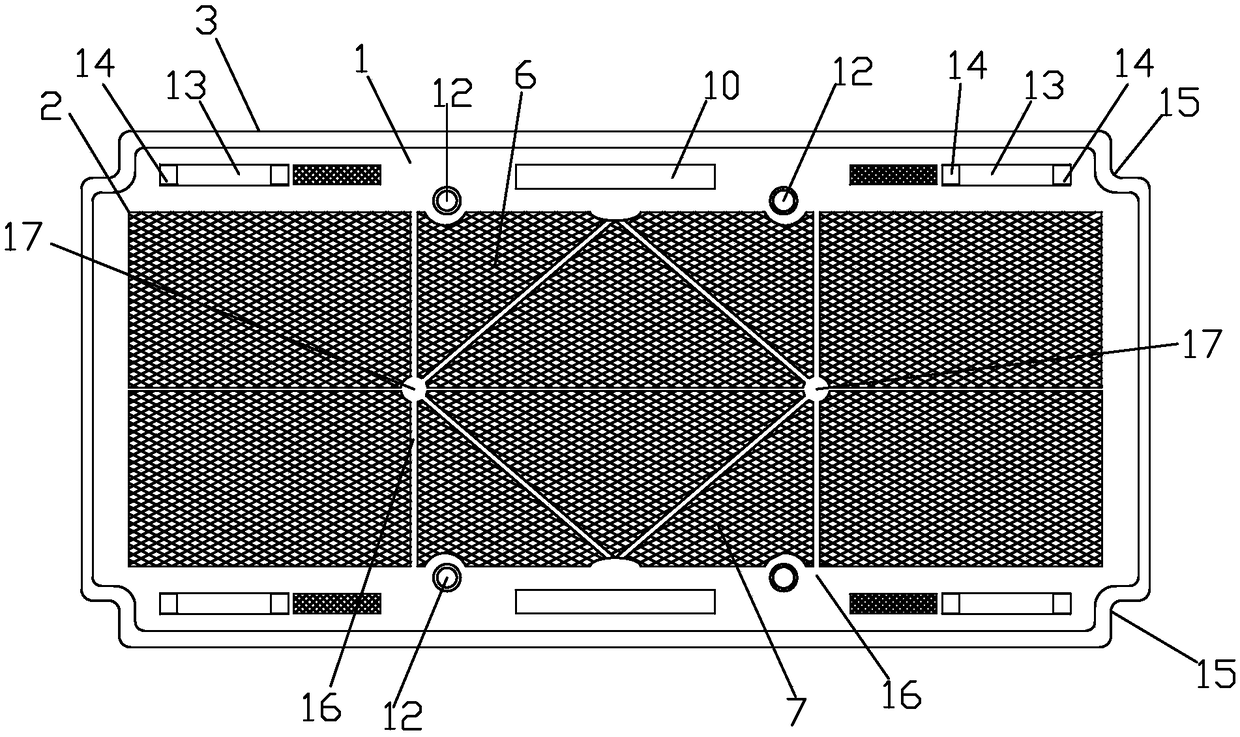

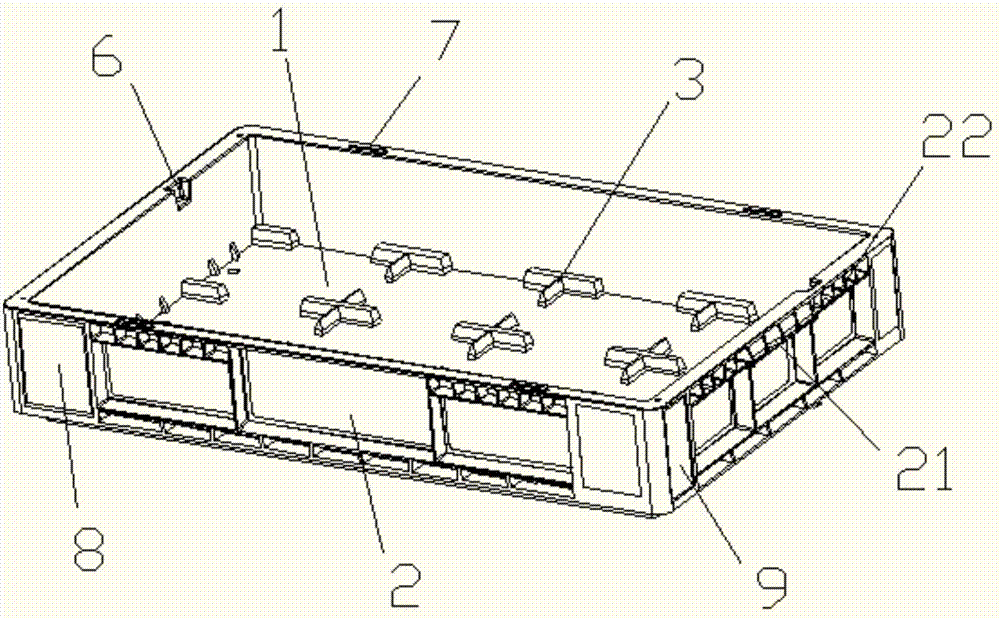

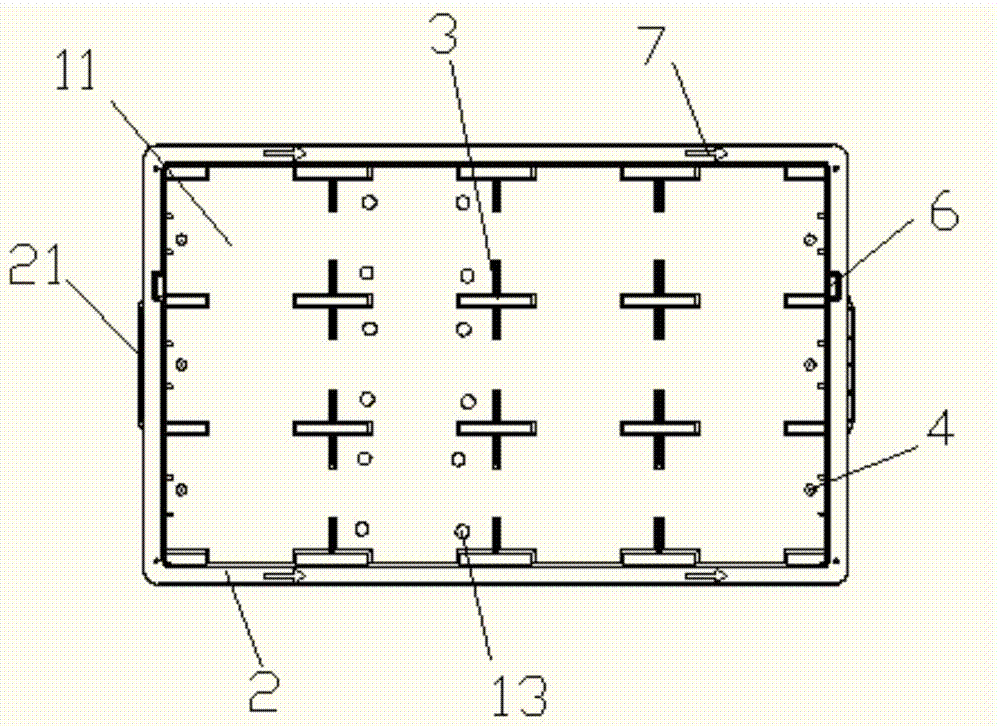

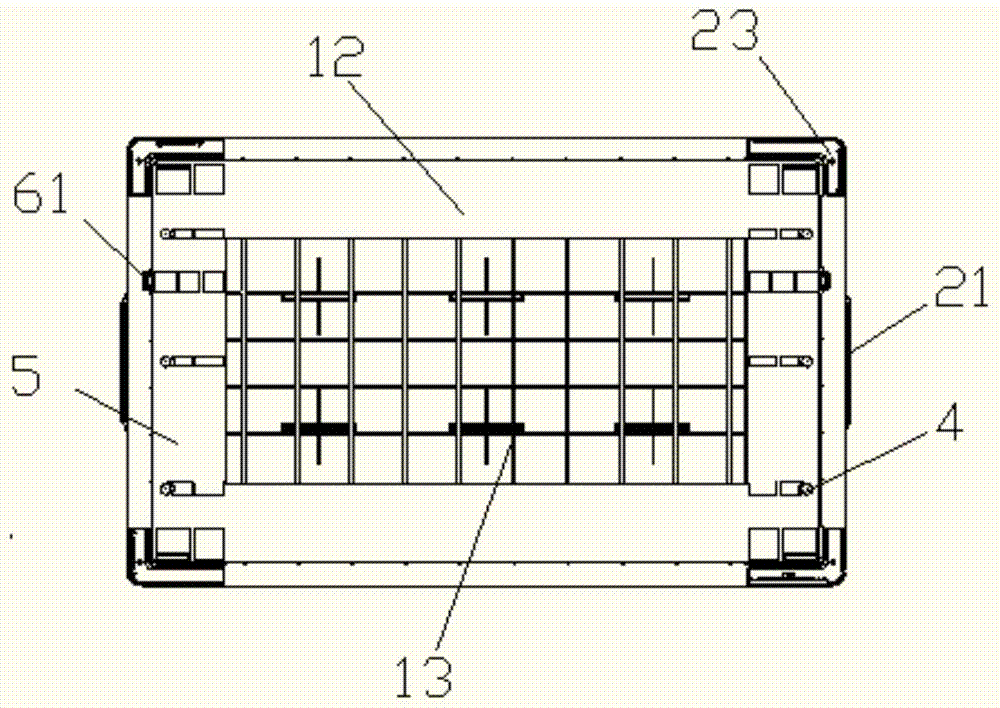

Stackable box

Owner:ANWOOD LOGISTICS SYST SUZHOU CO LTD

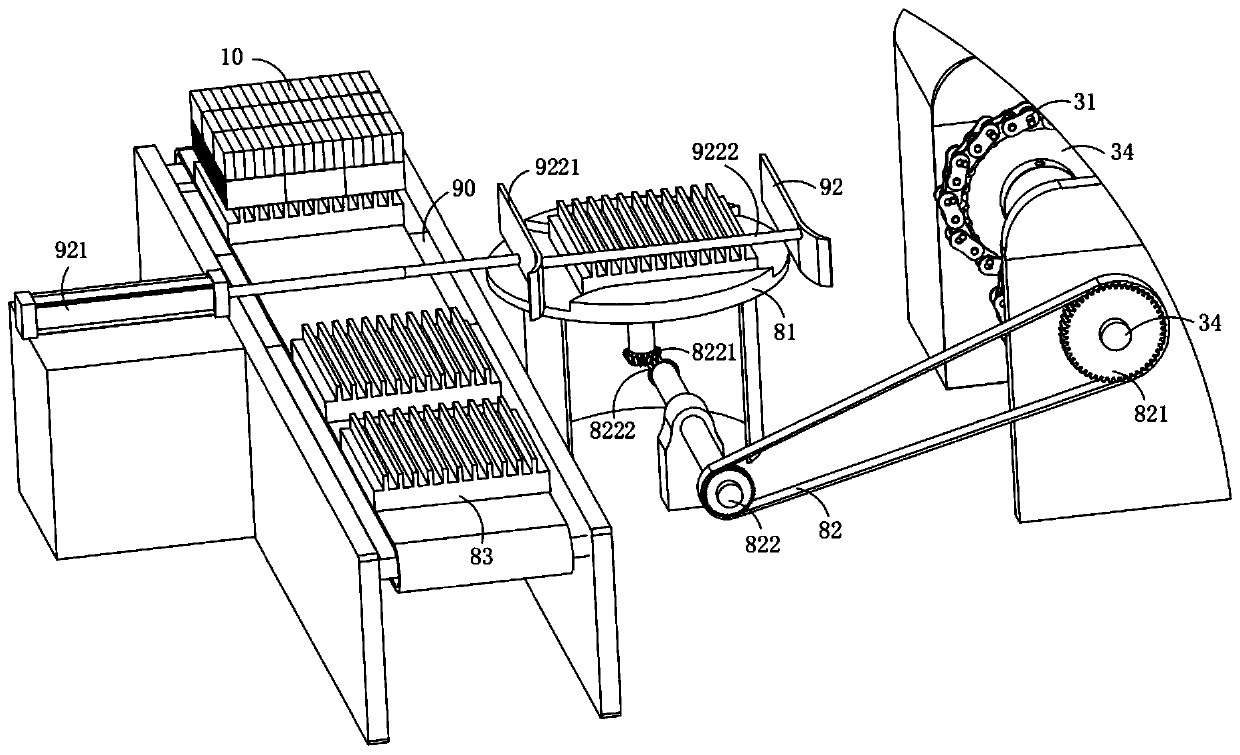

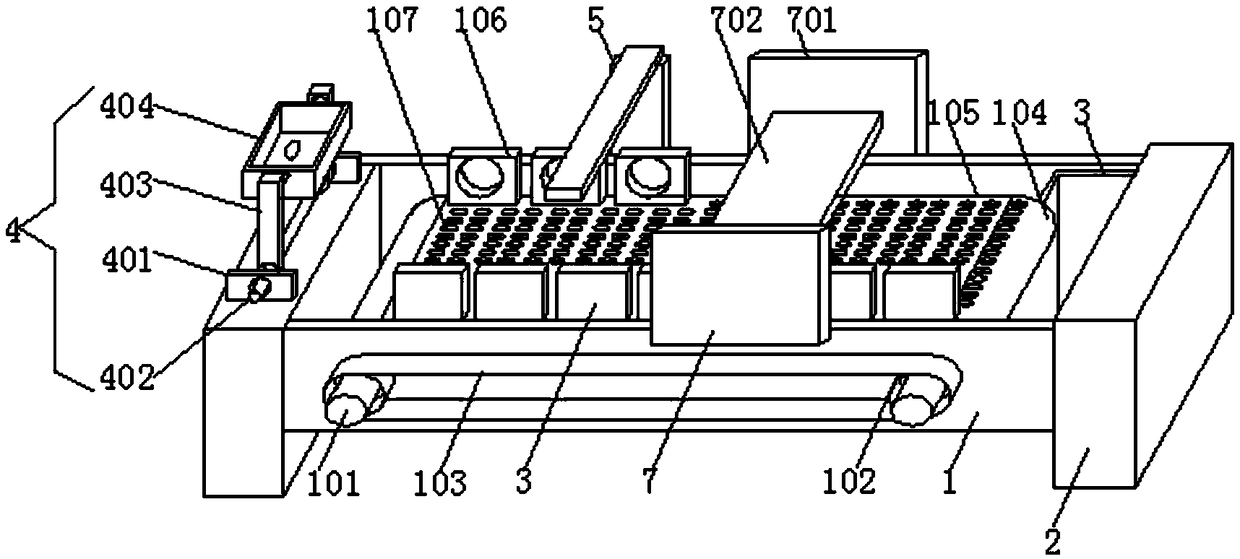

Sludge brick production equipment for hydrolysis and carbonization treatment

ActiveCN111113660ASmooth transferRealize layer by layer staggered stackingCeramic shaping plantsAuxillary shaping apparatusBrickSludge

The invention provides sludge brick production equipment for hydrolysis and carbonization treatment. According to the sludge brick production equipment, a stretchable brick receiving mechanism is arranged on a rotary conveying mechanism, and a folding mechanism and an unfolding mechanism are sequentially arranged on the conveying track of the brick receiving mechanism; the brick receiving mechanism bearing bricks is folded in the transverse direction and the longitudinal direction through the folding mechanism so that the bricks can be arranged in an attached mode, then the bricks are clampedin batches through a clamping mechanism, and layer-by-layer staggered stacking and transferring output of the bricks are completed through arranging a rotary stacking mechanism and a pushing and transferring mechanism in a matched mode; the unloaded brick receiving mechanism is unfolded in the transverse direction and the longitudinal direction through the unfolding mechanism so as to be matched with the next batch of brick receiving procedures; and full-process automation of brick pressing, conveying and stacking batch output is realized, and the technical problems that in the prior art, bricks cannot be transferred in batches, the automation degree is low, and the production efficiency is low are solved.

Owner:浙江合泽环境科技有限公司

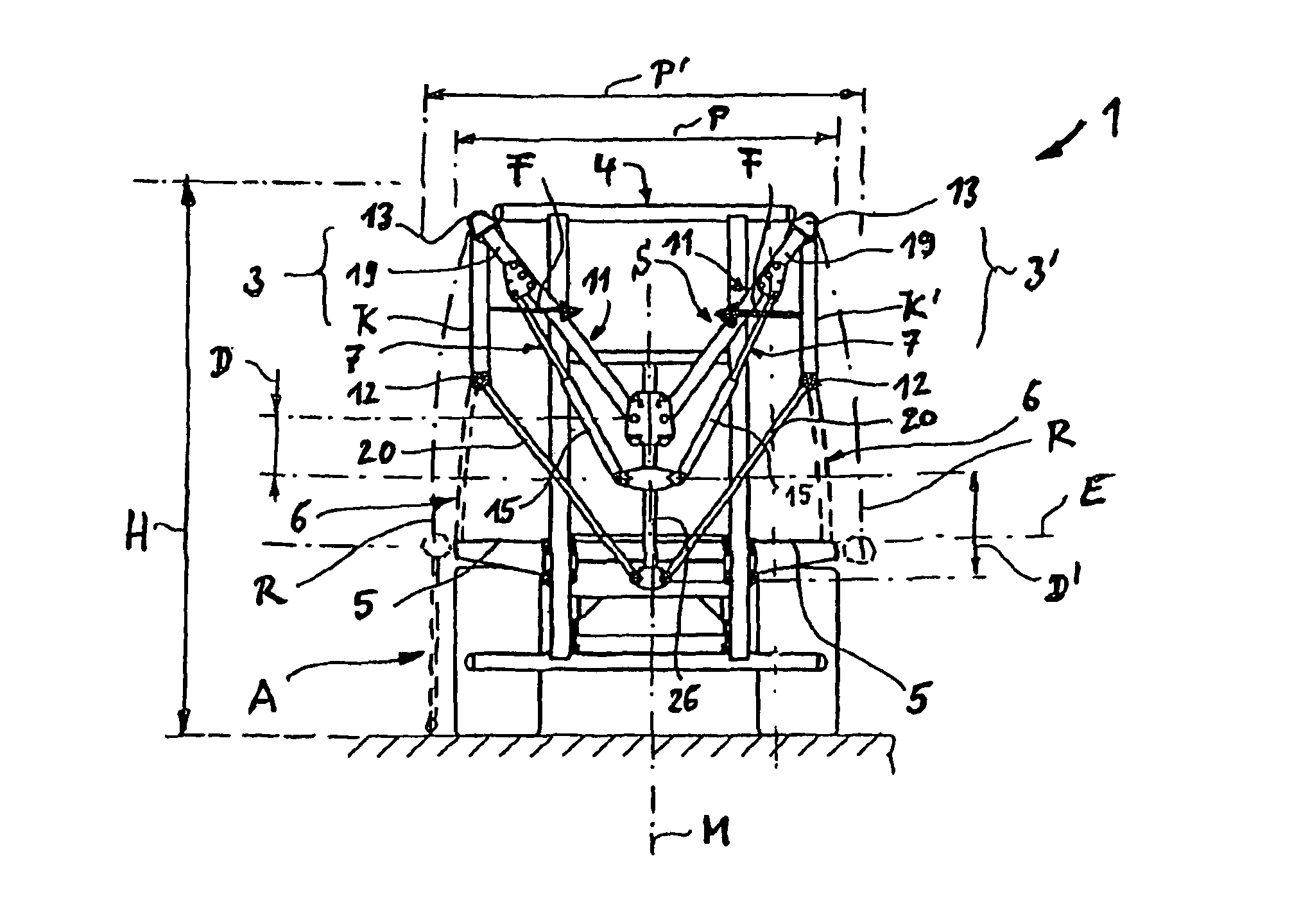

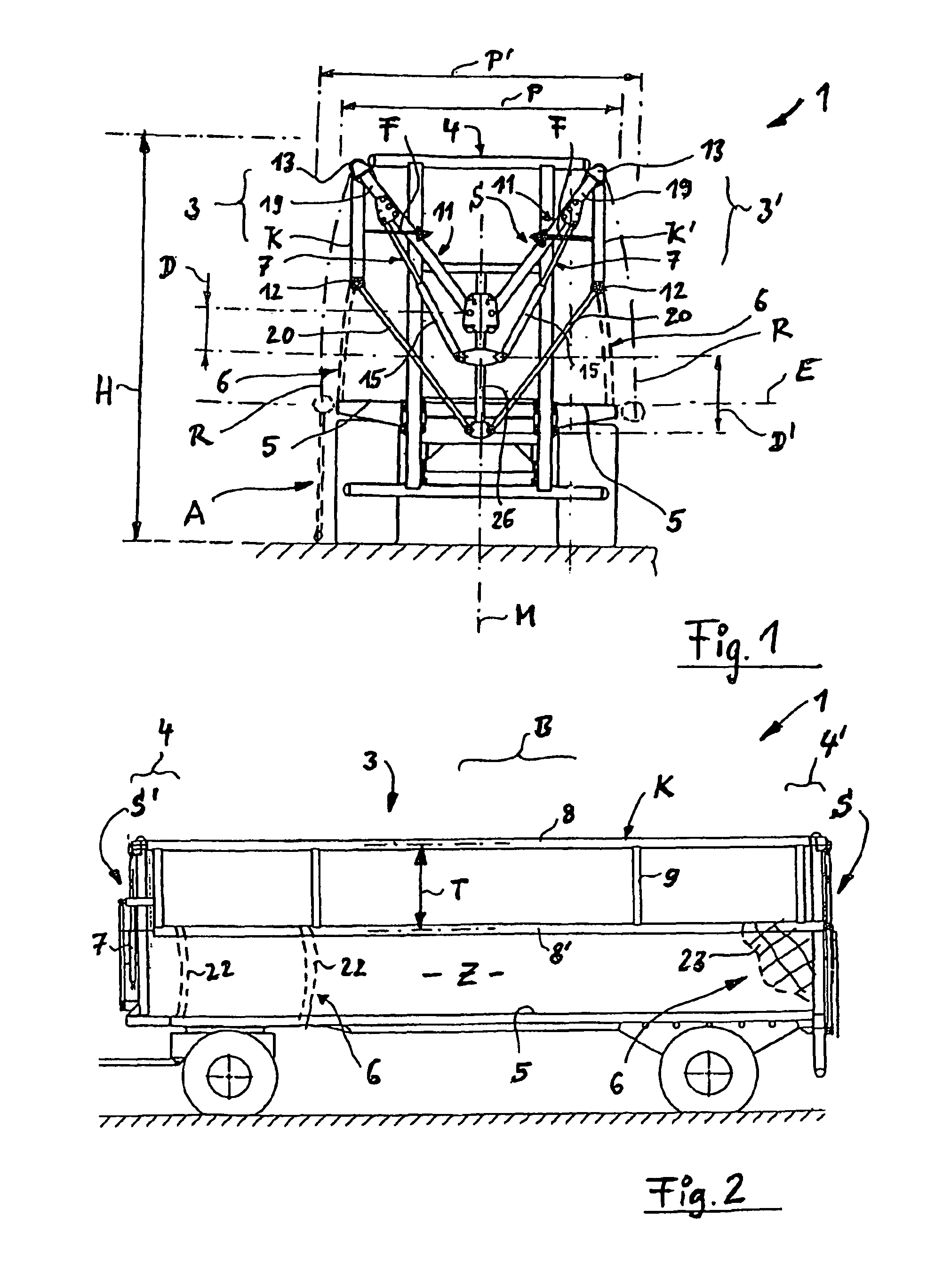

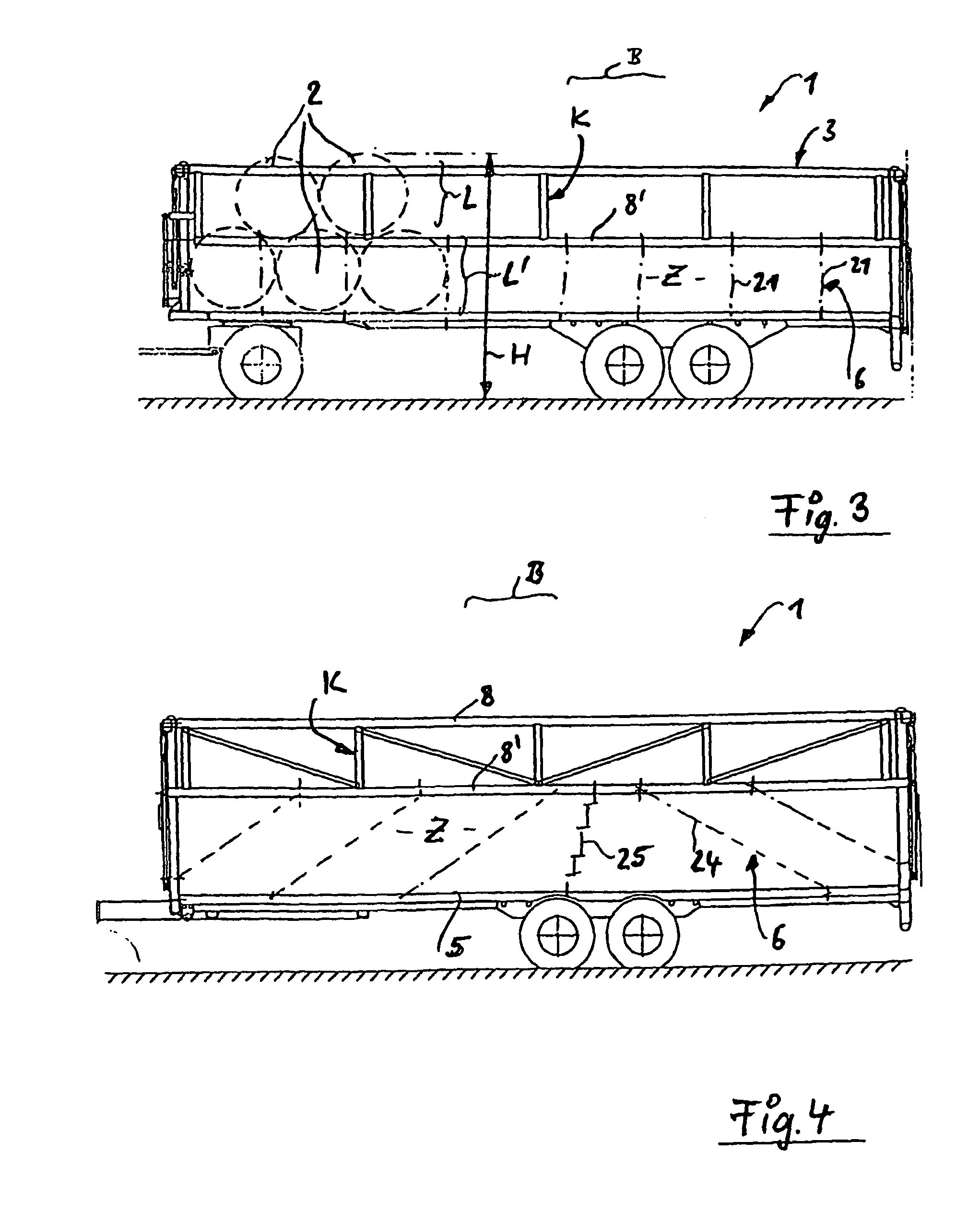

Transport wagon particularly for agricultural cargo

InactiveUS8523502B2Improve stack stabilityRisk of lossPreventing unwanted cargo movementLoadersAgricultural engineeringTruck

The invention relates to a transport wagon for receiving cargo, particularly made of agricultural harvest products, such as bales pressed from straw or silage. Such wagons comprise a loading platform, which extends beneath the cargo and is delimited by longitudinal and lateral side parts, wherein the transport chamber is accessible, particularly when the longitudinal side walls are opened. According to the invention, at least one of the longitudinal side walls is provided with a support device, by means of which the longitudinal side wall can be displaced from an open position close to the ground into a closed position, in which it captures at least one upper layer of the stacked cargo and secures it laterally.

Owner:KRASSORT GEORG

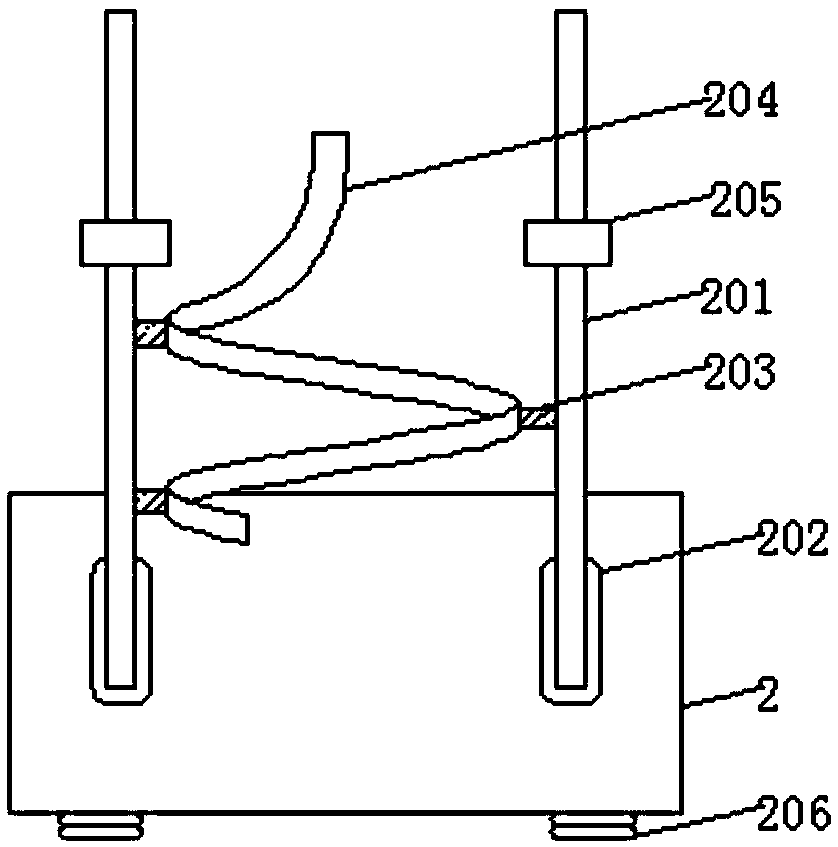

Cold drawing film wrapping packaging machine

InactiveCN105947323APrevent looseningStrong clamping forcePackagingElectrical and Electronics engineeringPackaging machine

The invention discloses a cold drawing film wrapping packaging machine. The cold drawing film wrapping packaging machine comprises a rack and two film sucking devices, wherein the two film sucking devices are mounted on the rack and are arranged oppositely. The cold drawing film wrapping packaging machine is characterized in that each film sucking device comprises a driving mechanism, a film sucking seat and at least one film sucking part; the driving mechanisms are mounted on the rack; the film sucking seats are connected with the driving mechanisms; the film sucking parts are mounted on the film sucking seats; air suction cavities which communicate with an external fan are arranged inside the film sucking parts; and two film sucking grooves are formed in the front side surfaces of the film sucking parts. Compared with the prior art, the cold drawing film wrapping packaging machine has the beneficial effects that the film sucking grooves are formed, so that a thin film can be clamped, and the thin film is effectively prevented from getting loose; film clamping parts act as secondary guarantee, so that the clamping force for the thin film is further improved, and the thin film is prevented from getting loose more effectively; and structures of the telescopic driving mechanisms are compact, the occupied space is small during mounting, and the cost is effectively reduced.

Owner:张敬潮

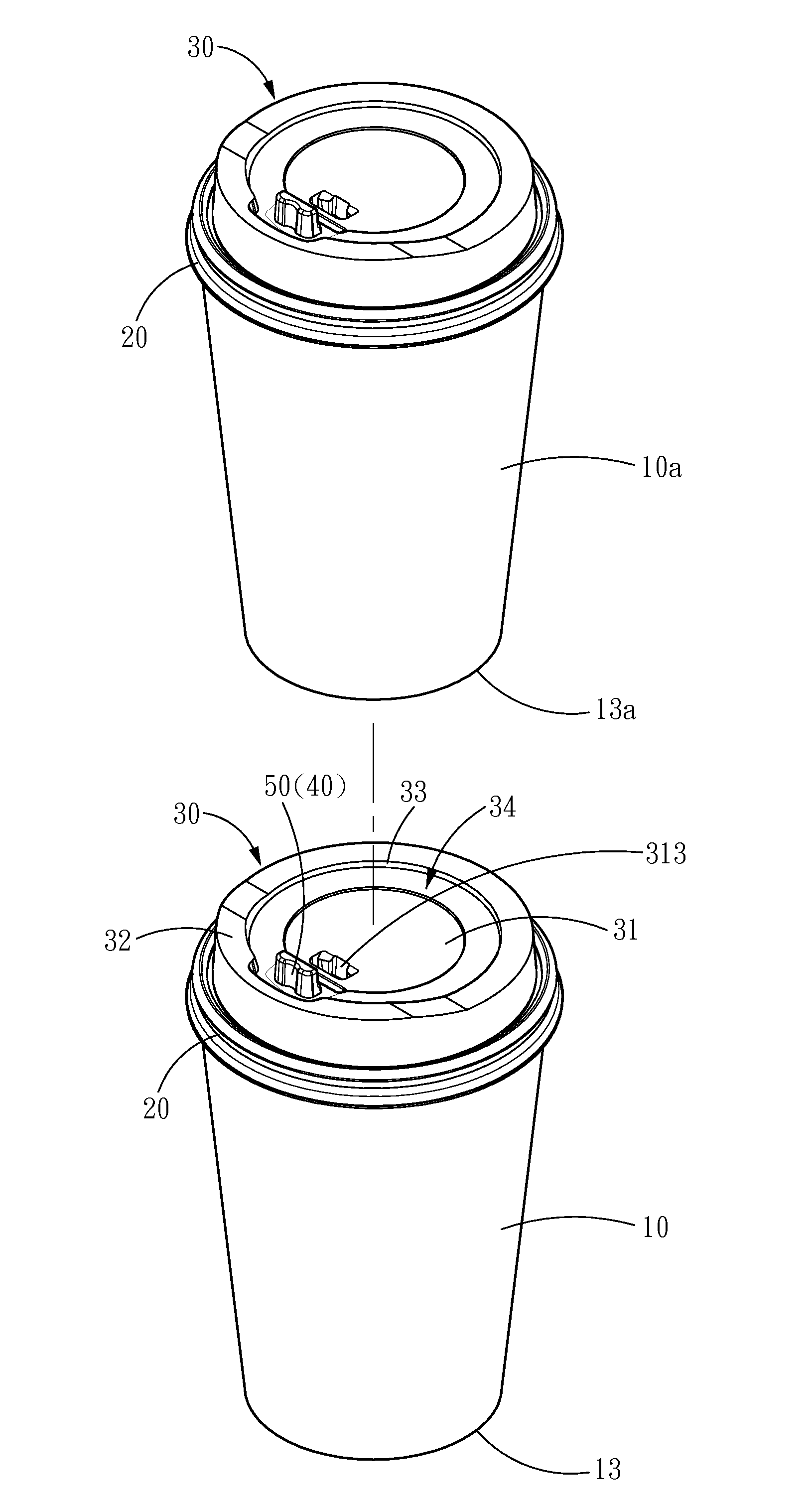

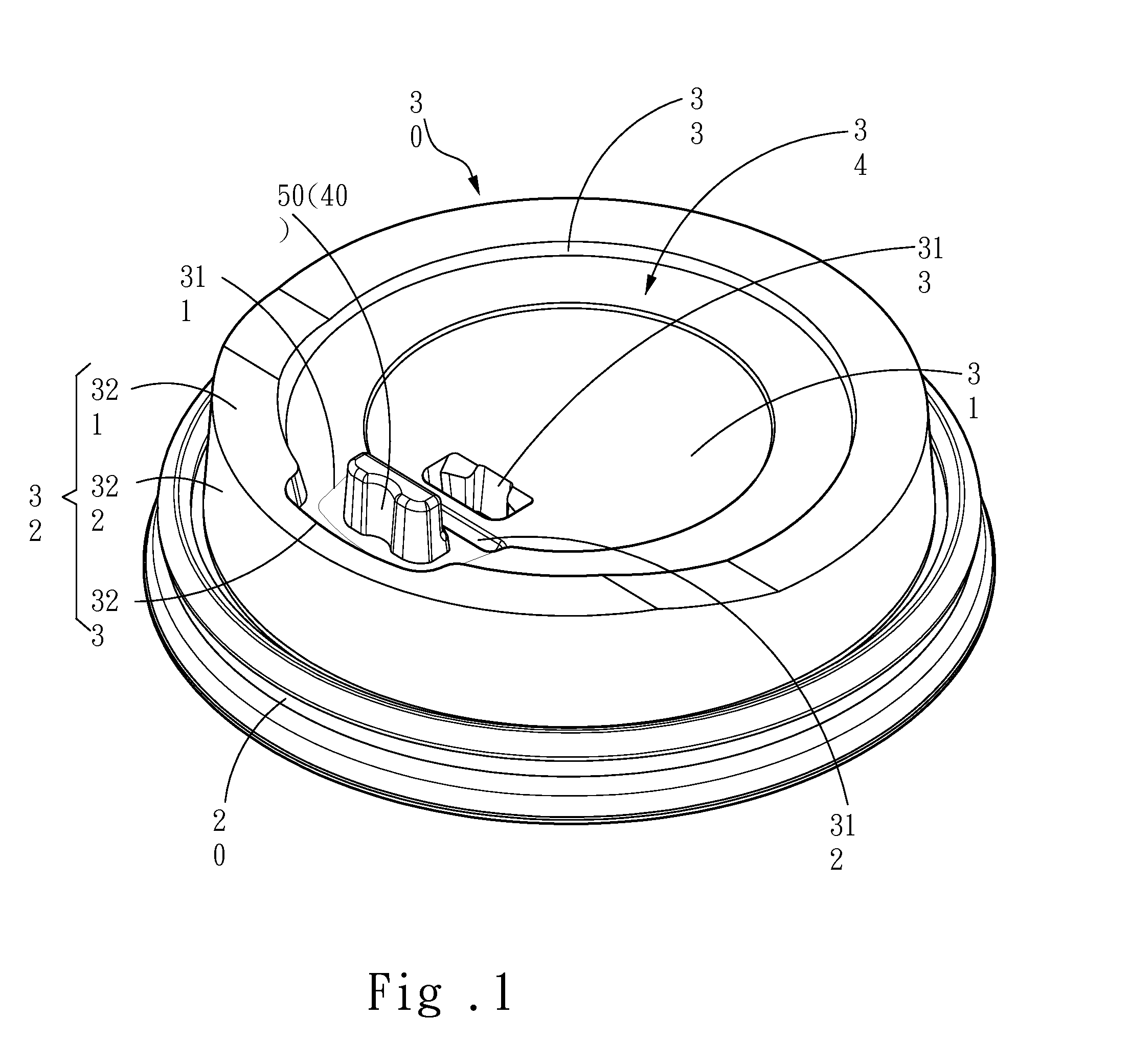

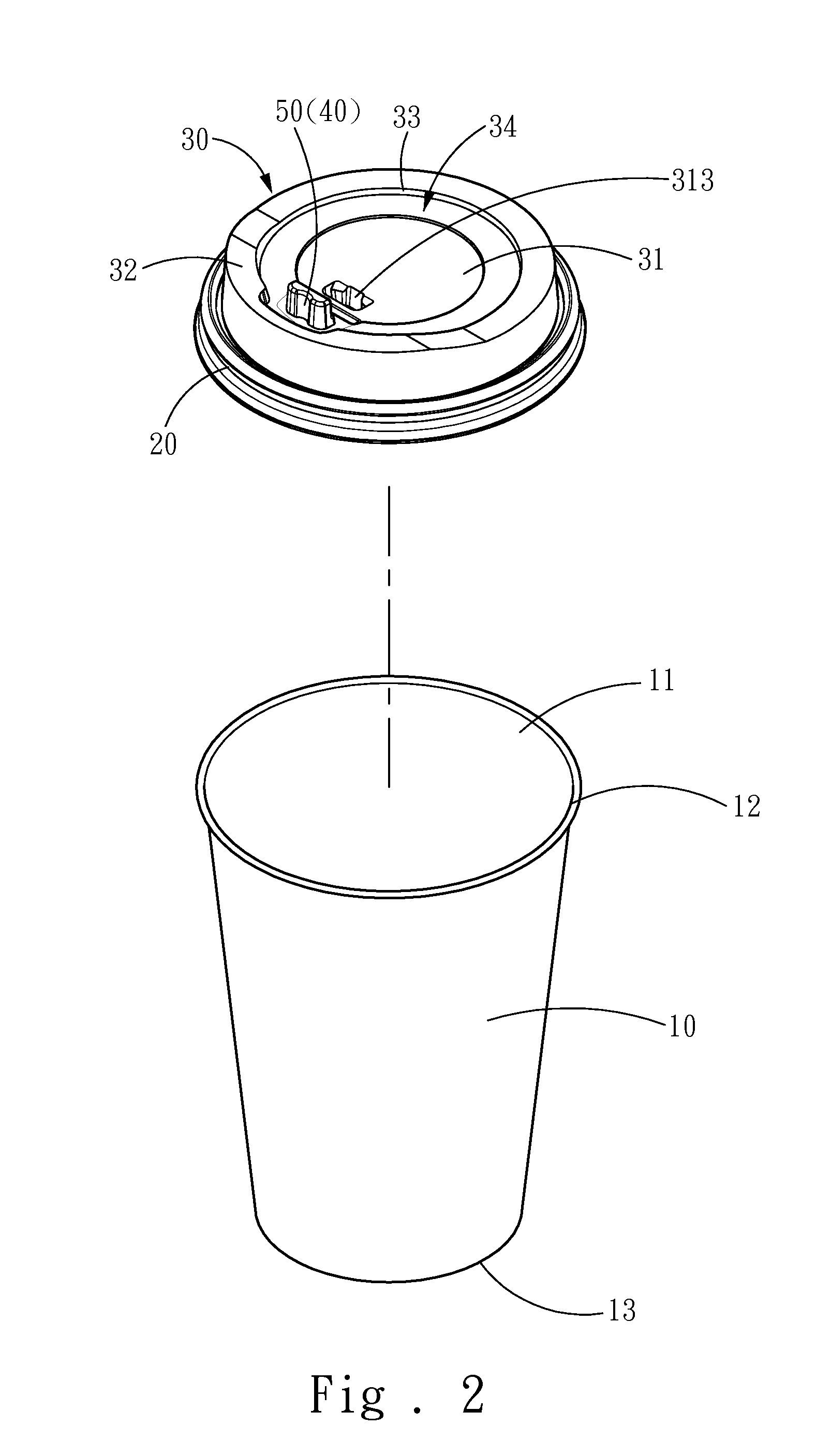

Stacking cup cap

InactiveUS20160325883A1Easy dust contaminationImprove stack stabilityRemovable lids/coversLidsEngineeringDirect communication

A stacking cup cap aims to cover a cup body which includes a cup top rim and a cup bottom side. The stacking cup cap includes a closing cap anchored on the cup top rim, a sealing lid connected to the closing cap and remote from the cup top rim and a drinking orifice. The sealing lid includes an indented stacking space to hold another cup body. The cup bottom side of another cup body is formed at a size mating the stacking space. The drinking orifice is located on the sealing lid corresponding to the stacking space to be covered by another cup body. Thus, through the stacking space a plurality of cup bodies can be stacked over one another at greater stability. After stacking the drinking orifice does not form direct communication with the exterior, hence can resolve the problem of dust contamination.

Owner:SHEN PLASTIC

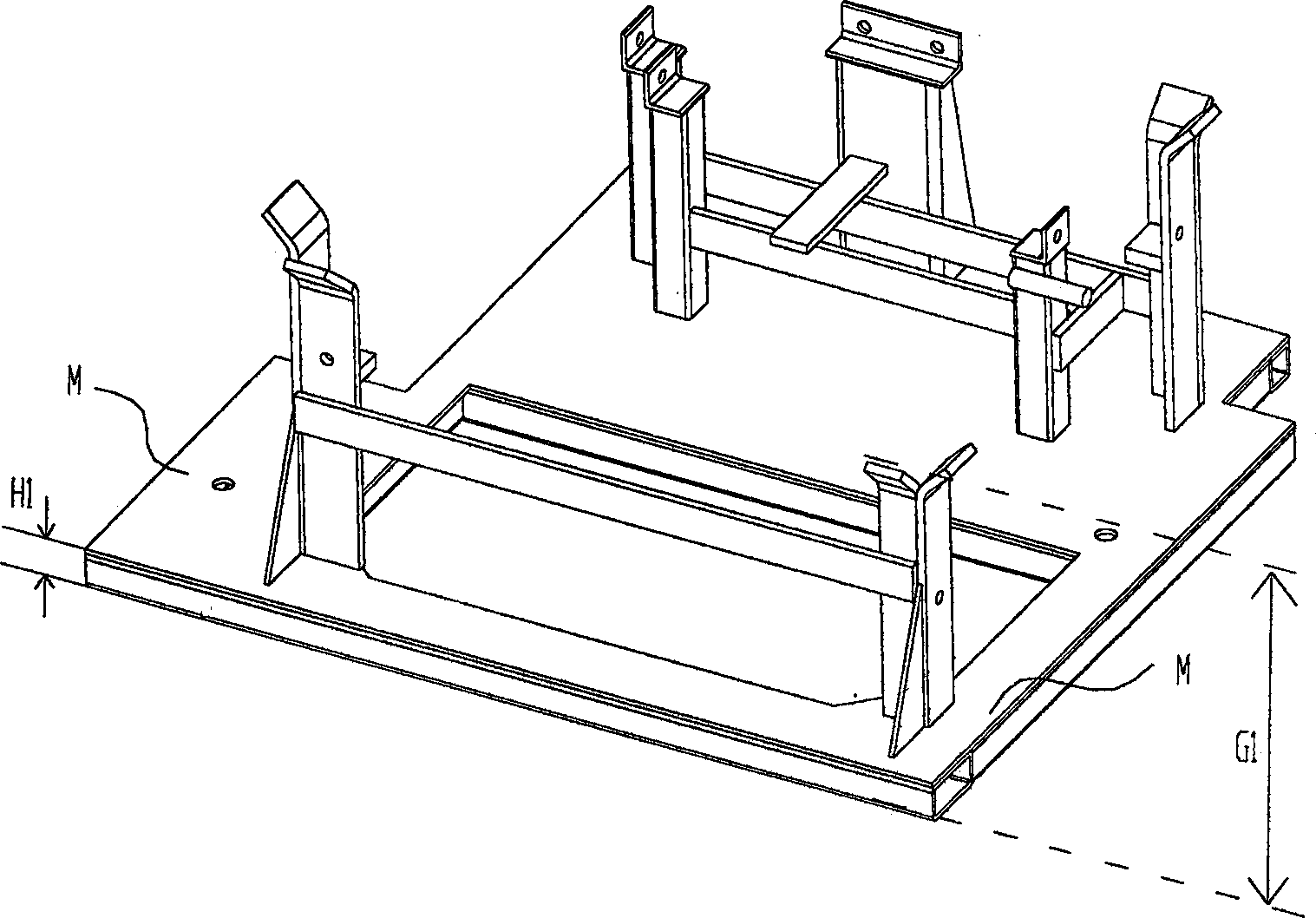

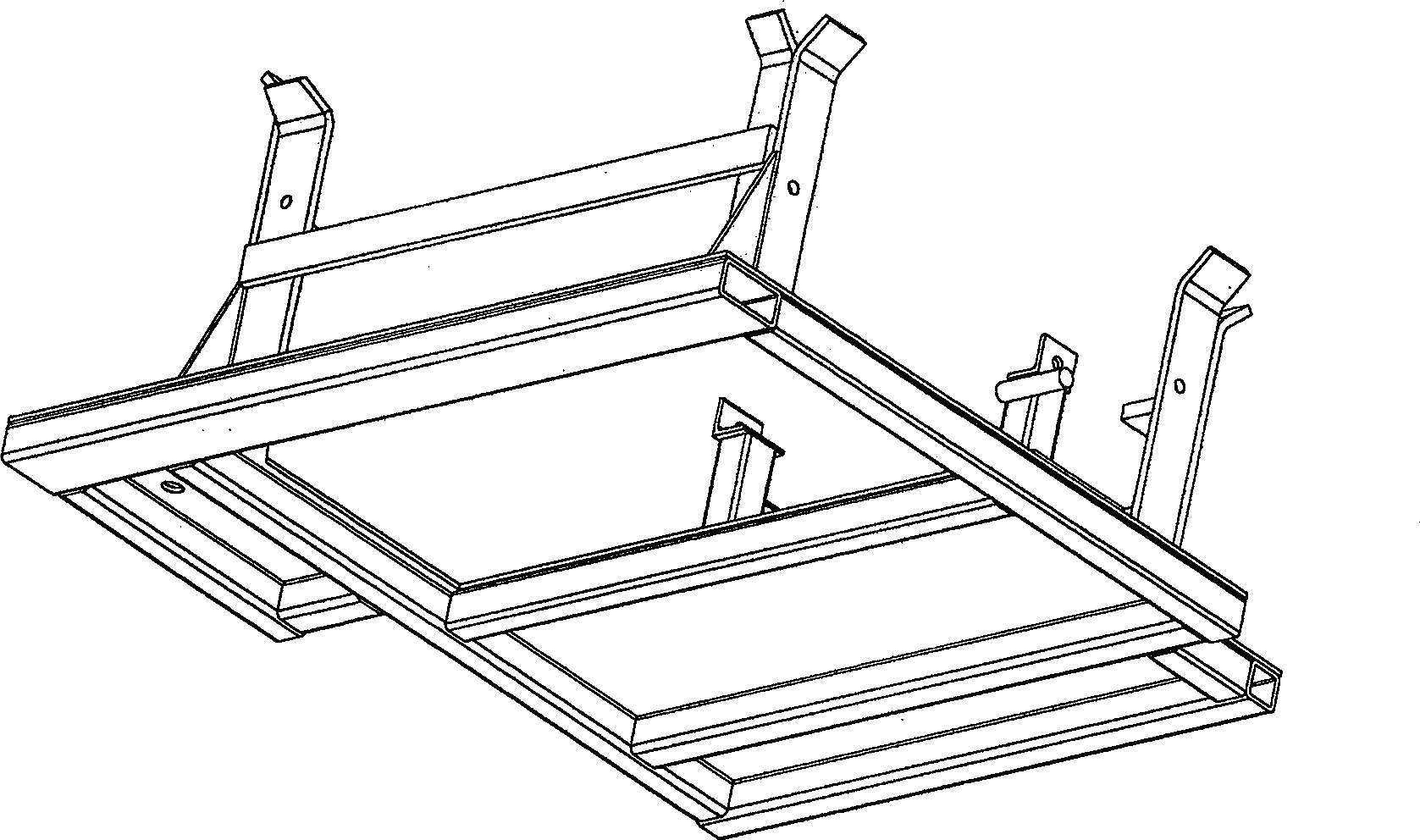

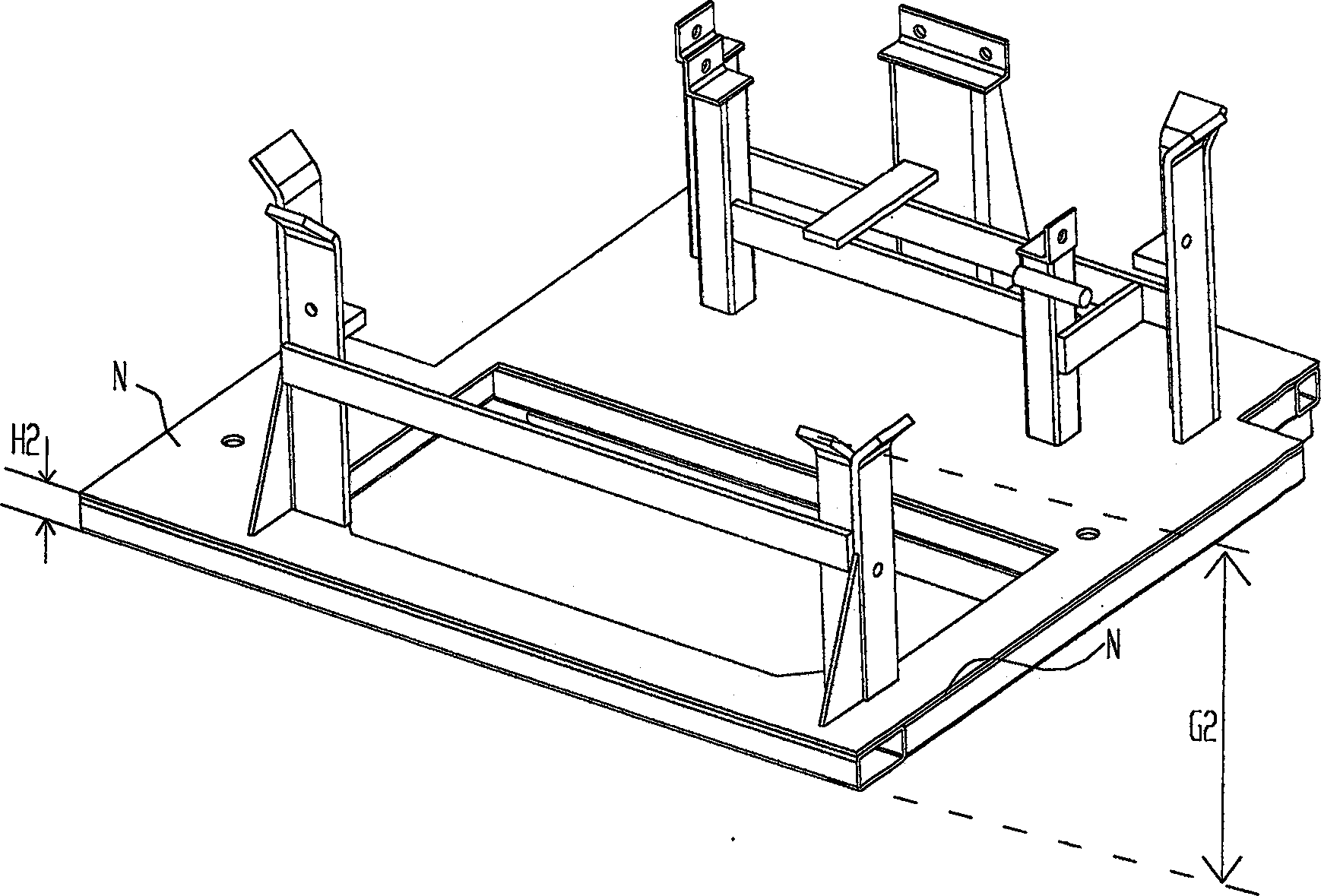

Tray box

InactiveCN1872629ALimit movementRealize loading and unloadingRigid containersPalletElectrical and Electronics engineering

A pallet case for transporting the detached parts of the pallet cases is composed of a frame consisting of external longitudinal and transverse beams and central beams, the first, the second and central limiting units arranged respectively on said beams and consisting of multiple groups of vertical posts at intervals, the first, the second and the third assembling spaces defined by said limiting vertical posts, and the first, the second and the third discrete parts assembling units respectively arranged in said assembling spaces.

Owner:CHINA INTERNATIONAL MARINE CONTAINERS (GROUP) CO LTD

Stackable box

Owner:ANWOOD LOGISTICS SYST SUZHOU CO LTD

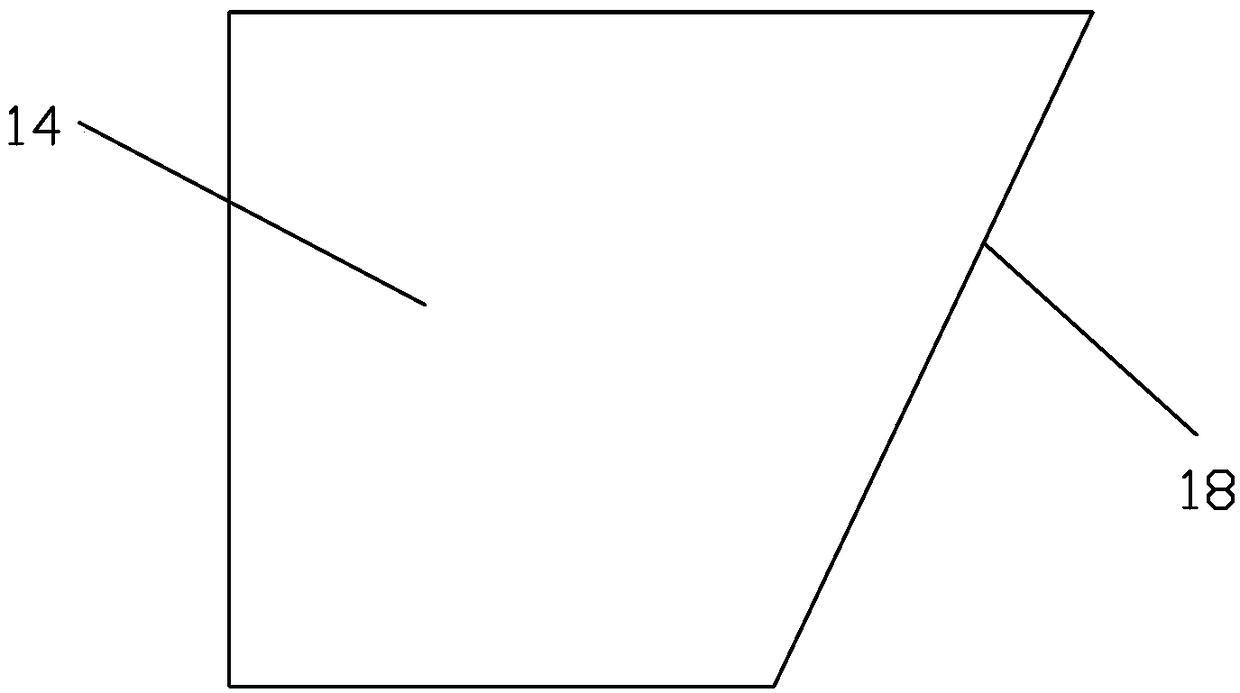

Transport plate for bagged goods

InactiveCN103842261AHigh strengthImprove rigidityRigid containersContainers with multiple articlesEngineeringMechanical engineering

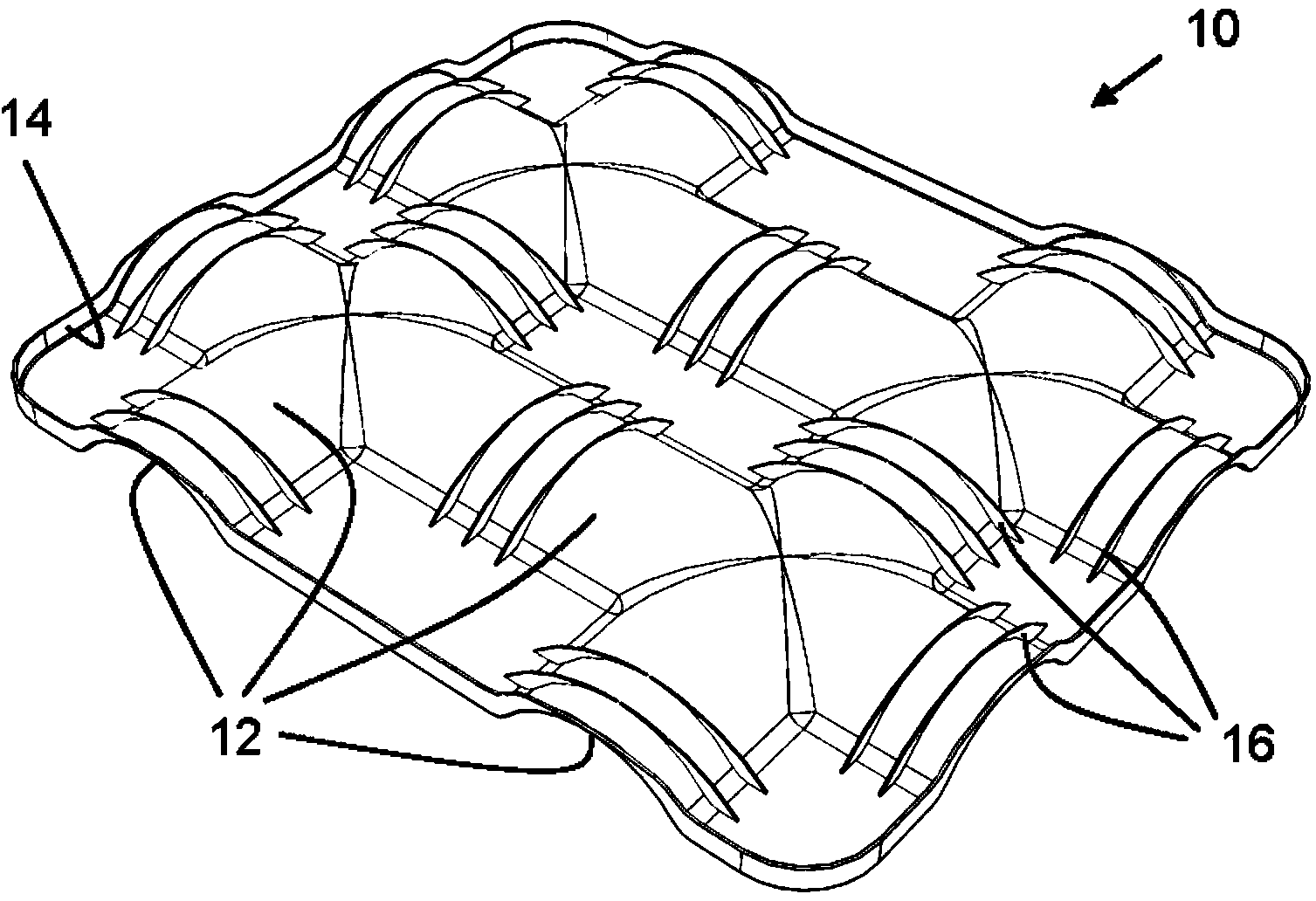

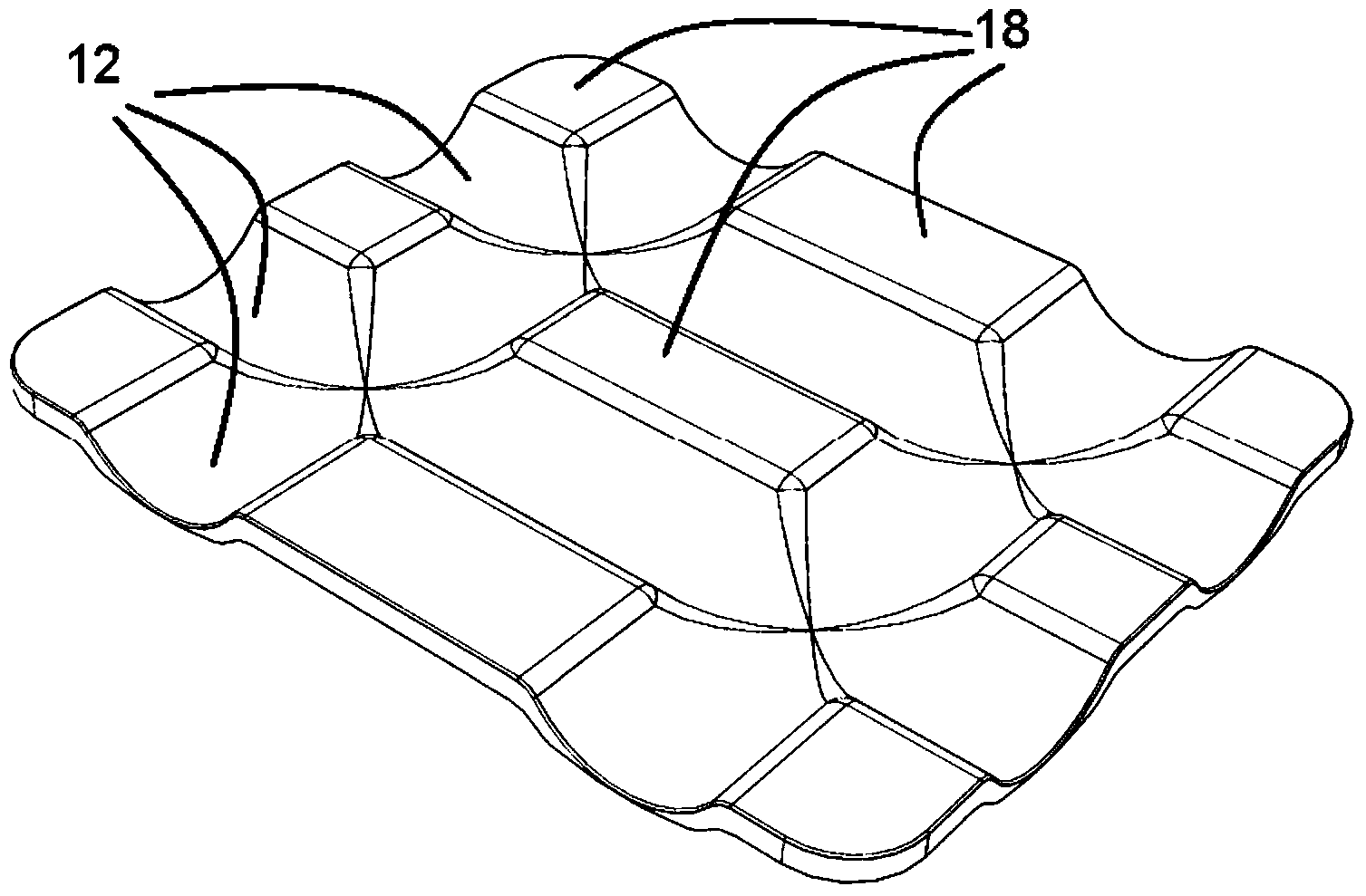

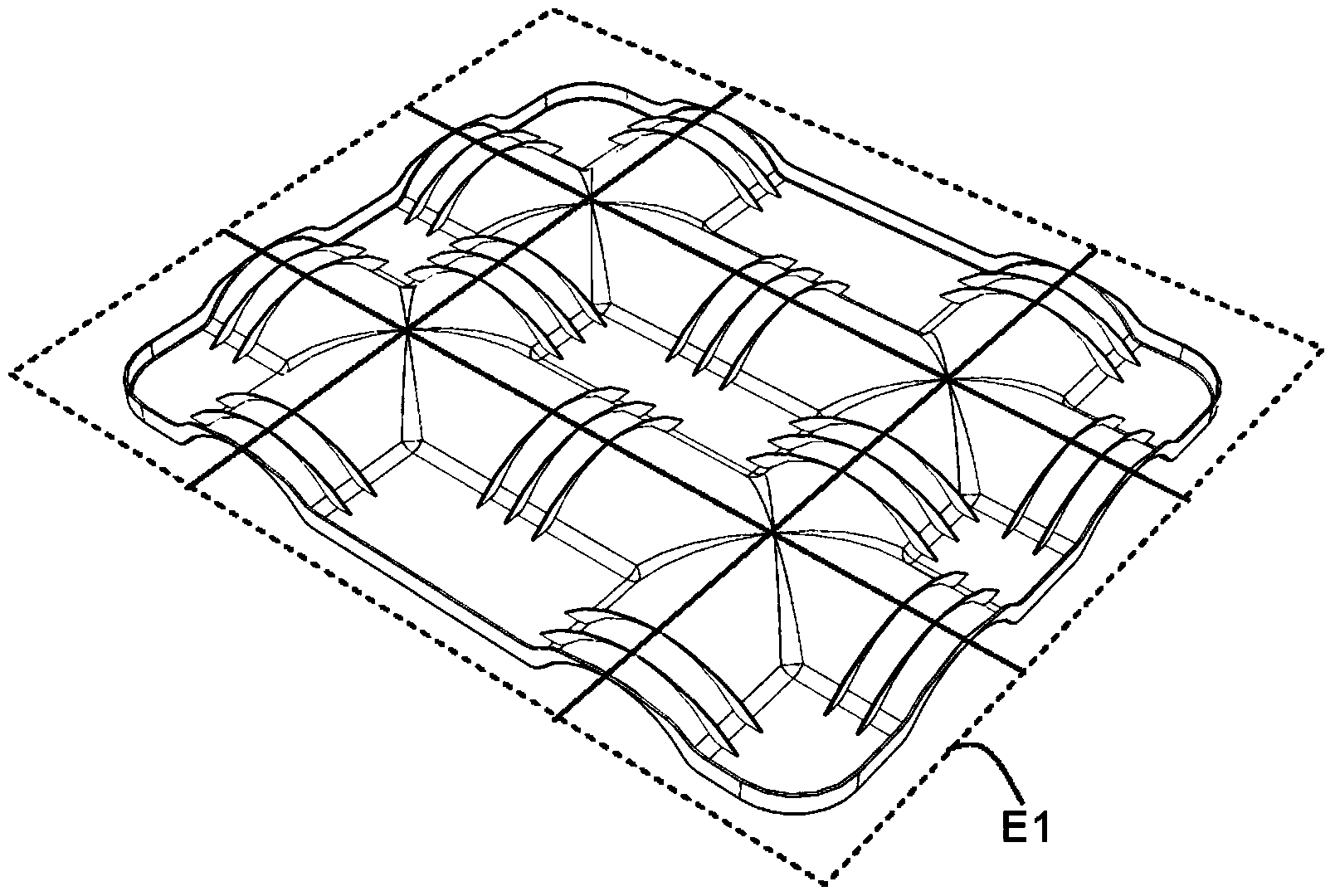

The invention relates to a transport plate (10) for transporting goods, in particular bagged goods, by means of a forklift, wherein the transport plate (10) in itself is shaped in such a way that the transport plate has at least two tunnel-shaped bulges (12) spaced from one another for accommodating forklift forks. The transport plate (10) has a peripheral, bent edge (14), which does not protrude beyond a plane defined by the outer vertices of the bulges (12).

Owner:SCHOELLER ARCA SYST

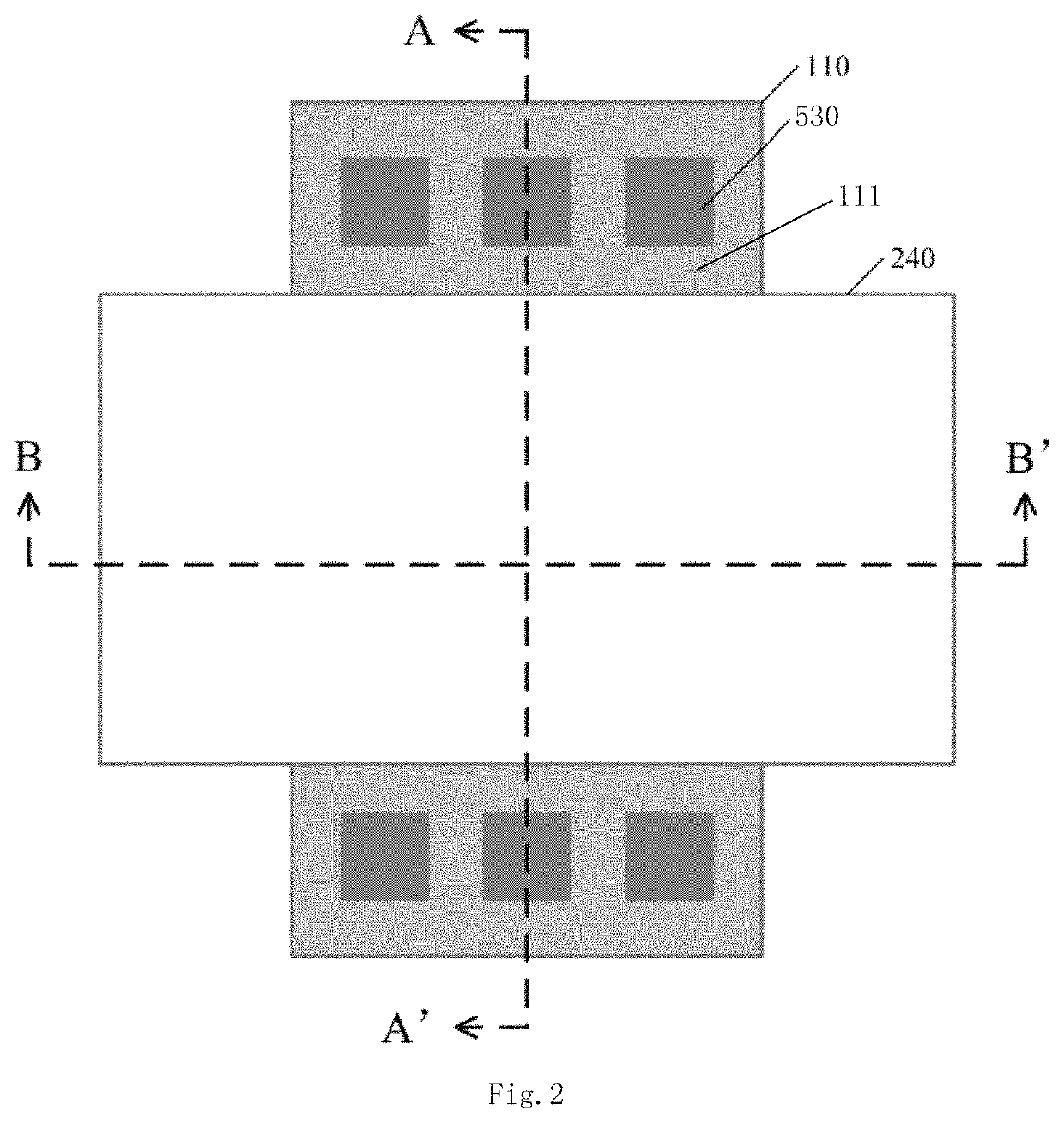

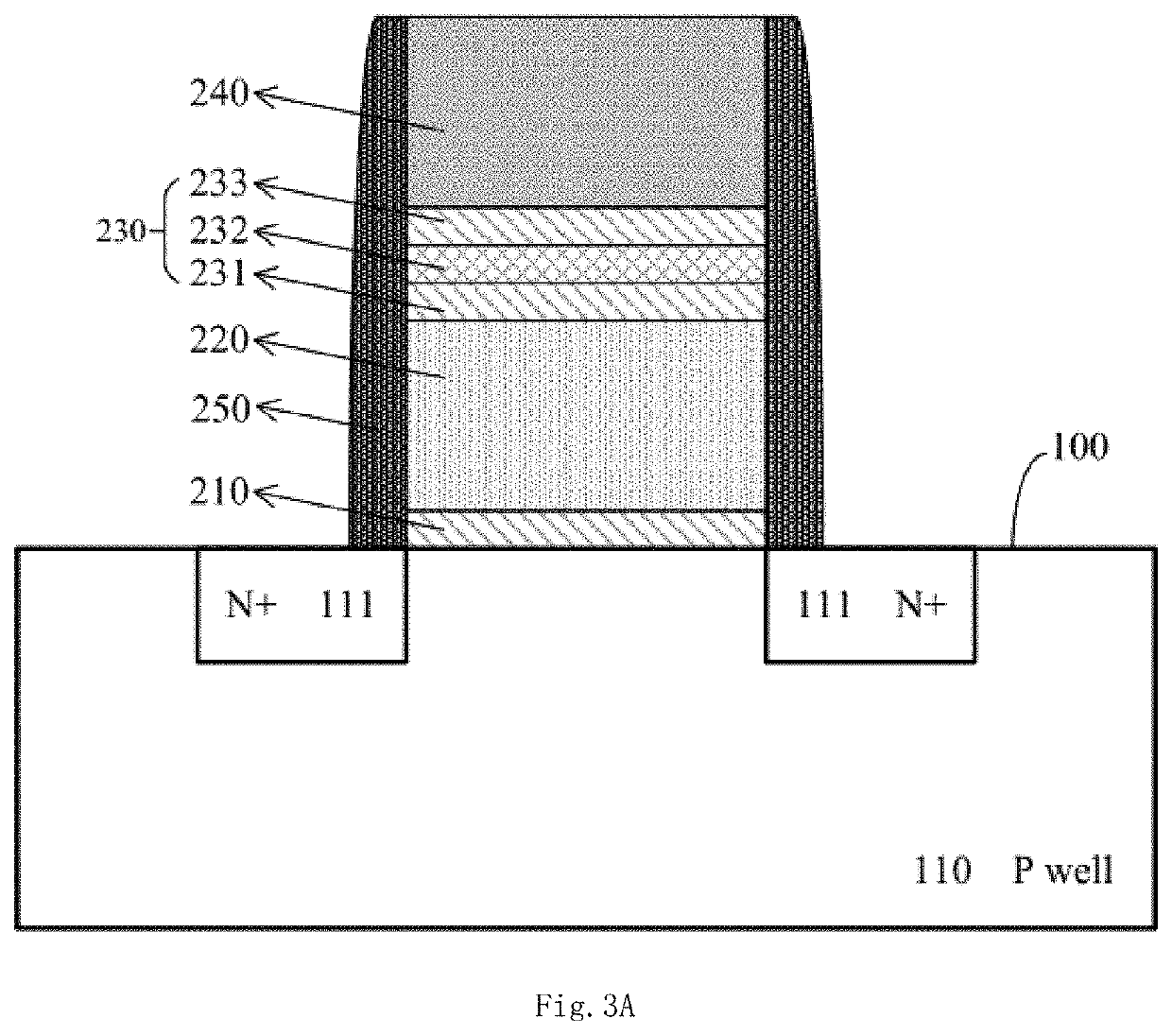

Stack capacitor, a flash memory device and a manufacturing method thereof

ActiveUS20210305265A1Improve stack stabilityReduce manufacturing costTransistorSolid-state devicesCapacitanceEngineering

The present disclosure provides a stack capacitor, a flash memory device, and a manufacturing method thereof. The stack capacitor of the flash memory device has a a memory transistor structure which at least comprises a substrate, and a tunneling oxide layer, a floating gate layer, an interlayer dielectric layer and a control gate layer which are sequentially stacked on the substrate, the interlayer dielectric layer of the stack capacitor comprises a first oxide layer and a nitride layer; the stack capacitor further comprises a first contact leading out of the control gate layer and a second contact leading out of the floating gate layer. The capacitance per unit area of the stack capacitor provided by the disclosure is effectively improved, and the size of the transistor device is reduced. The manufacturing method according to the disclosure does not add any additional photomask than a conventional process flow.

Owner:SHANGHAI HUALI MICROELECTRONICS CORP

Support device for materials handling

Owner:NG SOO SENG

Large scale insect culture shelf and application method thereof

PendingCN109006700AImprove stack stabilityImprove the quality of adultsCleaning using liquidsAnimal husbandrySlagLarva

The invention discloses a large scale insect culture shelf and an application method thereof; the large scale insect culture shelf comprises a shelf sheet and net plates arranged in the shelf sheet; the top and bottom of the shelf sheet are respectively provided with limit plug holes and machinery finger holes; the limit plug holes are arranged in the relative middle position; the machinery fingerholes are arranged on opposite positions on two sides; two sides of the machinery finger holes are provided with machinery finger fixed buckles; the limit plug holes can be used to stack the shelf and other shelves, and to uniformly place them; insect larva can suck on-shelf forages via net holes, and the forage residual slag can be kept on the shelf and easily cleaned off; in addition, the machinery fingers and the machinery finger holes can be connected so as to simply grab the shelves, thus easily transferring the shelves on one hand, realizing mechanization streamline culture, improving culturing efficiency, cleaning the shelves in a mechanization mode on the other hand without needing labor-washing, and saving time and labor force.

Owner:SHENGZHOU MOSANG HI TECH CO LTD

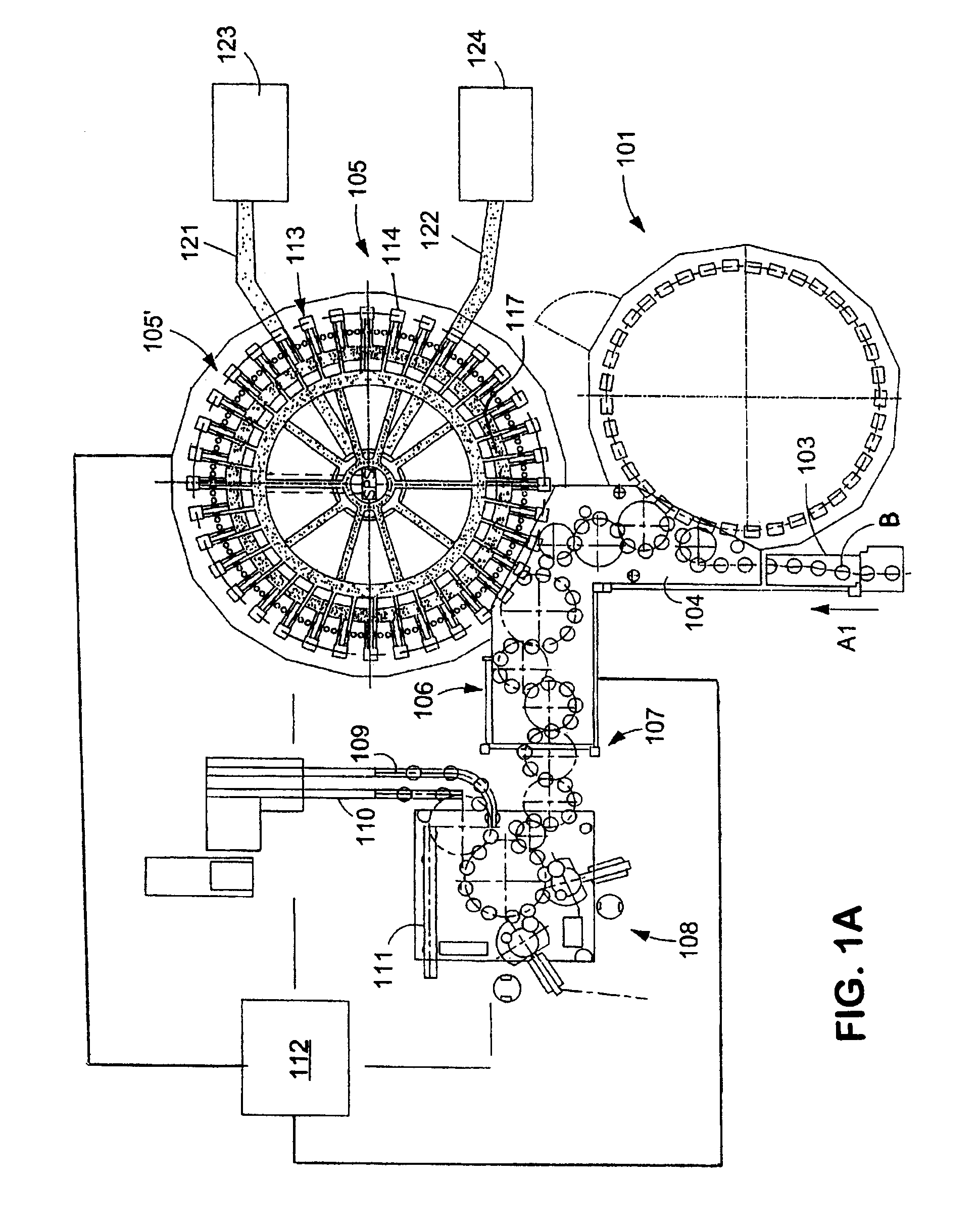

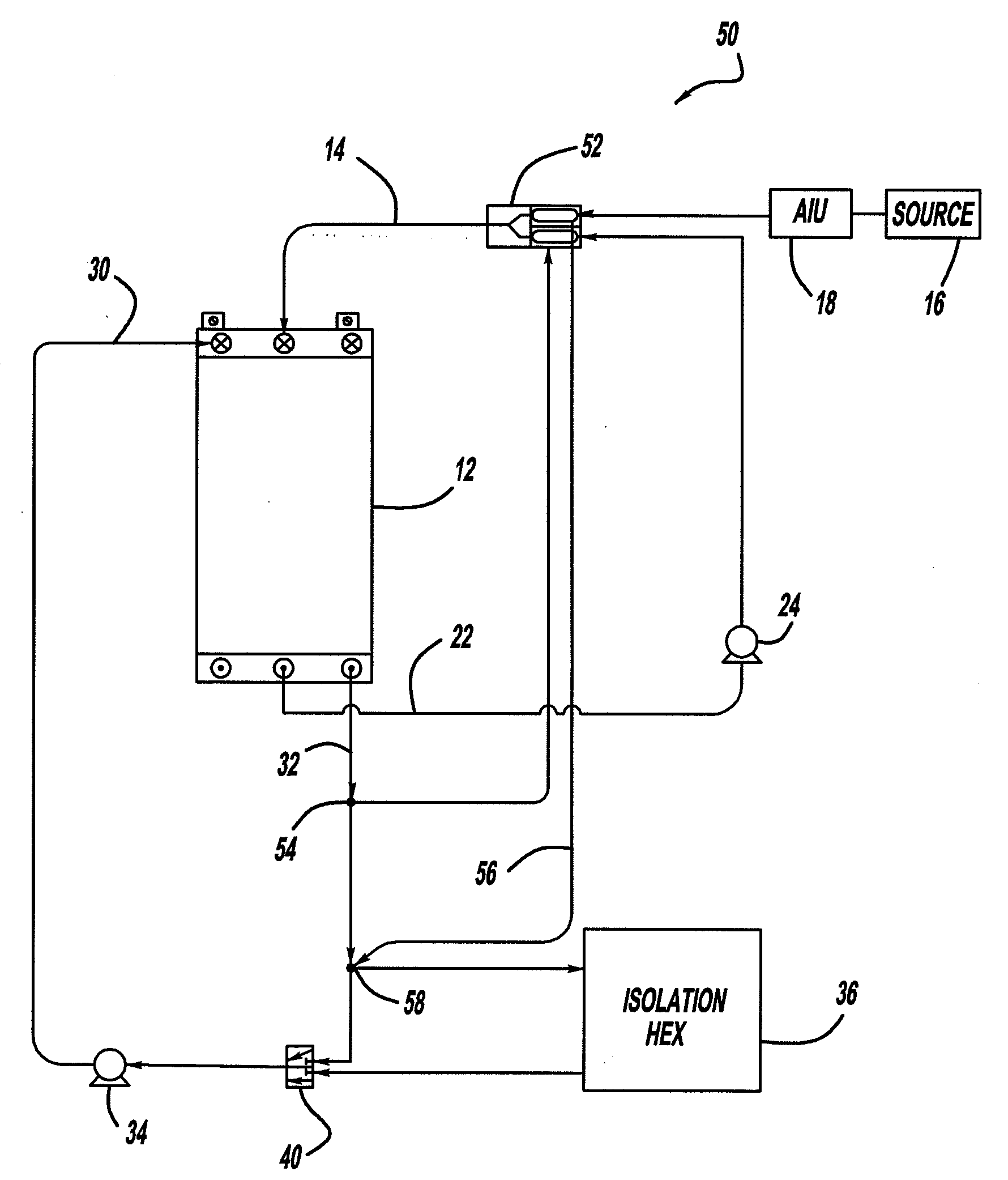

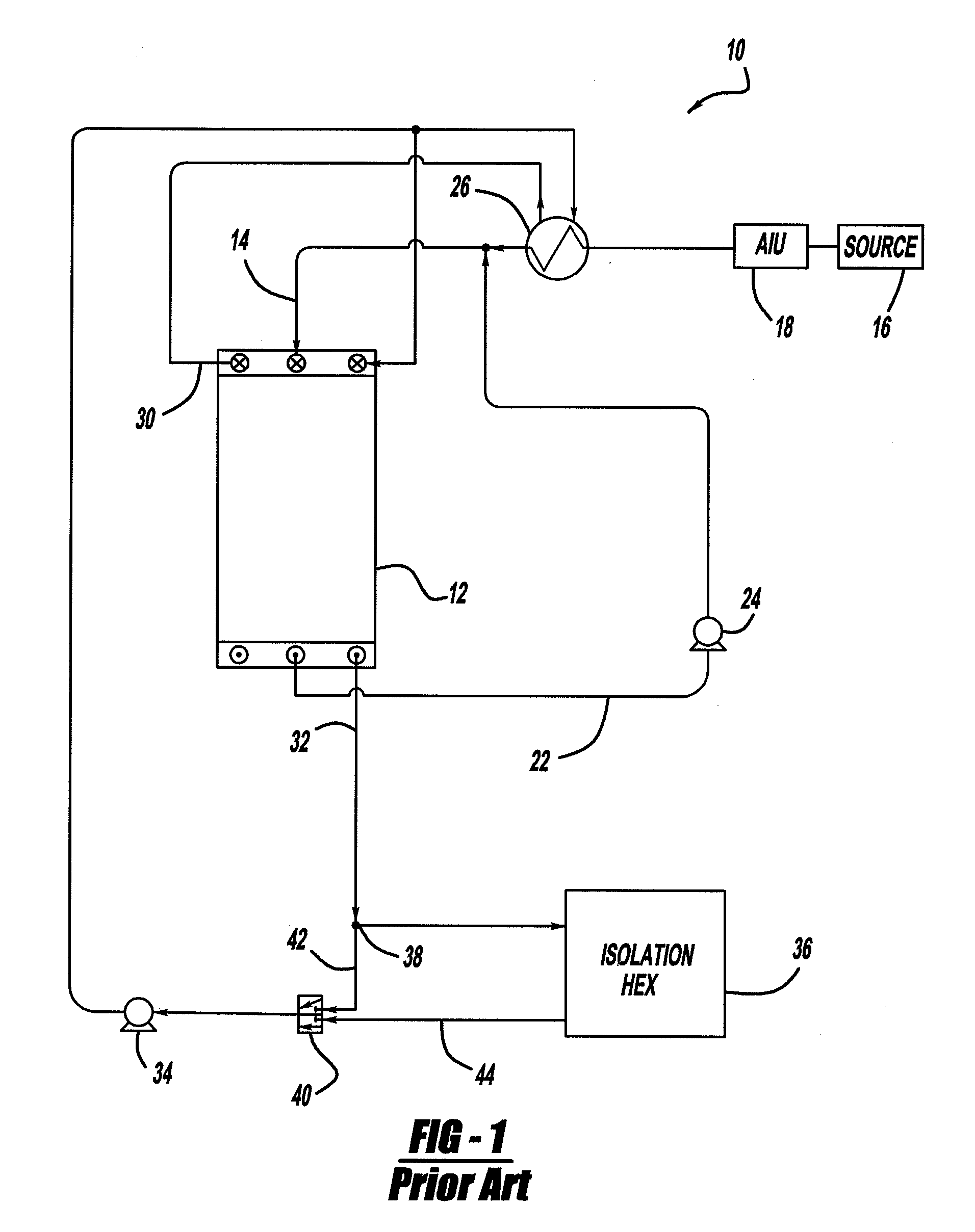

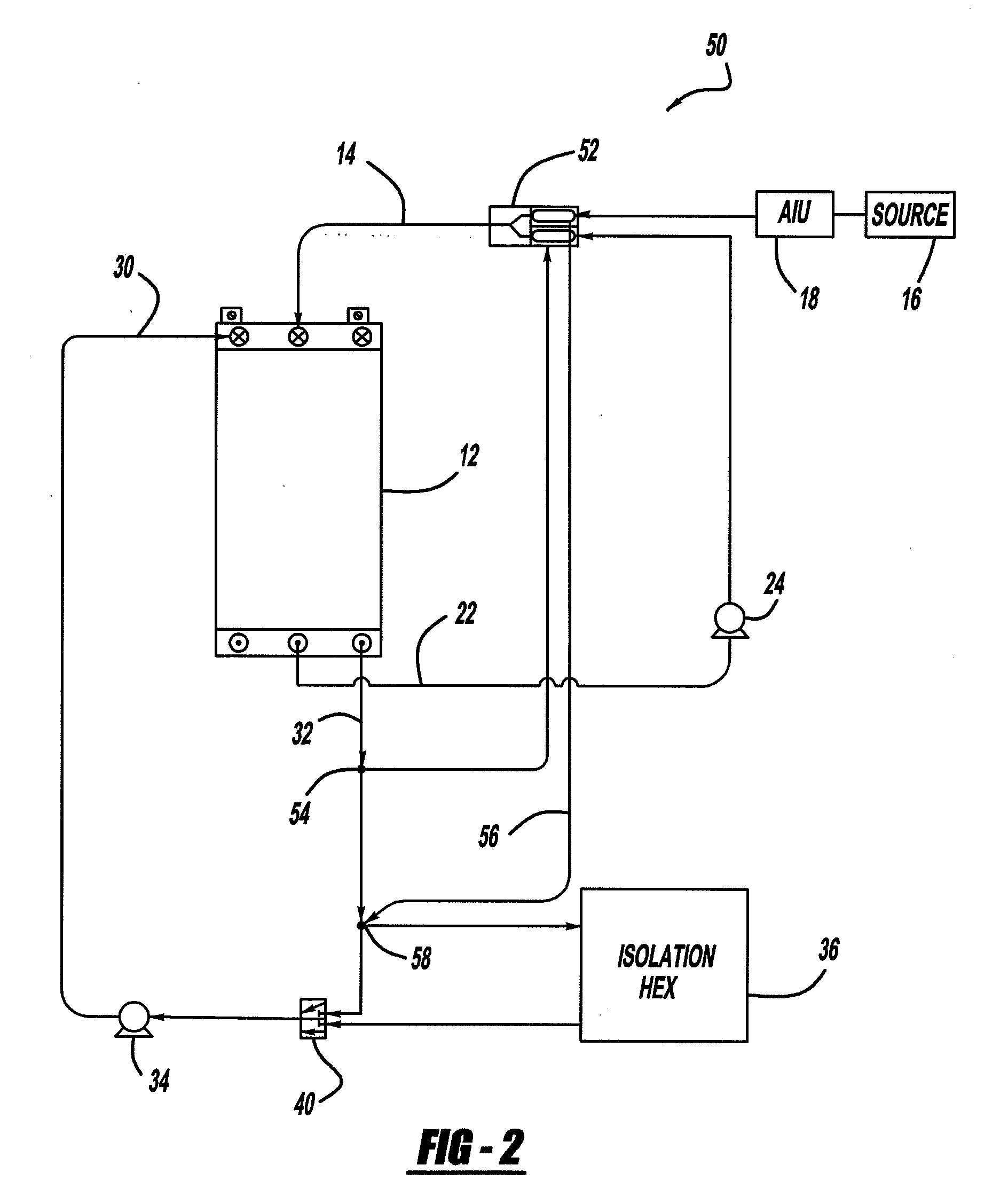

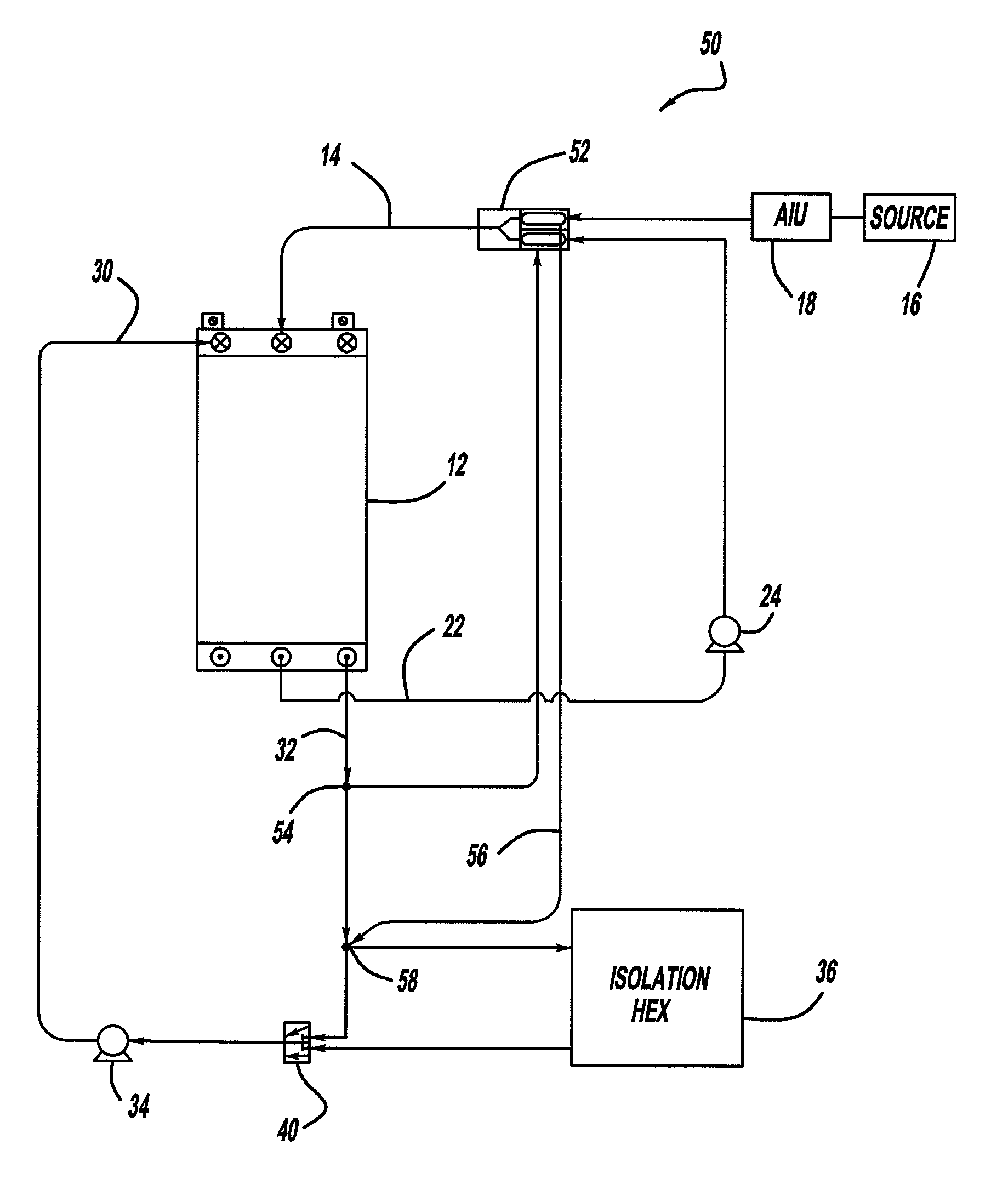

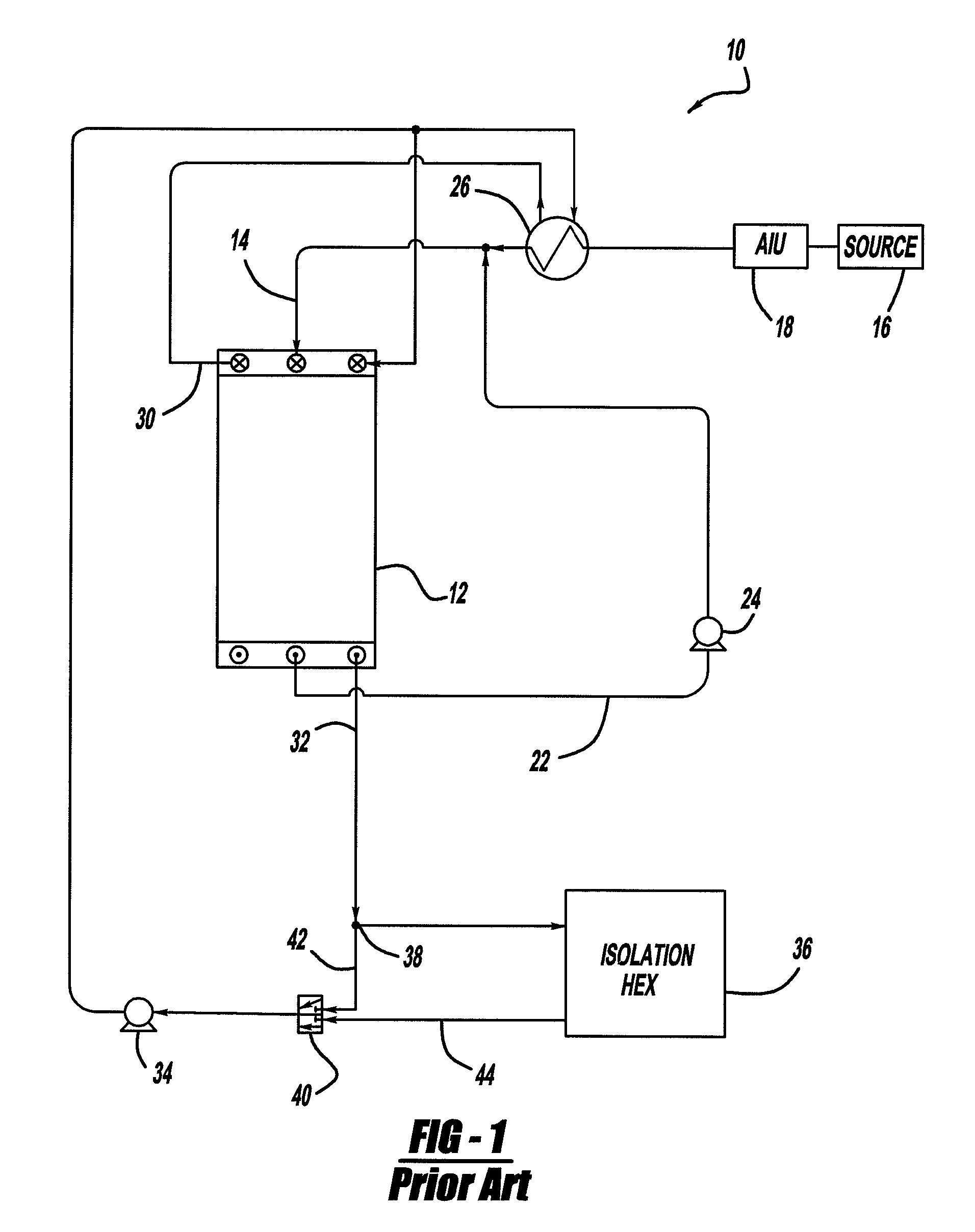

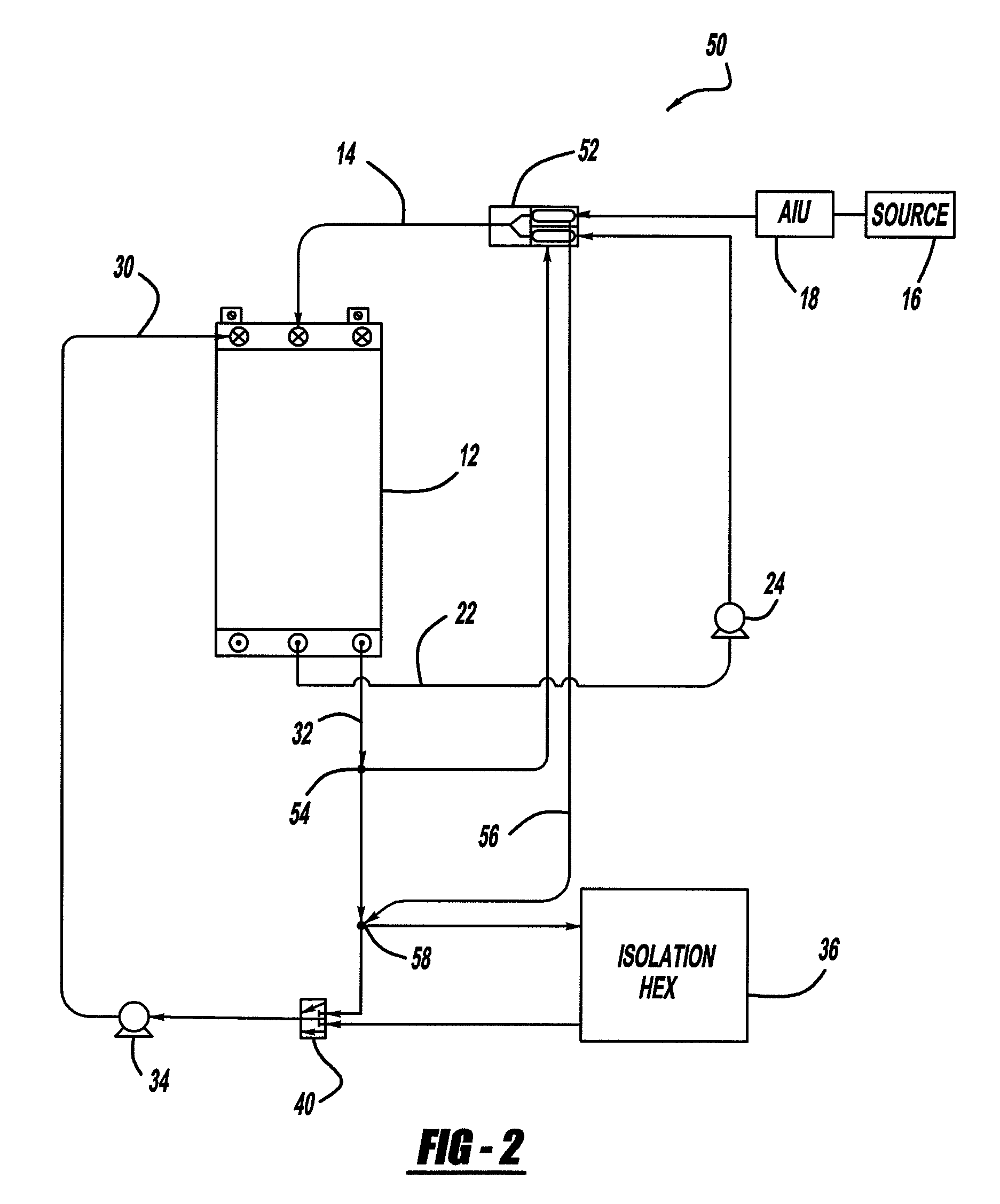

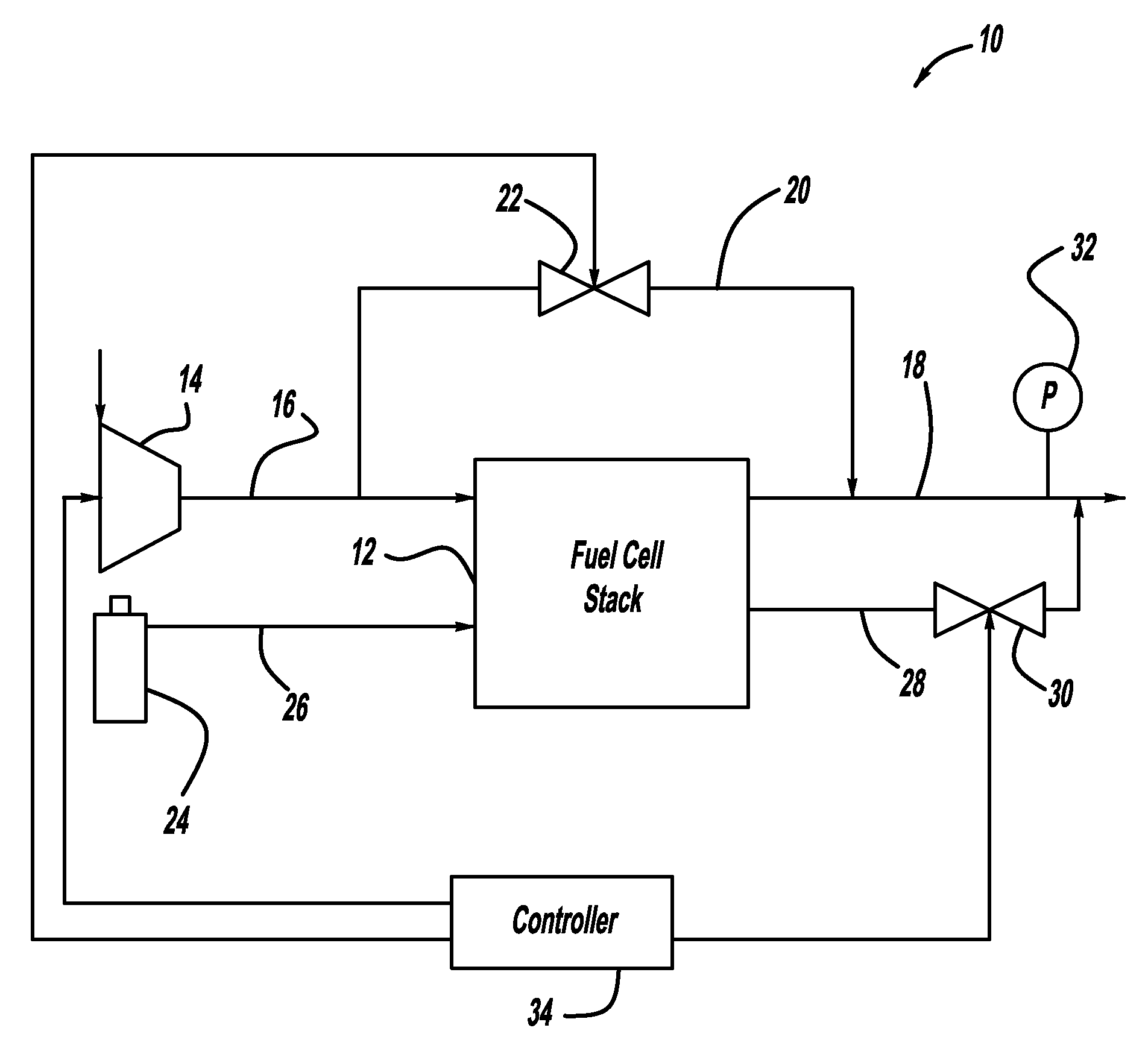

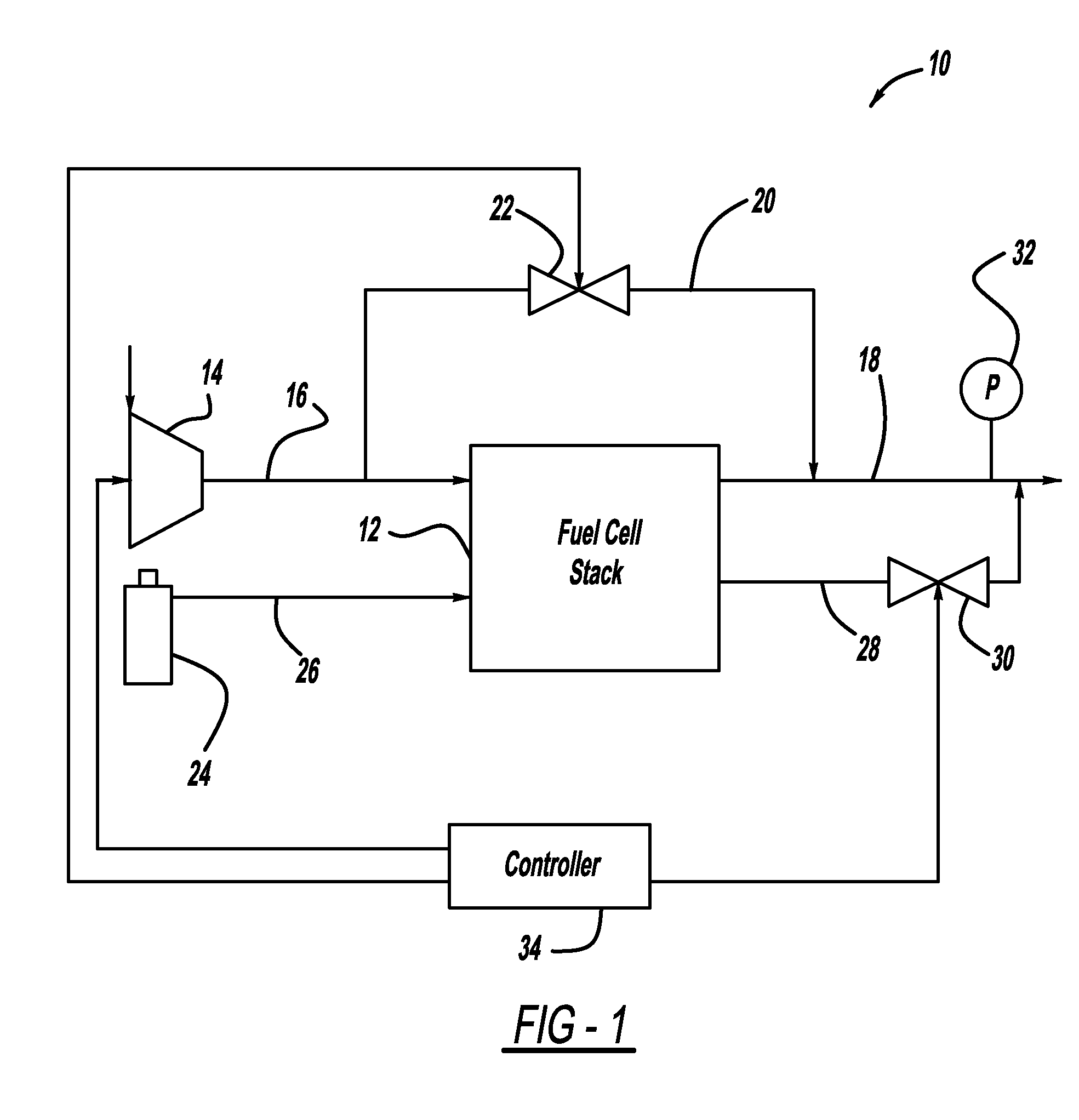

System Stability and Performance Improvement with Anode Heat Exchanger Plumbing and Re-Circulation Rate

ActiveUS20080199742A1Improve stack stabilityReduce formation of water dropletFuel cell heat exchangeFuel cell detailsLiquid waterPerformance improvement

A fuel cell system that increases stack stability by reducing the amount of liquid water droplets at the anode input of a fuel cell stack in the system. Re-circulated anode exhaust gas from the fuel cell stack and fresh hydrogen gas are sent to an anode heat exchanger so that both the fresh hydrogen gas and the re-circulated anode exhaust gas are heated to reduce the formation of water droplets in the anode input gas. Further, a portion of the heated cooling fluid directly from the fuel cell stack is sent to the heat exchanger to heat the fresh hydrogen gas and the re-circulation hydrogen before the cooling fluid is sent to an isolation heat exchanger to have its temperature reduced.

Owner:GM GLOBAL TECH OPERATIONS LLC

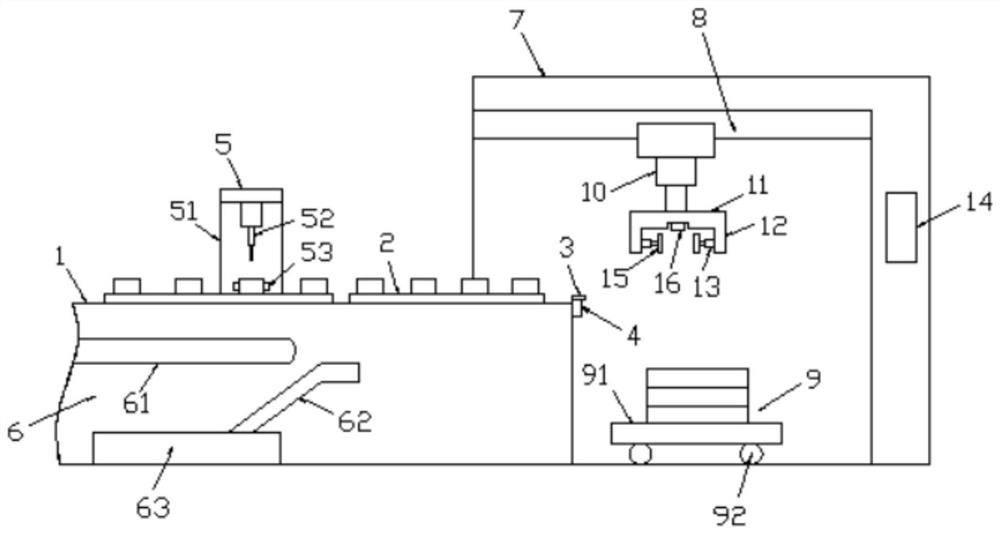

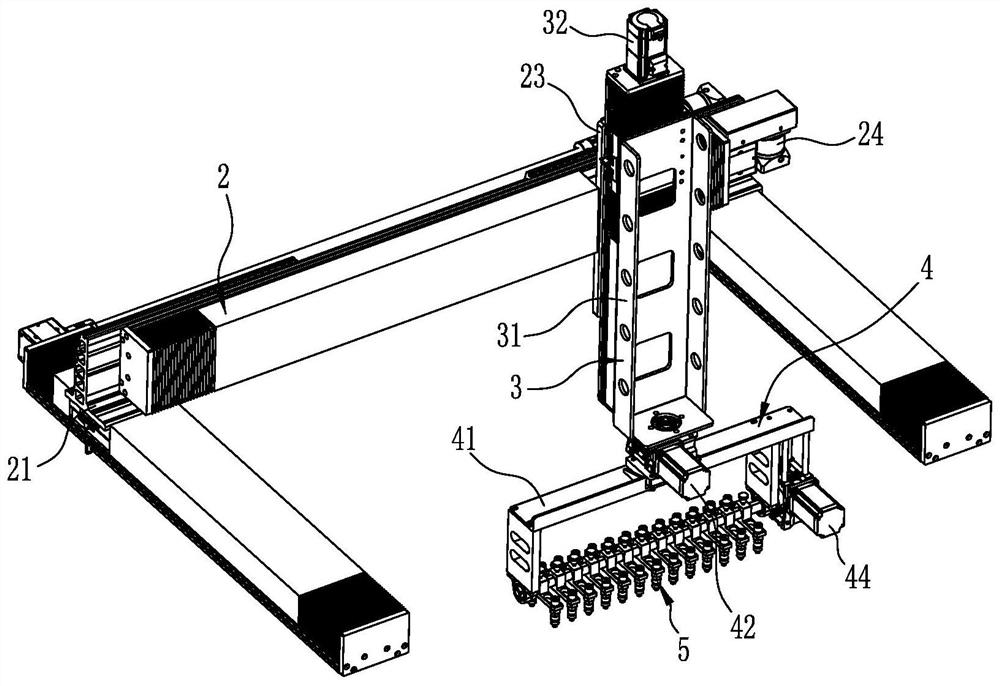

Stacking device of static pressure brick making machine

InactiveCN112157800AEasy to chooseReduce wasteAuxillary shaping apparatusStacking articlesBrickTester device

The invention belongs to the technical field of brick making machines, and particularly discloses a stacking device of a static pressure brick making machine. The stacking device comprises a conveyingframe extending out of the brick making machine, supporting plates for containing green bricks are conveyed on the conveying frame, a baffle with a light sensation probe is arranged at the tail end of the conveying frame, and a green brick crack detection device is arranged on the rear side of the conveying frame and comprises a support; a crack comprehensive tester is arranged at the position, corresponding to the green bricks, of the support, and a screening air cylinder is arranged at the position, below the crack comprehensive tester, of the support; a green brick collecting device is arranged at the front side of the conveying frame and comprises a conveying belt, an inclined plate is arranged at the tail end of the conveying belt, and a collecting box is arranged at the bottom of the inclined plate; and a machine frame is arranged at one side of the conveying frame, a PLC is installed on the machine frame, a guide rail is arranged in the rack, a green brick grabbing mechanism isarranged on the guide rail, and a conveying mechanism is arranged below the guide rail. According to the stacking device, the green bricks with cracks can be picked out in advance, so that resource waste is not liable to be caused, and the stacking stability is high.

Owner:HENAN BESTBUILDER NETWORK TECH CO LTD

System stability and performance improvement with anode heat exchanger plumbing and re-circulation rate

InactiveUS7919209B2Improve stack stabilityReduce formation of water dropletFuel cell heat exchangeHydrogenFuel cells

A fuel cell system that increases stack stability by reducing the amount of liquid water droplets at the anode input of a fuel cell stack in the system. Re-circulated anode exhaust gas from the fuel cell stack and fresh hydrogen gas are sent to an anode heat exchanger so that both the fresh hydrogen gas and the re-circulated anode exhaust gas are heated to reduce the formation of water droplets in the anode input gas. Further, a portion of the heated cooling fluid directly from the fuel cell stack is sent to the heat exchanger to heat the fresh hydrogen gas and the re-circulation hydrogen before the cooling fluid is sent to an isolation heat exchanger to have its temperature reduced.

Owner:GM GLOBAL TECH OPERATIONS LLC

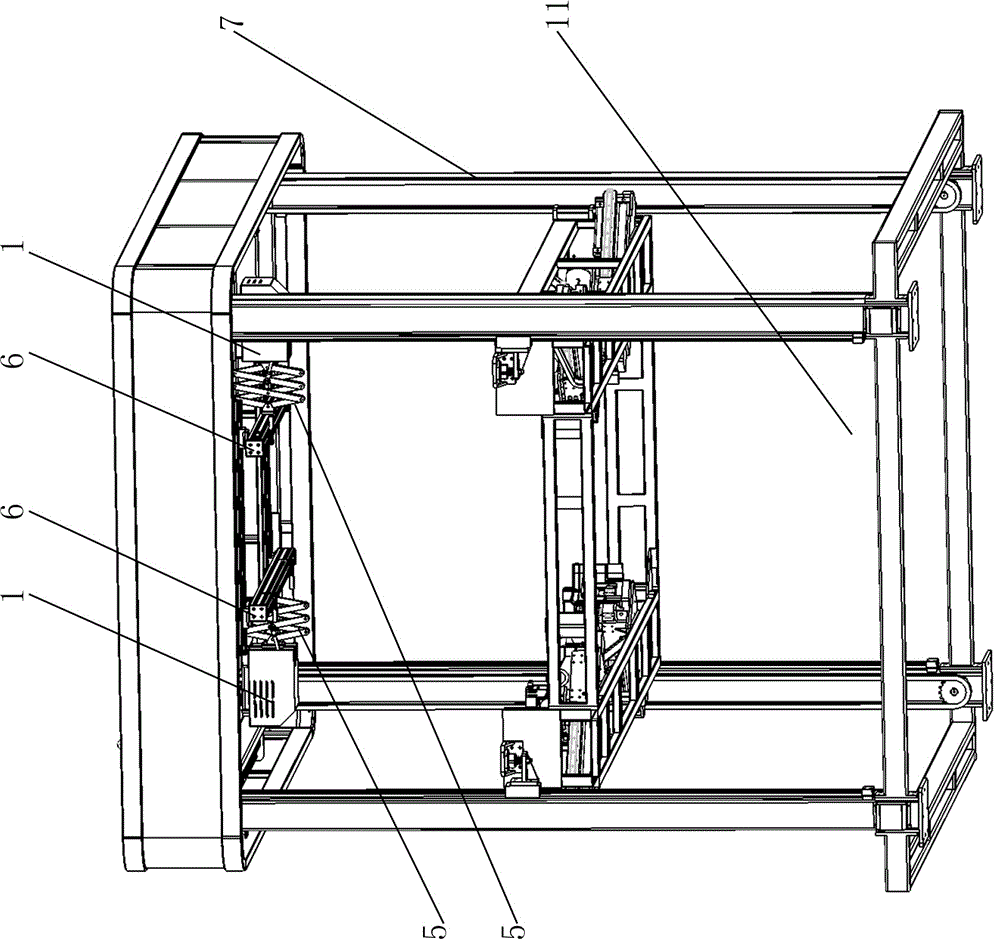

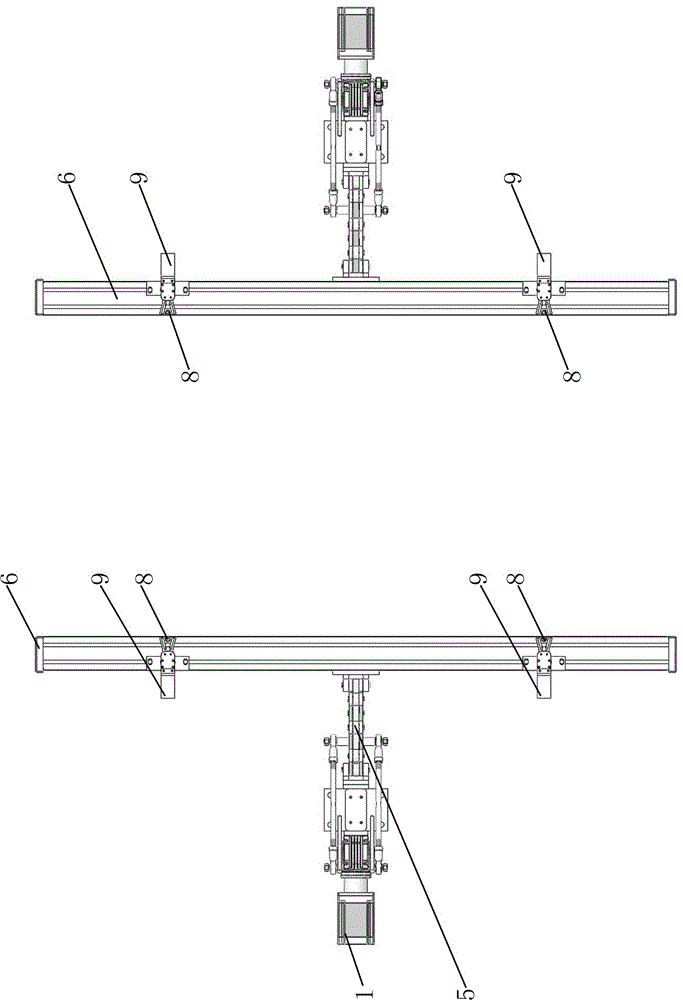

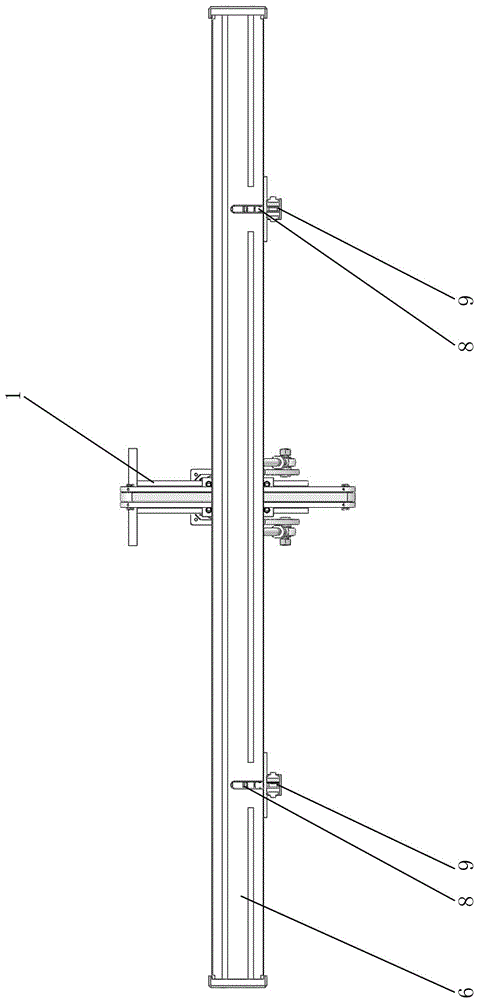

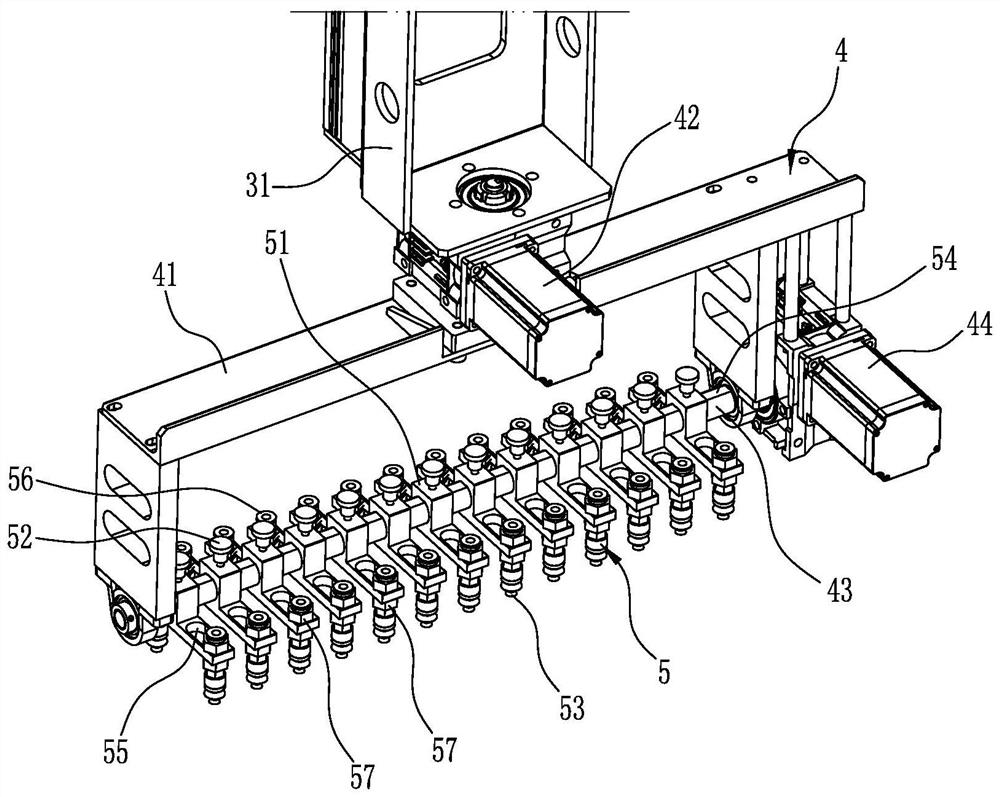

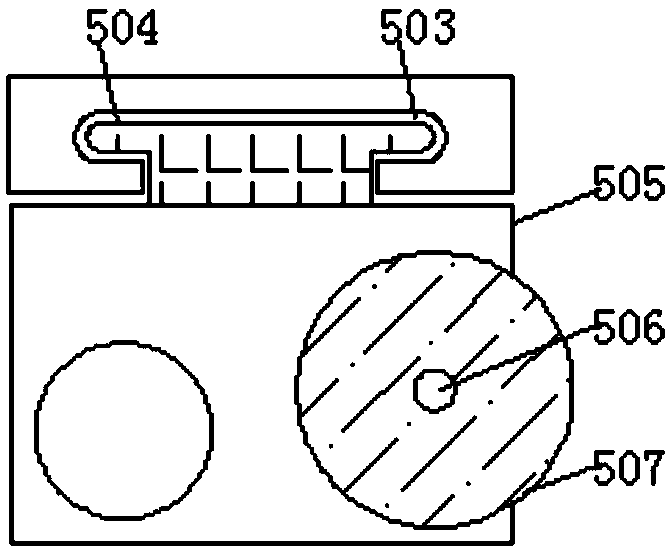

Intelligent magnetic shoe stacking system

PendingCN111924549AIncrease flexibilityImprove stack stabilityStacking articlesDe-stacking articlesStructural engineeringMechanical engineering

The invention discloses an intelligent magnetic shoe stacking system. The intelligent magnetic shoe stacking system comprises a rack. A stacking storage device is arranged on the rack. A magnetic shoetaking and placing device is mounted on the rack. A taking and placing lifting device and a horizontal shifting device are arranged between the magnetic shoe taking and placing device and the rack. The magnetic shoe taking and placing device comprises a horizontal rotating seat rotatably mounted on the taking and placing lifting device or the horizontal shifting device. The horizontal rotating seat is connected with a horizontal rotating driver. A taking and placing turnover shaft arranged transversely is rotatably mounted on the horizontal rotating seat. A plurality of shoe suction devices are arranged on the taking and placing turnover shaft. A turnover driver is arranged between the taking and placing turnover shaft and the horizontal rotating seat. Through the horizontal rotating seatand the taking and placing turnover shaft, the shoe suction device can suck magnetic shoes from multiple angles and can stack the magnetic shoes on the stacking storage device at more available postures during stacking storage. Therefore, the intelligent magnetic shoe stacking system improves the stacking flexibility and also improves the stacking stability and stacking space utilization rate.

Owner:上海奇宝智能科技有限公司

Volume reduction device for recycle treatment of waste ring-pull cans

ActiveCN108908998AAvoid pollutionEasy to collect and organizePressesWaste managementVolume reduction

The invention discloses a volume reduction device for recycle treatment of waste ring-pull cans. The device comprises a working rack, operation boxes are arranged at the two sides of the working rack,and a waste material barrel is arranged at the right side of an inner cavity of the working rack; a feeding device is arranged at the top of the operation box at the left side, a first opening deviceis arranged at the left side of the back face of a support, and a second opening device is arranged at the left side of the front face of the support; a flattening device is arranged at the right side of the working rack. According to the volume reduction device for recycle treatment of the waste ring-pull cans, the two ends of each waste ring-pull can and a can body are cut off and separated from each other through a splitting device, materials different in thickness are treated separately, residual liquid stored in the waste ring-pull cans can also be naturally released, and the situation is avoided that due to splashing, the environment is polluted; the can bodies are ground and flattened through the flattening device, it can be guaranteed that each flattened can body material is in aregular flat shape, and collection and arrangement are conducted conveniently.

Owner:南京萧台东机械制造有限公司

Integrated type electric turnover box and production method

PendingCN107458687AReduce connectionsIncrease productivityContainers to prevent mechanical damageRigid containersCustomer requirementsInjection moulding

The invention discloses an integrated type electric turnover box and a production method applied to the electric field. The integrated type electric turnover box is characterized by structurally comprising a bottom plate and side plates, wherein the bottom plate comprises an upper surface and a lower surface; the side plates are perpendicularly arranged on the upper surface; the side plates are enclosed to form a placing region; and the bottom plate and the four side plates are injection-molded integrally. The integrated type electric turnover box is injection-molded integrally, so that a connecting process of the side plates and the bottom plate is reduced, production efficiency is improved and production cost is reduced. Changes of the structure of the turnover box finished product can be realized by changing a mould shape according to different customer requirements, so that production efficiency of the turnover box is improved. The turnover box is manufactured through a model, so that the product dimension is more precise, structural dimension difference, caused by the connecting process of the bottom plate and the side plates, of the turnover box finished product is avoided, structural consistency of the turnover boxes produced in batch is effectively improved, stacking effect of the turnover box is guaranteed, stacking stability is improved, and guarantee is provided for a follow-up operation process.

Owner:SUZHOU YING CHUANG POWER TECH

Multifunctional intelligent mechanical arm

ActiveCN113059552APlace stableAvoid bumpingProgramme-controlled manipulatorGripping headsWorking environmentEngineering

The invention relates to the field of nuclear waste treatment, in particular to a multifunctional intelligent mechanical arm, and aims to provide the multifunctional intelligent mechanical arm. According to the technical scheme, the multifunctional intelligent mechanical arm comprises a moving system, a protection part taking system and a nuclear waste barrel clamping system; the moving system is connected with the protection part taking system; and the protection part taking system is connected with the nuclear waste barrel clamping system. According to the multifunctional intelligent mechanical arm, the effects that the multifunctional intelligent mechanical arm can adapt to various working environments, the simulated nuclear waste barrels are positioned and clamped, shaking during clamping is prevented, when the simulated nuclear waste barrels are stacked together, the outer surfaces of the simulated nuclear waste barrels can be wrapped with closed first clamping blocks and second clamping blocks, the simulated nuclear waste barrels are prevented from being collided, and the stacking stability is improved are achieved.

Owner:HENAN UNIV OF URBAN CONSTR

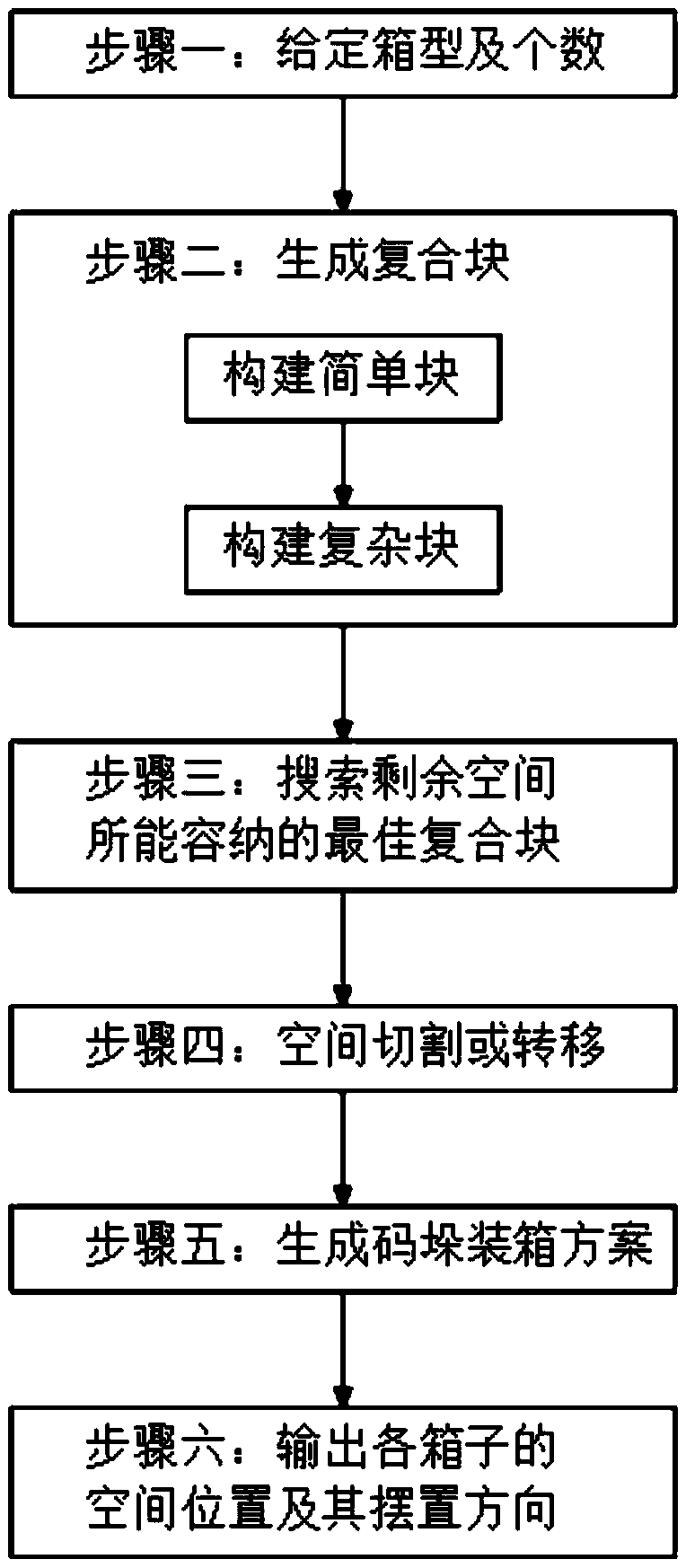

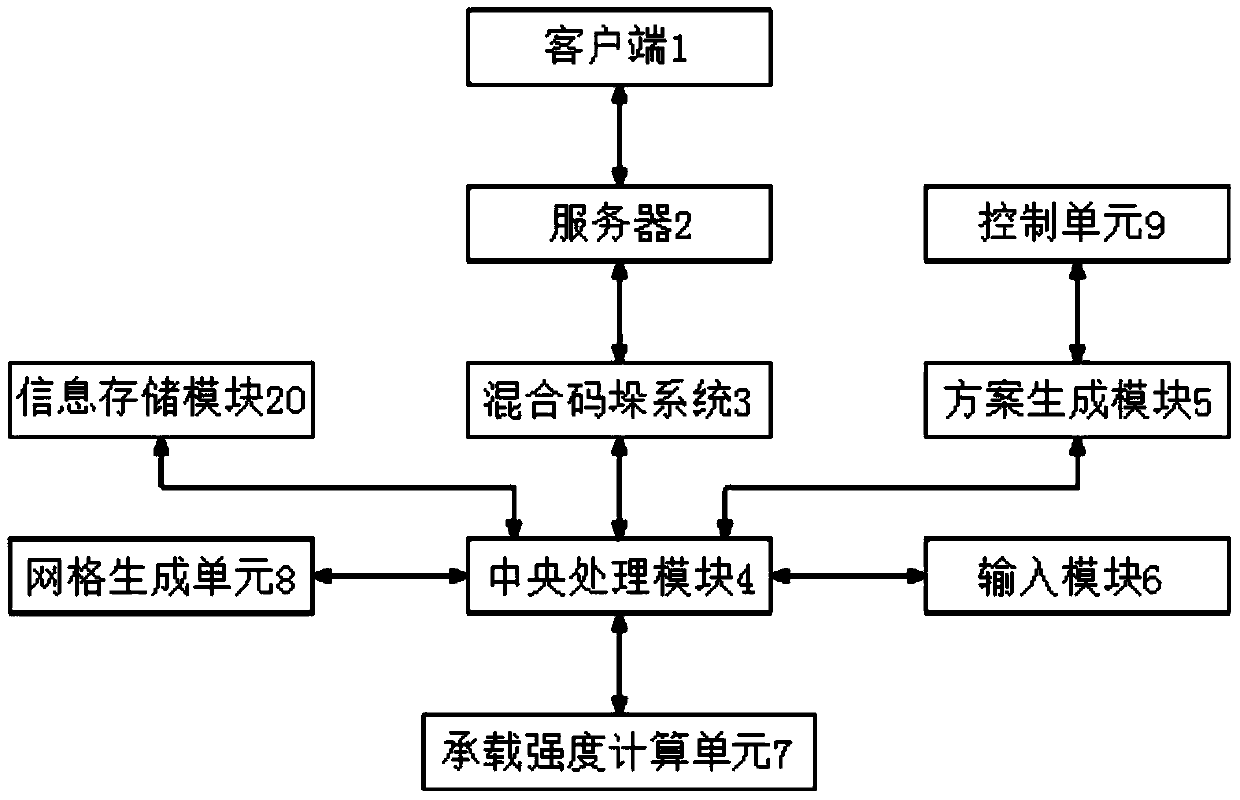

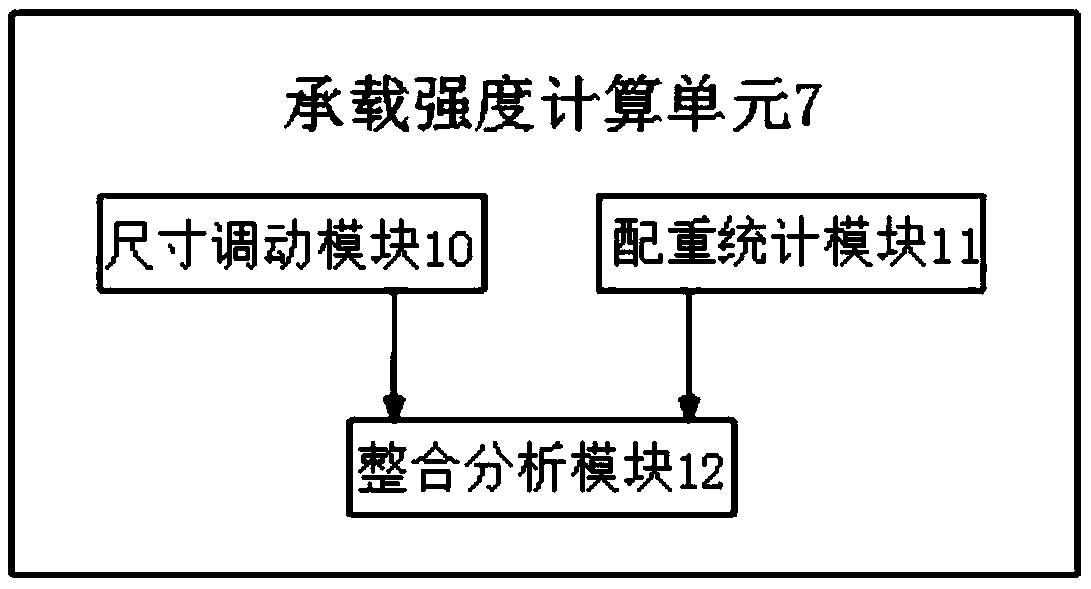

Offline mixed stacking method and system with high stacking stability

ActiveCN110723555AImprove stack stabilityEffective bearing strengthStacking articlesDe-stacking articlesAlgorithmIndustrial engineering

The invention discloses an offline mixed stacking method and system with high stacking stability. The method specifically comprises the following steps: (1) giving of box types and numbers: the box types are directly input in an input module by users; (2) composite blocks are generated; (3) optimal composite blocks capable of being accommodated by remaining space are searched; (4) the space cutting or transfer is performed; (5) stacking and boxing schemes are generated; and (6) space positions and placing directions of all boxes are output; and the method relates to the technical field of stacking. The offline mixed stacking method and system with high stacking stability calculate and count the product bearing capacity through set algorithms, can effectively guarantee the product integrityduring stacking to improve the product operation quality and stability, and meanwhile, can work offline to deviate from the network binding for independent work to reduce the probability of generating low product operation efficiency caused by accidental loss.

Owner:安吉智能物联技术有限公司

Online anode pressure bias to maximize bleed velocity while meeting emission constraint

ActiveUS20110189573A1Increases amount of water purgedSpeed maximizationFuel cell auxillariesHydrogenEngineering

A method that employs a model based approach to determine a maximum anode pressure set-point based on existing airflow in the exhaust gas line. This approach maximizes anode flow channel velocity during bleed events while meeting the hydrogen emission constraint, which in turn increases the amount of water purged from the anode flow channels to increase stack stability.

Owner:GM GLOBAL TECH OPERATIONS LLC

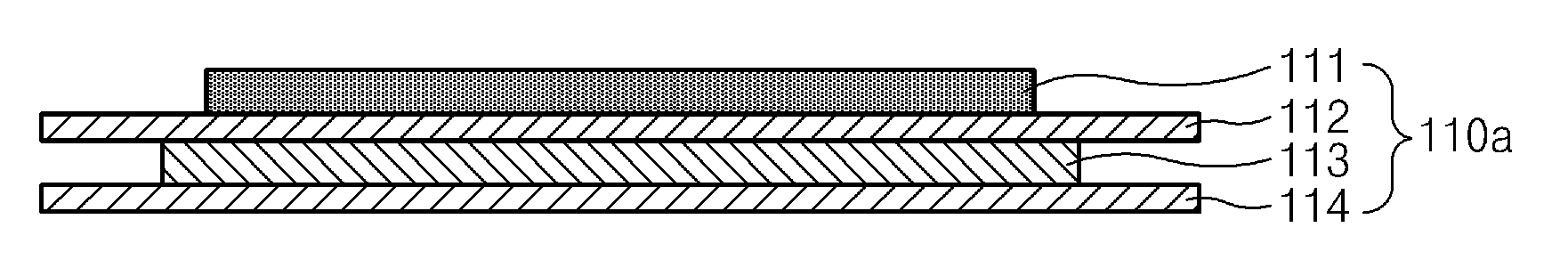

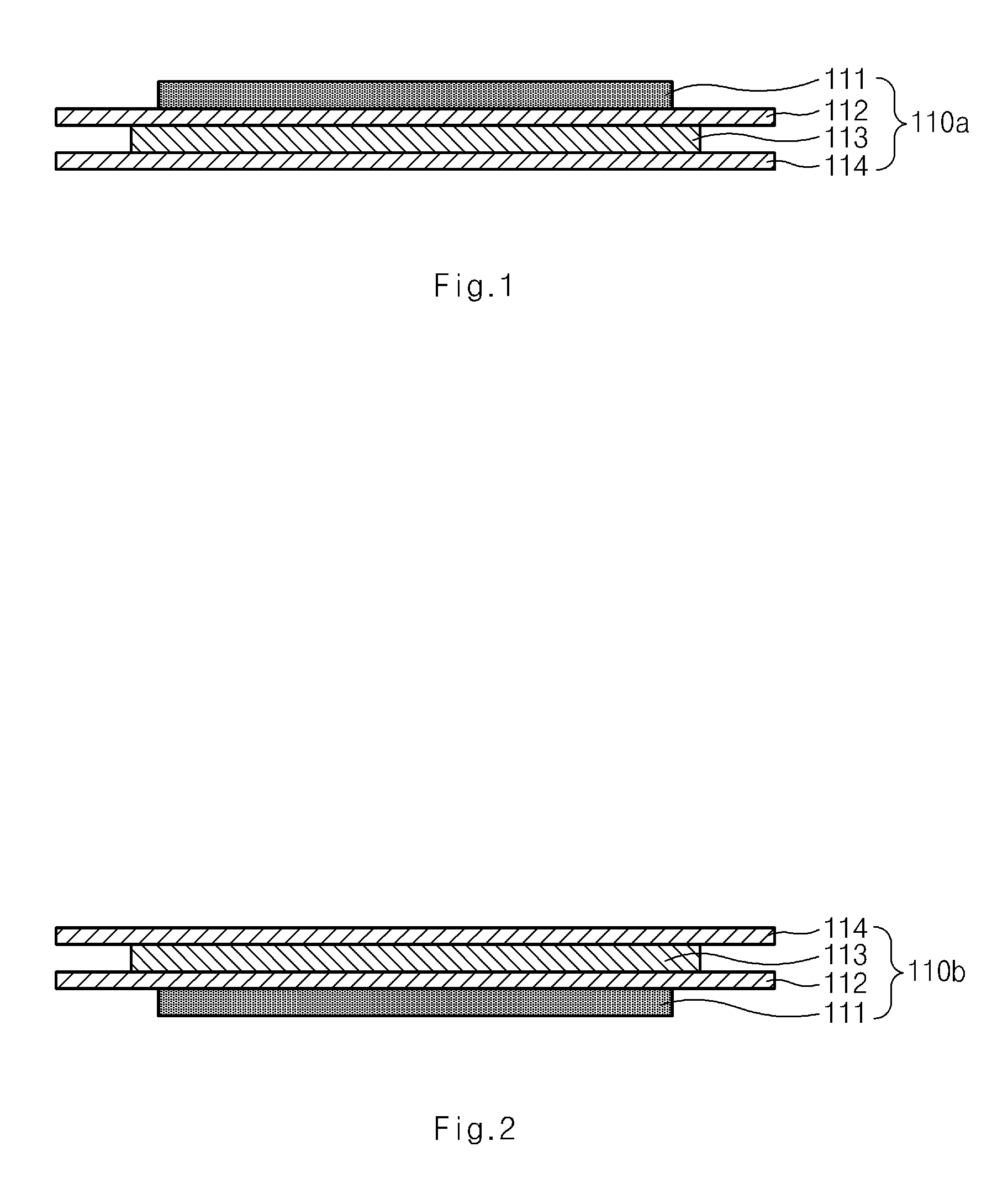

Electrode assembly

ActiveUS20150072241A1Easily realizeGood stacking stabilityLarge-sized flat cells/batteriesFinal product manufactureLayered structureEngineering

An electrode assembly includes a cell stack part having (a) a structure in which one kind of radical unit having a same number of electrodes and separators alternately disposed and integrally combined is repeatedly disposed, or (b) a structure in which at least two kinds of radical units having a same number of electrodes and separators alternately disposed and integrally combined are disposed in a predetermined order, and a fixing part extending from a top surface along a side to a bottom surface thereof for fixing the cell stack part. The one kind of radical unit has a four-layered structure in which first electrode, first separator, second electrode and second separator are sequentially stacked or a repeating structure in which the four-layered structure is repeatedly stacked, and each of the at least two kinds of radical units are stacked by ones to form the four-layered structure or the repeating structure.

Owner:LG ENERGY SOLUTION LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com