Energy accumulator module

a technology of energy accumulator and energy storage unit, which is applied in the manufacture of cell components, final product details, cell components, etc., can solve the problems of increasing assembly difficulty of corresponding energy storage units and additional connection components, and achieves simple insertion, reduce assembly costs, and accelerate assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

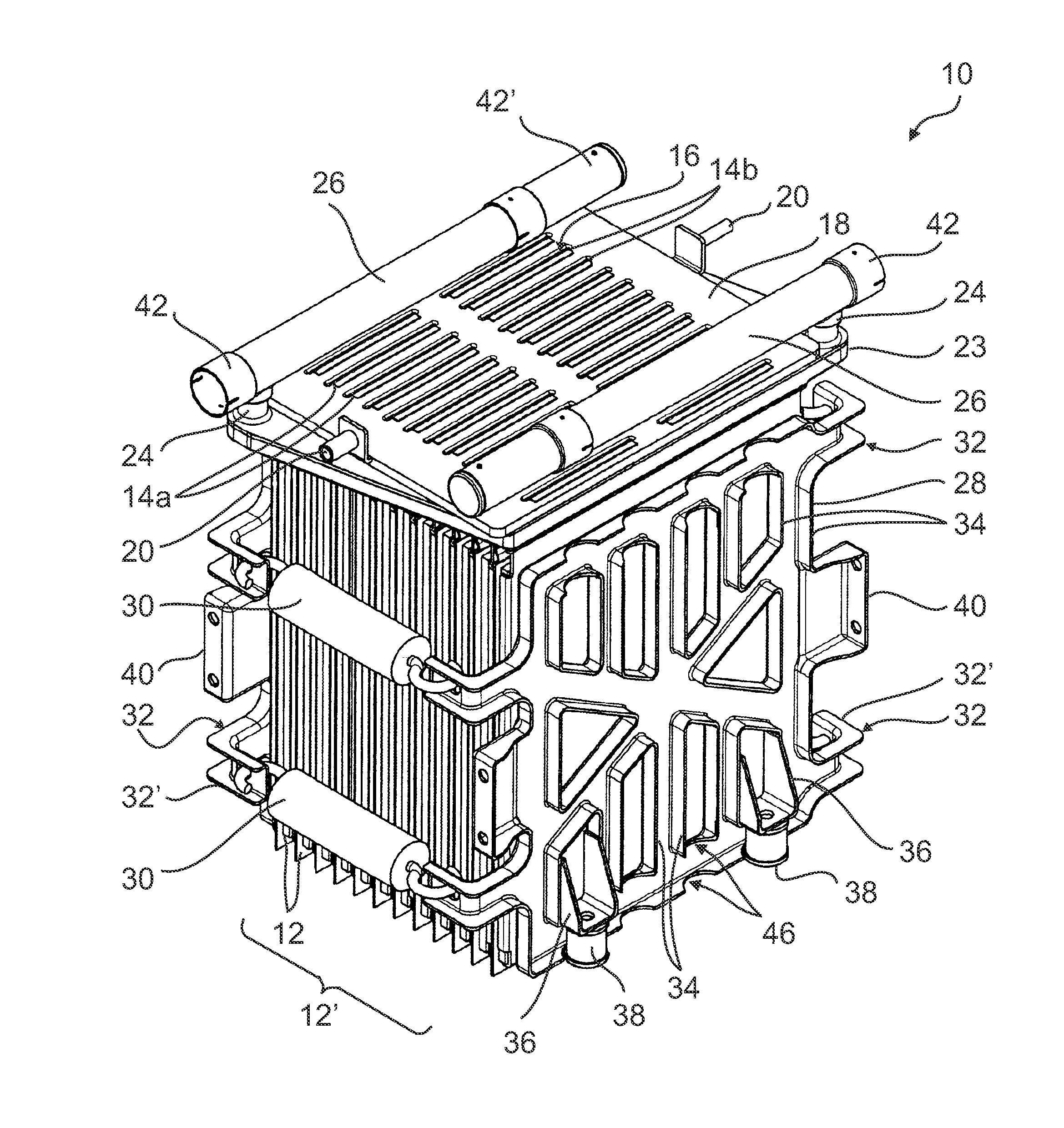

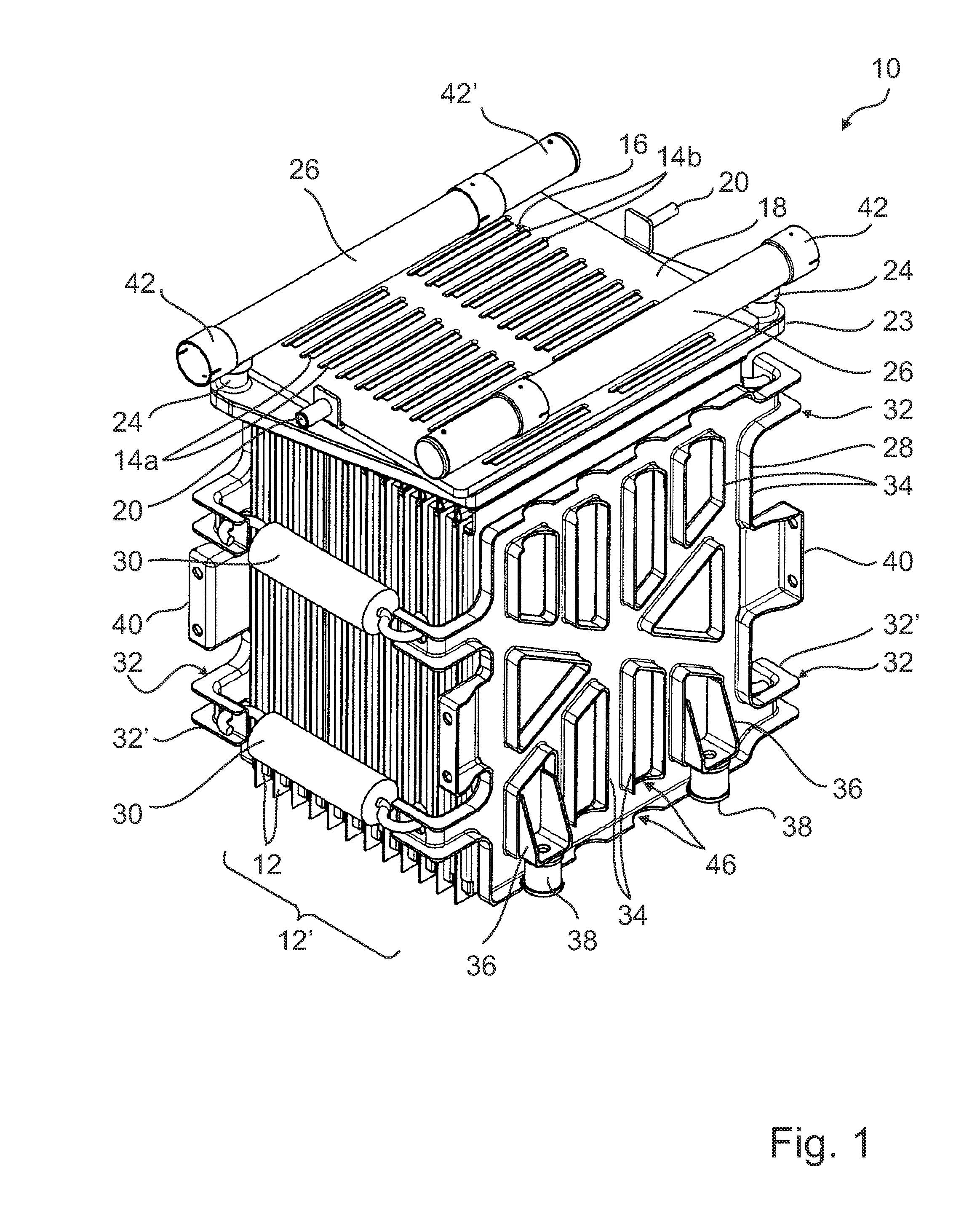

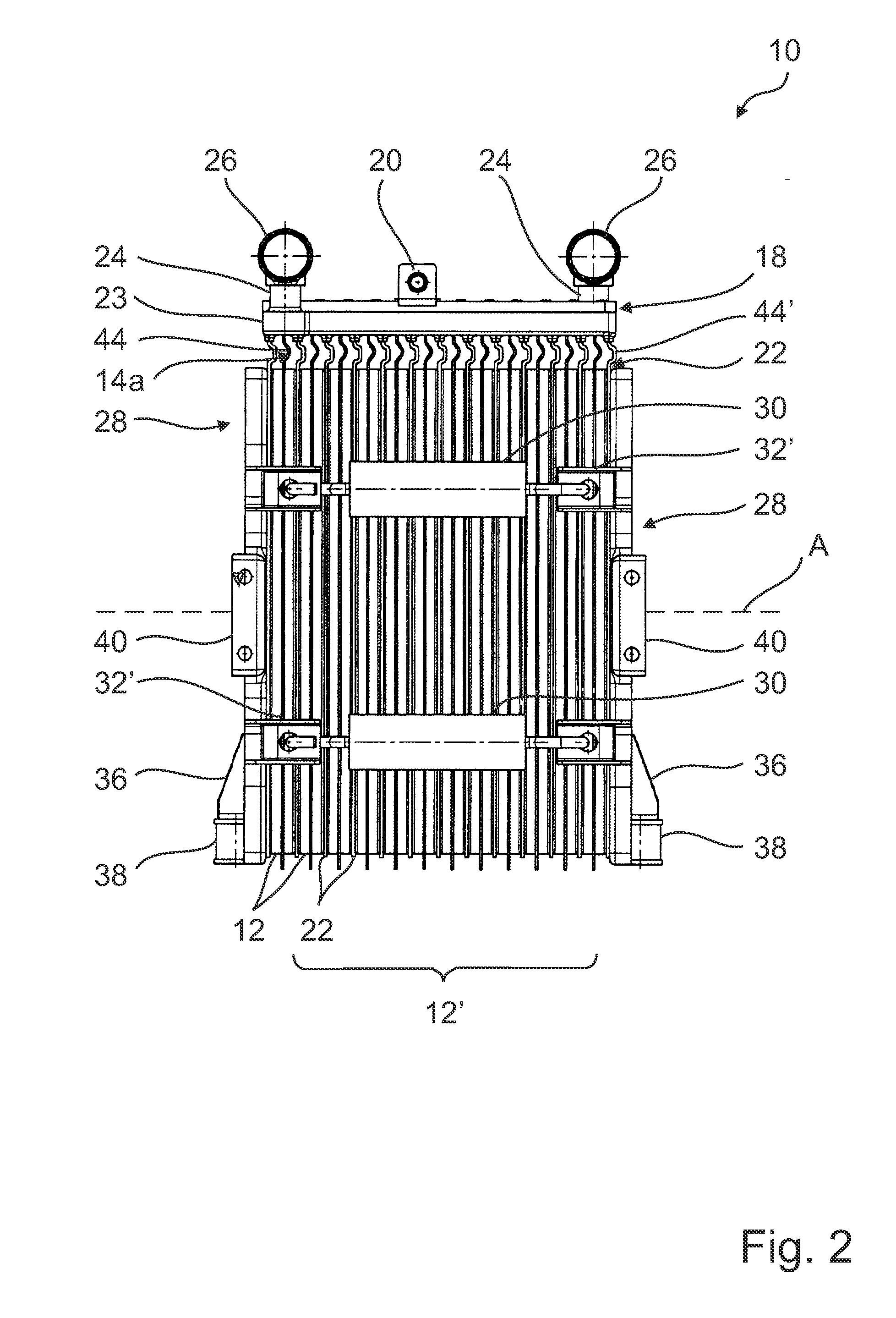

[0044]FIG. 1 shows a perspective view of an energy storage module 10 comprising a plurality of prismatic cells / flat cells 12 arranged in a cell stack 12′ in parallel with respect to one another. The flat cells 12 can, for example, be lithium-ion accumulator cells or double-layer capacitor cells (“supercaps”). Each of the individual cells 12 has two electrode tabs 14a, 14b, which are inserted through slots 16 of an interconnection board 18 provided for this purpose. The electrode tabs 14a, 14b reach through the interconnection board 18 and are, at the free top side thereof—i.e. at the side of the interconnection board 18 facing away from the flat cells 12-, connected to contact surfaces not shown, in order to provide electrical contact between the flat cells 12. The contacting between the flat cells 12 can, for example, be parallel or serial or comprise a mixed form of parallel and serial contacting.

[0045]The electrical energy stored in the flat cells 12 can be tapped via a plug and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com