Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

87results about How to "Improve performance on ice" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Pneumatic tire with tread

InactiveUS7671132B1Improve performance on iceImprove performanceSpecial tyresPolymer chemistryPlasticizer

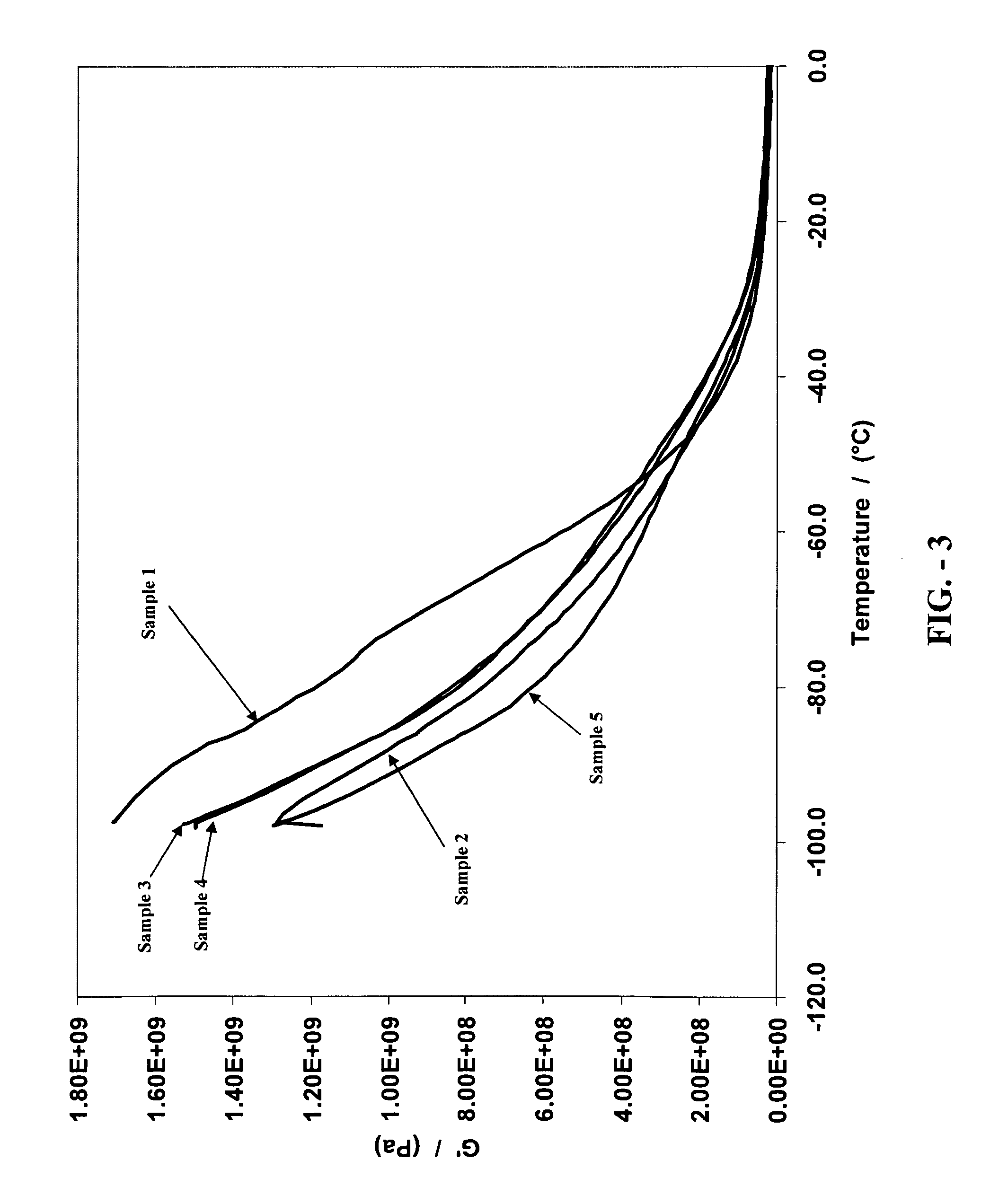

The present invention is directed to a pneumatic tire comprising a ground contacting tread, the tread comprising a rubber composition comprisingfrom 30 to 70 parts by weight, per 100 parts by weight of s first elastomer (phr) having a glass transition temperature Tg ranging from about −40° C. to about −10° C. and a solubility parameter ranging from about 4.1 MPa1 / 2 to about 4.5 MPa1 / 2;from 70 to 30 phr of a second elastomer having a Tg ranging from about −105° C. to about −30° C. and a solubility parameter ranging from about 3.7 MPa1 / 2 to about 4.1 MPa1 / 2;from 1 to 40 phr of a first plasticizer having a solubility parameter ranging from 3.4 MPa1 / 2 to 3.8 MPa1 / 2;from 1 to 20 phr of a second plasticizer having a solubility parameter ranging from 4.3 MPa1 / 2 to 4.7 MPa1 / 2; andfrom 30 to 150 phr of silica.

Owner:THE GOODYEAR TIRE & RUBBER CO

Tire

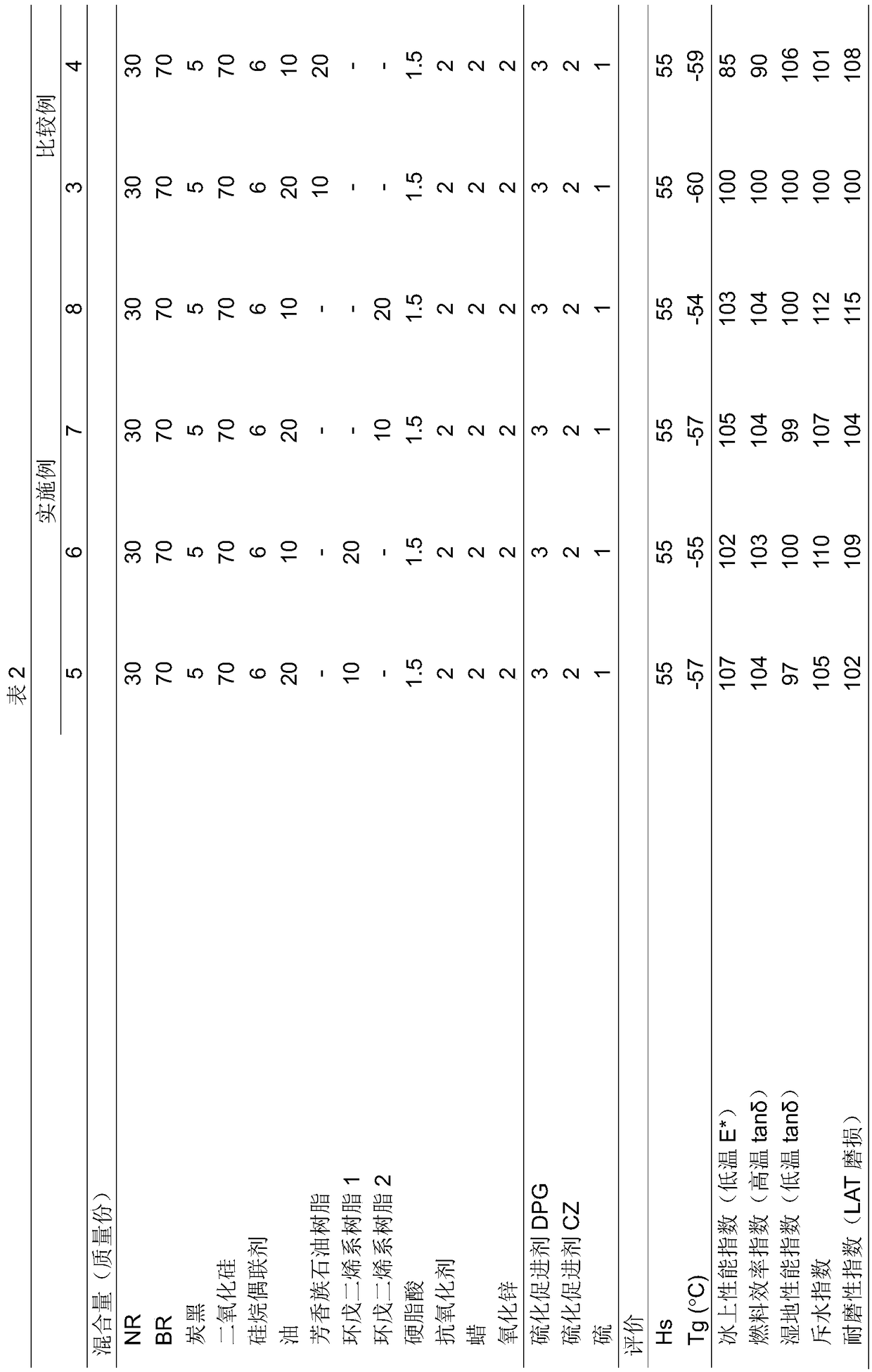

InactiveUS20110112212A1Reduce fuel consumptionImprove performance on iceSpecial tyresPolymer sciencePolymer chemistry

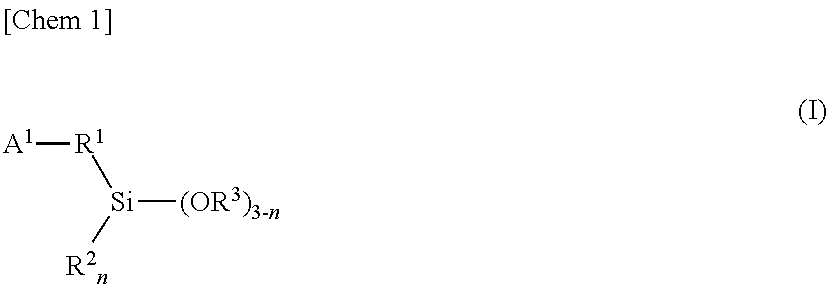

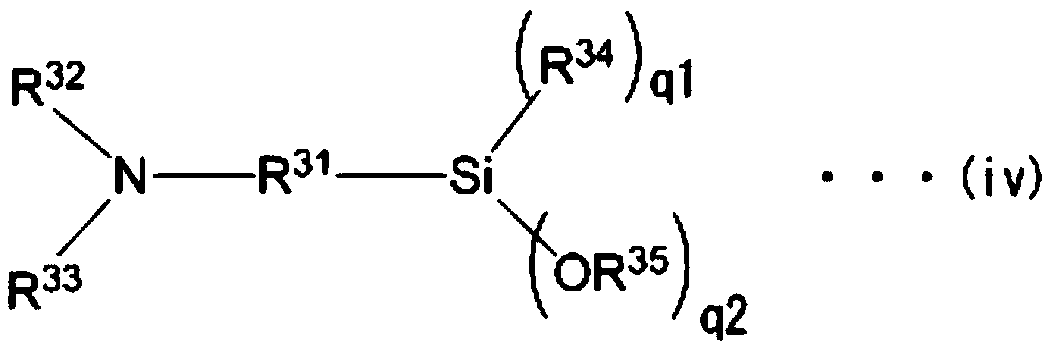

Provided is a tire using a rubber composition, in which: the rubber composition contains a rubber component and a filler; the rubber component contains (A) a modified conjugated diene polymer and (B) a modified conjugated diene-aromatic vinyl copolymer; a modifying agent used for each of the component (A) and the component (B) includes (C) a hydrocarbyloxysilane compound containing a nitrogen atom and a silicon atom or (D) a hydrocarbyloxysilane compound containing a silicon atom; a combination of an unmodified conjugated diene polymer and the modifying agent, and a combination of an unmodified conjugated diene-aromatic vinyl copolymer and the modifying agent include any one of the following items 1 to 3: 1: the conjugated diene polymer and the component (C), and the conjugated diene-aromatic vinyl copolymer and the component (D); 2: the conjugated diene polymer and the component (D), and the conjugated diene-aromatic vinyl copolymer and the component (C); and 3: the conjugated diene polymer and the component (C), and the conjugated diene-aromatic vinyl copolymer and the component (C); and the filler contains silica and carbon black at a mass ratio of 10:90 to 80:20, the tire having good low fuel consumption, good on-ice performance, good wet performance, and good dry performance.

Owner:BRIDGESTONE CORP

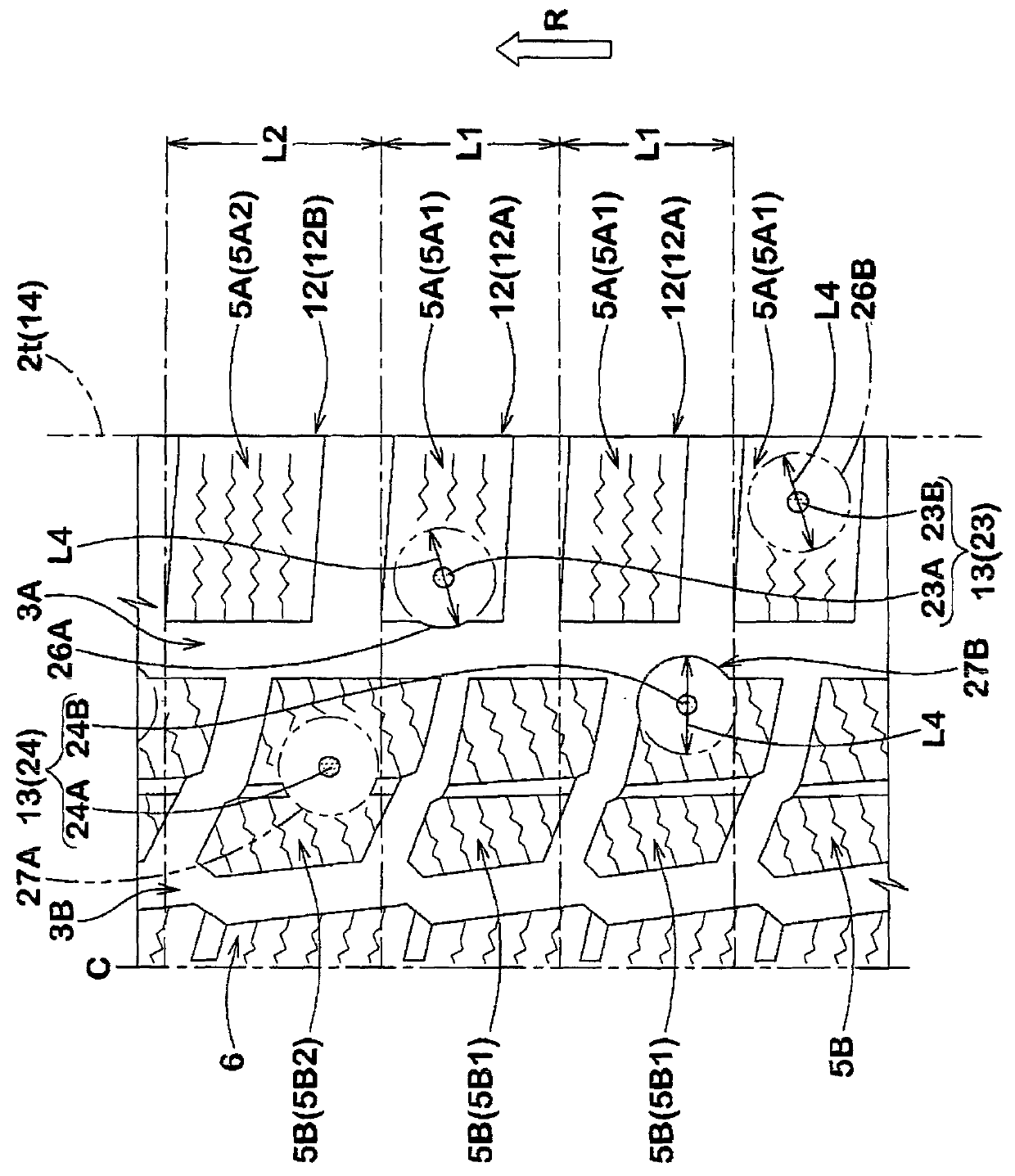

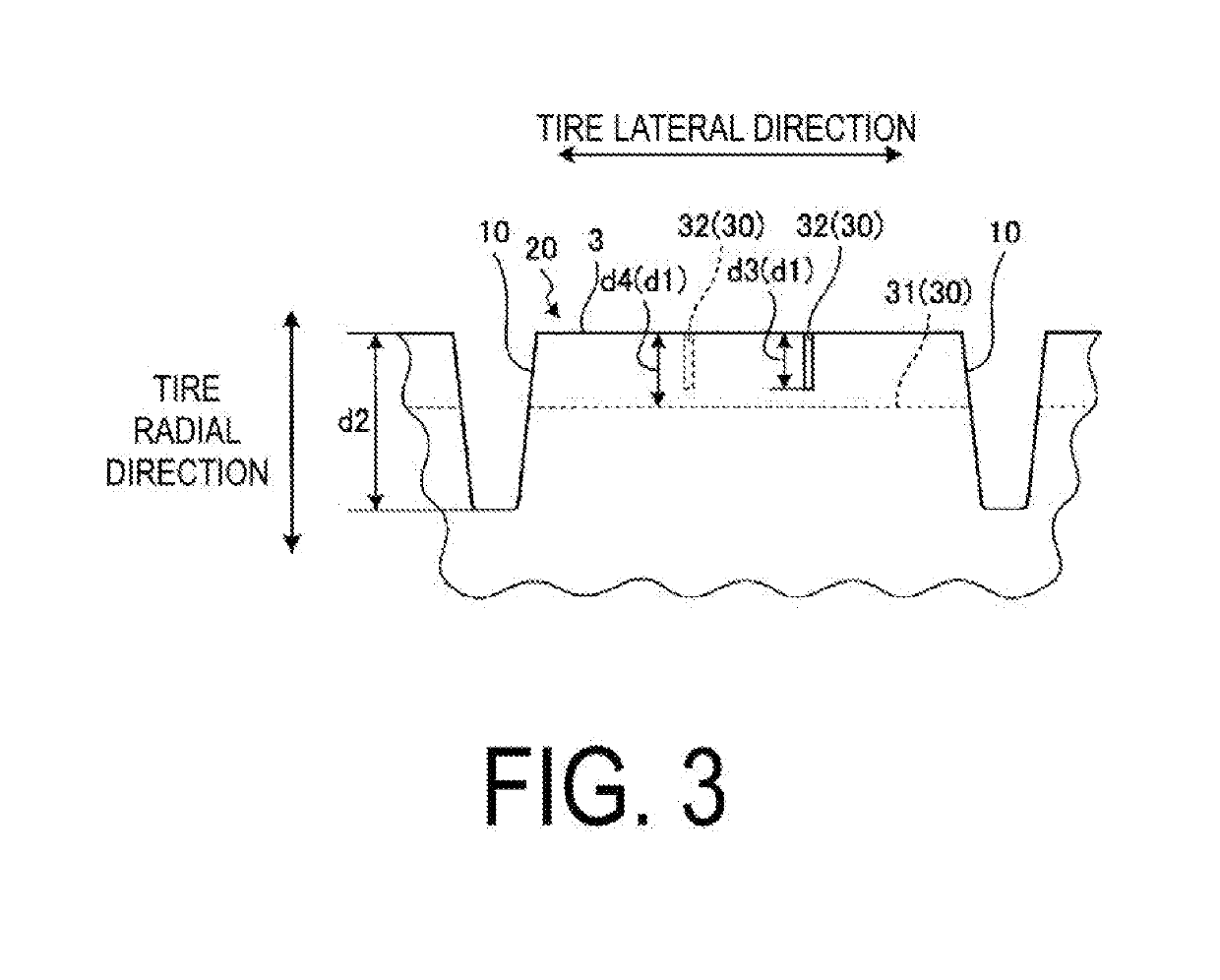

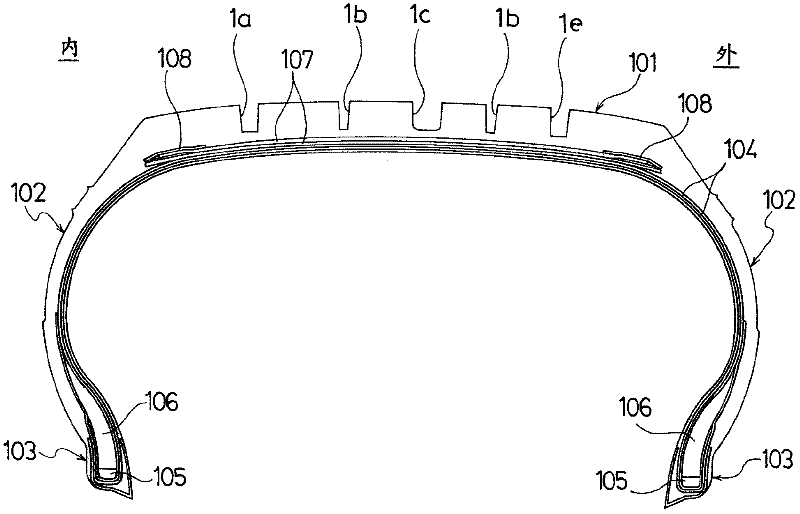

Pneumatic tire

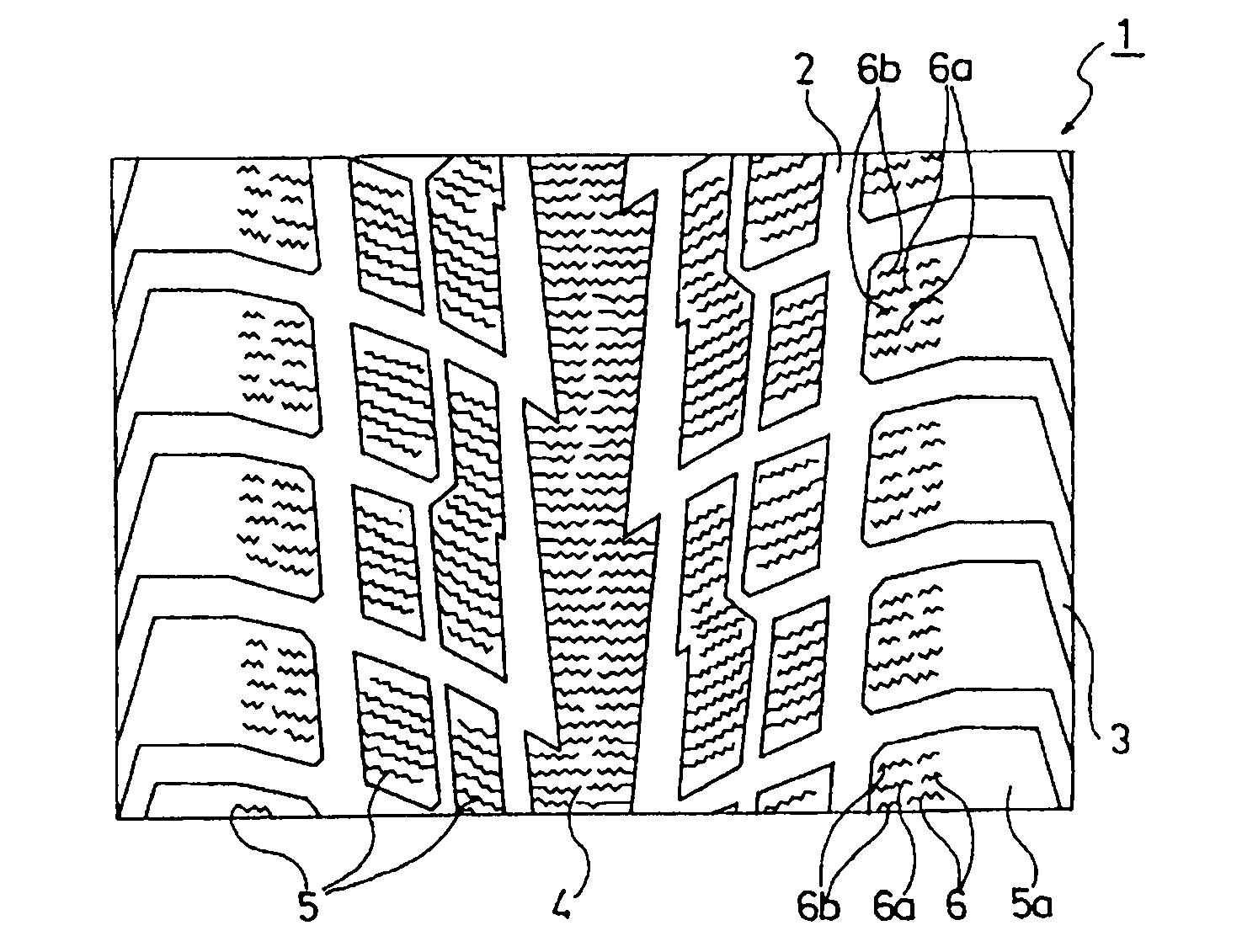

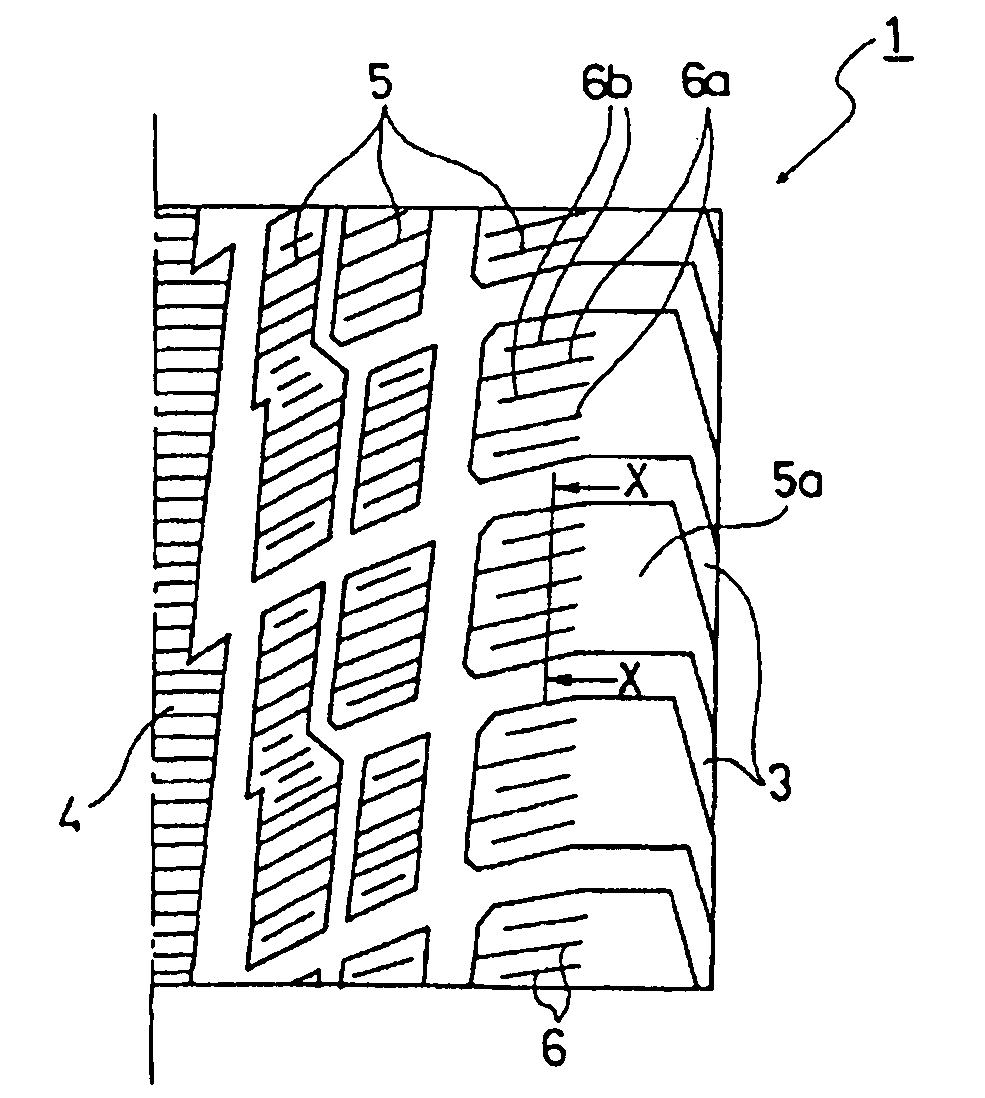

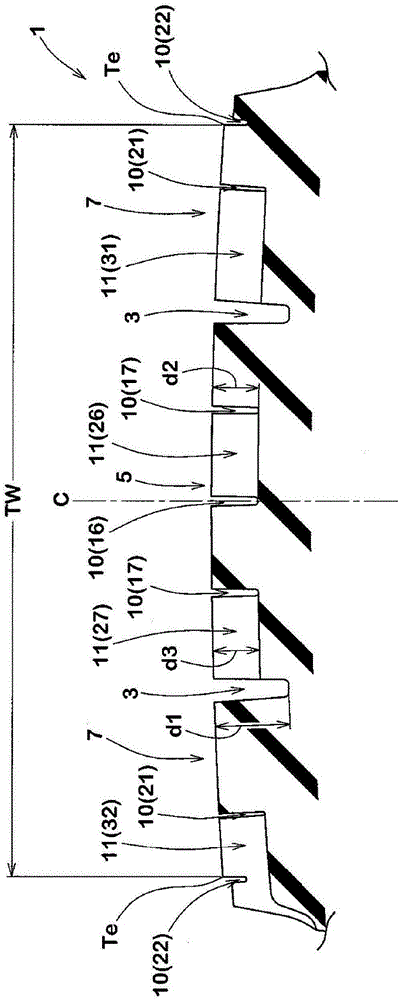

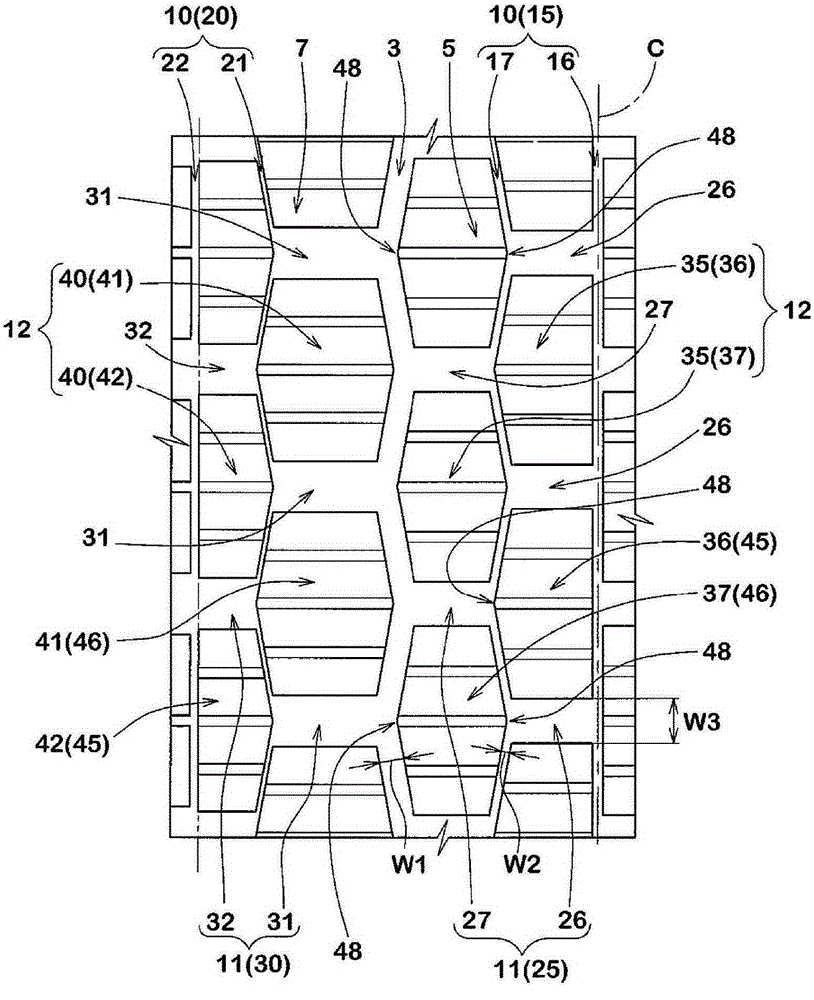

InactiveCN101678722AImprove performance on iceGuaranteed drainage functionTyre tread bands/patternsEngineeringRoad surface

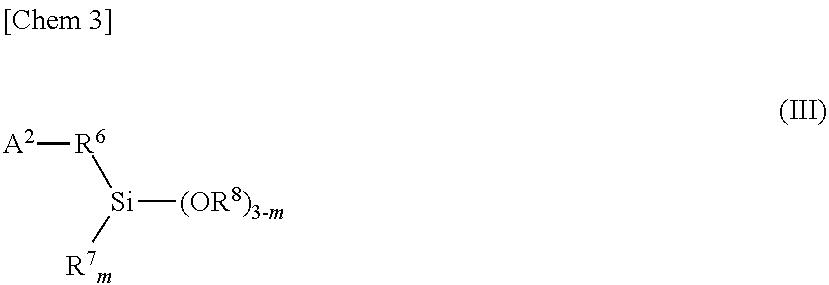

A pneumatic tire achieving good on-ice performance and good wet performance at the same time is provided. A pair of first main grooves extending in the circumferential direction of the tire is provided in the center region of a tread. A pair of second main grooves extending in the circumferential direction of the tire is provided on both the outer sides of the pair of first main grooves. First luggrooves and second lug grooves are alternately arranged in the circumferential direction of the tire such that the first lug grooves extend inward in the lateral direction of the tire from each shoulder end of the tread and communicate with the corresponding one of the first main grooves and further such that the second lug grooves extend inward in the lateral direction of the tire from the shoulder end of the tread and do not communicate with the corresponding one of the first main grooves. A center rib is arranged to extend between the pair of first main grooves. A shoulder block row composed of blocks is arranged between each second main groove and the corresponding one of the shoulder ends, and an intermediate shoulder block row composed of blocks is arranged between the second main groove and the adjacent one of the first main grooves. In the intermediate shoulder block row are arranged long blocks having a circumferential length equivalent to the length of two blocks of the shoulder block row.

Owner:THE YOKOHAMA RUBBER CO LTD

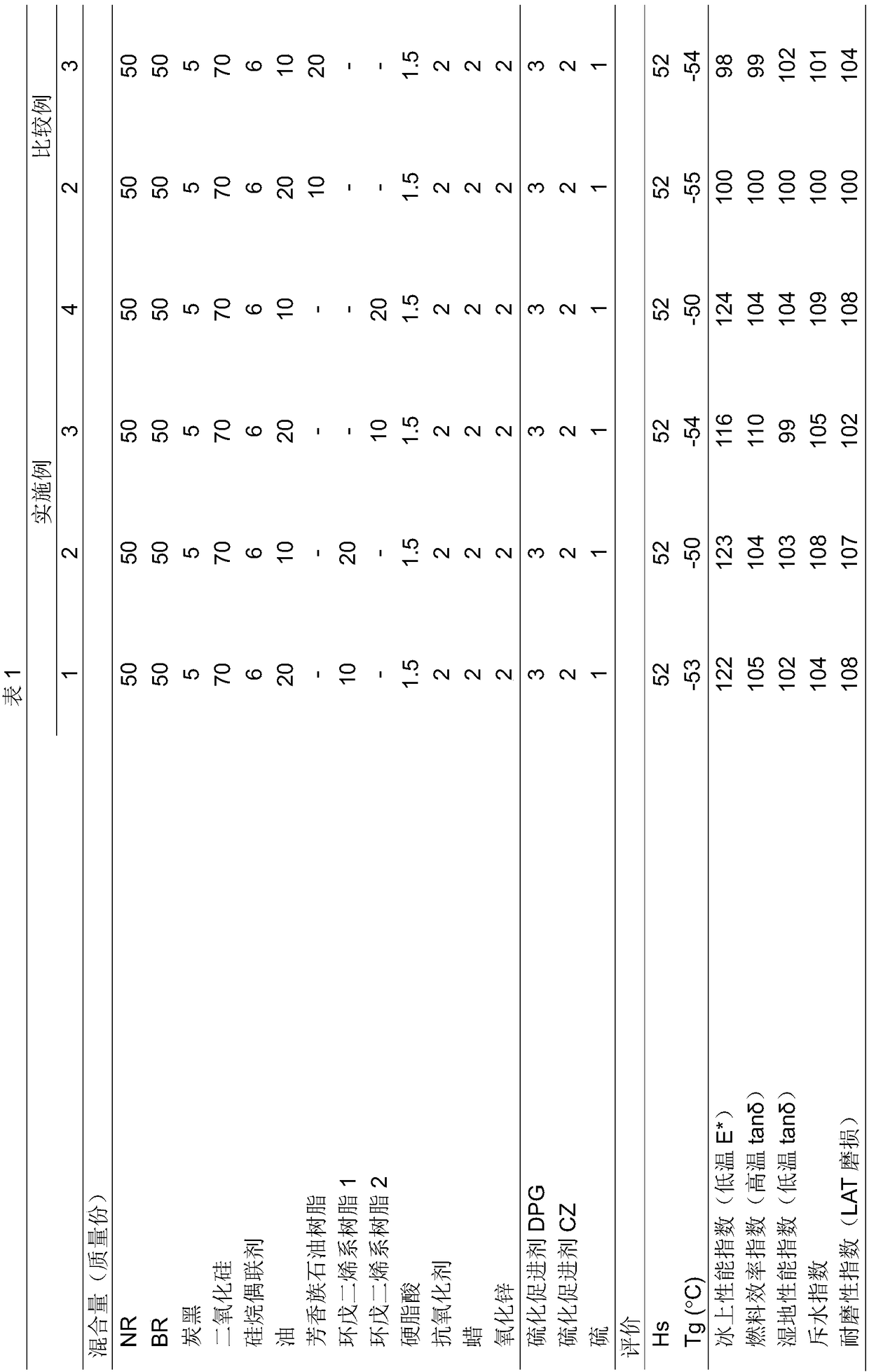

Rubber composition and pneumatic tire using the same

InactiveUS20090306269A1Improve propertiesImprove performance on iceSpecial tyresTyre tread bands/patternsFiberPolymer science

Provide are a rubber composition which enhances a reinforcing property with a filler and maintains a DRY performance and which has an excellent on-ice performance and a pneumatic tire prepared by using the above rubber composition for a tread. The rubber composition is characterized by having independent air bubbles and comprising (A) a rubber component comprising a natural rubber and an end-modified conjugated diene base polymer, (B) a fine particle-containing organic fiber and (C) a filler.

Owner:BRIDGESTONE CORP

Pneumatic tire

ActiveCN103182902ASmooth dischargeImprove drainage capacityTyre tread bands/patternsEngineeringRoad surface

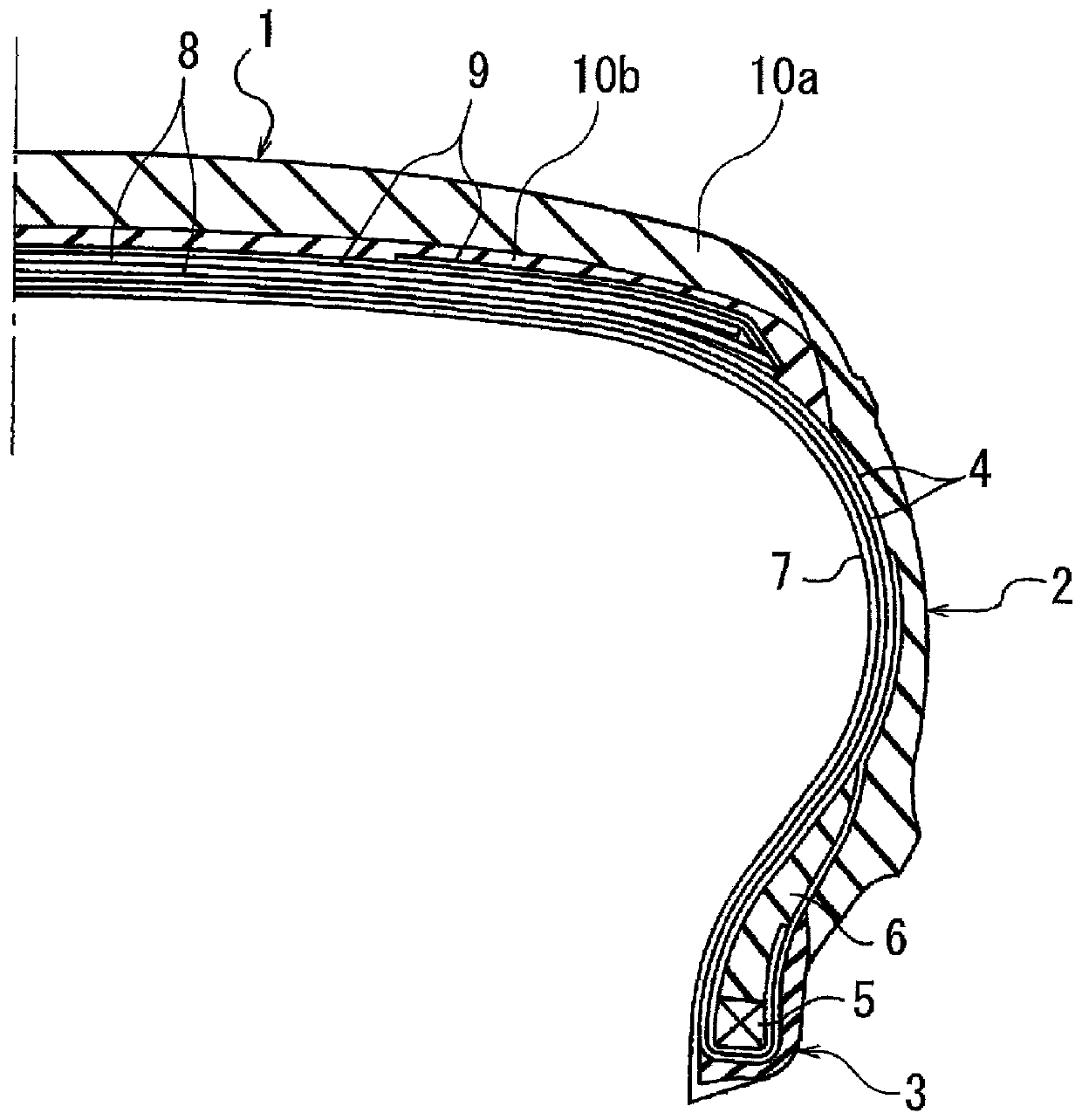

The present invention provides a pneumatic tire capable of improving the drainage performance, on-snow performance, and on-ice performance while maintaining the steering stability on a dry road surface. The pneumatic tire (1) has a designated mounting orientation with respect to a vehicle. A tread portion (2) divided into a center land portion (6), an outer middle land portion (7A), an inner middle land portion (7B), an outer shoulder land portion (8A), and an inner shoulder land portion (8B); the outer shoulder land portion (8A) enables outer shoulder blocks (22) which are sectioned by outer shoulder lateral grooves (5A) to be arranged circumferentially on the tire in a space manner; the inner shoulder land portion includes inner shoulder lateral grooves (26) having outer ends which are on the outside of the vehicle and form terminals in the land portion (8B), and inner shoulder auxiliary grooves (28); the inner middle land portion includes an inner middle sub-groove (18) which continuously extends in a circumferential direction and inner middle sipes (21) which extend between the inner middle sub-groove and the inner center longitudinal groove (3B).

Owner:SUMITOMO RUBBER IND LTD

Pneumatic tire

ActiveCN104275988AImprove on-snow performanceImprove performance on iceTyre tread bands/patternsEngineering

Owner:SUMITOMO RUBBER IND LTD

Pneumatic tire

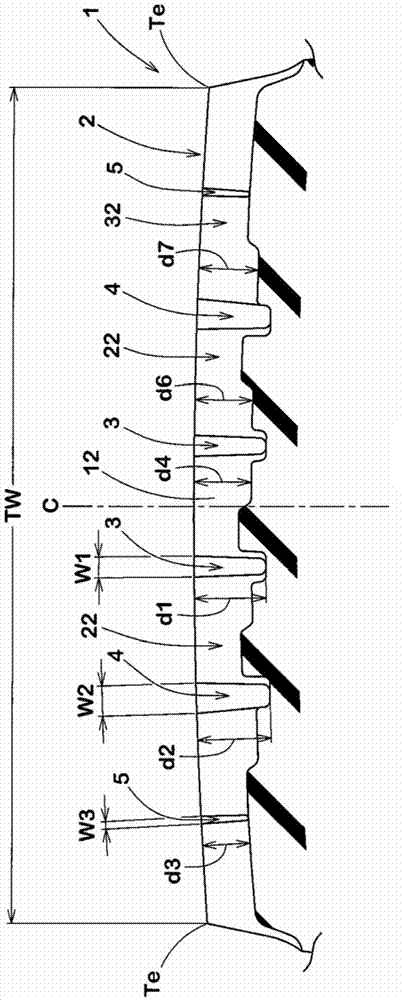

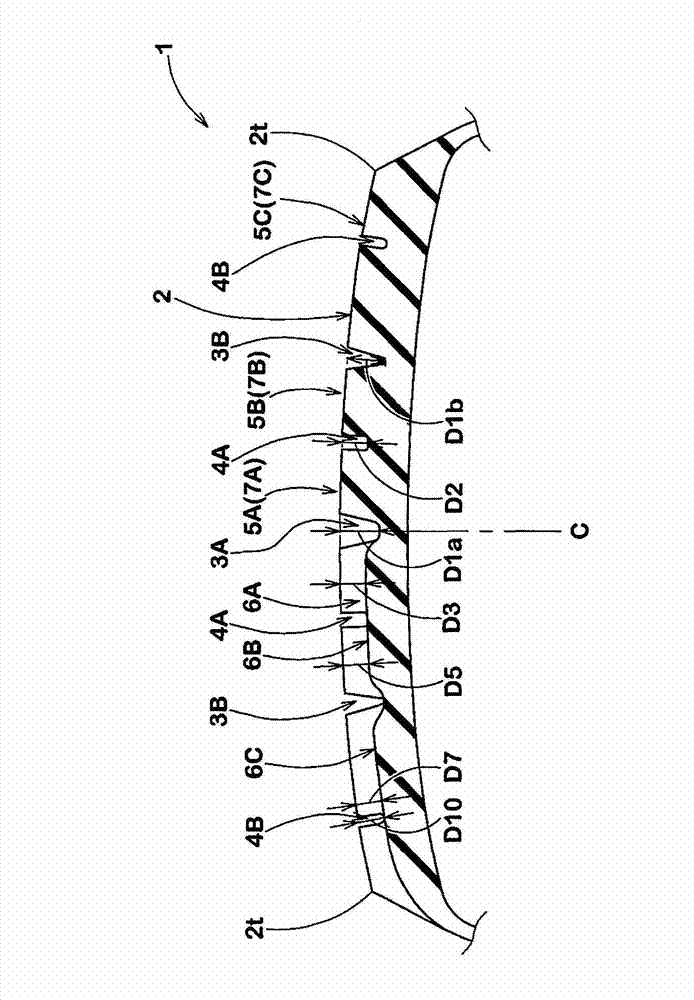

ActiveCN103303068ASmooth dischargeImprove on-snow performanceTyre tread bands/patternsMain channelChannel width

The invention provides a pneumatic tire, which can greatly improve performance on snow and draining performance. A tire face part (2) of the pneumatic tire (10) is provided with a central main channel (3A), a pair of tire shoulder main channels (3B), and a pair of central auxiliary channels (4A), and thereby an external side central land part (5B) and a tire shoulder land part (5C) are formed. The channel width (W1a) of the central main channel (3A) is larger than the channel width (W1b) of the tire shoulder main channels (3B). A tire shoulder transverse channel (6C) is disposed at the tire shoulder land part (5C). The angle (Alpha 7) of the tire shoulder transverse channel (6C) is larger than the angle (Alpha 4) of an outer side central transverse channel (6B). An outer end (6Bo) by which the outer side central transverse channel (6B) is communicated with the tire shoulder main channels (3B) and an inner end (6Ci) by which the tire shoulder transverse channel (6C) is communicated with the tire shoulder main channels (3B) are oppositely disposed with the tire shoulder main channel (3B) being arranged therebetween.

Owner:SUMITOMO RUBBER IND LTD

Tire

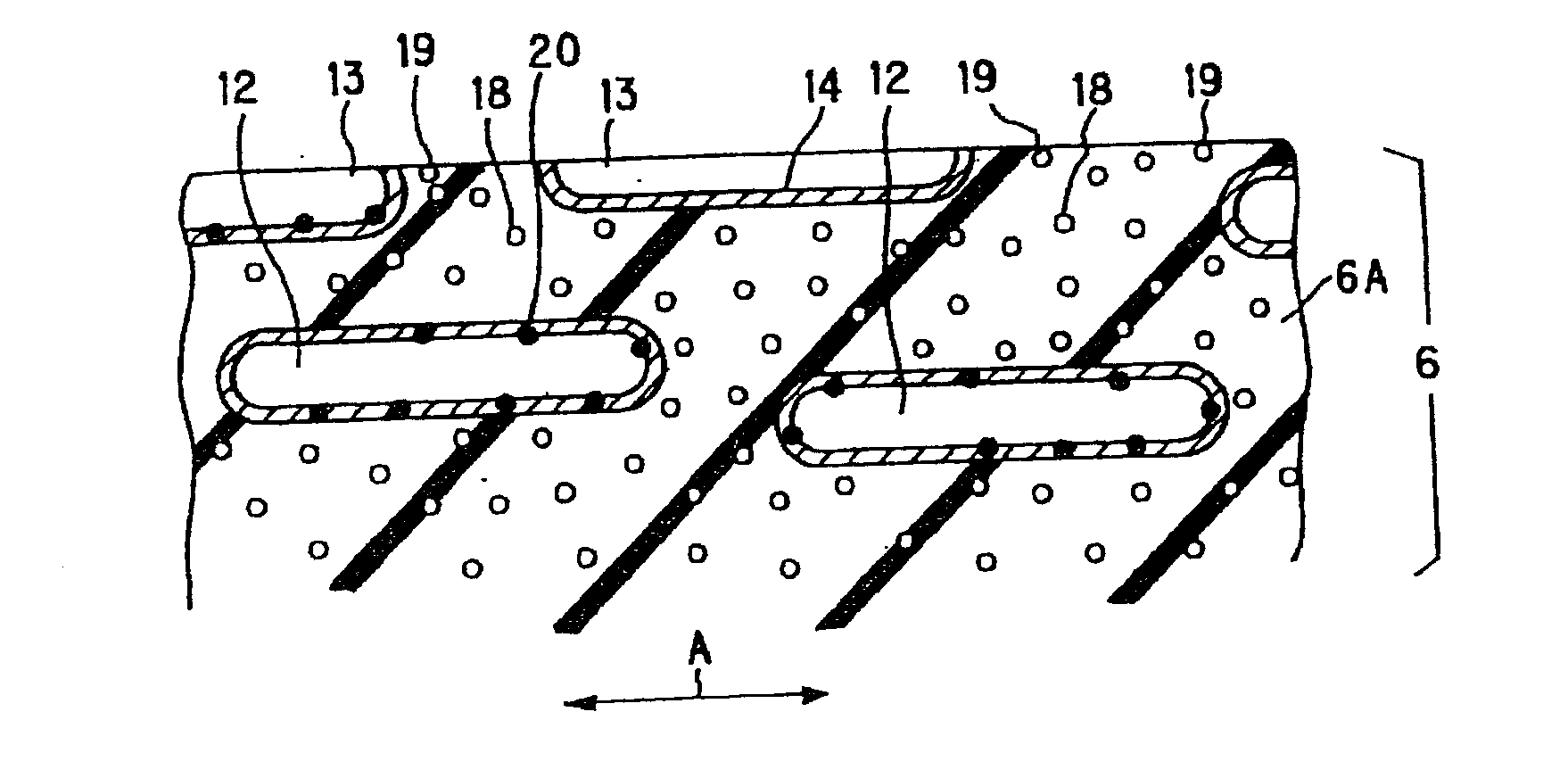

InactiveUS20080105346A1Improve drivabilityMaintain good propertiesSpecial tyresTyre tread bands/patternsRoad surfaceMechanical engineering

In order to solve the various conventional problems described above, the present invention provides a tire which is excellent in a braking property and a drivability (WET performance) on a wet road surface and which sufficiently displays an edge effect or a spike effect and is excellent in an on-ice performance (surface braking and driving performance). Further, the present invention provides a tire which enhances a workability in a plant and in which micro drain ditches exhibiting a water film-removing performance are surely formed. A foamed rubber layer provided on a surface of the tire substantially brought into contact with a road surface contains at least one inorganic compound powder having a particle diameter of 10 μm or less in a range of 5 to 20 mass parts per 100 mass parts of a rubber component.

Owner:BRIDGESTONE CORP

Pneumatic tire

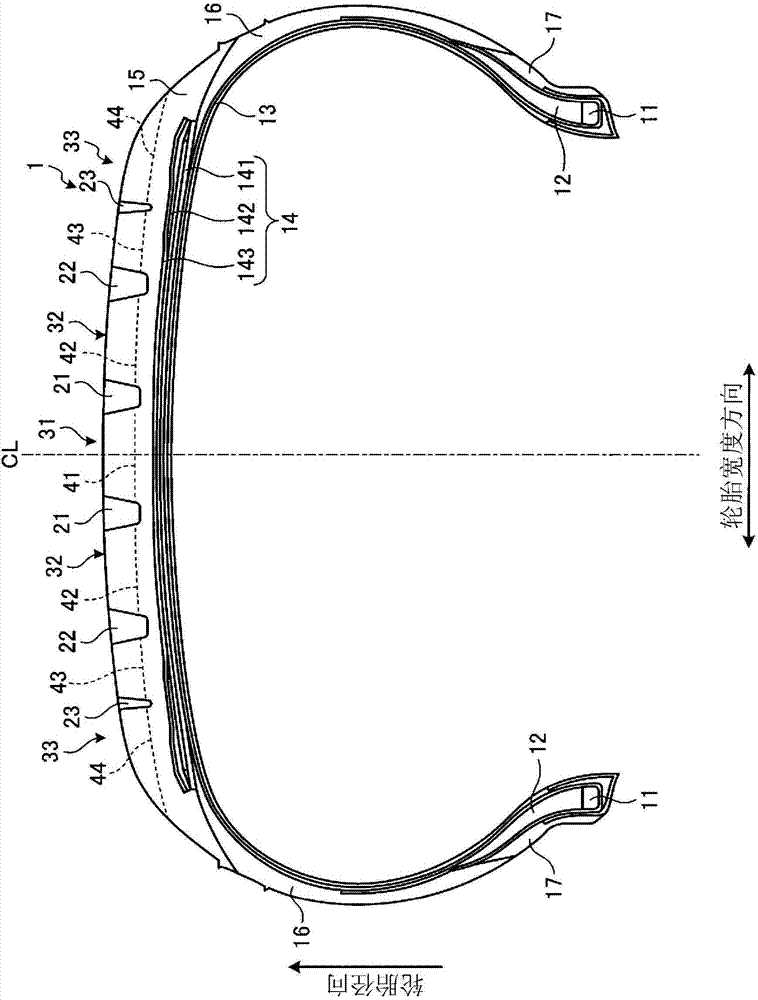

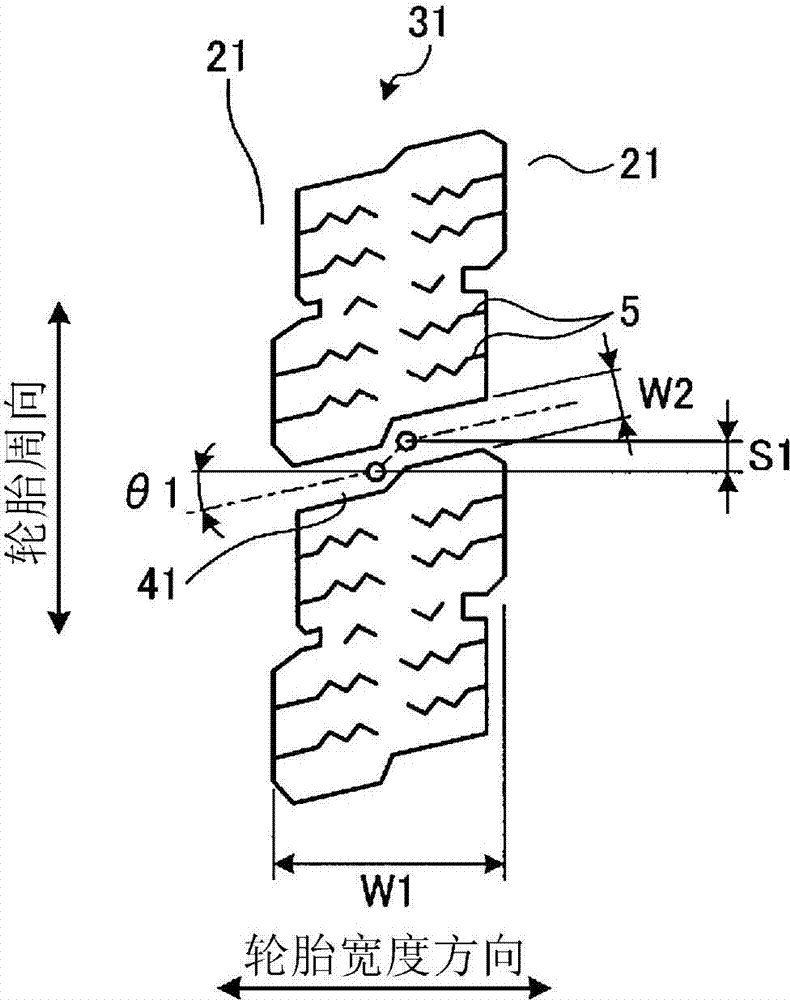

InactiveCN104768774AImprove performance on iceImprove on-snow performanceTyre tread bands/patternsEngineeringTread

This pneumatic tire (1) is provided with at least four circumferential main grooves (21, 22) extending in a tire circumferential direction, and a plurality of land portions (31-33) formed by being demarcated by the circumferential main grooves (21, 22). The pneumatic tire is further provided with a first lug groove (41) penetrating the center land portion (31) in a tire width direction, a circumferential narrow groove (23) disposed in the shoulder land portion (33) and extending in the tire circumferential direction, a second lug groove (43) extending inward from the circumferential narrow groove (23) in the tire width direction and open to the outermost circumferential main groove (22), and a third lug groove (44) extending outward from the circumferential narrow groove (23) in the tire width direction, open to a tread end, and disposed to be positionally displaced from the second lug groove (43) in the tire circumferential direction. The first lug groove (41) has a bent shape and is open with a see-through structure to the right and left circumferential main grooves (21, 22) that demarcate the center land portion (31).

Owner:THE YOKOHAMA RUBBER CO LTD

Pneumatic tire

InactiveCN102123878AImprove bending rigidityImprove performance on iceTyre tread bands/patternsMechanical engineering

Owner:THE YOKOHAMA RUBBER CO LTD

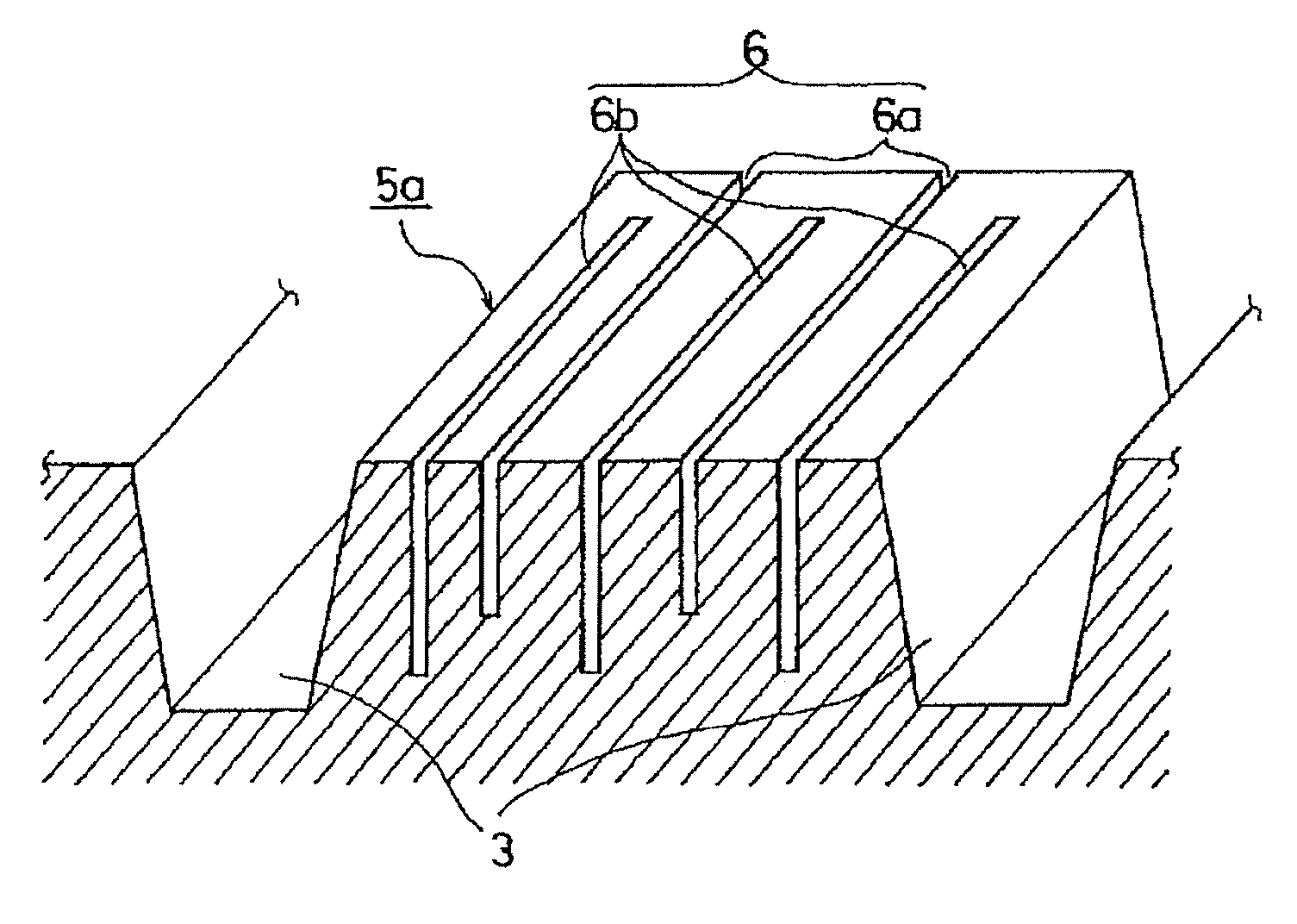

Pneumatic tire

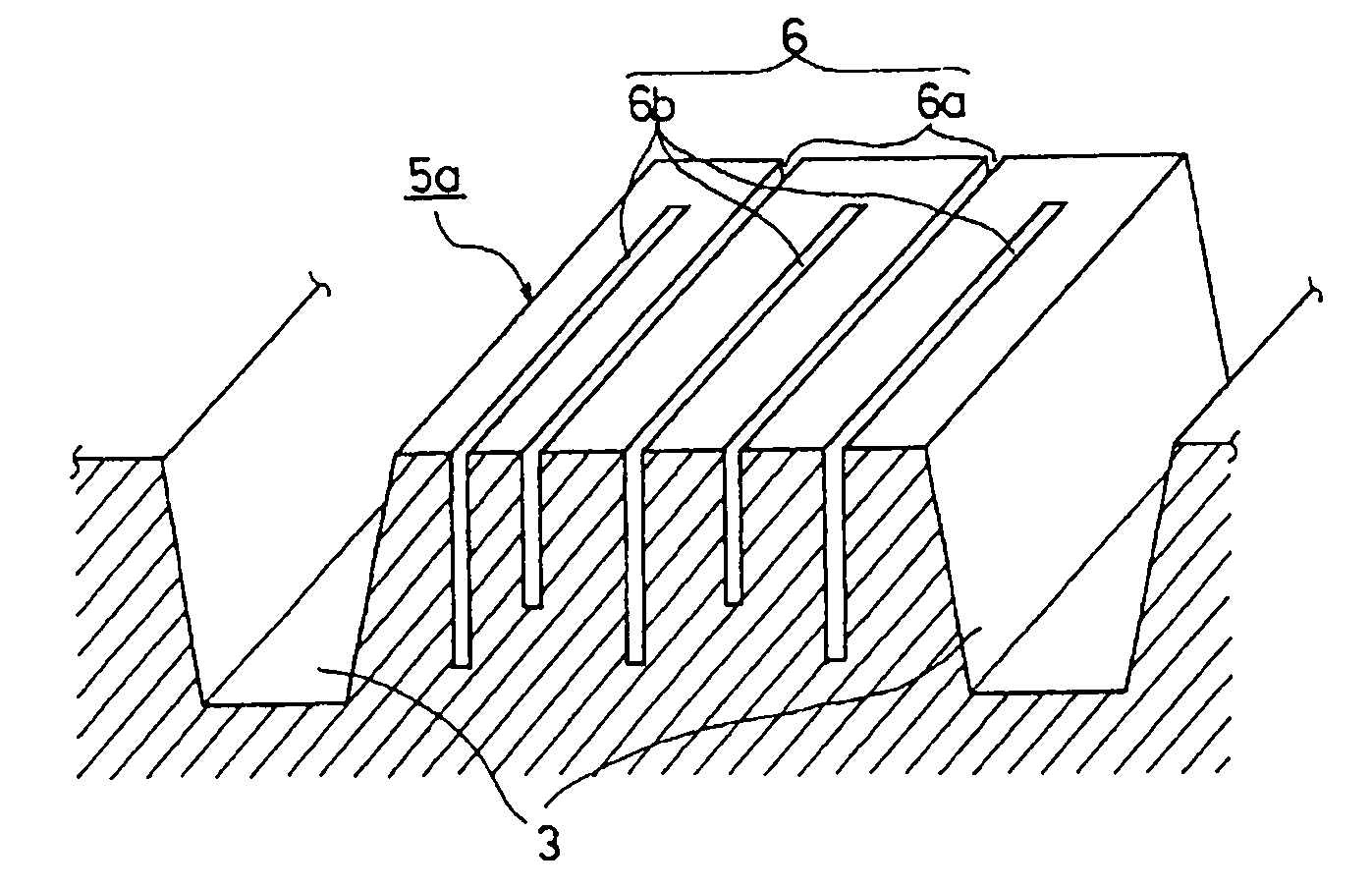

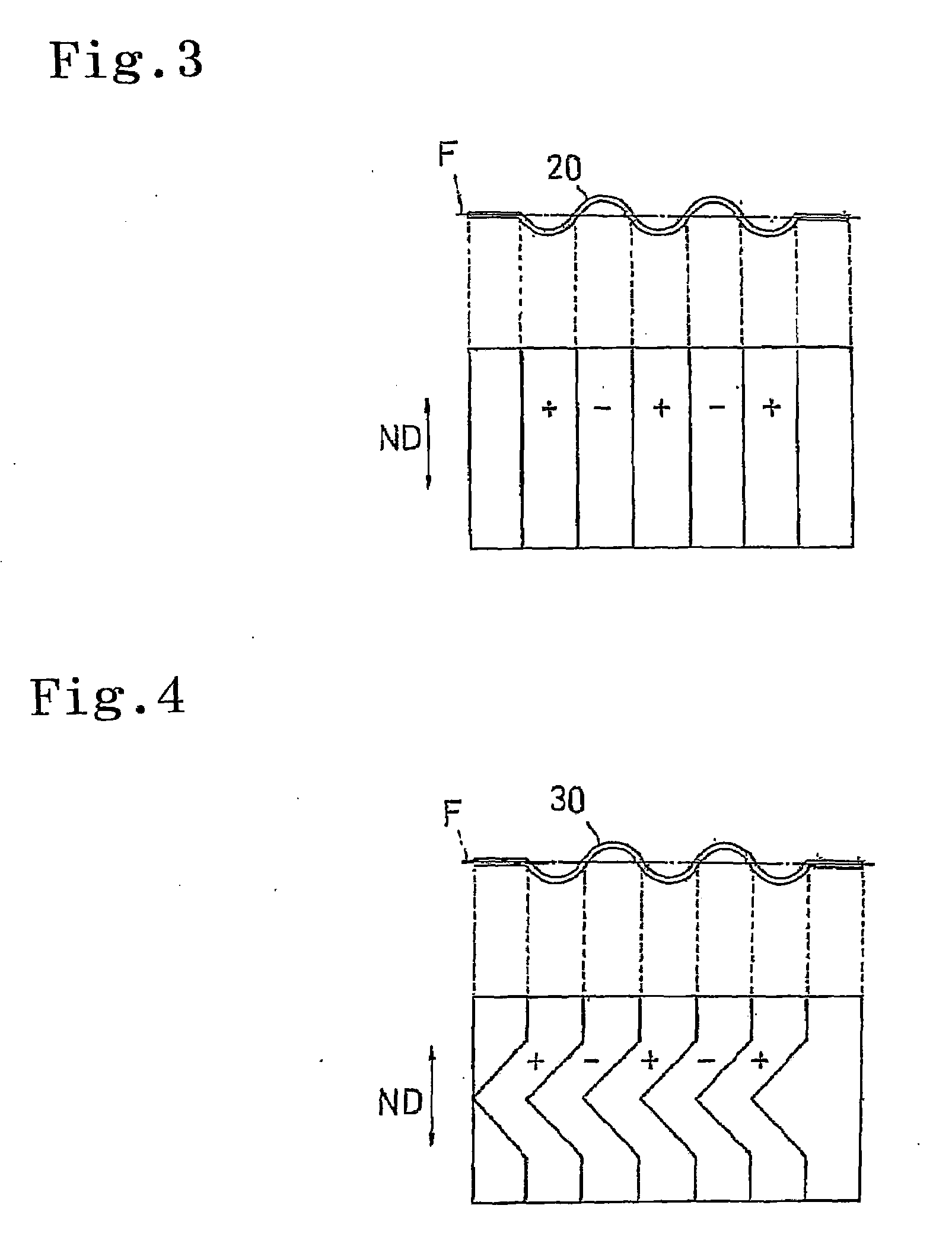

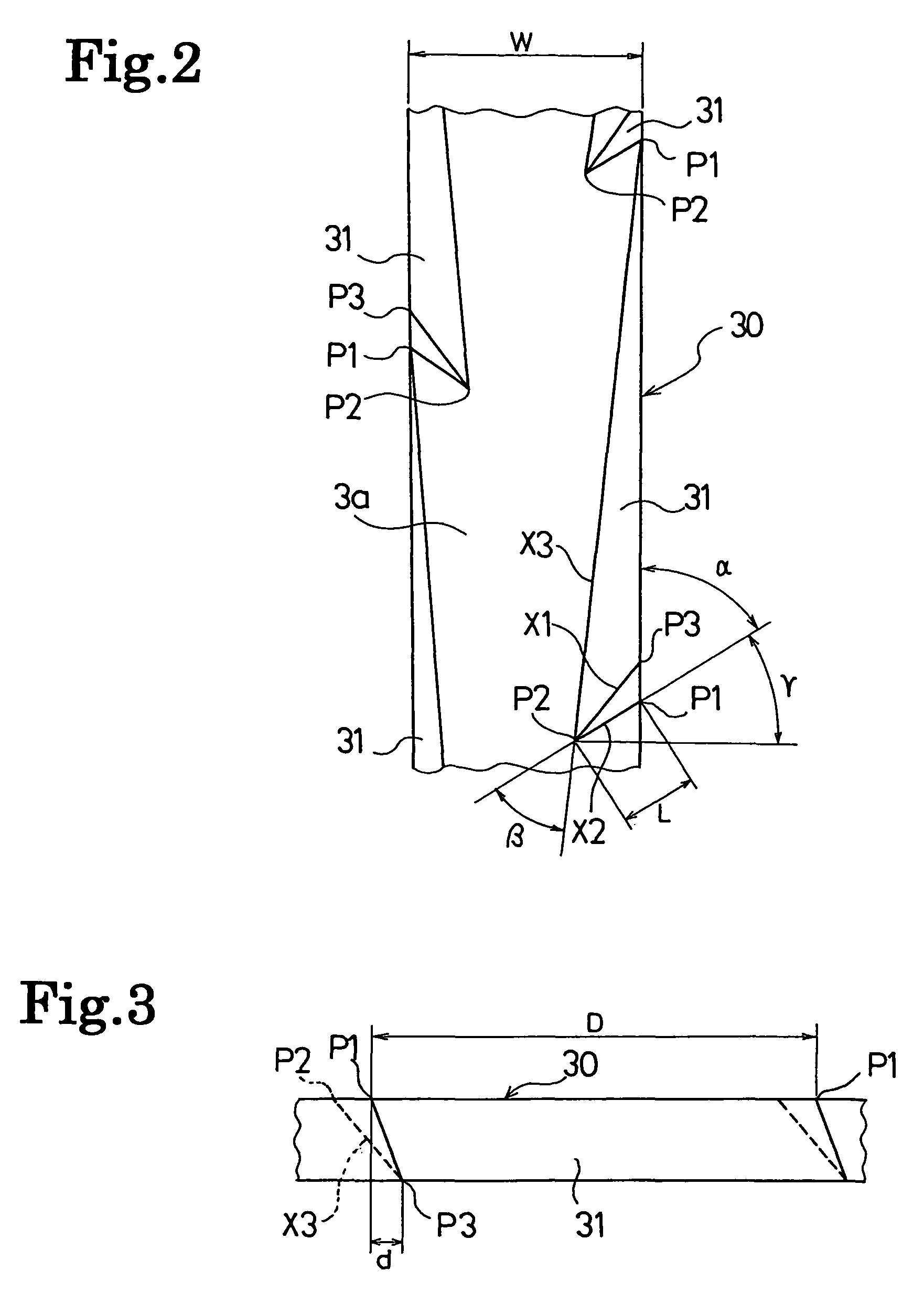

ActiveUS20080115870A1Suppress generationAvoid local stress concentrationsTyre tread bands/patternsNon-skid devicesEngineeringMechanical engineering

A sipe inner wall surface of a sipe is provided with a wavy first concave and convex row, a wavy second concave and convex row arranged in a sipe bottom side from the first concave and convex row so as to be spaced, and structured such that a wavelength is made shorter than the first concave and convex row so as to increase the number of waves, and a third concave and convex row extending toward the sipe bottom side in a branched manner while being inclined to a longitudinal direction side of the sipe with respect to a normal direction of a tread surface, and interposed between the first concave and convex row and the second concave and convex row so as to be connected to both elements.

Owner:TOYO TIRE & RUBBER CO LTD

Rubber composition for tire tread and pneumatic tire comprising the same

Provided are a pneumatic tire having extremely excellent on-ice performance, and a rubber composition for tire treads used to prepare the pneumatic tire. A rubber composition for tire treads, based on 100 parts by weight of diene rubber, the rubber composition contains 0.5 to 15 parts by weight of non- Metal fiber, 0.5-30 parts by weight of eggshell powder, and a pneumatic tire containing the rubber composition for tire tread.

Owner:SUMITOMO RUBBER IND LTD

Pneumatic tire

InactiveCN102310726AImprove on-snow performanceImprove performance on iceTyre tread bands/patternsAutomotive engineeringEngineering

The present invention relates to a pneumatic tire capable of improving snow and ice performances as well as noise performance. Shoulder pattern blocks are spacedly arranged on the tread portion of the pneumatic tire along the circumference of the tire. The shoulder pattern blocks are formed and divided by a pair of shoulder longitudinal grooves extending at the side closest to the tread ground end along the circumference of the tire, and by shoulder horizontal grooves extending between the tread ground end and the shoulder longitudinal grooves. Multiple reference space elements are configured and formed on the tread portion at two sides of the tire equator respectively along the circumference of the tire. The reference space element is formed by a space reference line, the tread ground end and the tire equator in a surrounding manner, wherein the space reference line runs through an intersection point between the shoulder longitudinal grooves and the shoulder horizontal grooves at one side edge portion of the circumference of the tire and is orthogonal to the tire equator surface. The reference space elements include at least two reference space elements with different tire circumferential lengths. In addition, each reference space element at least has a pin hole for mounting a pin.

Owner:SUMITOMO RUBBER IND LTD

Pneumatic tire

ActiveCN105365495AEfficient scrapingImprove performance on iceTyre tread bands/patternsWear resistantEngineering

The invention provides a pneumatic tire, which can be used on ice and is wear resistant. The tread (2) of the pneumatic tire (1) is provided with a pair of central main ditches (5), a central area (5), and tire shoulder areas (7). The central area (5) and each tire shoulder area (7) are provided multiple patterned blocks (12), which are defined by fine ditches (10) extending along the circumferential direction of the tire and cross ditches (11) extending along the axis of the tire. At least one of patterned blocks (12) is divided into patterned block small sheets (51) and patterned block large sheets (52) by a plurality of sipings (50); wherein the width of the patterned block large sheets (52) is larger than that of the patterned block small sheets (51). In each patterned block (12), the patterned block small sheets (51) and patterned block large sheets (52) are alternatively arranged along the circumferential direction of the tire.

Owner:SUMITOMO RUBBER IND LTD

Loading tire

InactiveCN1803479AInhibit wearImprove performance on iceTyre tread bands/patternsIndustrial engineering

The invention restrains uneven abrasion such as punching abrasion or heal and toe abrasion while exhibiting high performance on ice. A shoulder block Bo is provided with a vertical siping 5 in the circumferential direction of a tire, and a lateral siping in the axial direction of the tire, and the shoulder block Bo is divided into four sections: a first inner block piece Bli on one side in the circumferential direction of the tire and inside in the axial direction of the tire; a first outer block piece Blo on one side in the circumferential direction of the tire and outside in the axial direction of the tire; a second inner block piece B2i on the other side in the circumferential direction of the tire and inside in the axial direction of the tire; and a second outer block piece B2o on the other side in the circumferential direction of the tire and outside in the axial direction of the tire.

Owner:SUMITOMO RUBBER IND LTD

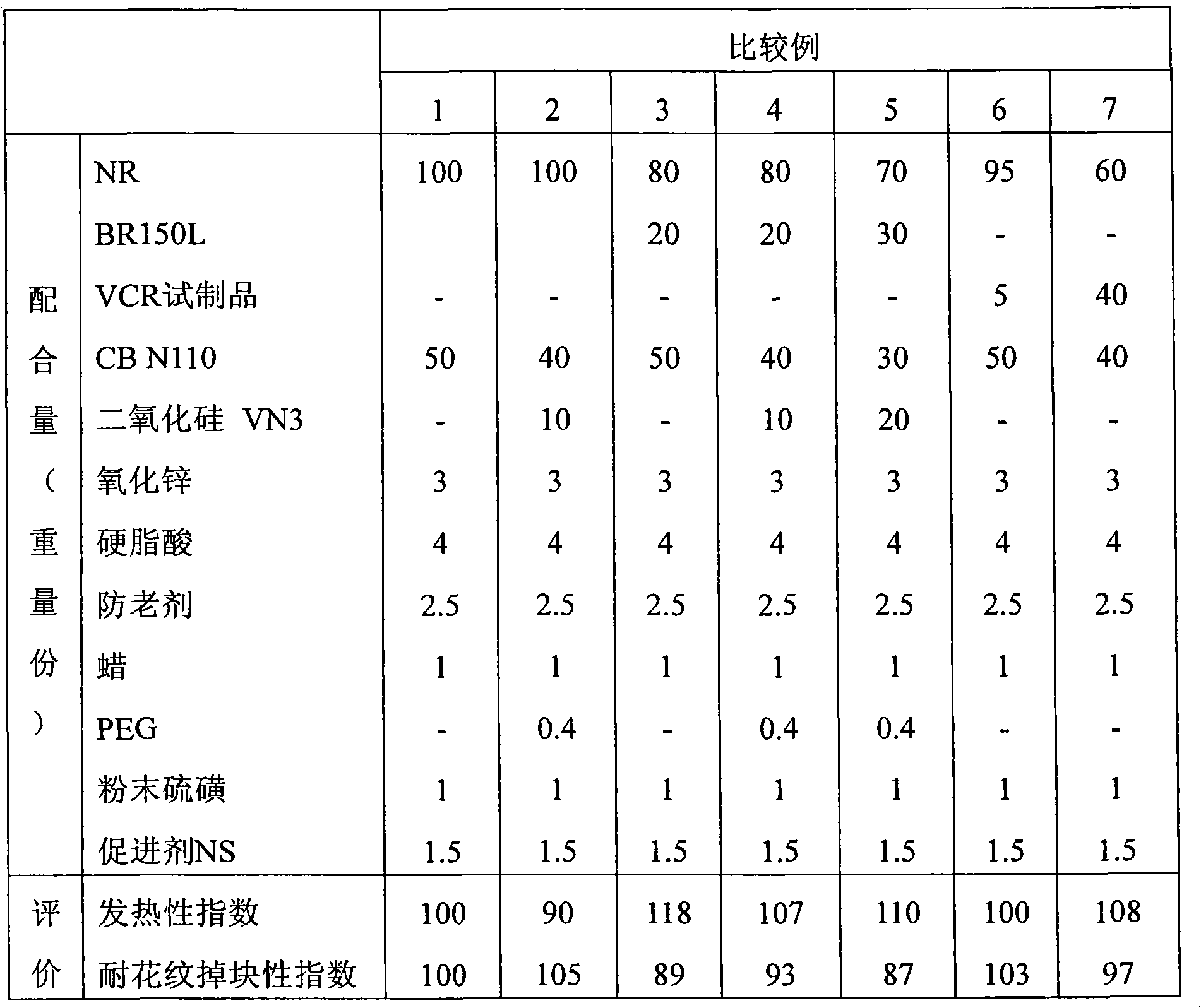

Rubber composition for tread

InactiveCN101356223AImprove wear resistanceImprove heating effectSpecial tyresPolymer scienceWear resistance

Use of polybutadiene containing specific syndiotactic poly(1,2-butadiene) in a tread rubber can improve wearing resistance without impairing chipping / cutting resistance. A rubber composition for treads is provided which contains a rubber ingredient containing 10-30 wt.% butadiene rubber which contains syndiotactic poly(1,2-butadiene) dispersed therein having an average primary-particle diameter of 100 nm or smaller.

Owner:SUMITOMO RUBBER IND LTD +1

Method for producing vulcanized rubber composition, vulcanized rubber composition, and studless tire using same

ActiveCN107108909AImprove performance on iceImprove wear resistanceSpecial tyresPolymer scienceSilicon dioxide

This method for producing a vulcanized rubber composition comprises (a) a step for preparing a master batch including a butadiene rubber and silica, (b) a step for preparing a master batch including an isoprene-based rubber and silica, (c) a step for kneading the master batch of (a) and the master batch of (b), and (d) a step for vulcanizing the kneaded product obtained in (c), wherein: the obtained vulcanized rubber composition has a BR phase and an IR phase that are incompatible with one another, and includes a predetermined amount of a terpene-based resin; the abundance ratio alpha of silica in a predetermined BR phase is 0.3 <= alpha <= 0.7 (formula 1); and the proportion beta of the butadiene rubber is 0.4 <= beta <= 0.8 (formula 2). Accordingly, this method can improve on-ice performance, wet performance, and wear resistance in a balanced manner, and can provide: a vulcanized rubber composition that has excellent on-ice performance, wet performance, and wear resistance; and a studless tire using said vulcanized rubber composition as a constituent of a tread.

Owner:SUMITOMO RUBBER IND LTD

Pneumatic tire with tread having cutaway portions formed in center rib

ActiveUS8474496B2Improve on-ice performanceLarge ratioTyre tread bands/patternsNon-skid devicesMechanical engineeringTread

A pneumatic tire includes a pair of first circumferential main grooves formed in the center region of a tread, a pair of second circumferential main grooves formed respectively outward of the corresponding first main grooves, a plurality of first lug grooves which each extend from one of the two shoulder ends of the tread inward in the tire-width direction and communicate with the corresponding first main groove, a plurality of second lug grooves alternately arranged in the tire circumferential direction which each extend from one of the two shoulder ends of the tread inward in the tire-width direction but do not communicate with the corresponding first main groove, a center rib defined between the pair of first main grooves and extends continuously in the tire circumferential direction, a shoulder block row defined between each of the second main grooves and a corresponding one of the shoulder ends and includes a plurality of blocks, and an intermediate block row defined between each of the first main grooves and a corresponding one of the second main grooves. Each intermediate block row includes long blocks each of which has a tire-circumferential-direction length equivalent to the total length of each two blocks included in the corresponding shoulder block row.

Owner:YOKOHAMA RUBBER CO LTD

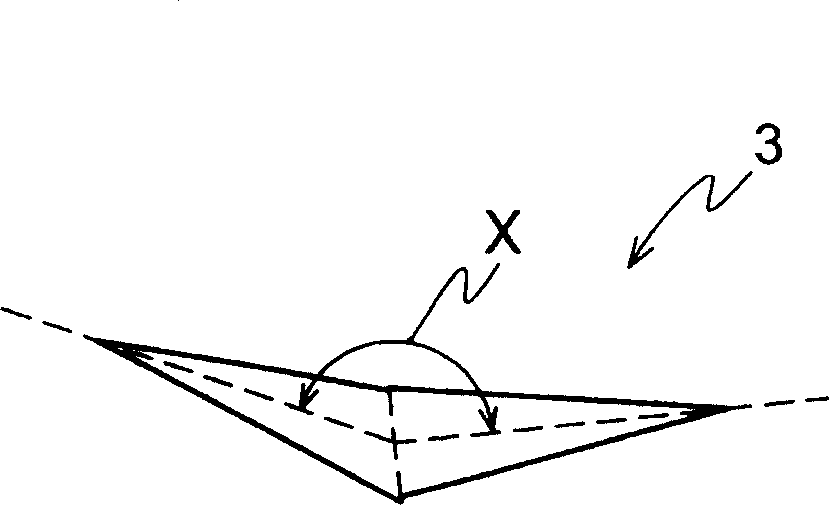

Tire for winter

ActiveCN105813859AExcellent performance on iceImprove performance on iceTyre tread bands/patternsMechanical engineeringTread

Provided is a tire for winter that exhibits exceptional on-ice performance. A tire (1) for winter is provided with a stud pin or a stud pin hole (8). Blocks (20) are sectioned in a tread part (2). Each of the blocks includes a triangular block (30) having a substantially triangular tread. The tread of the triangular block (30) includes a first peak (31) having the smallest interior angle, and a first edge (41) facing the first peak (31). The center (9) of the stud pin or the hole (8) is provided in the first edge (41) side of the triangular block (30).

Owner:SUMITOMO RUBBER IND LTD

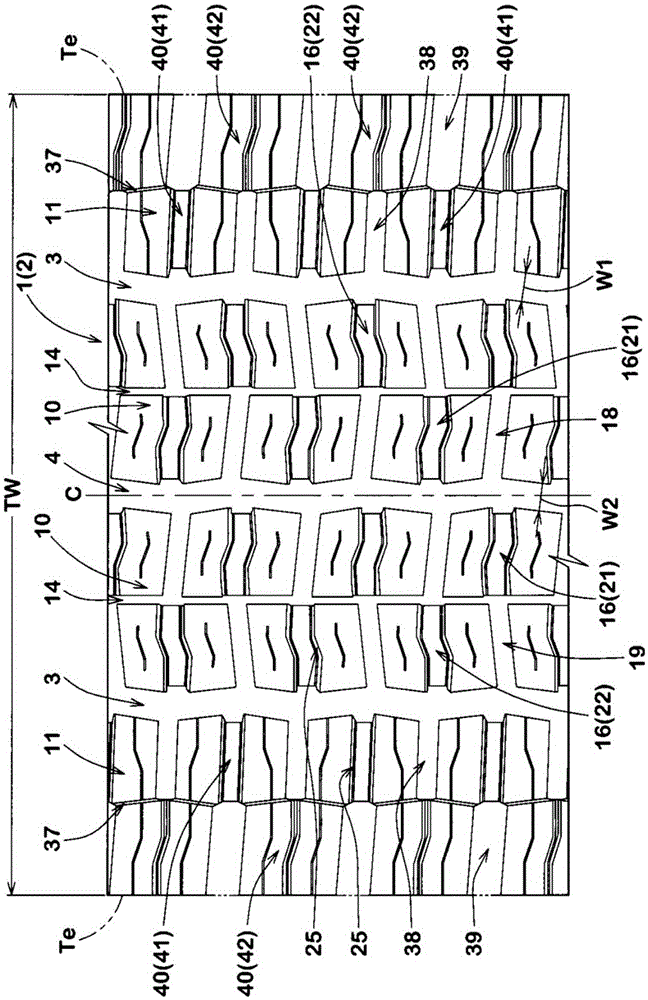

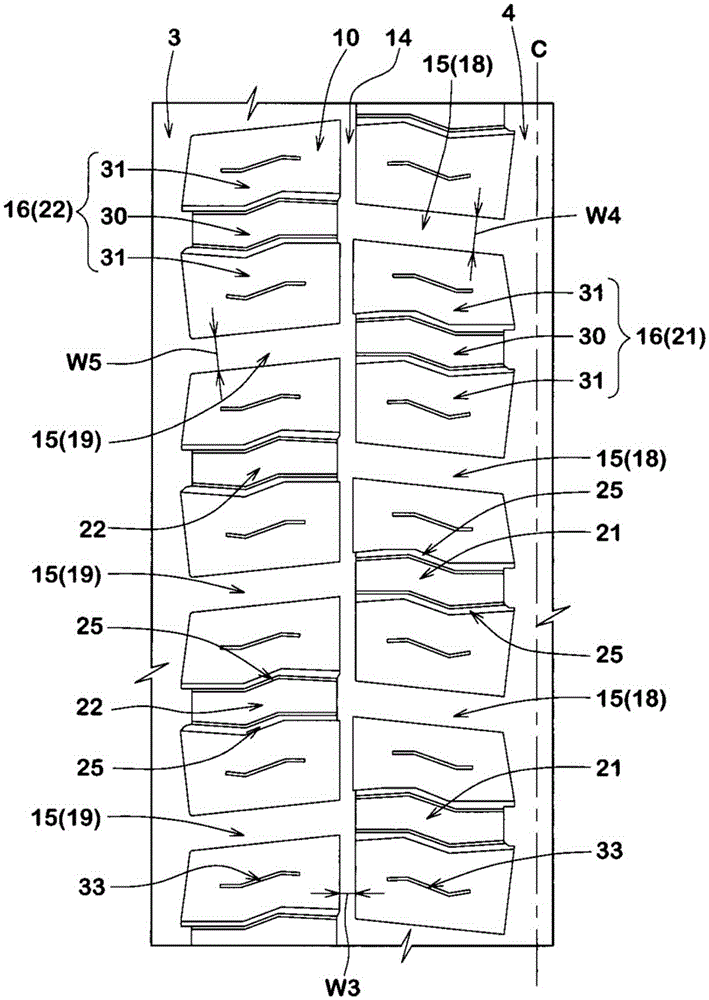

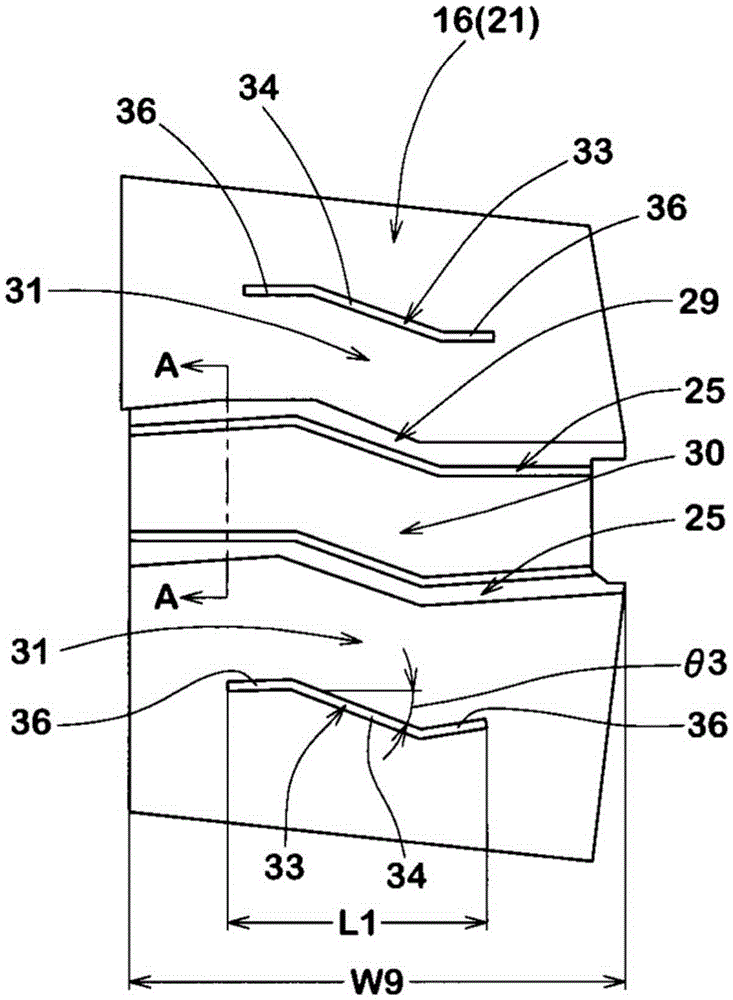

Heavy duty pneumatic tire

ActiveCN105691111AImprove performance on iceInhibits uneven wearHeavy duty tyresHeavy duty vehicleEngineeringHeavy duty

The invention provides a heavy duty pneumatic tire which can play excellent on-ice performance and the wear-resisting property. A tread portion 2 is divided into shoulder land regions 11 and middle land regions 10. The shoulder land regions 11 comprise shoulder pattern blocks 40. The middle land regions 10 comprise middle pattern blocks 16. At least one of the shoulder pattern blocks 40 and at least one of the middle pattern blocks 16 are each divided by two splitting sipes 25 into a central pattern block piece 30 and outside pattern block pieces 31 on both sides thereof. Each outside pattern block piece 31 of the middle pattern blocks 16 is provided with a closed sipe 33. Each outside pattern block piece 31 of the shoulder pattern blocks 40 is provided with an open sipe 45.

Owner:SUMITOMO RUBBER IND LTD

Pneumatic Tire

PendingUS20190118581A1Improve performance on iceImprove snow performanceHeavy duty tyresHeavy duty vehicleEngineeringMechanical engineering

A pneumatic tire includes a tread surface, a plurality of circumferential main grooves formed on the tread surface and extending in a tire circumference direction, a plurality of lug grooves formed on the tread surface and extending in a tire lateral direction, a plurality of blocks defined by the lug grooves on both sides in the tire circumferential direction and by the circumferential main grooves on at least one end in the tire lateral direction, and narrow grooves formed in the blocks. The narrow grooves include a plurality of bent portions as well as a circumferential narrow groove extending in the tire circumference direction and a lateral narrow groove extending in the tire lateral direction. The lateral narrow groove and the circumferential narrow groove are configured so that at least one thereof is provided in a plurality and includes a plurality of intersection points where the one intersects the other.

Owner:YOKOHAMA RUBBER CO LTD

Rubber composition and tire

ActiveCN108473723AImprove performance on iceSpecial tyresTyre tread bands/patternsConjugated dieneStyrene

As a rubber composition capable of greatly improving on-ice performance while suppressing a decrease in abrasion resistance of a tire, the present invention provides a rubber composition characterizedby the following: containing silica and at least three types of diene-based polymers that form a plurality of mutually incompatible polymer phases; in that a diene-based polymer (B), which is blendedat a quantity of 10 mass% or more relative to the total quantity of the diene-based polymers and which does not have the lowest or the highest glass transition temperature (Tg) among the diene-basedpolymers, is modified by a silicon atom-containing compound, and satisfies the relationship represented by the formula St+Vi / 2 <= 33 [in the formula, St is the content (mass%) of bonded styrene in thediene-based polymer (B) and Vi is the quantity (mass%) of vinyl bonds in the conjugated diene compound portion of the diene-based polymer (B)]; and in that the blending quantity of the silica is 25 parts by mass or more relative to a total of 100 parts by mass of the diene-based polymers.

Owner:BRIDGESTONE CORP

Rubber composition for tire and pneumatic tire

InactiveUS20160168364A1Suppress increase of rubber hardnessSuppress decrease of excellent on-ice performanceWood treatment detailsSpecial tyresPorosityCellulose

The increase of rubber hardness by the lapse of time is suppressed, and excellent on-ice performance due to porous cellulose particles is suppressed from being decreased. A rubber composition for a tire including 100 parts by mass of a rubber component including a diene rubber, from 0.3 to 20 parts by mass of porous cellulose particles having a porosity of from 75 to 95%, and from 1 to 30 parts by mass of a polymer gel that is crosslinked diene polymer particles having a functional group containing a hetero atom is disclosed. Furthermore, a pneumatic tire having a tread including the rubber composition is disclosed.

Owner:TOYO TIRE & RUBBER CO LTD

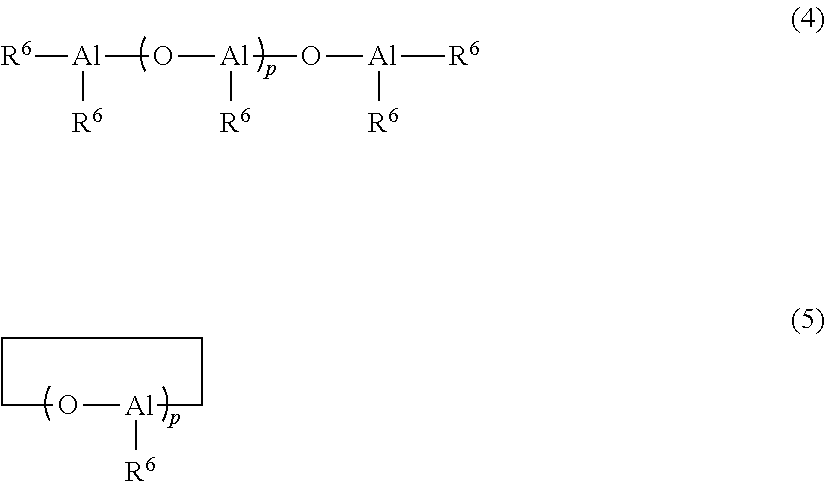

Process for preparing vulcanized rubber composition, vulcanized rubber composition and studless tire using same

ActiveUS20170240732A1Improve balanceImprove performance on iceSpecial tyresMasterbatchPolymer science

According to the process for preparing a vulcanized rubber composition of the invention comprising (a) a step of preparing a master batch comprising a modified conjugated diene polymer and silica, (b) a step of preparing a master batch comprising an isoprene rubber and silica, (c) a step of kneading the master batch obtained in (a) and the master batch obtained in (b), and (d) a step of vulcanizing a kneaded product obtained in (c), wherein the obtained vulcanized rubber composition comprises a phase A comprising a modified conjugated diene polymer and a phase B comprising an isoprene rubber, which are incompatible with each other, an abundance ratio α of silica in the phase A satisfies 0.5≦α≦0.9 (Relation 1), and a proportion β of the modified conjugated diene polymer satisfies 0.4≦β≦0.8 (Relation 2) it is possible to improve performance on ice and abrasion resistance and to provide a vulcanized rubber composition having excellent performance on ice and abrasion resistance, and a studless tire with a tread made using the same.

Owner:SUMITOMO RUBBER IND LTD

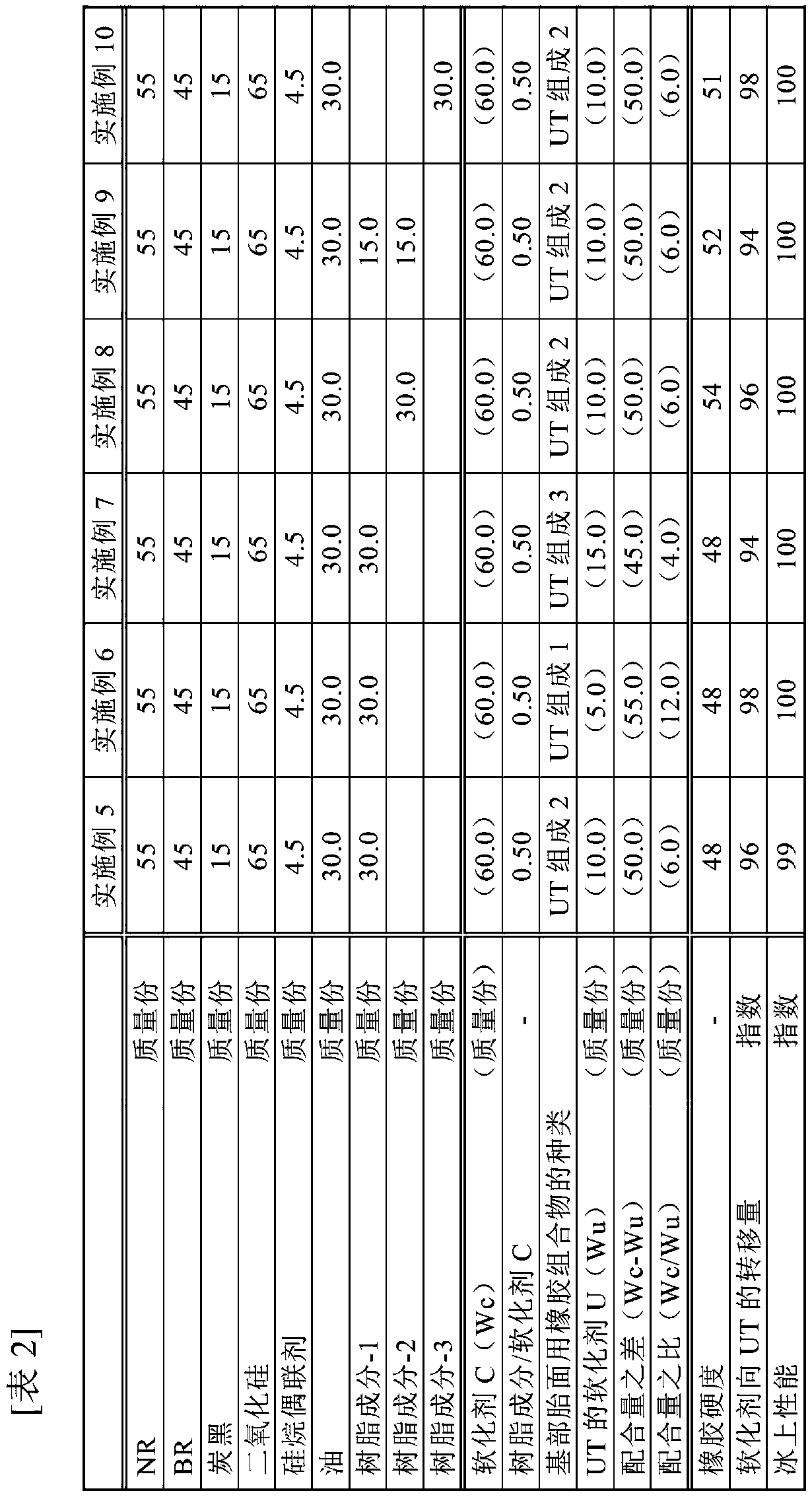

Winter tire

Owner:SUMITOMO RUBBER IND LTD

Pneumatic tire

InactiveCN110268014APromote migrationPrevent curingSpecial tyresTyre tread bands/patternsPlasticizerMass ratio

Owner:THE YOKOHAMA RUBBER CO LTD

Rubber composition and pneumatic tire

ActiveCN111465645AImprove performance on iceImprove abrasion resistanceRoad vehicle tyresRoad vehiclesPolymer sciencePolystyrene

The rubber composition of the present invention comprises 100 parts by mass of a rubber component (A) comprising 45-75 mass% natural rubber and 25-55 mass% one or more conjugated-diene-based polymersin which the conjugated-diene compound moieties have a combined styrene content of 25% or less, 1-40 parts by mass of an unmodified conjugated-diene-based polymer (B) which has a weight-average molecular weight of 5,000 or higher but less than 40,000 in terms of polystyrene as determined by GPC and in which the conjugated-diene compound moieties have a combined styrene content less than 10% and acombined vinyl content of 20% or higher, and a filler (C), wherein at least one of the conjugated-diene-based polymers contained in the rubber component (A) is a modified conjugated-diene-based polymer. The rubber composition gives tires having further improved on-ice performance and combining excellent on-ice performance with excellent wear resistance.

Owner:BRIDGESTONE CORP

Pneumatic tire

ActiveCN102529592AReduce rigidityReduced handling stabilityTyre tread bands/patternsMechanical engineeringTread

A pneumatic tire improved in on-ice performance and on-snow performance in good balance. The pneumatic tire includes a tread portion extending in a tire circumferential direction and forming a ring shape, a pair of sidewall portions on both sides of the tread portion, respectively, and a pair of bead portions on inner sides of the sidewall portions in a tire radial direction, respectively. The tread portion includes a plurality of longitudinal grooves extending in the tire circumferential direction and a plurality of lateral grooves extending in a tire width direction. The longitudinal and lateral grooves define a plurality of block rows each including a plurality of blocks. Each of the plurality of blocks included in at least one of the block rows includes at least three closed grooves including at least one first closed groove and at least one second closed groove.

Owner:THE YOKOHAMA RUBBER CO LTD

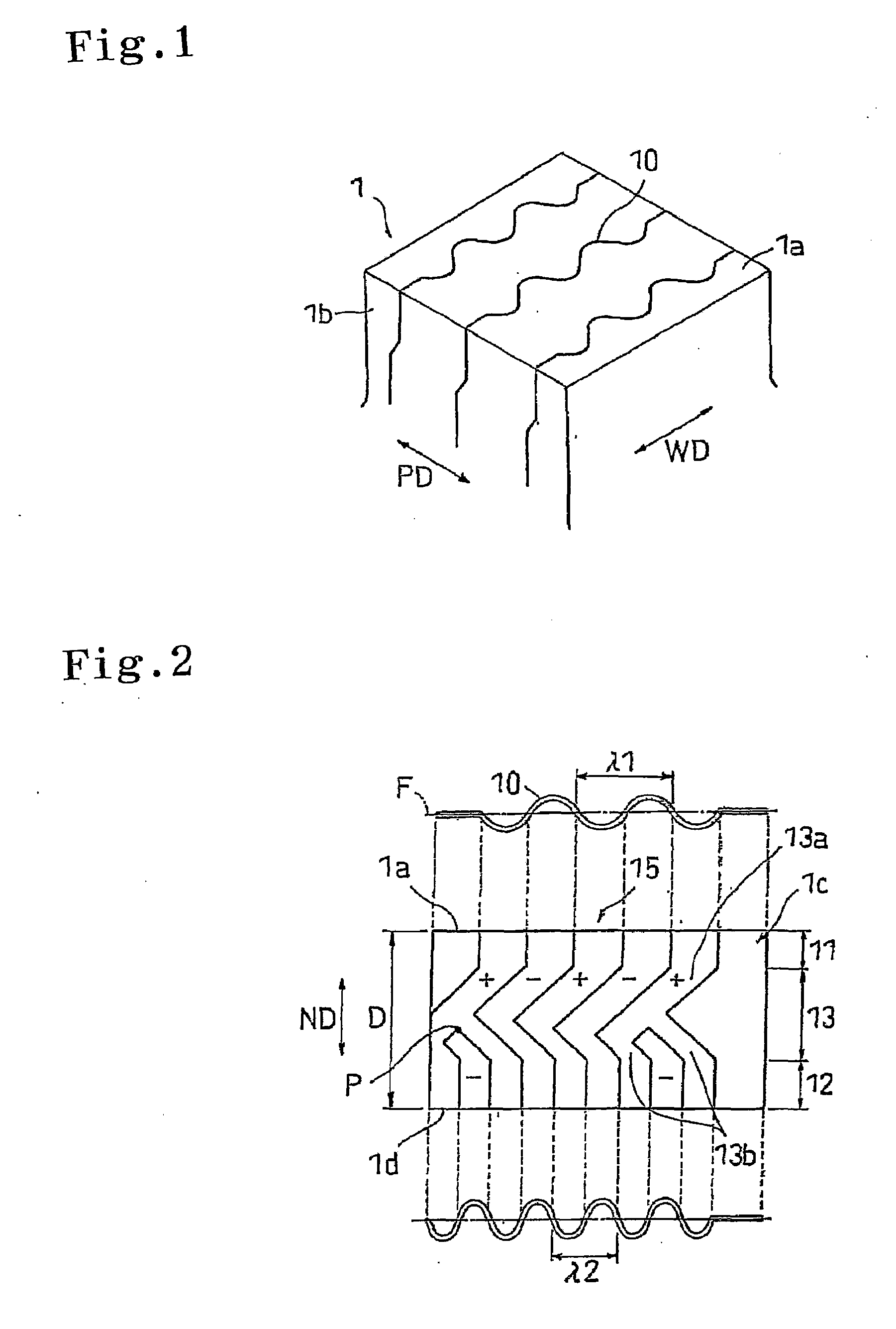

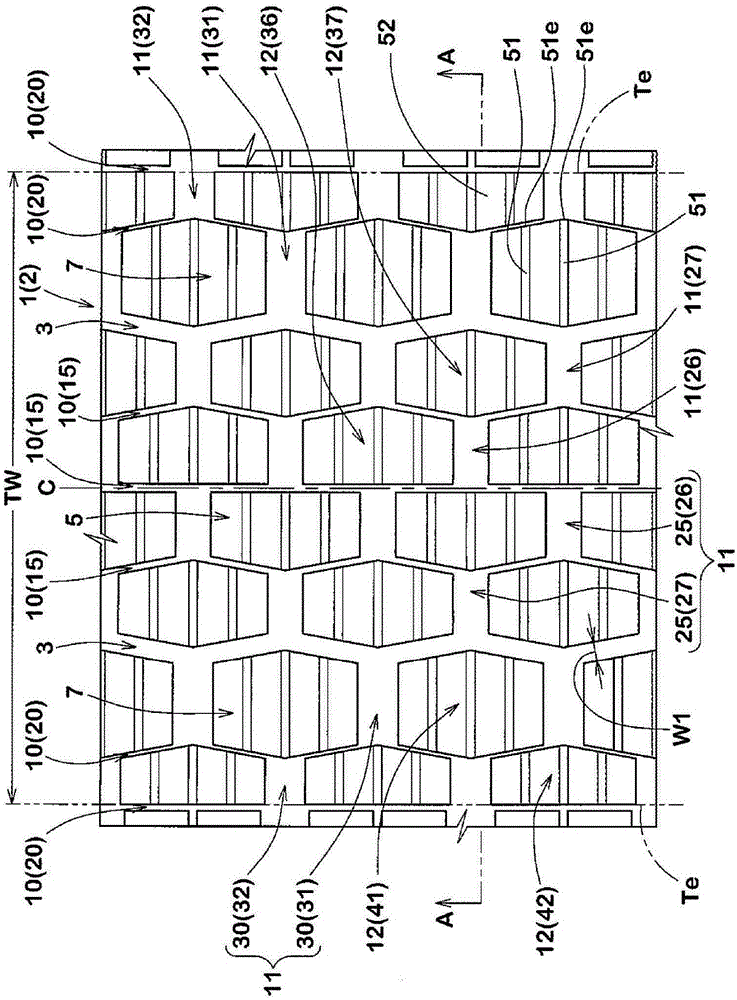

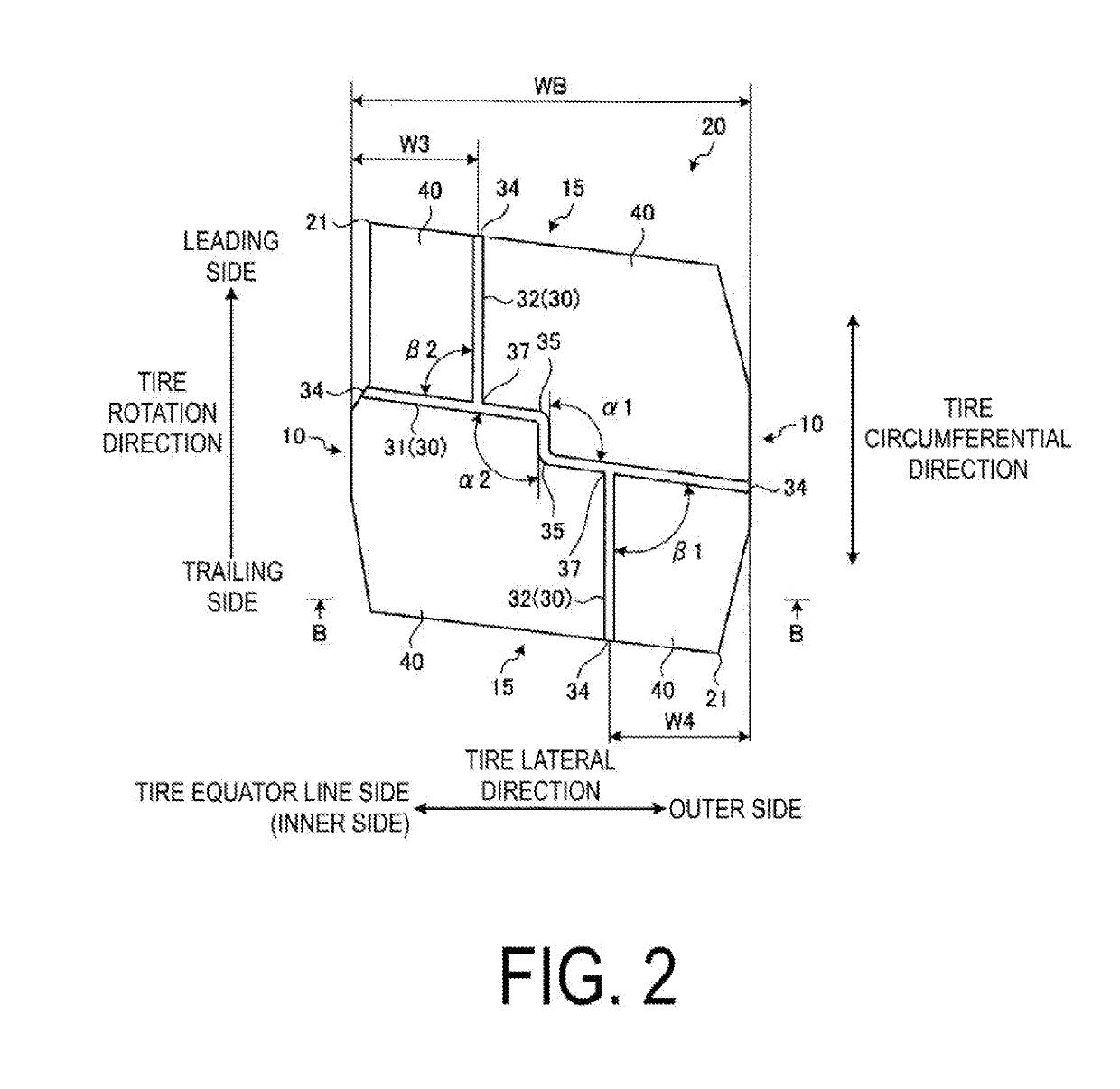

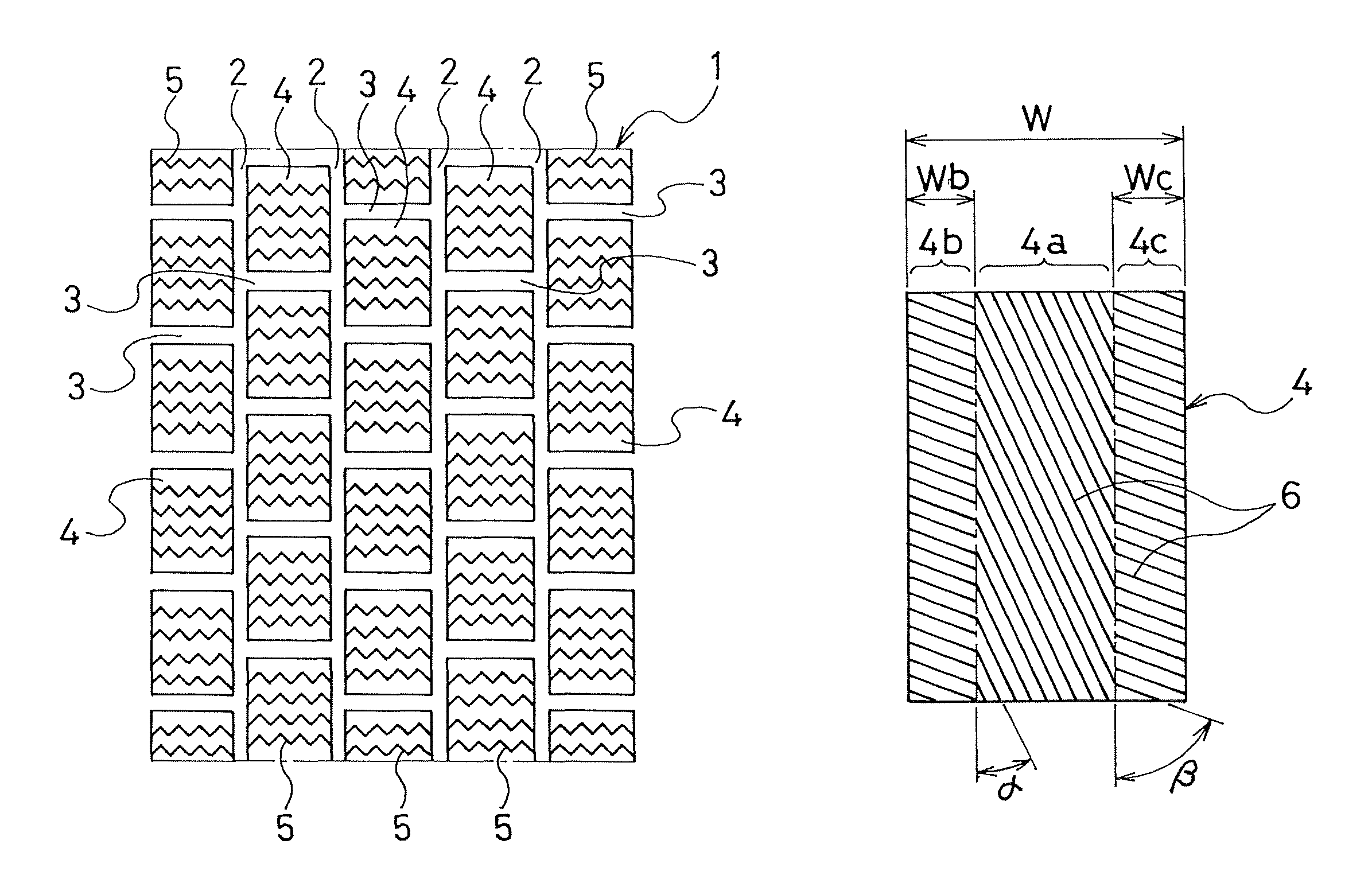

Pneumatic tire with tread having zigzag sipes and narrow grooves

ActiveUS8967210B2Easy to drainEnhance the edge effectTyre tread bands/patternsNon-skid devicesGround contactEngineering

Provided is a pneumatic tire having further improved ice performance achieved by narrow grooves. The pneumatic tire of the present invention is provided, in a tread, with land sections formed by partitioning the tread by grooves, and each of the land sections is provide with narrow grooves in a ground contact surface of the land section. The angle of tilt of the narrow grooves relative to the tire's circumferential direction is set to be larger in end regions located at both sides of a center region in a tire's lateral direction in each of the land sections than in the center region.

Owner:YOKOHAMA RUBBER CO LTD

Pneumatic tire

ActiveUS8813801B2Increased durabilityImprove performance on iceTyre tread bands/patternsNon-skid devicesMechanical engineeringTread

A pneumatic tire has a tread surface for simultaneously achieving both enhanced on-ice performance and enhanced durability. The pneumatic tire includes sipes extending in the width direction of the tire that are arranged at intervals in the circumferential direction of the tire at least in shoulder blocks that are divided by longitudinal grooves extending in the circumferential direction of the tire and by lateral grooves extending in the width direction of the tire. Open sipes and closed sipes are alternately arranged, and the depth of the open sipes is less than the depth of the closed sipes.

Owner:THE YOKOHAMA RUBBER CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com